Broan Elite EW5830SS, Eltie EW5836SS Instructions Manual

BmeAm+

Chimney

MODELS EW5830SS ,, EW5836SS

ange cod

FOR DOMESTIC

WARNING

TO REDUCE THE RISK OF FIRE, ELECTRIC SHOCK, OR iNJURY

TO PERSON(S) OBSERVE THE FOLLOWING:

1. Use this unit only in the manner intendedby the manufacturer. If

you have questions, contact the manufacturer at the address or

telephone number listed inthe warranty.

2. Before servicing or cleaning unit,switch power off at service panel

and lock service disconnecting means to prevent power from being

switch on accidentally. When the service disconnecting means

cannot be locked, securely fasten a prominent warning device,

such as a tag, to the service panel.

3. Installation work and electrical wiring must be done by qualified

personnel in accordance with all applicable codes and standards,

includingfire-ratedconstruction codes and standards.

4. Sufficient air is needed for proper combustion and exhausting

of gases through the flue (chimney) of fuel burning equipment to

prevent back drafting. Followthe heating equipment manufacturer's

guideline and safety standards such as those published by the

National Fire Protection Association (NFPA), and the American

Society for Heating, Refrigeration and Air Conditioning Engineers

(ASHRAE), and the local code authorities.

5. This product may have sharp edges. Be careful to avoid cuts and

abrasions during installationand cleaning.

6. When cutting or drilling intowall or ceiling, do not damage electrical

wiring and other hidden utilities.

7. Ductedfans must always be vented to the outdoors.

8. Use only metal ductwork.

9. Do not use this unit with any other solid-state speed control device.

10. Donot operate any fan with a damaged cord or plug. Discard fan or

returnto an authorized service facility for examination and/or repair.

11.GROUNDING INSTRUCTION: The appliance must be grounded.

Inthe event of an electrical short circuit, grounding reduces the risk

of electric shock byprovidingan escape wire for theelectric current.

The appliance is equipped witha cord having a grounding wire with

a grounding plug. The plug must be plugged intoan outlet that is

properly installedand grounded. WARNING: improper grounding

can result in a risk of electric shock. Consult a qualified electrician

if the grounding instructions are not completely understood, or if

doubt exists as to whether the appliance is properly grounded. Do

not use an extension cord. If the power supply cord is too short,

have a qualified electrician installan outlet near the appliance.

TO REDUCE THE RiSK OF A RANGE TOP GREASE FIRE:

a) Never leave surface units unattended at high settings. Boilovers

cause smoking and greasy spillovers that may ignite. Heat oils

slowly on lowormedium settings.

b) Always turn hood ON when cooking athigh heat or when flamb_ing

food (i.e. Cr_pes Suzette, Cherries Jubilee, Peppercorn Beef

Flamb_).

c) Clean ventilating fans frequently. Grease should not be allowed to

accumulate on fan or filters.

d) Use proper pan size. Always usecookware appropriate forthe size

of the surface element.

Page I

COOKING ONLY

WA.NING

TO REDUCE THE RiSK OF iNJURY TO PERSON(S) iN THE EVENT

OF A RANGE TOP GREASE FIRE, OBSERVE THE FOLLOWING*:

1. SMOTHER FLAMES with a close-fitting lid,cookie sheet, or metal

tray,then turn off the burner. BE CAREFULTO PREVENT BURNS.

IF THE FLAMES DO NOT GO OUT IMMEDIATELY,EVACUATE

AND CALL THE FIRE DEPARTMENT.

2. NEVER PICK UP A FLAMING PAN- You may be burned.

3. DO NOT USEWATER,includingwetdishcloths or towels- a violent

steam explosion will result.

4. Use an extinguisher ONLYif:

A. You know you havea Class ABC extinguisher, and you

know how to operate it.

B. The fire issmall and contained inthe area where itstarted.

C. The fire department is being called.

D. You can fight the fire with your back to an exit.

* Basedon "Kitchen FireSafety Tips" published by NFPA

CAUTION

1. For indooruse only.

2. For general ventilating use only.Do not use to exhaust hazardous

or explosive materials and vapors.

3. To avoid motor bearing damage and noisy and/or unbalanced

impeller,keepdrywall spray, construction dust, etc. off power unit.

4. Your hood motor has a thermal overload which will automatically

shut off the motor ifitbecomes overheated.The motor will restart

when it will cool down. If the motor continues to shut off and

restart, have the hood serviced.

5. The bottom of the hood MUST NOT BE LESS than 24" and

recommended at a maximum of 36" above cooktop for best

capture of cooking impurities.

6. Two installers are recommended because of the size of this

hood.

7. To reduce risk of fire and to properly exhaust air, be sure to duct

air outside. Do not exhaust air intospaces within wails or ceilings

or into attics, crawl spaces, or garages.

8. Becareful when installingthe decorative flue and hood,they may

have sharp edges.

9. This hood is not intended to be used as a shelf.

10. Please read specification label on product for further information

and requirements.

- Register your product online at: www.broan.com

Installer: Leavethis manual

with the homeowner.

Homeowner:Operationand Maintenance

instructionson pages7 & 8.

