Page 1

Operator's Manual

W

A

RNING

Read manual

before operating

lift. Failure to do

so may result in

serious bodily

injury and/or

property damage.

Keep manual in

lift storage pouch.

Oper

ual

Man

ator's

Operator's Manual

30651 Rev. B

October 2006

Braun NL Series

Braun NL Series

Patent #5,261,779

Patent #6,065,924

Patent #6,238,169

Patent #6,464,447

Patent #5,261,779

Patent #6,065,924

Patent #6,238,169

Patent #6,464,447

Patent #6,599,079

Patent #6,692,217

Patent #6,739,824

Patents Pending

Patent #6,599,079

Patent #6,692,217

Patent #6,739,824

Patents Pending

Operator's Manual for:

DOT — Public Use Lift

DOT — Public Use Lift

“DOT — Public Use Lift” verifies that this platform lift meets the

“public use lift” requirements of FMVSS No. 403. This lift may be

installed on all vehicles appropriate for the size and weight of the

lift, but must be installed on buses, school buses, and multipurpose passenger vehicles other than motor homes with a gross

vehicle weight rating (GVWR) that exceeds 4,536 kg (10,000 lb).

Public Use Wheelchair Lifts

"Providing Access to the World"

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT (574) 946-6153 FAX: (574) 946-4670

®

®

Page 2

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed

and assembled the finest lift available.

This manual includes safety precautions, lift operating instructions, manual operating instructions, and instructions for maintenance and lubrication

procedures.

Your lift is built for dependability, and will bring you years of pleasure

and independence, as long as maintenance is performed regularly and the lift

is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Page 3

Page 1

Contents

Warranty/Registration Instructions .................. 2, 3

Lift Terminology

Lift Terminology Illustration ........................................ 4

Introduction ................................................................ 5

Direction .................................................................... 5

Lift Components .................................................... 6, 7

Vehicle and Lift Interlocks ......................................... 7

Lift Actions and Functions .......................................... 8

Lift Operation Safety

Safety Symbols ......................................................... 9

Lift Operation Safety Precautions ...................... 10-13

Operation Notes and Details

Introduction/Lift Access Doors and Interlocks ......... 14

General Safety ......................................................... 15

Control Switches ..................................................... 15

Lift Features

Lift-Tite Latches™ ....................................... 16, 17

Inner Roll Stop ............................................ 18, 19

Outer Barrier ............................................... 19, 20

Outer Barrier Latch ..................................... 20, 21

Outer Barrier and Latch Operation ................... 21

Bridging ............................................................. 21

Handrails ........................................................... 21

Lift Passengers

Passenger Orientation (Boarding Direction) ..... 22

Standees ........................................................... 22

Yellow Boundaries ...................................... 22, 23

Vehicle (Floor Level) Loading and

Unloading .................................................... 23, 24

Wheelchair-Equipped Occupant Seat Belts ........... 25

Operation Procedure Review ........................... 25, 26

Preventive Maintenance ......................................... 26

Lift Operating Instructions ............................. 27-31

NHTSA Operations Checklist .............................. 32

Manual Operating Instructions ....................... 33-37

Decals and Antiskid ........................................ 38-40

Maintenance and Lubrication ......................... 41-49

Page 4

Page 2

Warranty and Registration Instructions

Immediately upon receiving your

lift, examine the unit for any damage. Notify the carrier at once with

any claims.

Two warranty/registration cards

(shown below) are located in

the pump cover owner's manual

storage pouch. The sales representative must process one of the

FDUGV7KHFRQVXPHUPXVWÀOORXW

vertical arm. A second I.D. tag is

located on the opposite pump side

tower. Both I.D. tags provide the

SURGXFWLGHQWLÀFDWLRQLQIRUPDWLRQDSpearing on the Warranty/Registration

card. Record the information in the

space provided on the next page.

This information must be provid-

HGZKHQÀOLQJDZDUUDQW\FODLPRU

ordering parts.

the other card and mail it to The

Braun Corporation. The warranty is

provided on the back cover of this

manual. The warranty cards must

be processed to activate the warranty.

Two Braun Serial No./Series No.

LGHQWLÀFDWLRQWDJVDUHSRVWHGRQWKH

lift. One I.D. tag (shown below) is

posted on the opposite pump side

OWNER'S WARRANTY REGISTRATION

PURCHASED FROM

DATE INSTALLED

NAME

ADDRESS

CITY

TELEPHONE

TO VALIDATE WARRANTY

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

NL917IB-04-02730-56-14CG

Sample

Warranty/Registration

Card

Serial No.Model No. Cylinder Code

Series No. Pump Code

Sample

Serial No./Series No.

,GHQWLÀFDWLRQ7DJ

NL917IB

e5*72/245*95/54*0110*00

1-800-THE LIFT™

BRAUNLIFT.COM™

The Braun Corporation

DOT Public Use Lift MODEL#

Max. Lifting Capacity - 800 lbs.

PATENT

PENDING-

5,261,779-6,065,924-6,238,169-6,46

4,447-6,599,079-6,692,217-6,739,824

5/8/06

MFG DATE

56 14CG

PUMP CODE CYLINDER

04-02730

SERIAL NUMBER

Page 5

Page 3

Warranty and Registration Instructions

Model No.

Series No.

Serial No.

Pump Code

Cylinder Code

Date of Manufacture

Note: This information must

be providedZKHQÀOLQJD

warranty claim or ordering

parts. Keep for future use.

Page 6

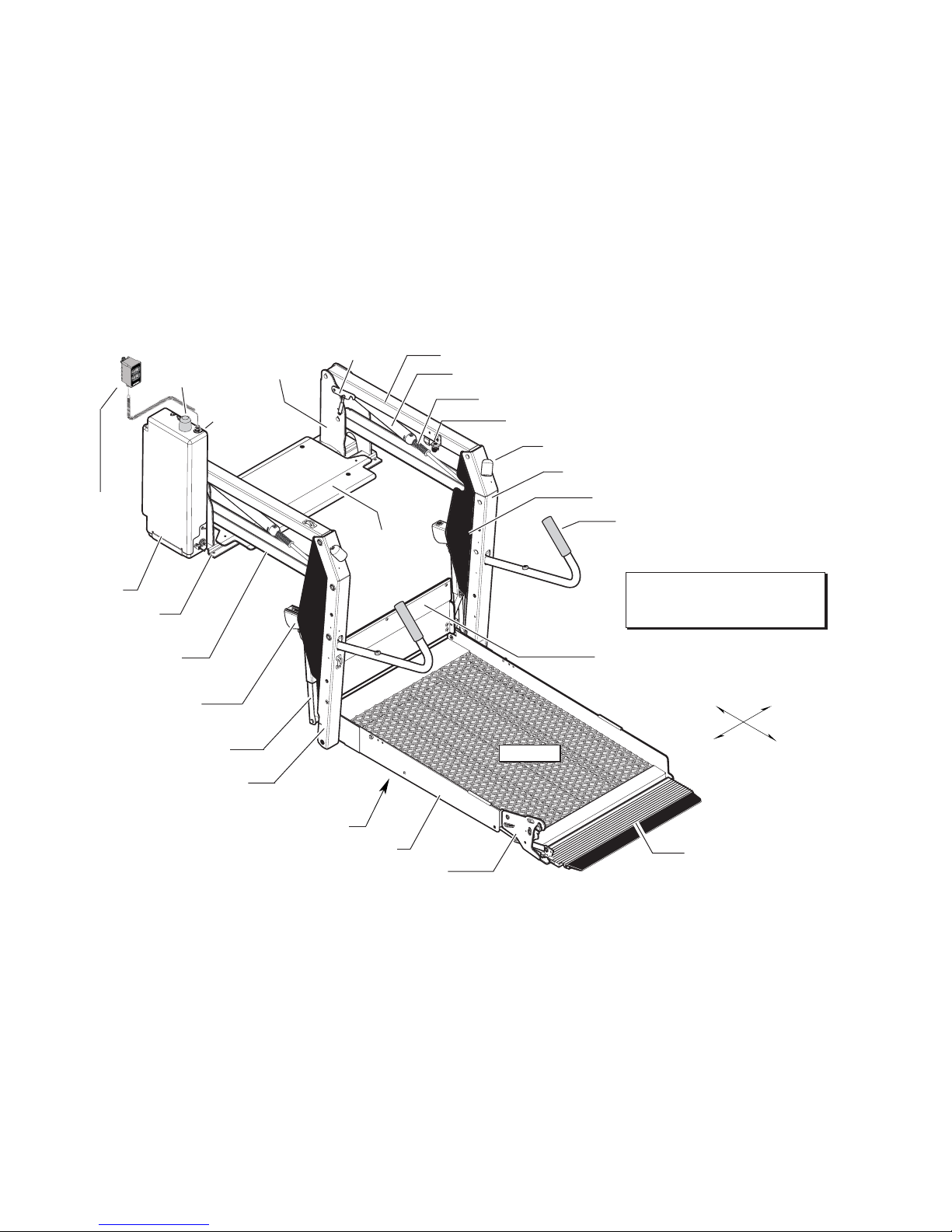

Page 4

UN

FO

LD

FO

LD

DOWN

UP

3

2

8

1

9

3

2

8

2

0

Pump

Module

Hand-Held

Pendant

Control

Base

Plate

Top Parallel Arms (2)

