Page 1

POST OFFICE BOX 702

MILWAUKEE, WI 53201 USA

©2010 Briggs & Stratton Corporation

BRIGGS&STRATTON

CORPORATION

MS - 0750 - 5/10

www.ThePowerPortal.com (Dealers)

BRIGGSandSTRATTON.COM (consumers)

272147 - Vanguard ™ Single Cylinder OHV Air-Cooled Engines

272144 - Vanguard

™

Twin Cylinder OHV Air-Cooled Engines

275429 - Vanguard

™

Twin Cylinder OHV Liquid-Cooled Engines

MS-1055 - Vanguard

™

3-Cylinder OHV Liquid-Cooled Diesel Engines

Other Briggs & Stratton

Commercial Power Repair Manuals:

Briggs & Stratton

VANGUARD

™

3-CYLINDER OHV LIQUID-COOLED GASOLINE ENGINES

5/10

Vanguard

™ 3-Cylinder OHV

Liquid-Cooled Gasoline Engines

Quality Starts With A

Master Service Technician

Page 2

FORWARD

This manual was written to assist engine technicians and service personnel with the repair and

maintenance procedures for Briggs & Stratton® engines. It assumes that persons using this manual have

been properly trained in and are familiar with the servicing procedures for these products, including the

proper use of required tools and safety equipment and the application of appropriate safety practices.

Persons untrained or unfamiliar with these procedures or products should not attempt to perform such

work.

Proper maintenance and repair is important to safe, reliable operation of all engines and engine-driven

systems. The troubleshooting, testing, maintenance, and repair procedures described in this manual are

appropriate for the Briggs & Stratton® engines described herein. Alternative methods or procedures may

pose risk to personal safety and the safety and/or reliability of the engine and are not endorsed or

recommended by Briggs & Stratton.

All information, illustrations, and specifications contained in this manual were based on the data available

at the time of publication. Briggs & Stratton Corporation reserves the right to change, alter, or otherwise

improve the product or the product manuals at any time without prior notice.

Briggs & Stratton offers two complementary publications to enhance understanding of engine technology,

maintenance, and repair. (Neither publication, however, is a substitution for a recognized training program

for engine technicians.)

• For consumers, Small Engine Care & Repair (p/n 274041) provides a comprehensive overview of how

small air-cooled engines work, basic troubleshooting, and step-by-step maintenance procedures.

• For engine technicians and consumers alike, an in-depth study of engine theory and operation can be

found in the textbook Small Engines (p/n CE8020).

Both publications can be purchased at BRIGGSandSTRATTON.COM or through a local Authorized Briggs

& Stratton Service Dealer.

Copyright © 2010 Briggs & Stratton Corporation

All rights reserved.

No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying or recording by any information storage and retrieval system, without

prior written permission from Briggs & Stratton Corporation.

Page 3

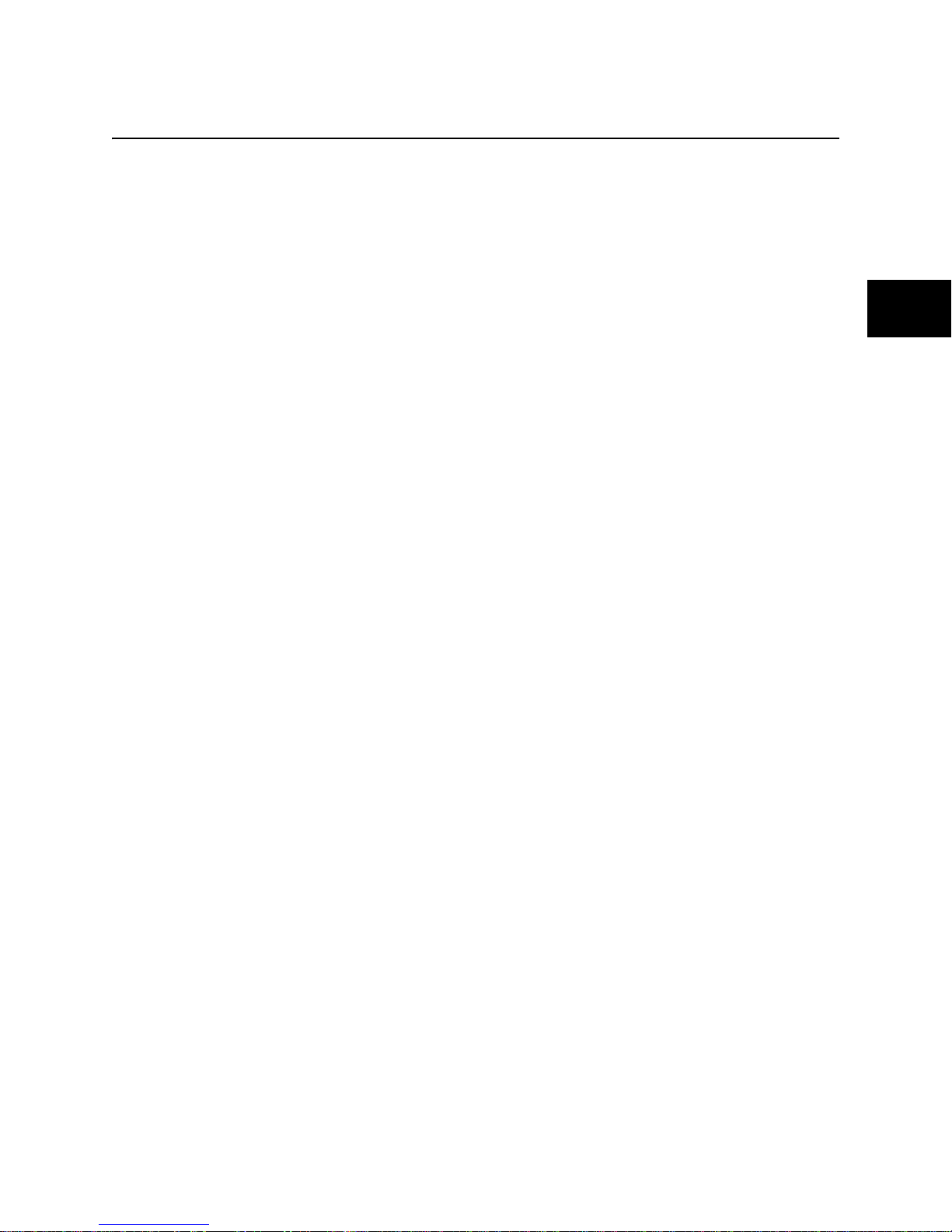

This engine repair manual includes the following

engine models:

• MODEL 430000

• MODEL 580000

6

Page 4

SECTION 1 - Safety

SECTION 2 - Cylinder Heads and Valves

SECTION 3 - Governor, Timing Gears, and Gear Case

SECTION 4 - Flywheel and Rear Seal Retainer

SECTION 5 - Cylinder Block Disassembly

SECTION 6 - Cylinder Block Inspection and Repair

SECTION 7 - Crankshaft, Camshaft, and Bearings

1

2

3

4

5

6

7

SECTION 8 - Pistons, Rings, and Connecting Rods

SECTION 9 - Cylinder Block Assembly

SECTION 10 - Fuel System and Related Components

SECTION 11 - Ignition, Electrical System

SECTION 12 - Lubrication System

SECTION 13 - Cooling System

SECTION 14 - Engine Specifications

8

9

10

11

12

13

14

Page 5

THISPROPER SERVICE AND REPAIR IS IMPORTANT

TO THE SAFE, ECONOMICAL AND RELIABLE

Page 6

SECTION 1 - SAFETY AND MAINTENANCE

SAFETY INFORMATION - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4

1

1

3

Page 7

1

1

SAFETY INFORMATION

This repair manual contains safety information

that is designed to:

• Make you aware of hazards associated

with engines.

• Inform you of the risk of injury associated

with those hazards.

• Tell you how to avoid or reduce the risk of

injury.

Signal Words in Safety Messages

The safety alert symbol is used to identify

safety information about hazards that can result

in personal injury.

A signal word (

is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In

addition, a hazard symbol may be used to

represent the type of hazard.

DANGER indicates a hazard which, if not

avoided, will result in death or serious

injury.

DANGER, WARNING, or CAUTION)

WAR NING

Before attempting to service this equipment,

read and understand this manual and the

operating instructions of the engine and the

equipment it powers.

Failure to follow instructions could result in

property damage, serious injury (including

paralysis) or even death.

Hazard Symbols and Meanings

FIRE EXPLOSION

ELECTRIC

SHOCK

WARNING indicates a hazard which, if

not avoided, could result in death or

serious injury.

CAUTION indicates a hazard which, if

not avoided, could result in minor or

moderate injury.

NOTICE indicates a situation that could

result in damage to the product.

Prior to work, read and understand the section(s)

of this manual that pertain to the job. Follow all

safety warnings.

• Always use fresh gasoline. Stale fuel can

cause gum deposits in the carburetor

and cause leakage, flow restrictions, or

other problems.

• Check fuel lines and fittings frequently for

cracks or leaks and replace if necessary.

EXPLOSIVE

PRESSURE

ENTANGLEMENT KICKBACK AMPUTATION

TOXIC

FUMES

Battery posts, terminals, and related accessories contain lead and lead compounds - chemicals known to the State of California to cause

cancer and reproductive harm. Wash hands

after handling.

HOT

SURFACE

READ

MANUAL

WARNING

GOGGLES

CHEMICAL

BURNS

4

Page 8

WARNING

WAR NING

Certain components in this product and its

related accessories contain chemicals known

to the State of California to cause cancer, birth

defects, or other reproductive harm. Wash

hands after handling.

WARNING

Briggs & Stratton does not approve or authorize the use of these engines on 3-wheel All

Terrain Vehicles (ATVs), motor bikes, fun/recreational go-karts, aircraft products, or vehicles intended for use in competitive events.

Use of these engines in such applications

could result in property damage, serious injury

(including paralysis), or even death.

WARNING

The engine exhaust from this product contains

chemicals known the State of California to

cause cancer, birth defects, and other reproductive harm.

WAR NING

Running engines produce heat.

Severe burns can occur on contact.

• Allow muffler, engine cylinder fins, and

radiator to cool before touching.

• Remove accumulated combustibles from

muffler area and cylinder area.

• It is a violation of California Public

Resource Code, Section 4442, to use or

operate the engine on any forest-covered,

brush-covered, or grass-covered land

unless the exhaust system is equipped

with a spark arrester, as defined in Section

4442, maintained in effective working

order. Other States and Federal jurisdictions may have similar laws. Contact the

original equipment manufacturer, retailer,

or dealer to obtain spark arrester

designed for the exhaust system installed

on this engine.

Fuel and its vapors are extremely flammable and explosive.

Fire or explosion can cause severe

burns or death.

When adding fuel:

• Turn engine OFF and let engine cool for at

least 2 minutes before removing the fuel

cap.

• Fill fuel tank outdoors or in a well-ventilated area.

• Do not overfill fuel tank. To allow for

expansion of the gasoline, do not fill above

the bottom of the fuel tank neck.

• Keep gasoline away from sparks, open

flames, pilot lights, heat and other ignition

sources.

• Check fuel lines, tank, cap, and fittings frequently for cracks or leaks. Replace if necessary.

• If fuel spills, wait until it evaporates before

starting engine.

When starting engine:

• Make sure spark plug, muffler, fuel cap,

and air cleaner are in place.

• Do not crank engine with spark plug

removed.

• If fuel spills, wait until it evaporates before

starting engine.

• If engine floods, set choke (if equipped) to

OPEN/RUN position. Place throttle (if

equipped) in FAST and crank until engine

starts.

When operating equipment:

• Do not tip engine or equipment at an

angle which would cause fuel to spill.

• Do not choke carburetor to stop engine.

• Never start or run the engine with the air

cleaner assembly (if equipped) or the air

filter (if equipped) removed.

When changing oil:

• If you drain the oil from the top oil fill tube,

the fuel tank must be empty or fuel can

leak out and result in a fire or explosion.

When transporting equipment:

• Transport with fuel tank empty or with fuel

shut-off valve set to OFF.

When storing gasoline or equipment with

fuel in the tank:

• Store away from furnaces, stoves, water

heaters, or other appliances that have a

pilot light or other ignition source because

they can ignite gasoline vapors.

1

1

5

Page 9

WAR NING

WAR NING

1

1

Unintentional sparking can result in fire

or electrical shock.

Unintentional start-up can result in

entanglement, traumatic amputation, or

severe lacerations.

Before performing adjustments or repairs:

• Disconnect spark plug wire and keep it

away from spark plug.

• Disconnect the negative (-) battery terminal.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

WAR NING

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting, or death.

• Start and run engine outdoors.

• Do not start or run engine in an enclosed

area, even if doors and windows are open.

WAR NING

Starting engine creates sparking.

Sparking can ignite nearby flammable

gases.

Explosion and fire could result.

• If there is a natural or LP gas leak in the

area, do not start engine.

• Do not use pressurized starting fluids

because vapors are flammable.

Charging batteries produce hydrogen

gas. Do not store or charge a battery

near an open flame or device that utilizes a pilot light or can create a spark.

WAR NING

Damaged, worn, or loose fuel components can leak fuel. Explosion or fire

could result.

• All fuel components should be in good

condition and properly maintained.

• Repairs should only be made with factory

approved parts.

• Repair work should be done by a qualified

technician.

• Flexible supply lines should be checked

regularly to make sure they are in good

condition.

WAR NING

Rapid retraction of starter cord (kickback) will pull hand and arm toward

engine faster than you can let go.

Broken bones, fractures, bruises, or

sprains could result.

• When starting engine, pull the starter cord

slowly until resistance is felt and then pull

rapidly to avoid kickback.

• Remove all external equipment/engine

loads before starting engine.

• Direct-coupled equipment components,

such as but not limited to blades, impellers, pulleys, and sprockets, must be

securely attached.

WAR NING

Rotating parts can contact or entangle

hands, feet, hair, clothing, or accessories.

Traumatic amputation or severe lacerations can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating

parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings, or items that could become

entangled in the equipment.

6

WAR NING

Prolonged or repeated contact with used

motor oil could cause injury.

• Used motor oil has been shown to cause

skin cancer in certain laboratory animals.

• Thoroughly wash exposed areas with

soap and water.

