Briggs & Stratton Twin Cylinder L-Head Repair Manual

For Briggs & Stratton Discount Parts Call 606-678-9623 or 606-561-4983

www.mymowerparts.com

GENERAL INFORMATION Section 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

IGNITION Section 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CARBURETION Section 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

GOVERNOR CONTROLS & GOVERNOR Section 4. . . . . . . . . . . . . . . . . . . . . . . .

COMPRESSION Section 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STARTERS Section 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ALTERNATORS Section 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

LUBRICATION Section 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE DISASSEMBLY Section 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CYLINDERS & BEARINGS Section 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

CRANKSHAFTS & CAMSHAFTS Section 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

PISTONS – RINGS – RODS Section 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ENGINE ASSEMBLY Section 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TABLE OF CONTENTS

(For Section Reference, See Pages VI through VIII.)

MUFFLERS Section 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I

Sleeve Bore Models: 400400, 400700, 402400, 402700, 404400, 404700, 422400, 422700, 462700

Aluminum Bore Models: 401400, 401700, 421400, 421700

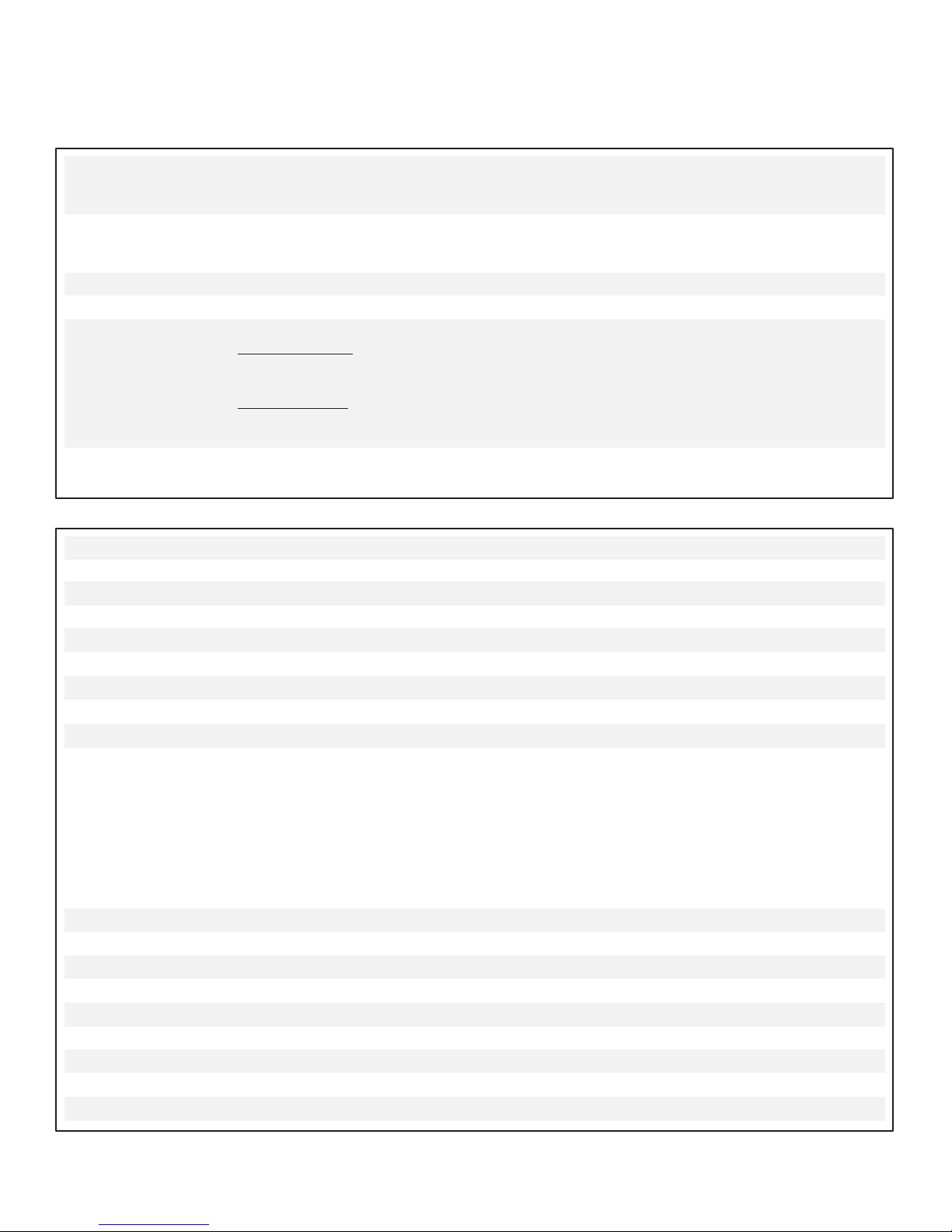

Torque Specifications – All Model Series

Common Specifications – All Model Series

Alternator (to cylinder) 20 in. lbs. (2.0 Nm)

Air Cleaner Base (to carb.) 25 in. lbs. (3.0 Nm)

Armature 25 in. lbs. (3.0 Nm)

Back Plate 150 in. lbs. (17.0 Nm)

Blower Housing 90 in. lbs. (10.0 Nm)

Breather 25 in. lbs. (3.0 Nm)

Carburetor (to manifold) 100 in. lbs. (11.0 Nm)

Carburetor Plug/Solenoid 100 in. lbs. (11.0 Nm)

Connecting Rod 190 in. lbs. (22.0 Nm)

Crankcase Cover/Sump

Horizontal Crankshaft

Crankcase Cover 225 in. lbs. (25.0 Nm)

Base 27 ft. lbs. (37.0 Nm)

Vertical Crankshaft

Steel Cover Plate 250 in. lbs. (28.0 Nm)

Aluminum Cover Plate 27 ft. lbs. (37.0 Nm)

Sump 225 in. lbs. (25.0 Nm)

Cylinder Head 160 in. lbs. (18.0 Nm)

Fan Retainer 150 in. lbs. (17.0 Nm)

Flywheel 150 ft. lbs. (203.0 Nm)

Governor Control Bracket 35 in. lbs. (4.0 Nm)

Governor Lever Nut 100 in. lbs. (11.0 Nm)

Intake Manifold 90 in. lbs. (10.0 Nm)

Spark Plug 200 in. lbs. (22.0 Nm)

Starter Motor 160 in. lbs. (18.0 Nm)

Starter Motor Thru Bolts 50 in. lbs. (6.0 Nm)

Armature Air Gap

Magnetron Ignition .008” – .012” (0.20 – 0.30 mm)

Breaker Point Ignition .010” – .014” (0.25 – 0.35 mm)

Crankshaft End Play

Vertical Shaft Engines .002” – .026” (0.05 – 0.66 mm)

Horizontal Shaft Engines .004” – .012” (0.10 – 0.30 mm)

**Governed Idle Speed (all models) 1200 – 1400 RPM

Spark Plug Gap .030” (0.76 mm)

Valve Clearance (Cold)

Springs Installed

Intake .004” – .006” (0.10 – 0.15 mm)

Exhaust .007” – .009” (0.17 – 0.22 mm)

Without Springs

Intake .006” – .008” (0.15 – 0.20 mm)

Exhaust .009” – .011” (0.22 – 0.28 mm)

** Top Governed Speed: See Briggs & Stratton Service Engine Sales Manual Microfiche MS-6255 or

Sales Manual MS-4052

COMMON SPECIFICATIONS FOR OPPOSED TWIN CYLINDER ENGINES

II

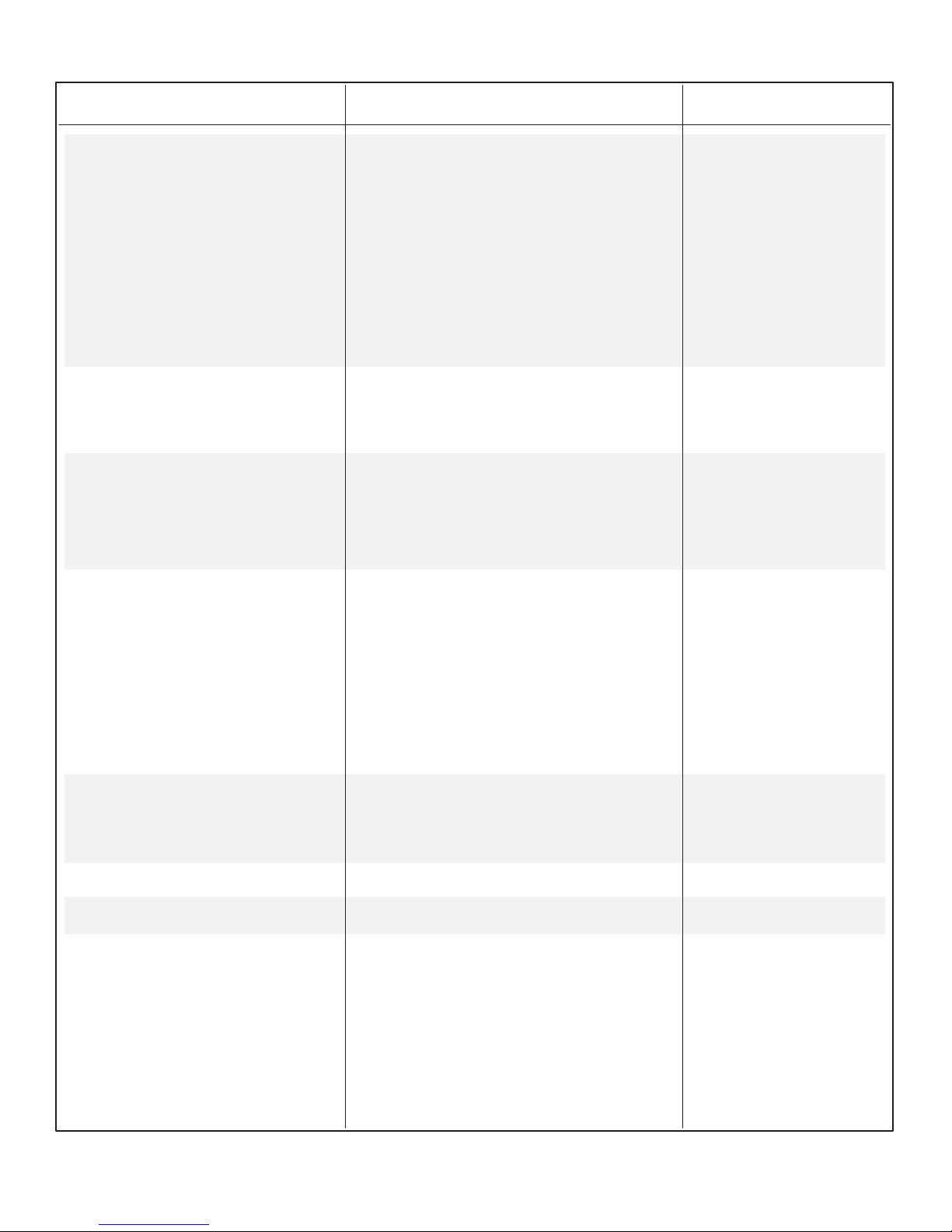

STANDARD AND REJECT DIMENSIONS – ALL MODEL SERIES

DESCRIPTION STANDARD DIMENSION REJECT DIMENSION

Cylinder

Bore (All) 3.4365” – 3.4375” (87.28 – 87.31 mm) 3.4405” (87.38 mm)

Out of round: Aluminum Bore .0025” (.06 mm)

Sleeve Bore .0015” (.04 mm)

Main Bearing (Magneto) 1.379” – 1.380” (35.02 – 35.05 mm) 1.383” (35.12 mm)

Cam Bearing (Magneto) .6252” – .6257” (15.88 – 15.89 mm) .6275” (15.93 mm)

Valve Guide .3145” – .3165” (7.98 – 8.04 mm) .330” (8.38 mm)

Valve Stem .310” (7.87 mm) .308” (7.82 mm)

Crankcase Cover

Main Bearing (PTO) 1.379” – 1.380” (35.02 – 35.05 mm) 1.383” (35.12 mm)

Cam Bearing (PTO) .6252” – .6257” (15.88 – 15.89 mm) .6275” (15.93 mm)

Crankshaft

Crankpin 1.6235” – 1.6243” (41.23 – 41.25 mm) 1.622” (41.20 mm)

Magneto Journal 1.3776” – 1.3784” (34.99 – 35.01 mm) 1.376” (34.95 mm)

PTO Journal 1.3776” – 1.3784” (34.99 – 35.01 mm) 1.376” (34.95 mm)

Camshaft

Journals .624” – .625” (15.85 – 15.87 mm) .623” (15.82 mm)

Lobes

Intake 14, 16, 18, 20 HP 1.1525” – 1.1555” (29.27 – 29.35 mm) 1.150” (29.20 mm)

Intake 12.5 HP 1.0575” – 1.0605” (26.86 – 26.93 mm) 1.055” (26.80 mm)

Exhaust 12.5, 14, 16, 18 HP 1.1225” – 1.1255” (28.50 – 28.58 mm) 1.120” (28.45 mm)

Exhaust 20 HP 1.1525” – 1.1555” (29.27 – 29.35 mm) 1.150” (29.20 mm)

Connecting Rod

Crankpin Bearing 1.625” – 1.6255” (41.27 – 41.28 mm) 1.627” (41.32 mm)

Piston Pin Bearing .8007” – .8011” (20.34 – 20.35 mm) .802” (20.37 mm)

Piston Pin .8003” – .8005” (20.32 – 20.33 mm) .799” (20.30 mm)

Piston Pin Bearing (Piston) .8005” – .801” (20.33 – 20.35 mm) .802” (20.37 mm)

Piston Rings

Ring End Gap

Aluminum Bore – Top & Center .007” – .017” (.18 – .43 mm) .035” (.90 mm)

Oil .007” – .017” (.18 – .43 mm) .045” (1.14 mm)

Cast Iron Bore – Top & Center .007” – .017” (.18 – .43 mm) .030” (.76 mm)

Oil .007” – .017” (.18 – .43 mm) .035” (.90 mm)

Ring Side Clearance (All) .0035” – .006” (.09 – .15 mm) .009” (.23 mm)

