Page 1

Service Manual for:

CJKA+%(8

CJKA+%(8

Under-Vehicle Lift

®

Private Use Wheelchair Lifts

www.braunlift.com

Series 02

DOT — Private Use Lift

DOT — Private Use Lift

“DOT — Private Use Lift” verifies that this platform lift meets only

the “private use lift” requirements of FMVSS No. 403. This lift may

be installed on all vehicles appropriate for the size and weight of

the lift, except for buses, school buses, and multi-purpose

passenger vehicles other than motor homes with a gross vehicle

weight rating (GVWR) that exceeds 4,536 kg (10,000 lb).

02

W

A

R N I N G

Man

ual

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

35033

November

2008

®

(574) 946-6153 FAX: (574) 946-4670

Patent #5,305,486

Patent #5,305,486

®

®

Read manual

before installing

or servicing lift.

Failure to do so

may result in

serious bodily

injury and/or

property damage.

Braun UVL SeriesTM

Braun UVL SeriesTM

Page 2

OWNER'S WARRANTY REGISTRATION

PURCHASED FROM

DATE INSTALLED

NAME

ADDRESS

CITY

TELEPHONE

TO VALIDATE WARRANTY

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed and

assembled the finest lift available.

This manual provides service-related material. Refer to the FMVSS No. 403

Quick Reference Installation Sheet for installation instructions, operating instructions

and maintenance procedures.

Braun UVL Series™ lifts are built for dependability and will provide years of pleasure and independence as long as the lift is installed and serviced as specified by a

Braun certified technician, and the lift is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Warranty and Registration Instructions

Immediately upon receiving the lift, examine the

unit for any damage. Notify the carrier at once

Series No.

Serial No.Model No.

with any claims.

NUVL603C 02-00025

Two warranty/registration cards (shown right) are

protected in a clear envelope and attached to the

lift protective shipping wrap. The sales representative must process one of the cards. The consumer

must fill out the other card and mail it to The Braun

Corporation. A detailed warranty section is provided

in this manual. The warranty cards must be

Sample Warranty/Registration Card

processed to activate the warranty.

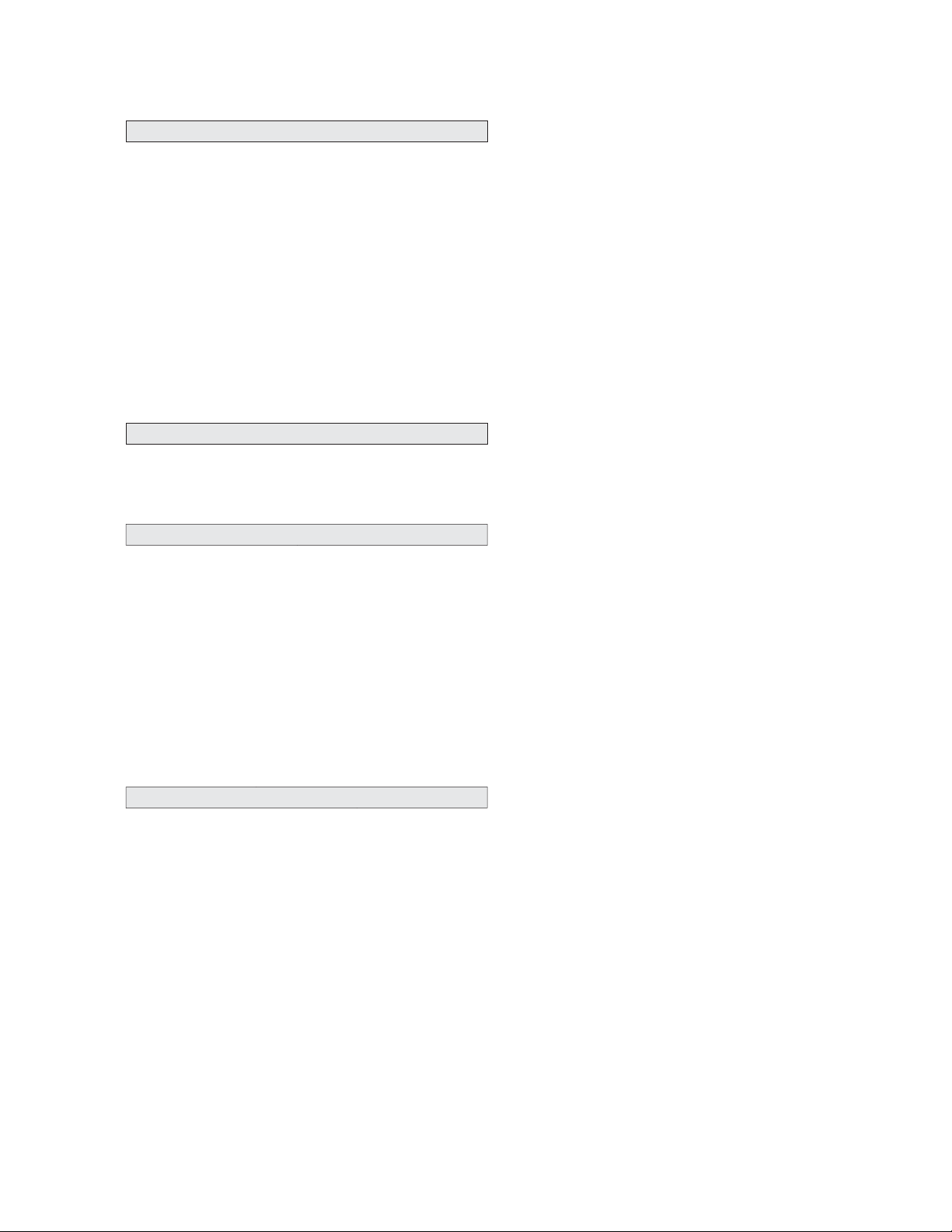

Two Braun Serial No./Series No. identification tags (shown below) are posted on the lift. One

I.D. tag is posted on the left platform side plate (outboard end). A second I.D. tag is located

inside of the pump module. Both I.D. tags provide the product identification information

provided on the warranty/registration card. Record the information in the space provided (or

document on a copy). This information must be provided when filing a warranty

claim or ordering parts.

The Braun Corporation

1-800-THE-LIFT

BRAUNMOBILITY.COM

DOT Private Use Lift MODEL#

NUVL603C

Max. Lifting Capacity - 750Lbs.

SERIAL NUMBER

02-00025

®

®

Model No.

Series No.

Serial No.

Sample Serial No./Series No. Identification Tag

11/12/2007

e5*72/245*95/54*0102*00

PATENT

5,305,486

MFG DATE

Pump Code

Cylinder Code

Date of Manufacture

Page 3

Contents

Troubleshooting and Maintenance

Lift Terminology ............................................................ 2

Switch and Sensor Locations ..................................... 3

Certification Checklist .................................................. 4

Adjustments and Calibration ....................................... 5

LCD Diagnostic Codes ................................................. 6

Floor Level and Inboard Locator Adjustments ..... 7-10

Lubrication Diagram ....................................................11

Maintenance and Lubrication Schedule ............... 12-14

Troubleshooting Diagnosis Chart ......................... 15-18

Notes ............................................................................ 19

Lift Wiring Schematic - Main ..................................... 20

Lift Wiring Schematic - Accessories ........................ 21

Hydraulics

Hydraulics Parts List .................................................. 22

Hydraulics Diagram .................................................... 23

Repair Parts

Pump Module

Pump Module Parts List ....................................... 24

Pump Module Diagram ......................................... 25

Lift Exploded Views

Complete Lift .......................................................... 26

Repair Parts List ................................................... 27

Housing Detail ........................................................ 28

Carriage Detail........................................................ 29

Platform Detail ........................................................ 30

Warranty

®

Braun

Limited Warranty .......................................31-33

Notes ............................................................................ 34

Page 1

Page 4

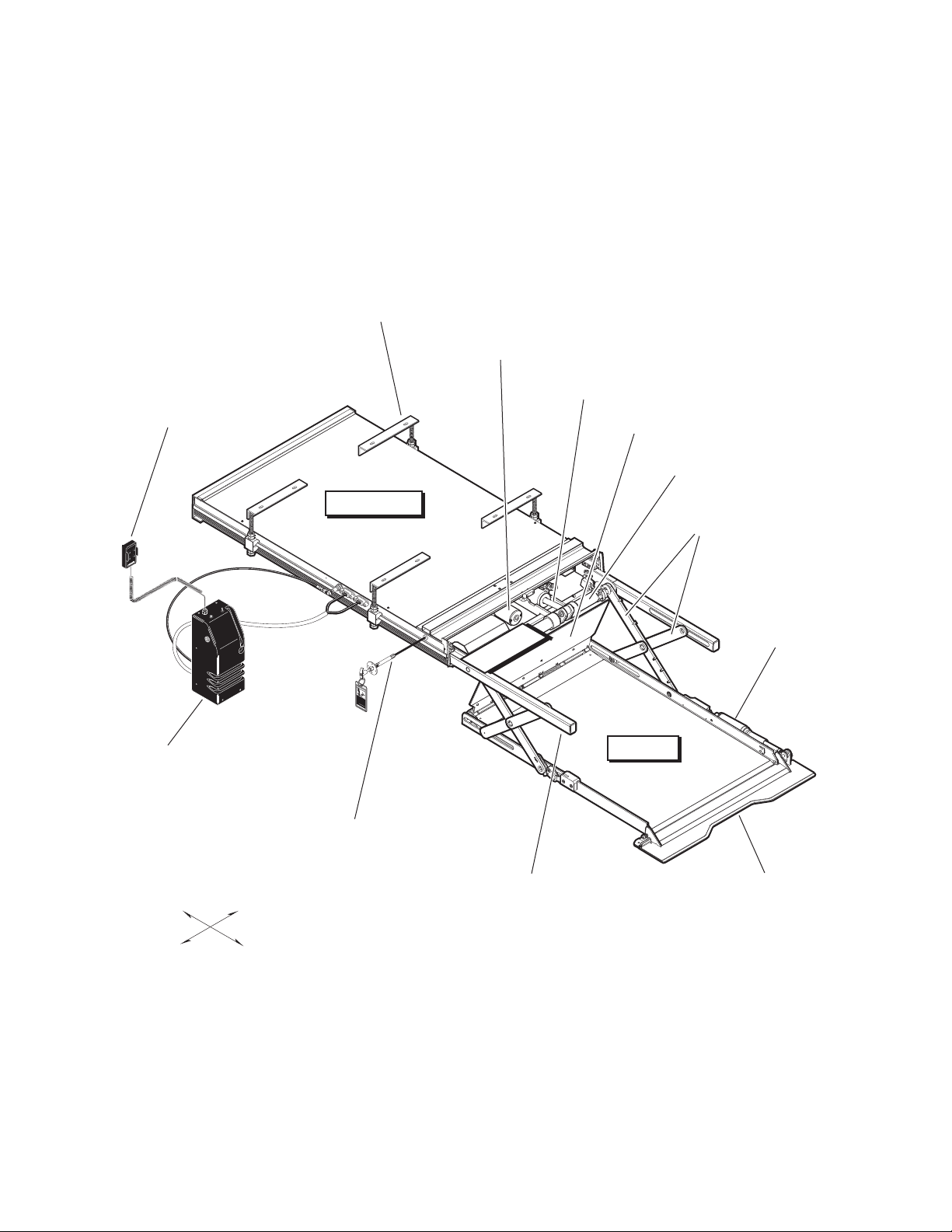

Hand-Held Attendant's

Control Box

Lift Terminology

Lift Mounting

Brackets (4)

Chain Drive

Motor

Hydraulic

Cylinder

Inboard

Locator

Torque

Tube

STOW

R

DOO

P

U

N

DOW

Module

Pump

Inboard

Lift Housing

Platform Cable-activated

Manual Release System

Right

Lifting

Arms

Outer Barrier

Actuator

Carriage

W

A

R

N

I

N

G

P

u

sh

ma

T

h

n

a

ual

n

and ou

dl

l

y m

e in

lock b

ove

t t

f

u

o

lly

Fa

platform in

e

ef

n

a

ilure to lock platfo

nd

o

gage pla

re dr

re

s

u

i

vi

l

t

deploy

n

t

i

f

n

g

o

vehi

u

r

m

nint

platform d

m

cl

e

e

e.

nt. Unintended

n

rm

r

d

e

sult

ed pla

ma

eployment

a

y

i

n

n

d/or p

t

se

f

o

rm

riou

roper

s

m

bo

a

ty da

y

dil

y

injury

Do not remove!

m

a

g

e

.

