Page 1

Operator/

Configuration

Manual

Edition 07/07

Page 2

Copyright by Brady Worldwide, Inc.

All specifications about delivery, design, performance and weight are given to

the best of our current knowledge and are subject to change without prior

notice.

All rights reserved, including those of the translations.

No part of this manual nor any translation may be reproduced or transmitted

in any form or by any means, for any purpose other than the purchaser’s

personal use, without the express written permission of Brady.

United States

Note: This equipment has been tested and found to comply with the limits for

a Class A digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

when the equipment is operated in a commercial environment. This

equipment generates, uses, and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause

harmful interference to radio communications. Operation of this equipment in

a residential area is likely to cause harmful interference in which case the user

will be required to correct the interference at his own expense.

Changes or modifications not expressly approved by the party responsible for

compliance could void the user’s authority to operate the equipment.

Industry Canada

This Class A digital apparatus meets all requirements of the Canadian

Interference-Causing Equipment Regulations.

Cet appareil numérique de la classe A respecte toutes les exigences du

Reglement sur le Matériel Brouilleur du Canada.

Taiwan

Europe

Warning — This is a Class A product. In a domestic environment, this

product may cause radio interference in which case the user may be required

to take adequate measures.

Page 3

Welcome to Brady’s Intelligent Printing System. The Brady IP Printer is a

main component to the fully integrated printing system. Working together, the

printer, media and software provide hassle free functionality and are

optimized to print Brady’s high quality specialized materials.

To gain the full benefit of the system, material and ribbons from Brady are

programmed with the ability to communicate with the printer and software.

Material identified with this logo will work in Brady mode on the printer.

Material marked with this logo will communicate with the printer and software

by the user selection in the software.

Page 4

Table of Contents

United States................................................. 1

Industry Canada ............................................ 1

Taiwan........................................................... 1

Europe........................................................... 1

Table of Contents ............................................................ i

Brady IP™ Printer Operator/Configuration Manual..... 1

Copyright .................................................................... 1

Safety and the Environment ....................................... 2

About the Printer ........................................................ 2

Intended Use of the Printer ........................................ 2

Safety ......................................................................... 3

Unpacking the Brady IP Printer .................................. 4

What’s in the Box ................................................. 4

Stress Free System Setup ......................................... 4

Installation....................................................................... 5

Printer Overview......................................................... 5

Printer Location .......................................................... 6

Printer Connections.................................................... 6

Power Supply....................................................... 6

Interface Connections .......................................... 7

USB Connection............................................ 8

RS-232 Connection ....................................... 8

Ethernet Connection...................................... 8

USB Printer Driver ............................................... 8

Printer Wizard................................................ 8

Multiple Printers............................................. 9

RS-232 or Ethernet Printer Driver...................... 12

Software Installation........................................... 13

On-line Status Monitor ....................................... 13

Media Setup ............................................................. 14

Brady Mode........................................................ 14

Metallized Material ............................................. 15

Hassle-Free Mode....................................... 15

Standard Mode............................................ 15

Sleeving Material ............................................... 16

i

Page 5

Table of Contents

Custom Material ................................................. 16

Standard Mode................................................... 16

Label Sensors........................................................... 17

Gap Sensors ...................................................... 17

Reflective Sensor ............................................... 18

Brady Mode.................................................. 18

Standard Mode ............................................ 18

Device Types ................................................................. 20

Driver Settings .......................................................... 20

Peel-Off Mode........................................................... 21

Tear-Off Mode .......................................................... 22

Loading the Ribbon and Material................................. 23

Loading the Ribbon................................................... 23

Loading the Material ................................................. 25

Reading the LCD Display ................................... 27

Feeding the Label — Peel-Off Mode.................. 28

Feeding the Label — Tear-Off Mode.................. 29

Synchronizing the Paper Feed ................................. 30

Control Panel................................................................. 31

LCD Panel Menu Diagram ........................................ 31

Control Panel Structure ............................................ 34

Functions in Print Mode ............................................ 34

Powersave Mode................................................ 34

Printer States...................................................... 34

‘Ready’ state ................................................ 34

‘Printing label’ state...................................... 35

‘Pause’ state ................................................ 35

‘Correctable error’ state ............................... 35

‘Irrecoverable error’ state ............................. 35

‘System fault’ state....................................... 35

Key Functions..................................................... 36

LCD/Menu Options ................................................... 36

Short Status........................................................ 37

Test .................................................................... 38

Overview ...................................................... 38

Status Print ................................................. 39

ii

Page 6

Table of Contents

Font List ...................................................... 40

Device List .................................................. 41

ASCII Dump Mode ...................................... 42

Test Grid...................................................... 44

Label Profile ................................................ 45

Setup Menu........................................................ 47

Local Settings ............................................. 47

Machine Parameters ................................... 48

Print Parameters ........................................ 50

Interfaces ........................................................... 52

Security ....................................................... 53

Firmware ............................................................ 54

Firmware Update via Interface .................... 54

Firmware Update from Memory Card.......... 55

Error Messages During Firmware Update... 56

Adjust Screen Brightness................................... 56

Calibration for Standard Material ....................... 57

Heat Settings for Print Darkness ................. 57

Speed Settings for Registration................... 57

Print Sample Label............................................. 58

Print Setting Label.............................................. 59

Cleaning and Simple Maintenance.............................. 60

General Cleaning ..................................................... 60

Cleaning the Printhead and Media Feed Rollers...... 60

Basic Troubleshooting Guide...................................... 62

Troubleshooting Chart.............................................. 62

Error Messages with Corrective Actions .................. 63

Additional Support ....................................................... 67

Technical Support Numbers/Online Help ................. 67

Repair and Replacement Parts ................................ 67

Product Registration................................................. 67

iii

Page 7

Table of Contents

Please use this page for your individual notes

iv

Page 8

Brady IP™ Printer Operator/Configuration

Brady IP™ Printer

Operator/Configuration Manual

Copyright

This manual is copyrighted with all rights reserved. No portion of this manual

can be copied or reproduced by any means without the consent of Brady

Worldwide Inc. While every precaution has been made to ensure accuracy in

the preparation of this document, Brady assumes no liability to any party for

any losses or damage caused by errors or omissions or by statements

resulting from negligence, accident or any other cause. Brady further

assumes no liability arising from the application or use of any product or

system described herein, nor any liability for incidental or consequential

damages arising from the use of this document. Brady disclaims all warranties

of merchantable or fitness for a particular purpose. Brady reserves the right to

make changes without further notice to any product or system herein to

improve reliability, functionality or design.

Reproduction of this material is strictly forbidden in part or in whole without the

written permission of Brady Worldwide Inc.

Every effort has been made to make this manual as accurate and complete as

possible. Brady Worldwide Inc. is not responsible for labeling inaccuracies,

and omissions occurring during the use of this manual.

This manual is proprietary to Brady Worldwide Inc. and may be revised from

time to time without notice.

Brady Worldwide Inc. disclaims any understanding to provide you with

revisions, if any. All brand or product names referenced in this manual are

trademarks or registered trademarks of their respected companies or

organizations. IP™ Printer, BradySoft™, LabelMark™ and IdentiLab™ are

registered trademarks of Brady Worldwide Inc., Windows

Microsoft Corporation.

®

is a trademark of

1

Page 9

Brady IP™ Printer Operator/Configuration

Safety and the Environment

Please read and understand this manual before using the Brady IP Printer for

the first time. This manual describes all of the main functions of the Brady IP

Printer. The functions actually available depend on the version ordered.

A detailed product description with all technical data can be found

online at www.bradyid.com, www.bradyeurope.com,

www.bradycorp.com.

About the Printer

The Brady IP printer is designed to work with BradySoft, IdentiLab or

LabelMark software. When used with one of those software packages, the

printer will automatically recognize all Brady IP enabled and compatible

materials up to 4 inches (101.6 mm) wide. For operation of the printer with

other materials, metallized labels and other software packages, refer to

Standard Mode on page 16.

Intended Use of the Printer

■ The Brady IP Printer is designed and manufactured in accordance with

applicable standards and recognized safety rules. However, danger to the

life and limb of the user or third parties and/or damage to the Brady IP

Printer and other tangible assets can arise during use.

■ The Brady IP Printer may only be used for its intended purpose, in perfect

working order and with regard to safety and dangers as stated in this

manual. In particular, faults which affect safety must be rectified

immediately.

■ The Brady IP Printer is intended exclusively for printing suitable materials

that have been approved by the manufacturer. Any other use shall be

regarded as improper use. The manufacturer/supplier shall not be liable for

damage resulting from unauthorized use; the user shall bear the risk alone.

■ Usage for the intended purpose also includes complying with the operating

manual, including the manufacturer’s maintenance recommendations and

specifications.

