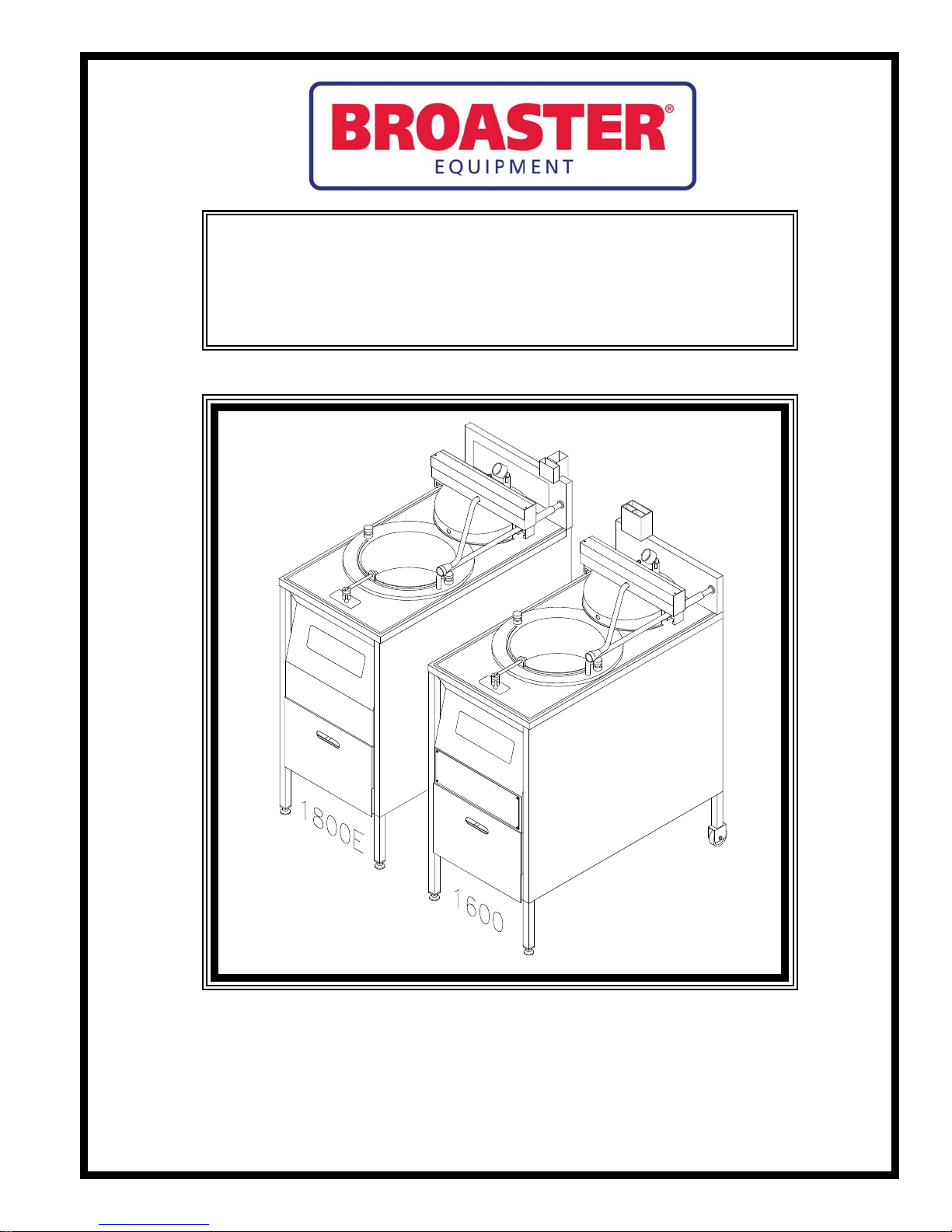

Broaster 1600, 1800, 1800E, 1600XP, 1600CE Installation Manual

...

INSTALLATION MANUAL

BROASTER® 1600 AND 1800

PRESSURE FRYER

Be sure ALL installers read, understand, and have access to this manual at all times.

Genuine Broaster Chicken®, Broasted®, Broaster Chicken®, Broaster Foods®. and Broasterie® are registered

trademarks. Usage is available only to licensed operators with written authorization from the Broaster Company.

2855 Cranston Road, Beloit, WI 53511-3991

Design Certified By:

1600: CSA, NSF and UL

1800: CSA (AGA & CGA), NSF and UL

The Broaster Company

608/365-0193 broaster.com

#14678 1/99 Rev: 10/14

© 1999 the Broaster Company

Printed In U.S.A.

All adjustments and repairs shall be made

FOR YOUR SAFETY

Do not use or store gasoline or other flammable vapors

or liquids in the vicinity of this or any other appliance.

Improper installation, adjustments, alteration, service or maintenance can cause

property damage, injury or death. Read the installation, operating and maintenance instructions thoroughly before installing or servicing this equipment.

For the sake of safety and clarity, the following words used in this manual are defined as follows:

Indicates an imminently hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in serious injury or death.

