Page 1

GB

Operating & Maintenance Instructions

E

Instrucciones de Mantenimiento & Operación

F

Instructions d’utilisation et de maintenance

Fource

21000, 21100

Briggs & Stratton Corporation

Milwaukee, Wisconsin 53201

www.briggsandstratton.com

Copyright 2004 by Briggs & Stratton Corporation

FORM NO. MS-5532-02/04

PRINTED IN U.S.A.

Page 2

Fig. 1

2

7

1

6

8

9

3

Fig. 2

Fig. 3

5

12

4

**

*

-20 0 20 40 60 80 100

°F

-30 -20 - 10 0 10 20 30 40

°C

32

Fig. 4

10

11

➌

➊

➋

Page 3

GBDDKE FGRI NNLPSSF

Note: (This note applies only to engines used in the U.S.A.) Maintenance, replacement or repair of the emission control devices and systems may be performed

by any nonroad engine repair establishment or individual. However, to obtain no charge repairs under the terms and provisions of the Briggs & Stratton

warranty statement, any service or emission control part repair or replacement must be performed by a factory authorized dealer.

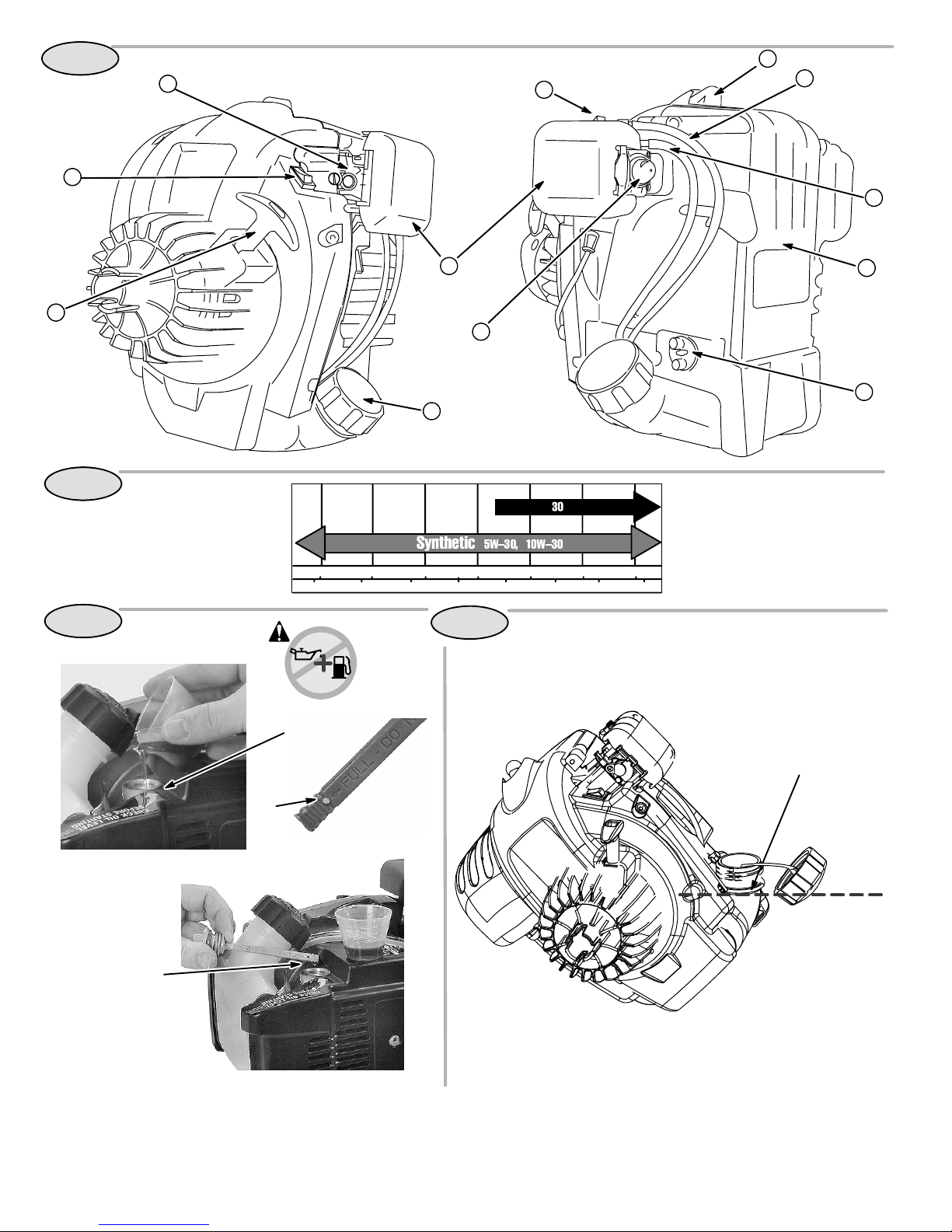

ENGINE COMPONENTS

Fig. 1

1

Carburetor

2

Stop switch

3

Rope handle

4

Fuel fill

5

Air cleaner

6

Choke

7

Resistor spark plug

8

Fuel return hose

9

Fuel intake hose

10

Engine Model / Type / Code number

XXXXXX XXXX-XX

11

Oil fill / dipstick

12

Primer bulb

Record your engine Model, Type and Code numbers

here for future use.

Record your date of purchase here for future use.

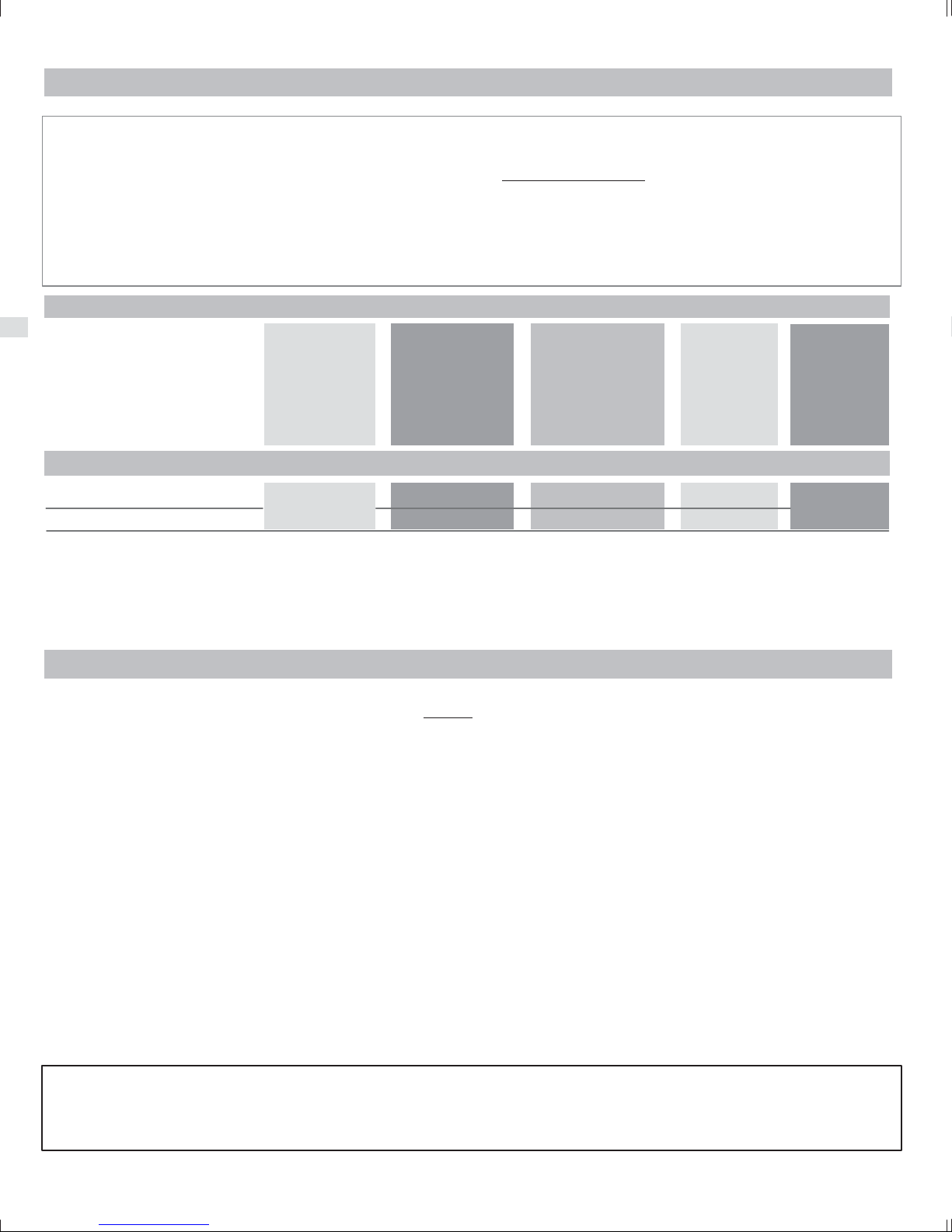

TECHNICAL INFORMATION

Power Ratings

The power ratings for an individual engine model are initially

developed by starting with SAE (Society of Automotive

Engineers) code J1940 (Small Engine Power & TorqueRating

Procedure) (Revision 2002-05). Given both the wide array of

products on which our engines are placed, and the variety of

environmentalissues applicable to operating the equipment, it

may be that the engine you have purchased will not develop

the rated horsepower when used in a piece of power

equipment (actual “on-site” power). This difference is due to a

variety of factors including, but not limited to, the following:

differences in altitude, temperature, barometric pressure,

humidity, fuel, engine lubrication, maximum governed engine

speed, individual engine to engine variability, design of the

particular piece of power equipment, the manner in which the

engine is operated, engine run-in to reduce friction and clean

out of combustion chambers, adjustments to the valves and

carburetor, and other factors. The power ratings may also be

adjusted based on comparisons to other similar engines

utilized in similar applications, and will therefore not

necessarily match the values derived using the foregoing

codes.

GENERAL INFORMATION

In the U.S.A., the 21000 and 21100 series engines covered in

this manual are certified by the California Air Resources Board

to meet emissions standards for 50 hours. Such certification

does not grant the purchaser, owner or operator of this engine

any additional warranties with respect to the performance or

operational life of this engine. This engine is warranted solely

according to the product and emissions warranties stated

elsewhere in this manual.

Model Series 21000

Bore 40 mm (1.575 in.)......................

Stroke 27 mm (1.065 in.)....................

Displacement 34 cc (2.074 cu. in.).............

Model Series 21100

Bore 40 mm (1.575 in.)......................

Stroke 32 mm (1.250 in.)....................

Displacement 40 cc (2.44 cu. in.)..............

TUNE-UP SPECIFICATIONS

Spark plug gap 0.76 mm (0.25 in.).............

Armature air gap 0.25 -- 0.36 mm.............

(0.010 -- 0.014 in.).........................

Intake valve clearance 0.05 -- 0.10 mm..........

(0.002 -- 0.004 in.).........................

Exhaust valve clearance 0.05 -- 0.10 mm........

(0.002 -- 0.004 in.).........................

Note: Engine power will decrease 3-1/2% for each 1,000 feet

(300 meters) above sea level and 1% for each 10° F

(5.6° C) above 77° F(25° C).

SAFETY SPECIFICATIONS

BEFORE OPERATING ENGINE

• Read entire Operating & Maintenance Instructions AND the instructions for the equipment

this engine powers.*

• Failure to follow instructions could result in

serious injury or death.

* Briggs & Stratton does not necessarily know what

equipment this engine will power. For that reason, you

should carefully read and understand the operating

instructions for the equipment on which your engine is

placed.

