Brady 1024 User Manual

Bradyprinter THT Model

1024 Thermal Transfer Printer

_______________________________________________________________________________

User’s Guide

LOGO W.H. Brady Co.

Automatic Indentification Products

CG Triumvirate is a trademark of Agfa Corporation.

Corrupad is a Trademark of Corrupad Protective Packaging Inc.

Bradyprinter THT Model 1024 is a Trademark of Brady USA Inc.

As an Energy Star Partner, Brady USA Inc. has determined that this

product meets the Energy Star guidelines for energy efficiency.

Information in this document is subject to change without notice and does

not represent a commitment on the part of Brady USA Inc. No part of this

manual may be reproduced or transmitted in any form or by any means,

for any purpose other than the purchaser's personal use, without the

expressed written permission of Brady USA Inc.

All rights reserved. Printed in the United States of America.

© Copyright 1997 by Brady USA Inc.

6555 W. Good Hope Road • Milwaukee, Wisconsin • 53223

800-537-8791 Customer Support

800-643-8766 Technical Support

Part Number: 88-2184-01

Revision: C

Agency Compliance and Approvals:

FCC: This device complies with Part 15 of FCC rules.

Note: This equipment has been tested and found to comply with the limits

for a Class A digital device, pursuant to Part 15 of the FCC

Rules. These limits are designed to provide reasonable protection

against harmful interference when the equipment is operated in a

commercial environment. This equipment generates, uses, and

can radiate radio frequency energy, and if not installed and used

in accordance with the instructions in this manual, it may cause

harmful interference to radio communications. Operation of this

equipment in a residential area is likely to cause harmful

interference in which case the user will be required to correct the

interference at his own expense.

Important Safety Instuctions

Your Bar Code Printer has been designed to give you many years of

safe, reliable service. As with all electrical equipment, there are a few

basic precautions you should take to avoid getting hurt or damaging the

Printer.

• Carefully read the installation and operating instructions provided

with your Printer.

• Read and follow all warning instruction labels on the Printer

itself.

• Place the Printer on a flat, firm, solid surface.

• To protect your Printer from overheating, make sure all openings

on the Printer are not blocked.

• Do not place the Printer on or near a heat source, (i.e., a radiator

or heat register).

• Do not use your Printer near water, or spill liquid of any kind into

it.

• Be certain that your power source matches the rating listed on the

bottom of the Printer. If you are unsure, check with your dealer

or with your local power company.

• Do not place the power cord where it will be walked on. If the

power cord becomes damaged or frayed replace it immediately.

• Do not insert anything into the ventilation slots or openings on the

Printer.

• Only qualified, trained service technicians should attempt to

repair your Printer.

♦♦ Contents

♦♦ Getting Started

1.0 Introduction ...............................................................1

1.1 Unpacking and Inspection...........................................1

1.2 Printer Specifications .................................................2

1.3 Connecting Power......................................................4

1.4 Switches and Indicators..............................................5

1.5 Interfacing to the Printer.............................................6

1.6 Loading Media...........................................................7

1.7 Loading Media for Peel Configuration........................8

1.8 Loading Ribbon (Thermal Transfer).......................... 9

1.9 Adjusting for Wide to Narrow Media........................ 11

1.10 Power-up Configuration and Self-Test......................12

1.11 Available Options .................................................... 13

♦♦ Printing Labels

2.0 Introduction .............................................................15

2.1 Programming Commands .........................................16

2.2 Programming Examples ........................................... 21

2.3 Configuration Command String................................ 22

2.4 Printing Bar Codes...................................................23

2.5 Memory Cartridges (Modules).................................. 24

♦♦ Maintenance

3.0 Introduction .............................................................25

3.1 Cleaning the Printhead..............................................25

3.2 Media Width Adjustment.......................................... 26

3.3 Fine Printhead Adjustment........................................27

3.4 Printhead Replacement............................................. 28

(continued)

i

Appendix A

ASCII Control Code Chart .............................................. A-1

Appendix B

Available Fonts and Bar Codes........................................B-1

Appendix C

Error Codes .....................................................................C-1

Appendix D

Warranty Information......................................................D-1

ii

♦♦ Getting Started

Figure 1-1 Printer Overview

1.0 Introduction

The Bradyprinter THT Model 1024, hereafter referred to as 'the Printer',

incorporates high performance/low cost thermal transfer label printing

capabilities. The combination of powerful capabilities, compact design,

and easy to use features make this Printer truly unique.

1.1 Unpacking and Inspection

Inspect the shipping container(s), if damage is evident, contact the carrier

to specify the nature and extent of the damage.

The Printer is packed in Corrupad recycled packaging and is enclosed

in a plastic bag to reduce the chance of moisture damage during shipment.

Remove the Printer from the plastic bag before use.

Along with this manual, the shipping container(s) should include the

following standard items:

• Label printer

• External power supply

• Special or additional items purchased.