III

IV

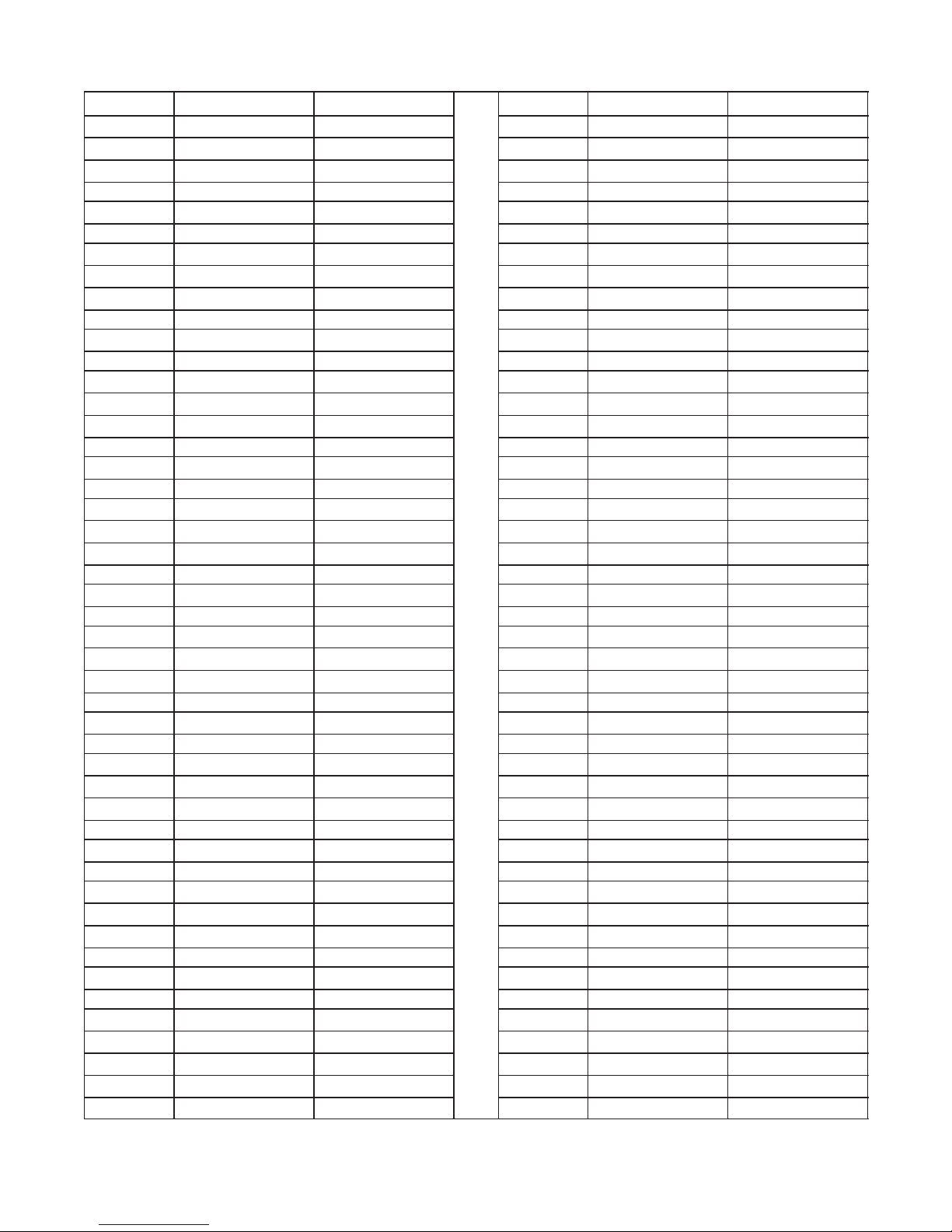

English to Metric Conversion Table

Fraction Decimal mm Fraction Decimal mm

1/64 0.0156 0.3969

33/64 0.5156 13.0969

1/32 0.0312 0.7938 17/32 0.5312 13.4938

3/64 0.0469 1.1906 35/64 05469 13.8906

1/16 0.0625 1.5875 9/16 0.5625 14.2875

5/64 0.0781 1.9844 37/64 0.5781 14.6844

3/32 0.0938 2.3812 19/32 0.5938 15.0812

7/64 0.1094 2.7781 39/64 0.6094 15.4781

1/8 0.1250 3.1750 5/8 0.6250 15.8750

9/64 0.1406 3.5719 41/64 0.6406 16.2719

5/32 0.1562 3.9688 21/32 0.6562 16.6688

11/64 0.1719 4.3656 43/64 0.6719 17.0656

3/16 0.1875 4.7625 11/16 0.6875 17.4625

13/64 0.2031 5.1594 45/64 0.7031 17.8594

7/32 0.2188 5.5562 23/32 0.7188 18.2562

15/64 0.2344 5.9531 47/64 0.7344 18.6531

1/4 0.2500 6.3500 3/4 0.7500 19.0500

17/64 0.2656 6.7469 49/64 0.7656 19.4469

9/32 0.2812 7.1438 25/32 0.7812 19.8438

19/64 0.2969 7.5406 51/64 0.7969 20.2406

5/16 0.3125 7.9375 13/16 0.8125 20.6375

21/64 0.3281 8.3344 53/64 0.8281 21.0344

11/32 0.3438 8.7312 27/32 0.8438 21.4312

23/64 0.3594 9.1281 55/64 0.8594 21.8281

3/8 0.3750 9.5250 7/8 0.8750 22.2250

25/64 0.3906 9.9219 57/64 0.8906 22.6219

13/32 0.4062 10.3188 29/32 0.9062 23.0188

27/64 0.4219 10.7156 59/64 0.9219 23.4156

7/16 0.4375 11.1125 15/16 0.9375 23.8125

29/64 0.4531 11.5094 61/64 0.9531 24.2094

15/32 0.4688 11.9062 31/32 0.9688 24.6062

31/64 0.4844 12.3031 63/64 0.9844 25.0031

1/2 0.5000 12.7000 1 1.0000 25.4000

V

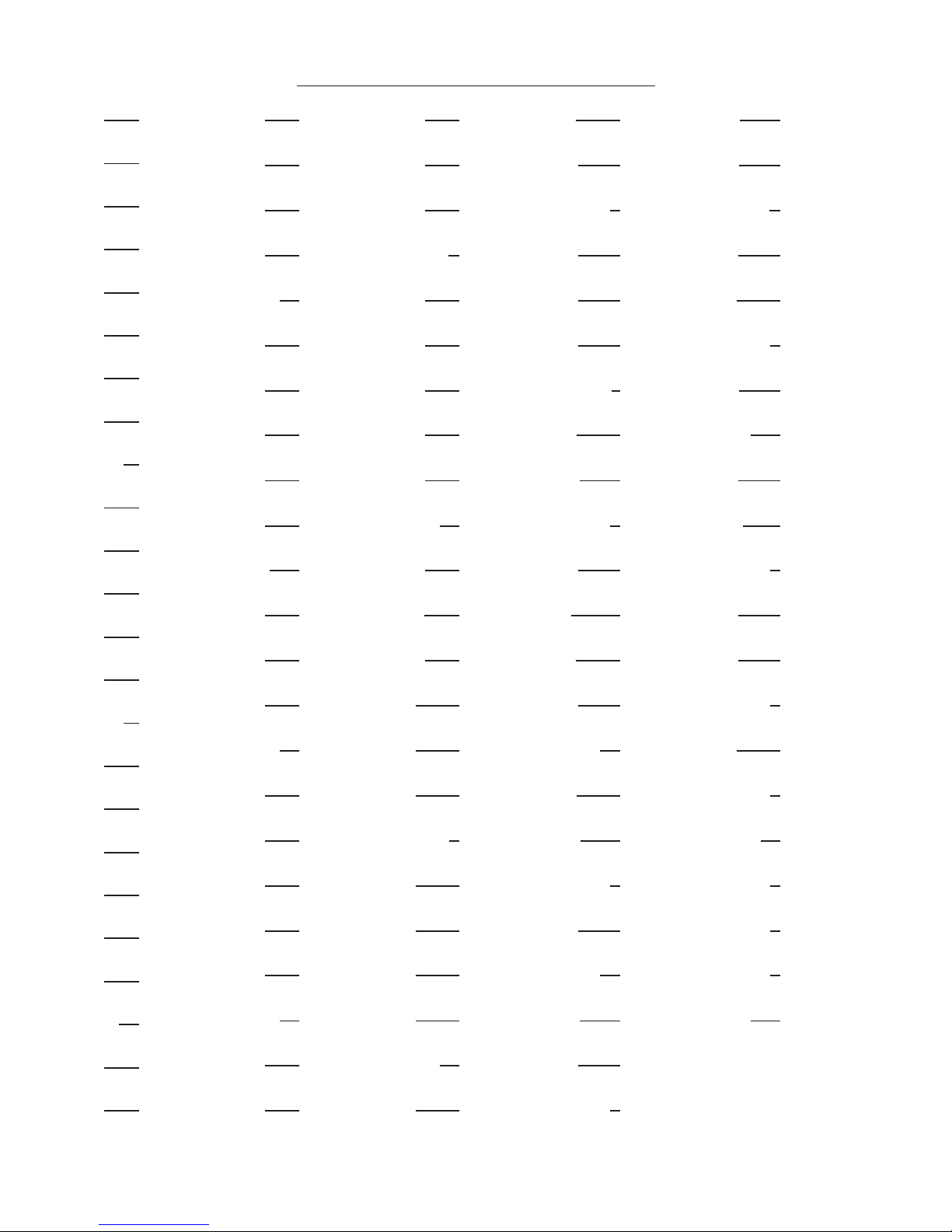

Drill Size – Decimal Equivalent In Inches

60 .040

59 .041

58 .042

57 .043

56 .0465

55 .052

54 .055

53 .0595

1/16 .0625

52 .0635

51 .067

50 .070

49 .073

48 .076

5/64 .0781

47 .0785

46 .081

45 .082

44 .086

43 .089

42 .0935

3/32 .0938

41 .096

40 .098

39 .0995

38 .1015

37 .104

36 .1065

7/64 .1094

35 .110

34 .111

33 .113

32 .116

31 .120

1/8 .125

30 .1285

29 .136

28 .1405

9/64 .1406

27 .144

26 .147

25 .1495

24 .152

23 .154

5/32 .1562

22 .157

21 .159

20 .161

19 .166

18 .1695

11/64 .1719

17 .173

16 .177

15 .180

14 .182

13 .185

3/16 .1875

12 .189

11 .191

10 .1935

9 .196

8 .199

7 .201

13/64 .2031

6 .204

5 .2055

4 .209

3 .213

7/32 .2188

2 .221

1 .228

A .234

15/64 .2344

B .238

C .242

D .246

E, 1/4 .250

F .257

G .261

17/64 .2656

H .266

I .272

J .277

K .281

9/32 .2812

L .290

M .295

19/64 .2969

N .302

5/16 .3125

O .316

P .323

21/64 .3281

Q .332

R .339

11/32 .3438

S .348

T .358

23/64 .3594

U .368

3/8 .375

V .377

W .386

25/64 .3906

X .397

Y .404

13/32 .4062

Z .413

27/64 .4219

7/16 .4375

29/64 .4531

15/32 .4688

31/64 .4844

1/2 .500

SECTION REFERENCE

(By Subject)

SECTION

VI

Air Cleaner 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance

Air Guides 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation

Alternators 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Identification

Test Equipment

Testing Output

Troubleshooting

Anti-Afterfire 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Gap

Installation/Removal

Testing

(Also See Check Ignition) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Battery 6B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cables

Charging

Checking

Recommendation

(Also See Checking Battery) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearings 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking

Installation/Removal

Repairing

Breaker Points 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment

Installation

Plunger Installation/Removal

Breather 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking

Installation/Removal

Camshaft

Checking 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Carburetor 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment

Anti-Afterfire Systems

Assembly/Disassembly

Basic Styles

Inspection

Intake Elbow

Manifolds

Removal

Replace Float Needle Seat

Replace Throttle Shaft Bushing

Testing Solenoid

Carburetor Controls 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Charging System (See Alternators) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Coils (See Armature) 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Compression Testing 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION REFERENCE (Continued)

SECTION

VII

Connecting Rod

Checking 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Contact Points (See Breaker Points) 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Controls, Governor, Choke 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustments

Crankcase Cover

Checking 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Crankshaft

Checking 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

End Play 11, 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Head 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bearings

Resizing Bore

Cylinder Balance Test 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Leakdown Test 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Dipper 8, 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Assembly 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Disassembly 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Identification System 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engine Specifications Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust System (See Mufflers) 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Flywheel 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation/Removal

(Also See Flywheel Identification) 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Recommendations 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Pump 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

General Information 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Governor 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment

Bushings

Governed Idle

(Also See Governed Idle Adjustment)3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Ignition 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications

(Also See Check Ignition) 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance Schedule 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Muffler 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspection

Installation/Removal

Mounting Bracket

Oil Cooler 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Drain 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Fill 1, 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Filter 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Gard 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pressure Switch 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Pump 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Recommendations 1, 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Seal 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SECTION REFERENCE (Continued)

SECTION

VIII

Oil Slinger 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Trough 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston

Assembly 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Removal 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piston Rings 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assembly/Removal

Checking

Pressure Lube 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Regulator/Rectifier 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remote Controls 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjustment

Governed Idle

Wire Travel

Spark Plug 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Speed Control Adjustment 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Splash Lube 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starters, Electric 6B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Assemble/Disassemble Starter

Assemble/Disassemble Starter Drive

Identification

Replace Brushes

Test Equipment

Testing

Troubleshooting

Starter, Rewind 6A. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Rope Installation/Removal

Spring Installation/Removal

Stop Switches 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing

Torque Specifications Preface. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Valves 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Guides – Installation/Removal

Refacing

Seals

Seats

Tappet Clearances

Valves – Installation/Removal

1

9904 1

Section 1

GENERAL INFORMATION

Section Contents

Page

MAINTENANCE 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel And Oil Recommendations 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gasoline 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lubrication 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Recommendations 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil – Splash Lube Engines 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil – Pressure Lube Engines 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Change Oil Filter 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Cooling System 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Replace Spark Plugs 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Cleaner Maintenance 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Dual Element Air Cleaner 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Service Pre-Cleaner 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Service Cartridge 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Combustion Chamber Deposits 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TROUBLESHOOTING 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Systematic Check 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (With Electric Starter) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Ignition (Engine Running) 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Checking For Fouled Spark Plug 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Carburetion 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Compression 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Leakdown Test 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Balance Test 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment Affecting Engine Operation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1

2

In the Interest of Safety

This safety alert symbol indicates that this

message involves personal safety. Words

danger, w ar ning a nd c aution i ndicate d egree

of hazard. Death, personal injury and/or

property damage may occur unless

instructions are followed carefully.

You are not ready to operate this engine if

you have not read and understood the

following safety items. Read this entire

owner’s manual and the operating

instructions of the equipment this engine

powers.

The Briggs & Stratton engine is made of the finest material in a state-of-the-art manufacturing facility. Please understand that Briggs

& Stratton sells engines to original equipment manufacturers. It also sells to others in the distribution chain who may sell to the

ultimate consumer, an equipment manufacturer, another distributor or a dealer. As a result, Briggs & Stratton does not necessarily

know the application on which the engine will be placed. For that reason, carefully read and understand the operating instructions of

the equipment before you repair or operate it.

You should also understand that there are equipment applications for which Briggs & Stratton does not approve the use of its engines. Briggs & Stratton engines are not to be used on vehicles with less than 4 wheels. They include motor bikes, aircraft products

and All Terrain Vehicles. Moreover, Briggs & Stratton does not approve of its engines being used in competitive events. F0R THAT

REASON, BRIGGS & STRATT ON ENGINES ARE NOT AUTHORIZED FOR ANY OF THESE APPLICATIONS. Failure to follow

this warning could result in death, serious injury (including paralysis) or property damage.

DO NOT run engine in an enclosed area.

(Exhaust gases contain carbon monoxide,

an odorless and deadly poison.)

DO NOT r emove f uel t ank c ap nor f ill f uel t ank

while engine is hot o r running. DO NOT refuel

indoors or in an unventilated area. (Allow

engine to cool 2 minutes before refueling.)

DO NOT place hands or feet near moving or rotating

parts.

DO NOT store, spill, or use gasoline near an open

flame, nor near an appliance like a stove, furnace, or

water heater that uses a pilot light or can create a

spark.

DO NOT refuel indoors or in an unventilated area.

DO NOT operate or tip engine/equipment at such a

severe angle that causes gasoline spillage.

DO NOT operate engine if gasoline is spilled or when

smell of gasoline is present or other explosive conditions exist. (Move equipment away from spill and avoid

any ignition until gasoline has evaporated.)

