Page 1

GHS HazCom

HazCom OSHA Standards and GHS Compliance

OSHA’s Hazard Communication Standard directly affects all

areas of chemical labeling and specify mandatory employee

training. This means you need to know exactly what the Global

Harmonized System (GHS) is and how it affects your business.

What is GHS?

GHS is an international system that the United Nations created

for the unified classification and labeling of chemicals. It

was officially adopted in the U.S. on March 26, 2012, by the

Occupational Safety and Health Administration (OSHA).

Why does GHS matter?

GHS compliance is important because it gives employees the

right to understand hazard information, rather than the right to

know about potential hazards.

OSHA HazCom violations

HazCom was #2 on OSHA’s Top 10 list of most

frequently cited standards for fiscal year 2017.

2017:

HazCom Labels

2016:

2015:

4,652 citations

5,677 citations

5,192 citations

Regulations

In the United States, OSHA is

enforcing GHS by adopting it

into its Hazard Communication

Standard (CFR 1910.1200). It is

focused on ensuring chemical

safety in the workplace by requiring

chemicals to be labeled and

chemical hazards to be identified in

a way that is easily understood by

workers. It entails:

1910.1200(h)(1)

Employee information and training

1910.1200(e)(1)

Developing, implementing and

maintaining a written HazCom

program

1910.1200(g)(1)

Developing and maintaining written

Safety Data Sheets

1910.1200(f)(1)

Labels on shipped containers

1910.1200(i)(1)

Employee training on new label

elements and Safety Data Sheets

2014:

2013:

5,161 citations

6,156 citations

HazCom Program

Training Labeling

362

Page 2

GHS HazCom

Full compliance was required as of June 1, 2016

OSHA published an updated Hazard Communication standard in 2012 that incorporated the major elements of the GHS standards.

A 3-year transitional period allowed companies time to fully implement the new GHS standards within their facility prior to the 2016

full compliance deadline. Below is an overview of each of the deadlines and some of the items that were required is listed below.

December 1, 2015June 1, 2015 June 1, 2016December 1, 2013

Employers must train

employees on the new

label elements and Safety

Data Sheet (SDS) format

✔

❏ Schedule and document

periodic re-training on

pictograms, labels and

SDS

✔

❏ Post GHS signs, posters,

and hand out wallet cards

✔

❏ Be able to demonstrate

that workers clearly

understand the hazards

associated with each

chemical they’re exposed

to, along with practice

measures they must take

✔

❏ Separate SDS and

Material Safety Data

Sheet (MSDS) binders

and sheets as part

of the management

system. This helps

you create secondary

container labels

with SDS information

and determine which

chemicals haven’t been

updated

Chemical manufacturers,

importers and distributors

reclassify chemicals, send

SDS and GHS labels

✔

❏ Identify secondary container

labeling needs and

procedures

✔

❏ Purchase GHS labeling

equipment and supplies

✔

❏ Implement labeling

procedures (create your

own or order pre-printed)

based on new SDS sheets

✔

❏

Archive old MSDS for

determined amount of time

(We recommend 30 years)

✔

❏ Re-train on GHS as well

as your existing HazCom

system (NFPA/HMIS) until

full conversion to GHS is

complete

Distributors send only

updated SDS and labels

✔

❏ Update your chemical

database as new SDSs are

received

✔

❏ Review and ensure that all

MSDS for any chemicals

received after December 1,

2015, have been converted

to SDS format

✔

❏ Notify and document

your communications

with suppliers who have

not provided new SDS

information

✔

❏

Audit all containers

for compliance with

updated regulations.

Establish policies to

control improperly labeled

containers

Employer full

compliance deadline

✔

❏ Ensure your training

policy is in place,

including new and

existing chemical

and internal product

changes. Annual training

is always recommended

✔

❏

Update and complete a

written HazCom program

that includes a system

of labeling, pictograms,

training schedule and

how/where to obtain more

information

✔

❏ Perform audits as

conditions change or

once a year to ensure

program effectiveness

Continually enhance your HazCom program

Throughout your journey to HazCom/GHS compliance, you

should always keep the following tasks in mind:

• Note any hazard or PPE changes on SDS sheets with each

chemical that comes into your facility. As new chemicals are

brought into your facility, new hazard and PPE needs may be

required

• Ensure your written HazCom program is updated and reflects

all internal and external changes

• Provide training to all new employees working with or around

hazardous chemicals

HazCom Labels

363

363

Page 3

GHS HazCom

Safety Data Sheets (SDS)

Formerly called Material Safety Data Sheets (MSDS), the new Safety Data Sheets (SDS) follow a consistent, user-friendly

format to communicate chemical hazards. They provide the information that’s needed to understand what the chemical is,

what hazards it presents and how to respond to these hazards. SDSs must accompany any hazardous chemicals that are

distributed. Most of the SDSs you need may be available online or through third party providers, such as MSDSonline.com.

When you need to create your compliant GHS labels, the SDS has the content you need. With the SDS information in hand,

you’re then ready to order pre-printed labels or quickly create labels onsite with the right printing system.

How do you obtain an SDS?

Chemical manufacturers, distributors or importers are required to create SDSs for any chemical they offer. These SDSs are

then provided to the companies that purchase and use the chemicals, in order to effectively communicate any relevant

chemical information and hazards.

The 16 elements of Safety Data Sheets (SDS)

The updated standards require that the chemical manufacturer, distributor or importer provide Safety Data

Sheets (SDS) for each hazardous chemical to communicate information on these hazards. Each SDS is

required to be presented in a consistent format, including the following sections:

Section 1: Identication

Chemical and recommended uses, and

supplier contact information.

Section 2: Hazard(s) Identication

Hazards of chemical and the appropriate warning information.

Section 3: Composition/Information of Ingredients

Ingredients contained in the products.

HazCom Labels

Section 4: First-Aid Measures

Initial care that should be given by an untrained

responder to an individual exposed to a chemical.