THE OPERATING & MAINTENANCE

INSTRUCTIONS CONTAIN SAFETY

INFORMATION TO

• Make you aware of hazards associated with

engines

• Inform you of the risk of injury associated with

those hazards, and

• Tell you how to avoid or reduce the risk of

injury.

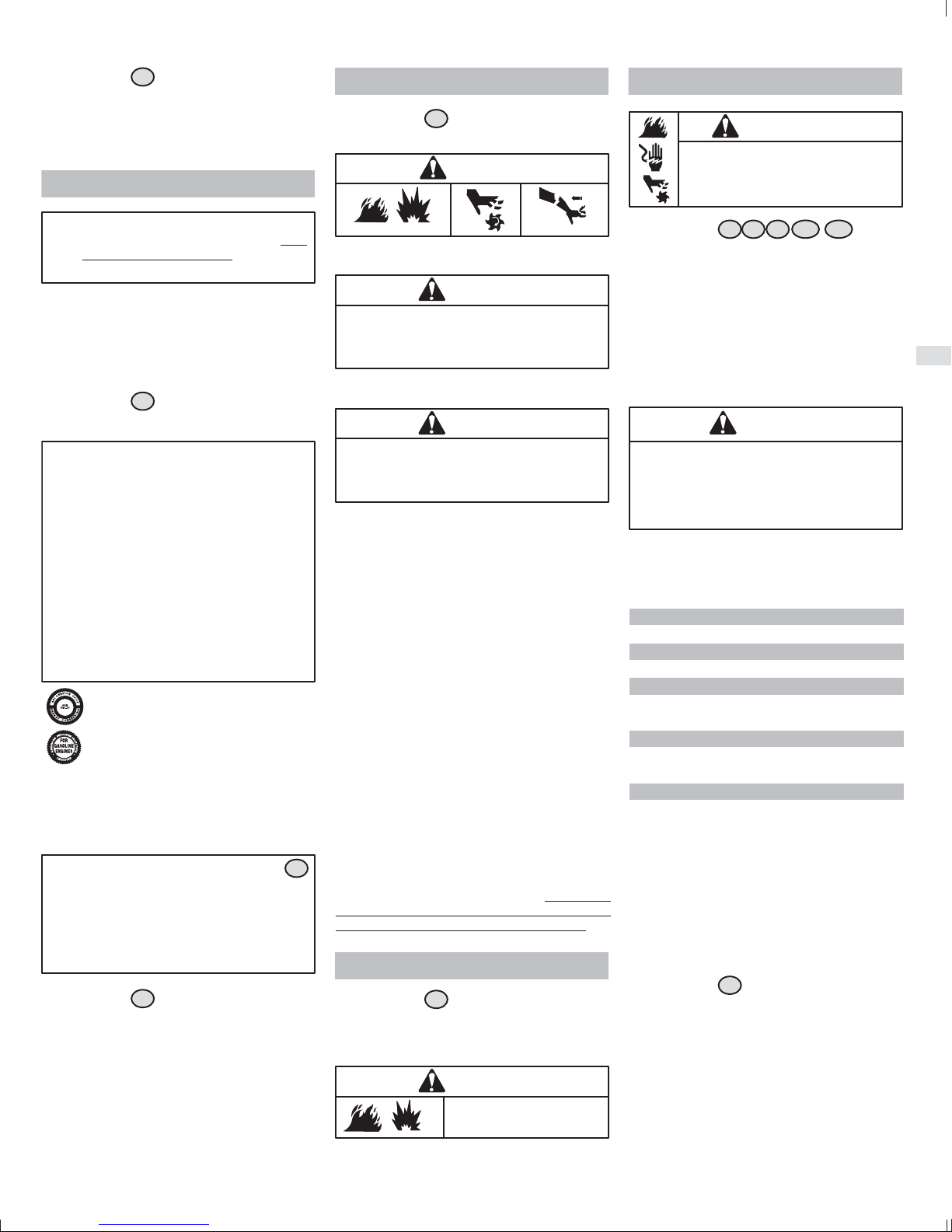

Hazard Symbols and Meanings

Fire

Kickback

Explosion

Toxic Fumes

Shock

Moving Parts

International Symbols and Meanings

Safety Alert

Read Operator’s

A signal word (DANGER, WARNING, or CAUTION) is used

with the alert symbol to indicate the likelihood and the potential

severity of injury. In addition, a hazard symbol may be used to

represent the type of hazard.

On Off

Manual

DANGER indicates a hazard which, if not avoided,

will result in death or serious injury.

WARNINGindicates a hazard which, if not avoided,

could result in death or serious injury.

CAUTION indicates a hazard which, if not avoided,

might result in minor or moderate injury.

CAUTION

indicates a situation that could result in damage to

the engine.

Oil

, when used without the alert symbol,

WARNING

The engine exhaust from this product contains chemicals known to the State of California to cause cancer,

birth defects, or other reproductive harm.

WARNING

Briggs & Stratton does not approve or authorize

the use of these engines on 3-wheel All Terrain

Vehicles (ATVs), motor bikes, aircraft products or

vehicles intended for use in competitive events.

Use of these engines in such applications could

result in property damage, serious injury (including

paralysis), or even death.

Stop

Fuel

Open

Choke

GB

Hot Surface

Full

Choke

Primer

bulb

1

Page 4

GBDDKE FGRI NNLPSSF

WARNING

Gasoline and its vapors are extremely

flammable and explosive.

Fire or explosion can cause severe

burns or death.

WHEN ADDING FUEL

• Turn engine OFF and let engine cool at least 2

minutes before removing gas cap.

• Fill fuel tank outdoors or in well-ventilated

area.

• Do not overfill fuel tank.

• Keep gasoline away from sparks, open

flames, pilot lights, heat, and other ignition

sources.

• Check fuel lines, tank, cap, and fittings

frequently for cracks or leaks. Replace if

necessary.

WHEN STARTING ENGINE

• Make sure spark plug, muffler,fuel cap and air

cleaner are in place.

• Do not crank engine with spark plug removed.

• If fuel spills, wait until it evaporates before

starting engine.

• If engine floods, set choke to OPEN/RUN

position, place throttle in FASTand crank until

engine starts.

WHEN OPERATING EQUIPMENT

• Do not choke carburetor to stop engine.

WHEN TRANSPORTING EQUIPMENT

• Transport with fuel tank EMPTY.

WHEN STORING GASOLINE OR EQUIPMENT WITH

FUEL IN TANK

• Store away from furnaces, stoves, water

heaters or other appliances that have pilot

light or other ignition source because they can

ignite gasoline vapors.

WARNING

Starting engine creates sparking.

Sparking can ignite nearby flammable

gases.

Explosion and fire could result.

• If there is natural or LP gas leakage in area,

do not start engine.

• Do not use pressurized starting fluids

because vapors are flammable.

WARNING

Rapid retraction of starter cord (kickback) will pull hand and arm toward

engine faster than you can let go.

Broken bones, fractures, bruises or

sprains could result.

• When starting engine, pull cord slowly until

resistance is felt, then pull rapidly.

• Direct coupled equipment components such

as, but not limited to, blades, impellors,

pulleys, sprockets, etc., must be securely

attached.

WARNING

Rotating parts can contact or entangle hands, feet, hair, clothing, or

accessories.

Traumatic amputation or severe

laceration can result.

• Operate equipment with guards in place.

• Keep hands and feet away from rotating parts.

• Tie up long hair and remove jewelry.

• Do not wear loose-fitting clothing, dangling

drawstrings or items that could become

caught.

WARNING

Running engines produce heat.

Engine parts, especially muffler,

become extremely hot.

Severe thermal burns can occur

on contact.

Combustible debris, such as

leaves, grass, brush, etc. can

catch fire.

• Allow muffler, engine cylinder and fins to cool

before touching.

• Remove accumulated combustibles from

muffler area and cylinder area.

• Install and maintain in working order a spark

arrester before using equipment on forestcovered, grass-covered, brush-covered

unimproved land. The state of California

requires this (Section 4442 of the California

Public Resources Code). Other states may

have similar laws. Federal laws apply on

federal land.

WARNING

Unintentional sparking can result

in fire or electric shock.

Unintentional start-up can result in

entanglement, traumatic amputation, or laceration.

BEFORE PERFORMING ADJUSTMENTS OR

REPAIRS

• Disconnect spark plug wire and keep it away

from spark plug.

WHEN TESTING FOR SPARK

• Use approved spark plug tester.

• Do not check for spark with spark plug

removed.

OIL RECOMMENDATIONS

CAUTION:

Engine shipped from Briggs & Stratton without oil. Before

starting engine

Use a high quality detergent oil classified “For Service SF, SG,

SH, SJ” or higher such as Briggs & Stratton 30, Part Number

100005. Use no special additives with recommended oils. Do

not mix oil with gasoline.

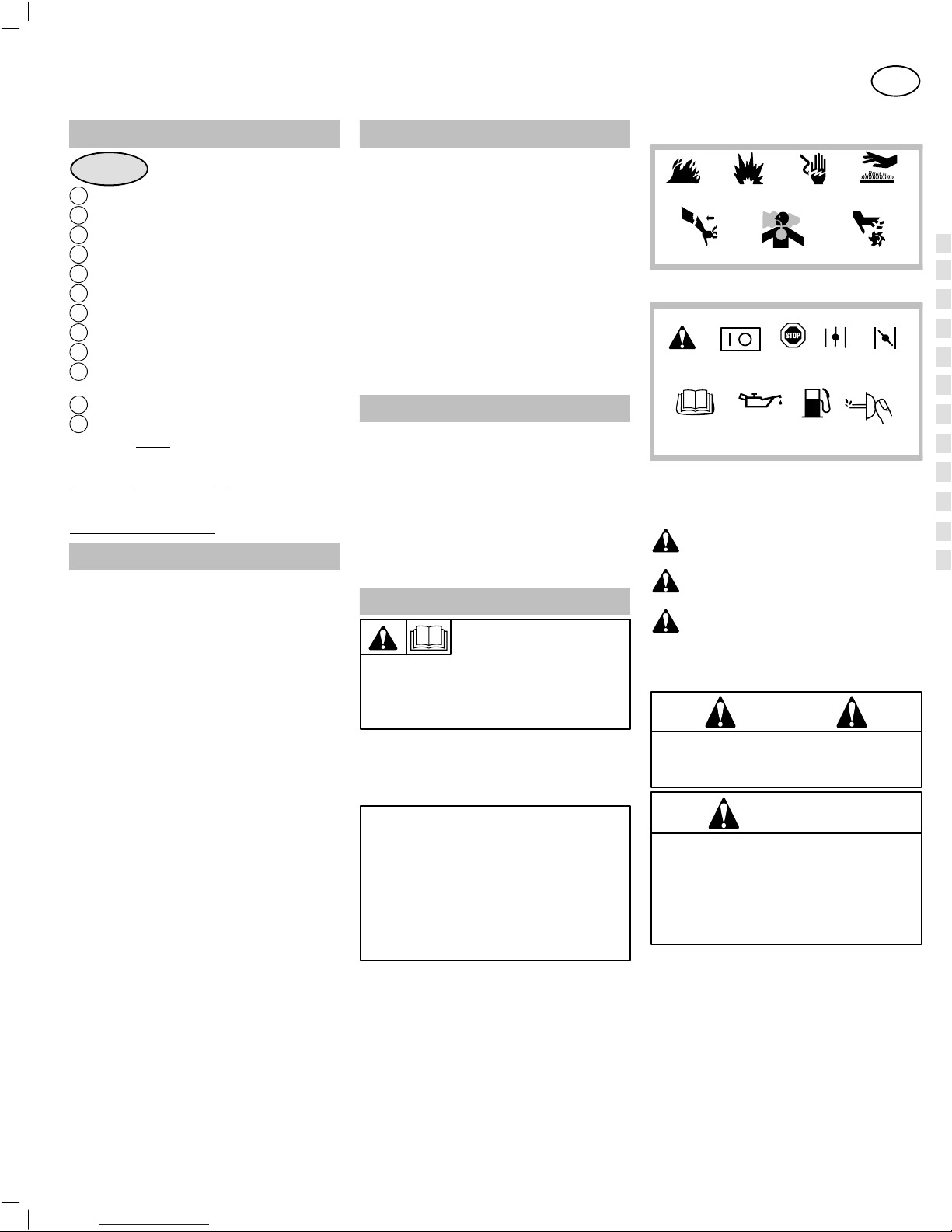

Fig. 2

, fill with oil. Do not over-fill.