DO NOT transport engine with fuel in tank or fuel

shut-off valve open.

DO NOT choke carburetor to stop engine, especially in

an enclosed vehicle. (Whenever possible, gradually

reduce engine speed before stopping.)

DO NOT tamper with governor springs, links or other

parts to increase engine speed. (Run engine at speed

set for equipment manufacturer.)

DO NOT check for spark with spark plug removed.

(Use an approved tester.)

DO NOT run engine without blower housing or other

safety shields removed when doing repairs.

DO NOT crank engine with spark plug removed. (If

engine is flooded, place throttle in FAST and crank until

engine starts.)

DO NOT strike f lywheel w ith a h ammer o r h ard object as

this may cause flywheel to shatter in operation. (To

remove flywheel, use Briggs & Stratton approved tools

and procedures only.)

DO NOT operate e ngine without a m uffler . (Inspect p eriodically and replace if worn or leaking. If engine is

equipped with muf fler deflector , i nspect periodically a nd

replace if necessary. Replacement parts must b e s ame

as on original equipment.)

DO NOT operate engine with an accumulation of

grass, leaves or other combustible material in muffler

area.

DO NOT use this engine on any forest covered, brush

covered, or grass covered unimproved land unless a

spark arrester is installed on muffler. The spark arrester must be maintained in working order by the owner

and/or operator. In the State of California the above is

required by law (Section 4442 of the California Public

Resources Code). Other states may have similar laws.

Federal laws apply on federal lands.

DO NOT touch hot muffler, cylinder, or fins which can

cause burns.

DO NOT s tart e ngine w ith a ir c leaner o r a ir c leaner c over

removed (or c over o ver carburetor air i ntake, i f S no/Gard

engine).

DO NOT a ttempt t o s tart e ngine w ith c utting b lade l oose

or removed. (Blade must b e t ight, o therwise a k ickback

may occur.)

4 Prior to work, read and understand the section(s) of this manual that pertain to the job. Follow all safety warnings.

4 PULL starter cord slowly

until resistance is felt. Then pull cord rapidly to avoid kickback and prevent hand or arm injury.

4 WEAR suitable eye protection (safety glasses, goggles or face shield when performing repair procedures).

4 PREVENT ACCIDENTA L S TARTING by removing spark

plug wire from spark plug when servicing engine or equipment. Disconnect negative wire from battery terminal if

equipped with electric starting system.

4 REMOVE blower housing periodically and clean engine.

Keep cylinder fins and governor parts free of dirt, grass

and other debris which can affect engine speed.

4 USE fresh gasoline. Stale fuel can gum carburetor and

cause leakage.

4 CHECK fuel lines and fittings frequently for cracks or

leaks. Replace if necessary.

4 USE ONLY Genuine Briggs & Stratton Parts or their

equivalent. The use of replacement parts which are not of

equivalent quality may damage the engine.

WARNING:

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects, or other reproductive harm.

1

3

BRIGGS & STRATTON NUMERICAL IDENTIFICATION SYSTEM

All Briggs & Stratton engines have a unique numerical identification system. Each engine is identified by a Model, Type

and Code number. Example: Model Type Code

422777 1125 01 99052115

This chart explains the numerical model designation system. It is possible to determine most of the important

mechanical features of the engine by merely knowing the model number. Here is how it works.

FIRST DIGIT

AFTER DISPLACEMENT

SECOND DIGIT

AFTER DISPLACEMENT

THIRD DIGIT

AFTER DISPLACEMENT

FOURTH DIGIT

AFTER DISPLACEMENT

CUBIC INCH

DISPLACEMENT

BASIC

DESIGN SERIES

CRANKSHAFT,

CARBURETOR,

GOVERNOR

PTO BEARING,

REDUCTION GEAR,

AUXILIARY DRIVE,

LUBRICATION

TYPE OF STARTER

ă6

ă8

ă9

10

11

12

13

16

17

18

19

22

23

24

25

26

28

29

30

31

32

35

38

40

42

46

0

1

2

3

4

5

6

7

8

9

A to Z

0 - Horizontal Shaft

Diaphragm Carburetor

Pneumatic Governor

1 - Horizontal Shaft

VacuĆJet Carburetor

Pneumatic Governor

2 - Horizontal Shaft

PulsaĆJet Carburetor

Pneumatic or Mechanical

Governor

3 - Horizontal Shaft

FloĆJet Carburetor

Pneumatic Governor

4 - Horizontal Shaft

FloĆJet Carburetor

Mechanical Governor

5 - Vertical Shaft

VacuĆJet Carburetor

Pneumatic or Mechanical

Governor

6 - Vertical Shaft

7 - Vertical Shaft

FloĆJet Carburetor

Pneumatic or Mechanical

Governor

8 - Vertical Shaft

FloĆJet Carburetor

Mechanical Governor

9 - Vertical Shaft

PulsaĆJet Carburetor

Pneumatic or Mechanical

Governor

0 - Plain Bearing/DU

NonĆFlange Mount

1 - Plain Bearing

Flange Mounting

2 - Sleeve Bearing

Flange Mounting

Splash Lube

3 - Ball Bearing

Flange Mounting

Splash Lube

4 - Ball Bearing

Flange Mounting

Pressure Lubrication on

Horizontal Shaft

5 - Plain Bearing

Gear Reduction

(6 to 1) CW Rotation

Flange Mounting

6 - Plain Bearing

Gear Reduction

(6 to 1) CCW Rotation

7 - Plain Bearing

Pressure Lubrication on

Vertical Shaft

8 - Plain Bearing

Auxiliary Drive (PTO)

Perpendicular to Crankshaft

9 - Plain Bearing

Auxiliary Drive

Parallel to Crankshaft

0 - Without Starter

1 - Rope Starter

2 - Rewind Starter

3 - Electric Starter Only

120 Volt Gear Drive

4 - Electric Starter/Generator

12 Volt Belt Drive

5 - Electric Starter Only

12 Volt Gear Drive

6 - Alternator Only

7 - Electric Starter

12 Volt Gear Drive

With Alternator

8 - Vertical Pull Starter or

Side Pull Starter

The type number identifies certain unique features such as the crankshaft or governor spring used on an engine.

The code n umber i dentifies t he a ssembly d ate o f t he e ngine. I n s ome i nstances i t i s n ecessary t o k now t he c ode n umber

as well as the model and type number when performing adjustments, repairs or ordering replacement parts for an

engine. Here is how it works.

Example: 99052115

A. The first two digits, 99, indicate the calendar year, 1999.

B. The second two digits, 05, indicate the calendar month, May.

C. The third two digits, 21, indicate the calendar month day.

D. The last two digits, 15, indicate the assembly line or manufacturing plant.

1

4

MAINTENANCE

Maintenance Schedule

5 Hours

or Daily

25 Hours or

Every Season

50 Hours or

Every Season

100 Hours or

Every Season

100-300

Hours

Check oil level♦

Change oil (splash lube)

Note 1

Change oil (pressure lube)

Note 1

Change oil filter

Note 1

Change air cleaner pre-cleaner

Note 2

Change air cleaner cartridge

Note 2

Clean cooling system

Note 2

* Inspect/clean spark arrester

(optional accessory)

Replace spark plugs

Replace in-line fuel filter

Remove combustion chamber deposits

♦Change oil after first 5 hours, then after every 50 hours or every season.

Note 1 Change oil every 25 hours when operating under heavy load or in high temperatures.

Note 2 Clean more often under dusty conditions or when airborne debris is present. Replace air cleaner parts, if very dirty.

Fuel And Oil Recommendations

Gasoline

We recommend the use of clean, fresh, lead-free

gasoline, and the use of BRIGGS & STRATTON

GASOLINE ADDITIVE, PART #5041. Leaded gasoline may be used if it is commercially available and if

lead-free is not available. A minimum of 77 octane is

recommended. The use of lead-free gasoline results in

fewer combustion deposits and longer valve life.

NOTE: Some fuels, called oxygenated or refor-

mulated gasolines, are gasolines blended

with alcohols or ethers. Excessive

amounts of these blends can damage the

fuel system or cause performance problems. Do not use gasoline which contains

Methanol.

If any undesirable operating symptoms occur, use

gasoline with a lower percentage of alcohol or ether.

We also recommend gasoline be purchased in small

quantities, not more than a 30 day supply. FRESH

gasoline minimizes gum deposits, and also will ensure

fuel volatility tailored for the season in which the engine

will be operated.

Lubrication

Oil has four purposes. It cools, cleans, seals and

lubricates. During normal operation, small particles of

metal from the cylinder walls, pistons, bearings and

combustion deposits will gradually contaminate the oil.

Dust particles from the air also contaminate the oil

forming an abrasive mixture which can cause wear to

all of the internal moving parts of the engine, if the oil is

not changed regularly. Fresh oil also assists in cooling.

Old oil gradually becomes thick and loses its cooling

ability as well as its lubricating qualities.

Two types of lubrication systems are available on

Briggs & Stratton ‘‘L” head twin cylinder engines:

1. Splash Lube

2. Pressure Lube

The splash lube system consists of a gear-driven oil

slinger on vertical crankshaft models or a connecting

rod dipper on horizontal crankshaft models.

The pressure lube system consists of a direct drive oil

pump which supplies oil to all bearing journals. Model

Series 400440, 400770, 402440, 402770, 404440,

404770, 422440, 422770 and 462770 engines are

equipped with a pressure lubrication system with an

attached or remote (optional) replaceable oil filter.

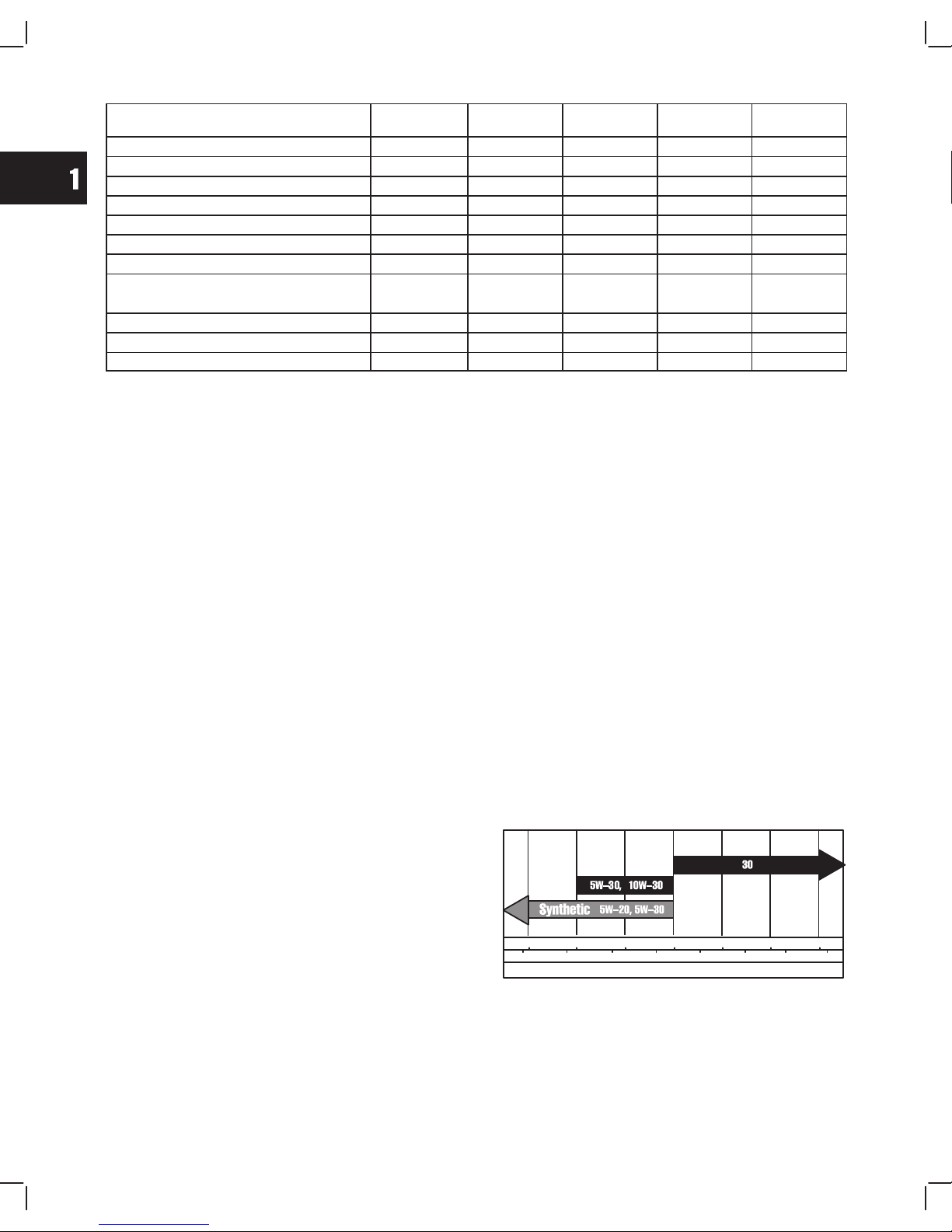

Oil Recommendations

We recommend the use of a high quality detergent oil

classified “For Service SE, SF, SG” such as Briggs &

Stratton 30 weight oil Part #100005 or Part #100028.

Detergent oils keep the engine cleaner and retard the

formation of gum and varnish deposits. No special

additives should be used with recommended oils.

* Air cooled engines run hotter than automotive

engines. Use of multi-viscosity oils (10W-30, etc.)

above 40° F (4° C) will result in high oil consumption

and possible engine damage. Check oil level more

frequently if using these types of oil.

** SAE 30 oil, if used below 40° F (4° C), will result in

hard starting and possible engine bore damage due

to inadequate lubrication.