Section 5: Fire-Fighting Measures

Recommendations for fighting a fire caused by the chemical.

Section 6: Accidental Release Measures

Appropriate response to spills, leaks or releases,

including containment and cleanup practices.

Section 7: Handling and Storage

Safe handling practices and conditions for safe storage.

Section 8: Exposure Controls/Personal Protection

Exposure limits, engineering controls and personal protective

measures to minimize worker exposure.

Without a comprehensive online system to save and manage SDS information, users would have to input data manually in

order to print the needed chemical labels. By utilizing Brady’s partnership with MSDSonline, labels can be quickly populated

and printed — saving you time and ensuring information is input correctly onto the label.

Section 9: Physical and Chemical Properties

Physical and chemical properties associated with the substance.

Section 10: Stability and Reactivity

Reactivity hazards and stability information.

Section 11: Toxicology Information

Toxicological and health effects information or indicates data is unavailable.

Section 12: Ecological Information (non-mandatory)

Environmental impact of the chemical(s) if it were released to the

environment.

Section 13: Disposal Considerations (non-mandatory)

Proper disposal practices, recycling or reclamation and

safe handling practices.

Section 14: Transport Information (non-mandatory)

Classification information for shipping and transporting.

Section 15: Regulatory Information (non-mandatory)

Safety, health and environmental regulations specific for the

product that is not indicated anywhere else on the SDS.

Section 16: Other Information

When the SDS was prepared or when the last known revision took place.

Brady’s partnership with MSDSonline.com

364

MSDSonline.com

Helps improve the real time

management of chemical

products and SDS

Brady Printers

Reliable label printing with a

range of durable materials

for specific applications or

regulation requirements.

MSDSonline customers use SDS

from their system to create labels

that are formatted with the GHS

label elements and can be printed

to a variety of Brady label printers.

Page 4

GHS HazCom

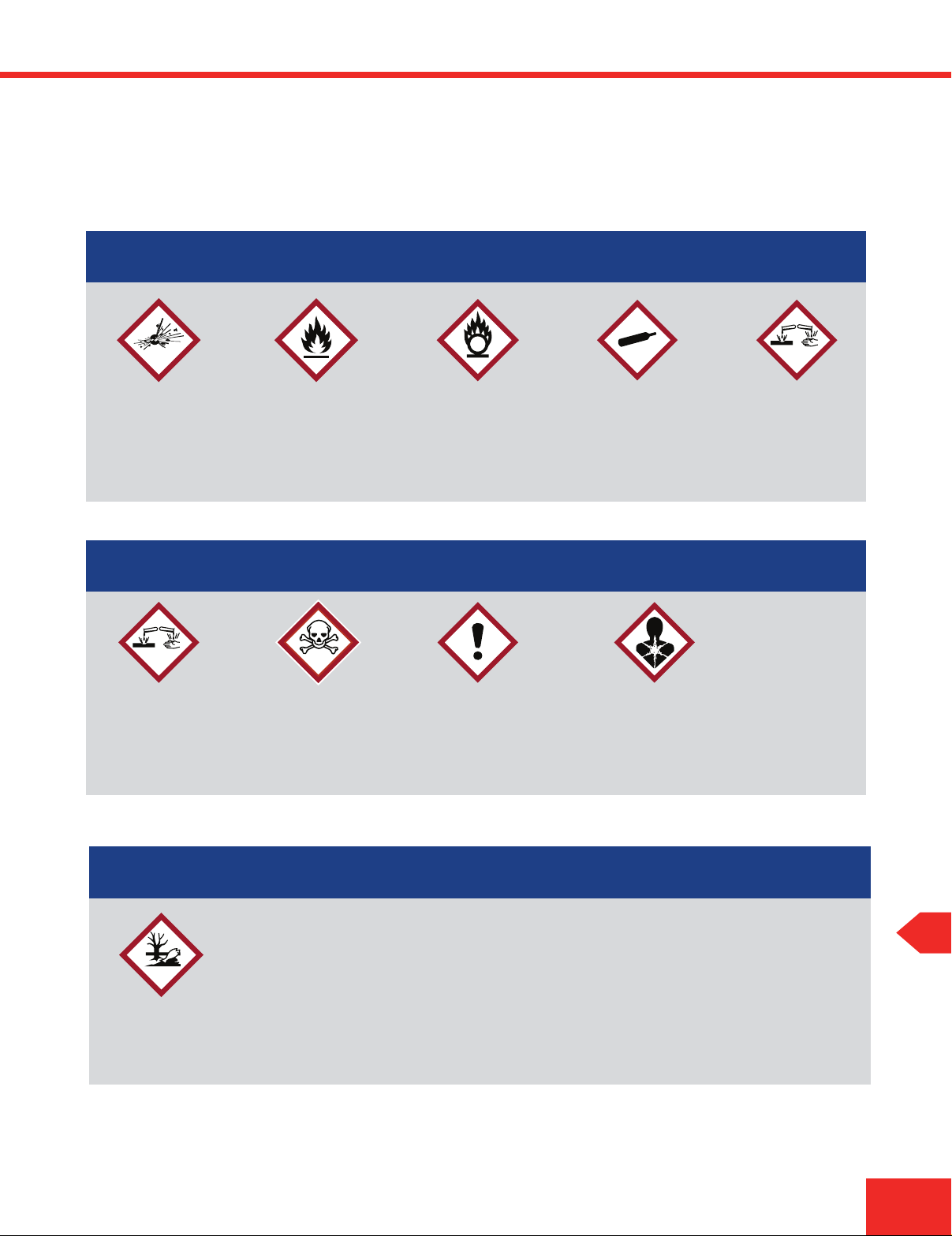

Symbols Guide

The new symbols, also known as hazard pictograms, each serve a special purpose and are used to identify hazardous

products. While the environmental pictogram was not mandated by OSHA, it is listed because it may be required by

other agencies for labeling.

