Page 1

Printer Applicator System

PAM 3600

Service Manual

Edition 1/07

Page 2

W.H. Brady

Lindestraat 21

Industriepark C3

9240 Zele Belgium

Phone: +32 52 457 811

e-mail: support@brady.be

All specications about delivery, design, performance and weight are given to the best of our current knowledge and are

subject to change without prior notice.

Identication Solutions Division

6555 W. Good Hope Road

PO Box 2131

Milwaukee, WI 53201 U.S.A.

Phone: 1-800-537-8791

Fax: 1-800-292-2289

Page 3

Service Manual PAM 3600 Table of Contents

Table of Contents

1 Introduction ................................................................................................................................................ 5

1.1 Scope of Information ................................................................................................................................... 5

1.2 Important Information .................................................................................................................................. 5

1.3 General Safety Instructions ......................................................................................................................... 6

1.4 Safe Handling of Electricity .......................................................................................................................... 7

1.5 Printer Types ............................................................................................................................................... 7

1.6 Component Location ................................................................................................................................... 8

Printer ....................................................................................................................................................8

Applicators ............................................................................................................................................. 9

Options................................................................................................................................................. 10

2 Expanded Functions for Servicing ........................................................................................................ 11

2.1 The Service Key and the OEM Key ............................................................................................................11

2.2 Expanded Functions in the "Setup" Menu ................................................................................................. 12

Print Parameters .................................................................................................................................. 12

Interfaces ............................................................................................................................................. 12

2.3 Expanded Functions in the "Test" Menu .................................................................................................... 13

Status Print ..........................................................................................................................................13

Device List ...........................................................................................................................................15

Label Prole ......................................................................................................................................... 16

Printhead Prole ..................................................................................................................................16

Event Log ............................................................................................................................................. 18

Print Directory of IFFS ......................................................................................................................... 18

2.4 Expanded functions in the "Service" Menu ................................................................................................ 19

Clearing the Service Counter ............................................................................................................... 19

Adjusting the Label Edge Sensor......................................................................................................... 20

Saving the NVRAM .............................................................................................................................. 20

Loading the NVRAM ............................................................................................................................ 21

Setting the Device Name ..................................................................................................................... 21

3 Maintenance .............................................................................................................................................22

3.1 General Cleaning ...................................................................................................................................... 22

3.2 Cleaning the Printhead .............................................................................................................................. 22

3.3 Cleaning the Print Roller and the Transport System ................................................................................. 23

3.4 Cleaning the Brake .................................................................................................................................... 24

3.5 Cleaning the Pad ....................................................................................................................................... 25

4 Replacing Assembly Units......................................................................................................................26

4.1 Recommended Tools ................................................................................................................................. 26

Standard Tools ..................................................................................................................................... 26

Special Tools ........................................................................................................................................ 26

4.2 Replacing the Printhead ............................................................................................................................ 27

4.3 Replacing the Print Roller and the Feed Roller ......................................................................................... 28

4.4 Replacing the Transport Locking Roller ..................................................................................................... 29

4.5 Replacing the Pinch Roller ........................................................................................................................ 30

4.6 Replacing the Label Edge Sensor ............................................................................................................. 32

4.7 Replacing the Slip Clutches ....................................................................................................................... 33

Replacing the Slip Clutch on the Ribbon Take Up Hub ........................................................................ 34

Replacing the Slip Clutch on the Ribbon Supply Hub .......................................................................... 35

Replacing the Slip Clutch on the Internal Rewinder............................................................................. 35

4.8 Replacing the Main Drive Motor ................................................................................................................ 36

4.9 Replacing the CPU PCB ............................................................................................................................ 37

4.10 Replacing the Power Unit .......................................................................................................................... 39

4.11 Replacing the Applicator Control PCB and Firmware Update of the Applicator Module ............................ 40

4.12 Replacing the Sensors .............................................................................................................................. 41

Sensors of the Printer Module ............................................................................................................. 41

Sensors of the Applicator Module ........................................................................................................ 46

4.13 Disassembling the Energy-Chains ............................................................................................................ 47

5 Adjustments .............................................................................................................................................48

5.1 Adjusting the Peel-off Table ....................................................................................................................... 48

5.2 Adjusting the Printhead ............................................................................................................................. 49

3Printer Applicator System PAM 3600

Page 4

Service Manual PAM 3600Table of Contents

5.3 Adjusting the Guide Plate .......................................................................................................................... 50

5.4 Adjusting the Sensors of the Peel-off Table ............................................................................................... 51

5.5 Adjusting the Sensors of the Printhead ..................................................................................................... 52

5.6 Adjusting the Torques at the Hubs ............................................................................................................. 53

Measuring the Traction at the Internal Rewinder ................................................................................. 53

Measuring the Traction at the Ribbon Take Up and the Ribbon Supply Hub ....................................... 54

Adjusting the Torques ..........................................................................................................................55

5.7 Adjusting the Brake at the Media Supply Hub ........................................................................................... 56

5.8 Adjusting the Label Edge Sensor .............................................................................................................. 57

5.9 Setting the Speed of the Compressed Air Driven Assemblies ................................................................... 57

Setting the Speed of the Peel-off Table Movement .............................................................................. 57

Setting the Speed of the Printhead Movement .................................................................................... 58

Setting the Speed of the Turn/Lift Cylinder Movement ........................................................................ 59

Setting the Speed of the Main Cylinder Movement.............................................................................. 60

5.10 Pneumatic Setting of the Printhead Pressure ............................................................................................ 61

5.11 Pneumatic Setting of the Brake ................................................................................................................. 62

5.12 Pneumatic Setting of the Supporting Air .................................................................................................... 63

5.13 Pneumatic Setting of the Table .................................................................................................................. 64

5.14 Adjusting the Sensors of the Applicator Module ........................................................................................ 65

Adjusting the Sensor Turn/Lift Cylinder................................................................................................ 65

Adjusting the Labeling Position Sensor ............................................................................................... 66

Adjusting the Sensor 1 Main Cylinder .................................................................................................. 67

Adjusting the Sensors 2 Main Cylinder (PAM 3602 only) .................................................................... 68

6 Problem Solution .....................................................................................................................................69

6.1 Errors During Printing ................................................................................................................................ 69

6.2 Failure of Device Functions ....................................................................................................................... 71

6.3 Permanently Displayed Hardware Errors .................................................................................................. 72

Appendix A: Block Diagram ............................................................................................................................. A-1

Appendix B: Circuit Diagrams ......................................................................................................................... B-1

PCB CPU: CPU, Clock Timer, Clock, BDM..........................................................................................................B-1

PCB CPU: Centronics, Interface Slot, RS-232 ....................................................................................................B-2

PCB CPU: dRAM, Flash ......................................................................................................................................B-3

PCB CPU: Printhead Connection ........................................................................................................................B-4

PCB CPU: FPGA, History RAM ...........................................................................................................................B-5

PCB CPU: Power Supply, Motor Driver ...............................................................................................................B-6

PCB CPU: Sensors, AD Converter ......................................................................................................................B-7

PCB CPU: USB Host ...........................................................................................................................................B-8

PCB 1 Control Panel ............................................................................................................................................B-9

PCB Control Panel .............................................................................................................................................B-10

PCB Applicator Control: Controller.....................................................................................................................B-11

PCB Applicator Control: Inputs/Outputs .............................................................................................................B-12

PCB Valve Connection .......................................................................................................................................B-13

PCB Ribbon Sensor ...........................................................................................................................................B-13