BReAN

MODELS EW5830SS ,, EW5836SS

Page 2

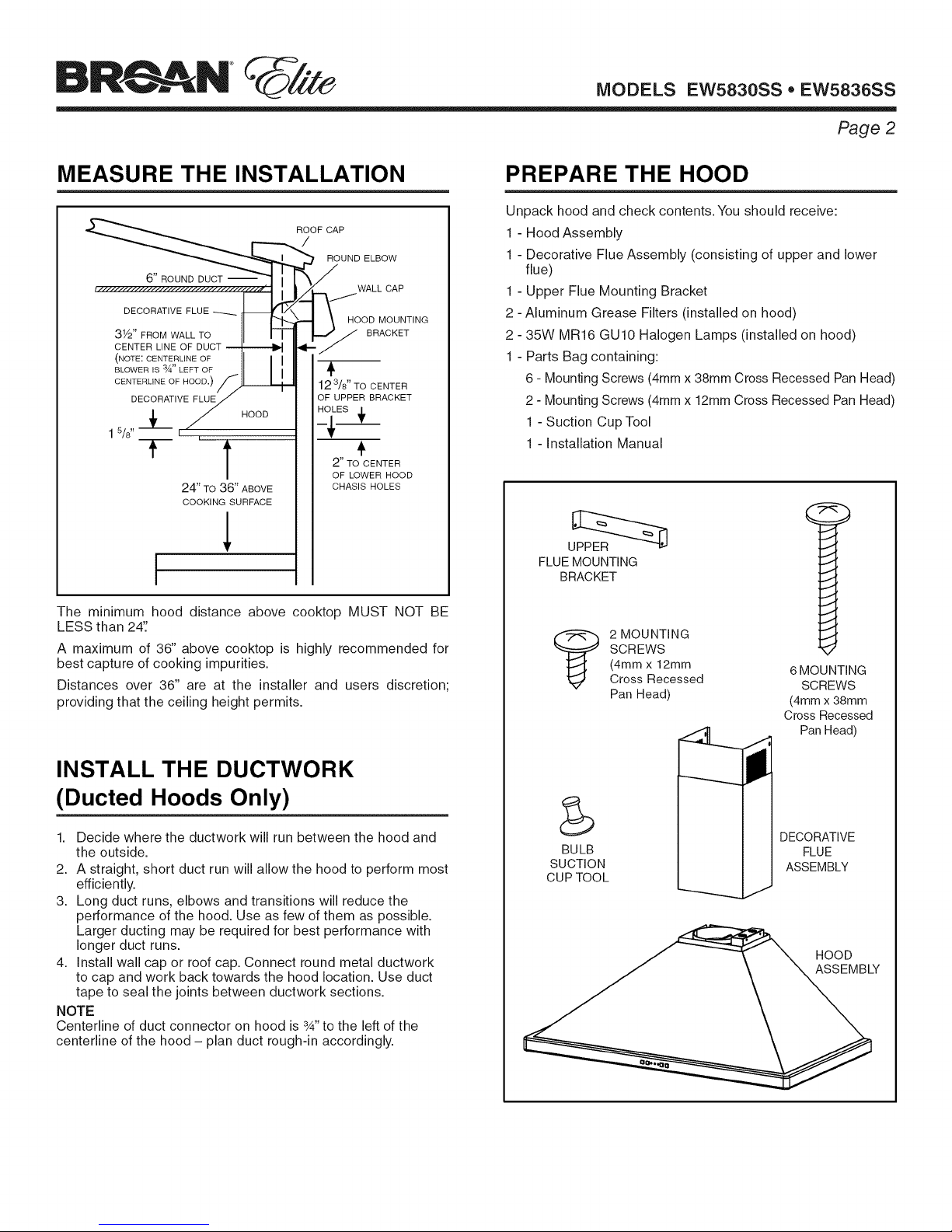

MEASURE THE INSTALLATION

/

ROUND ELBOW

ROOF CAP

J

////////////////////////////////-_/-_/_ _ ._ WALL CAP

DECORATIVE FLUE _ HOOD MOUNTING

3'/2"FROMWALLTO II I ! _ BRACKET

CENTER LINE OF DUCT _ ql"

(NOTE: CENTERLINE OF II I I

BLOWER IS 3_" LEFT OF II I i '_

CENTERLINE OF HOOD.) f_........_ 12 3/8"TO CENTER

DECORATIVE FLUE/" OF UPPER BRACKET

_L j_ HOOD--H_E--tJL

15/8" , " ,

---_ 2" TO CENTER

T '

24" TO 36" ABOVE CHASIS HOLES

COOKING SURFACE

OF LOWER HOOD

t

The minimum hood distance above cooktop MUST NOT BE

LESS than 24':

A maximum of 36" above cooktop is highly recommended for

best capture of cooking impurities.

Distances over 36" are at the installer and users discretion;

providing that the ceiling height permits.

PREPARE THE HOOD

Unpack hood and check contents. You should receive:

1 - Hood Assembly

1 - Decorative Flue Assembly (consisting of upper and lower

flue)

1 - Upper Flue Mounting Bracket

2 - Aluminum Grease Filters (installed on hood)

2 - 35W MR16 GU10 Halogen Lamps (installed on hood)

1 - Parts Bag containing:

6 - Mounting Screws (4mm x 38mm Cross Recessed Pan Head)

2 - Mounting Screws (4mm x 12mm Cross Recessed Pan Head)

1 - Suction Cup Tool

1 - Installation Manual

FLUEMOUNTING

BRACKET

SCREWS

(4mm x 12mm

2 MOUNTING

Cross Recessed

Pan Head)

6 MOUNTING

SCREWS

(4mm x 38mm

Cross Recessed

Pan Head)

INSTALL THE DUCTWORK

(Ducted Hoods Only)

1. Decide where the ductwork will run between the hood and

the outside.

2. A straight, short duct run will allow the hood to perform most

efficiently.

3. Long duct runs, elbows and transitions will reduce the

performance of the hood. Use as few of them as possible.

Larger ducting may be required for best performance with

longer duct runs.

4. Install wall cap or roof cap. Connect round metal ductwork

to cap and work back towards the hood location. Use duct

tape to seal the joints between ductwork sections.

NOTE

Centerline of duct connector on hood is 3/4,,to the left of the

centerline of the hood - plan duct rough-in accordingly.

