Page 1

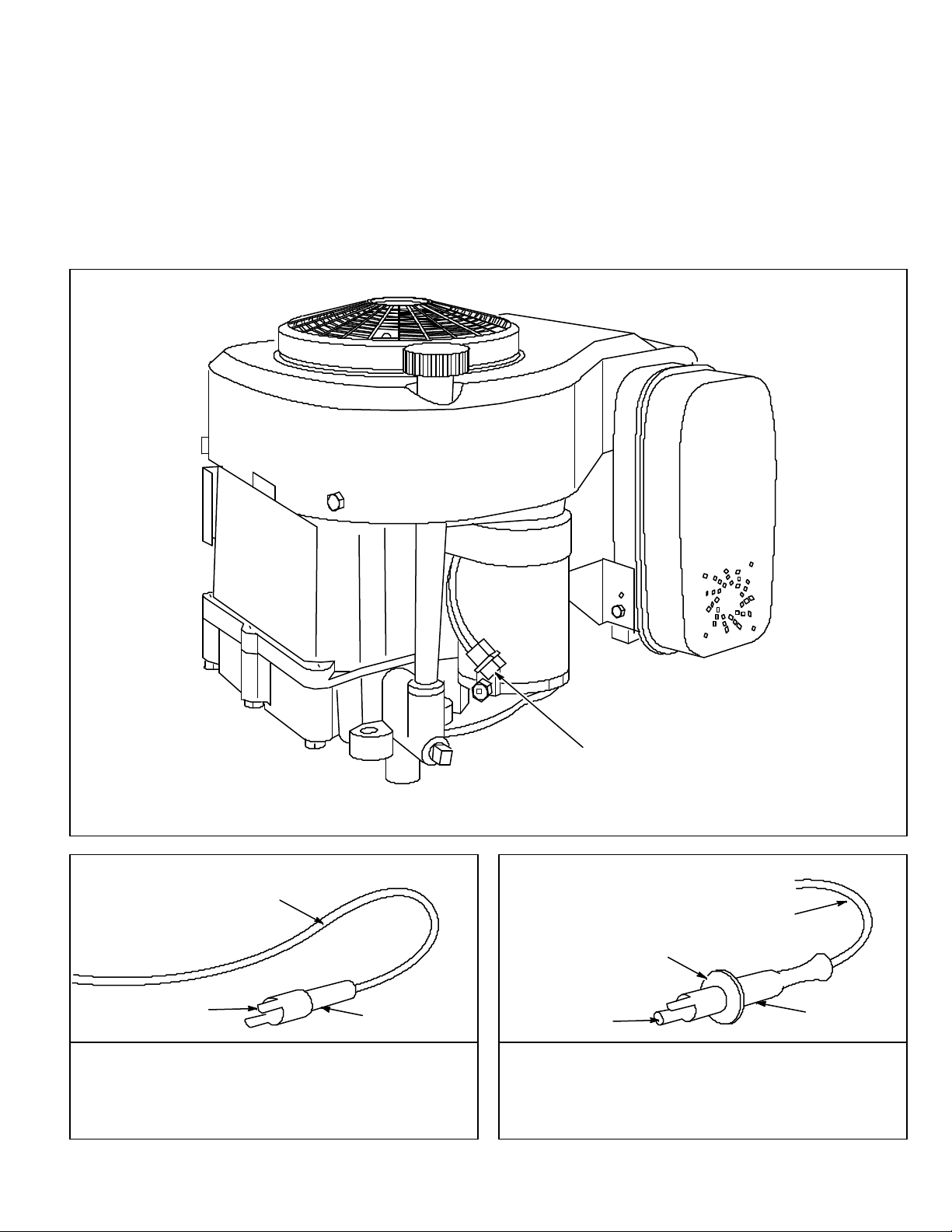

Alternator Identification

Briggs & Stratton engines are equipped with a number of different alternator systems to meet the requirements of equipment manufacturers. For example, a large lawn tractor with accessories may require a

16 amp regulated system, whereas a snow thrower with a single headlight requires an AC Only system.

Knowing the type of alternator system an engine is equipped with is important, particularly when an engine is being replaced.

Briggs & Stratton alternator systems are easily identified by the color of the stator output wire(s) and the

connector.

AC Only

ONE BLACK LEAD

FROM ENGINE

(STATOR)

TO EQUIPMENT

HARNESS

· 14 Volts AC for lighting circuit.

· One black lead from stator.

· White connector output lead.

WHITE CONNECTOR

OUTPUT LEAD

Stator Output Wire(s)

And Connector

(typical)

DC Only

ONE RED LEAD

FROM ENGINE

RED

CONNECTOR

TO EQUIPMENT

HARNESS

· 3ampDCunregulatedforchargingbattery.

· One red lead from stator.

· Diode encased at connector.

· Red connector output lead.