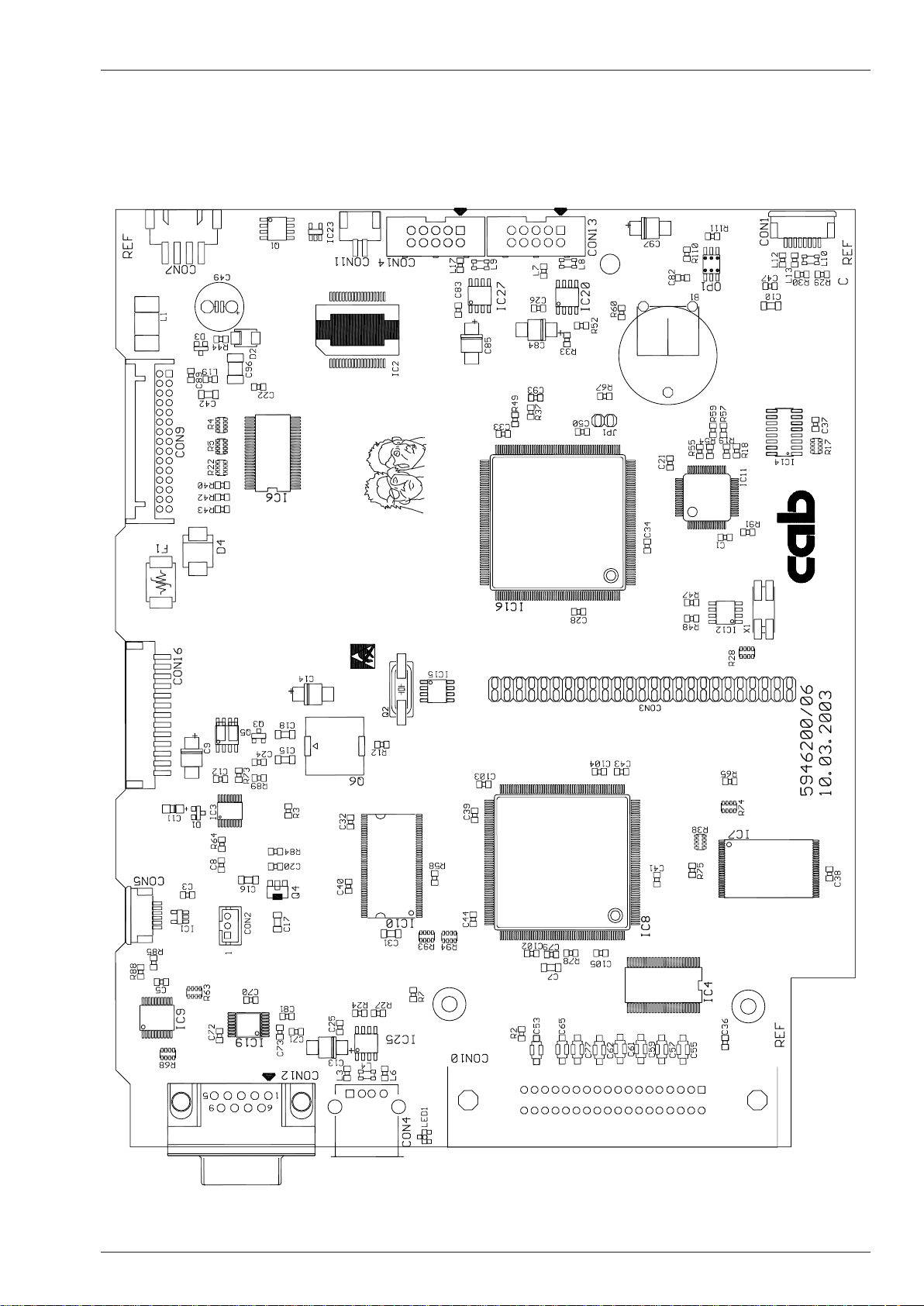

Appendix C: Layout Diagrams......................................................................................................................... C-1

PCB CPU: Components side .............................................................................................................................. C-1

PCB CPU: Soldering side ................................................................................................................................... C-2

PCB 1 Control Panel: Components side ............................................................................................................. C-3

PCB 1 Control Panel: Soldering side .................................................................................................................. C-3

PCB Control Panel .............................................................................................................................................. C-3

PCB Applicator Control: Components side ......................................................................................................... C-4

PCB Applicator control: Soldering side ............................................................................................................... C-4

PCB Valve Connection ........................................................................................................................................ C-5

PCB Ribbon Sensor: Components side .............................................................................................................. C-5

PCB Ribbon Sensor: Soldering side ................................................................................................................... C-5

Appendix D: Pneumatic Diagrams .................................................................................................................. D-1

PAM 3600 with Applicator 3602 .......................................................................................................................... D-1

PAM 3600 with Applicator 3603 .......................................................................................................................... D-2

Index I-1

4

Printer Applicator System PAM 3600

Page 5

Service Manual PAM 3600 1 Introduction

1 Introduction

1.1 Scope of Information

This manual is intended for use by qualied service and maintenance personnel.

The technical information included relates to hardware and mechanical parts of the Printer Applicator System PAM

3600.

Information related to operation will be found in the Operator's Manual.

If a problem occurs, which cannot be solved with the help of this manual, please contact the Technical Service

Department.

To adress see page 2.

1.2 Important Information

Important information contained in this manual is marked as follows:

WARNING!

Impending danger!

May cause death or physical injuries.

CAUTION!

Dangerous situation!

May cause equipment/material damage or data loss.

NOTICE!

Helpful additional information and tips for use.

In special cases a second symbol is additionally used to characterize the kind of danger.

See a sample for the risk of electric shock:

WARNING!

Mortal danger by electric shock!

Unplug power cord before opening the cover!

Printer Applicator System PAM 3600

5

Page 6

1.3 General Safety Instructions

Follow the general safety rules below:

Keep the area around the device clean at all times!

•

Avoid performing maintenance which might expose persons to danger or make the device a source of danger!

•

Keep housing or other parts of the device removed in a safe place during maintenance!

•

Keep tools out of the way to avoid injury to yourself or others not involved in the maintenance!

•

Do not wear loose clothing that could be caught in moving parts of the device. Button up your shirt or jacket

•

sleeves or roll them up. Tie back or put up long hair. Tuck the ends of scarves, ties and shawls into your

clothing and attach them with a non-conducting clip.

Do not wear jewelry, glasses with metal frame or clothing with metal fasteners!

•

WARNING!

Mortal danger by electric shock!

If such metal parts contact the device, they cause an increased current ow due to

good conductivity!

Service Manual PAM 36001 Introduction

Wear protective goggles at work as follows:

•

while driving pins or similar parts in or out with a hammer,

while working at an electric drilling machine,

while using spring hooks or springs,

while releasing or using of springs, snap rings and grip rings,

while soldering,

while using solvents, cleansers or other chemical substances,

in any case where injury to the eyes is possible.

-

Ret all protective devices such as covers, safety instructions, and grounding cable upon completion of the

•

maintenance work!

Replace all faulty or defective parts!

6

Printer Applicator System PAM 3600

Page 7

Service Manual PAM 3600 1 Introduction

1.4 Safe Handling of Electricity

Follow the additional instructions below when handling electricity:

Find out the positions of the emergency and the power switch in order to operate them quickly in an emergency

•

situation!

Do not work alone under dangerous working conditions or while working on devices with non-protected

•

voltages (over 50 V AC or 120 V DC)!

Turn off power to the printer before:

•

removing or installing power units,

working in the immediate vicinity of open power supply parts,

mechanical checkup of power supply parts,

changing circuit boards or electrical parts.

-

If you cannot avoid working on devices with non-protected voltages, follow these safety precautions:

•

Have a person nearby who is aware of the position and operation of the power switches, who will switch off

the power in case of danger.

Use only tools and test devices, which are suitable for the work being done.

Work only with one hand on devices that are switched on. Keep the other hand behind your back or in your

pocket until you have nished.

NOTICE!

A shock occurs only with a closed circuit. By using only one hand, as described above, you

would avoid a current ow through your own body.

Do not use worn or defective tools!

•

Never assume that a circuit is not powered. Always verify that there is no voltage present!

•

Always examine the work area for possible sources of danger, such as wet oors, defective extension cords,

•

faulty protective grounding connectors etc.

If you observe an accident with electricity:

•

Be careful and avoid danger to yourself.

-

Switch off power.

-

Request medical assistance.

-

Give rst aid if necessary.

-

1.5 Printer Types

There are two printers for the PAM 3600 systems available:

PAM 3630 with a printhead resolution of 300 dpi and

•

PAM 3660 with a printhead resolution of 600 dpi.

