Page 1

WTC0812A

WTC1012A

INSTALLATION, OPERATING AND

MAINTENANCE INSTRUCTIONS

WASHING MACHINE

LAVE-LINGE

WÄSCHMASCHINE

LAVADORA

MÁQUINA DE LAVAR

ROUPA

VASKEMASKINE

WASMACHINE

PRALKA

AUTOMATICÁ PRAČKA

CTPAHA

MAHA

ΠΛΥΝΤΗΡΙΟ ΡΟΥΧΩΝ

Page 2

- 2 -

D1

D2

D3

D4

D5

D6

D7

13

1

1

2

2

a

b

a

b

➀

➁

➀

➁

➃

➂

Page 3

- 3 -

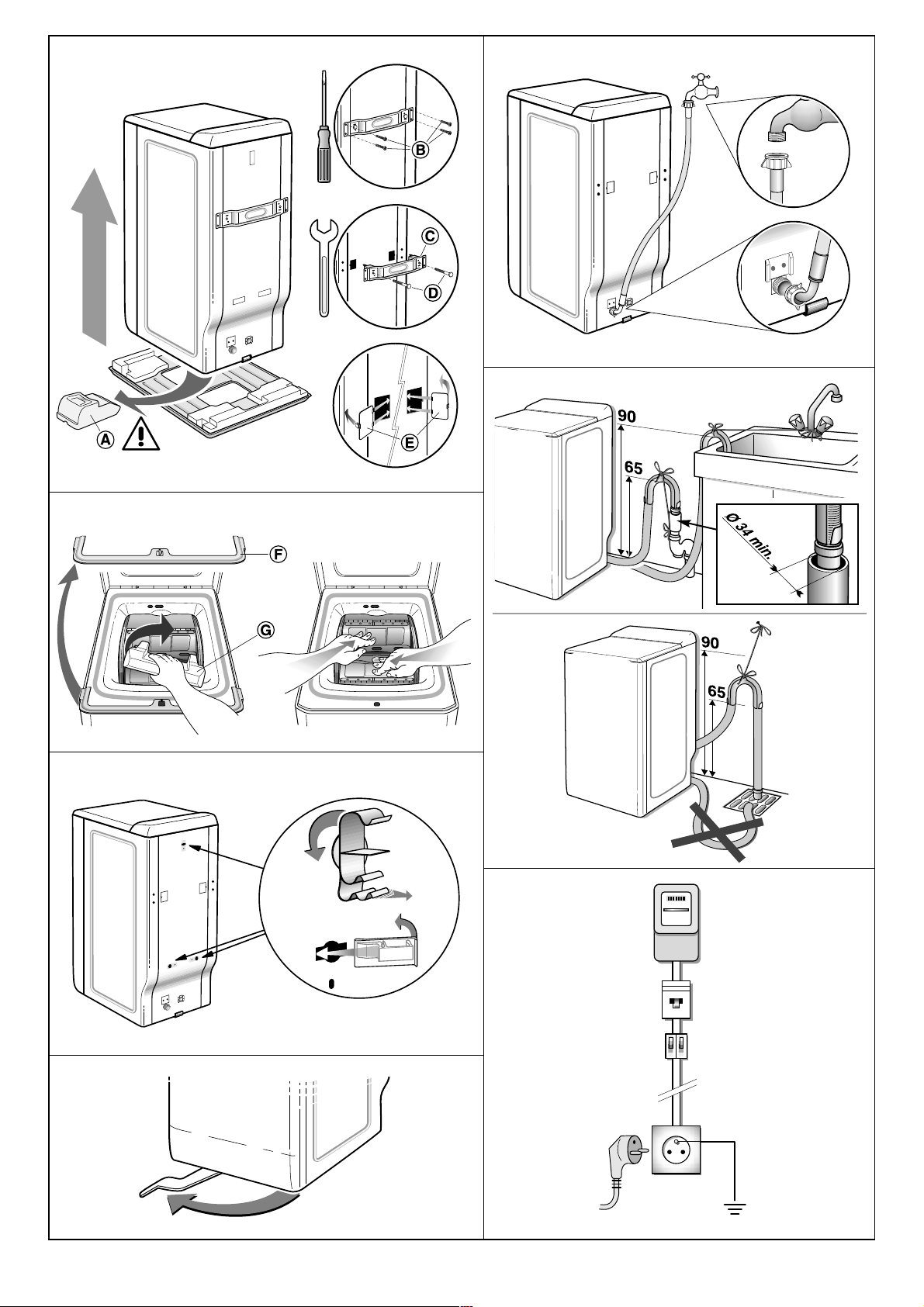

Removing the transport clamps from your machine

see diagrams D1-D2-D3

1 - Remove the washing machine from its plinth (check that the

wedge

훽

supporting the motor is not still inserted in the

machine) (

Diagram

D1.➀

)

2 - Remove the 4 screws훾with a screwdriver

(Diagram

D1.➁

)

3 - Remove the cross clamp훿by removing the 2 screws

(Diagram

D1.➂

)

using a 10 or 13mm spanner (depending on the

model). (Ensure that you remove the two plastic braces fixed on

the cross clamp at the same time as the clamp itself).