8

1

8

23

Platform

Rolling

Horizontal Arms

Outer

Barrier

Page 2

Left

Outboard

Page 5

Switch and Sensor Locations

Lift Out

Cam

73774

Lift Out

Limit Switch

73950A

Full Out

Limit Switch

73950A

Full Out

Cam

73775

Below Stow

Limit Switch

73950A

Floor Level

Limit Switch

73950A

Floor Level

Cam

73712

Below Stow

Cam

73712

Outer Barrier

Limit Switch

73950A

STOW

DOOR

UP

OWN

D

Inboard

Left

Right

Outboard

W

A

R

N

I

N

G

Pu

sh

Tm

a

h

n

a

uall

n

an

dle

d

y

o

m

i

n

l

ut to

o

o

f

c

ve

u

k

l

l

b

pl

y a

Fa

en

ef

a

i

nd

o

g

l

tf

u

re

a

o

r

result in

g

e to

rm

e plat

d

r

i

i

v

n

l

d

i

o

n

ep

c

f

g

o

k pl

unin

r

l

ve

o

m

plat

yment

hi

a

t

t

cle.

f

e

o

f

o

n

r

r

r

m

ded

e

m

.

sult in

Uni

m

de

a

p

an

y

p

lat

n

l

d/o

t

o

e

se

fo

yment may

n

r

r

d

r

m

i

pr

ed

o

u

o

s

p

bo

e

r

t

d

y

ily

d

amage

Do

inju

not rem

ry

.

81

8

2

3

ov

e!

Pressure

Transducer

30426

Page 3

Page 6

Certification Checklist

The following operations and conditions must be functionally verified in order for the lift to be FMVSS

403/404 compliant. If an operation does not function as described or a condition is not met, follow the referenced procedures to correct the problem or contact a Braun Corporation Product Support representative.

• Vehicle movement is prevented unless the lift door is closed, ensuring the lift is stowed.

1. Verify lift stowed signal (pin 9) in the 9 conductor plug on the side of the pump module has a +12 volt

signal.

2. Refer to the interlock installation instructions.

• Lift operation shall be inhibited unless the vehicle is stopped and vehicle movement is prevented.

1. Verify vehicle secure signal (pin 6) in the 9 conductor plug on the side of the pump module has a +12

volt signal.

2. Refer to the interlock installation instructions.

• The platform will not fold/stow when occupied.

- Refer to Platform Sense Calibration.

• The outer barrier will not raise if occupied.

- Refer to Outer Barrier Occupied Calibration procedure

• An audio warning (and visual warning for public use lifts) will activate if the threshold area is occupied

when the platform is a least 1" below floor level.

1. Make sure connectors to threshold mat are properly connected.

2. Call Product Support.

• Lift platform movement shall be interrupted unless the outer barrier is deployed (up).

- Check Barrier Down limit switch, wires and connector.

- Diagnostic LCD should display a value of “1” for OBAR SW when outer barrier is deployed (up).

Page 4

Page 7

Adjustment Procedures

Adjustments and Calibration

Lift Out Switch: The Lift Out Switch stops inward

travel of the carriage/platform during Stow function

(activated by the housing-mounted Lift Out Cam).

Move cam in to increase inward travel. Move cam

out to decrease inward travel.

Full Out Switch: The Full Out Switch stops outward travel of the carriage/platform during Deploy

(Up/Down) functions (activated by the housingmounted Full Out Cam). Move cam in to decrease

outward travel. Move cam out to increase outward

travel. Carriage rollers must be inside housing a

minimum 1/2". The platform will not raise or lower

until this switch is activated.

Floor Level Switch: See page 6 for procedures.

Stow Switch: The Stow Switch controls the height

of the carriage/platform before it moves inward during the Stow function (activated by the torque tubemounted Stow Cam). Rotate the cam in to decrease

platform height. Rotate the cam out to increase platform height. Adjust cam so lifting arms are aligned.

View the platform position in the housing.

Barrier Down Switch: This platform-mounted

switch prohibits the platform from raising unless the

outer barrier is in the full up position. The Up function is prohibited if the outer barrier detent pin is not

fully engaged also.

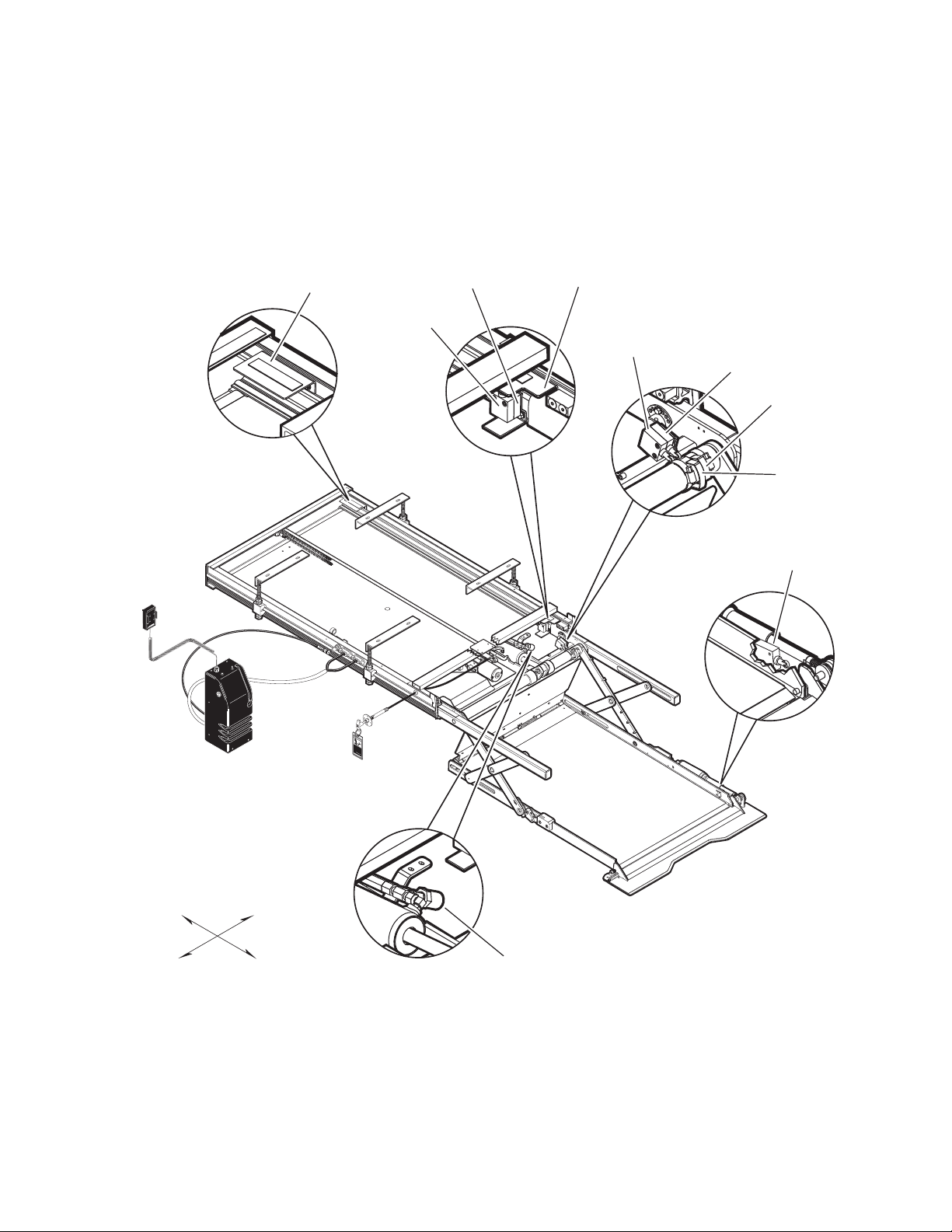

Remove eccentric plate mounting screw. Using

screwdriver or small rod, rotate the shaft clockwise to

increase carriage height. Rotate the shaft counterclockwise to decrease carriage height. Reinstall

mounting screw in nearest retainer hole. Adjust

left and right side eccentric shafts (screw positions

may vary from side to side). Adjust height such that

horizontal arms do not contact top or bottom of tracks

(align center).

Calibration Procedures

Platform Sense Calibration

1. Place 20 lbs. in the center of the platform.

2. Press UP button on the hand-held pendant to raise

the platform a minimum of 3" above stow level.

3. Press and hold 50# CAL button on control board.

While pressing the 50# CAL button, press and

hold the STOW button on the hand-held pendant.

The platform will lower to stow level, raise slightly,

lower to stow level, and begin inward travel.

Release the 50# CAL button when the platform

begins moving inward. The platform sensing is

now calibrated.

4. After calibration, the LCD screen should read “PF

OCCUPIED” when 50 lbs., or more, are present

on the platform. If 50 lbs. does not activate the

“platform occupied” signal readout, recalibrate with

less weight to lower the “occupied” setting or more

weight to increase the “occupied” setting.

Drive Chain Adjustment

In event the drive chain sags 1/2" or more, adjust

tension as detailed. Tighten to eliminate visible sag

but do not overtighten.

1. Remove bottom pan.

2. Pull the manual release cable and lock.

3. Remove adjustment bolt (tensioner) access

cover.

4. Loosen inside jam nut. Secure tensioner and

tighten outside jam nut. Tighten to eliminate visible chain sag but do not overtighten.

5. Lock jam nuts together making sure the tensioner roller is horizontal. Release and push the

manual cable in fully. Ensure platform is locked

by moving the platform in and out until chain

release assembly engages chain.

Carriage Ride Height Adjustment

The carriage horizontal arms move (roll) in and out

of the housing tracks on roller bearings. Following installation or extensive lift operation, clearance

between horizontal arms and tracks may diminish.

The eccentric shaft mounting plate allows height

adjustment.

Ground Sense Calibration

1. Press hand-held pendant DOWN switch to lower

platform fully to ground level.

2. While continuing to press the pendant DOWN

switch, press and then release the control board

O_BAR/GROUND LVL button.

3. Release the pendant DOWN switch. Ground

Level sensing is now calibrated.

4. After calibration, the outboard roll stop should

not unfold (down) until the platform is fully on the

ground.

Outer Barrier Occupied Calibration

1. Press hand-held pendant DOWN switch to lower

platform fully to ground level.

2. Once outer barrier is fully unfolded (ramp position),

release the pendant DOWN switch.

3. Press and hold the control board O_BAR/

GROUND LVL button. While holding O_BAR/

GROUND LVL button, press hand-held pendant

UP switch to raise the outer barrier. Be sure to

release O_BAR/GROUND LVL button when outer

barrier reaches approximately half full up (vertical)

position.

4. After calibration, the LCD screen should read

“OUT-BAR OCCUPIED” whenever there is weight

present on the outer barrier.

Page 5

Page 8

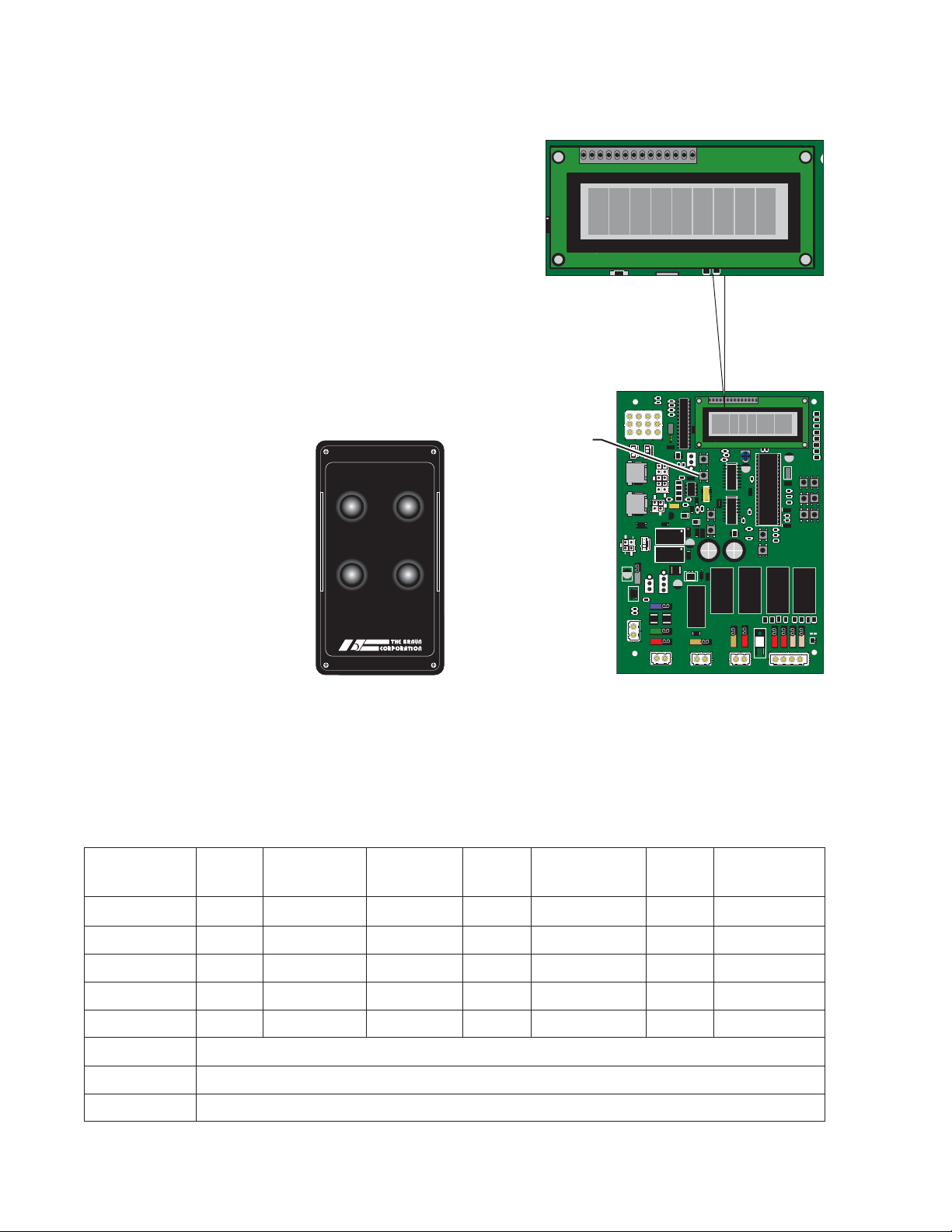

LCD Diagnostic Codes

2

C

To change the LCD display from cycle count to diagnostic

mode, press the “diag” button on the control board (see

illustration at right). When finished, press button again to

return to cycle count mode. When all of the harnesses

are correctly connected to the control board, the values

shown in the chart below will display when the corresponding action is taken. “1” will appear to the right of the switch

or sensor name on the LCD module when activated as

shown. If any other value appears on the LCD screen

during the specific diagnostic procedure, verify that the

correct harness is properly connected to both the control

board and the associated lift harness. Repeat the harness

diagnostic procedure. If an incorrect value is still present

after checking the harness and connections, contact The

Braun Corporation Product Support Department.