•

Both printers can be equipped with one of the applicator types

PAM 3602, tamp-blow applicator with vertical lift (main) cylinder and turn cylinder and

•

PAM 3603, tamp-blow applicator with vertical lift (main) cylinder and horizontal lift cylinder.

•

Printer Applicator System PAM 3600

7

Page 8

1.6 Component Location

21 22 23 24 25 26 272019

17 18

1 3 4 5 6 7

8

9

2

1110 12 1413

1615

Printer

Service Manual PAM 36001 Introduction

1 Ribbon take up hub

2 Control panel and display

3 Ribbon supply hub

4 Swing arm with guide roller

5 Guide roller

6 Media supply hub

7 Internal rewinder

8 Power connector

9 Power switch

10 Compressed air connector

11 Silencers

12 Frame

13 Sensor connector for the applicator

14 Compressed air connectors for the applicator

15 Printhead

16 Print roller

17 Peel-off table

18 Guide roller

19 Slot for an additional interface card

20 Connector warning sensor ribbon end

21 Connector warning sensor label end

22 PLC interface port

23 Connector warning light

24 RS-232 interface

25 USB master interface

26 Bi-directional parallel interface

27 Cover

Figure 1a Overview printer

8

Printer Applicator System PAM 3600

Page 9

Service Manual PAM 3600 1 Introduction

1

2

4

3

4

5

8

9

7

6

Applicators

PAM 3602 PAM 3603

Figure 1b Overview applicators

1 Energy-chains

2 Sensor 1 main cylinder

3 Main cylinder

4 Sensor 2 main cylinder (PAM 3602 only)

5 Slide valve

6 Lift cylinder (PAM 3603 only)

7 Turn cylinder (PAM 3602 only)

8 Pad holder

9 Pad

Printer Applicator System PAM 3600

9

Page 10

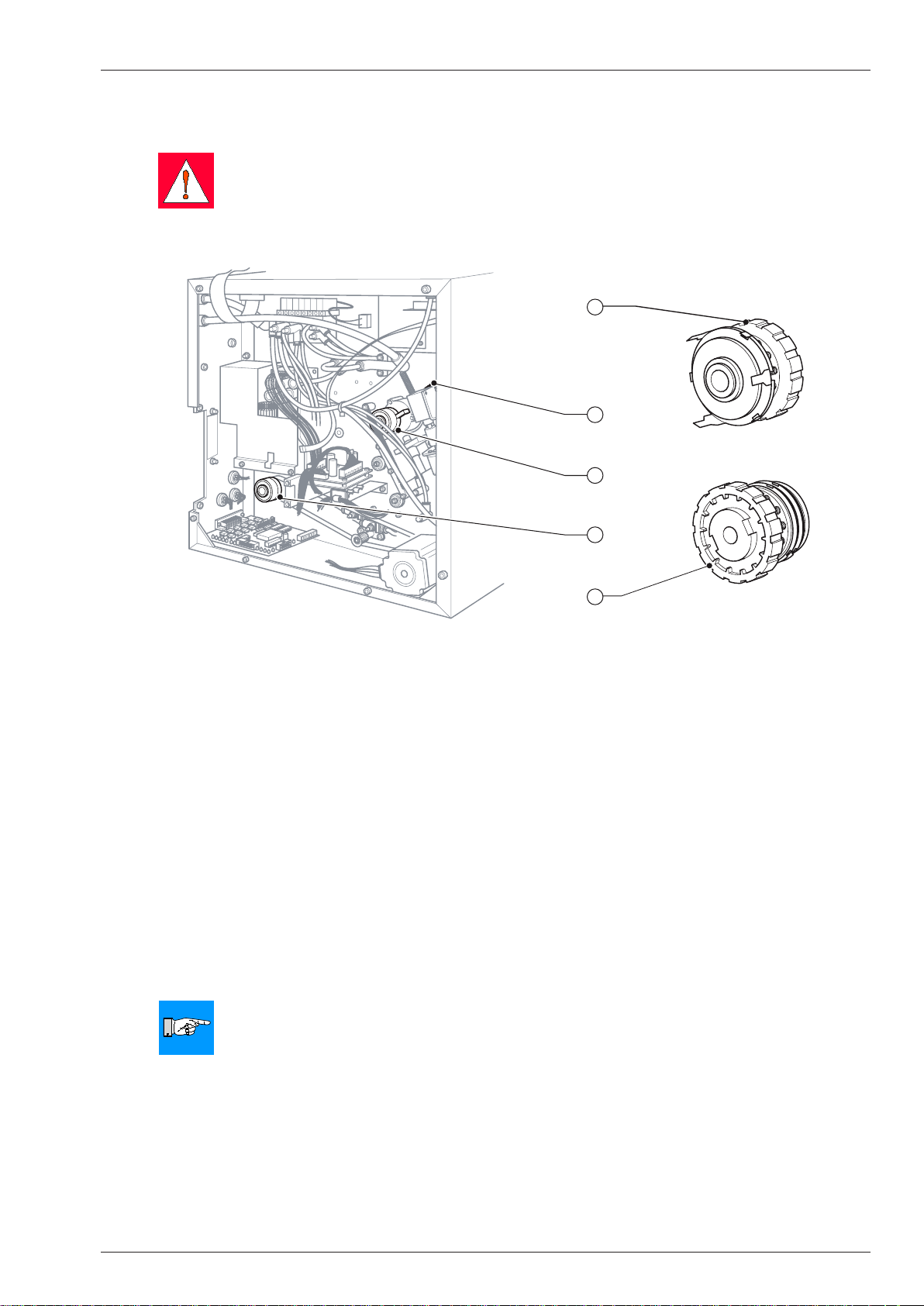

Options

1

2

3

4

5

Service Manual PAM 36001 Introduction

Figure 1c Overview options

1 Warning light

2 Warning sensor, ribbon end

3 Warning sensor, label end

4 Antistatic burst

5 Blow tube

10 Printer Applicator System PAM 3600

Page 11

Service Manual PAM 3600 2 Expanded Functions for Servicing

21

2 Expanded Functions for Servicing

2.1 The Service Key and the OEM Key

There are a service key (Part No. 5540301) and an OEM key (Part No. 5540304) for accessing special service

functions which are not accessible to the operator.

The OEM key enables:

selecting the correct device name (Set OEM Name).

•

The service key enables, among other functions:

adjustment of the label edge sensor,

•

clearing the service counters,

•

printing an expanded status report,

•

printing an event log,

•

saving the conguration data on a memory module (Save NVRAM),

•

loading the conguration data from a memory module (Load NVRAM).

•

Moreover, the conguration parameters stored in the printer for optional components (interface boards) are

also accessible with the service key inserted, even if they are not currently installed.

The information contained in the test printout is also expanded.

The printer offers the option of protecting certain functions - such as the complete printer conguration and

security-relevant memory module functions - from unauthorized access by means of a code number (PIN).

There is no PIN prompt when accessing the stated functions with the service key inserted, i. e. the protective

function is circumvented.

NOTICE!

Please ask your cab dealer about obtaining the service key or the OEM key.

Insert the respective key (1) into the USB master interface (2) on the side of the printer. This can be done while the

device is switched on.

Figure 2a Inserting the service key or the OEM key

1 Key

2 USB master interface

11Printer Applicator System PAM 3600

Page 12

2.2 Expanded Functions in the "Setup" Menu

There are a variety of parameters that can be set to congure the printer to specic requirements.

There are three different methods to set the parameters of the Printer Conguration:

Conguration via the control panel (see Operator's Manual),

•

Conguration via the optional Ethernet interface accessing the internal web server of the printer using a Java

•

enabled browser (see Operator's Manual of the optional Ethernet interface),

Conguration via immediate commands (described in the Programming Manual, chapter "Immediate

•

Commands").

Print Parameters

Protocol Error

With the service key inserted, the parameter "Protocol error" is accessible in the "Print parameters" submenu.

The protocol error parameter is "ON" in the standard setting. As a result, the printer switches to the error state after

receiving unknown or faulty data.

