Page 1

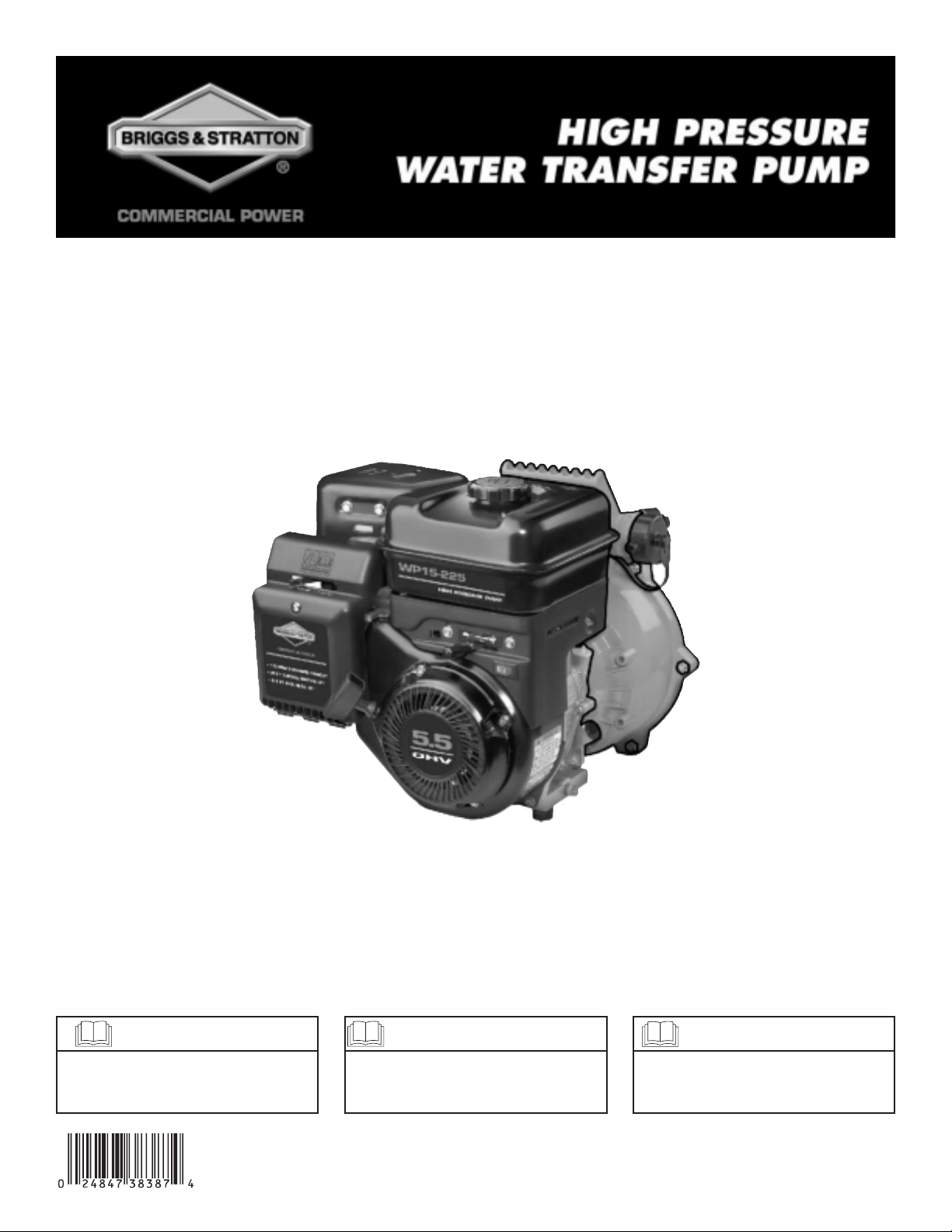

Model

073004

WP15-225

Operator’s Manual

Manuel d’utilisation

Manual del Operario

Questions? Help is just a moment away! Call: Helpline

Vous avez des questions? Vous n'avez pas besoin d'aller loin pour trouver de l'aide! Appelez: Ligne d'assistance

Preguntas? La ayuda es justa un momento lejos! Llame:Línea Directa

1-800-743-4115 M-F 8-5 CT

web: www.briggsandstratton.com

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON,WISCONSIN, U.S.A.

Manual No. 199785GS

Revision 1 (03/01/2006)

Before using this product, read this

manual and follow all Safety Rules and

Operating Instructions.

WARNING

Antes de utilizar el producto, lea este

manual y siga todas las Reglas de

Seguridad e Instrucciones de Uso.

ADVERTENCIA

Avant d’utiliser ce produit, veuillez lire

le manuel et suivre toutes les directives

relatives à la sécurité et à l’utilisation.

AVERTISSEMENT

Page 2

2

SAFETY RULES

TABLE OF CONTENTS

Safety Rules . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Know Your Water Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-7

Operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-11

Specifications. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13-16

Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19 & 22

Emission Control Warranty. . . . . . . . . . . . . . . . . . . . . 20-21

Warranty . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

EQUIPMENT

DESCRIPTION

Read this manual carefully and become

familiar with your water pump. Know its

applications, its limitations and any hazards

involved.

This water pump can be used to transfer water from a

flooded or unwanted location such as a basement. It can

also be used for draining swimming pools or for irrigation.

Every effort has been made to ensure that information in

this manual is accurate and current. However, we reserve

the right to change, alter or otherwise improve the product

and this document at any time without prior notice.

The Emissions Control System for this water pump is

warranted for standards set by the Environmental

Protection Agency and the California Air Resources Board.

SAFETY RULES

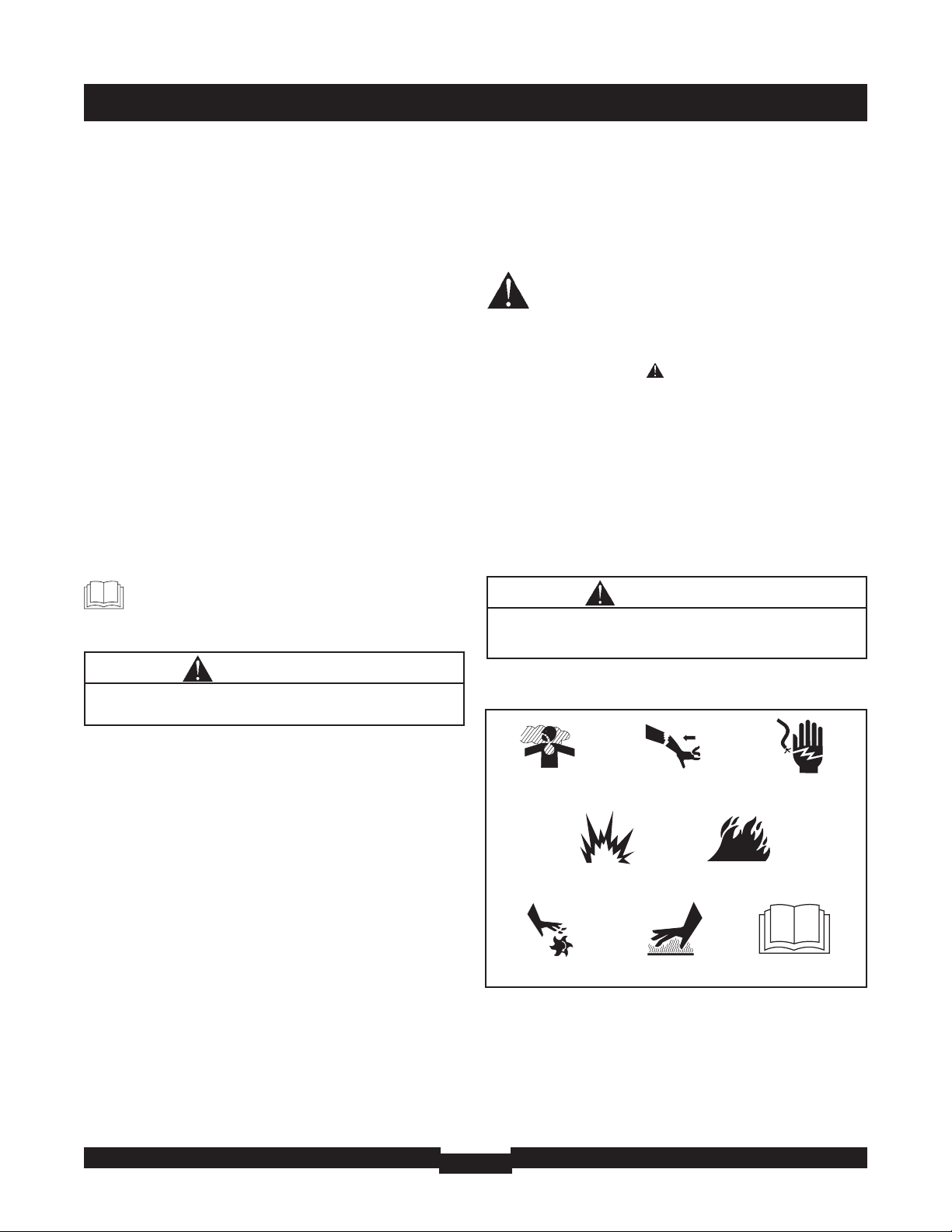

This is the safety alert symbol. It is used to

alert you to potential personal injury hazards.

Obey all safety messages that follow this

symbol to avoid possible injury or death.

The safety alert symbol ( ) is used with a signal word

(DANGER, CAUTION,WARNING), a pictorial and/or a

safety message to alert you to hazards. DANGER indicates

a hazard which, if not avoided, will result in death or serious

injury. WARNING indicates a hazard which, if not avoided,

could result in death or serious injury. CAUTION

indicates a hazard which, if not avoided, might result in

minor or moderate injury. CAUTION, when used

without the alert symbol, indicates a situation that could

result in equipment damage. Follow safety messages to

avoid or reduce the risk of injury or death.

Hazard Symbols and Meanings

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

WARNING

Fire

Explosion

Toxic Fumes

Hot Surface

Electrical Shock

Kickback

Copyright © 2006 Briggs & Stratton Power Products

Group, LLC. All rights reserved. No part of this material

may be reproduced or transmitted in any form by any

means without the express written permission of Briggs &

Stratton Power Products Group, LLC.

SAVE THESE INSTRUCTIONS

Moving Parts

These water pumps are manufactured to pump ONLY

clear water that is not intended for human consumption.

CAUTION

Operator’s Manual

Page 3

3

SAFETY RULES

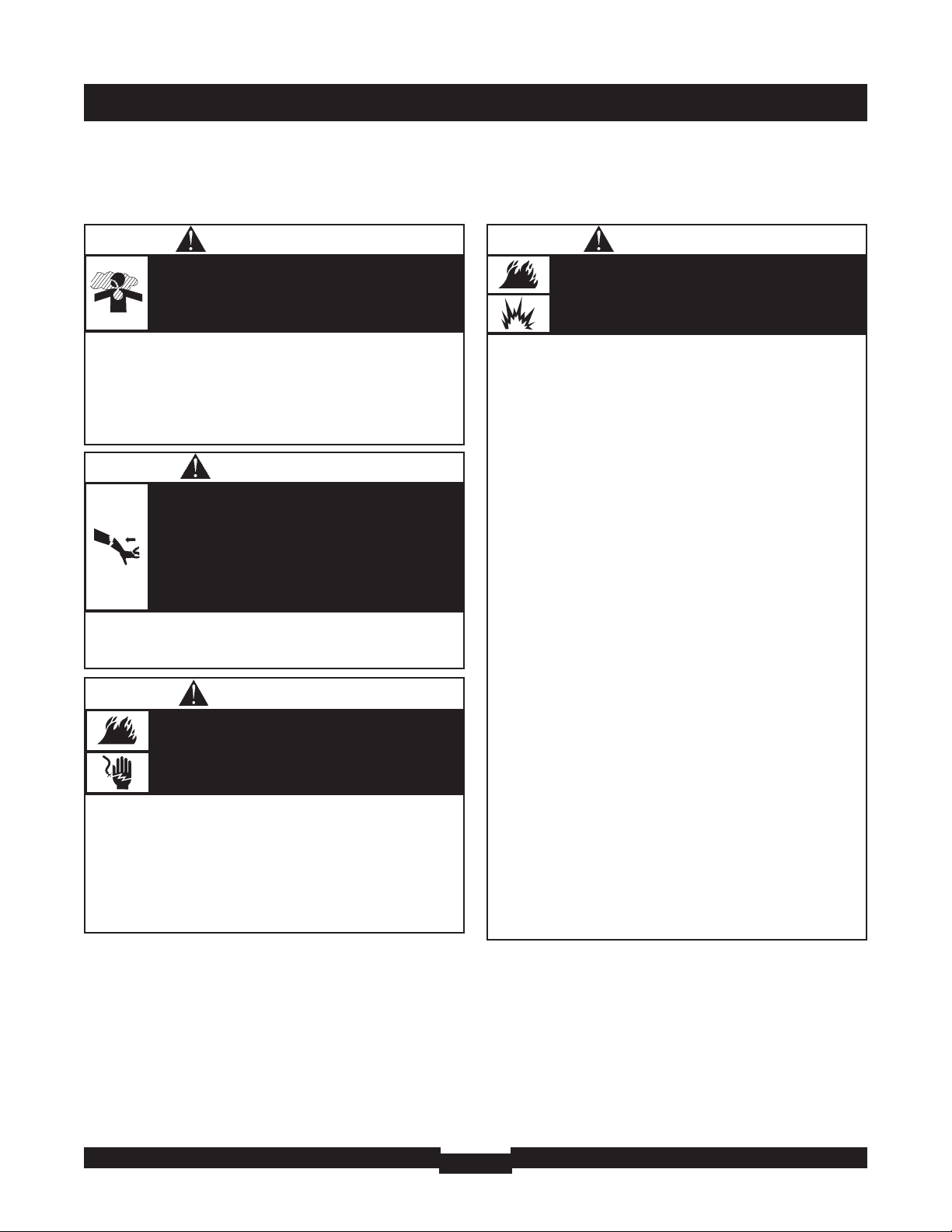

WHEN ADDING OR DRAINING FUEL

• Turn water pump OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve

pressure in tank.

• Fill or drain fuel tank outdoors.

• DO NOT overfill tank.Allow space for fuel expansion.

• Keep fuel away from sparks,open flames, pilot lights,heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

WHEN STARTING EQUIPMENT

• Ensure spark plug, muffler, fuel cap and air cleaner are in place.

• DO NOT crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before starting engine.

WHEN OPERATING EQUIPMENT

• DO NOT pump flammable liquids, such as fuel or fuel oils.

• This water pump is not for use in mobile equipment or

marine applications.

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• Secure water pump. Loads from hoses may cause tipover.

• DO NOT stop engine by moving choke lever to “Choke”

position.

WHEN TRANSPORTING OR REPAIRING

EQUIPMENT

• Transport/repair with fuel tank EMPTY or with fuel shutoff

valve OFF.

