Page 1

Figure-8 Eliminator Trailer

USER'S GUIDE & SAFETY MANUAL

CONDUX

Page 2

2

Read and understand all procedures and safety instructions before using a Condux Figure-8 Eliminator

Trailer. Observe all safety information on this page and note specific safety requirementsas explained

by procedures in this manual. Failure to follow these instructions could result in serious personal injury

or death.

Important Safety Notice

ADVERTENCIA:

Favor de leer y comprender todas las instucciones de operación y seguridad antes de usar la máquina. Si

Ud. no comprende las instrucciones favor de consultarle a su jefe.

READ MANUAL

FIRST

If you have questions on:

SAFETY - OPERATIONS - APPLICATIONS

CALL 1-800-533-2077

Save this user’s guide for future reference.

COMMUNICA TIONS WITH THE MANUFA CTURER

For any information related to the machine (use, maintenance, spare parts) always state Model, Serial

Number, Manufacturing Year and Order. This data can be found in the machine identification table.

Manufacturer:

Condux International Inc.

145 Kingswood Rd

Mankato, MN 56002-0247

1-507-387-6576

Fax 1-507-387-1442

Internet: http://www.condux.com

E-mail: cndxinfo@condux.com

CONDUX

Page 3

3

Table of Contents

1

2

5

6

7

9

8

Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Safe Operating Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Jobsite Set-Up Guidelines. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Electronic Control Features and Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

A. Hand-Held Wired Remote Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

B. Electronic Machine Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

C. Filters, Gate and Emergency Stop Details . . . . . . . . . . . . . . . . . . . . . . 10

Prepare for Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Load Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Power Winding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Unload Cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Prepare for Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Service and Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Appendices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

A. Parameters Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

B. Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Warranty Information. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

3

4

10

11

12

13

Page 4

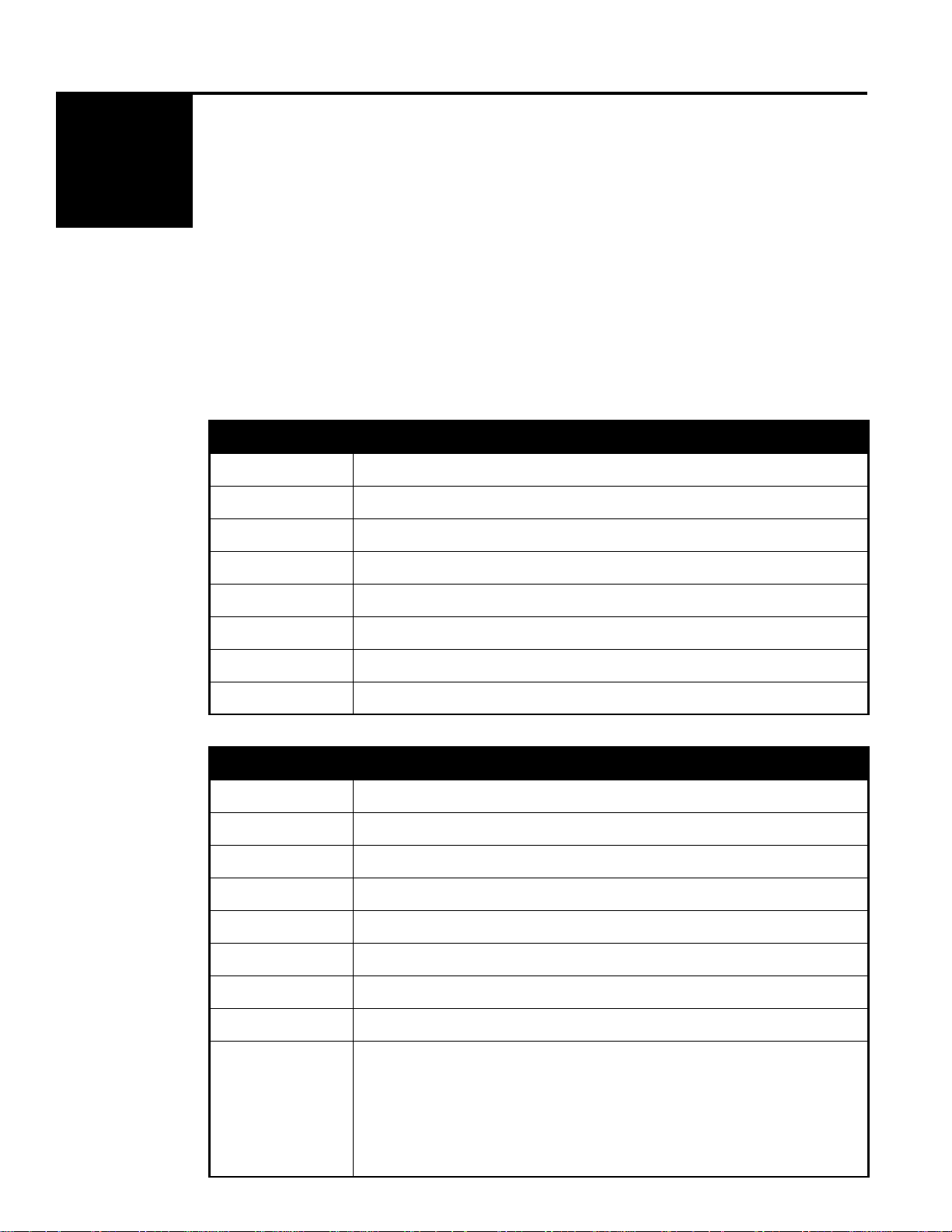

Technical Information

The Condux Figure-8 Eliminator Trailer is designed to greatly reduce cable splicing

and the need to manually “figure-eight” cable by allowing longer continuous runs

when no cable end is available. The Trailer removes cable from a cable reel, and

then dispenses it.

This unit is not intended for use where cable ends are available, nor is it a device for

transporting cable.

Do not figure-eight any dual strength member fiber optic cable using the Condux

Figure-8 Eliminator Trailer. Condux will not warranty or be held liable for any cable

damage resulting from the use of dual strength member fiber optic cable on the

Condux Figure-8 Eliminator Trailer.

In addition, the Condux Figure-8 Eliminator Trailer can be used as a hydraulic power

source in tandem with a Condux Fiber Optic Cable Blower.

• Figure 8 Eliminator trailer used to eliminate the need to manually figure-eight

fiber optic cable.

• Electronic control system to control all functions of the trailer.

• Single person operation.

• Drum and arm assembly fully enclosed (four sides) by safety cages.

• Cable to be loaded from ground level without having to climb into

trailer - access doors through safety cages.

• Storage for remote controller and its harness.

• Freewheel mode with variable drag - adjustable through electronic controls.

Used when cable is being pulled off the drum by the FO Blower.

• Arm assembly can be free wheel by switching on the solenoid.

• All components to be made of non-corrosive materials or be plated

or painted.

• Arms must be locked into position during transport to prevent the beam

from fatiguing.

• Trailer is to be used for handling cable in a figure 8 situation only. Not for

transporting cable. Occasional transport of cable may be required to

reposition the trailer on the job site.

B. CABLE HANDLING SPECIFICATIONS

• Maximum cable diameter of 1.05 inch.

