Bradley Corporation SN2003, SN2004, SN2023, SN2024, SN2005 Service manual

...

Parts & Service

Sentry Washfountain

Discontinued Models Prior to

February 1, 2013

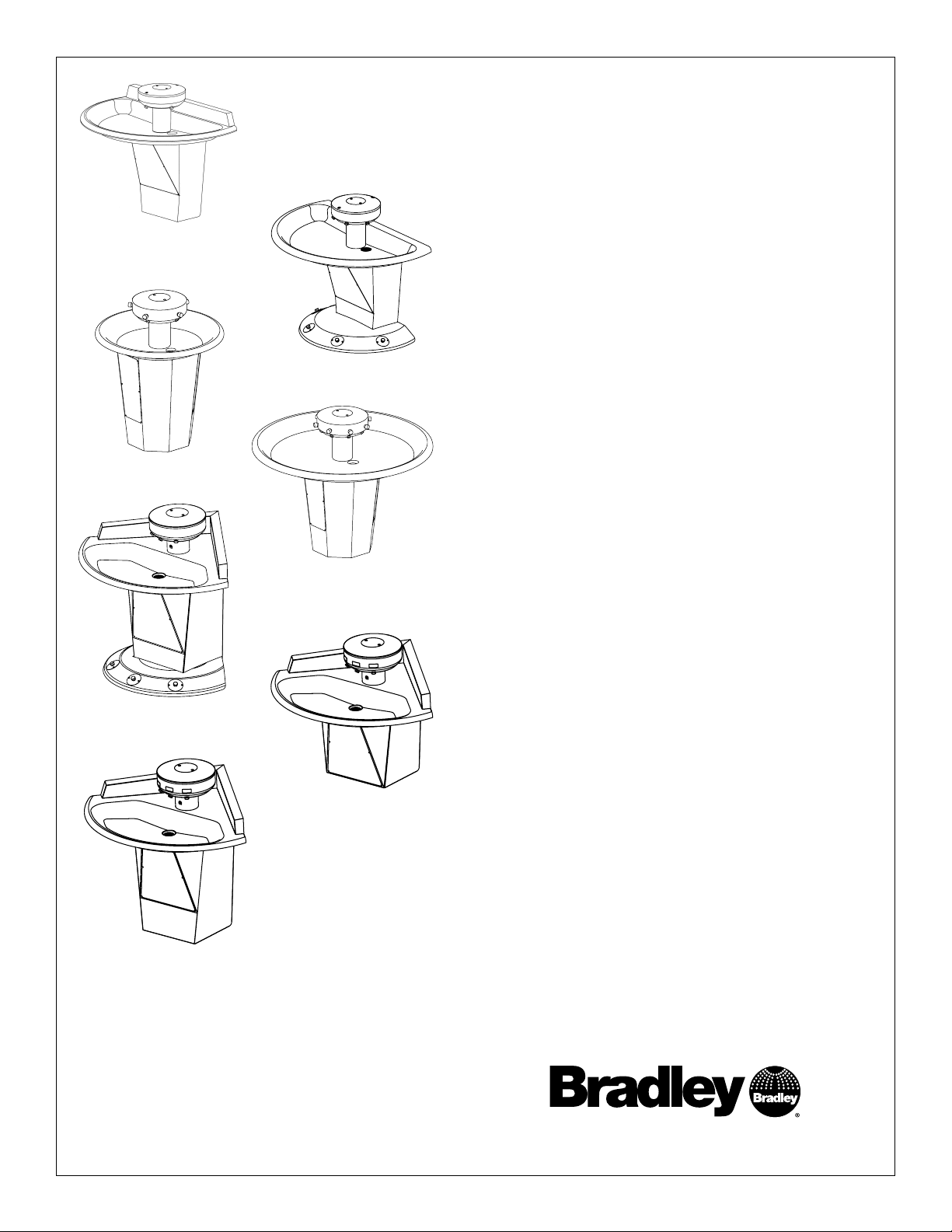

SN2003 (AST shown)

SN2005 (AST shown)

SN2013 (AST-4 shown)

SN2004 (AST-F shown)

SN2008 (AST shown)

SN2003

36" Semi-Circular, Floor-Mounted

SN2004

54" Semi-Circular, Floor-Mounted

SN2023

36" Semi-Circular, Wall-Mounted

SN2024

54" Semi-Circular, Wall-Mounted

SN2005

36" Circular, Floor-Mounted

SN2008

54" Circular, Floor-Mounted

SN2013

54" Corner, Floor-Mounted

SN2033

54" Corner, Wall-Mounted

SN2033 (IR shown)

SN2023 (IR shown)

215-1473 Rev. D; ECN 15-00-002

© 2015 Bradley

Page 1 of 31 3/24/2015

Table of Contents

How to Determine Drain Type ...................................................... 2

IR Assemblies, Troubleshooting and Wiring ................................ 3

Sentry Transformers ................................................................... 13

Supply Valves ........................................................................... 14

AST4 Assemblies, Adjustments and Troublshooting ................. 16

Thermostatic Mixing Valve Troubleshooting ............................... 23

Manual Mixing and Control Valves............................................. 25

Check Valve Troubleshooting Instructions ................................. 26

Care and Cleaning of Stainless Steel Sentry Washfountains .... 26

Soap System ............................................................................. 27

Pedestal Assembly..................................................................... 29