• Disconnect spark plug wire.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

• Secure discharge hose to avoid whipping.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

Keep hands and body clear from discharge of

pump.

WARNING

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

WATER PUMP

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

• Operate water pump ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate water pump inside any building, confined

area or enclosure, such as basements,garages or a similar

location, even if doors or windows are open.

Running water pump gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide can cause nausea,

fainting or death.

WARNING

Page 4

SAFETY RULES

4

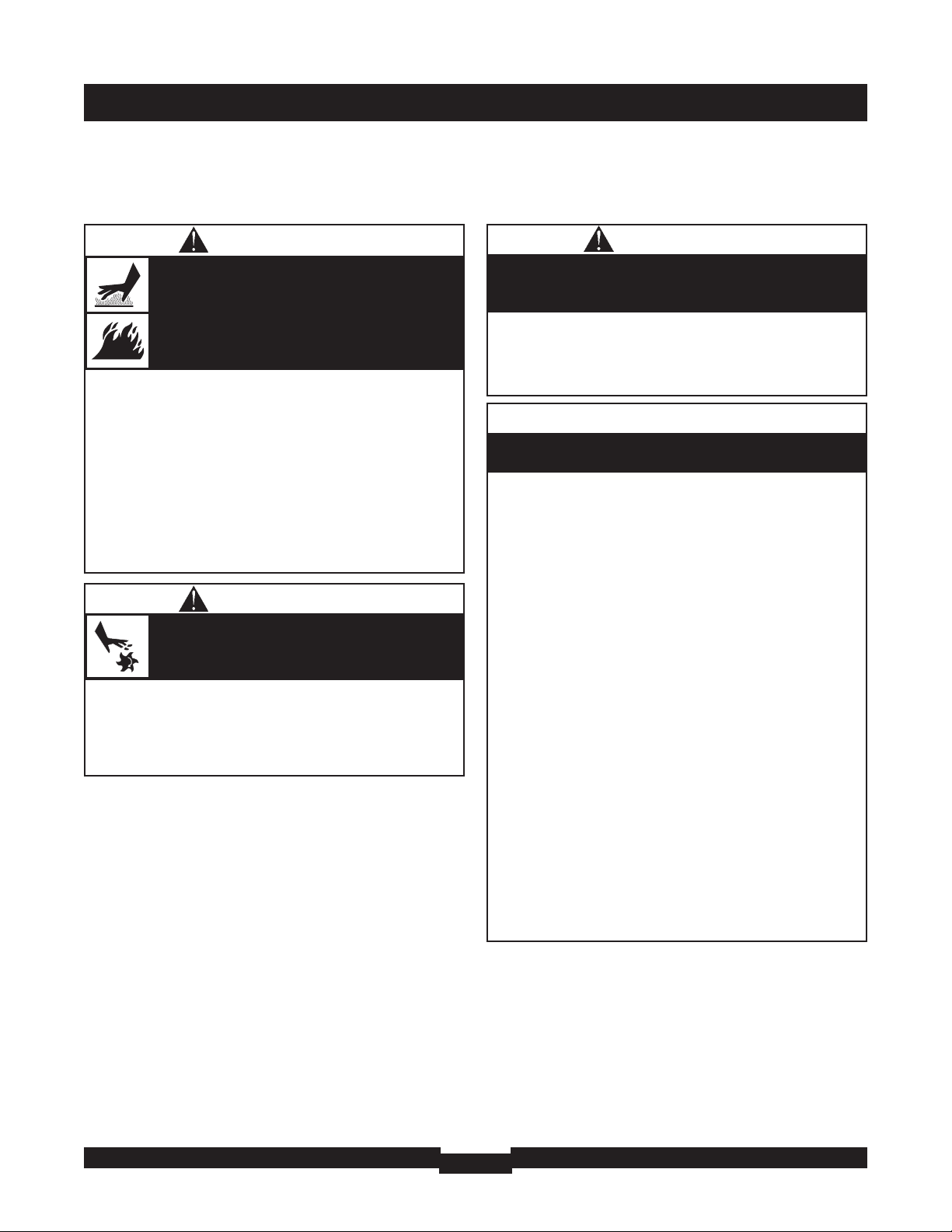

• DO NOT tamper with governed speed.

• DO NOT modify water pump in any way.

• DO NOT allow unqualified persons or children to operate or

service water pump.

Excessively high operating speeds increase risk of injury

and damage to water pump.

Excessively low speeds impose a heavy load.

CAUTION

• Be sure pump chamber is filled with water before starting the

engine. NEVER run pump without priming.

• Use a non-collapsible hose on the suction side of pump.

• Use water pump only for intended uses.

• If you have questions about intended use, ask dealer or call

1-800-743-4115.

• Pumping sea water, beverages, acids, chemical solutions, or any

other liquid that promotes corrosion can damage the pump.

• Ensure all connections are air tight.

• DO NOT obstruct the suction or discharge hose in any way.

• NEVER operate pump without strainer basket connected to

end of suction hose.

• DO NOT exceed suction head maximum of 8m (25 ft.) and

total head of 69m (225 ft.). Use shortest suction head possible

(see page 10).

• NEVER allow vehicles to drive over hoses. If a hose must be

positioned across a roadway, use planking on each side of hose

to allow vehicles to pass over without obstructing or

collapsing hose.

• Anchor pump to avoid “walking” or equipment movement,

especially if located near a ditch or edge of open ravine.The

equipment could fall in.

• Keep equipment away from edge of river or lake where it

could cause the bank to collapse.

• DO NOT insert any objects through cooling slots.

Improper treatment of water pump can damage it and

shorten its life.

CAUTION

• NEVER place hands or body parts inside of running pump or

hoses.

• DO NOT wear loose clothing, jewelry or anything that may

be caught in the starter or other rotating parts.

• Tie up long hair and remove jewelry.

Starter and other rotating parts can entangle

hands, hair, clothing, or accessories.

WARNING

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of water

pump including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Page 5

FEATURES AND CONTROLS

5

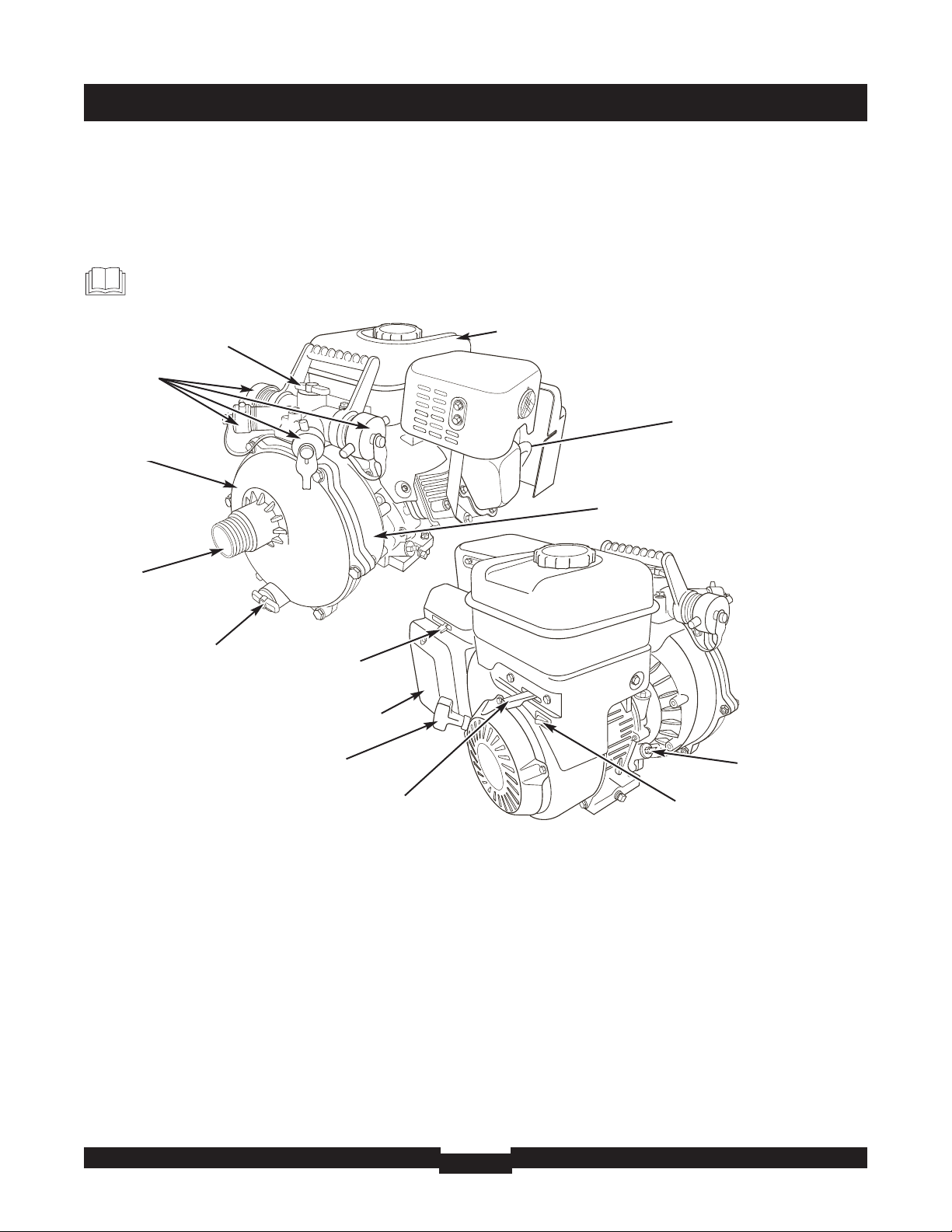

KNOW YOUR WATER PUMP

Read this operator’s manual and safety rules before operating your water pump.

Compare the illustrations with your water pump, to familiarize yourself with the locations of various controls and

adjustments. Save this manual for future reference.

Air Cleaner — Protects engine by filtering dust and

debris out of intake air.

Choke Lever — Used when starting a cold engine.

Discharge Outlets — Connect discharge hose here.

Engine Information (not shown) — Stamped on valve

cover. Provides model, type and trim number of engine.

Please have these readily available when calling for

assistance.

Fuel Shutoff Valve — Used to turn fuel supply on and

off to engine.

Fuel Tank — Capacity of one (1) U.S. gallons.

Oil Fill Cap — Check and fill engine with oil here.

On/Off Switch — Set this switch to "On" before using

starter handle. Set switch to "Off" to switch off engine.

Priming Plug — Fill pump with water here to prime

pump before starting.

Pump Chamber — Be sure to fill with water before

starting.

Serial Number Label — Provides model, revision and

serial number of water pump. Please have these readily

available when calling for assistance.

Starter Handle — Used to start the engine.

Strainer Basket (not shown) — Used to limit passage

of abrasive materials into the pump.

Suction Inlet — Connect reinforced suction hose here.

Engine Speed Lever — Used to adjust engine speed to

control pump output.

Water Drain Plug — Remove to drain water from pump

and flush internal components with clean water.

Fuel Tank

Air Cleaner

On/Off Switch

Water Drain Plug

Choke Lever

Starter Handle

Priming Plug

Oil Fill Cap

Discharge Outlets

Serial Number Label

Suction Inlet

Fuel Shutoff Valve

Engine Speed Lever

Pump Chamber

Page 6

ASSEMBLY

6

ASSEMBLY

Your water pump requires some assembly and is ready for

use after it has been properly serviced with the

recommended oil and fuel.

If you have any questions with the assembly of your water

pump, please call the helpline at 1-800-743-4115. If calling for

assistance, please have the model, revision,and serial number

from the serial number label available. See “Know Your Water

Pump” section for serial number label location.

Unpack Water Pump

1. Remove everything from carton except water pump.

2. Open carton completely by cutting each carton corner

from top to bottom.

Carton Contents

Items in the carton include:

• Water pump

• Oil bottle

• Parts bag (which includes the following):

• This operator’s manual

• Strainer basket and barb

• Hose clamp (3)

If any of the above parts are missing or damaged, call the

helpline at 1–800–743–4115.

Add Engine Oil

CAUTION! Any attempt to crank or start the engine

before it has been properly serviced with the

recommended oil may result in an engine failure.

1. Place water pump on a flat, level surface.

2. Clean area around oil fill and remove yellow oil fill cap.

3. Using oil funnel (optional), slowly pour entire contents

of provided oil bottle (18 oz.) into oil fill opening.

4. Replace oil fill cap and fully tighten.

NOTE: See the section “Oil” on page 14 to review oil

recommendations.

Add Fuel

NOTE:This gasoline engine is certified to operate on

gasoline. Exhaust Emission Control System: EM (Engine

Modifications).

1. Use clean, fresh, regular unleaded fuel with a minimum

of 85 octane. DO NOT use fuel which contains

Methanol. DO NOT mix oil with fuel. DO NOT use

fuel that contains more than 15% alcohol.

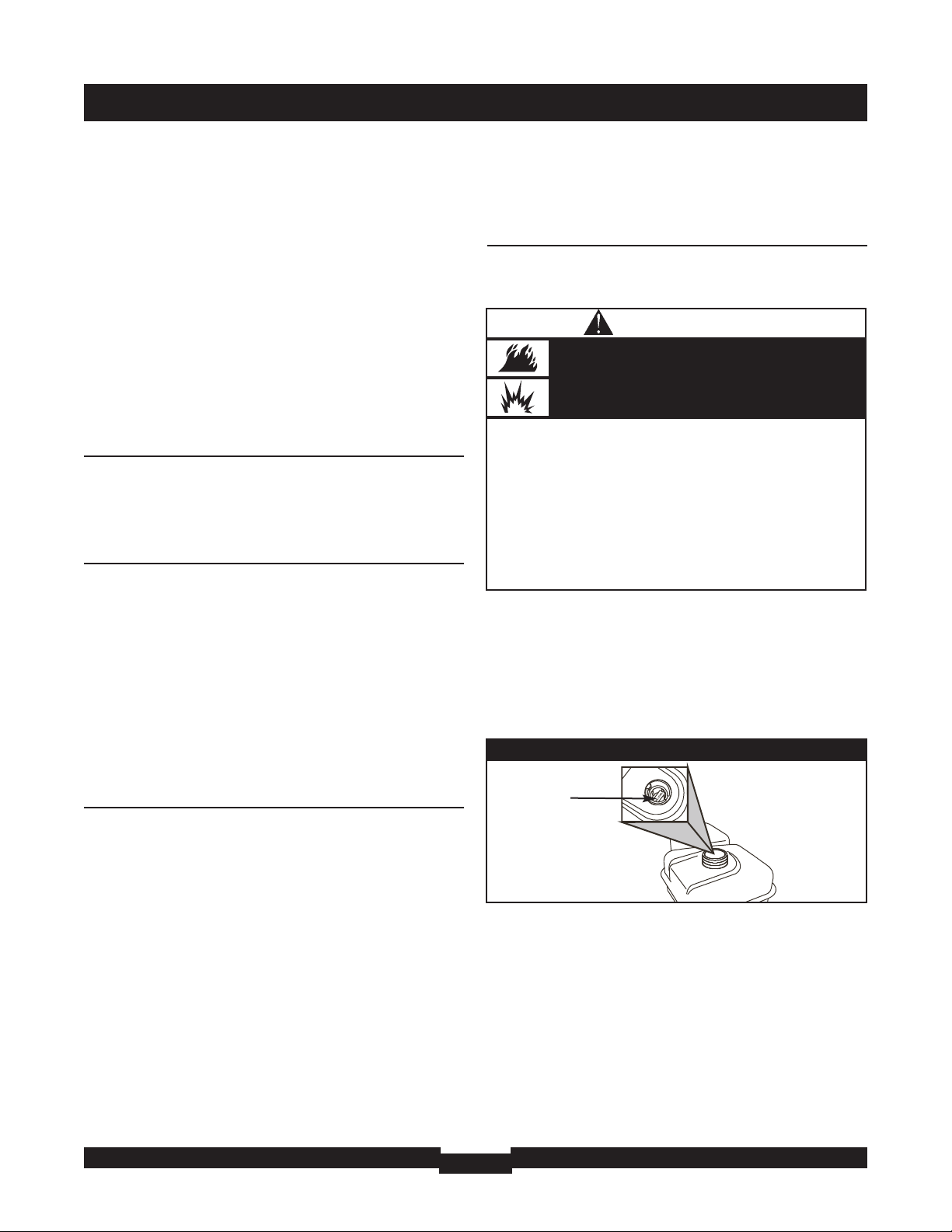

2. Clean area around fuel fill cap, remove fuel cap.

3. Slowly add regular unleaded fuel to fuel tank. Fill to red

fuel level indicator (Figure 1). Be careful not to overfill.