All basic functions (UP,

DOWN, STOW and

DOOR) should show a

value of 1 when activated

via a controlled input

(Hand-held Pendant,

Magnetic, Remote Entry

or 3rd Station Controls).

DOOR

STOW

DOWN UP

cycle

diag Button

OBAR S 1

R31

R39

102

R13

R5

243R

R20

C

D

A

B

R19

R18

Lift Devices

K

L

U14

JIH

G

D/S

U/D

C7

321

321

J1

J2

6H23EM

HAND-1

R28

6H23EM

103

HAND-2

U18

Magnetic

C9

V104

INLK-1

U21

OH

RL11

4 3 2 1

321

RL10

Operator

Door

IN

MAT

VR3

FS11

C16

35A

220

5Q6

IN L H

U20

R25

102

FS1

R43

1802

R41

1002

GND

VR2

VR1

PWR-IN

FS2

12V-B

FS8

LIGHT

U16

103

103

103

103

V104

8.00M

C6

V104

U15

cycle

B LIGHT A

103

103

Remote

R1

R16

R26

103

C105

U12

C14

D23

D24

D25

C15

102

V104

D26

R33

103

R11

R37

C5

R36

106 E

330

C8

103

V104

103

U7

U17

D13

D10D11

C22

6C5

100

VHA

D12

U19

R34

C12

5Q6

220

35A

RL9

D9

FS7

LIGHT

W

102

102

OB AR S 1

R31

diag

U5

SOMC1601

CLOSECLOSE

OPEN

C10

V104

C13

RL4

ALARM

ALARM

W

102

102

CONTRAST

102

102

R29

103

U3

R27

CHA

220

6C5

C21

R32

102

V104

U2

C1

ZD3

R38

102

R42

102

R9

103

50# CAL

SW1

R10

103

U22

103

GROUND LVL

O_BAR

SW2

C11

RL2

RL3

D21

D19

D18

FS10

FS9

MP916

0.010Ω

.5% R

FS5

R40

PUMP

VALVE

B_DN

R4

R2

R1

103

R6

103

R7

D20

D7

D8

D5

D6

D3

D4

D

D7

D8

D5

D6

D3

D4

D2 D1

C20

CHA

220

6C5

U8

8.00M

L_UP

L_DN

C4

V104

R15

102

R14

B_DN

B_UP

103

R8

103

C3

V104

L_IN

L_OUT

103

103

NUVL CONTROLLER REV-3.1-1

The Braun Corporation

C2

V104

RL1

D16

D17

D15

D14

R3

U9

FS6

FS4

FS3

L_IN

L_OUT

B_UP

Hand-held Pendant

LCD Display Moving Out

STLV SW 1 1

Stowed

Of Cassette

Moving Up

From Stow

At Floor

Level

Moving Down

From Stow

NUVL Control Board

Ground

Level

Ground Level

OB Out

LOUT SW 1

FOUT SW 1 1 1 1 1

FLV SW 1

OBAR SW 1 1 1 1 1 1

MAT SW = 1 when mat is activated.

DO SW = 1 when door is full open or pin 3 and pin 4 are jumpered.

*IBAR SW = 1 when inboard locator is activated

*(NUVL855C only)

Page 6

Page 9

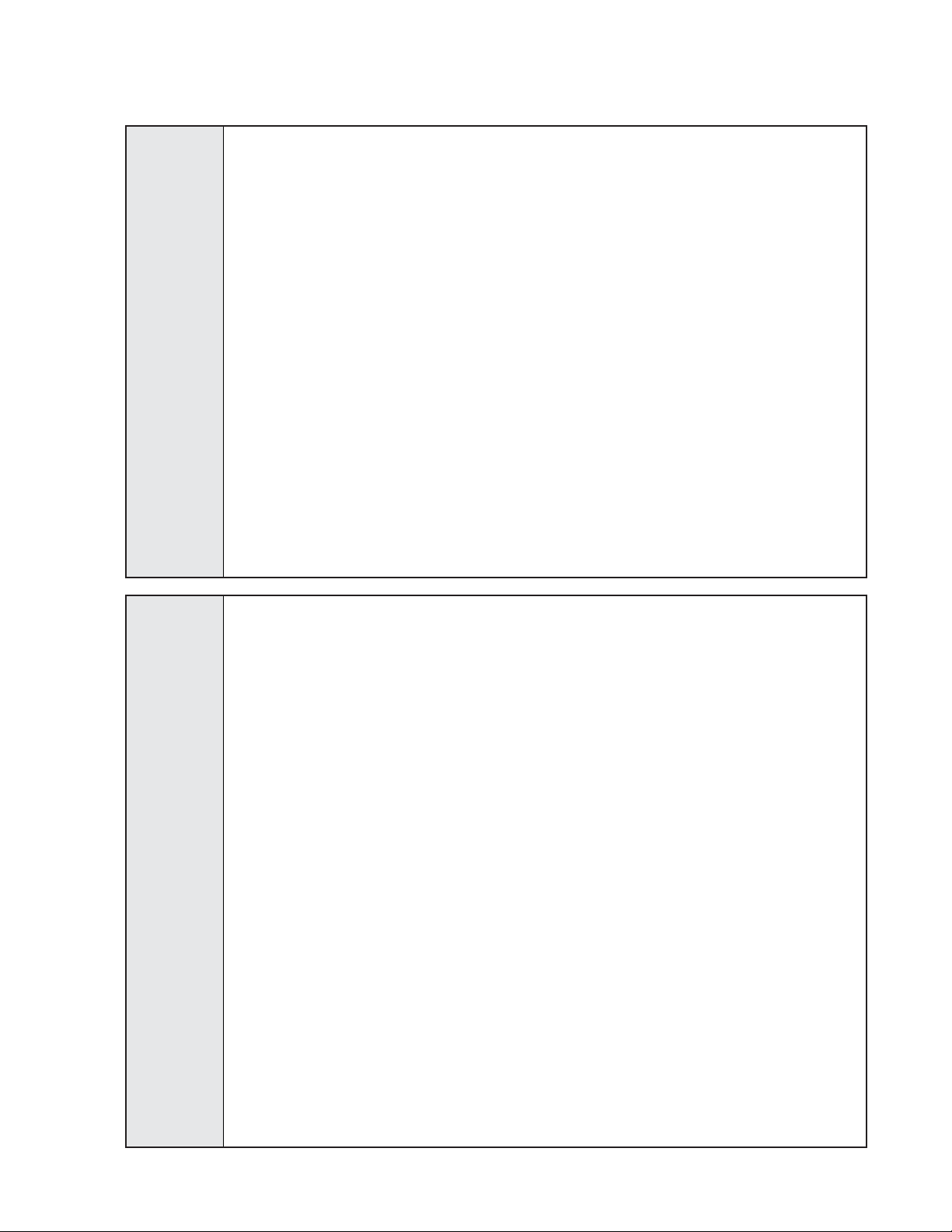

Floor Level and Inboard Locator Adjustments

Achieving proper floor level

positioning of the platform and

inboard locator requires a combination of Floor Level switch

adjustment and inboard locator

adjustment. Both are factory set

but must be inspected during

installation procedures (will vary

per vehicle application).

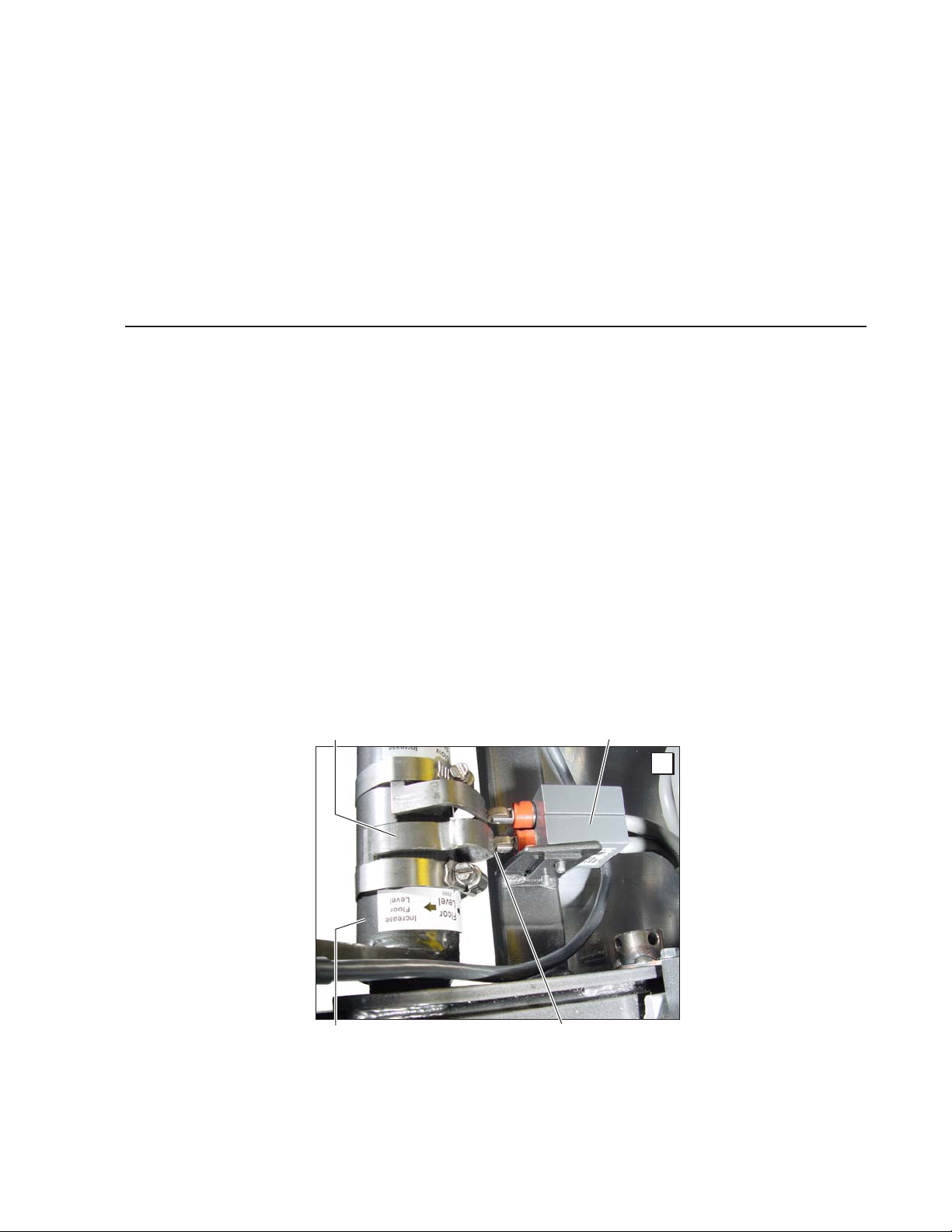

Floor Level Switch Adjustment

Adjust the Floor Level switch

first! (before adjusting the inboard

locator)!

The Floor Level switch stops upward travel of the platform during

the Up function (activated by the

torque tube-mounted Floor Level

cam).

Position the bottom of the lift plat-

Ensure the lift is positioned and

secured as specified on Quick

Reference Installation Sheet (supplied with lift) panels 1 and 2. Ad-

just the Floor Level switch first

(detailed below). Then, adjust

the inboard locator as detailed

in Inboard Locator Adjustment

Instructions (adjust only if neces-

form 1" above floor level (thresh-

old mat) using the manual op

eration system. Do not operate

the lift with the electric pump during adjustment procedures.

Loosen the clamp securing the

torque tube-mounted Floor Level

cam. Rotate the cam until the

Floor Level switch is activated

(cam depresses switch).

sary). The inboard locator must

rest properly on the vehicle floor

for wheelchair entry and exit.

Note: Check the floor level posi-

tion of the platform and the inboard locator after powering the

pump. Hydraulic pressure may affect platform height slightly. Fine

tuning adjustment (tweaking) of

the Floor Level switch may be

required.