When working with older computer operating systems, it may happen that the operating system’s print spooler

sends normal printer status messages (e.g. end of paper) back to the printer as ASCII text.

The printer cannot interpret this data and produces a long series of protocol errors. The protocol error display can

be switched off in such a case.

Service Manual PAM 36002 Expanded Functions for Servicing

CAUTION!

Data loss!

Protocol errors arising from faulty programming are also ignored in the "OFF" setting. There is a

risk of losing data.

Insert the service key into the Master USB socket.

1.

Switch from online mode to the ofine menu by pressing the key.

2.

Press the or key until you reach the "Setup" menu, and then press the key.

3.

Now select the "Print parameters" submenu and then the "Protocol error" parameter, then press the key.

4.

Set the parameter according to your requirements.

5.

Interfaces

The following parameters can be called or congured in the "Interfaces" submenu:

Character set,

•

IEEE1284,

•

RS-232.

•

If the optional interfaces

RS-422/485,

•

Ethernet and

•

Keyboard

•

are installed then these are also shown for setting.

12

NOTICE!

The parameters of the options "RS-422/485 interface", "Ethernet interface" and "Keyboard" can

be accessed with the service key, even if these components are not present.

Please refer to the "Printer Conguration" section of the printer or optional component operator's manuals for

instructions on how to perform the conguration and set the parameters.

Printer Applicator System PAM 3600

Page 13

Service Manual PAM 3600 2 Expanded Functions for Servicing

2.3 Expanded Functions in the "Test" Menu

The test functions allow the operator or the service personnel to obtain an overview of the most important printer

settings and hardware congurations.

The following functions can be called in the "Test" menu.

Short status*

•

Status print

•

Font list*

•

Device list

•

ASCII dump mode*

•

Test grid*

•

Label prole

•

Printhead prole

•

Event log

•

IFFS Print directory

•

NOTICE!

For functions marked with an * refer to the Operator's Manual. You will nd all the information

you need there.

Additional information to the Operator's Manual about the other test functions you will nd in

this section.

In order to reach the "Test" submenu, use the key to switch from online mode to the ofine menu.

Press the or key until you reach the "Test" menu, and then press the key.

Now select the desired test function.

Status Print

The status print contains information about the printer conguration and the status.

It will be printed with the heat level and the print speed set in the "Setup" menu.

NOTICE!

With the service key inserted, the status print also contains parameter settings of optional

components, even if these have not been installed and the values of the service counters.

You obtain the expanded status print as follows:

Insert the service key into the Master USB socket.

1.

Switch from online mode to the ofine menu by pressing the key.

2.

Press the key or until you reach the "Test" menu, and then press the key.

3.

Select the "Status print" function with the or key and conrm with the key.

4.

Start the printout with the pre-dispense key.

The printout can be aborted with the key.

The status printout contains the following information:

A Device type, version and date of the rmware

B Values of selected conguration parameters

C Switch-on time, number of prints and the print length, values of the service counters

D Printhead temperature, heating voltage

E Details about the working points of the label edge sensor

F Line pattern for evaluating the quality of the printed image

O Parameter settings of optional components

A typical status printout is shown in the following gure.

Printer Applicator System PAM 3600

13

Page 14

Service Manual PAM 36002 Expanded Functions for Servicing

D

C

B

A

F

E

O

O

Figure 2b Status Print with Service Key inserted

14

Printer Applicator System PAM 3600

Page 15

Service Manual PAM 3600 2 Expanded Functions for Servicing

Device List

The most important hardware components installed in the printer and the connected optional devices are listed in

the "Device list" submenu.

Please also refer to the "Test Functions" section of the Operator's Manual for the printout of the device list and

further information.

Proceed as follows to print the device list:

Insert the service key into the Master USB socket.

1.

Switch from online mode to the ofine menu by pressing the key.

2.

Press the or key until you reach the "Test" menu, and then press the key.

3.

Select the "Device list" function with the or key and conrm with the key.

4.

Start the printout with the pre-dispense key.

The printout can be aborted with the key.

The printout contains the following information:

CPU Type and serial number of the CPU PCB, revision number of the CPU PCB and FPGA

TPH Resolution and number of hot points of the thermal printhead

CARD* Capacity, manufacturer, serial number and version number of the FlashCard

SLOT* Type, serial number and revision number of the interfaces expansion card

USB [a]* Type and revision number of the installed

[b/c] s USB devices

a: Number of the USB device

b: Number of the USB device to which device a is connected

c: Port number of device b, to which device a is connected

s: Speed of the USB device (Low Speed or Full Speed)

Only with inserted service key:

Mfr. Manufacturer ID indicates the manufacturer of the USB device

Class Code number for the USB device class

Protocol Code number for the type of communication with the USB device

Phase Internal value for debugging purposes

(* This information is only printed if the corresponding devices are installed.)

Figure 2c Device List with Service Key inserted

Printer Applicator System PAM 3600

15

Page 16

Service Manual PAM 36002 Expanded Functions for Servicing

5

6

7

8

9

1

2

3

4

Label Prole

The label prole printout contains additional information with the service key inserted.

Print out the label prole as follows:

Insert the service key into the Master USB socket.

1.

Select the "Test" menu in the ofine menu and conrm with the key.

2.

Press the or key until you reach the "Label prole" function and conrm with the key.

3.

Start the printout with the pre-dispense key.

The printout can be aborted with the key.

Figure 2d Label Prole with Service Key inserted

1 Device name and current rmware version

2 Method of label detection (transmitted light/reex bottom)

3 Print speed and service information for adjusting the label sensor

4 Scale factor for the derivative diagram *

5 Coordinate in the direction of paper ow at which the label start was detected

6 Type of peripheral device connected

7 Information for the rmware developer

8 Stroke between start and end of the negative derivative *

9 Width of the negative derivative in motor increments *

Information marked with * are only available with the service key inserted.

Printhead Prole

When selecting the option "Printhead prole", a diagram will be printed which shows the resistance values for the

single printhead dots. This printout makes it possible to see the status of the printhead.

When a dot is damaged or defective its resistance value increases. When this error occurs, it causes white lines in

the print image from top to bottom. In some cases, the white line could cause an invalid scan of certain barcodes.

To print the printhead prole, load media (labels, continuous paper) and a transfer ribbon (if applicable), which

extends over the entire print width of the printer.

With "Printhead prole", the printer will not sense any label gaps, and will print non-stop.

Continuous paper works best for the prints.

NOTICE!

16

Printer Applicator System PAM 3600

Page 17

Service Manual PAM 3600 2 Expanded Functions for Servicing

Insert the service key into the Master USB socket.

1.

Switch from online mode to the ofine menu by pressing the key.

2.

Select the "Test" menu in the ofine menu and conrm with the key.

3.

Select the option "Printhead prole" by pressing the key or the key and conrm by pressing the key.

4.

NOTICE!

The measurement of the resistance values can take several minutes.

You will see the progress of this measurement on the display.

5. When the measurement has nished, start the printout by pressing the pre-dispense key.

6. The "Printhead prole" will be printed with the heat level and print speed set in the "Setup" menu.

To cancel the print, press the key.

The printout has a scale which marks the actual geometric position of the dots. The scale will be printed underneath

the black bar with the text "Printhead prole". It is possible to compare a single dot to the scale as demonstrated in

the following diagram.

The gure indicates a print image failure around 22.5 mm in the black bar. In the scale section of the diagram, a dot

with an increased resistance value appears around 22.5 mm. Using this comparison makes it clear that the image

fault on the top line is caused by a defective printhead and not a case of a dirty printhead surface.

Figure 2e Printhead Prole with Service Key inserted

Printer Applicator System PAM 3600

17

Page 18

2 Expanded Functions for Servicing

Event Log

The label printer stores the following events in the event log:

Hardware fault

•

Adjustment of the label sensor

•

Firmware updates

•

Service counters reset

•

The event log can only be called with the service key inserted.

Print out the event log as follows:

Insert the service key into the Master USB socket.

1.

Select the "Test" menu in the ofine menu and conrm with the key.

2.