Getting Started 1

1.2 Printer Specifications

Mechanical

Width

Depth

Height

Weight

Operating Temperature

Printer Specifications

Print Type

Print Speed

Resolution

Tear Bar

DRAM Memory

EPROM Memory

Media/Ribbon

Media Types

Max. Media Width

Max. Print Width

Min. Print Width

Max. Print Length

Min. Print Length

Media Thickness

Ribbon

8.8" (22.35 cm)

10.1" (25.65 cm)

6.2" (15.75 cm)

7 lbs. (15.4 kg)

40° F to 100° F (4° C to 38° C)

Thermal Transfer

1, 1.5, and 2" per second

203 dpi (8 dots/mm)

Tear up

512 kb

512 kb

Roll-Fed, Die-Cut, Continuous, Fan-Fold

4.65" (118 mm)

4.1" (104 mm)

1" (25 mm)

12" (305 mm) with standard RAM

.375" (.95 cm)

.5" (1.27 cm) w/ Present Sensor

.0025" - .01" (.0635 mm - .254 mm)

Matched to Media; approx. 4330"(110m)

long

1.5" O.D. on .5" core

2 Getting Started

Communications

Interface

Baud Speed

Handshaking

Parity

Stop Bits

Data Bits

RS-232 (DB-9), and Centronics Parallel

1200 to 19200 bps

Xon/Off, CTS, DTR

Even, Odd, or None

1 or 2

7 or 8

Electrical

External Power Supply

Nominal 115 or 230 VAC IN/ 19 VAC OUT

Fonts

10 Resident Styles

Resident Fonts Expandable to 8x

Reverse Image

Rotated 0, 90, 180, 270 degrees

Available Bar Codes

Code 39, Ext Code 39, Code 93, Ext Code 93, Code 128 UCC, Code 128

A, B & C, Codabar, Interleaved 2 of 5, UPC-A, UPC-E, UPC Ship C

Code, EAN-13, EAN-8, EAN 128, POSTNET, MaxiCode, PDF417

Options

Present Sensor

Memory Cartridges

External Cutter

DRAM Memory, (Expandable to 1MB)

Wall Mount

External Battery

Time/Date

External Media Supply

Getting Started 3

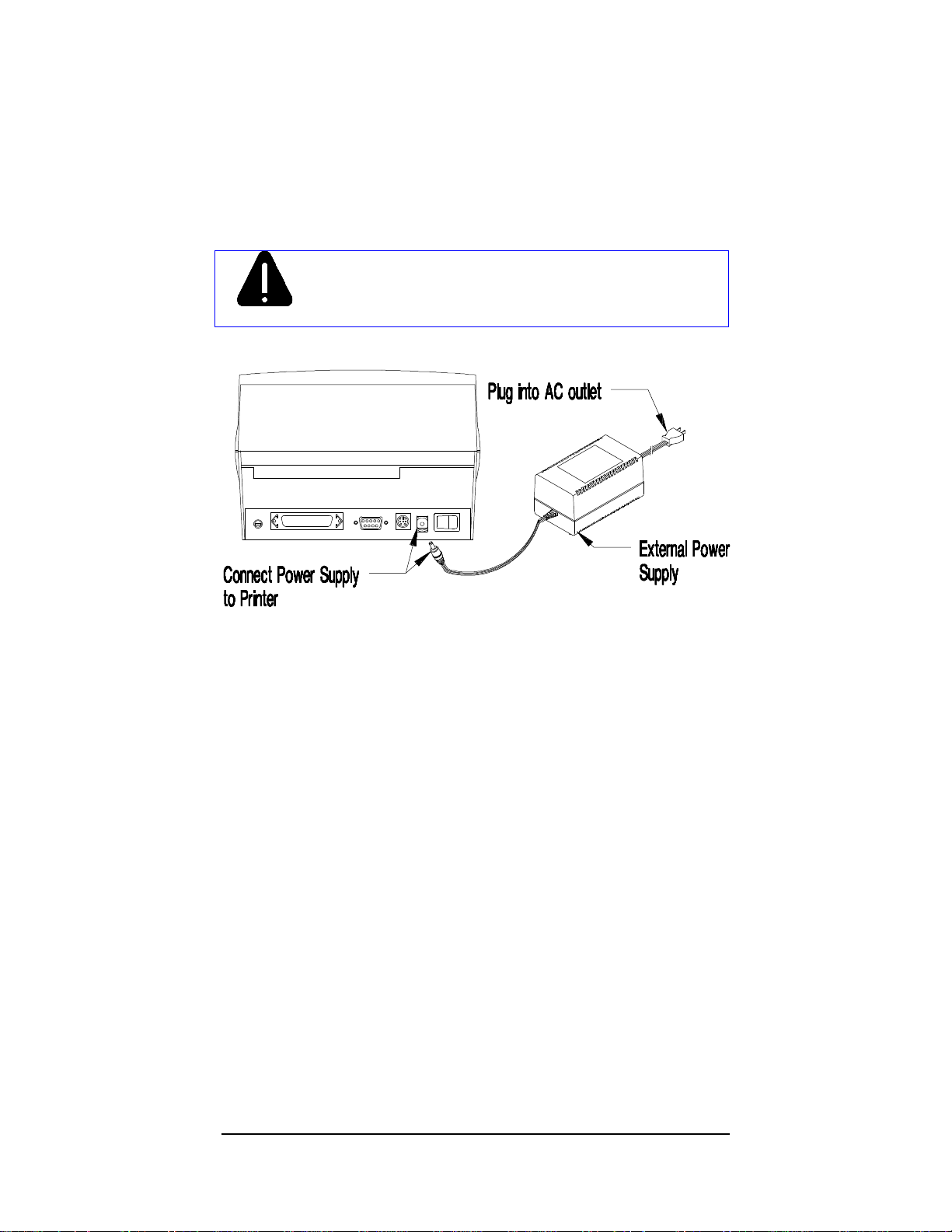

1.3 Connecting Power

The Printer is powered from an External Power Supply. The supply

connects to the Printer as shown below. Power supplies are available for

115 and 230 AC voltages. Ensure that the power supply shipped with the

Printer matches your electric service.

Connect power supply to Printer before plugging into AC

Caution!

outlet.

Figure 1-2 External Power Supply

4 Getting Started

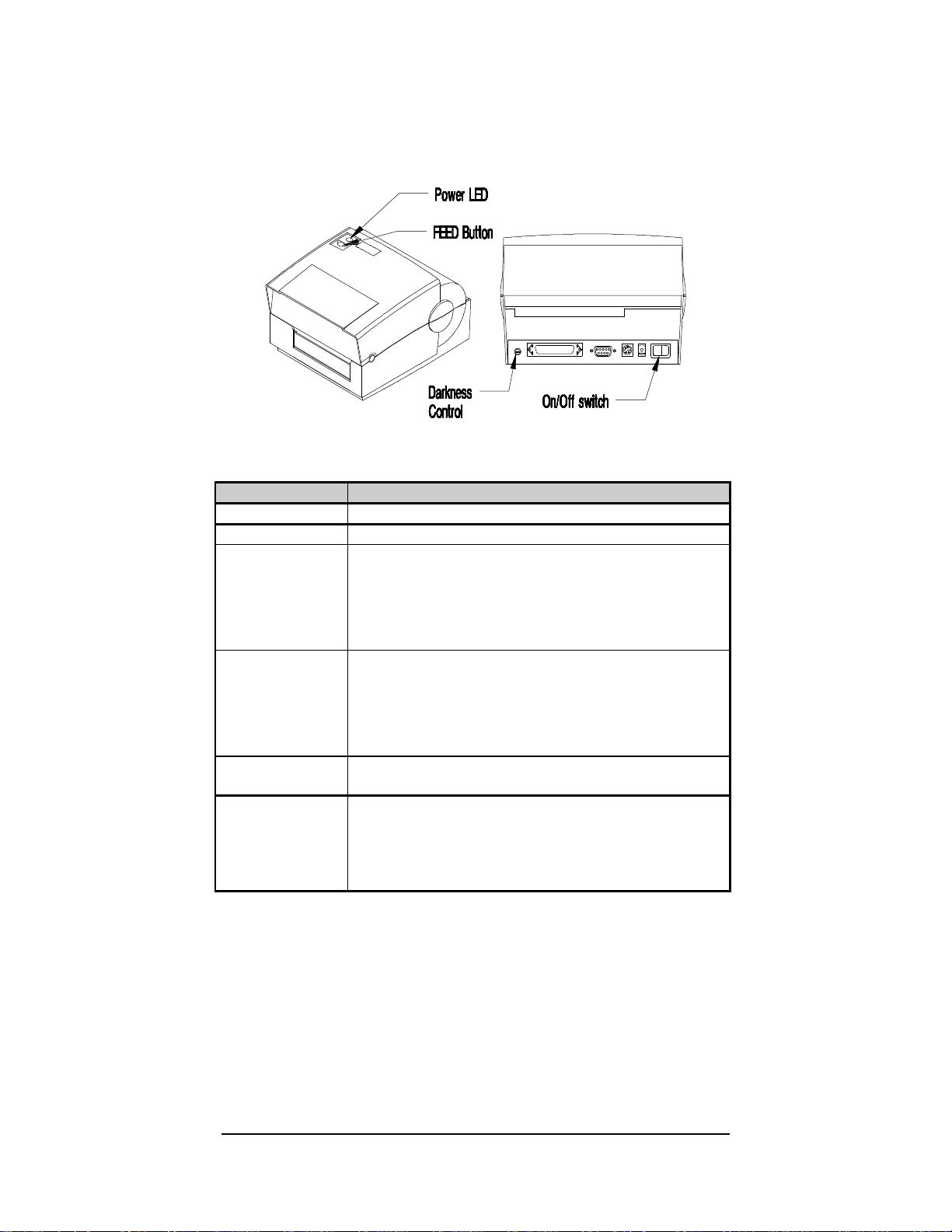

1.4 Switches and Indicators

Descriptions and locations of the Printer's switches and indicators are

shown below.

Figure 1-3 Switches and Indicator Locations

Switch/Indicator Function

On/Off switch Controls power to the Printer.

Feed Button

Printer in

ready state (LED On)

Press twice

Press once

Printer in

alarm state (LED fast

flash)

Press once

Darkness Control Used to balance a new Printhead so that it prints at the

Power LED

Solid On

Slow Flash

Fast Flash

Printer feeds media to first print position of next label.

Pauses Printer, press again to resume.

Clears alarm, feeds one label.

same level of darkness as the previous head.

Indicates power is supplied and the Printer is on.

Indicates the Printer is in a 'paused' condition.

Indicates the Printer is in an 'error' condition such as

Media Out, Ribbon Out (if equipped), or Jam.

Getting Started 5

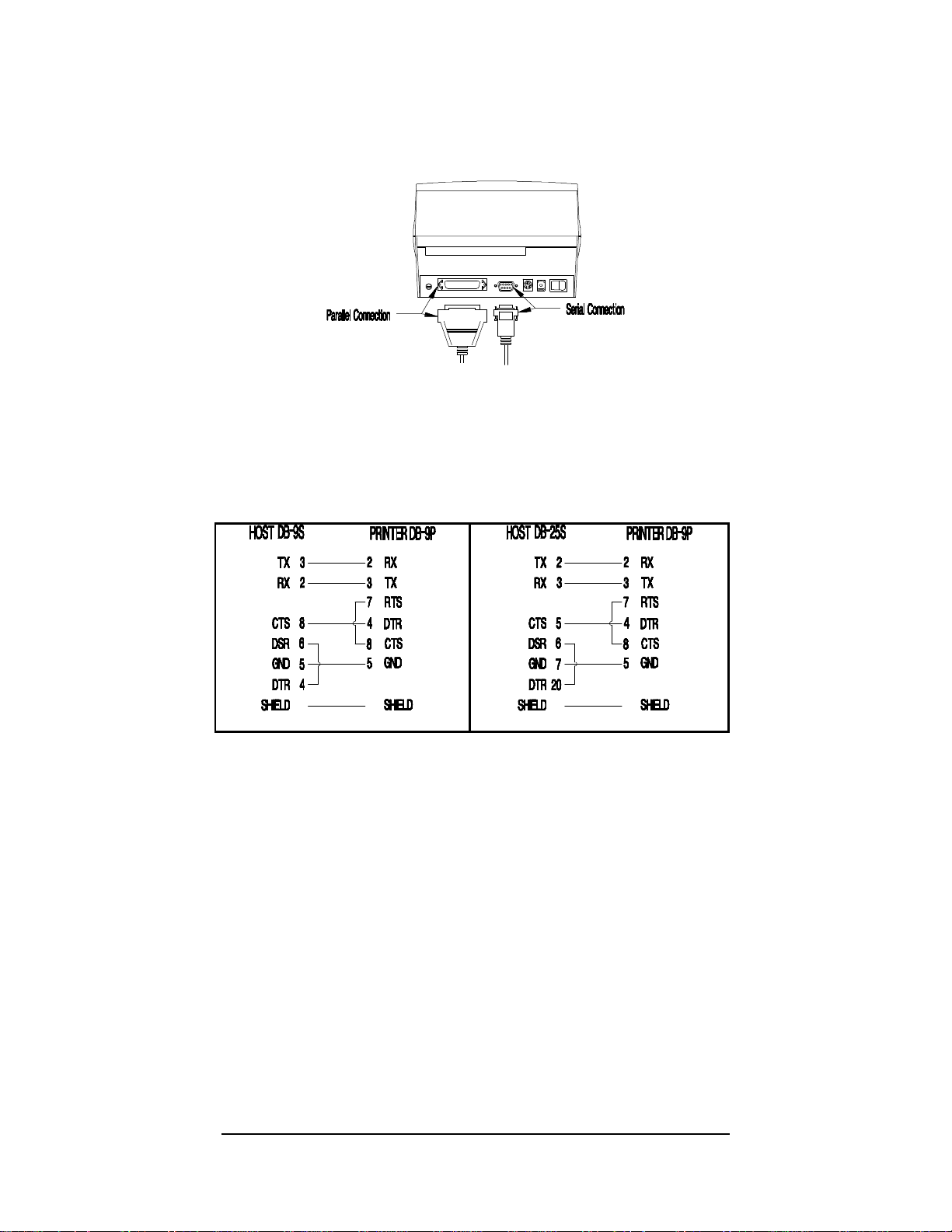

1.5 Interfacing to the Printer

The Printer can be connected to the host via a serial or parallel cable.

Figure 1-4 Interfacing

For most applications, the interface between the Printer and the Host will

be serial (RS-232C). An interface cable is needed to connect the Printer

to the host. Cable configurations for typical interfaces are shown below,

(contact your reseller for part numbers and ordering information).

Figure 1-5 Interface Cables

Other applications may require a parallel connection from the Printer to

the host. The Printer can be connected to the host with a standard parallel

printer cable.

6 Getting Started

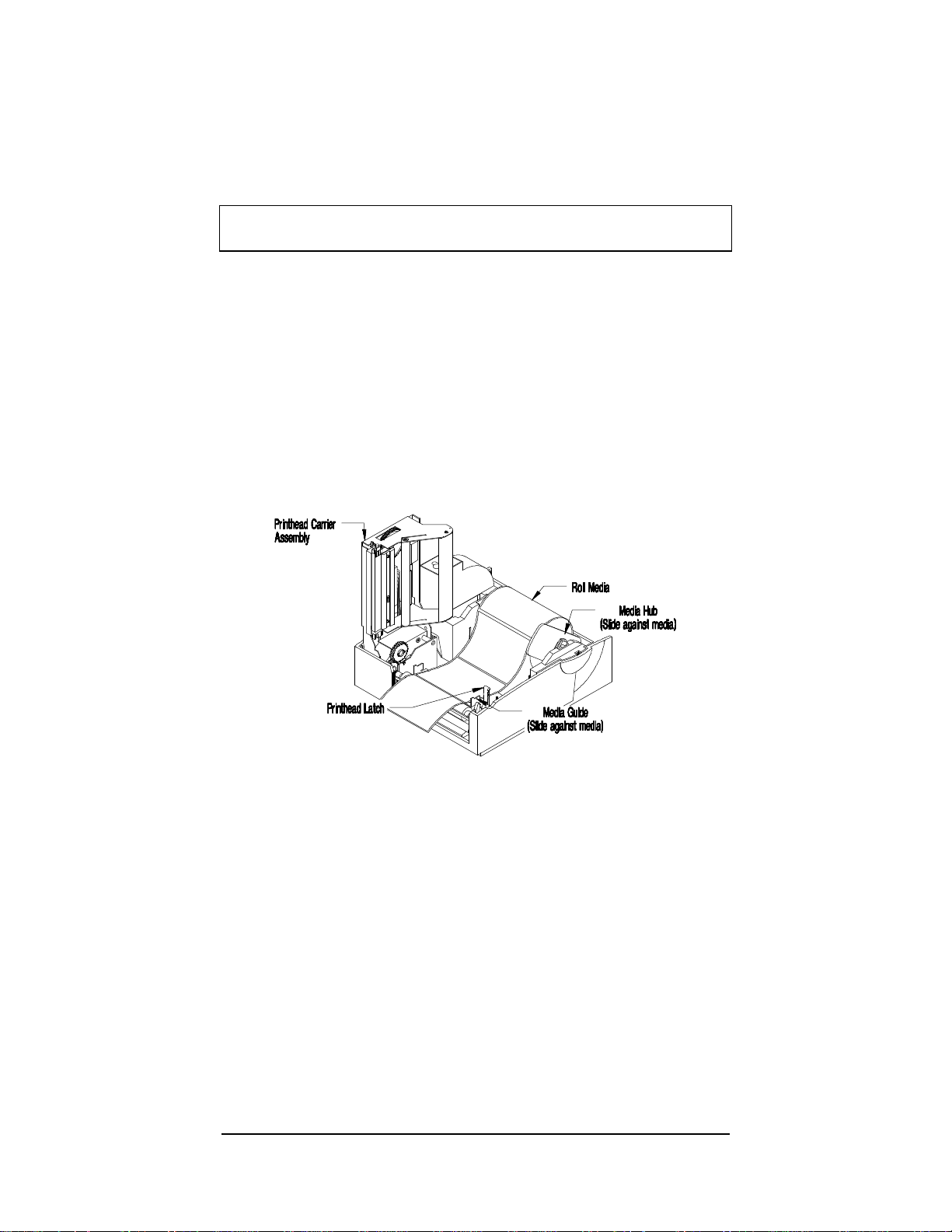

1.6 Loading Media

Due to its design, loading the Printer with media is a simple task. The

following steps outline the procedure.

Note: If your Printer is equipped with the External Media Supply Option

then you would load the media from the rear of the Printer.

1. Open the Printer's Top Cover.

2. Release the Printhead Carrier Assembly by pushing the Printhead

Latch. Raise the Assembly to its up position.

3. Place a roll of the chosen media on the Media Hub and place it in the

Printer. Ensure that the Media Hub is flush against the media.

4. Pull the media forward and out of the Printer. Ensure that the media's

labels are facing up.

5. Slide the Media Guide over until it is against the side of the media.

6. Close the Printhead Carrier Assembly, press down until it latches.

Figure 1-6 Media Loading

7. Close the Top Cover. Press the Feed Button several times to ensure

proper tracking.

Getting Started 7

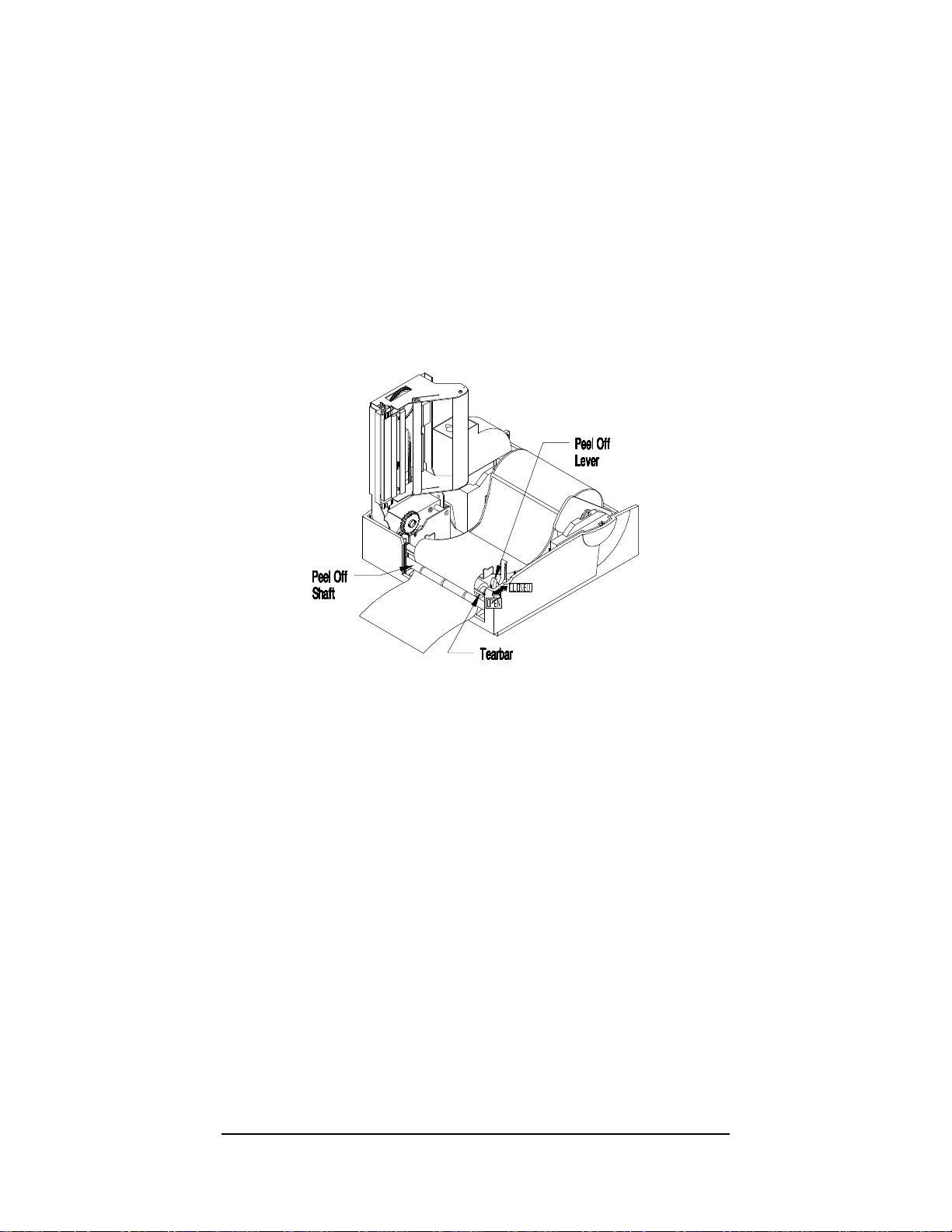

1.7 Loading Media for Peel Configuration

1. Open the Printer's Top Cover.

2. Release the Printhead Carrier Assembly by pushing the Printhead

Latch. Raise the Assembly to its up position.

3. Place a roll of the chosen media on the Media Hub and place it in the

Printer. Ensure that the Media Hub is flush against the media.

4. Move the Peel Off Lever forward to its open position.

5. Peel off eight inches of labels. Route the backing over the Tearbar

and behind the Peel Off Shaft as shown below:

Figure 1-7 Peel Off Media Loading

6. Slide the Media Guide over until it is against the side of the media.

7. Move the Peel Off Lever back to its closed position.

8. Close the Printhead Carrier Assembly, press down until it latches.

9. Close the Top Cover. Press the Feed Button several times to ensure

proper tracking. The labels should separate as the Printer feeds.

8 Getting Started

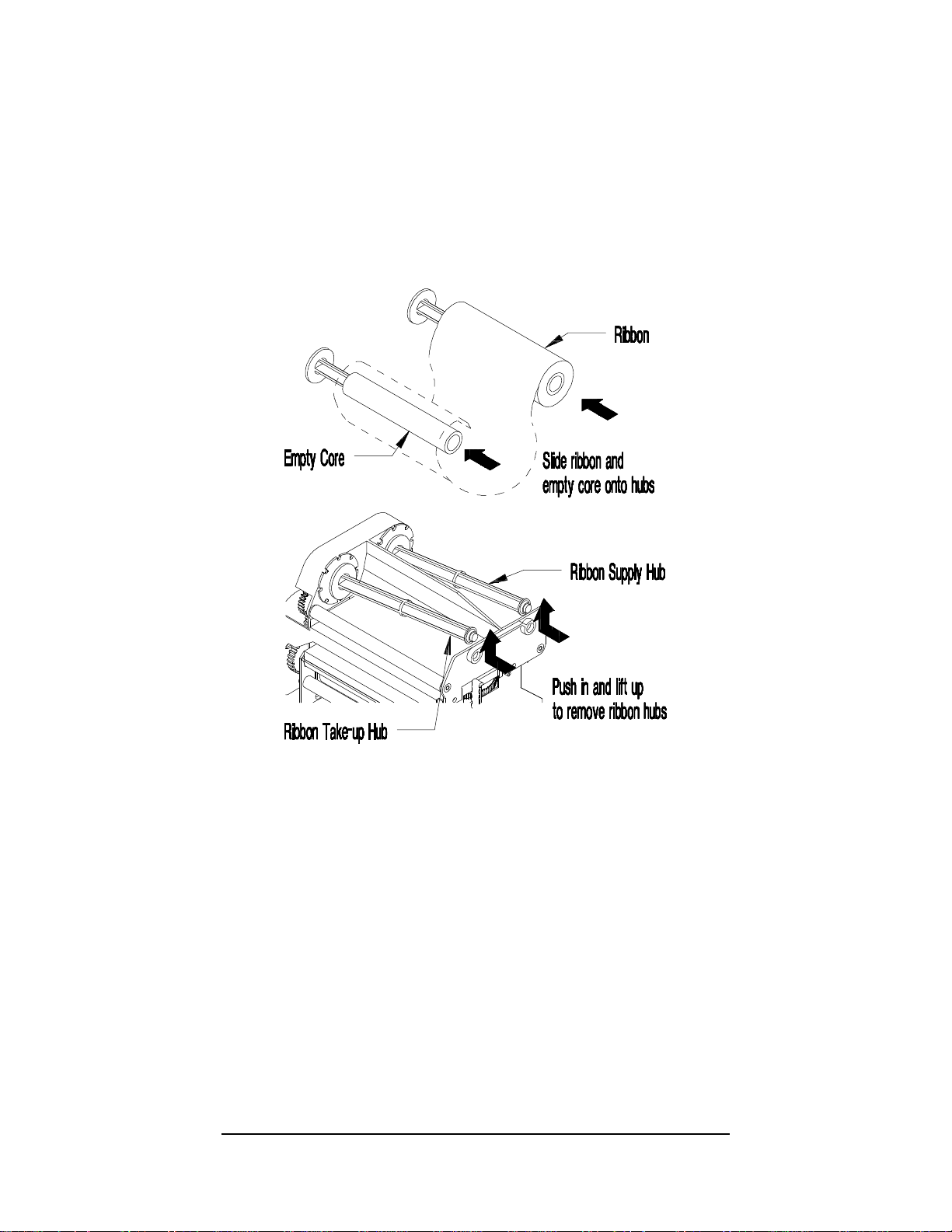

1.8 Loading Ribbon

1. Open the Printer's Top Cover.

2. Remove the two Ribbon Hubs.

3. Slide the ribbon onto the hub ensuring that the ribbon comes off the

roll as shown below.

Figure 1-8 Ribbon Hub Removal

4. Place the Ribbon Supply Hub back into the Thermal Transfer

Assembly.

Getting Started 9

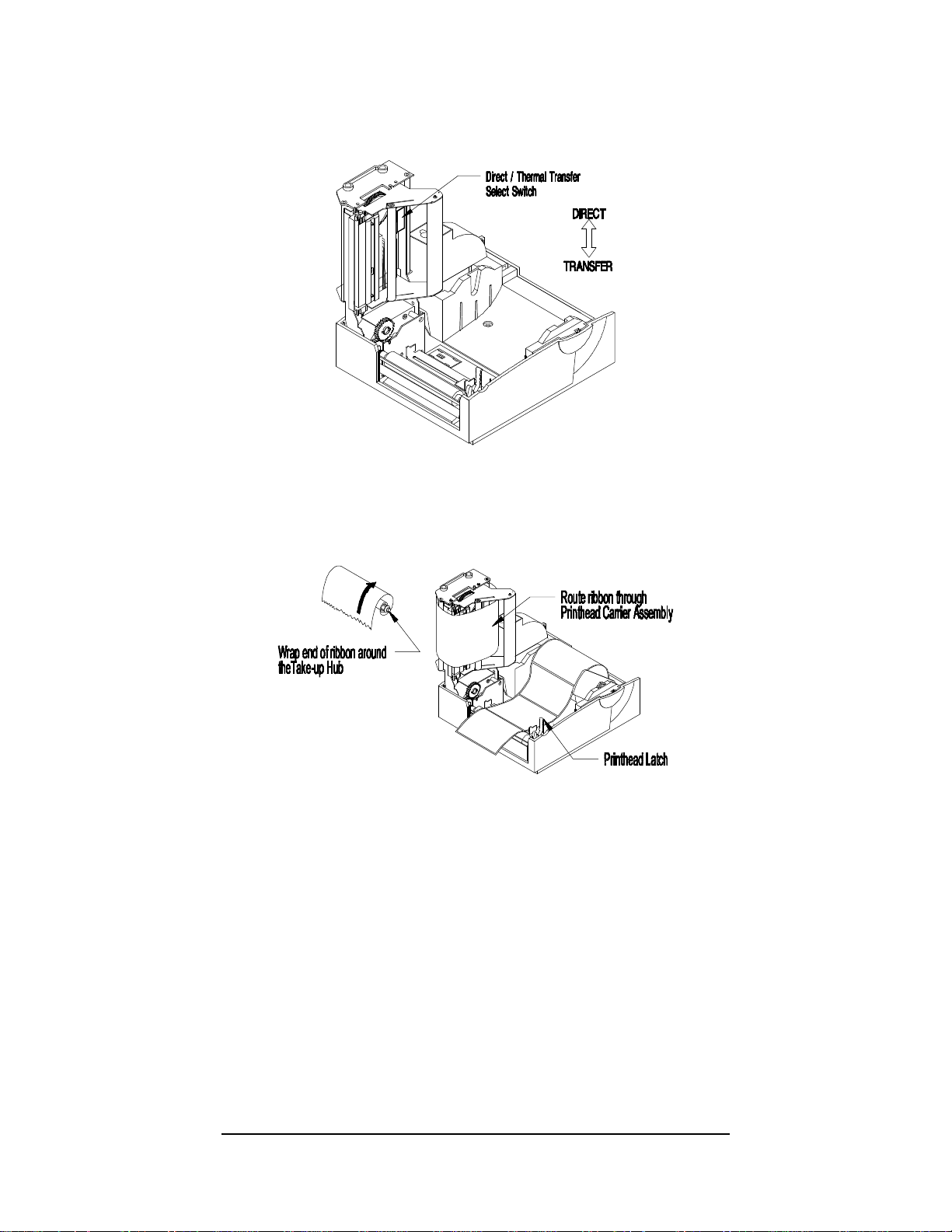

5. Make sure that the Direct/Thermal Transfer Switch is set to the

‘Transfer’ position for thermal-transfer printing.

