Page 1

Operator’s Manual

Model 21000 Model 21100

Fource

Fource

BRIGGSandSTRATTON.com

ECopyright Briggs & Stratton Corporation

Milwaukee, Wisconsin 53201 U.S.A.

Form No. 277097-3/07

Printed in U.S.A.

Page 2

Safety References

The safety alert symbol is used to identify safety

information about hazards that can result in personal

injury. A signal word (DANGER, WARNING, or

CAUTION) is used with the alert symbol to indicate the

likelihood and the potential severity of injury. In addition,

a hazard symbol may be used to represent the type of

hazard.

SYMBOLS ASSOCIATED

WITH THIS ENGINE:

Fire

Explosion

Read

Manual

Oil

DANGER indicates a hazard which, if not

avoided, will result in death or serious

injury.

WARNING indicates a hazard which, if not

avoided, could result in death or serious

injury.

CAUTION indicates a hazard which, if not

avoided, might result in minor or moderate

injury.

CAUTION, when used without the alert

symbol, indicates a situation that could result

in damage to the engine.

This manual contains safety

information to make you aware of

the hazards and risks associated with engines, and

how to avoid them. Because Briggs & Stratton does

not necessarily know what equipment this engine will

power, it is important that you read and understand

these instructions and the instructions for the

equipment this engine powers.

Kickback

Hot Surface

Toxic F u mes

Moving Parts

Shock

Primer

Fuel

Fuel Shutoff

On Off

Choke

Stop

WARNING

Briggs & Stratton does not approve or authorize the

use of these engines on 3-wheel All Terrain

Vehicles (ATVs), motor bikes, fun/recreational

go-karts, aircraft products or vehicles intended for

use in competitive events. Use of these engines in

such applications could result in property damage,

serious injury (including paralysis), or even death.

Safety References 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Table of Contents

Features 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 4. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Starting 5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stopping 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications and Emission Information 11. . . . . . . . . . .

Maintenance 12-14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty Information 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

2

WARNING

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

CAUTION

This engine is shipped from Briggs & Stratton

without oil. If you start the engine without oil,

the engine will be damaged beyond repair and

will not be covered under warranty.

Page 3

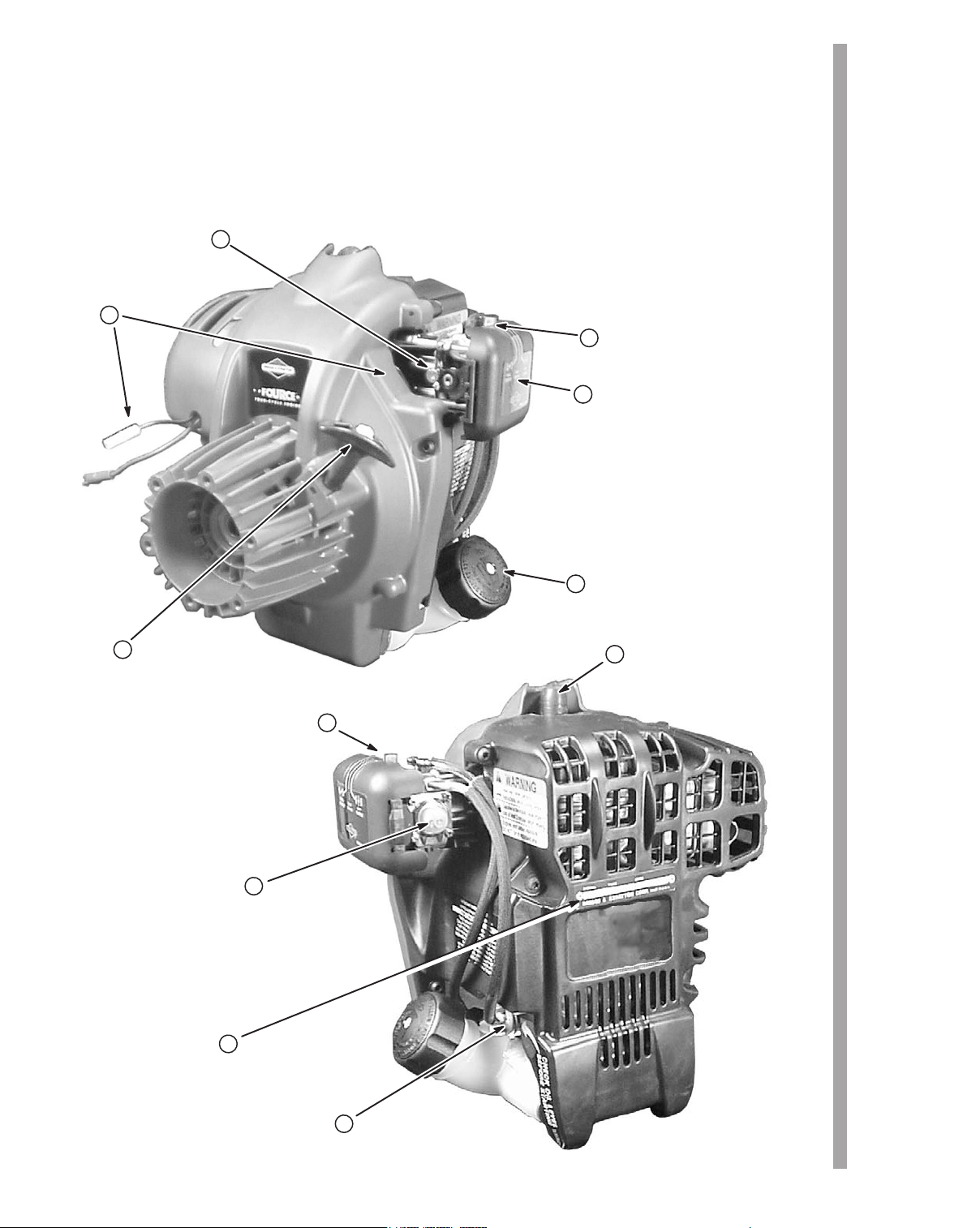

Features

1. Carburetor

2. Stop Switch location, if equipped/stop wires

3. Rope Handle

4. Fuel Fill

5. Air Cleaner

6. Choke

1

2

7. Spark Plug

8. Primer Bulb

9. Engine Identification

Model XXXXX Type XXXXXX Code

XXXXXXXX

10. Oil Fill/Dipstick

6

5

4

3

6

8

9

7

10

3

Page 4

Safety

CAUTION

This engine is shipped from Briggs & Stratton

without oil. If you start the engine without oil,

the engine will be damaged beyond repair and

will not be covered under warranty.