Indicates a potentially hazardous situation which, if not avoided, could

result in minor injury, property damage or both.

by an authorized Broaster Company representative.

when the cook/filter switch is moved to

If at any time the POWER

ON light does not turn off

the OFF position, contact your local

If there is a power failure, turn cook/filter

switch OFF. On the Model 2400GH, also

Broaster Company representative for

service immediately.

slide switch on gas valve OFF. DO NOT

attempt to operate unit during a power failure.

DO NOT operate unit

without filter pan and filter

pan cover in its proper position. Filter

2400GH: Post, in prominent locations,

instructions to be followed in the event that

pan cover must be wiped clean after

each filtering cycle.

the user smells gas. This information can be

obtained from your local gas supplier.

Make sure Pressure Relief

Valve and Pressure Gauge

Failure to read and

completely could result in serious injury

or death. Be sure ALL operators read,

understand this manual

ports on bottom of cover are clear of any

oil or grease buildup.

1600 Mechanical Controls:

understand and have access to this

manual at all times.

if exposed to heat. Laundering will not

remove the oil. Dispose of all oil-soiled

papers and rags in a trash container that

is in a ventilated area away from all

Rags or paper containing

cooking oil can catch fire

the cook/filter switch is moved to the

cook position, contact your local

If at any time the unit fails

to operate properly when

Broaster Company representative for

service immediately.

cooking equipment or other heat

sources such as direct sunlight.

W-1

broaster.com Manual #14678 1/99 Rev: 2/14

1600/1800E Solid State Controls:

If at any time the POWER

ON light does not turn off

when the cook/filter switch is moved to

the OFF position, contact your local

Broaster Company representative for

service immediately.

broaster.com Manual #14678 1/99 Rev: 2/14

W-2

TABLE OF CONTENTS

1 - PRE-INSTALLATION ....................................................................................................1 - 1

LOCATION...................................................................................................................1 - 1

CLEARANCE...............................................................................................................1 - 1

LEVELING ...................................................................................................................1 - 1

RECOMMENDED VENTILATION REQUIREMENTS....................................................1 - 2

General Requirements ........................................................................................1 - 2

