Page 1

Arc Flash Labels

Arc Flash Safety

What is arc ash and what causes it?

An arc flash is a short circuit through air that flashes from one

exposed live conductor to another conductor or ground. This

electrical fault can create a dangerous release of energy, including

thermal energy, acoustical energy, pressure wave or debris.

There are many ways an arc flash can occur, including:

• Close proximity of a high-amp source to a conductive object

• Dropping a tool or creating a spark

• Breaks or gaps in insulation

• Failing equipment due to use of substandard parts, improper

installation or even normal wear and tear

• Dust, corrosion or other impurities on the surface of the conductor

What impacts the size of an arc ash event?

Common variables that impact the size and energy

of an arc flash include:

• Amperage

• Voltage

• Arc gap

• Closure time

Arc Flash Labels

• Distance from arc

• Three phase vs. single phase

• Confined space

Did You Know?

Anything above 50V that could be worked

on while energized ,resulting in exposure to

electrical hazards, requires an arc flash label.

Examples include, but are not limited to:

• Switchboards

• Panel boards

• Motor control

centers

• Industrial control

panels

• Meter socket

enclosures

380

NFPA 70E Standard for Electrical Safety in the Workplace

OSHA cites and fines employers for failure to protect employees

from the dangers of arc flash under regulation 29 CFR 1910.333(a).

The National Fire Protection Association (NFPA) details how to

comply with this regulation through the NFPA 70E standard.

According to the NFPA 70E standard, there are six primary

responsibilities that facilities must meet, including:

1. Training for employees

2. Written safety program in place that is actionable

3. Personal protective equipment (PPE) available for employees

4. Insulated tools

5. Arc flash hazard degree calculations

6. Properly labeled equipment

Most recent updates (2018)

The NFPA 70E gets updated every three years.

Some of the most recent updates include:

• Updated training and retraining requirements

• Revision to arc flash warning label content

• Elimination of the PPE hazard category 0

• Elimination of prohibited approach boundary

• Additional boundary requirements

• Revisions to selecting appropriate PPE

• Minor terminology changes

(such as work shoes now referred to as footwear)

Page 2

What is an arc ash boundary?

An arc flash boundary is the distance at which an electrical

arc can flash outward and endanger employees working on

electrical equipment.

Additional boundary requirements include:

• Conductive articles of jewelry and clothing: Watchbands,

bracelets, rings, key chains, necklaces, metal frame

glasses, etc. shall not be worn within the restricted

approach boundary

• Working space: Space shall be kept clear and not used

for storage to permit safe operation and maintenance

• Barricades: When the arc flash boundary is greater than

the limited approach boundary, barricades shall not be

placed closer than the arc flash boundary

• Insulated tools: Employees shall use insulated tools

when working inside the restricted approach boundary of

exposed energized electrical conductors.