Replace the screws

훾

in their initial positions.

4 -

You must block off the two holes using the hole covers

provided

(supplied in the accessories bag)

(Diagram

D1.➃

)

5 - Remove the drum-tank assembly locking wedge

(DiagramD2)

.

To do this:

- Lift the lid on the machine

- Remove wedge

- Remove wedgeby turning it a quarter turn

- Release the drum doors, locked in the lower position, by

pressing down on both eaves simultaneously.

6 -

Remove the pipe support collars➀You must block off the

holes revealed with the hole covers

➁

supplied in the

accessories bag

(DiagramD3)

.

Connecting the cold water supply

Connect the supply hose

(DiagramD5)

:

- At one end to the connection on the back of the machine

- On the other end to a tap fitted with a threaded end 20mm dia. x

27 (3/4 BSP).

If you use a self-piercing tap, the useful aperture must have a

minimum diameter of 6mm.

Water supply:

- Minimum water pressure: 0.07 MPa or 0.7 bar

- Maximum water pressure: 1 MPa or 10 bars

Draining away the waste water

Fit the hose bracket provided inside your machine to the end of the

drain hose and then connect the hose

(DiagramD6)

:

• Either, temporarily, over a sink or a bathtub.

• Or permanently to a ventilated U-bend.

If your installation does not have a ventilated U-bend, check that the

connection is not sealed. In fact, to avoid any waste water flowing

back into the machine, you are strongly recommended to leave an

air gap between the machine’s drain hose and the drainpipe.

In any case, the drain hose bracket must be placed at a height of 65

to 90cm higher than the base of the machine.

Ensure that the drain hose is tied firmly in place with cord to

avoid the bracket coming loose during draining and causing a

flood.

The waste water can be drained away to the ground provided that

the drain hose passes through a point 65 to 90cm higher than the

base of the machine.

For your safety, you must comply with the instructions belo

Electrical supply

(DiagramD7)

• Before connecting your machine, you must ensure that your

installation’s electrical characteristics match those of your

machine (see the details provided on the information plate affixed

to the back of the machine).

• The electrical installation must comply with the prevailing

standards and the Electricity Board’s regulations in the country

concerned, particularly as regards Earthing and installation in

shower rooms.

We cannot be held responsible for any incident caused by the

machine being incorrectly earthed.

Advice on the electrical installation of your machine

• Do not use an extension lead, adapter or multiple socket.

• Never cut out the Earth wire.

• The socket must be readily accessible but out of the reach of

children.

If in any doubt, please contact your installer.

Installing your machine see diagrams

D4

Connecting your machine see diagrams

D5-D6-D7

BEFORE USING THE MACHINE IN ANY WAY, YOU MUST FIRST PERFORM THE FOLLOWING OPERATIONS.

These comprise removing all the components designed to immobilise the drum in your machine during transport.

These so-called “releasing” operations are necessary for your machine to operate correctly and to conform to the prevailing safety

standards.

If they are not carried out completely, this could cause severe damage to your machine while it is operating.

We would recommend that you keep all the locking components since

these must be refitted if you must subsequently transport your machine

again.

All these components, just like all the components in your machine, are

made of recyclable materials and it is useful to bear this in mind when you

eventually come to dispose of your machine at the end of its useful life.

Your machine has been scrupulously checked before it left the factory.

You may therefore notice a little water still remaining in the tank or the

products box.

Mounting it on castors:

If your machine is equipped with removable castors, you will be able

to move it quite easily.

To mount it on castors, swivel the lever on the bottom of the

machine from the right to the far left

(DiagramD4)

.

The machine must not rest on the “front” castors while it is

operating: remember to return the lever to its initial position.

Levelling the machine:

Use a spirit level to check that the floor is horizontal: maximum

slope 2°, i.e. a discrepancy of approximately 1cm over the width

and of 1.5cm over the depth of the machine.