Page 10

SECTION 2 - CYLINDER HEAD AND VALVES

REMOVE CYLINDER HEAD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9

DISASSEMBLE CYLINDER HEAD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -10

REMOVE VALVES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -11

INSPECT CYLINDER HEAD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -12

DISASSEMBLE ROCKER ARM SHAFT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -15

ASSEMBLE ROCKER ARM SHAFT- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -16

ASSEMBLE CYLINDER HEAD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -17

INSTALL CYLINDER HEAD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -18

ADJUST VALVES- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -20

2

7

Page 11

2

2

8

Page 12

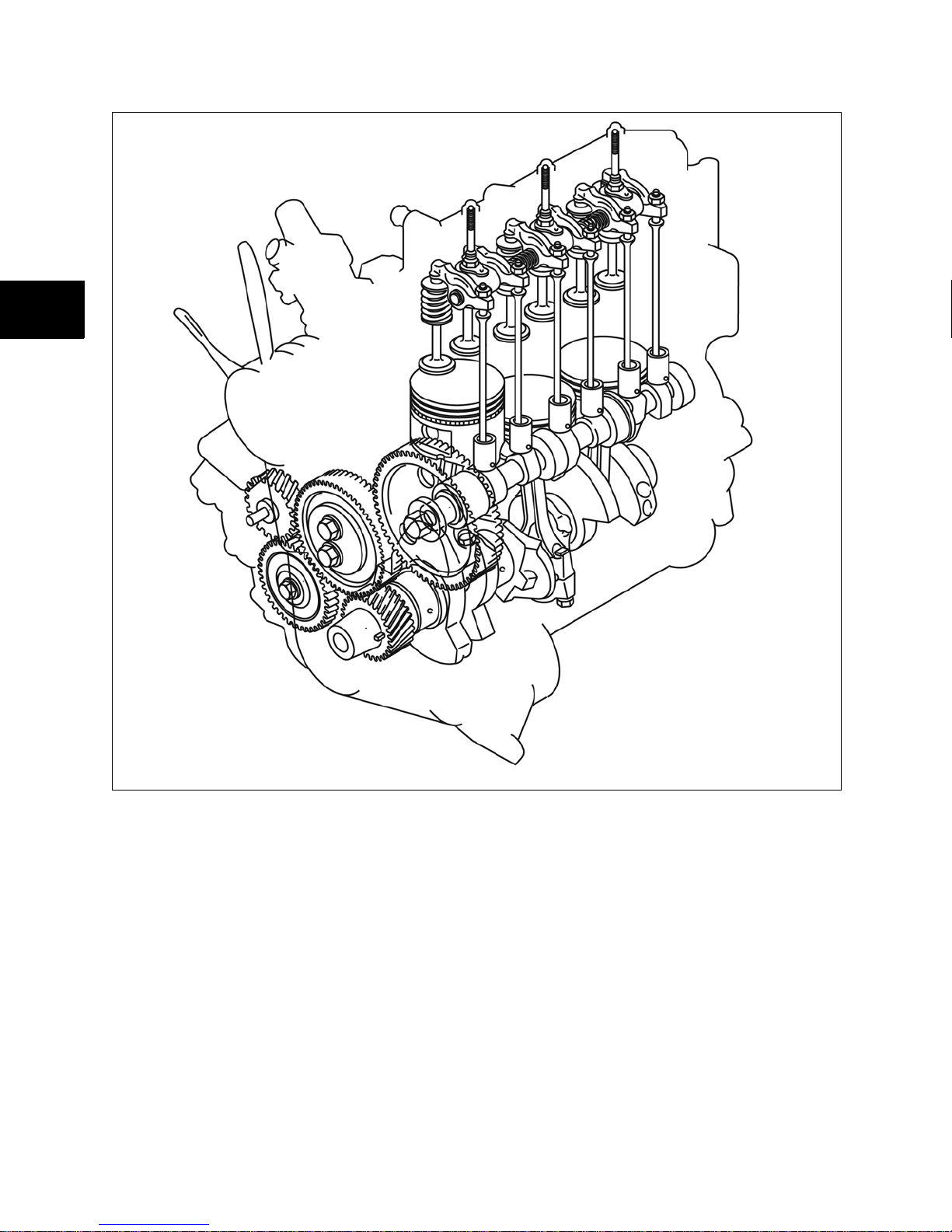

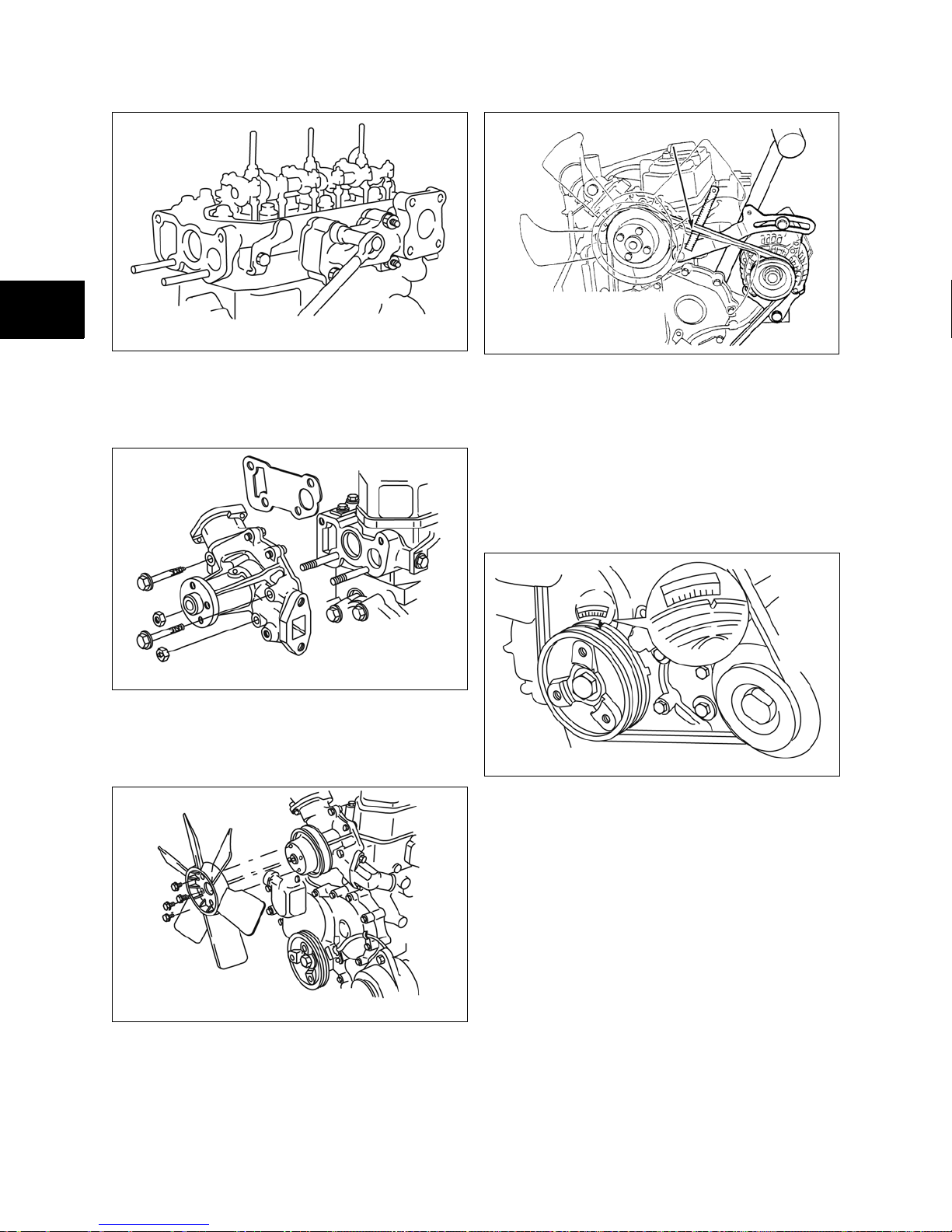

Remove Cylinder Head

1. Drain cooling system and disconnect radiator

hoses and bypass hose at water pump.

2. Remove the alternator adjusting bracket

screw (A, Figure 1), V-belt (B), and fan (C),

from the engine.

Figure 1

3. Remove the water pump pulley (A, Figure 2),

water pump (B), and exhaust manifold (C)

from the engine.

2

Figure 3

6. Remove the ignition coil bracket (Figure 4)

and the ignition coils.

NOTE: Remove the exhaust system before

removing exhaust manifold.

Figure 2

4. Remove the fuel line (A, Figure 3) and

governor link and spring (B).

5. Remove the intake manifold (C) and spark

plug wires and spark plugs (D).

Figure 4

7. Remove the valve cover (Figure 5).

Figure 5

8. Set the Number 1 piston at Top Dead Center

(TDC).

9

Page 13

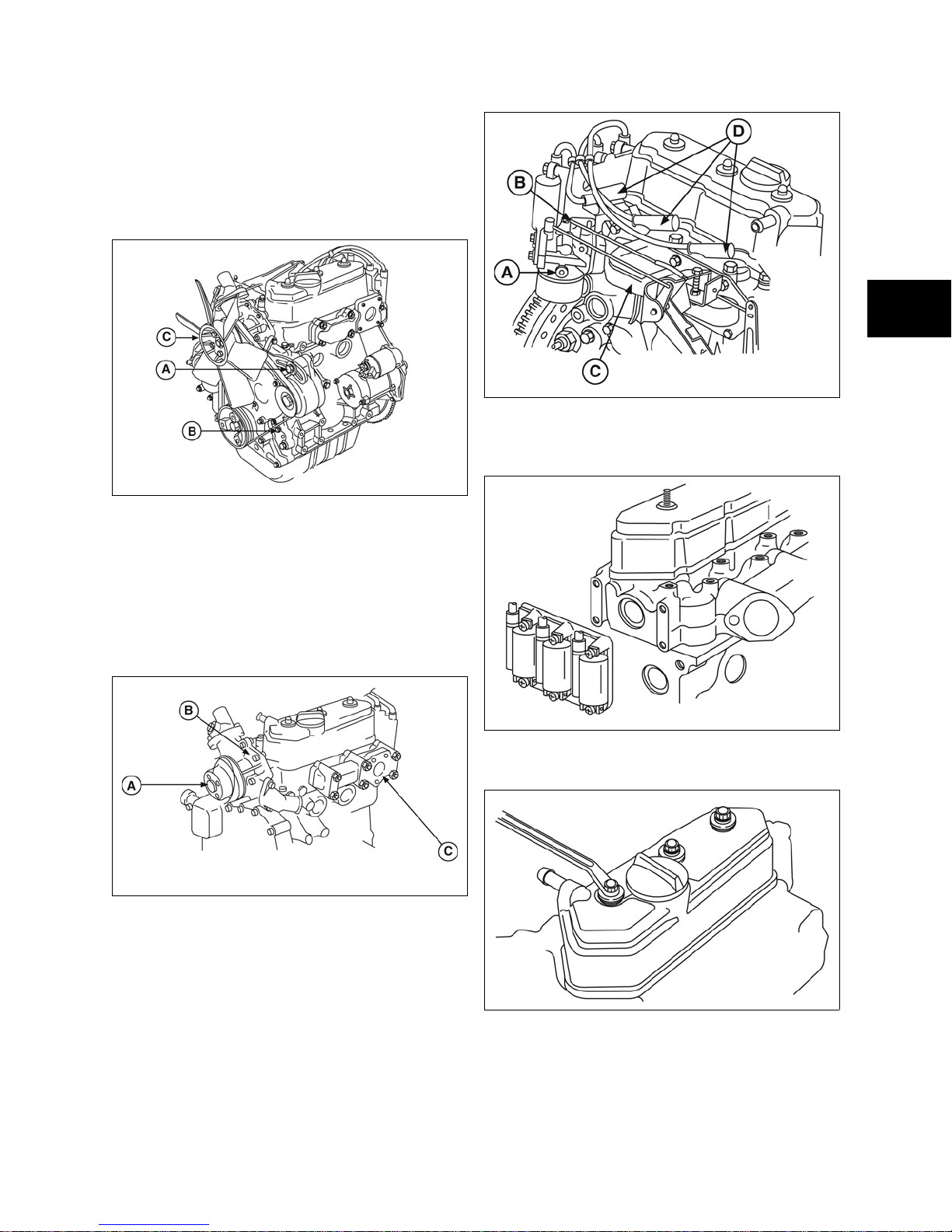

9. Rotate crankshaft pulley until timing mark on

pulley is aligned with reference point (A,

Figure 6) on timing cover (B).

Disassemble Cylinder Head

1. Loosen cylinder head bolts in the order

shown (Figure 8).

2

Figure 6

• If intake and exhaust valves have

clearance, the Number 1 piston is at TDC

(compression stroke).

• If intake and exhaust valves do not have

clearance, turn crankshaft pulley one

complete revolution. Valves will then have

clearance.

10. Remove rocker arm assembly (A, Figure 7)

and push rods.

11. Remove valve stem caps (B).

NOTE: Mark push rods so that they may be

reassembled in their original position.

2

Figure 8

Figure 7

10

Page 14

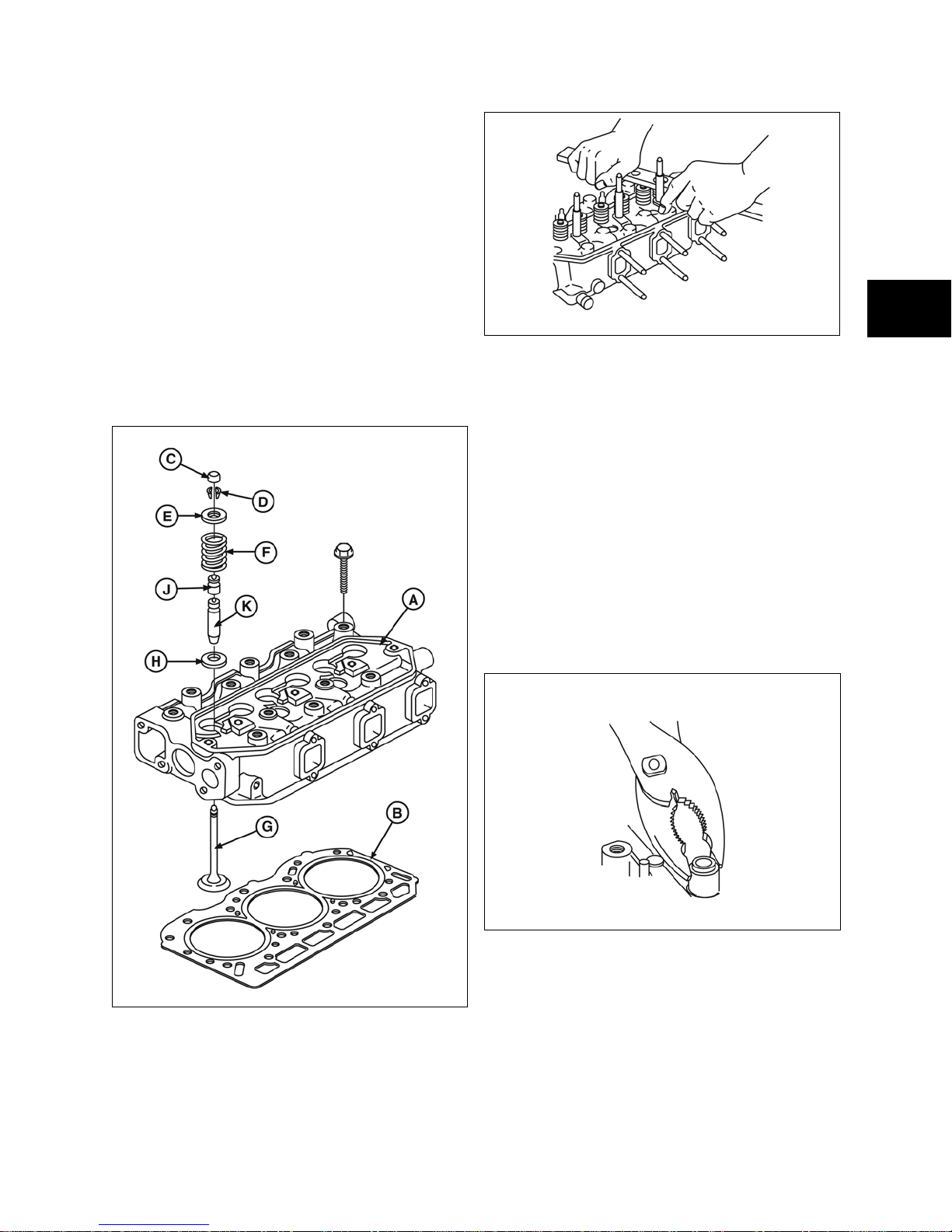

Remove Valves

2. Refer to the following cylinder head

components (Figure 9) when proceeding to

the next part of the disassembly process:

• (A) - Cylinder Head Assembly

• (B) - Cylinder Head Gasket

• (C) - Valve Stem Cap

• (D) - Valve Spring Retainer Locks

• (E) - Valve Spring Retainer

• (F) - Valve Spring

• (G) - Valve

• (H) - Valve Spring Seat

• (J) - Valve Stem Seal

• (K) - Valve Guide

2

Figure 10

NOTE: Place a shop rag or short section of fuel line

under valves inside combustion chamber to hold

valve in place while compressing spring.

4. Use Valve Spring Compressor #19417 to

compress valve springs. Remove the

following parts:

• Valve Spring Retainer Locks

• Valve Spring Retainer

• Valve Spring

• IN and EX valve

• Valve spring seats

5. Remove and discard valve stem seals

(Figure 11).

Figure 9

3. Remove valves (Figure 10).

11

Figure 11

Page 15

2

Inspect and Repair

Inspect Cylinder Head

NOTE: Be sure all gasket material is removed from

surfaces before checking. Use a gasket scraper if

necessary.

1. Inspect cylinder head for cracks or damage.

2. Use a straight edge (A, Figure 12) to check

cylinder head lower surface for distortion.