Chemical and physical risk symbols

Exploding Bomb

Explosives,

self-reactives,

organic peroxides

Health risk symbols

Corrosion

Skin corrosion;

eye damage

Flame

Flammable gases,

liquids, and solids;

self-reactives;

pyrophorics;

self-heating

Skull and

Crossbones

Acute toxicity

(severe, fatal)

Flame

Over Circle

Oxidizing gases,

liquids and solids

Exclamation Mark

Irritant, dermal

sensitizer, acute

toxicity (harmful)

Gas Cylinder

Compressed gases;

liquefied gases;

dissolved gases

Health Hazard

Carcinogens, respiratory

sensitizers, reproductive

toxicity, target organ toxicity,

germ cell mutagens

Corrosion

Corrosives

to metals

Environmental risk symbols

The Environmental Protection Agency (EPA) has not yet incorporated GHS into its Federal

Insecticide, Fungicide and Rodenticide Act (FIFRA) labeling requirements. Currently, a

combination product that contains a pesticide and a fertilizer is regulated as a pesticide

Environment

Aquatic toxicity

(Not regulated by OSHA)

product under the FIFRA and must continue to be labeled in accordance with 40 CFR Part

156. However, some pesticide products may still be required to have an SDS.

HazCom Labels

365

365

Page 5

Pentane

Brady Corporation

6555 West Good Hope Rd.

Milwaukee, WI 53223

414-358-0004

50 ml

See safety data sheet

for further details

regarding safe use of

this product.

H225: Highly flammable liquid and

vapour. - H319: Causes serious

eye irritation. - H336: May cause

drowsiness or dizziness.

P210: Keep away from

heat/sparks/open flames/hot

surfaces. - No smoking. P2235+P410: Keep cool. Protect

from sunlight. - P302: IF ON SKIN:

Seek medical attention. -P305: IF

IN EYES: Flush with lukewarm

water and seek medical

attention. - P370: In case of fire:

Do not extinguish unless leak

can be stopped safely. - P403:

Store in a well-ventilated place.

DANGER

109-66-0

332-903-9

676-129-89-1

(414) 324-7989

GHS HazCom

The Six Elements of GHS Labels

GHS labels for primary containers must have six key elements in order to be compliant to the HazCom 2012 standard. All

chemicals shipped from chemical manufacturers after June 1, 2015, must contain these six elements.

#6 Manufacturer information

Company name, address and

phone number. (SDS Section 1)

#1 Signal word

Indicates relative severity of

hazard. DANGER is used

for most severe instances,

while WARNiNG is less

severe. (SDS Section 2)

HazCom Labels

#2 Symbols (pictograms)

Convey health, physical and environmental

hazard information with red diamond

pictograms. May use a combination of one

to five symbols. (SDS Section 2)

#3 Product name

or identiers*

(SDS Section 1)

* Additional

Product

Identifiers

#4 Hazard statements

Phrases that describe the

nature of hazardous products

and associated risks if

precautionary action is not

taken. (SDS Section 2)

#5 Precautionary statements

Phrases associated with each

hazard statement, that describe

general preventative, response,

storage or disposal precautions.

(SDS Section 2)

366

Page 6

GHS HazCom

Primary vs. Secondary Container

Primary container labeling

Primary chemical containers are bags, barrels,

bottles, boxes, cans, cylinders, and drums that you

receive from the manufacturer. These containers

should be labeled following the GHS mandates

and include all six labeling elements.

When a label is on a container directly from a

supplier, this label cannot be removed, altered

or defaced. If it needs to replaced, the new label

must contain the same information as the original.

Secondary container labeling

Secondary containers are usually smaller than

primary container, such as spray bottles, jugs or jars.

They usually hold chemicals that are transferred from

a primary container.

Secondary containers must comply with GHS

workplace labeling requirements except when the

following criteria are met:

• The material is used within the work shift of the

individual who makes the transfer

• The worker who made the transfer is in the work

area the entire time during use

• The container stays in within the work area and in

the possession of the worker who filled the container

Regulation information

OSHA has not changed the general requirements

for secondary container labeling specifically.

Employers have the option to create their own

workplace labels by using all of the information

provided by the manufacturer or using a

combination of the elements in the GHS label

example on page 366.

Employers may continue to use rating systems

such as the National Fire Protection Association

(NFPA) diamonds or Hazardous Materials

Identification System (HMIS) requirements for

workplace labels, as long as they are consistent

with the HazCom 2012 / GHS standard.

HazCom Labels

367

367

Page 7

GHS Training

Hazard Communication Training

OSHA requires all employees who are covered under the 29 CFR 1910.1200 regulation must

complete initial training on the new Hazard Communication Standard updates and the GHS elements.

To help you achieve and sustain complete compliance, Brady offers a full suite of training options.

GHS HazCom Training Program (DVD)

Used for: Inital GHS Training

• Two-video program focused specifically on the GHS elements

• Fulfills an initial training requirement

• Program is intended to ensure employees:

• Understand the new GHS label elements

• Are able to identify the new GHS pictograms

• Are able to read and interpret GHS Safety Data Sheets (SDS)

• Includes: DVD with two videos (14 minute GHS Labeling Video and 10

minute GHS SDS Video), instructor’s guide, employee quiz, presentation

slides and five Employee Handbooks

Catalog # Description Qty.

132428 GHS HazCom Training Program Kit (English) 1

132429 Additional GHS HazCom Training Employee Handbooks (English) 5

HazCom Labels

HazCom Comprehensive Training Program (DVD)

Used for: Annual Refresher Training

• Fully comprehensive training program on OSHA’s Hazard Communication

Regulation (1910.1200) including GHS

• Fullfills annual refresher requirement

• Program is intended to ensure employees:

• Understand types of hazardous materials in the workplace

• Are able to read and understand labels and Safety Data Sheets (SDS)

• Are able to understand how to safely use hazardous materials

• Includes: DVD, instructor’s guide, employee quiz, presentation slides

and five Employee Handbooks

Catalog # Description Qty.