Adjustable Quiet-Ride Stow Blocks (2)

Main Cylinders (2)

Vertical Arm Covers (4)

Opposite Pump Side Vertical Arm

Handrails (2)

Outer Barrier Cylinder

(not visible -underside of platform)

Outer Barrier

(Automatic Outboard Roll Stop)

Rotating Pivot

Slide Arms (2)

Platform Pivot Arms (2)

Pump Side Vertical Arm

Bottom Parallel

Arms (2)

Platform Lights

Outboard

Right

Lift Terminology

Illustration

Lift-Tite™ Latches (2)

Unfold Assist Compression Springs (2)

Outer Barrier Latch

Platform Side Plates (2)

Platform

Left

Inboard

Towers (2)

Threshold

Warning

Plate

Audible

Threshold

Warning

Visual

Threshold

Warning

Inner Roll Stop

Page 7

Page 5

Lift Terminology

Introduction:

Braun NL Millennium Series

lifts are ADA compliant and

comply fully with National

+LJKZD\7UDIÀF6DIHW\$GPLQLVWUDWLRQ1+76$VSHFLÀFDWLRQV

The NL is commercial oriented

(intended for operation by an

attendant).

Lift models vary per size (lift

model numbers indicate lift

dimensions). NL Series lift

models can be equipped with

left or right side pump modules

as needed. A left side pumpequipped lift model is depicted

in the Lift Terminology Illustration (NL917IB). Right side

pump lift models are a mirrored

image of rear pump models

(pump module located on opposite end of base plate).

Refer to the Lift Terminology

,OOXVWUDWLRQIRULGHQWLÀFDWLRQRI

lift components.

Lift operation procedures

are identical for all NL Series

lift models. The operating

instructions contained in this

manual and appearing on liftposted operating instructions

decals address the lift control

switches and the corresponding lift functions. Instructions are provided for manual

operation of the lift in event of

power or equipment failure.

Terminology: Become familiar with the terminology that will

be used throughout this manual. Become familiar with the

LGHQWLÀFDWLRQRIOLIWFRPSRQHQWV

and their functions. Contact

your lift sales representative or

call The Braun Corporation at

1-800-THE LIFT

®

if any of this

information is not fully understood.

Direction: The terms "left,"

"right," "inboard," and "outboard" will be used throughout

this manual to indicate direction (as viewed from outside

the vehicle looking directly at

the lift). Refer to the Lift TermiQRORJ\,OOXVWUDWLRQVIRUFODULÀFDtion of direction terms.

Page 8

Page 6

Lift TerminologyLift Terminology

Lift Frame: The lift frame consists of the base plate, threshold

warning plate, towers, parallel

arms, vertical arms, platform

pivot arms and handrails. Two

main hydraulic cylinders are

housed in the parallel arms.

The electrical/hydraulic powered

lift frame components mechanically unfold, lower, raise and fold

the lift platform assembly.

Platform Assembly: The platform assembly consists of the

steel tubing frame with grating

surface upon which the wheelchair is positioned, the outer

barrier, outer barrier latch, the

inner roll stop, and the hydraulic

cylinder assembly that powers

the outer barrier.

Lift-Tite

™

Latches: The spring-

loaded latches prevent the

platform from unfolding from the

stowed position in the event of

platform drift. Further details

regarding Lift-Tite

™

latches are

provided on pages 16 and 17.

Outer Barrier: The cylinderpowered automatic outer barrier

provides a ramp for wheelchair

loading and unloading at ground

level. Photos and further details

regarding the outer barrier are

provided in the Operation Notes

section (pages 19-21).

Outer Barrier Latch: The springloaded latch locks the outer barrier in the vertical position when

the platform raises above ground

level.

Lift Components

Refer to the Lift Terminology Illustration on page 4.

Pump Module: The lift-mounted

pump module consists of the hydraulic pump, the manual hand

pump, the electronic control

board and electrical components

that power the lift electric/hydraulic systems.

Hand-held Pendant Control:

The hand-held attendant's

pendant control is connected to

the pump module. The handheld pendant is equipped with

two rocker switches, (UNFOLD,

FOLD, DOWN, and UP). The

momentary switches activate the

automatic lift functions.

Page 9

Page 7

Lift Terminology

Vehicle and Lift Interlocks

Braun Corporation NL917IB

Series lifts comply fully with all

NHTSA vehicle and lift interlock

VSHFLÀFDWLRQV9HKLFOHPRYHment is prohibited unless the lift

is fully stowed and the lift will

not function unless the vehicle

is parked and secured.

The NL features a visible and

audible threshold warning

system that will activate if the

threshold area is occupied

when the platform is one inch or

PRUHEHORZÁRRUOHYHO

The inner roll stop and outer

barrier sense weight to prohibit

lift operation. The lift will not

function if the inner roll stop or

the outer barrier are occupied.

The lift platform cannot be folded

(stowed) if occupied.

The inner roll stop features a

locking mechanism that prohibits the platform from lowering if

the lock does not engage. The

lift platform cannot be raised

more than 3" above ground

level unless the outer barrier is

in the vertical position and the

outer barrier latch is positively

engaged.

Inner Roll Stop: NL Series lift

models are equipped with an

automatic inboard roll stop that

also serves as the bridge plate.

The roll stop bridges the gap

between the lift platform and the

YHKLFOHÁRRU7KHLQQHUUROOVWRS

automatically rotates from the

horizontal position to the vertical position as the lift lowers and

raises. Further details regarding the automatic mechanical

inboard roll stop are provided on

pages 18 and 19.

Page 10

Page 8

Lift Terminology

F. FOLD (In) - Platform Fold:

Fold is the action of the platform

URWDWLQJXSDQGLQIURPWKHÁRRU

level (horizontal) position to fullystowed (vertical) position when

the FOLD switch is pressed.

Stowed Position: The lift is

stowed when the lift platform has

been fully raised and folded fully

(vertical position).

Floor Level: Floor level is the

position (height) the platform assembly reaches in order for the

wheelchair passenger to enter

and exit the vehicle (fully raised).

The platform automatically stops

DWÁRRUOHYHOZKHQXQIROGLQJIURP

the stowed position and when

raising from ground level.

Lift Actions and Functions

DEPLOY (A-C)

A. UNFOLD (Out) - Platform

Unfold: Unfold is the action

of the platform rotating out and

down from the fully-stowed

YHUWLFDOSRVLWLRQWRÁRRUOHYHO

(horizontal) position when the

UNFOLD switch is pressed.

B. DOWN - Platform Lower:

Down is the action of the platform

ORZHULQJIURPÁRRUOHYHOSRVLWLRQ

to fully-lowered (ground level)

position when the DOWN switch

is pressed.

C. DOWN - Outer Barrier

Unfold (Deploy) - When the

platform reaches the fully-low-

ered (ground) position and the

DOWN switch is continued to be

pressed, the outer barrier rotates

downward from vertical position

to ramp position.

STOW (D-F)

D. UP - Outer Barrier Fold

(Raise): When the lift is fully

lowered and the outer barrier is

in the ramp position, pressing

WKH83VZLWFKÀUVWURWDWHVWKH

outer barrier upward from ramp

position to vertical position.

E. UP - Platform Raise: Up is

the action of the platform raising

IURPJURXQGOHYHOWRÁRRUOHYHO

(fully-raised) position when the

UP switch is pressed.