Your machine’s surroundings:

If you are installing your machine next to another machine or a

unit, we recommend that you leave a gap between them to allow

for air circulation.

We also strongly recommend that you do NOT:

- Install your machine in a damp, poorly ventilated room.

- Install your machine in an area where it could be subject to water

splashes.

- Install your machine on a carpeted floor.

If you cannot avoid doing this, please take every precaution to avoid

blocking air circulation at the bottom of the machine in order to

ensure that the internal components are well ventilated.

Your machine conforms to European Directives EEC/73/23 (Low

Voltage Directive) and EEC/89/336 (Electromagnetic Compatibility)

as modified by Directive EEC/93/68.

On any new installation (following a move or resale, etc.),

the machine must be connected using new hoses. The old

hoses must not be reused.

You will find the following symbols used throughout this manual. They mean :

Safety instructions (for your machine and your washing), which must be observed

An electrical risk,

Important advice and information

Page 4

- 4 -

Automatic safety devices

Loading your washing

Before your first wash

Before making your first wash, we recommend that you carry out

a “COTTON 90 wash without pre-wash” and with no washing in

the drum, using a 1/2 measure of your usual detergent in order

to eliminate any residues from manufacturing that may remain in

your machine.

Perform these actions in the following order:

Open the machine

• Check that the “Start/Stop”( ) button is released.

• Depending on the model, lift the opening handle or press the push

button on the front of the machine.

The lid will open.

• Open the drum by pressing the button on the front door.

Insert your washing

For optimum washing performance, place your washing, preferably

sorted and folded, in the drum, distributing it evenly without heaping

it up. Mix large and small items to obtain an optimum, well-balanced

spin.

Close the drum

Ensure that the drum is correctly closed.

Check that the three hooks and the border of the button are

fully visible.

Loading the washing products

Dispensing the detergent

The amount of detergent to be used depends on the hardness of the

water, the extent to which your washing is soiled and the amount of

washing to be washed.

Please refer to the dosing instructions on your pack of detergent.

Warning: in most cases, the detergent manufacturer’s recommendations

apply to the drum filled to the maximum. Adjust the dosage correctly to

the weight of the washing you have placed in the machine.

These recommendations will help you to avoid using too much

detergent, which causes foam to be produced. Too much foam can

reduce your machine’s performance and increase the length of the

washing cycle and the consumption of water.

Detergents for woollens and delicate fabrics

You are recommended to use an appropriate detergent for washing

these fabrics (avoid placing such detergents directly on the drum

because they have an aggressive action on the metal).

The “WASH” container may contain powder or liquid but liquid

detergent should not be used for programmes WITH

Pre-wash

and/or WITH

“Delayed Start” (depending on the model).

Concentrated softener should be diluted with warm water.

Concentrated bleach must be diluted.

To fill the product containers correctly, place the lid fully open.

Do not exceed the MAX

level.

➀

➁➃➂

➀

Pre-wash container

(powder)

➁

Wash container

(powder or liquid)

➂

Softener

➃

Bleach

cl

Lid opening safety device:

As soon as the washing cycle starts, the lid on your machine will

lock.

As soon as the cycle is finished, or when the machine has stopped

with the drum full of water, the lid unlocks.

If you wish to open the lid during the cycle, release the “Start/Stop”

button( ) and wait at least 2 or 3 minutes for the lid safety device

to disengage.

Water safety device:

While the machine is operating the constant water level control

system prevents your machine from overflowing.

Spin safety device:

Your washing machine if fitted with a safety device that can restrict

spinning when it detects that the washing is poorly distributed.

In this case, your washing may be insufficiently spun. Redistribute

your washing evenly in the drum and programme a new spin.

Selecting a washing programme

Selecting the type of washing

__________________

Choose the most suitable programme for your type of washing.

COTTON

If your washing consists of

WHITES, COTTONS

or

LINEN

SYNTHETICS or COLOUREDS

If your washing consists of

COLOUREDS, HARD-WEARING SYNTHETICS

or

MIXED FIBRES

DELICATES and WOOLLENS

If your washing consists of

NET CURTAINS, DELICATE FABRICS

,

FRAGILE HOUSEHOLD TEXTILES

or

"MACHINE-WASHABLE WOOLS"

For more details, please refer to the programmes table on the

following page.

Selecting the temperature

______________________

Choose the most suitable temperature for your type of washing.

To do this, follow the instructions on the labels attached to most

textiles.

Please refer to the meanings of the symbols at the end of this

manual.