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe burns

or death.

WHEN ADDING FUEL

• Turn engine OFF and let engine cool at least 2

minutes before removing gas cap.

• Fill fuel tank outdoors or in well-ventilated area.

• Do not overfill fuel tank.

• Keep gasoline away from sparks, open flames,

pilot lights, heat, and other ignition sources.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

WHEN STARTING ENGINE

• Make sure spark plug, muffler, fuel cap and air

cleaner are in place.

• Do not crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before

starting engine.

• If engine floods, set choke to OPEN/RUN

position, place throttle in FAST and crank until

engine starts.

WHEN OPERATING EQUIPMENT

• Do not choke carburetor to stop engine.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY.

WHEN STORING GASOLINE OR EQUIPMENT WITH FUEL IN TANK

• Store away from furnaces, stoves, water

heaters or other appliances that have pilot light

or other ignition source because they can ignite

gasoline vapors.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable

gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area, do

not start engine.

• Do not use pressurized starting fluids because

vapors are flammable.

WARNING

Rapid retraction of starter cord (kickback)

will pull hand and arm toward engine

faster than you can let go.

Broken bones, fractures, bruises or

sprains could result.

• When starting engine, pull cord slowly until

resistance is felt, then pull rapidly.

• Direct coupled equipment components such as,

but not limited to, blades, impellers, pulleys,

sprockets, etc., must be securely attached.

WARNING

Rotating parts can contact or entangle

hands, feet, hair, clothing, or accessories.

Traumatic amputation or severe laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become caught.

WARNING

Engines give off carbon monoxide, an

odorless, colorless, poison gas.

Breathing carbon monoxide can cause

nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area,

even if doors or windows are open.

WARNING

Running engines produce heat. Engine

parts, especially muffler, become

extremely hot.

Severe thermal burns can occur on

contact.

Combustible debris, such as leaves,

grass, brush, etc. can catch fire.

• Allow muffler, engine cylinder and fins to cool

before touching.

• Remove accumulated debris from muffler area

and cylinder area.

• Install and maintain in working order a spark

arrester before using equipment on

forest-covered, grass-covered, brush-covered

unimproved land. The state of California

requires this (Section 4442 of the California

Public Resources Code). Other states may

have similar laws. Federal laws apply on federal

land.

4

Page 5

Starting

This engine is shipped WITHOUT oil. See section on oil

for recommendations, capacity, and filling details.