2

Page 10

Brady IP™ Printer Operator/Configuration

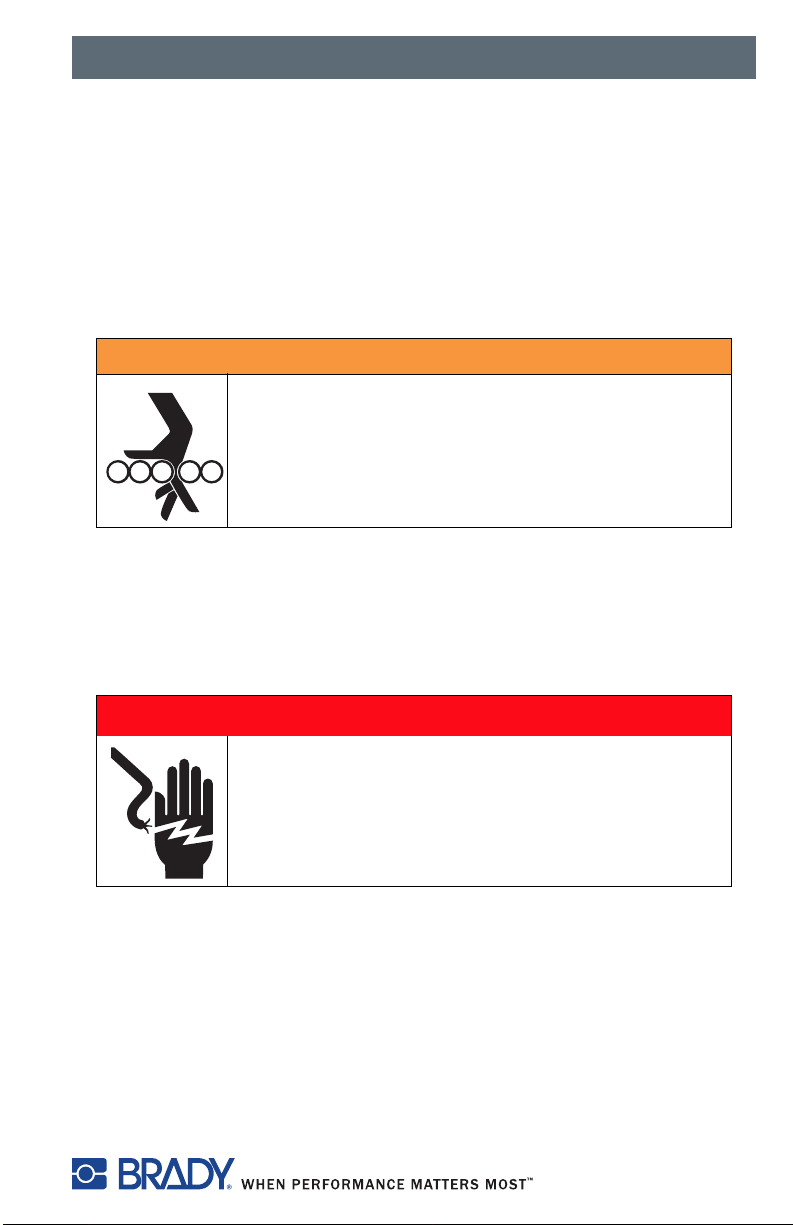

Safety

■ The Brady IP Printer is configured for voltages of 100 to 240 V ~, 50 to 60

Hz. Connect only to a grounded power outlet.

■ The Brady IP Printer may only be used in a dry environment, do not expose

it to moisture (water, mists, etc.).

■ If the Brady IP Printer is operated with the cover open, ensure that clothing,

hair, jewelry etc. do not come into contact with the exposed rotating parts.

A WARNING

Entanglement Hazard

• MOVING PARTS can entangle.

• AVOID wearing jewelry or loose fitting clothing.

• ALWAYS tie back long hair.

■ During the print process, the print assembly can become hot. Do not touch

the print assembly during operation, and allow the assembly to cool down

before changing material and before disassembly.

■ Perform only those actions described in this manual. Work going beyond

this may only be performed by trained personnel or service technicians.

A DANGER

Electric Shock Hazard

• DO NOT open the Brady IP Printer casing.

• UNPLUG power cord before servicing.

• CONTACTING power supply can cause

electrocution.

3

Page 11

Brady IP™ Printer Operator/Configuration

Unpacking the Brady IP Printer

Carefully unpack and inspect the printer for possible damage incurred during

shipping.

■ Check all exterior and interior surfaces for damage.

■ Check the Brady IP Printer for any possible transportation damage.

What’s in the Box

■ Brady IP Printer

■ Power cable

■ Printed “Quick Start Manual”

■ Product CD including Windows printer driver, electronic “Quick Start

Manual,” “Brady IP™ Printer Operator/Configuration Manual” and web links.

■ Software demo CD

■ Printer cleaning film

■ USB cable

NOTE: Please keep the original packaging, including the box, in the

event the printer must be returned.

Stress Free System Setup

Stress Free System Setup is available, free of charge, in North America.

Brady’s Stress Free System Setup helps you set up your new printer and

software.

To schedule a free phone setup assistance appointment, call 1-800-643-8766

and select Menu Option 4.

Stress

FREE

+

Setup

4

System

Page 12

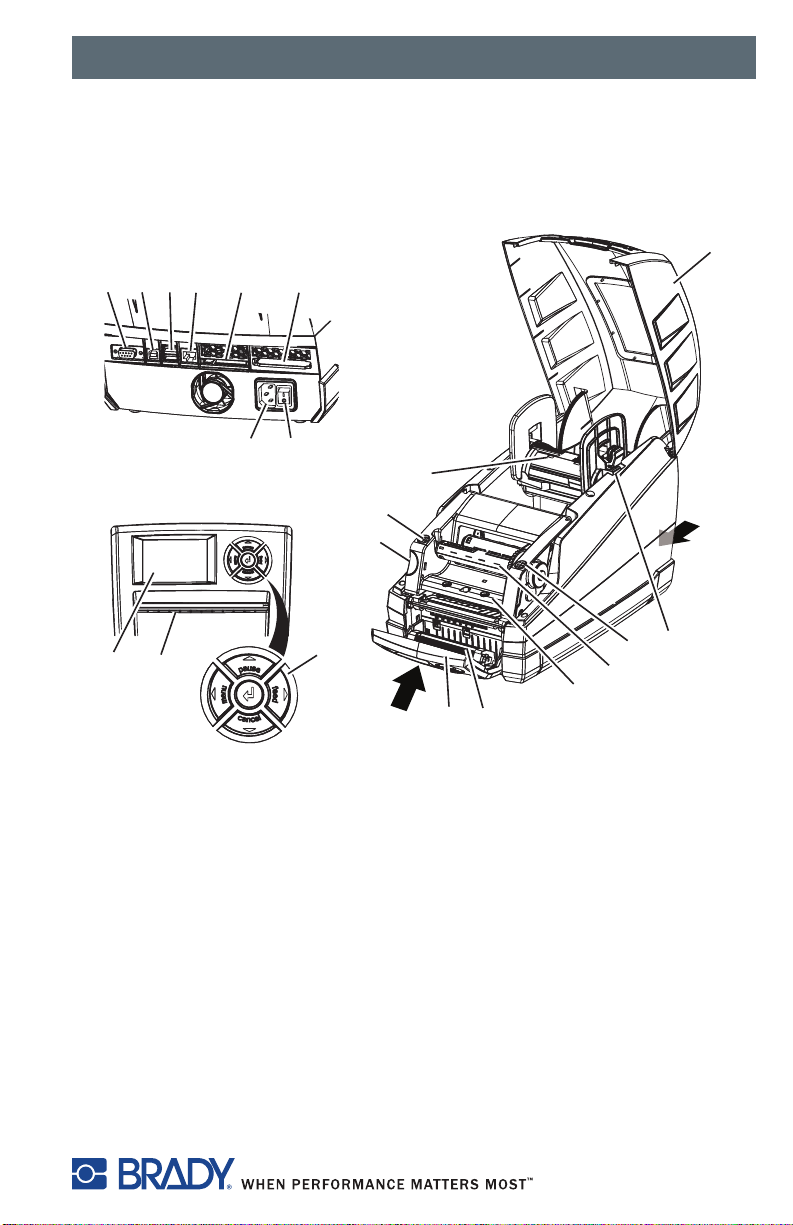

Printer Overview

Installation

Installation

VIEW A

1

2 34 5 7

6

8

VIEW B

18

19

1. RS-232 port

2. USB port

3. Two USB master ports for

keyboard or scanner

4. Ethernet port

5. CompactFlash card slot

6. Power connection socket

7. PC card slot, type II

8. Power switch

9. Printer cover

10. Material holder

20

Figure 1, Overview

15

12

10

13

14

16

17

B

11. Bracket grooves

12. Ribbon carrier close points

13. Ribbon take-up spindle

14. Printhead mounting with

printhead

15. Print module release button

16. Pressure roller

17. Control panel

18. LCD display

19. Slot for label output

20. Navigator pad

12

9

A

11

5

Page 13

Installation

Printer Location

NOTICE

The device and printing materials will be damaged

by moisture and wet conditions.

Set up Brady IP printers only in dry locations

protected from moisture.

NOTICE

Ensure that the foam transportation protection

has been removed from around the printhead.

■ Place the printer on a level surface away from moisture.

■ Open the Brady IP printer cover (Figure 1, 9).

■ For operation in Peel-off mode, ensure the drivers are set to Peel-off mode

and place the printer in such a position that the liner can run down without

hindrance. Refer to Peel-Off Mode on page 21 for additional information

about Peel-off mode.

Printer Connections

Power Supply

The printer is equipped with a universal power supply. The device can be

operated with a supply voltage of 100 to 240 V~, 50 to 60 Hz without

adjustment.

A CAUTION

Switch the printer power switch (Figure 1, 8) to the

off position (O) before connecting the printer to the

power supply.

1. Plug the power cable into the power connection socket on the back of the

printer (Figure 1, 6).

2. Plug the power cable into a grounded 100 to 240 V~, 50 to 60 Hz power

source.

NOTE: The Brady IP Printer senses the voltage type and automatically

adjusts for the power source.

6

Page 14

Installation

3. Connect the printer to the computer using the supplied USB cable, an

RS-232 cable or an Ethernet cable (refer to Interface Connections on

page 7).

4. If you do not have BradySoft, LabelMark or IdentiLab software installed

on your computer, refer to Software Installation on page 13.

5. Turn on the power switch on the back of the printer (Figure 2, 5). The

printer will perform a self test and then go into Ready mode.

NOTE: If a fault occurs during the system test, the symbol and the

type of fault are displayed on the LCD display. Refer to

Troubleshooting Chart on page 62 for additional information.