4. Install fuel cap and wait for any spilled fuel to evaporate.

CAUTION! Some fuels, called oxygenated or

reformulated fuel, are fuels blended with alcohols or ethers.

Excessive amounts of these blends can damage the fuel

system or cause performance problems. If any undesirable

operating symptoms occur, use fuel with a lower

percentage of alcohol or ether.

Fresh fuel prevents gum from forming in the fuel system or

on essential carburetor parts. Purchase fuel in quantity that

can be used in 30 days.

WHEN ADDING FUEL

• Turn water pump OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve

pressure in tank.

• Fill fuel tank outdoors.

• DO NOT overfill tank.Allow space for fuel expansion.

• Keep fuel away from sparks,open flames, pilot lights,heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

Figure 1 - Add Fuel to Indicator

Fuel Level

Indicator

Page 7

7

ASSEMBLY

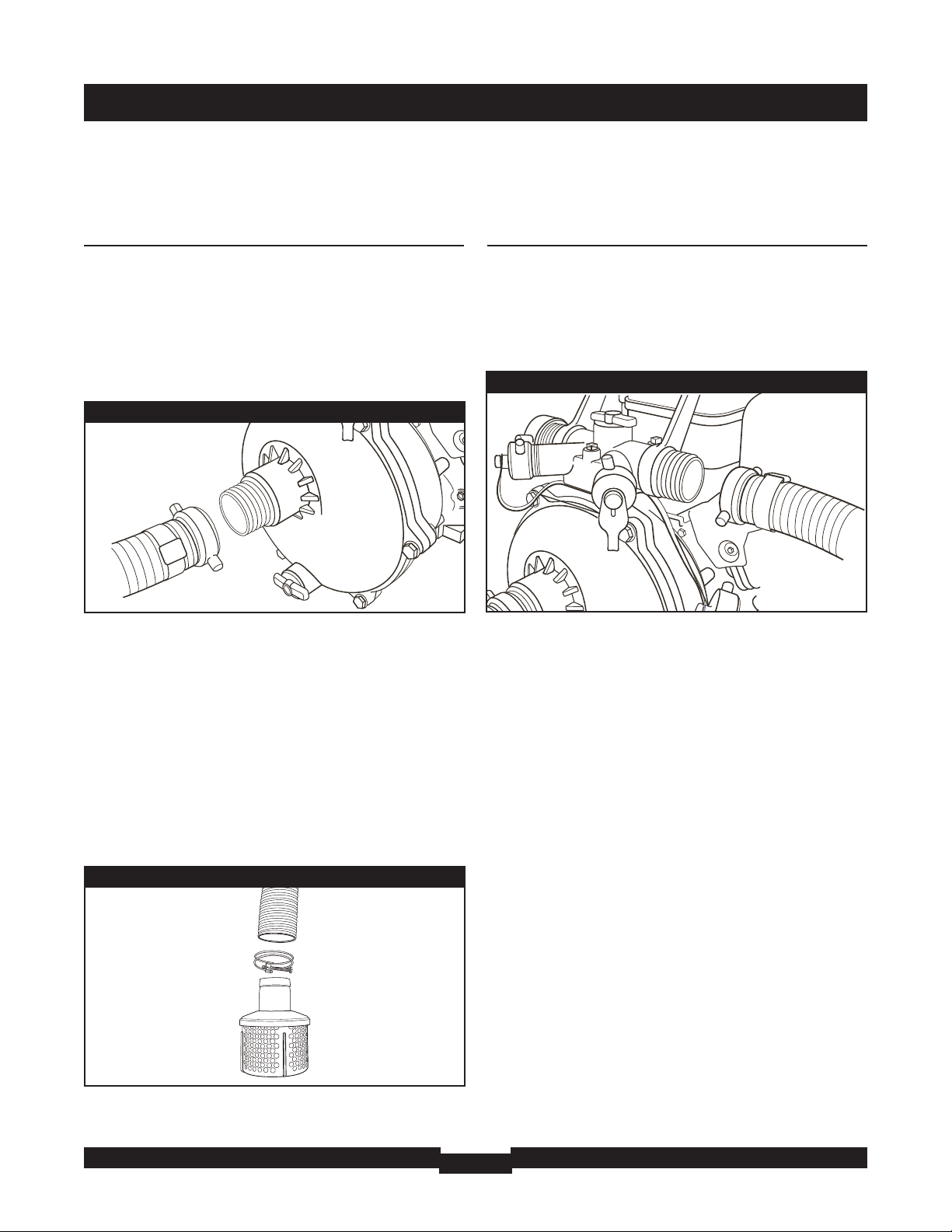

Attach Suction Hose

Attach Suction Hose to Pump

Use a 1-1/2” commercially available hose with threaded ends.

The suction hose must be reinforced with a non-collapsible

wall or braided material. DO NOT use a hose with an inside

diameter smaller than the pumps suction port size.

1. Screw suction hose onto pump in clockwise rotation

until suction hose is tightened securely (Figure 2).

Attach Suction Hose to Strainer Basket

You will need the following tools to install the suction hose

to the strainer basket:

• 1/4" or 6mm standard screwdriver

• Utility knife

IMPORTANT: Using a utility knife, cut off one threaded

end of suction hose to attach strainer basket.

Slide hose clamp over cut off end of suction hose.Attach

open end of suction hose to strainer hose barb (Figure 3).

Tighten hose clamp securely using a standard 1/4” (6mm)

screwdriver.

Attach Discharge Hose

Use a commercially available hose with threaded ends. DO

NOT use a hose with an inside diameter smaller than the

pump’s discharge port size.The pump has two 1” and two

1-1/2” diameter discharge ports.

1. Screw discharge hose onto pump in clockwise rotation

until discharge hose is tightened securely (Figure 4).

IMPORTANT: Be sure all unused discharge ports are

capped and tightened securely.

Figure 2 - Attach Suction Hose to Pump

Figure 3 - Attach Suction Hose to Strainer Basket

Figure 4 - Attach Discharge Hose to Pump

Page 8

8

USING THE WATER PUMP

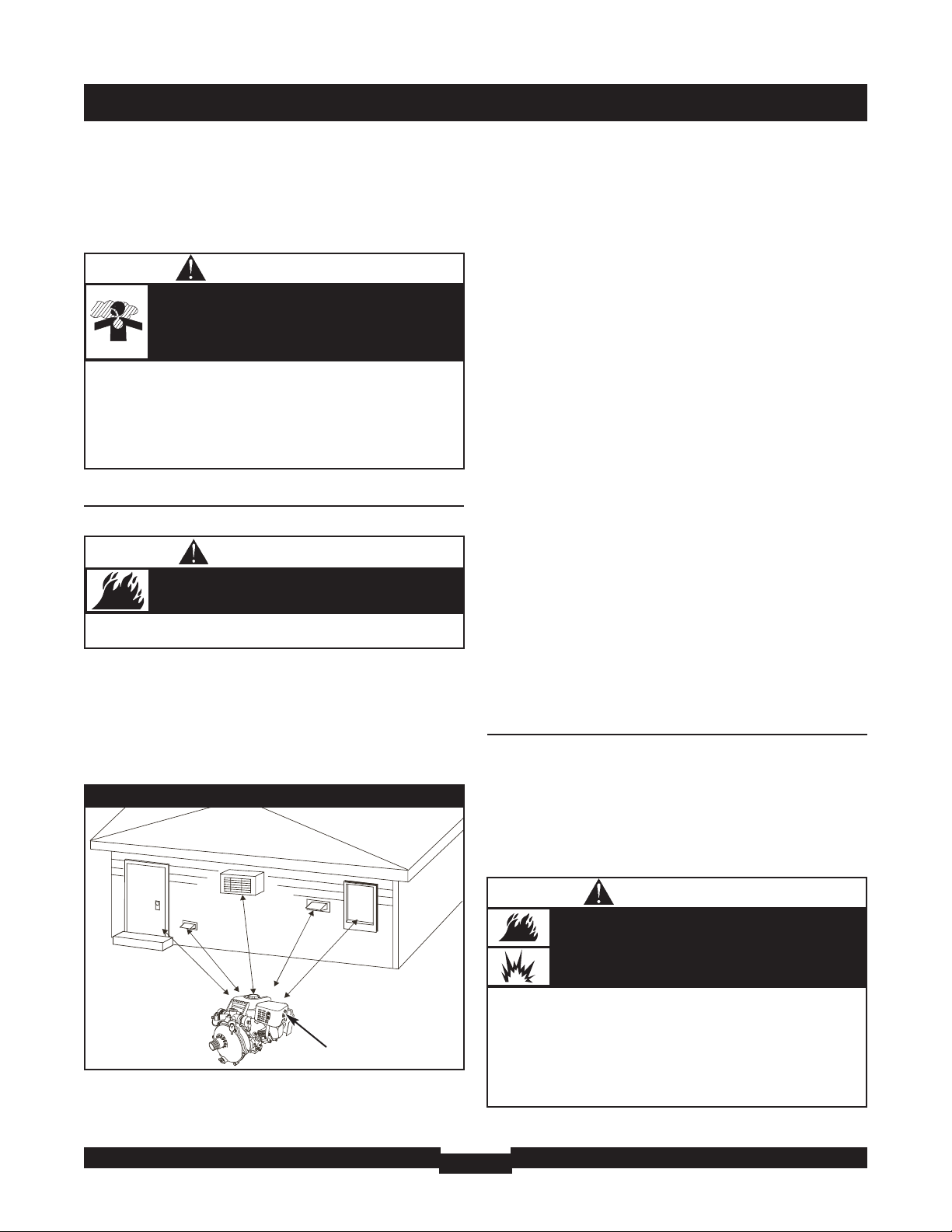

Safe Operating Considerations

Clearances and Air Movement

DO NOT place water pump where exhaust gas could

accumulate and enter inside or be drawn into a potentially

occupied building. Ensure exhaust gas is kept away from any

windows, doors, ventilation intakes or other openings that

can allow exhaust gas to collect in a confined area

(Figure 5). Prevailing winds and air currents should be taken

into consideration when positioning water pump.

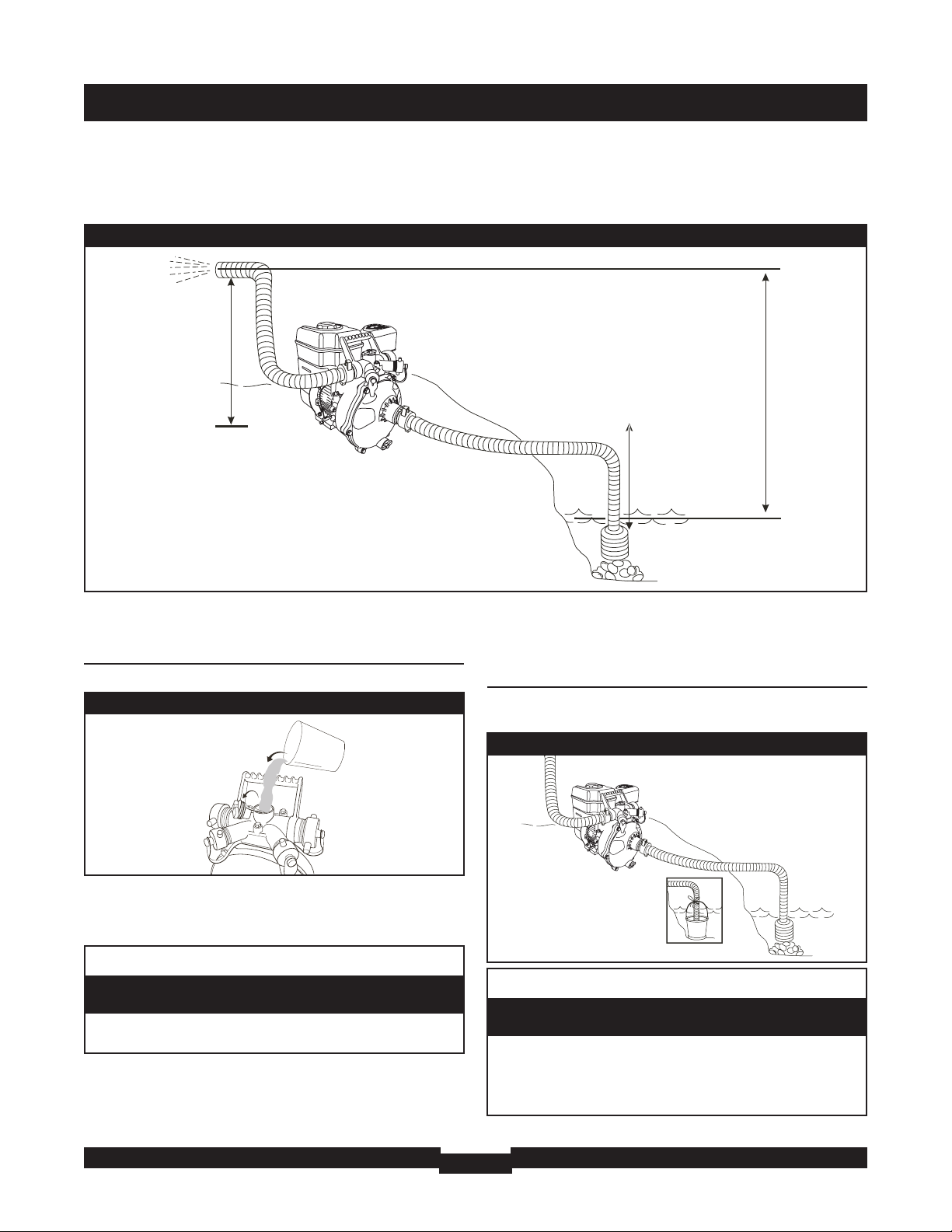

What is “Head”?