BULB

SUCTION

CUP TOOL

DECORATIVE

FLUE

ASSEMBLY

HOOD

ASSEMBLY

BReAN

MODELS EW5830SS • EW5836SS

Page 3

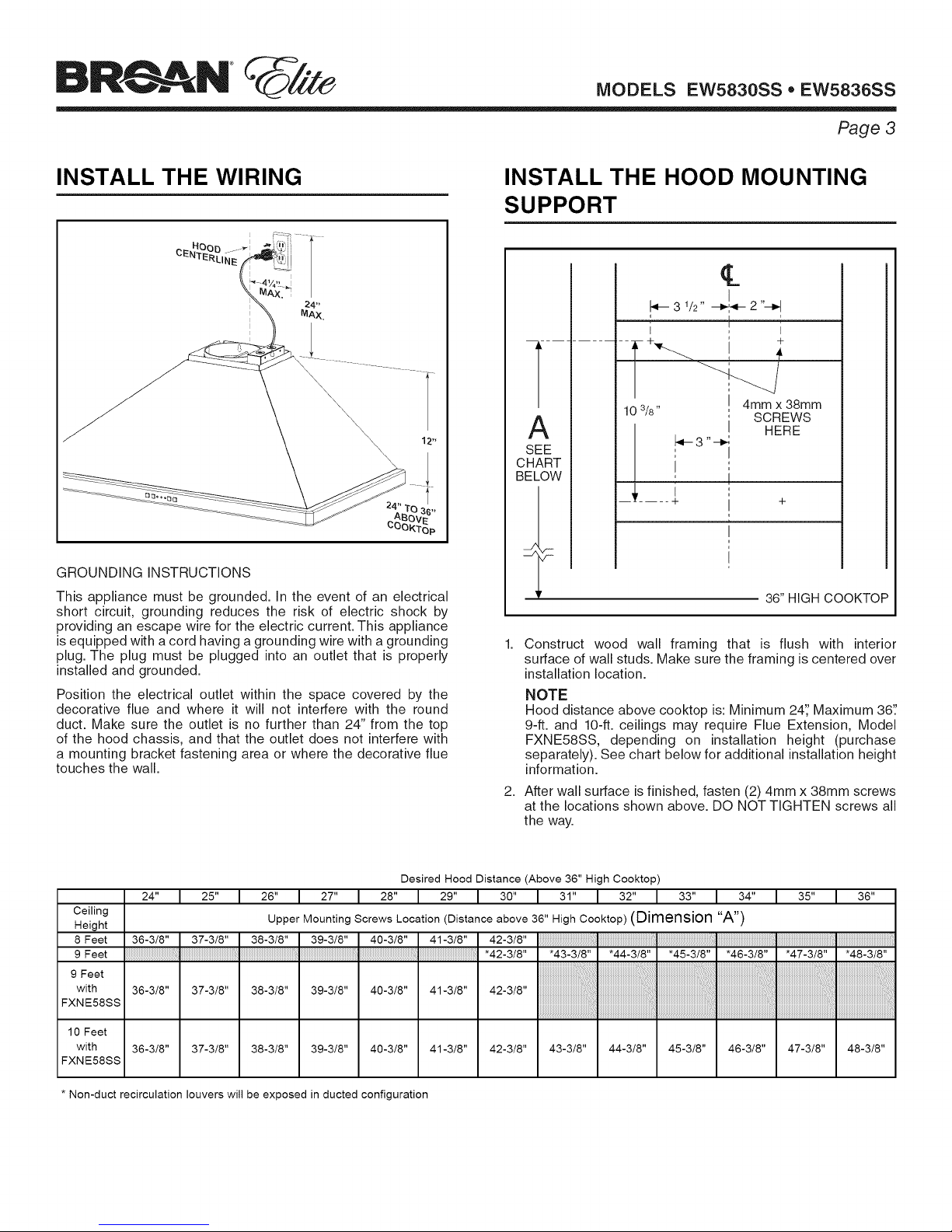

INSTALL THE WIRING INSTALL THE HOOD MOUNTING

SUPPORT

HOoD___

CENTERLINE

¢

I

I

4mm x 38mm

SCREWS

I

HERE

i

I

,

I

MAX.

\

\_ 12-

\\

\

I_-- 3 1/2" _4- 2 "-_

i

....... _-+_...

lO3/8'' ,,

_--3 "_,4

i i

J,....i

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of an electrical

short circuit, grounding reduces the risk of electric shock by

providing an escape wire for the electric current. This appliance

is equipped with a cord having a grounding wire with a grounding

plug. The plug must be plugged into an outlet that is properly

installed and grounded.

Position the electrical outlet within the space covered by the

decorative flue and where it will not interfere with the round

duct. Make sure the outlet is no further than 24" from the top

of the hood chassis, and that the outlet does not interfere with

a mounting bracket fastening area or where the decorative flue

touches the wall.

Desired Hood Distance (Above 36" High Cooktop)

Ceiling

Height

8 Feet

9 Feet

9 Feet

with

FXNE58SS

10 Feet

with

FXNE58SS

24" I 25" I 26" I 27" I 28" I 29" I 30" I 31" I 32" I 33" I 34" I 35" I 36"

Upper Mounting Screws Location (Distance above 36" High Cooktop) (Dimension "A")

36-3/8" 37-3/8" 38-3/8" 39-3/8" 40-3/8" 41-3/8" 42-3/8" ,,

........................................... "42-3/8" "43-3/8" "44-3/8" "45-3/8" "46-3/8" "47-3/8" "48-3/8"

36-3/8,,37-3/8,,38-3/8,,3g-3/8,,40-3/8,,41-3/8,,42-3/8,,

36-3/8" 37-3/8" 38-3/8" 39-3/8" 40-3/8" 41-3/8" 42-3/8" 43-3/8" 44-3/8" 45-3/8" 46-3/8" 47-3/8" 48-3/8"

i

36" HIGH COOKTOP

Construct wood wall framing that is flush with interior

surface of wall studs. Make sure the framing is centered over

installation location.

NOTE

Hood distance above cooktop is: Minimum 24" Maximum 36"

9-ft. and 10-ft. ceilings may require Flue Extension, Model

FXNE58SS, depending on installation height (purchase

separately). See chart below for additional installation height

information.

2.

After wall surface is finished, fasten (2) 4mm x 38ram screws

at the locations shown above. DO NOT TIGHTEN screws all

the way.

............................................. ..........................................................................................................................................................................................................- .

* Non-duct recirculation louvers will be exposed in ducted configuration

BmeAm+

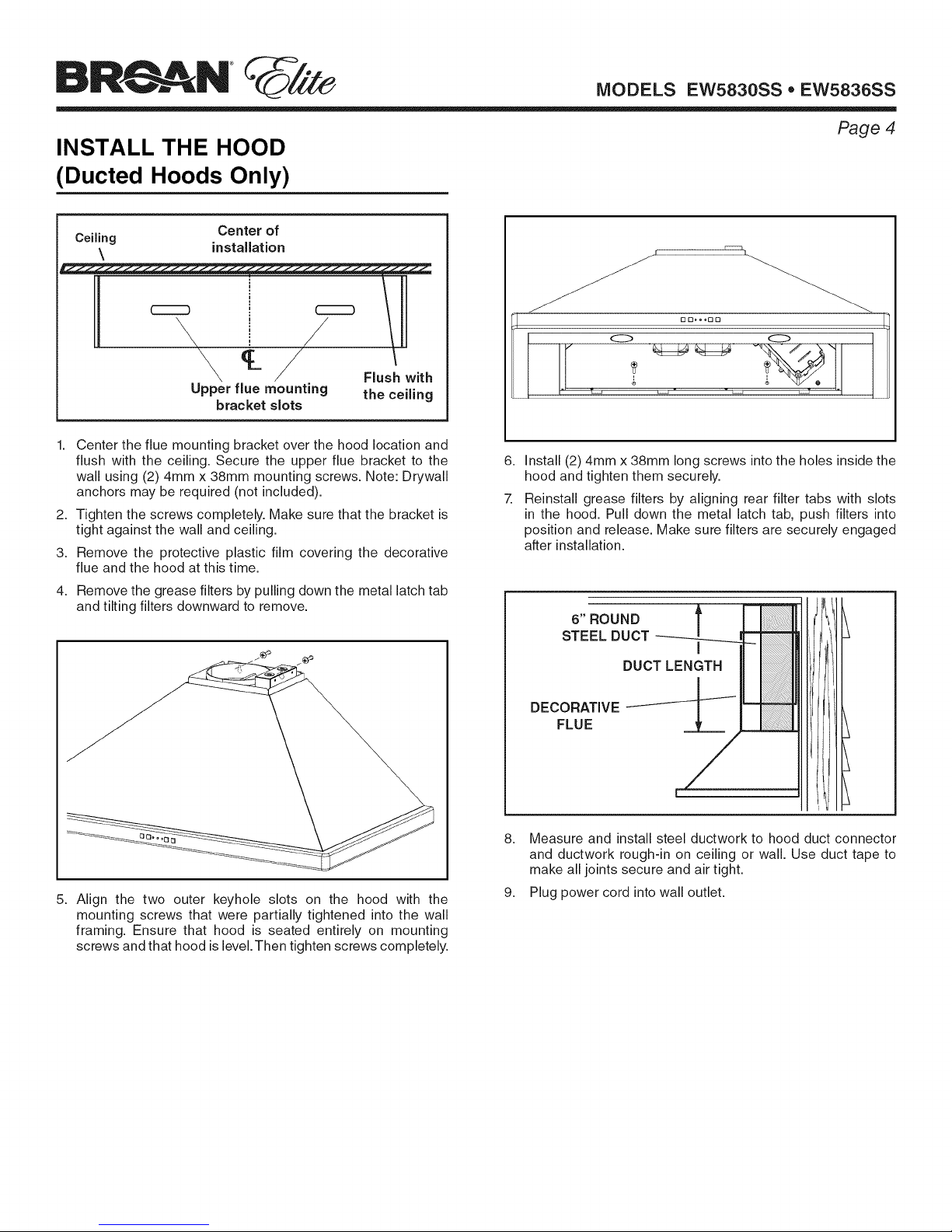

INSTALL THE HOOD

(Ducted Hoods Only)

MODELS EW5830SS ,, EW5836SS

Page 4

Ceiling

\ installation

Center of

/+

\+-/

Upper flue mounting the ceiling

bracket slots

Center the flue mounting bracket over the hood location and

flush with the ceiling. Secure the upper flue bracket to the

wall using (2) 4ram x 38mm mounting screws. Note: Drywall

anchors may be required (not included).