Backsplash Retrofit Kits ............................................................. 30

Shroud/Towel Dispensers .......................................................... 31

P.O. Box 309, Menomonee Falls, WI USA 53052-0309

800 BRADLEY (800 272 3539) +1 262 251 6000

bradleycorp.com

Sentry Washfountain Parts and Service Guide (Prior to February 1, 2013)

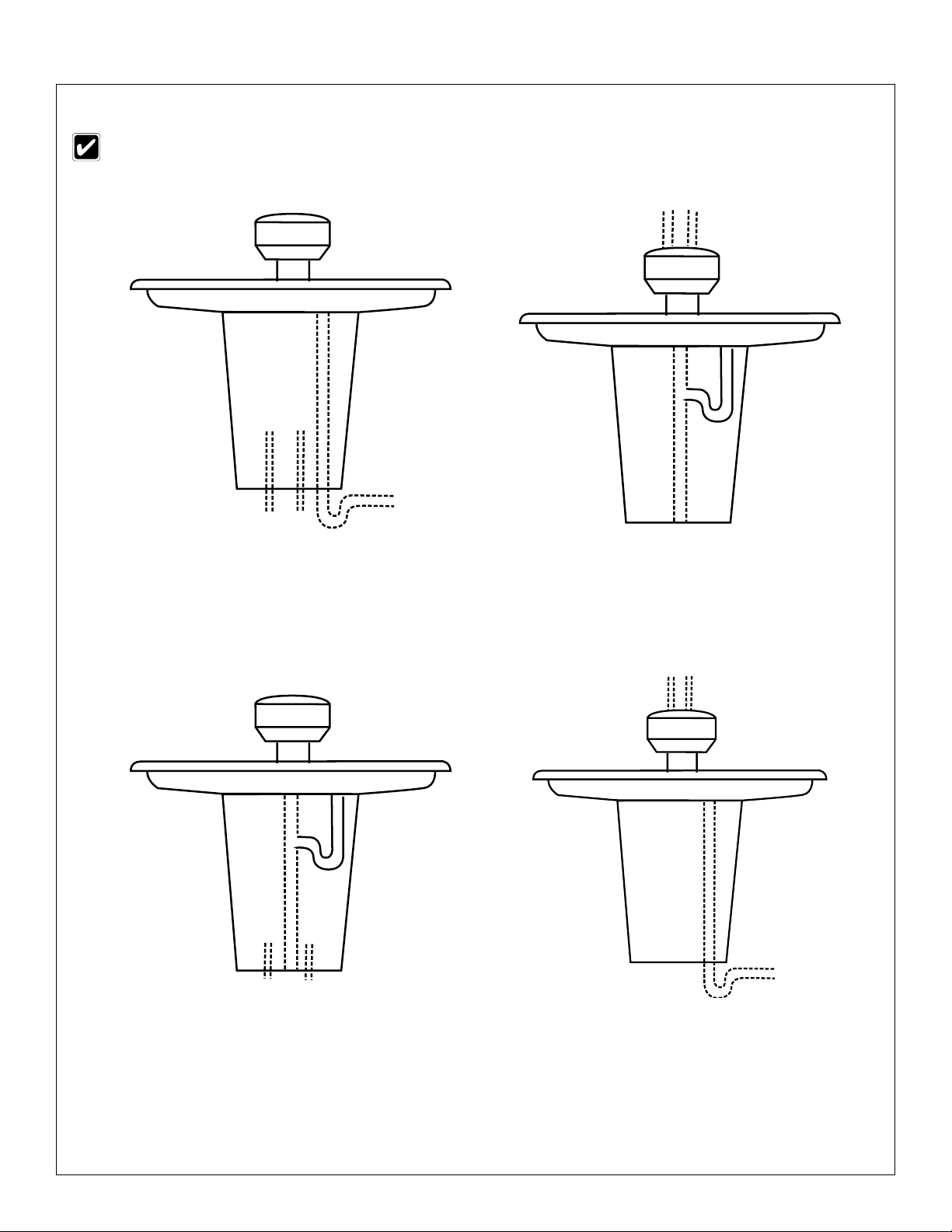

How to Determine Drain Type

Parts may vary depending upon drain type. Identify your drain type before continuing.

TYPE A:

SUPPLIES BELOW

VENT OFF DRAIN

P-TRAP FURNISHED BY OTHERS

TYPE B:

SUPPLIES ABOVE

CENTRALLY-RISING VENT

P-TRAP FURNISHED

TYPE H:

SUPPLIES BELOW

CENTRALLY-RISING VENT

P-TRAP FURNISHED

2

3/24/2015 Bradley • 215-1473 Rev. D; ECN 15-00-002

TYPE O:

SUPPLIES ABOVE

VENT OFF DRAIN

P-TRAP FURNISHED BY OTHERS

Parts and Service Guide (Prior to February 1, 2013) Sentry Washfountain

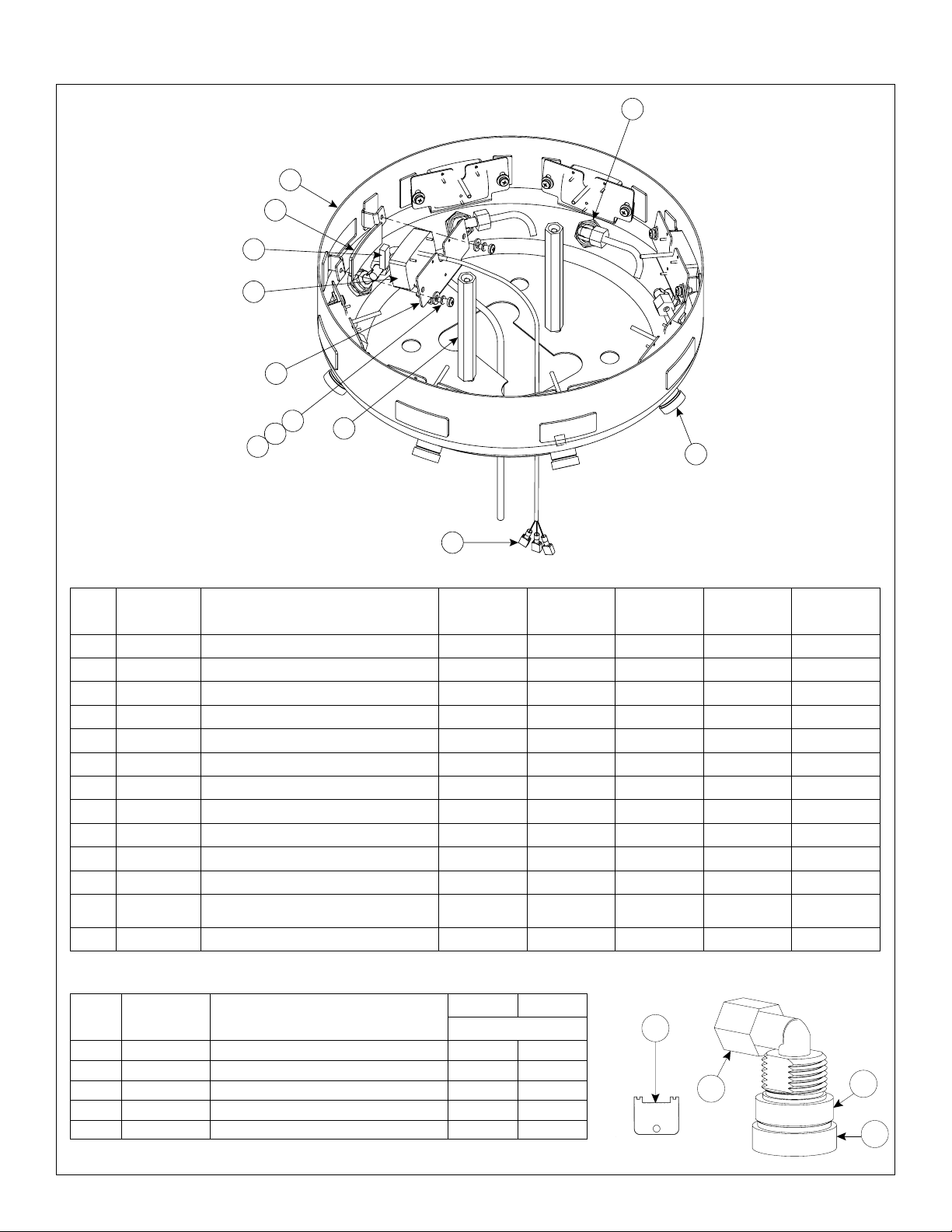

Infrared (IR) — Sprayhead Assembly

1

2

7

6

8

3

4

5

9

10

12

11

Parts List — Infrared Sensor and Module

Item Part No. Description

1 — Shell 1 1 1 1 1

2 269-982 Lens (window) 3 3 4 5 8

3 160-245 Screw 10-24 x 1/2" 6 6 8 10 16

4 142-002BT Lock Washer 6 6 8 10 16

5 142-002AV Flat washer 6 6 8 10 16

6 269-1184 Sensor 3 3 4 5 8

7 182-100 Lens Support (Rubber Block) 3 3 4 5 8

8 159-363 Sensor Mounting Bracket 3 3 4 5 8

9 161-082 Nut - Extension 1/4"-20 x 5-1/8" 2 2 2 2 2

10 269-621 Terminal - female disconnect 9 9 12 15 24

11 S05-157 Aerator Assembly (Std 0.5 GPM) 3 3 4 5 8

11 S05-172 Aerator Assembly (Optional 1.5

GPM)

12 110-115 Nut - 1/2" - 14 3 3 4 5 8

54" Corner

Qty.

3 3 4 5 8

36" Semi

Qty.

54" Semi

Qty.

36" Circle

Qty.

Parts List — Aerator Assembly

Item Part No. Description

1 S05-142A Std. Aerator, 0.5 GPM 1 —

1 153-397 Extra Flow Aerator, 1.5 GPM — 1

2 153-402A Adapter 1 1

3 145-090 90° Connector 1/4" tube x 1/8" NPT 1 1

4* 130-141 Spanner Wrench for Aerator — —

*Spanner wrench not included in Assemblies

S05-157 S05-172

Qty

4

3

54" Circle

Qty.

2

1

Bradley • 215-1473 Rev. D; ECN 15-00-007 3/24/2015

3

Sentry Washfountain Parts and Service Guide (Prior to February 1, 2013)

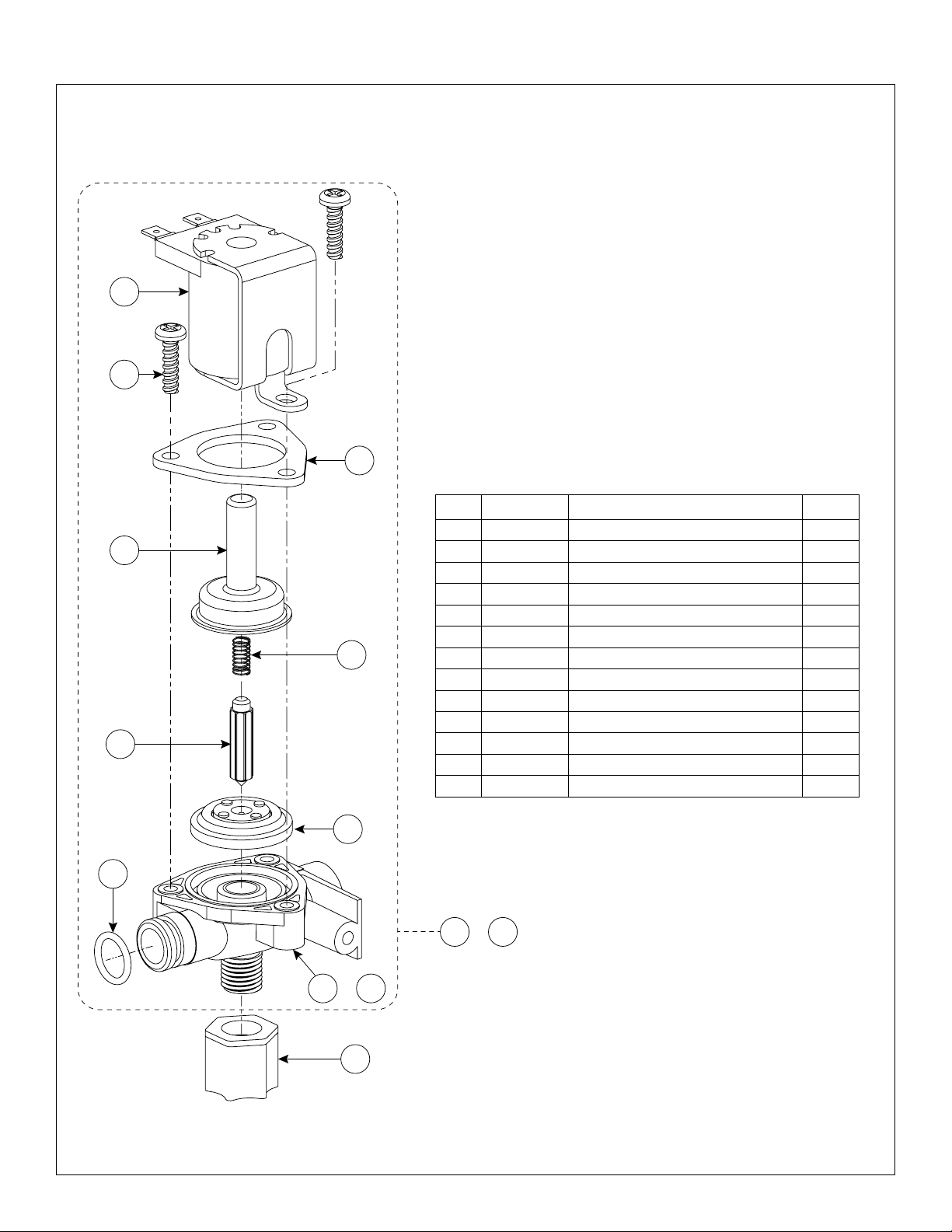

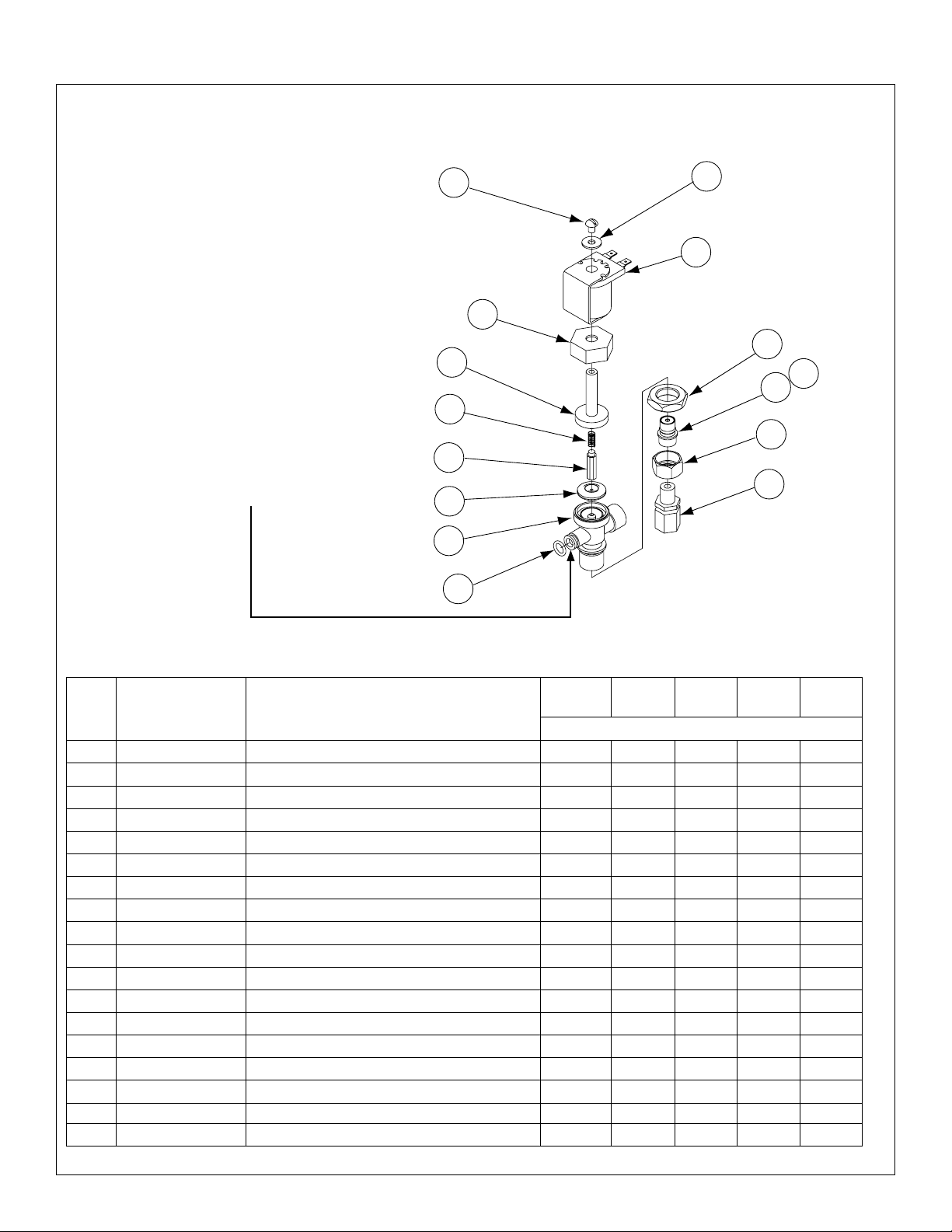

Infrared (IR) Part 1 — Solenoid Valve Assembly (24V Transformer)

Prior to February 1, 2013

6

5

4

3

2

14

1

11

7

8

12

10

13

3 Valve Assembly

Shown

9

Parts List — Solenoid Valve Assembly

54"

Item Part No. Description

1 S27-102 Stop/Check Valve 2 2 2 2 2

2 269-1735 Flex Hose 2 2 2 2 2

3 140-928 Bracket 1 1 1 — —

* 140-940 Bracket — — — 1 —

* 140-941 Bracket — — — — 1

4 269-625 Terminal Block 1 1 — 2 —

* 269-647 Terminal Block — — 1 — 2

5 P18-054 Screw #10-24 x 3/8 2 2 2 2 2

6 160-447 Screw #8-16 x 5/8 3 3 4 5 8

7 S01-524 Thermostatic Mixing Valve 1 1 1 1 1

8 S39-685 Adapter (Optional Single Tempered Line) 1 1 1 1 1

9 S07-067 Solenoid Valve - Closed Body (Black) 1 1 1 1 1

10 S07-067A Solenoid Valve - Thru Body (Gray) 2 2 3 4 7

11 R68-600011-B Tubing 1/4 OD Black ** ** ** ** **

12 R68-600011-G Tubing 1/4 OD Green ** ** ** ** **

13 R68-600011-R Tubing 1/4 OD Red ** ** ** ** **

* R68-600011-Y Tubing 1/4 OD Yellow — — ** ** **

* R68-600011 Tubing 1/4 OD Clear — — — ** —

14 S45-2146 Valve Assembly TMA 36S and 54K 1 1 — — —

* S45-2148 Valve Assembly TMA 54S — — 1 — —

* S45-2150 Valve Assembly TMA 36C — — — 1 —

* S45-2152 Valve Assembly TMA/IR 54C — — — — 1

Corner

36"

Semi

54"

Semi

Qty.

36"

Circle

54"

Circle

* Not Illustrated.

** Specify Length in feet.

4

3/24/2015 Bradley • 215-1473 Rev. D; ECN 15-00-002

Parts and Service Guide (Prior to February 1, 2013) Sentry Washfountain

Infrared (IR) Part 1 — Solenoid Valve Assembly (24V Transformer)

Prior to May 2, 2005

4

2

12

1

5

3

9

5

7

5 Valve Assembly

Shown

8

6

11

8

10

4 Valve Assembly

Shown

2

5

9

7

3

Supply Parts shown in

Supply Section

1

12

Parts List — Solenoid Valve Assembly

54"

Item Part No. Description

* S08-061 3 Valve Assy. with Bracket 1 1 — — —

1 S08-062 4 Valve Assy. with Bracket — — 1 — —

1 S08-358 5 Valve Assy. with Bracket — — — 1 —

* S08-359 8 Valve Assy. with Bracket — — — — 1

2 160-245 Screw for valve bracket 2 2 2 2 2

3 140-917 Valve Bracket - Semi & Corner 1 1 1 — —

3 140-918 Valve Bracket - Circle — — — 1 1

4 160-329 Screw 6-32 x 3/8" for terminal block 2 2 2 4 4

* 161-069 Lock Nut 6-32 for terminal block 2 2 2 4 4

5 269-625 Terminal Block - 3 Station 1 1 — 2 —

5 269-647 Terminal Block - 4 Station — — 1 — 2

* S53-128 Wire Assy. Black 3 3 4 5 8

* S53-129 Wire Assy. Red 3 3 4 5 8

* 269-645 Transformer 4RT Hard Wire 24V 1 1 1 — —

* 269-703 Transformer 8RT Hardwire 24V - Circle — — — 1 1

6 269-1248 U-Bolt 1 1 1 1 1

7 161-026 Nut 1/4"-20 2 2 2 2 2

8 269-1365 Hose - Braided Flexible 1 1 1 2 2

9 R68-600011 Tubing 1/4" OD (Specify Length in feet) — — — — —

10 269-1150 Tee - 1/2" Brass — — — 1 1

11 113-006DH 1/2" Close Nipple — — — 2 2

12 124-051 Anti-Rotation Gasket 1 1 — 2 —

12 124-052 Anti-Rotation Gasket — — 1 — 2

Corner

36"

Semi

54"

Semi

Qty.

36"

Circle

6

8

54"

Circle

* Specify Length in feet.

Bradley • 215-1473 Rev. D; ECN 15-00-007 3/24/2015

5

Sentry Washfountain Parts and Service Guide (Prior to February 1, 2013)

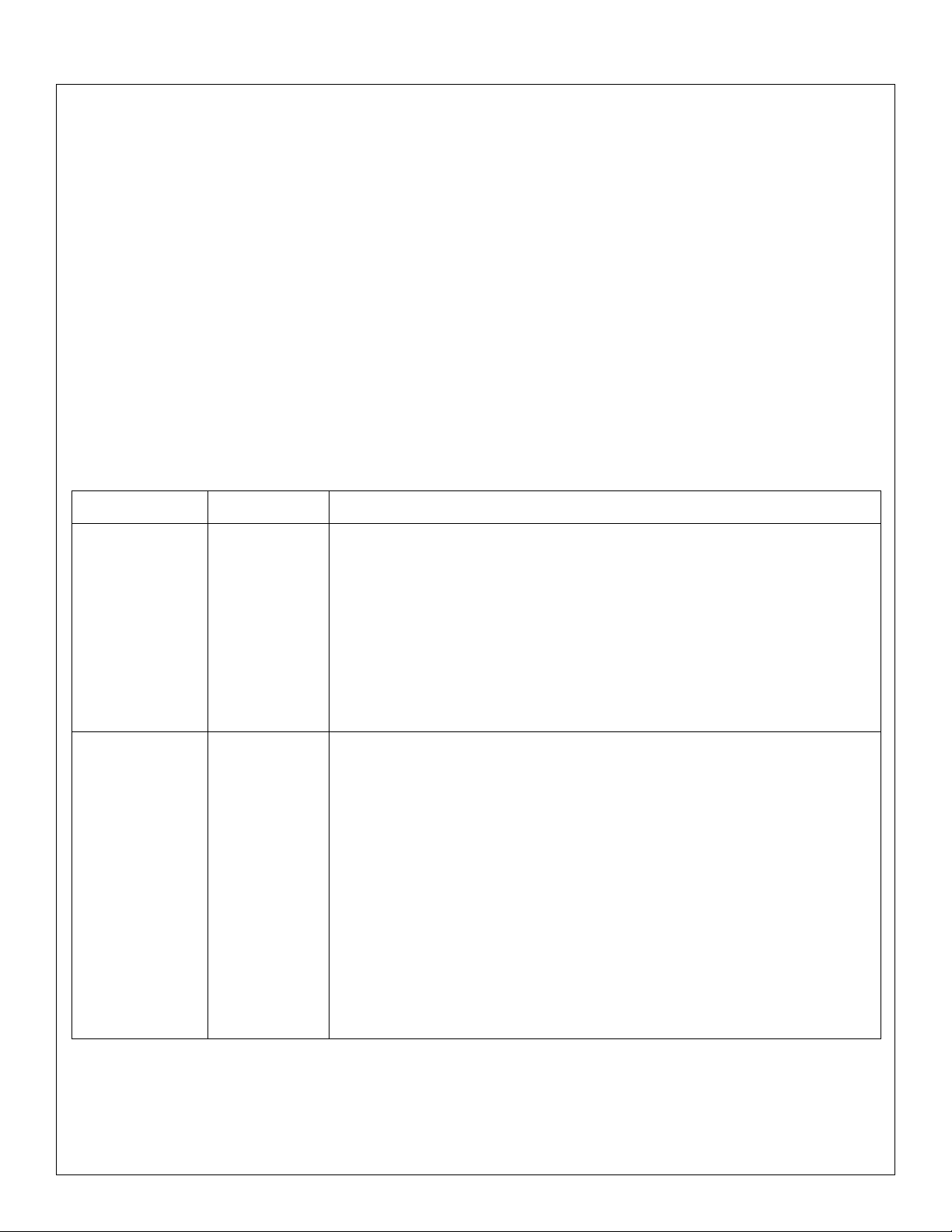

Infrared (IR) Part 2 — Solenoid Valve Assembly (24V Transformer)

Prior to February 1, 2013

11

10

9

Parts List — Solenoid Valve Assembly

Item Part No. Description Qty.