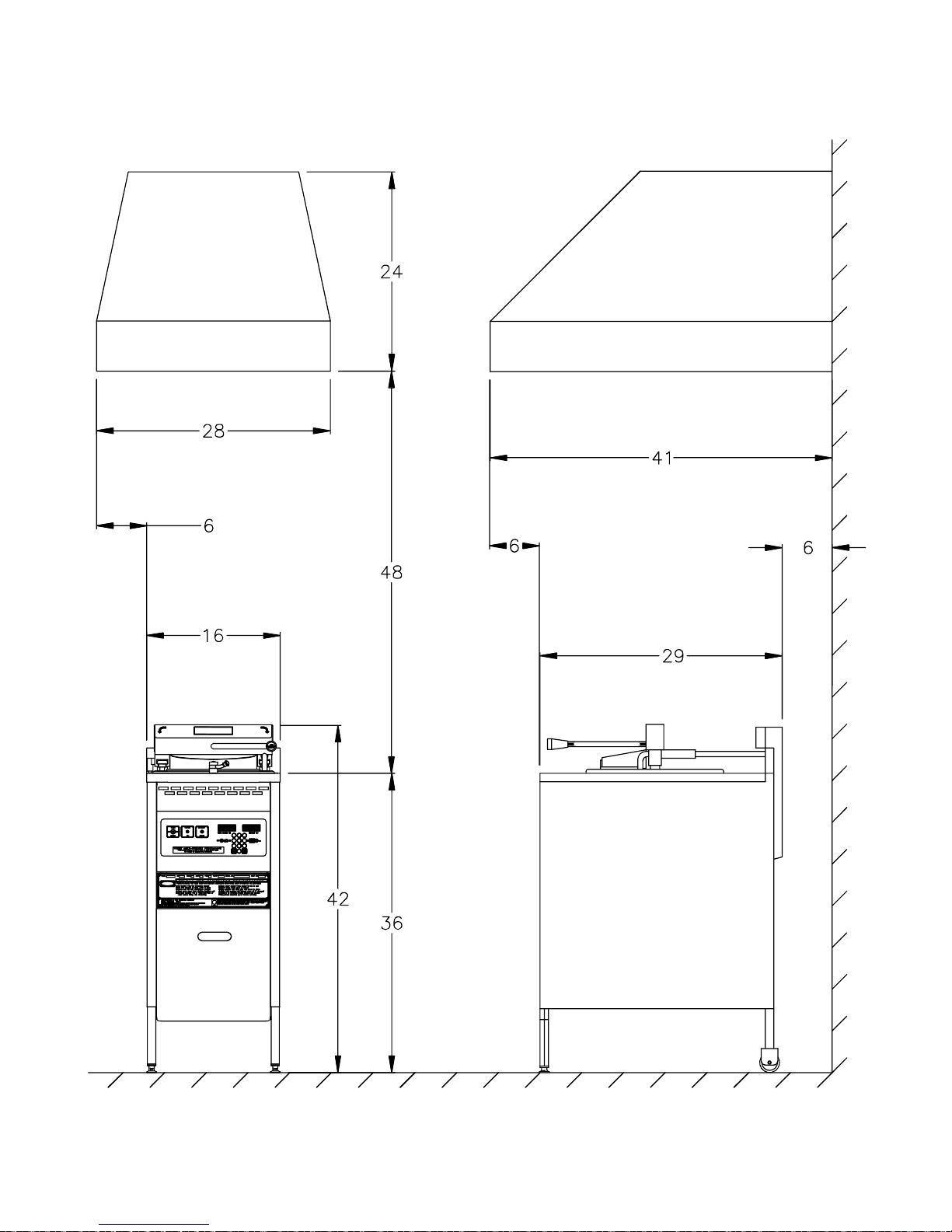

1600 Hood Dimensions In Inches .......................................................................1 - 3

1800 Hood Dimensions In Inches .......................................................................1 - 4

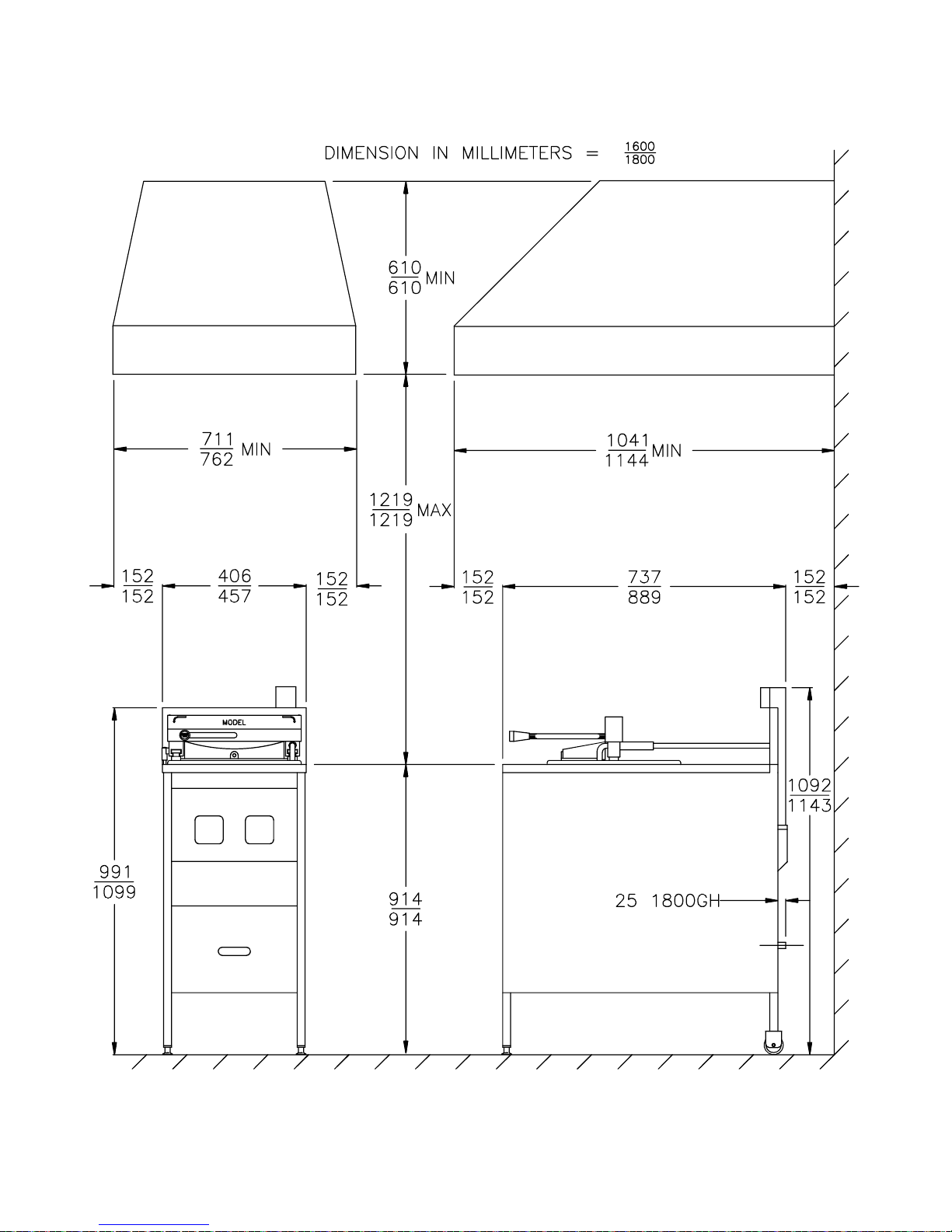

1600/1800 Hood Dimensions In Millimeters .......................................................1 - 5