1

(STATOR )

DIODE

Page 2

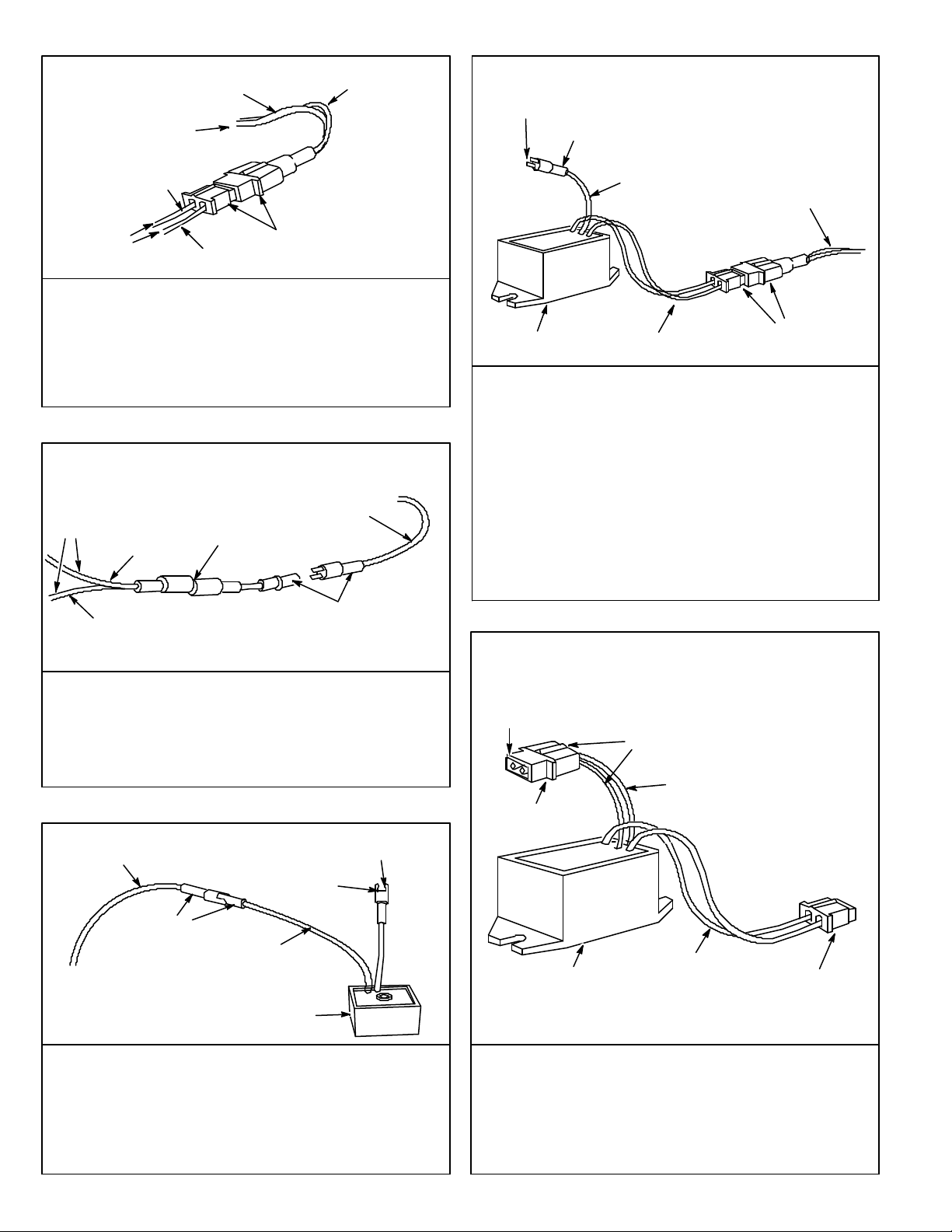

RED AND BLACK

LEADS FROM ENGINE

(STATOR)

Dual Circuit

RED LEAD

DC OUTPUT

BLACK LEAD

AC OUTPUT

TO EQUIPMENT

HARNESS

10 or 16 amp Regulated

RED CONNECTOR

OUTPUT LEAD

DC CHARGING CIRCUIT

RED LEAD

WHITE

TO EQUIPMENT

HARNESS

WHITE LEAD

AC FOR LIGHTS

CONNECTOR

· 3 amp DC unregulated for charging battery

(ONE red lead from stator).

· 14 Volts AC for lighting circuit

(ONE black lead from stator).

· Diode encased at connector.

· White connector with two pin terminals.

Tri-Circuit

ONE BLACK LEAD

FROM ENGINE

TO EQUIPMENT

HARNESS

TO BATTERY AND CLUTCH CIRCUIT

5 AMPS DC (-)

TO LIGHTS

WHITE LEAD

RED LEAD 5 AMPS DC (+)

TWO DIODES ENCASED

IN WIRE HARNESS

(STATOR)

GREEN

CONNECTOR

· 10 amp AC.

· One black lead from stator.

· Green connector.

· Two diodes encased in wire harness.

· Red and white output leads.

ONE BLACK LEAD

FROM ENGINE

(STATOR)

5 or 9 amp Regulated

RED

CONNECTOR

EQUIPMENT

HARNESS

TO

TWO BLACK LEADS

FROM ENGINE

(STATOR)

YELLOW

CONNECTOR

REGULATOR

RECTIFIER

ONE RED

LEAD

TWO YELLOW LEADS

· 10 or 16 amp DC regulated for

charging battery.

· Alternatoroutputisdeterminedbytheflywheel

alternator magnet size.

· 10 and 16 amp system use the same stator,

color coding and regulator-rectifier.

· Two black leads from stator.

· Yellow connector with two pin terminals.

· Two yellow leads to regulator-rectifier.

· One red lead from regulator-rectifier to red

connector output lead.

493219 Regulator/Rectifier

Used With Charge Indicator Circuit

TO EQUIPMENT

HARNESS

WHITE

CONNECTOR

RED WIRE AND RAISED

RIB INDICATES DC OUTPUT

BLUE WIRE

CHARGING INDICATOR

GREEN

CONNECTOR

YELLOW

WIRE

REGULATOR

RECTIFIER

· 5 or 9 amp DC regulated for charging battery.