Interface Connections

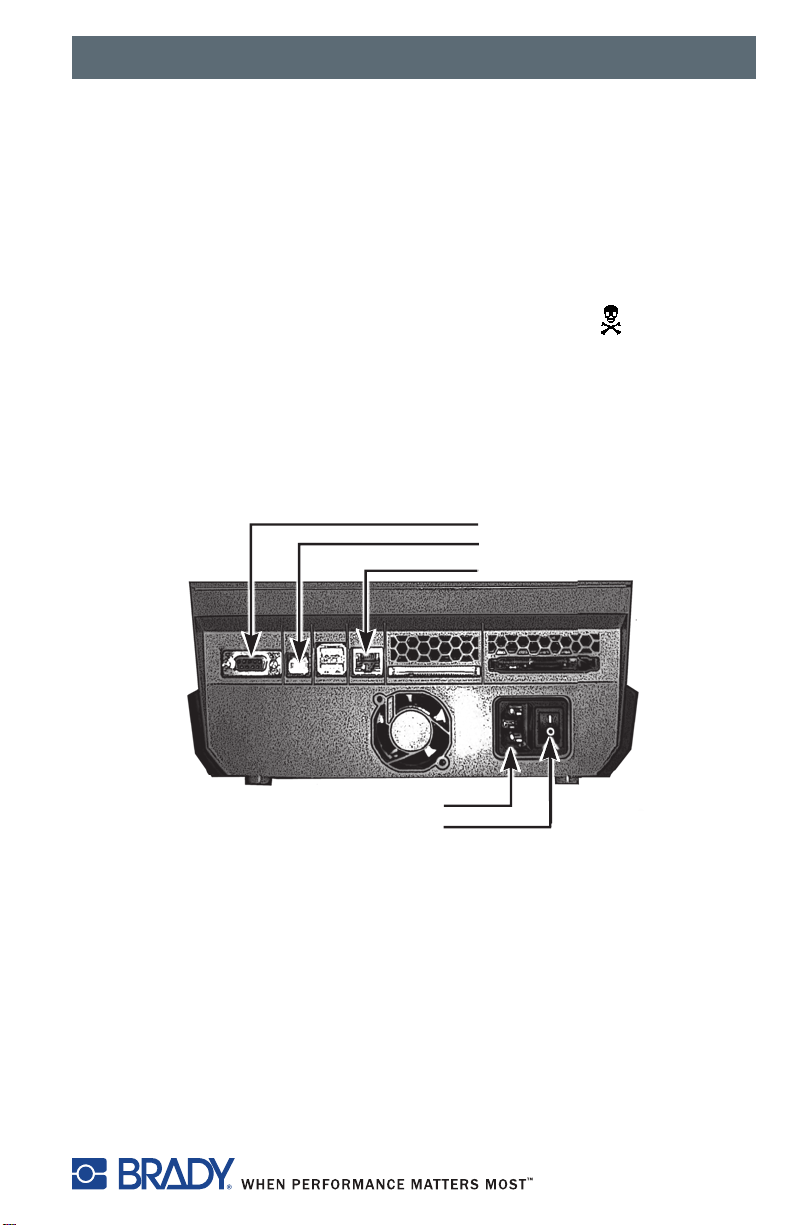

The printer has an RS-232 port (Figure 2, 1), a USB port (Figure 2, 2) and an

Ethernet port (Figure 2, 3).

1

2

3

4

5

Figure 2, Interfaces and Connectors

1. RS-232 port 4. Power connection socket

2. USB port 5. Power switch

3. Ethernet port

7

Page 15

Installation

USB Connection

1. Ensure that the Brady IP Printer is turned off.

2. Connect the printer to the computer using the supplied USB cable. The

USB cable connects to the printer at the USB port (Figure 2, 2) and to a

USB port on the computer.

RS-232 Connection

1. Ensure that the Brady IP Printer is turned off.

2. Connect the printer to the computer using an RS-232 cable (not

provided). The RS-232 cable connects to the printer at the port

(Figure 2, 1) and to the computer.

3. Secure the cable with the connection screws.

4. Configure the printer RS-232 interface to match the connected computer.

Refer to Interfaces on page 52.

Ethernet Connection

1. Ensure that the Brady IP Printer is turned off.

2. Connect the printer to the computer using an Ethernet cable (not

provided). The Ethernet cable connects to the printer at the Ethernet port

(Figure 2, 3) and to an Ethernet port on the computer or Local Area

Network (LAN).

USB Printer Driver

NOTICE

Do not install drivers if using Bradysoft. Bradysoft

uses its own drivers. Follow instructions included

with Bradysoft to set up your IP printer using

USB, serial or Ethernet connections.

Printer Wizard

1. Insert the product CD in the CD drive on your computer. Turn the printer

power on. Connect the USB cables (refer to USB Connection on page 8).

The Found New Hardware dialog box appears.

8

Page 16

Installation

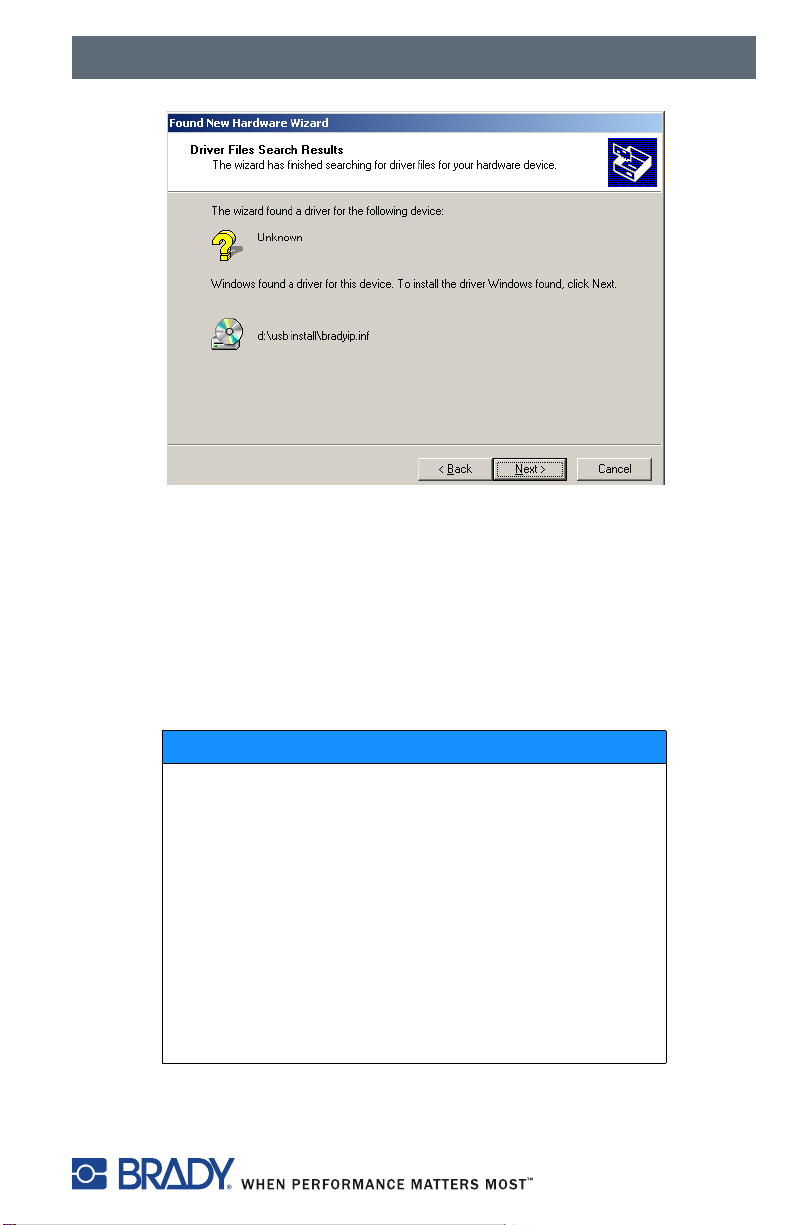

Figure 3, Found New Hardware Wizard

2. Click NEXT. The driver will load automatically.

This completes the installation of the printer driver. If you have additional IP

printers, using USB, to install, continue to Multiple Printers on page 9.

Multiple Printers

If you want to add an additional IP Printer to your PC, ensure the additional IP

Printer is powered on, then connect to your computer

NOTICE

When connected to your PC, the Found New

Hardware Wizard will appear. (At this point the

Plug and Play process should have created a new

USB virtual port. The Brady IP printer driver will

be added in later steps.) Cancel the New Hardware

wizard. If using Windows XP, skip ahead to step 1.

Otherwise, with Windows 2000, a copy of your

additional IP printer is automatically created but

must be deleted. Go to Start | Settings | Printers

and delete the last copy that was added by right

clicking on the icon of the last printer created, and

select delete.