Head refers to the height of a column of water that can be

delivered by the discharge of the pump.

Suction Head is the vertical distance between the center of

the pump and the surface of the liquid on the suction side

of the pump. May also be referred to as “suction lift”.The

atmospheric pressure of 14.7 psi at sea level limits suction

head lift to less than approximately 26 feet for any pump.

Discharge Head is the vertical distance between the pump’s

discharge port and the point of discharge, which is the

liquid surface if the hose is submerged or pumping into the

bottom of a tank.

Total Head is the sum of the suction head value plus the

discharge head value.

As water pumping height increases, pump output decreases.

The length, type, and size of the suction and discharge

hoses can also significantly affect pump output.

It is important for the suction operation to be the shorter

part of the total pumping action.This will decrease the

priming time and improve pump performance by increasing

the discharge head.

Suction head is a maximum of 25 feet and discharge head

should be a maximum of 200 feet.Total head can not be

more than 225 feet (Figure 6, next page).

Move Water Pump to Safe

Operating Location

For best pump performance, locate the pump on a flat, level

surface as close as possible to the water to be pumped.

Secure water pump to avoid tipover. Use hoses that are no

longer than necessary.

IMPORTANT: Direct open end of discharge hose away

from home, electrical devices or anything not desired to

get wet.

Figure 5 — Water Pump Clearance

Exhaust Port

Typical Water Pump Shown

• Operate water pump ONLY outdoors.

• Keep exhaust gas from entering a confined area through

windows, doors, ventilation intakes or other openings.

• DO NOT operate water pump inside any building, confined

area or enclosure, such as basements,garages or a similar

location, even if doors or windows are open.

Running water pump gives off carbon monoxide,

an odorless, colorless, poison gas.

Breathing carbon monoxide may cause nausea,

fainting or death.

WARNING

WHEN OPERATING EQUIPMENT

• This water pump is not for use in mobile equipment or

marine applications.

• DO NOT tip engine or equipment at angle which causes fuel

to spill.

• Secure water pump. Loads from hoses may cause tipover.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• Keep at least 5 ft. (152 cm) clearance on all sides of water

pump including overhead.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

OPERATION

Page 9

9

OPERATION

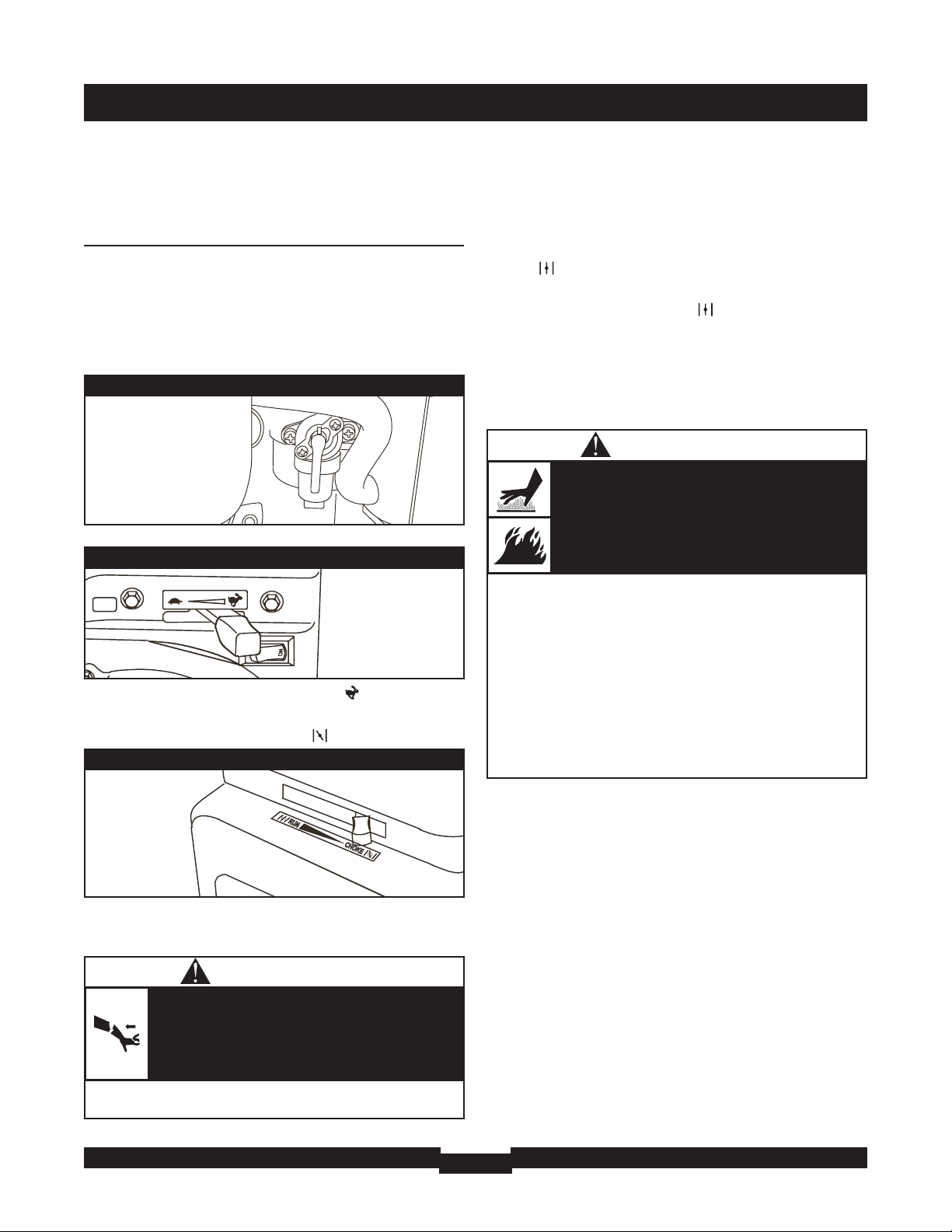

Prime the Water Pump

1. Remove plug from top of pump (Figure 7).

2. Fill pump with clean, clear water up to top of discharge

outlet (Figure 7).

3. Replace pump plug.

Locate Strainer Basket Into Water

Source

Place strainer basket into water to be pumped. Basket must

be fully immersed in water (Figure 8).

• NEVER operate pump without strainer connected to end of

suction hose.

• Keep strainer out of sand or silt, place in bucket or on stones.

• DO NOT let pump run dry or damage to seals may result.

Improper treatment of water pump can damage it and

shorten its life.

CAUTION

Figure 8 — Place Strainer Basket into Water

• Be sure pump chamber is filled with water before starting the

engine. NEVER run pump without priming.

Improper treatment of water pump can damage it and

shorten its life.

CAUTION

Figure 7 — Prime the Water Pump

Typical Water Pump Shown

Figure 6 — Head

Typical Water Pump Shown

Discharge Head

- 200 feet (61m)

Maximum

Suction Head

- 25 feet (8m)

Maximum

Total Head

- 225 feet (69m)

Maximum

Page 10

OPERATION

10

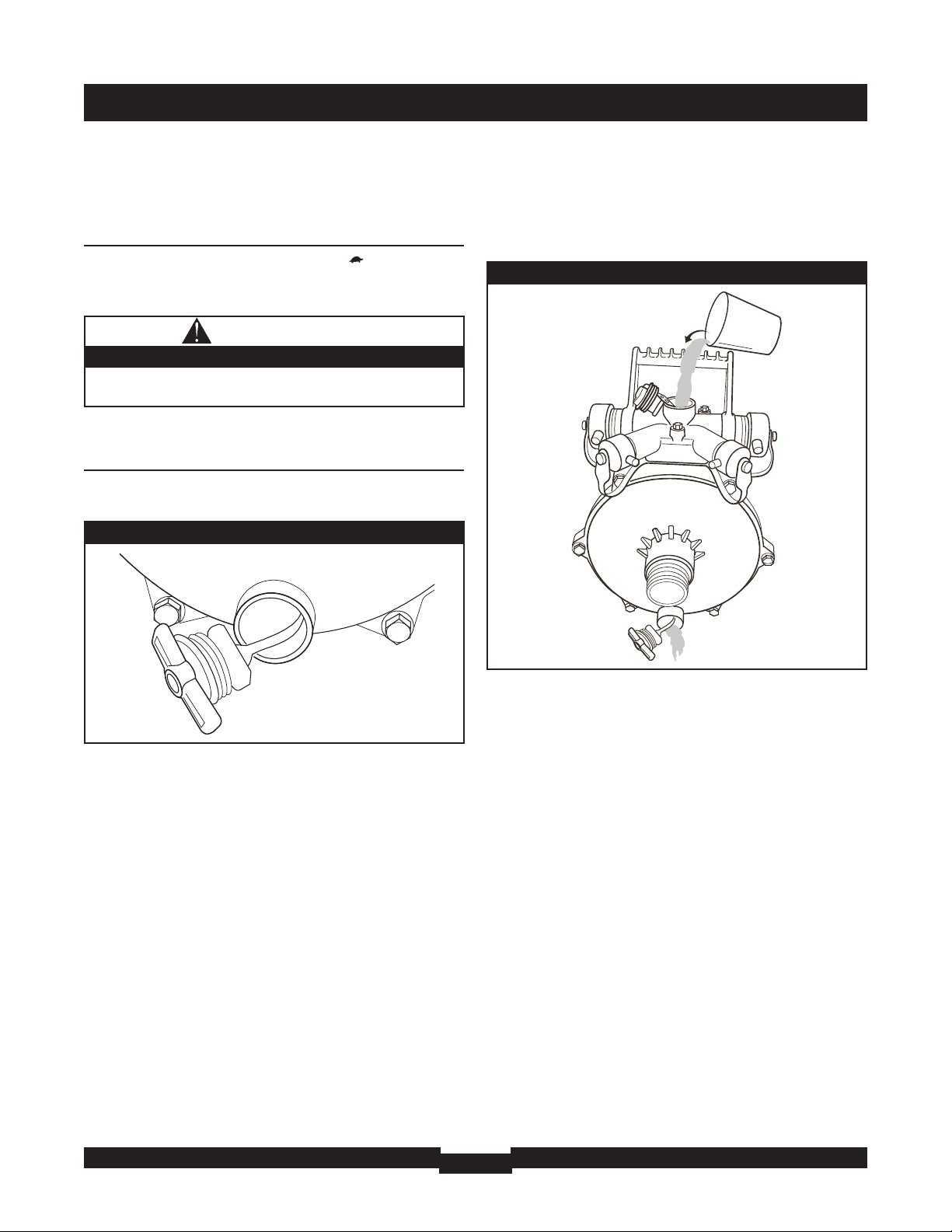

Starting the Water Pump

Use the following start instructions:

1. Make sure unit is on a flat, level surface and pump

chamber is primed.

2. Turn white fuel valve to “On” position (Figure 9).The

fuel valve handle will be vertical (pointing toward the

ground).

3. Push on/off switch to “On” position (Figure 10).

4. Move engine speed lever to “Fast” ( ) position

(Figure 10).

5. Move choke lever to “Choke” ( ) position (Figure 11).

6. Grasp recoil handle and pull slowly until slight

resistance is felt.Then pull handle rapidly to overcome

compression, prevent kickback and start engine.

IMPORTANT: If excessive fuel is present in the air/fuel

mixture causing a “flooded” condition, move choke lever to

“Run” ( ) position and pull handle repeatedly until engine

starts.

7. Move choke lever to “Run” ( ) position a short

distance at a time over several seconds in warm

weather or minutes in cold weather. Let engine run

smoothly before each change. Operate with choke in

“Run” position.

IMPORTANT: It may take a few minutes for water pump

to begin pumping water.

Pump output is controlled by adjusting engine speed.

Moving the engine speed lever in the “Fast” direction will

increase pump output, and moving the engine speed lever

in the “Slow” direction will decrease pump output.

• When starting engine, pull cord slowly until resistance is felt

and then pull rapidly to avoid kickback.

Rapid retraction of starter cord (kickback) will

pull hand and arm toward engine faster than

you can let go.

Broken bones, fractures, bruises or sprains could

result.

WARNING

Figure 10 — On/Off Switch and Engine Speed Lever

Switch is shown in

“On” position

Lever is shown in

“Fast” position

Figure 9 — Fuel Valve

Fuel Valve is shown in

“On” position

Figure 11 — Choke Lever

Choke Lever

shown in

“Choke”

position

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of water

pump including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Page 11

11

OPERATION

Stopping the Water Pump

1. Move engine speed lever to “Slow” ( ) position

(Figure 10).

2. Push on/off switch to “Off” position (Figure 10).

3. Turn white fuel valve to “Off” position (Figure 9).

Drain and Flush Water Pump

1. Disconnect and drain suction and discharge hoses.

2. Remove drain plug at bottom of pump (Figure 12).

3. Remove plug from top of pump and flush internal

components of pump with clean water (Figure 13).

4. Replace both plugs and twist.

Figure 12 — Remove Drain Plug

Figure 13 — Remove Plug from Top of Pump and Flush

• DO NOT stop engine by moving choke lever to “Choke”

position.

Backfire, fire or engine damage could occur.

CAUTION

Page 12

SPECIFICATIONS

12

ENGINE TECHNICAL

INFORMATION

These water pumps are powered by a single cylinder,

overhead valve (OHV), air cooled, low emissions engine.

In the State of California, these water pump engines are

certified by the California Air Resources Board to meet

emissions standards for 250 hours. Such certification does

not grant the purchaser, owner or operator of this engine

any additional warranties with respect to the performance

or operational life of this engine.The engine is warranted as

stated elsewhere in this manual.

Power Ratings

The power ratings for an individual engine model are

initially developed by starting with SAE (Society of

Automotive Engineers) code J1940 (Small Engine Power &

Torque Rating Procedure) (Revision 2002-05). Given both

the wide array of products on which our engines are

placed, and the variety of environmental issues applicable to

operating the equipment, it may be that the engine you

have purchased will not develop the rated horsepower

when used in a piece of power equipment (actual “on-site”

power).This difference is due to a variety of factors

including, but not limited to, the following: differences in

altitude, temperature, barometric pressure, humidity, fuel,

engine lubrication, maximum governed engine speed,

individual engine to engine variability, design of the

particular piece of power equipment, the manner in which

the engine is operated, engine run-in to reduce friction and

clean out of combustion chambers, adjustments to the

valves and carburetor, and other factors.The power ratings

may also be adjusted based on comparisons to other

similar engines utilized in similar applications, and will

therefore not necessarily match the values derived using

the foregoing codes.