132457 HazCom Comprehensive Training Program Kit 1

132458 Additional HazCom Comprehensive Training Employee Handbooks 5

368

Page 8

GHS Training

GHS Reference Center Poster

• This all-inclusive, large-format poster gets worker’s attention

and combines many of the most important changes into one

easy-to-read format

• Includes detailed information on:

- Safety Data Sheet (SDS) format

- GHS-formatted label elements

- GHS Hazard Pictograms

Catalog # Description Size Qty.

133209 GHS Reference Center Poster 25.5 in. x 39.5 in. 1 each

GHS Pictograms Wallet Cards

• Wallet Cards outline all nine GHS hazard pictograms

• A great training aid to help employees become familiar with

the new hazard pictograms, and as a handy reference for

when the new GHS labels are entering your facility

• Made of laminated cardstock

Catalog # Description Size Qty.

133208 GHS Pictograms Wallet Card 2.1 in. x 3.4 in. 10/pk

Pictogram Sign

GHS Intro Poster Pack

• Set of 3 informational posters puts critical GHS information

in your facility and to promote employee understanding

• Posters outline:

• An overview of the Globally Harmonized System of Classification and

Labeling of Chemicals

• Information regarding the new Safety Data Sheets format and outline

• Information regarding the new GHS-formatted label elements

Catalog # Description Size Qty.

133207 GHS Intro Posters 17 in. x 22 in. 1 set of 3

Format Sign

Label Elements Sign

GHS Reference Signs

• Post signs to remind and reinforce label, pictogram

and SDS training

• Choice of B-140 fiberglass or B-302 self-sticking polyester

Catalog # Description Material Size Qty.

133167 GHS Pictogram Overview Sign Fiberglass 14 in. x 10 in. 1

133170 GHS Pictogram Overview Sign Self-Sticking 14 in. x 10 in. 1

133168 GHS Label Elements Sign Fiberglass 10 in. x 14 in. 1

133171 GHS Label Elements Sign Self-Sticking 10 in. x 14 in. 1

133169 SDS Format Overview Sign Fiberglass 14 in. x 10 in. 1

133172 SDS Format Overview Sign Self-Sticking 14 in. x 10 in. 1

HazCom Labels

369

369

Page 9

GHS Labeling

Print-Your-Own GHS Labels

Achieve full GHS compliance throughout your facility by

utilizing easy-to-use label printers, label design software

and a wide range of label materials from Brady.

How can I create a GHS label?

Printer built-in touchscreen app

Many of Brady's printers feature an easy-to-use touchscreen

interface with built-in GHS label creation applications that make

creating GHS labels simple.

Brady Workstation GHS Labels App

The Brady Workstation GHS App features built-in, pre-formatted

layouts, pictograms, as well as drag and drop hazard statements

so there's no need to type them all in. Once your label is created,

print to any compatible Brady printer.

Brady’s partnership with MSDSonline.com

By utilizing Brady’s partnership with MSDSonline, labels can

be quickly populated using the SDS data managed within your

HazCom Labels

MSDSonline account – saving you time and ensuring information

is correctly input onto the label. Once the label is created, print

directly to a compatible Brady printer.

How can I print a GHS label?

Your printing solution can consist of a mono-color printer and label materials with pre-printed diamonds,

or use a multi-color printer to print your own red diamonds on any blank label material.

Mono-color printing

Pre-printed diamond labels

available for the following

Brady printers:

• BradyPrinter S3000,

BradyPrinter S3100,

BradyPrinter i3300,

®

BBP

35, BBP®37 and

®

BBP

85 printers

Multi-color printing

Color printers capable of

printing red diamonds on any

blank label material:

• BBP®35, BBP®37

color printers

• BradyJet J2000 and

J5000 color printers

370

Page 10

GHS Labeling

Pre-Printed and Custom Labels

If a full printing system isn't an option for you, Brady still has

solutions to help you get the GHS labels you need. From custom

label options to individual pictogram labels, Brady has you covered.

Die-cut GHS pictogram labels

Printing your own GHS labels but can’t get the pictograms

you need? Use Brady’s pre-printed GHS pictogram labels

to add the necessary icons to your label. These are a

great way to supplement mono-color label printers without

investing in a brand new label printing system.

Custom GHS labels

Have Brady create your GHS labels for you! It’s simple.

Just fill in the forms on the following pages with your label

content and specifications. Then send it back to Brady's

custom quote team for pricing. From there, use your quote

to place the order. That’s it!

Use with pre-printed

diamond picto labels

(sold separately)

Write-On GHS Labels

• Ample room to include product identifier, hazard

and precautionary statements, and emergency

contact information

• Durable vinyl material for indoor or outdoor use

• Accommodate Brady’s 5/8 in. or 1 in. pre-printed

red diamond pictogram labels (sold separately)

Catalog # Header Size Material Qty.

145957 Warning 4 in. x 6 in. Vinyl 50/pk

145956 Danger 4 in. x 6 in. Vinyl 50/pk

Die-cut picto labels included on every label

Write-On GHS and NFPA Labels

with Die-Cut GHS Pictos

• Convenient, write-on GHS labels

• Durable vinyl material for indoor or outdoor use

• Contains both GHS and NFPA label elements

• Included die-cut pictograms can be applied onto the label

Catalog # Header Size Material Qty.

148804 Warning 4 in. x 6 in. Vinyl 25/roll

148805 Danger 4 in. x 6 in. Vinyl 25/roll

HazCom Labels

371

371

Page 11

GHS Labeling

Die-Cut GHS Pictogram Labels

• To be applied to primary and secondary container labels

that do not already contain GHS pictogram symbols

• Ideal when printing black and white labels or when

pictograms are not available in the label design process

• Picto labels must accompany all other required GHS label

elements in order order to meet OSHA standards

Catalog # Size Material Qty.