· Alternator output (5 or 9 amp) is determinedby

flywheel alternator magnet size.

· Uses same stator as Tri-Circuit system.

· One black lead from stator.

· Green connector.

TWO YELLOW

493219 REGULATOR

RECTIFIER

LEADS

· Uses same stator as 10 and 16 amp system.

· DC output the same as 10 or 16 amp system.

· Charge indicator light andwiring supplied by

equipment manufacturer.

· Red DC output wire to white connector.

· Blue charge indicator wire to white connector.

2

YELLOW

CONNECTOR

Page 3

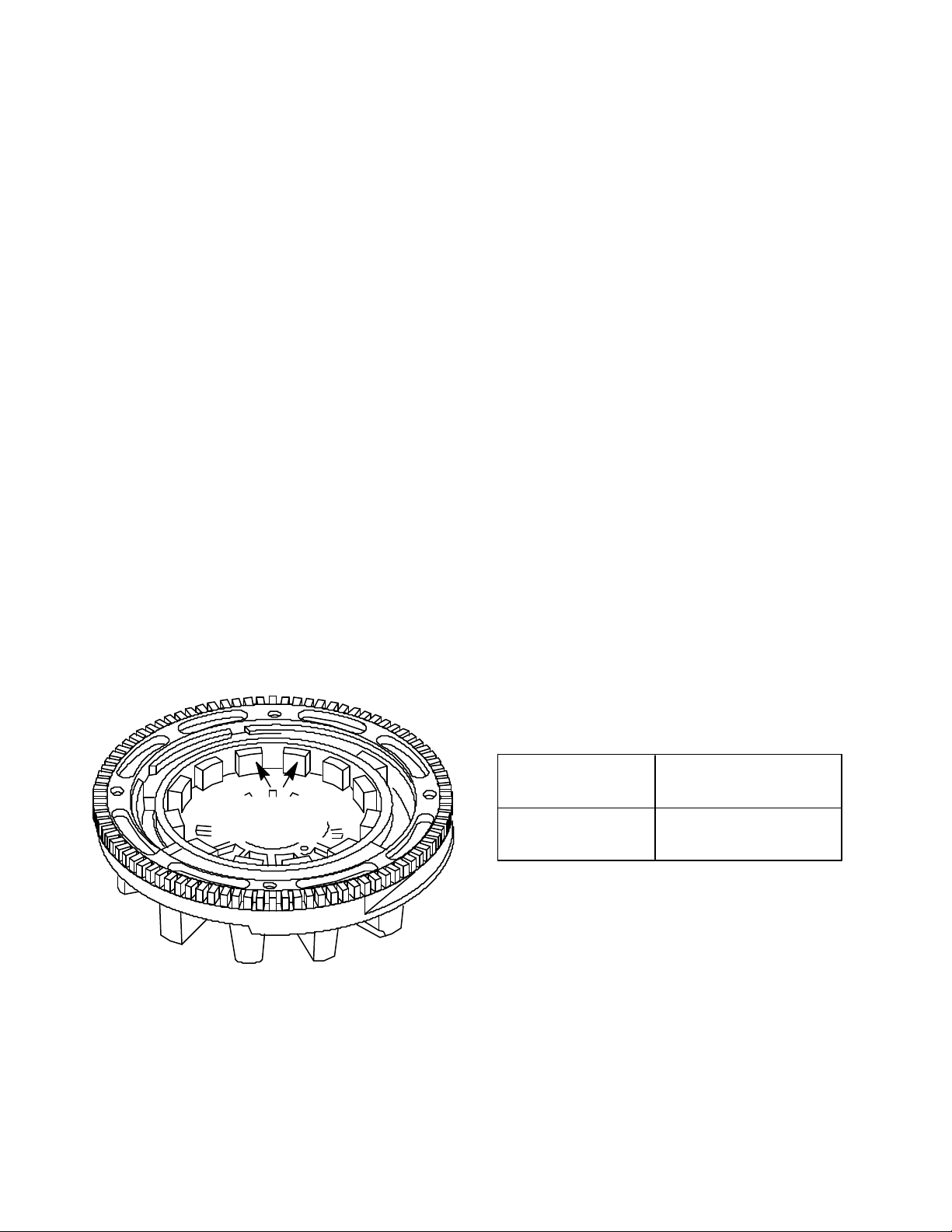

Engine/Alternator Replacement Information

With the exception of the AC Only alternator, all of the alternator systems referred to in this book have

a battery as part of the electrical system.

There are specialized applications that use an alternator without a battery. An example would be certain

generators or welders that use alternator output to excite an electrical field. For the equipment to function,

the alternator output must be very evenly matched to the equipment requirements. When replacing an

engine in these applications, the alternator must be the same as the original.

Replacing Briggs & Stratton Engines

When replacing an older Briggs & Stratton engine on a piece of equipment with a newer Briggs & Stratton

engine, sometimes the newer engine has an alternator system different from the alternator system on

the original engine. This means that the output connector on the replacement engine is not compatible

with the original wiring harness on the piece of equipment. For example, the original engine may have

been equipped with a Dual Circuit system and the replacement engine is equipped with a regulated system. We can integrate the two systems by making an adapter harness from readily available parts.