RECOMMENDED SAE VISCOSITY GRADES

°F

-20 0 20 40 60 80 100

°C

-30 -20 -10 0 10 20 30 40

TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

*

**

32

1

5

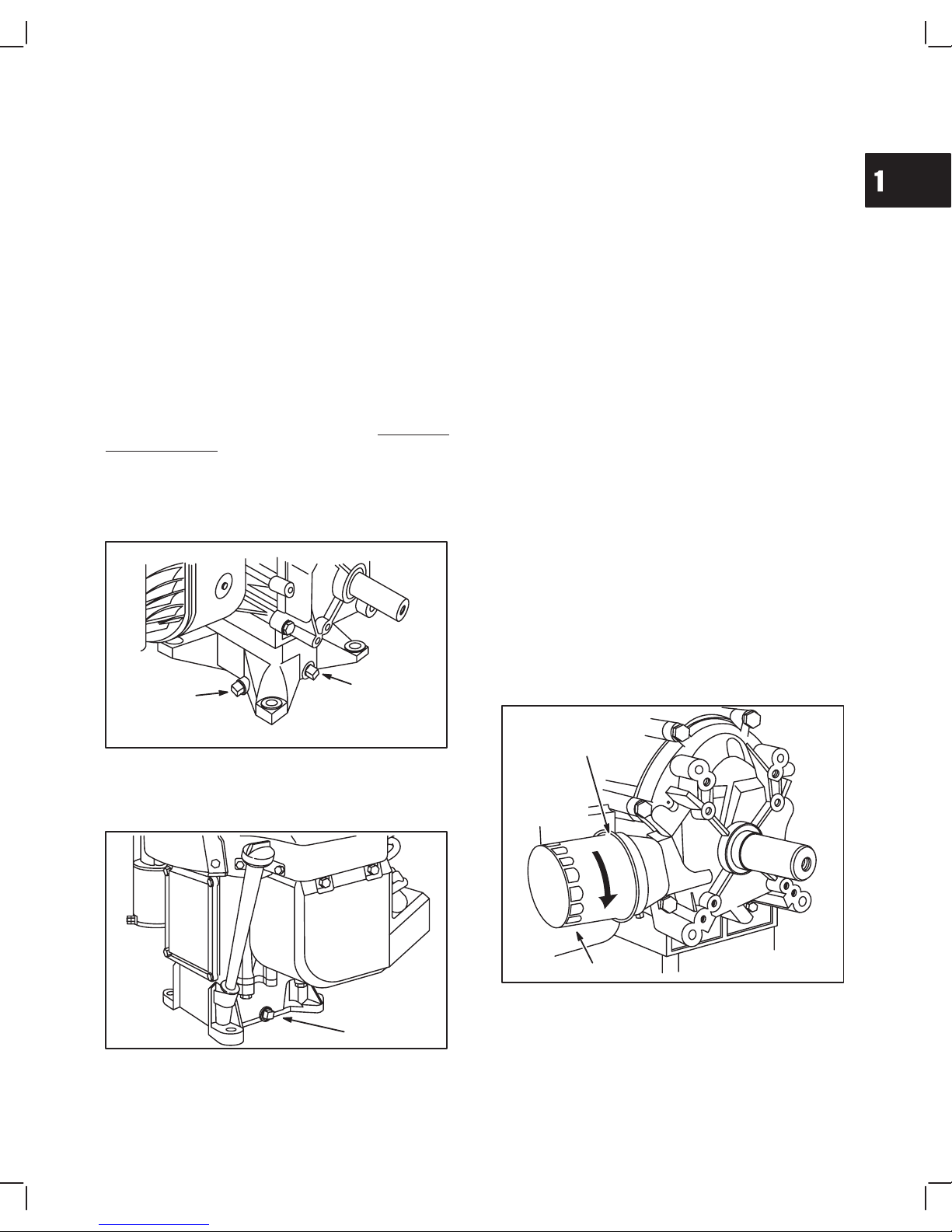

Change Oil – Splash Lube Engines

The crankcase capacity of twin cylinder engines

without oil filters is approximately three pints.

NOTE:Early production engines had approxi-

mately 3-1/2 pint (1.65 liter) oil capacity.

Use dipstick to check oil level.

IMPORTANT: DO NOT OVERFILL. Check a nd m ain tain oil level regularly. Change oil after first eight (8)

hours of operation.

Thereafter, change oil every fifty (50) hours of operation. Change oil more often if engine is operated in dirty

or dusty conditions or if engine is operated under

heavy loads or in high ambient air temperatures.

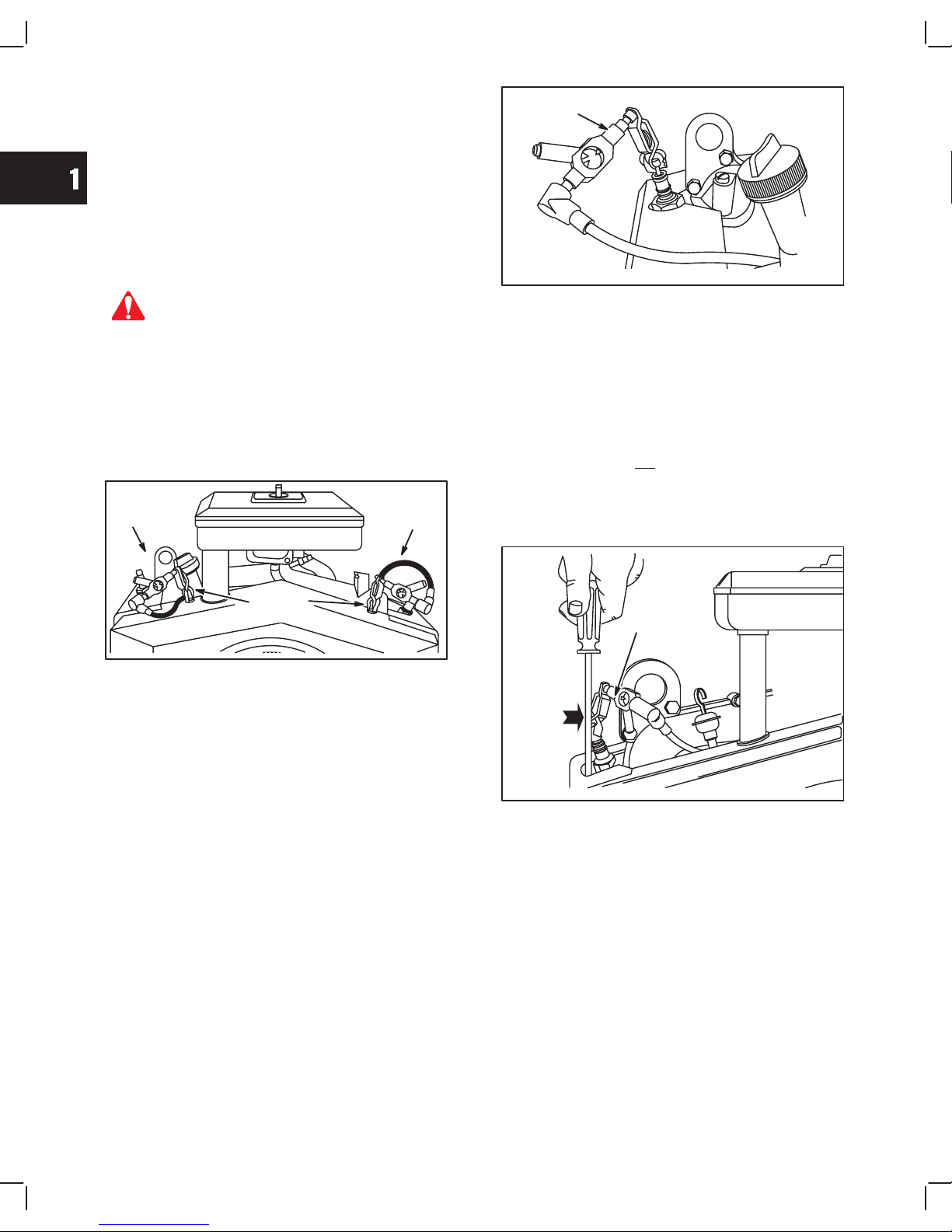

Remove oil drain plug and drain oil while engine is still

warm, Fig. 1 and Fig. 2. Replace drain plug.

Remove dipstick and refill slowly with new oil of proper

service classification and viscosity grade. Refill to full

mark on dipstick. When checking oil level, dipstick

must be screwed all the way in for accurate readings.

Start and run engine to check for oil leaks.

Fig. 1 – Horizontal Crankshaft Engine

OIL

DRAIN

PLUG

OIL

DRAIN

PLUG

OIL DRAIN

PLUG

Fig. 2 – Vertical Crankshaft Engine

Change Oil – Pressure Lube Engines

The crankcase capacity of pressure lube twin cylinder

engines is approximately:

3-1/2 Pints (1.65 liters) with filter

3 Pints (1.42 liters) without filter

IMPORTANT: DO NOT OVERFILL. Check and main-

tain oil level regularly. Change oil after first five (5)

hours of operation.

NOTE: Wh en checking oil level, dipstick must

be screwed all the way in for accurate

readings.

Thereafter, change oil every fifty (50) hours of operation. Change oil more often if engine is operated in dirty

or dusty conditions or if engine is operated under

heavy loads or in high ambient air temperatures.

Remove oil drain plug and drain oil while engine is still

warm, Fig. 1 and Fig. 2. Replace drain plug.

Change Oil Filter

Replace oil filter every 100 hours of operation. Before

installing new filter, lightly oil filter gasket with fresh

clean engine oil. Screw filter on by hand until gasket

contacts filter adapter. Tighten 1/2 to 3/4 turn more,

Fig. 3.

Remove dipstick and refill slowly with new oil of proper

service classification and viscosity grade. Start and

run engine to check for oil leaks.

Fig. 3 – Install Oil Filter

OIL

GASKET

1/2 – 3/4

TURN

OIL

FILTER

NOTE:A shorter oil filter 2-1/2” (64.0 mm) is

available for restricted access applications. Order Part #492932.

1

6

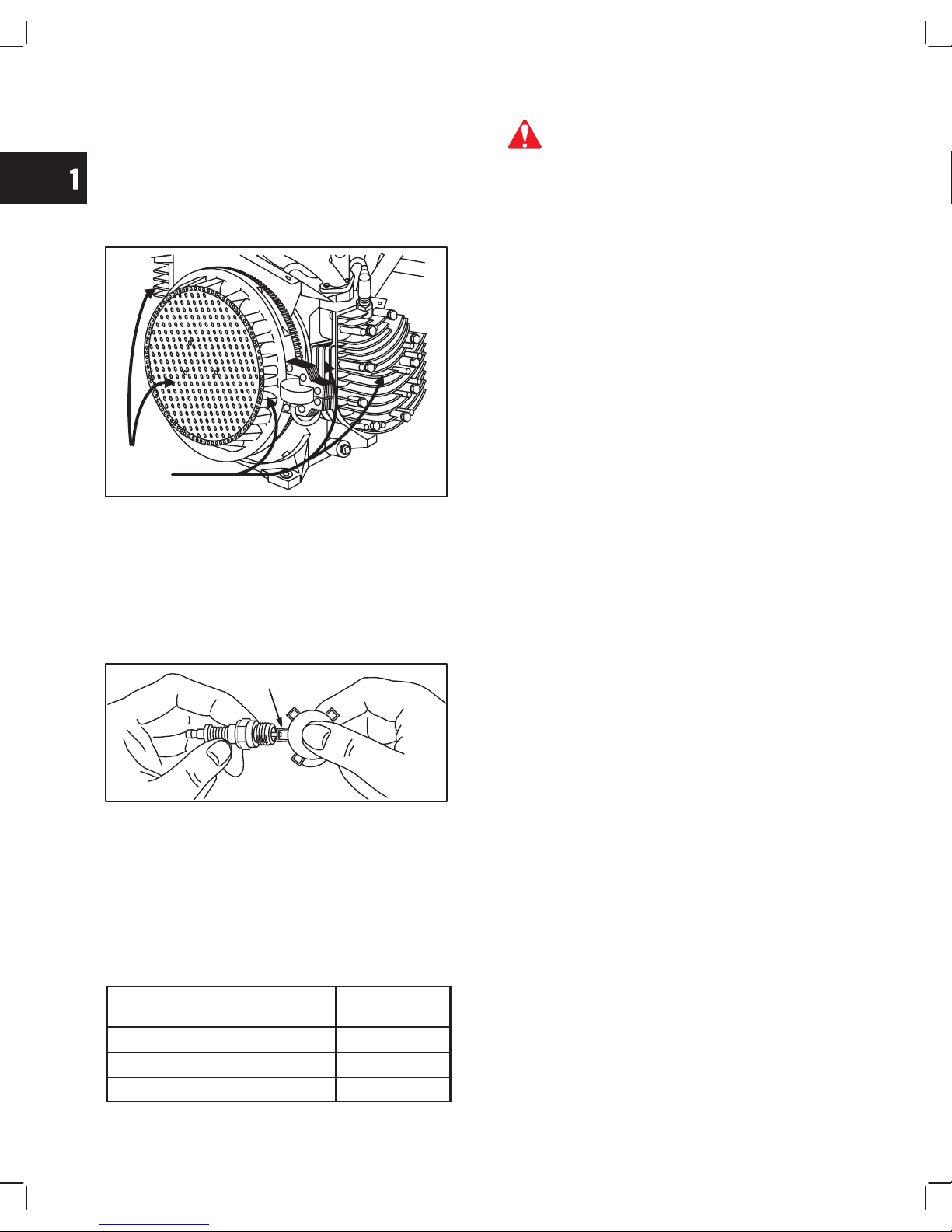

Clean Cooling System

Grass particles, chaff or dirt can clog the air cooling

system, especially after prolonged service in cutting

dry grass or very dirty air. Continued operation with a

clogged cooling system can cause severe overheating

and possible engine damage. Fig. 4 shows the blower

housing removed and areas to be cleaned. This should

be a regular maintenance operation, performed yearly

or every 100 hours, whichever comes first.

Fig. 4

Replace Spark Plugs

Replace spark plugs every 100 hours of operation or

every season, whichever occurs first. Replace spark

plugs if electrodes are burned away, or the porcelain is

cracked. Set spark plug gap at .030” (.76 mm) for all

models, Fig. 5.

Fig. 5 – Adjusting Spark Plug Gap

.030” (.76 mm)

WIRE GAUGE

NOTE:Do not blast clean spark plugs. Spark

plugs should be cleaned by scraping or

hand wire brushing and washing in a

commercial solvent.

The spark plugs recommended for Briggs & Stratton

twin cylinder engines are as follows:

Spark Plug

Type

Champion B&S Part No.

Standard Plug J-19 LM 492167

Resistor Plug RJ-19 LM 802592

Resistor Plug RJ-12 394539

Air Cleaner Maintenance

WARNING: NEVER OPERATE engine with

air cleaner cover or air cleaner element

removed! Fire may result.

A properly serviced air cleaner protects internal parts

of the engine from dirt and dust particles in the air. If air

cleaner instructions are not carefully followed, dirt and

dust which should be collected in the cleaner, will be

drawn into the engine. These particles are highly

abrasive and will cause the piston rings and cylinder

bore to wear quickly. As the rings and cylinder bore

become worn, these abrasive particles enter the

crankcase and contaminate the oil, forming an abrasive mixture which will cause wear on all of the internal

moving parts.

The air c leaner o n e very e ngine b rought i n f or a c heck u p

or repair should be examined and serviced. If the air

cleaner shows s igns o f n eglect o r d amage, s how i t t o t he

customer. Instruct the customer on proper care, to

ensure long engine life.

NOTE:Replace air cleaner gaskets and mounting

gaskets that are worn or damaged, to

prevent dirt and dust entering engine due

to improper sealing. Replace bent air

cleaner mounting bracket.