• Theoretical cable pulling tension of 187 lbs.

• Minimum bend radius of 20 times the cable diameter through the guide roller

blocks (20 * 1.05 = 21" bend radius).

• Minimum drum diameter 42 inches.

• Average cable loading speed 612 ft/ min or 40 RPM.

• Roller blocks can be easily operated with one hand.

• Cable capacity of 44000 ft of 1/2" cable, 20,000 ft of 3/4" cable, 11000 ft of

1.05" cable.

C.TRAILER SPECIFICATIONS

• Dual axle, rated for 12,000 lb capacity.

• Electric brake or surge brake.

• Pintle ring hitch for electric brake and ball hitch for surge brake.

• Dual safety chains, minimum 10,000 lb capacity

4

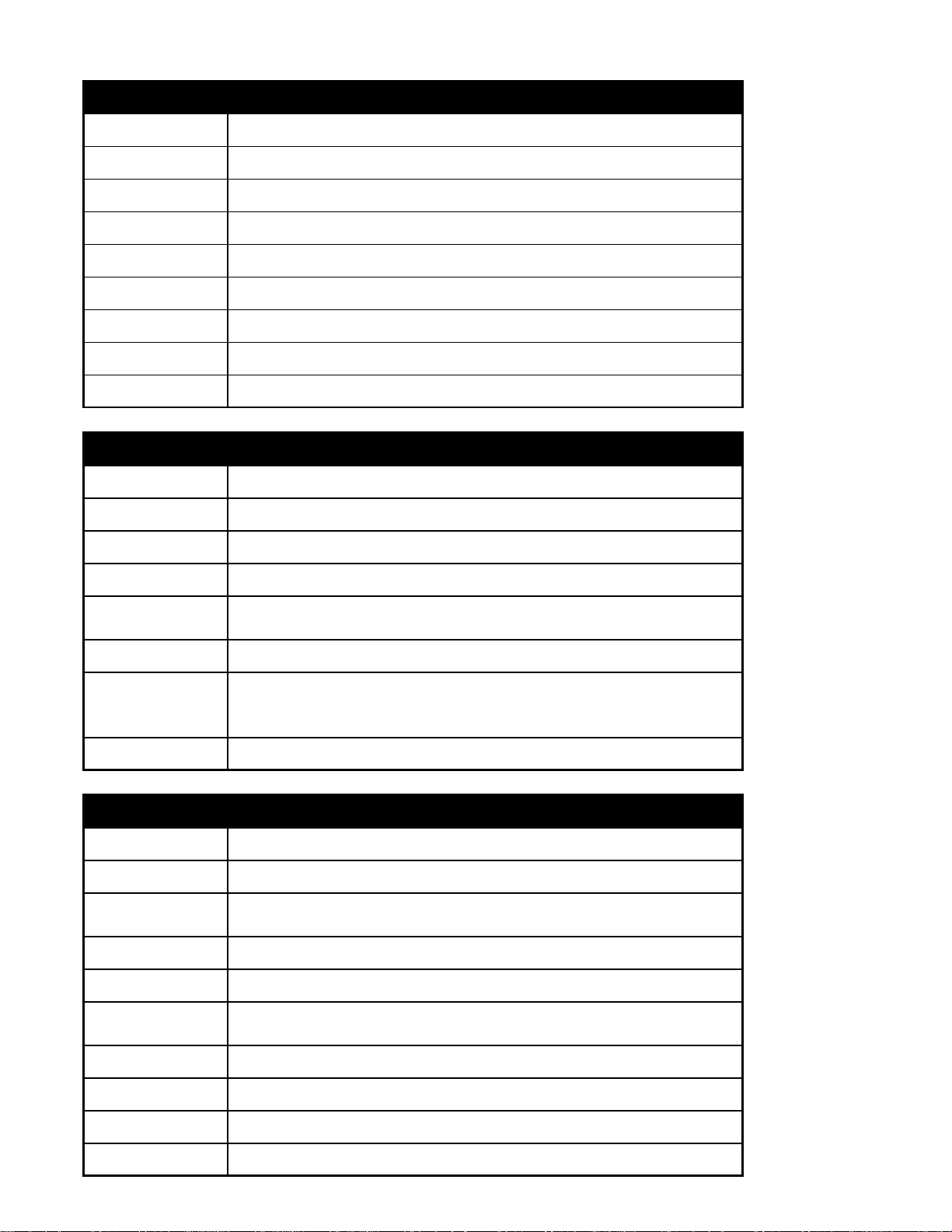

GENERAL SPECIFICATIONS

Figure-8 Eliminator

Trailer

Used to eliminate the need to manually figure-eight fiber optic cable.

Electronic Control

System

Control all functions of the trailer.

Drum & Arm Assembly

Fully enclosed on all four sides by safety cages.

Loading Cable

Loaded from ground level without having to climb into trailer - access doors through

safety cages.

Freewheel Mode with

Variable Drag

Adjustable through electronic controls, used when cable is being pulled off the drum by

Fiber Optic Blower.

Arm Assembly

Can be freewheel by switching on the disengage arm switch.

Arm Placement

Arms must be locked into position during transport to prevent the beam from fatiguing.

Trailer to be used for handling cable in figure-8 situation only. Not for transporting

cable.

Roller Block Operation

Easily operated with one hand.

CABLE HANDLING SPECIFICATIONS

1.05" (26.67 mm)

Maximum Cable

Diameter

48,000 ft of 1/2" diameter cable (15 km of 13 mm cable)

31,000 ft of 5/8" diameter cable (10 km of 16 mm cable)

Cable Capacity

Arm Speed

Stabilizer Jacks

Manual outrigger jacks.

40 RPM

22,000 ft of 3/4" diameter cable (7 km of 19 mm cable)

16,000 ft of 7/8" diameter cable (5 km of 22 mm cable)

12,000 ft of 1" diameter cable (4 km of 25 mm cable)

Minimum Drum

Diameter

Cable Loading Speed

42" (1,067 mm)

Maximum speed is 785 ft/min (239 m/min) on a full drum, Maximum speed is 440 ft/min

(134 m/min) on an empty drum

Max. Cable Loading

Tension

Minimum Bend Radius

20 times the cable diameter through guide roller (20 x 1.05= 21" (533 mm) bend radius)

160 lb. (712 N)

Trailer to be used for

Handling Cable

1.

Page 5

5

OUT OF RANGE

OUT OF RANGE

• Full DOT approved lighting package with reflective tape

• Front tongue jack, rated for 7,000 lb capacity.

• Target trailer weight 5,500 lb.

• Trailer width of 8' ft.

• Spare tire included.

• Maximum tongue weight 500 lb.

D. HYDRAULIC SPECIFICATIONS

• 16 HP gasoline engine set at 3000 RPM (16 HP diesel engine is an option).

• 8.4 cc or 0.51 cu. in. Sunstrand pump is used to generate up to 6.5 GPM fo

hydraulic fluid.

• System pressure is set at 2500 psi on the apitech valve.

• 12 Gallon fuel tank estimated to last up to 12 hours of operation.

• Hydraulic oil sight gauge is mounted on hydraulic tank to monitor oil level.