Arc Flash Labels

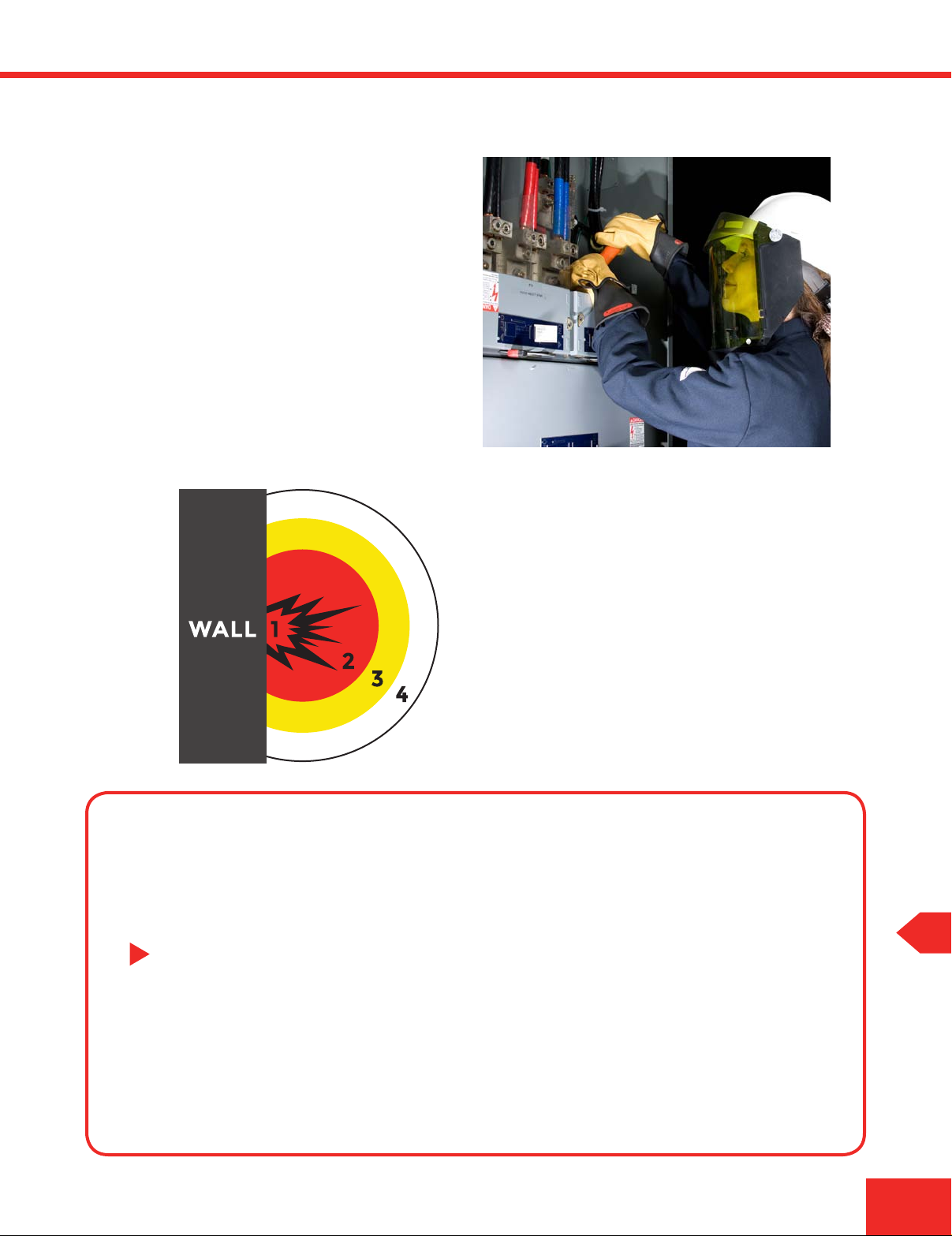

1. Exposed / energized conductor or circuit part

2. Restricted approach boundary

Distance where there is an increased

likelihood of electric shock

3. Limited approach boundary

Distance where a shock hazard exists

4. Arc ash boundary

Distance from an arc source where the

thermal energy exposure could cause

2nd degree burns on unprotected skin

Arc Flash Risk Assessment

The NFPA 70E 2015 edition requires employers to conduct an arc flash risk assessment to determine the amount

of thermal energy that could be generated from an arc flash incident. The information is then used to define a

flash protection boundary around the potential source, and to determine the level of arc-rated apparel and other

personal protection equipment required when employees cross the boundary while they work on or near explosive

live parts.

At minimum, the safety program needs to be audited at intervals not to exceed three years

and arc ash risk assessments shall be periodically reviewed at intervals not to exceed ve years.

Arc Flash Labels

Who should perform arc ash risk assessments?

Completing a best-in-class arc flash risk assessment in-house requires time, resources and analysis software to

accurately calculate arc flash risk. In addition, simple miscalculations can lead to incorrect incident energy levels

resulting in the improper use of PPE.

Brady’s Arc Flash Risk Assessment Service, performed by a licensed electrical engineer using power system

analysis software, enables you to not only reach compliance, but maintain compliance. Additional services also

include Arc Flash Audits and Arc Flash Safety Training.

381

381

Page 3

Arc Flash Labels

Arc Flash Labeling

Who’s responsible for labeling?

Arc flash labeling is the responsibility of the employer, not the

manufacturer or installer of the equipment.

What needs to be labeled?

Labeling is required for any piece of electrical equipment that is likely

to require examination, adjustment, service or maintenance while

energized, creating the potential for an arc flash incident to occur.

Any modifications or renovations to electrical equipment that

changes data on the label requires an updated arc flash risk

assessment and label.

Where should the label be placed?

Markings must be in a location that is clearly visible to workers before

they may be exposed to any potentially dangerous live parts. Typically,

the label is placed outside the panel or enclosure door.

What needs to appear on the label?

Once an arc flash risk assessment has been conducted, in which the arc flash boundary, the incident energy at the working

Arc Flash Labels

distance and the personal protective equipment required has been determined, Article 130.5 (C) in the 2015 edition of NFPA

70E further dictates that the label must contain these important elements.

Incident energy

and corresponding

working distance

Min. arc rating

of clothes

Arc ash

boundary

Site

specic

PPE

Arc Flash and Shock Hazard

Appropriate PPE Required

FLASH PROTECTION SHOCK PROTECTION

Incident Energy at:

Min. Arc Rating:

Arc Flash Boundary:

Glove Class:

PPE:

Shirt and pants or coverall, Nonmelting

(ASTM F1506) or Untreated Fiber) + hard hat

+ safety glasses + hearing protection

18 in.

