Broaster 2400GH Installation Manual

OPERATION MANUAL

BROASTER® 2400

PRESSURE FRYER

Be sure ALL installers read, understand, and have access to this manual at all times.

Design Certified By:

CSA & NSF

Genuine Broaster Chicken®, Broasted®, Broaster Chicken®, Broaster Foods®. and Broasterie® are registered

trademarks. Usage is available only to licensed operators with written authorization from the Broaster Company.

The Broaster Company

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193 broaster.com

Manual #15459 2/99 Rev: 5/14

© 2014 the Broaster Company

Printed In U.S.A.

All adjustments and repairs shall be made

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Improper installation, adjustments, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

Indicates an imminently hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property damage or both.

by an authorized Broaster Company representative.

when the cook/filter switch is moved to

If at any time the POWER

ON light does not turn off

the OFF position, contact your local

If there is a power failure, turn cook/filter

switch OFF. On the Model 2400GH, also

Broaster Company representative for

service immediately.

slide switch on gas valve OFF. DO NOT

attempt to operate unit during a power failure.

DO NOT operate unit

without filter pan and filter

pan cover in its proper position. Filter

2400GH: Post, in prominent locations,

instructions to be followed in the event that

pan cover must be wiped clean after

each filtering cycle.

the user smells gas. This information can be

obtained from your local gas supplier.

Make sure Pressure Relief

Valve and Pressure Gauge

Failure to read and

completely could result in serious injury

or death. Be sure ALL operators read,

understand this manual

ports on bottom of cover are clear of any

oil or grease buildup.

understand and have access to this

manual at all times.

Rags or paper containing

cooking oil can catch fire

if exposed to heat. Laundering will not

remove the oil. Dispose of all oil-soiled

papers and rags in a trash container that

is in a ventilated area away from all

cooking equipment or other heat

sources such as direct sunlight.

broaster.com Manual #15459 5/02 Rev: 2/14

TABLE OF CONTENTS

1 – LIMITED WARRANTY ..................................................................................................... 1-1

2 – OWNER’S RESPONSIBILITY ......................................................................................... 2-1

3 – INSTALLATION INSPECTION ........................................................................................ 3-1

Gas Conversion .......................................................................................................... 3-1

4 – GETTING TO KNOW YOUR BROASTER® PRESSURE FRYER .................................... 4-1

5 – PRE-COOKING PREPARATIONS .................................................................................. 5-1

O-RING LUBRICATION .................................................................................................... 5-1

COVER CHECK ................................................................................................................ 5-1

COOKING OIL .................................................................................................................. 5-1

Liquid Oil .....................................................................................................................5-1

Solid Shortening ......................................................................................................... 5-1

OIL LEVEL ........................................................................................................................ 5-2

FOOD AND CONDIMENTS .............................................................................................. 5-2

2400GH LIGHTING INSTRUCTIONS ............................................................................... 5-3

Start Up .......................................................................................................................5-3

Shut Down .................................................................................................................. 5-3

6 – CONTROL PANEL ........................................................................................................... 6-1

DUAL DISPLAY FAMILIARIZATION ................................................................................. 6-1

CONTROLLER BASIC

PROGRAMMING ....................................................................................................................6-2

Normal Operating Mode ............................................................................................. 6-2

Set Temperature ......................................................................................................... 6-2

Set Time ...................................................................................................................... 6-2

Set AUTO COMP (Automatic Time Compensation) .................................................... 6-2

Reset Cycle Counter ................................................................................................... 6-2

Preset Cook Mode ...................................................................................................... 6-3

Choose Preset Cook Cycle: ........................................................................................ 6-3

Change Cook Time: .................................................................................................... 6-3

Change Cook Temperature ........................................................................................ 6-3

Activate/Deactivate Auto Comp ................................................................................. 6-3

Advance to Next Preset .............................................................................................. 6-3

7 – COOKING WEIGHT, TEMPERATURE AND TIME ......................................................... 7-1

FRESH PRODUCTS ......................................................................................................... 7-1