Full Choke

Half Choke

Off Position

Choke Lever

Primer Bulb

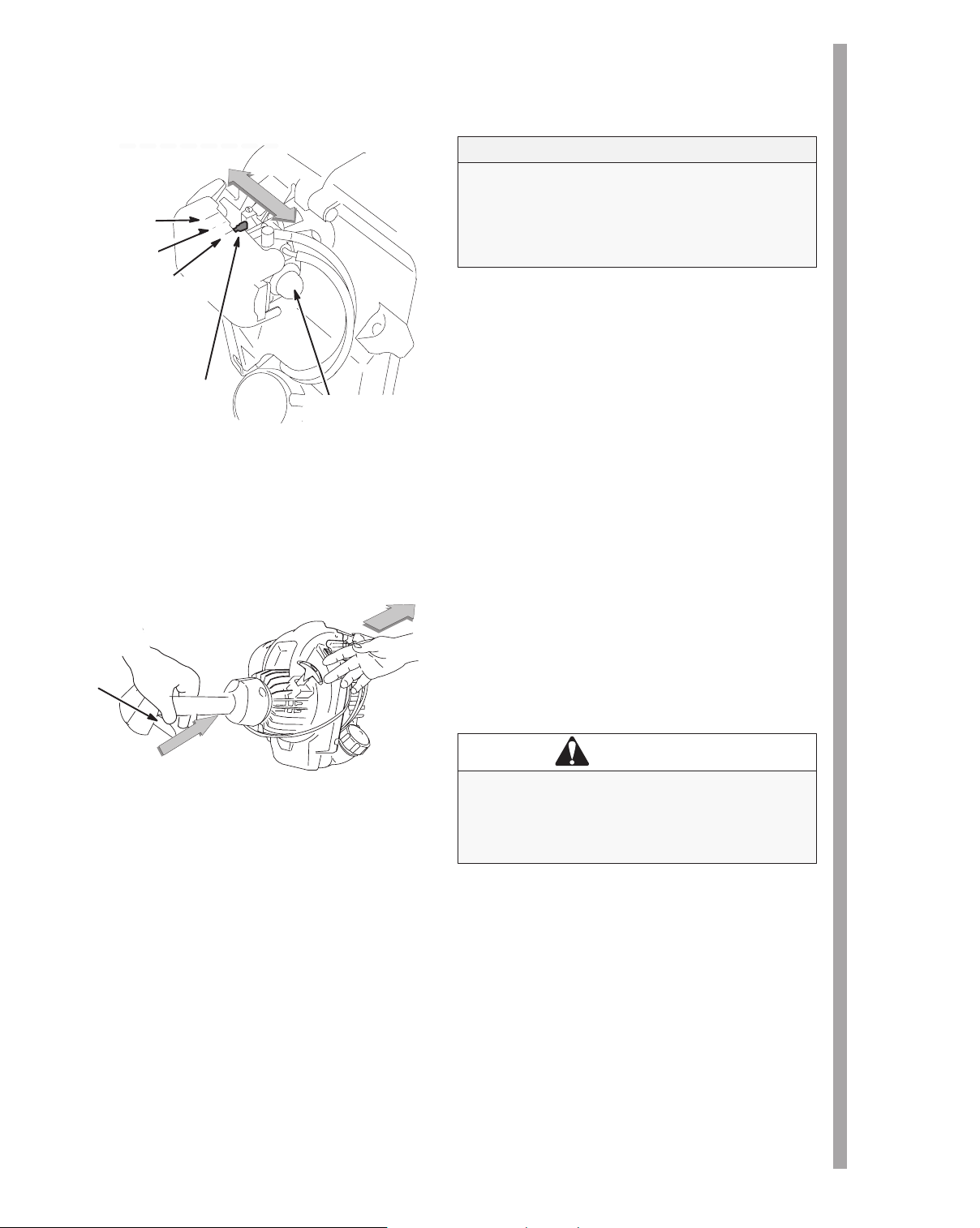

1. Set unit on flat surface and push primer bulb 15

times FOR A NEW ENGINE. Push primer bulb 8

times for all future starts.

2. Move red choke lever to the FULL CHOKE

position.

3. Not all applications have a throttle. If the

equipment has this a throttle, squeeze throttle

trigger. If the engine is still warm from a previous

start, do not squeeze throttle.

CAUTION

Operating engine at an excessive speed without

proper engine loading will cause damage. DO NOT

operate a string trimmer with a line shorter than

10’’ diameter for extended periods.

Typical

Throttle

Trigger

4. Pull starter handle sharply until engine runs.

5. Wait a maximum of 10 seconds, then move

choke lever to HALF CHOKE position.

6. Run the engine at HALF CHOKE for 20 seconds

or until unit accelerates smoothly. Move choke to

OFF position.

7. Wait a minimum of 20 seconds, then release

throttle trigger.

WARNING

The manufacturer of the equipment on which

this engine is installed specifies top speed at

which the engine will be operated. DO NOT

EXCEED this speed.

5

Page 6

Stopping

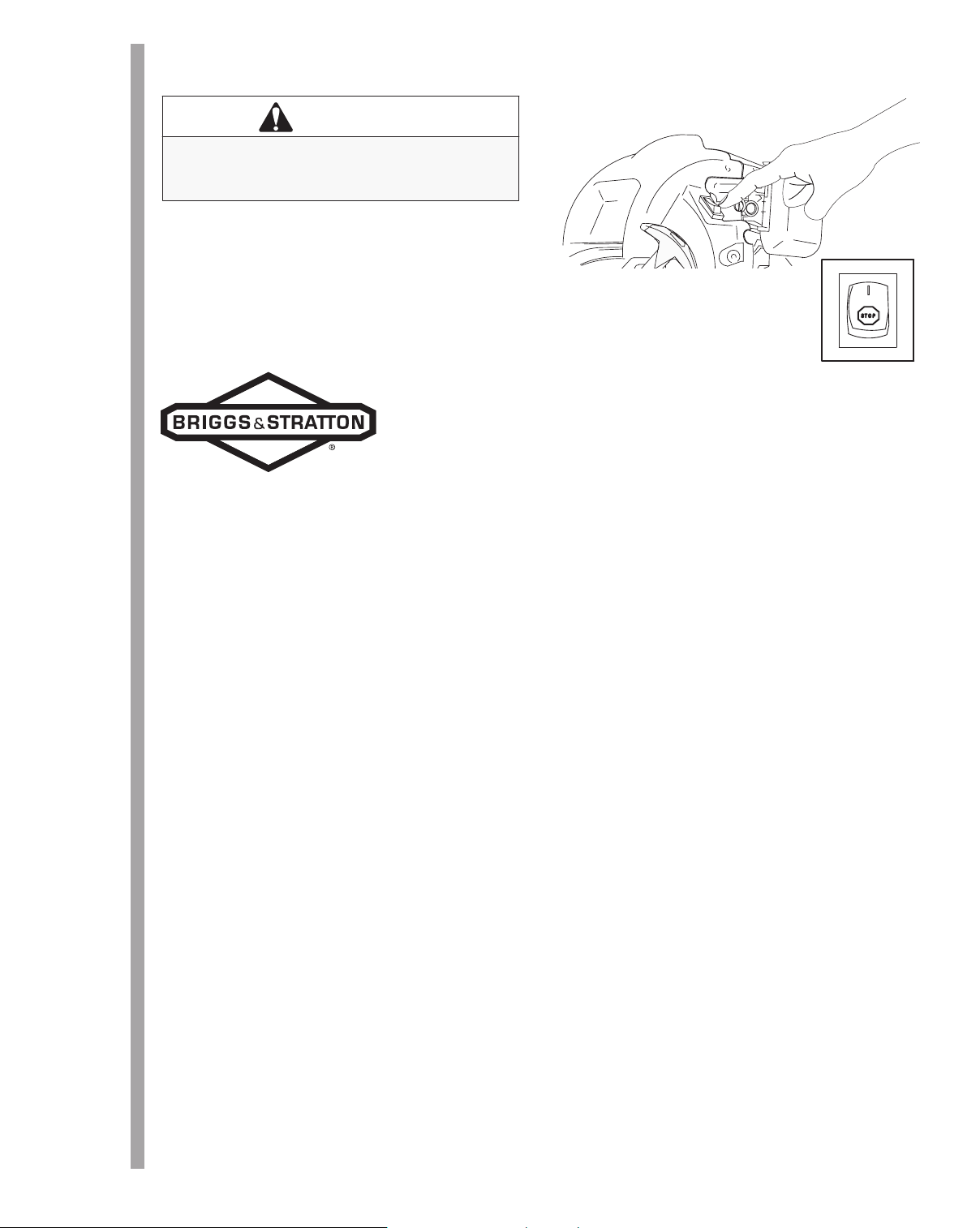

WARNING

Do not stop engine by moving choke control to

CHOKE. Backfire, fire or engine damage could

occur.