9

Page 17

Installation

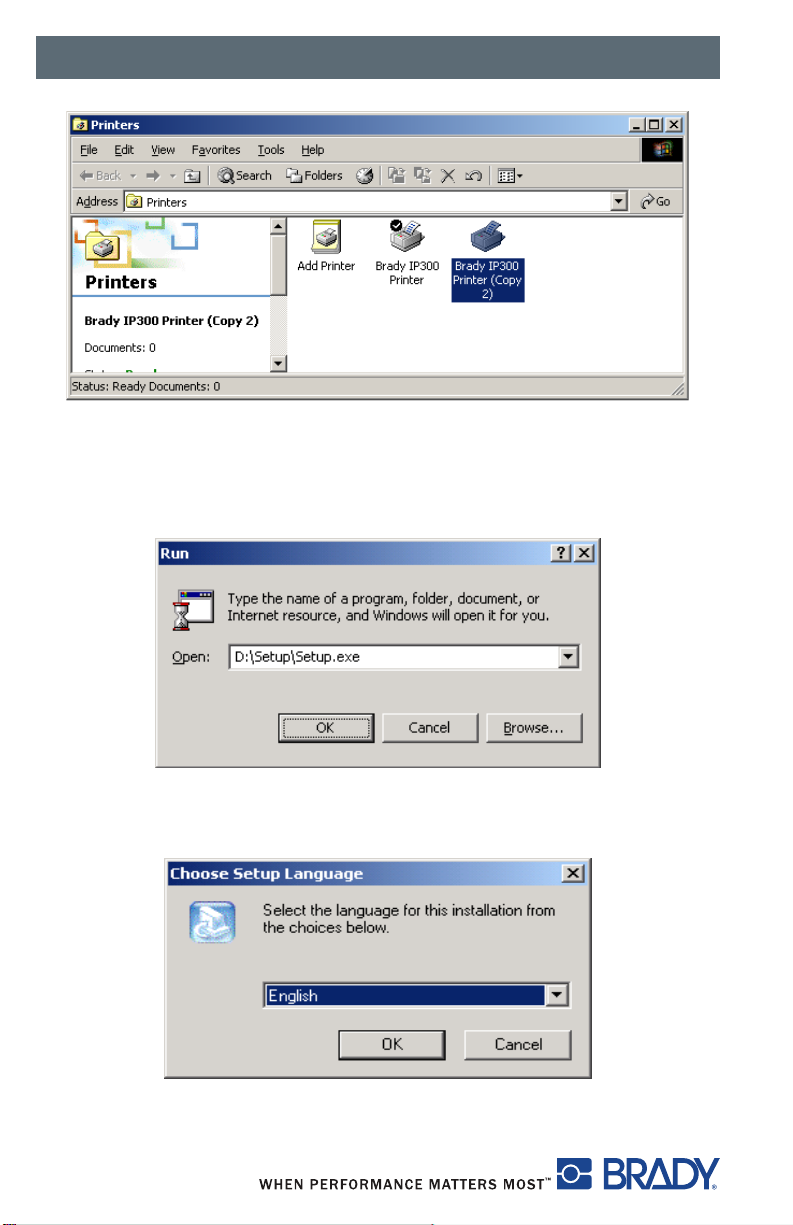

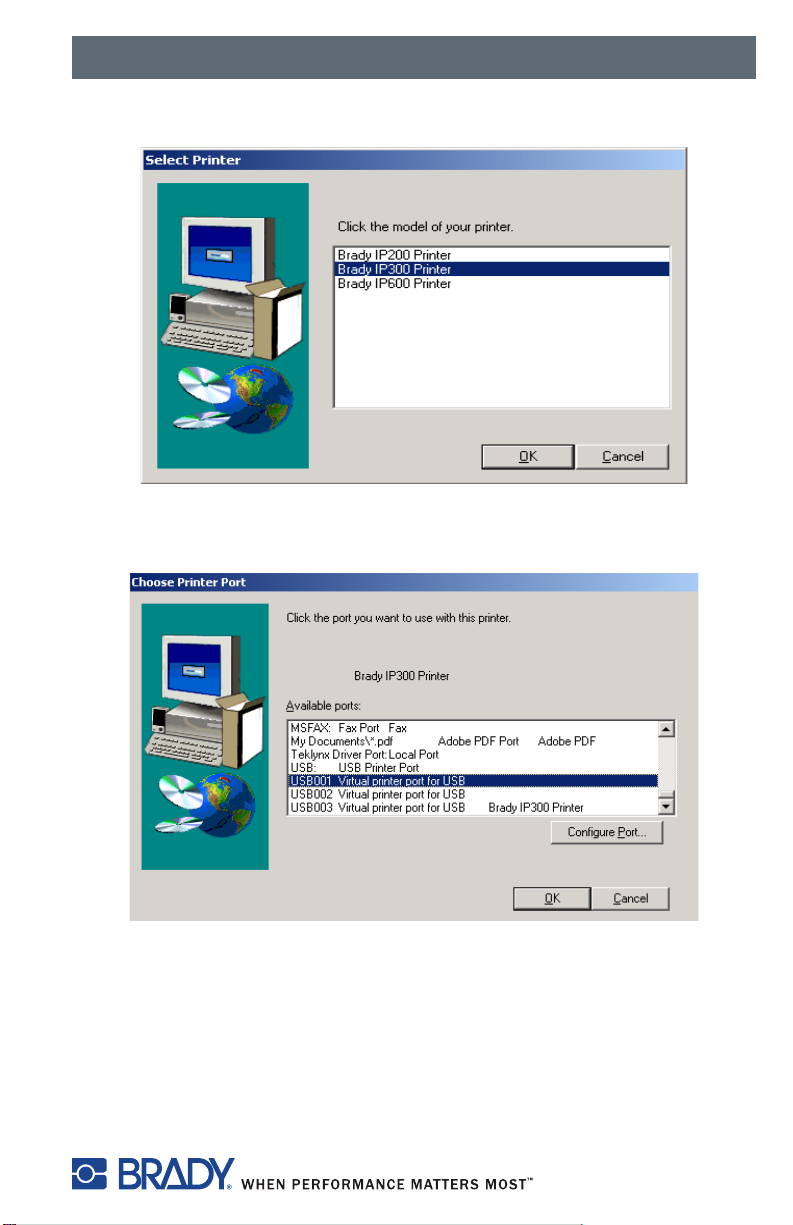

Figure 4, Printers Window

1. Ensure the Product CD is in the CD drive. Select Run from your

computer’s start menu. Choose the drive where the Product CD is

located. Choose Setup\Setup.exe. Choose OK.

2. Choose your language.

Figure 6, Choose Setup Language Dialog Box

10

Figure 5, Run Dialog Box

Page 18

3. Choose the printer.

Figure 7, Choose Printer Dialog Box

4. Choose the appropriate port.

Installation

Figure 8, Choose Printer Port Dialog Box

11

Page 19

Installation

5. Click Yes.

Figure 9, Read Only File Detected Dialog Box

6. Choose to restart your computer.

Figure 10, Restart Printer Dialog Box

7. Once your computer has restarted, ensure the added printer is powered

on and connected to your computer. Check to make sure the new printer

driver is not offline by choosing Start | Settings | Printers and right clicking

on the printer icon.

This completes the installation. Repeat this section for any additional IP

printers you will be installing on this computer.

RS-232 or Ethernet Printer Driver

To install an RS-232 or Ethernet printer driver, ensure that power is turned

OFF, connect the cable (refer to RS-232 Connection on page 8 or Ethernet

Connection on page 8 and complete steps 1 through 7 starting on page 10.

12

Page 20

Installation

Software Installation

If you do not have BradySoft, LabelMark or IdentiLab software installed on

your computer:

1. Insert the software CD in the CD drive on your computer.

2. Follow the autoload directions for software installation.

On-line Status Monitor

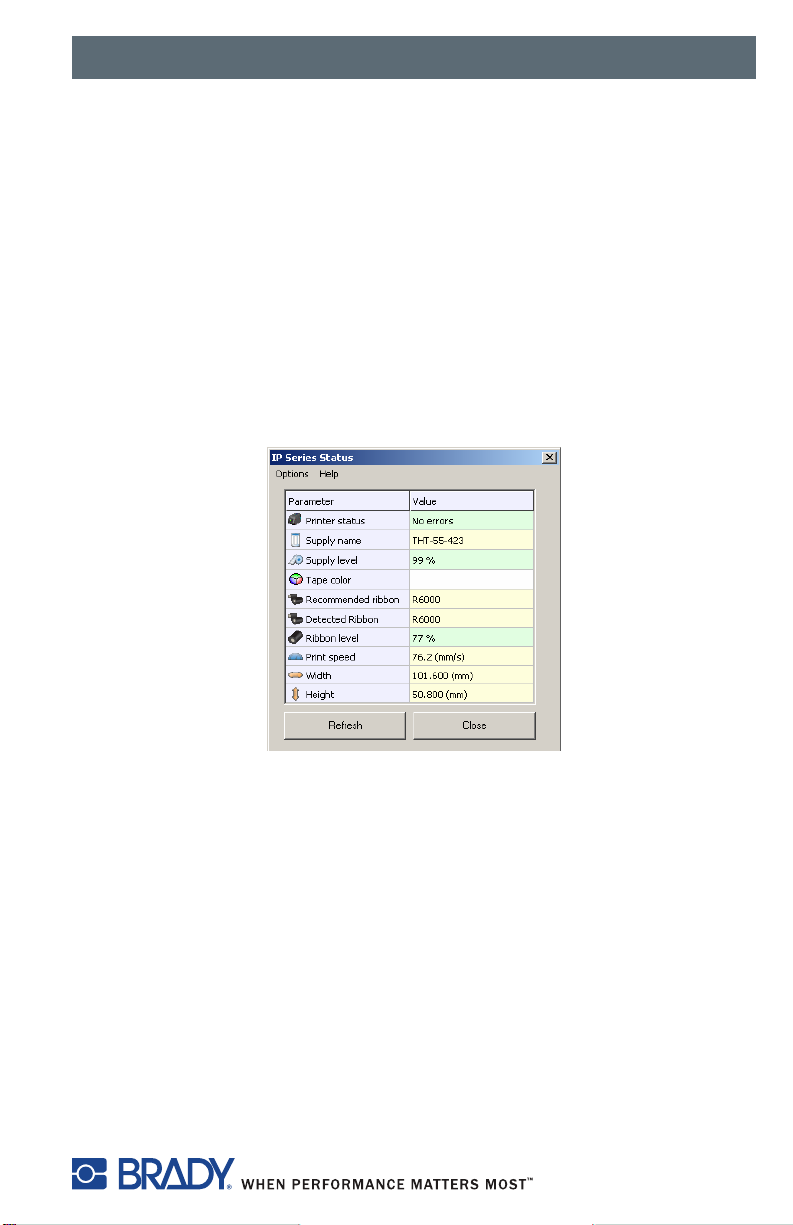

The On-line Status Monitor provides printer status information. From the

Options menu, you can select Warn if no Brady Smart Supply, Always on

top or Unit of Measure (inches or mm). The Help menu provides links to

Brady Online.

Figure 11, On-line Status Monitor

13

Page 21

Installation

Media Setup

Since print quality is affected by media and ribbon, printing speeds and printer

operating modes, it is very important to run tests for your applications.

We STRONGLY RECOMMEND the use of Brady-brand supplies and

LabelMark, IdentiLab or BradySoft labeling software for uninterrupted

high-quality printing. These products will allow you to use all of the special

features of the printer, especially Brady mode (hassle-free operation).

Brady Mode

The use of Brady-brand supplies and LabelMark, BradySoft or IdentiLab

labeling software allow access to the full operation of Brady mode. Brady

mode, or hassle-free operation, provides the following advantages:

■ The printer always automatically sets up the heat setting, print speed and

sensor information and verifies that the installed ribbon is approved for the

installed label.

■ The software recognizes what label is installed and automatically organizes

the label height and width, label printable area, zone information, label and

ribbon color, number of parts across the web, spacing between parts and

default rotation.

■ The software and printer will be properly configured whether you open an

existing part or create a new one.