Generally an unregulated DC system (DC Only, Dual Circuit) should not be used to replace a regulated

system because alternator output may not be sufficient for equipment requirements. However, because

the equipment requirements are usually much less on an unregulated DC system, a regulated system

may be used as a replacement. The regulator/rectifier prevents the battery from being over charged.

NOTE: The AC Only, DC Only, Dual Circuit, Tri-Circuit as well as the 5 and 10 amp regulated systems

use flywheels with small alternator magnets. The 9 and 16 amp regulated systems use flywheels with

the large alternator magnets. See figure below for magnet sizes.

*Small Magnet 7/8” x 11/16”

ALTERNATOR

MAGNETS

*Large Magnet 1-1/16” x 15/16”

(22mm x 18mm)

(27mm x 24mm)

* V Twin Alternator Magnet Size: Small 7/8” x 21/32” (22 mm x 17 mm)

Large 7/8” x 29/32” (22 mm x 23 mm)

3

Page 4

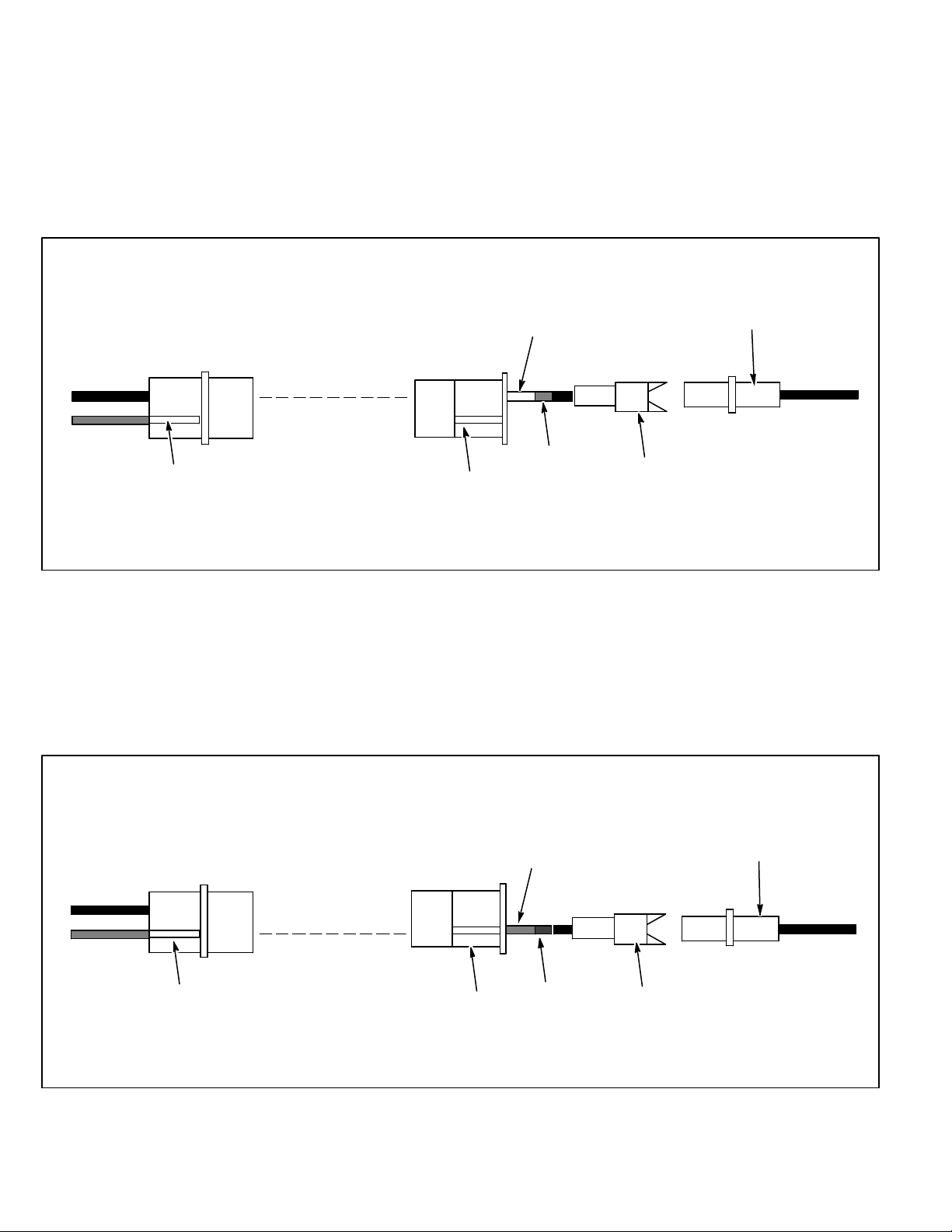

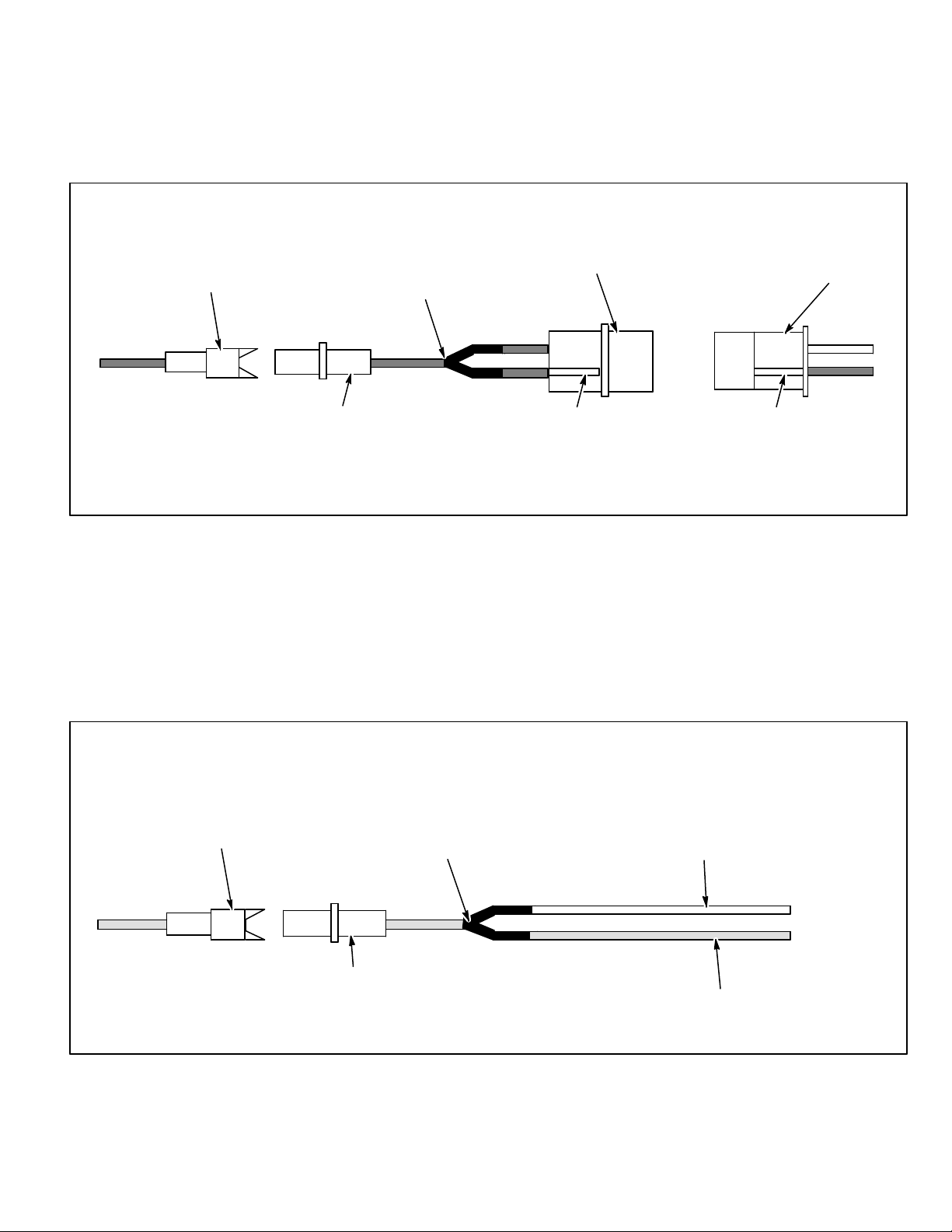

The following are alternator replacement combinations which require an adapter harness. All

of the necessary components are shown.

1. Original engine equipped with AC Only alternator.

Replacement engine equipped with Dual Circuit alternator.

Modify 393362 harness supplied with replacement engine by removing red DC wire. Then, splice

393537 connector into white AC wire and connect to equipment harness.

EQUIPMENT

HARNESS

DUAL CIRCUIT CONNECTOR

(FROM ENGINE)

AC

BLACK

DC

RED

RIB

393362

HARNESS

RIB

AC WIRE

(WHITE)

SPLICE

393537

CONNECTOR

(GREEN)

2. Original engine equipped with DC Only alternator.

Replacement engine equipped with Dual Circuit alternator.

Modify 393362 harness supplied with replacement engine by removing white AC wire. Then, splice

393537 connector into red DC wire and connect to equipment harness.

DUAL CIRCUIT CONNECTOR

(FROM ENGINE)

AC

BLACK

DC

RED

RIB

393362

HARNESS

4

RIB

DC WIRE

(RED)

SPLICE

393537

CONNECTOR

(GREEN)