2. Tighten the screws completely. Make sure that the bracket is

tight against the wall and ceiling.

3. Remove the protective plastic film covering the decorative

flue and the hood at this time.

4. Remove the grease filters by pulling down the metal latch tab

and tilting filters downward to remove.

OOoo°OO

0 0

6. Install (2) 4mm x 38mm long screws into the holes inside the

hood and tighten them securely.

7.

Reinstall grease filters by aligning rear filter tabs with slots

in the hood. Pull down the metal latch tab, push filters into

position and release. Make sure filters are securely engaged

after installation.

o,,ROUND

STEEL DUCT I

DUCT LENGTH

5. Align the two outer keyhole slots on the hood with the

mounting screws that were partially tightened into the wall

framing. Ensure that hood is seated entirely on mounting

screws and that hood is level.Then tighten screws completely.

DECORATIVEFLUE _

8. Measure and install steel ductwork to hood duct connector

and ductwork rough-in on ceiling or wall. Use duct tape to

make all joints secure and air tight.

9. Plug power cord into wall outlet.

BmeAm+

MODELS EW5830SS ,, EW5838SS

INSTALL THE HOOD

+ (Non-Ducted Hoods Only)

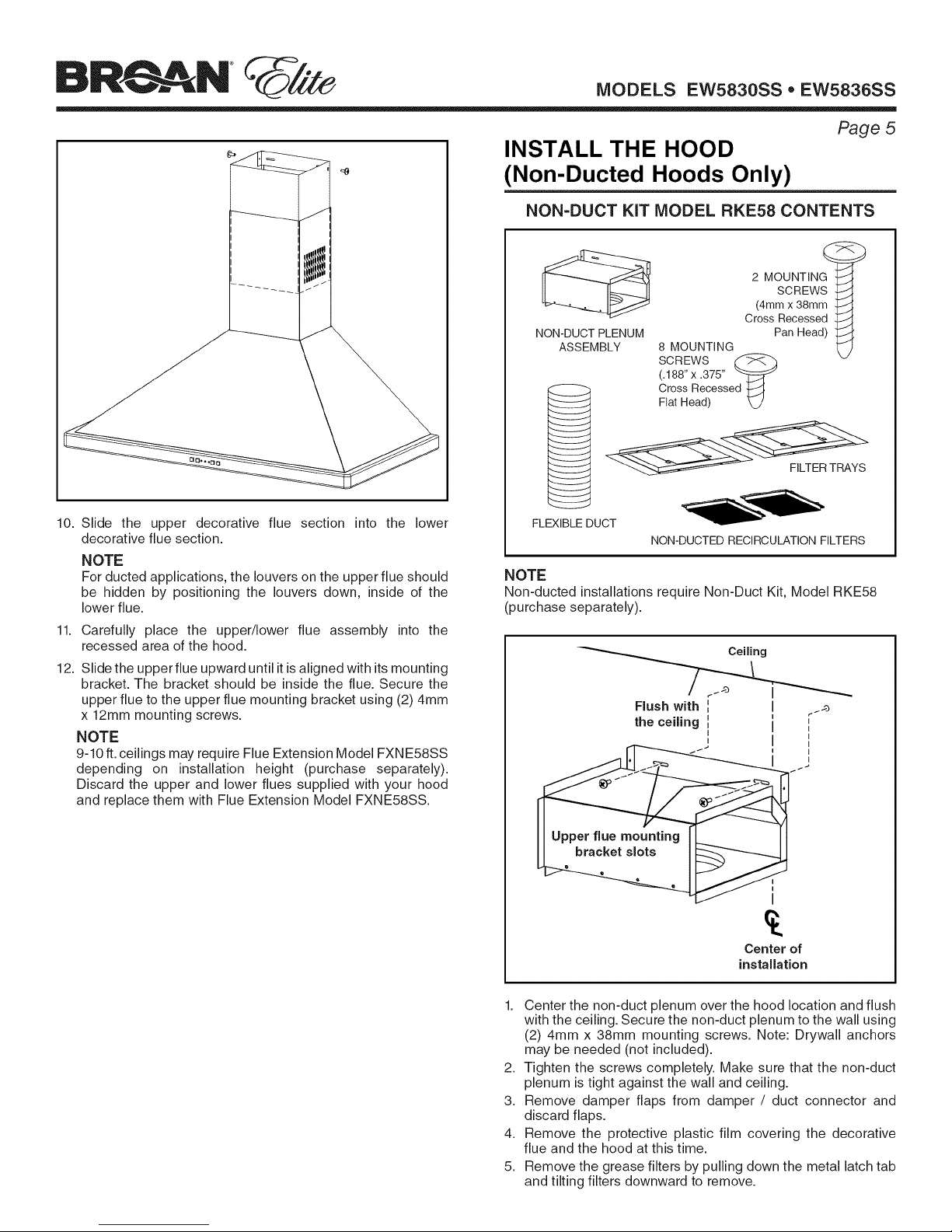

NON=DUCT KIT MODEL RKE58 CONTENTS

2 MOUNTING

(4mm x 38mm

Cross Recessed

NON-DUCTPLENUM

ASSEMBLY

8 MOUNTING

SCREWS

(.188"x.375" _:::_

CrossRecessed

FlatHead) _/

SCREWS

PanHead)

FILTERTRAYS

Page 5

I

10. Slide the upper decorative flue section into the lower

decorative flue section.

NOTE

For ducted applications, the louvers on the upper flue should

be hidden by positioning the louvers down, inside of the

lower flue.

11. Carefully place the upper/lower flue assembly into the

recessed area of the hood.

12. Slide the upper flue upward until it is aligned with its mounting

bracket. The bracket should be inside the flue. Secure the

upper flue to the upper flue mounting bracket using (2) 4mm

x 12mm mounting screws.

NOTE

9-10 ft.ceilings may require Flue Extension Model FXNE58SS

depending on installation height (purchase separately).

Discard the upper and lower flues supplied with your hood

and replace them with Flue Extension Model FXNE58SS.