Floor Level Cam

Torque Tube

Floor Level Switch

A

Cam depressing switch.

Page 7

Page 10

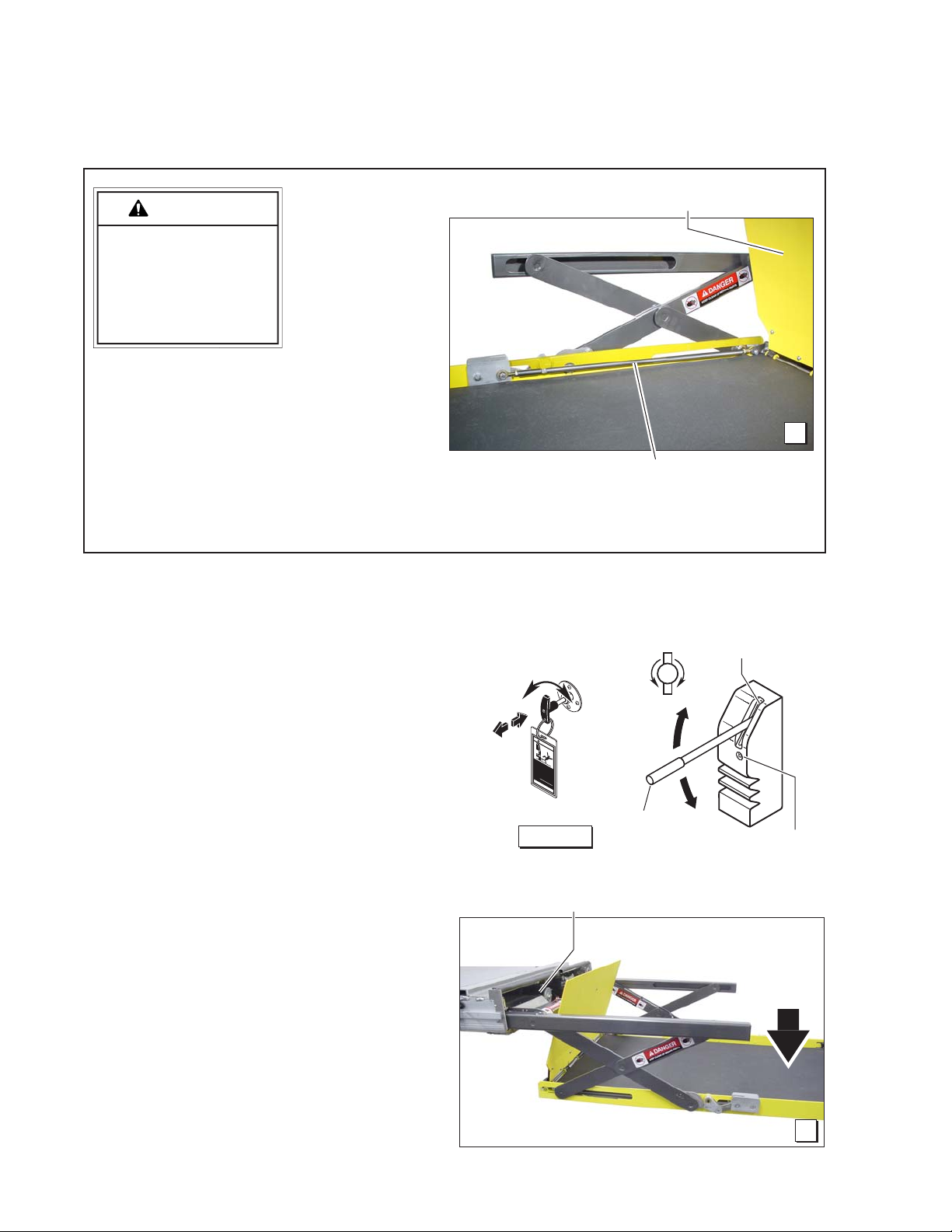

Floor Level and Inboard Locator Adjustments

CAUTION

Inboard Locator Adjustment

Do not adjust

inboard locator linkage rod

Do not adjust inboard locator linkage rod. Linkage

rod adjustment may

result in lift damage.

at this time!

Linkage rod

adjustment is not

required unless

extra usable

platform length

is needed. If

the angle of the inboard locator (when in the

vertical position) restricts the usable platform

length for the wheelchair passenger, adjustment of the linkage rod will change the angle.

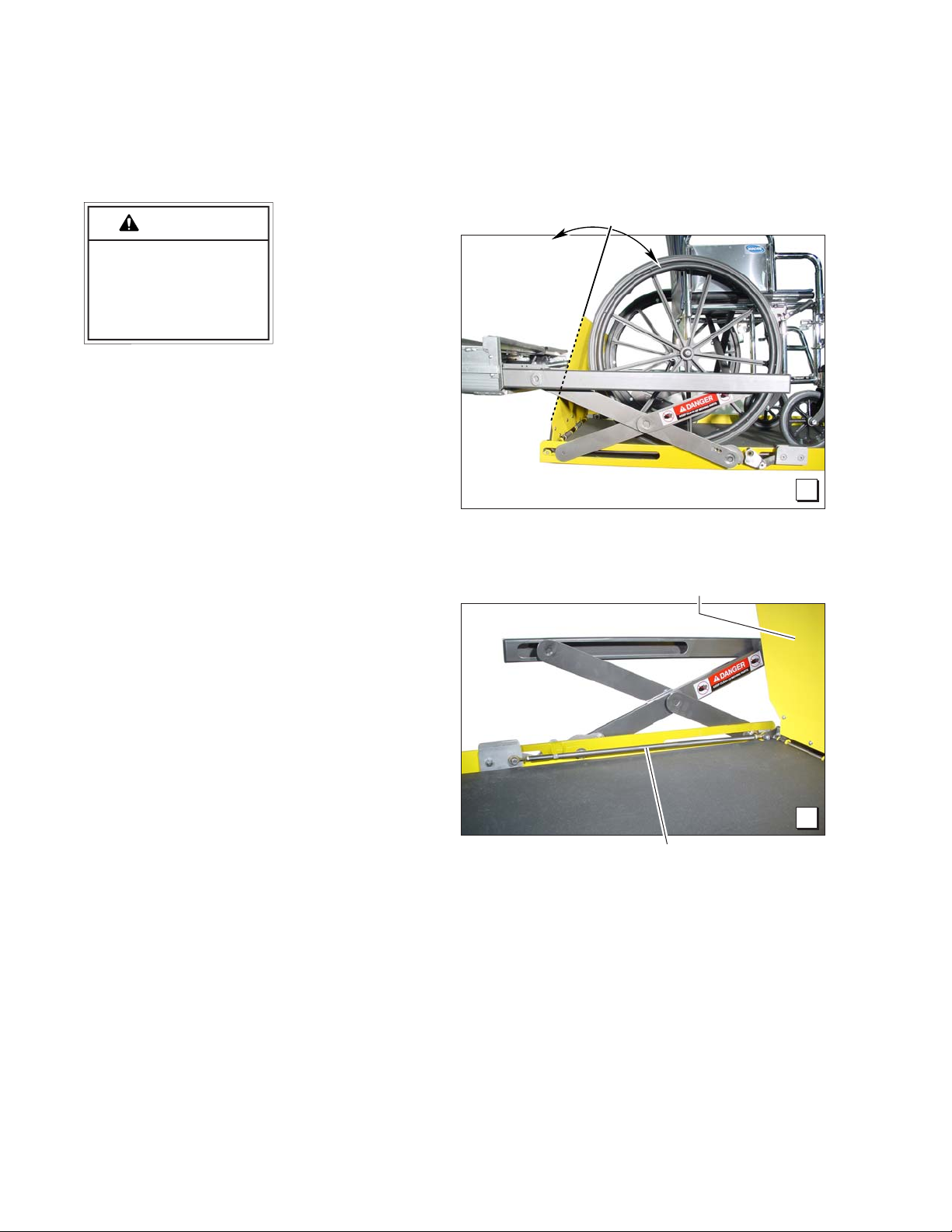

With the platform at ground level and the

inboard locator in the vertical position, there

should be a minimum of 1” clearance between

the inboard locator and torque tube.

Adjust the inboard locator as detailed in the

following procedures. Then, adjust the linkage

rod as detailed on page 9 (only if necessary).

1. Raise the lift platform fully (floor level) using the manual operation system (Manual

Operating Instructions detailed on Quick

Reference Installation Sheet). If the inboard

locator rests properly on the floor, do not ad-

just the inboard locator. Lower the platform

to ground level. If the angle of the inboard

locator (when in the vertical position), does

not restrict the usable platform length for the

wheelchair passenger, disregard inboard

locator adjustment procedures. See Photo H

on page 9. Refer to the following procedures

if adjustment is required.

Inboard Locator

Linkage Rod

Manual Operation Systems

T-Handle

Release

Cable

W

A

R

NI

N

G

Push T-handle in fully

manually move platfo

and out to engage platfo

lock before driving

Failure to lock platform may

and

result in unintended platform

rm in

deployment. Unintended

rm

veh

platform deployment

icle.

result in serious bodily injury

and/or property dam

may

Do not remove!

ag

e.

81823

Figure A

N

E

P

O

Pump

Handle

VALV E

Stow Level

B

Hand

Pump

C

L

O

S

E

Val ve

2. Position the lift platform below

stow level using the manual op-

eration system. See Photo C.

Lowering the platform will allow access to the cam bolt

securement nut. See Photo E.

Page 8

Platform

below

Stow

Level

C

Page 11

Floor Level and Inboard Locator Adjustments

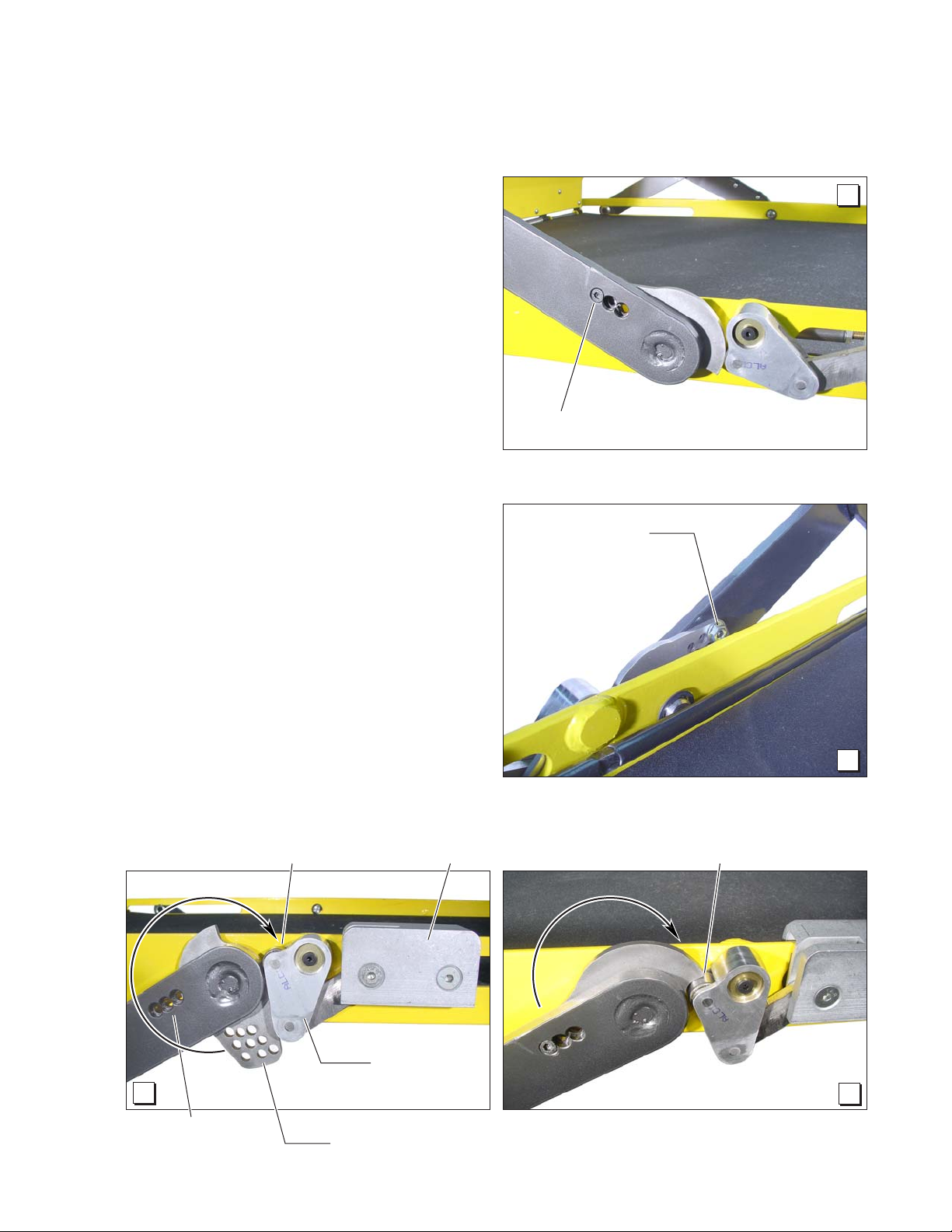

Inboard Locator Adjustment

3. Remove the 1/4" lock nut se-

curing the lifting arm cam bolt.