■ The printer LCD display also shows an estimated amount of labels and

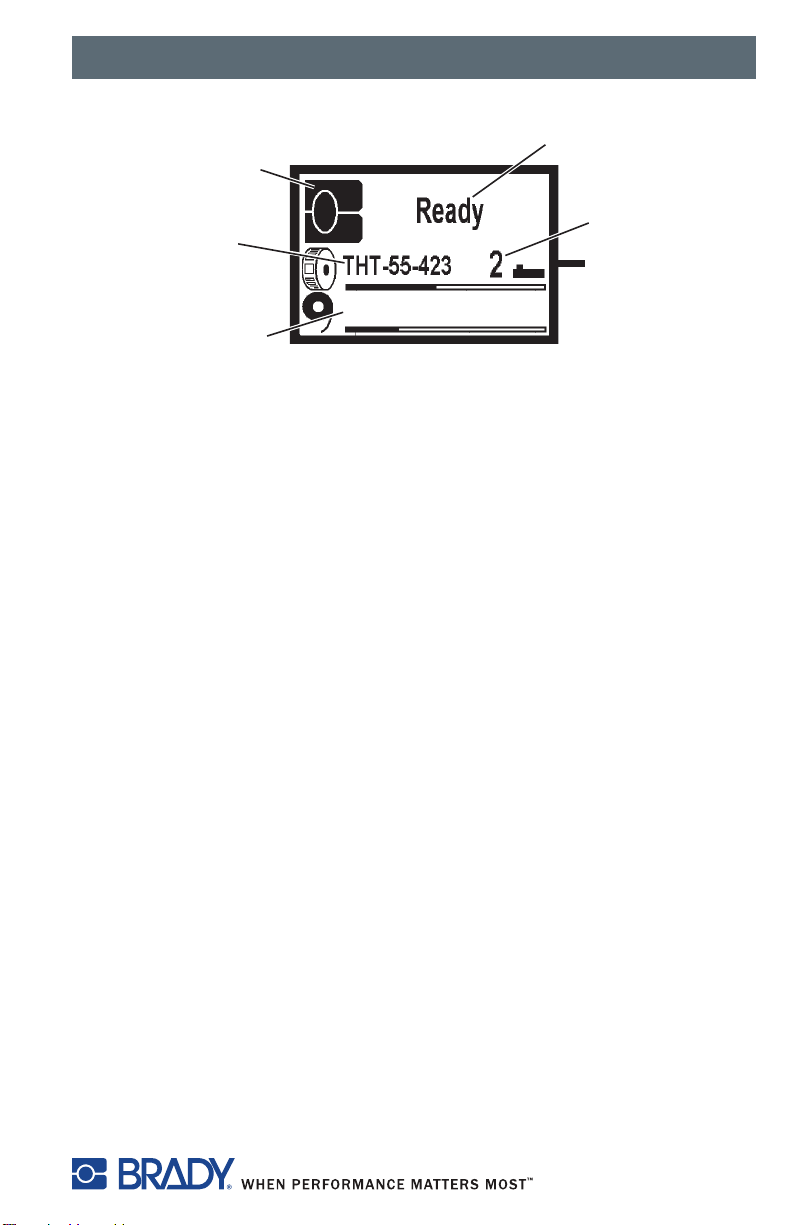

ribbon remaining (Figure 12).

■ If the printer is operated with non-Brady software and/or non-Brady labels,

the printer will function only as a standard THT printer. Refer to Standard

Mode on page 16.

The LCD display shows:

■ The Brady logo in the top, left corner which indicates that the printer is

operating in Brady mode.

■ The online status of the printer.

■ The material number and estimated amount remaining.

■ The ribbon type and estimated amount remaining.

14

Page 22

1

5

R60XX

4

Figure 12, Typical Ready Display

Installation

2

3

1. Designates printer in Brady

mode

2. Online printer status

3. Sensor position

These functions are fully enabled with Brady IP enabled or compatible

materials and Brady preferred software. For metallized Brady label material,

refer to Metallized Material on page 15.

4. Ribbon number and

estimated amount remaining

5. Material part number and

estimated amount remaining

Metallized Material

Hassle-Free Mode

If you are using Brady-brand supplies and LabelMark, IdentiLab or BradySoft

labeling software, the software will request selection of a part number prior to

operation. Once the part number is selected, Hassle-free mode is completely

operational.

Standard Mode

If you are not using Brady-brand supplies but LabelMark, IdentiLab or

BradySoft labeling software, the software will ask if metallized material is

installed when the printer cannot read a Brady IP enabled Supply. If you

answer “yes,” the software will request selection of a part number from a list

prior to operation. The Brady IP Printer will operate in Standard mode. Refer

to Standard Mode on page 16.

15

Page 23

Installation

Sleeving Material

Sleeving material is processed the same way as labels. If the material is

Brady-brand IP enabled, the printer will display the gap sensor switch setting

on the LCD display. This is true for only IP-enabled material (not compatible).

Refer to Gap Sensors on page 17. Set the gap sensor switch to the setting

displayed and the printer will operate in Brady mode. Refer to Brady Mode on

page 14.

If the material is not Brady-brand, the printer will operate in Standard mode.

Refer to Standard Mode on page 16.

Custom Material

Custom Brady material is processed in Hassle-free mode.

Standard Mode

If the printer is operated in Standard mode or with non-Brady software and the

user inserts Brady non-metallized label material, the printer will automatically

execute the basic functions of detecting heat setting, print speed and sensor

information. There is no way for the printer to determine label size. The user

will need to manually enter media print settings.

The LCD display shows:

■ The letter S in the top, left corner which indicates that the printer is

operating in Standard mode.

■ The online status of the printer.

Whenever possible, manually apply media print settings through the software.

16

Page 24

Label Sensors

Gap Sensors

Installation

2

1

50

40

30

20

10

0

Setting

21

3

2

1

Figure 13, Selecting the Gap Sensor

1. Gap sensor 1

3. Switch

2. Gap sensor 2

The printer has gap sensors (Figure 13, 1 and 2, receivers in the left picture,

transmitters in the right picture) which can detect the start and end of a label.

These sensors are controlled by a switch setting (Figure 13, 3). The switch

can be set to the left or to the right. All Brady IP enabled material will instruct

the user, via the front LCD display, which position to set the switch. For

non-standard material, set the sensor to position 2. Non-standard notched

material is dependent on specific supply criteria.

1. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and

press the green print module release button(Figure 1, 15) .

2. Move the switch (Figure 13, 3) to the left or right as required.

3. Lower the print module. Press firmly on the close points (Figure 1, 12) on

both sides on the module until the printhead clicks firmly into position.

4. Lift the control panel (Figure 1, 17) and press firmly until the panel clicks

into position.

5. Close the cover (Figure 1, 9).

NOTE: This switch cannot be made by the software.

17

Page 25

Installation

Reflective Sensor

The reflective sensor is used to detect notched material as well as to detect

black marks on the back of label stock. There is a clear label covering the

reflective sensor. (When operating in Brady mode, the LCD display will show

sensor placement information (Figure 14, 2).)

Brady Mode

1. The LCD will indicate Brady mode (Figure 14, 1) and show sensor

placement information (Figure 14, 2).

2. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and

press the green print module release button (Figure 1, 15).

3. Adjust the sensor knob (Figure 14, 4) with a pointed tool to the position

displayed on the LCD (Figure 14, 2).

4. Lower the Print Module (Figure 1, 14). Lift the control panel

(Figure 1, 17) and press firmly until the panel clicks into position.

5. Close the cover (Figure 1, 9).

Standard Mode

1. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and

press the green print module release button (Figure 1, 15).

2. Adjust the sensor knob (Figure 14, 4) with a pointed tool until the sensor

inside the sensor window (Figure 14, 3) is aligned with the edge of the

labels. If the label material is notched, the sensor must be aligned with the

notch.

3. Lower the print module (Figure 1, 14). Lift the control panel

(Figure 1, 17) and press firmly until the panel clicks into position.

4. Close the cover (Figure 1, 9).

18

Page 26

Installation

1

R60XX

3

50

40

30

20

10

0

A

Figure 14, Adjusting the Reflective Sensor

1. Designates printer in Brady

mode

2. Sensor position

Figure 15, Reflective Sensor Label

26

2

4

50

40

30

20

10

0

3. Sensor window

4. Sensor knob

5. Scale

01020304050

5

View A

19

Page 27

Device Types

Device Types

The Brady IP Printer has a Peel-off function and a Tear-off function.

Driver Settings

1. When in Start | Settings | Printers, right click on the IP printer. Choose

Properties, then Printing preferences. Then choose Paper/ Output; paper

size. Then Properties:

20

Figure 16, Printing Preferences Dialog Box

Page 28

Device Types

2. You can now choose the print mode: Tear-off, Peel-off (on or off) or none.

Figure 17, Custom Settings Dialog Box

Peel-Off Mode

The Brady IP Printer enables label output in Peel-off mode. In this mode, a

label is printed, separated from the liner and presented to the user. The

printer pauses until the label is removed. After the label is removed, the

printer prints the next label and the cycle continues.

NOTICE

A sensor prevents further printing until the printed

label has been removed from the Peel-off position.

Label stock is loaded as described in Feeding the Label — Peel-Off Mode on

page 28.

21

Page 29

Device Types

Tear-Off Mode

The Brady IP Printer enables label output in Tear-off mode. Tear-off mode is

when the last label is presented to the user so they can tear it off. After

printing, detach the label strip manually. Tear-off mode is selected in the

printer setup menu of the software package.

Label stock is loaded as described in Feeding the Label — Tear-Off Mode on

page 29.

After printing, the strip label is detached by hand. The Brady IP Printer is

equipped with a tear bar for this purpose.

22

Page 30

Loading the Ribbon and Material

Loading the Ribbon and Material

Loading the Ribbon

NOTICE

Do not use a ribbon for direct thermal printing.

NOTICE

When inserting a ribbon, ensure that the coated side faces

the labels, otherwise the printhead can become dirty.

1. Open the cover (Figure 1, 9) lower the control panel (Figure 1, 17) , and

press the green print module release button (Figure 1, 15).

1

5

2

Figure 18, Loading the Ribbon

1. Guide slot

2. Transfer ribbon spindle

3. Spacer

4. Square end

5. Guide slot

2

2

6

7

10

6. Coated side of ribbon

7. Close points

8. Ribbon take-up spindle

9. Adjustment wheel

10. Ribbon path

3

4

8

9

7

23

Page 31

Loading the Ribbon and Material

2. Push the old ribbon spindle (Figure 18, 2) slightly to the right to release

tension on the spindle and pull the left side of the spindle (Figure 18, 1)

toward you. Discard used ribbon.

3. Position the square end of the new ribbon spindle in the square notch on

the right side of the printer, push the spindle slightly to the right and slide

the other end of the spindle into the notch on the left side of the printer.

4. Thread the ribbon end forward, under the printhead and back over the

printhead (Figure 18, 10) to the ribbon take-up spindle (Figure 18, 8).

3

2

Figure 19, Ribbon Take-up Spindle

1. Square end

2. Ribbon hold-down tab

NOTE: If you need to remove the ribbon take-up spindle, push the

spindle slightly to the right and slide the other end of the spindle

out of the notch on the left side of the printer. Remove the ribbon

take-up spindle.

To replace the ribbon take-up spindle, position the square end

(Figure 19, 1) of the spindle in the square notch on the right side

of the printer, push the spindle slightly to the right and slide the

other end of the spindle into the notch on the left side of the

printer.

5. Slide the end of the ribbon under the ribbon hold-down tab (Figure 19, 2)

so that about 2 inches (50.8 mm) protrude past the tab.

NOTE: Install the ribbon so the ribbon path is under the take-up spindle,

NOT over the spindle.

