MODEL 169000

AIR FILTER GAUGE

Indoor Air Quality Products

INSTALLATION INSTRUCTIONS

AIR FILTER GAUGE

INSTALL CLEAN

FIL TER , R UN

BLOWER AND

ADJUST GAUGE

UP

POINTER TO

CLEAR AREA

IN CE NTE R

OF GR EEN

DOWN

R

E

T

L

I

F

E

G

N

A

H

C

N

A

E

L

C

S

I

R

E

T

L

I

F

APPLICATION

The 169000 Air Filter Gauge provides a visual indication of the need to replace the air filters in forced air heating and cooling

systems. The gauge is installed between the blower and the filter where a slight vacuum exists due to the air flow resistance

of the air filter. Air flowing into the gauge, around the calibration screw, lifts a vane in proportion to the negative pressure in

the blower compartment. As the air filter loads, the vacuum increases, raising the vane to indicate a filter change

is necessary.

The gauge may be calibrated in a negative pressure range from 0.1 to 0.4 inch w.c. When properly calibrated in this range a

vacuum increase of 0.10 to 0.15 inch w.c. will indicate a filter change is necessary.

PRECAUTIONS

The installer should be an experienced service technician. When drilling the hole

in the blower compartment extreme care should be taken not to damage

components within the heating or cooling system.

RETURN

AIR

INSTALLATION

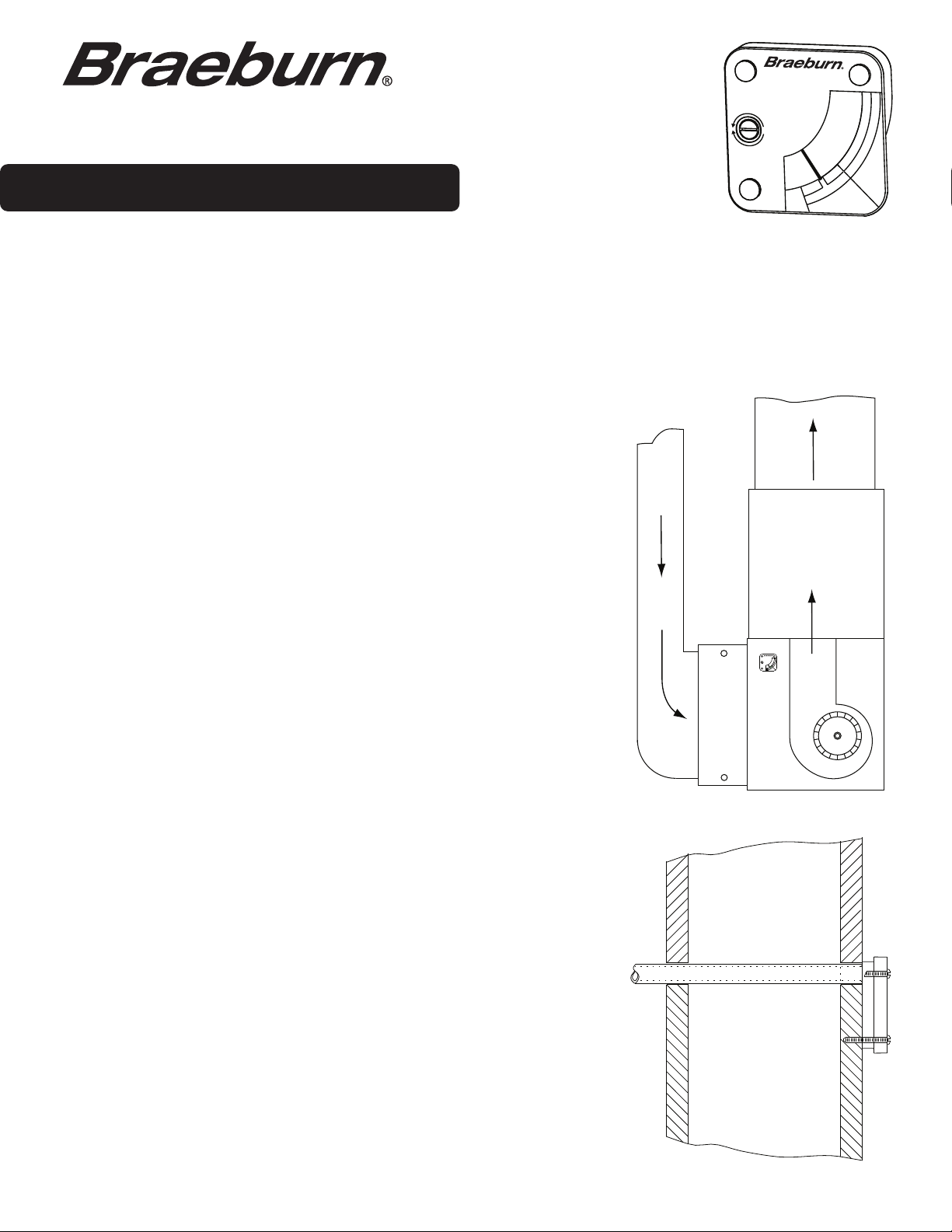

1.