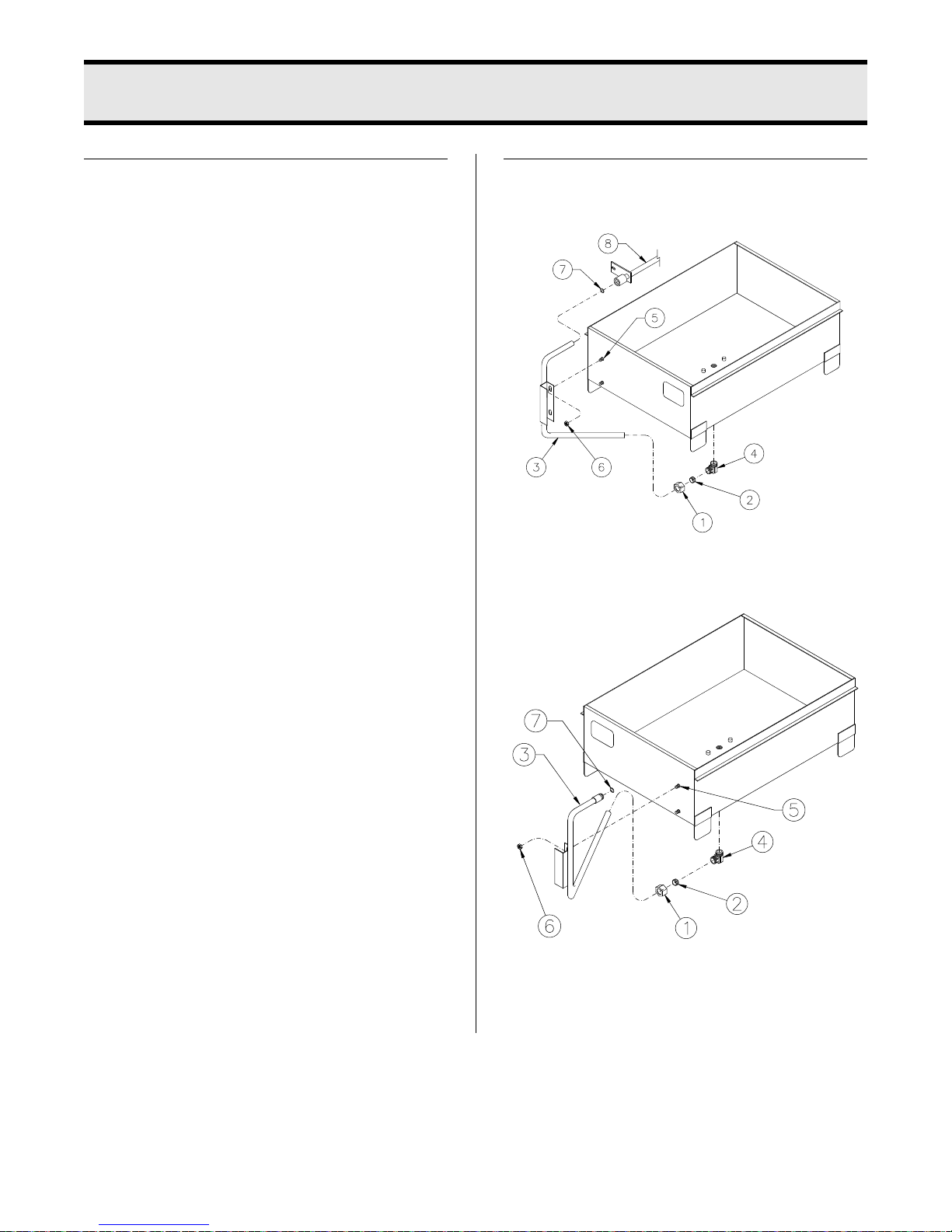

2 - FILTER PAN ASSEMBLY ..............................................................................................2 - 1

HARDWARE LIST........................................................................................................2 - 1

ASSEMBLY .................................................................................................................2 - 1

ADDITIONAL ADJUSTMENTS IF NEEDED.................................................................2 - 3

3 - 1600/1800E INSTALLATION.........................................................................................3 - 1

ELECTRICAL CHARACTERISTICS .............................................................................3 - 1

ELECTRICAL CONNECTIONS....................................................................................3 - 1

1600 Suggested Wiring Capacity Table..............................................................3 - 1

1800 Suggested Wiring Capacity Table..............................................................3 - 1

ELECTRICAL HOOK-UP .............................................................................................3 - 2

Access For Hook-Up ..........................................................................................3 - 2

Phase Wiring .......................................................................................................3 - 2

Unit Dimensions For Electrical Hook-Up ............................................................3 - 3

Wiring Diagrams

DOMESTIC:

1600 Mechanical ......................................................................................3 - 4

1600/1800E Solid State............................................................................3 - 8

EXPORT:

1600XP/1800EXP Mechanical ...............................................................3 - 12

1600XP/1800EXP Solid State ................................................................3 - 15

EU:

1600CE Mechanical ...............................................................................3 - 18

1600CE/1800ECE Solid State ................................................................3 - 19

United Kingdom:

1600UK/1800EUK ..................................................................................3 - 20

480V Units:

1800E 480V Δ.........................................................................................3 - 21

1600XP 240/480V...................................................................................3 - 22

1800XP 480V..........................................................................................3 - 24

broaster.com Manual #14678 1/99 Rev 3/14

i

4 - 1800GH INSTALLATION ...............................................................................................4 - 1

GENERAL REQUIREMENTS.......................................................................................4 - 1

EU: ......................................................................................................................4 - 1

USA & Canada ....................................................................................................4 - 1

ELECTRICAL CHARACTERISTICS .............................................................................4 - 2

ELECTRICAL CONNECTIONS....................................................................................4 - 2

WirIng Diagrams ....................................................................................................4 - 2

