Page 1

MVPplus Quick Reference Guide

Use this guide to operate your printer on a daily basis. For more detailed information, refer to the User Guide.

Contents

External View . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Printer Media Compartment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Types of Media. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Load Media . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Position the Media Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Select or Position the Transmissive Sensor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Adjust the Reflective Sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Ribbon Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

When to Use Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Coated Side of Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Load Ribbon. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Remove Used Ribbon . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Adjust Printhead Pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Control Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

Print a Configuration Label. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Configure the Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

How to View or Modify Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Basic Printer Parameters . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Cleaning Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clean the Exterior . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Clean the Printhead and Platen Roller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

© 2006 ZIH Corp. All product names and numbers are Brady

trademarks, and Brady and the Brady logo are registered

trademarks of Brady Corp. All rights reserved.

14069L-001 Rev. A

12/6/06

Page 2

External View

F

Figure 1 shows the outside of the printer.

External View

2

Figure 1 • Exterior of Printer

ront

1

2

Rear

3

4

Control panel

1

Media door

2

Power switch (O = Off, I = On)

3

AC power connector

4

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 3

Printer Media Compartment

3

Printer Media Compartment

Figure 2 shows the components inside the media compartment of your printer. Depending on

installed options, your printer may look slightly different.

Figure 2 • Printer Components

3

4

2

1

5

6

7

Printhead assembly

1

Control panel

2

Media door

3

Media supply spindle

4

8

Ribbon take-up spindle

5

Ribbon supply spindle

6

Dancer assembly

7

Printhead release latch

