Page 1

Technical Data Sheet

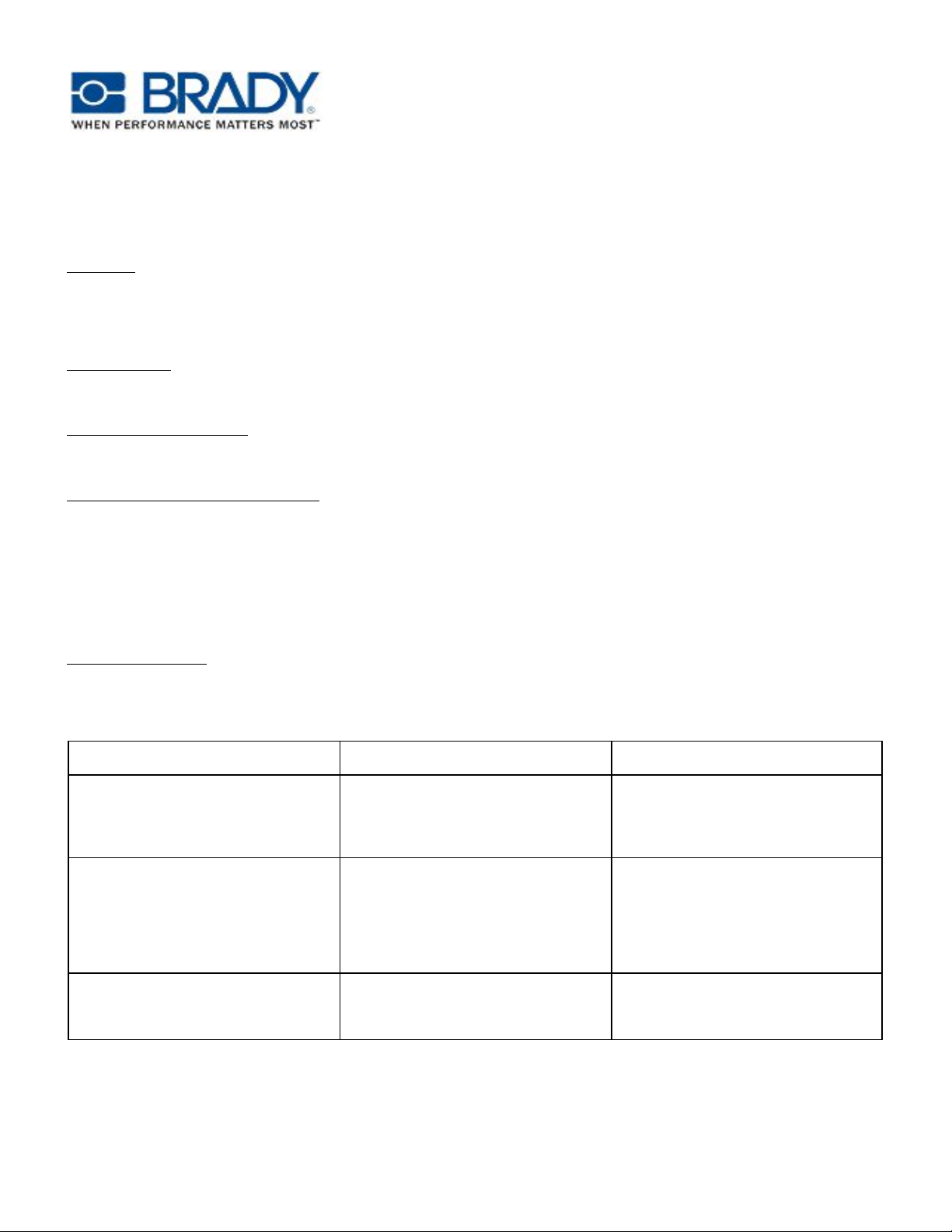

PHYSICAL PROPERTIES

TEST METHODS

AVERAGE RESULTS

Thickness

ASTM D 1000

-Substrate

-Adhesive

-Total

0.0034 inch (0.086 mm)

0.0010 inch (0.026 mm)

0.0044 inch (0.112 mm)

Adhesion to:

-Stainless Steel

-Polypropylene

ASTM D 1000

20 minute dwell

24 hour dwell

20 minute dwell

24 hour dwell

30 oz/in (33 N/100 mm)

40 oz/in (43 N/100 mm)

12 oz/in (13 N/100 mm)

20 oz/in (22 N/100 mm)

Tack

ASTM D 2979

Polyken

TM

Probe Tack

1 Second dwell

29 oz (789 g)

BRADY B-428 THERMAL TRANSFER PRINTABLE METALLIZED POLYESTER LABEL STOCK

TDS No. B-428

Effective Date: 06/05/2014

Description:

GENERAL

Print Technology: Thermal Transfer

Material Type: Metallized Polyester (3 mil film)

Finish: Matte, light gray appearance

Adhesive: Permanent Acrylic

APPLICATIONS

Designed for applications, like rating and serial plates, that utilize barcodes, alphanumerics, graphic symbols and logos and require

nameplate-like quality.

RECOMMENDED RIBBONS

Brady Series R4300

Brady Series R6200 (alternate)

REGULATORY/AGENCY APPROVALS

UL: B-428 is a UL Recognized Component when printed with the Brady Series R4300 Ribbon. See UL file MH17154 for specific

details. UL information can be accessed online at UL.com. Search in Certifications area.

CSA: B-428 is a CSA Accepted material when printed with the Brady Series R4300 Ribbon or R6200 Ribbon. See CSA

Acceptance Record LS 41833 for specific details. CSA information can be accessed online at directories.csa-international.org.

DIN VDE 0472 Part 815: Brady B-428 meets the requirements of a halogen-free material per DIN VDE 0472 part 815.

(Statement based on review of product construction and confirmatory halogen content test run at an independent test laboratory.)

Brady B-428 is RoHS compliant to 2005/618/EC MCV amendment to RoHS Directive 2002/95/EC.

SPECIAL FEATURES

B-428 is designed to withstand numerous solvents and variable temperatures when applied to various surfaces.

Details:

Performance properties tested on printed B-428 labels laminated to aluminum panels. Samples thermal transfer printed with

alphanumerics, and 5 mil and 10 mil minimum X dimension barcodes using a Series R4300 ribbon and a BradyPrinter

