Page 1

Operator's Manual for:

Private Use Wheelchair Lifts

W

A

Operator's Manual

RNING

“DOT — Private Use Lift” verifies that this platform lift meets only

the “private use lift” requirements of FMVSS No. 403. This lift may

be installed on all vehicles appropriate for the size and weight of

the lift, except for buses, school buses, and multi-purpose

passenger vehicles other than motor homes with a gross vehicle

weight rating (GVWR) that exceeds 4,536 kg (10,000 lb).

"Providing Access to the World"

Operator's Manual

32244 Rev. B

January 2008

International Corporate Hdqrs: P.O. Box 310 Winamac, IN 46996 USA

1-800-THE LIFT

Patent #5,261,779

Patent #5,261,779

Patent #6,065,924

Patent #6,065,924

Patent #6,238,169

Patent #6,238,169

Patent #6,464,447

Patent #6,464,447

DOT — Private Use Lift

DOT — Private Use Lift

®

(574) 946-6153 FAX: (574) 946-4670

Patent #6,599,079

Patent #6,599,079

Patent #6,692,217

Patent #6,692,217

Patent #6,739,824

Patent #6,739,824

Patents Pending

Patents Pending

Oper

ator's

Man

ual

Read manual

®

®

lift. Failure to do

before operating

Braun NL955 Series

Braun NL955 Series

so may result in

serious bodily

injury and/or

property damage.

Keep manual in

lift storage pouch.

Page 2

Congratulations

We at The Braun Corporation wish to express our fullest appreciation

on your new purchase. With you in mind, our skilled craftsmen have designed

and assembled the finest lift available.

This manual includes safety precautions, lift operating instructions, manual operating instructions, and instructions for maintenance and lubrication

procedures.

Your lift is built for dependability, and will bring you years of pleasure

and independence, as long as maintenance is performed regularly and the lift

is operated by an instructed person.

Sincerely,

THE BRAUN CORPORATION

Ralph W. Braun

Chief Executive Officer

Page 3

Contents

Warranty and Registration Instructions ........... 2, 3

Lift Terminology

Lift Terminology Illustration ........................................ 4

Introduction ................................................................ 5

Direction .................................................................... 5

Lift Components .................................................... 6, 7

Vehicle and Lift Interlocks ......................................... 7

Lift Actions and Functions .......................................... 8

Lift Operation Safety

Safety Symbols ......................................................... 9

Lift Operation Safety Precautions ...................... 10-13

Operation Notes and Details

Introduction .............................................................. 14

General Safety .................................................. 14, 15

Control Switches ................................................ 15-17

Lift Features

Lift-Tite™ Latches ........................................ 18, 19

Inboard Locator and Bridge Plate ............... 20, 21

Automatic Floor Level Switching ....................... 21

Outer Barrier and Side Entry ....................... 21-23

Outer Barrier Latch .......................................... 23

Outer Barrier and Latch Operation ................... 24

Lift Passengers

Passenger Orientation (Boarding Direction) ..... 25

Vehicle (Floor Level) Loading and

Unloading .......................................................... 25

Wheelchair-Equipped Occupant Seat Belts ........... 26

Operation Procedure Review ........................... 26, 27

Preventive Maintenance ................................... 27, 28

Lift Operating Instructions ............................. 29-35

NHTSA Operations Checklist .............................. 36

Manual Operating Instructions ....................... 37-39

Decals and Antiskid ........................................ 40-42

Maintenance and Lubrication ......................... 43-51

Page 1

Page 4

Warranty and Registration Instructions

Immediately upon receiving your

lift, examine the unit for any damage. Notify the carrier at once

with any claims.

Two warranty/registration cards

(shown below) are located in

the lift-mounted owner’s manual

storage pouch. The sales representative must process one of the

cards. The consumer must fill out

the other card and mail it to The

Series No. Pump Code

Serial No.Model No. Cylinder Code

OWNER'S WARRANTY REGISTRATION

NL955E3143-03-00001-56-14CF

PURCHASED FROM

NAME

ADDRESS

CITY

TELEPHONE

REGISTRATION CARDS MUST BE RETURNED TO THE BRAUN CORPORATION.

OWNER

STATE ZIP

TO VALIDATE WARRANTY

DATE INSTALLED

Braun Corporation. The warranty

is provided on the back cover of

this manual. The warranty cards

must be processed to activate

the warranty.

Two Braun Serial No./Series No.

Identification tags are posted on

the lift. One I.D. tag (shown below) is posted on the pump side

vertical arm. A second I.D. tag

is located on the opposite pump

Sample

Warranty/Registration

Card

Serial No./Series No.

side tower. Both I.D. tags provide

the product identification informa-

tion appearing on the Warranty/

Registration card. Record the

information in the space provided

on the next page.

This information must be pro-

vided when filing a warranty

claim or ordering parts.

The Braun Corporation

1-800-THE-LIFT

BRAUNLIFT.COM

DOT Private Use Lift MODEL#

NL955SE3143

Max. Lifting Capacity - 750Lbs.

SERIAL NUMBER

03-00001

PUMP CODE CYLINDER

56

MFG DATE

07/08/2005

Sample

Identification Tag

e5*72/245*95/54*0110*00

U.S. PATENT 5261779-5806632-6692217

TM

14CF

TM

Page 2

Page 5

Warranty and Registration Instructions

Model No.

Series No.

Serial No.

Pump Code

Cylinder Code

Date of Manufacture

Note: This information must

be provided when filing a

warranty claim or ordering

parts. Keep for future use.

Page 3

Page 6

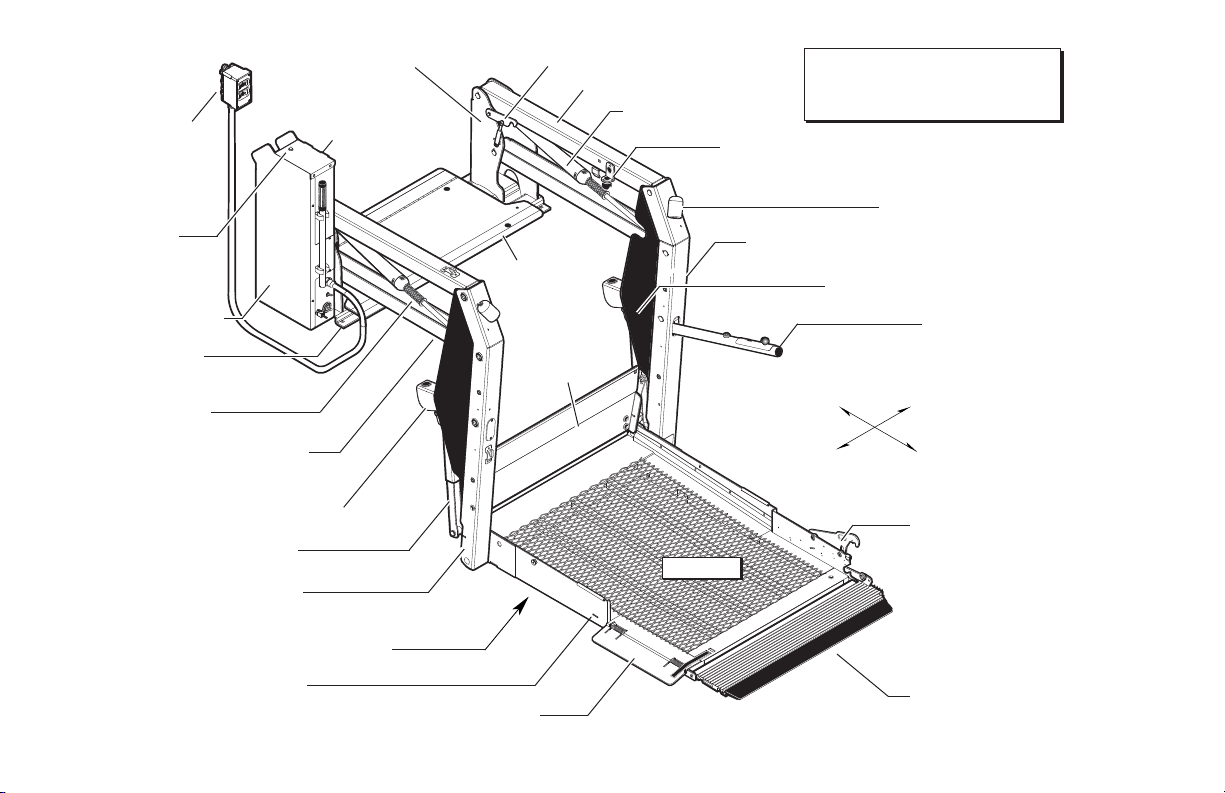

Hand-Held

Pendant

Control

Towers (2)