1. Depress stop switch located on the engine or

equipment to stop.

Need Assistance?

Go to www.briggsandstratton.com or call 1-800-233-3723

6

Page 7

Troubleshooting

CAUTION

Engine will not start

Out of fuel

• Prime engine

• If engine is cold, ensure choke is set

correctly.

• Add fuel

Engine flooded

• Set choke to FULL CHOKE position and

continue to pull starter handle.

Fouled spark plug/engine fails to

product spark

• Remove spark plug and clean it. Check

the spacing on the electrode and set the

gap to the correct dimension. See

Maintenance Section. If plug is damaged,

replace with a new spark plug.

• Ensure the spark plug is installed and wire

is connected.

This engine is shipped from Briggs & Stratton

without oil. If you start the engine without oil, the

engine will be damaged beyond repair and will

not be covered under warranty.

WARNING

• Ensure fuel cap is in place before

starting engine

• Turn engine OFF and let engine

cool at least 2 minutes before

removing fuel cap.

• Check fuel lines, tank, cap, and

fittings frequently for cracks or

leaks. Replace if necessary.

• Do not crank engine with spark plug

removed.

Engine is smoking or running rough

• There maybe slight oil accumulation in the

crankcase upon starting. This is normal.

• If excessive smoke or smoke is heavy,

ensure choke is in OFF CHOKE position.

• Check for fouled spark plug.

• Check air filter for debris.

CAUTION

If engine is tipped to transport equipment, to

remove debris, to drain oil, etc., keep the spark

plug side of engine up.

7

Page 8

Oil

Capacity

Engine holds approximately 3 ounces (90 ml).

Change oil after first 4 hours of use.

Oil Recommendation

• Use a high quality detergent oil classified “For

Service SF, SG, SH, SJ” or higher, such as Briggs &

Stratton SAE 30, Part Number 100091 (3.2oz) or

Briggs & Stratton Synthetic Oil, Part Number

100074.

• Do not use special additives.

• Choose a viscosity according to the table below.

SAE Viscosity Grades

**

*

-20 0 20 40 60 80 100

°F

-30 -20 -10 0 10 20 30 40

°C

STARTING TEMPERATURE RANGE ANTICIPATED BEFORE NEXT OIL CHANGE

Air cooled engines run hotter than automotive engines.

The use of non-synthetic multi-viscosity oils (5W-30,

10W-30, etc.) in temperatures above 40° F (4° C) will

result in higher than normal oil consumption. When

using a multi-viscosity oil, check oil level more

frequently.

32

CAUTION

Adding Oil

CAUTION

KEEP ENGINE LEVEL

Engine must be level, with oil fill facing up, to

check oil. If engine is not level, dipstick reading will

not be accurate. This will lead to possible over or

under filling causing damage to the engine.

• Check oil level before starting the engine.

• Check level daily, or after every eight (8) hours of

use.

• Keep oil level at FULL.

• DO NOT over fill. Use oil measure cup for filling.

• Add only half ounce to 1 ounce of oil at a time.

1 ounce

0.5 ounce

1. Place engine level. Remove dipstick. Use the oil

measure cup to pour oil slowly into engine.

Do not over fill.

CAUTION

* Synthetic oil must be used when operating engine

under 40_ F (4_ C) or engine damage will occur.

CAUTION

** Use of SAE 30 oil below 50° F (10° C) will result in hard

starting and possible engine damage due to inadequate

lubrication.

Oil Fill

2. Tighten dipstick down.

3. To check oil level, remove and wipe the dipstick

clean with cloth. Tighten dipstick down. Remove

and check oil level.

Dipstick

4. Verify FULL level of oil by presence of oil in hole

on dipstick, or by measure line.

Full

5. If needed, add only half ounce of oil at a time to

bring it to FULL. Re-check level.

8

Page 9

Changing Oil & Checking Level

Change oil after first 4 hours of use, then every 8 hours.

Change oil every 4 hours when operating the engine

under heavy load or in high temperatures.

WARNING

• Disconnect spark plug

wire and keep it away

from spark plug.

1. Change oil while engine is OFF but still warm,

ensure fuel cap is tightened securely.

2. Remove dipstick and drain oil in direction shown.

3. Place engine level. Using oil measure cup pour

oil slowly adding half ounce at a time. Do not

over fill.

Engine holds approximately 3 oz (90 ml).

Note:

4. To re-check oil level, remove dipstick and wipe

clean with cloth. Tighten dipstick down. Remove

and check oil level.

5. Replace dipstick tightly, and reconnect spark plug

wire before starting engine.

CAUTION

Used oil is a hazardous waste product. Dispose

of used oil properly. Do not discard with

household waste. Check with your local

authorities, service center, or dealer for safe

disposal/recycling facilities.

Oil

Fill

9

Page 10

Fuel

Type of Fuel to Use

• Use clean, fresh, regular unleaded gasoline with a

minimum of 85 octane. Fresh fuel prevents gum

from forming in the fuel system or on essential

carburetor parts. Purchase fuel in quantity that can

be used within 30 days.

• For engine protection use Briggs & Stratton

Gasoline Additive available from your Authorized

Briggs & Stratton Dealer.

• Do not use gasoline which contains Methanol.

• Do not mix oil with gasoline.

• This engine is certified to operate on gasoline.

Exhaust Emission Control System: EM (Engine

Modifications).

Adding Fuel

1. Turn engine OFF and let engine cool at least 2

minutes before removing gas cap.

2. Tilt engine at angle shown to properly fill fuel

tank.

CAUTION

Some fuels, called oxygenated or reformulated

fuels, are fuels blended with alcohols or ethers.