8

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 4

Types of Media

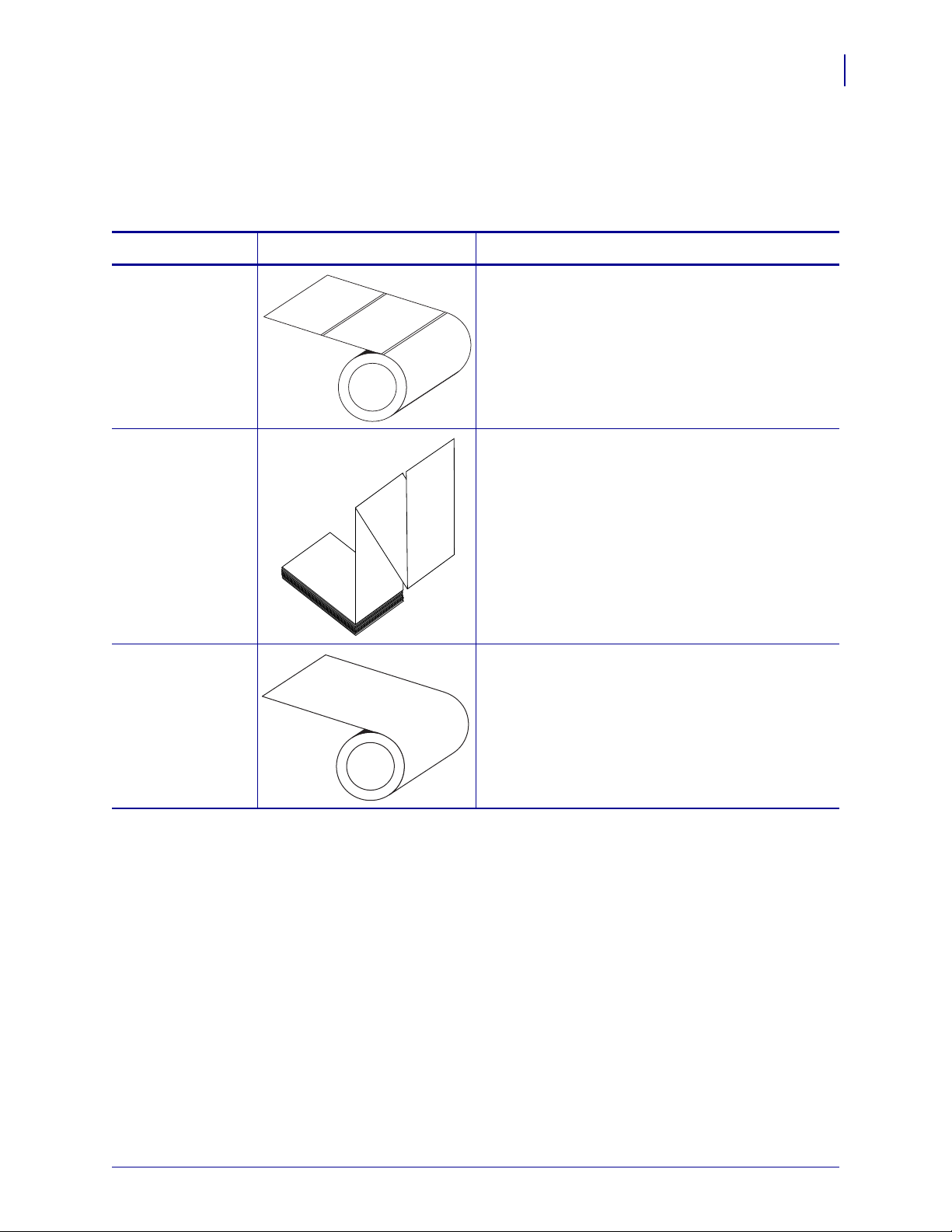

The printer can use various types of media (Table 1).

Table 1 • Types of Media

Media Type How It Looks Description

Types of Media

4

Non-Continuous

Roll Media

Non-Continuous

Fanfold Media

Continuous

Roll Media

Roll media is wound on a 3-in. (76-mm) core. Labels

have adhesive backing that sticks them to a liner, and

they are separated by gaps, holes, notches, or black

marks. Tags are separated by perforations.

Fanfold media is folded in a zigzag pattern. Fanfold

media can have the same label divisions as noncontinuous roll media. The divisions would fall on or

near the folds.

Continuous media is wound on a core and is without

gaps, holes, notches, or black marks. This allows the

image to be printed anywhere on the label. With

continuous media, use the transmissive sensor so the

printer can detect when the media runs out.

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 5

Load Media

5

Load Media

Use the instructions in this section to load roll media in Tear-Off mode (Figure 3). For

instructions for loading fanfold media or for loading in different print modes, refer to the

User Guide.

Figure 3 • Tear-Off Mode Media Path

Caution • When you are loading media or ribbon, remove all jewelry that could come into

contact with the printhead or other printer parts.

To Load Roll Media in Tear-Off Mode, complete these steps:

1. Remove and discard any tags or labels that are dirty or that are held by adhesives or tape.

Tag Stock Labels

2. Place the roll of media on the media supply spindle. Push the roll as far back as it will go.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 6

Load Media

123

3. Press the printhead release latch to open the printhead assembly. Lift the printhead until it

latches open.

4. Slide out the media guide.

6

5. Feed the media under the dancer assembly (1), through the slot in the transmissive

sensor (

2—standard transmissive sensor shown), and under the ribbon sensor (3).

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 7

Load Media

7

6. Push the media to the back of the transmissive sensor (1). Slide in the media guide (2)

until it touches the edge of the media.

1

2

7. Close the printhead assembly.

8. If the printer is paused (the Pause light is blinking), press PAUSE to enable printing.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 8

Position the Media Sensors

1

This printer uses two types of media sensors: transmissive and reflective.