Audible

Threshold

Warning

Lift-Tite™ Latches (2)

Top Parallel Arms (2)

Main Cylinders (2)

Lift Terminology

Illustration

Adjustable Quiet-Ride Stow Blocks (2)

Power

Indicator

Light

Pump Module

Base Plate

Unfold Assist Compression

Springs (2)

Bottom Parallel Arms (2)

Rotating Pivot Slide Arms (2)

Platform Pivot Arms (2)

Pump Side Vertical Arm

Outer Barrier Cylinder

(not visible -underside of platform)

Platform Side Plates (2)

Page 4

Threshold

Warning

Plate

Side Entry

Inboard

Locator

Platform

Platform Lights

Opposite Pump Side Vertical Arm

Vertical Arm Covers (4)

Switch Arm

Inboard

Left

Right

Outboard

Outer Barrier

Latch

Outer Barrier

Page 7

Lift Terminology

Introduction:

Braun NL955 Millennium Series

lifts comply fully with the National

Highway Traffic Safety Adminis-

tration (NHTSA) specifications.

The Braun NL955 is consumer

oriented (designed to allow operation by the wheelchair passenger). NL955 lift models provide

fully automatic operation of all

lift functions as well as optional

automatic door operators (if so

equipped).

Lift models vary per platform size

(lift model numbers indicate lift

dimensions). A standard NL955

lift model is depicted in the Lift

Terminology Illustration. Refer to

the Lift Terminology Illustration

for identification of lift compo-

nents.

Lift operation procedures are

identical for all NL955 Series

lift models. The operating

instructions contained in this

manual and appearing on liftposted operating instructions

decals address the lift control

switches and the corresponding lift functions. Instructions

are provided for manual operation of the lift in event of power

or equipment failure.

Terminology: Become familiar

with the terminology that will be

used throughout this manual.

Become familiar with the identifi-

cation of lift components and their

functions. Contact your lift sales

representative or call The Braun

Corporation at 1-800-THE LIFT

if any of this information is not

fully understood.

Direction: The terms “left,”

“right,” “inboard,” and “outboard”

will be used throughout this

manual to indicate direction (as

viewed from outside the vehicle

looking directly at the lift). Refer

to the Lift Terminology Illustration

for clarification of direction terms.

®

Page 5

Page 8

Lift Terminology

Lift Components

Refer to the Lift Terminology Illustration on page 4.

Pump Module: The lift-mounted

pump module consists of the

hydraulic pump, the manual

hand pump, the electronic

control board and electrical

components that power the lift

electric/hydraulic systems. The

pump module is equipped with

three function-labeled control

switches.

Hand-held Pendant Control:

The hand-held attendant's pendant control is connected to the

pump module. The hand-held

pendant is equipped with four

push button switches, (UNFOLD,

FOLD, DOWN, and UP). The

momentary switches activate the

automatic lift functions. The lift

function labels illuminate to identify the function(s).

Lift Frame: The lift frame consists of the base plate, threshold

warning plate, towers, parallel

arms, vertical arms, platform

pivot arms and switch arm. Two

main hydraulic cylinders are

housed in the parallel arms.

The electrical/hydraulic powered

lift frame components mechanically unfold, lower, raise and fold

the lift platform assembly.

Switch Arm: An additional

UP/DOWN switch is provided on

the switch arm.

Platform Assembly: The platform assembly consists of the

steel tubing frame with grating

surface upon which the wheelchair is positioned, the outer

barrier, outer barrier latch, the

inboard locator, side entry and the

hydraulic cylinder assembly that

powers the outer barrier.

Lift-Tite

™

Latches: The spring-

loaded latches prevent the

platform from unfolding from the

stowed position in the event of

platform drift. Further details

regarding Lift-Tite™ latches are

provided on pages 18 and 19.

Outer Barrier: The cylinderpowered automatic outer barrier

provides a ramp for wheelchair

loading and unloading at ground

Page 6

Page 9

Lift Terminology

level. The NL955 platform is

equipped with a side entry that

allows boarding and exiting in

tight parking situations. The

outer barrier and side entry function together in unison.

Outer Barrier Latch: The

spring-loaded latch locks the

outer barrier in the vertical position when the platform raises

above ground level.

Inboard Locator: NL955 Series

lift models are equipped with an

automatic inboard locator that

also serves as the bridge plate.

The bridge plate bridges the gap

between the lift platform and the

vehicle floor. The inboard loca-

tor/bridge plate automatically rotates from the horizontal position

to the vertical position as the

lift lowers and raises. Further

details regarding the automatic

mechanical inboard locator are

provided on pages 18 and 19.

Vehicle and Lift Interlocks

Braun Corporation NL955

Series lifts comply fully with all

NHTSA vehicle and lift interlock

specifications. Vehicle move-

ment is prohibited unless the lift

door is closed, ensuring the lift

is stowed. The lift will not function unless the vehicle is parked

and secured.

The NL955 features an audible

threshold warning system that

will activate if the threshold area

is occupied when the platform

is one inch or more below floor

level.

The inboard locator and outer

barrier sense weight to prohibit

lift operation. The lift will not

function if the inboard locator or

the outer barrier are occupied.

The lift platform cannot be folded

(stowed) if occupied

Page 7

Page 10

Lift Terminology

Lift Actions and Functions

DEPLOY (A-C)

A. UNFOLD (Out) - Platform

Unfold: Unfold is the action

of the platform rotating out and

down from the fully-stowed

(vertical) position to floor level

(horizontal) position when the

UNFOLD switch is pressed.

B. DOWN - Platform Lower:

Down is the action of the platform

lowering from floor level position

to fully-lowered (ground level)

position when the DOWN switch

is pressed.

C. DOWN - Outer Barrier

Unfold (Deploy) - When the

platform reaches the fully-low-

ered (ground) position and the

DOWN switch is continued to be

pressed, the outer barrier rotates

downward from vertical position

to ramp position.

STOW (D-F)

D. UP - Outer Barrier Fold

(Raise): When the lift is fully

lowered and the outer barrier is

in the ramp position, pressing

the UP switch first rotates the

outer barrier upward from ramp

position to vertical position.

E. UP - Platform Raise: Up is

the action of the platform raising

from ground level to floor level

(fully-raised) position when the

UP switch is pressed.

F. FOLD (In) - Platform Fold:

Fold is the action of the platform

rotating up and in from the floor

level (horizontal) position to fullystowed (vertical) position when

the FOLD switch is pressed.

Stowed Position: The lift is

stowed when the lift platform has

been fully raised and folded fully

(vertical position).

Floor Level: Floor level is the

position (height) the platform assembly reaches in order for the

wheelchair passenger to enter

and exit the vehicle (fully raised).

The platform automatically stops

at floor level when unfolding from

the stowed position and when

raising from ground level.

Page 8

Page 11

Safety Symbols

W

A

RNING

CAUTION

SAFETY FIRST! Know That ...

Lift Operation Safety

All information contained

A

in this manual and

supplements (if included), is provided for your safety. Familiarity

with proper operation instructions

as well as proper maintenance

procedures are necessary to ensure safe, troublefree operation.

Safety precautions are provided

to identify potentially hazardous

situations and provide instruction

on how to avoid them.

Note: Additional information provided to help clarify or detail a specific subject.

D

These symbols will appear throughout this manual as well as on the labels posted on your lift. Recognize

the seriousness of this information.

B

This symbol indicates

important safety information regarding a

potentially hazardous

situation that could

result in serious

bodily injury and/or

property damage.

C

This symbol indicates important information regarding

how to avoid a hazardous situation that

could result in minor

personal injury or

property damage.

Page 9

Page 12

Lift Operation Safety Precautions

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

If the lift operating

instructions, manual

operating instructions

and/or lift operation

safety precautions are

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Inspect lift before operation. Do not operate lift if you suspect lift damage, wear or any

abnormal condition.