DOMESTIC: 1800GH .........................................................................................4 - 2

EXPORT: 1800GH .............................................................................................4 - 3

EU: 1800GHCE .................................................................................................4 - 4

EU: 1800GHCE for United Kingdom..................................................................4 - 5

GAS CHARACTERISTICS ...........................................................................................4 - 6

BTU/HR Ratings..................................................................................................4 - 6

Gas Pressure And Orifices..................................................................................4 - 6

Gas Conversion ..................................................................................................4 - 6

High Altitude .......................................................................................................4 - 6

GAS PIPING ................................................................................................................4 - 7

Unit Dimensions For Gas Hook-Up ....................................................................4 - 7

Example Of Piping System Design .....................................................................4 - 8

5 - OPERATIONAL CHECK-OUT ......................................................................................5 - 1

COVER ASSEMBLY ....................................................................................................5 - 1

INITIAL STARTUP

Electric .............................................................................................................. 5 - 1

Gas .....................................................................................................................5 - 2

1800GH LIGHTING INSTRUCTIONS ..........................................................................5 - 2

Start-Up ..............................................................................................................5 - 2

Shut Down ..........................................................................................................5 - 3

AIR SHUTTER ADJUSTMENT ...................................................................................5 - 3

broaster.com Manual #14678 1/99 Rev: 3/14

ii

1 - PRE-INSTALLATION

LOCATION

For convenience and speed, location of the

unit should be given careful consideration.

If possible, locate the unit so the flow of

cooked product is in a straight line from

storage, in and out of the unit and to the

customer. Landing tables should be provided on at least one side of the unit.

• To avoid splashing of hot liquid, unit

must be restrained to prevent tipping.

This can be done by installing the unit in

a battery of appliances, in an alcove or

with adequate ties

• Provision must be made to eliminate

movement of the unit which might cause

strain on electrical and gas connections.

• DO NOT install unit where traffic areas

are on either side or in back of unit.

CLEARANCE

USA & EU:

Gas units are to be installed only in noncombustible locations. Minimum clearances for non-combustible construction is 0 inches from sides and 6 inches

from back.

CANADA:

Gas units are certified for installation on

a combustible floor. Minimum clearances for combustible construction is 1

inch from sides and 6 inches from back.

LEVELING

Adjust front feet to level entire unit. Add

additional blocking if necessary on a sloping floor.

1-1

broaster.com Manual #14678 1/99 Rev 2/14

RECOMMENDED VENTILATION

General Requirements:

REQUIREMENTS

Exhaust hood should comply with ANSI/

NFPA #96 or national, state and local

codes. All units must be under an adequate

power exhaust hood for ventilation of cooking vapors and products of combustion.

Precautions should be taken in the design

of the exhaust hood to avoid interference

with operation of the unit. Consult a local

ventilation company for fire suppression,

design and installation of a hood.

DO NOT extend the

exhaust stack or exhaust

flue of any unit. Doing so may cause a negative back draft causing malfunction and

interference with burner operation on the

1800GH and improper exhausting of cooking vapors on all units.

1. Exhaust hood must conform to applicable national, state and local codes.

2. It is recommended that requirements

of the National Fire Protection Association (NFPA), Standard No. 96 be followed for the design, installation and

use of exhaust system components.

This includes hoods, grease removal

devices, exhaust ducts, dampers, air

moving devices, auxiliary equipment

and fire extinguishing equipment for

the exhaust system and the cooking

equipment used therewith in commercial, industrial, institutional and similar

cooking applications.

3. Hood Size: The overhead canopy

type hood should be sized to completely cover the equipment it is

designed to ventilate plus an overhang

of at least 6 inches on all sides of

equipment not immediately adjacent

to walls or other construction extending above the cooking surface. Noncanopy, prefabricated “backshelf”

type hoods should be sized according

to the manufacturers specifications.

4. Exhaust Air Volume (minimum):

Canopy hood open on all four sides:

1800 cu. ft./minute. Canopy hood

open on three sides or less: 1200 cu.

ft./minute.

5. Exhaust Air Velocity: All exhaust

ducts should be sized to provide an air

velocity in the ducts of at least 1500

ft./minute.

1-2

broaster.com Manual #14678 1/99 Rev 2/14

1600 Hood Dimensions In Inches:

DANGER

MAXIMUM WORKING

PRESSURE 15 PSI

BEFORE OPERATINGCHECK OIL LEVELCAUTION!

0

21

475

8

3

6

9

MADE IN U.S.A.

SAFETY AND OPERATIN G INSTRUCTIONS

NSF

MANUFACT URED BY THE BROA STER COM PANY

MODEL 1600

UNLESS PRESSURE IS AT ZERO P.S.I.