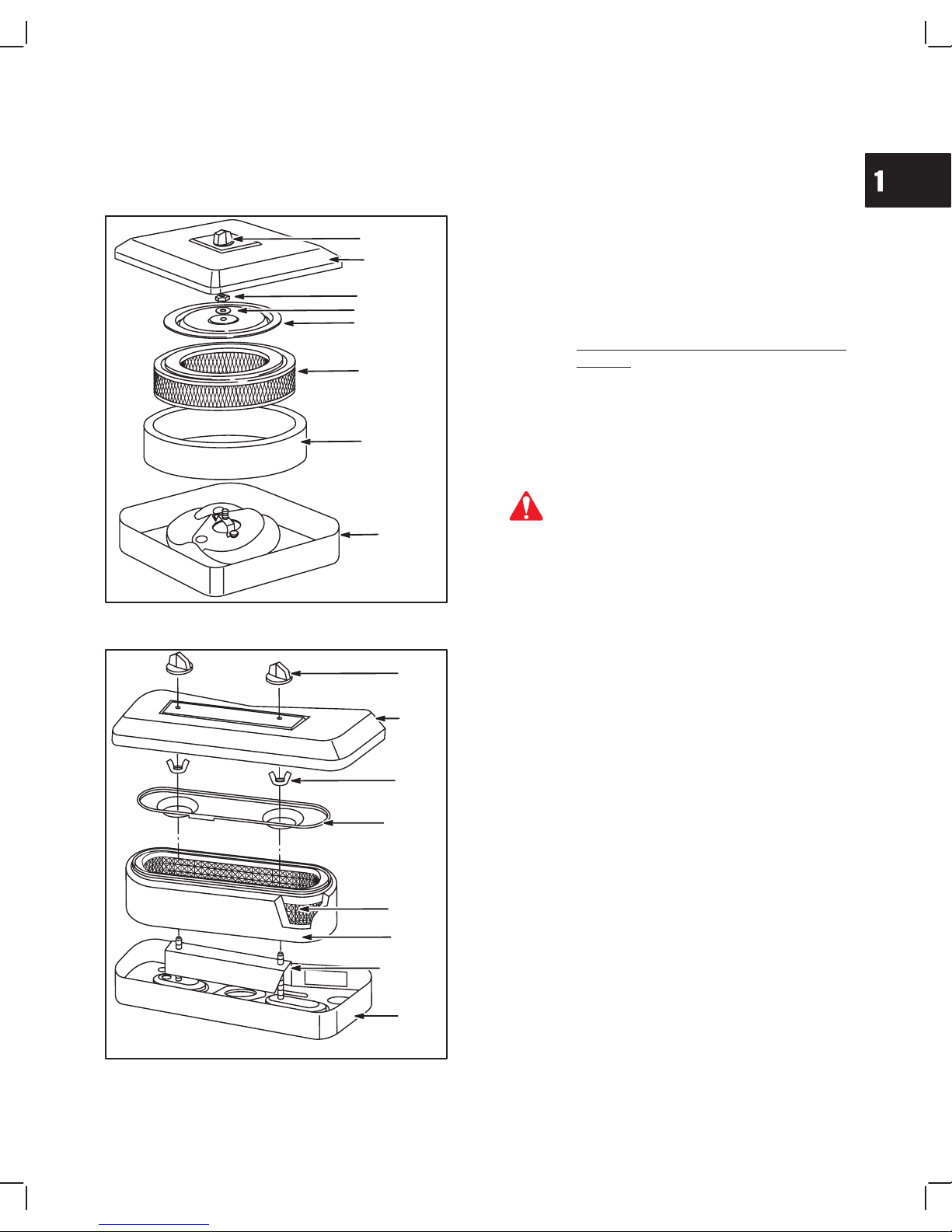

Service Dual Element Air Cleaner

Service/replace foam pre-cleaner at three month inter vals or every 25 hours, whichever occurs first, Fig. 6 or

Fig. 7. Replace cartridge every 100 hours or every

season, whichever occurs first.

NOTE:Service/replace air cleaner more often

under dusty conditions.

To Service Pre-Cleaner

1. Remove knob(s) and cover.

2. Remove foam pre-cleaner by sliding it off the paper cartridge.

3. Wash foam pre-cleaner in liquid detergent and

warm water.

a. Wrap foam pre-cleaner in cloth and squeeze

dry.

b. Saturate foam pre-cleaner in engine oil.

Squeeze to remove excess oil.

4. Install foam pre-cleaner over paper cartridge.

Reassemble cover a nd screw knob(s) down t ightly .

NOTE:Replace cup washer if damaged, Fig. 6 or

Fig. 7.

To Service Cartridge

1. Remove knob(s) and cover, Fig. 6 or Fig. 7.

a. Remove and inspect cartridge. Replace if

damaged or dirty.

1

7

DO NOT use petroleum solvents, such as kerosene, to

clean paper cartridge. They may cause cartridge to

deteriorate. DO NOT oil paper cartridge. DO NOT use

pressurized air to clean or dry paper cartridge.

b. Reinstall cartridge, cover plate, knob and

pre-cleaner.

2. Reinstall air cleaner cover, Fig. 6 or Fig. 7.

Fig. 6 – Air Cleaner, Horizontal Crankshaft Models

(Typical)

KNOB

COVER

WASHER

CUP

NUT

PAPER

CARTRIDGE

FOAM

PRE-CLEANER

BASE

Fig. 7 – Air Cleaner, Vertical Crankshaft Models

(Typical)

KNOB

COVER

CARTRIDGE

COVER

PAPER

CARTRIDGE

WING

NUTS

FOAM

PRE-CLEANER

BASE

SPIT BACK

SHIELD

Remove Combustion Chamber Deposits

Combustion chamber deposits should be removed

every 100 – 300 hours or whenever cylinder heads are

removed. See Section 5 for removal procedure.

Remove combustion chamber deposits from combustion chamber and around valves using a soft, hand wire

brush or scraper. With piston at Top Dead Center,

remove combustion chamber deposits from top of

piston. Use care to prevent combustion chamber

deposits from entering push rod or oil return cavity in

cylinder.

Take care not to damage cylinder, top of piston,

cylinder head and cylinder head gasket surfaces.

NOTE:Remove only

the combustion chamber

deposits. It is not necessary to remove the

discoloration marks on the piston, valves

and cylinder head. These marks are

normal and will not affect engine operation.

Remove the l oose deposits f rom around the top r ing

land area using compressed air or a soft bristle

brush.

WARNING: TO PREVENT eye injury always

wear eye protection when using compressed

air.

TROUBLESHOOTING

Most complaints concerning engine operation can be

classified as one or a combination of the following:

1. Will not start

2. Hard starting

3. Lack of power

4. Runs rough

5. Vibration

6. Overheating

7. High oil consumption

NOTE: What appears to be an engine malfunc-

tion may be a fault of the powered equipment rather than the engine. If equipment

is suspect, see Equipment Affecting

Engine Operation.

Systematic Check

If t he e ngine w ill not start a nd the cause o f malfunction

is not r eadily a pparent, perform a systematic c heck i n

the following order:

1. Ignition

2. Carburetion

3. Compression

This check-up, performed in a systematic manner, c an

usually be done in a matter of minutes. It is the quickest

and surest method of determining the cause of failure.

The basic check-up procedure is the same for all

engine models, while any variation, by model, will be

shown under the subject heading.

1

8

Check Ignition

(With Electric Starter)

NOTE:Magnetron ignition system requires a

minimum of 350 RPM to produce spark.

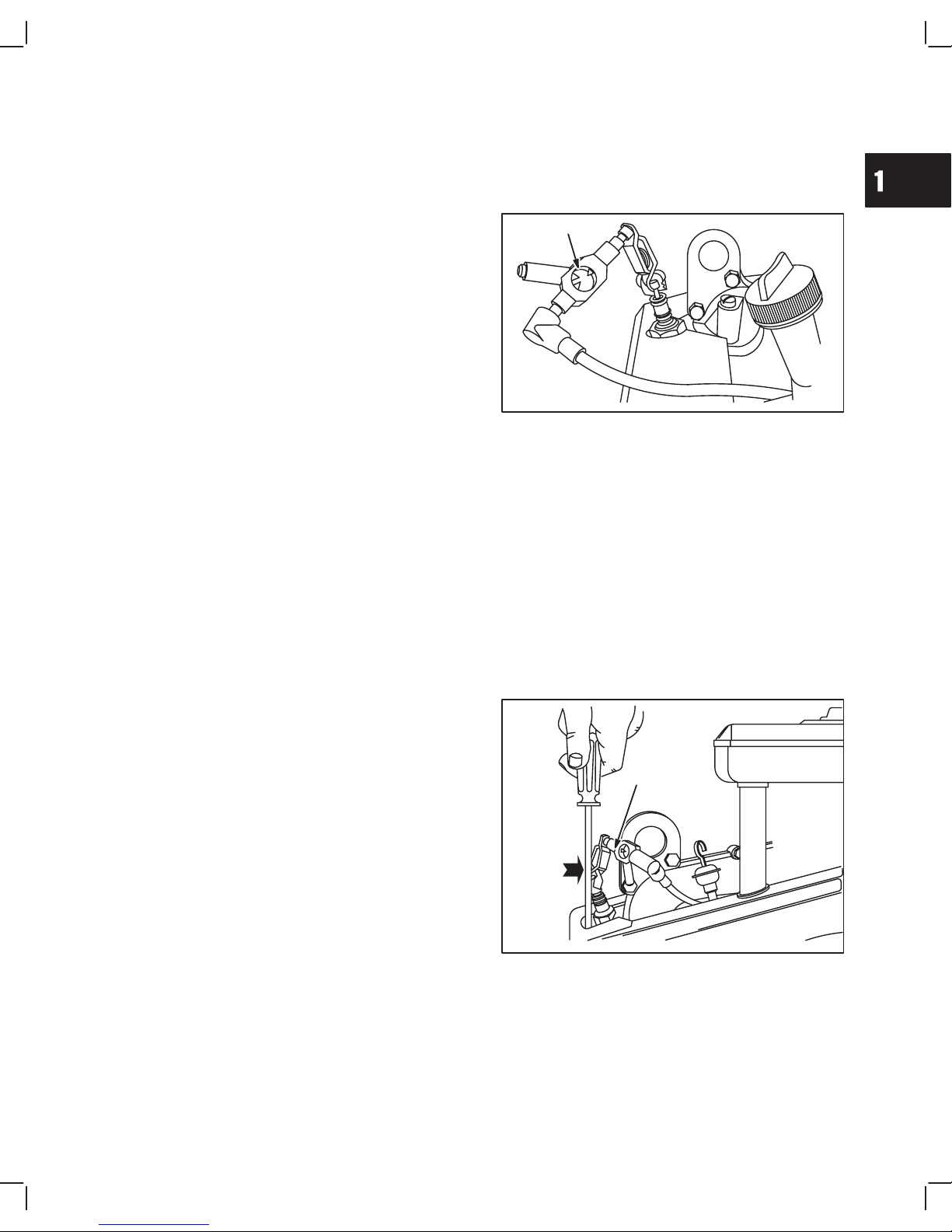

With spark plugs installed, attach a #19368 ignition

tester to each spark plug lead and ground the other end

of the tester as shown in Fig. 8. Spin the flywheel

rapidly with engine starter. If spark jumps the tester

gaps, you may assume the ignition system is functioning satisfactorily.

WARNING: ON MAGNETRON equipped

engines, spark can still occur with a sheared

flywheel key. A severe shock or kickback

hazard may exist.

NOTE:Engines equipped with Magnetron igni-

tion system will still display spark at tester

with a partially or fully sheared flywheel

key. A partially sheared flywheel key will

affect ignition timing and engine performance.

Fig. 8 – Checking Spark

IGNITION

TESTER

#19368

CYLINDER #1

CYLINDER #2

If spark does not occur look for –

1. Improperly operating interlock system

2. Sheared flywheel key (breaker points only)

3. Incorrect breaker point gap (when so equipped)

4. Dirty or burned breaker points (when so equipped)

5. Breaker plunger stuck or worn (when so equipped)

6. Shorted ground wire (when so equipped)

7. Shorted stop switch (when so equipped)

8. Condenser failure (breaker points only)

9. Incorrect armature air gap

10. Armature failure

11. Worn cam bearings and/or camshaft (breaker

points only)

Check Ignition

(Engine Running)

If engine runs but misses during operation, a quick

check to determine if ignition is or is not at fault can be

made by installing Tool #19368 ignition tester between

the spark plug lead and each spark plug, Fig. 9. With

the engine running, a spark miss will be readily

apparent. If spark jumps gap at ignition tester regularly,

and engine misses check for a fouled spark plug.

Fig. 9 – Running Check

IGNITION

TESTER

#19368

ATTACH

TESTER

TO EACH PLUG

Checking For Fouled Spark Plug

To check for a fouled spark plug or a non-functioning

cylinder, attach Tool #19368, ignition tester, between

the spark plug lead and each spark plug. With engine

running at top no load speed, ground one spark plug,

Fig. 10. The engine should continue to run on the other

cylinder. Repeat this test with the other cylinder. If the

engine will not continue to run when making this test,

the cylinder that is not

grounded is not functioning

and/or the spark plug is fouled. Install a new spark plug

before proceeding. If miss continues, problem may be

carburetion or compression. See Cylinder Balance

Test.

Fig. 10 – Checking for Fouled Plugs or Other Causes

GROUND WITH

SCREWDRIVER

IGNITION

TESTER

#19368

Check Carburetion

Before making a carburetion check, be sure the fuel

tank has an ample supply of fresh, clean gasoline. Be

sure that the shut-off valve, when equipped, is open

and fuel flows freely through the fuel line. Inspect and

adjust the needle valves. Check to see that the choke

closes completely . If engine will not start, remove and

inspect the spark plugs.

If plugs are wet, look for –

1. Over-choking

2. Excessively rich fuel mixture

a. See Section 3 for adjustment procedure.

3. Water in fuel

4. Float needle valve stuck open

1

9

If plugs are dry, look for –

1. Leaking carburetor mounting gaskets

2. Gummy or dirty carburetor

3. Float needle valve stuck shut

4. Inoperative fuel pump

5. Defective anti-afterfire solenoid or wiring.

A simple check to determine if the fuel is getting to the

combustion chamber through the carburetor is to

remove either spark plug and pour a small quantity of

gasoline through the spark plug hole. Replace the

plug. If the engine fires a few times and then stops, look

for the same conditions as for a dry plug.

Check Compression

Briggs & Stratton does not publish any compression

pressures, as it is extremely difficult to obtain an

accurate reading without special equipment.

It has been determined through testing, a simple and

accurate indication of compression can be made as

follows:

Remove both spark plugs and insert a compression

gauge into either cylinder (one cylinder at a time). Turn

engine over with engine starter until there is no further

increase in pressure. Record this reading. Repeat

procedure on other cylinder and record that reading.

The difference between both cylinders should not

exceed 25%. M ore than 2 5% i ndicates l oss o f c ompression in the cylinder with lower pressure. See example.

Example:

Cyl. #1 Cyl. #2 Diff. % Diff.

Eng. #1 65 PSI 60 PSI 5 PSI 7.6%

Eng. #2 75 PSI 55 PSI 20 PSI 26.7%

If compression is poor, look for –

1. Loose cylinder head bolts

2. Blown head gasket

3. Burned valves, valve seats and/or loose valve

seats

4. Insufficient tappet clearance

5. Warped cylinder head

6. Warped valve stems

7. Worn bore and/or rings

8. Broken connecting rods

Cylinder Leakdown Test

The cylinder leakdown tester, Tool # 19413, may be

used to test the sealing capability of the compression

components of each cylinder and quickly identify the

problem component.

Cylinder Balance Test

If the engine is hard starting, runs rough, misses or

lacks power, perform a cylinder balance test to

determine whether both cylinders are operating to their

full potential.

Tools Required

1. Tachometer, Tool #19200

2. Two #19368 Ignition Testers

3. Screwdriver with insulated handle

Attach ignition tester, Tool #19368, between the spark

plug lead and each spark plug, Fig. 11.

Fig. 11

IGNITION

TESTER

#19368

ATTACH

TESTER

TO EACH PLUG

Start and run engine running at top no load speed and

note spark at ignition testers. If the spark is equal at

both ignition testers, the problem is not ignition related.

A spark miss will be readily apparent. Now note RPM of

engine. Ground out one cylinder with screwdriver by

contacting alligator clip on ignition tester and a good

ground on engine, Fig. 12. Note RPM loss. Then

ground out the other spark plug and note the RPM loss.

If the difference between the two cylinders does not

exceed 75 RPM, the amount of work the two cylinders

are doing should be considered equal.

If the RPM loss is less than 75 RPM between cylinders

and the engine runs poorly, the problem is common to

both cylinders.