COTTON : from “cold” to 90°C

SYNTHETICS and COLOUREDS : from “cold” to 60°C

DELICATES and WOOLLENS : from “cold” to 40°C

Selecting the end of the programme

____________

a - Spinning

Select a spinning speed appropriate to the type of washing.

COTTON, SYNTHETICS

and COLOUREDS : from 400 rpm to maximum speed

DELICATES and WOOLLENS : from 400 rpm to 600 rpm

The spin speed is automatically restricted to 550 rpm in the

”Delicates and Woollens" programme.

b - Drip-drying

Select this option if you wish simply to drip-dry your washing.

To select this option, turn knob to the " " position.

If you programme “drip-dry”, the cycle ends is a gentle spin at

100 r.p.m.

Extra rinse

______________________________

An additional programme for "sensitive and allergic skins".

It adds an extra rinse to the "Cotton" and "Synthetics and Coloureds"

cycles.

Selecting this button has no effect during the “Delicates and

Woollens” cycle.

4

3

3

2

1

:

POWDERED

DETERGENT

:

LIQUID

DETERGENT

Page 5

- 5 -

Full drum stop

____________________________

This function should be used for textiles that you do not wish to

spin or if you expect to be away for a prolonged period after the

washing cycle has finished.

When this button is selected, the cycle is interrupted before the

final spin, allowing your washing to float in water to avoid

creasing.

Then:

- If you subsequently wish to spin and drain.

Simply release this button

The programme will finish automatically.

- Or if you wish just to drain.

Turn knob to the " " position and release the button.

Start /Stop

______________________________

Check that the electrical power cable is connected and

that the water tap is open. Also ensure that the drum doors and

the machine’s lid are correctly closed.

Press button in when you have finished programming the

machine. The washing cycle starts.

Once the cycle has finished, switch off the machine by releasing

button .

You can then open the lid and remove your washing.

Also release any other buttons you have selected.

As a safety precaution, we recommend that you disconnect

the power cable and turn off the water tap.

”Direct access to the washing”

Your machine is fitted with a system that positions the drum

doors in the upper position at the end of the cycle.

If this has not happened, this is because the washing was poorly

distributed in the drum.

In this case, turn the drum by hand to bring the doors into the

upper position.

6

6

6

1

5

BUTTON

DEPRESSED

BUTTON

RELEASED

START

STOP

STANDARD COMPARISON TESTING PROGRAMME

To comply with the statement on the label, the tests are conducted in accordance with European Directive 92/75/EEC at nominal capacity, ensuring complete use of the CEI

detergent from the start of the washing phase.

Maximum loads

”Cotton” and ”Coloureds”: 5 kg.

”Synthetics” and ” ”: 2.5 kg.

”Delicates and woollens”: 1 kg.

Programme ............................................................................ -

Temperature ....................................................................................60°C

Load ....................................................................................................5 kg

Duration ............................................................................................ 2 : 10

Energy. ......................................................................................1.15 kWh

Water ....................................................................................................55 l

800

max

rpm

600

400

MADE IN FRANCE

90˚C

80

70

60

50

40

30

Automatic Variable Capacity

5

1

Kg

1 23

5

6

4

90°C wash with pre-wash

90°C wash

ECO 40° or 60°C wash

Cold to 30°C wash

Spin, cotton, synthetics and coloureds

Delicate fabrics cold to 40°C wash

Rapid wash, all textiles, at 30°C

Rinse & spin, delicates & woollens

Intensive 40° to 60°C wash

40° to 60°C wash

Spin, delicates & woollens

Rinse & spin, cotton, synthetics and coloureds

Drain

Programmes examples

02 : 453

02 : 303

02 : 30

02 : 10

02 : 00

00 : 15

3

00 : 15

00 : 10

00 : 05

1

3

3

1

3

3

3

01 : 50

00 : 25

00 : 50

00 : 40

Programmes

Type of washing

90

30

90

30

→→

40

→→

6040

→→

6040

→→

6040

/

400

max

→→

400

600

→→

Page 6

- 6 -

Incidents that may occur

Some incidents may occur when using your machine: these are the points to be checked:

The cycle does not start - check:

• The programme has been completely selected:

• The machine is correctly being supplied with water and power

• The machine’s lid is properly closed

Foam overflows - check:

• You have not used too much detergent

• You have used a detergent suitable for washing machines:

- Drain and programme several rinses. Then restart the washing

programme.

Heavy vibration during spin - check:

• All the transport material has been removed correctly from the

machine

• The floor is horizontal

• The machine is not resting on its two “front” castors (depending

on the model).

A puddle of water forms around the machine

First of all remove the plug and the fuse and shut off the water

supply tap.