• Replace if damaged or if reject gauge

enters valve guide.

2

Figure 14

6. Use Bushing Driver #19367, and press out

valve guide bushing from combustion

chamber (Figure 15).

Figure 12

3. If mounting surfaces are distorted more than

0.1 mm (0.004 in), the cylinder head must be

replaced (Figure 13).

Figure 13

NOTE: It is not recommended that cylinder head

mounting surfaces be resurfaced.

4. Inspect intake and exhaust manifold

mounting surfaces in the same manner. Use

same specifications as cylinder head.

5. Inspect valve guide bushing for damage.

Check valve guide bushings for wear using

Reject Gauge #19382, (A, Figure 14).

Figure 15

7. Check valve guide bushing OD. Then

compare with the following specifications:

• Standard Bushing OD: 11.05 mm (0.435

in.)

• Replacement Bushing OD: 11.08 mm

(0.4362 in.)

8. If bushing OD measurement indicates that a

replacement bushing has already been

installed, the cylinder head must be replaced.

9. Using Bushing Driver #19416, press in new

valve guide bushing until tool bottoms on

cylinder head (Figure 16).

12

Page 16

2

Figure 16

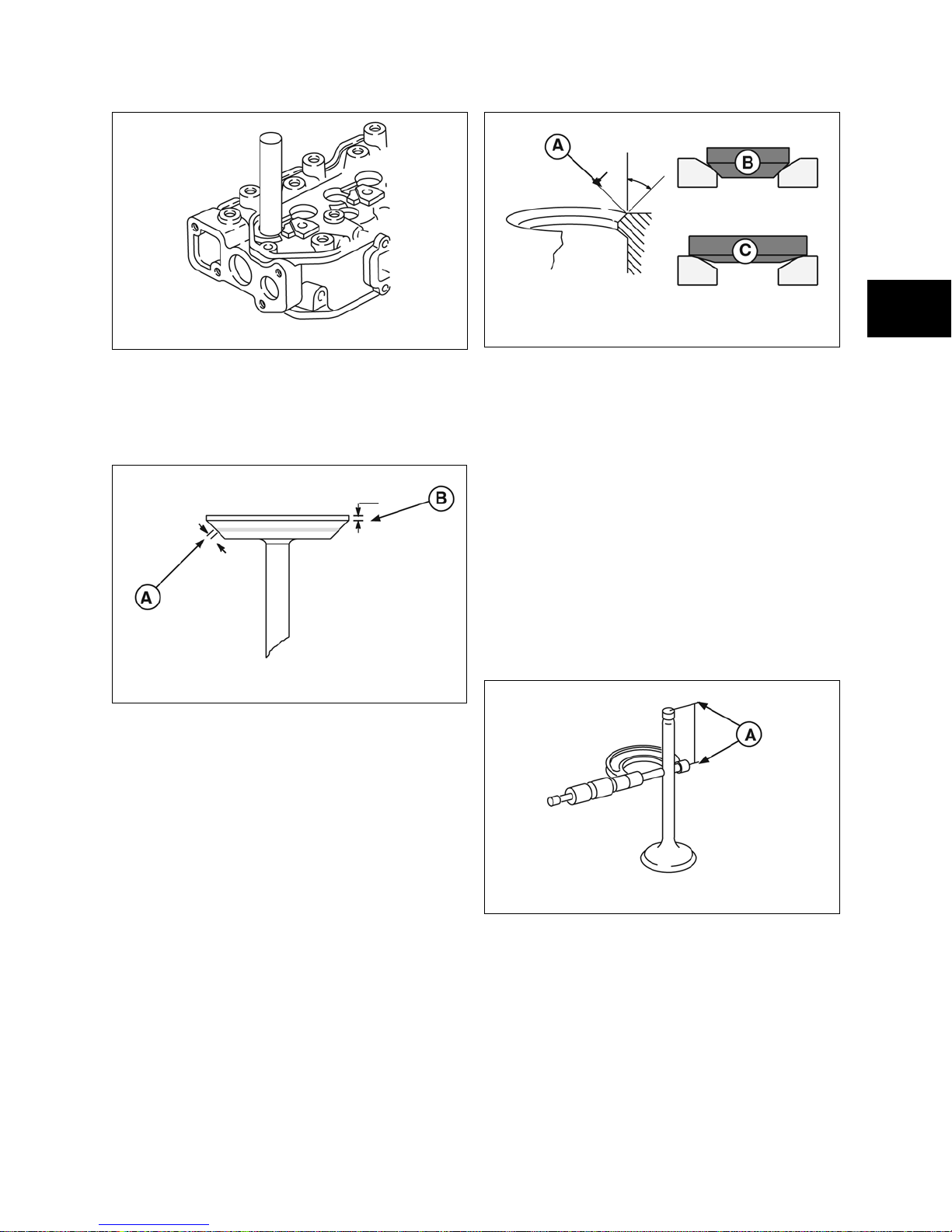

10. Valve faces may be resurfaced to 30°. Check

valve seat dimensions before resurfacing. (A,

Figure 17) should be 0.05 - 0.06” (1.2 -

1.6mm) and (B) should be at least 0.0312”.

Figure 17

• Lap valves and seats with Valve Lapping

Tool #19258 and Valve Lapping

Compound #94150.

11. Valve seats may be reconditioned using

Valve Seat Cutter #19446.

Figure 18

• Use a 45° (B) cutter to narrow seat from

bottom.

• Use a 15° (C) cutter to narrow seat from

top.

NOTE: If valve seat is loose or cracked, replace

cylinder head.

12. Measure valve stem diameter at specified

distance from end of valve (A, Figure 19).

• Replace IN if less than 0.2343 in. (5.952

mm).

• Replace EX if less than 0.2342 in. (5.948

mm).

NOTE: Inspect valve guide bushings first. If valve

guides are worn, they must be replaced before

refacing valve seats.

If valve seat is wider than 0.05 - 0.06” (1.2 - 1.6mm)

(A, Figure 18), a narrowing cutter should be used to

ensure that contact area of valve seat is centered

on face of valve.

13

Figure 19

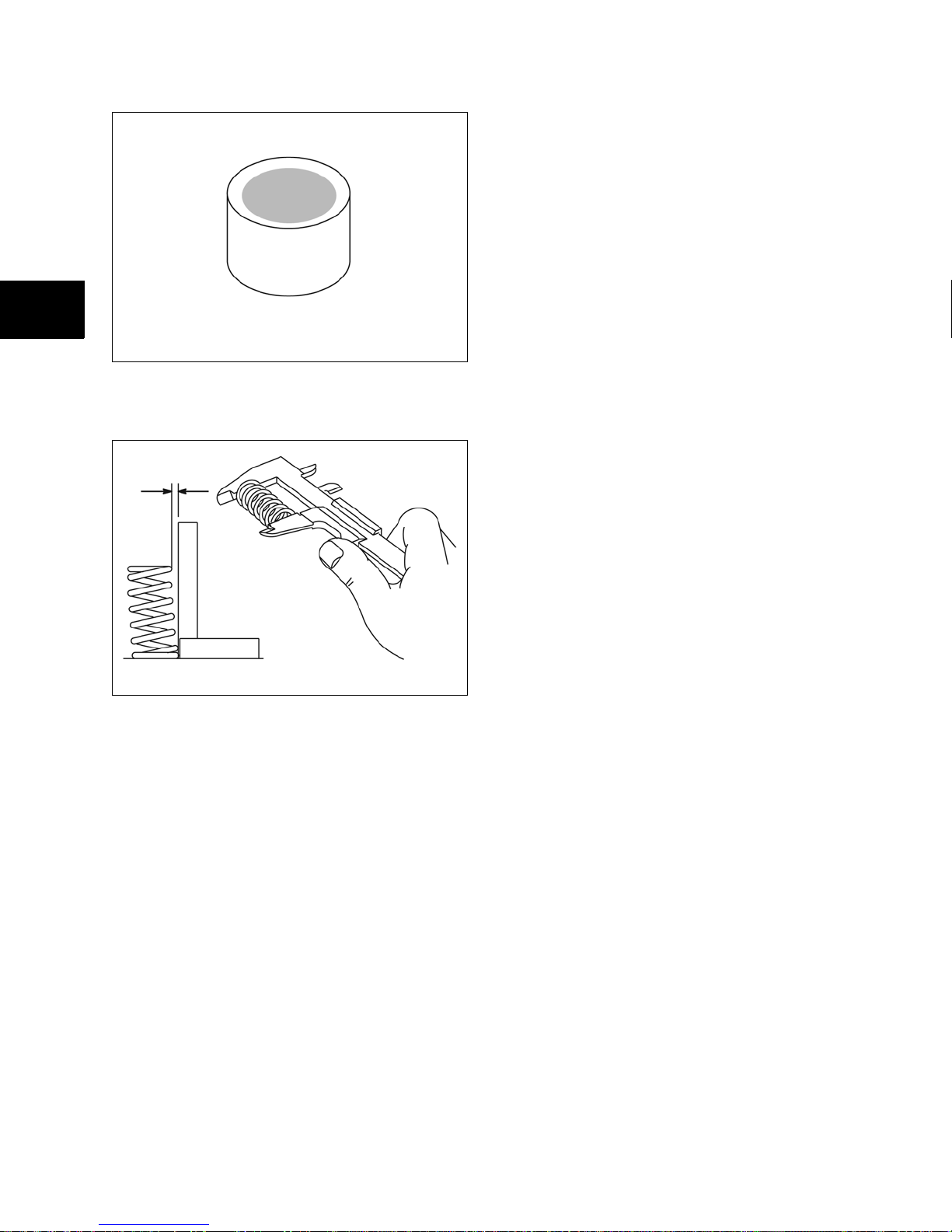

13. Inspect valve stem cap for wear (Figure 20).

Replace if cap is worn recessed.

Page 17

2

2

Figure 20

14. Inspect valve springs for squareness and

free length (Figure 21).

Figure 21

• Replace if out of square more than 0.040

in. (1.0 mm).

• Replace if free length is less than 0.150 in.

(29.2 mm).

14

Page 18

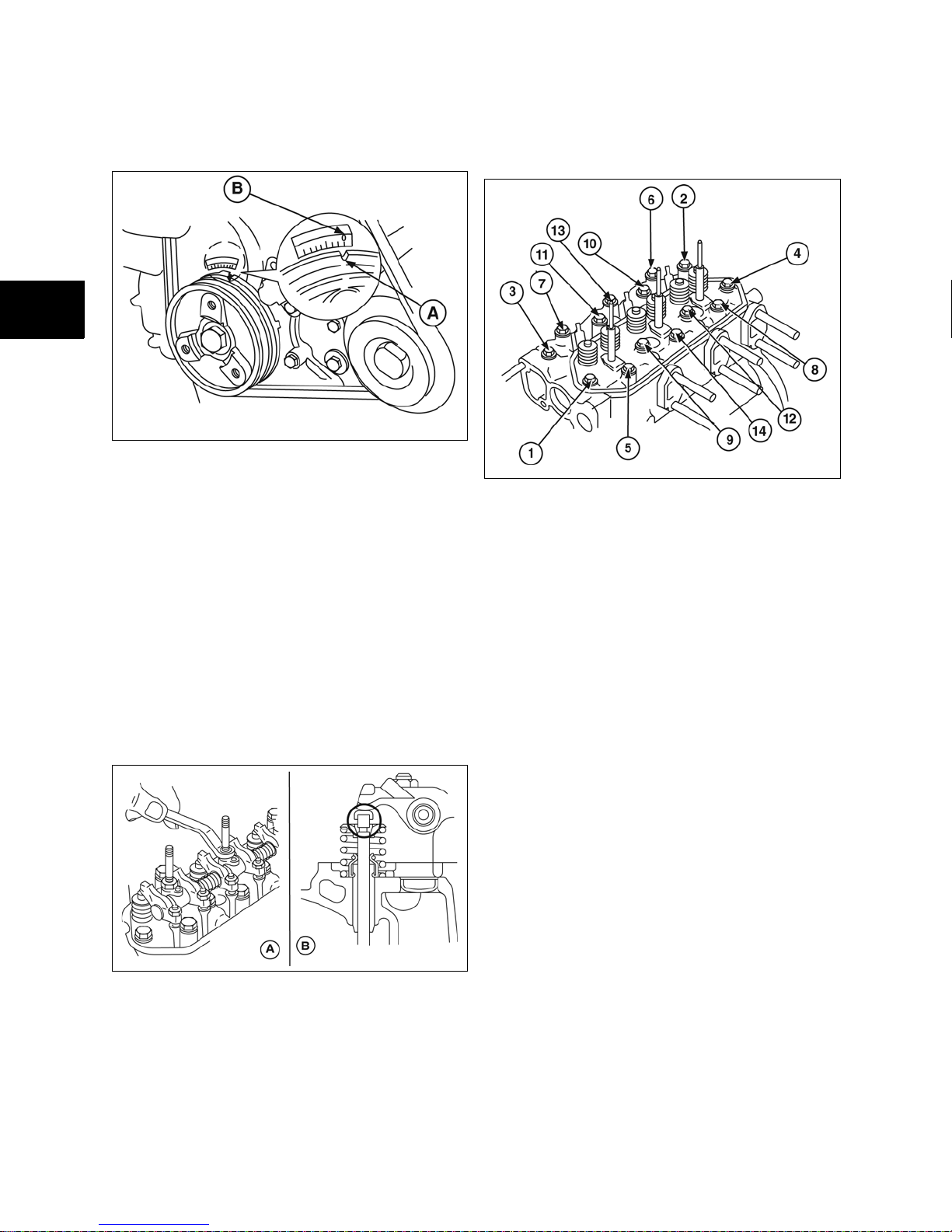

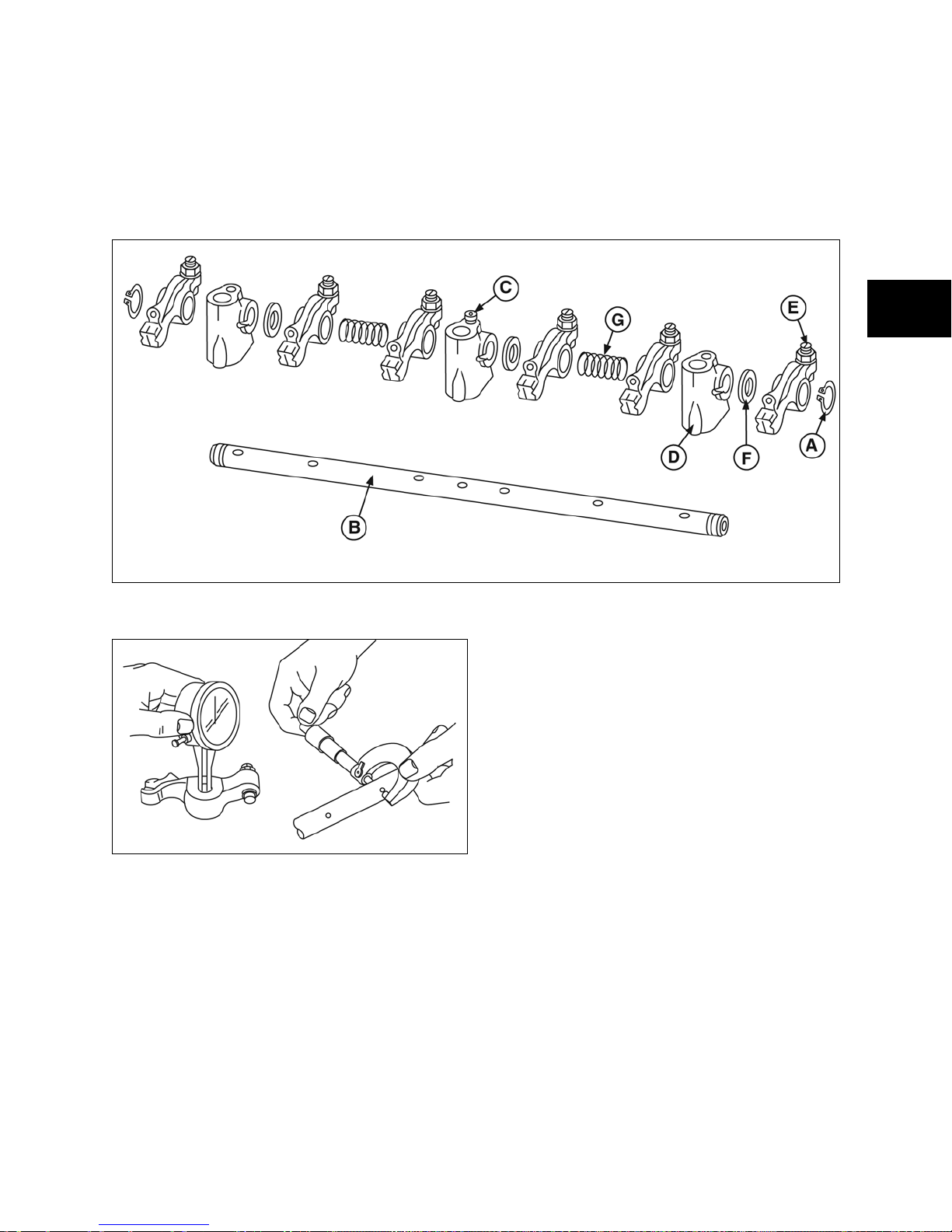

Disassemble Rocker Arm Shaft

Remove snap rings (A, Figure 22) from ends of

rocker arm shaft (B). Remove set screw (C) from

center rocker arm support (D). Disassemble rocker

arm assembly. Note position of rocker arms (E),

thrust washers (F) and springs (G).