B-7569 Vinyl

118815 5/8 in. Vinyl 1 card of 39

118816 1 in. Vinyl 1 card of 16

118817 2 in. Vinyl 1 card of 4

B-235 Paper

118869 5/8 in. Paper 1 card of 39

118870 1 in. Paper 1 card of 16

118871 2 in. Paper 1 card of 4

B-7451 Polyester

121188 1.5 in. Polyester 1 card of 20

121202 2 in. Polyester Roll of 250

121201 4 in. Polyester Roll of 250

HazCom Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118833 5/8 in. Vinyl 1 card of 39

118834 1 in. Vinyl 1 card of 16

118835 2 in. Vinyl 1 card of 4

B-235 Paper

118887 5/8 in. Paper 1 card of 39

118888 1 in. Paper 1 card of 16

118889 2 in. Paper 1 card of 4

B-7451 Polyester

121192 1.5 in. Polyester 1 card of 20

121207 2 in. Polyester Roll of 250

121206 4 in. Polyester Roll of 250

Explosive

Picto Labels

Gas Pressure

Picto Labels

Flammable

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118821 5/8 in. Vinyl 1 card of 39

118822 1 in. Vinyl 1 card of 16

118823 2 in. Vinyl 1 card of 4

B-235 Paper

118875 5/8 in. Paper 1 card of 39

118876 1 in. Paper 1 card of 16

118877 2 in. Paper 1 card of 4

B-7451 Polyester

121190 1.5 in. Polyester 1 card of 20

121203 2 in. Polyester Roll of 250

121189 4 in. Polyester Roll of 250

Corrosive

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118839 5/8 in. Vinyl 1 card of 39

118840 1 in. Vinyl 1 card of 16

118841 2 in. Vinyl 1 card of 4

B-235 Paper

118893 5/8 in. Paper 1 card of 39

118894 1 in. Paper 1 card of 16

118895 2 in. Paper 1 card of 4

B-7451 Polyester

121198 1.5 in. Polyester 1 card of 20

121213 2 in. Polyester Roll of 250

121197 4 in. Polyester Roll of 250

Oxidizing

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118827 5/8 in. Vinyl 1 card of 39

118828 1 in. Vinyl 1 card of 16

118829 2 in. Vinyl 1 card of 4

B-235 Paper

118881 5/8 in. Paper 1 card of 39

118882 1 in. Paper 1 card of 16

118883 2 in. Paper 1 card of 4

B-7451 Polyester

121191 1.5 in. Polyester 1 card of 20

121205 2 in. Polyester Roll of 250

121204 4 in. Polyester Roll of 250

Severe Toxic

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118845 5/8 in. Vinyl 1 card of 39

118846 1 in. Vinyl 1 card of 16

118847 2 in. Vinyl 1 card of 4

B-235 Paper

118899 5/8 in. Paper 1 card of 39

118900 1 in. Paper 1 card of 16

118901 2 in. Paper 1 card of 4

B-7451 Polyester

121200 1.5 in. Polyester 1 card of 20

121214 2 in. Polyester Roll of 250

121199 4 in. Polyester Roll of 250

372

Health Danger

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118851 5/8 in. Vinyl 1 card of 39

118852 1 in. Vinyl 1 card of 16

118853 2 in. Vinyl 1 card of 4

B-235 Paper

118905 5/8 in. Paper 1 card of 39

118906 1 in. Paper 1 card of 16

118907 2 in. Paper 1 card of 4

B-7451 Polyester

121196 1.5 in. Polyester 1 card of 20

121212 2 in. Polyester Roll of 250

121195 4 in. Polyester Roll of 250

Acute Toxic

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118857 5/8 in. Vinyl 1 card of 39

118858 1 in. Vinyl 1 card of 16

118859 2 in. Vinyl 1 card of 4

B-235 Paper

118911 5/8 in. Paper 1 card of 39

118912 1 in. Paper 1 card of 16

118913 2 in. Paper 1 card of 4

B-7451 Polyester

121193 1.5 in. Polyester 1 card of 20

121209 2 in. Polyester Roll of 250

121208 4 in. Polyester Roll of 250

Environmental

Picto Labels

Catalog # Size Material Qty.

B-7569 Vinyl

118863 5/8 in. Vinyl 1 card of 39

118864 1 in. Vinyl 1 card of 16

118865 2 in. Vinyl 1 card of 4

B-235 Paper

118917 5/8 in. Paper 1 card of 39

118918 1 in. Paper 1 card of 16

118919 2 in. Paper 1 card of 4

B-7451 Polyester

121194 1.5 in. Polyester 1 card of 20

121211 2 in. Polyester Roll of 250

121210 4 in. Polyester Roll of 250

Page 12

Custom Label Order Form

Custom GHS Label Form

When ordering a Custom GHS Label from Brady, please have a Safety Data Sheet (SDS) in hand to fill in the form. The SDS,

supplied from your chemical manufacturer must be up-to-date with GHS elements. All required label elements that are needed to

fill this form out are found in sections 1-3 in your chemical SDS. (Once label has been created a proof will be provided.)

Once complete, return this form to BradyUSAQuotes@BradyCorp.com or fax to 1-800-292-2289.

Customer Information

Company Name: Name:

Address1: Phone #:

Address2: Fax #:

City: State: Zip:

Email:

Distributor Information

Distributor:

Account #: Fax #: Phone #:

Contact Name:

Label Specications

Label Material

q

B-302 Self-Sticking Polyester

q B-946 Vinyl

q B-7569 Economy Vinyl

q B-235 Coated Paper

Quantity and Size

(minimum order qty. of 25)

q 3 in. x 5 in. Qty.

q 4 in. x 6 in. Qty.

q 4.5 in. x 7 in. Qty.