Fig. 12 – Cylinder Balance Test

GROUND WITH

SCREWDRIVER

IGNITION

TESTER

#19368

Things Which Affect Both Cylinders

1. Carburetion

2. Crankcase vacuum

3. Ignition timing – Magnetron Ignition

a. A partially sheared flywheel key will effect

ignition timing and engine performance.

1

10

If the RPM loss is greater than 75 RPM, this indicates

that the cylinder with the least RPM loss is the weakest

of the two cylinders. Look to that cylinder for a problem.

See Example.

Example:

Engine RPM – Both Cylinders = 3400 RPM

Engine RPM – #1 Cylinder Grounded = 3300 RPM

Engine RPM – #2 Cylinder Grounded = 3100 RPM

Conclusion: #1 cylinder is weakest of the two cylinders.

Things Which Affect One Cylinder

1. Spark plug

a. A fouled spark plug may indicate that the

carburetor is out of adjustment.

2. Leak in spark plug wire

3. Head gasket

4. Intake manifold

a. A leak at either end of the intake manifold will

only affect one cylinder, not both.

5. Valves

6. Rings

7. Piston

8. Cylinder

The cylinder balance test will also detect a cylinder that

is not functioning. When grounding out one cylinder

there will be no RPM loss. When the other cylinder is

grounded out the engine will stop.

NOTE:A twin cylinder engine will run well on one

cylinder as long as the power required for

the application does not exceed the power

produced by the one cylinder.

Equipment Affecting Engine Operation

Frequently, what appears to be a problem with engine

operation, such as hard starting, vibration, etc., may be

the fault of the equipment powered rather than the

engine itself. Since many varied types of equipment

are powered by Briggs & Stratton engines, it is not

possible to list all of the various conditions that may

exist. Listed are the most common effects of equip-

ment problems, and what to look for as the most

common cause.

Hard Starting, or Will Not Start

1. Loose belt – a loose belt like a loose blade can

cause a backlash effect, which will counteract

engine cranking effort.

2. Starting under load – see if the unit is disengaged

when engine is started; or if engaged, should not

have a heavy starting load.

3. Check remote control assembly for proper adjustment.

4. Check interlock system for shorted wires, loose or

corroded connections, or defective modules or

switches.

Engine Won’t Stop

1. Check equipment ignition stop switch.

2. Check for loose or disconnected equipment stop

switch wire.

Vibration

1. Cutter blade bent or out of balance – remove and

balance.

2. Mounting bolts loose – tighten.

Power Loss

1. Bind or drag in unit – if possible, disengage engine

and operate unit manually to feel for any binding

action.

2. Grass cuttings build-up under deck.

3. No lubrication in transmission or gear box.

4. Excessive drive belt tension may cause seizure.

Noise

1. Cutter blade coupling or pulley – an oversize or

worn coupling can result in knocking, usually

under acceleration. Check for fit, or tightness.

2. No lubricant in transmission or gear box.

2

9904 1

Section 2

IGNITION

Page

GENERAL INFORMATION 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ARMATURES 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Armature Testing – All Models 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Armature 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Armature – Breaker Point Ignition 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetron

Ignition – Composite Style Armature 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Magnetron

Ignition – Armature With Magnetron Module 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Magnetron

Module 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Magnetron

Module 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Armature – All models 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Armature Air Gap – All Models 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Routing Ignition Wires 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

BREAKER POINTS 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Breaker Points 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Breaker Point Plunger And Seal 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Plunger And Seal 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Breaker Points 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Adjust Breaker Points 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Clean Breaker Points 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Breaker Point Cover 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

FLYWHEEL 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Flywheel 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Flywheel Nut – Pre Twin II (Type Nos. Under 1100) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Flywheel Nut – Twin II (Type Nos. 1100 & Above) 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Remove Flywheel – All Models 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Inspect Flywheel Key, Keyways, Flywheel and Crankshaft 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Install Flywheel – All Models 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Torque Flywheel Nut – Pre Twin II Models (Type Nos. Under 1100) 10. . . . . . . . . . . . . . . . . . . . . . . .

Torque Flywheel Nut – Twin II Models (Type Nos. 1100 & Above) 10. . . . . . . . . . . . . . . . . . . . . . . . . .

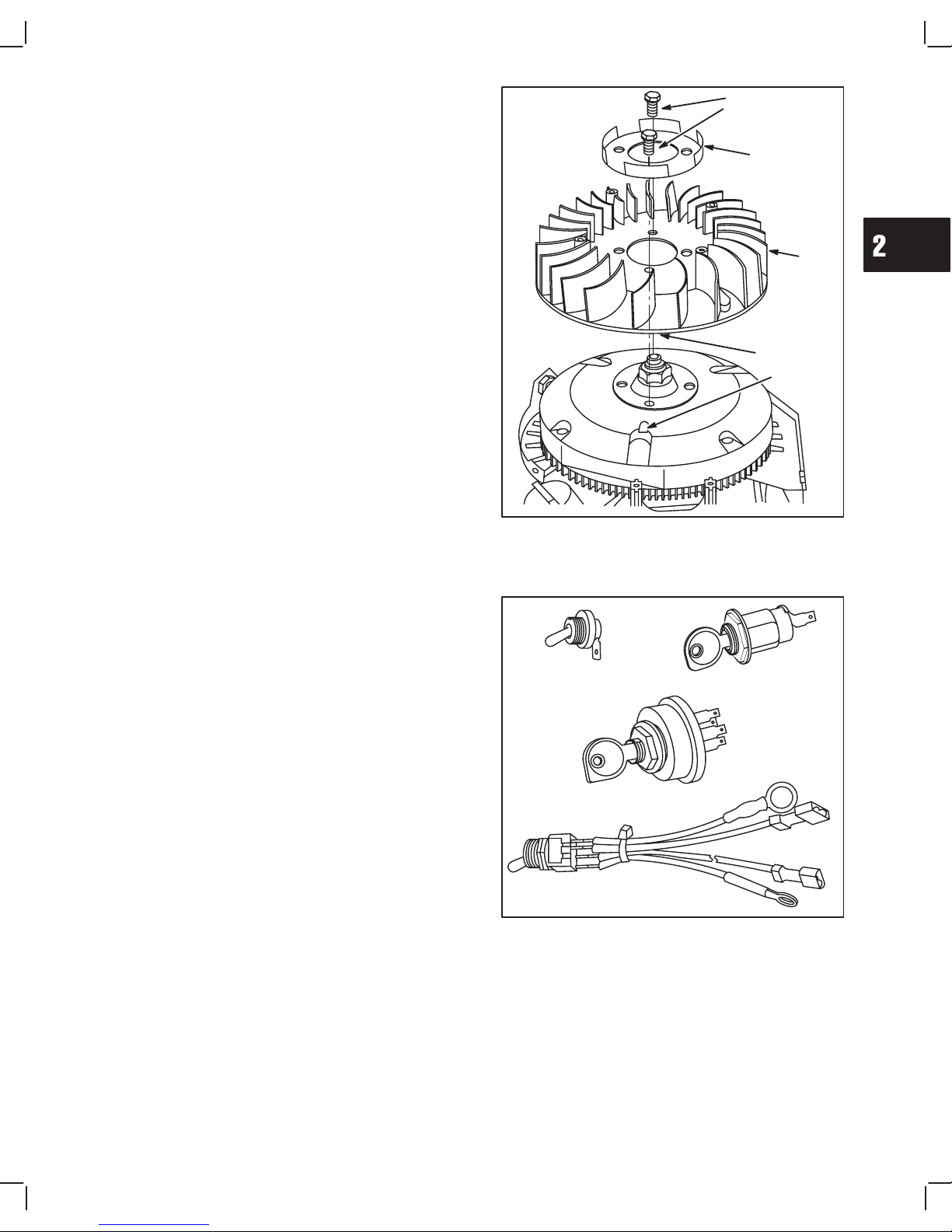

Flywheel Fan And Retainer (Type Nos. 1100 & Above) 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

STOP SWITCHES 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Equipment To Test Stop Switches 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Testing With Digital Multimeter 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Single Terminal Toggle Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Multiple Terminal Toggle Switch 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Single Terminal Rotary Key Switch 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Multiple Terminal Rotary Key Switch – Anti-afterfire Circuit 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Multiple Terminal Rotary Key Switch – Stop Switch Circuit 13. . . . . . . . . . . . . . . . . . . . . . . . . . .

Check Stationary Stop Switch 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Section Contents

2

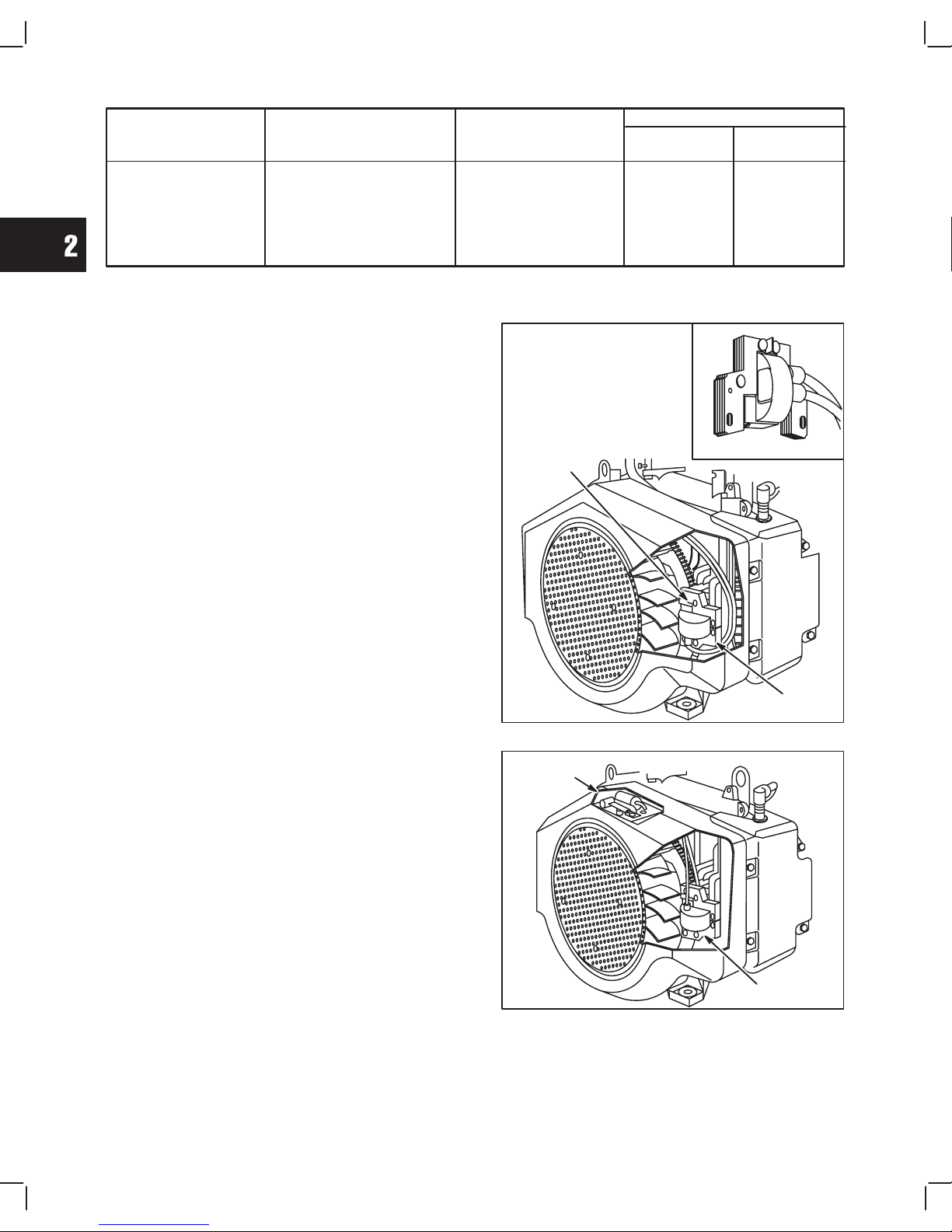

2

Basic

Model Series

Armature

Air Gap

Flywheel Puller

Part No.

Flywheel Nut Torque

Ft. Lbs. Nm

400000, 460000

With Magnetron

.008” to .012”

(.20 to .30 mm)

With Breaker Points

.010” to .014”

(.25 to .36 mm)

19203 150 203.0

BREAKER POINT IGNITION CONTACT POINT GAP: .020” (.51 mm)

CONDENSER CAPACITY: .18 TO .24 M.F.D.

SPECIFICATIONS FOR ALL OPPOSED TWIN CYLINDER ENGINE MODELS

See Section 1 For Spark Plug Maintenance and Specifications

GENERAL INFORMATION

Briggs & Stratton T win Cylinder engines use two types

of flywheel ignition systems:

1. Magnetron – Two versions of armatures have

been produced, NO TAG.

a. The composite type is a self-contained arma-

ture with transistor module.

b. Earlier versions have a replaceable Magne-

tron transistor module mounted o n the i gnition

armature.

The composite style Magnetron armature must be

replaced as an assembly.

The Magnetron module can only be installed on

armatures originally equipped with Magnetron

module.

Fig. 1 – Magnetron Ignition

COMPOSITE STYLE

MODULE

ARMATURE

2. Twin cylinder engines with type number below

0500, were equipped with a flywheel magneto system consisting of an ignition armature and external

breaker points and condenser mounted under a

breaker box, NO TAG.

ARMATURES

Armature Testing – All Models

The condition of the ignition armature can be accurately diagnosed using ignition tester, Tool #19368, as

described in “Troubleshooting” in Section 1.

Fig. 2 – Breaker Point Ignition

BREAKER

POINTS

ARMATURE

2

3

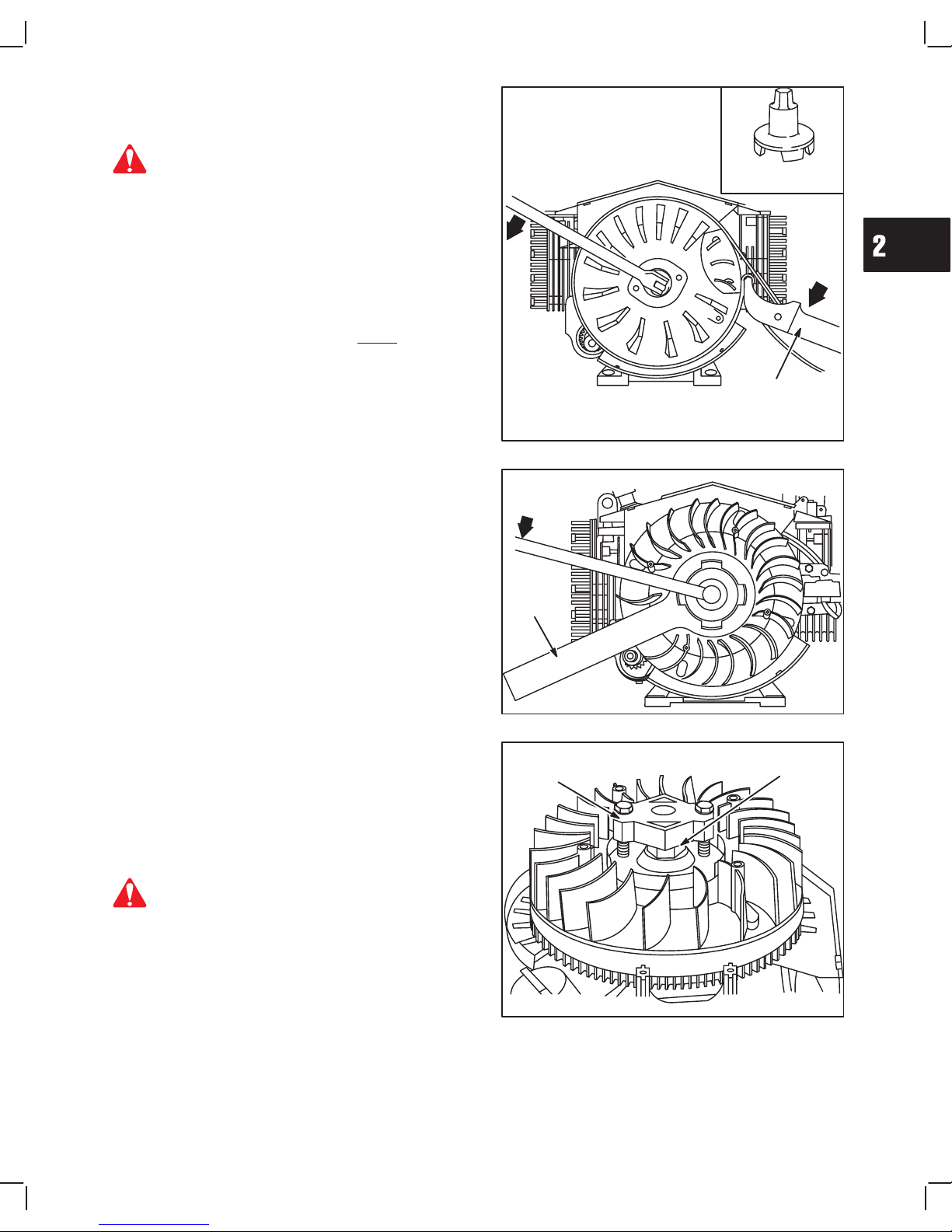

Remove Armature

All Models – The flywheel does not need to be

removed to service ignition except to check the

flywheel key.