2

Figure 22

1. Check rotor arms and shaft (Figure 23).

Figure 23

2. Check rocker arm bearing. Replace if greater

than 0.395 in. (10.03 mm).

3. Check rocker arm shaft. Replace if less than

0.392 in. (9.957 mm).

4. Check rocker arm studs for stripped threads

and replace if required.

15

Page 19

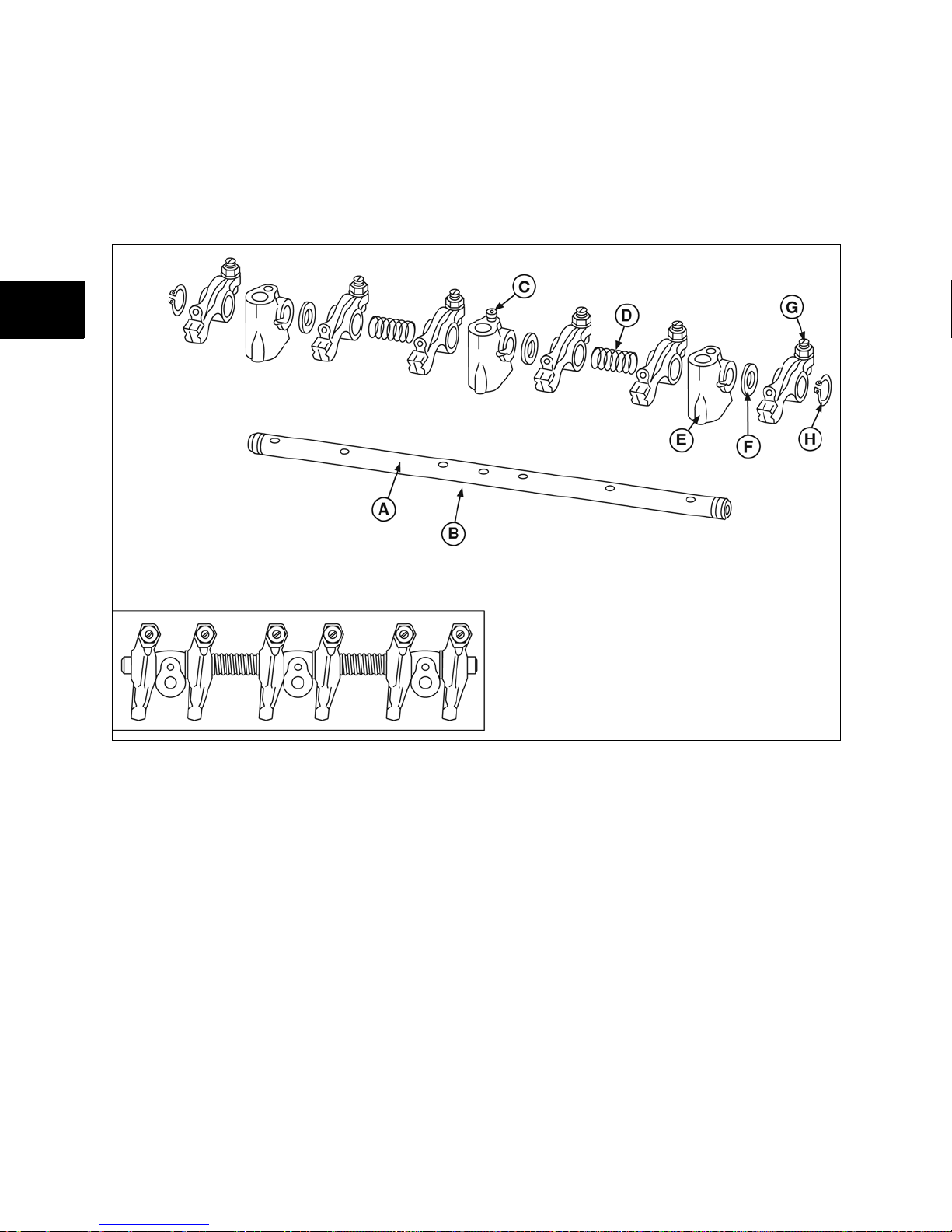

Assemble Rocker Arm Shaft

1. Oil all components before assembling.

2. Small grooves in rocker shaft (A) next to oil

holes (B) must face down.

3. Assemble rocker arm (G) components, noting

order of assembly shown in Figure 24.

2

2

Figure 24

4. Note position of three thrust washers (F),

springs (D), snap rings (H)

5. Install set screw (C) in center rocker arm

shaft support (E).

16

Page 20

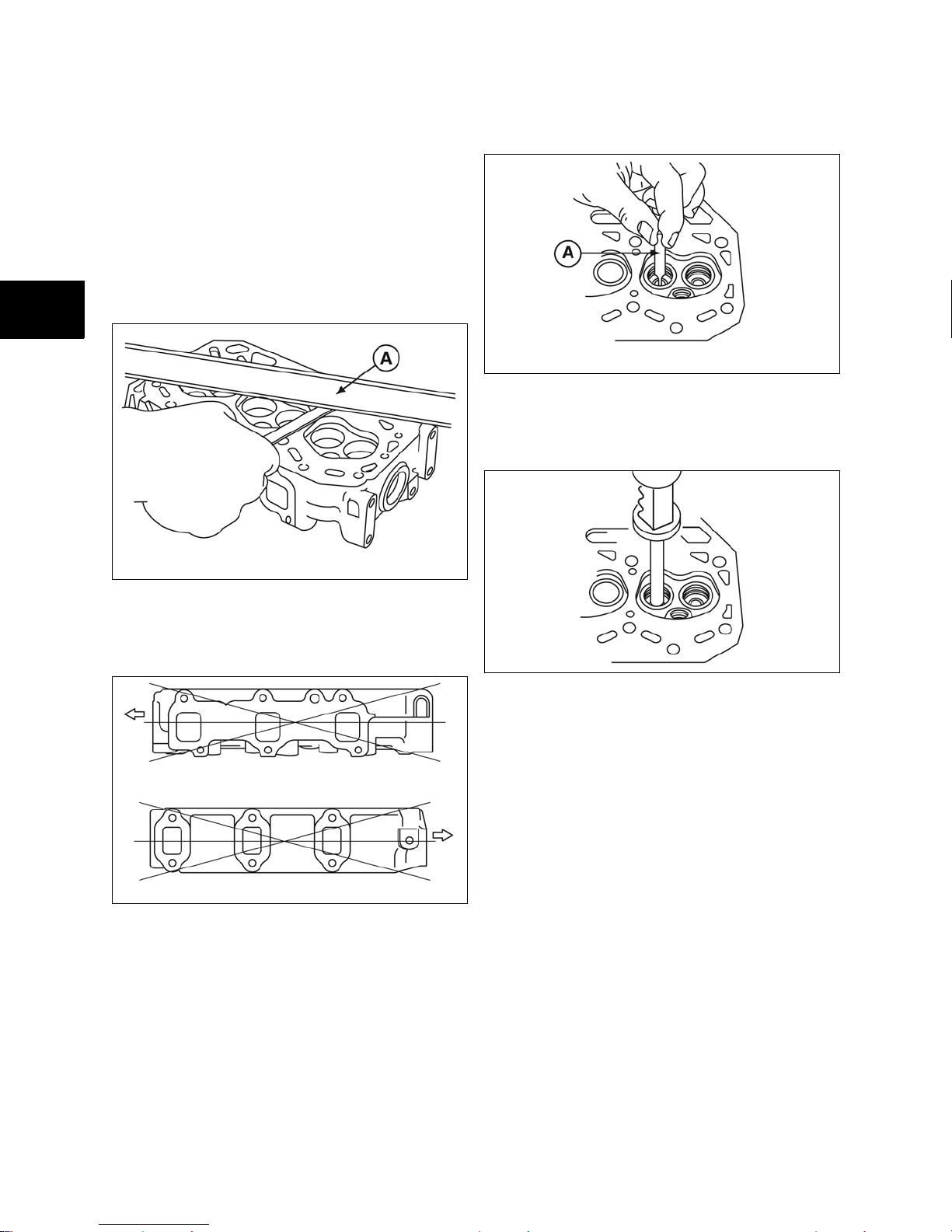

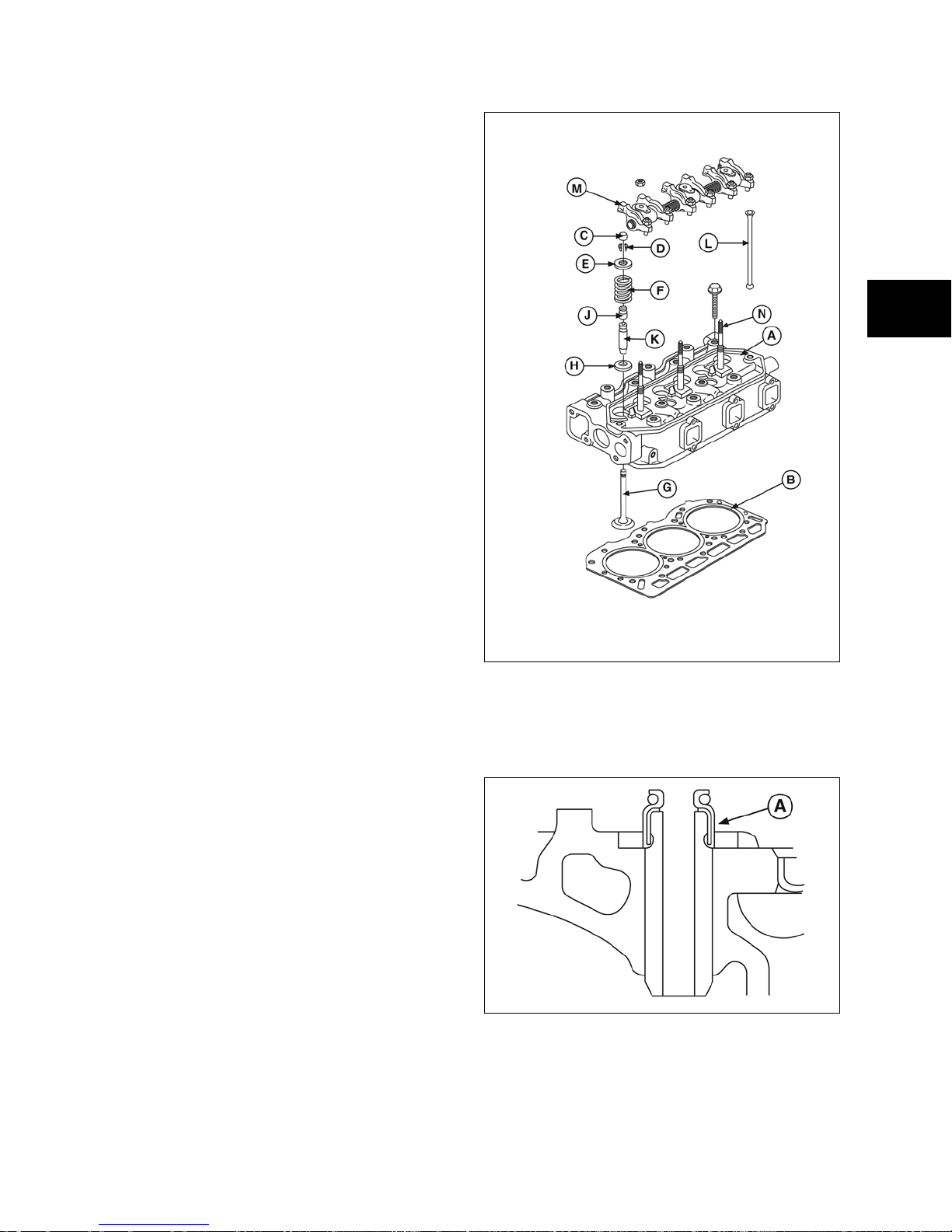

Assemble Cylinder Head

Cylinder Head Components (Figure 25)

• (A) - Cylinder Head

• (B) - Cylinder Head Gasket

• (C) - Valve Stem Cap

• (D) - Valve Spring Retainer Locks

• (E) - Valve Spring Retainer

• (F) - Valve Spring

• (G) - Valve

• (H) - Valve Spring Seat

• (J) - Valve Stem Seal

• (K) - Valve Guide

• (L) - Push Rod

• (M) - Rocker Arm Assembly

• (N) - Rocker Arm Stud

2

Figure 25

1. Install new valve stem seals (A, Figure 26).

Oil inner surface and lip of seal before

installing. Press seal on to valve guide

bushing until it bottoms.

Figure 26

2. Install valve spring seats (Figure 27).

17

Page 21

2

2

Figure 29

Figure 27

NOTE: Lightly coat valve stems with Valve Guide

Lubricant #93963, before installing valves.

3. Install valves.

4. Install valve springs (Figure 28) with Valve

Spring Compressor #19417.

Figure 28

NOTE: After installing valve spring retainer locks,

tap valve spring retainer lightly with a soft hammer

to ensure locks are seated.

Install Cylinder Head

1. Place cylinder head gasket over alignment

dowels on cylinder block (Figure 29).

NOTE: Make sure coolant, oil passages, and head

bolt holes are aligned.

2. Install cylinder head assembly.

3. Lubricate threads of cylinder head bolts with

engine oil.

4. Torque head bolts in 10 ft. lbs. (13.0 Nm)

increments in sequence shown (Figure 30).

Figure 30

NOTE: Current style head bolts are 9 mm diameter.

Early style head bolts are 8 mm diameter. Torque

specifications are different. Torque bolts to values

listed in Section 14 - Engine Specifications.

5. Lubricate push rods with engine oil then

install with recessed end up.

6. Install valve stem caps on valve stems. Install

rocker arm assembly (Figure 31).