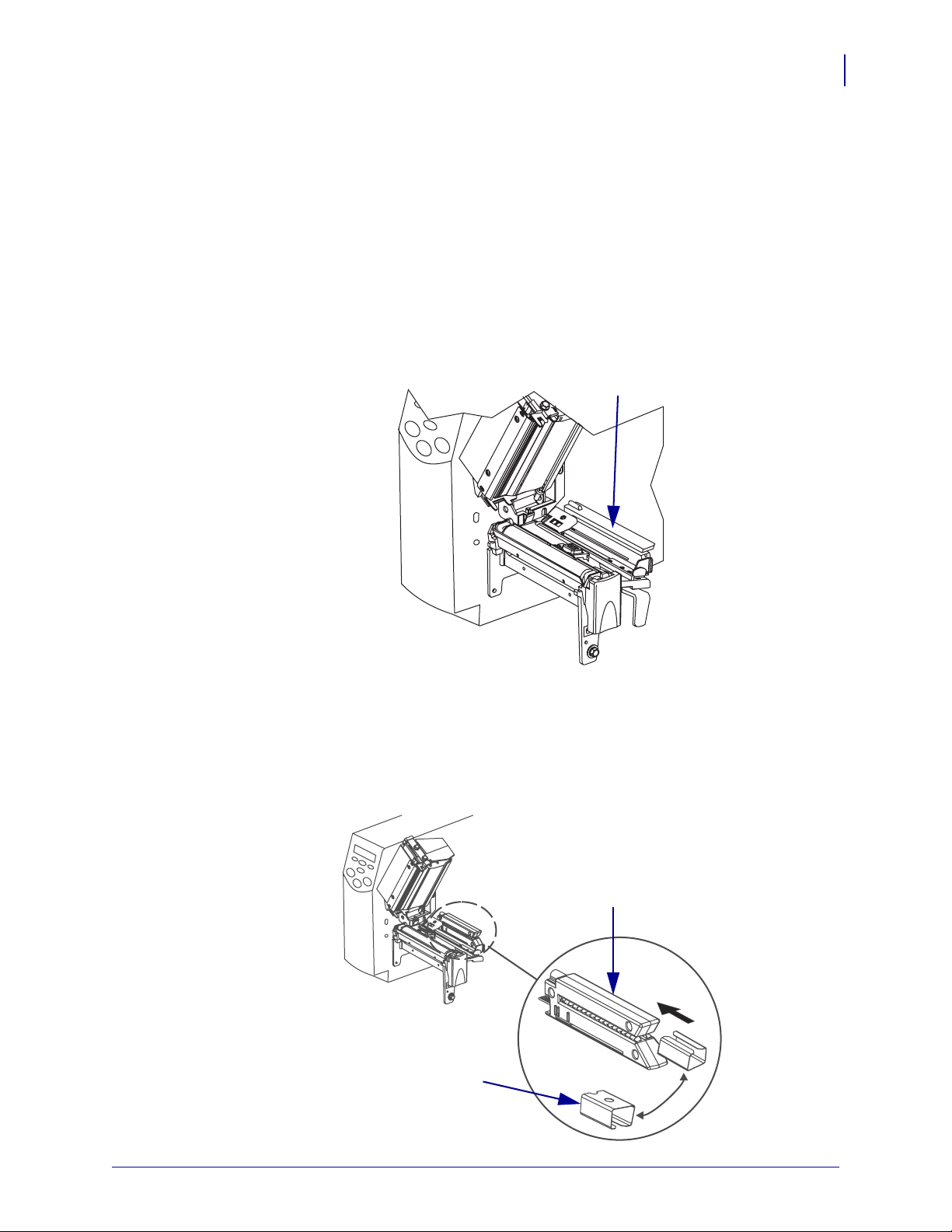

Select or Position the Transmissive Sensor

By default, the printer uses the transmissive sensor (Figure 4), which you can adjust for

optimal print performance. The reflective sensor is a secondary media sensing system that is

activated only if the transmissive sensor cannot be used to calibrate the media.

Figure 4 • Adjustable Transmissive Sensor

Position the Media Sensors

8

The transmissive sensor is equipped with a slide-on sensor sleeve (Figure 5). This sleeve has a

notch on one end and a hole in the middle, which help the printer calibrate media that has an

edge notch or an intra-label gap.

Figure 5 • Adjustable Transmissive Sensor and Sensor Sleeve

1

2

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 9

Position the Media Sensors

9

The positioning marks correspond to the notch and hole in the sensor sleeve.