• A5 micron high pressure and 10 micron low filter are used to keep the

hydraulic oil clean. Both filters will indicate on the ECB when elements

are plug.

• Apitech valve controlled (ECB controlled) hydraulic ME-24 Ross motor to

drive arms. Motor to have pulse sensor (30 pulses per rev).

• Apitech valve controlled (ECB controlled) 56 inches hydraulic cylinder to

move drum. Drum to have potentiometer mounted to provide signal feedback

on drum location.

• 2500 psi, 6.5 gpm external hydraulic circuit, controlled by Apitech valve

(ECB controlled). Plumbed at rear of trailer with quick connects for

Condux FO Blower.

• Thermostatic control valve is used on the inlet of the cooler to prevent

hydraulic fluid flowing through 7.8 HP cooler when the temperature has yet

to reach 100 C.

E. ELECTRONIC CONTROL SYSTEM SPECIFICATIONS

Contained within a separate set of documents:

• Remote Electronic Control Box Specification: K:\PRODUCT\Product Dev

Projects\1995\95—52 Figure 8 Trailer\Electronic Controls\Electronic

functions.lwp

• Machine Electronic Control Box Specification: K:\PRODUCT\Product Dev

Projects\1995\95—52 Figure 8 Trailer\Electronic Controls\Machine Control

Panel.lwp

F. ELECTRICAL / ELECTRONIC SPECIFICATIONS

• 12 volt DC electrical system.

• Two12 VDC battery.

• A20 ampere attenuettor is used to generate enough power for the

electrical system.

• Throttle, free wheel, strobe lights, work light, blower and controller switches

with fuse are place on the control panel.

• Glow plug is offer for diesel engine.

• Hour meter, emergency switch, hydraulic system pressure, fuel gauge choke

and push start button are also place on the control panel.

• Two strobe and four clearance lights are offered to satisfy the DOT

specification.

Mounts

For remote in/near control panel, also a mount on the Fiber Optic Cable Blower for the

remote.

Controls: throttle, arm disengage, strobe lights, work light, blower and controller

switches with fuses, also the hour meter, emergency stop switch, hydraulic system

pressure, fuel gauge, choke and push start button.

Glow Plug

Charges through main system, and it is isolated by a diode to prevent drawing from this

power supply for the work light, strobe lights, starter, blower, free wheel solenoid and

throttle.

Storage Area

Secured, weather resistant, and shock absorbing for the remote control and 65' (20 m)

of control cable.

Limit Switches

On all openings and tipping gates

Rear Electric Turk

Connector

To power to Fiber Optic Cable Blower

Tongue Weight

Engine

ELECTRICAL / ELECTRONIC SPECIFICATIONS

Electrical System

12 volt DC

System Pressure

3,000 psi (207 bar)

600-650 lb. (272-295 kg)

12 Gallon (45 liters) estimated to last up to 12 hours of operation

Filtration

TRAILER SPECIFICATIONS

Dual axle, rated for 12,000 lb. (5,443 kg) capacity

Electric

Pintle ring hitch for electric brake

Axle

Brakes

Hitch

Full DOT approved lighting package with reflective tape

Rated for 7,000 lb. (3,175 kg) capacity

6,500 lb. (2,948 kg)

8' (2.44 m) wide x 9' 6" (2.90 m) high x 21' 6" (6.55 m) long

Isolated 12 VDC Power

Supply for ECB

Used on inlet of the cooler to prevent hydraulic fluid flowing through 7.8 HP (5.8 kW)

cooler when temperature has yet to reach 100 C.

5 Micron high pressure and 10 micron low pressure filters used to keep hydraulic oil

clean.

Batteries

Two 12 volt VDC Batteries

2,500 psi (172 bar), 6.5 gpm (25 lpm) external hydraulic circuit.

Offered for the diesel engine

Lights

Two strobe and four clearance lights are offered to satisfy the DOT specification. Work

light is offered to operate the machine in the dark.

Dual Safety Chains

HYDRAULIC SPECIFICATIONS

16 HP @ 3170 RPM (12 kW @ 3170 RPM) Briggs & Stratton V-Twin Vanguaard

*16 HP (12 kW) Diesel engine is an option

Plumbed at rear of trailer with quick connects for Condux Fiber Optic Blower.

Lighting

Hydraulic Flowrate

7 gpm (26 lpm)

Hydraulic Fluid Sight

Gauge With

Thermometer

Mounted on hydraulic tank to monitor fluid level and fluid temperature

External Hydraulics

Thermostatic Control

Valve

Control Panel

Fuel Capacity

Front Tongue Jack

Trailer Weight

Trailer Dimension Size

Minimum 10,000 lb (4,536 kg) capacity

Page 6

6

Safe Operating Practices

Read and understand all procedures and safety instructions before using the Condux

Figure-8 Eliminator Trailer. Observe all safety information on this page and note

specific safety requirements as explained by procedures called out in this manual.

Failure to follow these instructions could result in serious personal injury, property

damage or death.

A.WORK AREA SAFETY

1. Wear personal protective equipment: hard hat, safety glasses, safety shoes, and

leather work gloves.

2. The safe operation of this equipment requires that the operators be on stable

footing.

3. Stay clear of cables or lines under tension.

4. Do not place cable spool too close to unit. Place the spool far enough away

from the unit to ensure proper control.

5. Do not tamper with relief valves or pressure reducing valves.

B. HYDRAULIC DEVICES

Escaping fluids under pressure can penetrate the skin and cause serious personal

injury. Observe the following precautions to avoid hydraulic hazards:

1. Tighten all connections before applying pressure. Relieve pressure when

connecting or disconnecting hoses when servicing the unit.

2. Check for leaks with a piece of cardboard. Do not use your hands!

3. Do not exceed working pressure of hydraulic hoses.

4. Visually inspect hoses regularly and replace if damaged.

C. ELECTRIC DEVICES

The Hand-Held Wired Remote Controller is an electrical device. Electric shock

hazards exist that could result in severe personal injury or death. Observe the

following precautions to avoid electrical hazards:

1. Do not operate in or near water. This includes setting the Hand-Held Wired

Remote Controller on a wet surface or exposing them to rain.

2. Do not remove cover of the Hand-Held Wired Remote Controller or Electronic

Machine Controller. There are no user-serviceable parts inside. Refer servicing

to qualified service personnel.

3. The Hydraulic Power Unit Controls Power Switch and Controller Power Switch

should be in the off position before connecting or disconnecting any cords.

2.