18

Page 22

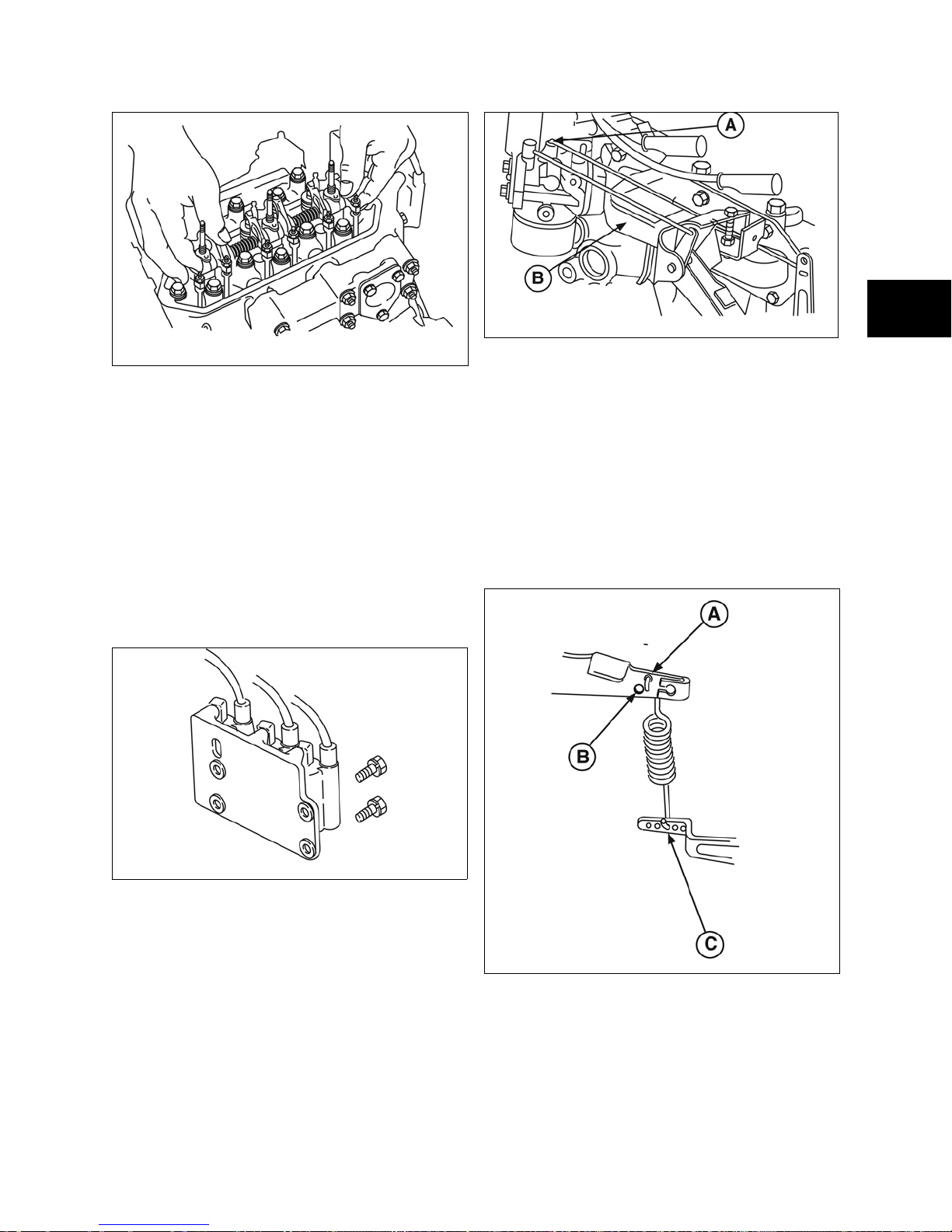

Figure 33

2

Figure 31

7. Install washers and torque nuts to values

listed in Section 14 - Engine Specifications.

NOTE: Make sure rocker adjustments studs are

seated in recessed end of push rods.

Install ignition coil bracket and ignition coils (Figure

32). Torque screws to values listed in Section 14 Engine Specifications.

8. Install ignition coil bracket and ignition coils

(Figure 32). Torque screws to values listed in

Section 14 - Engine Specifications.

10. Insert governor spring into original hole in

governor lever.

NOTE: Normal spring position is in center hole in

the governor lever (Figure 34).

NOTE: Governor spring must be installed in correct

hole in governor control lever by engine model.

• Model 430400 - Top Hole

• Model 580400 - Bottom Hole

Figure 32

9. Install intake manifold with new gasket. Install

governor link and spring (Figure 33). Torque

screws to values listed in Section 14 - Engine

Specifications.

19

Figure 34

11. Install exhaust manifold with new gasket

(Figure 35). Torque screws to values listed in

Section 14 - Engine Specifications.

Page 23

2

2

Figure 35

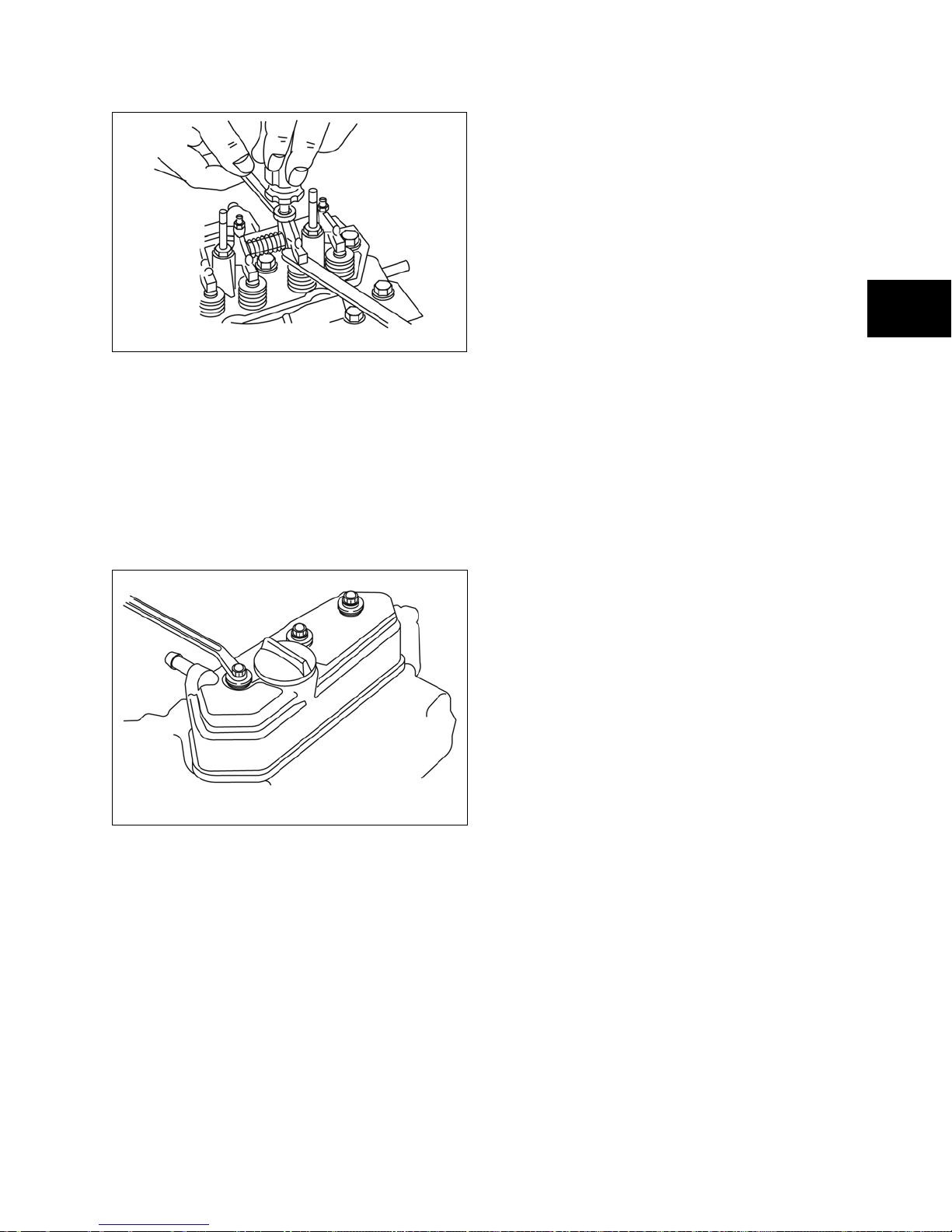

12. Install water pump with new gasket (Figure

36). Torque screws and nuts to values listed

in Section 14 - Engine Specifications.

Figure 36

13. Install water pump pulley (Figure 37). Install

fan (if equipped). Torque screws to values

listed in Section 14 - Engine Specifications.

Figure 38

NOTE: Belt deflection limit is 3/8-1/2 in./22 lb. (10.0-

12.0 mm/10 kg).

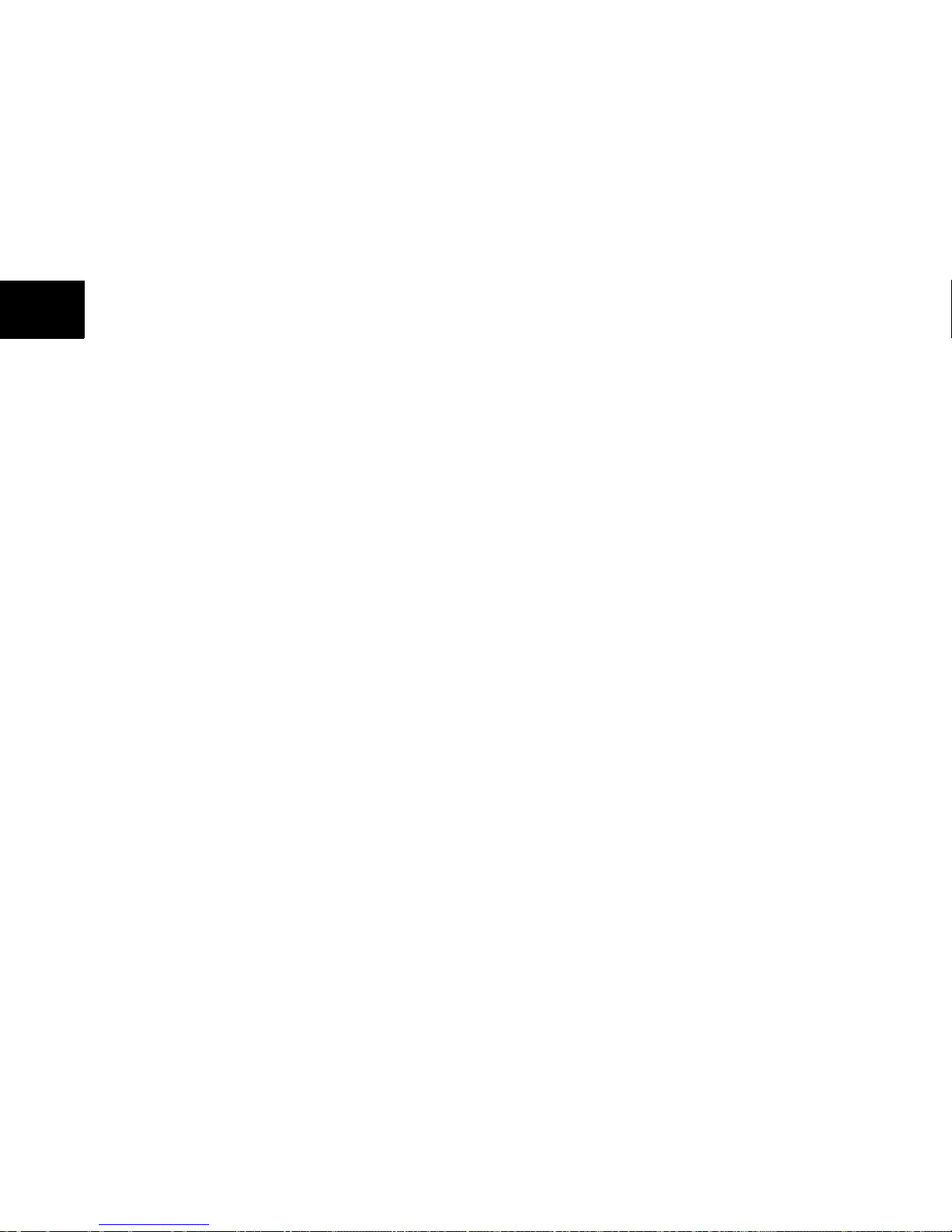

Adjust Valves

1. Before adjusting valves, make sure that the

Number 1 cylinder is at Top Dead Center

(TDC) - Compression Stroke (Figure 39).

Figure 39

Figure 37

14. Install V-belt (Figure 38). Install alternator

adjusting bolt. Torque bolt to values listed in

Section 14 - Engine Specifications.

20

2. Adjust valves and check (Figure 40).

• Valve Clearance (cold) IN and EX - 0.007

in. (0.18 mm).

• Torque adjusting screws and jam nuts

to values listed in Section 14 - Engine

Specifications.

Page 24

Figure 40

3. With Number 1 piston at TDC of compression

stroke, check and adjust valve clearances for

cylinders (Figure 41).

4. Rotate crankshaft one complete turn 360°

clockwise to check and adjust remaining

valves.

5. Install valve cover (Figure 41).Torque cover

nuts to values listed in Section 14 - Engine

Specifications.

2

Figure 41

6. Install spark plugs. Torque spark plugs

to values listed in Section 14 - Engine

Specifications.

21

Page 25

2

2

22

Page 26

SECTION 3 - GOVERNOR, TIMING GEARS, AND GEAR CASE

REMOVE TIMING GEAR COVER AND GEARS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -24

INSPECT GEARS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -25

REMOVE GEAR CASE- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -26

DISASSEMBLE GOVERNOR SHAFT ASSEMBLY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

REPLACE TIMING GEAR COVER OIL SEAL - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

ASSEMBLE GOVERNOR SHAFT ASSEMBLY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -27

ASSEMBLE TIMING GEAR CASE AND GEARS- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -28

ADJUST GOVERNOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

TROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -31

ELECTRONIC GOVERNOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -32

INSPECT GOVERNOR ACTUATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

3

REMOVE GOVERNOR ACTUATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

INSTALL GOVERNOR ACTUATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -33

23

Page 27

3

TIMING GEARS, GEAR CASE, ELECTRONIC GOVERNOR

3

Remove Timing Gear Cover and Gears

NOTE: Make sure the Number 1 cylinder is at Top

Dead Center (TDC), compression stroke. See

Section 2.

1. Remove V-belt and fan (if equipped).

2. Drain oil from engine.

NOTE: Before removing governor spring, note hole

position of governor spring in governor lever.

3. Remove governor link spring (A, Figure 1)

and governor link from carburetor.

4. Remove governor spring from governor lever

(B).

5. Loosen nut (C) and remove governor lever

from governor shaft.

24

Figure 1

Page 28

6. Remove oil pan screws and nuts.

7. Remove oil pan and discard gasket.

8. Remove oil pick-up tube (A, Figure 2) and

strainer. Discard gasket.

Figure 2

9. Remove bell housing adapter screw (if

equipped) and install Flywheel Holder

#19418 (A, Figure 3).

3

Figure 4

12. Remove governor gear (A, Figure 5),

governor cup (B), E-ring (C), governor gear

(D), and thrust washer (E).

13. Remove oil pump drive gear (F).

NOTE: Leave tool installed.

10. Remove crankshaft pulley using Tool #19420

(B).

Figure 3

11. Remove trigger (A, Figure 4) and wire.

Remove timing gear cover (B) and discard

timing gear gasket.

Figure 5

14. Check governor gear and oil pump drive gear

for damaged teeth.

Inspect Gears

1. Inspect gear teeth for wear or damage.

2. Check gear back lash between idler gear (A,

Figure 6) and crankshaft gear (B) using a dial

indicator.

• Set tip of indicator on gear tooth, then rock

idler gear back and forth noting indicator

reading.

• Crankshaft must not turn while checking.

25

Page 29

7. If gears are worn, it is recommended that

they be replaced as a set.

3

Figure 6

3. If back lash exceeds 0.008 in. (0.2 mm)

check idler gear bearing and shaft for wear

(Figure 7).

Reject dimensions for Idler Gear:

• ID - 0.345 in. (34.17 mm)

• OD - 1.335 in. (33.91 mm)

Figure 7

3

Figure 8

Remove Gear Case

1. Remove three screws (A, Figure 9) and

camshaft retainer.

2. Remove remaining five screws (B).

4. If idler gear bearing and shaft are within

specification, replace with new idler gear and

recheck.

5. If back lash exceeds 0.008 in. (0.2 mm) with

NEW idler gear, crankshaft gear is worn.

NOTE: If crankshaft gear is worn the crankshaft

must be replaced.

6. Hold idler gear and check gear backlash

between camshaft timing gear (A, Figure 8)

and idler gear (B) using a dial indicator.

NOTE: Idler gear must not turn while checking.