Figure 6 • Transmissive Sensor with Adjustment Tab Pointer

1

3

Sensor sleeve

1

Positioning marks

2

Adjustment tab pointer (outer position)

3

Adjustment tab pointer (inner position)

4

To adjust the transmissive sensor, complete these steps:

1. Press the printhead open lever to release the printhead assembly.

2. See Figure 4. Locate the transmissive sensor.

3. Push the sensor sleeve all the way in on the transmissive sensor.

1

2

4

2

4. Locate the white adjustment tab pointer on the back of the transmissive sensor.

5. What type of media are you using?

If you are using… Then…

Non-continuous media

with notched edges

Non-continuous media

without notched edges

Move the adjustment tab pointer to the inner positioning

mark. The point of the tab should align with the mark.

Move the adjustment tab to the outer positioning mark. The

point of the tab should align with the mark.

Continuous media Move the adjustment tab to the outer positioning mark. The

point of the tab should align with the mark.

Note • Certain types of media may require you to position the adjustment tab to locations

outside of the sensor sleeve.

6. Ensure the media and ribbon are properly positioned.

7. Close the printhead assembly.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 10

Adjust the Reflective Sensor

Note • This sensor is typically covered by a factory-installed plate. If you need to enable this

sensor, you must remove the plate.

The reflective sensor is compatible with most types of media. With non-continuous media, the

reflective sensor detects the start-of-label indicator (the notch, hole, black mark, or gap

between die-cut labels). With both continuous media and non-continuous media, the sensor

detects an out-of-paper condition.

Position the reflective sensor in the following way:

• directly under the notch, hole, or black mark with these types of labels

• anywhere along the width of the media if there is a gap between labels

• anywhere under the media for continuous media

The glow of the red light through the media may help you accurately position the sensor.

Figure 7 • Adjusting the Reflective Sensor

Position the Media Sensors

10

4

Printhead assembly

1

Reflective sensor

2

Reflective sensor positioning lever

3

Printhead release latch

4

1

2

3

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 11

Position the Media Sensors

11

To adjust the reflective sensor, complete these steps:

1. See Figure 7. Press the printhead release latch.

2. Lift the printhead until it latches open.

3. Locate the reflective sensor positioning lever.

4. Move the reflective sensor positioning lever across the width of the media until the

reflective sensor aligns with the gap or notch.

5. Close the printhead assembly.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 12

Ribbon Overview

Ribbon is a thin film that is coated on one side with wax, resin, or wax resin, which is

transferred to the media during the thermal transfer process.

When to Use Ribbon

Thermal transfer media requires ribbon for printing while direct thermal media does not.

To determine if ribbon must be used with a particular media, perform a media scratch test.

To perform a media scratch test, complete these steps:

1. Scratch the print surface of the media rapidly with your fingernail.

2. Did a black mark appear on the media?

If a black mark... Then the media is...

Does not appear on the media Thermal transfer. A ribbon is required.

Appears on the media Direct thermal. No ribbon is required.

Ribbon Overview

12

Coated Side of Ribbon

Ribbon can be wound with the coated side on the inside or outside (Figure 8). This printer can

only use ribbon that is coated on the outside.

Figure 8 • Ribbon Coated on Outside or Inside

To determine which side of a ribbon is coated, complete these steps:

1. Peel a label from its liner.

2. Press a corner of the sticky side of the label to the outer surface of the roll of ribbon.

3. Peel the label off of the ribbon.

Outside Inside

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 13

Ribbon Overview

13

4. Observe the results. Did flakes or particles of ink from the ribbon adhere to the label?

If ink from the ribbon... Then...

Adhered to the label The ribbon is coated on the outer surface.

Did not adhere to the label The ribbon is coated on the inner surface and cannot be

used in this printer. To verify this, repeat the test on the

other surface of the roll of ribbon.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 14

Load Ribbon

Always use ribbon that is wider than the media to protect the printhead from wear. For direct

thermal printing, do not load ribbon in the printer.

Figure 9 • Ribbon Path

Load Ribbon

14

3

2

1

Printhead assembly

1

Ribbon supply spindle

2

Ribbon take-up spindle

3

Tension blades

4

4

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 15

15

Load Ribbon

Caution • When you are loading media or ribbon, remove all jewelry that could come into

contact with the printhead or other printer parts.