Keep operator and bystanders clear of area in which the lift operates.

Lift Operation Safety

Read manual and supplement(s) before operating lift. Read

and become familiar with all safety precautions, operation

notes and details, operating instructions and manual operating instructions before operating the lift. Note: Wheelchair

passengers and all transit agency personnel (drivers and

wheelchair lift attendants) must read and become familiar

with the contents of this manual and supplement(s) before

operation.

Load and unload on level surface only.

Engage vehicle parking brake before operating lift.

Provide adequate clearance outside the vehicle to accommodate the lift before opening lift door(s) or operating lift.

Page 10

Page 13

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Lift Operation Safety

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Whenever a wheelchair passenger (or standee) is on the platform, the:

• Passenger must face outward.

• Wheelchair brakes must be locked.

• Inboard locator and outer barrier must be up (vertical).

• Outer barrier latch must be fully engaged.

Load and unload clear of vehicular traffic.

Do not overload or abuse. The load rating applies to both the raising and lowering functions

- continuous lifting capacity is 750 lbs.

Discontinue lift use immediately if any lift or vehicle interlock does not operate properly.

Do not operate or board the lift if you or your lift operator are intoxicated.

Do not raise front wheelchair wheels (pull wheelie) when loading (boarding) the platform.

Open lift door(s) fully and secure before operating lift.

Position and secure (buckle, engage, fasten, etc.) the wheelchair-equipped occupant seat

belt (torso restraint) before loading onto the wheelchair lift platform.

Lift attendants must ensure that lift occupants keep hands, arms and all other body parts

within the lift occupant area and clear of moving parts.

Page 11

Page 14

Lift Operation Safety Precautions

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Lift Operation Safety

Platform must be positioned at floor level (bridge plate

height) when loading or unloading in and out of vehicle.

If the lift operating

instructions, manual

operating instructions

and/or lift operation

safety precautions are

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Accidental activation of control switch(es) may cause unintended operation(s).

Page 12

Do not use platform inboard locator or outer barrier as a barrier (brake). Stop and brake wheelchair when loading onto

the platform (manually stop and brake manual wheelchairs

— stop powered wheelchairs with the wheelchair controls).

Turn powered (electric) wheelchairs off when on lift platform.

Press the DOWN switch until the entire platform rests on

ground level (lowered fully) and the outer barrier is fully

unfolded (ramp position) before loading or unloading a passenger at ground level.

Outer barrier must be fully unfolded (ramp position) until

the entire wheelchair crosses the barrier when loading or

unloading at ground level.

Page 15

Lift Operation Safety

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

W

A

RNING

Maintenance and lubrication procedures must be performed as specified in this manual by

authorized (certified) service personnel.

Replace missing, worn or illegible decals.

Keep this operator’s manual in lift-mounted manual storage pouch when not in use.

Never modify (alter) a Braun Corporation lift.

Do not use accessory devices not authorized by The Braun Corporation.

Do not remove any guards or covers.

Keep clear of any hydraulic leak.

Failure to follow these safety precautions may result in serious bodily injury and/or property damage.

Page 13

Page 16

Operation Notes and Details

W

A

RNING

Read and become

familiar with all lift

operation safety

precautions, operation notes and details,

operating instructions

and manual operating instructions prior

to operating the lift.

If this information is

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

NL955 Series “Private Use” lift

models are designed to allow

operation by the wheelchair

passenger. NL955 Series lifts

are typically installed in vehicles

equipped with fully-automatic

door operators. The NL955

provides fully automatic operation of all lift functions as well as

optional automatic door operators (if so equipped).

Note: An attendant must

manually open and close lift

door(s) in applications where

power door operator(s) are not

provided.

It is the responsibility of

the lift operator (attendant

and/or wheelchair passenger)

to properly activate all power

(lift and door) functions. Read

and become familiar with all lift

operation safety precautions,

operation notes and details,

lift operating instructions and

manual operating instructions

before attempting lift operating

procedures.

General Safety: Before operating the lift, always engage the

vehicle transmission in Park “P”

and engage the vehicle parking

brake. Note: Lift and vehicle

interlocks prevent lift operation

until the vehicle is immobilized.

Lift operators (attendants),

wheelchair passengers and bystanders must keep clear of the

area in which the power doors

(if equipped), and the lift operates (clear of all moving parts).

The lift occupant (passenger)

Page 14

Page 17

Operation Notes and Details

must keep hands, arms and all

other body parts within the lift occupant area and clear of moving

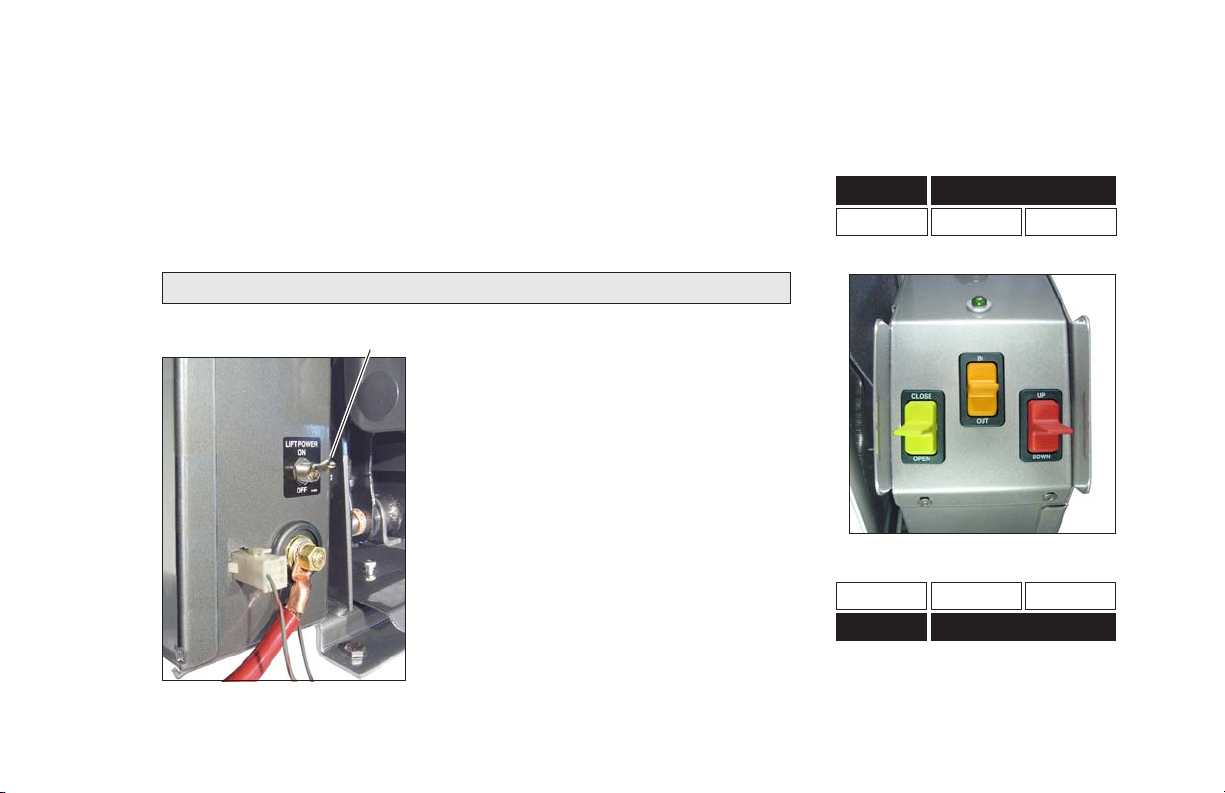

Control Switches

Lift Power Switch

parts. Follow all lift operation

and wheelchair passenger information detailed in this manual.

Lift Power ON/OFF Switch: This

switch must be in the ON position in

order to activate the lift controls. The

green Power Indicator Light mounted

on top of the pump module illuminates

to signal power to the lift.

Lift-mounted Control Switches:

The lift-mounted control switches activate the automatic lift functions and

optional door operators. The switches

are function labeled. Press the switches in the direction of the function label

to activate the intended lift function.