DO NOT O PEN COVER

COVER CLOSED

COVER OPEN

1-3

broaster.com Manual #14678 1/99 Rev 2/14

1800 Hood Dimensions In Inches:

1-4

broaster.com Manual #14678 1/99 Rev 2/14

1600/1800 Hood Dimension In

Millimeters:

1-5

broaster.com Manual #14678 1/99 Rev 2/14

2 - FILTER PAN ASSEMBLY

HARDWARE LIST

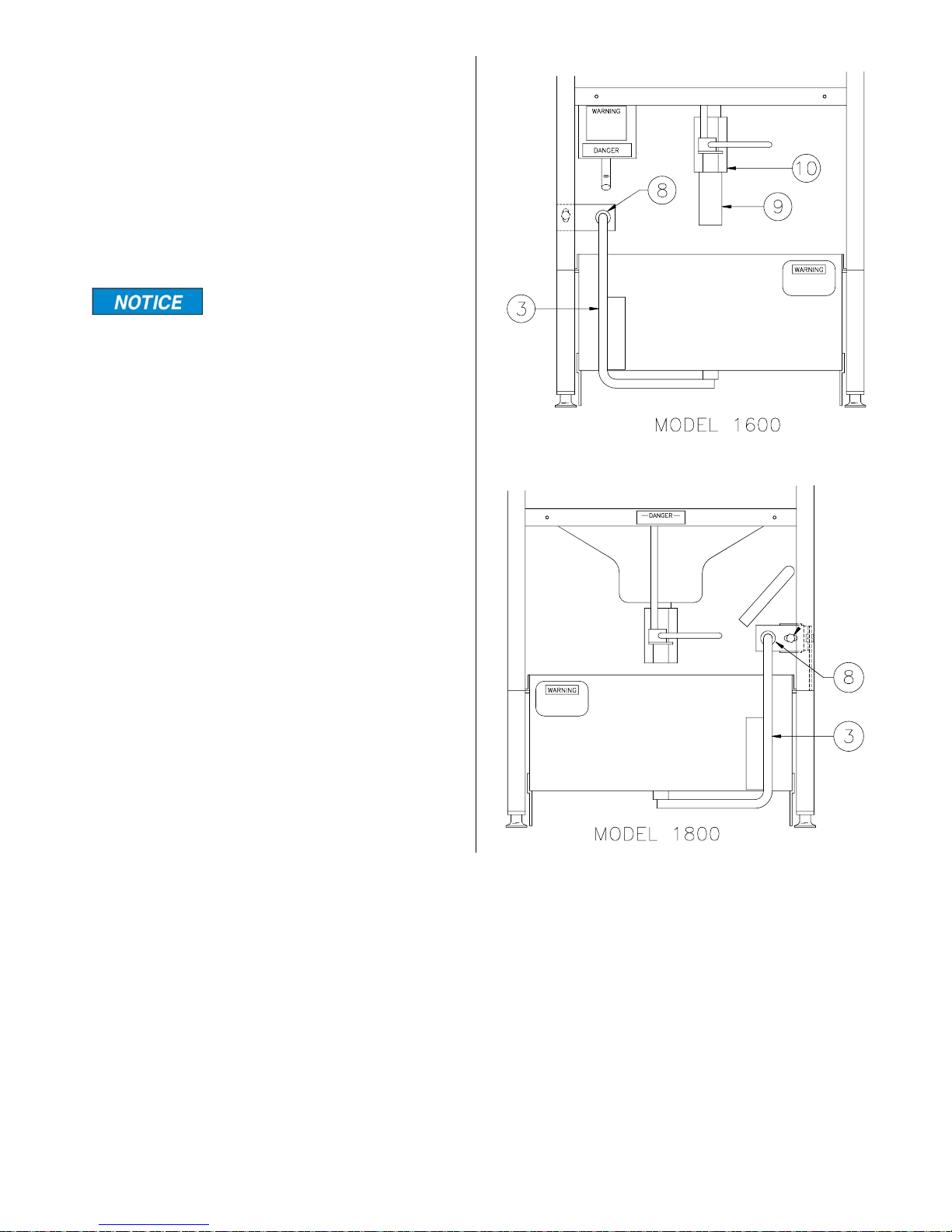

1600:

1 - Compression Nut #02536 (1)

2 - Brass Ferrule #02537 (1)

3 - Riser Line #11314 (1)

6 - Keps Nut #00522 (2)

7 - O-ring #09883 (3)

9 - Nipple #08696 (1)

1800:

1 - Compression Nut #02536 (1)

2 - Brass Ferrule #02537 (1)

3 - Riser Line #11308 (1)

6 - Keps Nut #00522 (2)

7 - O-ring #09883 (3)

ASSEMBLY

1600:

1800:

1. From bag of hardware, install compression nut (1) then ferrule (2) onto

riser line (3).

2-1

broaster.com Manual #14678 1/99 Rev 2/14

2. Install riser line (3) onto pan. First

install line into elbow (4) on bottom

center of pan while handle fits over

studs (5) on front of pan.

3. Install keps nuts (6) onto studs (5) but

do not tighten.

4. Tighten nut onto elbow (4).

Elbow may have to be

turned with a wrench if nut

will not start onto elbow.

5. .Lubricate O-ring (7) with cooking oil.

1600: Install O-ring (7) into inner

groove in suction line (6). Screw nipple

(9) into drain valve (10).

1800: Install O-ring (7) into groove on

riser line (3).

6. Install filter pan under unit and align

riser line (3) with suction line (8).

7. Tighten keps nuts (6) mounting riser

line (3) to filter pan.