While the machine is operating, the continuous water level control

prevents the water from overflowing. If, nevertheless, water escapes

from the machine, check:

• The drain hose bracket is correctly positioned on the drain pipe.

• The water supply connections on the machine and the tap are

watertight

The washing is not spun or not spun enough – check:

• You have not programmed a function cancelling the spin cycle,

e.g. “Drip-dry”.

The spin safety system has detected poor distribution of the

washing in the drum:

- In this case, untangle the washing and programme a new spin.

The machine does not drain – check:

• You have programmed a “Stop with drum full of water”.

• The drain pump filter is blocked:

- Clean it (for the procedure, see below)

• The drain hose is not kinked or crushed.

The lid will not open – check:

• The programme has finished completely

The lid remains locked all the time the programme is running.

The drum doors open to slowly

(for machines fitted with gently opening doors)

• Your machine has not operated for a long time

• It is located in too cold an area

• Detergent residue (powder) is blocking the hinges

- In all cases, everything returns to normal once the doors have

opened

Running maintenance see diagrams

D8-D9-D10-D11-D12

Cleaning the machine

(Diagram D8)

.

To clean the casing:

Use only soap and water.

To clean all the plastic components (control panel, plinth, etc.):

Use only a cloth dampened with water.

In all cases, do not use:

• Abrasive powders

• Metal or plastic sponges

• Alcohol-based products (alcohol, thinners, etc.)

Care of the internal components

To ensure better hygiene, we recommend that you:

• Leave the lid open for a short time after washing.

• Clean the plastic and rubber access components to the tank

approximately once a month using a slightly chlorinated product.

Run a rinsing cycle to remove any residue of this product.

• Run a washing cycle at 90°C at least once a month.

Periodic checks

We recommend that you check the condition of the water supply

and drain hoses. If you notice the slightest cracking, do not hesitate

to replace them with identical hoses available from the

manufacturer or his After-Sales service.

Replacing a water supply hose

When replacing the hose, ensure that the hose is tightly fastened

and that there is a seal at both ends.

Cleaning the products’ box

(Diagram D9)

.

Nettoyez régulièrement la boîte à produits. Pour cela :

- Press the bosses on each side of the box simultaneously to

extract it from its housing.

- Remove the siphons

from the rear of the box and separate

the box from its front cover

- Rinse everything under the tap (taking care to empty any excess

water remaining inside the box).

- Refit all the box’ components, ensuring that the box section itself

is properly clipped into the cover and then re-insert the complete

assembly into its location under the machine’s lid.

Cleaning the pump filter

This filter catches any small objects inadvertently left in the clothes

to avoid their disrupting the pump’s operation.

To clean the filter, proceed as follows:

- Open the drum doors. At the back of the drum, you will see a

plastic component

(Diagram

D10

)

- Unscrew this component.

To do this:

• Insert a rod (a pencil or a screwdriver, for instance) into the hole

in component

• While pressing down vertically with the rod, push component

towards the right until it releases from its housing

- Remove component

- Turn the drum slightly towards the front of the machine with the

doors open

(Diagram

D11).

Through the openings freed by removing component

you can

now access the pump filter

.

- Remove it from its housing

(Diagram

D11).

- Remove the various objects that may be inside it.

- Rinse it under the tap

(Diagram

D11).

- Re-insert it by pushing it fully into its housing, after checking that

the housing is clean.

- Re-insert component

, carefully positioning it in the openings at

the back of the drum and pushing it to the left until it is perfectly

engaged.

(Diagram

D12).

Frost risk

When there is a risk of frost, disconnect the water supply hose and

empty any water remaining in the drain hose by placing this as low

as possible in a basin.

Replacing the power cable

For your safety’s sake, this operation must be performed by the

manufacturer’s After-Sales service or a qualified professional

electrician.

Page 7

- 7 -

D8

+

S

A

V

O

N

E

A

U

D9

H

D12

D11

L

D10

➀

➁

CLANG

➀

➁

K

Page 8

57868-01 0902

After Sales Service :

Possible maintenance on your washing machine should be undertaken by :

- either your dealer,

- or another qualified mechanic who is an authorized agent for the brand appliances.

When making an appointment, state the complete reference of your equipment (model, type and serial number). This information appears on the

manufacturer's nameplate attached to the rear of the equipment.

Fabric cleaning code

cl

F

95

Wash : never exceed the recommended temperatures

Cold diluted bleach can be used

Iron : cold medium hot

Dry-cleaning : mineral spirit hexachlorethane all solvents

Do not use !

A

P

F

Loading...

Loading...