PRODUCT

SPECIFICATIONS

Model 073004

Water Pump Specifications

Suction Port Diameter . . . . . . . . . . . . . . . . . . . 1.5 in (38 mm)

Discharge Ports Diameter

2 @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 in (25 mm)

2 @ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1.5 in (38 mm)

Total Head . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 225 ft (69 m)

Maximum Head

Suction Lift . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 ft (8 m)

Discharge Lift . . . . . . . . . . . . . . . . . . . . . . . . 200 ft (61 m)

Maximum Discharge Capacity . 132 US gal (500 l) per minute

Shipping Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75 lbs.

Engine Specifications

Rated Horsepower . . . . . . . . . . . . . . . . . . . . . 5.5 at 3600 rpm

Bore . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.69 in. (68mm)

Stroke . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.20 in. (56mm)

Displacement . . . . . . . . . . . . . . . . . . . . . . . . 12.48 in. (206 cc)

Spark Plug

Type: . . . . . . . . . . . . . . Champion RC12YC or Equivalent

Set Gap To: . . . . . . . . . . . . . . . . . . . . 0.030inch (0.76mm)

Armature Air Gap: . . . . . . . . . . . . . . . . . . . . . . 0.010-0.014 in.

(0.25-0.36mm)

Valve clearance with valve springs installed and piston 1/4 in.

(6 mm) past top dead center of compression stroke (check when

engine is cold).

Intake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.004-0.006 in.

(0.10-0.15 mm)

Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.009-0.011 in.

(0.23-0.28 mm)

Fuel Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 U.S. gallons

Oil Capacity . . . . . . . . . . . . . . . . . . . .20 Ounces (.6 Liters)

Oil Type:

Above 40° F . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .SAE 30

Below 40° F . . . . . . . . . . . . . . . . .SAE 5W-30 or 10W-30

NOTE:For practical operation, the horsepower loading

should not exceed 85% of rated horsepower. Engine power

will decrease 3-1/2% for each 1,000 feet (300 meters)

above sea level and 1% for each 10° F (5.6° C) above 77° F

(25° C). It will operate satisfactorily at an angle up to 15°.

Page 13

13

General Recommendations

Regular maintenance will improve the performance and

extend the life of the water pump. See any authorized

Briggs & Stratton dealer for service.

The water pump’s warranty does not cover items that have

been subjected to operator abuse or negligence.To receive

full value from the warranty, the operator must maintain

water pump as instructed in this manual.

Some adjustments will need to be made periodically to

properly maintain your water pump.

All service and adjustments should be made at least once

each season. Follow the requirements in the “Maintenance

Schedule” chart above.

NOTE: Once a year you should clean or replace the spark

plug and replace the air filter.A new spark plug and clean

air filter assure proper fuel-air mixture and help your

engine run better and last longer.

Emissions Control

Maintenance, replacement or repair of the emissions control

devices and systems may be performed by any non-road

engine repair establishment or individual. See emissions

control system warranty, elsewhere in this manual.

Maintenance

Maintenance consists of keeping the water pump clean.

Store the unit in a clean dry environment where it will not

be exposed to excessive dust, dirt, moisture or any

corrosive vapors.Cooling air slots in the water pumps

engine must not become clogged with dirt, leaves or any

other foreign material.

NOTE: DO NOT use a garden hose to clean water pumps

engine.Water can enter engine fuel system and cause

problems.

Cleaning

Daily or before use, look around and underneath water

pump for signs of oil or fuel leaks. Clean accumulated debris

from inside and outside water pump.Keep linkage, spring and

other engine controls clean. Keep area around and behind

muffler free from any combustible debris.

Engine parts should be kept clean to reduce the risk of

overheating and ignition of accumulated debris.

• Use a damp cloth to wipe exterior surfaces clean.

• Use a soft bristle brush to loosen caked on dirt or oil.

• Use a vacuum cleaner to pick up loose dirt and debris.

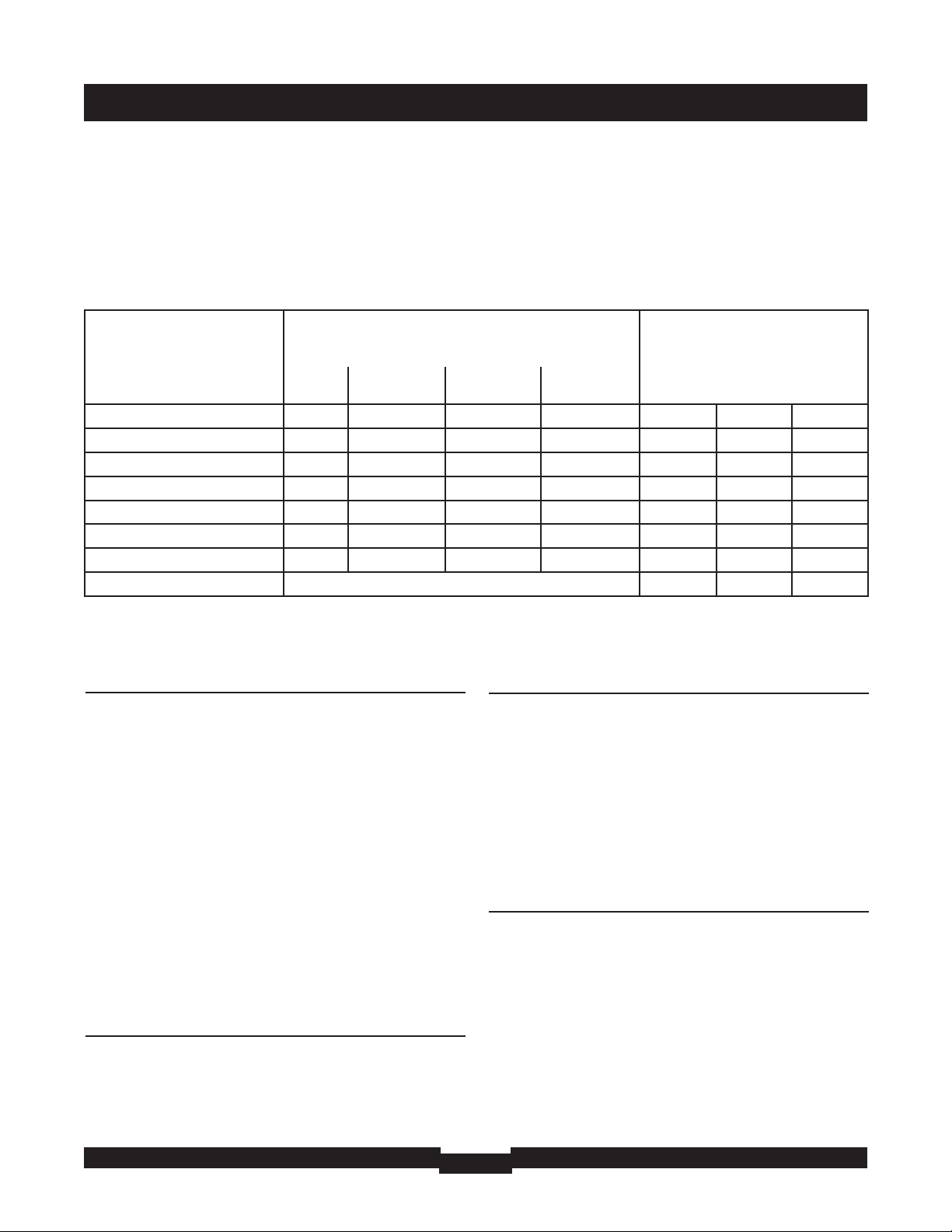

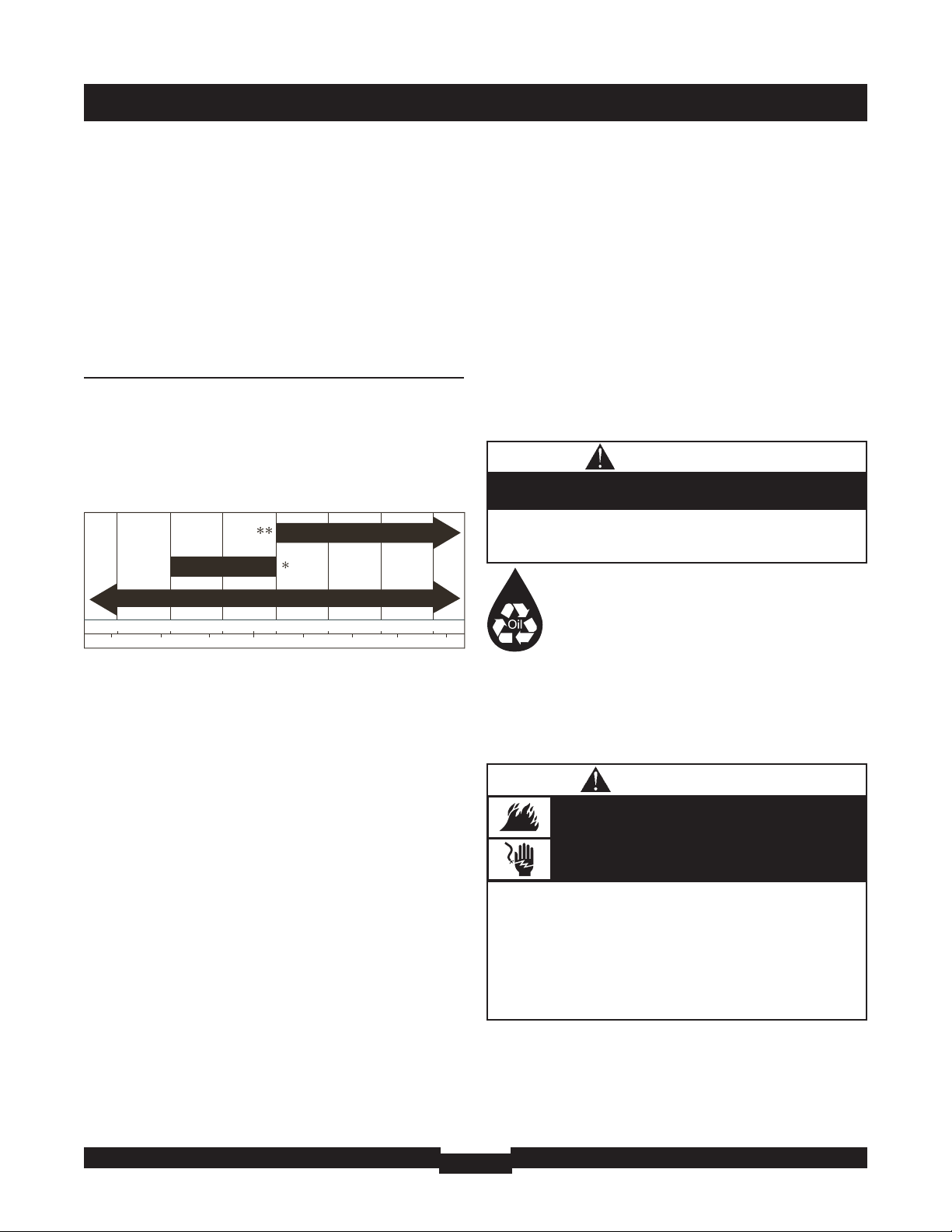

MAINTENANCE SCHEDULE

Follow the hourly or calendar intervals, whichever occurs first.

More frequent service is required when operating in adverse conditions noted below.

¹ Change oil after the first (5) operating hours and every 50 hours or every year, whichever occurs first, thereafter.

Change oil sooner when operating under dirty or dusty conditions.

² Replace more often under dirty or dusty conditions.

MAINTENANCE SCHEDULE

FILL IN DATES AS YOU COMPLETE

REGULAR SERVICE

SERVICE DATES

SERVICE DATES

MAINTENANCE TASK

Before

Each Use

Every 25 Hours

or Yearly

Every 50 Hours

or Yearly

Every 100 Hours

or Yearly

Clean debris

X

Check oil level

X

Change engine oil

X¹

Service air cleaner

X²

Service spark plug

X

Service spark arrester

X

Clean cooling system

X²

Prepare for storage If unit is to remain idle for longer than 30 days.

MAINTENANCE

Page 14

MAINTENANCE

14

• Use low pressure air (not to exceed 25 psi) to blow away

dirt. Inspect cooling air slots and opening on water pump.

These openings must be kept clean and unobstructed.

Remove silt and sludge buildup in pump body:

• Open priming plug and remove drain plug.

• Flush internal components of pump with clean water.

Oil

Oil Recommendations

NOTE:When adding oil to the engine crankcase, use only

high quality detergent oil rated with API service

classification SF, SG, SH, SJ or higher. DO NOT use special

additives.

1. Choose a viscosity according to the table below:

* The use of multi-viscosity oils (5W-30, 10W-30, etc.) in

temperatures above 40°F (4°C) will result in higher than

normal oil consumption.When using a multi-viscosity oil,

check oil more frequently.

** The use of SAE 30 oil in temperatures below 40°F (4°C)

will result in hard starting and possible engine bore damage

due to inadequate lubrication.

NOTE: Synthetic oil meeting ILSAC GF-2,API certification

mark and API service symbol with “SJ/CF ENERGY

CONSERVING” or higher, is an acceptable oil at all

temperatures. Use of synthetic oil does not alter required

oil change intervals.

Checking Oil Level

Oil level should be checked prior to each use or at least

every 8 hours of operation. Keep oil level maintained.

1. Make sure unit is on a level surface.

2. Remove oil fill cap and wipe clean with cloth.

3. Verify oil is at the point of overflowing at oil fill

opening.

Adding Engine Oil

1. Make sure unit is on a level surface.

2. Check oil level as described in “Checking Oil Level”.

3. If needed, slowly pour oil into oil fill opening to the

point of overflowing at oil fill cap.

Changing Engine Oil

Change the oil after the first 5 hours of operation. Change

oil every 50 hours thereafter. If you are using your water

pump under extremely dirty or dusty conditions, or in

extremely hot weather, change the oil more often.

KEEP OUT OF REACH OF CHILDREN.DON'T

POLLUTE. CONSERVE RESOURCES. RETURN

USED OIL TO COLLECTION CENTERS.

Change the oil while the engine is still warm from running,

as follows:

1. Make sure unit is on a level surface.

2. Disconnect the spark plug wire from the spark plug

and place the wire where it cannot contact spark plug.