26

Figure 9

3. Remove timing gear case and discard

gasket.

4. Remove oil pump rotor (Figure 10) from

cylinder block.

Page 30

Figure 12

3

Figure 10

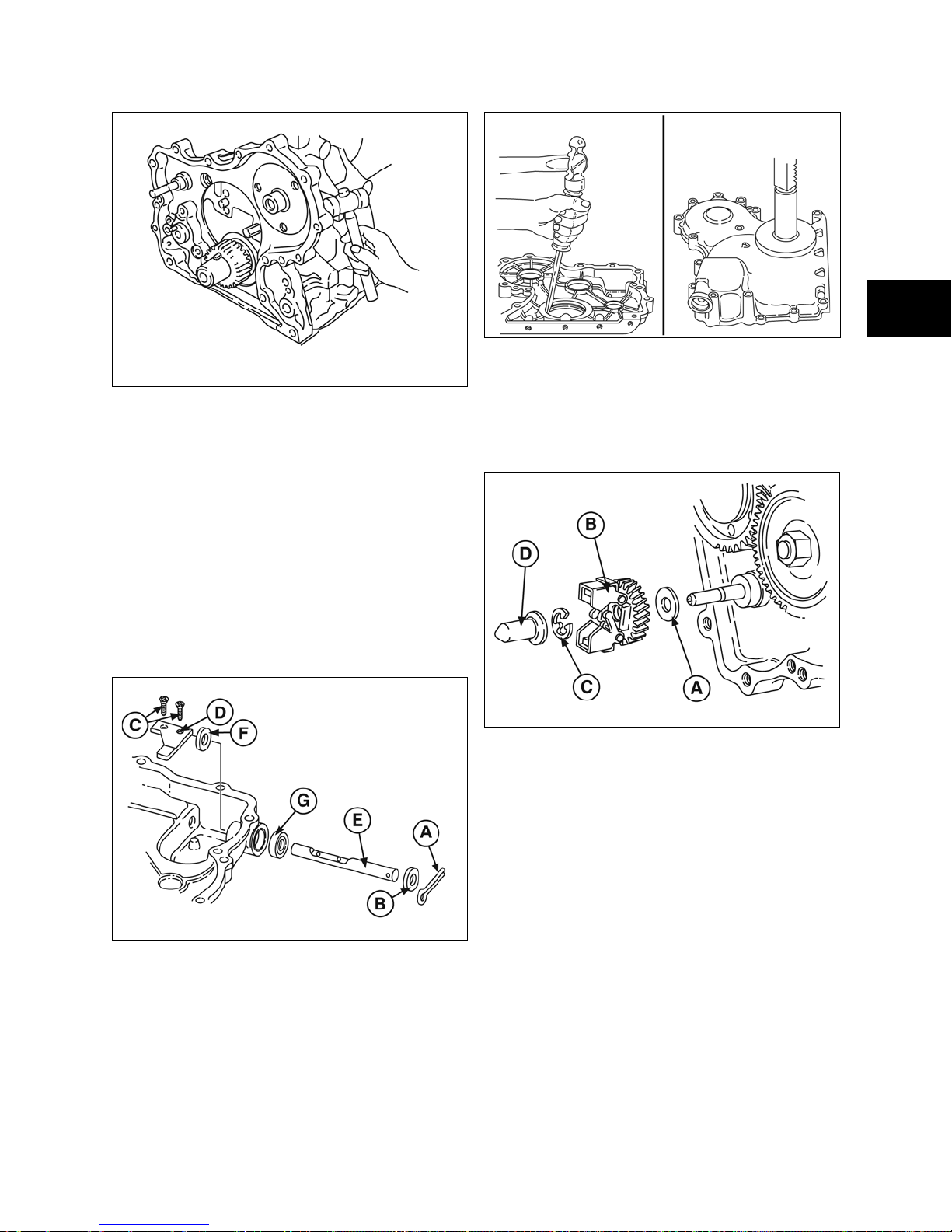

Disassemble Governor Shaft Assembly

1. Remove cotter pin (A, Figure 11) and washer

(B). Discard cotter pin.

2. Remove screws (C) and governor paddle (D)

using Torx® Driver #19445. Discard screws.

NOTE: Governor paddle screws are Torx® tamper

proof screws.

3. Remove shaft (E) and spacer (F).

4. Remove and discard oil seal (G).

Figure 11

Replace Timing Gear Cover Oil Seal

1. Drive out oil seal.

2. Use Seal Driver #19423 to install new oil seal

(Figure 12).

Assemble Governor Shaft Assembly

1. Install thrust washer (A, Figure 13) on shaft

followed by the governor gear (B), E-ring

(C), and governor cup (D).

Figure 13

NOTE: Lubricate governor shaft with engine oil

before installing.

2. Install new oil seal (A, Figure 14) with seal

lips in.

3. Install governor shaft (B) and spacer (C).

4. Install governor paddle (D) using new screws

(E). Use Torx® Driver #19445. Torque to

values listed in Section 14 - Engine

Specifications.

5. Install washer (F) and new cotter pin (G).

NOTE: Governor shaft must rotate freely.

27

Page 31

3

3

Figure 14

Assemble Timing Gear Case and Gears

1. Clean and lubricate oil pump rotor (A, Figure

15) with engine oil and install on cylinder

block.

NOTE: ID mark (B) on rotor must face cylinder

block.

Figure 16

NOTE: It may be necessary to rotate oil pump drive

to engage oil pump rotors.

NOTE: Position camshaft retainer so that the center

hole does not interfere with the camshaft.

3. Note position, length, and number of screws

(Figure 16).

• M6 x 1.1 in. (M6 x 28 mm): 4 (A)

• M6 x 0.7 in. (M6 x 18 mm): 3 (B)

• M6 x 0.6 in. (M6 x 16 mm): 1 (C)

4. Torque screws to values listed in Section 14 Engine Specifications.

5. Make sure crankshaft key is at the 12 o’clock

position (A, Figure 17).

Figure 15

2. Install timing gear case with new gasket.

Install camshaft retainer (A, Figure 16).

28

Figure 17

6. Assemble idler gear shaft with arrow up (A,

Figure 18).

Page 32

Figure 18

3

Engine models 430000 and 580000 built after date

code 990111007 are equipped with right angle

helical timing gears. Timing marks are identified by

letters (A, AA, B, BB, etc.), instead of numbers.

The timing procedure is the same.

7. With crankshaft key at the12 o’clock position,

assemble idler gear so that timing mark 11

(AA) is aligned with timing mark 1 (A) on

crankshaft gear, timing mark 22 (BB) is

aligned with timing mark 2 (B) on camshaft

gear (Figure 19).

Figure 20

10. Install timing gear cover with new gasket.

Note position, length, and number of screws

(Figure 21). Torque screws to values listed in

Section 14 - Engine Specifications.

• M6 x 2.5 in. (M6 x 65 mm): 2 (A)

• M6 x 2.1 in. (M6 x 55 mm): 3 (B)

• M6 x 1.1 in. (M6 x 30 mm): 7 (C)

• M6 Nut: 2 (D)

Figure 19

8. Install oil pump gear.

9. Torque screws to values listed in Section 14 Engine Specifications. Camshaft gear (A,

Figure 20), idler gear (B), and oil pump gear

(C).

29

Figure 21

11. Install crankshaft pulley with timing mark at

12 o’clock position (No. 1 cylinder) (Figure

22).

NOTE: Ensure alignment pin in crankshaft gear is

seated in hole in pulley.

Page 33

12. Remove flywheel holder (A) and install

trigger assembly and wire (B).

3

Figure 22

13. Install oil pick-up tube and strainer with new

gasket.

14. Apply a small bead of Permatex® No. 2 or

other similar sealant (A, Figure 23).

3

Figure 24

19. Insert governor spring into original hole in

governor lever.

NOTICE: Governor spring must be installed in

correct hole in governor control lever by engine

model (Figure 25).

• Model 430400 - Top Hole (A)

• Model 580400 - Bottom Hole (B)

Figure 23

15. Install oil pan with new gasket. Torque

screws and nuts to values shown in Section

14 - Engine Specifications.

16. Install V-belt and fan (if equipped).

17. Install governor lever (A, Figure 24) on to

governor shaft. Do not tighten governor nut

at this time.

18. Install governor link with spring (B).

30

Figure 25

Page 34

Adjust Governor

1. Move governor control lever (A, Figure 26)

up to end of travel and hold in this position

(throttle wide open).

2. Rotate governor shaft (B) clockwise to end of

travel.

3. Torque governor nut (C) to value listed in

Section 14 - Engine Specifications.

3

Figure 27

• If dimension is greater than 1 mm, perform

governor adjustment.

• If engine continues to hunt at top no load

speed, decrease governor sensitivity by

moving governor spring to next hole on

governor lever (Figure 28).

Figure 26

Troubleshooting

If engine hunts at top no load speed, check

governor adjustment as follows:

1. Stop engine.

2. Move equipment control to “FAST” position.

3. Disconnect governor link spring and link.

4. Rotate throttle wide open position.

NOTE: Position of governor link must be within 1

mm of center of hole in throttle (Figure 27).

NOTE: Moving spring away from governor shaft

pivot point decreases sensitivity. Moving spring

towards governor shaft pivot point increases

sensitivity.

Figure 28

31

Page 35

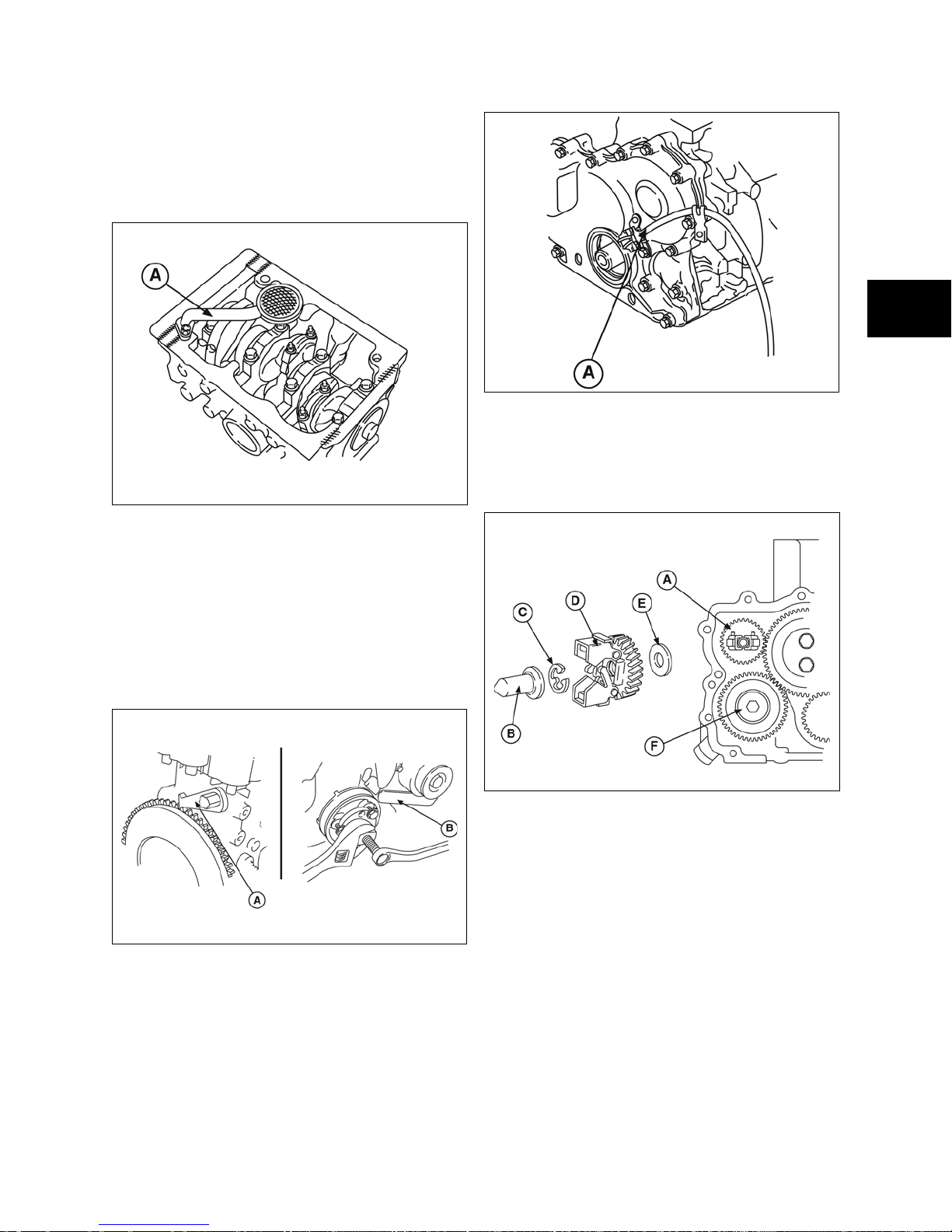

Electronic Governor

The ignition module and related wiring for the

electronic governor is supplied by the equipment

manufacturer.

NOTE: Engines equipped with an electronic

governor do not have mechanical governor

components.

3

3

A - Governor Actuator

B - Governor Link

C - Governor Link Spring

D - Wiring Harness

32

Page 36

Inspect Governor Actuator

1. Disconnect harness at connector (A, Figure

29).

2. Touch test leads (B) to terminals of a known

good 12 volt battery.

• Actuator lever (C) should quickly move the

throttle to a wide open position (D).

3. Remove test leads from battery terminals.

• Actuator lever should quickly move throttle

lever to idler position.

4. Replace actuator if not to specification.

Install Governor Actuator

1. Assemble governor link spring and link to

actuator lever (Figure 31).

NOTE: Open ends of spring must face cylinder

head.

2. Assemble actuator to mounting bracket

loosely. Do not tighten screws.

3

Figure 31

Figure 29

Remove Governor Actuator

1. Disconnect governor link spring and link (A,

Figure 30).

2. Remove two screws (B) and actuator (C).

3. Rotate throttle lever clockwise to end of travel

and hold in this position.

4. Slide actuator until governor link is positioned

slightly to rear of hole in throttle lever bushing

(Figure 32).

5. Torque mounting screws to values listed in

Section 14 - Engine Specifications.

6. Assemble governor link and spring to throttle

lever.

Figure 30

33

Figure 32

Page 37

3

3

34

Page 38

SECTION 4 - FLYWHEEL AND REAR SEAL RETAINER

REMOVE OIL PAN AND FLYWHEEL- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

REMOVE REAR SEAL RETAINER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

REPLACE OIL SEAL - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -36

INSTALL REAL SEAL RETAINER AND FLYWHEEL - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

INSTALL OIL PAN - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -37

4

35

Page 39

4

Removing Pan and Flywheel

1. Drain oil from engine.

2. Remove oil pan screws and nuts (Figure 1).

3. Remove oil pan and discard gasket.

Figure 1

4. Install Flywheel Holder #19418 (A, Figure 2).

Remove flywheel screws and flywheel.

Remove Rear Seal Retainer

1. Remove rear seal retainer and discard

gasket (Figure 3).

Figure 3

Replacing Oil Seal

1. Remove oil seal (Figure 4).

Figure 2

5. Inspect flywheel for cracks or damage.

Inspect flywheel ring gear for worn, chipped,

or cracked teeth.

NOTE: If ring gear is worn or damaged, the flywheel

must be replaced.

36

Figure 4

2. Lubricate outside diameter of oil seal.

3. Using a Seal Driver #19424, install new seal

(Figure 5).

Page 40

4

Figure 5

Installing Rear Seal Retainer and Flywheel

1. Install real seal retainer with new gasket

(Figure 6). Torque screws to values listed in

Section 14 - Engine Specifications.

Figure 6

Figure 7

3. Torque flywheel screws to values listed in

Section 14 - Engine Specifications.

4. Remove flywheel holder.

Install Oil Pan

1. Install oil pan with new gasket.

2. All small bead of Permatex® No. 2 or similar

sealant to crankcase areas (A, Figure 8).

2. Install flywheel (Figure 7).

NOTE: Apply Permatex® No. 2 or similar sealant to

flywheel screws.