Choose the SAE viscosity grade of oil

from this chart that matches the starting

temperature anticipated before the next

oil change.

CAUTION: Air cooled engines run hotter than

automotive engines. The use of non-synthetic

multi-viscosity oils (5W-30, 10W-30, etc.) in

temperatures above 40° F(4°C) will result in higher

than normal oil consumption. When using a

multi-viscosity oil, check oil level more frequently.

* CAUTION: Synthetic oil must be used

when operating engine under 40° F(4° C) or

engine damage will occur.

** CAUTION: SAE 30 oil, if used below 50° F

(10° C), will result in hard starting and possible

engine bore damage due to inadequate

lubrication.

Synthetic oil meeting ILSAC GF-2, API certification mark and API service symbol (shown

at left) with “SJ/CF ENERGY CONSERVING”

or higher, is an acceptable oil at all temperatures. Use of synthetic oil does not alter required

oil change intervals.

WARNING

Engines give off carbon monoxide, an odorless, colorless, poison gas.

Breathing carbon monoxide can

cause nausea, fainting or death.

• Start and run engine outdoors.

• Do not start or run engine in enclosed area,

even if doors or windows are open.

2

Page 5

GBDDKE FGRI NNLPSSF

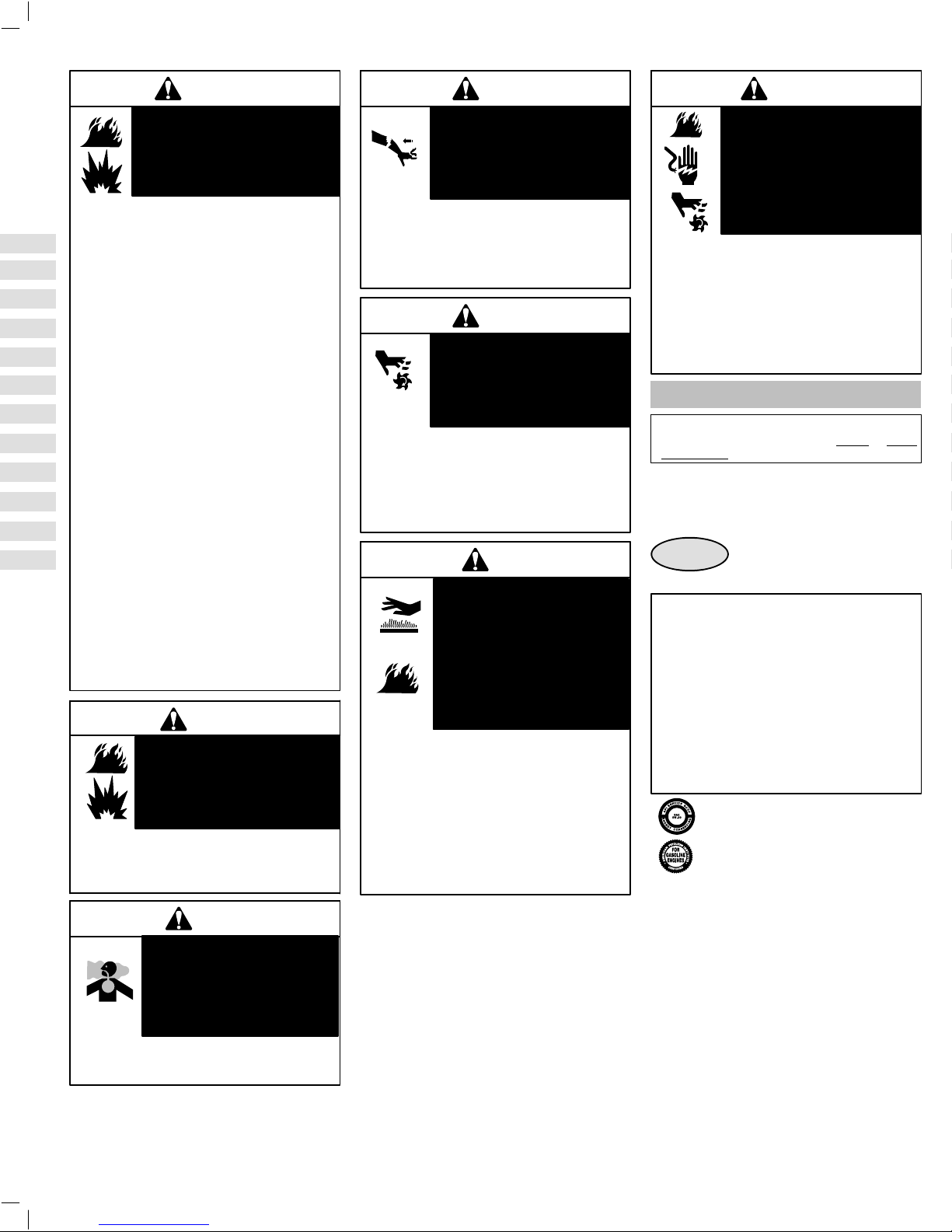

Checking or Adding Oil

CAUTION:

To check oil, engine must be level,

with oil fill facing up. if not level, dipstick reading

will not be accurate and could lead to possible

over/under filling of oil. This may lead to possible

engine damage.

• Check oil level before starting the engine.

• Check oil level before every use.

• Keep oil level at FULL.

• DO NOT overfill, use oil measure cup for filling.

• Add only 30ml (1 oz)

a time.

➊_-- 15ml (0.5 oz) ➋ ofoil at

➊

➋

Fig. 3

1. Place engine level. Remove dipstick. Using oil

measure cup, pour oil slowly. Do not overfill.

2. Tocheck oil level, remove dipstick and wipe clean

with cloth. Replace dipstick and tighten down.

3. Remove and check oil level. Level should be at

FULL mark.

4. Verify FULL level of oil by the presence of oil in

hole on dipstick, or by measure line.

5. If oil is required, add 15ml (0.5oz) oil at a time.

Recheck level.

OIL PROCEDURE

➊.

Note: Engine holds approximately 90 ml.

➋

FUEL RECOMMENDATIONS

Use clean, fresh, lead-free gasoline with a minimum of

85 octane. Leaded gasoline may be used if it is

commercially available and if unleaded is unavailable.

Purchase fuel in quantity that can be used within 30

days. See Storage.

In U.S.A. leaded gasoline may not be used. Some

fuels, called oxygenated or reformulated gasolines, are

gasolines blended with alcohols or ethers. Excessive

amounts of these blends can damage the fuel system

or cause performance problems. If any undesirable

operating symptoms occur, use gasoline with a lower

percentage of alcohol or ether.

This engine is certified to operate on gasoline. Exhaust

Emission Control System: EM (Engine Modifications).

Do not use gasoline which contains Methanol. Do not

mix oil with gasoline.

For engine protection, we recommend using Briggs &

Stratton Fuel Stabilizer available from an Authorized

Briggs & Stratton Service Dealer.

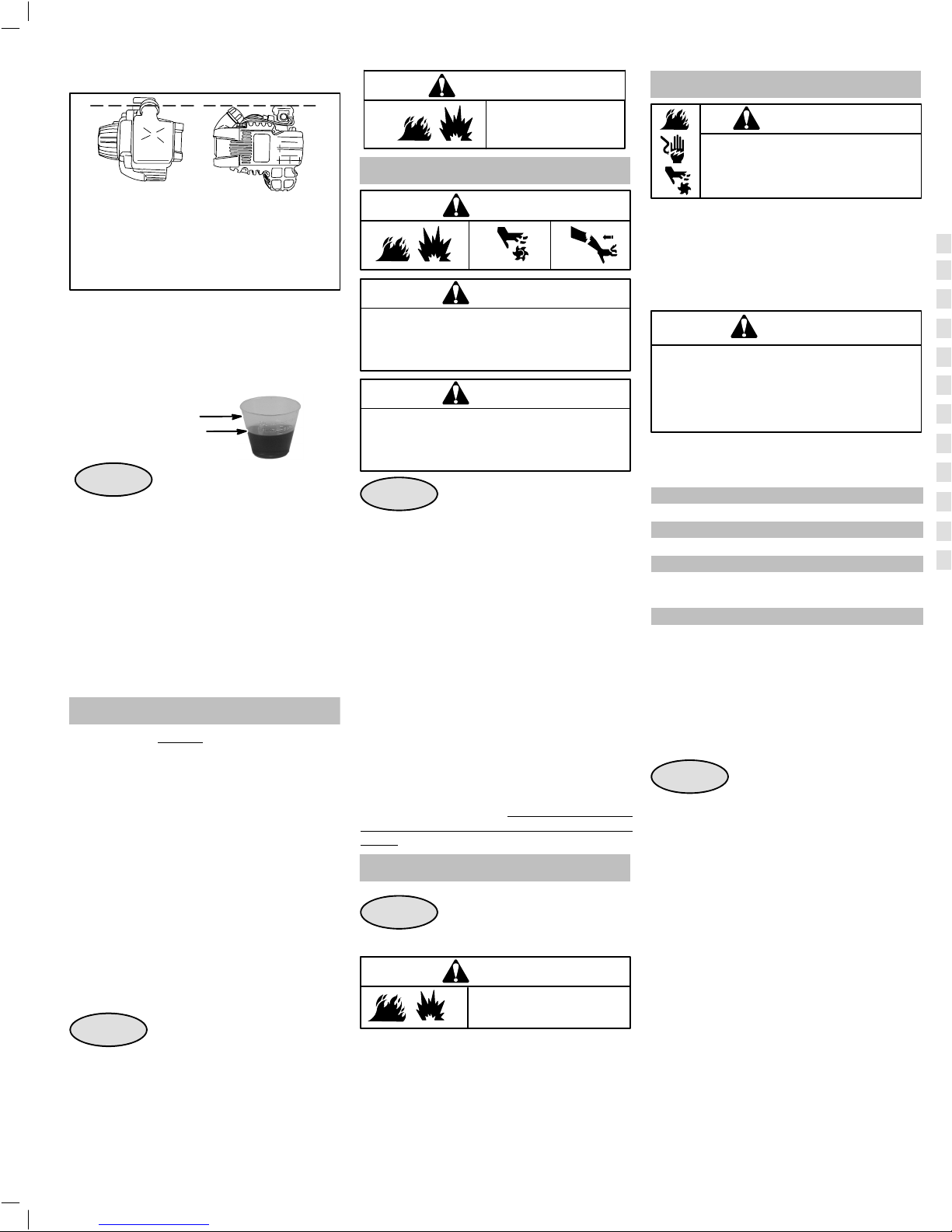

Fig. 4

Tilt engine at angle shown to properly refuel. Clean

around fuel fill before removing cap. Fill tank to

approximately 1-1/2 inches below top of neck to allow

for fuel expansion. Be careful not to overfill.

