Broaster 2400 Parts List

BROASTER

EQUIPMENT

®

PARTS MANUAL

BROASTER®

PRESSURE

Be sure ALL installers read, understand, and have access to this manual

----------

---------

----------

---------

2400

FRYER

at

all times.

I >

Genuine Broaster Chicken®, Broasted®, Broaster C

trademarks. Usage

Design Certified By: © 2002 Broaster Company

CS

A&

NSF

is

available only to licensed operato

Broaster

2855 Cranston Road, Beloit, WI 53511-3991

608/365-0193

Manual #15461 8/02 Rev 10/17

hick

en®, Broaster Foods®. and Broasterie® are registered

rs

with written authorization from the Bro aster Compan

Company

broaster.com

y.

Printed In U.SA

Do

not use

or

liquids in t

or

sto

he

FOR

re gas

vicin

YOUR

oline

ity

of

SAFETY

or other

this

or

fla

mm

any other

able vapors

appliance.

IAWARNINGI Improp

pro

nan

F

or the s

A.DANGER

IAWARNINGI Indicates a potentially hazardous situation which, if not avoided, could

ake

of

safe

Indicates

result in serious injury

result in serious injury

er

installation, ad

pert

y damage, inj ury

ce

inst

ruct

ions thoro ughly befo

ty

and clarity

an

imminently hazardous situation which,

just

or

, the followi

or

or

ments, alteration, service

dea

th. Read the i

re

inst

ng words used in this manual are defined as follows:

death.

death

.

alli

nst

allation, o

ng

or servicing this e

or

maintenance can cause

per

ating and mainte-

qui

pme

nt.

if

not

avoided, could

I A CAUTION I Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property

All adjus

by

sentativ

If

the

sw

sli

de

attempt

ur

e.

IAWARNINGI Failure

· · understand this manual

completely could result

or

understand and have access

manual

IAWARNINGI Rags_

if

exposed

remove

papers

is in a ventilated area

cooking equipment

sources such as direct sunlight.

tme

nts

and r

an au

tho

riz

ed Broa

e.

re

is a

pow

er

fai lure, turn c

itc h OFF. On

swi

tch

to operate unit during a

death.

at

the

and rags

the Mode

on gas val

Be

sure ALL operators read,

all times.

cooking oil

to

heat. Laundering will

oil. Dispose

in

epa

irs shall be made

ste

r Co mpany repre-

ook/

filt

l 2400GH, also

ve OFF.

to

or

p~per

a trash container that

away

or

other

DO N

OT

pow

rea~

and

in

serious injury

to

this

containi_!lg

can

catch

of

all oil-soiled

from all

heat

er

not

er

fail-

fire

damage

when

the

to

Broaster Company representative

service immediately.

pan

pan

each

Make

Pressure Gauge ports on

cover

buildup.

ports

oil

2400GH: Post, in p

instru

t

obtained from

or

both.

I A

WARNING

the

OFF position, disconnect

the

fryer and contact your local

I A WARNING I

cover

cover

filtering cycle.

sure Pressure Relief Valve and

are

I A WARNING I

on

or

grease buildup.

cti

ons

he

user smells gas. This

I H

at

ON

cook/filter

DO

without filter pan and filter

in its

must

clear

bottom

proper

be

of any oil

Make

Valve and Pressure

of

to

be

followed in the e

your loca

_any

hght does not

switch is moved

NOT

wiped

sure Pressure Relief

cover

ro

minent

time

operate unit

position. Fi

clean

bottom

or

are

loc

informa

l gas suppl

the

POWER

turn

the

power

for

lter

after

of

grease

Gauge

clear

of

ations,

vent that

tion can be

ier.

off

to

any

br

oaster.c

an

Manual #154

W-1

co

nt' d on n

61 8/02

Rev:

10/

ext

15

page

IAWARNINGI

· ·

c

omplies

with

Commercial

CSA

1.8

to

strain

to

the

Ma~e

device

the

Gas

guard

gas

s~re a restraining

1s

used

Standard

Ranges

against

for

, ANSI 283.11/

transmission

connectors.

that

of

A DANGER

move, causing

out,

or a possible

causing

an

explosive

Failure

fryer

could

hot

shortening

break

to

restrain

allow

in

the

condition

the

it

to

gas

to

spill

line

I

br

oaster.c

an

Manual #154

W-2

61 8/02 Rev: 10/

15

TABLE OF CONTENTS

1 - OUTER PANELS ........................................................................................................... 1 - 1

2 - COOKING WELL GROUP ............................................................................................ 2 - 1

3 - CONTROL PANELS ...................................................................................................... 3 - 1

4 - COVER AND YOKE GROUP ........................................................................................ 4 - 1

5 - PRESSURE EXHAUST SYSTEM ................................................................................. 5 - 1

6 - PRESSURE REGULATING

7 - POWER

INPUT

BOX ..................................................................................................... 7 - 1

VALVE

............................................................................... 6 - 1

2400GH ....................................................................................................................... 7 - 1

2400GHXP ................................................................................................................. 7 - 2

2400GHCE ............................................................................................................. .... 7 - 3

2400GHCE &

UL

w/FASTRON controller ................................................................... 7 - 4

2400E .......................................................................................................................... 7 - 5

8 - COOKING WELL PARTS .............................................................................................. 8 - 1

2400GH ....................................................................................................................... 8 - 1

2400E ........................................................................................................................

9

-2400GH

BURNER ASSEMBLY

..

8 - 2

US & Canada ............................................................................................................. 9 - 1

European Union ........................................................................................................ . 9 - 2

10

- 2400GH COMBUSTION CHAMBER ........................................................................

11

- FILTER SYSTEM .......................................................................................................

Electric .....................................................................................................................

Electric (Effective SE4C210700) ...............................................................................

10

11

11

11

- 1

-1

- 1

- 2

Gas (Effective SG4A500010) ............................ .......................... ............................... 11 - 3

Gas (Effective SG4H010300) ....................................................................................

11

- 4

Gas 2400GHCE & 2400GHUK ................................................................................. 11 - 5

12

- FOOD BASKET .........................................................................................................

13

- PART

NUMBER

LIST ................................................................................................

i

broaser.com Manual #1

5461

8/02

Rev: 9/

17

12

13

- 1

- 1

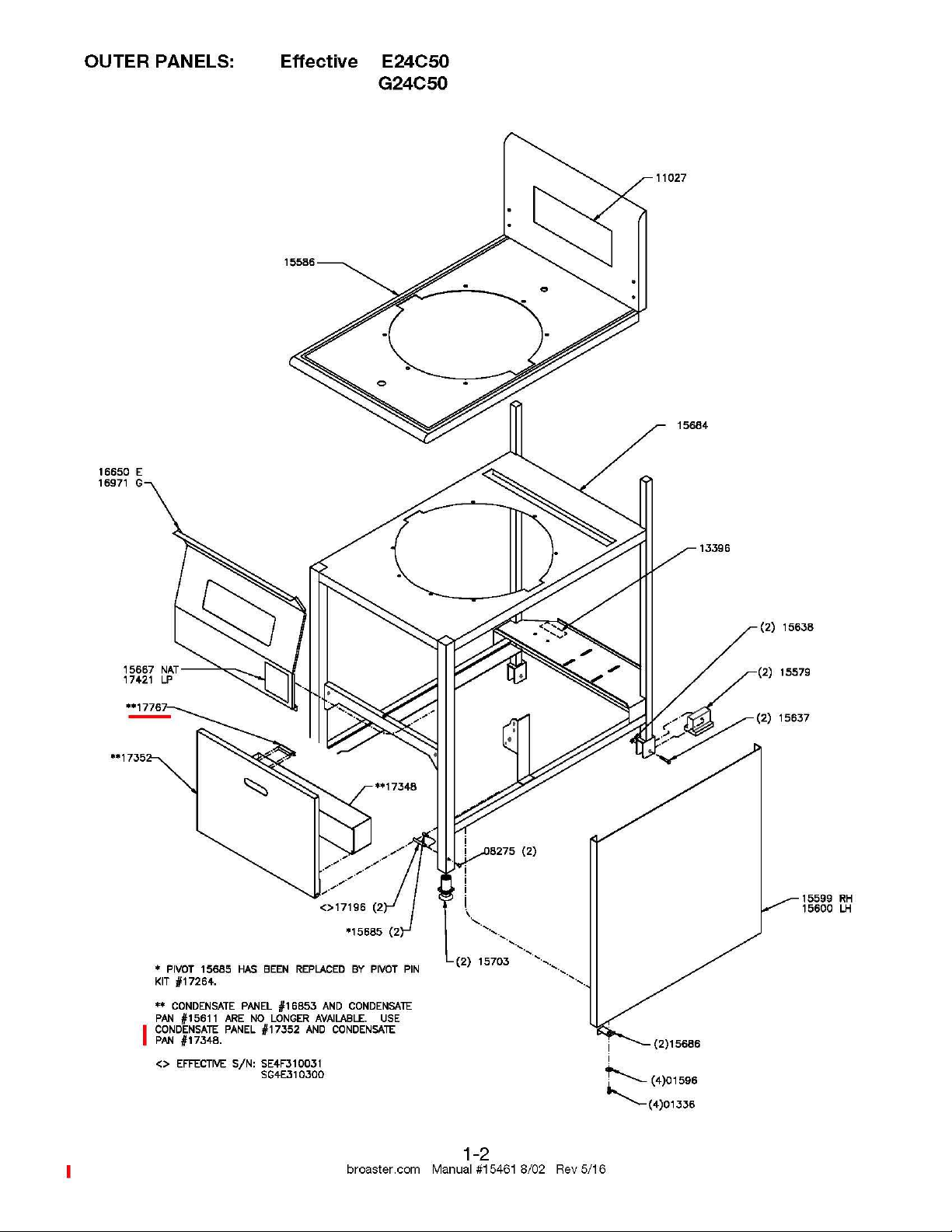

16650

16971 G

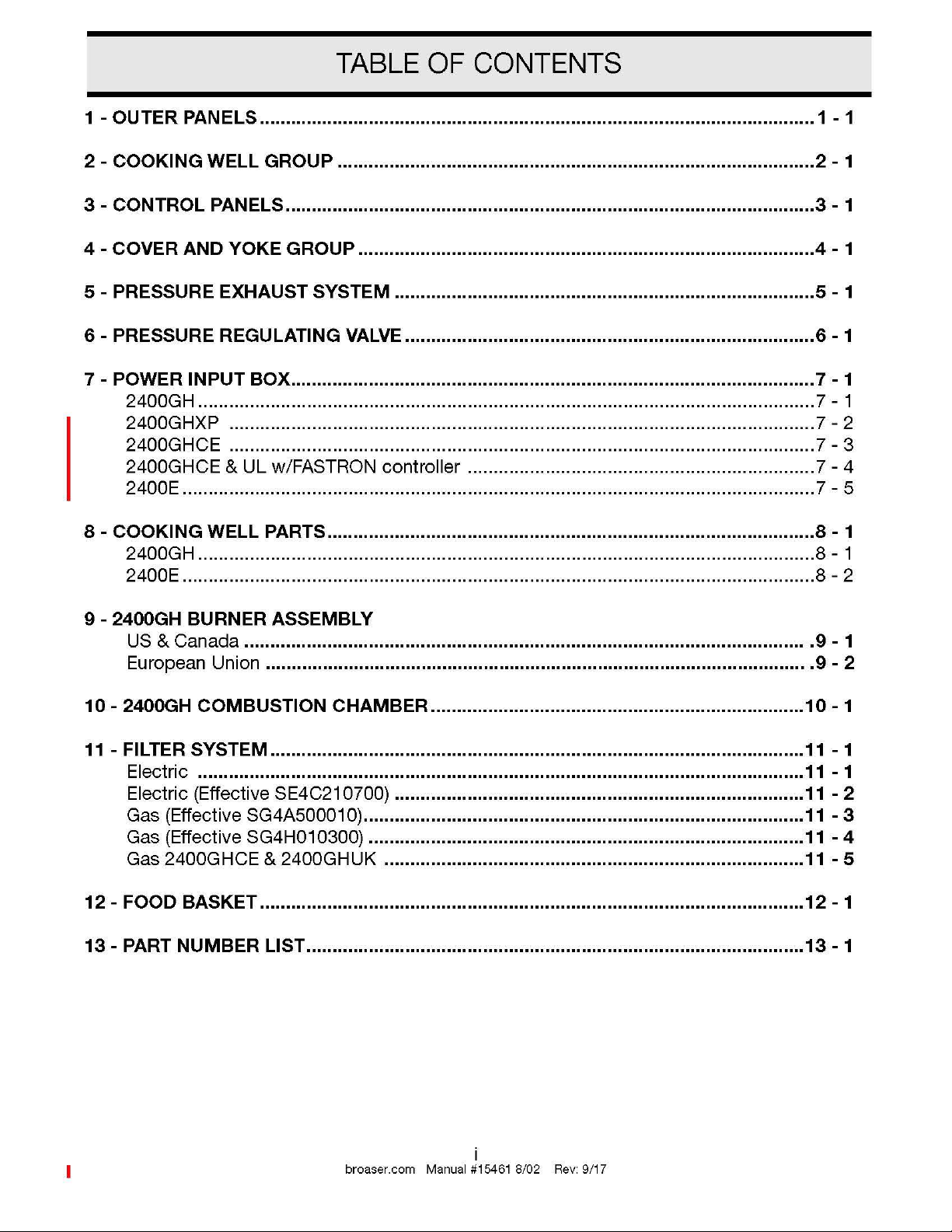

1 - OUTER PANELS

15684

E

••17352

•

PIVOT

15685

KIT

#17264.

••

CONDENSATE

PAN

#15611

CONDENSATE

PAN

#17348.

<>

EFFECTIVE

HAS BEEN

PANEL

ARE

NO

PANEL

S/N

: SE4f'310031

REPLACED

#16853

LONGER

#17352

SG4E310300

AVAILAB

ANO

BY

PIVOT

AND

CONDENSATE

LE.

CONDENSATE

USE

PIN

i

I

i

i

\

'·,,

·

-.

.

...............

....

...............

.

...........

i

i

t"-(4)01596

-............_ ( 4

)01336

13396

(2)

15638

15637

15599

15600

RH

LH

broaster.com Manual #15461

1-1

8/02 Rev 5/16

OUTER PANELS: Effective E24C50

G24C50

16650

E

16971 G

11027

1

5684

••1735

*

PIVOT

15685

KIT

#17264.

••

CONDENSATE

PAN

#15611

CONDENSATE

PAN

#17348.

<>

EFFECTIVE

HAS

PANEL

ARE

PANEL

S/N:

BEEN

#16853

NO

LONGER

#17352

SE4F310031

SG4E310300

REPLACED

AND

AVAILABLE.

AND

CONDENSATE

BY

PIVOT

PIN

CONDENSATE

USE

(2)

\

·, .

..........

,.

15703

'·,

...........

.....

._

..............

.

I

L'--(4)01596

- -............_(4)01336

(2)15686

1J396

(2)

15638

15637

15599

15600

RH

LH

broaster.com Manual #15461 8/02

1-2

Rev

5/16

<>

< 1 >

EFFECTIVE

EFFECTIVE

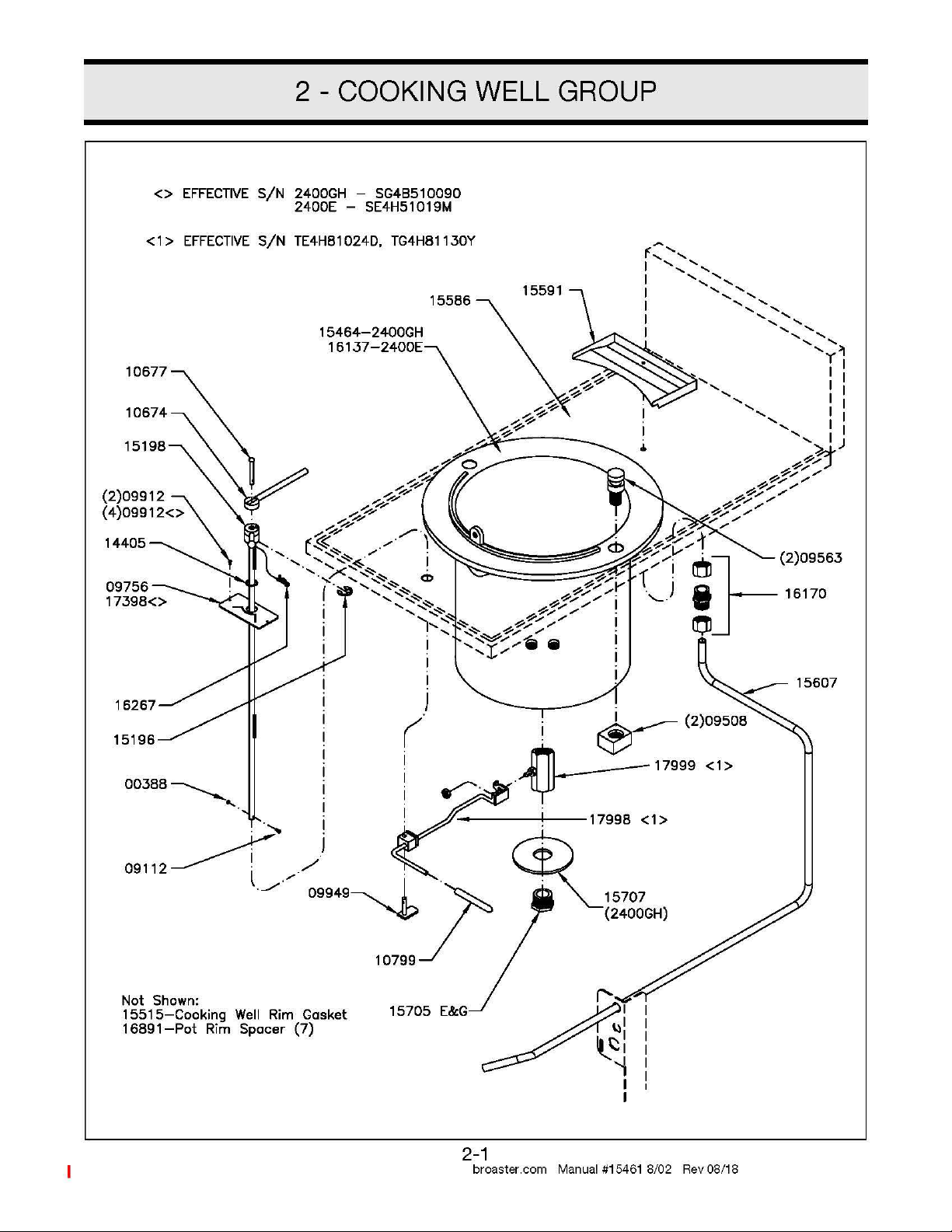

2 - COOKING WELL GROUP

S/N

2400GH - SG4B510090

2400E - SE4H51019M

S/N

TE4H81024D, TG4H81130Y

15464-2400GH

16137-2400E

(.

15586

I

I

I

J

15591

!

~

"'

.....

.....

.....

.....

(2)09508

..........

.....

.....

.....

15607

00388

---------

09112

Not Shown:

15515- Cooking

16891-Pot

Rim Spacer

.__

- ~

l

Well

.

./

__

_.../

09949~

Rim Gasket

(7)

-~17999<1>

l

.

-~

10799_/

15705

E&G

2-1

br

oaster .com Manual #15461 8/02 Rev 08/18

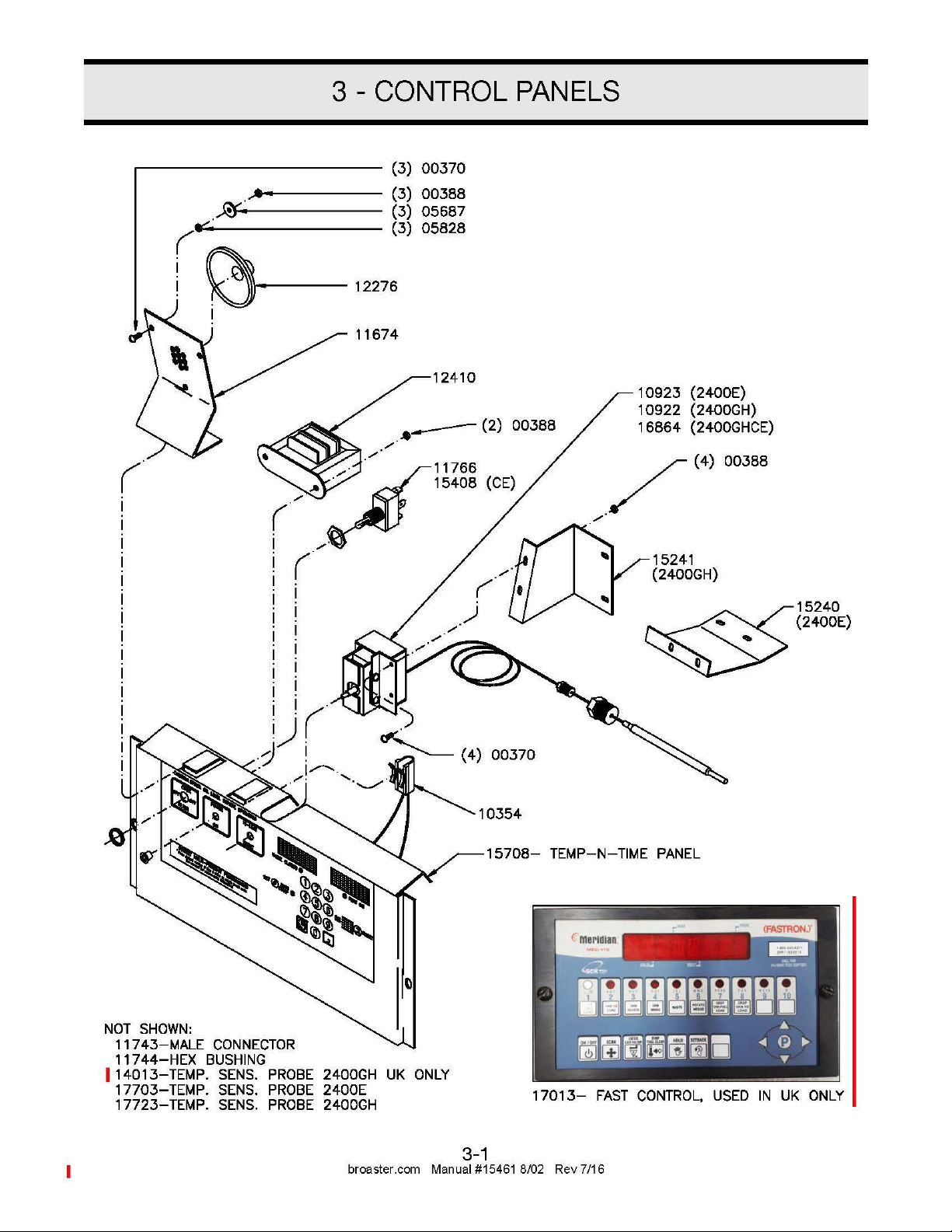

3 - CONTROL PANELS

.------------

(

(_

~

...

_______

~12276

I

------

(/

(3)

00370

(3)

00388

(3)

05687

(3)

05828

11674

12410

/

---

..

(2)

00388

;?·✓11766

_./~

15408

(CE)

(

10923 (2400E)

10922 (2400GH)

16864

/(4)

_,,,.

15241

(2400GH)

(2400GHCE)

00388

15240

(2400E)

NOT

SHOWN:

11743-MALE

11744-HEX

I 14

013-TEMP. SENS.

17703-TEMP.

17723-TEMP.

CONNECTOR

BUSHING

SENS.

SENS.

PROB

PROBE

PROBE

E 2400GH

2400E

2400GH

br

oaster.com Manual #15461 8/

UK

ONLY

3-1

00370

15708-

TEMP-N-TIME

17013-

02 Rev 7/16

FAST

PANEL

CONTROL,

USED

IN

UK

ONLY

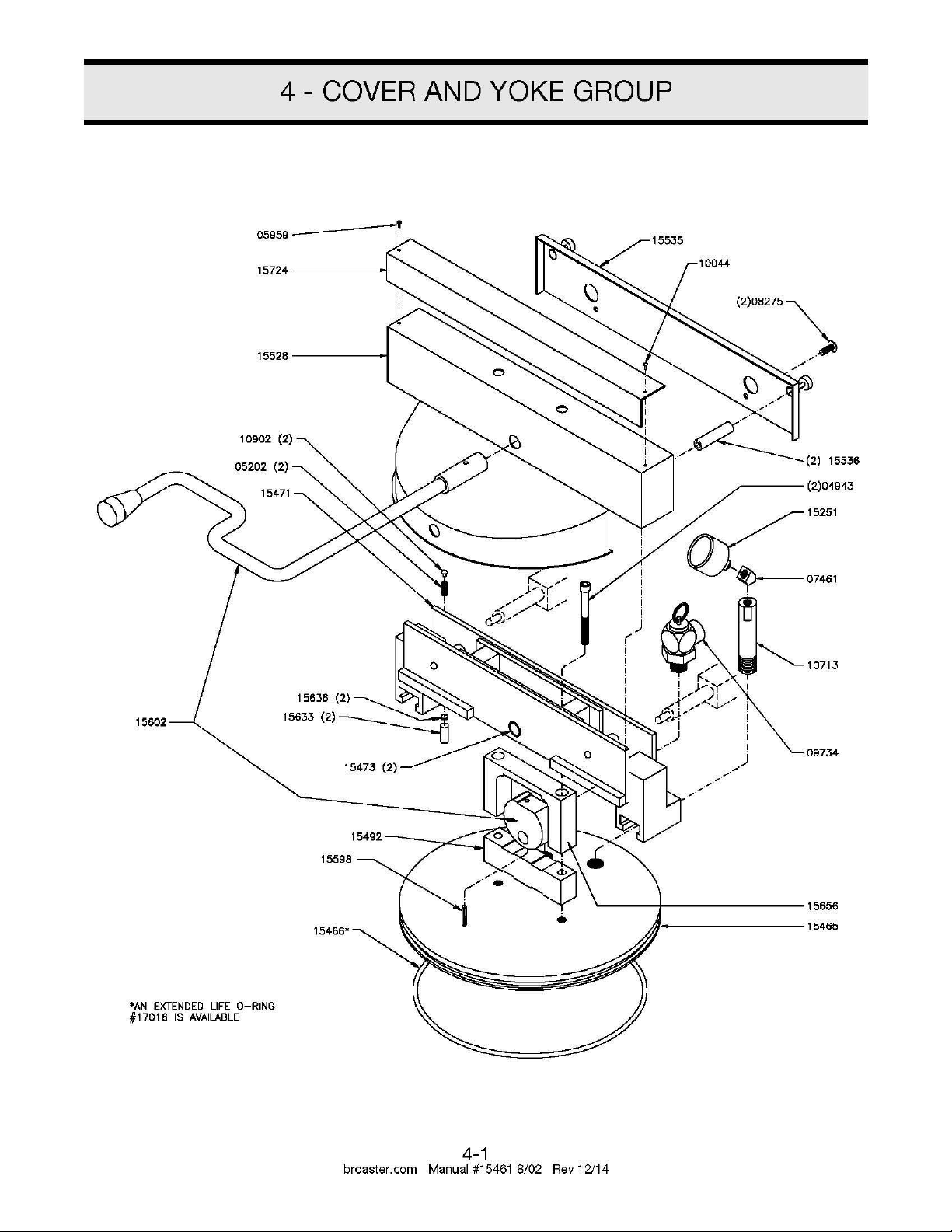

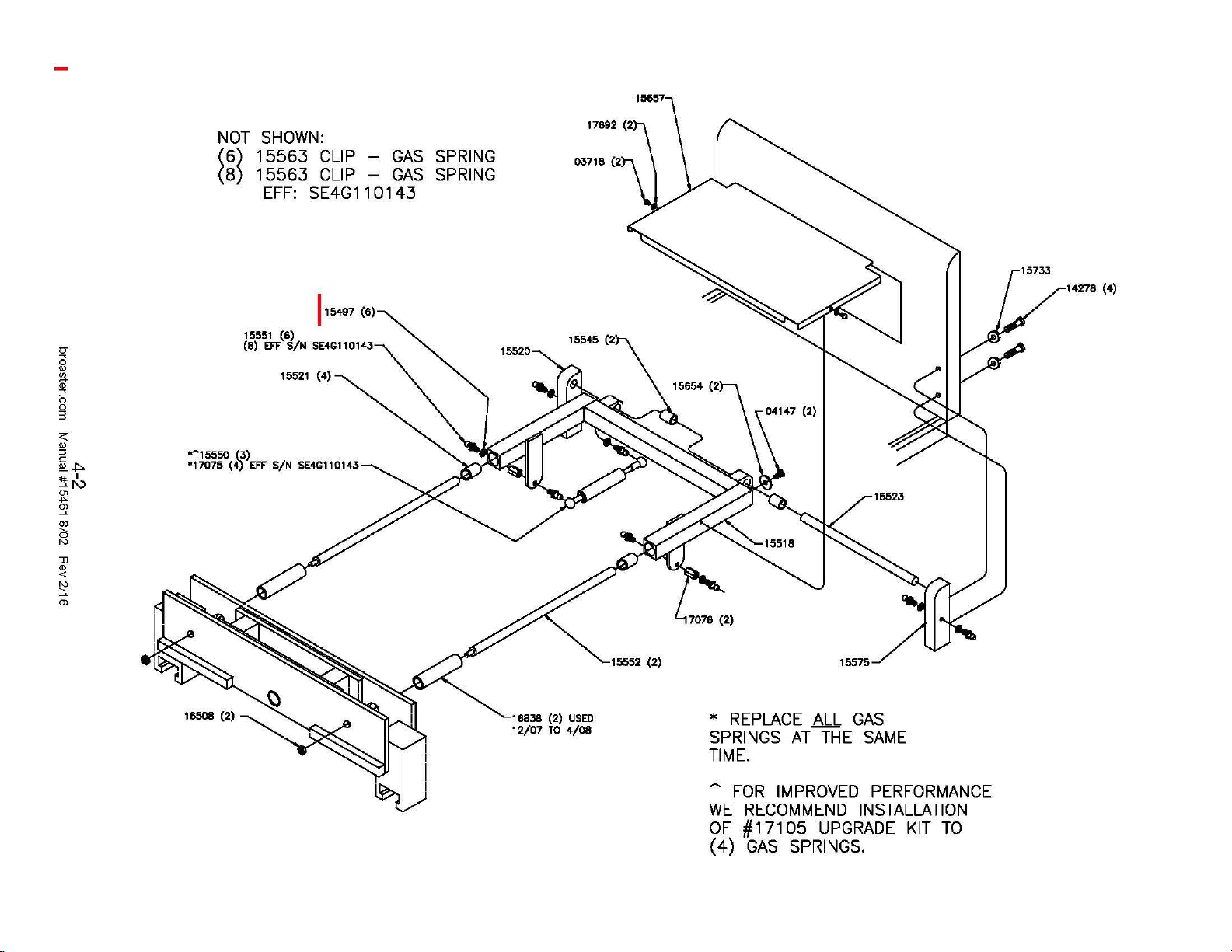

4 - COVER AND YOKE GROUP

05959------,

15724

------

(2)082'5~

15528------

10902

(2)

~---

,,.

/

(2)04943

09734

,,.

15536

•AN

EXTENDED

#17016

IS

AVAILABLE

LIFE

0-RING

broaster. com Manual

4-1

#15461

'-----+----------15656

8/02 Rev 12/14

/A----------

15465

CT

2

(/)

~

()

~

s::

:,

"'

i.i:,.

~I\)

'.{:

a,

~

00

c5

""

:0

(I)

<

~

a,

NOT

(6)

(8)

.-15550

•17075 (4)

SHOWN:

15563

15563

EFF:

15551 (6)

(8)

EFF

(3)

EFT

S/N SE4G110143

CLIP -GAS

CLIP -GAS

SE4G110143

115497 (6)

S/N

SE4G110143

SPRING

SPRING

-14278

(4)

*

REPLACE

SPRINGS

TIME.

"'

FOR

WE

RECOMMEND

OF

#17105

(4)

GAS

ALL

GAS

AT

THE

IMPROVED

UPGRADE

SPRINGS.