Label Content

Chemical/Product Name:

Signal Word:

(DANGER or WARNING)

Capacity:

Units:

Hazard Statements:

Located on your Safety Data Sheet, please include H-Code if available. i.e. H100

Precautionary Statements/First Aid:

Located on your Safety Data Sheet, please include P-Code if available. i.e. P100

Label Package

Roll Form (100 labels minimum)

q

q Individual Labels

GHS Pictograms:

Locate on your Safety Data Sheet and indicate pictogram number below:

1 minimum / 4 maximum

Diamond 1:

Diamond 2:

2. Severe Toxic 5. Environmental

Additional Label Content:

EC #:

CAS #:

Index #:

Reach Authorization #:

Internal Reference #:

Chemical Manufacturer Name:

Chemical Manufacturer Address:

Emergency Contact Phone #:

Multiple Languages Requested*

* Please indicate languages requested, then provide the necessary translations to

the customer service rep after you have received the initial English proof.

3. Explosive

Diamond 3:

Diamond 4:

8. Gas Pressure6. Acute Toxic

4. Flammable1. Corrosive

9. Health7. Oxidizing

HazCom Labels

373

373

Page 13

Hazard Communication (RTK)

NFPA

5 in. x 3 in. Container Labels

• Economical option for secondary

container labeling

• Available with NFPA Diamond or

HMIG Color Bar formats

Catalog # Material Format Qty.

99175 Paper HMIG Color Bar 500

121164 Vinyl HMIG Color Bar 500

99195 Paper NFPA 500

121146 Vinyl NFPA 500

Blank NFPA Placards

HazCom Labels

• Meets NFPA’s Code No. 704M and

Federal Standard 313

• Place on potentially hazardous equip.

• Use with Gothic style Quik-Align®

numbers and letters (sold separately)

Catalog # Description Size Qty.

58656 Fiberglass 11 in. 1

58510 Fiberglass 16 in. 1

58500 Vinyl 2.5 in. 10

58501 Vinyl 5 in. 10

58502 Vinyl 7.5 in. 10

58503 Vinyl 10 in. 10

58504 Vinyl 15 in. 10

58272 Reflective 5 in. 10

58273 Reflective 7.5 in. 10

58274 Reflective 10 in. 10

HMIG Color Bar

NFPA

HMIG Color Bar

2 in. x 1.25 in. Lab Labels

• Paper or vinyl materials in NFPA

Diamond or HMIG Color Bar formats

• Write-on labels allow you to customize

your message

Catalog # Material Format Qty.

58268 Paper HMIG Color Bar 500

121161 Vinyl HMIG Color Bar 500

99199 Paper NFPA 500

121163 Vinyl NFPA 500

NFPA Placard Kits

• Vinyl kits includes:

10 blank NFPA placards

10 characters each of 0 – 4, W, ,

OXY, ACID, COR and ALK

• Fiberglass kits includes:

1 blank NFPA placard

10 characters each of 0 – 4, W, ,

OXY, ACID, COR and ALK

Catalog # Description Size Qty.

50053 Vinyl 10 in. 1 kit

50054 Vinyl 15 in. 1 kit

50055 Fiberglass 11 in. 1 kit

50056 Fiberglass 16 in. 1 kit

3 in. x 5 in. Write-On Labels

• Customize these Blank RTK Labels

by writing your own message on them

and adding RTK pictograms

Catalog # Material Format Qty.

121056 Vinyl NFPA 50

NFPA Diamond Labels

Catalog # Description Size Qty.

53072 Vinyl 6 in. x 6 in. 500

NFPA Information Placards

• Placards graphically explain the NFPA

Hazard Identification Coding System

Catalog # Description Size Qty.

78788 Fiberglass 10 in. x 14 in. 1

58511 Vinyl 2.25 in. x 3.125 in. 1

76415 Vinyl 10 in. x 14 in. 1

374

HMIG Labels Station

• Features six 3/4 in. pockets for holding

sheet labels, one 5 in. dowel to hold

label rolls and a pen holder

• Displays hazard rating information

Catalog # Description Size Qty.

PD674E HMIG Label Station 11 in. x 18 in. 1

HMIG Self-Laminating Labels

• Self-adhesive polyester label includes

protective laminate cover

• Write in the rating on the left side

• Features index for required PPE

Catalog # Description Size Qty.

60332 Self-Lam Label 2 in. x 3.5 in. 25

60333 Self-Lam Label 3 in. x 5 in. 25

RTK Wallet Card

• Handy wallet-sized reference card of

the NFPA Hazard Identification

Coding System

Catalog # Description Size Qty.

58515 English 2.125 in. x 3.375 in. 25

89257 Spanish 2.125 in. x 3.375 in. 25

Page 14

Hazardous Waste Labels

Hazardous Waste Labels

• Labels comply with all current federal regulations regarding identification of hazardous waste materials for transportation

Catalog #

121155 Vinyl 6 in. x 6 in. 50

121151 Vinyl 6 in. x 6 in. 100

California Specific Labels

121157 Vinyl 6 in. x 6 in. 50

121152 Vinyl 6 in. x 6 in. 100

New Jersey Specific Labels

121156 Vinyl 6 in. x 6 in. 50

121144 Vinyl 6 in. x 6 in. 100

Material

Size Qty.

Catalog #

121158 Vinyl 6 in. x 6 in. 50

121153 Vinyl 6 in. x 6 in. 100

121159 Paper 6 in. x 6 in. 100

Catalog #

121061 Vinyl 4 in. x 4 in. 100

121438 Vinyl 6 in. x 6 in. 100

Waste Disposal Labels

• Use to easily identify and sort waste

Material

Material

Size Qty.

Size Qty.

Catalog #

121154 Vinyl 6 in. x 6 in. 50

60447 Vinyl 6 in. x 6 in. 100

121064 Paper 6 in. x 6 in. 100

Catalog #

87026 Paper 6 in. x 6 in. 50

87031 Vinyl 4 in. x 4 in. 50

87028 Vinyl 6 in. x 6 in. 50

Material

Material

Size Qty.

Size Qty.

Catalog #

121064 Vinyl 4 in. x 6 in. 50

121063 Vinyl 4 in. x 6 in. 100

60445 Paper 4 in. x 6 in. 100

Material

Size Qty.

