Page 1

PermaSleeve® Wire Markers

PermaSleeve® Wire Marking Sleeves

Brady non-adhesive, printable heat-shrink wire marking sleeves fit snugly around wires or cables for maximum

insulation protection. Their full-circle design provides fast and permanent wire marking. Clear, legible text can be

printed on the sleeve with a Brady printer for reliable wire identification.

Brady heat-shrink sleeving materials excel in extreme environments, including temperature fluctuations and

environments that require abrasion and chemical resistance. Brady offers a variety of materials available to print

using thermal transfer and dot matrix printers.

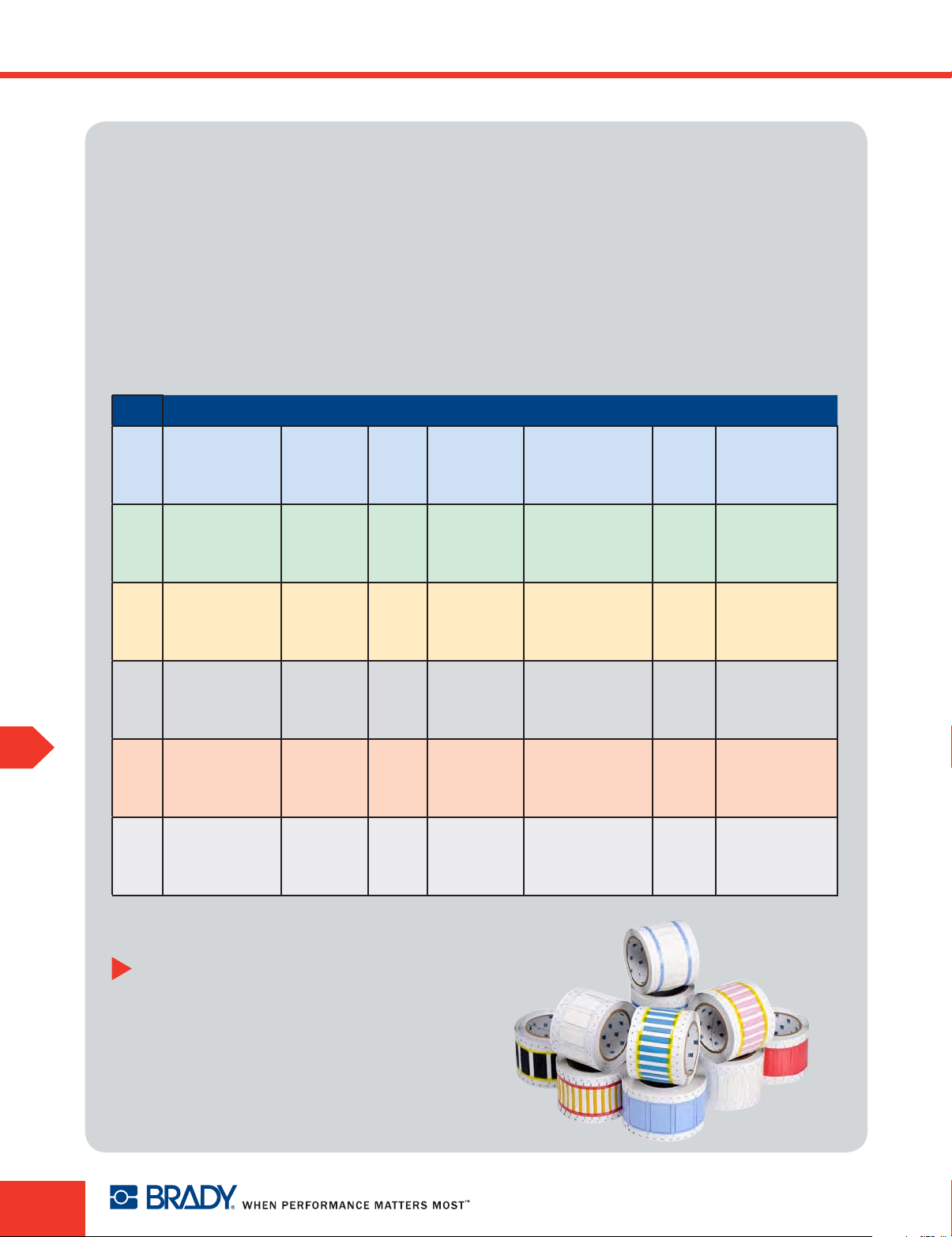

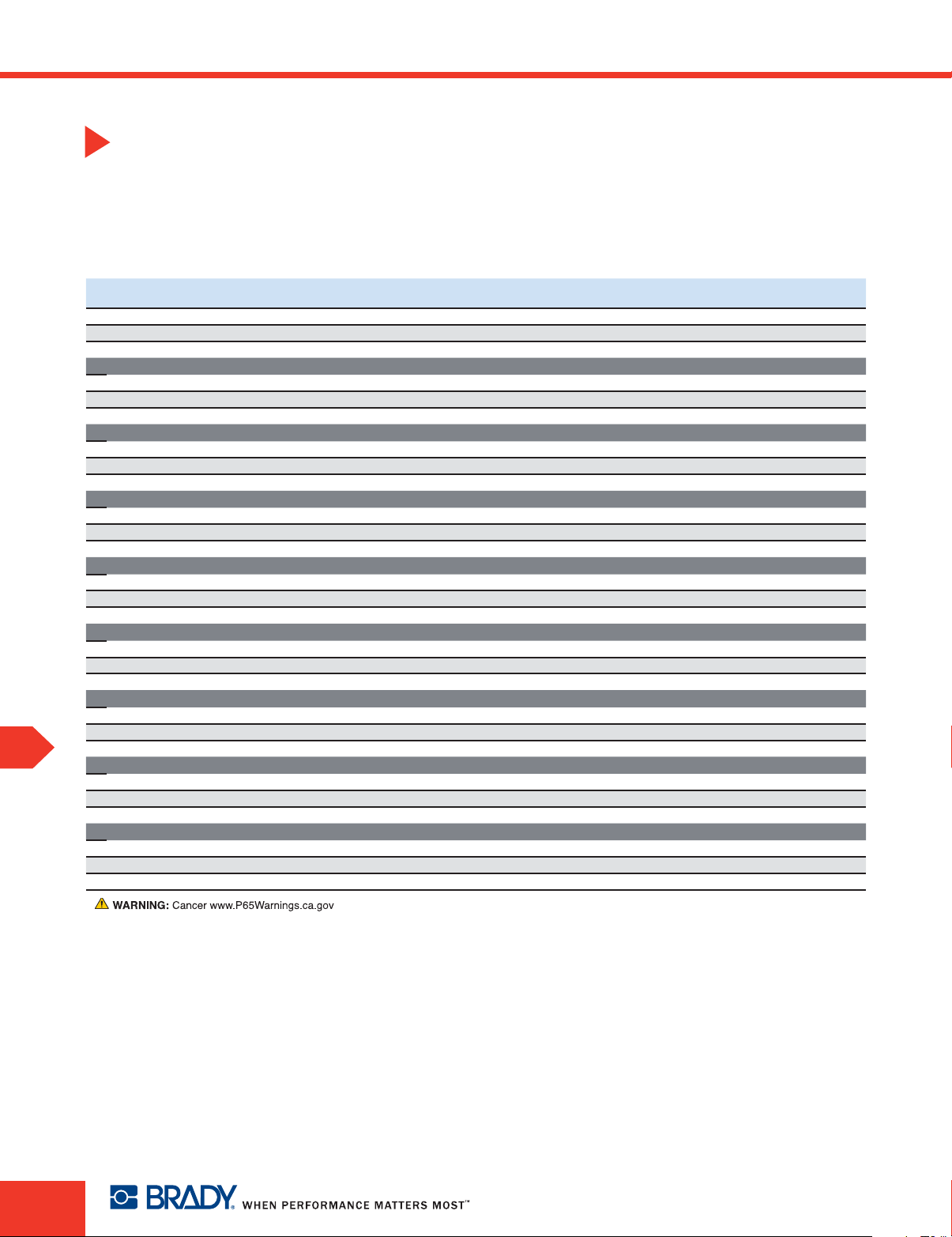

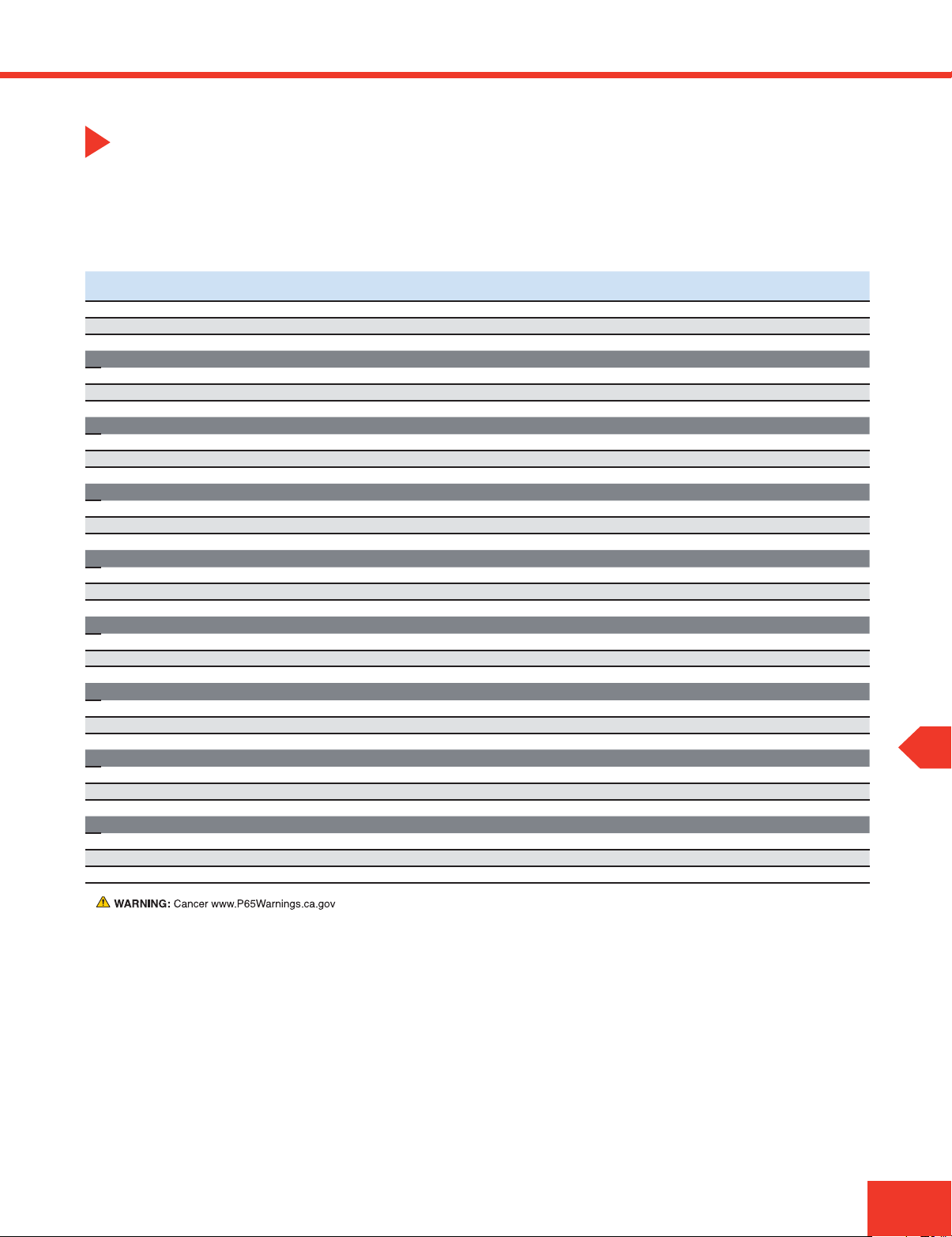

PermaSleeve Material Comparison Guide

Use the following table to help determine which PermaSleeves are right for your application. Then reference the

following pages for more information and all available catalog numbers.

3” Core Materials

Material Catalog # Prefix Description

B-342

B-344

B-345 2HT: Double-sided

B-7641

B-7642

PermaSleeves

B-7646

Shrink

Ratio

PS: Single-sided

3PS: Double-sided

2FR: Double-sided

2:1 ratio for 1500 dia.

3FR: Double-sided

3:1 ratio for 094–1000 dia.

LSZH: Single-sided

2LSZH: Double-sided

HX: Single-sided

2HX: Double-sided

DR: Double-sided Diesel Resistant 3:1 ratio