INDIVIDUALLY QUICK FROZEN (IQF) CHICKEN, FROZEN ............................................ 7-2

BROASTER FOODS COOKING CHART FOR 2400 PRESSURE FRYER ......................... 7-3

broaster.com Manual #15459 5/02 Rev: 2/14

i

8 – COOKING OIL CARE AND FILTERING ......................................................................... 8-1

OIL CARE ......................................................................................................................... 8-1

FILTERING ....................................................................................................................... 8-2

FILTERING HINTS ............................................................................................................ 8-3

9 – CLEANING ....................................................................................................................... 9-1

COOKING WELL .............................................................................................................. 9-1

FOOD BASKET ................................................................................................................. 9-2

UNIT SURFACES ............................................................................................................. 9-2

CONDENSATE PAN ......................................................................................................... 9-2

SLIDE RODS .................................................................................................................... 9-2

COVER ............................................................................................................................. 9-2

SPLASH SHIELD .............................................................................................................. 9-3

GAS SPRING COVERS .................................................................................................... 9-3

PROBE GUARD & BASKET GUIDES ............................................................................... 9-4

MINIMUM PREVENTIVE MAINTENANCE REQUIREMENTS ........................................... 9-5

10 – SHUTDOWN ................................................................................................................ 10-1

NIGHTLY ...................................................................................................................... 10-1

SEASONAL ................................................................................................................... 10-2

11 – TROUBLESHOOTING ................................................................................................. 12-1

ELECTRICAL TIPS ......................................................................................................... 12-1

SOLID STATE CONTROLLER TIPS ............................................................................... 12-2

GAS TIPS ....................................................................................................................... 12-2

COVER, YOKE, AND LIFT TIPS ..................................................................................... 12-3

PRESSURE SYSTEM TIPS ............................................................................................. 12-4

PRODUCT TIPS ............................................................................................................. 12-4

Fresh Chicken ........................................................................................................... 12-4

Individually Quick Frozen (IQF) Chicken ................................................................... 12-5

FILTERING TIPS ............................................................................................................. 12-6

broaster.com Manual #15459 5/02 Rev: 2/14

ii

1 – LIMITED WARRANTY

Subject to the terms and conditions of this warranty, the Broaster Company (Company) warrants that all equipment and parts manufactured or sold by the Company and purchased new from an authorized Company distributor are free from defects in material and workmanship for a period of one year from the date of installation (two

years on Solid State controllers and ten years on the Welded Stainless Steel Cooking Well), if installation is made

by a qualified installer under supervision by an authorized distributor in accordance with applicable laws and regulations. Warranty coverage is extended to the original purchaser only and is void if the equipment is resold. If an

authorized Company distributor is notified of a warranty claim during the warranty period, the Company will at its

option replace, recondition or repair at its factory any part or parts of the equipment which the Company judges

defective, provided the equipment has been subjected to normal usage, properly installed, operated and serviced

in accordance with Company operating instructions, and there is no evidence of accident, alteration or abuse of

the equipment or the use of unauthorized repair methods. All parts replaced under this warranty carry only the

unexpired term of the warranty.

Extended cooking well warranty will cover the cooking well only and does not include any parts attached to the

cooking well, including: probe guards, basket guides, latch columns, latch column blocks, insulation, splash

shield interlock, drain valve, filter lines and fittings, high limit, thermostat, temperature sensor probe, combustion

chamber and flue, elements, burner, all mounting hardware. The aforementioned excluded parts are covered

under the 1-year parts warranty. The extended warranty does not cover any cooking well that fails due to any misuse or abuse.

Any warranty claim on the cooking well must be presented to the Broaster Company or authorized Broaster Distributor from whom the pressure fryer was purchased. Repairs will be made by the Broaster Company only. Any

freight charges and distributor labor costs to install the repaired cooking well, as well as the cost of any other

parts replaced will be the responsibility of the equipment owner.