SAME

PERFORMANCE

INSTALLATION

KIT

TO

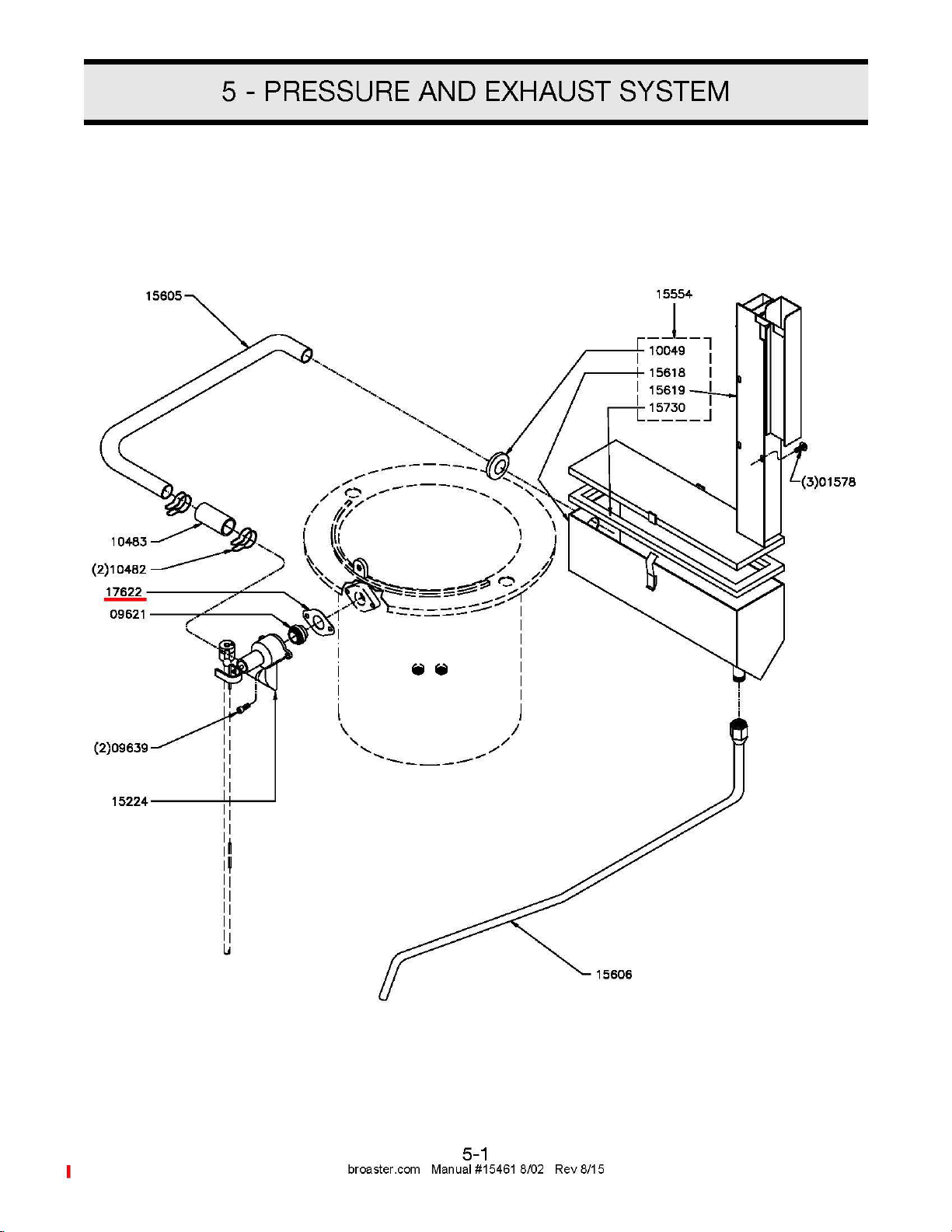

5 - PRESSURE AND EXHAUST SYSTEM

15605

,_ _ _.._I

---

15554

_

_l

__

10049 I

15618 I

I 15619

I 15730 I

L

--...I_______,

____

l

J

broaster.com Manual #15461 8/02 Rev 8/15

5-1

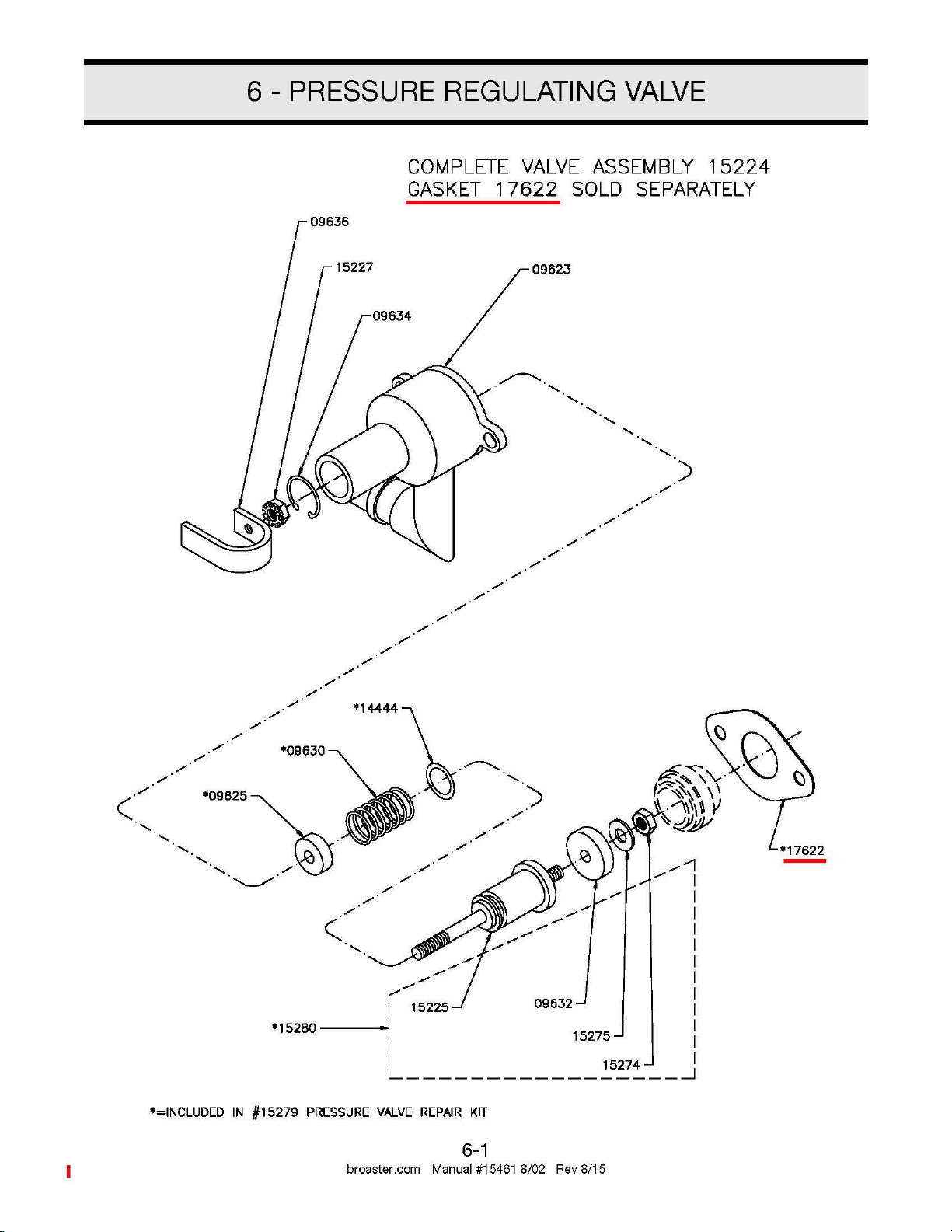

6 - PRESSURE

REGULATING

VALVE

(

/

'

/

'

/

'

/

/

'09625~

'

'

/

/

/

/

......._,,,,,

*09630

_,,,,,

/

_..IQ

/

(

COMPLETE VALVE ASSEMBLY

GASKET

17622

SOLD SEPARATELY

15224

'

'

'

'

'

'

)

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

/

~"'"\,,

fr~\\

~

-

/

/

/

/

/

/

/

/

/

. /

/\\~\

~d.#

\ \

I y

·

•=

INCLUDED

IN f15

*15280---

279

PRESSURE

'

09632

I

I 15

L-----------------~

VALVE

broaster.c

REPAIR

om Manu

KIT

6-1

al #15461 8/02

15275

V4

Rev 8/15

Loading...

Loading...