Press the or key until you reach the "Event log" function and conrm by pressing the key.

3.

Start the printout by pressing the pre-dispense key.

The printout can be aborted with the key.

Service Manual PAM 3600

Figure 2f Event log

Print Directory of IFFS

The IFFS (Internal Flash File System) is located on a Flash EPROM in the printer.

NOTICE!

As long as there was no write access on the IFFS the function "Print directory" is not shown.

The function "Print directory" can only be called with the service key inserted.

Start the printout of the directory as follows:

Insert the service key into the Master USB socket.

1.

Select the "Test" menu in the ofine menu and conrm with the key.

2.

Press the or key until you reach the "Print directory" function and conrm by pressing the key.

3.

Start the printout by pressing the pre-dispense key.

The printout can be aborted with the key.

From the printout you can get the following information:

First line: headline

•

For each le in the IFFS one line is printed with information about le name, le type, size of le in byte, date

•

and time for last change of le.

Last line: free memory in IFFS

•

18

Directory of internal Flash:

DEFAULT LBL 786 16.06.04 17:10

64718 bytes free

Figure 2g Printout Directory of IFFS

Printer Applicator System PAM 3600

Page 19

Service Manual PAM 3600 2 Expanded Functions for Servicing

2.4 Expanded functions in the "Service" Menu

In the "Service" menu, the operator only has access to the "Firmware update" and "Firmware from card" function.

The following functions are available after the service key respective the OEM key have been inserted:

Firmware update

Firmware from card*

Clear service counter

Adjust gap sensor

Save NVRAM*

Load NVRAM*

Set OEM Name

Functions marked with * are only available if the CF memory card is installed.

Clearing the Service Counter

The printer has two counter sets, a total and a service counter. The following data is recorded in both counter sets:

Operative time: time the printer has been switched on

Number of labels: number of labels printed

Transfer print: length of material printed in transfer print

Thermal direct: length of material printed in direct thermal print

The total counter contains the values for the total elapsed service life of the printer. The values of the total counter

are shown in both the short status and in the status printout.

The service counter can be reset with the use of the service key after major maintenance or repair work.

The service counter consequently provides information about the print output since the last reset.

The service counter is reset as follows:

Switch from online mode to the ofine menu by pressing the key.

1.

Press the or key until you reach the "Service" menu, and then press the key.

2.

Now select the "Clear service counter" function, and then press the key.

3.

"No" appears in the display. Change the selection to "Yes" with or and press .

4.

This resets the service counter.

You can check the value reset in the status printout.

Printer Applicator System PAM 3600

19

Page 20

Service Manual PAM 36002 Expanded Functions for Servicing

Adjusting the Label Edge Sensor

The function "Adjust gap sensor" enables the label edge sensor to be adjusted. This is necessary when the label

edge sensor itself or the CPU PCB are replaced.

NOTICE!

In order to avoid the inuence of light from the outside, check the adjustment of the sensor with

the cover closed and housing mounted!

Perform the adjustment as follows:

Insert the service key into the Master USB socket.

1.

Select the "Service" menu in the ofine menu and conrm with the key.

2.

Select the "Adjust gap sensor" function in the "Service" menu and conrm with the key.

3.

Open the printhead.

4.

The request "Please remove label stock" from label edge sensor appears in the display. Obey the request,

5.

close the printhead and conrm with the key.

The display now requests "Please insert liner" into the label edge sensor.

6.

Insert the liner material (without labels) into the label edge sensor, lock the printhead and conrm with the

key.

NOTICE!

Ensure that there are not any labels on the liner in the vicinity of the label edge sensor. This

would lead to a faulty alignment and a device malfunction.

7. "OK" appears in the display when the adjustment has been successful. Press the key again. The adjustment

has been completed now.

The message "Error" appears in the display if a fault occurs during the adjustment. If a fault recurs when the

adjustment is repeated, then there could be a defect in the following components:

Label edge sensor,

•

Label edge sensor connection cable or

•

CPU PCB.

•

Saving the NVRAM

The "Save NVRAM" function is used to save a printer conguration on a CompactFlash memory module.

This function is only accessible with the service key inserted and the CF card in the slot.

Save on the NVRAM as follows:

The printer is switched on.

Insert a CF card into the CF slot.

1.

Insert the service key into the Master USB socket.

2.

Select the "Save NVRAM" function in the "Service" menu and press the key.

3.

"No" appears in the display.

Change the selection to "Yes" with or and press the key. The saving begins and is indicated by the

4.

green LED next to the CF slot.

CAUTION!

Data loss!

Do not press the ejection key for the CF card while the green LED is lit.

If an error message appears in the display, this may indicate an unreadable CF card (e.g. unknown card type,

unformated card).

NOTICE!

To format the CompactFlash memory module, please refer to the "Memory Modules" section of

the Operator's Manual.

20 Printer Applicator System PAM 3600

Page 21

Service Manual PAM 3600 2 Expanded Functions for Servicing

Loading the NVRAM

The "Load NVRAM" function is used to reload a previously saved printer conguration from a CompactFlash

memory module.

This function is only accessible with the service key inserted and the CF card in the slot.

Load the NVRAM as follows:

The printer is switched on.

Insert a CF card containing the stored printer conguration into the CF slot.

1.

Insert the service key into the Master USB socket.

2.

Select the "Load NVRAM" function in the "Service" menu and press the key.

3.

"No" appears in the display.

Change the selection to "Yes" with the or key, and press the key.

4.

The loading process begins and is indicated by the green LED next to the CF slot.

CAUTION!

Data loss!

Do not press the ejection key for the CF card while the green LED is lit.

5. "OK" appears in the display when the loading process has nished. Press the key again.

An error message appears in the display if a fault occurred during the loading process.

In this case, try to repeat the loading process.

If an error occurs again, you have to reset the conguration parameters of the printer individually.

Setting the Device Name

The "Set OEM Name" function is used to adapt the CPU PCB to operating in the actual printer, because the CPU

PCB is qualied for several printer types. This adjustment is necessary after replacing the CPU PCB to detect

exactly the printer type over the interfaces.

This function is only accessible with the OEM key inserted.

Insert the OEM key into the Master USB socket.

1.

Select the "Set OEM Name" function in the "Service" menu and press the key.

2.

Select the device name with the or key.

3.

Conrm the selection by pressing the key.

4.

21Printer Applicator System PAM 3600

Page 22

3 Maintenance

1

The printer requires little maintenance.

It is important to clean the thermal printhead regularly. This guarantees a consistently good printed image and plays

a major part in preventing premature wear of the printhead.

Otherwise, the maintenance work is limited to occasion cleaning of the device and the rollers.

3.1 General Cleaning

Dust particles collect during operation, particularly around the printer’s mechanical parts.

Remove this dust with a soft brush or vacuum cleaner.

The outer surface of the printer may be cleaned with an all-purpose cleanser.

CAUTION!

Material damage!

Do not use abrasive cleansers or solvents!

3.2 Cleaning the Printhead

Service Manual PAM 36003 Maintenance

After extensive printer operation or if poor quality paper or ribbon has been used, foreign particles may collect on

the printhead. They cause characters or bar codes to appear light or faded, and can cause continuous light streaks

to always appear in the same physical position.

When this happens, you must clean the printhead.

We recommend cleaning the printhead every time changing the ribbon.

To clean the printhead, proceed as follows:

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 3a Cleaning the printhead

1 Print surface

Remove label stock and transfer ribbon from the printer.

1.

Remove the dirt and adhesive from the print surface (1) of the printhead using a cleaning pen.

2.

CAUTION!

Material damage!

Do not use any sharp objects to clean the print surface!

3. Allow the printhead to dry for 2 - 3 minutes.

22 Printer Applicator System PAM 3600

Page 23

Service Manual PAM 3600 3 Maintenance

1 2 3 2 2

3.3 Cleaning the Print Roller and the Transport System

If the print roller and the rollers of the transport system become contaminated with dirt, label adhesive, ink or rest of

labels, the movement of the media and print quality may also be adversely affected.