ADDING FUEL

WARNING

Before refueling, allow

engine to cool 2 minutes.

STARTING

WARNING

CAUTION

Check oil level before starting engine. Oil level

should be at Full mark on dipstick before starting

engine. If started without oil, engine damage will

occur.

CAUTION

Operating engine at an excessive speed without

proper engine loading will cause damage. Do not

operate a string trimmer with a line shorter than 10”

(25 cm) diameter.

Fig. 5

1. Add oil and fuel as instructed in this manual.

2. Push

ENGINE, 8 times for all consecutive starts.

3. Red choke lever ➋ should be in the FULL

CHOKE

4. Squeeze throttle trigger

➎ sharply until engine runs.

5. Wait a maximum 10 seconds, then move choke

lever to HALF CHOKE

6. Run the engine at HALF CHOKE for 20 seconds

or until unit accelerates smoothly. Move choke to

OFF

require a longer warm-up period on HALF

CHOKE)

7. Wait a minimum of 20 seconds, then release

throttle trigger.

STARTING A WARM ENGINE

H Follow steps under Starting, with the exception of

squeezing throttle trigger. It is not necessary

squeeze and hold throttle trigger to restart a

engine.

STOPPING

Fig. 5

• Depress stop switch ➑ to stop engine.

STARTING THE ENGINE

➊ primer bulb 15 times FOR NEW

➌ position.

➍ and pull starter handle

➏ position.

➐ position. (Colder temperatures will

warm

WARNING

DO NOT close choke to

stop engine.

MAINTENANCE

WARNING

To prevent accidental starting, remove

spark plug wire and ground it before

servicing.

Regular maintenance improves performance and

extends engine life. More frequent service is required

when operating in adverse conditions.

See any Authorized Briggs & Stratton Service Dealer

for correct replacement parts. Other parts may not

perform as well, may damage the engine, result in

injury, or void your warranty.

WARNING

Do not strike the flywheel with hammer or hard

object. If done, the flywheel may shatter during

operation.

Do not tamper with links or other parts to increase

engine speed.

Follow the hourly or calendar intervals, whichever

occur first. More frequent service is required when

operating in adverse conditions noted below.

Before Every Use

D Check oil level

First 4 Hours

D Change oil

Every 8 Hours or Every Season

D Change oil

D Service air cleaner *

Every 50 Hours or Every Season

D Replace spark plug**

D Check valve clearance

* Clean more often under dusty conditions, or when

airborne debris is present or after prolonged operation

cutting tall, dry grass.

** In some areas, local law requires using a resistor spark

plug to suppress ignition signals. If this engine was

originally equipped with resistor spark plug, use same

type of spark plug for replacement.

Fig. 6

1. Change oil while the engine is warm, ensure fuel

to

cap is tightened securely.

2. Remove dipstick, and drain oil

shown.

3. Place engine level. Using oil measure cup pour oil

slowly adding 0.5 oz. at a time

4. Tocheck oil level, remove dipstick and wipe clean

with cloth. Replace dipstick and tighten down.

5. Remove and check oil level. Level should be at

FULL mark.

6. Verify FULL level of oil by the presence of oil in

hole on dipstick, or by measure line.

7. If oil is required, add 15ml (0.5oz) oil at a time.

Recheck level.

8. Replace dipstick tightly before starting engine.

CHANGING OIL

& CHECKING LEVEL

➊ in direction

➋. Do not overfill.

Note: Engine holds approximately 90 ml.

➌

3

Page 6

GBDDKE FGRI NNLPSSF

Fig. 7

AIR CLEANER MAINTENANCE

Replace Oil-Foam element if very dirty or damaged.

• Push cover tab

away from engine to service air filter.

➊ to release cover, then pull cover

• Check and clean the intake chamber for dirt.

• Wash Oil-Foam element ➋ in liquid detergent

and water. Squeeze dry in a clean cloth. Saturate

Oil-Foam element in engine oil and squeeze in a

clean cloth to remove excess oil.

• Engine will smoke if too much oil is left on filter.

CAUTION:

Do not use pressurized air or solvents to clean.

Pressurized air can damage filter; solvents will

dissolve filter.

Fig. 8

SPARK PLUG MAINTENANCE

WARNING

DO NOT check for spark with spark

plug removed. Use only Briggs & Stratton Spark Tester, to check for spark. DO

NOT crank engine with spark plug

removed.

• The electrodes on a spark plug must be clean and

sharp to produce the powerful spark required for

ignition. If the spark plug is worn or dirty the harder

it is to start your engine. Replace the spark plug

each season.

• Spark plug gap should be .64 mm or 0.025 in.

➋

KEEP ENGINE CLEAN

Periodically remove grass and chaff build-up from

engine. Clean finger guard.

Do not spray engine with water to clean because water

could contaminate fuel. Clean with a brush or

compressed air.

WARNING

Engine should be kept clean to

reduce risk of overheating and

ignition of accumulated debris.

Clean engine when engine is cold.

STORAGE

The following precautions should be taken if storing

your trimmer unit for a period exceeding 30 days, or for

seasonal storage.

• While engine is still warm, change oil.

• Clean engine of surface debris, chaff or grass.

• Drain all fuel from fuel tank into proper receptacle

for storage.

• Press the primer bulb 15 times to purge fuel from

carburetor and fuel lines. Drain remaining fuel into

proper receptacle. If fuel is to be disposed, please

refer to local rules for proper disposal.

• Remove spark plug. Place 1 teaspoon or 5 cc of oil

into spark plug hole.

• Pull starter rope slowly 8-10 times to properly coat

the cylinder bore and piston for storage. Replace

spark plug and tighten. Any residual oil may burn

off in subsequent starts. This may result in white

smoke emission from muffler.

• This trimmer may be stored in a variety of

positions. It is best to store in horizontal position

with the spark plug up. Do not store or transport

with the spark plug down.

Note: Storing or transporting with the spark plug down

will result in hard starting and/or engine smoking.

WARNING

Store in a clean, dry area. DO NOT store

near a stove, furnace or water heater

which uses a pilot light or any device that

can create a spark.

• When removing the unit from storage, only use

fresh gasoline. Perform operation checks, see

maintenance schedule, before starting engine.

SERVICE

See an Authorized Briggs & Stratton Service Dealer.

Each one carries a stock of Genuine Briggs &

Stratton Parts and is equipped with special service

tools. Trained mechanics assure expert repair

service on all Briggs & Stratton engines. Only

dealers advertising as “Authorized Briggs &

Stratton” are required to meet Briggs & Stratton

standards.

Partial List of Genuine Briggs & Stratton Parts

Oil 100005..............................

Synthetic Oil 100074......................

Oil pump kit (uses standard electric drill 5056.....

to remove oil from engine quickly)

Gas additive 5041.........................

Fuel hose assembly 696935.................

Air filter-foam 696923......................

Resistor spark plug 696876..................

Spark tester 19368........................

Spark plug wrench 89838 -or- 5023............

Repair manual 275072.....................

To purchase, or view other produc ts Briggs &

Stratton has available, see an Authorized Briggs &

Stratton Service Dealer. Use our web site at

www.briggsandstratton.com to find a dealer

nearest you, or check the “Yellow Pages”.

Walking fingers logo and “Yellow Pages” are registered

trademarks in various jurisdictions.

Need Assistance? Go to the website or call,

1-800-233-3723, (U.S.A. and Canada) to hear a

menu of pre-recorded messages offering engine

maintenance information.

4

Page 7

GBDDKE FGRI NNLPSSF

Briggs & Stratton Corporation (B&S),

the California Air Resources Board (CARB)

Environmental Protection Agency (U.S. EPA)

Emission Control System Warranty Statement

(Owner’s Defect Warranty Rights and Obligations)

and the United States

EMISSION CONTROL WARRANTY COVERAGE IS APPLICABLE TO CERTIFIED ENGINES PURCHASED IN

CALIFORNIA IN 1995 AND THEREAFTER, WHICH ARE

USED IN CALIFORNIA, AND TO CERTIFIED MODEL

YEAR 1997 AND LATER ENGINES WHICH ARE PURCHASED AND USED ELSEWHERE IN THE UNITED

STATES (AND AFTER JANUARY 1, 2001 IN CANADA).

California, United States and Canada Emission Con-

trol Defects Warranty Statement

The California Air Resources Board (CARB), U.S. EPA

and B&S arepleased to explain the Emission Control System Warranty on your model year 2000 and later small offroad engine (SORE). In California, new small off-road

engines must be designed, built and equipped to meet the

State’s stringent anti-smog standards. Elsewhere in the

UnitedStates, new non-road,spark-ignition engines certified for model year 1997 and later,must meet similar standards set forth by the U.S. EPA. B&S must warrant the

emission control system on your engine for the periods of

time listed below, provided there has been no abuse,

neglect or improper maintenance of your small off-road

engine.

Your emission control system includes parts such as the

carburetor, air cleaner, ignition system, muffler and catalytic converter. Also included may be connectors and other emission related assemblies.

Where a warrantablecondition exists, B&S will repair your

small off-road engine at no cost to you including diagnosis, parts and labor.

Briggs & Stratton Emission Control

Defects Warranty Coverage

Small off-road engines are warranted relative to emission

control parts defects for a period of two years, subject to

provisions set forth below. If any covered part on your engine is defective, the part will be repaired or replaced by

B&S.

Owner’s Warranty Responsibilities

As the small off-road engine owner, you are responsible

for the performance of the required maintenance listed in

your Operating and Maintenance Instructions. B&S recommends that you retain all your receipts covering maintenance on your small off-road engine, but B&S cannot

deny warranty solely for the lack of receipts or for your failure to ensure the performance of all scheduled maintenance.

As the small off-road engine owner, you should however

be aware that B&S may deny you warranty coverage if

your small off-road engine or a part has failed due to

abuse, neglect, improper maintenance or unapproved

modifications.

Youare responsible for presenting your small off-road engine to an Authorized B&S Service Dealer as soon as a

problem exists. The undisputed warranty repairs should

be completed in a reasonable amount of time, not to exceed 30 days.

If you have any questions regarding your warranty rights

and responsibilities, you should contact a B&S Service

Representative at 1-414-259-5262.

The emission warranty is a defects warranty. Defects are

judged on normal engine performance. The warranty is

not related to an in-use emission test.

Briggs & Stratton Emission Control

Defects Warranty Provisions

The following are specific provisions relativeto your Emission Control Defects Warranty Coverage. It is in addition

to the B&S engine warranty for non-regulated engines

found in the Operating and Maintenance Instructions.

1. Warranted Parts

Coverage under this warranty extends only to the parts

listed below (the emission control systems parts) to the

extent these parts were present on the engine purchased.

a. Fuel Metering System

• Cold start enrichment system (soft choke)

• Carburetor and internal parts

• Fuel Pump

b. Air Induction System

• Air cleaner

• Intake manifold

c. Ignition System

• Spark plug(s)

• Magneto ignition system

d. Catalyst System

• Catalytic converter

• Exhaust manifold

• Air injection system or pulse valve

e. Miscellaneous Items Used in Above Systems

• Vacuum, temperature, position, time sensitive

valves and switches

• Connectors and assemblies

2. Length of Coverage

B&S warrants to the initial owner and each subsequent

purchaser that the Warranted Parts shall be free from defects in materials and workmanship which caused the failure of the Warranted Parts for a period of two years from

the date the engine is delivered to a retail purchaser.