EQUIPMENT

HARNESS

Page 5

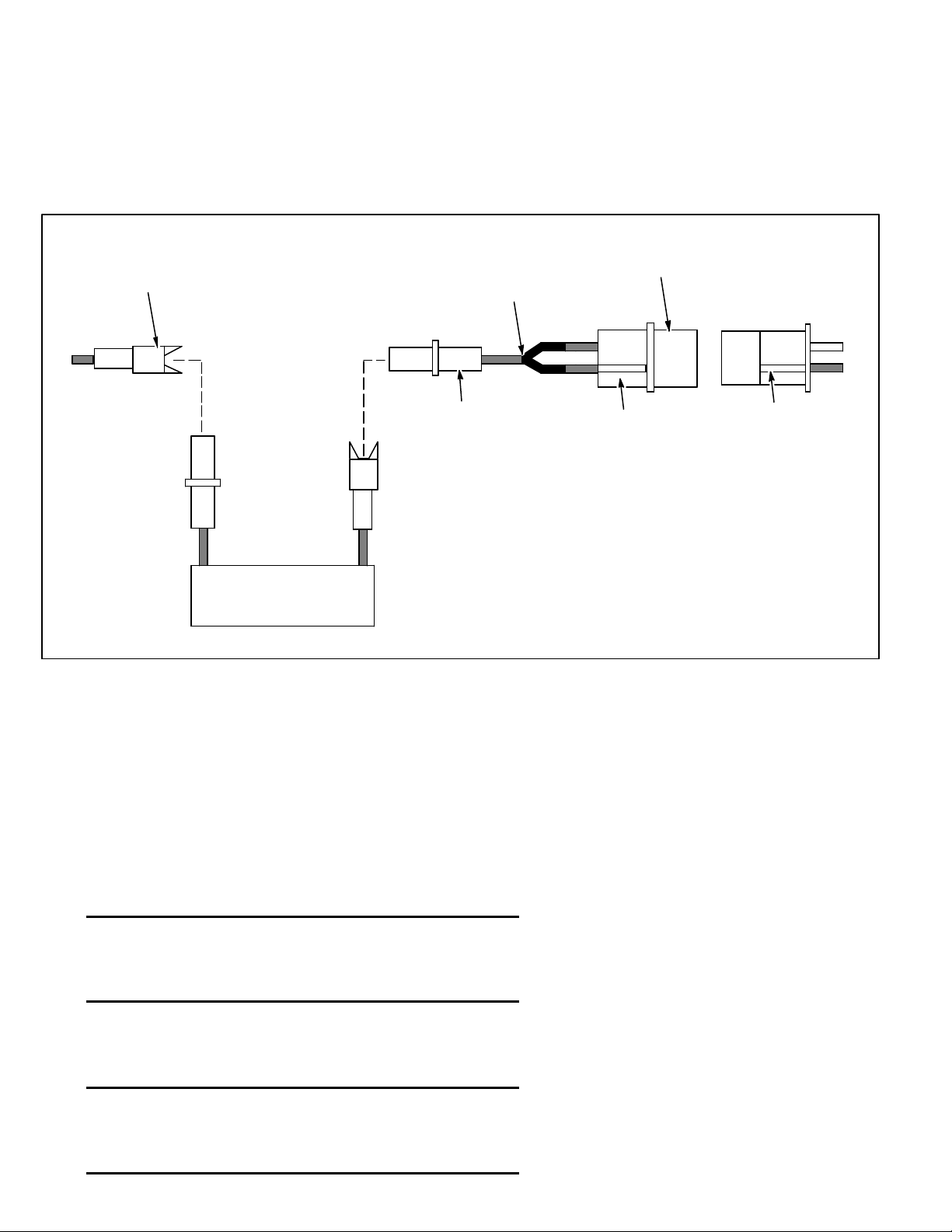

3. Original engine equipped with Dual Circuit alternator.

Replacement engine equipped with 5, 9, 10 or 16 amp regulated system.

Modify 393422 harness supplied with replacement engine by splicing in 399916 connector assembly. Connect to equipment harness.

399916 CONNECTOR

OUTPUT CONNECTOR

FROM REGULATOR

ASSEMBLY

SPLICE

EQUIPMENT

HARNESS

393422

HARNESS

RIB

RIB

4. Original engine equipped with Tri-Circuit alternator.

Replacement engine equipped with 5, 9, 10 or 16 amp regulated system.

Modify 393422 harness supplied with replacement engine by splicing into charging circuit wire and

lighting circuit wire in equipment harness. NOTE: THE DIODES MUST BE REMOVED FROM THE

EQUIPMENT HARNESS.

Diodes Must Be Removed From Equipment Harness

OUTPUT CONNECTOR

FROM REGULATOR

SPLICE

LIGHTING CIRCUIT WIRE

393422

HARNESS

EQUIPMENT

HARNESS

CHARGING CIRCUIT WIRE

5

Page 6

5. Original engine equipped with Dual Circuit alternator.

Replacement engine equipped Tri-Circuit alternator.

Discard 392606 diode harness supplied with new engine. Install 491546 regulator/rectifier. Add

393422 harness and modify by splicing in 399916 connector assembly. Connect to equipment harness.

399916 CONNECTOR

OUTPUT CONNECTOR

FROM ALTERNATOR

SPLICE

ASSEMBLY

RIB

EQUIPMENT

HARNESS

491546

REGULATOR/RECTIFIER

393422

HARNESS

RIB

6. Original engine equipped with 5 amp regulated system.

Replacement engine equipped with Tri-Circuit alternator.

Discard 392606 diode harness supplied with new engine. Transfer 491546 regulator/rectifier

from original engine. Connect to equipment harness.

The following alternator replacement combinations require no modifications.

7. Original engine equipped with DC Only alternator.

Replacement engine equipped with 5, 9, 10 or 16 amp regulated system.

Direct Replacement. Connect to equipment harness.

8. Original engine equipped with 5 amp regulated system.

Replacement engine equipped with 9, 10 or 16 amp regulated system.

Direct Replacement. Connect to equipment harness.

9. Original engine equipped with 9 amp regulated system.

Replacement engine equipped with 10 or 16 amp regulated system.

Direct Replacement. Connect to equipment harness.

10. Original engine equipped with 10 amp regulated system.

Replacement engine equipped with 9 or 16 amp regulated system.

Direct Replacement. Connect to equipment harness.

6

Page 7

Briggs & Stratton Engine Replacing Engine Of Another Manufacturer

When replacing the engine of another manufacturer with a Briggs & Stratton engine, the equipment

requirements must be known so that the replacement alternator system has the same output as the original system provided.

Often the equipment wiring harness is not compatible with the Briggs & Stratton alternator output harness. To create a compatible system it may be necessary to modify the the equipment wiring harness.

To do this a wiring diagram for the equipment is essential.