Catalog #

121439 Vinyl 6 in. x 6 in. 100

60363 Paper 6 in. x 6 in. 100

Catalog #

121140 Vinyl 6 in. x 6 in. 100

60366 Paper 6 in. x 6 in. 100

Catalog #

121432 Vinyl 6 in. x 6 in. 100

60367 Paper 6 in. x 6 in. 100

Material

Material

Material

Size Qty.

Size Qty.

Size Qty.

Catalog #

63240 Vinyl 6 in. x 6 in. 500

Catalog #

121437 Vinyl 6 in. x 6 in. 100

60362 Paper 6 in. x 6 in. 100

Catalog #

121434 Vinyl 6 in. x 6 in. 100

Material

Material

Material

Size Qty.

Size Qty.

Size Qty.

Catalog #

121062 Vinyl 6 in. x 6 in. 100

60369 Paper 6 in. x 6 in. 100

Catalog #

121433 Vinyl 6 in. x 6 in. 100

Catalog #

121435 Vinyl 6 in. x 6 in. 100

Material

Material

Material

Size Qty.

Size Qty.

Size Qty.

Catalog #

121436 Vinyl 6 in. x 6 in. 100

60364 Paper 6 in. x 6 in. 100

Catalog #

121431 Vinyl 6 in. x 6 in. 100

60365 Paper 6 in. x 6 in. 100

Material

Material

Size Qty.

Size Qty.

HazCom Labels

375

375

Page 15

Hazardous Material Shipping

Hazardous Material Shipping Labels

• Composite plastic material offers extreme weatherability so label

colors stay bright

• Super tacky adhesive back permanently bonds to most surfaces

(including low energy surfaces such as polyethylene bags)

• Labels withstand temperatures of -50°

Class 2:

121066 4 in. x 4 in.

Class 3: Class 4:

121067 4 in. x 4 in.

HazCom Labels

500/roll

500/roll

121065 4 in. x 4 in.

121069 4 in. x 4 in.

500/roll

121469 4 in. x 4 in.

500/roll

500/roll

121068 4 in. x 4 in.

500/roll

Placard Labels and GHS

While GHS requires proper

chemical labeling, the Department

of Transportation (DOT) requires

proper labeling when you’re

shipping chemicals.

This means when the product is

shipped, the outer package must

bear all of the required DOT marks

and labels as well as the GHS label

information if it is a primary container.

Essentially, DOT labeling does not

change with GHS, but when the

primary container is also the

shipping container, you’ll need both.

Class 5:

121071 4 in. x 4 in.

121473 4 in. x 4 in.

Die-Cut

Placard

Numbers

Catalog # Description Qty.

5010-* 1 in. Quik-Align Numbers 10pk

*Replace (*) with the desired number (0-9).

Example: To order die-cut 8, order # 5010-8.

500/roll

500/roll

121471 4 in. x 4 in.

121441 4 in. x 4 in.

500/roll

500/roll

Class 6:

121466 4 in. x 4 in.

500/roll

63473

Class 9:Class 8:Class 7:

121070 4 in. x 4 in.

500/roll

121141 4 in. x 4 in.

Vehicle Placard Signs

Brady also offers a wide range

of Vehicle Placard Signs for

shipping hazardous materials.

View signs on page 463.

4 in. x 4 in.

500/roll

500/roll

121467 4 in. x 4 in.

500/roll

376

Page 16

Regulations

OSHA standards require you

to have SDS on hand for all

chemicals at your facility.

1910.1200(g)(1)

Developing and maintaining

written Safety Data Sheets

1910.1200(i)(1)

Employee training on new

label elements and Safety Data

Sheets

Safety Information Centers

GHS SDS Binders

• Complies with OSHA regulations

• 1.5 in. dia. ring holds 275-300 sheets

3 in. dia. ring holds 600 sheets

• Features a durable polyethylene cover,

36 in. chain and a pair of sheet lifters

Catalog # Description

121183 1.5 in. SDS Binder, English

121184 3 in. SDS Binder, English

121185 1.5 in. SDS Binder, English/Spanish

121186 3 in. SDS Binder, English/Spanish

121187 3 in. SDS Binder, English/French

GHS SDS Centers

• 20 in. x 14 in. x 4.5 in. center offered

in English and Spanish

• Includes 1.5 in. SDS binder,

Right To Know Compliance Center

backboard and yellow wire rack

Catalog # Description

121370 SDS Center English

121371 SDS Center Spanish

Bilingual Training Insert

• This detailed binder insert package

contains:

• OSHA Haz-Com Standard highlights and

overview of program requirements

• Compliance checklist

• Two 15-page RTK training booklets,

• 2-Sided RTK poster (Spanish/English)

• 50 clear sheet protectors

• A-Z index tabs

Catalog # Description

BR801B Bilingual Binder Insert

Standard MSDS Binders

• 1.5 in. dia. rings hold 275-300 sheets

2.5 in. dia. ring holds 400-500 sheets

3 in. dia. ring holds 600 sheets

• Durable polyethylene cover, 36 in.

chain and pair of sheet lifters

Catalog # Description

2023 1.5 in. MSDS Binder

2024 2.5 in. MSDS Binder

2025 3.0 in. MSDS Binder

2026 1.5 in. Bilingual MSDS Binder

2027 2.5 in. Bilingual MSDS Binder

2028 3.0 in. Bilingual MSDS Binder

BR801B Binder Insert

Double RTK Center

• This center includes red polystyrene

board, 2 binder racks and two MSDS

binders

• Center size: 20 in. x 29 in. x 4.5 in.

Catalog # Description

2010DB Double RTK Compliance Center

Economy RTK Center

• Includes MSDS v-style sign,

8 in. x 14.5 in. x 6 in.