Remove Armature – Breaker Point Ignition

On engines with breaker points, it may be necessary to

remove carburetor or carburetor and intake manifold.

See Section 3 for removal procedure.

1. Remove spark plug leads and spark plugs.

2. Remove rotating screen and blower housing.

3. Remove armature primary wire from breaker

points, Fig. 3.

4. Remove two armature mounting screws and lift off

armature, Fig. 4.

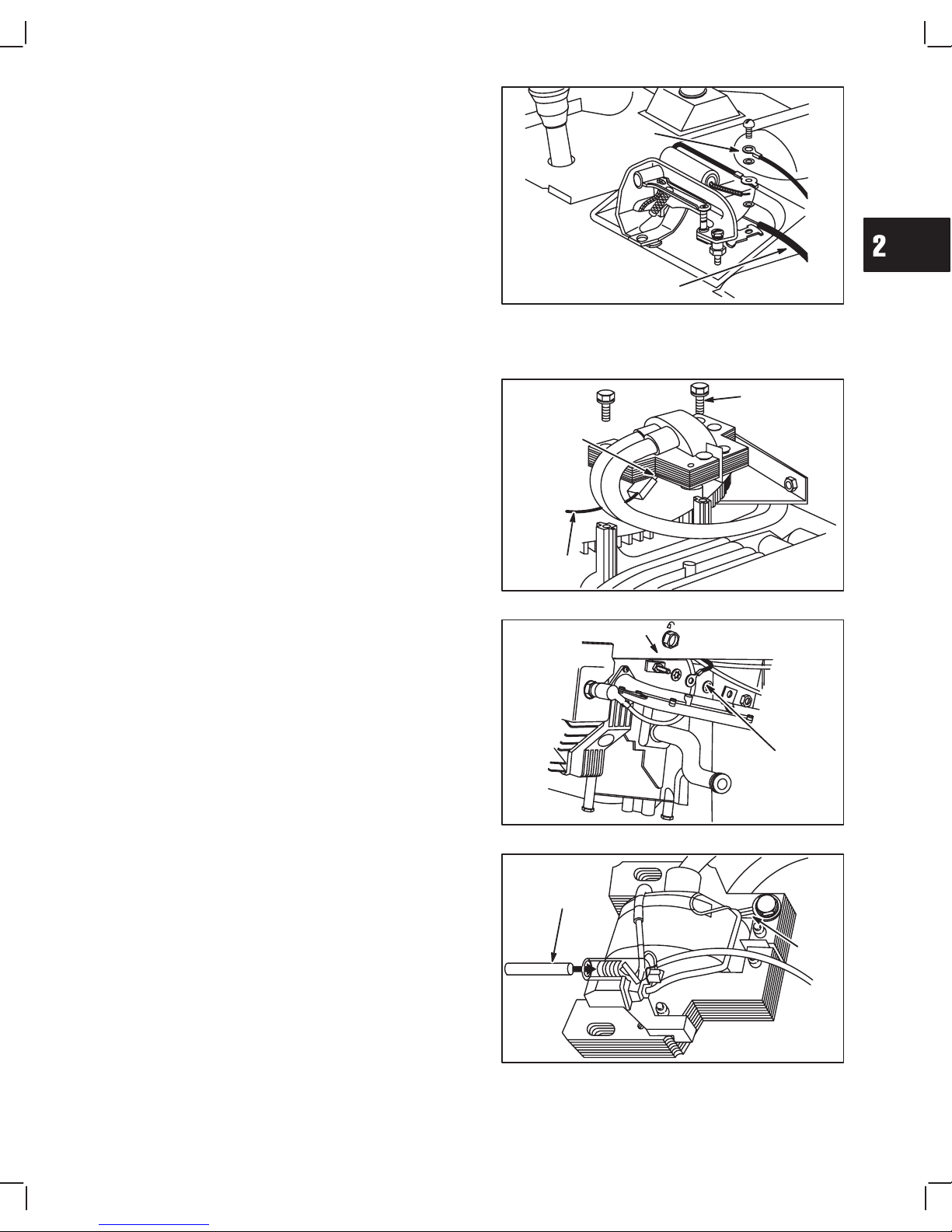

Fig. 3 – Remove Primary Wire

EQUIPMENT

STOP SWITCH

WIRE

ARMATURE

PRIMARY

WIRE

Magnetron Ignition – Composite Style

Armature

1. Remove spark plug leads and spark plugs.

2. Remove rotating screen and blower housing.

3. Remove armature screws and lift off armature,

Fig. 4.

a. Disconnect stop switch wire at armature.

Fig. 4 – Remove Armature

SPADE

TERMINAL

ARMATURE

SCREWS

GROUND

WIRE

Magnetron Ignition – Armature With

Magnetron

Module

1. Remove spark plug leads and spark plugs.

2. Remove rotating screen and blower housing.

3. Remove armature ground wire from stop switch

terminal, Fig. 5.

4. Remove armature screws and lift off armature,

Fig. 5.

Fig. 5 – Stop Switch Terminal

ARMATURE

GROUND

WIRE

STOP SWITCH TERMINAL

Remove Magnetron Module

1. Depress retainer and spring with 3/16” (4.5 mm)

punch and remove wires.

2. Remove ground wire screw from armature lamination.

Fig. 6 – Remove Wires

3/16” PUNCH

GROUND

WIRE

2

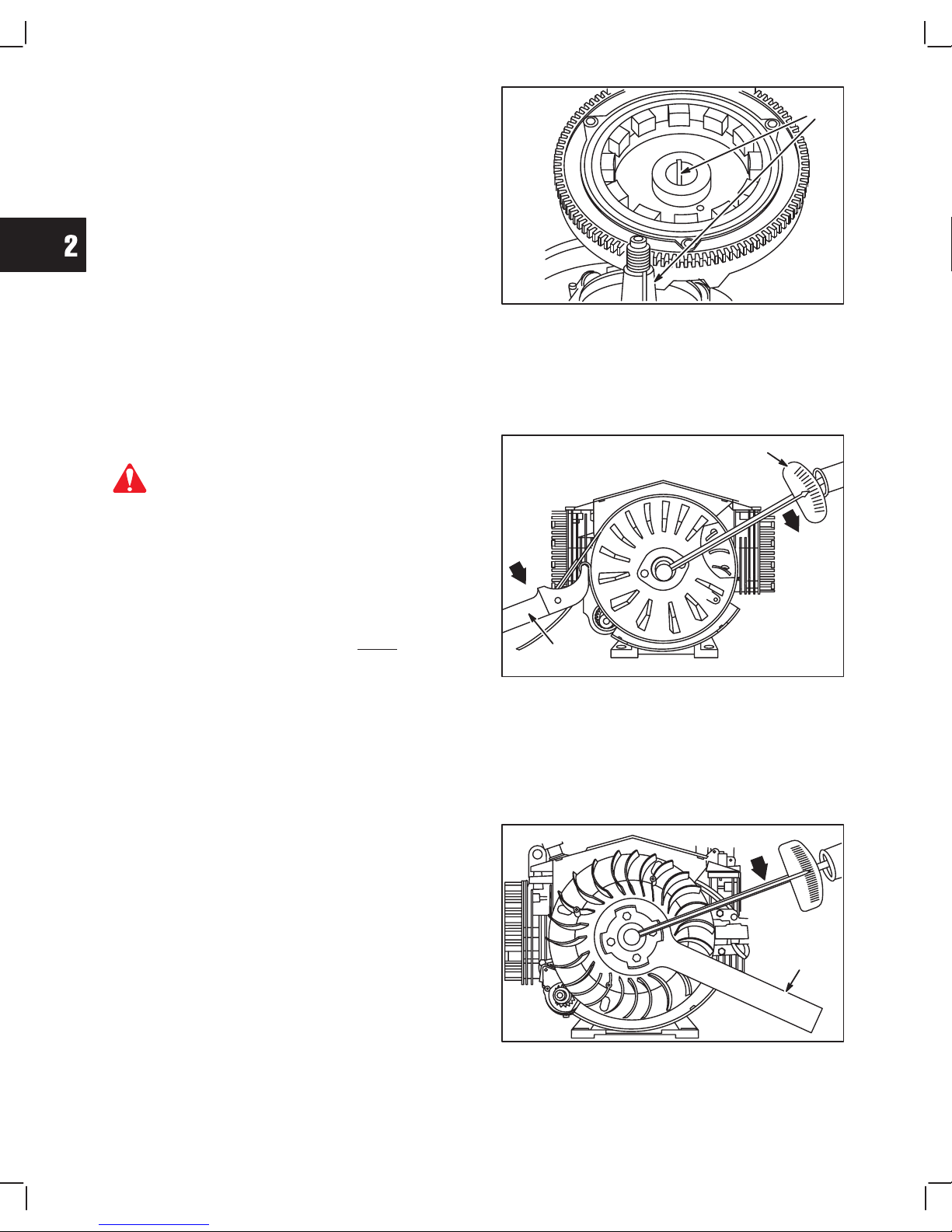

4

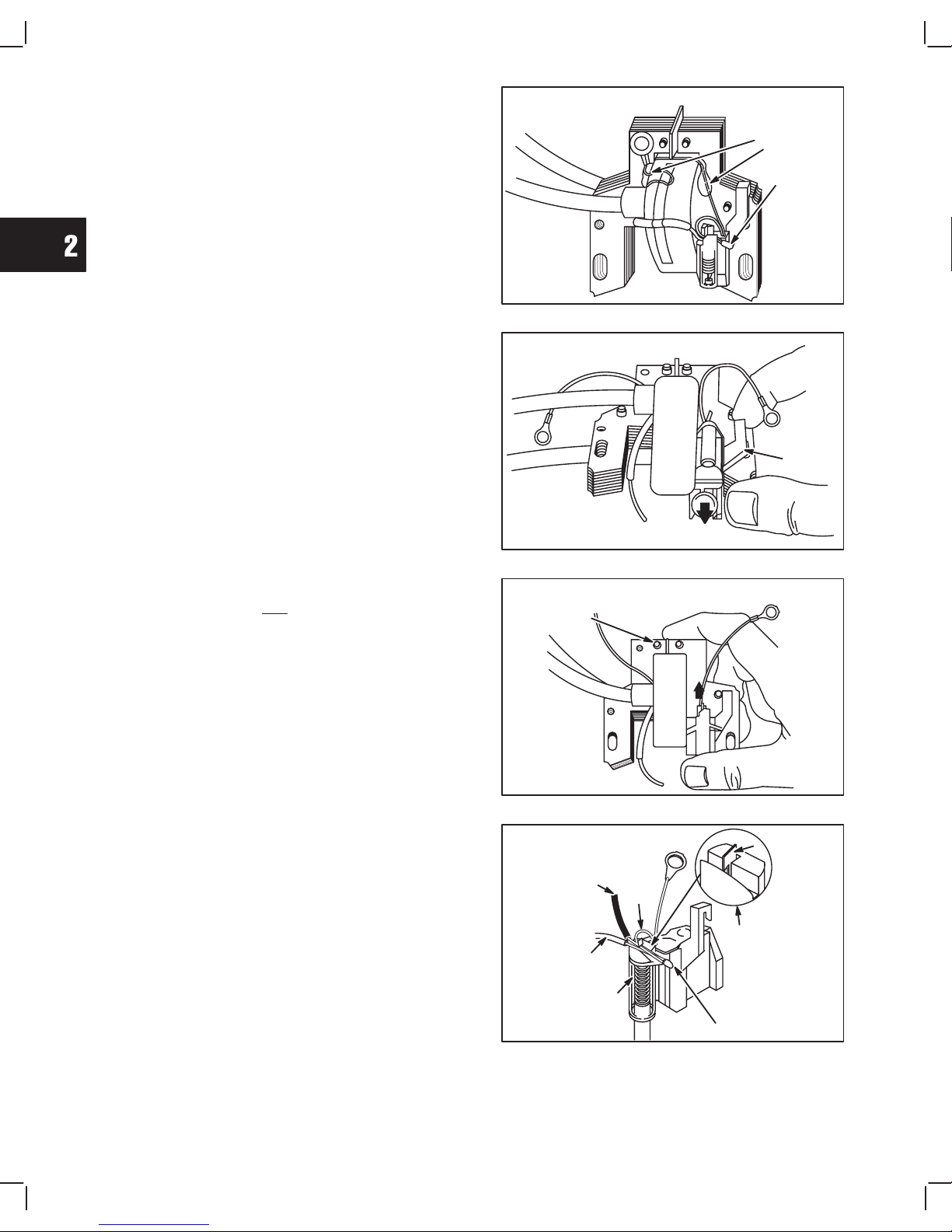

3. Remove sealant and or tape holding wires to

armature.

4. Unsolder and separate module wire and armature

primary wire, Fig. 7.

5. Separate armature ground wire and module

ground wire.

NOTE:Avoid damaging armature and module

when unsoldering or soldering.

Fig. 7 – Separate Wires

SEALANT

UNSOLDER

WIRE

BACK SIDE OF ARMATURE SHOWN

6. Move all wires so module will clear armature and

laminations.

7. Pry module retainer away lamination, Fig. 8.

8. Remove module.

Fig. 8 – Remove Module

MODULE

RETAINER

BACK SIDE OF ARMATURE SHOWN

Install Magnetron Module

NOTE:Module can only be installed on armatures

originally equipped with Magnetron.

The armature has a front side identified by the large

rivet heads. The module is installed with the retainer on

the back side (small rivet ends), Fig. 9.

1. Assemble module to back side of armature.

a. Make sure module retainer snaps over arma-

ture laminations.

Fig. 9 – Install Module

BACK SIDE OF ARMATURE SHOWN

SMALL

RIVET

ENDS

2. Depress spring and retainer and install armature

primary wire, module wire and ground wire from

stop switch, Fig. 10.