Page 7

7

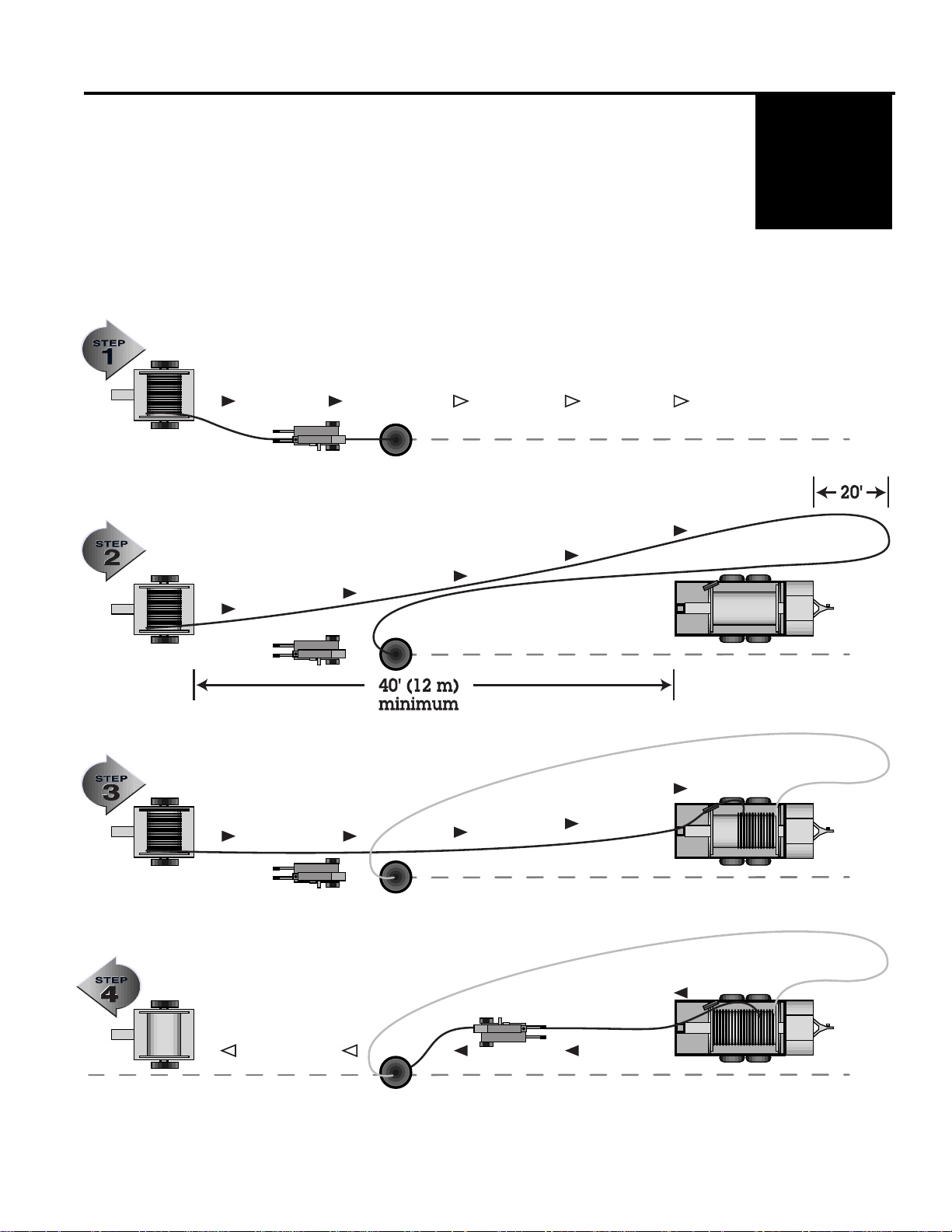

Jobsite Set-Up Guidelines

Time spent planning your equipment’s placement (layout) at the job site will benefit

both the operation of the equipment and the safety of your crew at the site. It is

best to determine the layout of all equipment before disconnecting, stabilizing and

leveling the Figure-8 Eliminator Trailer. Because no two job sites are the same, the

illustrations that follow should be used as general guidelines to get the most benefit

and safest operation from your Figure-8 Eliminator Trailer.

Cable Installation—First Run

Prepare Figure-8 Eliminator Trailer for Cable Loading

Load Cable to Figure-8 Eliminator Trailer

Cable Installation—Second Run

3.

Page 8

8

4.

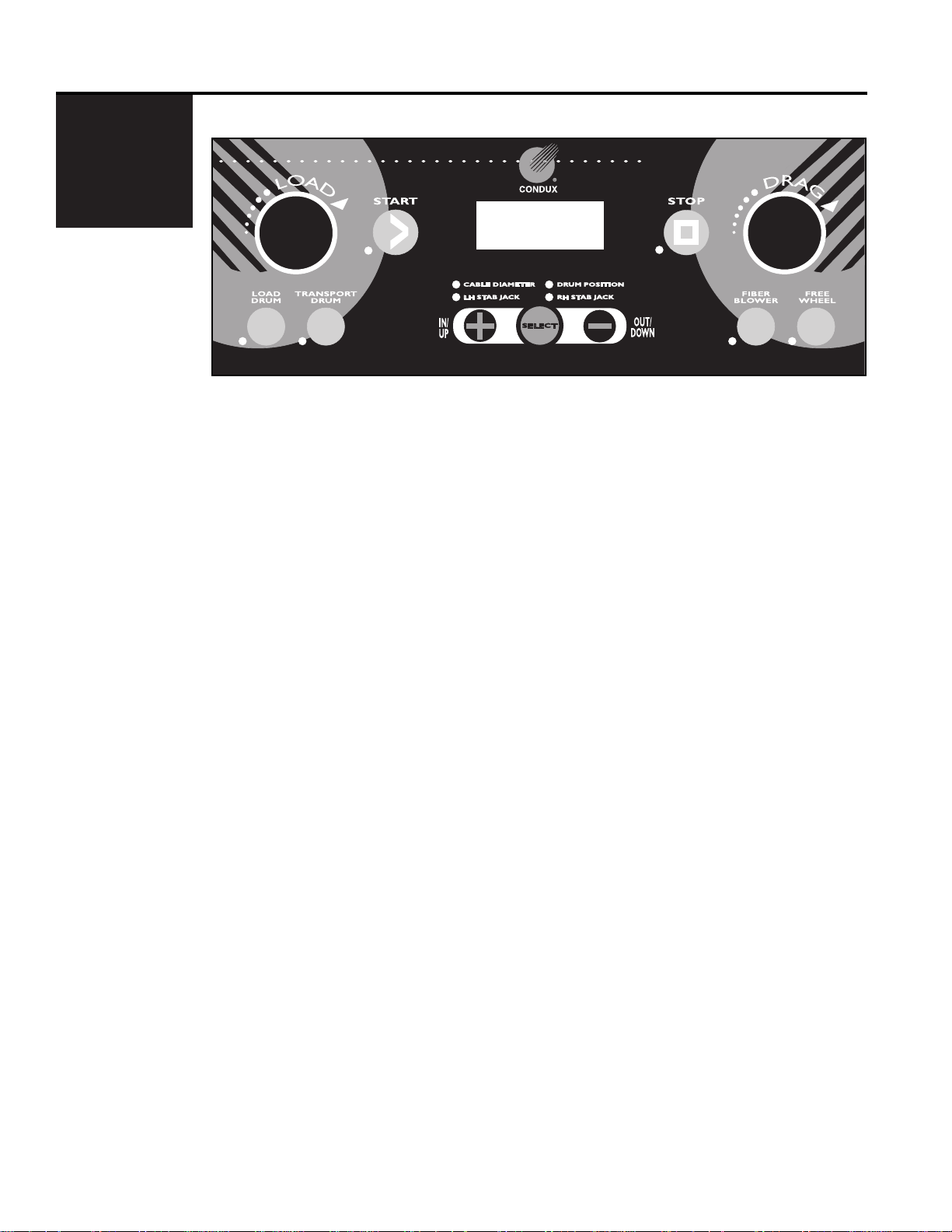

Electronic Control Features and Operation

A. HAND-HELD WIRED REMOTE CONTROLLER

Load Dial

• Controls the speed of the rotating arms from 0 rpm to maximum 40 rpm.