Industrial/

Military Grade

Fluid Resistant

High-Temperature

Resistant

Low Smoke,

Zero Halogen

Industrial/

Military Grade

3:1 ratio

3:1 or

2:1 ratio

2:1 ratio

2:1 ratio

2:1 ratio

Temp. Range Specs Compliance Rec. Ribbon Series

-67°F to 275°F

(-55°C to 135°C)

-67°F to 275°F

(-55°C to 135°C)

-67°F to 437°F

(-55°C to 225°C)

-22°F to 221°F

(-30°C to 105°C)

-40°F to 248°F

(-40°C to 120°C)

-55°F to 135°F

(-48°C to 57°C)

SAE-AS-23053/5

SAE-AS-81531

SAE-AS-23053/6 (Class 1)

SAE-AS-81531

NASA SP-R-0022A

Outgassing

SAE-AS-81531

SAE-AS-23053/18

EN45545-2 RoHS R6000 and R6600

SAE-AS-23053/5

Class 1 and 3

SAE-AS-81531

SAE-AS-81531

NF F 00-608 Type A and H

RoHS

UL

RoHS

RoHS

RoHS

RoHS R6600

R4300, R6600 and R6700

(with black sleeves)

R6600 and R6700

(with black sleeves)

R6000, R6600 and R6800

(with black sleeves)

R4300, R6000,

R6400 and R6600

196

Custom Sleeve Options Available

Brady offers custom options for many of the materials in this catalog.

Our dedicated, experienced custom quoting team can provide

pricing for your unique label needs.

Page 2

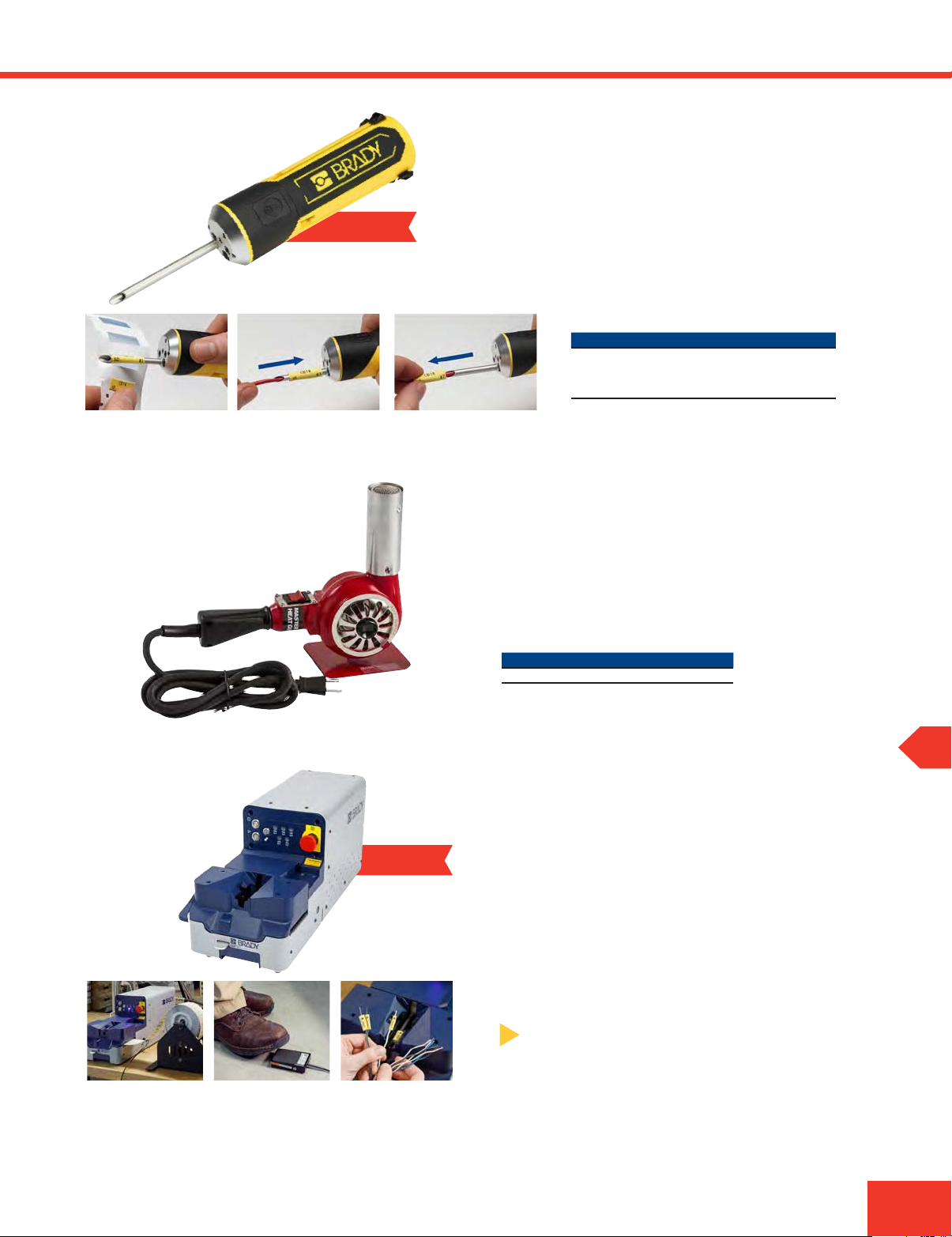

new

PermaSleeve® Wire Markers

QuickSleeve Handheld Sleeve Applicator

The QuickSleeve applicator is an intuitive multi-tool designed

to help you quickly apply sleeves onto wires in three simple

steps – just pick, slip and apply. This tools includes:

• Four specially designed slanted tubes sized for

sleeve sizes 0.094, 0.125, 0.187 and 0.250 inches

• Built-in LED flashlight for use in low-lit conditions

• Terminal block sized screwdriver

Pick

Slip

Apply

Catalog # Description Qty.

QS

QuickSleeve multi-tool with 4 tube

sizes (for 0.094, 0.125, 0.187 and

0.250 inches), terminal block sized

screwdriver and LED flashlight.

Brady Heat Gun

The Brady Heat Gun provides fast, even shrinkage

of BradySleeve™ and PermaSleeve

heat-shrinkable tubing. Deflector shield evenly

distributes forced air heat (minimum temperature

500˚F/260˚C) around sleeves of up to 0.750 in.

diameter for uniform shrinkage. Sturdy base with

rubber pad allows hands-off operation.

Catalog # Description Qty.

PMS-HG-1 Brady Heat Gun 1 each

®

markers or

1 each

3” Core Materials

Feed printed

PermaSleeve roll into

the BSP45 Applicator

Use the foot pedal to

trigger sleeve removal

from liner

new

Sleeve is now

ready for easy wire

application

BSP™45 Sleeve Applicator

An easy-to-use, faster and more cost-effective

alternative to manual sleeve application. It increases

wire sleeve application speed by up to 6-10 seconds

by automatically removing sleeves from the liner and

opening the sleeve for easy application. By eliminating

the tedious task of hand applying hundreds of wire

sleeves, it gives workers more time to focus on other

important tasks.

View page 238 to learn more and

shop compatible PermaSleeves.

PermaSleeves

197

Page 3

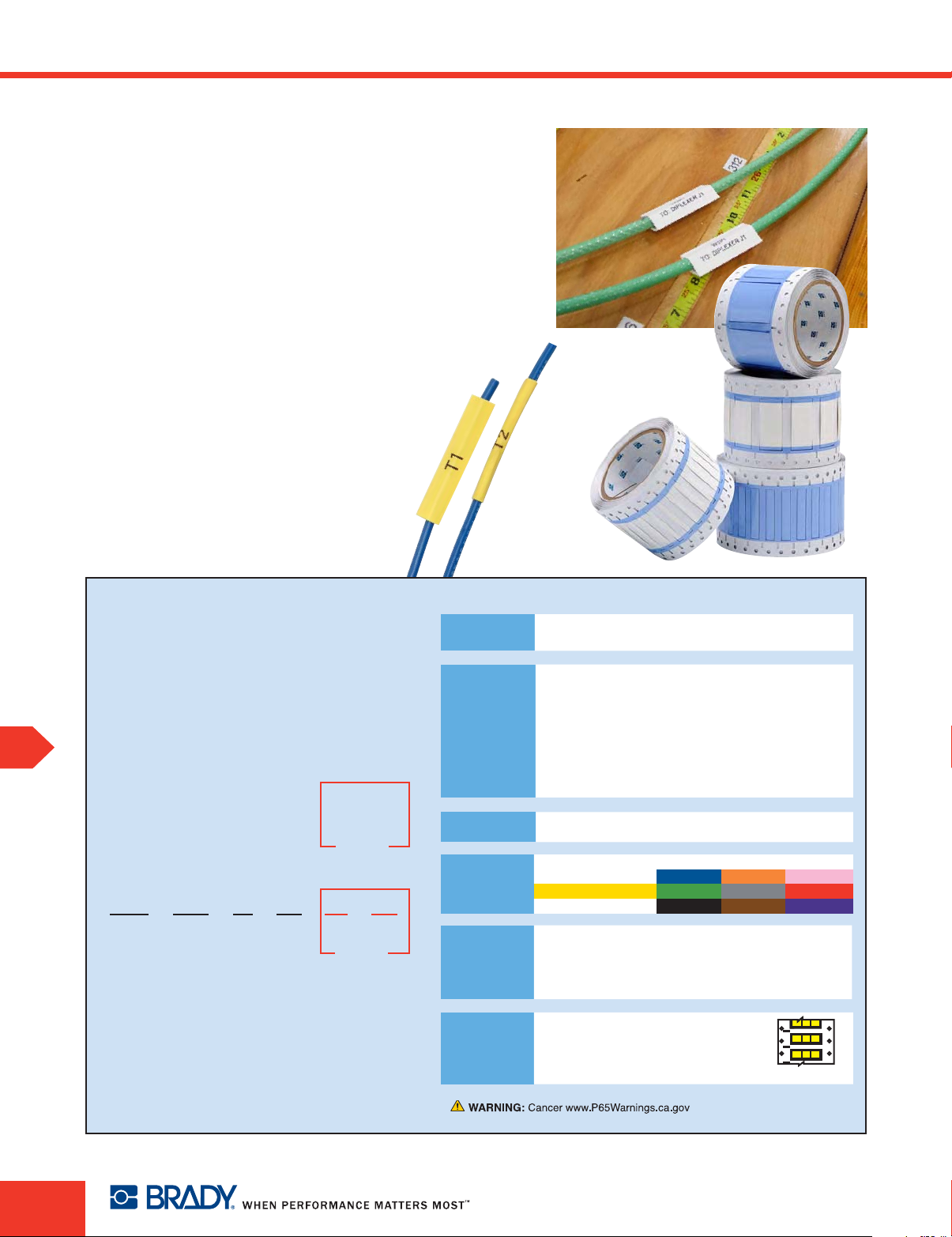

PermaSleeve® Wire Markers

B-342 PermaSleeve® PS

%!"

B-342 PermaSleeve PS Polyolefin Wire Marking Sleeves are

a 3:1 heat-shrinkable wire marking sleeve that fits snugly

around wires for identification and protection.

These fade-resistant and flame-retardant sleeves have an

operating temperature of -67°F to 275°F (-55°C to 130°C).

Meets Specications:

• SAE-AS-23053/5

• SAE-AS-81531

• RoHS compliant

• UL recognized

3” Core Materials

Tested per:

• ASTM E162

• ASTM E662

• MIL-STD-202

Create Your

B-342 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

3PS - 187 - 2 - WT - S - 4

Product Diameter Width Color Roll

PermaSleeves

Create your own:

Product Diameter Width Color Roll

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

BBP

BradyPrinter i5100 and IP

printer acceptable for

size 125 and larger.

- - - -

®

72 Double Sided Printer

Pieces

Qty

Optional

-

Pieces

Qty

Optional

Ribbon Series

R4300, R4502S, R5000,

R6600, R6700

STEP 1:

Product Type

STEP 2:

Diameter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Qty.

(optional)

STEP 6:

Pieces Per

Sleeve

(optional)

= Single Sided Printing

PS

= Double Sided Printing

3PS

= 3/32” 0.023" - 0.080" dia. 28 to 20 gauge

094

= 1/8” 0.046" - 0.110" dia. 22 to 16 gauge

125

= 3/16” 0.062" - 0.150" dia. 20 to 10 gauge

187

= 1/4” 0.094" - 0.215" dia. 16 to 8 gauge

250

= 3/8” 0.125" - 0.320" dia. 12 to 4 gauge

375

= 1/2” 0.187" - 0.450" dia. 8 to 1 gauge

500

= 3/4” 0.250" - 0.700" dia. 6 to 4/0 gauge

750

= 1” 0.333" - 0.950" dia. 2 to 0.950” dia.

1000

= 1-1/2” 0.500" - 1.400" dia. n/a

1500

150=1-1⁄2” sleeve width

=

2” sleeve width

2

Standard Colors Special Order Colors al Order Colors

WT = White BL = Blue OR = Orange PK = Pink

YL = Yellow GR = Green GY = Gray RD = Red

For standard quantity, leave blank. For small quantity, enter “S”.