3. Twist three wires together and solder with 60/40

Rosin core solder.

Fig. 10 – Install Wires in Module

MODULE

WIRE

ARMATURE

PRIMARY

WIRE

TO GROUND

TERMINAL

(STOP SWITCH)

SPRING &

RETAINER

SOLDER

HERE

MODULE

TERMINAL

RETAINER

2

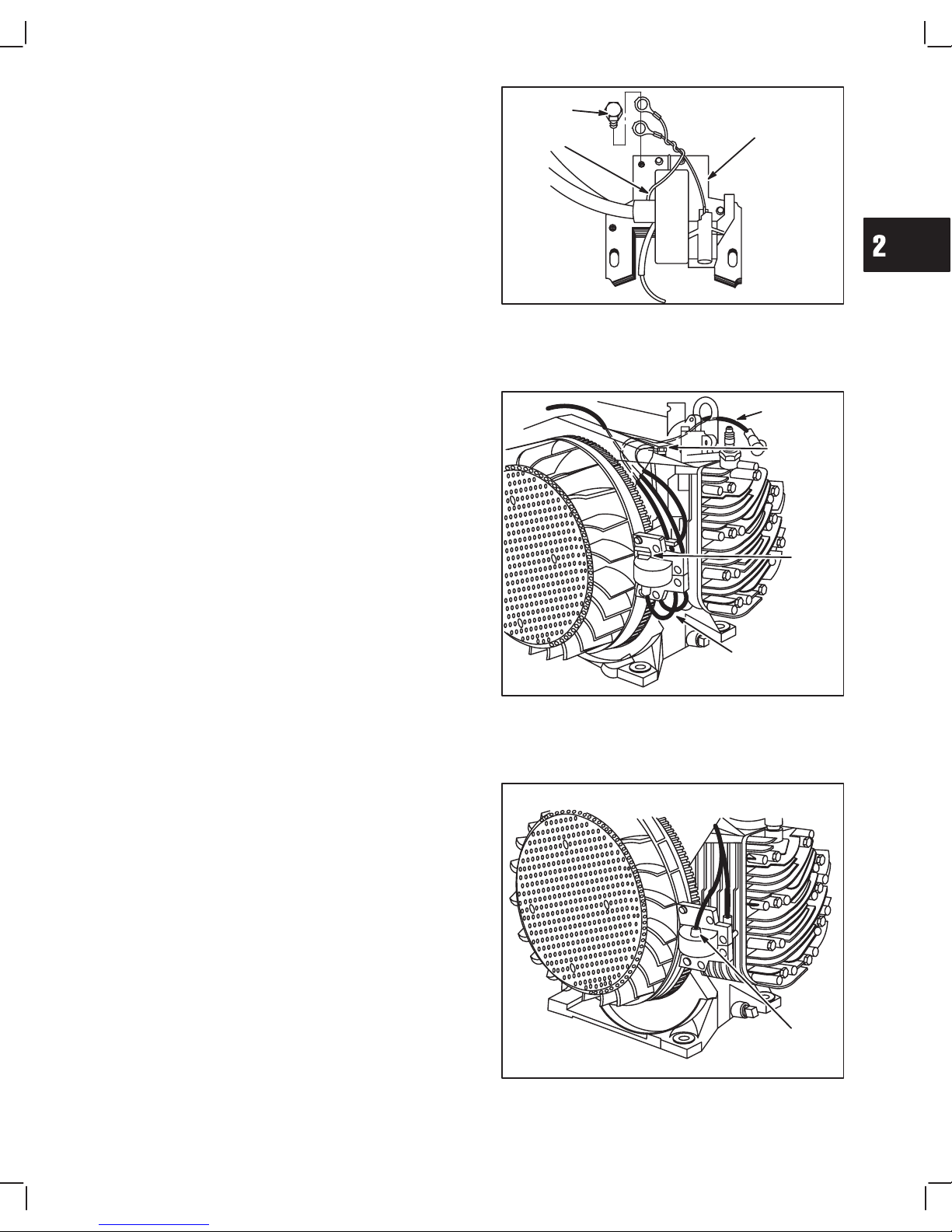

5

4. Twist armature ground wire and module ground

wire together and route wires as shown.

5. Attach ground wires to armature lamination with

ground screw, Fig. 11.

6. Seal wires to back of armature with Permatex

No. 2 or similar sealer to prevent wires from vibrating and breaking.

Fig. 11 – Attach Ground Wires

GROUND

WIRE

SCREW

ARMATURE

GROUND

WIRE

MODULE

GROUND

WIRE

Install Armature – All Models

Rotate flywheel so magnet is away from armature.

Note position of spark plug wires in illustrations for the

type of armature being installed, Fig. 12 or Fig. 13.

Install Magnetron armature on engine as shown in

Fig. 12.

Magnetron composite style armatures have identifications on the coil casing for correct assembly.

Fig. 12 – Install Armature – Magnetron

SHORTER WIRE

TO CYLINDER #1

GROUND WIRE

TERMINAL

MODULE

NOTE POSITION OF

SPARK PLUG WIRES

Install breaker point ignition armature as shown in

Fig. 13. The right hand mounting screw holds the

ground lead(s) on breaker point ignition systems.

Push armature away from flywheel and tighten one

screw to hold armature away from flywheel.

Fig. 13 – Install Armature – Breaker Points

NOTE POSITION

OF SPARK PLUG

WIRES

2

6

Adjust Armature Air Gap – All Models

1. Rotate flywheel until magnet is under armature

laminations.

2. Place thickness gauge between magnet and armature laminations, Fig. 14.

Magnetron Ignition: .008”-.012”

(.20 mm-.30 mm)

Breaker Point Ignition: .010”-.014”

(.25 mm-.36 mm)

3. Loosen mounting screw so magnet will pull armature down against thickness gauge.

a. Torque screws to 25 in. lbs. (2.8 Nm).

4. Rotate flywheel to remove thickness gauge.

Fig. 14 – Adjust Air Gap

GAUGE

Routing Ignition Wires

The ignition armature is mounted on No.1 cylinder. The

short spark plug lead goes through opening between

#1 breather and back plate, under intake manifold and

around to #1 spark plug, Fig. 15. Magnetron ground

wire, or armature primary wire (breaker points) uses

same opening to stop switch terminal. Long spark plug

lead is for #2 cylinder . Route through same opening in

back plate, and under intake manifold to #2 spark plug,

Fig. 15.

Fig. 15 – Typical Wire Routing

CYLINDER #2

#1 BREATHER

CYLINDER #1

BACK PLATE

STOP SWITCH

TERMINAL

BREAKER POINTS

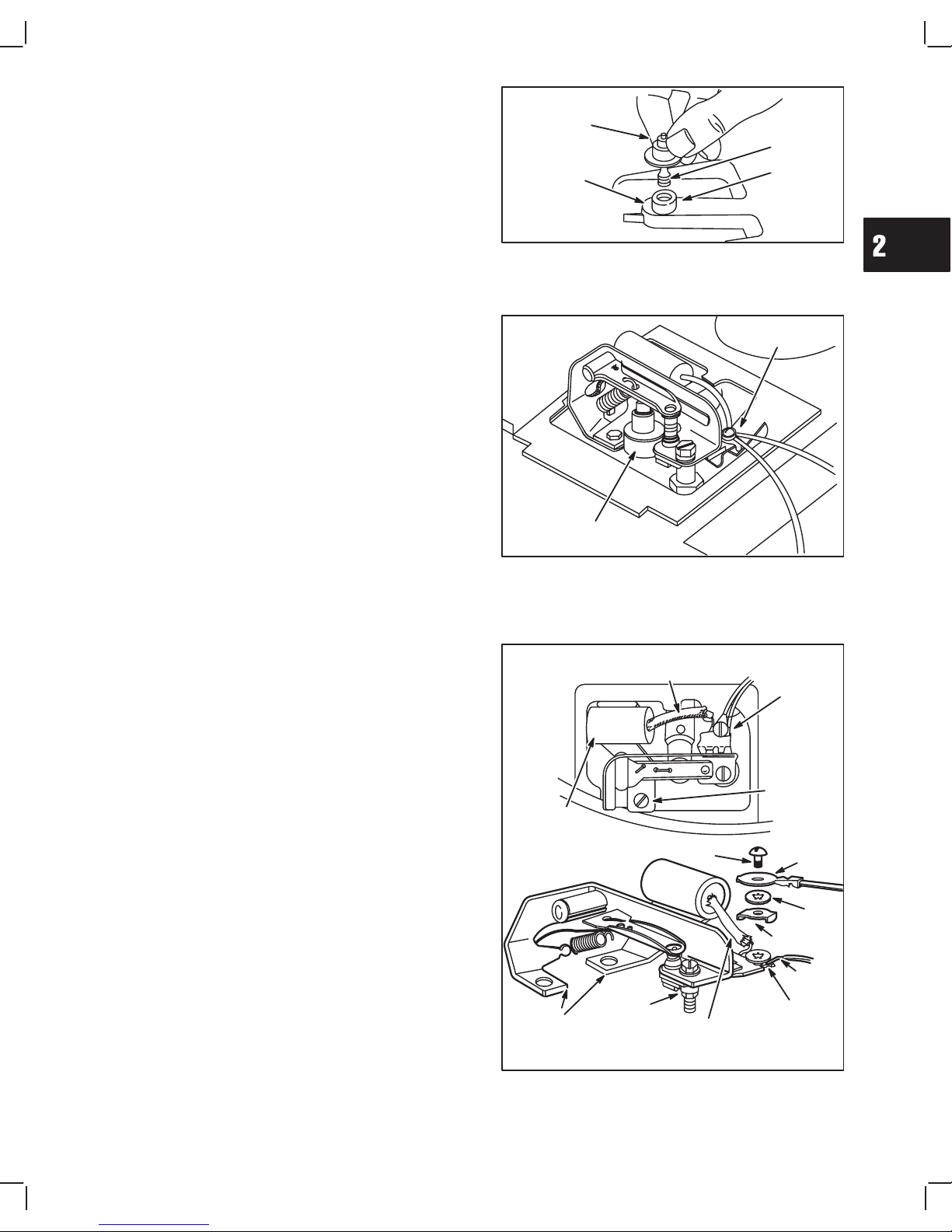

Remove Breaker Points

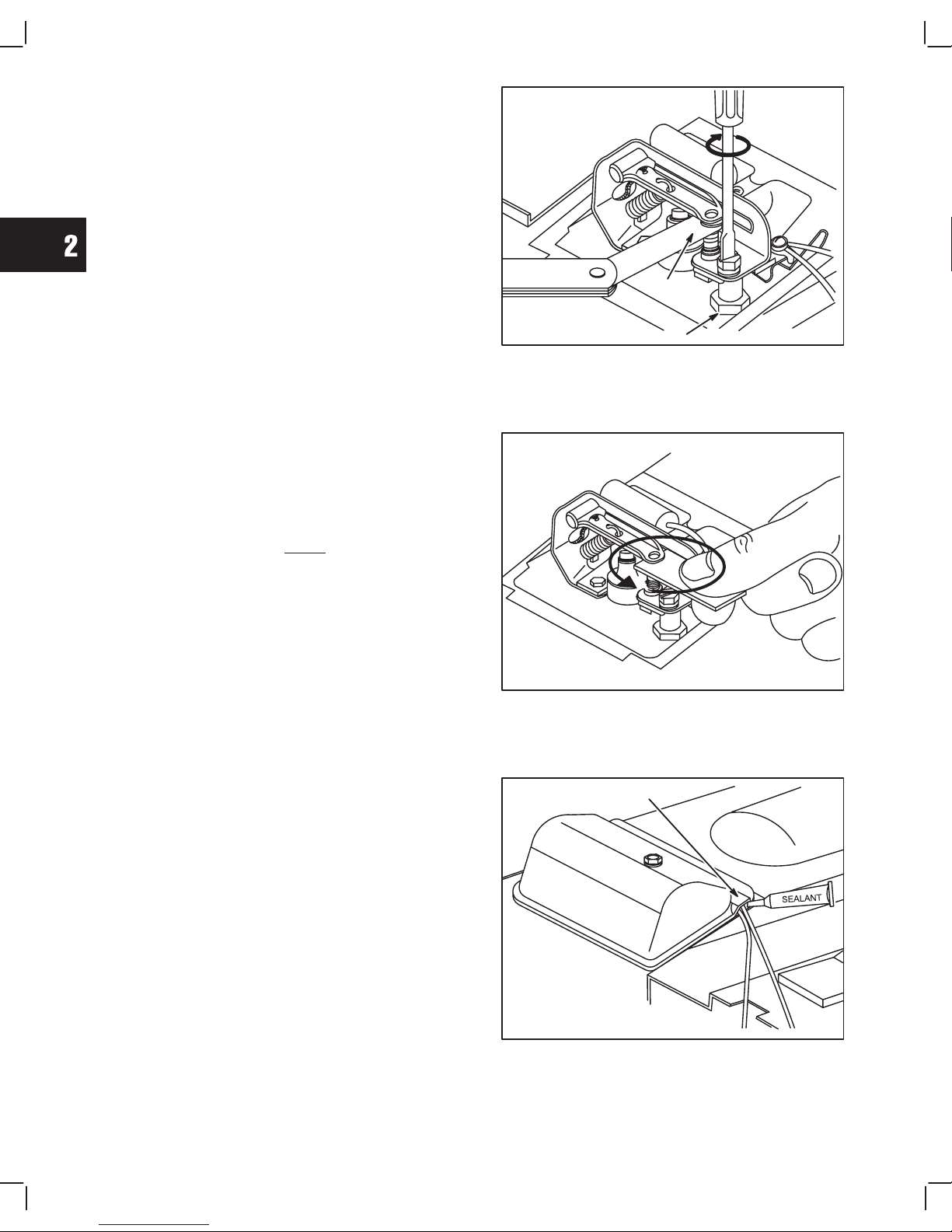

1. Remove screw and breaker point cover.

2. Remove condenser mounting screw.

3. Loosen lock nut, then adjusting screw, Fig. 16.

4. Remove breaker points and condenser.

5. Remove ground wire, condenser wire and primary

wire.

Fig. 16 – Remove Condenser and Points

LOOSEN

BREAKER

POINT

MOUNTING

BRACKET

ADJUSTING

SCREW

LOCK

NUT

CONDENSER

MOUNTING

SCREW

LOOSEN

Check Breaker Point Plunger And Seal

Reject length of plunger is 1.115” (28.32 mm), Fig. 17.

Replace plunger if worn if fiber tip is loose.

Replace plunger seal if torn or leaking.

Fig. 17 – Check Plunger and Seal

FIBER

TIP

PLUNGER

SEAL

REJECT AT

1.115” (28.32 mm)

UP

2

7

Install Plunger And Seal

1. Assemble seal to plunger.

2. Install plunger with fiber tip up, Fig. 18.

3. Slide seal over p lunger b oss u ntil i t c ontacts c ylinder.

Fig. 18 – Install Plunger and Seal

FIBER TIP UP

SEAL LIP

SHOULD

CONTACT

CYLINDER

GROOVE

PLUNGER

BOSS

Install Breaker Points

Place breaker point cover gasket on engine with tab to

right of breaker plunger boss, Fig. 19.

Fig. 19 – Install Cover Gasket

BREAKER

PLUNGER BOSS

GASKET

TAB

For ease of assembly, install ground wire, condenser

wire and armature primary wire to point terminal before

installing points, Fig. 20.