Press switches upward

for these functions:

Door(s) Platform

CLOSE FOLD

Yellow Orange Red

Yellow Orange Red

OPEN

Door(s) Platform

Press switches downward

UNFOLD

for these functions:

UP

DOWN

Page 15

Page 18

Control Switches (continued):

Operation Notes and Details

Hand-held Pendant Control: The hand-held

attendant's pendant control is equipped with four

push button switches, (UNFOLD, FOLD, DOWN,

and UP). The momentary switches activate the

automatic lift functions. Simply press the switch

labeled for the intended lift function.

When there is power

32525

FOLD

UP

to the lift, the lift function labels illuminate to

identify the function(s).

UNFOLD

DOWN

32526

Page 16

Switch Arm UP/DOWN Switch: A spring-loaded

horizontal-slide style switch is built in the switch

arm. The switch arm UP/DOWN switch activates

the platform, outer barrier and inboard locator

functions. Slide the switch knob out to the UP

position to raise the platform. Slide the knob in

to the DOWN position to lower the platform.

DOWN

UP

Page 19

Operation Notes and Details

W

A

RNING

Power Door Operator(s):

Optional power door operators

cannot be activated using the

hand-held pendant. Open and

close power doors using the

pump module OPEN/CLOSE

switch, optional remote control

or auxiliary 3rd Station control.

In the event the vehicle is not

Discontinue lift use

immediately if any

lift component does

not operate properly. Failure to do so

may result in serious

bodily injury and/or

property damage.

equipped with power door

operator(s), manually open and

close the door(s).

Auxiliary Control Switches:

A six-touch remote control

system, a third station control

and an outside control station

are available as options. All

auxiliary controls activate lift

functions and automatic door

operators.

Do not press lift-mounted

switches and auxiliary control

station switches at the same

time. Do not attempt to interface after-market control

systems.

Braun Corporation Aftermarket Control Systems

Policy:

The Braun Corporation

manufactures dedicated control systems for its products.

These control systems have

been designed and tested for

use in conjunction with specific Braun products. Braun

control systems are the only

control systems authorized

for use with Braun products.

Do not attempt to interface

aftermarket control systems

with Braun products. To do

so may result in serious

bodily injury and/or property damage.

Page 17

Page 20

Lift Features

W

A

RNING

Operation Notes and Details

Become familiar with all lift features and the proper operation

of the lift components before

attempting lift operation. Refer

to the Lift Terminology section

Discontinue lift use

immediately if any

lift component does

not operate properly. Failure to do so

may result in serious

bodily injury and/or

property damage.

Page 18

for identification of and desrciption

of lift components. Contact The

Braun Corporation immediately if

any of this information is not fully

understood. Call 1-800-THE LIFT®.

Engagement

Pin (Roller)

Engaged

Lift-Tite™

Lift-Tite™ Latches: NL955

Series lifts are equipped with LiftTite™ Latches. Lift-Tite™ Latches

prevent the platform from unfolding from the stowed position in

Latch

Latch

Page 21

Operation Notes and Details

the event of platform drift.

Due to the “all-hydraulic”

operation of the dual-cylinder

NL955, hydraulic fluid expansion, contraction or seepage

may occur. Any of these

conditions may result in platform drift (failure to hold the

platform in the folded or raised

position). Platform drift may

occur during lift shipment and/

or between extended periods

of non-lift use.

In the event that the platform

does not unfold when the UNFOLD switch is pressed, press

the FOLD switch momentarily

to disengage the Lift-Tite

™

latches (platform drift has

occurred). Then, press the

UNFOLD switch to unfold the

platform to floor level (stan-

dard operation). When manually

operating a lift equipped with

Lift-Tite™ latches, insert the pump

handle in the pump and stroke until the platform folds fully (stops).

Then, open the hand pump valve

(turn counterclockwise) to unfold

Latch

Engagement

Pin (Roller)

Disengaged

Lift-Tite™

the platform. Folding the platform fully first will ensure that the

Lift-Tite

™

latches will disengage

properly when the release valve

is opened. Manual Operating Instructions are provided on pages

37-39.

Latch

Page 19

Page 22

Operation Notes and Details

Lift Features (continued):

Inboard Locator and Bridge

Plate: NL955 Series lift models

are equipped with an automatic

inboard locator that also serves

as the bridge plate (inboard

locator photos below).

When the UNFOLD switch is

pressed and the platform unfolds

from stow position to floor level,

this mechanical locator/bridge

plate is automatically deployed to

the bridging (horizontal) position

to provide a bridge plate between

the platform and the lift base plate

(vehicle floor). The inboard edge

Fully-Deployed

(vertical)

Inboard

Locator

Inboard Locator

and Bridge Plate

The inboard locator/bridge

plate must overlap the base

plate a minimum 1/2".

Fully-Unfolded

(horizontal)

Inboard Locator

(bridging position)

of the bridge plate rests on the

threshold warning plate (base

plate).

The locator/bridge plate automatically folds (rotates) to the

vertical (roll stop) position when

the platform lowers to the ground

(DOWN switch is pressed). As

Page 20

Page 23

Operation Notes and Details

the UP switch is pressed and the

platform raises from ground level,

the inboard locator automatically

unfolds (rotates) to the horizontal (bridging) position when it

reaches vehicle floor level. The

bridge plate must overlap the lift

base plate a minimum 1/2".

When the FOLD switch is

pressed and the platform folds

from floor level to the stow (vertical) position, the bridge plate

automatically travels inboard to

the stowed position.

Interlock: The inboard locator

senses weight to prohibit lift operation if occupied.

Automatic Floor Level Switching: When the platform unfolds

from the stowed position, the platform stops automatically at floor

level when fully unfolded. When

raising the platform from ground

level, the platform automatically

stops at floor level when raised

fully.

Although the NL955 features

automatic floor level switching,

the lift operator (wheelchair passenger or attendant), must view

the platform to be certain the

platform is properly positioned at

vehicle floor level and the bridge

plate is properly positioned when

a passenger is entering or exiting

the vehicle. If the lift platform

does not automatically stop at

floor level as outlined,

discontinue lift operation immediately.

Outer Barrier and Side Entry:

The NL955 platform is equipped

with an outer barrier and a side

entry. See photos A, B and

C. The cylinder-powered outer

barrier and side entry provide a

Belt-operated Side Entry

A

Outer Barrier

Page 21

Page 24

Operation Notes and Details

Lift Features (continued)

ramp for wheelchair loading and

unloading at ground level. The

side entry is useful in tight parking

situations by reducing wheelchair

caster “turn-out” when boarding

and exiting the platform. The

barrier and side entry function in

unison. Discontinue lift oper-

Fully-Unfolded (Ramp position)

Outer Barrier and Side Entry

B

ation immediately if the outer

barrier or side entry do not

operate properly.

Outer Barrier: When the plat-

form lowers fully to ground level,

the roll stop cylinder compression spring automatically unfolds

(rotates) the outer barrier to the

ramp position (fully unfolded).

Disengaged

Barrier Latch

Note: The platform must raise

approximately three inches

before the latch engages fully.

Fully-Folded

(Up-vertical)

Outer Barrier

and

Side Entry

Although the outer barrier is liftpowered, activation of the barrier

is controlled by the lift operator.

Activating either DOWN switch

unfolds the barrier. The barrier is

cylinder-powered to automatically

fold (rotate) to the vertical position

when the UP switch is activated

(barrier raises before platform

raises).

Fully-Engaged Barrier Latch

C

3”

Latch Foot

Page 22

Page 25

Operation Notes and Details

W

A

RNING

Interlock: The outer barrier

senses weight to prohibit lift

operation if occupied.

Side Entry: When the platform

lowers fully to ground level, the

spring-loaded side entry unfolds

(rotates) to the ramp position

simultaneously with the outer

Discontinue lift use

immediately if any lift

component does not

operate properly.

Failure to do so may

result in serious

bodily injury and/or

property damage.

barrier (when DOWN switch is

activated). See photos A and B.

The belt and chain driven side

entry is powered by the barrier

cylinder to automatically fold (rotate) to the vertical position when

the UP switch is activated.

Outer Barrier Latch: A springloaded latch engages the outer

barrier when the barrier rotates

upward from ramp position to

the vertical position (UP switch

is activated to raise the platform

above ground level).