Fold the end of the ribbon back on top of itself over the tab.

3. Round end

4. Thumb lever

4

1

6. Turn the adjustment wheel (Figure 18, 9) a few complete revolutions, to

ensure that the ribbon will not pull out from under the ribbon hold-down

tab. The ribbon should now be snug and smoothed out against the

printhead.

24

Page 32

Loading the Ribbon and Material

NOTE: The spindle is self-adjusting and will smooth the ribbon out and

position it correctly as the adjustment wheel is turned.

NOTE: To remove ribbon from the ribbon take-up spindle, press and

hold the thumb lever (Figure 19, 4) to compress the spindle and

slide the ribbon off the spindle.

Loading the Material

Label rolls are supplied with different diameters. The material supply holder

can hold label rolls with a minimum core diameter of 3 inches (76 mm).

5

4

3

1

1

2

Figure 20, Material Supply Holder

1. Electrical contacts

2. Material supply holder

3. Green tab

1. Open the cover (Figure 1, 9), lower the control panel (Figure 1, 17) and

press the green print module release button (Figure 1, 15).

2. Remove the material supply holder (Figure 20, 2) from the printer by

lifting it up and out of the frame.

6

4. End piece

5. Labels

6. Printable side up

6

NOTICE

There are electrical contacts located under the side

tabs (Figure 20, 1) on both sides of the material

supply holder. Be careful not to damage these

electrical contacts or the Brady IP Printer will be

unable to read the material identification tag on the

labels.

25

Page 33

Loading the Ribbon and Material

3. Press and hold the green tab (Figure 20, 3) on the material supply holder

and slide the end piece (Figure 20, 4) outward.

4. Slide the Brady labeling material roll onto the material supply holder.

Make sure material roll is installed with label printable side (up) towards

printhead (Figure 20, 6). Reinstall the end piece (Figure 20, 4), which will

automatically center the roll on the holder.

5. Reinsert the material supply holder onto the bracket grooves on the

frame. Ensure the electrical contacts under the side tabs (Figure 20, 1)

are properly seated in the frame so the printer will correctly read the

material identification tag.

1

2

Figure 21, Alignment Guides

1. Green dial 2. Material guides

6. Thread the material under the print module, under the guides

(Figure 21, 2) and forward through the slot in the control panel.

7. Turn the green dial on the left (Figure 21, 1) to adjust the guides so they

just snug up against the labels. Do not tighten the guides enough to crimp

the labels.

8. Apply thumb pressure to the close points (Figure 18, 7) on both sides of

the print module until it latches securely in place. Once the print module is

latched in place, raise the front panel and snap it into the closed position.

9. Close the printer cover (Figure 1, 9).

26

Page 34

Loading the Ribbon and Material

Reading the LCD Display

The use of Brady-brand supplies and LabelMark, BradySoft or IdentiLab

labeling software allows access to the full operation of Brady mode. For

detailed information about Brady mode, refer to Brady Mode on page 14.

The LCD display should read Ready and display the type of material loaded

into the printer as well as the type of ribbon loaded. Figure 22 is an example

of a typical display.

2

1

3

5

R60XX

4

Figure 22, Typical Ready Display

1. Designates printer in Brady

mode

2. Online printer status

3. Sensor position

If the printer is in a state other than Ready, refer to the “Basic

Troubleshooting Guide on page 62 to determine what the problem might be.

If the printer is operated with non-Brady software and/or non-Brady labels, the

printer will function only as a standard THT printer. Refer to Standard Mode

on page 16 for additional information.

4. Ribbon number and

estimated amount remaining

5. Material part number and

estimated amount remaining

27

Page 35

Loading the Ribbon and Material

Feeding the Label — Peel-Off Mode

.

2

3

1

4

4

5

Figure 23, Peel-Off Mode

1. Pressure roller (engaged)

2. Pressure roller (disengaged)

4. Label backing

5. Label

3. Pressure roller

1. Load the labels on the material supply holder. Refer to Loading the

Material on page 25.

2. Position the label strip between the label guides (Figure 21, 2) and turn

the adjustment wheel (Figure 21, 1) to snug the guides just up against

the label strip. Be careful not to tighten the guides against the label strip

enough to crimp the label strip.

3. Press on the metal pins at each end of the pressure roller (Figure 23, 3)

and slide the roller from the disengaged position (Figure 23, 2) into the

engaged position (Figure 23, 1).

4. Remove the labels (Figure 23, 5) from about the first 6 inches

(152.4 mm) of the label backing (Figure 23, 4).

28

Page 36

Loading the Ribbon and Material

5. Feed the label backing (Figure 23, 4) out between the control panel and

the printer.

6. Make sure that there is enough slack in the label strip so the printer can

be closed without pulling the label strip backward.

7. Close the printer cover (Figure 1, 9).

Feeding the Label — Tear-Off Mode

.

1

2

3

4

Figure 24, Tear-Off Mode

1. Deflector

2. Adjustment Wheel

3. Label Guides

4. Print Roller

1. Load the labels on the material supply holder. Refer to Loading the

Material on page 25.

2. Position the label strip between the label guides (Figure 24, 3) and turn

the adjustment wheel (Figure 24, 2) to snug the guides just up against

the label strip. Be careful not to tighten the guides against the label strip

enough to crimp the label strip.

3. Close the printer cover (Figure 1, 9).

29

Page 37

Loading the Ribbon and Material

A CAUTION

Printhead damage caused by improper handling!

• Do not touch the bottom of the printhead with

fingers or sharp objects.

• Ensure that the labels are clean.

• Ensure that the label surfaces are smooth. Rough

labels act like emery paper and reduce the

service life of the printhead.

Print with the lowest possible printhead

temperature.

The printer is ready for operation when all connections are made and labels

and ribbon are loaded.

Synchronizing the Paper Feed

After the label stock has been inserted, the printer will calibrate automatically

if Brady IP enabled materials are used. If materials other than Brady IP

enabled are used, calibration is performed manually.

■ Select the material type in the software.

■ Press the feed key to start the synchronization.

■ Remove the blank labels produced during the synchronization.

30

Page 38

Control Panel

Control Panel

The user can control many printer operations with the control panel. These

options include:

■ Starting, interrupting, continuing and cancelling print jobs (refer to Key

Functions on page 36).

■ Setting print speed, interface configuration, language and time of day (refer

to Setup Menu on page 47).

■ Starting test functions (refer to Test on page 38),

■ Updating firmware (refer to Firmware on page 54).

Most adjustments should be performed through the software.

NOTICE

Whenever possible, control print jobs through the

software.

LCD Panel Menu Diagram

31

Page 39

Control Panel

Short

Memory

Te st

Te st

status

card

Label

Te st

ASCII

Dump

Device

Font

Status

Demo

dump

ASCII

profile

grid

Mode

list

list

print

label

(Card)

ServiceSetup Service

off

interval

Cleaning

Load

settings

Save

settings

PPP

Load

voucher

fr.

card

Firmw.

upd.

Firmware

Local

settings

Set

time

32

Menu

Memory

Enter/

card

Exit

Format

Copy

memory

Print

from

Label

card

card

directory

card

Setup

Local

settings

Set

Daylight

Timezone

Country

date

saving

USA

Page 40

Control Panel

Print

param.

Width

ASCII

Barcode

Pause

Error-

Backfeed

Tear-off

Label

sensor

level

Warn

Transfer

dump

error

reprint

reprint

smart

mode

Gap

sensor

ribbon

print

Security

Interfaces

Security

Ethernet Ethernet

RS-232 RS-232

Error

Network

address

Gateway

Gateway

mask

Subnet

IP

Address

DHCP

Handshake

rate

Baud

Mode

Debug

Time

Powersave

LCD

Contrast

LCD

Brightn.

position

Backfeed

sensor

Demand

sensor

Demand

Limit

Backfeed

Peel

speed

peel-off

delay

position

Print

param.

param.

Machine

Print

speed

level

Heat

Interfaces

Character

Default

set

card

slot

pos.

Tear-off

pos. Y

Printhead

pos. X

Printhead

33

Page 41

Control Panel

Control Panel Structure

1

2

Figure 25, Control Panel

The control panel consists of a graphic display (Figure 25, 1) and the

navigator pad (Figure 25, 2) with five integrated keys.

The graphic display indicates the current status of the printer, label and/or

ribbon numbers, if Brady-brand materials are used, the print job, faults and

the printer settings in the menu.

The key functions depend on the current printer status. The key pads (for

example, menu or feed) light up white in Print mode.

Functions in Print Mode

Powersave Mode

If the printer is not used for a lengthy period, it automatically switches to

Powersave mode.

The graphic appears in the display, and key lighting is switched off.

Press any key on the navigator pad to exit Powersave mode.

Printer States

‘Ready’ state

The printer is ready and can receive data.

The display shows the text Ready and label and/or ribbon numbers if

Brady-brand materials are used.

34

Page 42

Control Panel

‘Printing label’ state

The printer is currently processing an active print job. Data can be transmitted

for a new print job. The new print job will start when the previous one has

finished.

The display shows the message Printing label and the number of the

printed label in the print job.

‘Pause’ state

The printing process has been interrupted by the operator.

The display shows the text Pause and the symbol .

‘Correctable error’ state

An error has occurred that can be rectified by the operator without interrupting

the print job. The print job can be continued after the error has been rectified.

The display shows the symbol , the type of error and the number of labels

still to be printed.

‘Irrecoverable error’ state

An error has occurred that cannot be rectified without interrupting the print

job.

The display shows the symbol , the type of error and the number of labels

still to be printed.

‘System fault’ state

If a fault occurs during the system test, the symbol and type of error are

displayed.

■ Switch the printer off and then on again at the power switch.

or

■ Press the cancel key.

Call Service if the error occurs persistently.

35

Page 43

Control Panel

Key Functions

■ The up, down, left and right arrows are used for navigating in the menu.

■ The . key corresponds to the Enter key on a computer keyboard. It

confirms:

- Selection of a menu item.

- Entry of a parameter.

- Help information in the event of a fault.

Key Display State Function

menu lights Ready Ready Enter the offline menu.

feed lights Ready Ready Feed a blank label.

pause lights Ready Ready Stop printer after the end of a print

job.

Reprint the last label.

Print label Print label Interrupt print job.

Printer goes into Pause state.