To load ribbon, complete these steps:

1. Press the printhead release latch to open the printhead assembly. Lift the printhead until it

latches open.

2. Orient the ribbon with the loose end unrolling clockwise.

3. Place the roll of ribbon on the ribbon supply spindle (1) and push it all the way back.

1

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 16

Load Ribbon

4. Pull the end of the ribbon under the printhead assembly (1) and out the front of the printer.

1

5. Close the printhead assembly.

16

6. Wind the ribbon clockwise onto the ribbon take-up spindle (1).

1

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 17

17

Load Ribbon

Remove Used Ribbon

To remove used ribbon, complete these steps:

1.

Caution • Do not cut the ribbon directly on the ribbon take-up spindle. Doing so may

damage the spindle.

If the ribbon has not run out, cut or break it before the ribbon take-up spindle (1).

1

2.

To loosen the ribbon, squeeze it against the ribbon take-up spindle tension blades (1). At

the same time, turn the ribbon take-up spindle release knob counterclockwise (

2).

The tension blades collapse into the ribbon take-up spindle, loosening the ribbon.

1

2

3. Slide the used ribbon off of the ribbon take-up spindle and discard.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 18

Adjust Printhead Pressure

You may need to adjust printhead pressure if printing is too light on one side or if you use thick

media.

See Figure 10. The pressure adjustment dials have different settings that are designated by

blocks of increasing size embossed on the print mechanism. The smallest block (fully

counterclockwise) is considered position 1, and the largest block (fully clockwise) is

considered position 4 (or 7 for the 300MVPplus).

Figure 10 • Printhead Pressure Adjustment Dials

Adjust Printhead Pressure

18

1

1

2

2

Outside dial

Inside dial

To set printhead pressure, complete these steps:

1. Use Table 2 or Tab le 3 to select the initial dial settings for your media, depending on

which printer you have.

Table 2 • 200MVPplus Printhead Pressure

Media Width

1 in. (25.4 mm)

2 in. (51 mm)

3 in. (76 mm)

3.5 in. and up (89 mm and up)

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Inside Dial Outside Dial

31

41

32

33

Page 19

Adjust Printhead Pressure

19

Table 3 • 300MVPplus Printhead Pressure

Media Width

Inside Dial Outside Dial

2 in. (50 mm) 6 1

3 in. (75 mm) 6 2

4 in. (100 mm) 7 3

5 in. (125 mm) 7 4

5.5 in. and up (140 mm and up) 6 6

2. If necessary, adjust the pressure adjustment dials as follows:

If the media... Then...

Requires higher pressure to

Increase both dials one position.

print well

Shifts left while printing Increase the outside dial setting one position, or

decrease the inside dial setting one position.

Shifts right while printing Increase the inside dial setting one position, or

decrease the outside dial setting one position.

Prints too lightly on the left side

Increase the inside dial setting one position.

of the label.

Prints too lightly on the right

side of the label.

Increase the outside dial setting one position.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 20

Control Panel

PAUSE

The control panel (Figure 11) contains the lights that reflect basic operation and the buttons

that you may need to press during basic operation.

Control Panel

20

Figure 11 • Control Panel

1 2 3 4

5

6

Power light Indicates that the printer is on.

1

PAUSE light Blinks when the printer is paused.

2

Error light Blinks or remains on when the

3

printer needs attention.

Data light Blinks quickly when the printer is

4

receiving data.

LCD Shows the printer’s operating

5

status.

PAUSE button Starts or stops printer operation

6

when pressed.

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 21

Print a Configuration Label

21

Print a Configuration Label

A configuration label lists the printer settings that are stored in configuration memory. After

you load the media and ribbon (if necessary), print a configuration label as a record of your

printer’s current settings. Keep the label to use when troubleshooting printing problems.

To print a configuration label, complete these steps:

1. On the control panel, press SETUP/EXIT.

2. Press PLUS (+) or MINUS (-) to scroll through the parameters until you reach

LIST SETUP.