Excessive amounts of these blends can

damage the fuel system or cause performance

problems. If any undesirable operating

symptoms occur, use gasoline with a lower

percentage of alcohol or ether.

Fuel Fill

3. Remove cap and add fuel until level is

approximately 1’’ below top of fuel tank neck. Be

careful not to over fill.

4. Replace cap before starting.

10

Page 11

Specifications

CAUTION

All the components used to build this engine

assembly must remain in place for the proper

operation of this engine.

We recommend that you use an authorized Briggs &

Stratton Service Dealer for all maintenance and service

of the engine and engine parts. Use only genuine

Briggs & Stratton parts.

GENERAL INFORMATION

This is a single cylinder, air-cooled engine. It is a low

emissions engine.

In the state of California, Model 21000 and 21100 engines

are certified by the California Air Resources Board to

meet emissions standards for 50 hours. Such certification

does not grant the purchaser, owner or operator of this

engine any additional warranties with respect to the

performance or operational life of this engine. This engine

is warranted solely according to the product and

emissions warranties stated elsewhere in this manual.

Model 21000

Bore 1.575 in. (40 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stroke 1.065 in. (27 mm). . . . . . . . . . . . . . . . . . . . . . . . . .

Displacement 2.074 cu. in. (34 cc). . . . . . . . . . . . . . . . . .

Model 21100

Bore 1.575 in. (40 mm). . . . . . . . . . . . . . . . . . . . . . . . . . . .

Stroke 1.250 in. (31.75 mm). . . . . . . . . . . . . . . . . . . . . . .

Displacement 2.44 cu. in. (40 cc). . . . . . . . . . . . . . . . . . .

For practical operation, the horsepower loading should not

Note:

exceed 85% of rated horsepower. Engine power will decrease 3-1/2%

for each 1,000 feet (300 meters) above sea level and 1% for each 10°

F (5.6° C) above 77° F (25° C).

Tune-Up Specifications

Armature air gap 0.010 − 0.014 in. (0.25 − 0.36 mm). .

Spark plug gap 0.025 in. (0.64 mm). . . . . . . . . . . . . . . . .

Valve clearance with valve springs installed and piston 1/4

in. (6 mm) past top dead center (check when engine is

cold). See Repair Manual P/N 271172.

Intake 0.002 − 0.004 in. (0.05 − 0.10 mm). . . . . . . . . . . .

Exhaust 0.002 − 0.004 in. (0.05 − 0.10 mm). . . . . . . . . .

Model, Type and Code Number

To get replacement parts or technical assistance in the

future write your engine Model, Type and Code number

along with the date of purchase here. These numbers

are located on your engine. For the location, see

page 3, Engine Features.

Model

Type

Technical Information

Engine Power Rating Information

The gross power rating for individual gas engine

models is labeled in accordance with SAE (Society of

Automotive Engineers) code J1940 (Small Engine

Power & Torque Rating Procedure), and rating

performance has been obtained and corrected in

accordance with SAE J1995 (Revision 2002-05).

Torque values are derived at 3060 RPM; horsepower

values are derived at 3600 RPM. Actual gross engine

power will be lower and is affected by, among other

things, ambient operating conditions and

engine-to-engine variability. Given both the wide array

of products on which engines are placed and the

variety of environmental issues applicable to operating

the equipment, the gas engine will not develop the

rated gross power when used in a given piece of power

equipment (actual “on-site” or net power). This

difference is due to a variety of factors including, but

not limited to, accessories (air cleaner, exhaust,

charging, cooling, carburetor, fuel pump, etc.),

application limitations, ambient operating conditions

(temperature, humidity, altitude), and engine-to-engine

variability. Due to manufacturing and capacity

limitations, Briggs & Stratton may substitute an engine

of higher rated power for this Series engine.

Emission Information

Engines that are certified to meet the California Air Resources

Board (CARB) Tier 2 Emission Standards must display

information regarding the Emissions Durability Period and the

Air Index. Briggs & Stratton makes this information available to

the consumer on our emission labels. The engine emission

label will indicate certification information.

The Emissions Durability Period describes the number of

hours of actual running time for which the engine is certified to

be emissions compliant, assuming proper maintenance in

accordance with the Operating & Maintenance Instructions.

The following categories are used:

Moderate: Engine is certified to be emission compliant for 50

hours of actual engine running time.

Intermediate: Engine is certified to be emission compliant for

125 hours of actual engine running time.

Extended: Engine is certified to be emission compliant for 300

hours of actual engine running time. For example, a typical

walk-behind lawn mower is used 20 to 25 hours per year.

Therefore, the Emissions Durability Period of an engine with

an intermediate rating would equate to 10 to 12 years.

Certain Briggs & Stratton engines will be certified to meet the

United States Environmental Protection Agency (USEPA)

Phase 2 emission standards. For Phase 2 certified engines,

the Emissions Compliance Period referred to on the Emissions

Compliance label indicates the number of operating hours for

which the engine has been shown to meet Federal emission

requirements.

Code

For handheld engines:

Category C = 50 hours

Category B = 125 hours

Category A = 300 hours

11

Page 12

Maintenance

Regular maintenance will improve the performance and

extend the life of the engine. See any Authorized Briggs

& Stratton Dealer for service. Use only genuine

Briggs & Stratton parts. Other parts may not

perform as well, may damage the engine, and may

result in injury. In addition, use of other parts may void

your warranty.

Emission Control

Maintenance, replacement or repair of the emission

control devices and systems may be performed by

any nonroad engine repair establishment or

individual. However, to obtain no charge repairs under

the terms and provisions of the Briggs & Stratton

warranty statement, any service or emission control

part repair or replacement must be performed by a

factory authorized dealer.

WARNING

Unintentional sparking can result in

fire or electric shock.

Fire or explosion can cause severe

burns or death.

Unintentional start-up can result in

entanglement, traumatic

amputation, or laceration.

• Disconnect spark plug wire and keep it away

from spark plug.

• Disconnect battery at negative terminal (only

engines with electric start).