FLEXIBLE DUCT

NON-DUCTED RECIRCULATION FILTERS

NOTE

Non-ducted installations require Non-Duct Kit, Model RKE58

(purchase separately).

Ceiling

Flush with _

the ceiling +_

Center of

installation

+

I

1. Center the non-duct plenum over the hood location and flush

with the ceiling. Secure the non-duct plenum to the wall using

(2) 4ram x 38ram mounting screws. Note: Drywall anchors

may be needed (not included).

2. Tighten the screws completely. Make sure that the non-duct

plenum is tight against the wall and ceiling.

3. Remove damper flaps from damper / duct connector and

discard flaps.

4. Remove the protective plastic film covering the decorative

flue and the hood at this time.

5. Remove the grease filters by pulling down the metal latch tab

and tilting filters downward to remove.

BmeAm+

MODELS EW5830SS ,, EW5836SS

Page 6

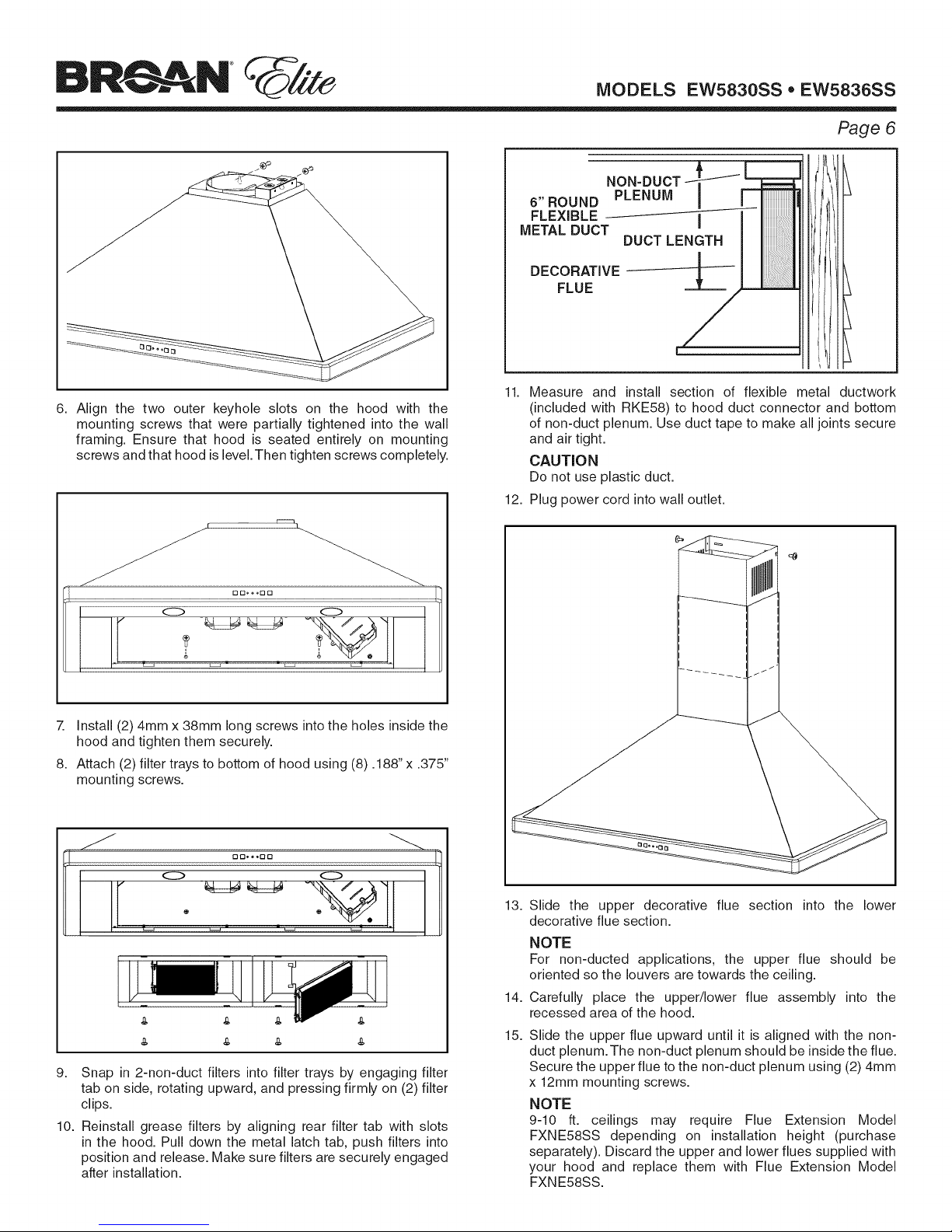

°,,.ou.op.E.uMI

FLEXIBLE

METAL DUCT DUCT LENGTH

DECORATIVE --_

6. Align the two outer keyhole slots on the hood with the

mounting screws that were partially tightened into the wall

framing. Ensure that hood is seated entirely on mounting

screws and that hood is level.Then tighten screws completely.

7. Install (2) 4mm x 38mm long screws into the holes inside the

hood and tighten them securely.

8. Attach (2)filter trays to bottom of hood using (8).188" x .375"

mounting screws.

FLUE _'

11. Measure and install section of flexible metal ductwork

(included with RKE58) to hood duct connector and bottom

of non-duct plenum. Use duct tape to make all joints secure

and air tight.

CAUTION

Do not use plastic duct.

12. Plug power cord into wall outlet.

t

J

O O

& &

& &

9. Snap in 2-non-duct filters into filter trays by engaging filter

tab on side, rotating upward, and pressing firmly on (2) filter

clips.

10. Reinstall grease filters by aligning rear filter tab with slots

in the hood. Pull down the metal latch tab, push filters into

position and release. Make sure filters are securely engaged

after installation.

13.

Slide the upper decorative flue section into the lower

decorative flue section.

NOTE

For non-ducted applications, the upper flue should be

oriented so the louvers are towards the ceiling.

14.

Carefully place the upper/lower flue assembly into the

recessed area of the hood.

15.

Slide the upper flue upward until it is aligned with the non-

duct plenum.The non-duct plenum should be inside the flue.

Secure the upper flue to the non-duct plenum using (2) 4ram

x 12mm mounting screws.

NOTE

9-10 ft. ceilings may require Flue Extension Model

FXNE58SS depending on installation height (purchase

separately). Discard the upper and lower flues supplied with

your hood and replace them with Flue Extension Model

FXNE58SS.

BReAN

OPERATION

MODELS EW5830SS,, EW5836SS

Page 7

Always turn the hood ON before cooking inorder to establish an air

flow in the kitchen. After turning off the range, let the hood run for a

few minutes to clear the air.