If sleeve diameter is 094–25 Standard = 2,500 Small (S) = 500

If sleeve diameter is 375 Standard = 1,000 Small (S) = 250

If sleeve diameter is 500 Standard = 500 Small (S) = 250

If sleeve diameter is 750–1500 Standard = 250 Small (S) = 100

1 marker per sleeve is standard,

if desired, the sleeve can be split into multiple pieces.

= Sleeve is slit to create 2 pieces

2

= Sleeve is slit to create 3 pieces

3

= Sleeve is slit to create 4 pieces

4

BL = Black BR = Brown VT = Violet

Example: “3” slit

198

*

Print Ribbons page 146

Material Guide page 264

Page 4

PermaSleeve® Wire Markers

y

B-342 PS PermaSleeve Wire Marking Sleeves:

Use the table below to browse standard white sleeves or build your own on page 198.

1.5” Sleeve Width, Single-sided Printable

Printer Compatibility: i7100, PR+, BBP72. i5100 and IP for size 125 and larger.

Recommended RIbbon Series: R4300, R4502S, R5000, R6600, R6700

Catalog # Color

* PS-094-150-WT-S White 500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 1.500 (38.1)

* PS-094-150-WT White 2,500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 1.500 (38.1)

* PS-125-150-WT-S White 500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 1.500 (38.1)

* PS-125-150-WT White 2,500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 1.500 (38.1)

* PS-187-150-WT-S White 500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 1.500 (38.1)

* PS-187-150-WT White 2,500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 1.500 (38.1)

* PS-250-150-WT-S White 500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

* PS-250-150-WT White 2,500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

* PS-375-150-WT-S White 250 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

* PS-375-150-WT White 1,000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Min. Max.

Supplied Dia.

Inch (mm)

Recovered Dia.

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve Width

Inch (mm)

* PS-500-150-WT-S White 250 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

PS-500-150-WT White 500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

*

*

physical property requirements of SAE AS23053/5 (Class 1) for Insulation

InsulatingMaterials whenprinted with R6600,R4300,R4502S, R6700Series

3” Core Materials

White,

ellow and black tubing tested

PermaSleeves

Print Ribbons page 146

Material Guide page 264

199

Page 5

PermaSleeve® Wire Markers

2” Sleeve Width, Single-sided Printable

Printer Compatibility: i7100, PR+, BBP72. i5100 and IP for size 125 and larger.

Recommended RIbbon Series: R4300, R4502S, R5000, R6600, R6700

Catalog # Color

* PS-094-2-WT-S White 500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-094-2-WT White 2,500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-094-2-WT-J White 10,000 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-125-2-WT-S White 500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* PS-125-2-WT White 2,500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

3” Core Materials

* PS-125-2-WT-J White 10,000 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* PS-187-2-WT-S White 500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* PS-187-2-WT White 2,500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* PS-187-2-WT-J White 10,000 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

B-342 PS PermaSleeve Wire Marking Sleeves:

Use the table below to browse standard white sleeves or build your own on page 198.

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Min. Max.

Supplied Dia.

Inch (mm)

Recovered Dia.

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve Width

Inch (mm)

PermaSleeves

* PS-250-2-WT-S White 500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-250-2-WT White 2,500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

*

PS-250-2-WT-J White 7,500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-375-2-WT-S White 250 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-375-2-WT White 1,000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-375-2-WT-J White 5,000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-500-2-WT-S White 250 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-500-2-WT White 500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-500-2-WT-J White 2,500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-750-2-WT-S White 100 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-750-2-WT White 250 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-750-2-WT-J White 1,000 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* PS-1000-2-WT-S White 100 2 to 0.950 dia. 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* PS-1000-2-WT White 250 2 to 0.950 dia. 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* PS-1000-2-WT-J White 1,000 2 to 0.950 dia. 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* PS-1500-2-WT-S White 100 N/A

* PS-1500-2-WT White 250 N/A 0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* PS-1500-2-WT-J White 2,000 N/A 0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

*

0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

200

Print Ribbons page 146

Material Guide page 264

Page 6

PermaSleeve® Wire Markers

B-342 PS PermaSleeve Wire Marking Sleeves:

Use the table below to browse standard white sleeves or build your own on page 198.

2” Sleeve Width, Double-sided Printable

Printer Compatibility: i7100, PR+, BBP72. i5100 and IP for size 125 and larger.

Recommended RIbbon Series: R4300, R4502S, R5000, R6600, R6700

Catalog # Color

* 3PS-094-2-WT-S White 500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-094-2-WT White 2,500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-094-2-WT-J White 10,000 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094 (2.4) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-125-2-WT-S White 500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-125-2-WT White 2,500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-125-2-WT-J White 10,000 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.047 (1.2) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-187-2-WT-S White 500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-187-2-WT White 2,500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-187-2-WT-J White 10,000 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* 3PS-250-2-WT-S White 500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-250-2-WT White 2,500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

*

3PS-250-2-WT-J White 7,500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Min. Max.

Supplied Dia.

Inch (mm)

Recovered Dia.

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve Width

Inch (mm)

* 3PS-375-2-WT-S White 250 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-375-2-WT White 1,000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-375-2-WT-J White 2,500 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-500-2-WT-S White 250 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-500-2-WT White 500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-500-2-WT-J White 2,500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-750-2-WT-S White 100 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-750-2-WT White 250 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-750-2-WT-J White 2,500 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750 (19.0) 0.250 (6.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* 3PS-1000-2-WT-S White 100 2 to 0.950 dia. 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* 3PS-1000-2-WT White 250 2 to 0.950 dia 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* 3PS-1000-2-WT-J White 2,500 2 to 0.950 dia 0.333 (8.5) - 0.950 (24.1) 1.000 (25.4) 0.375 (9.5) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* 3PS-1500-2-WT-S White 100 N/A

* 3PS-1500-2-WT White 250 N/A 0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

* 3PS-1500-2-WT-J White 1,000 N/A 0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

*

0.500 (12.7) - 1.400 (35.6) 1.500 (38.1) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

3” Core Materials

Print Ribbons page 146

Material Guide page 264

PermaSleeves

201

Page 7

PermaSleeve® Wire Markers

B-344 PermaSleeve® FR

Fluid Resistant Wire Marking Sleeves

B-344 PermaSleeve Fluid Resistant Wire Marking Sleeves are a

3:1 heat-shrinkable wire marking sleeve that fits snugly around wires

for identification and protection, and offers greater resistance to harsh

chemicals such as fuels, lubricants and cleaning solvents.

Meets specications:

• SAE-AS-23053/6 (Class 1)

• SAE-AS-81531

Tested per:

• ASTM E162

• ASTM E662

3” Core Materials

• MIL-STD-202G

Temp Range:

• -67°F to 275°F (-55°C to 135°C)

Shrink Ratio:

• 3:1 for 1” dia only

• 2:1 for 1-1/5” dia. only

PermaSleeves

Create Your

B-344 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

3FR - 187 - 2 - WT - S - 4

Product Diameter Width Color Roll

Create your own:

- - - -

Product Diameter Width Color Roll

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

®

72 Double Sided Printer

BBP

Ribbon Series

R6600, R6700

Qty

Qty

Pieces

Optional

-

Pieces

Optional

STEP 1:

Product Type

STEP 2:

Diamenter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Qty.

(optional)

STEP 6:

Pieces Per

Sleeve

(optional)

= Double-sided 3:1 shrink ratio for 094–1000 dia. only

3FR

= Double-sided 2:1 shrink ratio for 1500 dia. only

2FR

= 3/32” 0.023" - 0.080" dia. 28 to 20 gauge

094

= 1/8” 0.046" - 0.110" dia. 22 to 16 gauge

125

= 3/16” 0.062" - 0.150" dia. 20 to 10 gauge

187

= 1/4” 0.094" - 0.215" dia. 16 to 8 gauge

250

= 3/8” 0.125" - 0.320" dia. 12 to 4 gauge

375

= 1/2” 0.187" - 0.450" dia. 8 to 1 gauge

500

= 3/4” 0.250" - 0.700" dia. 6 to 4/0 gauge

750

= 1” 0.333" - 0.950" dia. 2 to 0.950” dia.

1000

= 1-1/2” 0.750" - 1.400" dia. n/a

1500

=

2

2” sleeve width

Standard Colors Special Order Colors al Order Colors

WT = White BL = Blue OR = Orange PK = Pink

YL = Yellow GR = Green GY = Gray RD = Red

For standard quantity, leave blank. For small quantity, enter “S”.