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 3b Cleaning the transport rollers and the print roller

1 Knurled knob

2 Roller

3 Print roller

Remove label stock and transfer ribbon from the printer.

1.

Unlock the transport locking roller by pressing the knurled knob (1) downward.

2.

Using a clean cloth and isopropyl alcohol, wipe off any accumulated dirt from the rollers (2) of the transport

3.

system and from the print roller (3).

Lock the transport locking roller.

4.

23Printer Applicator System PAM 3600

Page 24

3.4 Cleaning the Brake

1 2 3

It is recommended to clean the brake regularly. Otherwise it is possible that the transport of the paper is adversely

affected.

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Service Manual PAM 36003 Maintenance

Figure 3c Cleaning the brake

1 Brake

2 Screw

3 Brake plate

Remove label stock and transfer ribbon from the printer.

1.

Loosen the screw (2).

2.

Remove the brake plate (3).

3.

Using a soft brush or a vacuum cleaner, wipe off any accumulated dirt from the area around the brake (1).

4.

Remount the brake plate (3) and tighten the screw (2).

5.

24 Printer Applicator System PAM 3600

Page 25

Service Manual PAM 3600 3 Maintenance

1 2

3.5 Cleaning the Pad

During operation, dust particles accumulate on the pad. It is recommended to clean the pad regularly.

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 3d Cleaning the pad

1 Valve

2 Pad

Slightly pull the valve (1) until the bleed position is reached. So it is possible to move the pad manually.

1.

Slide the pad (2) to a position where the underside of the pad is easily accessible.

2.

Clean the underside of the pad.

3.

Remove particles with a soft brush or a vacuum cleaner.

Remove label fragments and traces of adhesive with alcohol if necessary.

The suction holes on the underside of the pad must be free.

4.

Perform a visual check of the pad (2) and the slide foil on the underside of the pad. If the slide foil is damaged,

5.

it must be replaced.

NOTICE!

Slide the valve (1) back to the operate position!

25Printer Applicator System PAM 3600

Page 26

4 Replacing Assembly Units

4.1 Recommended Tools

The following tools are recommended for servicing the PAM 3600 Printer-Applicator-System:

Standard Tools

double open-end wrench 4x5

double open-end wrench 5,5x7

double open-end wrench 8x9

double open-end wrench 10x13

double open-end wrench 12x14

double open-end wrench 14x17

allen key 1,5; angular

allen key 1,25; angular

allen key 2; angular

allen key 2,2; angular

allen key 3; angular

allen key 4; angular

allen key 5; angular

norm allen key 2,5; with hilt

precision allen key size 0

Philipps screw-driver size 1

Philipps screw-driver size 2

socket wrench 4,5

socket wrench 7

snap ring pliers

at pliers

Torx TX 20

-

Service Manual PAM 36004 Replacing Assembly Units

Special Tools

allen key 0.9 with long hilt (cab part number: 5945114)

spring hook (cab part number: 5906109)

spring scale 5 N (cab part number: 5909017)

spring scale 25 N (cab part number: 5909018)

spring scale 10 N (cab part number: 5906108)

test collar (cab part number: 5534199)

manometer (cab part number: 5538317)

tube loosener (manufacturer: SMC; SMC part number: TG-1)

-

26 Printer Applicator System PAM 3600

Page 27

Service Manual PAM 3600 4 Replacing Assembly Units

1 2 2 3

4.2 Replacing the Printhead

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

CAUTION!

Damages by electrostatic loading!

Ground yourself to the chassis before you remove or install the printhead. This will prevent a

static discharge from your body through the printhead to ground.

Figure 4a Replacing the printhead

1 Printhead locking screw

2 Plug

3 Printhead with head plate

Remove label stock and transfer ribbon from the printer.

1.

Release the printhead locking screw (1) and remove the printhead with the head plate (3) from the positioning

2.

pins.

Move the printhead with the head plate (3) and both cables carefully sideward until the plug connectors (2) are

3.

accessible.

Pull out the plug connectors (2) carefully.

4.

Connect the plugs (2) to the new printhead with head plate.

5.

Make sure that the PCB at the printhead will not be stressed mechanically.

CAUTION!

Material damage!

Handle the new printhead carefully to avoid scratching! The positioning pins must snap in on

both sides!

6. Slide the printhead with the head plate (3) onto the positioning pins. Make sure that the printhead is correctly

set into the positioning pins and then tighten the printhead locking screw (1) slightly. Note that the printhead ts

tightly in the bracket across the entire bracket.

7. Check the position of the both printhead cables. Make sure that the cables will not be stressed mechanically

and that they do not hinder other parts.

8. Perform a test print and adjust the printhead if necessary.

27Printer Applicator System PAM 3600

Page 28

4.3 Replacing the Print Roller and the Feed Roller

1 2 3 4

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Service Manual PAM 36004 Replacing Assembly Units

Figure 4b Replacing the print roller or the feed roller

1 Head plate

2 5 screws

3 Feed roller

4 Print roller

Remove label stock and transfer ribbon from the printer.

1.

Loosen and remove the 5 screws (2) from the head plate (1).

2.

Remove the head plate (1).

3.

Pull out the print roller (4) or the feed roller (3).

4.

Mount the components in reverse order.

5.

28 Printer Applicator System PAM 3600

Page 29

Service Manual PAM 3600 4 Replacing Assembly Units

1 2 3

4.4 Replacing the Transport Locking Roller

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 4c Replacing the transport locking roller

1 Transport locking roller

2 E-ring

3 Knurled knob

Remove label stock and transfer ribbon from the printer.

1.

Remove the two E-rings (2) from the axle.

2.

Unlock the transport locking roller (1) by pressing the knurled knob (3) downward.

3.

Pull out the knurled knob (3) with the axle.

4.

Remove the transport locking roller (1) and replace it.

5.

Mount the components in reverse order.

6.

29Printer Applicator System PAM 3600

Page 30

4.5 Replacing the Pinch Roller

1 2 3 4

5 6 7

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Service Manual PAM 36004 Replacing Assembly Units

Figure 4d Preparation

1 Gear

2 Belt

3 4 screws

4 Main motor

5 Belt

6 Pulley

7 Snap ring

Remove label stock and transfer ribbon from the printer.

1.

Unlock the transport locking roller by pressing down the knurled knob (10).

2.

Remove the cover at the rear side.

3.

Loosen the belt (2) by taking off it from the gear (1).

4.

Remove the four screws (3) at the main drive motor and take off the motor (4).

5.

Remove the belt (5) from the pulley (6).

6.

Remove the snap ring (7) from the axle of the pinch roller and take off the pulley (6).

7.

30 Printer Applicator System PAM 3600

Page 31

Service Manual PAM 3600 4 Replacing Assembly Units

9

10 11

138 12 14

Figure 4e Replacing the pinch roller

8 Transport locking roller

9 Spring

10 Knurled knob

11 Bearing plate

12 4 screws

13 Pinch roller

14 Guide roller

8. Hang out the spring (9).

NOTICE!

Pay attention on the spring on the other side of the transport locking roller (8), do not hang out it

by moving the roller or the knurled knob.

9. Loosen and remove the four screws (12) on the bearing plate (11).

10. Remove the bearing plate (11).

11. Replace the pinch roller (13).

12. Mount the bearing plate, consider here to thread the guide roller (14).

13. Lock the transport locking roller by pressing the knurled knob (10) upward.

14. Hang up the spring (9).

15. Mount the other components in reverse order.

31Printer Applicator System PAM 3600

Page 32

4.6 Replacing the Label Edge Sensor

43221

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Service Manual PAM 36004 Replacing Assembly Units

Figure 4f Replacing the label edge sensor

1 Cable

2 Label edge sensor

3 Hole

4 Screw

Remove label stock and transfer ribbon from the printer.

1.

Remove the cover at the rear side.

2.

Pull out the cable (1) from the label edge sensor (2).

3.

Remove the screw (4).

4.

Remove the label edge sensor (2) by pushing it through the mounting plate to the rear side.

5.

Push the new label edge sensor through the mounting plate.

6.

Put the screw (4) through the sensor into the hole (3) of the plate and tighten it.