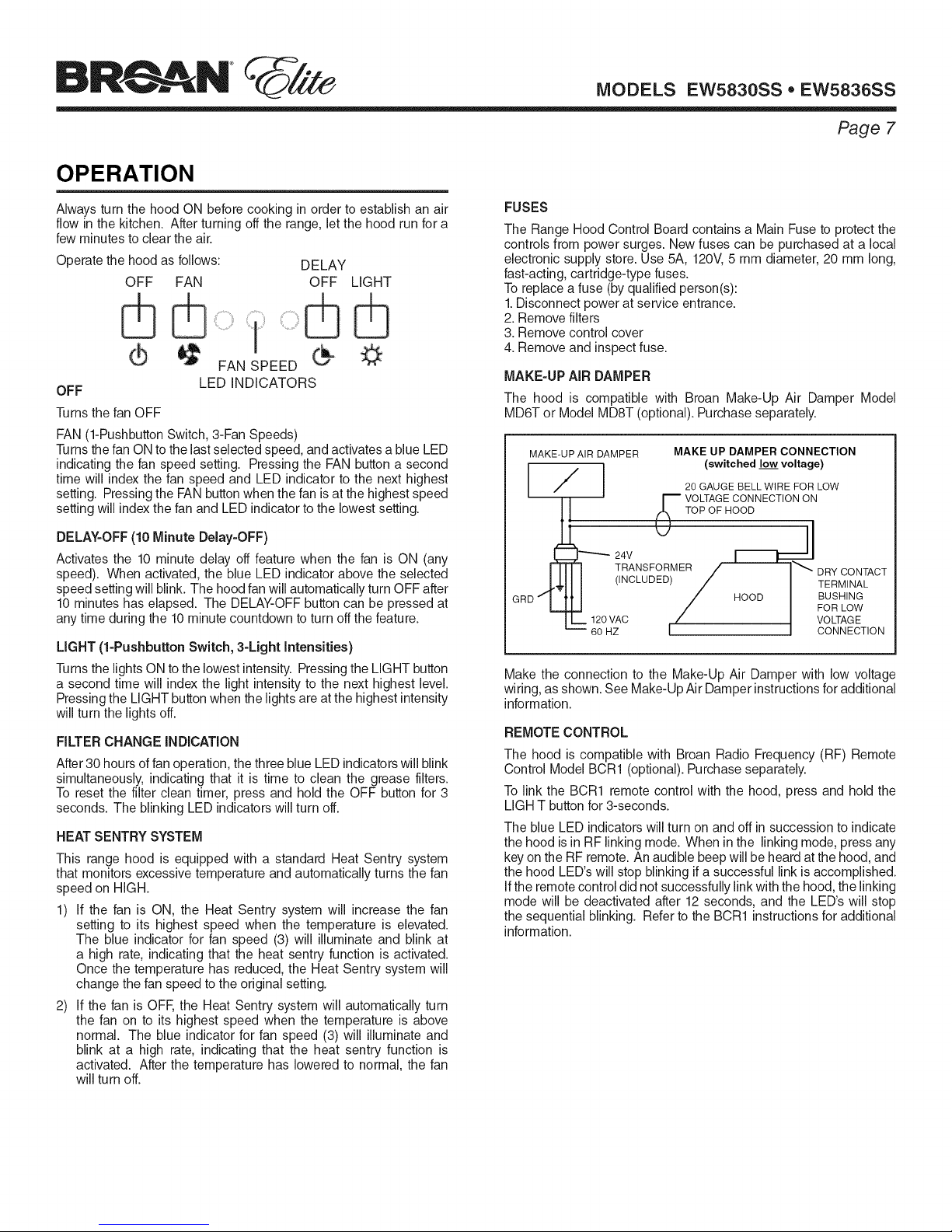

Operate the hood as follows: DELAY

OFF FAN OFF LIGHT

OFF

Turns the fan OFF

FAN (1-Pushbutton Switch, 3-Fan Speeds)

Turnsthe fan ON tothe last selected speed, and activates a blue LED

indicatingthe fan speed setting. Pressing the FAN button a second

time will index the fan speed and LED indicatorto the next highest

setting. Pressing the FAN button when the fan isat the highest speed

setting will indexthe fan and LED indicatorto the lowest setting.

DELAY=OFF(10 Minute Delay=OFF)

Activates the 10 minute delay off feature when the fan is ON (any

speed). When activated, the blue LED indicatorabove the selected

speed setting will blink. The hood fan will automatically turn OFF after

10 minutes has elapsed. The DELAY-OFF button can be pressed at

any time during the 10minute countdown to turn off the feature.

LIGHT (l=Pushbutton Switch, 3=Lightintensities)

Turnsthe lights ONto the lowest intensity.Pressing the LIGHT button

a second time will index the light intensityto the next highest level.

Pressing the LIGHT button when the lights are at the highest intensity

will turn the lights off.

FILTER CHANGE iNDiCATiON

After 30 hours of fan operation, thethree blue LED indicatorswill blink

simultaneously, indicatingthat it is time to clean the grease filters.

To reset the filter clean timer, press and hold the OFF button for 3

seconds. The blinking LED indicatorswill turn off.

HEAT SENTRY SYSTEM

This range hood is equipped with a standard Heat Sentry system

that monitors excessive temperature and automatically turns the fan

speed on HIGH.

1) If the fan is ON, the Heat Sentry system will increase the fan

setting to its highest speed when the temperature is elevated.

The blue indicator for fan speed (3) will illuminateand blink at

a high rate, indicatingthat the heat sentry function is activated.

Once the temperature has reduced, the Heat Sentry system will

change the fan speed to the original setting.

2) If the fan is OFF, the Heat Sentry system will automatically turn

the fan on to its highest speed when the temperature is above

normal. The blue indicatorfor fan speed (3) will illuminateand

blink at a high rate, indicating that the heat sentry function is

activated. After the temperature has lowered to normal, the fan

will turn off.

LED INDICATORS

FUSES

The Range Hood Control Board contains a Main Fuse to protect the

controls from power surges. New fuses can be purchased at a local

electronic supply store. Use 5A, 120V, 5 mm diameter, 20 mm long,

fast-acting, cartridge-type fuses.

Toreplace a fuse (by qualified person(s):

1.Disconnect power at service entrance.

2. Remove filters

3. Remove control cover

4. Remove and inspectfuse.

MAKE-UP AiR DAMPER

The hood is compatible with Broan Make-Up Air Damper Model

MD6T or Model MD8T (optional). Purchase separately.

MAKE-UP AIR DAMPER

/I

"'"-- 24V ____

GR

-- 60 HZ I CONNECTION

Make the connection to the Make-Up Air Damper with low voltage

wiring, as shown. See Make-Up Air Damper instructions for additional

information.

REMOTE CONTROL

The hood is compatible with Broan Radio Frequency (RF) Remote

Control Model BCR1 (optional). Purchase separately.

To link the BCR1 remote control with the hood, press and hold the

LIGHT button for 3-seconds.

The blue LED indicatorswill turn on and off in succession to indicate

the hood isin RF linking mode. When inthe linking mode, press any

keyon the RF remote. An audible beep will be heard at the hood, and

the hood LED's will stop blinking if a successful link is accomplished.

Ifthe remote control did not successfully link with the hood, the linking

mode will be deactivated after 12 seconds, and the LED's will stop

the sequential blinking. Refer to the BCR1 instructionsfor additional

information.