Service under this warranty shall be furnished only by an authorized Company distributor. The Company does not

send service representatives to furnish warranty service. Your authorized Company distributor should be contacted for warranty service.

This warranty covers on-site labor charges only, at a fixed rate, for one year from date of installation of new equipment only. Transportation charges, trip charges, zone fees, or other expenses in connection with warranty service

are the obligation of the owner unless otherwise specified in the original sales contract between the purchaser

and the authorized Company distributor from which the equipment is purchased. Please refer to that contract for

coverage as to those charges.

This warranty shall be void unless genuine Broaster® filter paper, Bro-Clean™ filtering compound, XL Filtering

Compound and Broaster Cooking Well Cleaner is used in conjunction with the equipment.

This warranty does not apply to consumable items and supplies such as O-rings, food baskets, bulbs, gaskets

and lamps.

The foregoing warranty is made in lieu of all other warranties, express or implied, and the Company specifically

disclaims any implied warranties of merchantability or fitness for a particular purpose. The Company’s full obligation under this warranty, and the purchaser’s sole remedy, shall be limited to replacement, reconditioning or repair

as specified above.

IN NO EVENT SHALL THE COMPANY BE LIABLE TO THE ORIGINAL OWNER OR ANY OTHER PERSON FOR

ANY INCIDENTAL, CONSEQUENTIAL OR SPECIAL DAMAGES RESULTING FROM THE USE OR INABILITY TO

USE THE EQUIPMENT COVERED HEREBY, WHETHER ARISING FROM BREACH OF WARRANTY, STRICT LIABILITY OR OTHERWISE.

The Company reserves the right to change or improve its products in any way without obligation to alter products

previously manufactured.

Used Company equipment or Company equipment not purchased from an authorized distributor carries no warranty expressed or implied.

1–1

broaster.com Manual #15459 5/02 Rev: 2/14

2 – OWNER’S RESPONSIBILITY

It is the owner’s responsibility to:

®

• Ensure the Broaster

Pressure Fryer is

properly maintained.

• Ensure all safety devices and warning

signs are in their original location and

are legible.

• Allow only properly trained personnel to

operate, clean and maintain a Broaster

®

Pressure Fryer.

• Retain this manual for future reference.

• Ensure main power supply is disconnected before the unit is serviced.

• When you sell, trade, dispose of or give

away your Broaster® Pressure Fryer,

you must make sure that all safety

devices and warning signs are intact

and legible and the operation manual is

included with the unit.

If you need replacement warning signs

or manuals, contact an authorized

Broaster Company representative or the

Broaster Company at 608/365-0193.

The Customer Service Department at the

Broaster Company should be contacted

at the time of sale or disposal of the

®

Broaster

Pressure Fryer so records

may be updated.

If you are a new owner of a used unit or

have relocated your Broaster Pressure

Fryer, please take a minute to notify us

by completing the Pre-Owned Equipment Registration page on our website.

It is NOT a warranty registration.

broaster.com/preowned-registration.htm

This information enables the Broaster

Company to better serve you and keep

you informed of changes in equipment,

condiments, or service bulletins.

• 2400GH:Keep burner area free and clear

of all combustible materials.

• 2400GH: DO NOT obstruct exhaust flue

or open area around bottom of unit at

the front, back and sides which would

restrict the flow of combustion and ventilation air.

broaster.com Manual #15459 5/02 Rev: 2/14

2–1

3 – INSTALLATION INSPECTION

Before operating unit, be sure installation meets all requirements in the Installation Manual provided with your unit.

Follow cleaning instructions as outlined in this

manual before operating

for the first time. See “Cleaning” on

page 9-1.

• A remote circuit breaker or fuse should

be installed in the main power supply

located in a path of exit and clearly identified.

• To avoid splashing of hot liquid, unit

must be restrained to prevent tipping.

This can be done by installing the unit in

a battery of appliances, in an alcove or

with adequate ties.

•See Safety Relief Valve on page 4-3.

DO NOT install unit where traffic areas

are on either side or behind unit.

2400GH:

Electrical Grounding

Instructions—The Model

2400GH is equipped with a three-prong

(grounding) plug to protect against

shock hazard. The plug must be plugged

directly into a properly grounded threeprong receptacle. DO NOT cut or remove

the grounding prong from this plug.

• A gas shutoff valve, installed in gas sup-

ply line, should be located in a path of

exit and clearly identified.

Gas Conversion

USA and Canada

• Contact your local Broaster Company

representative for converting from one

type of gas to another.

European Union

• Units manufactured for use in the Euro-

pean Union are not convertible from one

type of gas to another.

broaster.com Manual #15459 5/02 Rev: 2/14

3–1

4 – GETTING TO KNOW YOUR

iyvhz{ly

jvtwhu

zthy{{v|jo

For Gas

Models Only

BROASTER® PRESSURE FRYER

broaster.com Manual #15459 5/02 Rev: 1/14

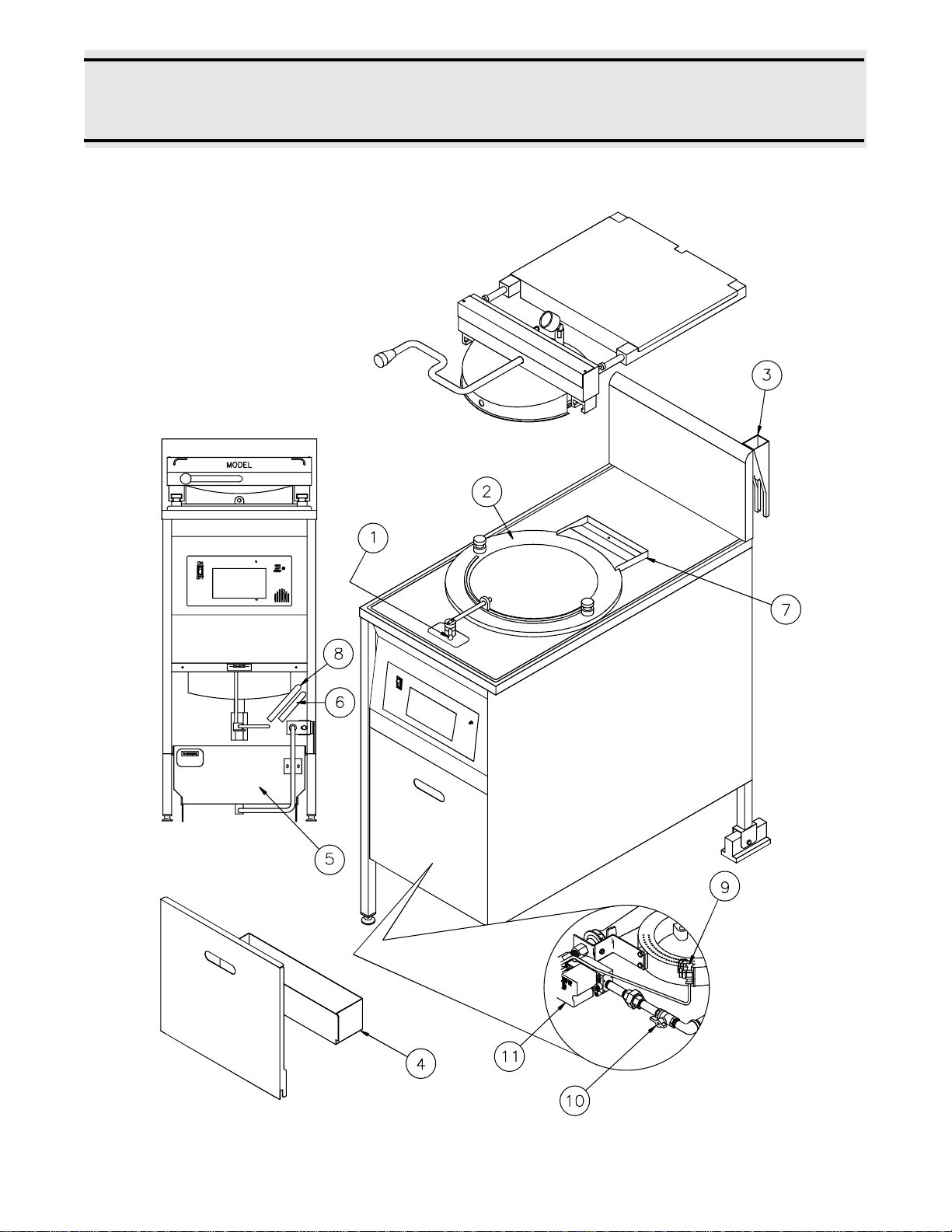

1. Pressure Regulating Valve: Opens

and closes pressure regulating valve.

When cover and valve are CLOSED,

this valve seals the cooking well,

allowing pressure to build. Valve is

preset to maintain pressure at 12-14

PSI during a cooking cycle. When

OPEN, all pressure is exhausted and

timer stops timing.

2. Cooking Well: Holds cooking oil.

3. Basket Lifter Holder: Holds basket

lifter when not in use.

4. Condensate Pan: Holds condensa-

tion drained from exhaust tank. Check

liquid level several times daily. Empty

as needed.

Water and hot oil DO NOT

mix. DO NOT pour

contents of condensate pan into cooking

well or filter pan. Hot oil could splash,

causing serious burns.

9. Pilot Burner: A small flame used to

ignite the main burner.

10. Manual Gas Shut Off Valve: Shuts off

gas flow to the gas valve. Gas will flow

when handle is in line with pipe. Turning handle crosswise to the pipe stops

gas flow.

11. Gas Valve: Regulates gas supply. The

valve has a two-position switch: OFF

stops all gas flow and ON allows gas

flow to pilot and main burner as

needed.

5. Filter Pan: Holds filter components

and filtering compound used to filter

hot oil.

HOT Surfaces!

Hot shortening! DO NOT

use this container to

transport hot shortening. Hot shortening

could splash, causing serious burns.

6. Exhaust Drain Tube: Directs conden-

sation from the exhaust tank into condensate pan.

7. Countertop Drip Pan: Collects con-

densate from the open cooking well

and directs it to the Drip Pan Drain

Line. Drip Pan is removable for cleaning.