• 1.5 in. MSDS binder with 300 sheet

capacity

Catalog # Description

2007 Economy RTK Center

RK085A Rack and Binder w/inserts

2005 Rack and Binder Only

RTK Compliance Center

• 20 in. x 14 in. x 4.5 in. compliance

center includes red polystyrene board,

binder rack and MSDS binder

• 1.5 in. binder w/ 300 sheet capacity

Catalog # Description

2010 Compliance Center

RK018A Compliance Center w/inserts

2010NB Compliance Center w/o binder

2010SP Spanish Compliance Center*

*Board is Spanish with 1.5 in. Bilingual Binder

HazCom Labels

High Visibilty SDS Signs

• High visibility signs easily mount and

project from the wall for easy viewing

• Made from heavy-duty B-493 plastic

Catalog # Style Size Qty

139786 V-Shape 6 in. x 9 in. x 4 in. 1

139787 L-Shape 8 in. x 8 in. 1

377

377

Page 17

Safety Information Centers

Information Centers

• Rugged poly backboard comes with

white PVC coated wire basket, allowing

for high visibility and convenience

• Tear resistant 3-ring binder holds

approx. 300 sheets and includes chain

and mounting hardware

• Center Size: 20 in. x 14 in.

Catalog # Description

IC326E Emergency Information Center

HazCom Labels

Bloodborne Pathogen

Compliance Center

• Wall-mount display includes a

1.5 in. binder that holds up to 300

pages of your exposure control plans

(not included)

• Center size: 20 in. x 14 in. x 4.5 in.

Catalog # Description

BH2010 Bloodborne Pathogen Center

BH2023 Exposure Control Binder only

Standard Operating

Procedures Center

• Poly backboard w/ white PVC coated

wire basket

• Rugged binder holds approximately

300 sheets and comes with an

attached chain

• Additional binders sold separately

Catalog # Description

SM681A Procedures Center

SM682A

Double Standard Operation Procedures

Center

Lockout Procedure Station

• Durable polystyrene board includes

pre-drilled holes and mounting

hardware

• Backboard dimensions:

20 in. x 14 in. x 4.5 in.

Catalog # Description

LOSP22 Station With Binder and 25 Forms

99289 Lockout Procedure Station With Binder Only

LOSB1 Lockout Procedure Binder Only

MSDS / Job Site Safety

Document Center

• Table top or wall mount center holds

one 3-ring binder in a weather resistant

and lockable polystyrene case

• Size: 13.5 in. x 13.5 in. x 4.75 in.

Catalog # Description

JS1 MSDS/Job Site Center

Standard RTK Center

• Acrylic board can hold up to

100 booklets and an MSDS binder

• Includes our 1.5 in. binder and

10 training booklets

• Center size: 30 in. x 24 in. x 4.5 in.

Catalog # Description

2001 Standard Right to Know Center

2012 Board Only

2002 Bilingual version*

*Includes 5 English booklets, 5 Spanish booklets

and a bilingual binder

378

Binder Holders

• PVC coated steel racks designed for

holding binders up to 3 in. ring dia.

• Single: 9 in. x 14 in. x 4.5 in.

Double: 9 in. x 14 in. x 6.5 in.

Catalog # Description Color Qty.

2014 Single Binder Holder Yellow 1

2014W Single Binder Holder White 1

104791 Double Binder Holder Yellow 1

104792 Double Binder Holder White 1

Suggestion Box

• Wall or table mount black acrylic box

w/ a lockable top and side pocket

• Box: 12 in. x 11.75 in. x 4.75 in.

Side pocket: 5 in. x 4 in. x 1.625 in.

Top drop slot: 9 in.

Catalog # Description

MC111E Suggestion Box

Page 18

Format 1

Safety Information Centers

Format 2

Conned Space

Entry Permits

• 8.5 in. x 11 in. forms include all

information required by OSHA’s

Confined Space Regulation

• Available in several materials to best

meet your facility’s environment

Catalog # Description Qty

EP1 Format 1 Permits 25/pk

65937

Format 2 Permits

(2-ply Carbonless)

25/pk

Conned Space

Permit Center

• Wall-mounted Permit Center provides

ready access to entry permits while

making employees aware of special

safety requirements

• Holds 8.5 in. x 11 in. forms

Holder dimensions: 15.75 in. x 23.5 in.

• Permit forms sold separately

Catalog # Description Qty

PC1

Permit Center

(Permit forms sold separately)

25/pk

Conned Space

Entry Permit Holder

• Provides a confined space warning and

easy access to permits

• Made of durable polycarbonate material

• Holds 8.5 in. x 11 in. forms

Holder dimensions: 12 in. x 19 in.

• Permit forms sold separately

Catalog # Description Qty

65903

Permit Holder

(Permit forms sold separately)

1

Safe-T-Grip® Fuse Pullers

• Provides maximum convenience

when removing or replacing

cartridge fuses

• Notched handles for no-slip grip

• Clearly marked amperage ranges

• Exceeds MIL specifications

• For 0-100A, 250V and 600V fuses

Catalog # Description

65280 Safe-T-Grip Fuse Pullers

E-Z Check® Plus

GFI Circuit Tester

• Checks for the following conditions:

correct wiring, open ground,

reverse polarity, open hot, open

neutral, hot on neutral, hot and

ground reversed with open hot and

ground fault interruption

Catalog # Description

65273 E-Z Check Plus GFI Circuit Tester

Battery Cleaning and

Charging Safety Kit

• Help minimize the risk of acid burns or

shocks while charging batteries

• Fully equipped portable kit includes:

• (1) pair of large unsupported neoprene over

natural rubber gloves

• (1) pair of clear chemical goggles

• (1) 45 in. x 35 in. black rubber apron

• (1) 8 in. synthetic brush

• (2) 9.25 in. x 14.5 in. chemical sorbent pads

• (1) quart neutralizing and cleaning agent

• (1) laminated instruction card

Catalog # Description

BCK Battery cleaning and charging kit

HazCom Labels

379

379

Loading...

Loading...