If sleeve diameter is 094–250 Standard = 2,500 Small (S) = 500

If sleeve diameter is 375 Standard = 1,000 Small (S) = 250

If sleeve diameter is 500 Standard = 500 Small (S) = 250

If sleeve diameter is 750–1500 Standard = 250 Small (S) = 100

1 marker per sleeve is standard,

if desired, the sleeve can be split into multiple pieces.

= Sleeve is slit to create 2 pieces

2

BL = Black BR = Brown VT = Violet

Example: “2” slit

202

Print Ribbons page 146

Material Guide page 264

Page 8

PermaSleeve® Wire Markers

B-344 FR PermaSleeve Wire Marking Sleeves:

Use the tables below to browse standard white sleeves or build your own on page 202.

3:1 Ratio, 2” Sleeve Width, Double-sided Printable

Printer Compatibility: i7100, PR+, BBP72

Recommended Ribbons: R6600, R6700

Catalog # Color

* 3FR-094-2-WT-S White 500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094" (2.4) 0.031" (0.79) .020" (0.508) +/- .003" (0.076) 2.00" (50.8)

* 3FR-094-2-WT White 2,500 28 to 20 0.023 (0.6) - 0.080 (2.0) 0.094" (2.4) 0.031" (0.79) .020" (0.508) +/- .003" (0.076) 2.00" (50.8)

* 3FR-125-2-WT-S White 500 22 to 16 0.042 (1.1) - 0.110 (2.8) 0.125 (3.2) 0.042" (1.07) .020" (0.508) +/- .003" (0.076) 2.00" (50.8)

* 3FR-125-2-WT White 2500 22 to 16 0.042 (1.1) - 0.110 (2.8) 0.125 (3.2) 0.042" (1.07) .020" (0.508) +/- .003" (0.076) 2.00" (50.8)

* 3FR-187-2-WT-S White 500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187" (4.7) 0.062" (1.57) .023" (0.584) +/- .003" (0.076) 2.00" (50.8)

* 3FR-187-2-WT White 2,500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187" (4.7) 0.062" (1.57) .023" (0.584) +/- .003" (0.076) 2.00" (50.8)

* 3FR-250-2-WT-S White 500 16 to 8 0.083 (2.1) - 0.215 (5.5) 0.250" (6.4) 0.083" (2.11) .023" (0.584) +/- .003" (0.076) 2.00" (50.8)

* 3FR-250-2-WT White 2,500 16 to 8 0.083 (2.1) - 0.215 (5.5) 0.250" (6.4) 0.083" (2.11) .023" (0.584) +/- .003" (0.076) 2.00" (50.8)

* 3FR-375-2-WT-S White 250 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375" (9.5) 0.125" (3.18) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

* 3FR-375-2-WT White 1,000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375" (9.5) 0.125" (3.18) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

*

3FR-500-2-WT-S White 250 8 to 1 0.166 (4.2) - 0.450 (11.4) 0.500" (12.7) 0.166" (4.22) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

* 3FR-500-2-WT White 500 8 to 1 0.166 (4.2) - 0.450 (11.4) 0.500" (12.7) 0.166" (4.22) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

* 3FR-750-2-WT-S White 100 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750" (19.0) 0.250" (6.35) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

* 3FR-750-2-WT White 250 6 to 4/0 0.250 (6.6) - 0.700 (17.8) 0.750" (19.0) 0.250" (6.35) .024" (0.610) +/- .003" (0.076) 2.00" (50.8)

* 3FR-1000-2-WT-S White 100 2 to 0.950 dia 0.333 (8.45) - 0.950 (24.13) 1.000" (25.4) 0.333" (8.46) .025" (0.635) +/- .003" (0.076) 2.00" (50.8)

* 3FR-1000-2-WT White 250 2 to 0.950 dia 0.333 (8.45) - 0.950 (24.13) 1.000" (25.4) 0.333" (8.46) .025" (0.635) +/- .003" (0.076) 2.00" (50.8)

*

Sleeves

Per Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered

Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

2:1 Ratio, 2” Sleeve Width, Double-sided Printable

Printer Compatibility: i7100, PR+, BBP72

Recommended Ribbons: R6600, R6700

Catalog # Color

* 2FR-1500-2-WT-S White 100 N/A 0.75 (19.05) - 1.450 (36.84) 1.500 (38.1) 0.75 (19.1) .035” (0.889) +/- .003” (0.076) 2.000 (50.8)

* 2FR-1500-2-WT White 250 N/A 0.75 (19.05) - 1.450 (36.84) 1.500 (38.1) 0.75 (19.1) .035” (0.889) +/- .003” (0.076) 2.000 (50.8)

*

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered

Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

3” Core Materials

PermaSleeves

Print Ribbons page 146

Material Guide page 264

203

Page 9

PermaSleeve® Wire Markers

B-345 PermaSleeve® HT

High Temperature PVDF

Wire Marking Sleeves

B-345 PermaSleeve HT High Temperature PVDF Wire Marking Sleeves are a 2:1

(3/32” is 3:1) heat-shrinkable wire marking sleeve specifically designed for high

temperature and low vacuum outgassing applications. These sleeves are made

of irradiated polyvinylidene fluoride (PVDF) and have an operating temperature

of -67°F to 437°F (-55°C to 225°C).

Meets specications:

• NASA SP-R-0022A Outgassing Performance

• SAE-AS-81531

• RoHS compliant

3” Core Materials

Tested per:

• SAE-AMS-DTL-23053/18, Class 2

• ASTM E162

• ASTM E662

• MIL-STD-202

Create Your

B-345 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

2HT - 187 - 2 - WT - S - 4

Product Diameter Width Color Roll

PermaSleeves

Create your own:

Product Diameter Width Color Roll

- - - -

Qty

Optional

Qty

Optional

-

Pieces

Pieces

STEP 1:

Product Type

STEP 2:

Diameter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Qty.

(optional)

= 3:1 Ratio, 094 Dia. Size Only, Double Sided Printing

3HT

= 2:1 Ratio, 125–1500 Dia. Sizes Only, Double Sided Printing

2HT

= 3/32” 0.031" - 0.080" dia. 26 to 20 gauge

094

= 1/8” 0.063” - 0.110” dia. 20 to 16 gauge

125

= 3/16” 0.094” - 0.150” dia. 16 to 10 gauge

187

= 1/4” 0.125” - 0.215” dia. 12 to 8 gauge

250

= 3/8” 0.187” - 0.320” dia. 8 to 4 gauge

375

= 1/2” 0.250” - 0.450” dia. 6 to 1 gauge

500

= 3/4” 0.375” - 0.700” dia. 2 to 4/0 gauge

750

= 1” 0.450” - 0.950” dia. 2/0 to 0.950” dia.

1000

= 1-1/2” 0.750” - 1.400” dia. n/a

1500

=

2

2” sleeve width

Standard Colors Special Order Colors

WT = White YL = Yellow PK = Pink

Only available in small quantity size, please enter “S”.

If sleeve diameter is 094–250 Standard Small (S) = 500

If sleeve diameter is 375-500 Standard Small (S) = 250

If sleeve diameter is 750–1500 Standard Small (S) = 100

BL = Blue BL = Black

204

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

®

72 Double Sided Printer

BBP

BradyPrinter i5100 and IP

printer acceptable for

size 125 and larger.

Ribbon Series

R6000, R6600

STEP 6:

Pieces Per

Sleeve

(optional)

1 marker per sleeve is standard,

if desired, the sleeve can be split into multiple pieces.

= Sleeve is slit to create 2 pieces

2

= Sleeve is slit to create 3 pieces

3

= Sleeve is slit to create 4 pieces

4

Example: “3” slit

Print Ribbons page 146

Material Guide page 264

Page 10

PermaSleeve® Wire Markers

y

B-345 HT PermaSleeve Wire Marking Sleeves:

Use the tables below to browse standard white sleeves or build your own on page 204.

3:1 Ratio, 2” Sleeve Width, Double-sided Printable

Printer Compatibility: i7100, PR+, BBP72. i5100 and IP for size 125 and larger.

Recommended Ribbons: R6000

Catalog # Color

3HT-094-2-WT-S White 500 26 to 20 0.031 (0.8) - 0.080 (2.0) 0.094 (2.4) 0.031 (0.8) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

3HT-094-2-WT-J White 10,000 26 to 20 0.031 (0.8) - 0.080 (2.0) 0.094 (2.4) 0.031 (0.8) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire

Gauge

2:1 Ratio, 2” Sleeve Width, Double-sided Printable

Printer Compatibility: i7100, PR+, BBP72. i5100 and IP for size 125 and larger.