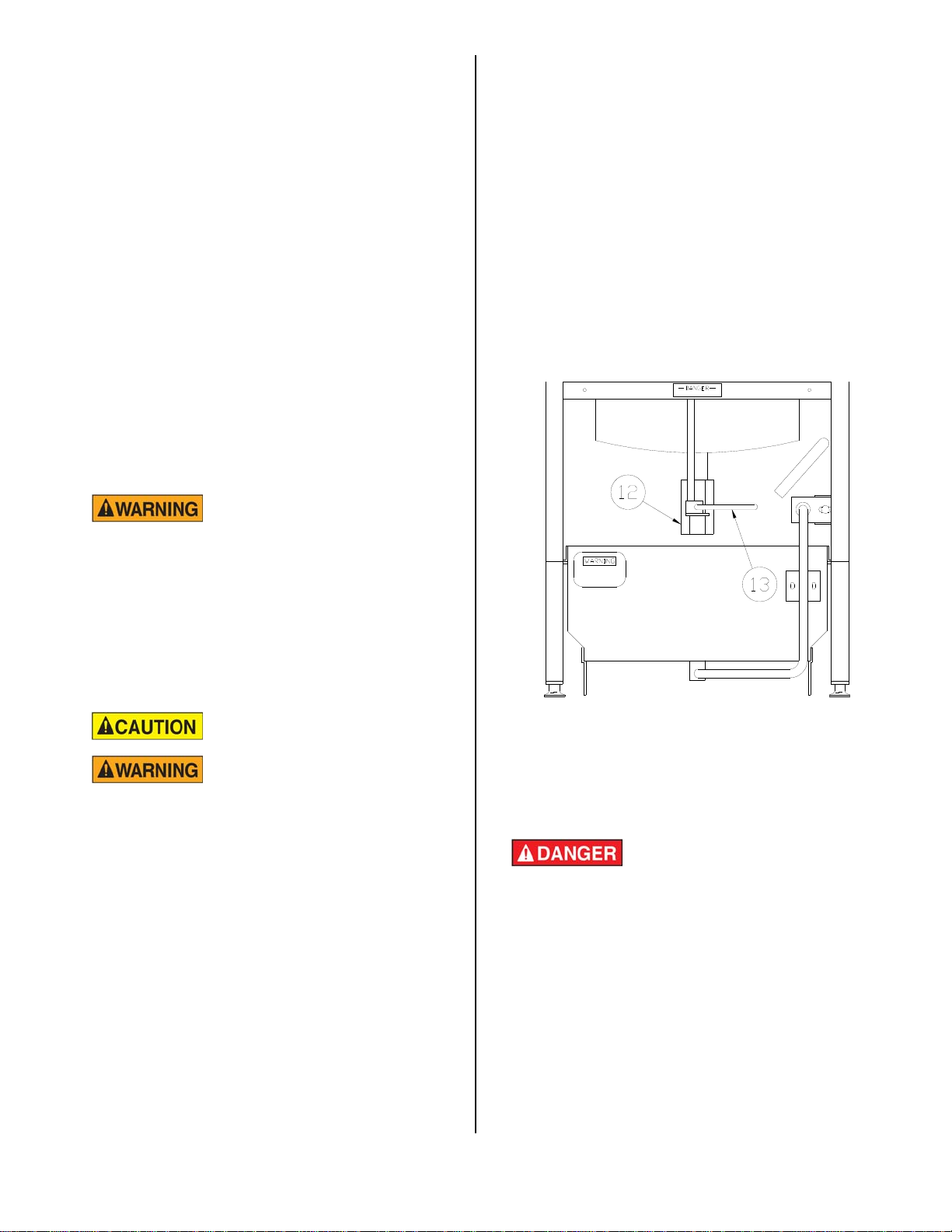

12. Drain Valve: Used to drain cooking oil

from cooking well into filter pan or

container made for handling hot oil.

Never drain oil unless

cook/filter switch is OFF

and pressure regulating valve is OPEN.

Hot oil could spray out under pressure,

causing serious burns.

13. Drain Valve Handle: Opens and

closes drain valve. When handle is

horizontal, valve is closed. When vertical, valve is open.

8. Drip Pan Drain Line: Directs counter-

top liquid toward Condensate Pan.