See Photos D and E. Do not

remove the bolt.

Raise the platform fully (floor

level) using the manual op-

eration system.

Remove the cam securement

bolt (lift inboard locator to relieve pressure on bolt).

Allow the inboard locator to rest

on the floor.

Rotate the cam so the cam follower bearing engages the cam

notch (saddle). See Photos F

and G.

Reinstall the cam securement

bolt in one of the three lifting

arm holes that best lines up

with one of the nine holes in the

cam. See Photos F and G.

D

Cam Bolt

1/4" Lock Nut

Reposition the securement bolt

lock nut. Note: Lowering the

platform will allow access to

cam bolt. Tighten securely.

Cam Notch (Saddle)

e

t

C

a

t

o

R

a

m

F

Lifting Arm

(3 available holes)

Slider Block

Rocker

Cam

(9 available holes)

E

Cam Notch (Saddle)

Engaging

Cam Follower Bearing

e

t

C

a

t

o

R

a

m

G

Page 9

Page 12

CAUTION

Floor Level and Inboard Locator Adjustments

Inboard Locator Linkage Rod Adjustment

Do not adjust the

inboard locator

linkage rod un-

Improper inboard

locator linkage rod

adjustment may

result in lift damage.

the vertical position) restricts the usable platform

length for the wheelchair passenger, adjustment

of the linkage rod will change the angle.

Adjust the inboard locator as detailed in the

previous procedures. Then, adjust the linkage

rod as detailed (only if necessary). If the link-

age rod is adjusted too long or too short, it will

exceed the travel of the slider block resulting in

damage to the cam follower bearing, the cam

and/or other components.

less extra usable

platform length

is needed. See

Photo H. If the angle of the inboard

locator (when in

Linkage rod adjustment affects angle

of inboard locator (vertical position).

H

Inboard Locator

1. Position the lift platform below stow level

using the manual operation system. Do

not operate the lift with the electric pump

during adjustment procedures.

2. Loosen the jam nuts at each end. Adjust

rod length as needed. Minimize adjustment. Carefully check the inboard locator

angle and operation using the manual

operation system. Ensure the rod has not

been over adjusted resulting in pressure on

components (damage will result). Tighten

the linkage rod jam nuts.

I

Linkage Rod

Page 10

Page 13

Lubrication Diagram

Drive Chain and Rollers

LO

Torque Tube

W

TO

S

OOR

D

P

U

OWN

D

Pivot Points

LO

Drive Chain

Release Latch

SG

Hydraulic

Cylinder

Pivot

Points

LO

Eccentric

Shaft

Rollers

(bearings)

LO

Torque

Tube

Pivot

Points

LO

Lifting Arm

Pivot Points

LO

Carriage

Rollers

(bearings)

LO

Rolling

Horizontal

Carriage Arm

Slot Area

DE

W

A

R

N

I

N

G

Pus

h

m

T-

a

h

n

an

ua

an

dl

l

ly mov

d

e

o

i

n

l

ut

o

ful

ck be

to en

e

l

y

Fa

p

latf

and

f

i

ore d

gage p

l

u

o

re

r

rm

esul

t

r

o

i

i

ving

l

n

l

a

t in uninte

depl

ock

tfor

veh

oyment.

p

m

pl

l

a

atform dep

icle

t

f

o

nded

rm

re

.

sul

Unin

m

ay

t in

p

and/

l

a

loyment

ten

tform

seri

or proper

d

e

o

d

u

s

m

b

ay

o

ty

d

i

l

d

y i

a

Do not rem

mag

nj

u

ry

e.

81

8

2

3

ove!

Outer Barrier

Detent Pin

Platform Cable-activated

Manual Release System

Lifting Arm

Pivot Points

LO

Inboard Locator

Linkage

Pivot Points

LO

Inboard Locator

Hinge

Pivot Points

LO

Outer Barrier

and

Lower Closure

Pivot Points

LO

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

LO - Light Oil

DE - Door-Ease

SG - Synthetic Grease

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Synthetic Grease Mobiltemp SHC32 12.5 oz.

(Multipurpose) Tube

15807

15806

28598

LO

Page 11

Page 14

Maintenance and Lubrication Schedule

W

A

RNING

Proper maintenance is necessary to ensure safe,

troublefree operation. Inspecting the lift for any wear,

damage or other abnormal conditions should be a part

of a regular service program. Simple inspections can

detect potential problems.

The maintenance and lubrication procedures specified in the following schedule must be performed by a

Braun authorized service representative at the scheduled intervals according to the number of cycles. NUVL

Series lifts are equipped with a cycle counter (digital

display built into the electronic control board).

NUVL Series lifts are equipped with hardened pins and

self-lubricating bushings to decrease wear, provide

smooth operation and extend the service life of the lift.

When servicing the lift at the recommended intervals,

inspection and lubrication procedures specified in the

previous sections should be repeated. Clean components and the surrounding area before applying

lubricants. LPS2 General Purpose Penetrating Oil is

recommended where Light Oil is called out. Use of improper lubricants can attract dirt or other contaminants

which could result in wear or damage to the components. Platform components exposed to contaminants

when lowered to the ground may require extra attention. Lift components requiring grease are lubricated

during assembly procedures. When replacing these

components, be sure to apply grease during installation procedures. Specified lubricants are available

from The Braun Corporation (part numbers on previous

page).

All listed inspection, lubrication and maintenance

procedures should be repeated at 750 cycle intervals

following the scheduled 4500 cycle maintenance proce-

dures. These intervals

are a general guideline

for scheduling maintenance procedures and

will vary according to

lift use and conditions.

Lifts exposed to severe

conditions (weather,

environment, contamination, heavy usage,

etc.) may require

inspection and maintenance procedures

to be performed more

Maintenance and

lubrication procedures

must be performed as

specified by an

authorized service

technician. Failure to

do so may result in

serious bodily injury

and/or property

damage.

often than specified.

Maintenance Indicator: The Lift Ready green LED

mounted on top of the pump cover will change color

to yellow after every 750 cycles. The yellow LED will

not affect the functions of the lift, but is a reminder to

complete necessary maintenance and lubrication.

Once the lift has been serviced, press the CYCLE button (located below LCD display on the control board)

until the Lift Ready LED changes back to green. The

CYCLE button also clears the lift cycle count (since

last service) but not the lifetime cycle count.

Discontinue lift use immediately if maintenance and

lubrication procedures are not properly performed,

or if there is any sign of wear, damage or improper

operation. Contact your sales representative or call

The Braun Corporation. One of our national Product

Support representatives will direct you to an authorized service technician who will inspect your lift.

Page 12

750

Cycles

Outer barrier and lower closure pivot

points (2)

Outer barrier detent pin pivot points (2)

Inboard locator hinge pivot points

Inboard locator linkage pivot points

Lifting arm center and platform pivot

points (bearings at all points)

Inspect outer barrier and lower closure

for proper operation

Inspect outer barrier seal and lower

closure gasket

Inspect outer barrier detent pin hairpin

cotter

Inspect lift for wear, damage or any

abnormal condition

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct or replace damaged parts.

Resecure, replace or correct as needed

Ensure hairpin cotter is present and can be removed

and inserted easily. Resecure, replace or correct as

needed.

Correct as needed.

Page 15

Maintenance and Lubrication Schedule

750

Cycles

Inspect lift for rattles

Check drive chain tension.

Inspect inboard locator and linkage for:

• Proper operation. Roll stop should rest solidly on

floor providing smooth transition.

• Positive securement

• Wear or damage

Check carriage ride height in housing

Check stow height/lifting arm alignment

Inspect wiring harnesses for securement, wear or

other damage

Check lower pan securement

Torque tube pivot bearings (4 places)

Correct as needed.

Pull out and lock manual release cable. Adjust

chain tension as needed. See Drive Chain

Adjustment.

Resecure, replace or correct as needed. See

Inboard Locator Adjustment Instructions.

Adjust as needed. See Carriage Ride Height

Adjustment.

Lifting arms should be horizontal, aligned with

each other and aligned with carriage. Adjust as

needed. See Switch Adjustment (Stow Switch).

Resecure, replace or correct as needed

Resecure, replace damaged parts or correct as

needed.

Apply Light Oil - See Lubrication Diagram

1500

Cycles

Carriage and eccentric shaft rollers (bearings)

Rolling horizontal carriage arm slot area

Hydraulic cylinder pivot points (4 per cylinder)

Drive chain and chain rollers

Drive chain release latch mechanism

Deploy lift, remove lower pan and blow out housing. Blow off platform also.

Deploy lift, remove lower pan and clean housing

tracks

Check drive chain tensioner, jam nuts and con

necting link for securement and/or misalignment.

Inspect drive chain release latch mechanism for

proper operation, positive securement, wear or

other damage

Inspect platform cable-activated manual release

system (T-handle/cable assembly and carriage

movement)

Apply Light Oil - See Lubrication Diagram

Apply Door-Ease - See Lubrication Diagram.

Apply to the surface area around both slots and

wipe off excess.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Synthetic Grease - See Lubrication Diagram

Use compressor and nozzle to remove all debris

from housing. Clean lower pan slot and apply

Antisieze to slot before reinstalling pan.

Use clean cloth and solvent to clean tracks.

Clean lower pan slot and apply Antisieze to slot

before reinstalling pan.

Correct or replace damaged parts and/or relubricate. See Drive Chain Adjustment.

Correct or replace damaged parts and/or relubricate.

Ensure T-handle release and cable assembly

operate properly. Ensure carriage can be manually extended and retracted freely.

Page 13

Page 16

Maintenance and Lubrication Schedule

1500

Cycles

Inspect limit switches for securement and proper

adjustment

Inspect carriage, lifting arm and eccentric shaft

rollers (bearings) for wear or damage, positive

securement and proper operation

Inspect external snap rings (e-clips):

• Carriage roller bearings (4)

• Lower lifting arm pins (4)

• Eccentric shaft track roller bearing (1)

Inspect lower lifting arm pins for wear or damage,

positive securement and proper adjustment

Inspect eccentric shaft pins, bearing mounting

screw, washers and securement hardware for

wear or damage, positive securement and proper

operation

Inspect torque tube cams for securement, wear or

damage

Inspect housing cam brackets for securement,

wear or damage

Inspect cylinder(s), hoses, fittings and hydraulic

connections for wear, damage or leaks

Inspect power cable

Resecure, replace or adjust as needed. See

Switch Adjustment.

Correct, replace damaged parts and/or relubricate.

Resecure, replace or correct as needed.

Resecure, replace damaged parts, lubricate or

correct as needed.

Resecure, replace damaged parts, lubricate or

correct as needed. See Carriage Ride Height

Adjustment.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed.

Tighten, repair or replace if needed.

Resecure, repair or replace if needed.

4500

Cycles

Consecutive

750 Cycle

Intervals

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination. Inspect the hydraulic system (cylinder, hoses,

fittings, seals, etc.) for leaks if fluid level is low.

Inspect lifting arm bushings and pivot pins for visible wear or damage

Inspect outer barrier pivot pin mounting bolts (2)

Mounting

Decals and Antiskid

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Use Braun 87010R (5606 aviation fluid). Do

not mix with Dextron III or other hydraulic fluids.

Check fluid level with platform lowered fully.

Fill to maximum fluid level indicated on reservoir

(specified on decal). Do not overfill. If fluid

level decal is not present - measure 7/8" from the

bottom of fill tube to locate fluid level.

Replace if needed.

Tighten or replace if needed

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing.