8. See Operation Manual for additional

assembly.

2-2

broaster.com Manual #14678 1/99 Rev 2/14

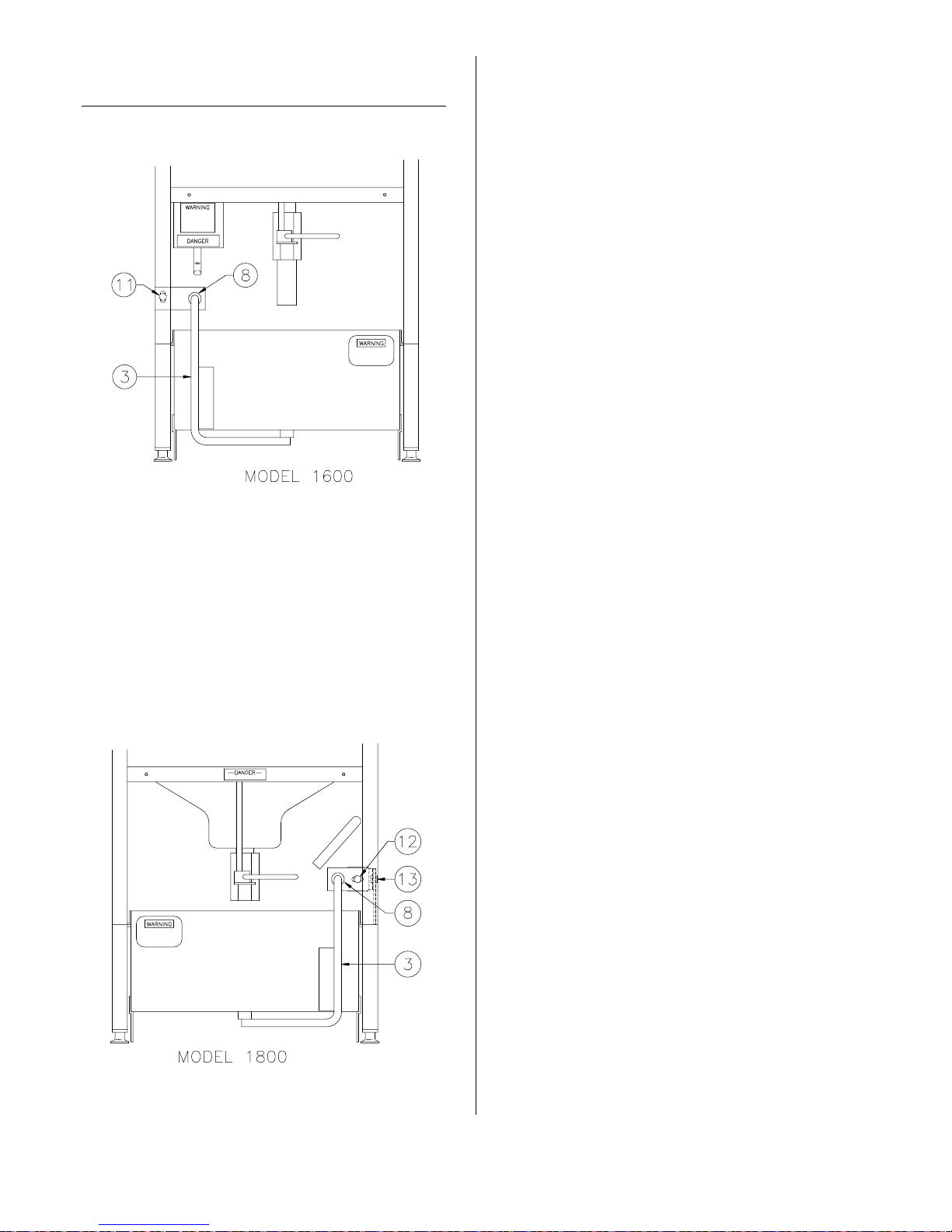

ADDITIONAL ADJUSTMENTS

2. Loosen bolt (12) and nut and bolt (13).

IF NEEDED

1600:

1. Loosen nut and bolt (11).

3. Push pan under unit. By hand, move

suction line (8) until riser line (3) is fully

inserted into suction line.

4. Tighten all nuts and bolts.

5. Replace side panel

2. Push pan under unit. By hand, move

suction line (8) until riser line (3) is fully

inserted into suction line.

3. Tighten all nuts and bolts.

1800:

1. Remove side panel.

2-3

broaster.com Manual #14678 1/99 Rev 2/14

3 - 1600/1800E INSTALLATION

ELECTRICAL CHARACTERISTICS

These models are available for either 208,

240 or 480 applied voltage, 60Hz, 3 phase

electrical connection in the USA and several voltages for export applications.

Be sure to check the wiring diagram located

inside the front panel. It shows electrical

circuits and connections. See Access For

Hook-Up under ELECTRICAL HOOK-UP.

• All electrical work must conform with the

requirements of national, state and local

electrical codes.

• When installing or servicing the unit,

always check the dataplate located on

the front panel (1600) or toward the rear

of the counter top (1800) to make certain proper parts are used and the correct service rendered. DO NOT apply a

voltage to any unit other than that

shown on the dataplate. If in doubt,

consult your local power company.