1 110-231 Nut 1/4 Tube 1

8

7

6

5

4

2 118-307 Valve Body 1/4" Closed 1

3 118-307A Valve Body 1/4" Thru 1

4 125-165 O-Ring 1

5 269-983 Diaphragm 1

6 269-577 Armature 1

7 269-578 Spring 1

8 269-1729 Armature Housing 1

9 269-1730 Clamp 1

10 160-447 Screw #8-16 x 5/8 3

11 269-579 Coil, Solenoid Valve 1

12 S07-067S Solenoid Valve Closed Body (Black) 1

13 S07-067AS Solenoid Valve Thru Body (Gray) 1

12 or

13

or

3

1

2

6

3/24/2015 Bradley • 215-1473 Rev. D; ECN 15-00-002

Parts and Service Guide (Prior to February 1, 2013) Sentry Washfountain

Infrared (IR) Part 2 — Solenoid Valve Assembly (24V Transformer)

S07-040 Individual (End), S07-041 Ganged

(Prior to May 2, 2005)

S07-040 Solenoid Valve (Individual)

Used by itself, or is the last one (opposite

end of the water inlet) in a group.

S07-041 Solenoid Valve (Ganged)

Used in a group, except the last in line.

Body is drilled to allow water to pass thru

into the next in line. This valve includes

O-Ring 125-145 to seal to the next valve.

1

4

5

6

7

8

2

3

11

13

12

14

15

9

10

Parts List — Solenoid Valve Assembly

54"

Item Part No. Description

1–9 S07-040 Valve Individual 1 1 1 2 2

1–10 S07-041 Valve Ganged 2 2 3 3 6

1 160-066 Screw 10-24 x 1/4 RD 3 3 4 5 8

2 142-002AZ Washer Stainless Steel 3 3 4 5 8

3 269-579 Coil - Solenoid Valve 3 3 4 5 8

4 110-194 Nut - Bonnet 3 3 4 5 8

5 121-028 Bonnet 3 3 4 5 8

6 269-578 Spring 3 3 4 5 8

7 269-577 Armature 3 3 4 5 8

8 269-580 Diaphragm 3 3 4 5 8

9 118-237 Valve Body Individual 1 1 1 2 2

9 118-238 Valve Body Ganged 2 2 3 3 6

10 125-145 O-Ring (for ganged valve body) 2 2 3 3 6

11 110-224 Nut 3 3 4 5 8

12 129-049 Tailpiece 3 3 4 5 8

13 125-145 O-Ring 3 3 4 5 8

14 110-195 Tailpiece Nut 3 3 4 5 8

15 145-090 Elbow, 1/8 NPTM x 1/4 Tube 3 3 4 5 8

Corner

36"

Semi

54"

Semi

Qty.

36"

Circle

54"

Circle

Bradley • 215-1473 Rev. D; ECN 15-00-007 3/24/2015

7

Sentry Washfountain Parts and Service Guide (Prior to February 1, 2013)

Infrared (IR) — Sensor and Solenoid Valve Troubleshooting

If a station is not functioning properly it is most likely either the solenoid valve or the sensor.

Troubleshooting multi station units is fairly easy, as you can swap parts (actually just by changing the wires) and use

the process of elimination to figure out which of the 2 parts is causing the problem.

How the system operates:

1. The transformer sends 24 volts to the sensor.

2. The sensor acts only as a switch.

3. When hands go into the active field of the sensor, the sensor activates and sends a power signal on to the

solenoid valve.

4. The power signal activates and opens the solenoid valve which allows the water to flow to the sprayhead.

The solenoid valve stays open allowing water to flow as long as it is receiving a signal form the sensor

(hands remain in the active field).

5. When hands are removed from the active field, the sensor turns off (note some models have a slight delay

feature built-in.) and shuts off the power signal to the solenoid valve.

CAUTION: Turn off water supplies to unit before troubleshooting.

Problem Cause Solution

An individual

operating station

fails to shut off and

drips.

An individual

operating station

fails to turn on.

There is debris

trapped between

the diaphragm

and the valve

seat.

A failed coil for

the valve or

loose electrical

connection to the

terminal.

Remove debris between diaphragm and the valve seat.

1. Remove the three #8 Phillips-head screws that hold the solenoid valve assembly

together. Be careful not to lose the armature or spring.

2. Remove the diaphragm. Remove any particles that have been trapped between the

diaphragm and the valve seat. Rinse off the diaphragm and inspect for damage.

Make sure the center orifice and both small side orifices are open.

3. Reassemble in reverse order, being careful not to overtighten the Phillips-head

screws or you may crack the plastic valve body. Tighten until the armature plate

makes contact with the plastic body.

4. Reconnect the wiring per the appropriate diagram on next 4 pages.

Test the station to determine cause.

1. Disconnect the wires from the coil of an adjacent valve. Disconnect the wires from

the problem valve and reconnect to the adjacent valve.

2. Turn on electrical and water supplies to the unit. Pass your hand in front of the

sensor of the problem station, and the adjacent station should turn on.

a. If the adjacent station turns on and cycles normally, replace the coil on the

b. If the adjacent valve fails to turn on, inspect the wires from the sensor cable

problem valve.

and do the following:

• make sure there are no breaks and that the fully insulated disconnect

terminals are firmly crimped in place;

• turn off the electrical and water supplies;

• reconnect to the adjacent valve and turn on the water supplies to the unit;

• pass your hand in front of the sensor. If the station still fails to turn on,

replace the sensor.