3. Press SELECT to select the parameter.

4. Press PLUS (+) to confirm printing.

A configuration label prints (Figure 12).

Figure 12 • Configuration Label

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 22

Configure the Printer

Use the LCD on the control panel to view and adjust printer settings.

Note • Your label preparation software or the printer driver may override adjustments made

through the control panel. Refer to the software or driver documentation for more

information.

How to View or Modify Parameters

To view or modify parameters, complete these steps:

1. Press SETUP/EXIT to enter Setup mode.

2. While viewing parameters, press PLUS (+) to continue to the next parameter, or press

MINUS (-) to return to the previous parameter in the cycle.

3. Press SELECT when you wish to modify a parameter or view its options.

4. Press or to modify the parameter.

When a parameter is changed, an asterisk (*) appears in the upper left corner of the display

to indicate that the value is different from the one currently active in the printer.

Configure the Printer

22

5. Press SETUP/EXIT.

The LCD displays

6. Press to display the save options (Table 4).

LCD Description

PERMANENT

TEMPORARY

CANCEL

LOAD DEFAULTS

LOAD LAST SAVE

DEFAULT NET

SAVE CHANGES.

Table 4 • Save Options When Leaving Setup Mode

Stores values in the printer even when power is turned off.

Saves the changes until power is turned off.

Cancels all changes made since you entered Setup mode,

except for changes made to the darkness and tear-off settings,

which go into effect as soon as they are made.

Restores all parameters other than the network settings back to

the factory defaults. Use care when loading defaults because

you will need to reload all settings that you changed manually.

Note • Loading factory defaults causes the printer to

auto-calibrate.

Loads values from the last permanent save.

Restores the wired and wireless network settings back to

factory defaults.

7. Press SETUP/EXIT to select the displayed choice.

When the configuration and calibration sequence is done,

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

PRINTER READY displays.

Page 23

Configure the Printer

23

Basic Printer Parameters

Table 5 shows some parameters that you may need to change to configure your printer

initially. Refer to the User Guide for the complete list of printer parameters.

Menu Display Description

Table 5 • Printer Parameters

DARKNESS

PRINT MODE

MEDIA TYPE

SENSOR TYPE

SENSOR SELECT

PRINT METHOD

Adjust Print Darkness

Default: +10

Range: 0 to 30

Select Print Mode

Default: TEAR-OFF

Selections: TEAR-OFF, PEEL-OFF, CUTTER, REWIND

Set Media Type

See Types of Media on page 4 for more information about media types.

Default: NON-CONTINUOUS

Selections: CONTINUOUS, NON-CONTINUOUS

Set the Sensor Type

Default: WEB

Selections: WEB (gaps or perforations between labels), MARK (black marks on

the back of the liner to indicate where labels end)

Select a Sensor

Default: TRANSMISSIVE

Selections: AUTO SELECT (the printer uses what it thinks is the best sensor),

REFLECTIVE (black mark media), TRANSMISSIVE (most other media types)

Select Print Method

Default: THERMAL TRANSFER

Selections: THERMAL TRANSFER (uses ribbon), DIRECT THERMAL

(does not use ribbon)

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 24

Cleaning Procedures

Cleaning Procedures

Important • Brady is not responsible for damage caused by the use of cleaning fluids on this

printer.

Specific cleaning procedures are provided on the following pages. shows the recommended

cleaning schedule. These intervals are intended as guidelines only. You may have to clean

more often, depending upon your application and media.

Table 6 • Recommended Cleaning Schedule

Area Method Interval

Printhead Solvent* Direct Thermal Mode: After every roll of

Platen roller Solvent*

Media sensors Air blow

media (or 500 feet of fanfold media).

Thermal Transfer Mode: After every roll of

ribbon or three rolls of media.

Ribbon sensor Air blow

Media path Solvent*

.

24

Ribbon path Solvent*

Pinch roller. (part of Peel-Off option) Solvent*

Cutter

module

If cutting continuous,

pressure-sensitive media

If cutting tag stock or label

liner material

Solvent* After every roll of media (or more often,

depending upon your application and media).