Recommended Ribbons: R6000

Catalog # Color

2HT-125-2-WT-S White 500 20 to 16 0.063 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.062 (1.6) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-187-2-WT-S White 500 16 to 10 0.094 (2.4) - 0.150 (3.8) 0.187 (4.7) 0.093 (2.4) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-250-2-WT-S White 500 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.125 (3.2) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-375-2-WT-S White 250 8 to 4 0.187 (4.7) - 0.320 (8.1) 0.375 (9.5) 0.187 (4.7) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-500-2-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.250 (6.4) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-750-2-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) 0.015 (0.4) ± 0.003 (0.07) 2.000 (50.8)

2HT-1000-2-WT-S White 100 2/0 to 0.950 dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.017 (0.4) ± 0.004 (0.1) 2.000 (50.8)

2HT-1500-2-WT-S White 100 N/A 0.750 (19.1) - 1.400 (35.6) 1.500 (38.1) 0.750 (19.1) 0.024 (0.6) ± 0.004 (0.1) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

Sleeve

Width

Inch (mm)

ellow and black tubing tested

White,

3” Core Materials

marking has very good environmental, abrasion, and chemical

PermaSleeves

Print Ribbons page 146

Material Guide page 264

205

Page 11

PermaSleeve® Wire Markers

B-7641 PermaSleeve® LSZH

Low Smoke Zero Halogen

%!"

B-7641 PermaSleeve LSZH polyolefin wire marking sleeves are

2:1 heat-shrinkable, low smoke and zero halogen. These wire

marking sleeves offer outstanding fire safety properties and

minimal smoke emission.

These low smoke zero halogen materials have an operating

temperature of -22°F to 221°F (-30°C to 105°C).

Meets specications:

• SAE-AS-81531

• EN45545-2

• RoHS compliant

3” Core Materials

Tested per:

• ASTM E162

• ASTM E662

• MIL-STD-202

PermaSleeves

Create Your

B-7641 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

LSZH

Product Diameter Width Color Roll

Create your own:

Product Diameter Width Color Roll

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

BBP

- 187 - 2 - WT - S - 4

- - - -

Ribbon Series

R6000, R6600

®

72 Double Sided Printer

Qty

Optional

Qty

Optional

-

Pieces

Pieces

STEP 1:

Product Type

STEP 2:

Diameter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Size

(optional)

STEP 6:

Pieces Per

Sleeve

(optional)

= Single Sided Printing

LSZH

= Double Sided Printing

2LSZH

= 3/32” 0.047” - 0.080” dia. 24 to 20 gauge

094

= 1/8” 0.062” - 0.110” dia. 20 to 16 gauge

125

= 3/16” 0.094” - 0.151” dia. 16 to 10 gauge

187

= 1/4” 0.125” - 0.215” dia. 12 to 8 gauge

250

= 3/8” 0.188” - 0.320” dia. 8 to 4 gauge

375

= 1/2” 0.250” - 0.450” dia. 6 to 1 gauge

500

= 3/4” 0.375” - 0.700” dia. 2 to 4/0 gauge

750

= 1” 0.450” - 0.950” dia. 2/0 to 0.950” dia.

1000

= 1-1/2” 0.750” - 1.400” dia. n/a

1500

= 2” 1.000” - 1.900” dia. n/a

2000

150=1-1⁄2” sleeve width

=

2

2” sleeve width

=

3

3” sleeve width (only available in 1000, 1500 and 2000 dia. parts)

Standard Colors Special Order Colors al Order Colors

WT = White BL = Blue OR = Orange RD = Red

YL = Yellow GR = Green GY = Gray VT = Violet

For standard quantity, leave blank. For small quantity, enter “S”.

If sleeve diameter is 094–187 Standard = 2,500 Small (S) = 500

If sleeve diameter is 250-375 Standard = 1,000 Small (S) = 250

If sleeve diameter is 500 Standard = 500 Small (S) = 250

If sleeve diameter is 750–1500 Standard = 250 Small (S) = 100

If sleeve diameter is 2000 Standard = 100 Small (S) = 50

1 marker per sleeve is standard,

if desired, the sleeve can be split into multiple pieces.

= Sleeve is slit to create 2 pieces

2

= Sleeve is slit to create 3 pieces

3

= Sleeve is slit to create 4 pieces

4

Example: “3” slit

206

Print Ribbons page 146

Material Guide page 264

Page 12

PermaSleeve® Wire Markers

B-7641 LSZH PermaSleeve Wire Markers:

Use the table below to browse standard white sleeves or build your own on page 206.

1.5” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R6000, R6600

Catalog # Color

LSZH-094-150-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 1.500 (38.1)

LSZH-094-150-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 1.500 (38.1)

LSZH-125-150-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

LSZH-125-150-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

LSZH-187-150-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

LSZH-187-150-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 1.500 (38.1)

LSZH-250-150-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 1.500 (38.1)

LSZH-250-150-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 1.500 (38.1)

LSZH-375-150-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 1.500 (38.1)

LSZH-375-150-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 1.500 (38.1)

LSZH-500-150-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 1.500 (38.1)

LSZH-500-150-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7)

LSZH-750-150-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 1.500 (38.1)

LSZH-750-150-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 1.500 (38.1)

LSZH-1000-150-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 1.500 (38.1)

LSZH-1000-150-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 1.500 (38.1)

LSZH-1500-150-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 1.500 (38.1)

LSZH-1500-150-WT-S White 100 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 1.500 (38.1)

LSZH-2000-150-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 1.500 (38.1)

LSZH-2000-150-WT-S White 50 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 1.500 (38.1)

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

0.252 (6.4) .028 (0.7) ± .002 (0.05) 1.500 (38.1)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

3” Core Materials

Custom Sleeve Options Available

Brady offers custom options for many of the materials in this

catalog. Our dedicated, experienced custom quoting team

can provide pricing for your unique label needs.

Contact Brady Customer Service at 1-888-250-3082 for

more information and to order your custom labels.

Print Ribbons page 146

Material Guide page 264

PermaSleeves

207

Page 13

PermaSleeve® Wire Markers

2” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R6000, R6600

Catalog # Color

LSZH-094-2-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 2.000 (50.8)

LSZH-094-2-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 2.000 (50.8)

ZH-094-2-WT-J White 10,000 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 2.000 (50.8)

LSZH-125-2-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

LSZH-125-2-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

ZH-125-2-WT-J White 10,000 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

3” Core Materials

PermaSleeves

LSZH-187-2-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

LSZH-187-2-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

ZH-187-2-WT-J White 10,000 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

LSZH-250-2-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 2.000 (50.8)

LSZH-250-2-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 2.000 (50.8)

ZH-250-2-WT-J White 7,500 12 to 8

LSZH-375-2-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

LSZH-375-2-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

ZH-375-2-WT-J White 5,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

LSZH-500-2-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

LSZH-500-2-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

ZH-500-2-WT-J White 2,500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

LSZH-750-2-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 2.000 (50.8)

LSZH-750-2-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 2.000 (50.8)

ZH-750-2-WT-J White 2,500 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 2.000 (50.8)

LSZH-1000-2-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

LSZH-1000-2-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

ZH-1000-2-WT-J White 2,500 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

LSZH-1500-2-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

ZH-1500-2-WT-J White 1,000 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

LSZH-2000-2-WT-S White 50

LSZH-2000-2-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

ZH-2000-2-WT-J White 1,000 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

B-7641 LSZH PermaSleeve Wire Markers:

Use the tables below to browse standard white sleeves or build your own on page 206.

Sleeves

Per Roll

Approx.

Wire

Gauge

N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

Range of Wire Diameter

Inch (mm)

Min. Max.

0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 2.000 (50.8)

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

208

3” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R6000, R6600

Catalog # Color

ZH-1000-3-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 3.000 (76.2)

ZH-1500-3-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 3.000 (76.2)

LSZH-2000-3-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 3.000 (76.2)

Sleeves

Per Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Print Ribbons page 146

Material Guide page 264

Sleeve

Width

Inch (mm)

Page 14

PermaSleeve® Wire Markers

B-7641 LSZH PermaSleeve Wire Markers:

Use the table below to browse standard white sleeves or build your own on page 206.