The gauge must be located where it can sense pressure conditions in the

(Figure 1)

blower compartment between the filter and the blower. Select a location on

a

vertical surface enclosing the blower compartment and drill a 3/8" hole.

2. Remove the protective paper from the foam adhesive strip on the back

of the gauge.

3. Mount the gauge in a level position with the pressure sensing tube

projecting into the blower compartment.

4. See “CALIBRATION”.

OPTIONAL REMOTE INSTALLATION

(Figure 2)

FIELD SUPPLIED: One (1) piece of 5/16” (inside diameter) vinyl tubing up to 10

feet in

1.

Select a location on the blower compartment between the air filter and the

length, and three (3) #4-24 x 1” screws.

blower and drill a 7/16" diameter hole. Insert one end of the vinyl tubing

about 2" into the hole.

2.

On a wall, enclosing the furnace room for example, mark a position where

the filter gauge can be easily seen and is within reach of the vinyl tube.

3.

Drill a 1/2" diameter hole through the wall and feed the vinyl tube through

the

hole. Keep overall length of tubing used as short as possible.

GAUGE

AIR FILTER GAGE

INSTALL CLEAN

FILTER, RUN

BLOWER AND

ADJUST GAGE

UP

POINTER TO

R

CLEAR AREA

E

IN CENTER

T

OF GREEN

L

I

F

E

G

N

A

DOWN

H

C

N

A

E

L

C

S

I

R

E

T

L

I

F

AIR

FILTER

BLOWER

Figure 1

4.

Push the three plastic retainer clips out from the back of the gauge with a

blunt tool. They will be replaced with the three #4-24 x 1" screws included.

5.

Push the vinyl tubing over the pressure sensing tube of the gauge and

move the gauge back against the wall in a level position. Drill three 3/32"

diameter holes through the gauge holes. Drive the three screws to hold the

gauge in place

. Do not overtighten.

6. See “CALIBRATION”.

Figure 2

CALIBRATION

Install a clean filter and run blower on highest speed.

With a small screwdriver adjust the calibration screw, on

the face of the gauge, to put the pointer in the clear area

in the center of the green "FILTER IS CLEAN" range.

GREEN

OPERATION

AIR FILTER GAUGE

INSTALL CLEAN

FI LTER , R UN

UP

BLOWER AN D

ADJUST GAUGE

POINTER TO

CLEAR AREA

IN CE NTE R

OF GR EEN

DOWN

U.S.

PAT.

6190442

R

E

T

L

I

F

E

G

N

A

H

C

N

A

E

L

C

S

I

R

E

T

L

I

F

As the air filter begins to clog the pointer will move up

in the gauge. When the pointer moves into the red

"CHANGE FILTER" range a clean filter should be

installed.

RED

AIR FILTER GAUGE

INSTALL CLEAN

FI LTER , R UN

UP

BLOWER AN D

ADJUST GAUGE

POINTER TO

CLEAR AREA

IN CE NTE R

OF GR EEN

DOWN

U.S.

PAT.