203 Thermal Transfer Printer.

TM

THT Model

Page 2

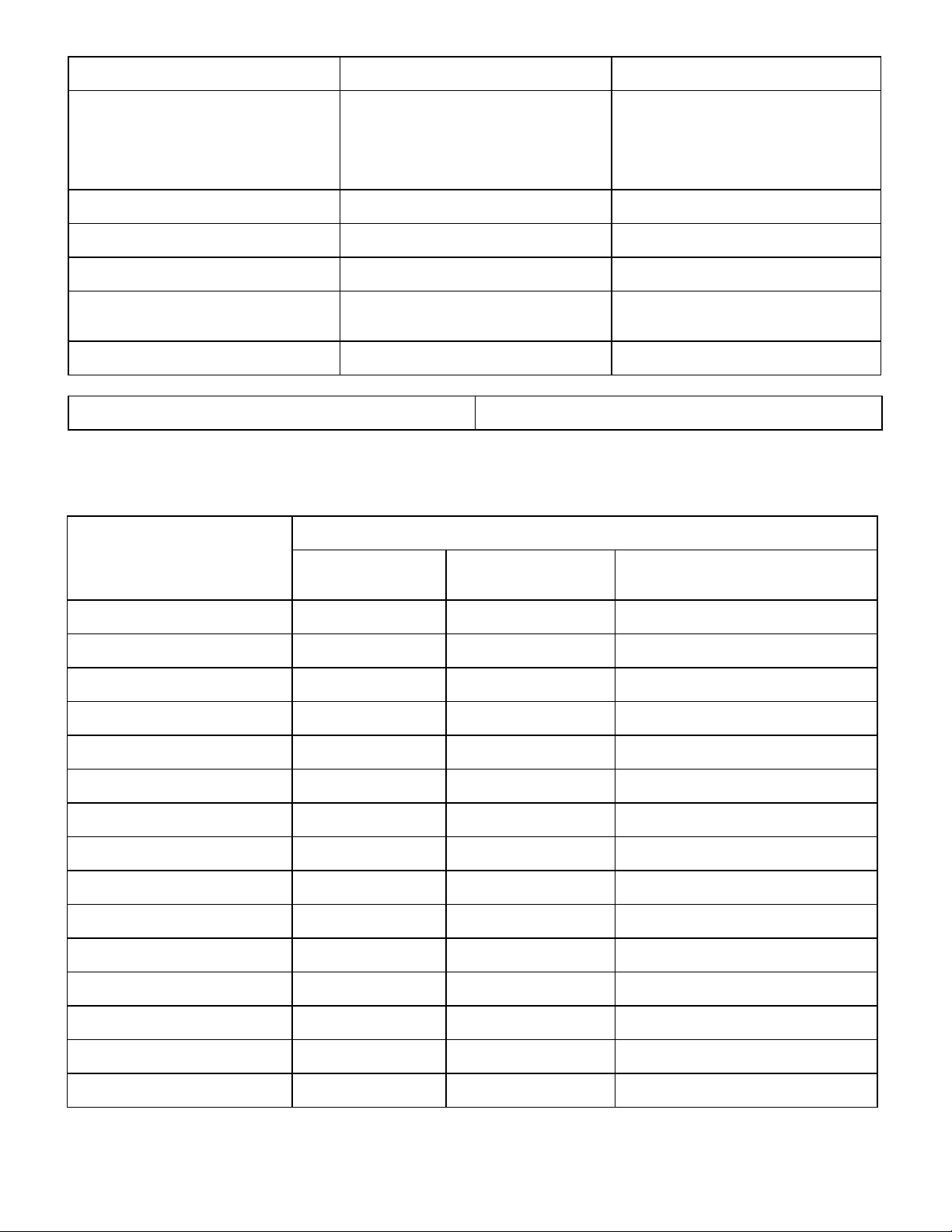

PERFORMANCE PROPERTIES

TEST METHODS

TYPICAL RESULTS

High Service Temperature

30 days at various temperatures

No visible effect to label at 248°F

(120°C), Slight discoloration at 293°F

(145°C), Moderate discoloration at

320°F

(160°C), but label is still functional

Low Service Temperature

30 days at -40°F (-40°C)

No visible effect

Humidity Resistance

30 days at 100°F (37°C), 95% R.H.

No visible effect

UV Light Resistance

30 days in UV Sunlighter

TM

100

No visible effect

Weatherability

ASTM G155, Cycle 1

30 days in Xenon Arc Weatherometer

Slight topcoat yellowing

Salt Fog Resistance

30 days in 5% salt fog

No visible effect PERFORMANCE PROPERTY

CHEMICAL RESISTANCE

Samples printed with a Series R4300 black ribbon and a Series R6200 black ribbon using a BradyPrinter

CHEMICAL REAGENT

SUBJECTIVE OBSERVATION OF VISUAL CHANGE (R4300 RIBBON)

EFFECT TO LABEL

STOCK

EFFECT TO PRINT

EFFECT TO PRINT WITH RUB

Methyl Ethyl Ketone

No visible effect

No visible effect

Moderate print removal

1,1,1-Trichloroethane

No visible effect

No visible effect

Moderate print removal

Toluene

No visible effect

No visible effect

Moderate print removal

Mineral Spirits

No visible effect

No visible effect

No visible effect

JP-8 Jet Fuel

No visible effect

No visible effect

No visible effect

SAE 20 WT Oil

No visible effect

No visible effect

No visible effect

SAE 20 WT Oil @ 70C

No visible effect

No visible effect

Severe print removal

IPA

No visible effect

No visible effect

No visible effect

ASTM #3

No visible effect

No visible effect

No visible effect

Mil 5606 oil

No visible effect

No visible effect

No visible effect

Skydrol® 500B

No visible effect

No visible effect

Slight print removal

Super Agitene®

No visible effect

No visible effect

No visible effect

Deionized Water

No visible effect

No visible effect

No visible effect

3% Alconox® Detergent

No visible effect

No visible effect

No visible effect

10% Sulfuric Acid Solution

No visible effect

No visible effect

No visible effect

TM

THT Model 203 Thermal

Transfer Printer. Test was conducted at room temperature after 24 hour dwell. Testing consisted of 5 cycles of 10 minute

immersions in the specified chemical reagent followed by 30 minute recovery periods. After final immersion, samples rubbed 10

times with cotton swab saturated with test fluid.