Page 14

Page 17

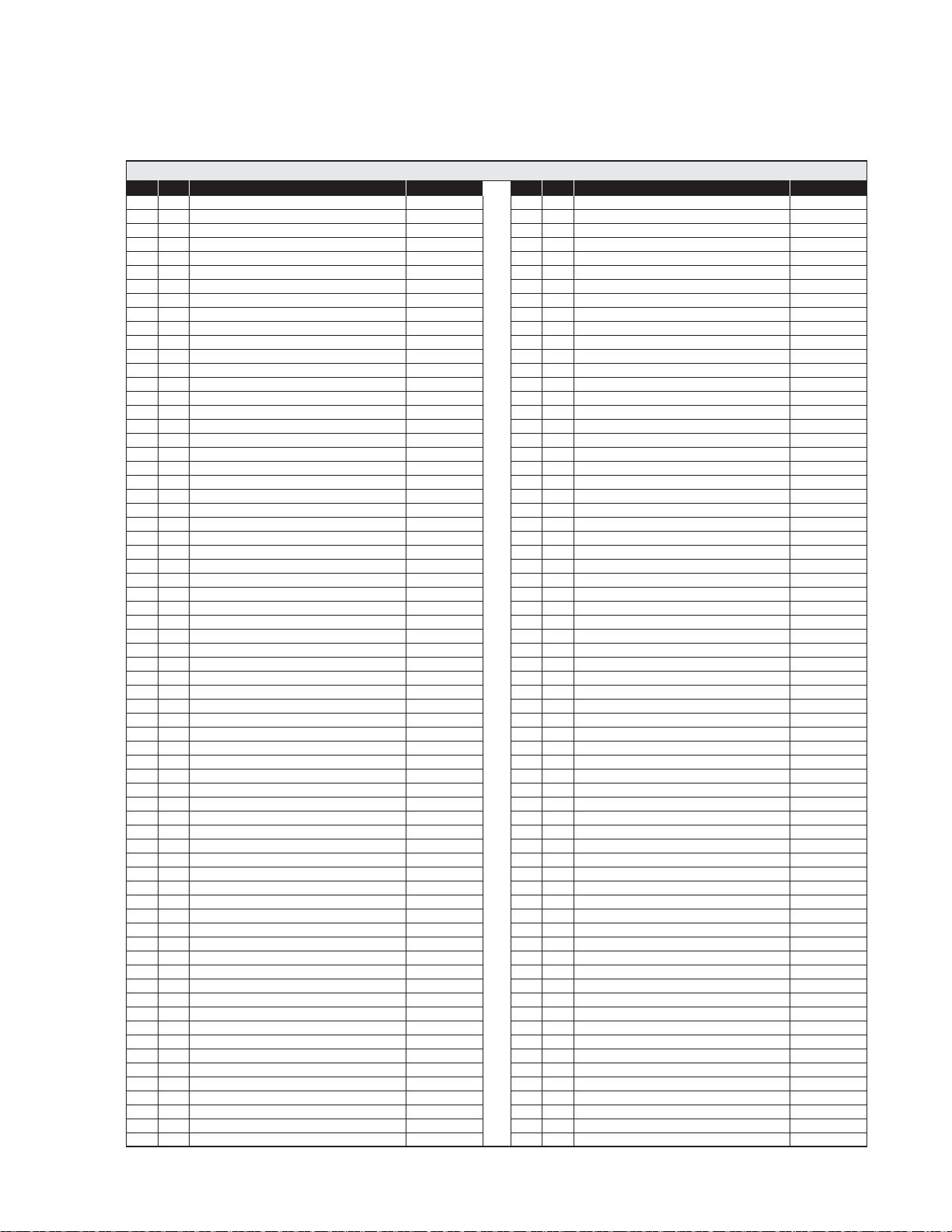

Troubleshooting Diagnosis Chart

A

RNING

W

Troubleshooting and

repair procedures

must be performed

as specified by au-

thorized service personnel only. Failure

to do so may result

in serious bodily

injury and/or property

damage.

If a problem occurs with your lift,

discontinue operation immediately! Do not attempt repairs

yourself. Contact your dealer or

call The Braun Corporation. One

of our national service representatives will direct you to an

authorized service repairman who

will inspect your lift.

The cause of the problem can

be determined by locating the lift

function and related symptom in

the Troubleshooting Diagnosis

Charts. The specific cause and

remedy can then be determined

by process of elimination. A Wiring Diagram, Electrical Schematic, Hydraulic Diagram and

Hydraulic Schematic are provided

to aid in troubleshooting.

A Repair Parts section with exploded views and corresponding

parts lists is also provided. Correct the problem if possible. If the

problem continues, contact The

Braun Corporation.

FUNCTION POSSIBLE CAUSE REMEDY

1.00

NO

OPERATION

1.11 Low Battery

1.12 Bad ground

1.13 Poor plug connections

1.14 Blown fuse

1.15 Circuit Sentry

Check vehicle battery

Check for good ground between vehicle chassis

and 3/8” bolt on back of power pack.

Check all plugs for proper contact.

Check fuses on P.C. board.

Manually reset Circuit Sentry (circuit breaker).

2.00

PUMP RUNS

BUT WILL

NOT LIFT

PLATFORM

3.00

PUMP DOES

NOT RUN

WITH MAN-

UAL OVER-

RIDE OR

HAND-HELD

PENDANT

1.16 Circuit Breaker

1.17 Defective Interlock

2.11 Hydraulic valve open

2.12 Pump mounted horizontal

2.13 No oil (low)

3.11 Up Solenoid

3.12 Bad power and ground

Circuit breaker should automatically reset, otherwise replace.

Check for voltage on gray wire with pink stripes in

interlock plug connected to P.C. board.

Flush valve by operating manual override switches

up and down at same time for 4 to 5 seconds

several times.

Power pack must be mounted vertically.

Use Braun 87010R (5606 aviation fluid). Do

not mix with Dextron III or other hydraulic fluids.

Check fluid level with platform lowered fully.

Fill to maximum fluid level indicated on reservoir

(specified on decal). Do not overfill. If fluid level

decal is not present - measure 7/8" from the bottom of fill tube to locate fluid level.

Check for power on black wire going from solenoid

to motor.

See 1.00

Page 15

Page 18

Troubleshooting Diagnosis Chart

FUNCTION POSSIBLE CAUSE REMEDY

4.00

LIFT WILL

GO UP WITH

OVERRIDE

SWITCH BUT

NOT WITH

HAND-HELD

PENDANT

5.00

LIFT WILL

NOT GO

DOWN WITH

MANUAL

OVERRIDE

OR WITH

HAND-HELD

PENDANT OR

GOES DOWN

SLOWLY

OR DRIFTS

DOWN BY

ITSELF

4.11 Outer Barrier switch is not

activated or defective.

4.12 Full Out switch is not activated or defective.

4.13 Hand-held pendant not working properly.

5.11 Hydraulic down valve bad

5.12 Dirty down valve (clogged)

Check diagnostic LCD for Outer Barrier switch status. Barrier is down or barrier release pin partially

out. See Outer Barrier Occupied Calibration on

page 5. Replace switch as necessary.

Check diagnostic LCD for Full Out switch status.

Adjust or replace switch as necessary.

Check for hand-held pendant illumination and

continuity of the switches. Verify Door Open switch

is functioning correctly.

Check for power on red wire from P.C. board to

Down solenoid when pushing override button or

hand-held pendant button. Replace if necessary.

Flush valve by operating Up & Down manual

override buttons at same time for 4 to 5 seconds

several times.

6.00

LIFT WILL GO

DOWN WITH

OVERRIDE

BUT NOT WITH

HAND-HELD

PENDANT

7.00

LIFT WILL NOT

GO OUT WITH

HAND-HELD

PENDANT

8.00

LIFT WILL NOT

GO OUT WITH

OVERRIDE OR

HAND-HELD

PENDANT

9.00

LIFT WILL NOT

STOW WITH

HAND-HELD

PENDANT

6.11 Full Out switch out of adjust-

ment or defective.

6.12 Door Full Close switch out of

adjustment or defective.

7.11 Missing shunt

7.12 Door Open switch out of adjust-

ment or defective

8.11 Poor plug connections

8.12 Bad in/out motor

8.13 Bad power and ground

9.11 Stow switch out of adjustment

or defective.

9.12 Platform is occupied or out of

calibration.

Check diagnostic LCD for Full Out switch status.

Adjust or replace switch as necessary.

Check switch for proper operation/adjustment.

Adjust or replace switch as necessary.

Verify shunt (jumper) is located in the Door Operator 4-conductor jack (jumper pins 3 & 4) on the

control board when door operators are not used.

Check switch for proper operation/adjustment.

Adjust or replace switch as necessary.

Check harness connections A1, A2, B1 and B2

Check power at motor. Replace motor if necessary.

See 1.00

Check diagnostic LCD for Stow switch status.

Adjust or replace as necessary.

Remove weight from platform. See Platform

Sense Calibration on page 5.

Page 16

Page 19

Troubleshooting Diagnosis Chart

FUNCTION POSSIBLE CAUSE REMEDY

10.00

BARRIER WILL

NOT OPERATE

UP OR DOWN

WITH HAND-

HELD PENDANT

OR OVERRIDE

SWITCHES

11.00

BARRIER

OPERATES WITH

OVERRIDE

SWITCH BUT

WILL NOT GO

UP WITH HANDHELD PENDANT

12.00

BARRIER

OPERATES

WITH OVER-

RIDE SWITCH

BUT WILL NOT

GO DOWN WITH

HAND-HELD

PENDANT

10.11 Poor plug connections

10.12 Faulty barrier actuator motor or

actuator out of adjustment

10.13 Bad power and ground

11.11 Faulty Outer Barrier switch

11.12 Barrier occupied

12.11 Faulty Pressure Transducer

12.12 Stow switch out of adjustment or defective

12.13 Full Out switch out of

adjustment or defective

Check harness connectors A1 and A2, E1, N1,

N2, E1, F1 and F2.

Check power at motor. Adjust or replace actuator

if necessary.

See 1.00

Check diagnostic LCD for Outer Barrier Switch

status. Adjust or replace switch as necessary.

Remove weight from barrier. See Outer Barrier

Occupied Calibration on page 5.

Check Pressure Transducer. Adjust or replace

as necessary. See Ground Sense Calibration on

page 5.

Check diagnostic LCD for Stow switch status.

Adjust or replace as necessary.

Check diagnostic LCD for Full Out switch status.

Adjust or replace as needed.

13.00

SWITCHES

DO NOT

CHANGE

STATE IN

DIAGNOSTIC

MODE

14.00

DOORS

DO NOT

OPEN

15.00

DOORS

DO NOT

CLOSE

13.11 No power going to switches

13.12 Faulty wiring

13.13 Faulty connections

14.11 Faulty wiring

15.11 Lift Out switch out of adjustment

or defective

Check power on connector A1, pins 1 and 2.

Check continuity of wires from switches to connector

A2.

Check for proper connections on each switch and

on each connector on the harnesses. Replace contact if necessary. See diagram on following page.

Check for proper wiring to door openers.

Lift not stowed fully. Adjust lift out switch or

replace.

Page 17

Page 20

Troubleshooting Diagnosis Chart

CONTACT REMOVAL

1. Remove orange wedge using

needle nose pliers or a hook shaped

wire to pull wedge straight out.

2. To remove the contacts, gently pull

wire backwards, while at the same

time releasing the locking finger by

moving it away from the contact with

a screwdriver.

3. Hold the rear seal in place, as

removing the contact will displace

the seal

Page 18

Page 21

NOTES

This page intentionally left blank.

Page 19

Page 22

Lift Wiring Schematic - Main

GN / WH

RD / BK RD / BK

BK BK

GN / W

BAR DN

SW PWR

BAR DN PWR

RD / BKBKRD / WH

GN / WH

GN / W

BK

RD / BK

BAR DN

SW PWR

BAR DN PWR

SW PWR

IGN PWR

BELOW STOW

FULL OUT

NOT FULL OUT

LIFT OUT

BAR DN

GND SENS

SAFETY

RD

GN

OR

BU

GN / BK

OR / BK

BK

BU / BK

BK / W

RD / WH

RD / WH

BAR UP PWR

BELOW STOW

RD

RD / WH

BAR UP PWR

BK / W

BU / BKWHBK

BUORGNRDOR / BK

GN / BK

FULL OUT

NOT FULL OUT

SAFETY

FLOOR IN

FLOOR LVL

SW PWR

LIFT OUT

GND SENS

BK / WH

BU / BKWHBK

BUORGNRDOR / BK

GN / BK

BK

BK / WH

BU / BK

OR / BK

GN / BK

BU

OR

GN

RD / WH

GN / WH

GND SENS

FULL OUT FULL OUT

NOT FULL OUT NOT FULL OUT

BELOW STOW BELOW STOW

F1

1

1

2

2

RD / BK

3

3

BK

4

4

FLOOR IN

FLOOR LVL

WH

BK

OR

IN-OUT

MOTOR

OR

M

BK

LIFT HOUSING / CARRIAGE

HARNESS #73920A

LIFT OUT FLOOR LVL FULL OUT STOW

IGN PWR

WH

FLOOR LVL

FLOOR IN

SAFETY

F2

SW PWR

LIFT OUT

RD

BK

OR

BU

NO

C

BK

WH

RD RD

A

B

ABC

ABC

BU

NOT USED

IGN PWR

CARRIAGE / PLATFORM

HARNESS #73930A

BAR UP PWR

BAR DN PWR

BAR DN

SW PWR

BKBKBK

WHW

RDRD

GNGN

OROR

BUBU

NOT USED

RD / BKRD / BK

GN / BK

OR / BK

BU / BK

BK / WH

RD / WH

GN / WH

BU / WHBU / WH

BK / RDBK / RD

NOT USED

NOT USED

NOT USED

NOT USED

WH / RDWH / RD

OR / RDOR / RD

BU / RD

RD / GN

BK

NO

WH WH

C

NC

BK

G2

G1

BK / WH

A

ABC

BK / WH

NOT USED

C

WH

BK

1

1

WH

2

2

RD

3

3

GN

4

4

NOT USED

5

5

BU

6

6

NOT USED

7

7

RD / BK

8

8

GN / BK

9

9

OR / BK

10

10

BU / BK

11

11

BK / WH

12

12

D1

D2

RD / WH

1

1

GN / WH

2

2

BU / WH

3

3

BK / RD

4

4

NOT USED

5

5

NOT USED

6

6

NOT USED

7

7

NOT USED

8

8

WH / RD

9

9

OR / RD

10

10

BU / RD

11

11

RD / GN

12

12

E2

E1

NC

RD

BKBKWH

RD

H2

B

C

BK

NOT USED

RD

BK

OR

BU

ABC

H1

BK BK

BU / BK

RD RD

O1 O2

121

N1 N2

A

B

C

I1

BK

BU / BK

NOT USED

OR / BK

RD

BK BK

2

WH WH

A

RD RD

B

BK BK

C

SW PWR

IGN PWR

BELOW STOW

FULL OUT

LIFT OUT

BAR DN

GND SENS

SAFETY

INBRD BAR INBRD BAR

FLOOR LVL

BAR UP PWR

BAR DN PWR

MOT OUT PWR

MOT IN PWR

MOT IN PWR

MOT OUT PWR

BAR DN PWR

BAR UP PWR

STOW / GND SENS

A

B

C

ABC

BK (+IN)

R (-OUT)

BK

#75960NA

BK (+IN)

R (-OUT)

NOT USED NOT USED

J2

#31710A

A

B

C

ABC

BK

OR / BK

NOT USED

BARRIER ACTUATOR

MOTOR

RD BK

M

A

B

C

ABC

J1

BK

GN / BK

NOT USED

GN / BK

BK

WH

RD

GN

BU

RD / BK

GN / BK

OR / BK

BU / BK

BK / WH

RD / WH

GN / WH

BU / WH

BK / RD

WH / RD

OR / RD

BU / RD

RD / GN

NO

C

NC

GNGN

OROR

BAR DN

C

BK

GN

WH

A

B

ABC

OR

NO

RD RD

BKBKWHWHRD RD

BK

NC

BK

K2

K1 L1

C

L2 M2

C

WH

NO

NC

BKBKWHWHRD RD

A

B

C

ABC

BK

RDRD

NOT USED

SW PWR

IGN PWR

BELOW STOW

FULL OUT

LIFT OUT

BAR DN

GND SENS

SAFETY

FLOOR LVL

BAR UP PWR

BAR DN PWR

MOT OUT PWR

MOT IN PWR

MOT IN PWR

MOT OUT PWR

BAR DN PWR

BAR UP PWR

POWER PACK / LIFT HOUSING

HARNESS #34425A-1200

M1

#32426A

J2

3

2

1

2

3

1

P2

OR

BK

DK.BU

DK.GN

K E Y

SYMBOL DESCRIPTION

BATTERY

CHASSIS GROUND

CIRCUIT BREAKER

CONNECTORS

JUNCTION

M

86

85

87

30

87A

NO

C

NC

+

-

MOTOR

RELAY

SWITCH

MICROSWITCH

SOLENOID

DIODE

PRESSURE

TRANSDUCER

LED

BEEPER

GN

OR / BK

BU / BK

BU

RD / BK

RD

GN / BK

BK / WH

RD / WH

GN / WH

BU / WH

BK / RD

WH / RD

OR / RD

BU / RD

RD / GN

HAND

PENDNT

NOTE: SEE LIFT ACCESSORY

ELECTRICAL SCHEMATIC FOR

A2

OPTIONAL COMPONENTS.

J4

654

654

YL

YL

DK.BU

BK

DK.GN

OR

DOOR OPEN

SWITCH

#100044-001

#73908A

#33495A

YL / WH

GY / PK

THRESHOLD

MAT

GROUND

#34422A

WH

BK

#33491A

CIRCUIT

PUMP GROUND

DK BU

LT GN / GN

RD / WH

X1

1

1

X2

INTERLOCK

GY / PK

LIFT POWER SWITCH

YL / WH

GY / RD

789

65432

789

65432

GY / RD

YL / LT BL

BREAKER

RD

AUX.

WH

BAT.

RD / WH

WH

YL

DK.BU

BK

DK.GN

OR

NOT USED

NOT USED

DK BU

GY / PK

YL / WH

BK

RD

BEEPER

ALARM

P4

1

1

2

2

3

3

4

4

5

5

6

6

1

2

3

4

5

6

BK

4

4

RD

3

3

2

2

1

1

1

1

2

2

3

3

4

4

V2

121

2

POWER-IN

GND

212

1

12V

U2

+

-

BU/BK

NOT USED

RD

GN/BK

BK/WHBURD/BK

769

8

11

10

12

C

H

L

F

D

E

LIFT DEVICES

HAND - 1

DASH SW

3

2

1

HAND - 2

DOOR OPERATOR

WAKE UP

12V INPUT

HIGH OUTPUT

LOW OUTPUT

MAT

INTERLOCK 2

LIGHT

1

2

#34420A

RD

BK

G

I

UP/DN

REMOTE ENTRY

#35089A

(LIFT STOWED SIGNAL +12V OUTPUT)

(VEHICLE SECURE SIGNAL +12V INPUT)

WHGNOR/BK

NOT USED

BK

21435

A

J

K

B

COUNTER

3

2

1

5

7

9

6

8

10

4

3

MAGNETIC ENTRY

2

1

INTERLOCK 1

3

2

1

ALARM

1

2

1

2

T2

RD

BK

SHUNT

COM

STOW

DASH SW

DOOR/STOW

1

3

2

4

VALVE

1

1

#33487A

RD

FLR LVL

PUMP

2

2

OR / RD

Y2

LIGHT

NUVL

PC

BOARD

#34564A

OR / RD

WH

RD

CIRCUIT

SENTRY

RD / WH

GN / WH

BU / WH

BK / RD

WH / RD

OR / RD

BU / RD

RD / GN

#31235A

RD

WH

SERVICE / INTERLOCK LED

2

1

B

A

CHIP

#34566

LIFT IN

LIFT OUT

BAR UP

BAR DN

2

3

1

4

2

3

1

4

B2

BK / RD

BU / WH

RD / WH

GN / WH

RD

MOTOR

SOLENOID

GROUND

RD

BK / RD

WH / RD

RD

SOLENOID

RD RD

W

WH

BK

PUMP

M

HYDRAULIC

PUMP MOTOR

BATTERY

OR / RD

BU / WH

DOWN

BK

RD / WH

RD / GN

GN / WH

BU / RD

GROUND

GROUND

GROUND

Page 20

Page 23

Lift Wiring Schematic - Lift Accessories

Unfold for:

Lift Wiring

Schematic

-Main

HAND PENDANT 25’ EXTENSION

1

2

3

4

5

6

UP/DOWN

DOOR/STOW

TO DOOR

OPERATOR

#73947N-2500

WH

BK

RD

GN

YL

BU

3RD STATION CONTROL

#32196KS

UP

BK

RD

#31934A

BK

RD

WH

GN

GN

GN

RD

BK

BK

RD

WH

GN

DOWN

STOW

DOOR

DOOR CUT OUT ADAPTER

2

1

1

2

PLATFORM

LIGHTS

WH

BK

RD

GN

YL

BU

1

2

3

3

2

1

4

3

2

1

RD

BK

#34423A

1

1

2

2

3

3

4

4

5

5

6

6

#33496KS REMOTE, RECEIVER & HARNESS

#86476 REMOTE & RECEIVER

#86477

1

3

5

7

YL

H

L

D

E

LIFT DEVICES

HAND - 1

1

2

3

9

101112

9

101112

RD

OR

9

8

10

G

C

I

F

3RD

STATION

UP/DN

8

8

RD

7

B

7

GN

WH

YL

OR

6

J

4

6

5

4

6

GN

WH

3

5

4

A

K

3

2

1

2

1

3

2

BKBKBUBU

#33496A

1

2

B

LIGHT

3RD

STATION

DOOR/STOW

REMOTE ENTRY

HAND - 2

1

2

3

4

5

6

4

3

DOOR OPERATOR

2

1

WAKE UP

1

2

12V INPUT

3

HIGH OUTPUT

4

LOW OUTPUT

9

8

10

MAGNETIC ENTRY

2

4

6

GN

4

4

BN

3

3

YL

2

2

WH

1

1

1

3

5

7

INTERLOCK 1

1

MAT

2

3

2

1

INTERLOCK 2

POWER-IN

GND

2

1

12V

LIGHT

U2

ALARM

1

1

2

1

2

RD

BK

2

VALVE

1

A

PUMP

2

#86483

DOWN

UP

STOW DOOR

CLOSE

THE BRAUN

CORPORATION

86478

#33574A

#33574A

NUVL

PC

BOARD

#34564A

BAR DN

4

LIFT OUT

BAR UP

2

3

NOT USED

NOT USED

TAILLIGHT MAGNETIC SWITCHES-FORD

#25564A

NOT USED

6

6

BN

GN

YL

WH

BK

5

5

BK

4

4

BK

3

3

NOT USED

2

2

WH

1

1

#33576K

CLOSE

WH

BK

STOW

WH

BK

DOWN

WH

BK

RD

MAGNET

SN

RD

MAGNET

SN

RD

MAGNET

SN

K E Y

SYMBOL DESCRIPTION

LIFT IN

1

MAGNET

SN

JUNCTION

SWITCH

MAGNETIC SWITCH

LAMP

Page 21

Page 24

Hydraulic Parts List

Item Qty. Description Part #

1 1 Pump Assembly (M259 with Reservoir/with Back-up pump) 87060

2 1 Motor, Pump - 12 Volt 14785-IS

3 1 Valve, “Down” (with Solenoid) 14901

4 1 Clamp, Reservoir - H-48 17069

5 1 Reservoir Replacement Kit (Includes Item #10) 88188K

6 1 O-Ring (only), Hand Pump Mounting 17351

7 1 Hand Pump (Backup) with O-Rings (Includes Item #6) 87065

8 3 Screw, 1/4-20 x 1 3/4”, Allen Head 17351

9 1 Handle with Grip 17206A

10 1 Fitting, 3/8” Male NPT x 3/8” Barbed 87618

11 2 Clamp, Hose - 5/8” O.D. - Worm Drive 84325

12 1 Tubing, 3/8” x 5/8”, Tygothane - Clear 82066R012

13 1 Plug, 3/8” Plastic Hose 81580

14 1 Fitting, 90°-1/8” Male Pipe x 1/8” Barbed 87563

15 1 Tube, 1/4” O.D. x 1/8” I.D. - Plastic 81557R014

16 1 Plug, 1/8” Plastic Tube 81583

17 1 Adapter, 1/4” Male NPT x 7/16-20 Male JIC 37° 10130

18 1 Hose Assembly, 1/4” x 154” - Female Swivel 7/16-20 JIC 37° 32785A-154

19 1 Fitting, 90° - 7/16-20 Male JIC 37° x 1/4” Male NPT 87569

20 1 Coupling, Hydraulic Quick Connect x 1/4” Female NPT 87614

21 1 Nipple, Hydraulic Quick Connect x 1/4” Female NPT 87615

22 1 Nut, 9/16-18, Hex Jam 83077

23 1 Fitting Assembly, Bulk Head 73777A

24 1 Hose Assembly, 1/8” x 60” - Female Swivel 7/16-20 JIC 37° 16004A-060

25 1 Fitting, 90° - 9/16” Male O-Ring x 7/16-20 Male JIC 37° 87622

26 1 Valve, Flow Control 87049

27 1 Adaptor, Hydraulic Internal 87560

28 1 Fitting, Tee - 1/4” Male NPT - 1/4” Female NPT - 1/4” Male NPT 26786

29 1 Fitting, 7/16” Female O-Ring x 1/4-18 NPT Male 29305

30 1 Switch, Pressure Transducer 30426

31 1 Fitting, 90° - 1/4” Female NPT Swivel x 7/16-20 O-Ring 26789

32 1 Cylinder, UVL Retracting 87055N

33 1 Clamp, Hose - Solenoid Mounting 29663

34 1 Solenoid, Up - Trombetta 31129

35 1 Diode Assembly, Up Solenoid 73906A

Page 22

Page 25

Hydraulic Diagram

33

1

34

35

13

24

Arrow must

25

26

face pump

27

28

32

30

29

31

2

3

4

11

12

11

10

6

5

9

7

8

16

14

15

23

22

21

20

17

19

18

Page 23

Page 26

Pump Module Parts List

Item Qty. Description Part #

1 1 Pump Assembly, M259 87060

2 1 Adapter, 1/4” Male NPT x 7/16-20 Male JIC 37° 10130

3 1 Hose Assembly, 1/4”- F. Swivel 7/16-20 JIC 37°

4 1 Fitting, 90° - 7/16-20 Male JIC 37° x 1/4” Male NPT 87569

5 1 Coupling, Hydraulic Quick Connect x 1/4” Female NPT 87614

6 1 Fitting, 3/8” Male NPT x 3/8” Barbed 87618

7 1 Tubing, 3/8” x 5/8”, Tygothane - Clear 82066R012

8 2 Clamp, Hose - 5/8” O.D. - Worm Drive 84325

9 1 Plug, 3/8” Plastic Tubing 81580

10 1 Fitting, 90°-1/8” Male Pipe x 1/8” Barbed 87563

11 1 Tube, 1/4” O.D. x 1/8” I.D. - Plastic 81557R014

12 1 Plug, 1/8” Plastic Tube 81583

13 1 Clamp, Hose - Solenoid Mounting 29663

14 1 Solenoid, Up - Trombetta 31129

15 1 Diode Assembly, Up Solenoid 73906A

16 1 Diode Assembly, Down Valve Solenoid 73907A

17 1 Terminal, 14/16 Gage Male Spade - 1/4” Fully Insulated 78036

18 2 Jumper Assembly, 12 Gage x 4” 73943A

19 1 Eyelet, 5/16” Insulated - Red 86267

20 1 Weldment, Bracket - PC Board Mounting 73824W

21 1 Circuit Breaker, 20 Amp - Self Reset 16453

22 1 Clip, Cable - 7/16” Plastic 15777

23 2 Screw, 10-32 x 3/8”, Pan Head Philips, Thread Cutting 82755

24 4 Standoff, .25” PCB - Nylon 86739

25 4 Screw, #6 x 3/8”. Self Tap, Flat Head 82764

26 5 Bumper, 1/2” Dia. x 1/4” Tall - Rubber 82064

27 1 Electrical Board Assembly w/Program Chip 34564A

28 1 Beeper, Constant - High Output 33251

29 1 Edge Liner, 1/8” x 6”, Q-Trim 13910R006

30 1 Edge Liner, 1/8” x 4”, Q-Trim 13910R004

31 1 Washer, .328” x .562” x .042” 83583

32 3 Screw, 5/16-18 x 1/2”, Serrated Washer Head, Hex 82881

33 1 Plate, Power Pack Mounting 73822N

34 1 Bracket, Power Pack Mounting ✘ 73825

35 7 Screw, 1/4-20 x 3/8”, Pan Head Phillips ✘ 82769

36 2 Washer, Lock - 1/4” External Tooth ✘ 83588

37 1 Lamp, Bicolored LED Panel 30728

38 1 Fitting, Strain Relief - Liquid Tight 30753

39 1 Switch, Toggle 12185

40 1 Harness, Interlock 33495A

41 1 Plate, Interlock Plug / Cover Reinforcement 31345

42 1 Harness, Lift Interlock Connection 35089A

43 1 Harness, Service / Power Indicator 31235A

44 2 Rivet, Pop, 1/8” Dia. x .188/.250” 84249

45 1 Cover, UVL Power Pack w/Decals ✘ 73820RNA-02

46 1 Hand Pendant Assembly, NHTSA NUVL ✘ 32426A

47 1 Harness, Alarm 34420A

48 1 Ground Cable - Black 68874

49 1 Screw, 5/16-18 x 3/4”, Serrated Washer Head, Hex 32464

50 1 Harness, Power 33491A

51 1 Harness, Pump / Valve 33487A

52 1 Handle, Back-up Pump ✘ 17206A

53 2 Clamp, Spring - Pump Handle ✘ 12350

54 2 Screw, #10-32 x 3/8”, Flat Head - Phillips ✘ 82767

55 2 Washer, #10 Flat ✘ 11541

56 2 Nut, #10-32, Hex ✘ 11542

32785A-154

✘ Indicates items available for replacement part purposes only. These items are not included with replacement pump

modules.

Page 24

Page 27

Pump Module Diagram

13

46

STOW

DOOR

UP

DOWN

7

8

9

8

14

12

53

55

6

37

RD

WH

38

33

49

39

1

32

35

48

36

LIFT

STOWED

SIGNAL

34

(OUTPUT)

42

40

41

VEHICLE

SECURE

SIGNAL

38

(INPUT)

TO

PUMP

44

43

4

5

GROUND

2

11

TO

CIRCUIT

SENTRY

18

TO

DOWN

10

SOLENOID

15

19

25

25

25

18

TO

DOWN

SOLENOID

21

22

24

17

51

56

52

53

16

55

56

35

35

45

50

28

23

54

24

31

RD

BK

47

26

24

32

27

54

29

3

30

24

20

35

35

Page 25

Page 28

Unfold for:

Pump Module

Exploded

View

Complete Lift Exploded View

39

39

104

39

13

39

85

39

105

110

38

38

39

14

15

1

2

103

127

92

91

99

14

9

13

10

6

100

12

11

17

18

94

101

60

39

16

2

39

106

109

38

38

70

38

38

2

2

3

99

4

39

96

107

5

95

38

39

97

31

99

8

75

129

7

107

9

98

5

54

39

38

49

59

24

23

21

58

19

24

21

23

29

30

29

13

11

26

20

26

60

39

60

34

26

35

22

53

36

62

49

20

25

21

60

39

22

26

39

34

35

49

27

49

51

50

52

28

24

111

24

48

65

32

45

63

65

39

56

62

41

40

41

50

56

52

56

51

39

37

102

116

113

57

64

63

45

67

26

64

57

33

21

39

56

27

56

24

115

130

128

125

126

108

124

28

24

37

70

68

112

118

121

122

123

119

120

132

70

133

69

61

86

88

114

114

114

117

71

76

76

76

77

76

44

77

46

47

24

134

90

38

38

38

38

72

76

76

44

47

46

89

43

55

134

24

83

39

78

74

57

73

84

87

66

45

66

45

63

64

55

131

42

81

80

82

79

93

Page 26

Page 29

Repair Parts List

Item Qty. Description Part No.

1 1 Housing Weldment 73101NW

2 4 Clamp, Lift Mounting 73733

3 4 Nut, 1/4

" NC Rivet 83020

4 1 Chain Release Assembly 73760A

5 5 Screw, 1/4-20 x 1, Serrated Hex 82760

6 1 Bracket, In-Out Cam, Inboard 73774

7 1 Bracket, In-Out Cam, Outboard 73775

8 1 Block, Carriage Stop 75781N

9 4 Screw, 1/4-20 x 3/4", Washer Head 24750

10 1 Chain Tensioner Weldment 76750W

11 3 Roller, Chain Idler, Nylon 73706

12 1 Screw, 5/16 x 1/4" Shoulder, Soc. Hd., 1/4-20 82751

13 5 Nut, 1/4-20 Nylock, Full Thread 83070

14 2 Nut, 1/2-20, Hex, Jam 83022

15 1 Cover, Chain Tensioner 71754

16 1 Fitting Assembly, Bulk Head 73777A

17 1 Nut, 9/16-18 Hex Jam ZP 83077

18 1 Nipple, Hydraulic Quick Disconnect 87615

19 1 Carriage Weldment 73201NW

20 2 Shaft Bearing Weldment 73230W

21 4 Bearing, Track Roller 20 x 52mm 84305

22 2 Shaft, Eccentric Bearing Weldment 73230W

23 2 E-Clip 3/4" Bowed .580 Groove 84377

24 8 E-Clip 3/4" .580 Groove DIA 84376

25 1 Washer, .2811" ID x .625" OD x .055" 83511

26 6 Screw, 1/4-20 x 3/8", Serrated Hex 82761

27 2 Washer, Front Scissor Arm 73748

28 2 Bearing, Scissor/Carriage Tube 84320

29 2 Bushing, 3/4" ID x 3/8", Peer12FB06 900-0455

30 1 Cylinder 87055N

31 1 U-Channel, Edge Trim 82000R012

32 1 Pin, Cylinder Rod Mounting Long 75700N

33 1 Pin, Cylinder Rod Mounting 75701N

34 2 Washer, UVL Cylinder Rod Pin 31137

35 2 Nut, 9/16-18 x 5/16" Thick Stainless Jam 31176

36 1 Motor, Electric, In/Out - w/Sprocket and Dowel 73780AS

37 2 Plug, 1 1/2" x 2" x 11 Gauge Tube 81582

38 1 Tape, 1/16" x 3/4" Double Face 82033R333

39 27 Screw, 10-32 x 3/8" Pan Head, Thread Cut 82755

40 2 Cam, Torque Shaft Actuator 73712

41 2 Clamp, 1 5/16" x 2 1/4" x 1/2", Worm Drive 26400

42 1 Barrier, NUVL603C, Weldment 73321NWY

43 1 Platform Weldment 73301NWY

44 2 E-Clip, 3/8" Shaft 84383

45 6 Washer, #10 Internal Tooth 11540

46 2 Screw, 5/16-24 x 7/8", Flat Hd. Soc. Cap 82763

47 2 Retainer, Scissor Bearing 73737

48 1 Cam, Rear Barrier 74403

49 4 Washer, .328" x .562" x .042" 83583

50 2 Bearing, Scissor Platform 84321

51 2 Washer, Rear Scissor Bearing 73755

52 2 Washer, Rear Scissor Arm 73749

53 1 Bolt, 1/4-20 x 5/8" Socket Head 82333

54 1 Shield, Carriage Wire Harness 73742

55 2 Washer, .390 x .625 x .073, SS 83585

56 6 Clamp, 1/4" ID Nylon Loop, Black 84396

57 3 Plate, Switch Bracket, Tap 68280-1

58 2 Screw, 1/4-20 x 2 3/4", Serrated Hex 82759

59 2 Screw, 5/16 x 2 SHLD SKT HD 1/4-20 SS 82758

60 4 Clamp, Insulate 1" 20535

61 1 Plate, Rear Barrier 73401N-15GMG

62 2 Washer, .758 ID x 1.245 OD x .06 25141

63 5 Limit Switch Assembly 73950AS

64 3 Tape, Limit Switch Mounting Pad 73747

65 4 Screw, 10-32 x 1 1/2", Socket Cap 82717

66 2 Screw, 10-32 x 7/8", Socket Cap 82778

67 1 Bracket, Switch In/Out Mounting 73719

68 1 Nut, 5/16-24 LH Hex Jam ZP 83076

Item Qty. Description Part No.

69 1 Skid, Rear Barrier 74402-15

70 2 Nut, 10-32 Serrated Flange ZP 83080

71 2 Screw, 10-32 x 1/2" PH PN ZP 82744

72 1 Shaft, Rear Barrier Hinge 74413

73 1 Closure, Weldment, NUVL603C 73330NW

74 1 Cover, Platform Wiring Harness 73738

75 1 Nut, 1/4-20, Serrated Hex 83064

76 8 Screw, 1/4

77 2 Spring, Torsion 85101EVO

78 1 Barrier Actuator Assembly 74340-3S

79

1 Screw, 1/2" x 1/2" SHLD SKT HD x 3/8-16 25929

80 1 Pin, Barrier Clevis Release 73741-2

81 1 Ring, Clevis Pin 5/16

82 1 Clip, Hairpin, 5/16

83 1 Screw, 5/16 x 1 1/4

84 1 Spring, Lower Closure Torsion 73335

85 1 Plate, Platform Floor 74306-1

86 1 Hinge Weldment Rear Barrier 74420NW

87 1 Ring, Retaining 5/8

88 1 Catch, Weldment, Rear Barrier 74415W

89 1 Block, Nylon Slider Inside 74410

90 1 Block, Nylon Slider Outside 74409

91 2 Rivet, Pop, SD64BS-3/16

92 1 Bracket, Lower Housing Cover 73108

93 1 Plug, Poly Finish, 1

94 1 Cover, Lower 73732-2

95 3 Screw, 10-32 x 3/8

96 1 Lip, LH Side Seal 73745N

97 1 Lip, RH Side Shield 73744N

98 1 Cam, 7/8

99 1 Tape, 1

100 1 Chain, Nickel Plated Roller, #35 84314R120

101 1 Connector Link, #35 Chain 84317

102 1 Rod End, 5/16-24 Male 84384

103 4 Screw, 1/4-20 x 1 1/2

104 1 Cover, Upper 73730N

105 1 Lid, Upper Edge Seal 73746N

106 1 Bearing, Rear Barrier Slide 31127

107 2 Nut, 3/8-24 Jam, ZP 83074

108 1 Bolt, 1/4-20 x 1/2

109 2 Bolt, 1/4-20 x 1

110 1 Tape, 1/8 x 2

111 1 Nut, 1/4-20 Lock, Hex 10775

112 2 Rod End, 5/16-24 Left Hand Male 84385

113 2 Nut, 5/16-24 Hex, Jam ZP 83075

114 3 Nut, 5/16-24 Nylock Plated 83079

115 1 Tie Rod, Rear Barrier 74407

116 1 Bolt, 5/16-24 x 1

117 1 Block, Rear Barrier Slider 74408

118 1 Rocker, Rear Barrier 74404

119 1 Bolt, 5/16-24 x 2 1/4

120 1 Bolt, 5/16-24 x 2

121 1 Link, Rear Barrier 74406

122 1 Bearing, Split 1/4

123 1 Bushing, Link, Rear Barrier 74411

124 2 Pin, .25

125 1 Bearing, 5/8 I.D. x 5/8

126 1 Washer, .281 x .75 x .06 Brass 83592

127 1 Manual Release Cable Assy. Kit 73770-600

128 1 Cam Follower, 1/4 I.D. x 3/4

129 2 Screw, 3/8-16 x 1 3/4

-20 x 3/8 FL SOC CAP HD 23471

" 11390

" DIA Shaft 84382

" Shoulder Socket Head 82751

" 84189

"- .13/.25, Auto Black 11513

" Hole, Black 81576

", Flat HD PH ZP 82767

" UVL Follower 84052

" Wide S-Face Foam 82015R

" Washer HD TYPF 24751

" Socket Low HD 82335

" Socket HD, SS 24752

" Foam Adhesive 82054R048

" SKT BTN PLTD 82348

" SKT Flat 82346

" SKT Flat Plated 82347

" I.D. x 1/4" Long 84395

" x .81" Dowel 74412

" LG Split 84394