The original keyswitch may also create a problem. Even though the keyswitch harness connectors

appear to be identical, there are internal differences to keyswitches. Therefore it is necessary to have

a diagram of the keyswitch showing the terminal positions and their functions. For example, see the

5 terminal switch diagrams in Figure 1 and Figure 2. The keyswitch in Figure 1 is compatible with all

Briggs & Stratton alternators. Note in Figure 2, that when the “brand X” keyswitch is in the START

position there is no battery voltage available to the #2 switch terminal. Consequently, if the replacement Briggs & Stratton engine was equipped with a carburetor solenoid, it would not function. This

is why it is important to have a diagram of the keyswitch when replacing engines, or replace the

keyswitch with one that is compatible with all Briggs & Stratton alternator systems.

NOTE: The 5 terminal Briggs & Stratton keyswitch, part no. 490066, shown in Fig. 1 has been replaced

by a 6 terminal keyswitch, part no. 493625. The additional terminal provides a direct connection for the

charging lead at the keyswitch.

B & S Switch Terminal Positions

Terminal

No. Function

1 Ground (Used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

5 To Battery (battery terminal on solenoid)

M

L

2

3

S

5

1

G

B

OFF RUN

L

2

1

G

L

M

32

5

1

G

B

M

3

S

4

5

B

Brand X Switch Terminal Positions

Terminal

No Function

1 Accessory

2 To Stop Switch Terminal On Engine (Ground)

3 To Regulator (Charging)

4 To Solenoid (tab terminal)

5 To Battery (battery terminal on solenoid)

M

R

2

3

S

S

44

1

A

OFF

4 4

5

B

M

R

2

3

S

4

5

1

B

A

M

1

A

R

32

S

5

B

RUN

START

Fig. 1

START

Fig. 2

It is not possible to show all of the wiring diagrams or keyswitch combinations that are used by

equipment manufacturers. However, the following wiring diagrams for the most popular Briggs &

Stratton engines may be used as a guide when replacing an engine. The wiring diagrams show the type

of keyswitch that is compatible with the alternator system shown.

7

Page 8

Typical Dual Circuit Alternator

Wiring Diagram

5 Pole Switch -- Briggs & Stratton Part No. 490066

HEADLIGHTS

ALTERNATOR

AC OUTPUT

WIRE

HEADLIGHT

SWITCH

DIODE

+

AMMETER

--

ANTI-AFTERFIRE

SOLENOID

DC OUTPUT

WIRE

BATTERY

TERMINAL

KEY SWITCH

32

1

SOLENOID

5

4

STOP

SWITCH

TERMINAL

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

-

Key Switch Test

1. OFF *1 + 3

2. RUN 2 + 5

3. START 2 + 4 + 5

* Terminal 1 Grounded Internally

To Key Switch Case

+

STARTER MOTOR

12 VOLT BATTERY

Terminal No. FunctionSwitch Position Continuity

1 Ground (Used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

5 To Battery (battery terminal on solenoid)

8

Page 9

Typical Dual Circuit Alternator

Wiring Diagram

6 Pole Switch -- Briggs & Stratton Part No. 493625

HEADLIGHTS

ALTERNATOR

AC OUTPUT

WIRE

HEADLIGHT

SWITCH

DIODE

ANTI-AFTERFIRE

SOLENOID

DC OUTPUT

WIRE

Ammeter

+ --

BATTERY

TERMINAL

KEY SWITCH

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

+

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always be connected to the alternator side.

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

*Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

9

STARTER MOTOR

Page 10

Typical 16 amp Regulated Alternator

Wiring Diagram

5 Pole Switch -- Briggs & Stratton Part No. 490066

HEADLIGHTS

AC OUTPUT

WIRE

ALTERNATOR

REGULATOR

RECTIFIER

HEADLIGHT

SWITCH

DC OUTPUT

WIRE

+

AMMETER

--

ANTI-AFTERFIRE

SOLENOID

BATTERY

TERMINAL

KEY SWITCH

32

1

SOLENOID

5

4

STOP

SWITCH

TERMINAL

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

-

Key Switch Test

Switch Position Continuity

1. OFF *1 + 3

2. RUN 2 + 5

3. START 2 + 4 + 5

* Terminal 1 Grounded Internally

To Key Switch Case

+

STARTER MOTOR

12 VOLT BATTERY

Terminal No. Function

1 Ground (Used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

5 To Battery (battery terminal on solenoid)

10

Page 11

Typical 16 amp Regulated Alternator

Wiring Diagram

6 Pole Switch -- Briggs & Stratton Part No. 493625

HEADLIGHTS

AC OUTPUT

WIRE

ALTERNATOR

REGULATOR

RECTIFIER

HEADLIGHT

SWITCH

DC OUTPUT

WIRE

ANTI-AFTERFIRE

SOLENOID

AMMETER

+ --

BATTERY

TERMINAL

KEY SWITCH

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

+

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always beconnected to the alternator side.

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

* Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

11

STARTER MOTOR

Page 12

Typical 16 amp Regulated Alternator Wiring Diagram

With Charge Indicator Light

6 Pole Switch -- Briggs & Stratton Part No. 493625

HEADLIGHTS

AC OUTPUT

WIRE

ALTERNATOR

REGULATOR

RECTIFIER

HEADLIGHT

SWITCH

CHARGE

INDICATOR

LIGHT

BLUE WIRE

RED WIRE

DC OUTPUT

RAISED RIB

BATTERY

TERMINAL

ANTI-AFTERFIRE

SOLENOID

AMMETER

+ --

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always be connected to the alternator side.