• Use only correct tools.

During maintenance or repairs:

• Do not strike the flywheel with a hammer or

hard object because the flywheel may later

shatter during operation.

• Do not tamper with governor spring, links or

other parts to increase engine speed.

When testing for spark:

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

Follow the instructions and schedules indicated below.

Task

Perform task at hourly

or calendar interval,

whichever comes first.

Check Oil Level

Change Oil **

Service AIr Filter*

Clean/Replace Spark Plugs

* Clean more often under dusty conditions or when airborne debris is present. Replace air cleaner, if very dirty.

** Change oil after first 4 hours of use, then every 8 hours. Change oil every 4 hours when operating the engine

under heavy load or in high temperatures.

12

Page 13

Air Cleaner

Check and clean the intake chamber for dirt. If the foam

air filter is dirty and worn, replace with clean filter.

1. Push cover tab to release cover, then pull cover

away from engine to service air filter.

Clean intake

area

Cover

Tab

CAUTION

Do not use pressurized air or solvents to clean

cartridge. Pressurized air can damage cartridge;

solvents will dissolve cartridge.

WARNING

Ensure air cleaner, retainer, and cover are

properly installed before starting engine.

Foam Air Fil-

ter

Foam Air Filter

To clean wash in liquid detergent and water. Squeeze

dry in a clean cloth. Allow to dry thoroughly. Dip foam

air filter in clean engine oil, then squeeze out excess oil

in clean cloth. Engine will smoke if too much oil is left

on the filter.

13

Page 14

Cleaning Debris

Daily or before every use, clean accumulated debris

from engine. Keep linkage, spring and controls clean.

Keep area behind muffler free of any combustible

debris.

Spark Plug

Check the spark plug every 50 hours. Replace the

spark plug if upon inspection the electrode is burned or

worn. Ensure the spark plug is clean. Check the gap

with a feeler gauge and reset if necessary. Use only

Briggs & Stratton Spark Tester (part number 19368) to

check for spark.

Champion style plug set gap at 0.025 in.. . . . . . . . . . . .

NGK style plug set gap at 0.020-0.024 in.. . . . . . . . . . . .

Use a wire gauge tool to check

the gap on the spark plug.

CAUTION

Do not use water to clean engine parts. Water

could contaminate fuel system. Use a brush or dry

cloth.

WARNING

Engine parts should be kept clean to reduce the risk

of overheating and ignition of accumulated debris.

WARNING

Ensure air cleaner, retainer, and cover are

properly installed before starting engine.

Note: In some areas, local law requires using a resistor

spark plug to suppress ignition signals. If this engine

was originally equipped with a resistor spark plug, use

same type for replacement.

Fuel System

WARNING

Replacement parts for fuel system (cap, hoses,

tanks, filters, etc.) must be the original parts, otherwise fire can occur.

14

Page 15

Storage

The following precautions should be taken if storing

your trimmer unit for a period exceeding 30 days, or for

seasonal storage.

• While engine is still warm, change oil.

• Clean engine of surface debris, chaff or grass.

• Drain all fuel from fuel tank into proper receptacle

for storage.

• Press primer bulb 15 times to purge fuel from

carburetor and fuel lines. Drain remaining fuel into

proper receptacle. If fuel is to be disposed, please

refer to local rules for proper disposal.

• Remove spark plug. Place 1 teaspoon or 5 ml. of oil

into spark plug hole.

• Pull starter rope slowly 8-10 times to properly coat

the cylinder bore and piston for storage. Replace

spark plug and tighten. Any residual oil may burn off

in subsequent starts. This may result in white

smoke emission from muffler.

• This trimmer may be stored in a variety of positions.

It is best to store in horizontal position with the

spark plug up. Do not store or transport with the

spark plug down.

Storing or transporting with the spark plug down

Note:

will result in hard starting and/or engine smoking.

• Store in a clean dry area.

• When removing unit from storage, only use fresh

gasoline. Perform operation checks (see

maintenance schedule) before starting engine.

WARNING

When storing fuel or equipment with fuel in

tank:

• Store away from furnaces, stoves, water heaters,

or other appliances that have a pilot light or other

ignition source because they can ignite vapors.

When Transporting Equipment:

• Transport with fuel tank EMPTY or with

fuel shut-off valve OFF.

15

Page 16

Service

See an Authorized Briggs & Stratton Service Dealer for

all your engine service needs. Each one carries a stock

of Genuine Briggs & Stratton Parts and is equipped

with special service tools. Trained mechanics assure

expert repair service on all Briggs & Stratton engines.

Only dealers advertising as “Authorized Briggs &

Stratton” are required to meet Briggs &

Stratton standards.

When you purchase equipment

powered by Briggs & Stratton, you are

assured of highly skilled, reliable

engine service at more than 30,000

Authorized Service Dealers worldwide,

including more than 6,000 Master

Service Technicians. Look for these

signs wherever Briggs & Stratton

service is offered.

You may find the nearest Authorized Service Dealer

in our dealer locator map at

www.briggsandstratton.com, or by

calling 1-800-233-3723

PARTIAL LIST OF

GENUINE BRIGGS & STRATTON

PARTS

PART PART NO.

Air Filter Foam 696923. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil (3.2 oz) 100091. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil (20 oz) 100005. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil Synthetic (32 oz) 100074. . . . . . . . . . . . . . . . . . . . . . .

Fuel Stabilizer 5041. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 696876. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug Wrench 19374. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Tester 19368. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Tachometer 19389. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

An illustrated shop manual includes common

specifications and detailed information covering

adjustment, tune-up and repair of Briggs & Stratton

single cylinder, 4 cycle engines. It is available for

purchase from an Authorized Briggs & Stratton Service

Dealer or you can order it from

www.briggsandstratton.com.

16

Page 17

Warranty Information

Briggs & Stratton Corporation (B&S), the California Air Resources Board (CARB)

and the United States Environmental Protection Agency (U.S. EPA)

Emissions Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

The California Air Resources Board (CARB), U.S. EPA and

B&S are pleased to explain the Emissions Control System

Warranty on your small off-road engine (SORE). In

California, new small off-road engines model year 2006 and

later must be designed, built and equipped to meet the

State’s stringent anti-smog standards.

Elsewhere in the United States, new non-road, spark-ignition

engines certified for model year 1997 and later must meet

similar standards set forth by the U.S. EPA. B&S must

warrant the emissions control system on your engine for the

periods of time listed below, provided there has been no

abuse, neglect or improper maintenance of your small

off-road engine.

Your emissions control system includes parts such as the

carburetor, air cleaner, ignition system, fuel line, muffler and

catalytic converter. Also included may be connectors and

other emissions related assemblies.

Where a warrantable condition exists, B&S will repair your

small off-road engine at no cost to you including diagnosis,

parts and labor.

Briggs & Stratton Emissions Control Defects Warranty Coverage

Small off-road engines are warranted relative to emissions control parts defects for a period of two years, subject to provisions set

forth below. If any covered part on your engine is defective, the part will be repaired or replaced by B&S.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible for

the performance of the required maintenance listed in your

Operating and Maintenance Instructions. B&S recommends

that you retain all your receipts covering maintenance on

your small off-road engine, but B&S cannot deny warranty

solely for the lack of receipts or for your failure to ensure the

performance of all scheduled maintenance.

As the small off-road engine owner, you should however be

aware that B&S may deny your warranty coverage if your

small off-road engine or a part has failed due to abuse,

neglect, improper maintenance or unapproved

modifications.

You are responsible for presenting your small off-road engine

to an Authorized B&S Service Dealer as soon as a problem

exists.

The undisputed warranty repairs should be completed in a

reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights and

responsibilities, you should contact a B&S Service

Representative at 1-414-259-5262.

The emissions warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is not

related to an in-use emissions test.

Briggs & Stratton Emissions Control Defects Warranty Provisions

The following are specific provisions relative to your Emissions Control Defects Warranty Coverage. It is in addition to the B&S

engine warranty for non-regulated engines found in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emissions control systems parts) to the

extent these parts were present on the engine

purchased.

a. Fuel Metering System

• Cold start enrichment system

• Carburetor and internal parts

• Fuel pump

• Fuel line, fuel line fittings, clamps

• Fuel tank, cap and tether

• Carbon canister

b. Air Induction System

• Air cleaner

• Intake manifold

• Purge and vent line

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system, Pulse valve

e. Miscellaneous Items

• Vacuum, temperature, position, time sensitive

valves and switches

• Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and each subsequent

purchaser that the Warranted Parts shall be free from

defects in materials and workmanship which caused the

failure of the Warranted Parts for a period of two years

from the date the engine is delivered to a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be

performed at no charge to the owner, including

diagnostic labor which leads to the determination that a

Warranted Part is defective, if the diagnostic work is

performed at an Authorized B&S Service Dealer. For

emissions warranty service contact your nearest

Authorized B&S Service Dealer as listed in the “Yellow

Pages” under “Engines, Gasoline,” “Gasoline Engines,”

“Lawn Mowers,” or similar category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the

provisions of the B&S Engine Warranty Policy. Warranty

coverage shall be excluded for failures of Warranted

Parts which are not original B&S parts or because of

abuse, neglect or improper maintenance as set forth in

the B&S Engine Warranty Policy. B&S is not liable to

cover failures of Warranted Parts caused by the use of

add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for

replacement as required maintenance or which is

scheduled only for regular inspection to the effect of

“repair or replace as necessary” shall be warranted as to

defects for the warranty period. Any Warranted Part which

is scheduled for replacement as required maintenance

shall be warranted as to defects only for the period of time

up to the first scheduled replacement for that part. Any

replacement part that is equivalent in performance and

durability may be used in the performance of any

maintenance or repairs. The owner is responsible for the

performance of all required maintenance, as defined in

the B&S Operating and Maintenance Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any

engine components caused by the failure of any

Warranted Part still under warranty.

17

Page 18

ABOUT YOUR ENGINE WARRANTY

Briggs & Stratton welcomes warranty repair and

apologizes to you for being inconvenienced. Any

Authorized Service Dealer may perform warranty

repairs. Most warranty repairs are handled routinely,

but sometimes requests for warranty service may not

be appropriate. For example, warranty would not apply

if engine damage occurred because of misuse, lack of

routine maintenance, shipping, handling, warehousing

or improper installation. Similarly, warranty is void if

the serial number of the engine has been removed or

the engine has been altered or modified.

If a customer differs with the decision of the Service

Dealer, an investigation will be made to determine

whether the warranty applies. Ask the Service Dealer

to submit all supporting facts to his Distributor or the

Factory for review. If the Distributor or the Factory

decides that the claim is justified, the customer will be

fully reimbursed for those items that are defective. To

avoid misunderstanding which might occur between

the customer and the Dealer, listed below are some of

the causes of engine failure that the warranty does not

cover.

3. Leaking carburetors, clogged fuel pipes, sticking

valves, or other damage, caused by using

contaminated or stale fuel.

4. Parts which are scored or broken because an

engine was operated with insufficient or

contaminated lubricating oil, or an incorrect grade

of lubricating oil (check and refill when necessary

and change at recommended intervals.) OIL

GARD may not shut down running engine. Engine

damage may occur if oil level is not properly

maintained.

5. Repair or adjustment of associated parts or

assemblies such as clutches, transmissions,

remote controls, etc., which are not manufactured

by Briggs & Stratton.

6. Damage or wear to parts caused by dirt, which

entered the engine because of improper air

cleaner maintenance, re-assembly, or use of a

non-original air cleaner element or cartridge. (At

recommended intervals, clean and and/or replace

the filter as stated in the Operator’s Manual.

Normal wear:

Engines, like all mechanical devices, need periodic

parts service and replacement to perform well.

Warranty will not cover repair when normal use has

exhausted the life of a part or an engine.

Improper maintenance:

The life of an engine depends upon the conditions

under which it operates, and the care it receives.

Some applications, such as tillers, pumps and rotary

mowers, are very often used in dusty or dirty

conditions, which can cause what appears to be

premature wear. Such wear, when caused by dirt,

dust, spark plug cleaning grit, or other abrasive

material that has entered the engine because of

improper maintenance, is not covered by warranty.

This warranty covers engine related defective

material and/or workmanship only

replacement or refund of the equipment to which

the engine may be mounted. Nor does the

warranty extend to repairs required because of:

1. PROBLEMS CAUSED BY PARTS THAT ARE

NOT ORIGINAL BRIGGS & STRATTON PARTS.

2. Equipment controls or installations that prevent

starting, cause unsatisfactory engine performance,

or shorten engine life. (Contact equipment

manufacturer.)

, and not

7. Parts damaged by over-speeding, or overheating

caused by grass, debris, or dirt, which plugs or

clogs the cooling fins, or flywheel area, or damage

caused by operating the engine in a confined area

without sufficient ventilation. Clean engine debris

at recommended intervals as stated in the

Operator’s Manual.

8. Engine or equipment parts broken by excessive

vibration caused by a loose engine mounting,

loose cutter blades, unbalanced blades or loose or

unbalanced impellers, improper attachment of

equipment to engine crankshaft, over-speeding or

other abuse in operation.

9. A bent or broken crankshaft, caused by striking a

solid object with the cutter blade of a rotary lawn

mower, or excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e.,

combustion chamber, valves, valve seats, valve

guides, or burned starter motor windings, caused

by the use of alternate fuels such as, liquified

petroleum, natural gas, altered gasolines, etc.

Warranty service is available only through

authorized service dealers by Briggs & Stratton

Corporation. Locate your nearest Authorized

Service Dealer in our dealer locator map on

www.briggsandstratton.com or by calling

1-800-233-3723, or as listed in the ‘Yellow Pagest’.

18

Page 19

BRIGGS & STRATTON ENGINE OWNER WARRANTY POLICY

Effective 12/06

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) of the engine that is defective

LIMITED WARRANTY

in material or workmanship or both. Transportation charges on product submitted for repair or replacement

under this warranty must be borne by purchaser. This warranty is effective for and is subject to the time

periods and conditions stated below. For warranty service, find the nearest Authorized Service Dealer in

our dealer locator map at www.briggsandstratton.com, or by calling 1-800-233-3723, or as listed in the

‘Yellow Pages™’.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM

PURCHASE, OR TO THE EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE

EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE

EXTENT EXCLUSION IS PERMITTED BY LAW. Some states or countries do not allow limitations on how

long an implied warranty lasts, and some states or countries do not allow the exclusion or limitation of

incidental or consequential damages, so the above limitation and exclusion may not apply to you. This

warranty gives you specific legal rights and you may also have other rights which vary from state to state and

country to country.

WARRANTY TERMS **

Brand / Product Type Consumer Use Commercial Use

Vanguard 2 years 2 years

Extended Life Series, I/C, Intek I/C, Intek Pro 2 years 1 year

Kerosene Fuel Operated Engines 1 year 90 days

All Other Briggs & Stratton Engines 2 years 90 days

** Engines used on Home Standby Generator applications are warranted under consumer use only.

This warranty does not apply to engines on equipment used for prime power in place of a utility.

Engines used in competitive racing or on commercial or rental tracks are not warranted.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and

continues for the period of time stated in the table above. “Consumer use” means personal residential household use

by a retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or

rental purposes. Once an engine has experienced commercial use, it shall thereafter be considered as a commercial

use engine for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON

PRODUCTS. SAVE YOUR PROOF OF PURCHASE RECEIPT. IF YOU DO NOT PROVIDE PROOF OF THE

INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING

DATE OF THE PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

Briggs & Stratton Engines Are Made Under One Or More Of The Following Patents: Design D-247,177 (Other Patents Pending)

6,691,683

6,647,942

6,622,683

6,615,787

6,617,725

6,603,227

6,595,897

6,595,176

6,584,964

6,557,833

6,542,074

6,520,141

6,495,267

6,494,175

6,472,790

6,460,502

6,456,515

6,382,166

6,369,532

6,356,003

6,349,688

6,347,614

6,325,036

6,311,663

6,284,123

6,263,852

6,260,529

6,242,828

6,239,709

6,237,555

6,230,678

6,213,083

6,202,616

6,145,487

6,142,257

6,135,426

6,116,212

6,105,548

6,347,614

6,082,323

6,077,063

6,064,027

6,040,767

6,014,808

6,012,420

5,992,367

5,904,124

5,894,715

5,887,678

5,852,951

5,843,345

5,823,153

5,819,513

5,813,384

5,809,958

5,803,035

5,765,713

5,732,555

5,645,025

5,642,701

5,628352

5,619,845

5,606,948

5,606,851

5,605,130

5,497,679

5,548,955

5,546,901

5,445,014

5,503,125

5,501,203

5,497,679

5,320,795

5,301,643

5,271,363

5,269,713

5,265,700

5,243,878

5,235,943

5,234,038

5,228,487

5,197,426

5,197,425

5,197,422

5,191,864

5,188,069

5,186,142

5,150,674

5,138,996

5,086,890

5,070,829

5,058,544

5,040,644

5,009,208

4,996,956

4,977,879

4,977,877

4,971,219

4,895,119

4,875,448

4,819,593

4,720,638

4,719,682

4,633,556

4,630,498

4,522,080

4,520,288

4,512,499

4,453,507

4,430,984

D 476,629

D 457,891

D 368,187

D 375,963

D 309,457

D 372,871

D 361,771

D 356,951

D 309,457

D 308,872

D 308,871

19

Page 20

Loading...

Loading...