(INCLUDED) / TERMINAL

__ 120 VAC / VOLTAGE

MAKE UP DAMPER CONNECTION

(switched low voltage)

20 GAUGE BELL WIRE FOR LOW

TOP OF HOOD

(_ OLTAGE CONNECTION ON

HOOD BUSHING

DRY CONTACTTRANSFORMER J

FOR LOW

BReAN

CLEANING & MAINTENANCE

For performance, appearance, and health reasons, clean filter, fan

and grease-laden surfaces. Use only a dean cloth and mild detergent

solution on stainless and painted surfaces.

Clean all-metal filters in the dishwasher using a non-phosphate

detergent. Discoloration of the filter may occur if using phosphate

detergents, or as a result of local water conditions - but this will not

affect filter performance. This discoloration is not covered by the

warranty.

Clean the non-duct recirculating filter surfaces frequently with a damp

cloth and a mild detergent. DO NOT immersefilters in water or put in

dishwasher. Change the non-duct recirculating filters every 6 months.

For replacement non-duct recirculating filters - purchase $99010365

or Model FILTERE56.

The motor is permanently lubricated and never needs oiling. If the

motor bearings make excessive or unusual noise, replace the blower

assembly with an exact service replacement.

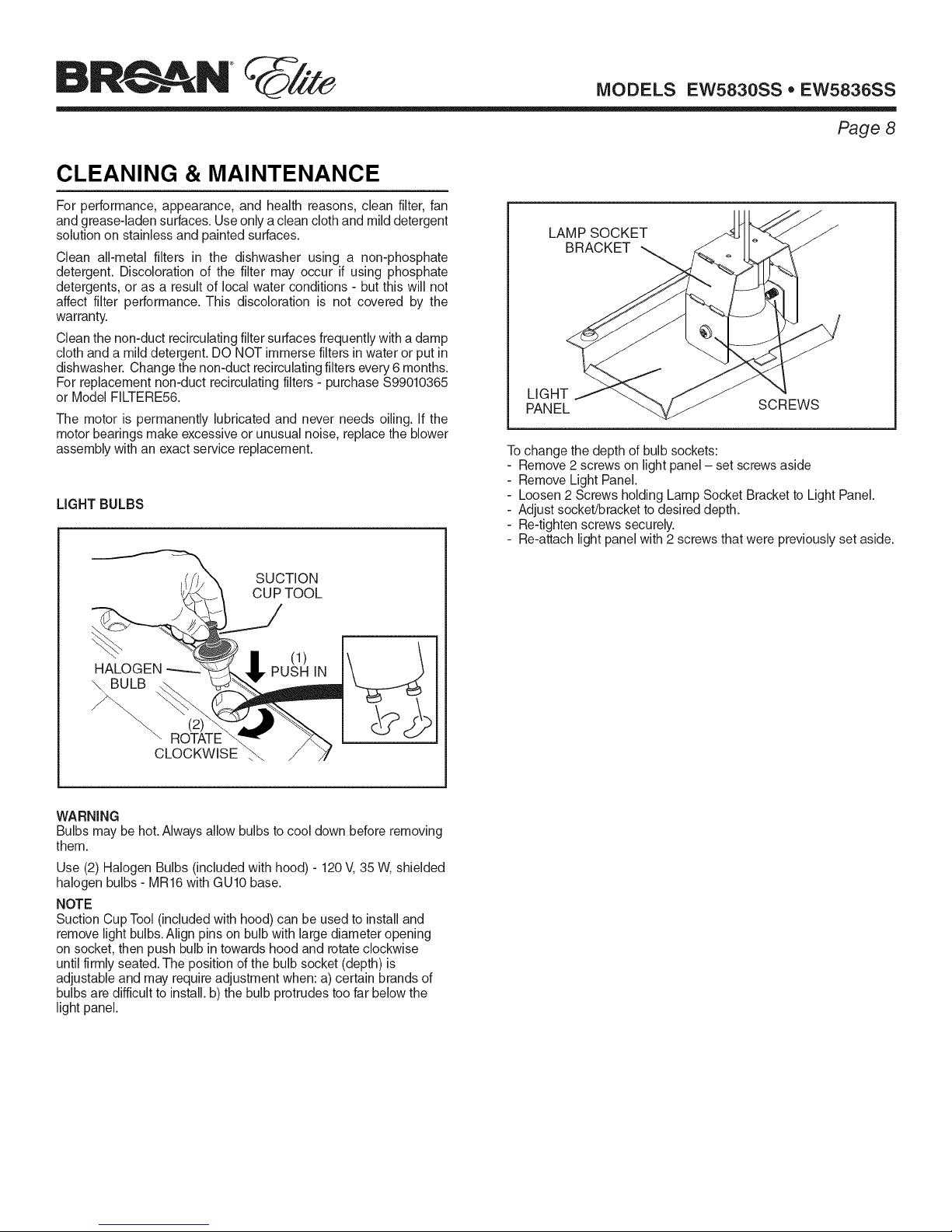

LIGHT BULBS

MODELS EW5830SS ,, EW5836SS

Page 8

LAMP SOCKET

BRACKET

LIGHT

PANEL SCREWS

To change the depth of bulb sockets:

- Remove 2 screws on light panel- set screws aside

- Remove Light Panel.

- Loosen 2 Screws holding Lamp Socket Bracket to Light Panel.

- Adjust socket!bracket to desired depth.

- Re-tighten screws securely.

- Re-attach light panel with 2 screws that were previously set aside.

SUCTION

CUP TOOL

HALOGEN

\ ROTATE .

CLOCKWISE ._

WARNING

Bulbs may be hot. Always allow bulbs to cool down before removing

them.

Use (2) Halogen Bulbs (included with hood) - 120 V, 35 W, shielded

halogen bulbs - MR16 with GU10 base.

NOTE

Suction Cup Tool (included with hood) can be used to install and

remove light bulbs. Align pins on bulb with large diameter opening

on socket, then push bulb in towards hood and rotate clockwise

until firmly seated. The position of the bulb socket (depth)is

adjustable and may require adjustment when: a)certain brands of

bulbs are difficult to install,b) the bulb protrudes too far below the

light panel.