Load Drum button

• Moves the drum to the rear of the machine so the cable can be loaded onto

the machine.

• Stop button will stop the drum from moving and stop this function.

• Pressing the Load Drum button while the function is active will have the same

effect as pressing the Stop button.

Transport Drum button

• Moves the drum to the front of the machine for transport.

• Stop button will stop the drum from moving and stop this function.

• Pressing the Transport Drum button while the function is active will have the

same effect as pressing the Stop button.

Start / On button

• Starts the machine so the Load Dial is functional and allows the arms

to rotate.

• Stop button will stop the arms from rotating and stop this function.

• Load Dial must be turned all the way to zero (counterclockwise) in order to activate the start button. LED will flash if the Load Dial is not all the way to zero.

4 digit 7 segment LED display

• Normally displays the cable diameter in millimeters or the Drum Position.

• Also displays error codes when an error condition is encountered: FL 1-FULL

if the pressure filter is full; FL 2-FULL if the return filter is full; or door-OPEn

when one of the safety gates is open. These error conditions will flash between

the first and second words and will display for 5-10 seconds before going

back to displaying the cable diameter or Drum Position. They will cycle on

approximately every 20-30 seconds.

• An additional error code will be displayed when connected to the Condux FO

Blower and the blower has been stopped by the blower electronics: FOCBStOP. This error condition will flash between the first and second words and will

display as long as the trailer has been disabled by the blower. This condition

can be cleared by pressing the Stop button.

Page 9

9

Stop button

• This button will stop all operations of the machine.

• LED beside button is lit when none of the other functions are operating. Also

functions as a “power on” indicator.

• If arms are rotating, they will take approximately 2 seconds to stop.

• If the Condux FO Blower has stopped the machine, pressing the Stop button will

clear the stop forced by the blower.

+ / In / Up button and - / Out / Down button

• Increments the cable diameter when the Cable Diameter LED is selected.

• Moves the Drum Position backwards or forwards while loading or

unloading cable.

Select button

• Allows selection between Cable Diameter and Drum Position.

Cable Diameter LED

• Indicates that the cable diameter can be adjusted up or down with the

+ / - buttons.

• Cable diameter can be adjusted only when NOT loading or unloading cable.

Cannot be adjusted when Load Drum or Transport Drum are operating or when

Condux FO Blower has stopped the machine.

Drum Position LED

• Drum Position can be adjusted at any time when loading or unloading cable.

• (+) Key speeds drum up, (-) key slows drum down.

• Readout on the LCD display is relative to the Drum Position on the trailer and is

not an indication of speed or distance.

LH Stab Jack & RH Stab Jack LEDs

• These functions are not used.

Drag Dial

• Controls the amount of drag on the rotating arms when in free wheel mode.

• Dial will control drag from very little drag on the arms to a very large amount

of drag.

Fiber Blower button

• Activates the external circuit that provides hydraulic fluid to the Condux

FO Blower.

• LED beside button is lit when the circuit is activated.

• Free Wheel button and function will also be activated when the Fiber Blower

button is pressed.

• Stop button will remove power from this circuit and stop this function and the

free wheel function, both LED’s will go out.

• Pressing the Fiber Blower button while the function is active will close the

hydraulic circuit and the fiber blower LED will go out, however, the Free Wheel

button and function will NOT be stopped.

Free Wheel button

• Places the trailer into free wheel mode.

• Free Wheel button and function will also be activated when the Fiber Blower

button is pressed. However, the Fiber Blower button and function will NOT be

automatically activated when the Free Wheel button is pressed.

• Stop button will stop this function and the fiber blower function.

• Pressing the Free Wheel button while the function is active will stop the free

wheel mode and the Fiber Blower will also be stopped.

Page 10

B. ELECTRONIC MACHINE CONTROLLER

Refer to page 11 for a full explanation of the Electronic Machine Controller functions.

C. FILTERS, GATE & EMERGENCY STOP DETAILS

The Filters, Gate and Emergency Stop devices are connected in a fail-safe

configuration. This means, these devices require a closed contact in normal working

condition. When the circuit goes open circuit, a fault condition results. The following

illustrations indicate the expected result.

Pressure Filter

When the Pressure

Filter is contaminated

and restricts the flow of

oil, the pressure build

up in the canister will

cause the indicator

contacts to open or an open circuit condition occurs from a broken cable or

terminal, the following is displayed. The trailer will continue to operate at a

reduced performance level.

Return Filter

When the Return Filter

is contaminated and

restricts the flow of oil,

the pressure build up in

the canister will cause

the indicator contacts to open or an open circuit condition occurs from a

broken cable or terminal, the following is displayed. The trailer will continue

to operate at a reduced performance level.

Cage Gates

When the Access

Doors are opened or

the Tilt Panels are not

tilted out, or the circuit

to the Access Door

sensor is damaged, the following is displayed. The trailer will NOT continue

to operate and the condition must be corrected.

Emergency Stop

When the Emergency

Stop is activated or the

circuit to the E/Stop is

damaged the following

will be displayed. The

trailer will NOT continue to operate and the condition must be corrected.

10

Green LED

Red LED

▲▲

▲▲

▲▲

Green LED

Red LED

Green LED

Red LED

Green LED

Red LED

▲▲

Page 11

11

Emergency

Stop

Safety Cage

Pressure Filter

Return Filter

Drum Circuit

Arm Circuit

Blower Circuit

Jack Circuit

FUNCTION

DESCRIPTION GREEN LED RED LED OFF

Green LED indicates that no

Emergency Stop buttons have

been pressed.

Green LED indicates that all

Access Doors are closed.

Green LED indicates that

the Pressure Filter is in good

condition.

Green LED indicates that

the Return Filter is in good

condition.

Green LED indicates that the

drum valve has been activated

and the potentiometer (position

sensor) is reading the Drum

Position.

Green LED indicates that

the arm valve (server) has been

activated and the

speed sensor is reading the

motor rotation.

Green LED indicates that

the Blower Circuit has been

activated.

This function is not used.

Red LED indicates that one of

the Emergency Stop buttons

has been pressed.

Red LED indicates that one

of the Access Doors is open or

the Tilt Panel is not tilted open.

Red LED indicates that the

Pressure Filter is full and in

need of cleaning / replacing.

The Red LED will stay lit until

maintenance is completed. The

trailer will continue to operate at

a reduced performance level.

Red LED indicates that the

Return Filter is full and in

need of cleaning / replacing.

The Red LED will stay lit until

maintenance is completed. The

trailer will continue to operate at

a reduced performance level.

Red LED will display if the drum

is not moving.