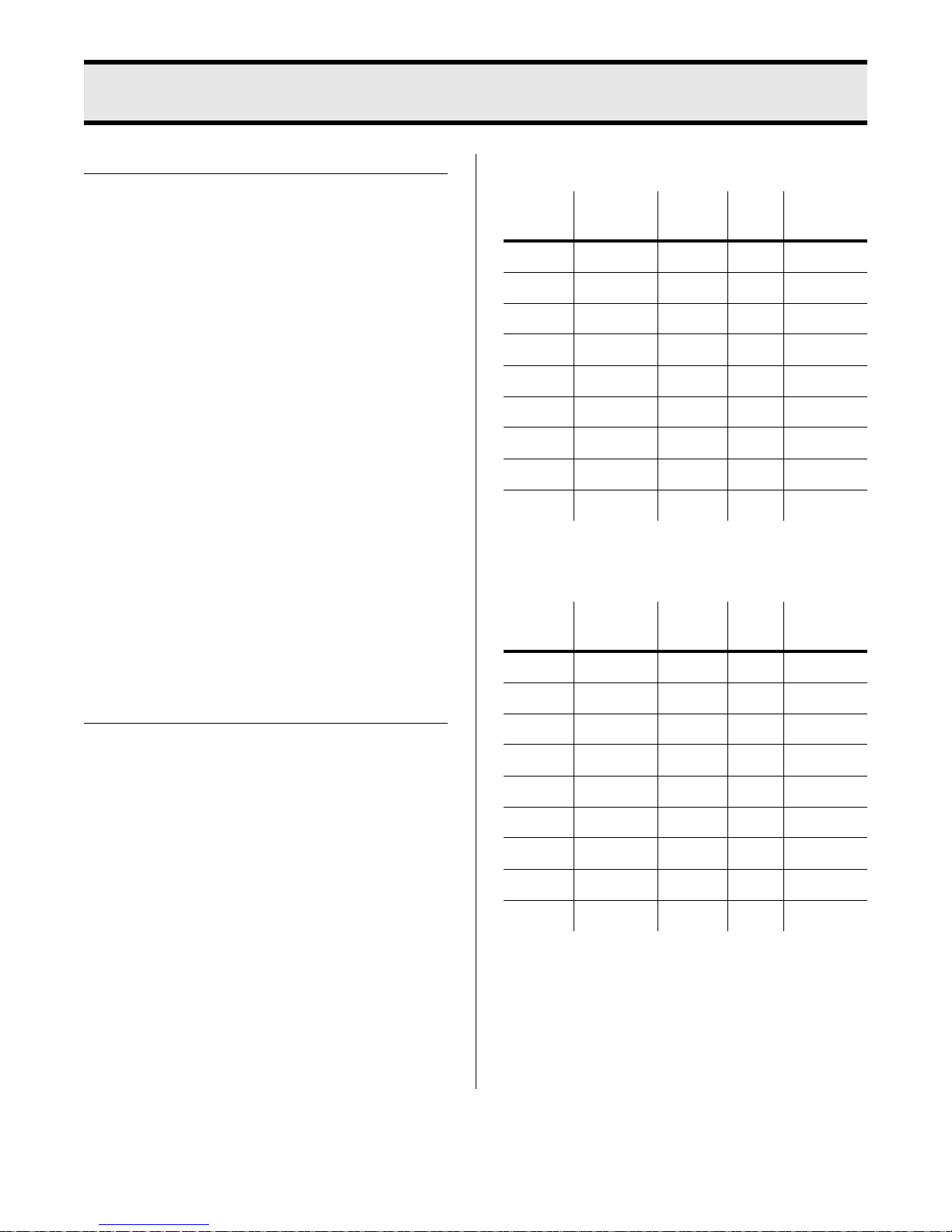

1600 Suggested Wiring Capacity Table:

Phase Volts Amps Wire

1 208 29 #8 40

1 220 30.5 #8 40

1 230 26 #8 40

1 240 27 #8 40

3 208 17 #10 25

3 240 16 #10 20

3 220/380 10.2 #10 15

3 230/400 8.7 #10 15

3 240/415 9.1 #10 15

Breaker

or Fuse

1800E Suggested Wiring Capacity Table:

Phase Volts Amps Wire

1 208 48 #8 60

Breaker

or Fuse

ELECTRICAL CONNECTIONS

• A remote circuit breaker or fuse should

be installed in main power supply

located in a path of exit and clearly identified.

• When installed, the unit must be electrically grounded in accordance with local

codes, or in the absence of local codes,

with the National Electrical Code, ANSI/

NFPA 70, or for Canada, the Canadian

Electrical Code, CSA C22.2, as applicable.

• Use copper wire only for connections.

• If power run is over 50 feet, use next

larger size wire.

1 220 50 #8 60

1 230 43 #8 60

1 240 45 #8 60

3 208 28 #8 40

3 240 26 #8 40

3 220/380 16.8 #10 20

3 230/400 14.3 #10 20

3 240/415 15 #10 20

broaster.com Manual #14678 1/99 Rev 2/14

3-1

Loading...

Loading...