2” Sleeve Width, Double-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R6000, R6600

Catalog # Color

2LSZH-094-2-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 2.000 (50.8)

2LSZH-094-2-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) .021 (0.5) ± .004 (0.1) 2.000 (50.8)

2LSZH-125-2-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

2LSZH-125-2-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

2LSZH-187-2-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

2LSZH-187-2-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

2LSZH-250-2-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 2.000 (50.8)

2LSZH-250-2-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) .029 (0.7) ± .003 (0.07) 2.000 (50.8)

2LSZH-375-2-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

2LSZH-375-2-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

2LSZH-500-2-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

2LSZH-500-2-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) .028 (0.7) ± .002 (0.05) 2.000 (50.8)

2LSZH-750-2-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 2.000 (50.8)

2LSZH-750-2-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.375 (9.5) .031 (0.8) ± .003 (0.07) 2.000 (50.8)

2LSZH-1000-2-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

2LSZH-1000-2-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) .036 (0.9) ± .003 (0.07) 2.000 (50.8)

2LSZH-1500-2-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

2LSZH-2000-2-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

2LSZH-2000-2-WT-S White 50 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) .038 (1.0) ± .003 (0.07) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire Gauge

Range of Wire Diameter

Min. Max.

Supplied Dia.

Inch (mm)

Recovered Dia.

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve Width

Inch (mm)

3” Core Materials

PermaSleeves

Print Ribbons page 146

Material Guide page 264

209

Page 15

PermaSleeve® Wire Markers

B-7642 PermaSleeve® HX

%!"

B-7642 PermaSleeve HX Polyolefin Wire Marking Sleeves are

2:1 heat-shrinkable wire marking sleeves. The sleeves are hightemperature rated, highly flame-retardant and very flexible.

These heat-shrinkable wire marking sleeves have an operating

temperature of -40°F to 248°F (-40°C to 120°C).

Meets specications:

• SAE-AS-23053/5 Class 1 and 3

• SAE-AS-81531

• RoHS compliant

Tested per:

3” Core Materials

• ASTM E162

• ASTM E662

• MIL-STD-202

PermaSleeves

Create Your

B-7642 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

2HX - 187 - 2 - WT - S - 4

Product Diameter Width Color Roll

Create your own:

- - - -

Product Diameter Width Color Roll

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

®

72 Double Sided Printer

BBP

Ribbon Series

R4300, R6000,

R6400, R6600

Qty

Optional

Qty

Optional

Pieces

-

Pieces

STEP 1:

Product Type

STEP 2:

Diameter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Size

(optional)

STEP 6:

Pieces Per

Sleeve

(optional)

= Single Sided Printing

HX

= Double Sided Printing

2HX

= 3/32” 0.047” - 0.080” dia. 24 to 20 gauge

094

= 1/8” 0.062” - 0.110” dia. 20 to 16 gauge

125

= 3/16” 0.094” - 0.151” dia. 16 to 10 gauge

187

= 1/4” 0.125” - 0.215” dia. 12 to 8 gauge

250

= 3/8” 0.188” - 0.320” dia. 8 to 4 gauge

375

= 1/2” 0.250” - 0.450” dia. 6 to 1 gauge

500

= 3/4” 0.375” - 0.700” dia. 2 to 4/0 gauge

750

= 1” 0.450” - 0.950” dia. 2/0 to 0.950” dia.

1000

= 1-1/2” 0.750” - 1.400” dia. n/a

1500

= 2” 1.000” - 1.900” dia. n/a

2000

150=1-1⁄2” sleeve width

=

2

2” sleeve width

=

3

3” sleeve width (only available in 1000, 1500 and 2000 dia. parts)

Standard Colors Special Order Colors

WT = White YL = Yellow BL = Blue OR = Orange GY = Gray

For standard quantity, leave blank. For small quantity, enter “S”. For jumbo

If sleeve dia. is 094–187 Standard = 2,500 Small (S) = 500 Jumbo (J) = 10,000

If sleeve dia. is 250 Standard = 1,000 Small (S) = 250 Jumbo (J) = 7,500

If sleeve dia. is 375 Standard = 1,000 Small (S) = 250 Jumbo (J) = 2,500

If sleeve dia. is 500 Standard = 500 Small (S) = 250 Jumbo (J) = 2,500

If sleeve dia. is 750-1000 Standard = 250 Small (S) = 100 Jumbo (J) = 2,500

If sleeve dia. is 1500 Standard = 250 Small (S) = 100 Jumbo (J) = 1,000

If sleeve dia. is 2000 Standard = 100 Small (S) = 50 Jumbo (J) = 1,000

1 marker per sleeve is standard,

if desired, the sleeve can be split into multiple pieces.

= Sleeve is slit to create 2 pieces

2

= Sleeve is slit to create 3 pieces

3

= Sleeve is slit to create 4 pieces

4

BK = Black GR = Green RD = Red VT = Violet

quantity

, enter “J”.

Example: “3” slit

210

Print Ribbons page 146

Material Guide page 264

Page 16

PermaSleeve® Wire Markers

B-7642 HX PermaSleeve Wire Markers:

Use the table below to browse standard white sleeves or build your own on page 210.

1.5” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R4300, R6000, R6400, R6600

Catalog # Color

HX-094-150-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-094-150-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-094-150-WT-J White 10,000 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-125-150-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-125-150-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-125-150-WT-J White 10,000 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-187-150-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-187-150-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-187-150-WT-J White 10,000 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 1.500 (38.1)

HX-250-150-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-250-150-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-250-150-WT-J White 7,500 12 to 8

HX-375-150-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-375-150-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-375-150-WT-J White 2,500 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-500-150-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-500-150-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-500-150-WT-J White 2,500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

HX-750-150-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 1.500 (38.1)

HX-750-150-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 1.500 (38.1)

HX-750-150-WT-J White 2,500 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 1.500 (38.1)

HX-1000-150-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 1.500 (38.1)

HX-1000-150-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 1.500 (38.1)

HX-1000-150-WT-J White 2,500 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 1.500 (38.1)

HX-1500-150-WT-S White 100 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 1.500 (38.1)

HX-1500-150-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 1.500 (38.1)

HX-1500-150-WT-J White 1,000

HX-2000-150-WT-S White 50 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 1.500 (38.1)

HX-2000-150-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 1.500 (38.1)

HX-2000-150-WT-J White 1,000 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 1.500 (38.1)

Sleeves

Per Roll

Approx.

Wire

Gauge

N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 1.500 (38.1)

Range of Wire Diameter

Inch (mm)

Min. Max.

0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 1.500 (38.1)

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

3” Core Materials

Print Ribbons page 146

Material Guide page 264

PermaSleeves

211

Page 17

PermaSleeve® Wire Markers

B-7642 HX PermaSleeve Wire Markers:

Use the tables below to browse standard white sleeves or build your own on page 210.

2” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R4300, R6000, R6400, R6600

Catalog # Color

HX-094-2-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-094-2-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-094-2-WT-J White 10,000 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-125-2-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-125-2-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-125-2-WT-J White 10,000 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

3” Core Materials

PermaSleeves

HX-187-2-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-187-2-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-187-2-WT-J White 10,000 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

HX-250-2-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-250-2-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-250-2-WT-J White 7,500 12 to 8

HX-375-2-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-375-2-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-375-2-WT-J White 2,500 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-500-2-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-500-2-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-500-2-WT-J White 2,500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

HX-750-2-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

HX-750-2-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

HX-750-2-WT-J White 2,500 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

HX-1000-2-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

HX-1000-2-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

HX-1000-2-WT-J White 2,500 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

HX-1500-2-WT-S White 100 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

HX-1500-2-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

HX-1500-2-WT-J White 1,000

HX-2000-2-WT-S White 50 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

HX-2000-2-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

HX-2000-2-WT-J White 1,000 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

212

3” Sleeve Width, Single-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R4300, R6000, R6400, R6600

Catalog # Color

HX-1000-3-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 3.000 (76.2)

HX-1000-3-WT-J White 2,500 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 3.000 (76.2)

HX-1500-3-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 3.000 (76.2)

HX-1500-3-WT-J White 1,000 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 3.000 (76.2)

HX-2000-3-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 3.000 (76.2)

HX-2000-3-WT-J White 1,000 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 3.000 (76.2)

Sleeves

Per Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Print Ribbons page 146

Material Guide page 264

Sleeve

Width

Inch (mm)

Page 18

PermaSleeve® Wire Markers

B-7642 HX PermaSleeve Wire Markers:

Use the table below to browse standard white sleeves or build your own on page 210.