37

Figure 8

3. Torque screws and nuts to values listed in

Section 14 - Engine Specifications.

Page 41

4

38

Page 42

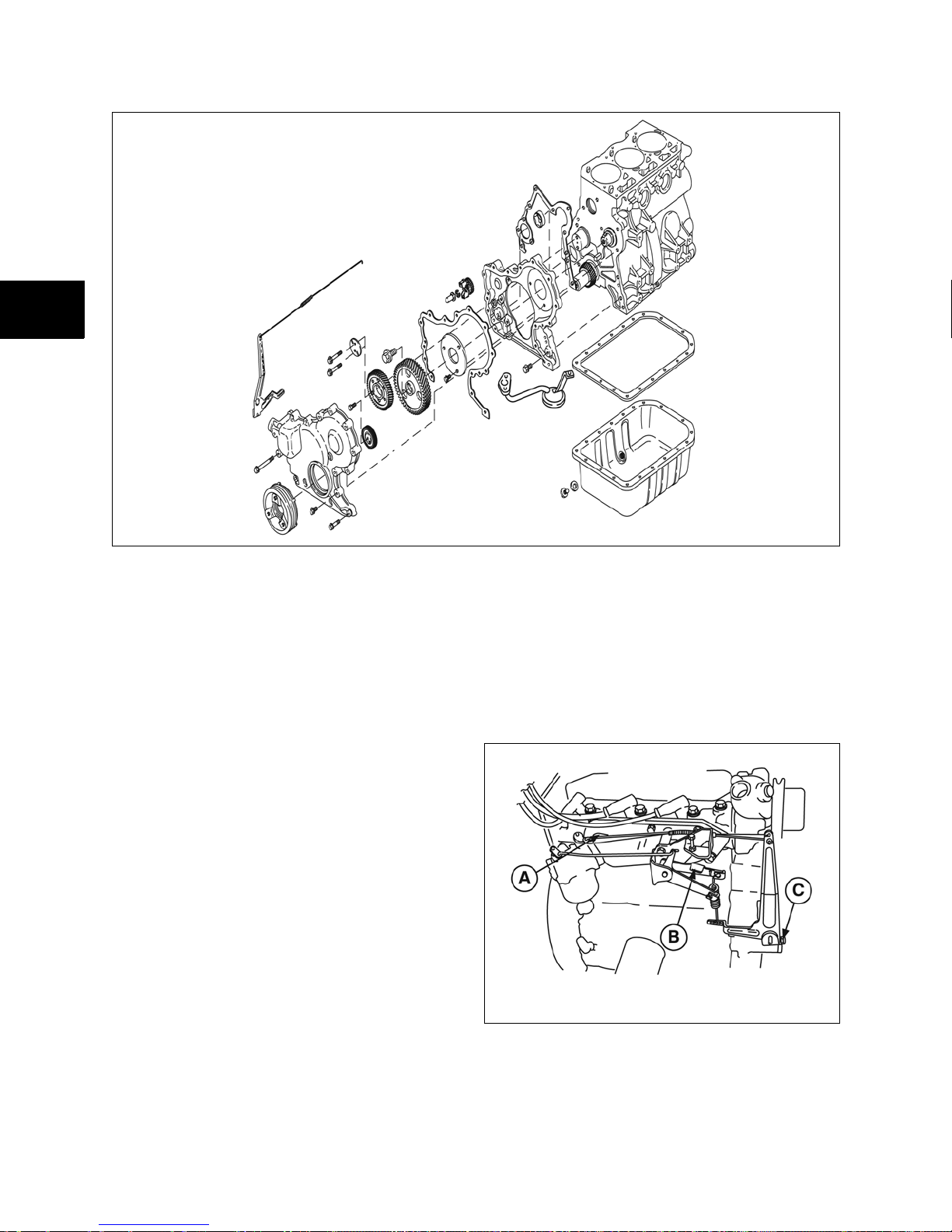

SECTION 5 - CYLINDER BLOCK DISASSEMBLY

CYLINDER BLOCK

CYLINDER BLOCK DISASSEMBLY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -40

5

39

Page 43

5

Cylinder Block Disassembly

An automotive type engine stand is recommended

when complete engine disassembly is required.

See drawings below for dimensions to make an

engine stand mounting fixture. The engine stand

shown below is manufactured by Snap-On®.

40

Page 44

1. Remove cylinder head. See Section 2.

2. Remove oil pan, timing cover, gears, and

case. See Section 3.

3. Remove flywheel and rear seal retainer. See

Section 4.

4. Remove starter motor (Figure 1).

Figure 1

5. Remove alternator bracket and alternator

(Figure 2).

5

Figure 3

7. Remove camshaft (Figure 4).

NOTE: Use care when removing camshaft to

prevent damaging cam bearing, journals, and lobes.

Figure 2

6. Remove valve lifters (Figure 3).

NOTE: Number lifters so that they may be

reinstalled in the same position.

41

Figure 4

8. Remove oil pick-up tube and strainer (Figure

5). Discard gasket.

Page 45

5

NOTE: Main bearing caps are numbered 1 through

4.

Figure 5

9. Remove connecting rod and piston

assemblies (Figure 6).

NOTE: Remove carbon or ridge from cylinder and

number connecting rod/piston assemblies before

removing from cylinders.

• Remove connecting rod cap with lower

bearing.

• Push connecting rod and piston out

through top of cylinder.

• Reassemble connecting rod cap to

connecting rod to prevent interchanging

components.

Figure 7

11. Remove crankshaft (A, Figure 8).

• Remove crankshaft thrust washers (#3

main bearing).

• Remove upper main bearings from

saddles and place with respective bearing

caps.

Figure 8

Figure 6

10. Remove crankshaft main bearing caps,

keeping main bearings with their respective

caps (Figure 7).

42

Page 46

SECTION 6 - CYLINDER BLOCK INSPECTION AND REPAIR

CHECK CYLINDER BLOCK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -44

CHECK CYLINDER BORE FOR WEAR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -44

REPLACE CAMSHAFT BEARINGS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

REPLACE CAMSHAFT PLUG - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -45

6

43

Page 47

Inspect Cylinder Block

1. Remove all traces of sealant and gasket

material from mounting surfaces. Inspect

cylinder block for damage, cracks, and

stripped threads.

2. Inspect cylinder block deck for distortion

(Figure 1).

• Distortion Limit - 0.003 in. (0.08 mm).

6

Figure 1

3. If cylinder block exceeds limits shown, it may

be resurfaced (Figure 2).

6

Figure 3

NOTE: Always resize to exactly 0.010 in. (0.25mm)

over standard bore size. If this is done accurately,

the service oversize rings and pistons will fit

perfectly and proper clearances will be maintained.

3. Check valve lifter bore (Figure 4).

• Standard Dimension - 0.709 in. (18.02

mm)

• Reject Dimension - 0.711 in. (18.05 mm)

4. Check valve lifter (Figure 4).

• Standard Dimension - 0.708 in. (17.98

mm)

• Reject Dimension - 0.705 in. (17.91 mm)

Figure 2

Inspect Cylinder Bore for Wear:

1. Measure cylinder bore in 6 points at right

angles (Figure 3).

2. If cylinder bore is worn more than 0.003 in.

(0.075 mm) or more than 0.0015 in. (0.035

mm) out of round, it must be resized.

44

Figure 4

5. Check Camshaft bearing (Figure 5).

• Replace if greater than 1.42 in. (36.06 mm)

Page 48

Figure 5

Replace Camshaft Bearing

1. Using Camshaft Bearing Puller #19421,

remove camshaft bearing (Figure 6).

Replace Camshaft Plug

1. Remove rear camshaft plug (Figure 8).

NOTICE: Use a wood dowel or brass rod to prevent

damage to the camshaft bearing.

6

Figure 8

2. Using Camshaft Bearing Driver #19422,

install new camshaft plug flush with cylinder

block (Figure 9).

Figure 6

2. Using Camshaft Bearing Driver #19422.

install camshaft bearing (Figure 7).

Figure 7

45

Figure 9

NOTE: If cylinder block is being resized, the

following parts should be removed so that the

cylinder block can be thoroughly cleaned.

3. Remove oil pressure switch (A, Figure 10),

water gallery plug (B), and oil filter adapter

(C).

Page 49

6

6

Figure 10

4. Remove timing gear oil nozzle (A, Figure 11).

Figure 11

5. When reinstalling oil nozzle, oil hole must be

positioned at a 45° angle, pointing towards

the idler gear (A, Figure 12).

Figure 12

46

Page 50

SECTION 7 - CRANKSHAFT, CAMSHAFT AND BEARINGS

INSPECT CRANKSHAFT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -48

CHECK MAIN BEARING CLEARANCES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -49

CHECK CONNECTING ROD BEARING CLEARANCES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

CHECK CRANKSHAFT END PLAY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -50

INSPECT CAMSHAFT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -51

7

47

Page 51

Inspect Crankshaft

1. Inspect crankshaft journals for grooves or

signs of scoring. If found, crankshaft must

be re-ground or replaced.

2. Check the main bearing and crankpin

journals for wear and taper (Figure 1).

7

Figure 1

• Standard Size (Main) - 1.6525 - 1.6535 in.

(41.976 - 42.000 mm)

• Standard Size (Crankpin) - 1.4557 - 1.4567

in. (36.976 - 37.000 mm)

• Maximum out of round and taper - 0.0008

in. (0.02 mm)

3. If crankshaft journals are not within

specification, the crankshaft may be reground and 0.010 in. (0.25 mm) undersize

bearings installed. See illustrated parts list for

part numbers.

4. Check the crankshaft for run-out at #3 main

bearing journal (Figure 2).

7

Figure 2

• Maximum Run-out - 0.0023 in. (0.06 mm)

NOTE: If run-out exceeds specification shown, the

crankshaft must be replaced.

5. Check crankshaft timing gear teeth for

damage (Figure 3). If timing gear teeth are

damaged or worn, the crankshaft must be

replaced.

NOTE: See Section 3 for procedure to check

crankshaft timing gear for wear.

48

Figure 3

Page 52

Check Main Bearing Clearances

NOTE: If main bearings show signs of flaking or

scoring, bearings must be replaced.

NOTE: Main bearing saddles in cylinder block, main

bearing caps, main bearings, and crankshaft

journals must be clean and free of oil.

1. With upper main bearings installed, install

crankshaft.

2. Lay a strip of plastigage lengthwise on journal

(A, Figure 4).

NOTE: Do not lay plastigage across hole in

crankshaft journal.

Figure 4

7

Figure 5

4. Remove the bearing cap. Measure the

plastigage at its widest point (A, Figure 6). If

the clearance is not within specification,

replace the bearings.

• Standard Main Bearing Clearance -

0.0008 - 0.0017 in. (0.020 - 0.044 mm)

• Reject Main Bearing Clearance - 0.0028

in. (0.07 mm)

3. Assemble main bearing cap with bearing

(Figure 5) and torque to values listed in

Section 14 - Engine Specifications.

NOTE: Do not allow crankshaft to rotate.

Figure 6

5. Repeat procedure for each main bearing.

49

Page 53

7

Check Connecting Rod Bearing Clearances

NOTE: If connecting rod bearings show signs of

flaking or scoring, bearings must be replaced.

NOTE: Connecting rod bearings and crankpin

journals must be clean and free of oil.

1. With upper bearing assembled to the

connecting rod, install the connecting rod.

2. Lay a strip of plastigage lengthwise on journal

(A, Figure 7).

NOTE: Do not lay plastigage across hole in

crankshaft journal.

4. Remove the connecting rod cap. Measure the

plastigage at its widest point (A, Figure 9). If

the clearance is not within specification,

replace the bearings.

• Standard Main Bearing Clearance -

0.0008 - 0.0017 in. (0.020 - 0.044 mm)

• Reject Main Bearing Clearance - 0.0028

in. (0.07 mm)

7

Figure 9

Figure 7

3. Assemble connecting rod cap with bearing

and torque to values listed in Section 14

(Figure 8).

NOTE: Do not allow crankshaft to rotate.

5. Repeat procedure for each main bearing.

Check Crankshaft End Play

1. With thrust washers installed, check

crankshaft end play at #3 main bearing

(Figure 10).

• Standard Crankshaft End Play - 0.0008 -

0.009 in. (0.020 - 0.23 mm)

• Limit Crankshaft End Play - 0.012 in. (0.30

mm)

2. If end play exceeds limit,0.005 in. (0.13 mm),

over size thrust washers are available. See

illustrated parts list for part numbers.

Figure 8

50

Page 54

Figure 12

7

Figure 10

Inspect Camshaft

1. Measure camshaft lobe height (Figure 11). If

lobes are not to specification, replace the

camshaft.

• Standard Intake/Exhaust - 1.183 - 1.186 in.

(30.065 - 30.135 mm)

• Reject Intake/Exhaust - 1.179 in. (29.965

mm)

Figure 11

3. Measure camshaft run-out (Figure 13).

• Maximum Run-out - 0.0012 in. (0.03 mm)

4. If a run-out exceeds specification, the

camshaft must be replaced.

Figure 13

2. Measure camshaft journals (Figure 12).

51

Page 55

7

7

52

Page 56

SECTION 8 - PISTON, RINGS AND CONNECTING ROD

DISASSEMBLE PISTON AND CONNECTING ROD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -54

INSPECT PISTONS AND RINGS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -54

CHECK PISTON PIN AND CONNECTING ROD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -55

ASSEMBLE PISTON AND CONNECTING ROD - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -56

ASSEMBLE PISTON RINGS TO PISTON - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -56

8

53

Disassemble Piston and Connecting Rod

1. Remove compression rings using Ring

Expander #19340 (Figure 1).

Page 57

8

Figure 1

2. Oil ring may be removed by hand by spiraling

top scraper into center ring groove, then into

top groove and off piston. Repeat for bottom

scraper, then remove expander.

3. Disassemble piston from connecting rod

using Piston Pin Fixture #19419.

NOTE: Piston pin stop (A, Figure 2) must be

removed from support (B) when disassembling

piston and connecting rod.

If the cylinder bore is to be resized there is no

reason to check the piston as a new oversized

piston will be used.

If the cylinder is not going to be resized, and the

piston shows no signs of scoring, the piston should

be checked.

1. Check side clearance of ring grooves using

NEW rings (A, Figure 3). If a 0.0045 in. (0.11

mm) feeler gauge can be inserted, the ring

groove is worn. The piston must be

replaced.

Figure 3

4. Insert threaded driver (C) through piston pin

from FRONT side of piston and thread into

pilot.

5. Place piston with driver onto support with

arrow on piston facing up.

6. Press out piston pin.

Figure 2

2. Check ring end gap (Figure 4).

3. Clean carbon from end of rings and insert

approximately 1.0 in. (25 mm) into cylinder.

Figure 4

4. Check piston pin bore (Figure 5).

Inspect Piston and Rings

54

Page 58

3. Check crankpin bearing end of connecting

rod (Figure 8).

8

Figure 5

• Replace if greater than 0.710 in. (18.03

mm) or 0.0004 in. (0.01 mm) out of round.

Check Piston Pin and Connecting Rod

1. Check piston pin (Figure 6).

Figure 6

• Replace if less than 0.708 in. (17.98 mm)

or 0.0004 in. (0.01 mm) out of round.

2. Check piston pin bearing (Figure 7).

Figure 8

• Maximum out of round: 0.0008 in. (0.02

mm)

• If out of round exceeds specification

shown, the connecting rod must be

replaced.

4. Check for bent or twisted connecting rod

(Figure 9).

Figure 9

NOTE: Thrust faces must be free of any burrs or

nicks or connecting rod will not lay flat on surface

plate.

• With connecting rod on a surface plate,

any distortion will be evident by a rocking

motion.

• If a 0.002 in. (0.05 mm) feeler gauge can

be inserted at piston pin end of

connecting rod, the rod must be replaced.

Figure 7

• Replace if greater than 17.98 mm (0.708

in.) or 0.01 mm (0.004 in.) out of round.

55

Page 59

8

Assemble Piston and Connecting Rod

1. Assemble piston to connecting rod using

Piston Pin Fixture #19419.