If the drum circuit has been

activated and the drum is

moving, but the red LED is

constantly lit, the potentiometer

isn’t reading a change in the

Drum Position. This would

indicate that either the

potentiometer is bad or the

valve isn’t operating.

The red LED may flash while

the drum is moving. This is normal.

Red LED will display if the

arm is not moving.

If the Arm Circuit has been

activated and the arm is moving,

but the red LED is constantly lit,

the speed sensor isn’t reading a

change in the arm position. This

would indicate that either the

speed sensor is bad or the valve

isn’t operating.

The red LED may flash while

the arm is moving. This is normal.

Both LEDs would be OFF when

the Drum Circuit isn’t activated

at all.

Both LEDs would be OFF when

the Arm Circuit isn’t activated

at all.

LED would be OFF when the

Blower Circuit isn’t activated

at all.

Page 12

12

Prepare for Operation

It is essential that the Figure-8 Eliminator Trailer be properly set up before operation.

Using the following procedure will allow the unit to be set up in a short period of time

and yield optimum performance.

A. The trailer may be disconnected from the tow vehicle or left connected,

depending on your specific job site conditions.

B. Use wheel chocks (not included) to prevent trailer movement.

C. Disconnect Arm Lock. Unscrew the locking mechanism (Figure 1). Fold back

(Figure 2) and secure with safety pin (Figure 3).

Figure 2. Fold Back Arm

5.

Figure 1. Disconnect Arm Lock

Figure 3. Secure With Safety Pin

Page 13

13

D. Stabilize the trailer. Use only the

adjustable leveling jacks (3 supplied) for

trailer stabilizing and leveling. Jacks

must be placed securely on jack mounts

located on the trailer frame at the rear

of the trailer and on the tongue

(Figure 4). Do not attempt to locate

jacks in any other position. To secure a

jack in position, align jack with a jack

mount and insert safety pin (Figure 5).

Raise and lower jacks by rotating

crank handle.

E. Open Tilt Panels on the safety cage by

pulling the release cable located on both

the front and rear ends (Figure 6). Lock

Tilt Panels into open position with the

attached safety pin (Figure 7).

Figure 5. Align Jack with a Jack

Mount and Insert Safety Pin

Figure 6. Open Tilt Panels

Figure 7. Lock Tilt Panels Into

Open Position

Figure 4. Jack Mounts

Page 14

F. Move drum into load position

NOTE: Before starting the engine, check hydraulic fluid level, engine oil level,

and diesel/gasoline fuel level.

1. Hook up electronics. Connect both the Electronic Machine Controller

(Figure 8) and the Hand-Held Wired Remote Controller (Figure 9).

2. Start the engine using the electric start switch at the Electronic Machine

Controller panel (Figure 10).

IMPORTANT! It is critical to warm the hydraulic fluid to 100°F before

operating the machine. Hydraulic fluid temperature is indicated by a

thermometer in the engine compartment (Figure 9a).

3. Turn the controller on by using the switch at the Electronic Machine

Controller panel (Figure 10).

4. Engage the Engine Throttle. Pull out knob located on the Electronic

Machine Controller panel. Or, turn on the throttle switch (if equipped with

electronic throttle).

5. Push Load Drum button on the

Hand-Held Wired Remote Controller.

The drum will move and automatically

stop when in load position.

(See Section 4).

Figure 8. Connect Electronic

Machine Controller

Figure 9. Connect Hand-Held

Wired Remote Controller

14

Figure 9a. Hydraulic Fluid

Thermometer

Page 15

15

Figure 10. Electronic Machine Controller Panel

15

Page 16

16

6.

Load Cable

To begin the loading procedure the cable must be threaded and secured properly

through the fairlead assembly, quad keeper rollers, double keeper rollers, cable notch

and cable clamp. Proper cable threading is essential for a successful winding.

Because there is no “free end” of the cable at this point in the installation, a procedure has been developed to thread the cable on to the drum using cable slack.

A. Open the Access Doors in the safety cage’s Tilt Panels by pulling the

release cable located on each Access Door (Figures 11 & 12).

CAUTION: Follow cable manufacturers guidelines for minimum bend radius for

cable you are using. Failure to do so may result in permanent damage to cable.

CAUTION: Do not figure-eight any dual strength member fiber optic cable using

the Condux Figure-8 Eliminator Trailer. Condux will not warranty or be held

liable for any cable damage resulting from the use of dual strength member

fiber optic cable on the Condux Figure-8 Eliminator Trailer.

B. Pull out slack from the cable reel to pass at least 20 ft. (6.1 m) beyond

the front (engine) end of the Figure-8 Eliminator Trailer (Figure 13).

C. Turn on the Arm Disengage switch on the Electronic Machine Controller

panel (Figure 10).

Figure 11. Pull Release Cable

Figure 12. Open Access Doors

Figure 13. Cable Slack

Page 17

17

D. Rotate arms manually until the far rearward quad block is in a horizontal

position (Figure 14).

E. Open rear fairlead assembly (Figure

15) and lay cable in place (Figure 16).

Important! Cable is loaded from the

back of the trailer to the front using

additional cable from the cable reel,

NOT from the cable slack pulled out in

step B.

F. Open the quad keeper roller by lifting

the roller and pin from its seat

(Figure 17) and lay cable in place.

G.Close and lock the quad keeper roller

(Figure 18).

Figure 14. Position First Quad

Block Horizontally

Figure 15. Open Rear Fairlead

Assembly

Figure 17. LIft Roller And Pin

From Seat And Place Cable

Figure 18. Close and Lock Quad

Keeper Roller

Figure 16. Lay Cable In Place

Page 18

18

H. Close and lock the fairlead roller assembly (Figure 19).

I. Proceed to next keeper roller on the arm. Continue to rotate arms

manually and be sure to extract cable from the reel, not from the slack

pulled out in step B.

J. Open quad keeper roller and lay cable in place as in step F. Close and

lock quad keeper roller as in step G (Figure 20).

K. Manually rotate arms to locate 3 double keeper rollers (Figure 21) in

sequence. Follow the procedure to open, lay in cable, and close as in steps

F and G (Figure 22).

L. Manually rotate arms to locate the final quad keeper roller and follow

the procedure to open, lay in cable and close as in steps F and G.

Figure 19. Close and Lock

Fairlead Roller

Figure 20. Place Cable In Next

Quad Keeper Roller

Figure 21. Locate 3 Double

Keeper Rollers

Figure 22. Place Cable In Double

Keeper Rollers

Page 19

19

M. Manually spin arms around until the cable nests on the drum (Figure 23).

N. Nest cable in notch on drum (Figure 24).

O. Open cable clamp and secure cable inside (Figure 25).

P. Manually turn arms to wrap 2 complete wraps on drum.

Q. Turn off Arm Disengage switch.

R. Tighten manual wraps against front of drum (Figure 26).

S. Close Access Doors on Tilt Panels and at rear of trailer.

Figure 25. Open Cable Clamp

And Secure Cable Inside

Figure 23. Manually Spin Arms

Figure 24. Nest Cable In Notch

On Drum

Figure 26.Tighten Manual Wraps

Page 20

20

Power Winding

The Condux Figure-8 Eliminator Trailer is capable of winding cable at an average

speed of 600 ft/min (179 m/min) or about 40 RPM. This productivity will vary with

cable diameter, job site layout and equipment condition.