2” Sleeve Width, Double-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R4300, R6000, R6400, R6600

Catalog # Color

2HX-094-2-WT-S White 500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-094-2-WT White 2,500 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-094-2-WT-J White 10,000 24 to 20 0.047 (1.2) - 0.080 (2.0) 0.094 (2.4) 0.047 (1.2) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-125-2-WT-S White 500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-125-2-WT White 2,500 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-125-2-WT-J White 10,000 20 to 16 0.062 (1.6) - 0.110 (2.8) 0.125 (3.2) 0.063 (1.6) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-187-2-WT-S White 500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-187-2-WT White 2,500 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-187-2-WT-J White 10,000 16 to 10 0.094 (2.4) - 0.151 (3.8) 0.187 (4.8) 0.094 (2.4) 0.020 (0.5) ± 0.003 (0.07) 2.000 (50.8)

2HX-250-2-WT-S White 250 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-250-2-WT White 1,000 12 to 8 0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-250-2-WT-J White 7,500 12 to 8

2HX-375-2-WT-S White 250 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-375-2-WT White 1,000 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-375-2-WT-J White 2,500 8 to 4 0.188 (4.8) - 0.320 (8.1) 0.375 (9.5) 0.189 (4.8) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-500-2-WT-S White 250 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-500-2-WT White 500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-500-2-WT-J White 2,500 6 to 1 0.250 (6.4) - 0.450 (11.4) 0.500 (12.7) 0.252 (6.4) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

2HX-750-2-WT-S White 100 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

2HX-750-2-WT White 250 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

2HX-750-2-WT-J White 2,500 2 to 4/0 0.375 (9.5) - 0.700 (17.8) 0.750 (19.0) 0.374 (9.5) 0.030 (0.8) ± 0.003 (0.07) 2.000 (50.8)

2HX-1000-2-WT-S White 100 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

2HX-1000-2-WT White 250 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

2HX-1000-2-WT-J White 2,500 2/0 to 0.950" dia. 0.450 (11.4) - 0.950 (24.1) 1.000 (25.4) 0.500 (12.7) 0.035 (0.9) ± 0.005 (0.1) 2.000 (50.8)

2HX-1500-2-WT-S White 100 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

2HX-1500-2-WT White 250 N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

2HX-1500-2-WT-J White 1,000

2HX-2000-2-WT-S White 50 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

2HX-2000-2-WT White 100 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

2HX-2000-2-WT-J White 1,000 N/A 1.000 (25.4) - 1.900 (48.3) 2.000 (50.8) 1.000 (25.4) 0.045 (1.1) ± 0.007 (0.2) 2.000 (50.8)

Sleeves

Per Roll

Approx.

Wire

Gauge

N/A 0.750 (19.0) - 1.400 (35.6) 1.500 (38.1) 0.752 (19.1) 0.040 (1.0) ± 0.006 (0.2) 2.000 (50.8)

Range of Wire Diameter

Inch (mm)

Min. Max.

0.125 (3.2) - 0.215 (5.5) 0.250 (6.4) 0.126 (3.2) 0.025 (0.6) ± 0.003 (0.07) 2.000 (50.8)

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve

Width

Inch (mm)

3” Core Materials

Print Ribbons page 146

Material Guide page 264

PermaSleeves

213

Page 19

PermaSleeve® Wire Markers

B-7646 PermaSleeve® DR

[%

Wire Marking Sleeves

Brady B-7646 diesel resistant wire marking sleeves are a

yellow, 3:1 ratio heat-shrinkable wire marking sleeves. These

thermal transfer printable sleeves feature a double-sided

format.

B-7646 PermaSleeve markers have been developed for wire

and cable identification in applications that have exposure

to organic fluids, common fuels, lubricants and solvents for

extended periods of time and at high temperatures.

These heat-shrinkable wire marking sleeves have an

operating temperature of -55°F to 135°F (-48°C to 57°C).

Meets specications:

3” Core Materials

• SAE-AS-81531

Tested per:

• MIL-STD-202 method 215k

• NF F 00-608 Type A and H

PermaSleeves

Create Your

B-7646 PermaSleeve:

Use these steps to create a sleeve

specific to your needs.

Example catalog number:

DR - 187 - 2 - WT - S - 4

Product Diameter Width Color Roll

Create your own:

- - - -

Product Diameter Width Color Roll

Printer Compatibility

BradyPrinter i7100

PR Plus Printer

®

72 Double Sided Printer

BBP

Ribbon Series

R2000, R4300, R4502S,

R5000, R6600, R6700

Qty

Qty

Pieces

Optional

-

Pieces

Optional

STEP 1:

Product Type

STEP 2:

Diameter

STEP 3:

Sleeve Width

STEP 4:

Color

STEP 5:

Roll Size

STEP 6:

Pieces Per

Sleeve

(optional)

*

= Double Sided Printing

DR

= 1/8” 0.062” - 0.110” dia. 20 to 16 gauge

125

= 3/16” 0.094” - 0.151” dia. 16 to 10 gauge

187

= 1/4” 0.125” - 0.215” dia. 12 to 8 gauge

250

= 3/8” 0.188” - 0.320” dia. 8 to 4 gauge

375

= 1/2” 0.250” - 0.450” dia. 6 to 1 gauge

500

=

2

2” sleeve width

Standard Color

YL = Yellow

If sleeve diameter is 125–250 Standard = 2,500

If sleeve diameter is 375 Standard = 1,000

If sleeve diameter is 500 Standard = 500

if desired, the sleeve can be split into multiple pieces.

2

3

4

Only available in standard quantity, leave blank.

1 marker per sleeve is standard,

= Sleeve is slit to create 2 pieces

= Sleeve is slit to create 3 pieces

= Sleeve is slit to create 4 pieces

Example: “3” slit

214

Print Ribbons page 146

Material Guide page 264

Page 20

PermaSleeve® Wire Markers

B-7646 DR PermaSleeve Wire Markers:

Use the table below to browse standard yellow sleeves or build your own on page 214.

2” Sleeve Width, Double-sided Printable

Compatible Printers: i7100, PR+, BBP72

Recommended Ribbons: R6600

Catalog # Color

* DR-125-2-YL Yellow 2500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 2.000 (50.8)

* DR-125-2-YL-2 Yellow 5000 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 1.000 (25.4)

* DR-125-2-YL-3 Yellow 7500 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 0.500(12.7)

* DR-125-2-YL-4 Yellow 10000 22 to 16 0.046 (1.2) - 0.110 (2.8) 0.125 (3.2) 0.024 (0.6) .024 (0.6) ± .003 (0.07) 0.250 (6.4)

* DR-187-2-YL Yellow 2500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 2.000 (50.8)

* DR-187-2-YL-2 Yellow 5000 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 1.000 (25.4)

* DR-187-2-YL-3 Yellow 7500 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 0.500(12.7)

* DR-187-2-YL-4 Yellow 10000 20 to 10 0.062 (1.6) - 0.150 (3.8) 0.187 (4.7) 0.062 (1.6) .020 (0.5) ± .003 (0.07) 0.250 (6.4)

* DR-250-2-YL Yellow 2500 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* DR-250-2-YL-2 Yellow 5000 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 1.000 (25.4)

* DR-250-2-YL-3 Yellow 7500 16 to 8

* DR-250-2-YL-4 Yellow 10000 16 to 8 0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 0.250 (6.4)

* DR-375-2-YL Yellow 1000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* DR-375-2-YL-2 Yellow 2000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 1.000 (25.4)

* DR-375-2-YL-3 Yellow 3000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 0.500(12.7)

* DR-375-2-YL-4 Yellow 4000 12 to 4 0.125 (3.2) - 0.320 (8.13) 0.375 (9.5) 0.125 (3.1) .025 (0.6) ± .003 (0.07) 0.250 (6.4)

* DR-500-2-YL Yellow 500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 2.000 (50.8)

* DR-500-2-YL-2 Yellow 1000 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 1.000 (25.4)

* DR-500-2-YL-3 Yellow 1500 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 0.500(12.7)

* DR-500-2-YL-4 Yellow 2000 8 to 1 0.187 (4.8) - 0.450 (11.4) 0.500 (12.7) 0.187 (4.7) .025 (0.6) ± .003 (0.07) 0.250 (6.4)

*

Sleeves Per

Roll

Approx.

Wire

Gauge

Range of Wire Diameter

Inch (mm)

Min. Max.

0.094 (2.4) - 0.215 (5.5) 0.250 (6.4) 0.093 (2.4) .025 (0.6) ± .003 (0.07) 0.500(12.7)

Supplied

Diameter

Inch (mm)

Recovered

Diameter

Inch (mm)

Recovered Wall Thickness

Inch (mm)

Sleeve Width

Inch (mm)

Custom

Sleeve Options Available

Brady offers custom options for many of the materials in this

catalog. Our dedicated, experienced custom quoting team

can provide pricing for your unique label needs.

3” Core Materials

PermaSleeves

Print Ribbons page 146

Material Guide page 264

215

Loading...

Loading...