Page 3

10% Sodium Hydroxide Solution

No visible effect

No visible effect

No visible effect

CHEMICAL REAGENT

SUBJECTIVE OBSERVATION OF VISUAL CHANGE (R4300 RIBBON)

EFFECT TO LABEL

STOCK

EFFECT TO PRINT

EFFECT TO PRINT WITH RUB

Methyl Ethyl Ketone

No visible effect

No visible effect

Moderate print removal

1,1,1-Trichloroethane

No visible effect

No visible effect

Moderate print removal

Toluene

No visible effect

No visible effect

Moderate print removal

Mineral Spirits

No visible effect

No visible effect

Slight print removal

JP-8 Jet Fuel

No visible effect

No visible effect

Slight print removal

SAE 20 WT Oil

No visible effect

No visible effect

No visible effect

SAE 20 WT Oil @ 70C

No visible effect

No visible effect

Severe print removal

IPA

No visible effect

No visible effect

Slight print removal

ASTM #3

No visible effect

No visible effect

No visible effect

Mil 5606 oil

No visible effect

No visible effect

Slight print removal

Skydrol® 500B

No visible effect

No visible effect

Moderate print removal

Super Agitene®

No visible effect

No visible effect

Slight print removal

Deionized Water

No visible effect

No visible effect

No visible effect

3% Alconox® Detergent

No visible effect

No visible effect

No visible effect

10% Sulfuric Acid Solution

No visible effect

No visible effect

No visible effect

10% Sodium Hydroxide Solution

No visible effect

No visible effect

No visible effect

Shelf Life:

Two years when stored in its original packaging in an environment below 80°F (27°C) and 60%RH.

Trademarks:

Alconox® is a registered trademark of Alconox Co.

BradyPrinter

Polyken

Skydrol® is a registered trademark of the Monsanto Company

Sunlighter

Super Agitene® is a registered trademark of Graymills Corporation

ASTM: American Society for Testing and Materials (U.S.A.)

CSA: Canadian Standards Association

PSTC: Pressure Sensitive Tape Council (U.S.A.)

SAE: Society of Automotive Engineers (U.S.A.)

UL: Underwriters Laboratories INc. (U.S.A.)

All S.I. units are mathematically derived from the U.S. conventional units

Note: All values shown are averages and should not be used for specification purposes.

TM

is a trademark of Brady Worldwide, Inc.

TM

is a trademark of Testing Machines Inc.

TM

is a trademark of the Test Lab Apparatus Company

Page 4

Test data and test results contained in this document are for general information only and shall not be relied upon by Brady customers for designs

and specifications, or be relied on as meeting specified performance criteria. Customers desiring to develop specifications or performance criteria

for specific product applications should contact Brady for further information.

Product compliance information is based upon information provided by suppliers of the raw materials used by Brady to manufacture this product or

based on results of testing using recognized analytical methods performed by a third party, independent laboratory. As such, Brady makes no

independent representations or warranties, express or implied, and assumes no liability in connection with the use of this information.

WARRANTY

Brady products are sold with the understanding that the buyers will test them in actual use and determine for themselves their adaptability to their

intended uses. Brady warrants to the buyers that its products are free from defects in material and workmanship, but limits its obligation under this

warranty to replacement of the product shown to Brady’s satisfaction to have been defective at the time Brady sold it. This warranty does not extend

to any persons obtaining the product from the buyers. This warranty is in lieu of any other warranty, express or implied, including, but not limited to,

any implied warranty of merchantability or fitness for a particular purpose, and of any other obligations or liability on Brady’s part. Under no

circumstances will Brady be liable for any loss, damage, expense, or consequential damages of any kind arising in connection with the use, or

inability to use, Brady’s products.

Copyright 2017 Brady Worldwide, Inc. All Rights Reserved

Material may not be reproduced or distributed in any form without written permission.

__________________________________________________________________________________________________________________________________

Loading...

Loading...