Pause Pause Continue print job. Printer goes into

Print label state.

flashes Correctable

error

cancel lights Ready Ready Delete internal memory. The last

Print label Print label

Pause Pause

Correctable

error

flashes Irrecoverable

error

.

lights Error Call help. Concise information for

Continue the print job after

rectifying the fault. Printer goes into

Print label state.

label can no longer be reprinted.

Short press

print job.

Longer press

current print job and deletes all

print jobs.

rectifying the fault is displayed.

J cancels the current

J cancels the

LCD/Menu Options

Parameters for configuring the printer are found in the Setup menu on the

printer. Your printer is mainly configured via the operating LCD display during

initial start-up and when making major changes to the operating conditions.

Changes required for processing different print jobs should be implemented

via software settings.

You can protect the Setup menu from unauthorized access with a code

number (PIN). Refer to Security on page 53 for additional information.

36

Page 44

Control Panel

Short Status

The Short status menu provides an overview of important status

information in the display of the printer.

1. Press the menu key.

2. Select Short status menu.

3. Scroll through the individual lines with the S and T keys.

4. Use the

The following configuration parameters are displayed in the Short status

menu:

Line Meaning Example

1 Printer type IP/300

2 Version number of the printer operating system

3 Creation date of firmware (Aug 11 2006)

4 Version number of the system loader

5 Creation date of the bootloader (Jul 24 2006)

6 Revision of the CPU PCB PCB Rev. 05

7 Revision of the CPU CPU Rev. 3

8 Serial number of the PCB CPU CPU

9 Resolution of the installed thermal printhead TPH

10 Previously printed paper lengths Transfer 181.44 m

11 Previously printed paper length (thermal print) Thermal 13.17 m

12 IP address of the Brady IP Printer when

key to exit the menu.

Firmware V1.00

(firmware)

Bootloader V1.14

(bootloader)

#132062821190

300dpi,1248dots

192.168.9.14

connected to a network

37

Page 45

Control Panel

Test

Overview

The printer is equipped with different test functions providing information

about:

■ The most important configuration parameters.

■ The fonts available in the printer.

■ The hardware components and connected peripheral devices.

■ The print image quality and state of the thermal printhead.

■ The function of label detection in conjunction with the optical properties of

the label medium.

■ The label data sent from the computer or memory card.

The test functions are found in the Test menu:

1. Press the menu key.

2. Select Test menu.

3. Switch to the test function level with the T key.

4. Select the desired test function with the X and W keys.

5. Start the selected test function with the

Figure 26, Sample Test Label

key.

38

Page 46

Control Panel

Status Print

The Status print function prints a test image containing information on the

configuration and status of the printer. The printout occurs using the heat level

and print speed specified in the Setup > Print param. menu.

NOTE: Continuous media is most suitable for this function.

1. Press the menu key.

2. Select Test > Status print menu.

3. Press the

key.

You can cancel the printout with the cancel key.

The printout contains the following information:

■ Device type

■ Version and creation date of the firmware

■ Version and creation date of the system loader (bootloader)

■ Current values of selected local settings (refer to Local Settings on

page 47)

■ Current values of selected device settings (refer to Device List on page 41)

■ Current values of selected print parameters (refer to Print Parameters on

page 50)

■ Current values of selected interface parameters (refer to Interfaces on

page 52)

■ Status of PIN activation (refer to Security on page 53)

■ Operation time

■ Number of labels printed

■ Printed length with thermal transfer printing and thermal direct printing

■ Current measured values of the printhead temperature and heat voltage

■ Information about the label sensor

■ Lines used to evaluate the print quality

39

Page 47

Control Panel

Font List

The Font list function prints the most important parameters of the fonts

available in the printer. The table contains both the original fonts and

user-loaded fonts.

NOTE: Continuous media is most suitable for this function.

1. Press the menu key.

2. Select Test > Font list menu.

3. Press the

You can cancel the printout with the cancel key.

The font parameters have the following meanings:

Column Meaning

No. ID number of the font required for programming (command T).

Name Name with which the font is saved internally.

Type Type of font generation. This provides information on the

Description Explanations of the font: size, font family. The printout occurs in

key.

Figure 27, Font List

variability of the font and is important when programming

(command T).

the appropriate font.

40

Page 48

Control Panel

Device List

The Device list function prints out the most important information on

hardware components of the printer and connected devices.

NOTE: Continuous media is most suitable for this function.

1. Press the menu key.

2. Select Test > Device list menu.

3. Press the

You can cancel the printout with the cancel key.

Name Information

CPU Type and serial number of the CPU PCB

TPH Resolution and heating point number of the installed thermal

I/F [x] Type of interfaces installed

key.

Figure 28, Device List

Revision of CPU PCB and FPGA

printhead.

x: Number of interface

41

Page 49

Control Panel

ASCII Dump Mode

ASCII Dump mode offers the option of checking incoming control sequences

at the interface when working with direct programming. The incoming

commands at the printer are printed out as text. In addition, a corresponding

error message is printed out immediately after an error occurs.

The printout is started after four lines have been received.

NOTE: Continuous media is most suitable for this function.

NOTE: You can adjust the width of the printout down to 2 inches

(50 mm) with the Width ASCII dump parameter.

1. Press the menu key.

2. Select Test > ASCII Dump Mode menu.

3. Press the

4. Use the feed key to call up the last few lines of a label description.

You can cancel the printout with the cancel key.

Figure 30 is an illustration of a sample ASCII Dump printout.

key to switch to Monitor mode.

Figure 29, ASCII Dump Mode

42

Page 50

Control Panel

Figure 30, Sample ASCII Dump Mode

43

Page 51

Control Panel

Test Grid

The Test grid function prints out the geometric pattern on a background

grid. This allows you to assess the evenness of the print quality.

NOTE: Continuous media is most suitable for this function.

1. Press the menu key.

2. Select Test > Test grid menu.

3. Press the

The geometric pattern is printed every five seconds once the Test grid

function is started. You can adjust the printer during the pauses between the

printouts.

You can cancel the printout with the cancel key.

key to start the printout.

Figure 31, Test Grid

44

Page 52

Control Panel

Label Profile

The Label profile function carries out a longer label advance. It saves the

values measured by the label sensor here and then prints them out in two

diagrams. The printout is used to check label detection in conjunction with the

optical properties of the label medium.

1. Select the label sensor to be tested in Setup > Print param. Refer to

Print Parameters on page 50.

2. Load the label medium to be tested into the printer.

3. Press the menu key.

4. Select Test > Label profile menu.

5. Press the

sensor measures the transparency/reflection capacity of the label

material. The message Test print OK appears in the display once the

advance is complete.

6. Load printable material which extends across the entire printing width.

7. Press the

You can cancel the printout with the cancel key.

key. The printer performs a longer label advance. The label

key to start the diagram printout.

Figure 32, Label Profile

45

Page 53

Control Panel

Figure 33, Typical Label Profile Graph

Description of Label Profile Graph

1 Direction of paper flow at which the label start was detected

2 Type of peripheral device connected

3 Information for the firmware developer

4 Width of the negative derivative in motor increments

5 Stroke between start and end of the negative derivative

6 Scale factor for the derivative diagram

7 Service information for adjusting the label sensor

8 Method of label detection (transmitted light/reflex bottom)

9 Device name and current firmware version

46

Page 54

Control Panel

Setup Menu

Local Settings

Press the menu key.

Select Setup > Local settings.

Parameter Meaning Default

Country Sets the display language and the

country-specific date and time formats.

USA

Timezone Adapts the time display on the printer to the time

zone in relation to UTC (Universal Time

Coordinated).

Daylight

saving

Set date Sets the system date in the format

Set time Sets the system time in HH:MM:SS format.

Selects daylight savings time applicable for the

region. The time changes automatically when

daylight savings time begins and ends.

DD.MM.YYYY (DD: day, MM: month,

YYYY: year). The print output of the date varies

depending on the format set via the country

parameter.

When changing the time, ensure that the

timezone, daylight saving and set date

parameters are set correctly.

UTC

USA

–

–

47

Page 55

Control Panel

Machine Parameters

Press the menu key.

Select Setup > Machine param.

Parameter Meaning Default

Printhead

pos. X

Printhead

pos. Y

Demand

sensor

Shifting of the entire print image perpendicular to

the direction of paper flow.

The absolute shifting is limited by the margins of the

print zone. Those are determined by the width of the

printing line on the printhead.

You can also set the Printhead pos. X via

software. The offset values from the Machine

param. menu and the software are added together.

Shifting of the entire print image in the direction of

paper flow. With positive values, printing begins

later in the direction of paper flow.

Shifting of the print image in the direction of paper

flow also influences the peel and tear positions.

Correct the peel position and tear position

parameters by the same value in the opposite

direction.

You can also set the Printhead pos. Y via

software. The offset values from the Machine

param. menu and the software are added together.

Configuration of the Peel-off parameters for devices

with Peel-off function.

0.0 mm

0.0 mm

> Peel

position

48

In the peel position or individual label tear-off

position, the label may not advance enough for the

operator to get a grip on the label and remove it.

Increasing this value from zero advances the

printed label the selected distance until it is

removed. After the label is removed, the next label

automatically moves to the correct printing position.

The maximum recommended setting for the peel

position is 6.0 mm.

0.0 mm

Page 56

Control Panel

Parameter Meaning Default

>Backfeed

delay

Delay time between removing the label from the

peel position and the backfeed of the label.

250 ms

> Limit

peel-off

spd.

Brightn.

LCD

Contrast

LCD

Time

Powersave

Debug mode Operating mode which supports the firmware

Limitation of the print speed in the Peel-off mode to

100 mm/s.

Brightness of the LCD display from 1 to 10. 10

Contrast of the LCD display from 4 to 8. 6

Time between the last operation and the activation

of Powersave mode.

programmer when localizing errors.

On

5 min.

Off

49

Page 57

Control Panel

Print Parameters

Press the menu key.

Select Setup > Print param.

Parameter Meaning Default

Heat level Heating value to compensate for different

thermal behavior of printheads. Changing

this value is necessary if the printing intensity

has changed after replacing the printhead.

To adapt the printing intensity when using

different media, print speeds or printing

contents, you should change the heat level in

the software. The settings from the Print

param. menu and the software are added

together.

The heat level setting also affects the test

printouts.

Print speed Basic print speed setting.

You can specify the print speed for each print

job via software.

The print speed setting also affects the test

printouts.

Transfer

print

Warn level

ribbon

On for thermal transfer printing: Sensor for

monitoring the transfer ribbon is activated.