BReAN

MODELS EW5830SS ,, EW5836SS

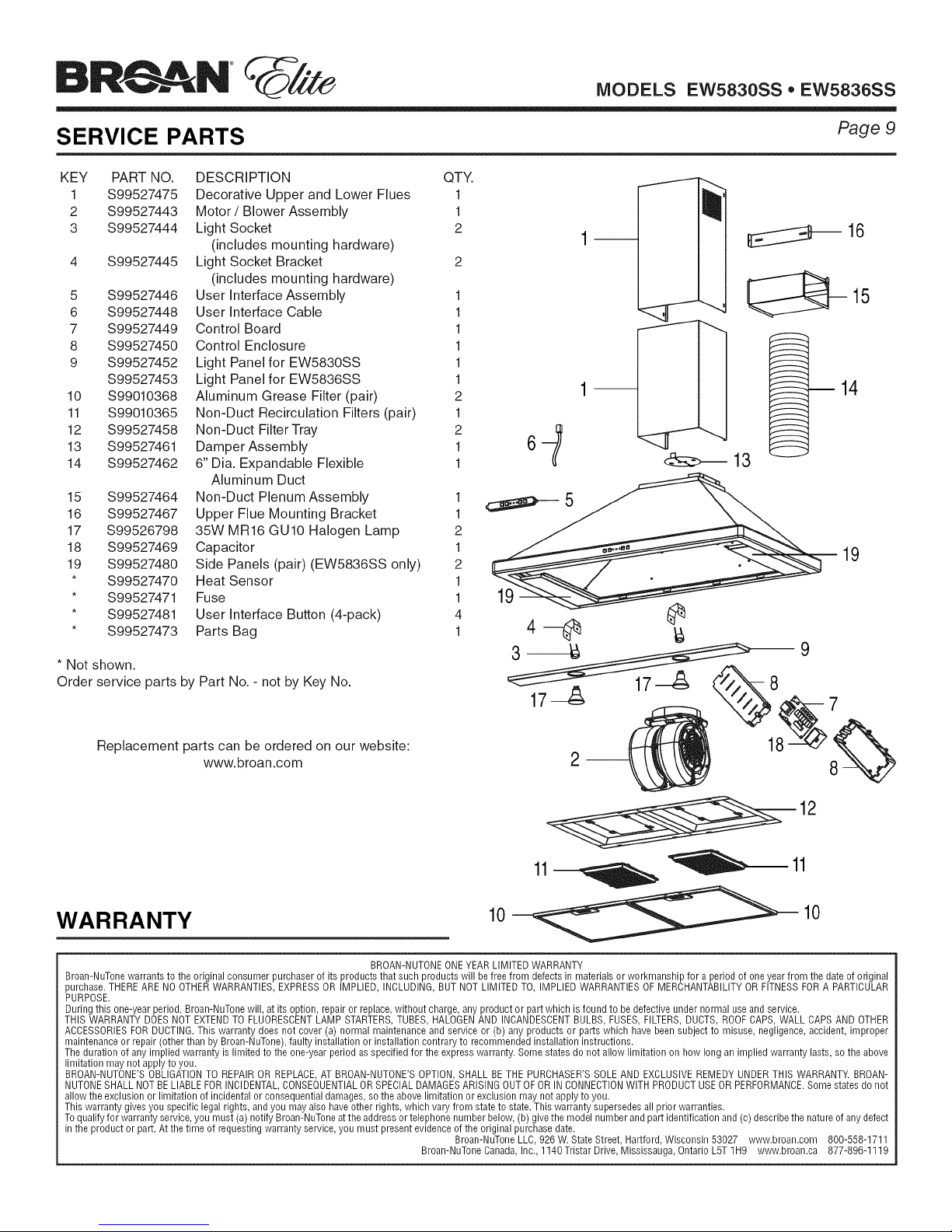

SERVICE PARTS Page9

KEY PART NO.

1 S99527475

2 S99527443

3 S99527444

S99527445

5

S99527446

S99527448

6

7

S99527449

8

S99527450

9

S99527452

S99527453

S99010368

lO

11

S99010365

12

S99527458

13

S99527461

14

S99527462

15 S99527464

16 S99527467

17 S99526798

18 S99527469

19 S99527480

* S99527470

* S99527471

* S99527481

* S99527473

DESCRIPTION QTY.

Decorative Upper and Lower Flues 1

Motor / Blower Assembly 1

Light Socket 2

(includes mounting hardware)

Light Socket Bracket 2

(includes mounting hardware)

User Interface Assembly 1

User Interface Cable 1

Control Board 1

Control Enclosure 1

Light Panel for EW5830SS 1

Light Panel for EW5836SS 1

Aluminum Grease Filter (pair) 2

Non-Duct Recirculation Filters (pair) 1

Non-Duct Filter Tray 2

Damper Assembly 1

6" Dia. Expandable Flexible 1

Aluminum Duct

Non-Duct Plenum Assembly 1

Upper Flue Mounting Bracket 1

35W MR16 GU10 Halogen Lamp 2

Capacitor 1

Side Panels (pair) (EW5836SS only) 2

Heat Sensor 1

Fuse 1

User Interface Button (4-pack) 4

Parts Bag 1

14

19

* Not shown.

Order service parts by Part No. - not by Key No.

Replacement parts can be ordered on our website:

www.broan.com

B12

11 11

WARRANTY

Broan-NuTonewarrants to the original consumer purchaser of its products that such products will be free from defects in materials or workmanship for a periodof oneyear from the dateof original

purchase.THERE ARE NO OTHERWARRANTIES, EXPRESSOR IMPLIED, INCLUDING, BUTNOT LIMITED TO, IMPLIEDWARRANTIESOFMERCHANTABILITYORFITNESSFORA PARTICULAR

PURPOSE.

During this one-year period, Broan-NuTonewill, at its option, repair or replace,without charge, any product or part which is found to be defectiveunder normal use and service.

THIS WARRANTY DOESNOT EXTENDTO FLUORESCENTLAMPSTARTERS,TUBES, HALOGENAND INCANDESCENTBULBS,FUSES, FILTERS,DUCTS,ROOFCAPS,WALL CAPS AND OTHER

ACCESSORIESFORDUCTING.This warranty does not cover (a) normal maintenance and service or (b) any products or parts which havebeen subject to misuse, negligence, accident, improper

maintenanceor repair (other than by Broan-NuTone), faulty installation or installation contrary to recommended installation instructions.

The duration of any implied warranty is limited to the one-year period as specified for the express warranty. Some states do not allow limitation on how long an implied warranty lasts,so the above

limitation may not apply to you.

BROAN-NUTONE'SOBLIGATIONTO REPAIROR REPLACE,AT BROAN-NUTONE'SOPTION, SHALL BETHE PURCHASER'SSOLEAND EXCLUSIVEREMEDY UNDERTHIS WARRANTY.BROAN-

NUTONESHALLNOT BELIABLEFORINCIDENTAL,CONSEQUENTIALORSPECIALDAMAGESARISING OUTOFOR INCONNECTIONWITH PRODUCTUSEORPERFORMANCE.Some statesdo not

allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

This warranty gives you specific legal rights, andyou mayalso haveother rights, which vary from state to state.This warranty supersedes all prior warranties.

Toqualify for warranty service,you must (a) notify Broan-NuToneat the address or telephone number below, (b) give the model number and part identification and (c) describe the nature of any defect

in the product orpart. Atthe time of requesting warranty service, you must presentevidence ofthe original purchase date.

BROAN-NUTONEONEYEARLIMITEDWARRANTY

Broan-NuToneCanada, Inc., 1140Tristar Drive, Mississauga, Ontario L5T 1H9 www.broan.ca 877-896-1119

10 10

Broan-NuTone LLC,926 W. StateStreet, Hartford, Wisconsin 53027 www.broan.com 800-558-1711

Loading...

Loading...