Brita STEAM C1000, STEAM C500 Product information

PURITY C

Steam

Proven technology re-invented

for small to mid-sized steamers

and ovens

The PURITY C Steam lter cartridges, specially developed for small to medium-sized combi steamers and ovens, reduce carbonate hardness in drinking

water and, as a result, prevent limescale formation in equipment. In addition,

the lter medium retains metal ions such as lead or copper and reduces

substances, for example chlorine, that can negatively affect taste and aroma.

Opt for clean.

Opt for green.

Environmental protection and recycling are part of the BRITA corporate

philosophy. BRITA established a recycling programme for exhausted lter

cartridges. Since 1992 all parts of BRITA cartridges can be completely

reprocessed so that the materials can be recycled.

The bene ts to you

• Limescale deposits and the associated machine breakdowns are reduced,

as are additional service and repair costs. Fine steam jets remain open

longer.

• Baked products, sh, meat and vegetables are cooked to their best:

elements, such as chlorine, that could impair taste and aroma are

removed for improved taste.

• BRITA’s established easy-to-handle cartridge exchange system

• Bypass settings are specially adapted to direct injection and boiler

systems.

• Improved ow rate of up to 300 l/h with 1 bar pressure loss.

y

B

p

i

l

l

a

e

s

t

n

I

F

o

r

C

o

n

s

i

s

t

e

s

®

.