NOTE: Arrow on piston (A, Figure 10) and ID mark

(B) on rod must face same side.

2. Lubricate piston pin with engine oil. Then,

insert threaded driver (C) through piston pin

(D) and thread into pilot (E).

3. With arrow on piston and ID mark on rod

facing up, insert pilot through piston and

connecting rod.

Assemble Piston Rings to Piston

1. Install oil ring expander first.

2. Spiral bottom oil control ring into top ring

groove, center ring groove, and then into

position below expander (Figure 12).

3. Repeat for upper oil control ring.

Figure 12

Figure 10

4. Insert piston pin stop (A, Figure 11) in bottom

of piston support (B).

Figure 11

5. With arrow on piston up, place assembly onto

support.

6. Press in piston pin until pilot bottoms on stop.

7. After assembly, make sure the piston rotates

freely on connecting rod.

4. Using ring expander, install center

compression ring then, top compression ring

with ID marks up (Figure 13).

5. Stagger ring end gaps.

6. Rotate oil control ring ends 180° from each

other.

Figure 13

56

Page 60

SECTION 9 - CYLINDER BLOCK ASSEMBLY

INSTALL CRANKSHAFT- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -58

INSTALL PISTONS AND CONNECTING RODS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -59

GENERAL ASSEMBLY- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -59

INSTALL TIMING GEAR CASE, CAMSHAFT, AND GEARS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -60

INSTALL OIL PAN - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -62

INSTALL ALTERNATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -62

GENERAL ASSEMBLY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -62

9

57

Page 61

9

Install Crankshaft

1. Install main bearings in cylinder block.

NOTE: Upper bearing has an oil groove

(A, Figure 1) and oil holes (B).

Figure 1

2. Install upper main bearings in their respective

saddles.

3. Ensure bearing is seated in saddle and tang

in bearing is aligned with notch in saddle.

Lubricate bearings with engine oil.

4. Install lower main bearings in bearing caps

(Figure 2).

Figure 3

9. Install main bearing caps. Lubricate threads

of screws with engine oil.

10. Install bearing caps in their respective

positions with arrows facing front.

11. Start with Number 3 bearing cap (Figure 4)

and torque bearing caps one at a time in

sequence shown to values listed in Section

14 - Engine Specifications.

Figure 2

5. Be sure bearing is seated in bearing cap and

tang in bearing is aligned with notch in

bearing cap.

6. Lubricate bearings with engine oil.

7. Install crankshaft with gear facing front of

cylinder block (Figure 3). Take care not to

damage journals or bearings.

8. Install crankshaft shims on No. 3 main

bearings web with grooves facing out.

Lubricate journals with engine oil.

58

Figure 4

12. Recheck crankshaft end play.

• Crankshaft end play - 0.001 - 0.009 in.

(0.025 - 0.23 mm)

NOTE: After torquing bearing cap, make sure

crankshaft rotates freely before proceeding to next

bearing cap.

Page 62

Install Pistons and Connecting Rods

1. Install connecting rod bearings. Be sure tang

on bearing is seated in notch (A, Figure 5) in

connecting rod and cap.

2. Install a piece of vinyl tubing (B) over each

connecting rod screw to prevent damage to

screw threads or crankpin when installing

piston and connecting rod.

Figure 5

3. Rotate crankshaft so that crankpin is at

bottom of stroke. Lubricate cylinder walls,

pistons and rings, bearings, and crankpins.

4. Using Tool Ring Compressor #19070, install

piston and connecting rod assemblies with

arrow on piston facing front.

5. Install connecting rod cap with ID mark

(A, Figure 6) facing front. Lubricate threads

and torque nuts to values listed in Section 14

- Engine Specifications.

General Assembly

1. Install gasket, oil pick-up tube and strainer

(Figure 7). Torque screws to values listed in

Section 14 - Engine Specifications.

9

Figure 7

2. Install gasket and rear seal retainer

(A, Figure 8). Torque screws to values listed

in Section 14 - Engine Specifications.

3. Install starter motor (B) and torque screws to

values listed in Section 14 - Engine

Specifications.

Figure 6

NOTE: After torquing rod cap, make sure

crankshaft rotates freely before proceeding to next

cylinder.

59

Figure 8

4. Install flywheel and flywheel holder

(A, Figure 9).

5. Apply sealant to flywheel screws and torque

to values listed in Section 14 - Engine

Specifications.

Page 63

9

Figure 9

Figure 11

Install Timing Gear Case, Camshaft, and Gears

1. Lubricate oil pump rotor (A, Figure 10) with

engine oil and install in cylinder block.

• ID mark (B) on rotor must face cylinder

block.

Figure 10

2. Install timing gear case with new gasket

(Figure 11).It may be necessary to rotate oil

pump drive to engage oil pump rotors.

3. Note position, length, and quantity of screws

as shown.

• M6 x 1.1 in. (M6 x 28mm): 4 (A).

• M6 x 1.5 in. (M6 x 16mm): 1 (B).

4. Torque screws to values listed in Section 14 Engine Specifications.

5. Lubricate and install camshaft in cylinder

block. Take care not to damage lobes or cam

bearing.

6. Install camshaft retainer (A, Figure 12).

7. Install three screws (B) and torque to values

listed in Section 14 - Engine Specifications.

NOTE: Position camshaft retainer so that the center

hole does not interfere with camshaft.

Figure 12

8. Rotate crankshaft so that they key is at the 12

o’clock position (A, Figure 13).

60

Page 64

9

Figure 13

9. Assemble idler gear shaft (A, Figure 14) with

ID mark (B) up.

Figure 14

Engine models 430000 and 580000 after date code

990111007 are equipped with right angle helical

timing gears. Timing marks are identified by letters

(A, AA, B, BB, etc.), instead of numbers. The

timing procedure is the same.

10. With the crankshaft key at the 12 o’clock

position, assemble idler gear so that timing

mark 11 (AA) is aligned with timing mark 1

(A) in crankshaft gear, timing mark 22 (BB)

is aligned with timing mark 2 (B) on camshaft

gear (Figure 15).

Figure 15

11. Install camshaft gear (A, Figure 16), idler

gear (B), and oil pump gear (C). Torque

screws to values listed in Section 14 - Engine

Specifications.

Figure 16

12. Install timing gear cover with new gasket.

13. Note position, length, and number of screws

(Figure 17).

• M6 x 2.5 in. (M6 x 65 mm): 2 (A).

• M6 x 2.1 in. (M6 x 55 mm): 3 (B).

• M6 x 1.1 in. (M6 x 30 mm): 7 (C).

• M6 Nuts: 2 (D).

61

Page 65

9

Figure 17

14. Torque screws to values listed in Section 14 Engine Specifications.

15. Install crankshaft pulley with timing mark at

12 o'clock position (Number 1 cylinder).

NOTE: Be sure alignment pin in crankshaft gear is

seated in hole in pulley.

16. Torque screw to values listed in Section 14 Engine Specifications.

17. Remove flywheel holder.

18. Install trigger assembly (A, Figure 18) and

wire.

Figure 19

3. Torque screws to values listed in Section 14 Engine Specifications.

Install Alternator

1. Install alternator bracket and alternator

(Figure 20).

Figure 20

2. Torque screws to values listed in Section 14 Engine Specifications.

Figure 18

Install Oil Pan

1. Install oil pan with new gasket.

2. Apply a small bead of sealant to crankcase

areas (A, Figure 19).

62

General Assembly

1. Lubricate tappets with engine oil and install in

cylinder block.

2. See Section 2 for installation of cylinder head

and related components.

3. See Section 3 for governor adjustment

procedure.

Page 66

SECTION 10 - CARBURETOR AND RELATED COMPONENTS

MANUAL CHOKE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -66

REMOVE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -66

DISASSEMBLE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -66

CLEAN CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -68

INSPECT CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -68

CHECK THROTTLE, CHOKE SHAFT, AND BODY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -68

ASSEMBLE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

INSTALL THROTTLE SHAFT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

INSTALL CHOKE VALVE - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -69

INSTALL FLOAT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

INSTALL CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -70

10

INITIAL CARBURETOR ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

FINAL CARBURETOR ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -71

AUTOMATIC CHOKE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -73

REMOVE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -73

DISASSEMBLE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -73

CLEAN CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -75

INSPECT CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -75

CHECK THROTTLE, CHOKE SHAFT, AND BODY - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -76

ASSEMBLE CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -76

CHECK VACUUM CHOKE BREAK - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -78

ADJUST CHOKE PRE-LOAD LEVER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -78

CHECK P.T.C. HEATER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

INSTALL CARBURETOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

INSTALL VACUUM LIMITER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -79

63

Page 67

INITIAL CARBURETOR ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -280

FINAL CARBURETOR ADJUSTMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 280

ELECTRIC FUEL PUMP - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -81

CHECK FUEL PUMP OUTPUT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

TEST EQUIPMENT - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

10

TEST FUEL PUMP WIRING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -82

ANTI-AFTERFIRE SOLENOID - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -83

TEST ANTI-AFTERFIRE SOLENOID - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -83

TEST SOLENOID- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -83

FUEL FILTER - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -84

CARBURETOR MAIN JETS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -84

ELECTRONIC FUEL INJECTION SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

EFI COMPONENTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -85

TROUBLESHOOTING - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

ELECTRICAL SYSTEM - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -89

FAULT CODES - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -90

FLASH CODE ON MIL INDICATOR - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -91

TROUBLESHOOTING CHARTS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -92

64

Page 68

10

MANUAL CHOKE CARBURETOR

AUTOMATIC CHOKE CARBURETOR

65

Page 69

10

Manual Choke Carburetor

Remove Carburetor

1. Disconnect fuel line (A, Figure 1).

2. Remove air cleaner tube from carburetor air

horn. Disconnect fuel solenoid wire, if

equipped.

Figure 1

6. Remove choke link (A, Figure 3) from choke

lever.

Figure 3

7. Remove nuts, air horn (A, Figure 4),

carburetor (B), and insulator (C). Discard

gaskets (D).

3. Unhook governor link spring (B) from throttle

lever and disconnect governor link (C).

4. Disconnect choke link (D) at choke lever.

Proceed to Step 7.

NOTE: Early style choke links were manufactured

with a “Z” bend (Figure 3). To remove choke link the

governor control bracket must be removed.

Proceed to Steps 5 and 6.

5. Disconnect governor spring (A, Figure 2).

Remove two screws and governor control

bracket (B) from intake manifold.

Figure 4

Disassemble Carburetor

1. Remove anti-afterfire solenoid (A, Figure 5),

bowl screw (B), washer (C), and carburetor

bowl (D).

Figure 2

66

Page 70

Figure 5

4. Remove fixed high speed jet (A, Figure 8).

5. Remove emulsion tube (B).

10

2. Drive out float hinge pin (A, Figure 6) from

choke plate side of carburetor (B) with a

small punch. Remove float (C) and fuel inlet

valve (D).

Figure 6

3. Remove carburetor bowl gasket

(A, Figure 7).

Figure 8

NOTE: Consult the illustrated parts list for correct

part number for special high altitude jet, if required.

6. Remove idle jet (A, Figure 9).

Figure 9

7. If idle mixture screw (A, Figure 10) is

equipped with adjustment limiter cap, use

pliers to remove it before removing idle

mixture valve.

8. Remove idle mixture screw and spring (B).

Figure 7

67

Page 71

10

Figure 10

9. Remove screw and choke plate

(A, Figure 11).

10. Remove choke shaft (B) and spring (C).

Figure 11

NOTE: If engine is equipped with an electronic

governor system, DO NOT remove throttle plate or

throttle shaft. This is a precision assembly and

should not be disassembled.

Figure 12

Clean Carburetor

Remove gasket material from mounting surfaces.

Gummy or dirty carburetors should be cleaned in a

carburetor cleaner. DO NOT soak rubber,

neoprene, or plastic parts in cleaner.

NOTICE: If engine is equipped with an electronic

governor system, DO NOT clean carburetor in

carburetor cleaner. The carburetor is equipped with

sealed ball bearings for the throttle shaft, which will

be damaged if the carburetor is immersed in

carburetor cleaner. Ball bearings are not

replaceable.

Inspect Carburetor

Inspect all parts for wear, cracks, nicks, and burrs.

Inspect float for leaks. Replace all damaged parts.

Inspect Throttle, Choke Shaft, and Body for

Wear

1. Lay carburetor on flat surface and check

throttle and choke shaft clearance

(Figure 13).

11. If engine is not equipped with an electronic

governor, proceed to step 12.

12. Mark throttle plate (A, Figure 12) before

removing so that it may be reinstalled in the

same position. Sides of throttle plate are

beveled.

13. Remove two screws, throttle plate, throttle

shaft (B) with collar (C) and seal (D). Discard

seal.

68

NOTE: Throttle shaft and choke shaft clearance

must not exceed 0.010 in. (.25 mm).

Page 72

10

Figure 13

2. Inspect throttle shaft and choke shaft for wear

(Figure 14).

Figure 14

• Replace if worn.

• If carburetor body is worn, replace

carburetor.

Assemble Carburetor

Figure 15

Install Choke Valve

1. Assemble spring (A, Figure 16) to choke

shaft (B) and insert in body.

2. Rotate shaft clockwise to pre-load spring.

3. Install choke plate with hole facing fuel inlet

side of body (C).

Figure 16

4. Assemble the emulsion tube (A, Figure 17),

the fixed high speed jet (B), and the idle jet

(C).

NOTE: When assembling carburetor, use new

seals and gaskets.

Install Throttle Shaft

1. Install seal (A, Figure 15) with grooved side

out.

2. Assemble collar (B) to throttle shaft and insert

in body.

3. Install throttle plate and screws (C).

69

Page 73

10

4. Install idle mixture screw (A, Figure 20) and

spring (B).

Figure 17

Install Float

1. Assemble inlet valve (A, Figure 18) to float.

2. Install float hinge pin (B) from throttle side of

carburetor.

Figure 18

3. Install gasket (A, Figure 19) and float bowl

(B).

Figure 20

NOTE: DO NOT tighten idle mixture screw.

Install Carburetor

1. Assemble insulator (A, Figure 21) with

gaskets, carburetor (B), and air horn (C) with

gasket (D) to intake manifold.

Figure 21

Figure 19

70

2. Torque nuts to values listed in Section 14 Engine Specifications.

3. Install governor link, spring, and choke link.

NOTE: Proceed to Step 5 if choke link is early style

with “Z” bend.

4. Reinstall air cleaner tube and fuel line.

5. Install choke link. Assemble governor control

bracket to intake manifold. Torque screws to

values listed in Section 14 - Engine

Specifications.

Page 74

6. Assemble governor spring (A, Figure 22) to

governor control lever (B).

NOTE: Governor spring must be installed in correct

hole in governor control lever by engine model.

• Model 430400 - Top Hole

• Model 580400 - Bottom Hole

Figure 22

Initial Carburetor Adjustment

1. Turn idle mixture screw clockwise until it just

seats. DO NOT FORCE. Turn screw counterclockwise 1/2 turn (Figure 23). This setting

will permit engine to start.

NOTE: Final adjustment will be made with engine

running.

Final Carburetor Adjustment

NOTICE: All carburetor adjustments must be made

with the air cleaner installed.

1. Start and run engine at low speed for

approximately five minutes. Or, if equipped

with a temperature gauge, until needle

moves from C or COLD position.

2. With control lever on equipment in SLOW

position, hold throttle lever (A, Figure 24)

against idle speed screw and adjust idle

speed to 1200 RPM.

Figure 24

3. SLOWLY turn idle mixture screw clockwise

until engine speed just starts to slow (lean

mixture).

4. Then SLOWLY turn idle mixture screw

counter-clockwise until engine speed just

starts to slow (rich mixture).

5. Turn idle mixture screw (A, Figure 25) to mid

point between rich and lean.

10

Figure 23

71

Figure 25

Page 75

6. Hold throttle lever against idle speed screw

and readjust idle speed to 1500 RPM, or

equipment manufacturer’s specification.

NOTE: If carburetor is equipped with an idle mixture

limiter cap, install at this time.

7. Position limiter cap (B) so that stop(s) on the

limiter cap are at mid point between stop(s)