3. No Charge

Repair or replacement of any Warranted Part will be per-

formed at no charge to the owner, including diagnostic labor which leads to the determination that a Warranted

Part is defective, if the diagnostic work is performed at an

Authorized B&S Service Dealer. For emissions warranty

service contact your nearest Authorized B&S Service

Dealer as listed in the “Yellow Pages” under “Engines,

Gasoline,” “Gasoline Engines,” “Lawn Mowers,” or similar

category.

4. Claims and Coverage Exclusions

Warranty claims shall be filed in accordance with the pro-

visions of the B&S Engine WarrantyPolicy.Warranty coverage shall be excluded for f ailures of Warranted Parts

which are not original B&S parts or because of abuse, neglect or improper maintenance as set forth in the B&S Engine Warranty Policy. B&S is not liable to cover failures of

Warranted Parts caused by the use of add-on, non-original, or modified parts.

5. Maintenance

Any Warranted Part which is not scheduled for replace-

ment as required maintenance or which is scheduled only

for regular inspection to the effect of “repair or replace as

necessary” shall be warranted as to defects for the war ranty period. Any Warranted Part which is scheduled for

replacement as required maintenance shall be warranted

as to defects only for the period of time up to the first

scheduled replacement for that part. Any replacement

part that is equivalent in performance and durability may

be used in the performance of any maintenance or repairs. The owner is responsible for the performance of all

required maintenance, as defined in the B&S Operating

and Maintenance Instructions.

6. Consequential Coverage

Coverage hereunder shall extend to the failure of any en-

gine components caused by the failure of any Warranted

Part still under warranty.

Look For Relevant Emission

Durability Period and

Air Index Information On

Your Engine Emission Label

Engines that are certified to meet the California Air

Resources Board (CARB) Tier 2 Emission Standards

must display information regarding the Emissions Durability Period and the Air Index. Briggs & Stratton makes

this information available to the consumer on our emission labels. The engine label will indicate certification

information.

The Emission Durability Period describes the number

of hours of actual running time for which the engine is

certified to be emission compliant, assuming proper

maintenance in accordance with the Operating & Maintenance Instructions. The following categories are used:

Moderate: Engine is certified to be emission

compliant for 125 hours of actual engine running time.

Intermediate: Engine is certified to be emission

compliant for 250 hours of actual engine running time.

Extended: Engine is certified to be emission

compliant for 500 hours of actual engine running time.

Forexample, a typical walk-behind lawn mower is used 20

to 25 hours per year. Therefore, the Emission Durability

Period of an engine with an intermediate rating would

equate to 10 to 12 years.

The Air Index is a calculated number describing the

relative level of emission for a specific engine family. The

lower the Air Index, the cleaner the engine. This

information is displayed in graphical form on the emission

label.

In the state of California, the 120000 series engines

covered in this manual are certified by the California Air

Resources Board to meet emissions standards for 125

hours. Such certification does not grant the purchaser,

owner or operator of this engine any additional warranties

with respect to the performance or operational life of this

engine. This engine is warranted solely according to the

productand emissions warrantiesstatedelsewhere in this

manual.

After July 1, 2000, Look For Emissions

Compliance Period On Engine Emissions

Compliance Label

After July 1, 2000 certain Briggs & Stratton engines will be

certified to meet the United States Environmental Protection Agency (USEPA) Phase 2 emission standards. For

Phase 2 certified engines, the Emissions Compliance

Period referred to on the Emissions Compliance label

indicates the number of operating hours for which the

engine has been shown to meet Federal emission

requirements.Forengines less than 225 cc displacement,

Category C = 125 hours, B = 250 hours and A = 500 hours.

For engines of 225 cc or more, Category C = 250 hours, B

= 500 hours and A = 1000 hours.

The displacement of Model Series 21000 engines is 34cc.

The displacement of Model Series 21100 engines is 40cc.

This is a generic representation of the emission label typically found

on a certified engine.

5

Page 8

GBDDKE FGRI NNLPSSF

BRIGGS & STRATTON ENGINE OWNER WARRANTY POLICY

Effective January 1, 2003 replaces all undated Warranties and all Warranties dated before January 1, 2003

Briggs & Stratton Corporation will repair or replace, free of charge, any part(s) of the engine that is defective in material or workmanship or both. Transportation charges on parts submitted for repair or replacement under this warranty must be borne by purchaser.This warranty is effective for the time

periods and subject to the conditions stated below. For warranty service, find the nearest Authorized Service Dealer in our dealer locator map at

www.briggsandstratton.com, or by calling 1-800-233-3723, or as listed in the ‘Yellow Pages’.

THERE IS NO OTHER EXPRESS WARRANTY. IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE, ARE LIMITED TO ONE YEAR FROM PURCHASE, OR TO THE EXTENT PERMITTED BY LAW ANY AND ALL IMPLIED WARRANTIES ARE EXCLUDED. LIABILITY FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARE EXCLUDED TO THE EXTENT EXCLUSION IS

PERMITTED BY LAW. Some states or countries do not allow limitations on how long an implied warranty lasts, and some states or countries do not

allowthe exclusion or limitation of incidental or consequential damages, so the above limitation and exclusion may not apply to you. This warranty gives

you specific legal rights and you may also have other rights which vary from state to state and country to country.

OUR PRODUCT

LIMITED WARRANTY

VANGUARD

ELS

I/Cr

Industrial Plus

Intek

(Sleeve Bore)

Fource

Intek

(Kool Bore)

Power Built OHV

QUANTUMr

Quattro

Q45

Sprint

Classic

Etek

WARRANTY PERIOD*

Consumer Use

2 years

2 years

Commercial Use

* Note the following special warranty periods: 2 years for Classic engines in the European Union and Eastern European countries, for all consumer products in the European Union, and

for emission control systems on engines certified by EPA and CARB. 5 years for consumer use, 90 days for commercial use of Touch-N-Mowstarter on Quantum and Intek engines.

Engines used in competitive racing or on commercial or rental tracks are not warrantied.

The warranty period begins on the date of purchase by the first retail consumer or commercial end user, and continues for the period of time stated in the table above. “Consumer use”

means personal residential household use by a retail consumer. “Commercial use” means all other uses, including use for commercial, income producing or rental purposes. Once an

engine has experienced commercial use, it shall thereafter be considered as a commercial use engine for purposes of this warranty.

NO WARRANTY REGISTRATION IS NECESSARY TO OBTAIN WARRANTY ON BRIGGS & STRATTON PRODUCTS. SAVE YOUR PROOF OF PURCHASE RECEIPT.IF

YOU DO NOT PROVIDE PROOF OF THE INITIAL PURCHASE DATE AT THE TIME WARRANTY SERVICE IS REQUESTED, THE MANUFACTURING DATE OF THE

PRODUCT WILL BE USED TO DETERMINE THE WARRANTY PERIOD.

2 years

90 days1 year

1 year

90 days

1 year

ABOUT YOUR ENGINE WARRANTY

Briggs & Stratton welcomes warranty repair and apologizes to

you for being inconvenienced. Any Authorized Service Dealer

may perform warranty repairs. Most warranty repairs are handled routinely, but sometimes requests for warranty service

may not be appropriate. For example, warranty would not apply

if engine damage occurred because of misuse, lack of routine

maintenance, shipping, handling, warehousing or improper

installation. Similarly, warranty is void if the serial number of the

engine has been removed or the engine has been altered or

modified.

If a customer differs with the decision of the Service Dealer, an

investigation will be made to determine whether the warranty

applies. Ask the Service Dealer to submit all supporting facts to

his Distributor or the Factory for review. If the Distributor or the

Factory decides that the claim is justified, the customer will be

fully reimbursed for those items that are defective. To avoid misunderstanding which might occur between the customer and

the Dealer, listed below are some of the causes of engine failure

that the warranty does not cover.

Normal wear:

Engines, like all mechanical devices, need periodic parts service and replacement to perform well. Warranty will not cover

repair when normal use has exhausted the life of a part or an

engine.

Improper maintenance:

Thelife of anengine depends upon the conditions under which it

operates, and the care it receives. Some applications, such as

tillers, pumps and rotary mowers, are very often used in dusty or

dirty conditions, which can cause what appears to be premature

wear.Such wear,when caused by dirt, dust, spark plug cleaning

Briggs & Stratton Engines Are Made Under One Or More Of The Following Patents: Design D-247,177 (Other Patents Pending)

6,325,036

6,284,123

6,260,529

6,230,678

6,202,616

6,116,212

6,077,063

6,064,027

6,014,808

5,894,715

5,852,951

5,823,153

5,819,513

5,813,384

5,765,713

5,645,025

5,642,701

5,619,845

5,606,948

5,606,851

5,548,955

5,546,901

5,503,125

5,501,203

grit, or other abrasive material that has entered the engine because of improper maintenance, is not covered by warranty.

Thiswarranty covers engine related defective materialand/

or workmanship only, and not replacement or refund of the

equipment to which the engine may be mounted. Nor does

the warranty extend to repairs required because of:

1. PROBLEMS CAUSED BY PARTS THAT ARE NOT

ORIGINAL BRIGGS & STRATTON PARTS.

2. Equipment controls or installations that prevent starting,

cause unsatisfactory engine performance, or shorten engine life. (Contact equipment manufacturer.)

3. Leaking carburetors, clogged fuel pipes, sticking valves,

or other damage, caused by using contaminated or stale

fuel. (Use clean, fresh, lead-free gasoline and Briggs &

Stratton Fuel Stabilizer, Part No. 5041.)

4. Parts which are scored or broken because an engine was

operated with insufficient or contaminated lubricating oil,

or an incorrect grade of lubricating oil (check oil level daily

or after every 8 hours of operation. Refill when necessary

and change at recommended intervals.) OIL GARD

may not shut down running engine. Engine damage may

occur if oil level is not properly maintained. Read Operating & Maintenance Instructions.

5. Repair or adjustment of associated parts or assemblies

such as clutches, transmissions, remote controls, etc.,

which are not manufactured by Briggs & Stratton.

6. Damage or wear to parts caused by dirt, which entered

the engine because of improper air cleaner maintenance,

re-assembly, or use of a non-original air cleaner element

or cartridge. (At recommended intervals, clean and re-oil

5,497,679

5,320,795

5,271,363

5,269,713

5,265,700

5,243,878

5,235,943

5,197,425

5,197,422

5,191,864

5,188,069

5,186,142

5,138,996

5,086,890

5,070,829

5,058,544

5,040,644

5,009,208

the Oil-Foam element or the foam pre-cleaner, and

replace the cartridge.) Read Operating & Maintenance

Instructions.

7. Parts damaged by over-speeding, or overheating caused

by grass, debris, or dirt, which plugs or clogs the cooling

fins, or flywheel area, or damage caused by operating the

engine in a confined area without sufficient ventilation.

(Clean fins on the cylinder, cylinder head and flywheel at

recommendedintervals.) Read Operating &Maintenance

Instructions.

8. Engine or equipment parts broken by excessive vibration

caused by a loose engine mounting, loose cutter blades,

unbalanced blades or loose or unbalanced impellers, improper attachment of equipment to engine crankshaft,

over-speeding or other abuse in operation.

9. A bent or broken crankshaft, caused by striking a solid object with the cutter blade of a rotary lawn mower, or excessive v-belt tightness.

10. Routine tune-up or adjustment of the engine.

11. Engine or engine component failure, i.e., combustion

chamber, valves, valve seats, valve guides, or burned

starter motor windings, caused by the use of alternate

fuels such as, liquified petroleum, natural gas, altered

gasolines, etc.