s

t

l

u

s

e

R

n

o

i

t

n

a

t

r

t

F

l

i

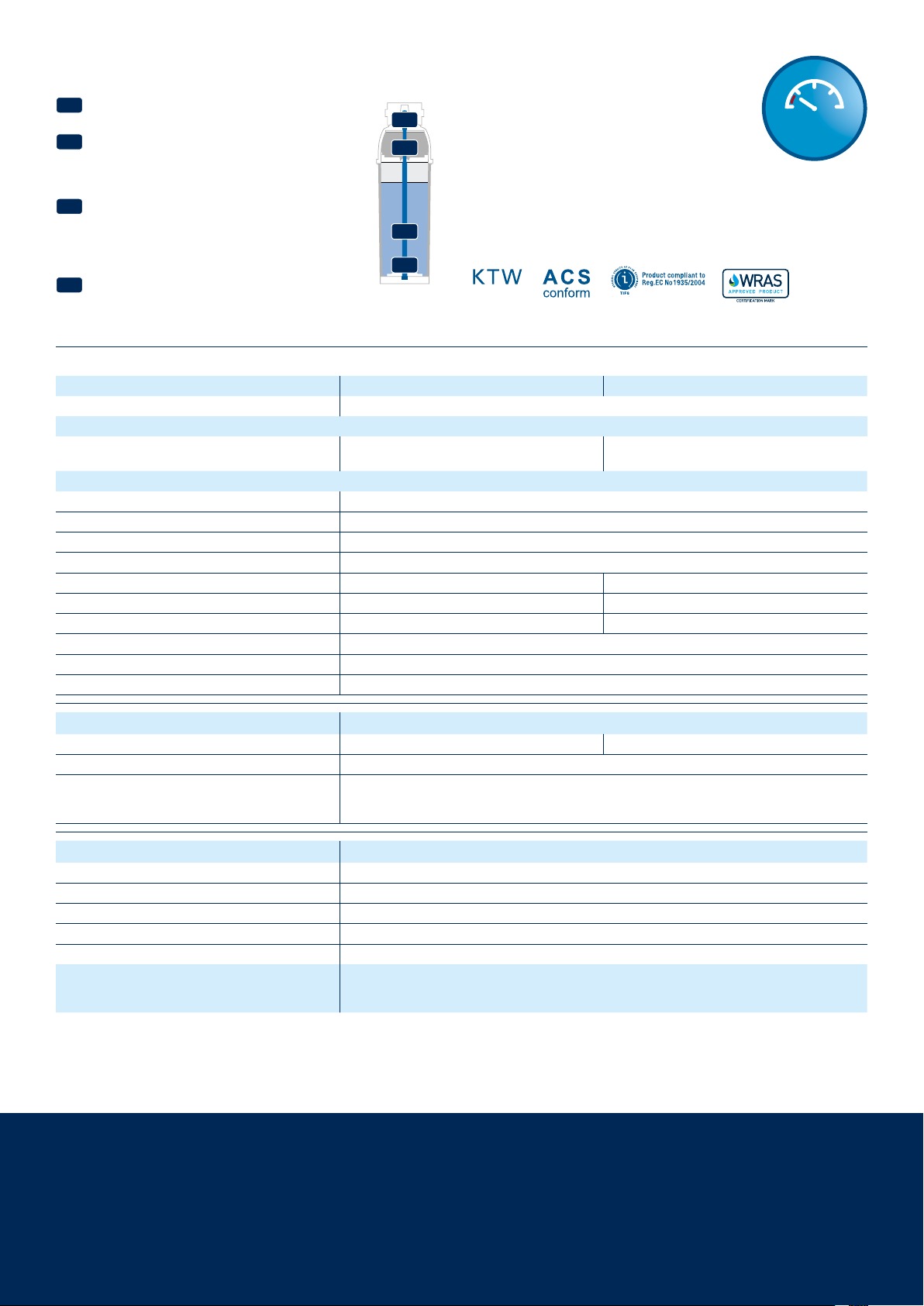

Systematic ltration technology Quality and safety

1

Pre-ltration

A pre-lter reliably retains coarse particles

2

Carbonate hardness reduction

The PURITY C Steam lter medium reduces carbona-

4

3

te hardness. As a result, unwanted limescale formation is prevented.

3

Activated carbon ltration

The water runs through an activated carbon lter to

remove all substances such as chlorine and organic

2

elements that have an adverse effect on taste and

aroma.

4

Fine ltration

At the end of the ltration process a eece retains

any ne particles.

explanation of the lter tech-

1

The illustration serves as

nology. It is not to scale.

PURITY C Steam PURITY C500 Steam PURITY C1100 Steam

Technology decarbonisation

PURITY C Steam lter head with variable bypass

1

combi steamers/ovens (at a carbonate hard-

Capacity

ness of 10 °dH and a bypass setting of 1)

Filter system*

Max. operating pressure 2 bar to max. 8.6 bar

Water intake temperature 4 – 30 °C

Flow rate with 1 bar pressure loss 300 l/h

Nominal ow 100 l/h

Pressure loss at nominal ow 0.1 bar 0.2 bar

Dimensions (W/D/H) with lter head 144 / 144 / 557 mm 184 / 184 / 557 mm

Weight (dry/wet) 4.6 / 6.9 kg 7.7 / 12.5 kg

Water inlet and outlet connections G 3/8“

Operating position horizontal and vertical

Operation use after inhouse softening units possible

Optimum water quality

Outstanding and consistent water quality –

free of unwanted elements that could impair

taste and aroma.

Maximum product safety

For uninterrupted operation and safe use.

Simple to use

Operation is simpler and easier than ever.

The food safety of BRITA Professional water lter products

is tested and monitored by independent institutes.

tested*

*applies to all materials in contact with water

4,675 l 7,907 l

r

u

r

o

e

y

p

r

l

a

e

b

m

e

m

e

R

S

e

c

u

r

c

e

m

e

n

t

.

.

s

t

e

e

n

e

y

b

o

r

u

PURITY C Steam Order number

Filter cartridge 1023320 (Pack 1) 1023328 (Pack 1)

Filter head 1023325 (Pack 1), 1023315 (Pack 20)

PURITY C Steam lter head set (lter head, backow

preventer 3/8“, carbonate hardness test, 2x reducer set

1026234

3/8“ internal thread – 3/4“ external thread)

Accessories Order number

Backow preventer 3/8“ 1000639 (Pack 3)

Carbonate hardness test 710800

Reducer set 3/8“ internal thread – 3/4“ external thread 1000898 (Pack 2)

Hose DN13, 2.0m, 3/4“ – 3/4“ 1007721

BRITA FlowMeter 10 – 100 1033041

1

The capacities given have been tested and calculated on the basis of normal application and machine

Explanatory notes

conditions. Due to external inuences (e.g. variations in raw water quality and/or machine type),

deviations from these results can occur.

* The PURITY C Steam lter system can only be operated with the PURITY C Steam lter head.

Only drinking water quality may be used as the water supply for BRITA water lters.

For more information, contact:

BRITA GmbH

Heinrich-Hertz-Strasse 4 | 65232 Taunusstein | Germany | Tel.: +49 6128 746-5765

Fax: +49 6128 746-5010 | professional@brita.net | www.professional.brita.net

BRITA Water Filter Systems Ltd.

BRITA House | 9 Granville Way | Bicester | Oxfordshire OX26 4JT | Great Britain

Tel.: +44 844 742-4990 | Fax: +44 844 742-4902 | clientservices@brita.co.uk | www.brita.co.uk

PN: 1028072-005 seitenwind.com 09/19 Errors and omissions excepted.

Loading...

Loading...