0.45 cal/cm^

10 in.

Shock Risk When

Cover is Removed

2

Limited Approach

Restricted Ap-

proach

00

Bus Name:

Prot Dev: 100/3 BS-18 LAB PNL

PNL_P-5

480 VAC

42 in.

12 in.

Header

Shock hazard

information

382

Page 4

Arc Flash Labels

Brady Arc Flash Solutions

Arc ash services

Brady understands the importance of electrical safety as a whole

and has licensed engineers who understand not only arc flash

safety, but also the firsthand impact of arc flash risk. We work

with your team to best protect your employees based on your

custom facility and program requirements.

• Arc Flash Risk Assessment

A Brady safety electrical engineer completes your assessment,

provides you with a detailed assessment report, including your

single-line diagram, and installs the correct arc flash labels.

• Arc Flash Audit

Let our electrical engineer perform your arc flash audit and

ensure your assessment is up to date and compliant.

• Arc Flash Safety Training

This custom approach to training incorporates both the NFPA

regulation and your company-specific arc flash requirements

to ensure participating employees can apply their knowledge.

Print your own labels

Create and print customized arc flash labels when

and where you need them with an on-demand label

printer. When you’re working on a project, you can stop

handwriting your labels, and print all the labels you need

in batches. You also avoid the hassle of having to select,

order and wait for pre-printed labels to arrive.

Pre-printed die-cut labels

Pre-printed arc flash labels with the arc flash PPE

category and a list of the required PPE relieve the

employer from having to hand-write this information.

As with the check box labels, a version for both arc

flash and shock hazards is available.

Arc Flash Labels

383

383

Page 5

Arc Flash Labels

Pre-Printed Arc Flash Labels

• Labels come with the hazard category and PPE requirements preprinted

• Write in specifics such as minimum arc rating, protection boundary, etc.

• B-7569 vinyl can be written on with pen or marker

DANGER

Arc Flash & Shock Hazard

Appropriate PPE Required

FLASH PROTECTION

Arc Flash Boundary

Hazard Risk Category

Incident Energy (cal/cm

Corresponding Work Distance

VAC Shock Hazard When:

Minimum Arc Rating of Clothing

Nominal System Voltage

PPE: Arc-rated long sleeve shirt and long pants OR arc-rated coverall

Arc-rated flash suit jacket, pants and hood

Hard hat (with arc-rated hard hat liner AN)

Safety glasses or safety goggles

Equipment ID:

#000000 BRADYID.COM

Catalog # Header Hazard Size Qty

121085 Warning 1 5 in. x 7 in. 5/pk.

121087 Warning 2 5 in. x 7 in. 5/pk.

121091 Warning 3 5 in. x 7 in. 5/pk.

121093 Warning 4 5 in. x 7 in. 5/pk.

121086 Danger 1 5 in. x 7 in. 5/pk.

121088 Danger 2 5 in. x 7 in. 5/pk.

121092 Danger 3 5 in. x 7 in. 5/pk.

121094 Danger 4 5 in. x 7 in. 5/pk.

Write-On Arc Flash Labels

Arc Flash Labels

• Write in specifics such as minimum arc rating, protection boundary, etc.

• B-7569 vinyl can be written on with pen or marker

Catalog # Header Size Qty

121077 Warning 5 in. x 7 in. 5/pk.

121078 Danger 5 in. x 7 in. 5/pk.

SHOCK PROTECTION

Limited Approach Boundary

4

Restricted Approach Boundary

2

40

Prohibited Approach Boundary

)

Class

PPE:

V-rating

Hearing protection (ear canal inserts)

Arc-rated gloves and leather work shoes

Y1234567

*Y1234567*

Arc Flash Hazard

Appropriate PPE Required

Flash Protection Boundary

Hazard Risk Category

Flash Protection Equipment

Arc-rated long sleeve shirt and long pants OR arc-rated coverall

Arc-rated flash suit hood or arc-rated face

shield and arc-rated balaclava

Hard hat and safety glasses or safety goggles

Hearing protection (ear canal inserts)

Leather gloves and leather work shoes

Equipment ID:

2 8

#000000 BRADYID.COM

Incident Energy (cal/cm2)