Note: The platform must raise

approximately three inches be-

fore the latch engages fully (see

photo C on page 22).

The latch disengages the barrier

when the platform lowers fully

(reaches ground level) and the

latch foot contacts the ground

(latch raises above the barrier).

The lift operator or attendant must

be certain the entire platform

reaches and rests safely on the

ground.

Page 23

Page 26

Operation Notes and Details

Lift Features (continued):

Interlock: Lift platform move-

ment will be interrupted unless

the barrier is raised and the

outer barrier latch is positively

engaged.

Outer Barrier and Latch Operation: The lift operator must

activate the DOWN switch to

lower the platform fully to the

ground. The lift operator or attendant must view the platform

as it lowers to be certain the

entire platform reaches and

rests safely on the ground. Stop

activating the DOWN switch if

any portion of the platform is obstructed while descending or the

platform does not reach ground

level for any reason (contact

with an obstruction, mechanical

failure, exceeding the lift “floorto-ground” capacity, etc.).

After the platform is fully lowered

(platform reaches the ground),

the lift operator should continue

to press the DOWN switch to

unfold the outer barrier and the

side entry fully (ramp position).

Note: The outer barrier and side

entry must be fully unfolded

until the entire wheelchair has

crossed when loading or unloading at ground level. Discontin-

ue lift operation immediately

if the barrier or latch do not

operate properly.

Bridging: The NL955 incorpo-

rates a bridging feature. This

feature stops the down travel of

the platform if the outboard end

of the platform contacts a raised

surface (such as a curb), preventing the operator from lowering the

inboard end of the platform.

Switch Arm: The switch arm

automatically unfolds to the deployed position when the platform

unfolds and folds automatically

to the stowed position when the

platform folds. The passenger

may choose to grip the switch arm

when on the lift platform.

Note: The switch arm is equipped

with an UP/DOWN control switch

(page 16). Discontinue lift

operation immediately if the

switch arm does not operate

properly.

Page 24

Page 27

Operation Notes and Details

Lift Passengers

Do not attempt to load or unload a

passenger in a wheelchair or other

apparatus that does not fit on the

platform area. Do not exceed the

750 pound load capacity of the lift.

Passenger Orientation (Boarding Direction): The wheelchair

passenger must face outward

whenever on the platform.

The passenger must be positioned

in the center of the platform to

prevent side-to-side load imbalance. Other persons should not

ride on the platform with the

wheelchair passenger.

The wheelchair brakes must be

locked, the inboard locator and

the outer barrier must be in the

fully-up (vertical) position, and

the outer barrier latch must be

fully engaged whenever a

wheelchair passenger is on

the platform.

Do not use the outer barrier as

a brake. Stop and brake the

wheelchair when fully loaded

on the platform. Manually stop

and brake manual wheelchairs.

Stop powered wheelchairs with

the wheelchair controls. Turn

powered (electric) wheelchairs

off when on the platform.

Interlock: An audible threshold warning will activate if the

threshold area is occupied when

the platform is one inch or more

below the level. The threshold

warning plate identifies the

platform threshold area.

Vehicle (Floor Level) Loading

and Unloading: The platform

must be fully raised (at floor

level) and the bridge plate must

be properly positioned when

loading or unloading a passenger

in or out of the vehicle. Although

the NL955 features automatic

floor level switching, it is the

responsibility of the lift operator to ensure the platform and

the bridge plate are properly

positioned at floor level when

loading and unloading passengers.

If the outer barrier, inboard locator

or any other lift component does

not operate as outlined in this

manual, discontinue lift use im-

mediately and contact your sales

representative or call The Braun

®

Corporation at 1-800-THE LIFT

.

Page 25

Page 28

W

A

RNING

Operation Notes and Details

One of our national Product

Support representatives will

direct you to an authorized

service technician who will

inspect your lift.

Position and secure

(buckle, engage,

fasten, etc.) the

wheelchair-equipped

occupant seat belt

before loading onto

the wheelchair lift

platform. Failure to

do so may result in

serious bodily injury

and/or property damage.

Wheelchair-Equipped Occupant Seat Belts

The Braun Corporation recommends wheelchair passengers

position and buckle their wheelchair-equipped seat belt (torso

restraint) as specified by the

manufacture before loading onto

a wheelchair lift.

Different types of disabilities

require different types of wheelchairs and different types of

wheelchair-equipped occupant

restraint belt systems (torso restraint). It is the responsibility of

the wheelchair passenger to have

his or her wheelchair equipped

with an occupant restraint (seat

belt) under the direction of their

health care professional.

Wheelchair lift attendants should

be instructed on any special

needs and/or procedures required

for safe transport of wheelchair

passengers.

Operation Procedure Review

The Braun Corporation recommends that the wheelchair lift

user and/or attendant review the

safety precautions and operation procedures appearing in this

manual and on lift-posted decals

with your wheelchair lift sales

representative, before attempt-

ing lift operation. Any questions

or concerns can be answered by

your sales representative at that

time.

Page 26

Page 29

Operation Notes and Details

Using your own wheelchair,

operate the lift through all functions and enter and exit the

vehicle with the sales representative on hand to ensure the lift

is right for you as the end user

(applicable for your use based

on your physical abilities and the

physical characteristics of your

personal wheelchair). Become

familiar with the proper operation

of your lift before operating the

lift by yourself.

This lift operator’s manual must

be stored in the lift-mounted

manual storage pouch when

not in use.

Preventive Maintenance

Maintenance is necessary to

ensure safe and trouble-free lift

operation. Preventive lift maintenance consisting of careful

inspections of your lift system and

cleaning the lift should be a part

of your routine. Simple inspections can detect potential lift

operational problems.

Regular preventive maintenance

will reduce potential lift operation downtime and increase the

service life of the lift, as well as

enhancing safety.

During routine inspections, operate the lift through a minimum of

one complete cycle and note the

following:

• Do the automatic door(s) open

fully (if equipped)?

• Does the lift safely clear the

door(s) when unfolding and

folding?

• Do the lift control switches func-

tion properly?

• Do the automatic inboard loca-

tor and outer barrier operate

properly?

• Does the outer barrier latch

operate properly?

• Does the switch arm fuction

properly?

• Is the power source adequate or

weak?

Page 27

Page 30

W

A

RNING

Maintenance and

lubrication procedures

must be performed

by authorized service

personnel as specified

in this manual. Failure

to do so may result in

serious bodily injury

and/or property

damage.

Operation Notes and Details

Exposure to harsh weather elements, environment conditions,

or heavy usage, etc. may require

more frequent maintenance and

lubrication procedures.

Preventive maintenance visual

inspections do not take the place

of the procedures specified in

the Maintenance and Lubrication Schedule provided on pages

44-51 of this manual. Refer to

the Maintenance and Lubrication

section in this manual for further

details.

Page 28

Page 31

W

A

RNING

W

A

RNING

Read and become

familiar with all lift

operation safety

precautions, operation notes and details,

operating instructions

and manual operating instructions prior

to operating the lift.

If this information is

not fully understood,

contact The Braun

Corporation immediately. Failure to do so

may result in serious

bodily injury and/or

property damage.

Lift Operating Instructions

Before lift operation, park the vehicle

on a level surface, away from vehicular traffic. Place the vehicle transmis-

sion in “Park” and engage the parking

brake.

Photos appearing in the Lift Operating

Instructions depict lift functions being

activated by lift-mounted control

switches only. Lift-posted Warnings

and Lift Operating Instructions decal

31893 provides lift operating instructions. Replace any missing, worn or

illegible decals.

If your lift does not function as intended or an audible warning signal is

activated, review the NHTSA Operations Checklist on page 36. Follow

the Manual Operating Instructions on

pages 37-39 in the event of a power

or equipment failure.

Whenever a

passenger is on the

platform, the:

• Passenger must

face outward.

• Wheelchair brakes

must be locked.

• Inboard locator and

outer barrier must

be UP.

Failure to do so may

result in serious

bodily injury and/or

property damage.

Page 29

Page 32

Lift Operating Instructions

A B

To Open Door(s):

Automatic Door Operator(s):

Press yellow OPEN switch until

door(s) are fully open. Release

switch.

Manual Door(s):

Manually open door(s) fully and

secure.

To Unfold Platform (Out):

Press orange UNFOLD switch

until platform stops (unfolds fully

– reaches floor level). Release

switch.

DC

Page 30

Page 33

Lift Operating Instructions

E F

DOWN

G

To Unload Passenger:

1. Read notes below! Load passen-

ger onto platform facing outward

and lock wheelchair brakes.

Note: Outer barrier must be UP

and barrier latch must be fully

engaged before loading passen-

ger onto platform. Lower head to

clear vehicle door jamb header.

2. Press red DOWN switch until the

entire platform reaches ground

level (stops) and outer barrier

unfolds fully (see Photos H and I).

Release switch.

Switch Arm: Slide knob in to

DOWN position. See Photo G.

H

Page 31

Page 34

Lift Operating Instructions

I

K

To Unload Passenger: (continued)

3. Unlock wheelchair brakes and un-

load passenger from platform.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair has crossed the

roll stop. See Photos K and L.

J

L

Page 32

Page 35

Lift Operating Instructions

M N

UP

O

To Load Passenger:

1. Load passenger onto platform

facing outward and lock wheelchair brakes.

Note: Outer barrier must be fully

unfolded (ramp position) until the

entire wheelchair has crossed the

roll stop. See Photos K and L.

2. Press red UP switch until platform

stops (reaches floor level). Re-

lease switch. See Photo S.

Switch Arm: Slide knob out to UP

position.

Note: Outer barrier must be UP

and barrier latch must be fully

engaged before raising platform.

Platform will raise above ground

level approximately three inches

before latch engages fully.

approximately 3˝

P

Page 33

Page 36

Lift Operating Instructions

Q

S

To Load Passenger (continued):

3. Unlock wheelchair brakes and

load passenger from platform into

vehicle. Note: Lower head to

clear door jamb header.

To Fold Platform (In):

Press orange FOLD switch until

platform stops (fully folded).

Release switch.

R

T

Page 34

Page 37

Lift Operating Instructions

U

To Close Door(s):

Automatic Door Operator(s):

Press yellow CLOSE switch until

door(s) are fully closed. Release

switch.

Manual Door(s):

Manually close door(s) fully.

Page 35

Page 38

NHTSA Operations Checklist

W

A

RNING

The following operations have been verified upon installation.

This operational checklist can be used at any time to verify the

lift is fully functional.

Verified:

Vehicle movement is prevented unless the lift door is

closed, ensuring the lift is stowed.

Lift operation shall be prevented unless the vehicle is

stopped and vehicle movement is prevented.

The platform will not fold/stow if occupied.

The inboard locator will not raise if occupied.

The outer barrier will not raise if occupied.

A warning will activate if the threshold area is occupied

when the platform is at least one inch below floor level.

Lift platform movement shall be interrupted unless the outer

barrier is deployed.

Discontinue lift use

immediately if any lift

or vehicle interlock

does not operate

properly. Failure to

so so may result in

serious bodily injury

and/or property

damage.

Page 36

Page 39

Manual Operating Instructions

O

P

E

N

C

L

O

S

E

If you experience power or equipment failure, refer to the Manual

Operating Instructions to operate

the lift. Instructions and photos

are provided for all steps that

differ from standard lift operation

procedures. Manual Instructions

Decal 31894 (posted on pump

cover) provides manual operating

instructions also. Refer to the Lift

Release Valve

Operating Instructions for all normal

lift operation procedures (such as

loading and unloading passengers).

Follow all Lift Operation Safety

Precautions!

approximate

1/16” intervals

maximum

30 inch lbs

minimum

15 inch lbs

seats

(stops)

Valve Tightening

Specification:

Once valve seats

(stops), tighten 15

to 30 inch pounds

as shown.

Note: Close backup

pump release valve

securely before operating

A

electric pump.

Release Valve

Page 37

Page 40

Manual Operating Instructions

Refer to photos and illustration

of release valve on page 37.

Hand Pump Handle

B

To Unfold Platform (Out):

Using hand pump handle (Photo B):

1. Close hand pump valve (place

slotted end of pump handle onto

backup pump release valve and

turn clockwise).

2. Insert handle in pump and stroke

until platform folds fully (stops).

See Photo E on page 39.

3. Open hand pump valve (turn

counterclockwise) until platform

reaches floor level. Open 1/2

turn only.

4. Close hand pump valve (turn

clockwise).

Note: Valve must be tight, but do

not overtighten.

Down (To Lower):

Place slotted end of pump handle

onto back-up pump release valve

and turn counterclockwise (open

— 1/2 turn only) until the platform

reaches ground level and the outer

barrier unfolds.

Open

(Down)

Close

(Up/Stop)

C

Page 38

Page 41

Manual Operating Instructions

Refer to photos and illustration of

release valve on page 37.

Open

(Down)

Close

(Up/Stop)

D

Up (To Raise):

Using hand pump handle:

a. Place slotted end of pump

handle onto back-up pump release valve and turn clockwise

to close securely. See Photo D.

Note: Valve must be tight, but

do not overtighten.

b. Insert handle into back-up pump

and stroke until platform reaches

floor level (see Photo E).

To Fold Platform (In):

Insert handle into back-up pump

and stroke until platform stops

(folds fully). See Photo E.

Note: Close back-up pump

release valve securely before

operating electric pump. Store

pump handle in clamps shown

in Photo B on page 38.

E

Page 39

Page 42

W

A

RNING

Decals and Antiskid

Replace missing, worn

or illegible decals.

Failure to do so may

result in serious bodily

injury and/or property

damage.

Note: Clean surfaces as

detailed on page 42 before

posting decals.

25675

A

RNING

Lift installation and servicing prohibited by

anyone who has not been certified by The Braun

Corporation Sales and Service School. Certified

service technicians should call 1-800-THE LIFT

to receive applicable installation/service manual.

Failure to follow this policy may result in serious

bodily injury and/or property damage.

W

25675

The lift is only as safe as

the operator. Replace

any missing, worn or

illegible decals! Part

numbers are provided for

decals. Inspect your lift for

missing, worn or illegible

decals. Call 1-800-THE

®

LIFT

for replacements.

26701

31132

A

RNIN G

W

31132

UP

26701

DOWN

Decals

29823

29823

31893

21494

®

LIFT POWER

ON

OFF

21494

31894

MANUAL

OPERATION

Using hand pump handle:

TO UNFOLD PLATFORM:

1. Close hand pump valve

(turn clockwise).

2. Insert handle in pump

and stroke until platform

folds fully (stops).

3. Open hand pump valve

(turn counterclockwise)

until platform reaches

floor level. Open

1/2 turn only.

4. Close hand

pump

valve (turn

clockwise).

DOWN (TO LOWER):

Open hand pump valve (turn

counterclockwise). Open 1/2 turn only.

UP (TO RAISE):

1. Close hand pump valve

(turn clockwise).

2. Insert handle in pump

and stroke platform

reaches floor level.

TO FOLD PLATFORM:

Insert handle in

pump and stroke.

Note: Close valve

before operating

electric pump.

DOT — Private Use Lift

C

L

N

O

E

S

P

E

O

OPEN

CLOSE

31894

A

RNING

W

• Read manual before

operating lift.

• Load and unload on

level surface only.

• Engage vehicle

parking brake

before operating lift.

• Provide adequate

clearance outside

of vehicle to

accommodate lift.

• Do not operate lift

if you suspect lift

damage, wear or any

abnormal condition.

• Keep operator and

bystanders clear

of area in which

lift operates.

Whenever a

wheelchair

passenger is on

the platform, the:

• Passenger must

face outward

• Wheelchair brakes

must be locked

• Inboard locator

and outer barrier

must be up.

Failure to follow

these rules may

result in serious

bodily injury and/or

property damage.

LIFT

OPERATING

INSTRUCTIONS

TO OPEN DOOR(S):

Press OPEN switch

until door(s) are

fully open.

TO UNFOLD

PLATFORM:

Press UNFOLD

switch until

platform stops

(reaches floor level).

TO UNLOAD

PASSENGER:

1. Load passenger

onto platform

facing outward

and lock

wheelchair brakes.

2. Press DOWN

switch until

platform reaches

ground level and

outer barrier

unfolds fully.

3. Unlock wheelchair

brakes and unload

passenger from

platform.

TO LOAD

PASSENGER:

1. Load passenger

onto platform

facing outward

and lock

wheelchair brakes.

2. Press UP switch

until platform

stops (reaches

floor level) and

inboard locator

unfolds.

3. Unlock wheelchair

brakes and unload

passenger from

platform.

TO FOLD PLATFORM:

Press FOLD

switch until

platform stops.

TO CLOSE DOOR(S):

Press CLOSE

switch until door(s)

are fully closed.

DOT

Private Use Lift

31893

Page 40

Page 43

Decals and Antiskid

Decals

32410

"

LCD Lift Codes

" above

Listed below are codes that the lift controller

outputs during lift operation. The codes will be

displayed on an LCD screen located on the lift

control board inside the pump module.

Non-Flashing Numbers

01 – Platform stowed

02 – Platform unfolding

03 – Platform unfolding paused

04 – Platform at floor level

05 – Platform beginning to lower

06 – Platform lowering (threshold cannot be

occupied from this point down)

07 – Outer barrier moving to horizontal

position

08 – Platform at ground level

09 – Outer barrier moving to vertical position

10 – Platform raising

11 – Platform raising paused at floor

12 – Platform folding (limited pressure)

13 – Platform folding (full pressure)

14 – Timed fold (cinching lift tite) or (anti-rattle

state)

15 – Platform folding stopped

16 – Paused fold

17 – Platform between ground and 3

ground

18 – Platform above 3

19 – Outer barrier moving to horizontal

postion

20 – The doors are not fully opened (only

applicable when door operators are

installed)

21 – The doors are opening (only applicable

when door operators are installed)

22 – The doors are closing (only applicable

when door operators are installed)

28 – Illegal function/not defined

29 – Interlock fault not recognized (or has

been cleared but a motion button is still

pressed)

30 – Platform location unknown

31 – Platform location transition state;

attempting to locate position

35 – Two or more motion buttons are being

pressed

36 – The retention belt cannot be buckled

while trying to fold or unfold

37 – Motion button being pressed is not a

valid motion

50 – Outer barrier is not up above inboard

barrier locked position

51 – Threshold is occupied when platform is

1

" or more below floor level

52 – Inner rollstop is not up and locked below

inner rollstop locked position

53 – Inner rollstop occupied sensor is not

activated between floor and inner rollstop

up position

54 – Outer barrier is occupied before it is up

55 – Outer barrier is not latched when above

the inner rollstop locked position

(Millennium only)

56 – Outer barrier is not up and latched and

bridge switch did not deactivate

57 – Outer barrier is not up and latched and

ground detect switch did not deactivate

(Century and Vista only)

58 – Outer barrier is not up and latched and the

platform is 3

" above the ground

59 – Outer barrier is not up after pausing

platform travel

60 – The kickout gas springs are worn, replace

before using

75 – Low voltage detected; must turn off power

switch to reset LCD

77 – Vehicle secure interlock has not been

activated

90 – Position will be set if you keep holding the

button until it beeps

91 – Position is out of a predetermined

acceptable range of floor position

92 – Bridge switch is not made, needs adjusting

93 – Inner rollstop occupied switch is not made,

position needs to be moved or switch

should be adjusted

94 – Outer barrier is not made, fix and try again

95 – Outer barrier latch is not made (check for

jumper on Century and Vista lifts, check

latch on Millennium lifts)

99 – Controller program is not valid; replace

controller

Flashing Numbers

Flashing 65 – Unfold button is pressed

Flashing 66 – Fold button is pressed

Flashing 67 – Down button is pressed

Flashing 68 – Up button is pressed

Flashing 69 – Bridge switch is activated

Flashing 70 – Outer barrier latch switch is

activated

Flashing 71 – Ground detect switch is activated

Flashing 72 – Outer barrier up switch is activated

Flashing 73 – Inner rollstop up switch is activated

Flashing 74 – Inner rollstop occupied switch is

activated

Flashing 76 – Outboard barrier occupied switch

is activated

Flashing 78 – Threshold tape switch “A” is

activated

Flashing 79 – Threshold tape switch “B” is

activated

Flashing 80 – Position set button is pressed

Flashing 81 – Single function UP / FOLD /

CLOSE button is pressed

Flashing 82 – Single function OPEN / UNFOLD /

DOWN button is pressed

Flashing 87 – CLOSE button is pressed

Flashing 88 – OPEN button is pressed

Flashing 89 – Door full open switch is activated

(or jumper is installed on control

board)

25580

25580

30787

A

U T I O N

C

32201

PLATFORM FOLD

RELIEF VALVE

ADJUSTMENT

Improper handling

and/or servicing

Platform Fold

Relief Valve:

See service

manual for

adjustment

procedure.

32410

32201

procedures may

result in

electrostatic

discharge (ESD)!

ESD may result in

electronic module

damage.

30787

18229

MADE IN

AMERICA

Quality inspected

By:

25652

18229

25652

Page 41

Page 44

Inspect your lift for any

W

A

RNING

missing or worn antiskid.

Order as needed.

Decals and Antiskid

Antiskid

Replace missing

or worn antiskid.

Failure to do so may

result in serious

bodily injury and/or

property damage.

Page 42

Note: Clean surfaces

with isopropyl alcohol

before decal or antiskid

application. Use a clean

cloth or paper towels.

Do not use oily shop

rags. Wipe surface free

of residue with dry portion of cleaning cloth.

Available Antiskid

Size Color Part No.

2" x 12" Black #24172-BK

2" x 12" Yellow #24172-YL

3" x 8" Black #31188-BK

3" x 12" Black #24173-BK

3" x 12" Yellow #24173-YL

6" x 12" Black #24174-BK

6" x 12" Yellow #24174-YL

Page 45

Maintenance and Lubrication

W

A

RNING

Proper maintenance is necessary to ensure

safe, troublefree operation. Inspecting the lift for

any wear, damage or other abnormal conditions

should be a part of a regular service program.

Simple inspections can detect potential problems.

The maintenance and lubrication procedures

specified in the following schedule must be performed by a Braun authorized service representative at the scheduled intervals according to the

number of cycles.

NL Series lifts are equipped with hardened pins

and self-lubricating bushings to decrease wear,

provide smooth operation and extend the service life of the lift.

When servicing the lift at the recommended

intervals, inspection and lubrication procedures

specified in the previous sections should be

repeated. Clean the components and the surrounding area before applying lubricants.

LPS2 General Purpose Penetrating Oil is

recommended where

Light Oil is called out.

Use of improper lubricants can attract dirt

or other contaminants

which could result in

wear or damage to the

components. Platform

components exposed

to contaminants when

lowered to the ground

may require extra

attention.

Lift components requiring grease are lubricated

during assembly procedures. When these components are replaced, grease must be applied during

installation procedures. Specified lubricants are

available from The Braun Corporation (part numbers provided on page 44).

Maintenance and

lubrication procedures must be performed as specified

by an authorized

service technician.

Failure to do so may

result in serious

bodily injury and/or

property damage.

Page 43

Page 46

Maintenance and Lubrication

All listed inspection, lubrication and maintenance

procedures should be repeated at “750 cycle”

intervals following the scheduled “4500 Cycles”

maintenance. These intervals are a general

guideline for scheduling maintenance procedures

and will vary according to lift use and conditions.

Lifts exposed to severe conditions (weather,

environment, contamination, heavy usage, etc.)

may require inspection and maintenance procedures to be performed more often than specified.

Maintenance Indicator: The Lift Ready green

LED mounted on top of the pump cover will begin

to blink after every 750 cycles. The blinking LED

will not affect the functions of the lift, but is a

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

Specified (recommended) Available Braun

Lubricant Type Lubricant Amount Part No.

LO - Light Oil

DE - Door-Ease

LG - Light Grease

Light Penetrating Oil LPS2, General Purpose 11 oz.

(30 weight or equivalent) Penetrating Oil Aerosol Can

Stainless Stick Door-Ease 1.68 oz.

Style (tube) Stick (tube)

Light Grease Lubriplate 14 oz.

(Multipurpose) Can

reminder to complete necessary maintenance and

lubrication. Once the lift has been serviced, fully

stow the lift. Once stowed, press the UP button

on the hand pendant and the Floor Level Set button on the back side of the pump cover until the

Lift Ready green LED stops blinking.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly performed, or if there is any sign of wear, damage or

improper operation. Contact your sales representative or call The Braun Corporation at 1-800-THE

®

. One of our national Product Support repre-

LIFT

sentatives will direct you to an authorized service

technician who will inspect your lift.

15807

15806

15805

Page 44

Page 47

Parallel Arm

Pivot Pins (8)

LO

Lift-Tite Latches

(Tower Pivot Points - 2)

LO

Maintenance and Lubrication

Lift-Tite Latch Dampening

Spring (2 springs - 4 Points)

LO

Parallel Arm

Pivot Pins (8)

LO

Switch Arm Pivot Pins (2)

LO

Inboard Locator

Pivot Points

LO

Note: LPS2 General

Purpose Penetrating Oil

is available in eleven

ounce aerosol cans from

The Braun Corporation

(part number 15807).

Note: Clean lubrication

points before applying

lubricants.

UHMW Bearing (4)

DE

Rotating Pivot

Slide Arm Pivot Pins

LO

Platform Fold Axles (2)

LO

Platform Pivot Pin (2 Points)

LO

Lift-Tite Latch Roller Assemblies (2)

LO

Side Entry Hinge

Pivot Points (4)

LO

Outer Barrier Latch LO

Outer Barrier Hinge

Pivot Points (2)

LO

Outer Barrier

Latch Lever

LO

Page 45

Page 48

Maintenance and Lubrication Schedule

750

Cycles

Outer barrier hinge pivot points (2)

Outer barrier latch (pivot/slide points)

Outer barrier latch lever pivot points

Lift-Tite™ latches (tower pivot points - 2)

Lift-Tite™ latch gas (dampening) spring pivot

points (2 springs - 4 points)

™

Inspect Lift-Tite

or damage (bent, deformed or misaligned), positive securement (external snap rings) and proper

operation

Inspect outer barrier for proper operation

Inspect outer barrier latch for proper operation,

positive securement, and detached or missing

spring

Inspect lift for wear, damage or any abnormal

condition

Inspect lift for rattles

latches and gas springs for wear

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Resecure, replace defective parts or otherwise

correct as needed. Note: Apply Light Grease to

™

Lift-Tite

Correct or replace defective parts.

Correct or replace defective parts and/or relubricate. See Lubrication Diagram

Correct as needed.

Correct as needed.

latch tower pivot point if replacing latch.

Page 46

Page 49

Maintenance and Lubrication Schedule

Perform all procedures listed in previous section also

1500

Cycles

continued

Platform pivot pin bearings (2)

Platform fold axles (2)

Inboard locator lever bearings (2)

Inboard locator lever slot (2)

Rotating pivot slide arm pivot pins (2)

Parallel arm pivot bearings (16)

Switch arm pivot pin bearings (2)

Hydraulic cylinder bushings (8)

Inspect Lift-Tite™ latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inboard locator for:

• Wear or damage

• Proper operation. Inboard locator should just rest

on top surface of the base plate.

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct, replace defective parts and/or relubricate.

Resecure, replace or correct as needed. See

Platform Angle Instructions and Platform Floor

Level Adjustment Instructions.

Page 47

Page 50

Maintenance and Lubrication Schedule

continued

1500

Cycles

Perform all procedures listed in previous section also

Inspect switch arm components for wear or damage, and for proper operation.

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly.

Inspect external snap rings/e-clips:

• Rotating pivot slide arm pivot pins (2 per pin)

• Rotating pivot slide arm roller axles (2 per pin)

• Platform cylinder pivot pins (2 per pin)

• Platform fold axles (1 per axle)

• Inboard locator lever bracket pins (1 per pin)

• Lift-Tite

Inspect platform fold axles and bearings for wear

or damage and positive securement.

Inspect Side Entry for proper operation, positive

securement and wear or damage to nylon belt and

roller chain.

spring)

™

latch gas (dampening) spring (2 per

Replace defective parts.

Resecure, replace or adjust as needed.

Realign towers and vertical arms. Lubricate or

correct as needed.

Resecure or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Oil.

Correct or replace defective parts.

Page 48

Page 51

Maintenance and Lubrication Schedule

1500

Cycles

4500

Cycles

continued

Remove pump module cover and inspect:

• Hydraulic hoses, fittings and connections for

wear or leaks.

• Harness cables, wires, terminals and connec-

tions for securement or damage.

• Control board, circuit breaker, power switch and

lights for securement or damage.

Perform all procedures listed in previous sections also

Inspect cotter pins on platform pivot pin (2).

Hydraulic Fluid (Pump) - Check level. Note: Fluid

should be changed if there is visible contamination.

Inspect the hydraulic system (cylinder, hoses, fit-

tings, seals, etc.) for leaks if fluid level is low.

Inspect cylinders, fittings and hydraulic connections

for wear, damage or leaks.

Inspect outer barrier cylinder hose assembly (hose,

fasteners, connections, etc.) for wear, damage or

leakage.

Resecure, replace or correct as needed.

Resecure, replace or correct as needed.

Use Braun 32840-QT (Exxon® Univis HVI 26)

hydraulic fluid (do not mix with Dextron III or other

hydraulic fluids). Check fluid level with platform

lowered fully and roll stop unfolded fully. Fill

to within 1/2˝ of the bottom of the 1-1/2˝ fill tube

(neck).

Tighten, repair or replace if needed.

Tighten, repair or replace if needed.

Page 49

Page 52

Maintenance and Lubrication Schedule

continued

4500

Cycles

Perform all procedures listed in previous section also

Inspect parallel arms, bushings and pivot pins for

visible wear or damage.

Inspect parallel arm pivot pin mounting bolts (8).

Inspect platform pivot pin, bushings and vertical

arms for wear, damage and positive securement.

Inspect upper/lower fold arms, rotating pivot slide

arms, slide support arms and associated pivot pins,

bushings, and bearings for visible wear or damage.

Inspect gas springs (cylinders) for wear or damage,

proper operation and positive securement.

Inspect rotating pivot slide arm UHMW slide bearings (buttons).

Inspect vertical arm plastic covers.

Inspect power cable.

Replace if needed.

Tighten or replace if needed.

Replace defective parts and resecure as needed.

Apply Light Grease during reassembly procedures.

Replace if needed.

Tighten, replace or correct as needed

Apply Door-Ease or replace if needed. See Lubrication Diagram.

Resecure or replace if needed.

Resecure, repair or replace if needed.

Page 50

Page 53

Maintenance and Lubrication Schedule

4500

Cycles

Consecutive

750 Cycle

Intervals

Mounting

Decals and Antiskid

Repeat all previously listed inspection, lubrication and maintenance procedures at 750 cycle

intervals.

Check to see that the lift is securely anchored to

the vehicle and there are no loose bolts, broken

welds, or stress fractures.

Replace decals if worn, missing or illegible. Replace antiskid if worn or missing. See Decals and

Antiskid section on pages 40-42.

Page 51

Page 54

"Providing Access to the World"

®

Over 300 Braun

Dealers Worldwide

Page 55

The Braun Corporation of Winamac, Indiana, warrants that it will repair (or replace at

Braun’s sole option) any defect in material or workmanship in its wheelchair lift for three years,

providing the lift is installed, operated and maintained properly. This warranty is limited to the

Operator's Manual

Braun NL955 Series

Braun NL955 Series

All illustrations, descriptions and specifications in this manual are based on the latest product information available

All illustrations, descriptions and specifications in this manual are based on the latest product information available

at the time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

at the time of publication. The Braun Corporation reserves the right to make changes at any time without notice.

32244 Rev. B January 2008

32244 Rev. B January 2008

original purchaser and does not cover defects in the motor vehicle on which it is installed, or

defects in the lift caused by a defect in any part of the motor vehicle.

This warranty commences on the date the lift is put in service, providing the warranty

registration card is completed and received by The Braun Corporation within 20 days of purchase.

If no warranty card is received, the warranty will expire three years from the date of manufacture

as identified on the lift serial number tag.

This warranty also covers the cost of labor for the repair (or replacement at Braun’s sole

option) of parts for one year when performed by an authorized Braun representative. (A labor