Off for thermal direct printing: Sensor for

monitoring the transfer ribbon is not

activated.

You can overwrite the setting for each print

job via software.

Warning sent via the Ethernet interface by

way of an SNMP message or e-mail sent

when the remaining diameter of the ribbon

supply roll undershoots the set value

1.2–3 inches (32–74 mm).

0

100 mm/s

On

Off

50

Page 58

Control Panel

Parameter Meaning Default

Label

sensor

Tear-off

mode

Backfeed Method for backfeeding the label medium.

ErrorReprint

Pause

reprint

Method for detecting the starting end of the

label.

Gap sensor: Detection using changes in

the transparency between the label and label

gap.

Bottom-Reflect: Detection using reflex

marks on the bottom of the material and

notched material.

Positioning the label medium for tearing off at

the Tear-off plate.

On: Additional advancement of the label

medium which positions the label gap after

the last printed label at the dispense plate.

Off: Label advance stops once the last label

has fully passed the print line.

Backfeeding is necessary in the Tear-off and

Peel-off modes since a label is pushed out

past the front edge of the next label above

the print line when peeling or tearing.

always: Backfeeding occurs independently

of label contents.

smart: Backfeeding only occurs when the

next label is not yet fully prepared when

peeling or tearing the current label.

Otherwise, the second label is pushed on

and completed after removal of the first label

without backfeeding.

On: With a correctable error and

corresponding troubleshooting, the label

being printed when the error occurs is

repeated.

Off: Print job is continued with the next

label.

Printing another label with the information of

the previous print job by pressing the pause

key. This function can be executed until the

print buffer is cleared with the cancel key.

Gap

Sensor

Off

smart

On

Off

51

Page 59

Control Panel

Parameter Meaning Default

Barcode

error

Width ASCII

dump

Interfaces

Press the menu key.

Select Setup > Interfaces.

On: With faulty barcode contents or size

specifications, printing is interrupted.

Off: Printing is not interrupted if an error

occurs. If barcode contents are faulty, the

printer attempts to replace the incorrect data

with valid characters (e.g. zeros). If barcode

size specifications are faulty, a gray area is

printed instead of the barcode.

Width of the printing area in the Monitor

mode test function.

With the Automatic setting, the printout of the

control sequences arriving at the printer

occurs over the maximum printing width. You

can reduce the printing area width down to

2 inches (50.8 mm).

On

Automatic

Parameter Meaning Default

Default

card slot

Character

set

RS-232 Sets the interface parameters Baud rate and

52

Selects the primary card slot. Select one of the

card slots on the back of the printer

(CompactFlash, PC Card or Ext.

CompactFlash)

Selects the character set table.

Switching the character set via software is not

possible. You can access characters not

available in the selected character set by using

the Unicode table.

Handshake for data transfer via the serial

RS-232 interface.

Recommended settings are 115200 and

hardware handshake.

Compact

Flash

Windows

1252

115200

RTS/CTS

Page 60

Control Panel

Parameter Meaning Default

> DHCP Method of issuing IP address

On: Dynamic issuing of IP address by the

DHCP server

Off: Direct issuing of the IP address by the

operator

> IP IP address of the Brady IP Printer. Only valid

with DHCP = Off.

> Mask Subnet mask (classification and address range)

of the local network. Only valid with DHCP =

Off.

> Gateway Connection address between the local network

and other networks. The IP address of the

computer (router) on the network. The address

of the router can also be issued via DHCP.

> Network

error

Printer switches to Error mode when problems

with the network connection occur.

On

Off

Off

Security

By activating a PIN, you can protect the Setup menu, certain memory card

functions and the firmware update from unauthorized access. The protected

menu items are marked with the symbol and are only accessible after the

PIN is entered.

1. Press the menu key.

2. Select Setup > Security > Security menu.

3. Select On with the X and W keys.

4. Accept the setting with the

5. Select On with the X and

6. Select PIN with the X key.

7. Select the digit of the PIN to be changed with the X and W keys.

8. Assign the selected digit a number with the S and T keys.

9. Repeat these two steps for the remaining digits of the PIN.

10. Accept the setting with the

key.

W keys.

key.

53

Page 61

Control Panel

Firmware

NOTICE

Do not power down or remove the memory card

during a firmware upgrade.

The printer firmware is saved in a Flash EPROM. You can update the

firmware using the following functions:

■ Firmware upd.: Copy a firmware file from a computer connected to one

of the interfaces of the Brady IP Printer. Refer to Firmware Update via

Interface on page 54. Brady Support can provide additional information

about current firmware available on the Brady website.

■ Firmw. fr. card: Copy a firmware file from a memory card. Refer to

Firmware Update from Memory Card on page 55.

Firmware Update via Interface

1. Press the menu key.

2. Select Service > Firmware upd. menu.

3. Press the

4. The Firmware-Upd message appears in the display.

5. Press the

6. If Firmware upd. is protected via a PIN, use the S, T, X and W keys

to enter the code number and confirm with the

7. Open the DOS input window on the PC.

8. Configure the serial interface of the PC with the mode command. Enter

the command mode com1: baud=115200 parity=n data=8 stop=1, for

example.

9. Send the firmware file (e.g. 304_6811.x2) to the printer. Enter the

command copy /b 304_6811.x2 com1:, for example.

10. A progress indicator is displayed while the firmware is being copied. OK

appears in the display once copying is successfully completed.

11. Press the

54

key.

key.

key.

key.

Page 62

Control Panel

Firmware Update from Memory Card

1. Format CompactFlash memory card in printer.

The directories “fonts,” “images,” “labels” and “misc” are created on the

memory card.

2. Copy the firmware file to the “misc” directory in a CompactFlash drive.

3. Insert the prepared memory card into the printer.

4. Press the menu button.

5. Select Service > Firmw. fr. card menu.

6. Press the

7. If the function Firmw. fr. card is protected via a PIN, use the S, T,

X and W keys to enter the code number and confirm with the

The names of the firmware files found on the memory card are shown in the

display.

8. If several firmware files are found on the memory card, select the desired

file with the S and T keys.

9. Press the

The selected firmware file is copied. A progress indicator is displayed while

the firmware is being copied. OK appears in the display once copying is

successfully completed.

10. Press the

key.

key.

key.

key.

55

Page 63

Control Panel

Error Messages During Firmware Update

If an error occurs during the update, one of the following error codes is shown

in the display:

Error

code

NOTE: If an error occurs with a firmware update, the old firmware

Meaning

C Checksum error.

/b may have been forgotten in the COPY command or the file is

defective.

H Header error.

/b may have been forgotten in the COPY command or the file is

defective.

E EPROM could not be cleared.

V Programming voltage is too low.

P Programming error.

version is no longer usable. Restart programming.

Adjust Screen Brightness

Brightn.

LCD

Contrast

LCD

Adjust the LCD display brightness (1 to 10). 10

Adjust the LCD display contrast (4 to 8). 6

56

Page 64

Control Panel

Calibration for Standard Material

Heat Settings for Print Darkness

With the use of Brady material, the heat settings in the setup print parameters

menu may vary greatly. Setting the heat excessively high can result in not

only melting the ribbon but also damaging the printhead. If your material does

not have a recommended heat setting, it is recommended that you set the

heat at -20, which is the lowest possible value. At this point print a label and

evaluate it for quality. If the label is too light, change the heat setting by one or

two values in the positive direction and retry printing a label. Keep repeating

this process until you get a quality label. Once you have determined the heat

setting for this particular material, record it so that the next time you use this

material you will know where to set the heat settings.

Heat settings can also be adjusted in your Brady software.

Speed Settings for Registration

Recommended speed is one or two inches per second.

57

Page 65

Control Panel

Print Sample Label

A sample label is imbedded in the firmware and can be printed through the

test menu.

58

Figure 34, Sample Print Label

Page 66

Print Setting Label

To validate the settings, print the configuration label.

Control Panel

Figure 35, Configuration Label

59

Page 67

Cleaning and Simple Maintenance

Cleaning and Simple Maintenance

A DANGER

Electric Shock Hazard

Disconnect power to the printer before starting any

maintenance work.

It is important to clean the thermal printhead regularly. This guarantees a

consistently good printed image and will prevent premature wear of the

printhead.

Other maintenance is limited to occasional cleaning of the printer.

General Cleaning

NOTICE

Do not use abrasive cleaners or solvents for cleaning

external surfaces or modules. Do not use lubricating

agents of any kind.

The printer can be damaged by abrasive cleansers.

Lubricating agents can damage the finish and mechanical

parts inside the printer.

■ Remove dust and particles from the print area with a soft brush, vacuum

cleaner or compressed air.

■ Clean the cover of the printer.

■ Remove any dust and debris from the interior of the printer using a soft

bristle brush or vacuum cleaner. Inspect this area after every four rolls of

media.

Cleaning the Printhead and Media Feed Rollers

It is important that the printhead be cleaned on a regular bases. If debris

builds up on the printhead you will see vertical un-printed lines appearing in

the labels. Continuing to print under these conditions can cause the heat from

the printhead to damage the printhead.

60

Page 68

Cleaning and Simple Maintenance

A CAUTION

Printhead Damage

• Do not use sharp objects to clean the printhead.

• Do not touch the protective glass layer on the

printhead.

A CAUTION

Risk of injury from the hot printhead.

Ensure that the printhead has cooled down before starting

cleaning.

To clean the printhead and/or media feed rollers:

1. Turn off the printer power.

2. Open the cover, lower the control panel and push the green print module

release button (refer to Loading the Ribbon on page 23).

3. Remove the transfer ribbon and the label stock (refer to Loading the

Ribbon and Material on page 23).

4. Use a cotton swab and a solvent of 90% isopropyl alcohol or a

Preventative Maintenance Kit to carefully rub the surface of the printhead

(Figure 36, 2) and the media feed rollers (Figure 36, 1) being careful not

to scratch the printhead.

5. Allow the printhead and media feed rollers to dry for about two to three

minutes before restarting the printer.

50

1

40

30

20

10

0

Figure 36, Printhead and Media Feed Rollers

2

If the vertical lines still appear after cleaning the printhead, the printhead may

be damaged.

NOTICE

Printhead replacement should always be performed by a

qualified and properly trained technician.

61

Page 69

Basic Troubleshooting Guide

Basic Troubleshooting Guide

Troubleshooting Chart

Problem Cause Remedy

Transfer ribbon

creases.

Print image has

smears or voids.

Printer does not stop

after transfer ribbon

runs out.

Printer prints a