6190442

R

E

T

L

I

F

E

G

N

A

H

C

N

A

E

L

C

S

I

R

E

T

L

I

F

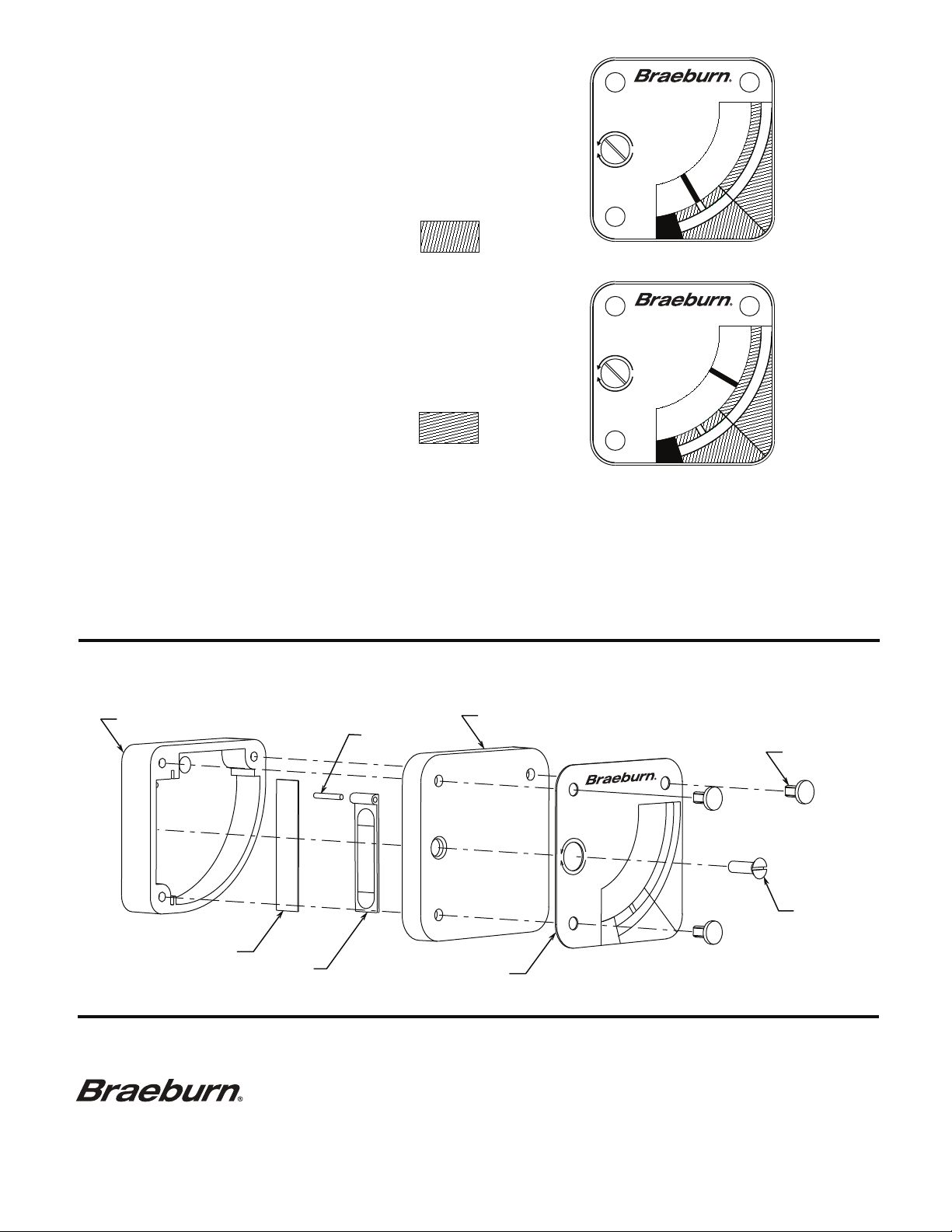

SERVICE

The gauge may be disassembled for service although this should rarely be required since it contains a small filter

screen to stop dust from entering the area of the vane. Remove gauge and, from the back, push white plastic

clips out with a blunt tool. Remove calibration screw, lift off clear cover and dust all parts with a clean brush.

Reassemble and test that the vane moves freely in the gauge. A fresh adhesive strip may be required to reinstall.

U.S. PAT. 6190442

EXPLODED VIEW

GAUGE HOUSING

PIN

GAUGE COVER

RETAINER CLIP

FILTER SCREEN

VANE

Braeburn Systems LLC

2215 Cornell Avenue • Montgomery, IL 60538

Technical Assistance: www.braeburnonline.com

Call us toll-free: 866-268-5599 (U.S.)

630-844-1968 (Outside the U.S.)

©2010 Braeburn Systems LLC • All Rights Reserved • 169000-100-001

DIAL PLATE

AIR FILTER GAUGE

UP

DOWN

INSTALL CLEAN

FILTER, RUN

BLOWER AND

ADJUST GAUGE

POINTER TO

CLEAR AREA

IN CENTER

OF GREEN

R

E

T

L

I

F

E

G

N

A

H

C

N

A

E

L

C

S

I

R

E

T

L

I

F

CALIBRATION

SCREW

FOAM ADHESIVE STRIP - NOT SHOWN

Loading...

Loading...