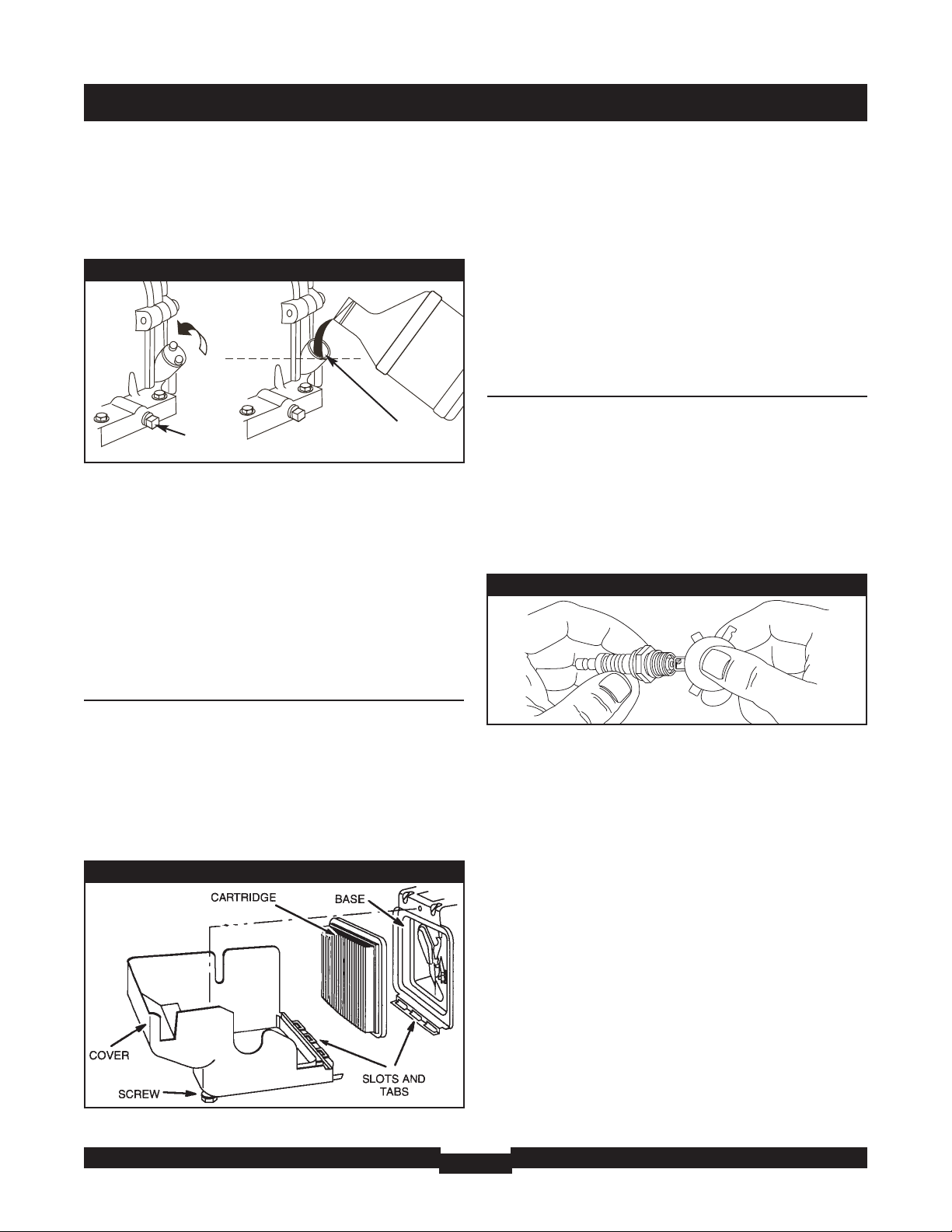

• Used motor oil has been shown to cause skin cancer in

certain laboratory animals.

• Thoroughly wash exposed areas with soap and water.

Avoid prolonged or repeated skin contact with used

motor oil.

CAUTION

WHEN ADJUSTING OR MAKING REPAIRS TO YOUR

WATER PUMP

• Disconnect the spark plug wire from the spark plug and place

the wire where it cannot contact spark plug.

WHEN TESTING FOR ENGINE SPARK

• Use approved spark plug tester.

• DO NOT check for spark with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

Synthetic 5W-30,10W-30

5W-30, 10W-30

30

°F -20 0 20 32 40 60 80 100

°C -30 -20 -10 0 10 20 30 40

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

Page 15

MAINTENANCE

15

3. Clean area around oil drain plug.The oil drain plug is

located at base of engine, opposite carburetor (Figure 14).

4. Remove oil drain plug and drain oil completely into a

suitable container.

5. Reinstall oil drain plug and tighten securely. Remove oil

fill cap.

6. Slowly pour oil (about 20 oz.) into oil fill opening to

the point of overflowing at oil fill cap (Figure 14). DO

NOT overfill.

7. Reinstall oil fill cap. Finger tighten cap securely.

8. Wipe up any spilled oil.

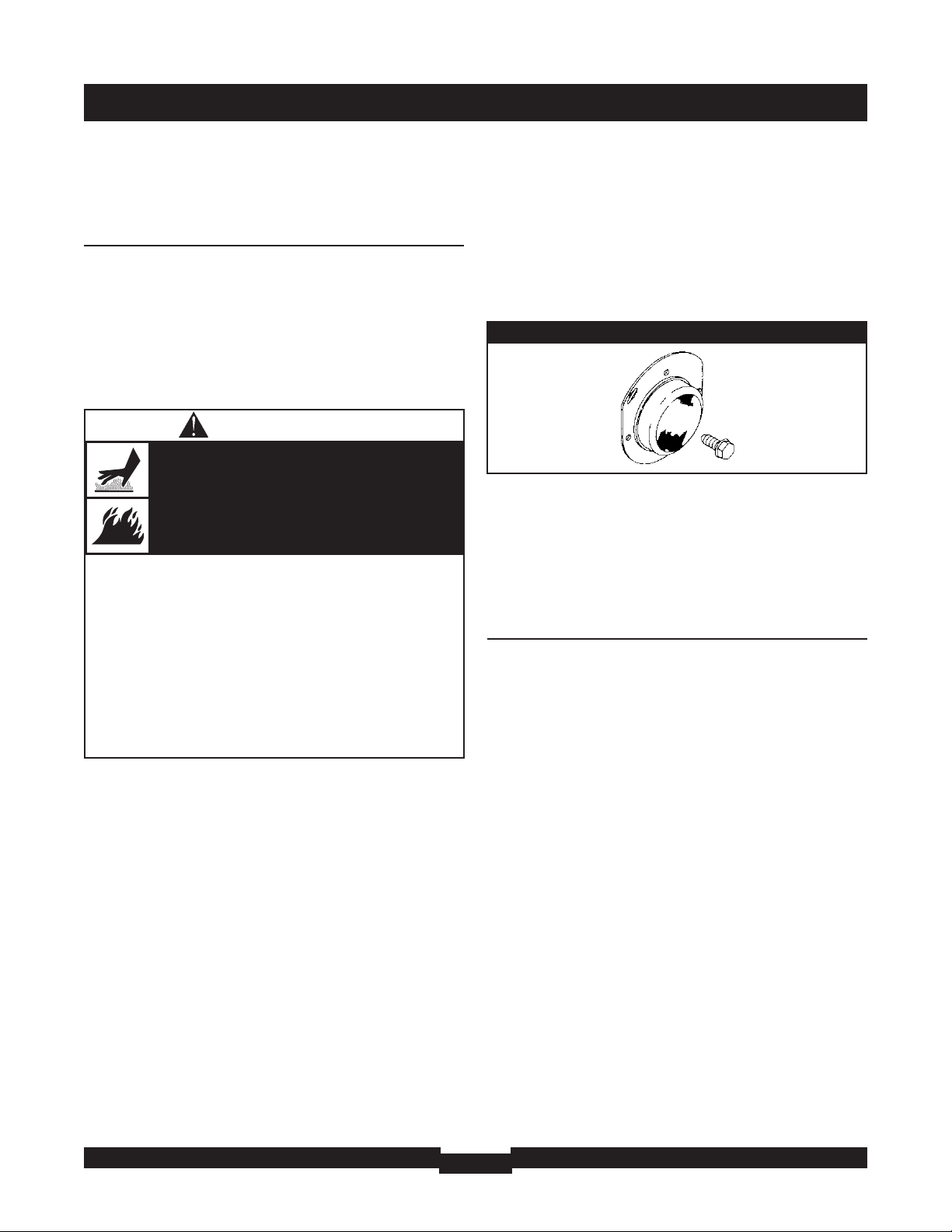

Service Air Cleaner

Your engine will not run properly and may be damaged if

you run it with a dirty air cleaner.

Replace the air cleaner every 25 hours of operation or

once each year, whichever comes first. Replace more often

if operating under dirty or dusty conditions.

To service the air cleaner, follow these steps:

1. Loosen screw and tilt cover down (Figure 15).

2. Carefully remove cartridge assembly.

3. To clean cartridge, gently tap pleated paper side on a

flat surface.

4. Reinstall clean or new cartridge inside cover.

5. Insert cover’s tabs into slots in bottom of base.

6. Tilt cover up and tighten screw securely to base.

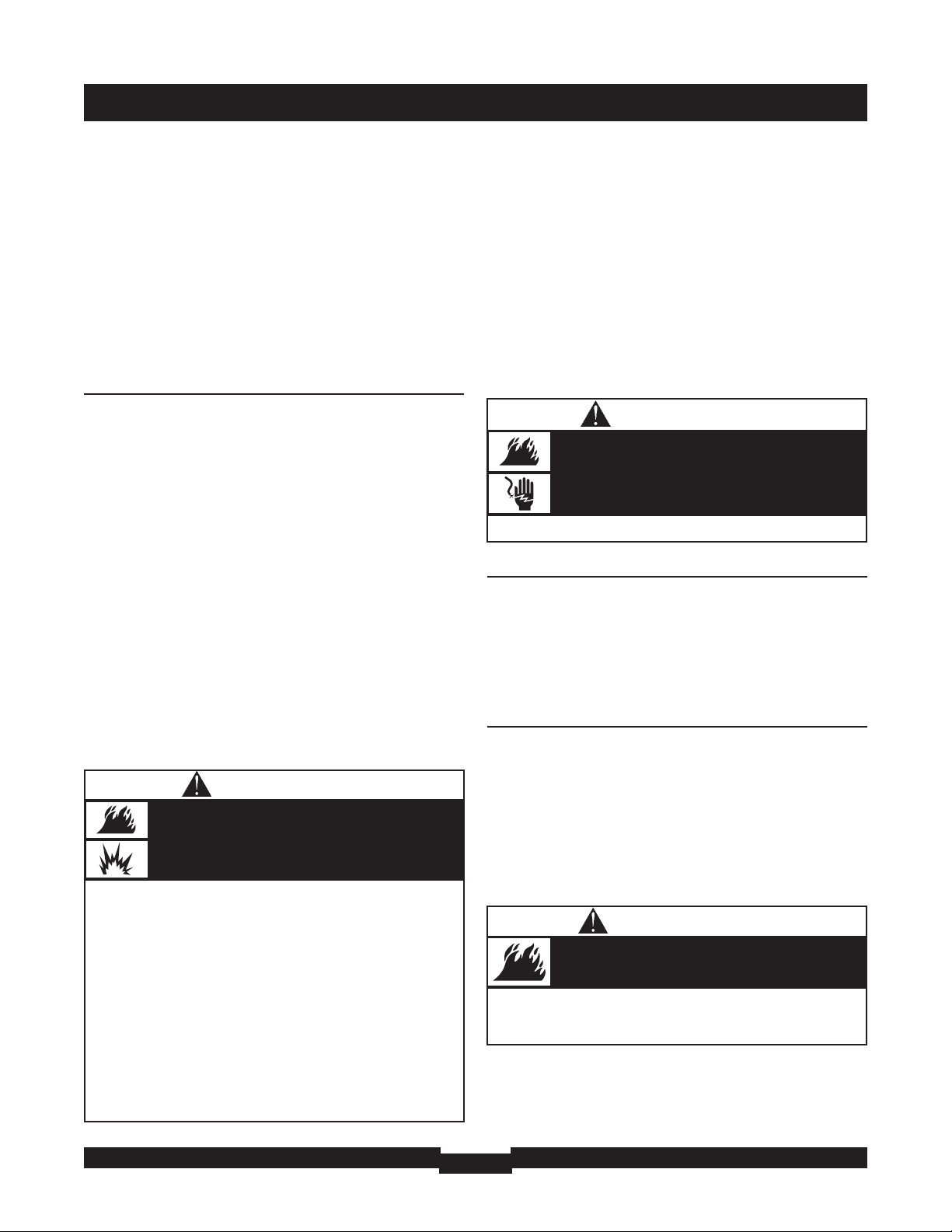

Service Spark Plug

Change the spark plug every 100 hours of operation or

once each year, whichever comes first.This will help your

engine to start easier and run better.

1. Clean area around spark plug.

2. Remove and inspect spark plug.

3. Check electrode gap with wire feeler gauge and set

spark plug gap to 0.030 inch (0.76mm) if necessary

(Figure 16).

4. Replace spark plug if electrodes are pitted, burned or

porcelain is cracked. Use the recommended

replacement plug.

5. Install spark plug and tighten firmly.

Figure 15 - Air Cleaner

Figure 16 — Spark Plug

Figure 14 — Oil Drain Plug and Oil Fill Cap

Oil Drain Plug

Oil Fill Opening

Page 16

MAINTENANCE

16

Clean Spark Arrester Screen

The engine exhaust muffler may be equipped a spark

arrester screen. If equipped, inspect and clean the screen

every 50 hours of operation or once each year, whichever

comes first.

If you use your water pump on any forest-covered, brushcovered, or grass-covered unimproved land, it must have a

spark arrester.The spark arrester must be maintained in

good condition by the owner/operator.

If the engine has been running, the muffler will be very hot.

Allow the muffler to cool before servicing the spark

arrester.

• Remove spark arrester screen for cleaning and inspection

(Figure 17).

• Inspect screen and replace if torn, perforated or

otherwise damaged. DO NOT use a defective screen. If

screen is not damaged, clean it with commercial solvent.

• Reattach spark arrester screen to muffler.

NOTE:You can purchase a new spark arrester screen by

contacting your local Briggs & Stratton service center.

Air Cooling System

Over time debris may accumulate in cylinder cooling fins

and cannot be observed without partial engine disassembly.

For this reason, we recommend you have an authorized

Briggs & Stratton service dealer clean the cooling system

per recommended intervals (see “Maintenance Schedule”

on page 13). Equally important is to keep top of engine free

from debris. See “Cleaning”.

Figure 17 - Spark Arrester

Typical Spark

Arrester Shown

• DO NOT touch hot surfaces and avoid hot exhaust gases.

• Allow equipment to cool before touching.

• Keep at least 5 ft. (152 cm) clearance on all sides of water

pump including overhead.

• Code of Federal Regulation (CFR) Title 36 Parks, Forests,and

Public Property require equipment powered by an internal

combustion engine to have a spark arrester, maintained in

effective working order, complying to USDA Forest service

standard 5100-1C or later revision. In the State of California a

spark arrester is required under section 4442 of the California

Public resources code. Other states may have similar laws.

Running engines produce heat.Temperature of

muffler and nearby areas can reach or exceed

150°F (65°C).

Severe burns can occur on contact.

Exhaust heat/gases can ignite combustibles,

structures or damage fuel tank causing a fire.

WARNING

Page 17

17

STORAGE

The water pump should be started at least once every

seven days and allowed to run at least 30 minutes. If this

cannot be done and you must store the unit for more than

30 days, use the following information as a guide to prepare

it for storage.

Long Term Storage Instructions

It is important to prevent gum deposits from forming in

essential fuel system parts, such as the carburetor, fuel filter,

fuel hose or tank during storage.Also, experience indicates

that alcohol-blended fuels (called gasohol, ethanol or

methanol) can attract moisture, which leads to separation

and formation of acids during storage.Acidic fuel can

damage the fuel system of an engine while in storage.

Fuel Additive:

If adding a fuel additive, fill the fuel tank with fresh fuel. If

only partially filled, air in the tank will promote fuel

deterioration during storage. Engine and fuel can be stored

up to 24 months with additive.

• Add fuel additive following manufacturer’s instructions.

• Run the engine outdoors for 30 seconds to be sure that

treated fuel has replaced the untreated fuel in the

carburetor.

If fuel additive is not used, remove all fuel from tank and

run engine until it stops from lack of fuel.

Change Oil

While engine is still warm, drain oil from crankcase. Refill

with recommended grade.

Oil Cylinder Bore

• Remove spark plug and pour about 1 ounce (30ml) of

clean engine oil into the cylinder.

• Install spark plug and pull starter handle slowly to

distribute oil.

Water Pump

1. Drain water pump as described in “Drain and Flush

Water Pump”.

2. Clean water pump as described in “Cleaning”.

3. Check that openings on water pump are open and

unobstructed.

Other Storage Tips

1. DO NOT store fuel from one season to another.

2. Replace fuel can if it starts to rust. Contaminated fuel

will cause engine problems.

3. If possible, store unit indoors and cover it to give

protection from dust and dirt. BE SURE TO EMPTY

FUEL TANK.

4. Cover unit with a suitable protective cover that does

not retain moisture.

5. Store water pump in clean, dry area.

WHEN STORING FUEL OR EQUIPMENT WITH FUEL

IN TANK

• Store away from furnaces, stoves, water heaters, clothes

dryers or other appliances that have pilot light or other

ignition source because they can ignite fuel vapors.

WHEN DRAINING FUEL

• Turn water pump OFF and let it cool at least 2 minutes

before removing fuel cap. Loosen cap slowly to relieve

pressure in tank.

• Drain fuel tank outdoors.

• Keep fuel away from sparks,open flames, pilot lights,heat, and

other ignition sources.

• DO NOT light a cigarette or smoke.

Fuel and its vapors are extremely flammable and

explosive.

Fire or explosion can cause severe burns or

death.

WARNING

• NEVER pull starter handle with spark plug removed.

Unintentional sparking can result in fire or

electric shock.

WARNING

• DO NOT place a storage cover over a hot water pump.

• Let equipment cool for a sufficient time before placing the

cover on the equipment.

Storage covers can be flammable.

WARNING

STORAGE

Page 18

TROUBLESHOOTING

18

TROUBLESHOOTING

Problem Cause Correction

No pump output or low

pump output when water

pump is running.

1. Pump not primed.

2. Suction hose restricted, collapsed,

damaged, too long, or diameter too

small.

3. Strainer not completely under water.

4. Air leak at suction hose connector.

5. Strainer clogged.

6. Discharge hose restricted, damaged, too

long, or diameter too small.

7. Excessive or marginal head.

8. Engine speed lever is in “Slow” position.

1. Fill pump chamber with water and

prime pump.

2. Replace suction hose.

3. Sink the strainer and the end of

suction hose completely under water.

4. Replace sealing washer if missing or

damaged.Tighten hose connector and

clamp.

5. Clean debris from strainer.

6. Replace discharge hose.

7. Relocate pump and/or hoses to

reduce head.

8. Move engine speed lever to “Fast”

position.

Engine will not start; lacks

power; starts and runs

rough; or "hunts" or falters.

1. Rocker switch set to "Off".

2. Fuel valve is in "Off" position.

3. Dirty air cleaner.

4. Out of fuel.

5. Stale or contaminated fuel or water in

fuel.

6. Spark plug wire not connected to spark

plug.

7. Bad spark plug.

8. Excessive fuel is present in the air/fuel

mixture causing a “flooded” condition.

9. Excessively rich fuel mixture.

10. Intake valve stuck open or closed.

11. Engine has lost compression.

12. Carburetor is running too rich or too

lean.

1. Set switch to "On".

2. Turn fuel valve to "On" position.

3. Clean or replace air cleaner.

4. Wait two minutes and fill fuel tank.

5. Drain fuel tank and carburetor; fill

with fresh fuel.

6. Connect wire to spark plug.

7. Replace spark plug.

8. Wait 5 minutes and re-crank engine.

9. Contact Authorized service facility.

10. Contact Authorized service facility.

11. Contact Authorized service facility.

12. Contact Authorized service facility.

Engine shuts down when

running.

Out of gasoline. Wait two minutes and fill fuel tank.

Page 19

NOTES

19

NOTES

Page 20

EMISSIONS CONTROL SYSTEM WARRANTY

Briggs & Stratton Corporation (B&S), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emissions Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

California, United States and Canada Emissions Control

Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA and B&S are

pleased to explain the Emissions Control System Warranty on your

small off–road engine (SORE). In California, new small off–road engines

model year 2006 and later must be designed, built and equipped to

meet the State’s stringent anti–smog standards. Elsewhere in the

United States, new non–road, spark–ignition engines certified for model

year 1997 and later must meet similar standards set forth by the U.S.

EPA. B&S must warrant the emissions control system on your engine

for the periods of time listed below, provided there has been no abuse,

neglect or improper maintenance of your small off–road engine.

Your emissions control system includes parts such as the carburetor, air

cleaner, ignition system,fuel line, muffler and catalytic converter.Also

included may be connectors and other emissions related assemblies.

Where a warrantable condition exists, B&S will repair your small

off–road engine at no cost to you including diagnosis, parts and labor.

Briggs & Stratton Emissions Control Defects Warranty

Coverage

Small off–road engines are warranted relative to emissions control

parts defects for a period of two years, subject to provisions set forth

below.If any covered part on your engine is defective, the part will be

repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the small off–road engine owner, you are responsible for the

performance of the required maintenance listed in your Operating and

Maintenance Instructions. B&S recommends that you retain all your

receipts covering maintenance on your small off–road engine, but B&S

cannot deny warranty solely for the lack of receipts or for your failure

to ensure the performance of all scheduled maintenance.

As the small off–road engine owner, you should however be aware that

B&S may deny you warranty coverage if your small off–road engine or

a part has failed due to abuse, neglect, improper maintenance or

unapproved modifications.

You are responsible for presenting your small off–road engine to an

Authorized B&S Service Dealer as soon as a problem exists.The

undisputed warranty repairs should be completed in a reasonable

amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service Representative at

1–414–259–5262.

The emissions warranty is a defects warranty. Defects are judged on

normal engine performance.The warranty is not related to an in–use

emissions test.

Briggs & Stratton Emissions Control Defects Warranty

Provisions

The following are specific provisions relative to your Emissions Control

Defects Warranty Coverage. It is in addition to the B&S engine

warranty for non–regulated engines found in the Owner’s Manual.

1. Warranted Parts

Coverage under this warranty extends only to the parts listed

below (the emissions control systems parts) to the extent these

parts were present on the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

• Fuel line, fuel line fittings, clamps

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position,time sensitive valves and

switches

• Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and each subsequent purchaser

that the Warranted Parts shall be free from defects in materials

and workmanship which caused the failure of the Warranted Parts

for a period of two years from the date the engine is delivered to

a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be performed

at no charge to the owner, including diagnostic labor which leads

to the determination that a Warranted Part is defective, if the

diagnostic work is performed at an Authorized B&S Service

Dealer. For emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow Pages”

under “Engines, Gasoline,” “Gasoline Engines,” “Lawn Mowers,” or

similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the provisions of

the B&S Engine Warranty Policy.Warranty coverage shall be

excluded for failures of Warranted Parts which are not original

B&S parts or because of abuse, neglect or improper maintenance

as set forth in the B&S Engine Warranty Policy. B&S is not liable to

cover failures of Warranted Parts caused by the use of add–on,

non–original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replacement as

required maintenance or which is scheduled only for regular

inspection to the effect of “repair or replace as necessary” shall

be warranted as to defects for the warranty period.Any

Warranted Part which is scheduled for replacement as required

maintenance shall be warranted as to defects only for the period

of time up to the first scheduled replacement for that part.Any

replacement part that is equivalent in performance and durability

may be used in the performance of any maintenance or repairs.

The owner is responsible for the performance of all required

maintenance, as defined in the B&S Owner’s Manual.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any engine

components caused by the failure of any Warranted Part still

under warranty.

Page 21

Emissions Durability Period and Air

Index Information On Your Engine

Emissions Label

Engines that are certified to meet the California Air Resources

Board (CARB) Tier 2 Emission Standards must display

information regarding the Emissions Durability Period and Air

Index.The engine manufacturer makes this information available

to the consumer on emission labels.

The Emissions Durability Period describes the number of

hours of actual running time for which the engine is certified to

be emissions compliant, assuming proper maintenance in

accordance with the Operating & Maintenance Instructions.The

following categories are used:

Moderate: Engine is certified to be emission compliant for

125 hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for

250 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for

500 hours of actual engine running time.

For example, a typical walk-behind lawn mower is used 20 to

25 hours per year.Therefore, the Emissions Durability

Period of an engine with an intermediate rating would

equate to 10 to 12 years.

The Air Index is a calculated number describing the relative

level of emissions for a specific engine family.The lower the Air

Index, the cleaner the engine.This information is displayed in

graphical form on the emisions label.

Emissions Compliance Period On

Engine Emissions Compliance Label

After July 1, 2000 certain Briggs & Stratton engines will be

certified to meet the United States Environmental Protection

Agency (USEPA) Phase 2 emission standards. For phase 2 certified

engines, the Emissions Compliance Period referred to on the

Emissions Compliance label indicates the number of operating

hours for which the engine has been shown to meet Federal

emission requirements. For engines less than 225 cc displacement,

Category C = 125 hours, B = 250 hours and A = 500 hours. For

engines of 225 cc or more, Category C = 250 hours, B = 500

hours and A = 1000 hours.

This engine has an intermediate rating with and Air Index of 2.

The EPA Emissions compliance period is Category B.The

diplacement of these engines is 206 cc.

Below is a generic representation of the emission label typically

found on a certified engine.

Page 22

NOTES

22

NOTES

Page 23

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC WATER PUMP OWNER WARRANTY POLICY

LIMITED WARRANTY

Briggs & Stratton Power Products Group, LLC will repair or replace, free of charge, any part(s) of the water pump that is

defective in material or workmanship or both. Transportation charges on product submitted for repair or replacement under this

warranty must be borne by purchaser. This warranty is effective for the time periods and subject to the conditions stated below.

For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at www.briggspowerproducts.com.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT

PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or

countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not allow the

exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from state to state or country to country.

2 years

2 years

Consumer Use

Commercial Use

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the

period of time stated above. “Consumer use" means personal residential household use by a retail consumer. “Commercial use"

means all other uses, including use for commercial, income producing or rental purposes. Once equipment has experienced

commercial use, it shall thereafter be considered as commercial use for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE

YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME

WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE PRODUCT WILL BE USED TO DETERMINE

THE WARRANTY PERIOD.

ABOUT YOUR WARRANTY

We welcome warranty repair and apologize to you for being inconvenienced. Any Authorized Service Dealer may perform warranty

repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service may not be appropriate. For

example, warranty service would not apply if equipment damage occurred because of misuse, lack of routine maintenance,

shipping, handling, warehousing or improper installation. Similarly, the warranty is void if the manufacturing date or the serial number

on the water pump or engine has been removed or the equipment has been altered or modified. During the warranty period, the

Authorized Service Dealer, at its option, will repair or replace any part that, upon examination, is found to be defective under normal

use and service. This warranty will not cover the following repairs and equipment:

• Normal Wear: Outdoor Power Equipment, like all mechanical devices, needs periodic parts and service to perform well. This

warranty does not cover repair when normal use has exhausted the life of a part or the equipment.

• Installation and Maintenance: This warranty does not apply to equipment or parts that have been subjected to improper or

unauthorized installation or alteration and modification, misuse, negligence, accident, overloading, overspeeding, improper

maintenance, repair or storage so as, in our judgment, to adversely affect its performance and reliability. This warranty also does

not cover normal maintenance such as air filters, adjustments, fuel system cleaning and obstruction (due to chemical, dirt, etc.).

• Other Exclusions: This warranty excludes wear items such as seals, o-rings, etc.This warranty also excludes pumps that have

been run without water or subjected to freezing or chemical deterioration. This water pump is warranted for use in clear water

applications, as certain components will experience accelerated wear depending on the percentage and abrasive degree of

sediment passing through the pump. Accessory parts, such as hoses or strainers, are excluded from the product warranty. This

warranty excludes failures due to acts of God and other force majeure events beyond the manufacturers control.

BRIGGS & STRATTON POWER PRODUCTS GROUP, LLC

JEFFERSON, WI, USA

Effective February 1, 2006 replaces all undated Warranties and all Warranties dated before February 1, 2006

198201E, Rev 0, 2/24/2006

WARRANTY PERIOD

Page 24

24

RÈGLES DE SÉCURITÉ

TABLE DES MATIÈRES

Règles de sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

Connaître votre pompe à eau. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Assemblage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28-29

Fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30-33

Spécifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35-38

Entreposage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Dépannage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Garantie du dispositif antipollution . . . . . . . . . . . . . . . . . . . . 41-42

Garantie . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

DESCRIPTION DE L'ÉQUIPEMENT

Lisez bien ce manuel et familiarisez-vous avec

votre pompe à eau. Sachez à quoi elle peut servir,

ses limites et les dangers qui y sont associés.

Cette pompe à eau peut être utilisée pour transférer de l’eau

d’un emplacement inondé ou non voulu, tel que le sous-sol.Elle

peut aussi servir pour la vidange des piscines ou pour l’irrigation.

Tout a été fait pour s'assurer que les renseignements contenus

dans ce manuel soient exacts et à jour.Toutefois, nous nous

réservons le droit de changer, de modifier ou d'améliorer le

produit et ce document en tout temps, et ce, sans préavis.

Le dispositif antipollution de cette pompe à eau répond aux

normes de la Environmental Protection Agency et le California Air

Resources Board.

RÈGLES DE SÉCURITÉ

Voici le symbole utilisé pour les avertissements de

sécurité. Il est utilisé pour vous avertir des dangers

possibles de blessure. Respectez tous les messages

de sécurité qui suivent ce symbole pour éviter des

blessures ou des décès.

Le symbole d'avertissement de sécurité ( ) est utilisé avec un

mot signal (DANGER, MISE EN GARDE, AVERTISSEMENT), une

image et/ou un message de sécurité vous avertissant des risques.

Le mot DANGER indique un danger qui, s'il n'est pas évité,

causera la mort ou des blessures graves. Le mot

AVERTISSEMENT indique un risque qui, s'il n'est pas évité,

pourrait causer la mort ou des blessures graves.Le terme MISE

EN GARDE indique un risque qui, s'il n'est pas évité, pourrait

causer des blessures mineures ou modérées. Le terme MISE EN

GARDE, utilisé sans pictogramme de sécurité, indique une

situation qui pourrait causer des dommages à l'équipement. Suivez

les directives des messages de sécurité pour éviter ou réduire les

risques de blessures ou de décès.

Symboles de risque et leur signification

Les gaz d'échappement de ce produit contiennent des

produits chimiques reconnus par l'État de la Californie

comme causant des cancers et des malformations

congénitales ou d'autres problèmes de reproduction.

AVERTISSEMENT

Incendie

Explosion

Fumée toxique

Surface chaude

Choc électrique

Recul

Pièces mobiles

CONSERVEZ CES DIRECTIVES

Ces pompes à eau sont conçues pour pomper SEULEMENT de

l'eau claire qui n'est pas destinée à la consommation par des

humains.

MISE EN GARDE

Manuel d’utilisation

Page 25

25

RÈGLES DE SÉCURITÉ

• Faites fonctionner la pompe à eau UNIQUEMENT à l'extérieur.

• Assurez-vous que les gaz d'échappement ne puissent entrer dans un

espace restreint par une fenêtre, une porte, une prise d'aération ou

une autre ouverture.

• NE faites PAS fonctionner la pompe à eau à l'intérieur d'un bâtiment,

dans un espace restreint ou d'un lieu clos, dans des garages ou

d’autres emplacements similaires, même si les fenêtres et les portes

sont ouvertes.

Une pompe à eau en marche dégage du monoxyde de

carbone, un gaz inodore, incolore et toxique.

L'inhalation du monoxyde de carbone peut causer

des nausées, l'évanouissement ou la mort.

AVERTISSEMENT

LORS DE L'AJOUT OU DE LA VIDANGE DU

CARBURANT

• Éteignez la pompe à eau et laissez-la refroidir au moins 2 minutes

avant de retirer le bouchon à essence. Dévissez lentement le bouchon

pour libérer la pression dans le réservoir.

• Remplissez ou vidangez le réservoir d'essence à l'extérieur.

• NE remplissez PAS trop le réservoir.Laissez de l'espace pour

l'expansion de l'essence.

• Gardez l'essence loin des étincelles, des flammes nues,des veilleuses,

de la chaleur et des autres sources d'allumage.

• N'allumez PAS de cigarette et NE fumez PAS.

LORS DU DÉMARRAGE DE L'ÉQUIPEMENT

• Assurez-vous que la bougie d'allumage, le silencieux,le bouchon à

essence et le filtre à air sont en place.

• NE démarrez PAS le moteur lorsque la bougie d'allumage est enlevée.

• Si du carburant est renversé, attendez qu'il s'évapore avant de

démarrer le moteur.

LORS DU FONCTIONNEMENT DE L'ÉQUIPEMENT

• NE pompez PAS des liquides inflammables comme de l'essence ou du

mazout.

• Cette pompe à eau n'est pas conçue pour être utilisée dans de

l'équipement mobile ou les applications marines.

• NE penchez PAS le moteur ou l'équipement à un angle où l'essence

peut se déverser.

• Fixez la pompe à eau. Les charges contenues dans les boyaux peuvent

entraîner un renversement.

• N'arrêtez PAS le moteur en plaçant le levier d'étrangleur à la position

"Choke".

LORS DU TRANSPORT OU DE LA RÉPARATION DE

L'ÉQUIPEMENT

• Le réservoir d'essence doit être VIDE ou le robinet d'arrêt de

carburant doit être à la position fermée (OFF) pendant le transport

ou la réparation.

• Débranchez le câble de la bougie d'allumage.

LORS DE L'ENTREPOSAGE DE L'ESSENCE OU DE

L'ÉQUIPEMENT AVEC DE L'ESSENCE DANS LE

RÉSERVOIR

• Entreposez la pompe loin des fournaises, poêle, chauffe-eau, sécheuses

ou autres électroménagers munis d'une veilleuse ou d'une source

d'allumage car ils pourraient allumer les vapeurs d'essence.

L'essence et ses vapeurs sont extrêmement

inflammables et explosives.

Un incendie ou une explosion peut causer des

brûlures graves ou la mort.

AVERTISSEMENT

• Lors du démarrage du moteur,tirez lentement sur la corde jusqu'à ce

que vous sentiez une résistance et tirez alors rapidement afin d'éviter

un effet de recul.

• Fixez le tuyau d'échappement pour éviter un coup de fouet.

Une rétroaction rapide de la corde du démarreur (effet

de recul) tirera votre main et votre bras vers le moteur

plus rapidement que vous ne pouvez relâcher la corde.

Vous risquez ainsi de subir des fractures, des

ecchymoses ou des entorses.

Tenir les mains et le corps éloignés du dispositif

d'échappement de la pompe.

AVERTISSEMENT

LORS DU RÉGLAGE OU DES RÉPARATIONS DE

VOTRE POMPE À EAU

• Débranchez le câble de bougie de la bougie d'allumage et placez-le à

un endroit où il ne peut être en contact avec la bougie.

LORS DE TESTS D'ALLUMAGE DU MOTEUR

• Utilisez un vérificateur de bougies d'allumage approuvé.

• NE vérifiez PAS l'allumage lorsque la bougie d'allumage est enlevée.

Une étincelle involontaire peut causer un incendie ou

un choc électrique.

AVERTISSEMENT

Page 26

26

RÈGLES DE SÉCURITÉ

• NE modifiez PAS la vitesse régulée du moteur.

• NE modifiez PAS la pompe à eau, d'aucune façon.

• NE laissez PAS les personnes non qualifiées ou les enfants opérer ou

entretenir la pompe à eau.

Des vitesses de fonctionnement excessivement élevées

peuvent causer des blessures ou endommager la pompe à eau.

Des vitesses excessivement lentes produisent une charge

importante.

MISE EN GARDE

• Assurez-vous que la chambre de la pompe est pleine d'eau avant de

lancer le moteur. Ne faites JAMAIS fonctionner la pompe sans

l'amorcer.

• Utilisez un boyau semi-rigide du côté aspiration de la pompe.

• Utilisez la pompe à eau seulement pour les utilisations pour lesquelles

elle est conçue.

• Si vous avez des questions sur l'utilisation prévue de la pompe, posezles à votre détaillant ou appelez au 1 (800) 743-4115.

• Ne pompez que de l'eau qui n'est pas destinée à la consommation des

humains.

• Pomper de l'eau de mer,des breuvages, des acides, des solutions

chimiques ou tout autre liquide qui favorise la corrosion peut

endommager la pompe.

• Assurez-vous que toutes les connexions sont étanches à l'air.

• N'obstruez PAS le boyau d'entrée ou d'évacuation, d'aucune manière.

• Ne faites JAMAIS fonctionner la pompe sans panier-filtre à l'extrémité

du boyau d'aspiration.

• NE dépassez PAS la hauteur d’aspiration maximale de 8 m (25 pi) et

une hauteur totale de 69 m (225 pi). Utilisez la hauteur d’aspiration la

plus courte possible (voit la page 31).

• Ne laissez JAMAIS de véhicules passer sur les boyaux. Si un boyau

doit traverser une route, utilisez des planches de chaque côté du

boyau pour permettre aux véhicules de passer sans l'obstruer ou

l'écraser.

• Ancrez la pompe pour l'empêcher de bouger ou empêcher le

déplacement de l'équipement, en particulier si elle est située près d'un

fossé ou d'un ravin ouvert. L'équipement pourrait tomber dans le

fossé ou le ravin.

• Placez l'équipement loin du bord d'une rivière ou d'un lac dont la

berge pourrait s'effondrer.

• N'insérez AUCUN objet dans les fentes de refroidissement.

Le traitement inadéquat de la pompe à eau peut l'endommager

et réduire sa durée de vie utile.

MISE EN GARDE

• Ne placez JAMAIS vos mains ou des parties de votre corps à

l'intérieur de la pompe ou des boyaux lorsqu'elle fonctionne.

• NE portez PAS de vêtements amples, de bijoux ou autres accessoires

qui pourraient se prendre dans le démarreur ou d'autres pièces

rotatives.

• Attachez les cheveux longs et enlevez vos bijoux.

Le démarreur et d'autres pièces rotatives peuvent

happer des mains, des cheveux, des vêtements ou des

accessoires.

AVERTISSEMENT

• NE TOUCHEZ PAS aux pièces chaudes et évitez le contact avec les

gaz d’échappement.

• Laissez l'équipement refroidir avant de le toucher.

• Laissez un dégagement d’au moins 1,52 m (5 pi) tout autour de la

pompe à eau, y compris au-dessus.

• Le Code of Federal Regulation (CFR) Title 36 Parks,Forests,and Public

Property exige que de l’équipement alimenté par un moteur à

combustion interne soit doté d’un pare-étincelles et constamment

maintenu en bon état fonctionnement, conformément à la norme de

service 5100-1C de la USDA Forest ou à une révision de celle-ci.Dans

l’État de la Californie, un pare-étincelles est requis en vertu de la section

4442 du California Public Resources Code. Il se peut que d’autres États

aient des lois semblables.aux terres fédérales. Si vous équipez le silencieux

d'un pare-étincelles, il doit être en bon état de fonctionnement.

Les moteurs en fonctionnement produisent de la

chaleur. La température du silencieux et des endroits

à proximité peuvent atteindre, voire dépasser 150°F

(65°C).

Le contact de ces pièces risque de causer de graves

brûlures.

La chaleur et les gaz d’échappement peuvent

enflammer des matériaux combustibles et les

structures ainsi que causer des dommages au

réservoir d’essence et entraîner un incendie.

AVERTISSEMENT

Page 27

27

FONCTIONS ET COMMANDES

CONNAÎTRE VOTRE POMPE À EAU

Lisez ce manuel d'utilisation et les règles de sécurité avant d'utiliser votre pompe à eau.

Comparez les illustrations à votre pompe à eau pour vous familiariser avec l'emplacement des diverses commandes et réglages.

Conservez ce manuel pour référence future.

Amorceur - Remplissez la pompe d'eau ici pour amorcer la

pompe avant de la faire démarrer.

Bouchon de remplissage - Vérifiez le niveau d'huile et videz

l'huile à moteur ici.

Bouchon de vidange d'eau - Retirez-le pour vidanger l'eau de

la pompe et rincez les composants internes avec de l'eau claire.

Chambre de la pompe - Assurez-vous qu'elle est pleine d'eau

avant de lancer le moteur.

Étiquette du numéro de série - Indique le numéro de modèle,

de révision et de série de la pompe à eau.Veuillez avoir ces

renseignements sous la main lors d'appel de service.

Filtre à air — Protège le moteur en filtrant la poussière et les

débris dans la prise d'air.

information de moteur (pas montré) - Affranchi sur la

couverture de soupape. Indique le numéro de modèle, de type et

tailler de la moteur.Veuillez avoir ces renseignements sous la main

lors d'appel de service.

Interrupteur ON/OFF - Réglez cet interrupteur sur "On"

avant d'utiliser le lanceur. Réglez l'interrupteur sur "Off" pour

arrêter le moteur.

Lanceur - Utilisé pour le démarrage du moteur.

Levier d'étrangleur - Utilisé lors du démarrage à froid d'un

moteur.

Levier de papillon - Utilisé pour régler la vitesse du moteur afin

de contrôler le débit de la pompe.

Orifice d'évacuation - Branchez le boyau d'évacuation à cet

endroit.

Panier-filtre (pas montré) - Utilisé pour limiter le passage de

matériels abrasifs dans la pompe.

Prise d'aspiration - Branchez le boyau d'aspiration renforcé ici.

Réservoir d'essence - Capacité de un (1) gallon américain (3,8 l).

Robinet d'arrêt de carburant - Utilisé pour alimenter le moteur

en essence ou pour couper l'alimentation en essence du moteur.

Réservoir d'essence

Filtre à air

Interrupteur ON/OFF

Bouchon de

vidange d'eau

Levier d'étrangleur

Lanceur

Amorceur

Bouchon de

remplissage d'huile

Orifices d'évacuation

Étiquette du numéro

de série

Prise d'aspiration

Robinet d'arrêt

de carburant

Levier de papillon

Chambre de

la pompe

Page 28

28

ASSEMBLAGE

ASSEMBLAGE

Votre pompe à eau doit être assemblée et vous pourrez l'utiliser

après l'avoir correctement remplie d'huile et d'essence

recommandées.

Si vous avez des questions au sujet de l’assemblage de votre

pompe à eau, veuillez appeler la ligne d’aide au 1-800-743-4115.

Si vous téléphonez pour obtenir de l'aide, veuillez avoir les

renseignements de l'étiquette du numéro de série suivants sous la

main : numéro de modèle, de révision et de série. Consultez la

section “Familiarisez-vous avec la pompe à eau” pour déterminer

son emplacement.

Déballage de la pompe à eau

1. Sortez tous les composants de la boîte d'expédition à

l'exception de la pompe à eau.

2. Ouvrez la boîte d'expédition en coupant tous les coins de la

boîte du haut vers le bas.

Contenu de la boîte

Voici ce que vous trouverez dans la boîte :

• Pompe à eau

• Bouteille d'huile

• Sac de pièces (comprenant ce qui suit):

• Ce manuel d'utilisation

• Panier-filtre et barbelure

• Bride de serrage (3)

Si l'une des pièces mentionnées est manquante ou endommagée,

appelez la ligne d'aide au 1-800-743-4115.

Ajout de l'huile à moteur

MISE EN GARDE!Toute tentative de démarrer le moteur

sans qu'il ait été rempli avec l'huile recommandée risque

d'entraîner un bris de moteur.

1. Placez la pompe à eau sur une surface plane.

2. Nettoyez la surface autour de l'orifice de remplissage d'huile

et enlevez le bouchon de remplissage d'huile jaune.

3. À l'aide d'un entonnoir pour huile (optionnel), versez

lentement le contenu complet de la bouteille d'huile (18 oz)

fournie dans l'orifice de remplissage.

4. Replacez le bouchon de remplissage d'huile et serrez le

solidement.

REMARQUE: Consultez la section “Huile” à la page 36 au sujet

des recommandations relatives à l’huile.

Ajout de l'essence

REMARQUE: Le fonctionnement avec de l'essence est certifié

avec ce moteur à essence. Dispositif antipollution de

l'échappement : EM (Modifications de moteur).

1. Utilisez de l'essence SANS PLOMB ordinaire propre et