+

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

* Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

12

Starter Motor

Page 13

Typical 5/9 amp Regulated Alternator

Wiring Diagram

6 Pole Switch -- Briggs & Stratton Part No. 493625

TRI-- CIRCUIT

STATOR

AC OUTPUT

HEADLIGHTS

WIRE

Alternator

REGULATOR

RECTIFIER

HEADLIGHT

SWITCH

DC OUTPUT

WIRE

ANTI-AFTERFIRE

SOLENOID

AMMETER

+ --

BATTERY

TERMINAL

KEY SWITCH

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

+

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always be connected to the alternator side.

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

* Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

13

STARTER MOTOR

Page 14

Typical 5/9 amp Regulated Alternator

Wiring Diagram

6 Pole Switch -- Briggs & Stratton Part No. 493625

TRI-- CIRCUIT

STATOR

AC OUTPUT

HEADLIGHTS

WIRE

Alternator

REGULATOR

RECTIFIER

HEADLIGHT

SWITCH

DC OUTPUT

WIRE

ANTI-AFTERFIRE

SOLENOID

AMMETER

+ --

BATTERY

TERMINAL

KEY SWITCH

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

+

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always be connected to the alternator side.

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

* Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

13

STARTER MOTOR

Page 15

Typical Tri-Circuit Alternator

Wiring Diagram

6 Pole Switch -- Briggs & Stratton Part No. 493625

TRI-- CIRCUIT

STATOR

HEADLIGHTS

HEADLIGHT

SWITCH

ALTERNATOR

-- DC OUTPUT

WIRE

AC OUTPUT

WIRE

+DC OUTPUT

WIRE

CLUTCH

SWITCH

AMMETER

+ --

ANTI-AFTERFIRE

SOLENOID

BATTERY

TERMINAL

KEY SWITCH

1

6

Ammeter

(optional)

+--

SOLENOID

STOP

SWITCH

TERMINAL

32

4

5

SOLENOID TAB

TERMINAL

STARTER

TERMINAL

ELECTRIC

CLUTCH

+

Key Switch Test

-

12 VOLT BATTERY

With ammeter shown in optional position, note that -- and + symbols are

reversed. The + symbol must always be connected to the alternator side.

Switch Position Continuity Terminal No. Function

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

1 To Ground (used only with insulated panel)

2 To Carburetor Solenoid.

3 To Stop Switch Terminal On Engine

4 To Solenoid (tab terminal)

* Terminal 1 Grounded Internally

To Key Switch Case

5 To Battery (battery terminal on solenoid)

6 To Alternator (DC Output)

14

STARTER MOTOR

Page 16

* Terminal 1 Grounded Internally To Key Switch Case

1. OFF *1 + 3

2. RUN 2 + 5

3. START 2 + 4 + 5

system to 6 pole switch.

Switch Position Continuity

HEADLIGHTS

HEADLIGHT

SWITCH

Note: If clutch switch is in ON position with

keyswitch OFF, battery will discharge thru clutch.

To prevent this, route wire B to #2 terminal on key-

switch. However, anti-afterfire solenoid will not shut

off. Remove anti-afterfire solenoid or convert

ALTERNATOR

-- DC OUTPUT

WIRE

AMMETER

+

--

+ DC OUTPUT

CLUTCH SWITCH

B

OFF

RESISTOR

A

ON

ELECTRIC CLUTCH

WIRE

AC OUTPUT

WIRE

5 Pole Switch -- Briggs & Stratton Part No. 490066

TRI--CIRCUIT

STATOR

Wiring Diagram -- With Resistor

Typical Tri-Circuit Alternator

See Note

ANTI-AFTERFIRE

SOLENOID

+

TERMINAL

12 VOLT BATTERY

SOLENOID

TERMINAL

STARTER

--

STARTER MOTOR

BATTERY

1

KEY SWITCH

32

5

4

SOLENOID TAB

TERMINAL

TERMINAL

SWITCH

STOP

15

Page 17

HEADLIGHTS

Switch Position Continuity

1. OFF *1 + 3 + 6

2. RUN 2 + 5 + 6

3. START 2 + 4 + 5

* Terminal 1 Grounded Internally

To Key Switch Case

Key Switch Test

AMMETER

+

--

CLUTCH DPDT SWITCH

ON

ELECTRIC

CLUTCH

OFF

RESISTOR

HEADLIGHT

SWITCH

ALTERNATOR

-- DC OUTPUT

WIRE

AC OUTPUT

6 Pole Switch -- Briggs & StrattonPart No.493625

+DC OUTPUT

WIRE

WIRE

TRI--CIRCUIT

STATOR

Wiring Diagram -- With Resistor

Typical Tri-Circuit Alternator

TERMINAL

BATTERY

ANTI-AFTERFIRE

SOLENOID

+

12 VOLT BATTERY

SOLENOID

6

--

TERMINAL

STARTER

MOTOR

SOLENOID TAB

STARTER

TERMINAL

1

5

32

KEY SWITCH

4

TERMINAL

SWITCH

STOP

16

Page 18

MS-0415-2/98 ã Copyright 1998 by Briggs & Stratton Corporation Printed in U.S.A.

www.briggsandstratton.com

MS-0415-2/98 ã Copyright 1998 by Briggs & Stratton Corporation Printed in U.S.A.

www.briggsandstratton.com

Loading...

Loading...