Figure 1-9 Selecting Print Type

6. Route the ribbon through the Printhead Carrier Assembly as shown.

Figure 1-10 Ribbon Routing

7. Close the Top Cover. Press the Feed Button several times to ensure

proper tracking.

10 Getting Started

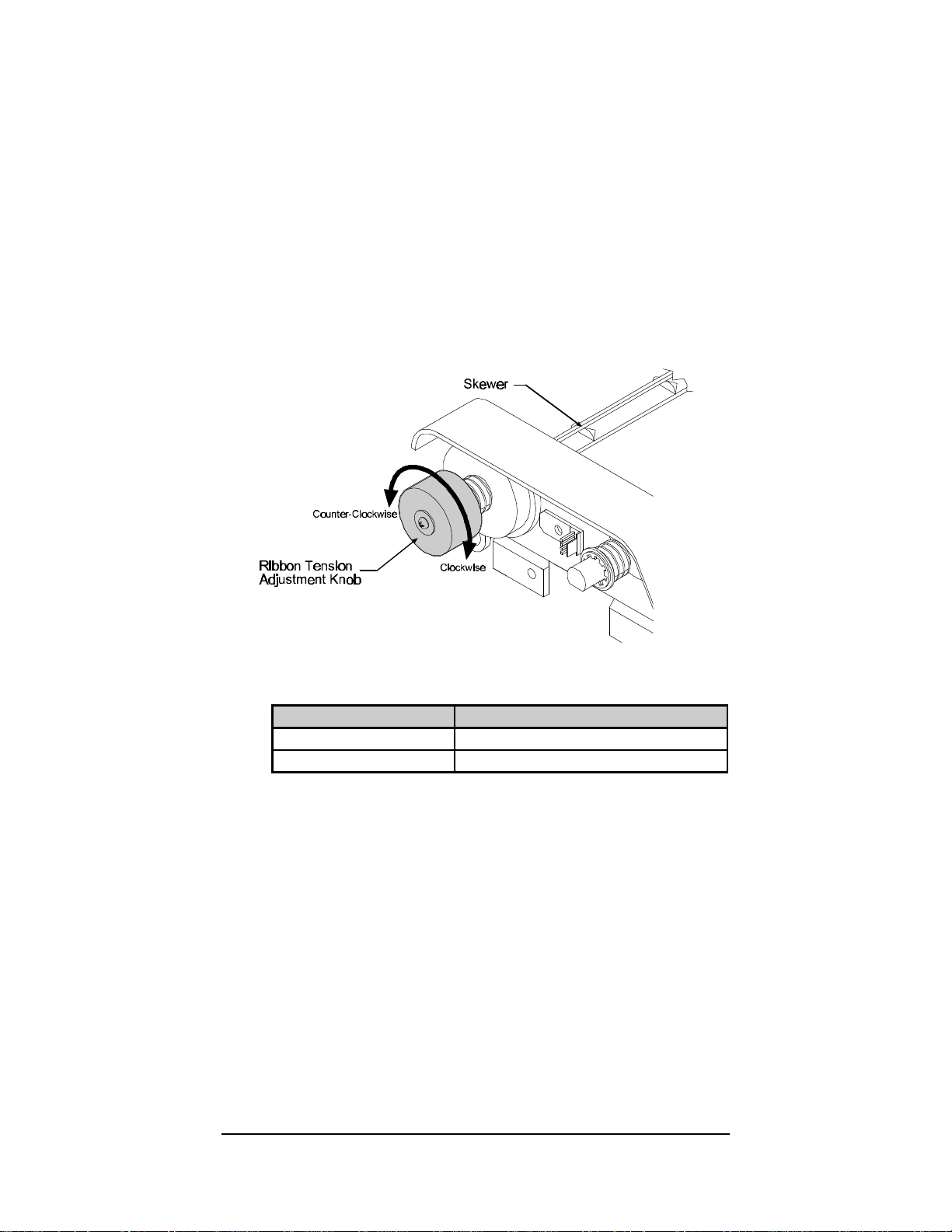

1.9 Adjusting for Wide or Narrow Ribbons

The Ribbon Handler has a built in adjustment for controlling tension

on the Ribbon Supply Hub. This adjustment provides for better

results when using different width ribbons.

1. Turn ‘off’ the Printer.

2. Hold the Ribbon Supply Spindle and rotate the Ribbon Tension

Adjustment Knob to meet your printing needs based on the table

below. Ensure that the Ribbon Tension Adjustment Knob is

turned fully to the Clockwise or Counter-Clockwise position.

1-11 Adjustments for media

Direction of Rotation Effect

Clockwise Use this position for narrow ribbons

Counter-Clockwise Use this position for wide ribbons

Getting Started 11

Loading...

Loading...