broaster.com Manual #15459 5/02 Rev: 1/14

4–2

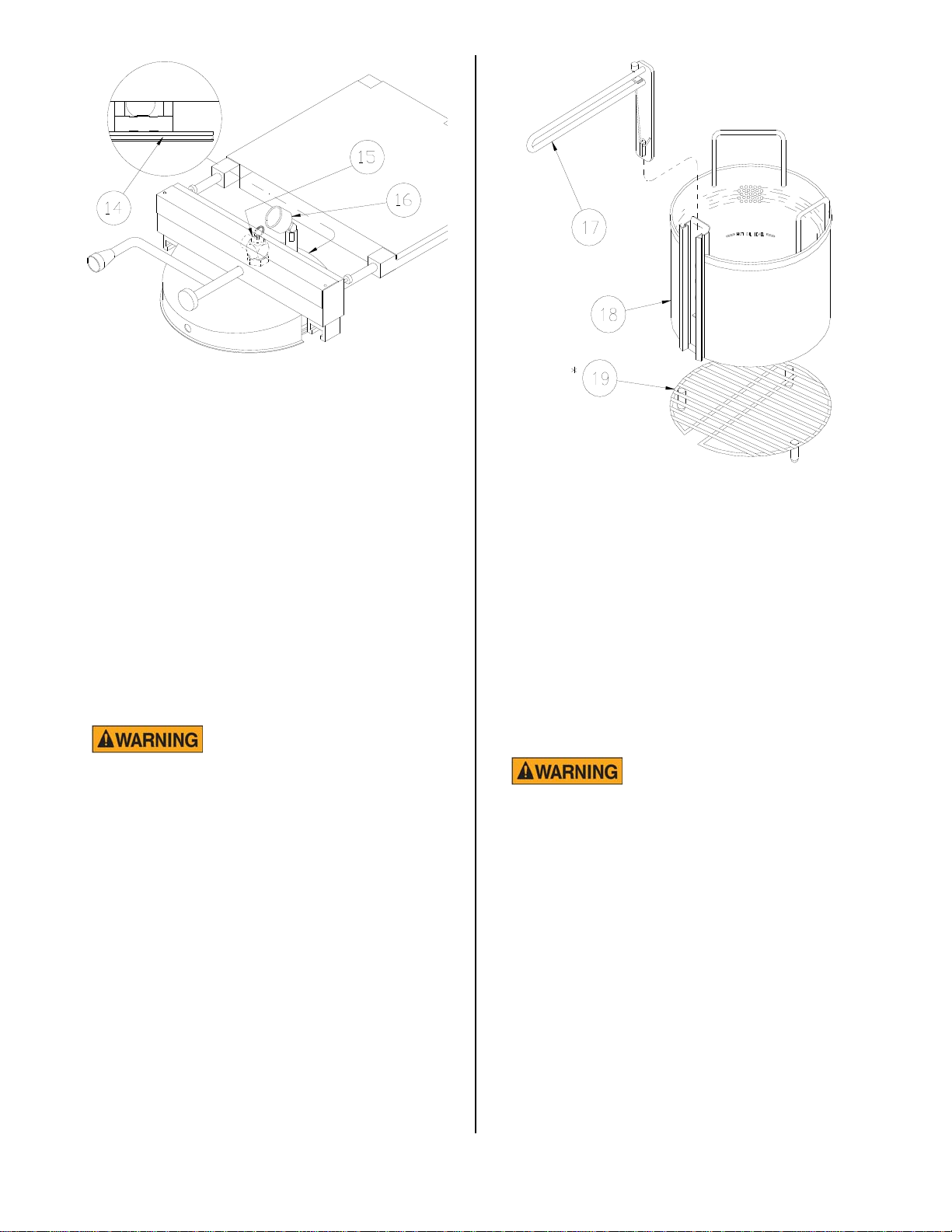

14. Cover O-Ring: Forms a seal when

cover is lowered into the cooking well.

15. Safety Relief Valve: This valve will

open in the event pressure in the

cooking well meets relief pressure of

valve. A properly installed valve has

the outlet facing toward rear corner of

the countertop. DO NOT use valve to

release pressure at the end of a cooking cycle. If valve leaks during normal

operation, DO NOT operate the unit

until valve is replaced by an authorized

Broaster Company representative.

Keep away from safety

relief valve opening

unless wearing heat and steam

protective apparel. Escaping steam

could cause serious burns.

17. Basket Lifter: Used to raise and lower

food basket into the cooking well.

18. Food Basket: Holds product for cook-

ing. Indicates proper level of oil at

operating temperature.

19. Basket Support Grate: Used in the

bottom of the cooking well to support

the basket w/o feet at the proper

height. (Model 2400GH only)

Basket, lifting handle and

basket support grate are

hot, use gloves when handling. Hot

surfaces could cause serious burns.

Test valve once a month. Also test

before and after an extended shutdown. Using a hot mitt, lift valve handle during a cook cycle until pressure

is released from cooking well. Allow

valve to snap closed.

16. Pressure Gauge: Indicates pressure

within the cooking well. Normal operating pressure is 12-14 PSI.

broaster.com Manual #15459 5/02 Rev: 1/14

Loading...

Loading...