8

3/24/2015 Bradley • 215-1473 Rev. D; ECN 15-00-002

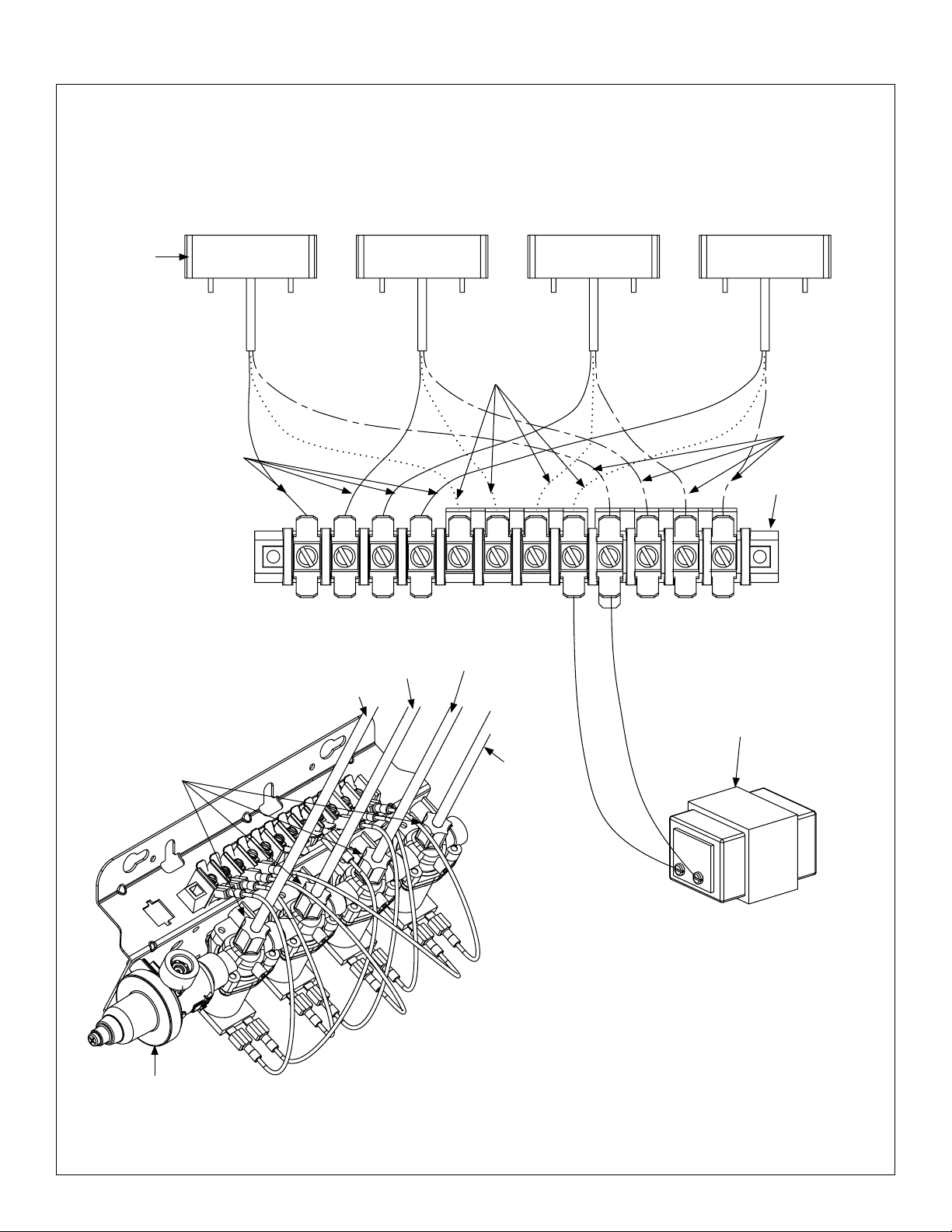

Parts and Service Guide (Prior to February 1, 2013) Sentry Washfountain

Infrared (IR) SN2003, SN2023, SN2013, SN2033 Wiring Diagram

Prior to February 1, 2013

IR Sensor

(269-1184)

Black

Left

Sensor

(Black)

3

Black

Center

Sensor

(Green)

2

Blue

Blue

Right Sensor

(Red)

1

Red

Terminal Block

(269-625)

Brown

To p

Navigator Mixing

Valve or Tempered

Line Adaptor

Transformer

(269-645)

Green Supply Tube

Black Supply Tube

Compression Nut

Red Supply

Tube

To p

Valve Set

(S45-2521 or S45-2522)

1

2

3

Bradley • 215-1473 Rev. D; ECN 15-00-007 3/24/2015

9

Sentry Washfountain Parts and Service Guide (Prior to February 1, 2013)

Infrared (IR) SN2004, SN2024 Wiring Diagram

Prior to February 1, 2013

IR Sensor

(269-1184)

Sensor

(Yellow)

Black

Sensor

4

Black Blue Red

(Black)

3

Blue

Sensor

(Green)

2

Sensor

(Red)

1

Brown

Terminal Block

(269-647)

To p

RightLeft

Compression Nut

Navigator

Mixing Valve or

Tempered Line

Adaptor

Black Supply Tube

Yellow Supply Tube

3

4

Green Supply

Tube

Transformer

(269-645)

Red Supply

Tube

To p

1

2

Valve Set

(S45-2523 or S45-2524)

10

3/24/2015 Bradley • 215-1473 Rev. D; ECN 15-00-002

Loading...

Loading...