Solvent* and

After every two or three rolls of media.

air blow

Tear-off/peel-off bar Solvent* Once a month.

Take-label sensor Air blow Once every six months.

* Brady recommends using Preventive Maintenance Kit (part number PCK-4). In place of this kit, you may use a clean swab

dipped in a solution of isopropyl alcohol (minimum 90%) and deionized water (maximum 10%).

Clean the Exterior

You may clean the exterior surfaces of the printer with a lint-free cloth and a small amount of a

mild detergent, if necessary. Do not use harsh or abrasive cleaning agents or solvents.

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 25

Cleaning Procedures

25

Clean the Printhead and Platen Roller

You can minimize printhead wear and maintain print quality with regular preventive measures.

To avoid abrasion:

• Clean the printhead frequently, and use well-lubricated thermal transfer ribbons with

backings optimized to reduce friction.

• Minimize printhead pressure and burn temperature settings by optimizing the balance

between the two.

• Ensure that the thermal transfer ribbon is as wide or wider than the label media to prevent

exposing the elements to the more abrasive label material.

For best results, clean the printhead after changing every roll of ribbon. Inconsistent print

quality, such as voids in the bar code or graphics, may indicate a dirty printhead.

-

Note • For printers with a peel assembly, keep the peel assembly closed while cleaning the

platen roller to reduce the risk of bending the tear-off/peel-off bar.

Figure 13 • Location of the Printhead and Platen Roller

2

Printhead assembly

1

Platen roller

2

1

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 26

Cleaning Procedures

Caution • The printhead may be hot and could cause severe burns. Allow the printhead

to cool.

Caution • Before touching the printhead assembly, discharge any built-up static electricity

by touching the metal printer frame or by using an anti-static wriststrap and mat.

To clean the printhead and platen roller, complete these steps:

1. Open the printhead assembly.

2. Remove the media and ribbon.

3. Using the swab from the Preventive Maintenance Kit (part number PCK-4), wipe along

the brown strip on the printhead assembly from end to end. In place of the Preventive

Maintenance Kit, you may use a clean swab dipped in a solution of isopropyl alcohol

(minimum 90%) and deionized water (maximum 10%). Allow the solvent to evaporate.

26

4. While manually rotating the platen roller, clean it thoroughly with the swab. Allow the

solvent to evaporate.

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Page 27

Cleaning Procedures

27

5. Reload media and ribbon, and close the printhead assembly.

Note • If performing this procedure does not improve print quality, try cleaning the

printhead with Save-A-Printhead cleaning film. This specially coated material removes

contamination buildup without damaging the printhead. Call your authorized Brady

reseller for more information.

14069L-001 Rev. A MVPplus Quick Reference Guide 12/6/06

Page 28

Fuse Replacement

A user-replaceable AC power fuse is located just below the AC power switch at the rear of the

printer. The replacement fuse is a 5 × 20 mm fast-blow style rated at 5 Amp/250 VAC.

Caution • Turn off (O) the printer and disconnect it from the power source before

performing the following maintenance.

2

1

Fuse Replacement

28

Figure 14 • Replacing the Fuse

4

3

Slot

1

Fuse holder

2

Fuse

3

Fuse socket

4

To replace the fuse, complete these steps:

1. See Figure 14. Insert the tip of a flat blade screwdriver into the slot in the end of the fuse

holder.

2. Turn the screwdriver counterclockwise until the fuse holder disengages from fuse socket.

3. Remove the fuse holder from the fuse socket.

4. Remove the old fuse from the fuse holder.

5. Insert a new, compatible fuse into the fuse holder.

6. Place the fuse holder into the fuse socket.

7. Insert the tip of a flat blade screwdriver into the slot in the end of the fuse holder.

8. With the screwdriver, press in gently, and then turn the screwdriver clockwise until the

fuse holder engages.

12/6/06 MVPplus Quick Reference Guide 14069L-001 Rev. A

Loading...

Loading...