Warranty is available only through service dealers which

have been authorized by Briggs & Stratton Corporation.

your nearest Authorized Service Dealer is listed in the “Yellow Pages” of your telephone directory under “Engines,

Gasoline” or “Gasoline Engines,” “Lawn Mowers,” or similar category.

4,996,956

4,977,879

4,971,219

4,895,119

4,819,593

4,719,682

4,633,556

4,630,498

4,522,080

4,520,288

4,512,499

4,453,507

4,430,984 DES. 308,871

DES. 308,872

DES. 309,457

DES. 356,951

DES. 361,771

DES. 375,963

6

Page 9

E

COMPONENTES DEL MOTOR

VEA LA FIG.

1

Carburador

2

Suiche de Parada

3

Manija de la Cuerda

4

Llenado de combustible

5

Filtro de Aire

6

Estrangulador

7

Bujía con resistencia

8

Manguera de Retorno de Combustible

9

Manguera de Admisión de Combustible

10

Aceite

11

Motor Modelo / Tipo / Número de Código

XXXXXX XXXX−XX

Registre los números del Modelo, Tipo y Código de

su motor aquí para un futuro uso.

Registre aquí su fecha de compra para un futuro uso.

1

INFORMACIÓN TÉCNICA

Clasificación de Potencia

La clasificación de potencia para un modelo de motor en

particular se desarrolla inicialmente comenzando con el

código J1940 de SAE (Sociedad de Ingenieros Automotrices)

(Procedimiento de Clasificación de Potencia & Torque del

Motor Pequeño) (Revisión 2002−05). Dado ambos un amplio

conjunto de productos en los cuales son puestos nuestros

motores, y la variedad de asuntos ambientales aplicables al

operar el equipo, puede que el motor que usted haya

comprado no desarrolle la potencia nominal cuando sea

usado en una parte del equipo acoplado (potencia real

en−el sitio"). Esta diferencia es debido a una variedad de

factores incluyendo, pero no limitándose a, lo siguiente:

diferencias en altitud, temperatura, presión barométrica,

humedad, combustible, lubricación del motor, máxima

velocidad regulada del motor, el motor particular a la

variabilidad del motor, diseño de la parte en particular del

equipo acoplado, la manera en la cual es operado el motor, el

despegue −del motor para reducir la fricción y la limpieza de las

cámaras de combustión, los ajustes a las válvulas y al

carburador, y otra variedad de factores. Esta clasificación de

potencia puede también ser ajustada basándose en

comparaciones a otros motores semejantes utilizados en

aplicaciones similares, y por lo tanto no se igualarán

necesariamente los valores derivados usando los códigos

anteriores.

ESPECIFICACIONES DE AJUSTE

Entrehierro de la bujía 0.76 mm (0.25 pulg.). . . . . .

Entrehierro del inducido 0.25 − 0.36 mm. . . . . . . .

(0.010 − 0.014 pulg.). . . . . . . . . . . . . . . . . . . . . . .

Tolerancia de la válvula de admisión 0.05 − 0.10 mm

(0.002 − 0.004 pulgadas). . . . . . . . . . . . . . . . . . . .

Tolerancia de la válvula de escape 0.05 − 0.10 mm.

(0.002 − 0.004 pulgadas). . . . . . . . . . . . . . . . . . . .

Nota: La potencia del motor disminuirá 3−1/2% por cada

1,000 pies (300 metros) sobre el nivel del mar y un 1% por

cada 10° F (5.6° C) por encima de 77° F (25° C).

En los Estados Unidos de América, los motores series 21000 y

21100 que se cubren en este manual están certificados por la

Junta de Recursos Ambientales de California por cumplir las

normas de emisiones durante 50 horas. Tal certificación no

reconoce al comprador, propietario u operador de este motor

ninguna garantía adicional con respecto al desempeño o vida

operacional de este motor. Este motor está garantizado

únicamente conforme a las garantías del producto y de

emisiones declaradas en otra parte en este manual.

ESPECIFICACIONES DE SEGURIDAD

ANTES DE OPERAR EL MOTOR

• Lea completamente las Instrucciones

de Mantenimiento & Operación Y las

instrucciones para el equipo acoplado a este

motor.*

• Dejar de seguir las instrucciones podría

ocasionar lesiones graves o incluso la muerte.

LAS INSTRUCCIONES DE MANTENIMIENTO &

OPERACIÓN CONTIENEN INFORMACION DE

SEGURIDAD PARA

• Hacer que usted tome conciencia de los

peligros asociados con los motores

• Informarlo a usted del riesgo de las heridas

asociado con aquellos peligros, y

• Contarle como evitar o reducir el riesgo de

una herida.

* Briggs & Stratton no conoce necesariamente el equipo que

va a acoplar este motor. Por esta razón, usted debe leer

cuidadosamente y comprender las instrucciones de

operación para el equipo en el cual es colocado su motor.

SÍMBOLOS DE PELIGRO

SÍMBOLOS INTERNACIONALES

Aviso de

Seguridad

Lea el Manual

del Operario

identificar información de seguridad concerniente a los

peligros que pueden producir lesiones personales.

Una palabra señalizada (PELIGRO, ADVERTENCIA o

PRECAUCION) es usada con el símbolo de aviso para indicar

la probabilidad de una herida y su gravedad potencial.

Además, un símbolo de peligro puede ser utilizado para

representar el tipo de peligro.

On Off

Aceite

El símbolo de aviso de seguridad es usado para

PELIGRO indica un peligro que si no es evitado,

ocasionará la muerte o heridas graves.

ADVERTENCIA indica un peligro que si no es

evitado, ocasionaría la muerte o heridas graves.

PRECAUCION indica un peligro que si no es

evitado, podría ocasionar heridas menores o

moderadas.

PRECAUCION, cuando es usado sin el símbolo de

aviso, indica una situación que podría ocasionar

daños en el motor.

Parada

Estrangu−

lador

Abierto

Combustible

E

Estran−

gulación

Tot a l

Bulbo

cebador

Modelos Serie: 21000

Diámetro Interno 40 mm (1.575 pulg.). . . . . . . . . . .

Carrera 27 mm (1.065 pulg.). . . . . . . . . . . . . . . . . .

Desplazamiento 34 CC (2.074 pulgadas cúbicas). .

Modelo Serie 21100

Diámetro Interno 40 mm (1.575 pulg.). . . . . . . . . . .

Carrera 32 mm (1.250 pulg.). . . . . . . . . . . . . . . . . .

Desplazamiento 40 CC (2.44 pulgadas cúbicas). . .

Fuego

Partes en

Movimiento

Explosión

Gases Tóxicos

Contra−

golpe

19

Superficie

Caliente

Descarga Eléctrica

Page 10

E

ADVERTENCIA

La gasolina y sus vapores son

extremadamente inflamables y

explosivos.

El fuego o una explosión pueden causar

graves quemaduras o la muerte.

CUANDO AÑADA COMBUSTIBLE

• Gire el motor hacia la posición OFF y deje que

el motor se enfríe por lo menos 2 minutos

antes de remover la tapa de gasolina.

• Llene el tanque de combustible en exteriores

o en un área bien ventilada.

• No llene demasiado el tanque de

combustible. Llene el tanque

aproximadamente 40 mm (1−1/2 pulgadas)

por debajo de la parte superior del cuello para

permitir la expansión del combustible.

• Mantenga la gasolina a distancia de chispas,

llamas abiertas, luces piloto, calor y otras

fuentes de encendido.

• Compruebe con frecuencia si existen grietas

o fugas en los conductos de combustible, el

tanque, la tapa y en los accesorios.

Cámbielos si es necesario.

CUANDO DE ARRANQUE AL MOTOR

• Asegúrese que la bujía, el mofle, la tapa de

combustible y el filtro de aire estén en su

lugar.

• No haga girar el motor si removió la bujía.

• Si se derramó combustible, espere hasta que

se haya evaporado antes de dar arranque al

motor.

• Si el motor se inunda, ajuste el estrangulador

a la posición OPEN/RUN, coloque el

acelerador en la posición FAST y haga girar el

motor hasta que arranque.

CUANDO OPERE EL EQUIPO

• No incline el motor ni el equipo a un ángulo

que pueda ocasionar derrames de gasolina.

• No ahogue el carburador para detener el

motor.

CUANDO TRANSPORTE EL EQUIPO

• Transpórtelo con el tanque de combustible

VACIO o con la válvula de cierre de

combustible en la posición OFF.

CUANDO ALMACENE GASOLINA O EL EQUIPO

CON COMBUSTIBLE EN EL TANQUE

• Almacene a distancia de hornos, estufas,

calentadores de agua u otros aparatos que

utilicen luz piloto u otras fuentes de

encendido ya que estos pueden encender los

vapores de gasolina.

ADVERTENCIA

Dar arranque al motor crea chispeo.

El chispeo puede encender los gases

inflamables cercanos.

Podría presentarse fuego o una

explosión.

• Si hay una fuga de gas natural o LP en el

área, no de arranque al motor.

• No use líquidos de arranque presurizado ya

que los vapores son inflamables.

ADVERTENCIA

Los motores emiten monóxido de

carbono, un gas venenoso que

carece de olor y de color.

Respirar monóxido de carbono

puede ocasionar náuseas,

desmayos o la muerte.

• De arranque al motor y opérelo en exteriores.

• No de arranque al motor ni lo opere en un

área encerrada, aun cuando las puertas o las

ventanas se encuentren abiertas.

ADVERTENCIA

El gas de escape del motor que produce este

producto contiene químicos conocidos para el

Estado de California que ocasionan cáncer,

defectos de nacimiento, u otros daños

reproductivos.

ADVERTENCIA

Briggs & Stratton no aprueba ni autoriza el uso de

estos motores en Vehículos Todo Terreno de

3−ruedas (ATVs), bicicletas motorizadas,

productos para la aviación o en vehículos que

tengan como fin ser usados en eventos

competitivos. El uso de estos motores en tales

aplicaciones podría ocasionar daños a la

propiedad, lesiones graves (incluyendo parálisis),

o incluso la muerte.

ADVERTENCIA

La retracción rápida de la cuerda de

arranque (contragolpe) le halará la

mano y el brazo hacia el motor más

rápido de lo que usted la pueda

dejar ir.

Podrían ocasionarse roturas de

huesos, fracturas, moretones o

torceduras.

• Cuando de arranque al motor, hale

lentamente la cuerda hasta que se sienta

resistencia, después hale la cuerda

rápidamente.

• Remueva todas las cargas externas del

equipo/motor antes de dar arranque al motor.

• Los componentes de acople directo del

equipo tal como, pero no limitados a,

cuchillas, impulsores, poleas, dientes de

piñones, etc. se deben asegurar firmemente.

ADVERTENCIA

El funcionamiento de los motores

produce calor. Las partes de los

motores, especialmente el mofle,

se calientan demasiado.

Pueden ocurrir graves quemaduras

a causa de su contacto.

Desechos combustibles, tal como

hojas, grama maleza, etc. pueden

alcanzar a encenderse.

• Deje que el mofle, el cilindro y las aletas del

motor se enfríen antes de tocarlos.

• Remueva los combustibles acumulados en el

área del mofle y en el área del cilindro.

• Instale y mantenga en orden de

funcionamiento un atrapachispas antes de

utilizar el equipo en una zona con vegetación

tupida o en terrenos agrestes con grama. El

Estado de California lo exige (Sección 4442

del Código de Recursos Públicos de

California). Otros estados pueden tener leyes

similares. Las leyes federales se aplican en

tierras federales.

ADVERTENCIA

Un chispeo involuntario puede

producir fuego o una descarga

eléctrica.

Una puesta en marcha involuntaria

puede ocasionar un enredo, una

amputación traumática o una

laceración.

ANTES DE HACER AJUSTES O REPARACIONES

• Desconecte el cable de la bujía y manténgalo

a distancia de bujía.

• Desconecte la batería en la terminal negativa

(únicamente motores con arranque

eléctrico).

CUANDO COMPRUEBE CHISPA

• Utilice un probador de bujías aprobado.

• NO compruebe chispa si removió la bujía.

RECOMENDACIONES DE COMBUSTIBLE

Use gasolina corriente sin plomo, con un mínimo de

87 octanos, que esté limpia y fresca.

Puede usarse gasolina con plomo si ésta es

comercialmente disponible y si no se dispone de

gasolina sin plomo.

Compre una provisión de combustible que pueda

usarse en un período de 30 días. El combustible fresco

evita que se formen depósitos de goma en el sistema

de combustible.

Este motor está certificado para operar con gasolina.

Sistema de Control de Emisiones de Escape: EM

(Modificaciones del Motor).

ADVERTENCIA

APAGUE EL MOTOR Y DEJE QUE SE

ENFRIE POR LO MENOS DURANTE

2 MINUTOS ANTES DE REMOVER EL

TAPON DE COMBUSTIBLE PARA

REAPROVISIONAR.

No use gasolina que contenga Metanol. No mezcle

aceite con gasolina.

20

Page 11

E

VEA LA FIG.

5

Incline el motor al ángulo mostrado para llenar

apropiadamente el tanque de combustible.

Llene el tanque hasta aproximadamente

1−1/2 pulgadas por debajo de la parte superior del

cuello para permitir la expansión del combustible. No lo

llene demasiado el tanque. Coloque nuevamente el

tapón de combustible antes de arrancar.

RECOMENDACIONES DE ACEITE

PRECAUCIÓN

El motor es despachado de Briggs & Stratton sin

aceite. Antes de dar arranque al motor,

aprovisiónelo de aceite. No lo llene demasiado.

CAPACIDAD DE ACEITE: 90 ml (3 onzas)

Use un aceite detergente de alta calidad clasificado

Para Servicio SH, SJ" o superior. No use aditivos

especiales con aceites recomendados. Elija un grado

de viscosidad de aceite del cuadro.

VEA LA FIG.

PRECAUCION: El aceite de viscosidad

SAE 30, si es usado por debajo de 50° F

(10° C), producirá dificultad de arranque y

un posible daño en el bloque del motor

debido a una lubricación inadecuada.

* PRECAUCION: El aceite sintético debe

ser usado cuando se opere el motor bajo

una temperatura de 40

contrario ocurrirá un daño en el motor.

** PRECAUCION: El uso de aceites

multígrados no sintéticos (5W−30, 10W−30,

etc.) a temperaturas superiores a 40° F

(4° C) producirá más alto consumo de

aceite del normal.

El aceite sintético que cumple con ILSAC GF−2,

marca de certificación API y símbolo de servicio

API (mostrado a la izquierda) con CONSERVA−

CION DE ENERGIA SJ/CF" o superior, es un

aceite aceptable para todas las temperaturas. El

uso de aceites sintéticos no altera los intervalos

de cambio de aceite requeridos.

COMPROBACIÓN O APROVISIONAMIENTO DE

ACEITE

PRECAUCION: VEA LA FIG.

Para comprobar el aceite, el motor debe estar a

nivel, con el tubo de llenado de aceite hacia arriba. Si

no se encuentra a nivel, la lectura de la varilla

indicadora de nivel no será exacta y podría conducir a

un llenado de aceite excesivo o insuficiente. Esto

puede ocasionar un posible daño en el motor.

VEA LA FIG.

• Remueva la varilla indicadora de nivel de aceite

para añadir aceite

• Después de remover la varilla indicadora de nivel

de aceite, límpiela con un trapo limpio, insértela y

apriétela nuevamente.

• Remueva la varilla indicadora de nivel y

compruebe el nivel de aceite. El aceite debe

alcanzar la marca FULL

• Si se requiere aceite, añádalo lentamente

la taza de Medición de Aceite. Añada únicamente

de 1 onza

2

° F (4° C) o de lo

3

4

.

en la varilla.

. Use

a 0.5 onzas de aceite a la vez.

ARRANQUE

VEA LA FIG.

Compruebe el nivel de aceite antes de darle

arranque al motor. El aceite debe alcanzar la marca

Full en la varilla indicadora de nivel antes de darle

arranque al motor. Si el motor es arrancado sin

aceite, ocurrirá un daño en el motor.

Operar un motor a una velocidad excesiva sin la

carga adecuada en el motor ocasionará daños. No

opere una guadañadora de nylon con una cuerda

más corta de 10" (25 cm) de diámetro.

ARRANQUE DEL MOTOR

• Compruebe el nivel de aceite.

• Añada combustible y re−instale la tapa de

combustible.

• Coloque la unidad sobre una superficie plana.

• Oprima el

MOTOR NUEVO, 8 veces para todos los

arranques consecutivos.

• La palanca del estrangulador

posición de estrangulación total

• Apriete el gatillo del acelerador

de arranque

el motor.

• Espere 10 segundos, después mueva la palanca

del estrangulador hacia posición de MEDIO

ESTRANGULADOR

• Espere un mínimo de 20 segundos, después

mueva el estrangulador hacia la posición OFF

• Suelte el gatillo del acelerador.

ARRANQUE DE UN MOTOR CALIENTE

6

ADVERTENCIA

PRECAUCIÓN

PRECAUCIÓN

bulbo cebador 15 veces PARA UN

debe estar en la

.

y hale la manija

rigurosamente hasta que funcione

.

H Siga los pasos establecidos bajo el aparte:

Arranque, sin presionar el gatillo del acelerador. No es

necesario presionar y sostener el gatillo del acelerador

para volver a dar arranque a un motor caliente.

PARADA

VEA LA FIG.

• Oprima el suiche de parada para detener el motor.

6

ADVERTENCIA

NO cierre el estrangulador

para detener el motor.

MANTENIMIENTO

ADVERTENCIA

Para prevenir un arranque accidental,

remueva el cable de la bujía y

conéctelo a tierra antes de darle

servicio.

VEA LAS FIGURAS

7 8 9

10 11

El mantenimiento regular mejora el funcionamiento y

alarga la vida del motor. Se requiere un servicio más

frecuente cuando se opere en condiciones adversas.

Busque un Distribuidor de Servicio Autorizado

Briggs & Stratton para conseguir los repuestos

correctos. Otras partes pueden no funcionar bien y

podrían dañar el motor, ocasionar lesiones o invalidad

su garantía.

ADVERTENCIA

No golpee la volante con un martillo ni con un objeto

pesado, Si lo hace, la volante puede cizallarse

durante la operación.

NO manipule las varillas u otras partes para

incrementar la velocidad del motor.

Siga los intervalos por horas de trabajo o por

calendario, lo que ocurra primero. Se puede requerir

un servicio más frecuente cuando se opera bajo

condiciones adversas como las anotadas a

continuación.

Antes de Cada Uso

D Compruebe el nivel de aceite

Las Primeras 4 horas

D Cambie aceite

Cada 8 horas o cada estación

D Cambie aceite

D De servicio al filtro de aire *

Cada 50 horas o cada estación

D Cambie el filtro de combustible

D Cambie la bujía**

Cada estación

D Compruebe la tolerancia de la válvula

* Limpie con mayor frecuencia bajo condiciones de mucho

polvo, o cuando se presenten muchos desechos en el

aire o después de una operación prolongada cortando

grama alta y seca.

** En algunas áreas las leyes locales requieren el uso de

una bujía con resistencia para suprimir las señales de

encendido. Si este motor vino originalmente equipado

con una bujía con resistencia, utilice el mismo tipo de

bujía cuando la vaya a cambiar.

MANTENIMIENTO PARA EL ACEITE

VEA LA FIG.

Cambie el aceite mientras que el motor esté caliente,

asegúrese que el tapón de combustible esté

firmemente asegurado.

Remueva la varilla indicadora de nivel de aceite, y

drene el aceite en la dirección mostrada.

Coloque el motor a nivel. Remueva la varilla indicadora

de nivel de aceite. Con una taza de medición de aceite

vierta aceite lentamente añadiendo 0.5 onzas a la

. NO LO LLENE DEMASIADO.

vez

Vea el procedimiento de llenado de aceite bajo el

aparte: Recomendaciones para el Aceite.

7

21

Page 12

E

MANTENIMIENTO PARA EL FILTRO DE

AIRE

VEA LA FIG.

Cambie el elemento de Espuma−Aceitada si está

muy sucio o dañado.

• Presione la aleta de la tapa

aparte después la tapa del motor para darle

servicio al filtro de aire.

• Revise y limpie la cámara de admisión por si tiene

suciedades.

• Lave el elemento de Espuma−Aceitada

detergente líquido y agua. Escurra hasta secarlo

con un trapo limpio. Sature el elemento de

Espuma−Aceitada en aceite para motor y

escúrralo en un trapo limpio para remover el

exceso de aceite.

• El motor echará humo si se deja mucho aceite en

el filtro.

PRECAUCIÓN

No use aire a presión ni solventes para limpiar el

filtro. El aire a presión puede dañar el filtro; los

solventes deshacen el filtro.

8

para liberar la tapa,

en

MANTENIMIENTO DE LA BUJÍA

VEA LA FIG.

• Los electrodos en una bujía deben estar limpios y

agudos para producir la chispa de gran alcance

requerida para el encendido. Si la bujía está

desgastada o sucia más difícil será arrancar el su

motor. Cambie la bujía cada estación.

• El entrehierro de la bujía debe ser de .64 mm o

0.025 pulgadas.

9

ADVERTENCIA

NO compruebe chispa si removió la

bujía. Use únicamente el Probador de

Chispa Briggs & Stratton, para compro−

bar chispa. No de arranque al motor si

removió la bujía.

FILTRO DE COMBUSTIBLE

INCORPORADO AL TANQUE

VEA LA FIG.

Drene el tanque de combustible antes de

cambiar el filtro de combustible. El

combustible puede escaparse, creando

Los repuestos para el sistema de combustible

(tapones, mangueras, tanques, filtros, etc.)

deben ser iguales a las partes originales, de lo

contrario puede ocurrir un incendio.

PRECAUCIÓN

El filtro

admisión de combustible

filtro a la manguera adecuada se ocasionarán

daños en su motor.

un peligro de incendio/explosión.

debe estar asegurado a la manguera de

10

ADVERTENCIA

. Si no se asegura el

MANTENGA LIMPIO EL MOTOR

Remueva periódicamente los cortes de grama y los

desechos acumulados en el motor. Limpie el protector

de dedos.

No rocíe el motor con agua para limpiar el motor ya que

el agua podría contaminar el combustible. Límpielo

con un cepillo o con aire comprimido.

ADVERTENCIA

El motor debe mantenerse limpio

para reducir el riesgo de

enciendan los desechos que estén acumulados.

Limpie el motor cuando esté frío.

recalentamiento y evitar que se

AJUSTES

AJUSTES DEL CARBURADOR

VEA LA FIG.

11

ADVERTENCIA

El fabricante del equipo en el cual es instalado el

motor especifica la velocidad máxima en la cual

será operado el motor. NO EXCEDA esta

velocidad.

El carburador en este motor es de bajas emisiones. El

tornillo de velocidad de ralentí viene ajustado de

fábrica.

PARA AJUSTAR EL CARBURADOR Y AJUSTAR LA

VELOCIDAD DE RALENTI

• Prenda el motor y caliéntelo aproximadamente

durante 5 minutos antes de hacer ajustes.

• Con el motor funcionando, libere el control del

acelerador.

• Para comprobar la velocidad de ralentí use un

tacómetro (B&S P/N 19389).

• Mueva la palanca del acelerador

tornillo de velocidad de ralentí

• Gire el tornillo en sentido de las agujas del reloj

para incrementar la velocidad, en sentido

contrario al de las agujas del reloj para disminuir la

velocidad. Ajuste el tornillo de velocidad de ralentí

hasta obtener 4000 rpm mínimo.

• Libere la palanca del acelerador. Presione el

control del acelerador para acelerar el motor. El

motor debe acelerar suavemente.

contra el

, y sosténgalo.

BODEGAJE

Los motores almacenados durante más de 30 días

necesitan atención especial.

Para prevenir que se forme goma en el sistema del

combustible o en las partes esenciales del carburador:

a) si el tanque de combustible contiene gasolina

oxigenada o reformulada (gasolina mezclada con un

alcohol o con éter), opere el motor hasta que éste se

detenga por la falta de combustible, o b) si el tanque de

combustible contiene gasolina, opere también el motor

hasta que éste se detenga por la falta de combustible,

o añada un estabilizador de gasolina a la gasolina en el

tanque.

Nota: Si se usa un estabilizador, opere el motor durante

varios minutos para que el aditivo circule por el

carburador. Después se puede almacenar el motor y el

combustible.

1. Cambie aceite

2. Remueva la bujía y vierta aproximadamente

15 ml (1/2 onza) de aceite para motor en el

interior del cilindro. Coloque de nuevo la bujía y

haga girar el motor lentamente para distribuir el

aceite.

3. Limpie los desechos del motor.

4. Almacene en un área limpia y seca.

Se recomienda el uso del Estabilizador de Combustible

Briggs & Stratton disponible a través de cualquier

Distribuidor de Servicio Autorizado Briggs & Stratton.

ADVERTENCIA

No almacene cerca de una estufa, horno

o calentador de agua los cuales utilicen

testigo piloto ni cerca de cualquier

dispositivo que pueda crear chispa.

SERVICIO

Busque un Centro de Servicio Autorizado

Briggs & Stratton. Cada centro mantiene un stock

de Partes Originales Briggs & Stratton y está

equipado con herramientas de servicio especiales.

Los mecánicos entrenados le garantizan un experto

servicio de reparación en todos los motores

Briggs & Stratton. Sólo los centros que se anuncien

como Autorizados por Briggs & Stratton" satisfacen

los estándares requeridos por Briggs & Stratton.

Lista Parcial de Partes Originales

Aceite 100005. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Aceite Sintético 100074. . . . . . . . . . . . . . . . . . . . .

Kit bomba de aceite 5056. . . . . . . . . . . . . . . . . . .

(usa un taladro eléctrico estándar para remover

rápidamente el aceite del motor)

Aditivo para gasolina 5041. . . . . . . . . . . . . . . . . .

Filtro de combustible 696918. . . . . . . . . . . . . . . . .

Conjunto manguera de combustible 696935. . . . . . .

Espuma−filtro de aire 696923. . . . . . . . . . . . . . . . .

Bujía con resistencia 696876. . . . . . . . . . . . . . . . .

Probador de chispa 19368. . . . . . . . . . . . . . . . . .

Llave de bujía 89838 −o− 5023. . . . . . . . . . . . . . . .

Manual de Reparación 275072. . . . . . . . . . . . . . . .

Para comprar, o visualizar otros productos

que Briggs & Stratton tenga disponibles,

consulte un Distribuidor de Servicio Autorizado

Briggs & Stratton. Utilice nuestro sitio web en

Briggs & Stratton

www.briggsandstratton.com para encontrar

el distribuidor más cercano a usted, o busque en las

Páginas Amarillas".

El logo de los dedos caminando y las Páginas

Amarillas" son marcas registradas en varias

jurisdicciones.

Necesita Asistencia? Visite nuestro sitio web o

marque el 1−800−233−3723, (Estados Unidos y

Canadá) para escuchar un menú de mensajes

pre−grabados que le ofrecen información

relacionada con el mantenimiento del motor.

22

Page 13

E

Briggs & Stratton Corporation (B&S), Junta de

Recursos Ambientales de California (CARB) y Agencia

de Protección Ambiental de los Estados Unidos (U.S.

EPA) / Declaración de la Garantía del Sistema de

Control de Emisiones (Derechos y Obligaciones del

Propietario de la Garantía de Defectos)

LA COBERTURA DE LA GARANTIA DEL CONTROL DE

EMISIONES ES APLICABLE A LOS MOTORES

CERTIFICADOS QUE HAYAN SIDO COMPRADOS EN

CALIFORNIA A PARTIR DE 1995 Y DESPUÉS DE ESTA

FECHA, LOS CUALES SEAN USADOS EN CALIFORNIA, Y

PARA LOS MOTORES CERTIFICADOS MODELOS 1997 EN

ADELANTE QUE SEAN COMPRADOS Y USADOS EN OTRA

PARTE DE LOS ESTADOS UNIDOS (Y A PARTIR DE ENERO

1 DE 2001 EN CANADA).

Declaración de la Garantía de Defectos del Sistema de

Control de Emisiones de California, Estados Unidos y

La Junta de Recursos Ambientales (CARB), La Agencia de

Protección Ambiental de los Estados Unidos U.S. EPA y B&S

se complacen en explicarles la Garantía del Sistema de

Control de Emisiones de su motor pequeño modelo 2000 y

posteriores para uso en terrenos sin pavimento (SORE). En

California, los nuevos motores pequeños para uso en

terrenos sin pavimento deben ser diseñados, fabricados y

equipados para cumplir los rigurosos estándares anti−smog

del Estado. En cualquier otra parte de los Estados Unidos, los

nuevos motores de encendido por chispa para no uso en

carreteras modelos 1997 y posteriores, deben cumplir

estándares similares a los establecidos por la Agencia de

Protección Ambiental de los Estados Unidos (U.S. EPA). B&S

debe garantizar el sistema de control de emisiones en su

motor por los períodos de tiempo listados abajo, teniendo en

cuenta que no haya habido abuso, negligencia o

mantenimiento no apropiado en su motor pequeño para uso

en terrenos sin pavimento.

Su sistema de control de emisiones incluye partes tales como

el carburador, el filtro de aire, el sistema de encendido, el

mofle y el convertidor catalítico. También puede incluir

conectores y otros conjuntos relacionados con el sistema de

emisiones.

Siempre que exista una condición de garantía, B&S reparará

su motor pequeño para uso en terrenos sin pavimento sin

ningún costo para usted incluyendo el diagnóstico, las partes

y la mano de obra.

Cobertura de la Garantía de Defectos del Sistema de

Control de Emisiones Briggs & Stratton

Los motores pequeños para uso en terrenos sin pavimento se

garantizan relativo a los defectos de las partes del sistema de

control de emisiones durante un período de dos años, sujeto a

las provisiones establecidas abajo. Si alguna de las partes

bajo cobertura en su motor se encuentra defectuosa, la parte

será reparada o reemplazada por B&S.

Responsabilidades del Propietario de la Garantía

Como propietario de un motor pequeño para uso en terrenos

sin pavimento, usted es responsable de que se lleve a cabo el

mantenimiento requerido el cual se indica en sus

Instrucciones de Mantenimiento y Operación. B&S le

recomienda guardar todos sus recibos que cubran el

mantenimiento en su motor pequeño para uso en terrenos sin

pavimento, pero B&S no solo puede negar la garantía por la

falta de recibos sino por su omisión al asegurar la realización

de todo el mantenimiento programado.

No obstante, como propietario de un motor pequeño para uso

en terrenos sin pavimento, usted tiene que darse cuenta que

B&S puede negarle la cobertura de la garantía si su motor

pequeño para uso en terrenos sin pavimento o una de sus

partes ha fallado debido a abuso, negligencia, mantenimiento

incorrecto o modificaciones no aprobadas

Usted es responsable de presentar su motor pequeño para

uso en terrenos sin pavimento a un Distribuidor de Servicio

Autorizado B&S tan pronto se presente el problema. Las

reparaciones bajo garantía indisputables deben completarse

en un período de tiempo razonable que no se exceda de

30 días.

Si usted tiene algunas preguntas relacionadas con los

derechos y responsabilidades de la garantía, debe contactar

a un Representante de Servicio B&S marcando el teléfono:

1−414−259−5262.

La garantía de emisiones es una garantía de defectos. Los

defectos son juzgados en el desempeño normal de un motor.

La garantía no está relacionada con una prueba de emisiones

en uso.

Canadá

Provisiones de la Garantía de Defectos del Sistema

de Control de Emisiones Briggs & Stratton

Las siguientes son provisiones específicas relativas a la

Cobertura de Garantía de Defectos del Sistema de Control de

Emisiones. Es una adición a la garantía del motor B&S para

los motores no−regulados encontrados en las Instrucciones

de Mantenimiento y Operación.

1. Partes Garantizadas

La cobertura bajo esta garantía se extiende únicamente a

las partes listadas abajo (partes de los sistemas de

control de emisiones) a la extensión que estas partes

estaban presentes en el motor comprado.

a. Sistema de Medición de Combustible

• Sistema de Enriquecimiento de Arranque en Frío

(estrangulación suave)

• Carburador y Partes Internas

• Bomba de Combustible

b. Sistema de Inducción de Aire

• Filtro de Aire

• Múltiple de Admisión

c. Sistema de Encendido

• Bujía(s)

• Sistema de Encendido con Magneto

d. Sistema Catalizador

• Convertidor Catalítico

• Múltiple de Escape

• Sistema de Inyección de Aire o Válvula de

Pulsación

e. Items Varios Usados en los Sistemas Anteriores

• Vacío, Temperatura, Posición, Válvulas

Sensitivas de Tiempo y Suiches

• Conectores y Conjuntos

2. Duración de la Cobertura

B&S garantiza al propietario inicial y a cada comprador

subsecuente que las Partes Garantizadas estarán libres

de defectos en materiales y mano de obra la cual haya

ocasionado fallas de las Partes Garantizadas por un

período de dos años a partir de la fecha en que es

entregado el motor a un comprador detallista.

3. Sin Costo

La reparación o cambio de cualquier Parte Garantizada

se llevará a cabo sin costo alguno para el propietario,

incluyendo la labor de diagnóstico la cual conduce a la

determinación de que esa Parte Garantizada es

defectuosa, si el trabajo de diagnóstico es realizado en un

Centro de Servicio Autorizado B&S. Para servicio de

garantía de emisiones contacte su Centro de Servicio

Autorizado B&S más cercano listado en las Páginas

Amarillas" bajo Motores, Gasolina", Motores a

Gasolina", Máquinas Cortacésped" o en una categoría

similar.

4. Reclamos y Exclusiones de la Cobertura

Los reclamos de la garantía se completarán de acuerdo

con las provisiones de la Póliza de Garantía del Motor

B&S. La cobertura de la garantía estará excluida para

fallas de las Partes Garantizadas las cuales no sean

partes originales B&S o por abuso, negligencia o

mantenimiento incorrecto según se establece en la Póliza

de Garantía del Motor B&S. B&S no se hace responsable

de cubrir fallas de Partes Garantizadas ocasionadas por

el uso de adición de partes, partes no−originales o partes

modificadas.

5. Mantenimiento

Cualquier parte garantizada la cual no esté programada