Important! Always start the winding operation slowly, and gradually increase

speed to attain maximum operation efficiency and cable safety.

The power winding procedure requires fluent use of both electronic controllers, the

Electronic Machine Controller and the Hand-Held Wired Remote Controller. Review

the features and functions of the electronic controllers in Section 4 of this manual

before beginning the power winding operation.

The drum moves a distance of one cable

diameter for every rotation of the arm

during power winding. It may be

necessary to make minor adjustments in

the speed of the drum movement during

winding to ensure cable nests neatly on

the drum (Figure 27). Note that the cable

being placed needs to be slightly behind

the cable wrapped on the drum to keep

wraps tight (Figure 27).

Important! Large spaces between

cable or overlapping of cable will

compromise the unloading procedure

(Section 8) or may cause the drum to

fill prematurely. Use the following

corrective actions when needed to

keep even wraps of cable on the drum.

Overlapping Cable: While loading, you

may double the speed of the drum for

every rotation of the arm by pressing the

(+) key on the Hand-Held Wired Remote

Controller. This means the drum will

move 2 cable diameters for every rotation

of

the arm.

Space Between Cable: While loading you

may half the speed of the drum for every

rotation of the arm by pressing the (-) key

on the Hand-Held Wired Remote

Controller. This means the drum will

move 1/2 a cable diameter for every rotation of the arm.

Follow steps Athrough H for trouble-free

Power Winding (Cable Loading) operation.

7.

Figure 27. Proper Cable Winding

Page 21

21

CAUTION! Side Tilt Panels must remain open and pinned, Access Doors must

remain closed during Power Winding operations. Be sure side panels are

securely pinned in the open position. Failure to do this may cause damage to

machine and cable.

A. Turn on electronic controller’s switch on control panel.

B. Input cable diameter using the Select and (+) and (-) keys on the Hand-Held

Wired Remote Controller. The reading is in millimeters only.

NOTE: A Vernier Caliper (supplied) or a cable diameter gauge (not included) can be

used to measure outside cable diameter (OD) on site.

C. Start the engine by depressing the electric start button on the Electronic

Machine Controller panel.

D. Turn the throttle up on the engine.

E. Be sure the Load Dial on the Hand-Held Wired Remote Controller is set at

zero (counterclockwise). The loading process will not start if the Load Dial

is not set at zero.

F. Press the Start button on the

Hand-Held Wired Remote. The

LED will come on. If the LED is

flashing, the Load Dial was not set

to zero. Turn the Load Dial com-

pletely to zero (counterclockwise)

and press the Start button again.

G. Begin winding by gradually turning

the Load Dial on the Hand-Held

Wired Remote Controller

clockwise (Figure 28). Winding

speed will continue to increase

as the dial is turned clockwise

and will decrease by turning

counterclockwise.

Important! Always start the winding operation slowly, and gradually increase

speed to attain maximum operation efficiency and cable safety.

Important! The operation may be shut down immediately by any one of the

following actions:

• Stop button is depressed on the Hand-Held Wired Remote Controller.

• Access Door is opened.

• Emergency Stop button is depressed at the Electronic Machine

Controller panel. (Requires restart of the electronic controllers.)

H. The drum will automatically reverse directions at the ends of the drum as

the power winding continues.

Figure 28.Wind Load Dial

Clockwise

Page 22

22

I. Discontinue power winding when there are approximately 5 to 6

wraps of cable left on the cable spool. The last 5 to 6 wraps should be

removed from the spool by hand. Turn Load Dial counterclockwise to zero

and stop engine by turning off at machine control panel.

CAUTION! Remove the last 5 to 6 wraps of cable slowly by hand to avoid end

of cable whipping freely off the cable spool during power winding.

NOTE: If you must turn off the controllers during the power winding operation at any

time before it is complete, there is a special procedure that must be followed to

resume operation. The drum direction must be noted and corrected if necessary.

1. Turn on both electronic controllers, Electronic Machine Controller and

Hand-Held Wired Remote Controller with switch on main panel.

2. Start the engine by depressing the electric start button on the machine

control panel.

3. Turn the throttle up on the engine.

4. Be sure the Load Dial on the Hand-Held Wired Remote Controller is set at zero

(counterclockwise). The loading process will not start if the Load Dial is not set

at zero. Press the Start button and begin winding the cable.

5. If the drum begins to move in the wrong direction, stop the operation promptly

by depressing the Stop button on the Hand-Held Wired Remote Controller.

6. Change the drum movement to the correct direction by pushing the Load Drum

or Transport Drum button on the Hand-Held Wired Remote Controller.

• Load Drum (moves drum towards the rear)

• Transport Drum (moves drum towards the front)

7. Resume power winding operations from step 7-F.

Unload Cable

Cable may be unloaded on to a cable reel or directly to a Condux Fiber Optic Cable

Blower. Unloading Cable requires the Figure-8 Eliminator Trailer to be in

Free Wheel mode and requires drag on the cable at all times to avoid whiplashing

and tangling of cable.

A. Start the Engine

B. Start the Controller

C. Increase Throttle

D.Press Free Wheel Button on hand-held wired Remote Controller

E. Check Drum movement for proper direction. If the drum begins to move in the

wrong direction, stop the operation promptly by depressing the Stop button on

the Hand-Held Wired Remote Controller. Change the drum movement to the

correct direction by pushing the Load Drum button or Transport Drum button on

the Hand-Held Wired Remote Controller.

8.

Page 23

23

F. Use the Drag dial to adjust the amount of drag placed on the arms during

unloading. It is essential to keep cable from developing slack. Start with

very little drag and increase to desired level and monitor throughout entire

unloading process.

G.Remove last 4-5 wraps manually. Activate the Arm Disengage switch on the

Electronic Machine Controller panel and rotate arms by hand.

H.Remove cable from quad and single keeper rollers using the procedure

described in Section 7.

Prepare For Transport

Care should always be taken to position drum for transport and properly stow

components in the Condux Figure-8 Eliminator Trailer. After cable is unloaded,

prepare for transport in the following way:

CAUTION: Condux Figure-8 Eliminator Trailer is not intended to transport

cable. Cable should be completely unloaded before transporting trailer to

another location.

A. Move drum into Transport position by pressing the Transport Drum key on the

Hand-Held Wired Remote Controller. Drum should be at the far forward position

for transport.

B. Release the arms with the Arm Disengage switch on the control panel.

C.Mount the Arm Lock to the arm housing (Figure 29).

D.Turn off the Arm Disengage switch.

E. Shut engine off.

F. Close Access Doors at sides and rear of trailer.

G.Close Tilt Panels on both sides of trailer.

Figure 29. Mount Arm Lock

Figure 30. Stow Controllers

9.

Page 24

24

H.Turn off Machine and Hand-Held Wired Remote Controller.

I. Disconnect electronics and stow controllers in bin below Electronic Machine

Controller (Figure 30).