7.

Reassemble the other parts in reverse order.

8.

NOTICE!

Make sure that the cable does not touch or hinder moving parts.

9. Adjust the label edge sensor (see section 2.4).

32 Printer Applicator System PAM 3600

Page 33

Service Manual PAM 3600 4 Replacing Assembly Units

1

3

4

2

4.7 Replacing the Slip Clutches

The rewinders for the ribbon and the media and the brake for the ribbon supply hub are equipped with slip clutches.

A slip clutch has to be replaced when it can not longer be adjusted. The assembly instructions for the clutches also

have to be observed when a winder has to be replaced.

The winding torque of the clutch always has to be readjusted after replacing a clutch or if it has been disassembled

at any intermediate time.

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 4g Slip clutches

1 Clutch of the ribbon take up hub

2 Motor for the ribbon take up hub

3 Clutch of the ribbon supply hub

4 Clutch of the internal rewinder

Remove label stock and transfer ribbon from the printer.

1.

Remove the cover at the rear side.

2.

Replace the respective clutch as described on the next pages.

3.

Mount the cover at the rear side.

4.

33Printer Applicator System PAM 3600

Page 34

Replacing the Slip Clutch on the Ribbon Take Up Hub

1 21 3 54

7 86 4 59

Service Manual PAM 36004 Replacing Assembly Units

Figure 4h Slip clutch on the ribbon take up hub

1 Screw

2 Motor bracket

3 Tappet

4 Slip clutch

5 Bearing on the take up hub

6 Lugs of the clutch

7 2 set screws

8 Knurled nut of the clutch

9 Feeler gauge

Pull out the plug of the motor (g. 4g, 2).

1.

Remove the two screws (1) and the bracket (2) with the motor assembly and the tappet (3).

2.

Loosen the knurled nut (8) of the slip clutch (4) by a few turns clockwise to reach the two set screws (7).

3.

Loosen the two set screws (7).

4.

Remove the slip clutch (4) from the axle of the ribbon take up hub.

5.

Slide the new clutch onto the axle.

6.

When pressing the clutch against the bearing (5) the knurled nut (8) must not touch the bearing. Check it by

7.

using a feeler gauge (9) or a label strip.

If the knurled nut touches the bearing, tighten the knurled nut a little and check the clearance again.

Press the clutch against the bearing and tighten the two set screws (7).

8.

Mount the complete motor bracket (2) with the screws (1).

9.

Ensure that all lugs (6) of the slip clutch snap into the slots of the tappet (3).

Put the plug of the motor into the corresponding socket.

10.

Adjust the torque of the new slip clutch (see section 5.6).

11.

34 Printer Applicator System PAM 3600

Page 35

Service Manual PAM 3600

5

3

3

4

4

5

6

6

7

7

2

2

1

1

1 2 3 4 5 6

5

3

3

4

4

5

6

6

7

7

2

2

1

1

1 2 3 4 5

Replacing the Slip Clutch on the Ribbon Supply Hub

Figure 4i Slip clutch on the ribbon supply hub

1 Snap ring

2 Washer

3 Clutch

4 Lug

5 Flat

6 Spring legs

4 Replacing Assembly Units

Remove the snap ring (1) and the washer (2).

1.

Remove the clutch (3).

2.

Insert the new clutch, make sure that the lug (4) is located between the spring legs (6) and that the clutch has

3.

the right position to the at (5) on the hub.

Remount the washer (2) and the snap ring (1).

4.

Replacing the Slip Clutch on the Internal Rewinder

Figure 4k Slip clutch on the internal rewinder

1 Snap ring

2 Washer

3 Clutch

4 Slot

5 Lug

Remove the CPU PCB.

1.

Remove the snap ring (1) and the washer (2).

2.

Remove the clutch (3).

3.

Insert the new clutch, make sure that the lugs (5) snap into the slots (4).

4.

Remount the washer (2) and the snap ring (1).

5.

Remount the CPU PCB.

6.

35Printer Applicator System PAM 3600

Page 36

4.8 Replacing the Main Drive Motor

Ribbon

G-TESTED

05/N31

MOTORHEADLOCKPERIPERIPANEL

PRINTHEAD

POMER SUPPLY

GAP SENSOR

IEEE1284

USB MASTER SERIAL

1 2

3 4 5 6

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Service Manual PAM 36004 Replacing Assembly Units

Figure 4l Replacing the main drive motor

1 CPU PCB

2 Plug

3 Gear

4 Belt

5 4 screws

6 Main drive motor

Remove the cover at the rear side.

1.

Loosen the belt (4) by taking off it from the gear (3).

2.

Pull out the plug (2) of the motor from the CPU PCB.

3.

Remove the four screws (5) of the motor (6).

4.

Replace the main drive motor (6).

5.

Fasten the motor by tightening the four screws (5).

6.

Put the plug (2) of the new motor into the socket of the PCB.

7.

Tighten the belt (4) by putting it on the gear (3).

8.

Mount the cover at the rear side.

9.

36 Printer Applicator System PAM 3600

Page 37

Service Manual PAM 3600 4 Replacing Assembly Units

1

3 42 5

4.9 Replacing the CPU PCB

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 4m Replacing the CPU PCB

1 Fixing screw

2 Stepper motor driver

3 CPU PCB

4 Heat conductor pad

5 Cooling rib

If possible backup the settings of the printer conguration on a CompactFlash card as described in the chapter

1.

"Save NVRAM".

Pull out all interface connectors at the side of the printer.

2.

Remove a possibly installed interface card (Ethernet, USB Slave, Twinax-/Coax Converter, RS-422/485).

3.

Remove the cover.

4.

Remove the cable across the CPU PCB (3).

5.

Pull out all plugs of the CPU PCB (3).

6.

Remove the 4 screws (1) xing the PCB.

7.

Remove the CPU PCB (3).

8.

To provide reliable functioning of the printer, a good thermal contact between the stepper motor driver (2) on the

CPU PCB (3) and the cooling rib (5) of the chassis is necessary. Therefore a pad of heat conductor foil (4) is located

between the cooling rib and the stepper motor driver.

When replacing the CPU PCB, the pad may remain on the defective board. To replace a pad, one spare pad (Part

No. 5943182) is delivered with the replacement board.

9. Check if the heat conductor pad (4) is sticking on the cooling rib (5) after removing the defective board.

10. Before attaching the new heat conductor pad, remove any pieces of old foil from the cooling rib. Peel the cover

foil from the white pad surface rst and stick it to the cooling rib as shown in the gure.

11. Now peel the cover foil from the pink surface of the heat conductor pad.

37Printer Applicator System PAM 3600

Page 38

G-TESTED

05/N31

MOTORHEADLOCKPERIPERIPANEL

PRINTHEAD

POMER SUPPLY

GAP SENSOR

IEEE1284

USB MASTER SERIAL

ibbonR

9

6

7

11

10

12

13

14

8

Figure 4n Connectors at the CPU PCB

6 Label edge sensor

7 Low-voltage input from power pack

8 Printhead logic connector

9 Control panel

10 Transfer ribbon sensor

11 Applicator control PCB

12 Applicator control PCB (alternative)

13 Sensor transport locking roller

14 Motor

Service Manual PAM 36004 Replacing Assembly Units

Mounting the CPU PCB:

12. Attach the PCB and secure it with four screws M4x10 (1).

13. Insert all plugs (see gure 4n).

14. Reinstall the cable across the CPU PCB (3).

15. Reassemble the cover.

16. Reinstall the power supply connector and the connectors for the peripheral interfaces, your optional interface

card inclusive.

17. If necessary carry out a rmware update.

18. Adjust the label edge sensor (see section 5.8).

19. Perform the needful adjustments in the Printer Conguration.

38 Printer Applicator System PAM 3600

Page 39

Service Manual PAM 3600 4 Replacing Assembly Units

3

4

1

6

2

5

4.10 Replacing the Power Unit

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

WARNING!

Mortal danger by electric shock!