Page 11

Page 9

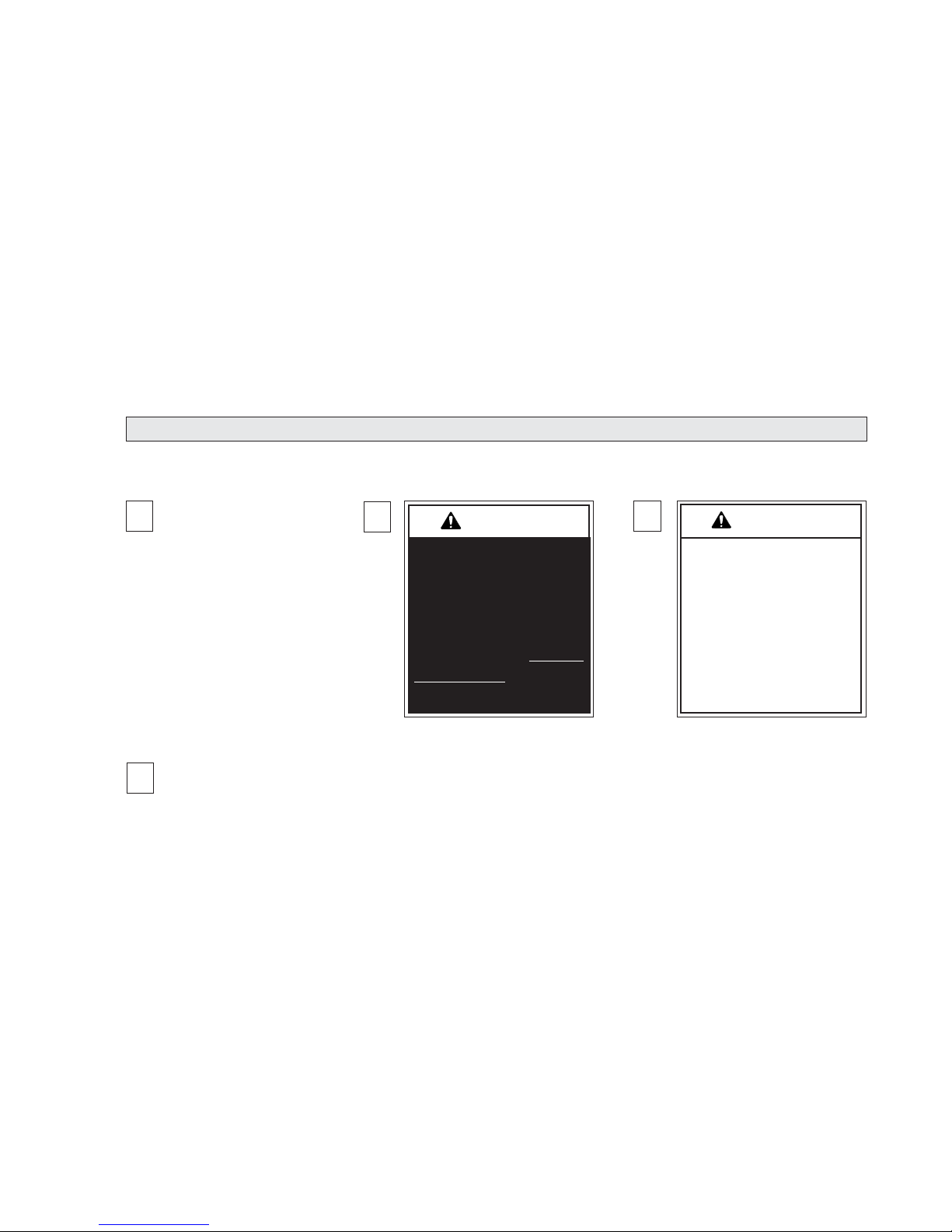

Safety Symbols

Lift Operation Safety

SAFETY FIRST! Know That....

C

CAUTION

This symbol indicates

important information

regarding how to

avoid a hazardous

situation that could

result in minor personal injury or property damage.

A

supplements (if included), is provided for your safety. Familiarity

with proper operation instructions

as well as proper maintenance

procedures are necessary to ensure safe, troublefree operation.

Safety precautions are provided

to identify potentially hazardous

situations and provide instruction

on how to avoid them.

All information contained

in this manual and

B

W

A

RNING

This symbol indicates

important safety

information regarding

a potentially hazardous situation that

could result in serious

bodily injury and/or

property damage.

D

Note:$GGLWLRQDOLQIRUPDWLRQSURYLGHGWRKHOSFODULI\RUGHWDLODVSHFLÀFVXEMHFW

These symbols will appear throughout this manual as well as on the labels posted on your lift. Recognize

the seriousness of this information.

Page 12

Page 10

Lift Operation Safety Precautions

W

A

RNING

If the lift operating

instructions, manual

operating instructions

and/or lift operation

safety precautions are

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Read manual and supplement(s) before operating lift. Read

and become familiar with all safety precautions, operation

notes and details, operating instructions and manual operating instructions before operating the lift. Note: Wheelchair

passengers and all transit agency personnel (drivers and

wheelchair lift attendants) must read and become familiar

with the contents of this manual and supplement(s) before

operation.

Load and unload on level surface only.

Engage vehicle parking brake before operating lift.

Provide adequate clearance outside the vehicle to accommodate the lift before opening lift door(s) or operating lift.

W

A

RNING

Lift Operation Safety

W

A

RNING

W

A

RNING

W

A

RNING

Inspect lift before operation. Do not operate lift if you suspect lift damage, wear or any

abnormal condition.

Keep operator and bystanders clear of area in which the lift operates.

W

A

RNING

W

A

RNING

Page 13

Page 11

W

A

RNING

Whenever a wheelchair passenger (or standee) is on the platform, the:

• Passenger must be positioned fully inside yellow boundaries

• Wheelchair brakes must be locked

• Inner roll stop and outer barrier must be up (vertical)

• Outer barrier latch must be fully engaged

• Passenger should grip both handrails (if able).

/RDGDQGXQORDGFOHDURIYHKLFXODUWUDIÀF

Do not overload or abuse. The load rating applies to both the raising and lowering functions - continuous lifting capacity is 800 lbs.

Discontinue lift use immediately if any lift or vehicle interlock does not operate properly.

Do not operate or board the lift if you or your lift operator are intoxicated.

Do not raise front wheelchair wheels (pull wheelie) when loading (boarding) the platform.

Open lift door(s) fully and secure before operating lift.

Position and secure (buckle, engage, fasten, etc.) the wheelchair-equipped occupant

seat belt (torso restraint) before loading onto the wheelchair lift platform.

W

A

RNING

W

A

RNING

Lift Operation Safety

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Page 14

Page 12

Lift Operation Safety

Lift attendants must ensure that lift occupants keep hands,

arms and all other body parts within the lift occupant area

and clear of moving parts.

3ODWIRUPPXVWEHSRVLWLRQHGDWÁRRUOHYHOUROOVWRSKHLJKW

when loading or unloading in and out of vehicle.

Do not use platform inner roll stop or outer barrier as a

brake. Stop and brake wheelchair when loading onto the

platform (manually stop and brake manual wheelchairs

— stop powered wheelchairs with the wheelchair controls).

Turn powered (electric) wheelchairs off when on lift platform.

Press the DOWN switch until the entire platform rests on

ground level (lowered fully) and the outer barrier is fully

unfolded (ramp position) before loading or unloading a passenger at ground level.

W

A

RNING

Lift Operation Safety Precautions (continued)

W

A

RNING

If the lift operating

instructions, manual

operating instructions

and/or lift operation

safety precautions are

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Outer barrier must be fully unfolded (ramp position) until front and rear wheelchair wheels

cross the barrier when loading or unloading at ground level.

Page 15

Page 13

Lift Operation Safety

W

A

RNING

Accidental activation of control switch(es) may cause unintended operation(s).

0DLQWHQDQFHDQGOXEULFDWLRQSURFHGXUHVPXVWEHSHUIRUPHGDVVSHFLÀHGLQWKLVPDQXDOE\

DXWKRUL]HGFHUWLÀHGVHUYLFHSHUVRQQHO

Replace missing, worn or illegible decals.

Keep owner’s (operator's) manual in lift-mounted manual storage pouch at all times.

Never modify (alter) a Braun Corporation lift.

Do not use accessory devices not authorized by The Braun Corporation.

Do not remove any guards or covers.

Keep clear of any hydraulic leak.

Failure to follow these safety precautions may result in serious bodily injury and/or property damage.

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Page 16

Page 14

Operation Notes and Details

NL Series “Public Use” lift models

DUHVSHFLÀFDOO\GHVLJQHGWREH

operated by an attendant. The Lift

Operating Instructions contained

in this manual and posted on the

lift provide instructions for operation of the lift only. Read and

become familiar with all lift operation safety precautions, operation notes and details, operating

instructions and manual operating

instructions before attempting lift

operation procedures.

Lift Access Doors and Interlocks: Attendants must become

familiar with the vehicle lift access

door system and vehicle interlock

system(s). Transit vehicles and

OLIWDFFHVVGRRUFRQÀJXUDWLRQV

vary. Door securement devices

(latches, hooks, cables, etc.) and

procedures to operate them vary.

Instructions for operation of

vehicle interlocks and door

securement systems are not

addressed in this manual or on

lift-posted operating instructions

decals due to the variety of procedures required for operating them.

Braun Corporation NL Series

lifts comply fully with all NHTSA

YHKLFOHDQGOLIWLQWHUORFNVSHFLÀFDtions (detailed on pages 7 and 32).

Infringement of any lift interlock

will prohibit lift operation.

It is the responsibility of the lift

operator (attendant) to properly

open, secure and close the vehicle

lift door(s), to activate the vehicle

interlock(s), to load and unload the

wheelchair passenger (or standee)

on and off the lift platform, and to

properly activate all lift functions.

W

A

RNING

Read and become

familiar with all lift

operation safety

precautions, operation notes and details,

operating instructions

and manual operating instructions prior

to operating the lift.

If this information is

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Page 17

Page 15

Operation Notes and Details

General Safety: The lift operator

(attendant) and bystanders must

keep clear of the area in which

the lift operates and clear of all

moving parts. Lift attendants

must ensure that lift occupants

(passengers) keep hands, arms

and all other body parts within

the lift occupant area and clear of

moving parts.

Control Switches

Hand-held Pendant Control:

The hand-held attendant's

pendant control is equipped with

two rocker switches, (UNFOLD,

FOLD, DOWN, and UP). The

momentary switches activate the

automatic lift functions.

Lift Power ON/OFF Switch:

This switch must be in the ON

position in order to activate the

lift. The green Power Indicator

Light mounted on top of the pump

module illuminates to signal power

to the lift.

Simply press the switch labeled

for the intended function.

Hand-held Pendant

DOWN

UP

FOLD

UNFOLD

32525

32526

Page 18

Page 16

Operation Notes and Details

Lift Features

W

A

RNING

Discontinue lift use

immediately if any

lift component does

not operate properly. Failure to do so

may result in serious

bodily injury and/or

property damage.

information is not understood.

Lift-Tite

™

Latches: NL Series

lifts are equipped with Lift-Tite

™

Latches. Lift-Tite™ Latches pre-

Engaged

Lift-Tite

™

Latch

Latch En-

gagement

Pin (Roller)

IRULGHQWLÀFDWLRQRIVSHFLÀFOLIW

components if not clearly depicted in this section. Contact The

Braun Corporation at 1-800-THE

LIFT

®

immediately if any of this

Become familiar with all lift

features and the proper operation of the lift components before

attempting lift operation. Refer to

the Lift Terminology Illustrations

Page 19

Page 17

vent the platform from unfolding

from the stowed position in the

event of platform drift. Due to

the “all-hydraulic” operation of

the dual-cylinder NL, hydraulic

ÁXLGH[SDQVLRQFRQWUDFWLRQRU

seepage may occur. Any of

these conditions may result in

platform drift (failure to hold the

platform in the folded or raised

position). Platform drift may

occur during lift shipment and/or

between extended periods of

non-lift use.

In the event that the platform

does not unfold when the

UNFOLD switch is pressed,

press the FOLD switch momentarily to disengage the

Lift-Tite

™

latches (platform drift

has occurred). Then, press the

UNFOLD switch to unfold the

Disengaged

Lift-Tite

™

Latch

Latch Engagement

Pin (Roller)

Operation Notes and Details

SODWIRUPWRÁRRUOHYHOVWDQGDUG

operation).

When manually operating a lift

equipped with Lift-Tite

™

latches,

insert the pump handle in the

pump and stroke until the platform folds fully (stops). Then,

open the hand pump valve (turn

counterclockwise) to unfold the

platform. Folding the platform fully

ÀUVWZLOOHQVXUHWKDWWKH/LIW7LWH

™

latches will disengage properly

when the release valve is opened.

Manual Operating Instructions are

provided on pages 33-37.

Page 20

Page 18

Lift Features (continued)

Inner Roll Stop

Fully-Deployed

(vertical)

Inner

Roll Stop

The inner roll stop must

overlap the base plate a

minimum 1/2".

Fully-Unfolded

(horizontal)

Inner Roll Stop

(bridging position)

Operation Notes and Details

Inner Roll Stop: NL Series lift

models are equipped with an

automatic inner roll stop that

also serves as the bridge plate

(inner roll stop photos below).

When the UNFOLD switch is

pressed and the platform unfolds

IURPVWRZSRVLWLRQWRÁRRUOHYHO

this mechanical roll stop is automatically deployed to the bridging

(horizontal) position to provide a

bridge plate between the platform

and the lift base plate (vehicle

ÁRRU7KHLQERDUGHGJHRIWKH

bridge plate rests on the threshold

warning plate (base plate).

The roll stop automatically folds

(rotates) to the vertical (roll stop)

position when the platform lowers

to the ground (DOWN switch is

pressed).

As the UP switch is pressed and

the platform raises from ground

level, the inner roll stop automatically unfolds (rotates) to the

Page 21

Page 19

Operation Notes and Details

horizontal (bridging) position

ZKHQLWUHDFKHVYHKLFOHÁRRUOHYel. The roll stop must overlap the

lift base plate a minimum 1/2".

When the FOLD switch is

pressed and the platform folds

IURPÁRRUOHYHOWRWKHVWRZYHUWLcal) position, the roll stop auto-

matically travels inboard to the

stowed position.

Interlock Features: The inner

roll stop features a locking

mechanism that prohibits the platform from lowering if the lock is

not engaged. The inner roll stop

also senses weight to prohibit lift

operation. The lift will not function

if inner roll stop is occupied.

Discontinue lift operation immediately if the inner roll stop

does not operate properly.

Outer Barrier: This cylinder-pow-

ered barrier provides a ramp for

wheelchair loading and unloading

at ground level (see photos on

following page). When the platform lowers fully to ground level,

the cylinder compression spring

W

A

RNING

Discontinue lift use

immediately if any

lift component does

not operate properly. Failure to do so

may result in serious

bodily injury and/or

property damage.

automatically unfolds (rotates)

the barrier to the ramp position

(fully unfolded).

Although the outer barrier is

lift-powered, the activation of

the barrier is controlled by the

lift operator (attendant). Pressing the DOWN switch unfolds

the barrier. The outer barrier is

cylinder-powered to automatically fold (rotate) to the vertical

position as shown when the UP

switch is pressed (barrier raises

before platform raises).

Interlock: The outer barrier

senses weight to prohibit lift operation. The lift will not function

if the outer barrier is occupied.

Page 22

Page 20

3"

Note: Platform must raise

approximately three inches

before latch engages fully.

Outer Barrier

Fully-Unfolded Barrier (Ramp position)

Fully-Folded

Outer Barrier

(Up-vertical)

Disengaged

Outer Barrier

Latch

Operation Notes and Details

Lift Features (continued)

Discontinue lift operation immediately if the outer barrier

does not operate properly.

Outer Barrier Latch: A spring-

loaded latch engages the outer

Latch Foot

barrier when the barrier rotates

upward from ramp position to

the vertical position (UP switch

is pressed to raise the platform

above ground level). Note: The

platform must raise approximately

three inches before the latch

engages fully (see photos on

previous page).

Interlock: Lift platform movement shall be interrupted unless

the outer barrier is raised (vertical position) and the outer barrier

latch is positively engaged.

Fully-Engaged Outboard Barrier Latch

Page 23

Page 21

Operation Notes and Details

After the platform is fully lowered, the attendant should continue to press the DOWN switch

to unfold the outer barrier fully

(ramp position). Note: The

barrier must be fully unfolded

until the entire wheelchair (or

standee) has crossed the barrier

when loading or unloading at

ground level. Discontinue lift

operation immediately if the

outer barrier or latch do not

operate properly.

Bridging: The NL incorpo-

rates a bridging feature. This

feature stops the down travel

of the platform if the outboard

end of the platform contacts a

raised surface (such as a curb),

preventing the operator from

lowering the inboard end of the

platform.

The latch disengages the barrier

when the platform lowers fully

(reaches ground level) and the

latch foot contacts the ground

(latch raises above the barrier).

Outer Barrier and Latch Operation: The lift attendant must

press the DOWN switch to lower

the platform fully to the ground.

The attendant must view the

platform as it lowers to be cer-

tain the entire platform reaches

and rests safely on the ground.

Stop pressing the DOWN switch

if any portion of the platform is

obstructed while descending

or the entire platform does not

reach ground level for any rea-

son (contact with an obstruction,

mechanical failure, exceeding

WKHOLIW´ÁRRUWRJURXQGµFDSDFLW\

etc.).

Handrails: Dual handrails are

provided for wheelchair passenger (or standee) use. The

handrails unfold automatically

to the deployed (horizontal)

position when the lift unfolds

and automatically fold to the

stowed (vertical) position when

the platform folds.

If able, passengers should

grip both handrails when on

the lift platform. Discontinue

lift operation immediately if

the handrails do not operate

properly.

Page 24

Page 22

Operation Notes and Details

ity of the lift. The lift attendant

should not ride on the platform

with the passenger.

Passenger Orientation (Boarding Direction): Braun NL Series

wheelchair lifts accommodate

both inboard and outboard

facing wheelchair passengers

or standees. Inboard facing of

wheelchair lift passengers is not

prohibited, but outboard facing

of passengers is recommended

by The Braun Corporation.

Braun NL Series lifts permit both

inboard and outboard facing of

wheelchair and mobility aid users and accommodate persons

using walkers, crutches, canes

or braces or who otherwise have

GLIÀFXOW\XVLQJVWHSV

Standees: Lift Operating Instructions apply to wheelchair passengers and standees. Standees

should stand in the center of the

platform (fully inside the yellow

boundaries) and grip both handrails (if able) when on platform.

Yellow Boundaries: The passenger must be positioned in the

center of the platform to prevent side-to-side load imbalance.

The lift attendant (operator)

should not ride on the platform

with the passenger.

Yellow platform loading boundar-

LHVDUHLGHQWLÀHGLQWKHIROORZLQJ

manner. The yellow powdercoated inner roll stop and outer

barrier identify the inboard and

outboard ends of the platform. A

yellow powder-coated guard is lo-

If you are an attendant operating

the lift, it is your responsibility to

perform safe loading and unloading procedures. Wheelchair lift

attendants should be instructed

on any special needs and/or procedures required for safe transport of wheelchair passengers.

The lift operator and bystanders

must keep clear of the area in

which the lift operates. Observe

your passenger at all times during lift operation.

Do not attempt to load or unload

a passenger in a wheelchair or

RWKHUDSSDUDWXVWKDWGRHVQRWÀW

on the platform area. Do not exceed the 800 pound load capac-

Lift Passengers

Page 25

Page 23

Operation Notes and Details

cated on the pump-side platform

side plate. A yellow boundary

VWULSGHFDOLVDIÀ[HGWRWKHRSposite platform side plate. Yellow

plastic caps are placed on the

dual handrails.

The threshold warning plate is

powder-coated yellow to identify the platform threshold area.

Interlock: A visible and audible

threshold warning system will activate if the threshold area is occupied when the platform is one

LQFKRUPRUHEHORZÁRRUOHYHO

The attendant must always be

certain the wheelchair passenger

or standee is properly positioned

on the platform (fully inside yel-

low boundaries) and the wheelchair brakes are locked when a

passenger is on the lift platform.

The lift passenger must keep

hands, arms and all other body

parts within the lift occupant area

and clear of all moving parts.

Vehicle (Floor Level) Loading

and Unloading: The platform

PXVWEHIXOO\UDLVHGDWÁRRUOHYHO

and the bridge plate must be

properly positioned when loading

or unloading passengers in or out

of the vehicle. It is the respon-

sibility of the lift attendant to

ensure the platform and the

bridge plate are properly posiWLRQHGDWÁRRUOHYHOZKHQORDGing and unloading passengers.

W

A

RNING

Whenever a

passenger is on the

platform, the:

• Passenger must be

positioned fully

inside yellow

boundaries

• Wheelchair brakes

must be locked

• Inner roll stop and

outer barrier must

be UP

Failure to follow these

rules may result in

serious bodily injury

and/or property damage.

Page 26

Page 24

Operation Notes and Details

The wheelchair brakes must

be locked, the outer barrier

must be in the fully-up (vertical)

position and the outer barrier

latch must be fully engaged

whenever a passenger is on

the platform.

Do not use the outer barrier as

a brake. Stop and brake the

wheelchair when fully loaded

on the platform. Manually stop

and brake manual wheelchairs.

Stop powered wheelchairs with

the wheelchair controls. Turn

powered (electric) wheelchairs

off when on the platform.

If the outer barrier, inner roll

stop, handrails or any other lift

component does not operate as

Lift Passengers (continued)

W

A

RNING

Discontinue lift use

immediately if any

lift component does

not operate properly. Failure to do so

may result in serious

bodily injury and/or

property damage.

outlined in this manual, discontinue lift use immediately and

contact The Braun Corporation

sales representative in your

area or call The Braun Corporation at 1-800-THE LIFT

®

. One

of our national Product Support

representatives will direct you

to an authorized service technician who will inspect your lift.

Page 27

Page 25

Operation Notes and Details

Wheelchair-Equipped

Occupant Seat Belts

The Braun Corporation recommends wheelchair passengers

position and buckle their wheel-

W

A

RNING

Operation Procedure Review

The Braun Corporation recommends that transit agency

supervisors and wheelchair lift

attendants review the safety

precautions and operation

procedures appearing in this

manual and on lift-posted decals

with your wheelchair lift sales

representative (dealer), before

attempting lift operation.

Any questions or concerns can

be answered by the sales representative at that time. Operate

the lift through all functions with

your sales representative on

hand to ensure the proper use

and operation of the wheelchair

lift is understood.

chair-equipped seat belt (torso

restraint) before loading onto a

wheelchair lift.

Different types of disabilities

require different types of wheelchairs and different types of

wheelchair-equipped occupant

restraint belt systems (torso

restraints). It is the responsibility of the wheelchair passenger

to have his or her wheelchair

equipped with an occupant

restraint (seat belt) under the

direction of their health care

professional.

Wheelchair lift attendants

should be instructed on any

special needs and/or procedures

required for safe transport of

wheelchair passengers.

Position and secure

(buckle, engage,

fasten, etc.) the

wheelchair-equipped

occupant seat belt

before loading onto

the wheelchair lift

platform. Failure to

do so may result in

serious bodily injury

and/or property

damage.

Page 28

Page 26

Transit agency supervisors

should train and educate their

lift attendants on the proper use

and operation of the wheelchair

lift if it is not possible for the

attendants to review the safety

precautions and operation procedures with the wheelchair lift

sales representative.

The lift operator's manual must

be stored in the lift-mounted

manual storage pouch at all

times.

Preventive Maintenance:

Maintenance is necessary to ensure safe and troublefree lift operation. General preventive lift

maintenance consisting of care-

ful inspections of the lift system

and cleaning the lift should be

Operation Notes and Details

a part of your transit agency's

daily lift service program. Simple

inspections can detect potential

lift operational problems.

Regular preventive maintenance

will reduce potential lift operation downtime and increase the

service life of the lift, as well

as possibly detecting potential

hazards.

Exposure to harsh weather elements, environmental conditions,

or heavy usage may require

more frequent maintenance and

lubrication procedures.

Preventive maintenance visual inspections do not take the

SODFHRIWKHSURFHGXUHVVSHFLÀHG

in the Maintenance and Lubrication Schedule provided on pages

W

A

RNING

Maintenance and

lubrication procedures

must be performed

by authorized service

SHUVRQQHODVVSHFLÀHG

in this manual. Failure

to do so may result in

serious bodily injury

and/or property

damage.

41-49 of this manual. Refer to

the Maintenance and Lubrication section for further details.

Page 29

Page 27

W

A

RNING

Read and become

familiar with all lift

operation safety

precautions, operation notes and details,

operating instructions

and manual operating instructions prior

to operating the lift.

If this information is

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Lift Operating Instructions

W

A

RNING

Whenever a

passenger is on the

platform, the:

• Passenger must be

positioned fully inside yellow boundaries

• Wheelchair brakes

must be locked

• Inner roll stop and

outer barrier must

be UP

Failure to follow these

rules may result in

serious bodily injury

and/or property

damage.

Before lift operation, park the ve-

hicle on a level surface, away from

YHKLFXODUWUDIÀF3ODFHWKHYHKLFOH

transmission in "Park" and engage

the parking brake.

Lift Operating Instructions photos

depict lift model NL917IB. Instructions and procedures are applicable for all NL Series lift models.

Lift-posted Warnings and Lift

Operating Instructions decal 30695

provides lift operating instructions.

Replace any missing, worn or illegible decals.

If your lift does not function as intended or an audible warning signal

is activated, review the NHTSA Operations Checklist on page 32. Follow the Manual Operating Instructions on pages 33-37 in the event

of a power or equipment failure.

Page 30

Page 28

Open Door(s) and Secure

To Unfold Platform:

Stand clear and press the UN-

FOLD switch until the platform

stops (reaches ÁRRUOHYHO- unfolds

fully). Release switch.

Note: In event platform does

not unfold, press FOLD switch to

release Lift-Tite

™

latches.

To Unload Passenger:

1. Read Note below! Load passen-

ger onto platform and lock wheelchair brakes.

Note: Passenger must be positioned fully inside yellow bound-

aries, outer barrier must be UP

and outer barrier latch must be

engaged.

Lift Operating Instructions

DOWN

UP

FOLD

UNFOLD

32525

32526

Page 31

Page 29

To Unload Passenger (continued):

2. Press DOWN switch until the entire platform reaches ground level

(see Photo B) and the outer barrier unfolds fully (ramp position).

See Photo C. Release switch.

3. Unlock wheelchair brakes and

unload passenger from platform.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair (or standee) has

crossed the outer barrier. See

Photos E and F on page 30 also.

B

D

C

Lift Operating Instructions

A

DOWN

UP

FOLD

UNFOLD

32525

32526

Page 32

Page 30

F

E

H

G

Lift Operating Instructions

To Load Passenger:

1. Read Notes below! Load pas-

senger onto platform and lock

wheelchair brakes. See Photo G.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair (or standee) has

crossed the outer barrier. See

Photos E and F.

Note: Passenger must be positioned fully inside yellow bound-

aries.

Page 33

Page 31

J

L

To Load Passenger (continued):

2. Press UP switch (Photo I) to fold

outer barrier UP fully (vertical

- see Photo H), and raise the platform to ÁRRUOHYHO. See Photo J.

Release switch.

3. Unlock wheelchair brakes and

unload passenger from platform.

To Fold Platform:

Press FOLD switch until platform

stops (fully folded). See Photos

K and L. Release switch.

Close Door(s)

I

K

DOWN

UP

FOLD

UNFOLD

32525

32526

DOWN

UP

FOLD

UNFOLD

32525

32526

Lift Operating Instructions

Page 34

Page 32

NHTSA Operations Checklist

W

A

RNING

Discontinue lift use

immediately if any lift

or vehicle interlock

does not operate

properly. Failure to

do so may result in

serious bodily injury

and/or property

damage.

9HULÀHG

Vehicle movement is prevented unless the lift door

is closed, ensuring the lift is stowed.

Lift operation shall be prevented unless the vehicle

is stopped and vehicle movement is prevented.

The platform will not fold/stow if occupied.

The inner roll stop will not raise if occupied.

The outer barrier will not raise if occupied.

Verify platform lighting* when lift is deployed and

pendant illumination when it is powered.

An audio warning (and visual warning for public lifts)

will activate if the threshold area is occupied when

WKHSODWIRUPLVDWOHDVWRQHLQFKEHORZÁRRUOHYHO

Lowering the platform beyond the inner roll stop locking

position is allowed

only when the inner

roll stop is locked in

position.

Lift platform movement shall be

interrupted unless

the outer barrier

is raised and the

outer barrier latch is

positevely engaged.

7KHIROORZLQJRSHUDWLRQVKDYHEHHQYHULÀHGXSRQ

installation. This operational checklist can be used

at any time to verify the lift is fully functional.

*Public use vehicle manufacturers are responsible

for complying with the lift lighting requirements in

Federal Motor Vehicle Safety Standard No. 404,

Platform Lift Installations in Motor Vehicles (49 CFR

571.404).

Page 35

Page 33

Manual Operating Instructions

If you experience power or

equipment failure, refer to the

Manual Operating Instructions

to operate the lift. Instructions

and photos are provided for

all steps that differ from standard lift operation procedures.

The Manual Instructions decal

(posted inside pump cover)

provides manual operating

Hand

Pump

Handle

Turn wing 1/4 turn.

Rotate top clip to access handle.

Pump

Cover

Lock

Unlock

instructions also. Note: A right

side pump lift model is depicted

in the photos. Left side pump

applications are a mirrored image. Refer to the Lift Operat-

Page 36

Page 34

Manual Operating Instructions

Release Valve

maximum

30 inch lbs

minimum

15 inch lbs

seats

(stops)

O

P

E

N

C

L

O

S

E

approximate

1/16" intervals

Valve Tightening

6SHFLÀFDWLRQ

Once valve seats

(stops), tighten 15

to 30 inch pounds

as shown.

Release Valve

Note: Close backup pump release valve

securely before operating electric pump.

A

Hand Pump

ing Instructions for all normal lift

operation procedures (such as

loading and unloading passengers). Follow all Lift Operation

Safety Precautions!

Remove the pump cover to gain

access to the pump handle and

the hand pump. See photos on

page 33. To remove the pump

cover, turn the wing nut located

on top 1/4 turn and lift the pump

cover off. The pump handle

is inside this cover secured by

two clips. Rotate the top clip to

remove the pump handle.

Page 37

Page 35

Manual Operating Instructions

Remove pump cover to access

hand pump and pump handle as

outlined on page 33. Refer to

release valve photos and illustration on page 34.

To Unfold Platform (Out):

Place slotted end of pump handle

onto backup pump release valve

and turn counterclockwise (open

1/2 turn only) until the platform

reaches ground level and roll stop

unfolds.

B

C

Using hand pump handle (Photo B):

1. Close hand pump valve (place

slotted end of pump handle onto

backup pump release valve and

turn clockwise).

2. Insert handle in pump and stroke

until platform folds fully (stops).

3. Open hand pump valve (turn

counterclockwise) until platform

UHDFKHVÁRRUOHYHOOpen 1/2

turn only.

4. Close hand pump valve (turn

clockwise).

Note: Valve must be tight, but do

not overtighten.

Stroking

Hand

Pump

Down (To Lower):

Open

(Down)

Close

(Up/Stop)

Page 38

Page 36

Stroking

Hand

Pump

Open

(Down)

Close

(Up/Stop)

Up (To Raise):

Manual Operating Instructions

E

Using hand pump handle:

1. Place slotted end of pump handle onto backup pump release

valve and turn clockwise to

close securely. See Photo D.

Note: Valve must be tight, but

do not overtighten.

2. Insert handle into backup

pump and stroke until platform

reaches ÁRRUOHYHO(see Photo

E).

To Fold Platform (In):

Insert handle into backup pump

and stroke until platform stops

(folds fully). See Photo E.

D

Remove pump cover to access

hand pump and pump handle as

outlined on page 33. Refer to

release valve photos and illustration on page 34.

Note: Close backup pump

release valve securely before

operating electric pump.

Store pump handle and install

pump cover as outlined on page

37.

Page 39

Page 37

Manual Operating Instructions

To Store Pump Handle:

1. Insert bottom of handle behind

bottom clip. See page 33.

2. Rotate top clip to secure (lock)

handle.

To Install Pump Cover:

1. Position cover over module

back cover and red warning

light. See Photo F.

2. Align outside cover lip with

bottom cover offset and insert

outside cover. See Photo G.

3. Insert wing stud and rotate 1/4

turn to lock cover. See Photo

H.

Align and insert bottom of cover.

F

HG

Lock

Unlock

Position cover over red light.

Page 40

Page 38

W

A

RNIN G

LIFT OPERATING

INSTRUCTIONS

OPEN DOOR(S) AND SECURE

TO UNFOLD PLATFORM:

Stand clear and press

UNFOLD switch until

platform stops (reaches

floor level).

Note: In event platform

does not unfold, press

FOLD switch to release

Lift-Tite™ latches.

TO UNLOAD PASSENGER:

1. Load passenger onto

platform and lock wheelchair

brakes.

2. Press DOWN switch until

entire platform reaches

ground level and outer

barrier unfolds fully.

3. Unlock wheelchair brakes

and unload passenger from

platform.

TO LOAD PASSENGER:

1. Load passenger onto

platform and lock wheelchair

brakes.

2. Press UP switch to fold

outer barrier up and raise

platform to floor level.

3. Unlock wheelchair brakes

and unload passenger from

platform.

TO FOLD PLATFORM:

Press FOLD switch until

platform stops. Release

switch.

CLOSE DOOR(S)

DOT — Public Use Lift

30695

Whenever a wheelchair

passenger is on the platform,

the:

• Passenger must be

positioned fully inside

yellow boundaries

• Wheelchair brakes must

be locked

• Inner roll stop and outer

barrier must be up

Failure to follow these rules

may result in serious bodily

injury and/or property damage.

• Read manual before operating

lift.

• Load and unload on level

surface only.

• Engage vehicle parking brake

before operating lift.

• Provide adequate clearance

outside of vehicle to

accommodate lift.

• Do not operate lift if you

suspect lift damage, wear or

any abnormal condition.

• Keep operator and bystanders

clear of area in which lift

operates.

29052

29052

29823

Replace missing, worn

or illegible decals.

Failure to do so may

result in serious bodily

injury and/or property

damage.

W

A

RNING

Decals and Antiskid

Decals

The lift is only as safe as

the operator. Replace

any missing, worn or

illegible decals! Part

numbers are provided for

decals. Inspect your lift for

missing, worn or illegible

decals. Call 1-800-THE

LIFT

®

for replacements.

31412

21494

30695

Note: Clean surfaces as

detailed on page 40 before

posting decals.

25675

®

29823

W

A

RNING

Lift installation and servicing prohibited by

anyone who has not been certified by The Braun

Corporation Sales and Service School. Certified

service technicians should call 1-800-THE LIFT

to receive applicable installation/service manual.

Failure to follow this policy may result in serious

bodily injury and/or property damage.

25675

21494

LIFT POWER

ON

OFF

OPERATING

INSTRUCTIONS

Read warnings and operate

lift as outlined on LIFT

OPERATING INSTRUCTIONS

decal. Lift operating

instructions apply to wheelchair

passengers and standees.

Standees: Standees must

stand at center of platform

(fully inside yellow boundaries),

grip handrails and lower head.

Interlocks: Interlocks vary in

type and operation. Interlocks

must be operational as defined

in NHTSA Operations Checklist.

DOT — Public Use Lift

31045

31045

O

P

E

N

C

L

O

S

E

OPEN

VALVE

CLOSE

UNLOCK

LOCK

TO REMOVE PUMP HANDLE:

1. Rotate top clip.

Using hand pump handle:

TO UNFOLD PLATFORM (OUT):

1. Close hand pump valve

(turn clockwise).

2. Insert handle in pump and

stroke until platform folds

fully (stops).

3. Open hand pump valve (turn

counterclockwise) until

platform reaches floor level.

Open 1/2 turn only.

4. Close hand pump valve

(turn clockwise).

DOWN (TO LOWER):

Open hand pump valve (turn

counterclockwise). Open

1/2 turn only.

UP (TO RAISE):

1. Close hand pump valve

(turn clockwise).

2. Insert handle in pump and

stroke until platform reaches

floor level.

TO FOLD PLATFORM (IN):

Insert handle in pump and stroke.

Note: Close valve before

operating electric pump.

TO STORE PUMP HANDLE:

1. Insert bottom of handle

behind bottom clip.

2. Rotate clip to lock.

DOT — Public Use Lift

31412

MANUAL OPERATION

Page 41

Page 39

Decals and Antiskid

25580

32410

57 – Outer barrier is not up and latched and

ground detect switch did not deactivate

(Century and Vista only)

58 – Outer barrier is not up and latched and the

platform is 3

" above the ground

59 – Outer barrier is not up after pausing

platform travel

60 – The kickout gas springs are worn, replace

before using

75 – Low voltage detected; must turn off power

switch to reset LCD

77 – Vehicle secure interlock has not been

activated

90 – Position will be set if you keep holding the

button until it beeps

91 – Position is out of a predetermined

acceptable range of floor position

92 – Bridge switch is not made, needs adjusting

93 – Inner rollstop occupied switch is not made,

position needs to be moved or switch

should be adjusted

94 – Outer barrier is not made, fix and try again

95 – Outer barrier latch is not made (check for

jumper on Century and Vista lifts, check

latch on Millennium lifts)

99 – Controller program is not valid; replace

controller

Flashing Numbers

Flashing 65 – Unfold button is pressed

Flashing 66 – Fold button is pressed

Flashing 67 – Down button is pressed

Flashing 68 – Up button is pressed

Flashing 69 – Bridge switch is activated

Flashing 70 – Outer barrier latch switch is

activated

Flashing 71 – Ground detect switch is activated

Flashing 72 – Outer barrier up switch is activated

Flashing 73 – Inner rollstop up switch is activated

Flashing 74 – Inner rollstop occupied switch is

activated

Flashing 76 – Outboard barrier occupied switch

is activated

Flashing 78 – Threshold tape switch “A” is

activated

Flashing 79 – Threshold tape switch “B” is

activated

Flashing 80 – Position set button is pressed

Flashing 81 – Single function UP / FOLD /

CLOSE button is pressed

Flashing 82 – Single function OPEN / UNFOLD /

DOWN button is pressed

Flashing 87 – CLOSE button is pressed

Flashing 88 – OPEN button is pressed

Flashing 89 – Door full open switch is activated

(or jumper is installed on control

board)

LCD Lift Codes

Listed below are codes that the lift controller

outputs during lift operation. The codes will be

displayed on an LCD screen located on the lift

control board inside the pump module.

Non-Flashing Numbers

01 – Platform stowed

02 – Platform unfolding

03 – Platform unfolding paused

04 – Platform at floor level

05 – Platform beginning to lower

06 – Platform lowering (threshold cannot be

occupied from this point down)

07 – Outer barrier moving to horizontal

position

08 – Platform at ground level

09 – Outer barrier moving to vertical position

10 – Platform raising

11 – Platform raising paused at floor

12 – Platform folding (limited pressure)

13 – Platform folding (full pressure)

14 – Timed fold (cinching lift tite) or (anti-rattle

state)

15 – Platform folding stopped

16 – Paused fold

17 – Platform between ground and 3

" above

ground

18 – Platform above 3

"

19 – Outer barrier moving to horizontal

postion

20 – The doors are not fully opened (only

applicable when door operators are

installed)

21 – The doors are opening (only applicable

when door operators are installed)

22 – The doors are closing (only applicable

when door operators are installed)

28 – Illegal function/not defined

29 – Interlock fault not recognized (or has

been cleared but a motion button is still

pressed)

30 – Platform location unknown

31 – Platform location transition state;

attempting to locate position

35 – Two or more motion buttons are being

pressed

36 – The retention belt cannot be buckled

while trying to fold or unfold

37 – Motion button being pressed is not a

valid motion

50 – Outer barrier is not up above inboard

barrier locked position

51 – Threshold is occupied when platform is

1

" or more below floor level

52 – Inner rollstop is not up and locked below

inner rollstop locked position

53 – Inner rollstop occupied sensor is not

activated between floor and inner rollstop

up position

54 – Outer barrier is occupied before it is up

55 – Outer barrier is not latched when above

the inner rollstop locked position

(Millennium only)

56 – Outer barrier is not up and latched and

bridge switch did not deactivate

32410

32201

32201

PLATFORM FOLD

RELIEF VA LVE

ADJUSTMENT

Platform Fold

Relief Valve:

See service

manual for

adjustment

procedure.

30787

Improper handling

and/or servicing

procedures may

result in

electrostatic

discharge (ESD)!

ESD may result in

electronic module

damage.

C

A

U T I O N

30787

25580

Decals

31132

W

A

RNIN G

31132

W

A

RNING

Adjust switch as specified

in installation/service

manual.

HYDRAULIC

PRESSURE SWITCH

ADJUSTMENT

Improper hydraulic

pressure switch

adjustment may result

in serious bodily injury

and/or property damage.

27154

27154

Rotate to floor before

operating lift.

32845

C

A

UTION

32845

Page 42

Page 40

Decals and Antiskid

29051

MANUAL

OPERATION

Turn wing

1/4 turn for

hand pump

access.

29051

Lock

Unlock

1" Wide Yellow Boundary Tape

30236R

(order by the inch as needed)

W

A

RNING

Contact The Braun

Corporation before

adjusting hydraulic

pressure relief

valve. Failure to

do so may result

in serious bodily

injury and/or

property damage.

22249

25652

18229

25652

MADE IN

AMERICA

Quality inspected

By:

18229

22249

Decals

Inspect your lift for any missing or worn antiskid. Order

as needed. Note: Clean

surfaces with isopropyl alcohol before decal or antiskid

application. Use a clean

cloth or paper towels. Do

not use oily shop rags. Wipe

surface free of residue with

dry portion of cleaning cloth.

Replace missing or

worn antiskid.

Failure to do so may

result in serious

bodily injury and/or

property damage.

W

A

RNING

2" x 12" Black #24172-BK

2" x 12" Yellow #24172-YL

3" x 8" Black #31188-BK

3" x 12" Black #24173-BK

3" x 12" Yellow #24173-YL

6" x 12" Black #24174-BK

6" x 12" Yellow #24174-YL

Size Color Part No.

Available Antiskid

Page 43

Page 41

Maintenance and Lubrication

Proper maintenance is necessary to ensure

safe, troublefree operation. Inspecting the lift for

any wear, damage or other abnormal conditions

should be a part of all transit agencies's daily

service program. Simple inspections can detect

potential problems.

The maintenance and lubrication procedures

VSHFLÀHGLQWKHIROORZLQJVFKHGXOHmust be per-

formed by a Braun authorized service representative at the scheduled intervals according to the

number of cycles.

NL Series lifts are equipped with hardened pins

and self-lubricating bushings to decrease wear,

provide smooth operation and extend the service life of the lift.

When servicing the lift at the recommended

intervals, inspection and lubrication procedures

VSHFLÀHGLQWKHSUHYLRXVVHFWLRQVVKRXOGEH

repeated. Clean the components and the surrounding area before applying lubricants.

LPS2 General

Purpose Penetrating

Oil is recommended

where Light Oil is

called out. Use of improper lubricants can

attract dirt or other

contaminants which

could result in wear or

damage to the components. Platform

components exposed

to contaminants when

lowered to the ground

may require extra

attention.

Maintenance and

lubrication procedures must be per-

IRUPHGDVVSHFLÀHG

by an authorized

service technician.

Failure to do so may

result in serious

bodily injury and/or

property damage.

W

A

RNING

Lift components requiring grease are lubricated

during assembly procedures. When these components are replaced, grease must be applied during

LQVWDOODWLRQSURFHGXUHV6SHFLÀHGOXEULFDQWVDUH

available from The Braun Corporation (part numbers provided on page 42).

Page 44

Page 42

Maintenance and Lubrication

All listed inspection, lubrication and maintenance

procedures should be repeated at “750 cycle”

intervals following the scheduled “4500 Cycles”

maintenance. These intervals are a general

guideline for scheduling maintenance procedures

and will vary according to lift use and conditions.

Lifts exposed to severe conditions (weather,

environment, contamination, heavy usage, etc.)

may require inspection and maintenance proce-

GXUHVWREHSHUIRUPHGPRUHRIWHQWKDQVSHFLÀHG

Maintenance Indicator: The Lift Ready green

LED mounted on top of the pump cover will begin

to blink after every 750 cycles. The blinking LED

will not affect the functions of the lift, but is a

reminder to complete necessary maintenance and

lubrication. Once the lift has been serviced, fully

stow the lift. Once stowed, press the UP button

on the hand pendant and the Floor Level Set button on the back side of the pump cover until the

Lift Ready green LED stops blinking.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly performed, or if there is any sign of wear, damage or

improper operation. Contact your sales representative or call The Braun Corporation at 1-800-THE

LIFT

®

. One of our national Product Support representatives will direct you to an authorized service

technician who will inspect your lift.

6SHFLÀHGUHFRPPHQGHG $YDLODEOH %UDXQ

Lubricant Type Lubricant Amount Part No.

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

LO - Light Oil

DE - Door-Ease

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

LG - Light Grease

15807

15806

15805

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Page 45

Page 43

Lubrication

Diagram

UNFO

L

D

F

O

L

D

DO

W

N

UP

3

2

8

1

9

3

2

8

2

0

Handrail Pivot Pins (2)

LO

Parallel Arm Pivot Pins (8)

LO

Lift-Tite Latches

(Tower Pivot Points - 2) LO

Lift-Tite Latch Dampening Spring

(2 springs - 4 Points) LO

Parallel Arm

Pivot Pins (8)

LO

Inner Roll Stop (IB)

Pivot Points

LO

Outer Barrier Hinge

Pivot Points (2)

LO

Outer Barrier Latch Lever

LO

Outer Barrier Latch LO

Platform Pivot Pin (2 Points)

LO

Platform Fold Axles (2)

LO

Rotating Pivot Slide

Arm UHMW Slide (4)

DE

Rotating Pivot

Slide Arm Pivot Pins

LO

Lift-Tite Latch Roller Assemblies (2)

LO

Page 46

Page 44

Maintenance and Lubrication Schedule

750

Cycles

Outer barrier hinge pivot points (2)

Outer barrier latch (pivot/slide points)

Outer barrier latch lever pivot points

Lift-Tite

™

latches (tower pivot points - 2)

Lift-Tite

™

latch gas (dampening) spring pivot

points (2 springs - 4 points)

Inspect Lift-Tite

™

latches and gas springs for wear

or damage (bent, deformed or misaligned), positive securement (external snap rings) and proper

operation

Inspect outer barrier for proper operation

Inspect outer barrier latch for proper operation,

positive securement, and detached or missing

spring

Inspect lift for wear, damage or any abnormal

condition

Inspect lift for rattles

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Resecure, replace defective parts or otherwise

correct as needed. Note: Apply Light Grease to

Lift-Tite

™

latch tower pivot point if replacing latch.

Correct or replace defective parts.

Correct or replace defective parts and/or relubricate. See Lubrication Diagram

Correct as needed.

Correct as needed.

Page 47

Page 45

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct, replace defective parts and/or relubricate.

Resecure, replace or correct as needed. See

Platform Angle Instructions and Microswitch

Adjustment Instructions.

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

Platform pivot pin bearings (2)

Platform fold axles (2)

Inner roll stop lever bearings (2)

Inner roll stop lever slot (2)

Rotating pivot slide arm pivot pins (2)

Parallel arm pivot bearings (16)

Handrail pivot pin bearings (4)

Hydraulic cylinder bushings (8)

Inspect Lift-Tite

™

latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inner roll stop for:

• Wear or damage

• Proper operation. Roll stop should just rest on

top surface of the base plate.

• Positive securement (both ends)

1500

Cycles

continued

Page 48

Page 46

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

Inspect handrail components for wear or damage,

and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Inspect external snap rings:

• Handrail pivot pins (2 per pin)

• Platform slide/rotate pivot pins (2 per pin)

• Platform fold axles (1 per axle)

• Inner roll stop lever bracket pins

(1 per pin)

• Lift-Tite

™

latch gas (dampening) spring (2 per

spring)

Inspect platform fold axles and bearings for wear

or damage and positive securement

Replace defective parts.

Resecure, replace or adjust as needed. See

Microswitch Adjustment Instructions.

Realign towers and vertical arms. Lubricate or

correct as needed.

Resecure or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Oil.

1500

Cycles

continued

Page 49

Page 47

Maintenance and Lubrication Schedule

Resecure, replace or correct as needed

Use Braun 32840-QT (Exxon

®

Univis HVI 26)

K\GUDXOLFÁXLGdo not mix with Dextron III or other

K\GUDXOLFÁXLGV&KHFNÁXLGOHYHOZLWKplatform

lowered fully and roll stop unfolded fully. Fill

WRZLWKLQßRIWKHERWWRPRIWKHßÀOOWXEH

(neck).

Tighten, repair or replace if needed.

Tighten, repair or replace if needed.

Inspect cotter pins on platform pivot pin (2)

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination.

,QVSHFWWKHK\GUDXOLFV\VWHPF\OLQGHUKRVHVÀWWLQJVVHDOVHWFIRUOHDNVLIÁXLGOHYHOLVORZ

,QVSHFWF\OLQGHUVÀWWLQJVDQGK\GUDXOLFFRQQHFWLRQV

for wear, damage or leaks

Inspect outer barrier cylinder hose assembly (hose,

fasteners, connections, etc.) for wear, damage or

leakage (if equipped)

4500

Cycles

Perform all procedures listed in previous sections also

1500

Cycles

Resecure, replace or correct as needed.Remove pump module cover and inspect:

+\GUDXOLFKRVHVÀWWLQJVDQGFRQQHFWLRQVIRU

wear or leaks

• Harness cables, wires, terminals and connec-

tions for securement or damage

• Control board, circuit breaker, power switch and

lights for securement or damage

continued

Page 50

Page 48

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

Replace if needed.

Tighten or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Grease during reassembly procedures.

Replace if needed.

Tighten, replace or correct as needed

Apply Door-Ease or replace if needed. See Lubrication Diagram.

Resecure or replace if needed.

Resecure, repair or replace if needed.

Inspect parallel arms, bushings and pivot pins for

visible wear or damage

Inspect parallel arm pivot pin mounting bolts (8)

Inspect platform pivot pin, bushings and vertical

arms for wear, damage and positive securement

Inspect upper/lower fold arms, rotating pivot slide

arms, slide support arms and associated pivot pins,

bushings, and bearings for visible wear or damage

Inspect gas springs (cylinders) for wear or damage,

proper operation and positive securement

Inspect rotating pivot slide arm UHMW slide bearings (buttons)

Inspect vertical arm plastic covers

Inspect power cable

4500

Cycles

continued

Page 51

Page 49

Maintenance and Lubrication Schedule

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing. See Decals and

Antiskid section on pages 38-40.

Mounting

Decals and Antiskid

4500

Cycles

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Consecutive

750 Cycle

Intervals

Page 52

"Providing Access to the World"

®

Over 300 Braun

Dealers Worldwide

Page 53

Operator's Manual

The Braun Corporation of Winamac, Indiana, warrants its wheelchair lift against defects