J. Pull locking pin and secure in hole below latch for transport.

K. Release jacks by turning crank. Wind jack up to approximately 3 inches

(76.2 mm) above surface and rotate jack 90 degrees on its mount. Secure

with pin for transport.

L. Connect trailer to tow vehicle (if previously disconnected).

Service & Maintenance

A. Follow Briggs and Stratton Owners Manual for engine maintenance (the engine

oil drain is located beneath the trailer).

B. Inspect tires (LT 225/75R16) for proper wear and always keep inflated to the

specification denoted on the sidewall of the tire.

C.Inspect lighting and replace bulbs as required.

D.Maintain the hydraulic fluid with auto transmission fluid (Mercon/Dexron III) at

least three quarter tank.

E. Replace filters and auto transmission fluid when it turns brown color or after

500 hours of operation (the reservoir drain is located beneath the trailer).

Troubleshooting Guide

11.

Problem

Drum moving in the wrong direction

while loading and unloading after the

machine was shut down.

Drum is moving faster or slower than

the arms.

Machine will not run after pressing

load button or the load button LED

kept turning off after pushing it.

Load LED is flashing after pressed.

Solution

Move the drum towards engine using

transport drum button or move it

towards the arms using the load drum

button to guide the controller in the

correct direction of the drum.

The drum speed can be adjusted

using ‘+’ or ‘-’ button depending on the

drum direction and speed.

Check the Access Doors if they are

closed and Tilt Panels are tilted.

Turn Load Dial completely

counterclockwise (to zero) and press

button again.

10.

Page 25

25

Parameter Settings

These parameter settings are loaded into the controllers at the factory and should

not need adjustment. Please contact the factory before making any changes to the

parameter settings and for instructions on getting into the programming mode.

A.

Display Actual Setting Setting Command/ Procedure

CBLE 15 15 Default cable diameter.

POSN 0-2500 0-2500 Drum position reading of the

potentiometer. It is used to locate the

drum loading and transport position.

B1 55 Bias transport to engine—to set the drum

sensitivity moving toward the engine.

B2 55 Bias load to server—to set the drum

sensitivity moving toward the arms.

B3 55 Bias server load—to set the motor

sensitivity rotating the arms.

B4 0 0 Bias free wheel—keep it at zero.

LENG 1360 1360 Drum length measuring between the two

flanges—always set it at 1360.

SCNT 336 Drum position for loading.

ECNT 2026 Drum position for transporting.

GAIN 5 5

D1 100 100 Minimum drag.

D2 60 60 Maximum drag.

SLAG 0 0 Pulses on server before spool

move—always set it at zero.

7PNH 140 146 The speed of the drum moving to

transport position.

LOAD 140 141 The speed of the drum moving to

load position.

APPENDIX

Page 26

26

B.

Replacement Parts

Part Number Description

1 02267200 Kit, Tail Light-Waterproof Low Profile

2 02278509 Connector, Trailer 7-Way Blade

3 02288776 Cord set, Fig 8 Remote to Blower

4 02288779 Latch, T Handle-W/Lock

5 02288812 Spring, Gas

6 02288814 Cord set, Fig 8 Potentiometer

7 02288815 Cord set, Fig 8 Motor Signal

8 02288875 Caliper, Cable Diameter Fig-8

9 02288896 Bag, Fig 8 Remote Controller

10 08735110 Controller, Machine-Fig 8 Trailer

11 08735120 Control, Hand Remote-Fig 8 Trailer

12 08735130 Cord set, Fig 8 Remote Control

13 08735712 Tow ball, Male-Lock Assembly

14 08737001 Kit, Filter Replacement

15 08737002 Kit, Receptacle Turck Replacement

16 08737003 Kit, Limit Switch Replacement

17 08737004 Kit, Potentiometer Replacement

18 08737005 Kit, Channel Replacement

19 08737006 Kit, Hydraulic Hose Replacement

20 08737007 Kit, Quick Disconnect Replacement

21 08737008 Kit, Drum Eccentric Roller

22 08737009 Kit, Drum Horizontal Roller

23 08737010 Kit, Cable Blocks Accessories

24 08737011 Kit, V Quad Block Roller

25 08737012 Kit, Quad Block Roller

26 08737013 Kit, Dual Block Roller

27 08737014 Kit, Fairlead Latch

28 08737015 Kit, Fairlead Roller

APPENDIX

Page 27

27

Warranty Information

A. FACTORY ASSISTANCE

Condux International can provide further advice regarding any problems with the

installation, service, assembly, or disassembly of the Figure-8 Eliminator Trailer. Call

toll free at 1-800-533-2077 (USA and Canada) or 1-507-387-6576 and ask for

assistance. The Figure-8 Eliminator Trailer can be returned to the factory at any time

for service or repair; however, a Return Material Authorization (RMA) must be

obtained from Condux before shipping. Condux will not accept returned items without

an RMA.

B. LIMITED W ARRANTY

Condux International, Inc. extends the following warranty to the original purchaser of

these goods for use, subject to the qualifications indicated: Condux International,

Incorporated warrants to the original purchaser for use that the goods or any

component thereof manufactured by Condux International will be free from defects in

workmanship for the period of one year from the date of purchase. Provided such

goods are installed, maintained, and used in accordance with Condux’s written

instructions.

Lack of routine maintenance as specified in the maintenance section of the

User’s Guide will void the warranty.

Components not manufactured by Condux International but used within the assembly

provided by Condux International are subject to the warranty period as specified by

the individual manufacturer of said component, provided such goods are installed,

maintained, and used in accordance with Condux’s and the original manufacturer’s

written instructions.

Condux’s sole liability and the purchaser’s sole remedy for a failure of goods under

this limited warranty, and for any and all claims arising from the purchase and use of

the goods, shall be limited to the repair and replacement of the goods that do not

conform to this warranty.

To obtain repair or replacement service under the limited warranty, the purchaser

must contact the factory for a Return Material Authorization (RMA). Once obtained,

send the RMA along with the defective part or goods, transportation prepaid, to:

Condux International, Inc.

145 Kingswood Road

Mankato, MN 56001 USA

THERE ARE NO EXPRESS WARRANTIES COVERING THESE GOODS

OTHER THAN AS SET FORTH ABOVE.THE IMPLIED WARRANTIES OR

MERCHANTABILITY AND FITNESS FOR A PARTICULAR PURPOSE ARE

LIMITED IN DURATION TO ONE YEAR FROM DATE OF PURCHASE.

CONDUX ASSUMES NO LIABILITY IN CONNECTION WITH THE INSTALLATION

OR USE OF THIS PRODUCT, EXCEPT AS STATED IN THIS LIMITED WARRANTY.

CONDUX WILL IN NO EVENT BE LIABLE FOR INCIDENTAL OR

CONSEQUENTIAL DAMAGES.

13.

Page 28

28

© Copyright 2000, Condux International, Inc.

Printed in USA

Literature Part Number: 08739999

Revision Number: 1.0

Condux International, Inc.

P.O. Box 247 • 145 Kingswood Road, Mankato, MN 56002-0247 USA

1-507-387-6576 • 1-800-533-2077 • FAX 1-507-387-1442

Internet: http://www.condux.com • e-mail: cndxinfo@condux.com

Loading...

Loading...