Y1234567

*Y1234567*

Catalog # Header Hazard Size Qty

121097 Warning 1 4 in. x 6 in. 5/pk.

121099 Warning 2 4 in. x 6 in. 5/pk.

121101 Warning 3 4 in. x 6 in. 5/pk.

121103 Warning 4 4 in. x 6 in. 5/pk.

121098 Danger 1 4 in. x 6 in. 5/pk.

121100 Danger 2 4 in. x 6 in. 5/pk.

121102 Danger 3 4 in. x 6 in. 5/pk.

121104 Danger 4 4 in. x 6 in. 5/pk.

Catalog # Header Size Qty

121079 Warning 4 in. x 6 in. 5/pk.

121080 Danger 4 in. x 6 in. 5/pk.

Arc ash hazard

categories and PPE

requirements

Required Flash

Protection Equipment*

Arc-rated longsleeve shirt and long

pants (or arc-rated coverall)

Hazard

Category

Incident

energy

4 cal/cm

Hazard

Category

Incident

energy

8 cal/cm

Hazard

Category

Incident

energy

25 cal/cm

Hazard

Category

Incident

energy

40 cal/cm

Arc-rated face shield or

arc flash hood

Arc-rated jacket, parka, rainwear or

1

hard hat liner (as needed)

Hard hat

Safety glasses or safety goggles

2

Hearing protection (ear canal inserts)

Leather gloves

Leather footwear (as needed)

Arc-rated longsleeve shirt and long

pants (or arc-rated coverall)

Arc-rated face shield or

arc flash hood

Arc-rated jacket, parka, rainwear or

2

hard hat liner (as needed)

Hard hat

Safety glasses or safety goggles

2

Hearing protection (ear canal inserts)

Leather gloves

Leather footwear

Arc-rated longsleeve shirt and long

pants (or arc-rated coverall)

Arc-rated arc flash

suit jacket and pants

Arc-rated arc flash hood

Arc-rated jacket, parka or rainwear

3

(as needed)

Hard hat and arc-rated hard hat liner

Safety glasses or safety goggles

2

Hearing protection (ear canal inserts)

Leather footwear

Arc-rated gloves

Arc-rated longsleeve shirt and long

pants (or arc-rated coverall)

Arc-rated arc flash

suit jacket and pants

Arc-rated arc flash hood

Arc-rated jacket, parka or rainwear

4

(as needed)

Hard hat and arc-rated hard hat liner

Safety glasses or safety goggles

2

Hearing protection (ear canal inserts)

Leather footwear

Arc-rated gloves

384

Catalog # Header Size Qty

145975 Danger 5 in. x 7 in. 5/pk.

145974 Danger 4 in. x 6 in. 5/pk.

145973 Warning 5 in. x 7 in. 5/pk.

145972 Warning 4 in. x 6 in. 5/pk.

* Arc rating of PPE should correspond

with the Hazard Category and Incident

Energy present.Voltage-rated gloves

and other shock protection may also

be required when working on exposed

energized electrical parts.

Page 6

Poster

• Highlights the common causes of arc

flash and provides safe work practices

and personal protection equipment

requirements

• Laminated on both sides to stand up to

industrial environments

• Full-color printing and eye-catching

graphics for optimum visual impact

• Poster reflects all changes from NFPA

70E-2015 regulation

Catalog # Description Quantity

104571 18 in. x 24 in. poster 1 each

Sign

Label

Sign and Label

• Post signs and labels in the work area

and near electrical equipment to boost

awareness and compliance

• Signs and labels specify the personal

protection equipment required for each

arc flash hazard category

• Sign and label reflects all changes

from NFPA 70E-2015 regulation

• Sign: B-401 rigid plastic with

laminated graphics

Label: B-302 self-sticking polyester

with overlaminate

Catalog # Description Quantity

102523 7 in. x 10 in. sign 1 each

102524 3.5 in. x 5 in. label 5/pack

Arc Flash Labels

Front

Back

Wallet Card

• Ensure compliance and safety by

providing each employee with their

own arc flash wallet card

• Card specifies the personal protection

equipment required for each arc flash

hazard category

• Made of laminated cardstock

• Reflects all changes from

NFPA 70E-2015 regulation

Catalog # Description Quantity

102525 2.1 in. x 3.4 in. card 25/pack

On-Site Arc Flash Training Service

Under the NFPA 70E standard, arc flash training must be

completed every three years.

Brady’s Arc Flash Safety Training is a custom approach to

training that includes:

• Custom training materials with NFPA regulations and your

company-specific arc flash information

• On-site interactive training session

• Attendees receive a workbook and a certificate of completion

Training topics include:

• What is an arc flash and related information, such as

boundaries, labeling, work permits and PPE requirements

• OSHA regulations, responsibilities, training and PPE

• NFPA updates, compliance and PPE tables

• The difference between qualified and unqualified employees

• And more

Arc Flash Labels

385

385

Loading...

Loading...