While switched-on, the power unit has a voltage of up to 380 V as a function of the

capacitor. However, when the printer or power unit is switched off, this voltage falls to

non dangerous levels (< 42 V) within one minute. Be aware of these hazards!

Figure 4o Replacing the power unit

1 Fixing screw for the cover plate

2 Power input module connector

3 Cover plate

4 Fixing screw for the power unit

5 Power cable connector

6 Printhead power cable connector

Remove the cover.

1.

Dismount the CPU PCB as described in section 4.9.

2.

Remove the three screws M4x6 (1) and the cover plate (3).

3.

Pull out the following connectors from the power unit:

4.

- power input (2)

- power cable (5)

- printhead power connection (6).

Remove the two screws (4) and the power supply.

5.

To t the new power supply follow the above steps in reverse order.

6.

39Printer Applicator System PAM 3600

Page 40

Service Manual PAM 36004 Replacing Assembly Units

1 2 3

24

4.11 Replacing the Applicator Control PCB and Firmware Update of the Applicator Module

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Figure 4p Replacing the applicator control PCB

1 Fixing screw

2 Controller with rmware

3 Applicator control PCB

4 PLCC extractor

Replacing the PCB

Remove the cover.

1.

Dismount the CPU PCB as described in section 4.9.

2.

Pull out all plugs from the applicator control PCB (3).

3.

Remove the three screws (1) xing the PCB (3).

4.

Remove the PCB and replace it.

5.

Reassemble in reverse order.

6.

Firmware Update

Dismantle the applicator control PCB.

1.

Pull off the controller (2) with a PLCC extractor (4) and press in the controller containing the new rmware.

2.

Reassemble in reverse order.

3.

40 Printer Applicator System PAM 3600

Page 41

Service Manual PAM 3600 4 Replacing Assembly Units

Ribbon

G-TESTED

05/N31

MOTORHEADLOCKPERIPERIPANEL

PRINTHEAD

POMER SUPPLY

GAP SENSOR

IEEE1284

USB MASTER SERIAL

LED8

STRT1

LED7

EUEB

LED6

RST

LED5

ESP

LED4 LED3

START

LED9

VWE

LED10

VWT

LED11

TIV

LED12

TIH DKO

LED14

DKU

LED1

LED2

CON3

CON5

CON6

CON4

CON8

CON7

CON2

CON1

OC4

OC3

OC5

OC7

OC6

OC8

OC1

OC2

OC9

OC10

IC8 IC5 IC4

IC7

IC9

IC6

IC1

C1

Q1

C2C2

C23

C3

IC2

IC3

LED13

1 2 3 4 6 75

4.12 Replacing the Sensors

WARNING!

Mortal danger by electric shock!

Disconnect power supply!

Switch off compressed air!

Sensors of the Printer Module

Figure 4q Replacing the sensors of the printer module

1 Cable holder, sensors peel-off table

2 Cable holder, sensor printhead cylinder

3 Applicator control PCB

4 Plug for switch paper end

5 Plug for sensors peel-off table and printhead cylinder

6 CPU PCB

7 Plug for sensor transport locking roller

41Printer Applicator System PAM 3600

Page 42

Sensors peel-off table

View AC

A

B

D-A93V

D-A93V

View B

View C

11 12 129 108 10

Service Manual PAM 36004 Replacing Assembly Units

Figure 4r Replacing the sensors peel-off table

8 Canal

9 Cable

10 Screw

11 Base plate

12 Sensor peel-off table

Remove label stock and transfer ribbon from the printer.

1.

2.

3.

4.

Remove the cover.

Remove the cable from the cable holder (1).

Remove the plug (5) from the applicator control PCB (3), loosen the screws of the concerning cable and

remove it.

Loosen the screw (do not remove it) on the concerning sensor (12) and remove the sensor.

5.

Pull out the cable with the sensor.

6.

Therefore loosen (not remove) the two screws (10) on the base plate (11) below the peel-off table.

Now it is possible to move the cylinder above the base plate to push the sensor with the cable (9) through the

canal (8) and the mounting plate to the rear side.

Replace the sensor and reassemble in reverse order.

7.

NOTICE!

Pay attention before tighten the two screws (10):

Put the cable carefully in the canal (8) and click the holes of the cylinder into the positioning

pins at the base plate.

8. Connect the printer to the power supply, switch on printer and compressed air.

9. Check the replaced sensor of correct adjusting and adjust it if necessary (see section 5.4).

42 Printer Applicator System PAM 3600

Page 43

Service Manual PAM 3600 4 Replacing Assembly Units

13 14

View A

A

15 1516 17 18

Sensor transport locking roller

Figure 4s Preparation

13 Head plate

14 5 screws

Remove label stock and transfer ribbon from the printer.

1.

Remove the cover.

2.

Pull out the concerning plug (g. 4q, 7) on the CPU PCB (g. 4q, 6).

3.

Loosen the ve screws (14) and remove the head plate (13).

4.

Move the whole mounting forward.

5.

Figure 4t Replacing the sensor transport locking roller

15 Screw

16 Bracket

17 Screw

18 Sensor transport locking roller

6. Loosen the two screws (15) on the bracket (16).

7. Take out the bracket with the mounted sensor.

8. Loosen the two screws (17) holding the sensor (18).

9. Replace the sensor and reassemble in reverse order.

10. Connect the printer to the power supply, switch on printer and compressed air.

43Printer Applicator System PAM 3600

Page 44

Sensors printhead cylinder

19 19

Service Manual PAM 36004 Replacing Assembly Units

Figure 4u Replacing the printhead cylinder sensors

19 Printhead cylinder sensor

Remove the cover.

1.

Loosen the screw on the concerning sensor (19).

2.

Remove the cable from the cable holder (g. 4q, 2).

3.

Remove the plug (g. 4q, 5) from the applicator control PCB (g. 4q, 3), loosen the screws of the concerning

4.

cable and remove it.

Replace the sensor and reassemble in reverse order.

5.

Connect the printer to the power supply, switch on printer and compressed air.

6.

Check the replaced sensor of correct adjusting and adjust if necessary (see section 5.5).

7.

44 Printer Applicator System PAM 3600

Page 45

Service Manual PAM 3600 4 Replacing Assembly Units

BLOW-

AIR

VACUUM

LIFT

CYL.

BRAKE

TABLE

SUPPORT

AIR

PRINT

HEAD

ROTATE

CYL.

20 2221 23

Switch paper end

Figure 4v Replacing switch paper end

20 Switch paper end

21 3 screws

22 Plate

23 Screw

Remove label stock and transfer ribbon from the printer.

1.

Remove the cover.

2.

Remove the ange and the adapter from the media supply hub.

3.

Remove the three screws (21) and the plate (22) from the media supply hub.

4.

Remove the two screws of the micro switch paper end (20).

5.

Pull out the concerning plug (g. 4q, 4) on the applicator control PCB (g. 4q, 3).

6.

Remove the four screws (23), move the manifold assembly with the concerning PCB and pull out the plug (g.

7.

4q, 4) through the hole in the mounting plate.

Mount all components in reverse order.

8.

45Printer Applicator System PAM 3600

Page 46

1 1 1

9135303_02

2

1

3

4

5

7

8

6

9

2 3

4 Replacing Assembly Units

Sensors of the Applicator Module

Service Manual PAM 3600

Figure 4w Unscrewing the sensors of the applicator module

1 Sensors

Unscrew the respective sensor (1) by loosening the corresponding screw.

1.

Figure 4x Replacing the sensors of the applicator module

2 Plug

3 Screw

2. Pull out the plug (2).

3. Remove the cover of the plug by loosen the screw (3).

4. Remove the concerning cable from the connector by loosen the respective screws.

5. Open the energy-chains if necessary (see section 4.13).

6. Replace the sensor and reassemble in reverse order.

7. Connect the printer to the power supply, switch on printer and compressed air.

8. Adjust the replaced sensor if necessary (see section 5.14).

46 Printer Applicator System PAM 3600

Page 47

Service Manual PAM 3600 4 Replacing Assembly Units

2 31

4.13 Disassembling the Energy-Chains

If a cable contained in the energy-chains is to be changed, proceed as follows: