Page 1

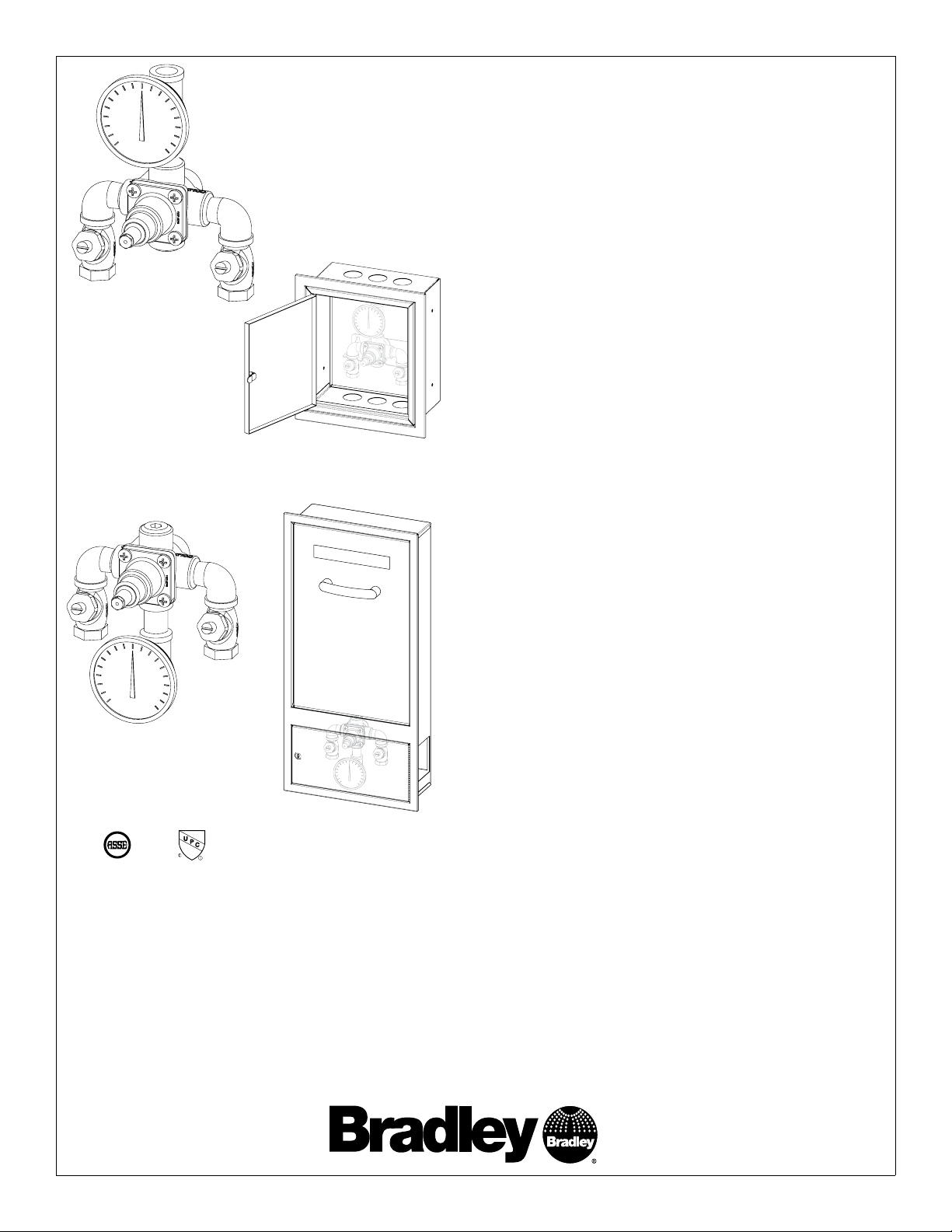

S19-2000

Installation

S19-2000,

S19-2000EFX Series

Thermostatic Mixing Valve

with Optional Cabinet

Robinet

thermostatique

mélangeur

avec cabinet facultatif

(Cabinet Only)

S19-2000EFX

ASSE 1071 & cUPC Certified

Inlet Connections: 1/2" NPT

Outlet Connection: 1/2" NPT

Temperature Range: 65° – 90° F

Maximum Pressure: 125 PSI

Inlet Temperature Hot: 120° – 180° F

Inlet Temperature Cold: 33° – 80° F

Minimum Temperature Differential

(from valve set point): 20° F

Flow at 30 psi: 7.3 gpm

Minimum Cold Water Bypass at 30 psid: 5.6 gpm

Minimum Flow: 1.5 gpm

Maximum Flow with Cold Water Shut-Off: 0.5 gpm

S19-292

(Cabinet Only)

S86-066

Válvula mezcladora termostática

con armario opcional

Table of Contents

Supplies Required ..................................................... 2

Optional Equipment Installation ................................ 2

Dimensions ............................................................... 3

Installation Instructions ............................................. 4

Troubleshooting ......................................................... 6

Sommaire

Fournitures requises ................................................. 9

Installation de l’équipement optionnel ....................... 9

Dimensions ............................................................. 10

Instructions relatives à l’installation ......................... 11

Dépannage ............................................................. 13

Tabla de contenidos

Materiales necesarios ............................................. 16

Instalaciones de equipos opcionales ...................... 16

Dimensiones ........................................................... 17

Instrucciones de instalación .................................... 18

Solución de problemas ........................................... 20

Raccords d’arrivée : 1/2 po NPT

Raccord de sortie : 1/2 po NPT

Plage de température : 65 – 90 °F

Pression maximum : 125 lb/po

Température d’arrivée, eau chaude : 120 – 180 °F

Température d’arrivée, eau froide : 33 – 80 °F

Différence de température minimum

(à partir de valeur de consigne de robinet) : 20 °F

Débit à 30 psi : 7.3 gpm

Dérivation d’eau froide minimum à 30 psid : 5.6 gpm

Débit minimum : 1.5 gpm

Débit maximum avec arrêt d’eau froide : 0.5 gpm

2

Conexiones de entrada: NPT de 1/2 pulg.

Conexión de salida: NPT de 1/2 pulg.

Rango de temperaturas: 65 – 90 °F

Presión máxima: 125 PSI

Temperatura de entrada, caliente: 120 – 180 °F

Temperatura de entrada, fría: 33 – 80 °F

Diferencial de temperatura mínima

(desde el punto de ajuste de la válvula): 20 °F

Flujo a 2,1 bar: 7.3 gpm

Derivación mínima de agua fría a 2,1 bar: 5.6 gpm

Flujo mínimo: 1.5 gpm

Flujo máximo con retención de agua fría: 0.5 gpm

215-1291 Rev. R; ECN 14-09-026

© 2014 Bradley

Page 1 of 22 7/23/2014

P.O. Box 309, Menomonee Falls, WI 53052-0309

Phone: 1.800.BRADLEY Fax: 262.253.4161

bradleycorp.com

Page 2

S19-2000, S19-2000EFX Installation

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

IMPORTANT!

Read this entire installation manual to ensure proper installation. When

finished with the installation, file this manual with the owner or maintenance

department. Compliance and conformity to local codes and ordinances is

the responsibility of the installer.

Separate parts from packaging and make sure all parts are accounted for

before discarding packaging material. If any parts are missing, do not begin

installation until you obtain the missing parts.

Valve shall be accessible for testing, adjusting and maintenance in the

installed position.

Make sure that all water supply lines have been flushed and then completely

turned off before beginning installation. Debris in supply lines can cause

valves to malfunction.

Product warranties may be found under “Products” on our web site at

bradleycorp.com.

Supplies recommended for installation

• Lockable shut-off on the outlet if tempered water is supplied to one or more emergency fixtures

• Lockable shut-off on the inlets/supplies

• (6) 1/4" wall anchors and fasteners for surface-mounted cabinet

• (4) 1/4" fasteners (and wall anchors, if necessary) for recess-mounted cabinet

• Unions on all connections to facilitate removal of valve

Tools required for temperature adjustment

• 5/64" Allen wrench

• Blade screwdriver

Install Optional Cabinet (If not installing cabinet, skip to Step 2)

1

If installing S19-2000EFX into Dropdown Eyewash Cabinet S19-292,

please see mounting instructions supplied with cabinet.

Recessed Cabinet:

1. Rough-in wall opening 11-1/2" W x 13" H.

2. Insert the cabinet and secure to wall with four 1/4" fasteners

properly anchored (supplied by installer.)

3. Install two anchors and screws through the valve bracket in

back of the cabinet into a secure brace (supplied by installer) or

into wall. This will support the valve.

4. Install the valve nipples and one-half of the union ball valve

using pipe sealant or teflon tape. Install the other half of the

union ball valve onto inlet and outlet pipe.

5. Insert the valve into the bracket in the cabinet (right side goes

in first). Continue with the valve installation procedure.

6. Position the wall flange tight to the wall and caulk in place.

Surface-Mounted Cabinet:

1. Measure and mark the cabinet mounting hole locations

at the dimensions shown on next page. Install six 3/8" wall

anchors (supplied by installer).

2. Position the cabinet onto the wall and secure into place

with six 3/8" wall fasteners (supplied by installer).

3. Install the valve nipples and one-half of the union ball

valve using pipe sealant or teflon tape. Then install the

other half of the union ball valve onto the inlet and outlet

piping.

4. Insert the valve into the bracket in the cabinet (right

side of the valve goes in first). Continue with the valve

installation procedure.

2 7/23/2014 Bradley • 215-1291 Rev. R; ECN 14-09-026

Page 3

Installation S19-2000, S19-2000EFX

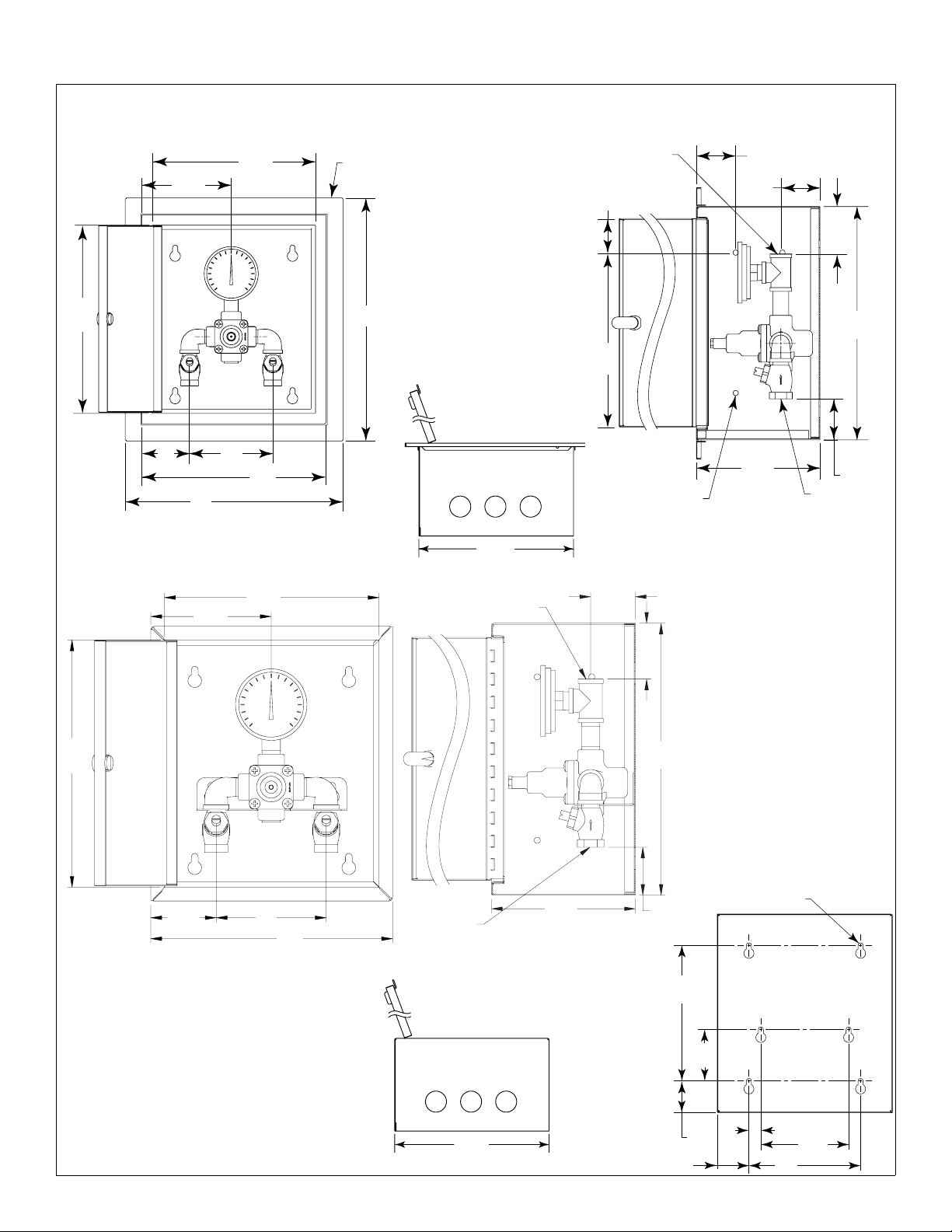

Optional Recessed Cabinet

Front View

11¼"

(286)

Door

(76)

9¾"

(248)

5"

(127)

Door

11"

(279)

Box

5³⁄₈"

(137)

3"

13"

(330)

Wall

Flange

14½"

(368)

Optional Surface-Mounted Cabinet

9¾"

(248)

5½"

(140)

Door

Bottom View

11"

(279)

½" NPT

Outlet

2½"

(64)

7-1/2"

(190)

2"

(51)

½" NPT

Outlet

⁹⁄₃₂" Dia. Holes

(4) each side,

(8) Total

Side View

(51)

(165)

2"

6½"

(51)

(mm)

2"

2½"

(64)

12½"

(318)

2¼"

(57)

½" NPT

Inlets

11¼"

(286)

Door

(76)

2½"

(64)

12½"

(318)

Mounting Hole

Locations

⁵⁄₁₆" (8) Dia. Holes

3"

5"

(127)

11"

(279)

Box

½" NPT

Inlets

6½"

(165)

2¼"

(57)

8½"

(216)

3¼"

(83)

(6) Total

¾"

2"

11"

(279)

(51)

(19)

(51)

2"

7"

(178)

5½"

(140)

Bradley • 215-1291 Rev. R; ECN 14-09-026 7/23/2014 3

Page 4

S19-2000, S19-2000EFX Installation

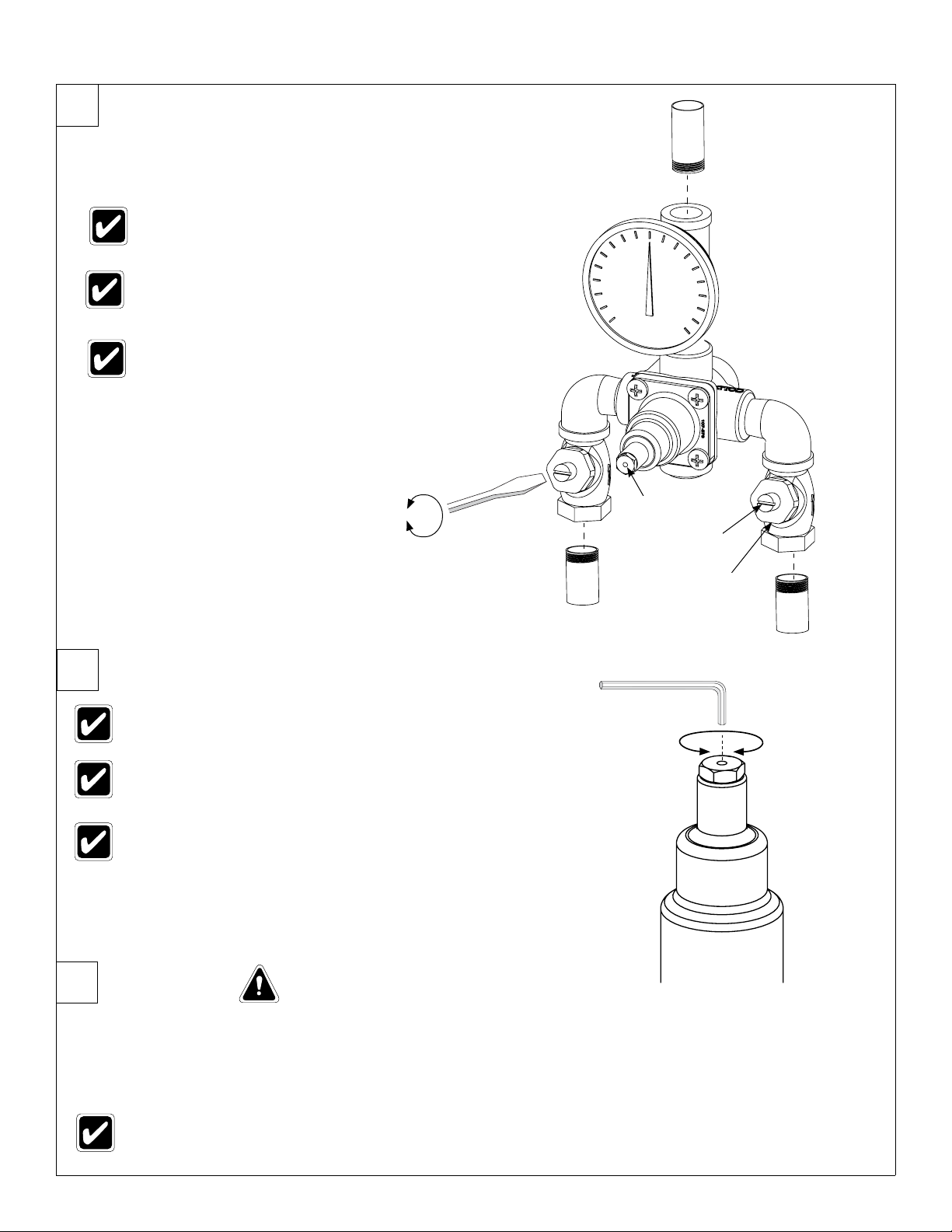

Connect Supply Lines and Fixture

2

Tempered Water

(to Fixture)

Check for leaks by pressurizing

unit SLOWLY.

Check the temperature when approx. 3-5 gpm water

flow is reached (equivalent to one eye wash or face

wash) and adjust if necessary.

When the check stops are in the fully open

(opera ting) position, the stem will extend

approximately 1/2" (13mm) from the stem nut.

Adjust Temperature with Water Running

3

Check the temperature when approximately 3 – 5 gpm

water flow is reached (equivalent to one eye wash).

No single emergency fixture supplied by this device

shall have a minimum flow rate less then 1.5 gpm.

This device must be checked for final temperature and adjusted as

necessary. The standard preset factory temperature setting is 85°F

(29°C) [the range of the valve is 65°F–90°F (18°C–32°C)]. Insert

Allen Wrench through the hole in the cap and into the set screw

to adjust. Consult proper medical and/or safety authorities for the

optimum temperature recommended for your particular application.

Open

Close

S19-2000 Shown

HOT

5/64" Allen Wrench

Hole In Cap

Stem

Stem Nut

COLD

H

C

Test Unit

4

Shut the hot water supply off by closing hot water inlet valve or supply check valve. While the hot water supply is turned off,

check to make sure the cold water continues to flow. If the cold water is flowing properly, reopen the hot water supply.

Shut the cold water supply off by closing the cold water inlet valve or supply check valve. While the cold water supply is off,

check to make sure that the hot water flow has shut down to less then 0.5 gpm. If hot water is shut down, fully reopen cold

water supply.

Test the system weekly (turn on the water supply and check for constant control of the desired set temperature).

DO NOT SKIP THIS STEP!!!

4 7/23/2014 Bradley • 215-1291 Rev. R; ECN 14-09-026

Page 5

Installation S19-2000, S19-2000EFX

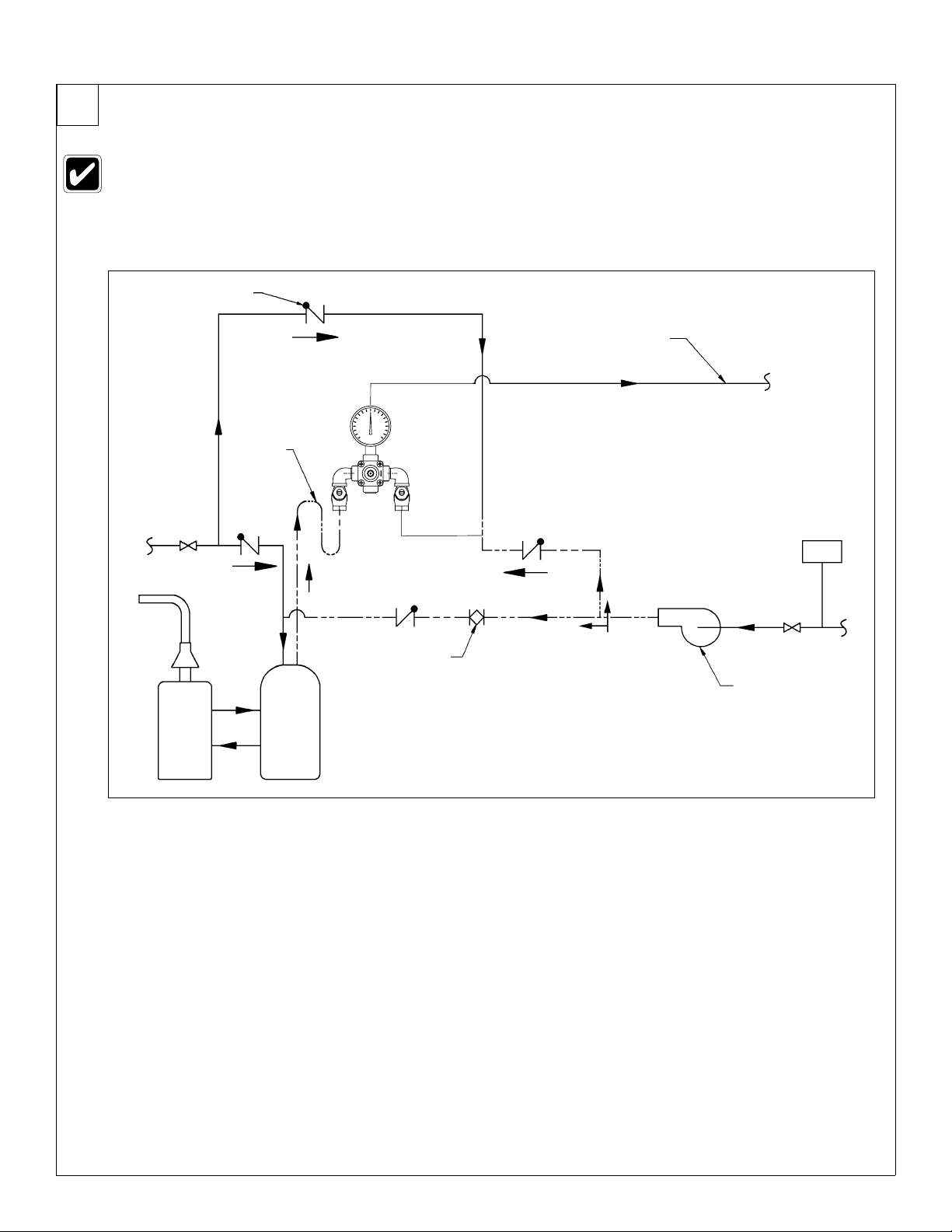

Optional Water Recirculation Setup

5

Recirculating the water in the system provides constant regulation of the water temperature. Flush the supply lines thoroughly

after completing installation. Close off all fixtures and label them as not available for use durin g the recirculating process.

Check Valve

(Typ)

Cold

Water

Water

Heater

COLD

Heat Trap

28" Drop

Storage

Tank

HOT

Balancing Valve (Typ)

Tempered Water Flow

Return Flow

Temperature Switch

Recirculated

Tempered

Water

Recirculating Pump

1. Turn off the recirculating pump and turn on the water supply at emergency fixture (a water flow rate of 3 – 5 gpm is required).

2. Let the water run through the system until a consistent temperature is obtained. If you do not obtain the required temperature,

refer to step #3 on previous page for temperature readjustment.

3. As soon as the water reaches the proper temperature, turn on the recirculating pump (make certain the proper system

temperature has been achieved before proceeding).

4. Check the water temperature at the return pump. If the temperature exceeds the appropriate level by 2°F, adjust the temperature

high-limit switch (this will turn off the pump). Wait until the return water temperature is 5°F below the appropriate level and adjust the

low-limit switch (this will turn the pump back on).

5. Open the balancing valve completely.

6. Turn off all fixtures and make sure there is no water running through the system (the cold inlet pipe should feel warm to the touch).

7. Let the system run for 30 minutes or longer without water. If, after thirty minutes, the water temperature increases, you may

readjust the temperature by slowly closing the balancing valve until the appropriate temperature is reached.

Bradley • 215-1291 Rev. R; ECN 14-09-026 7/23/2014 5

Page 6

S19-2000, S19-2000EFX Installation

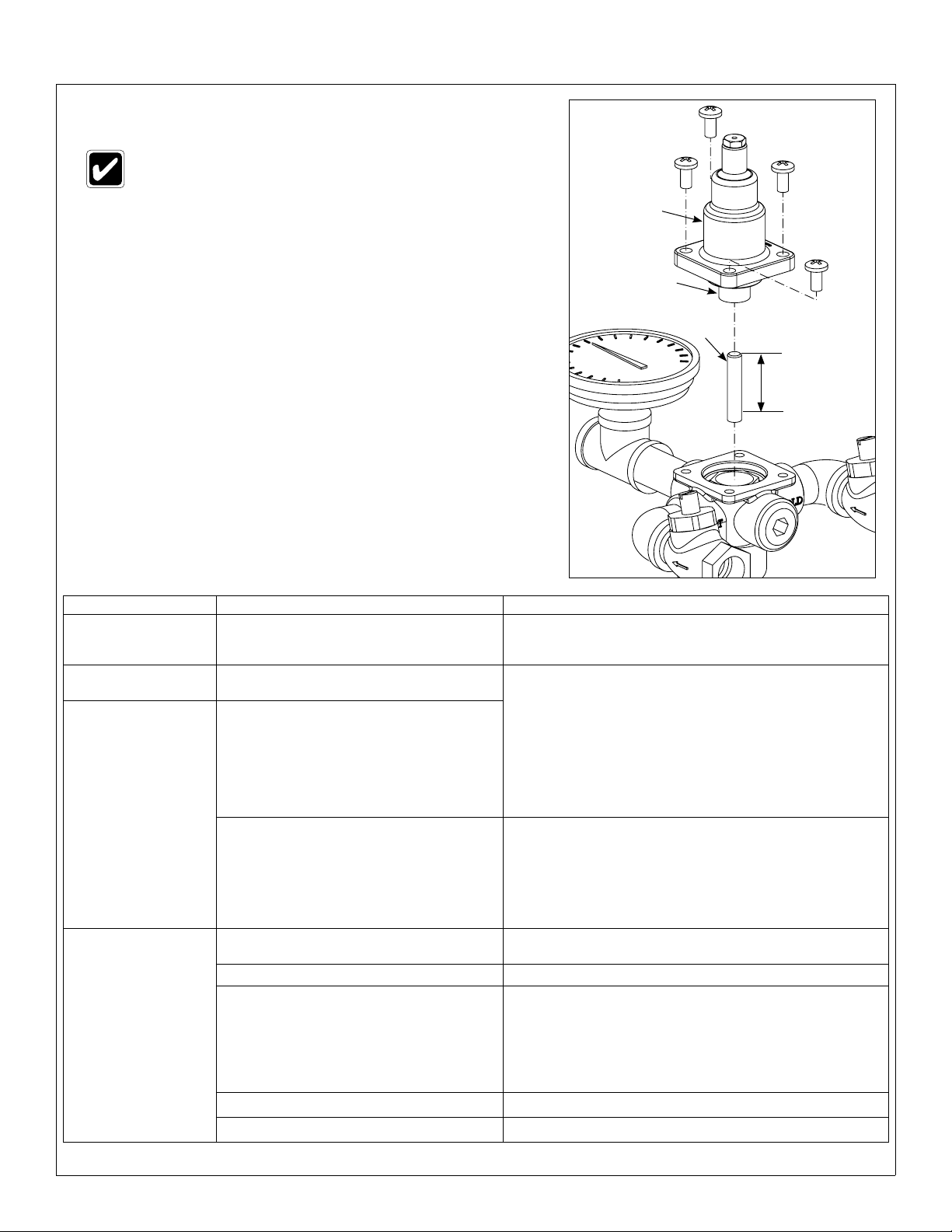

Troubleshooting Thermostatic Mixing Valve

Before attempting to troubleshoot the valve or

disassemble the components, check for the following:

• Stop/check valves are fully open (the slotted stem

extends approximately 1/2" from the stem nut) and

that all inlet and outlet shut-off valves are open.

• Hot and cold inlet pipes are connected properly,

and that there are no cross-connectio ns or leaking

stop/check valves.

• Water heater output is at least 20° F above the set

temperature.

Be sure to close the appropriate shut-off valves prior

to disassembly of the valve and reopen the valves

after inspection and repair is complete.

Top Cap &

Thermostat

Thermostat

Bellows

5/16" Push

Rod

Push Rod length

should extend

15/16" – 1-3/16"

into Bellows

Problem Cause Solution

External leaks in the

system

No hot water flow (cold

water flow only)

Limited water flow The inlet shut-off valve may be partially closed

Temperature fluctuation

or improper Temperature

Either the NPT joints or the o-rings have been

damaged.

The thermostat has failed and, subsequently, the

safety shut-off has engaged.

or there has been a significant decrease in water

pressure.

Dirt and debris have collected on the check

screen or seat, limiting the movement of the stop

and checks.

The stop and check sections of the valve do not

move freely.

Thermostat is slowly failing. Check Thermostat as described above, or replace.

Inlet supply line to the mixing valve is being

shared by other pieces of equipment that are

used only periodically, such as laundry appliances

or washdown stations. It may reduce the inlet

pressure to the mixing valve to less than 3 PSI.

The supply line size may not be large enough to

supply both the valve and the other appliances.

Recirculation is not balanced. Review recirculation set up on page 5.

Piston does not move freely and must be cleaned. See next page for piston disassembly and cleaning directions.

Replace the NPT joints and/or o-rings where necessary. For

replacement of o-rings, contact your Bradley representative and ask

for O-Ring Seal Kit (S65-170).

Inspect Thermostat:

1. Remove the top cap and thermostat.

2. Insert the 5/16" dia. push rod into the thermostat bellows.

3. Mark the length the push rod extends into the bellows (at room

temperature, with 10 lb. of force. the length should be approx.

15/16" – 1-3/16").

4. If the push rod length is not in the proper range, the thermostat

must be replaced (it cannot be repaired). Contact your Bradley

representative and ask for Thermostat Kit (S65-171).

Clean Stop and check Valves:

Remove the stop and checks, clean the seat and reassemble the

valve. Do not remove the seat. The components may be brushed

with a small wire brush to remove debris. A pair of tweezers works

well for pulling debris out from the seat. If the stop and checks need

to be replaced, contact your Bradley representative and ask for

Check/Stop Kit (S27-102-Rough Brass, or S27-292A-Chrome).

Clean Stop and Check Valves as described above.

Enlarge the supply line size, reconfigure the supply line or regulate

the supply usage.

6 7/23/2014 Bradley • 215-1291 Rev. R; ECN 14-09-026

Page 7

Installation S19-2000, S19-2000EFX

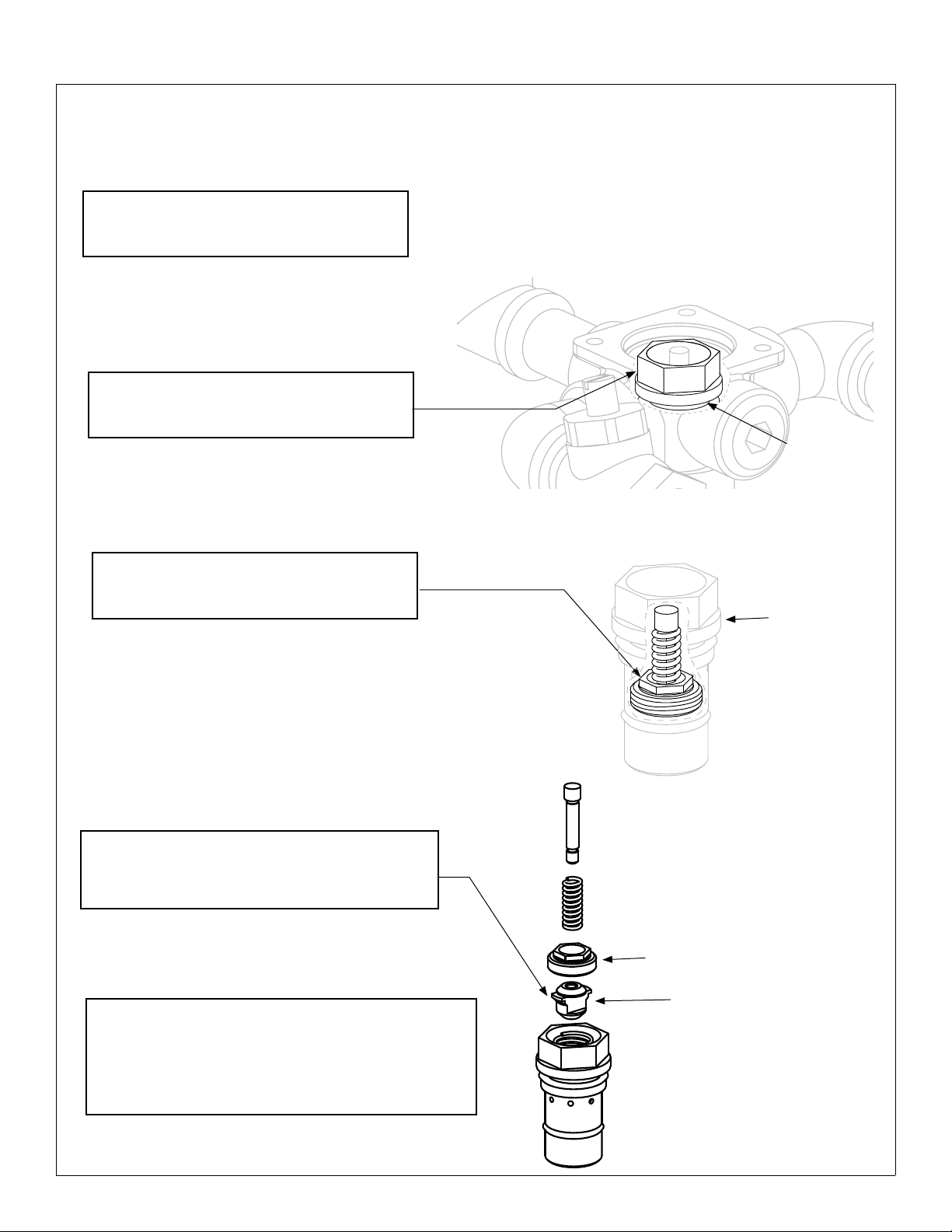

Troubleshooting: Piston Disassembly and Cleaning

Remove the Top Cap and Thermostat

Assembly as shown on Page 6. Set the

A

5/8" Push Rod aside.

Using a 15/16" socket wrench, loosen the

piston liner from the valve body and lift

B

out with a needle-nose pliers.

Piston Liner

Using a 1/2 deep socket wrench, loosen

the piston upper seat from the piston liner

C

and lift out parts with a needle-nose pliers.

Dissamble and clean the piston assembly parts

D

with any cleaner suitable for brass and stainless

steel. (if necessary, use a 400-grit sandpaper to

polish and hone the piston and liner.)

Re-assemble the piston assembly. Push the

mechanism up and down several times to make sure

the piston moves smoothly and consistently. If it is not

E

consistent, repeat Procedure D until it moves freely, or

replace. Contact your Bradley representative and ask

for Piston/Liner Kit (part number S65-172).

Piston Liner

Piston Upper Seat

Piston

Bradley • 215-1291 Rev. R; ECN 14-09-026 7/23/2014 7

Page 8

S19-2000, S19-2000EFX Installation

Parts Breakdown

5

1/2" Street Ell

Thermometer

1/2" Brass

Tee

1/2" x 2"

Brass Nipple

12

4

3

2

Valve Body

8

7

6

1/2" Pipe

Plug

11

10

9

1/2" Street Ell

19

17

15

14

18

16

13

Check Stop

Thermostat Kit S65-171

Item Qty. Description

11 1 Thermostat

12 1 O-Ring

13 1 O-Ring

Piston & Liner Kit S65-172

Item Qty. Description

2 1 O-Ring

3 1 O-Ring

4 1 Liner

5 1 Spring

6 1 Piston

7 1 Spring

8 1 Overheat Screw

9 1 Upper Seat

O-Ring Kit S65-170

Item Qty. Description

2 1 O-Ring

3 1 O-Ring

12 1 O-Ring

13 1 O-Ring

Check Stop

Center Section Kit S65-303

Item Qty. Description

2 1 O-Ring

3 1 O-Ring

4 1 Liner

5 1 Spring

6 1 Piston

7 1 Spring

8 1 Overheat Screw

9 1 Upper Seat

10 1 Push Rod

11 1 Thermostat

12 1 O-Ring

13 1 O-Ring

14 1 Control Cap

15 1 Set Screw

16 1 Label

17 1 Set Screw

18 4 1/4 Screw

19 1 Cap

Flexible Connection Lines for S19-2000EFX

When used with S19-292, order Part

No. 269-653 (3 supplied with unit).

Kit numbers for rough brass finish. Contact

Bradley for other configurations.

As of November 2001, the piston (Item 7) has

replaced the seal holder and seal as a direct

replacement.

As of June 2008, the brass control cap (item

15) has been replaced by a plastic cap. All

internal components are identical.

As of July 2012, the Temperature Adjustment

Control (items 15, 17 and 19) have been

updated and are compatible with all units using

the plastic Control Cap (June 2008 to present).

8 7/23/2014 Bradley • 215-1291 Rev. R; ECN 14-09-026

Page 9

Installation S19-2000, S19-2000EFX

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

IMPORTANT!

Lire ce manuel d’installation dans son intégralité pour garantir une

installation appropriée. Une fois celle-ci terminée, classer ce manuel auprès

du service à la clientèle ou d’entretien. L’installateur est responsable de

respecter la conformité aux codes et ordonnances locaux.

Séparer les pièces de l’emballage et veiller à bien avoir toutes les pièces

avant de jeter le matériau d’emballage. Le cas échéant, ne pas commencer

l’installation avant d’avoir obtenu les pièces manquantes.

La vanne doit être accessible en position installée pour les essais, les

réglages et l'entretien.

Veiller à bien vidanger et fermer toutes les conduites d’eau avant de

commencer l’installation. Tout débris dans les conduites d’alimentation peut

provoquer un mauvais fonctionnement des vannes.

Les garanties du produit se trouvent sous la rubrique « Products »

(Produits) sur notre site Web à bradleycorp.com

Fournitures requises pour l’installation :

• Robinet d’arrêt verrouillable sur la sortie en cas d’alimentation d’eau tempérée vers un ou plusieurs appareils d’urgence

• Robinet d’arrêt verrouillable sur les arrivées/alimentations

• (6) Ancrages muraux et fixations 3/8 po pour armoire montée en surface

• (4) Fixations 1/4 po (et ancrages muraux, si nécessaire) pour armoire encastrée

• Raccords sur toutes les connexions pour faciliter la dépose du robinet

Outils requis pour réglage de température

• Clé Allen 5/64 po

• Tournevis à lame

Poser l’armoire en option (si l’installation est sans armoire, passer à l’étape 2).

1

En cas de pose du S19-2000EFX dans l’armoire de douche oculaire escamotable

S19-292, voir les instructions de montage fournies avec l’armoire.

Armoire encastrée :

1. Ouverture murale pour plomberie brute 292 mm L x 330 mm H

(11-1/2 po L x 13 po H).

2. Insérer l’armoire et la fixer au mur avec quatre fixations 1/4 po

adéquatement ancrées (fournies par l’installateur).

3. Installer deux ancrages et vis à travers le support de robinet à l’arrière

de l’armoire et dans un contrevent sécuritaire (fourni par l’installateur) ou

dans un mur. Cela soutiendra le robinet.

4. Installer les raccords filetés du robinet et la moitié du clapet à bille

du raccord en utilisant un produit d’étanchéité pour tuyaux ou du ruban

téflon. Installer l’autre moitié du clapet à bille du raccord sur le tuyau

d’entrée et de sortie.

5. Insérer le robinet dans le support dans l’armoire (le côté droit entre en

premier). Continuer avec la procédure d’installation du robinet.

Armoire montée en surface :

1. Mesurer et marquer les emplacements des trous de montage

de l’armoire selon les dimensions indiquées à la page suivante.

Installer six ancrages muraux de 3/8 po (fournis par l’installateur).

2. Positionner l’armoire dans le mur et fixer en place avec six

fixations murales de 3/8 po (fournies par l’installateur).

3. Installer les raccords filetés du robinet et la moitié du clapet à

bille du raccord en utilisant un produit d’étanchéité pour tuyaux

ou du ruban téflon. Puis installer l’autre moitié du clapet à bille du

raccord sur le tuyau d’entrée et de sortie.

4. Insérer le robinet dans le support dans l’armoire (le côté

droit du robinet entre en premier). Continuer avec la procédure

d’installation du robinet.

6. Positionner la rosace murale tout contre le mur et colmater en place.

Bradley • 215-1291 Rév. R; ECN 14-09-026 7/23/2014 9

Page 10

S19-2000, S19-2000EFX Installation

Armoire encastrée en option

11¼"

(286)

Porte

Vue de face

5³⁄₈"

(137)

3"

(76)

13"

(330)

5"

(127)

9¾"

(248)

Porte

(279)

Boîtier

11"

Bride

murale

14½"

(368)

Armoire en option montée en surface

9¾"

(248)

5½"

(140)

Porte

Vue de dessous

11"

(279)

Sortie

½" NPT

2½"

(64)

7½"

(190)

(51)

Sortie

½" NPT

Trous de Ø ⁹⁄₃₂" (7)

(4) de chaque côté,

(8) au total

2"

2½"

(64)

Vue latérale

2"

(51)

6½"

(165)

(51)

(mm)

2"

2½"

(64)

12½"

(318)

2¼"

(57)

Arrivées

½" NPT

11¼"

(286)

Porte

12½"

(318)

Emplacements de

trous de montage

Trous de Ø ⁵⁄₁₆" (8)

¾"

(19)

(6) au total

7"

(178)

5½"

(140)

(76)

3"

5"

(127)

11"

(279)

Boîtier

Arrivées

½" NPT

11"

(279)

6-1/2"

(165)

2¼"

(57)

8½"

(216)

2"

(51)

(51)

3¼"

(83)

2"

10 7/23/2014 Bradley • 215-1291 Rév. R; ECN 14-09-026

Page 11

Installation S19-2000, S19-2000EFX

Raccorder les conduites d’alimentation et l’appareil

2

Eau tempérée

(vers l’appareil)

Mettre LENTEMENT sous

pression pour vérifier l’étanchéité.

Contrôler la température lorsque le débit d’eau atteint

11 à 19 l/min (3 à 5 gal/min) (équivalent à une douche

oculaire ou faciale) et l’ajuster le cas échéant.

Lorsque les clapets de non-retour sont

complètement ouverts (en marche), la tige

dépasse du capuchon d’environ 13 mm (1/2 po).

Ouvrir

Fermer

S19-2000 représenté

Régler la température pendant que l’eau coule

3

Contrôler la température lorsque le débit d’eau atteint

11 à 19 l/min (3 à 5 gal/min) (équivalent à une douche

oculaire).

Aucun dispositif d’urgence fourni par ce dispositif a n’a

un débit minimum inférieur à 1,5 GPM (5,7 L/min).

Contrôler la température finale du dispositif et l’ajuster le cas

échéant. La température de consigne standard préréglée à l’usine

est de 29 °C (85 °F) [la plage du robinet est de 18 à 32 °C (65 à

90 °F)]. Insérez la clé Allen à travers l’orifice du capuchon et dans

la vis de calage pour régler. Consulter les autorités médicales et/

ou de sécurité appropriées pour connaître la température optimale

recommandée pour l’application en question.

Tige de clapet

de non-retour

CHAUD

5/64" Clé Allen

Orifice du

capuchon

Capuchon

de tige

C

FROID

F

Tester le robinet

4

Fermer l’alimentation d’eau chaude en fermant le clapet ou le robinet d’arrivée d’eau chaude. Pendant que l’alimentation d’eau

chaude est coupée, vérifier que l’eau froide continue de s’écouler. Si l’eau froide s’écoule correctement, rouvrir l’alimentation

d’eau chaude.

Fermer l’alimentation d’eau froide en fermant le clapet ou le robinet d’arrivée d’eau froide. L'arrivée d'eau froide étant coupée,

s'assurer que le débit d'eau chaude a été réduit jusqu'à moins de 0,5 gal/min (1,9 l/min). Si l’eau chaude est coupée, rouvrir

complètement l’arrivée d’eau froide.

Effectuer un essai du système chaque semaine (ouvrir l’arrivée d’eau et vérifier la bonne régulation à la température de consigne

souhaitée).

NE PAS SAUTER CETTE ÉTAPE!!!

Bradley • 215-1291 Rév. R; ECN 14-09-026 7/23/2014 11

Page 12

S19-2000, S19-2000EFX Installation

Configuration de recirculation en option

5

La recirculation de l’eau dans le circuit assure une régulation constante de la température de l’eau. Purger les conduites

d’alimentation avec soin après avoir terminé l’installation. Fermer tous les appareils et les condamner provisoirement durant

le processus de recirculation.

Clapet de non-retour

(typ.)

Eau froide

Chauffe-eau

FROID

Piège à chaleur

Chute de 28"

(711 mm)

Réservoir

CHAUD

Robinet d’équilibrage (typ.)

Flux d’eau tempérée

Flux de retour

Rupteur thermique

Eau tempérée

recirculée

Pompe de recirculation

1. Couper la pompe de recirculation et ouvrir l’alimentation d’eau au niveau de l’appareil d’urgence (un débit d’eau de 11 à 19 l/min

[3 à 5 gal/min] est requis).

2. Laisser l’eau s’écouler à travers le système jusqu’à obtenir une température constante. Si la température souhaitée n’est pas

obtenue, réajuster la température comme indiqué à l’étape 3 à la page précédente.

3. Dès que l’eau atteint la bonne température, activer la pompe de recirculation (vérifier que la température correcte a été obtenue

dans le système avant de poursuivre).

4. Contrôler la température de l’eau au niveau de la pompe de retour. Si la température dépasse le niveau approprié de 1 °C (2 °F),

ajuster le rupteur thermique haut (pour arrêter la pompe). Attendre que la température de retour de l’eau soit de 3 °C (5 °F) en

dessous du niveau approprié puis ajuster le rupteur thermique bas (pour remettre la pompe en marche).

5. Ouvrir complètement le robinet d’équilibrage.

6. Couper tous les appareils et vérifier qu’aucune eau ne circule à travers le système (le tuyau d’arrivée d’eau froide doit être tiède

au toucher).

7. Laisser le système fonctionner pendant 30 minutes ou plus sans eau. Si, au bout de trente minutes, la température de l’eau

augmente, elle peut être réajustée en fermant lentement le robinet d’équilibrage jusqu’à atteindre la température qui convient.

12 7/23/2014 Bradley • 215-1291 Rév. R; ECN 14-09-026

Page 13

Installation S19-2000, S19-2000EFX

Dépannage du robinet mélangeur thermostatique

Avant d’essayer de dépanner le robinet ou de

démonter les composantes, vérifier ce qui suit :

• Les clapets de non-retour sont totalement ouverts

(la tige fendue dépasse d’environ 13 mm (1/2 po)

du capuchon et tous les robinets d’arrêt d’arrivée

et de sortie sont ouverts.

• Les conduites d’arrivée d’eau chaude et froide

sont correctement raccordées et il n’existe ni de

raccordements croisés ni de fuite des clapets de

non-retour.

• La sortie du chauffe-eau est d’au moins 11 °C

(20 °F) au-dessus de la température de consigne.

Veiller à bien fermer les robinets d’arrêt adéquats

avant de démonter le robinet et de les rouvrir après

inspection et une fois la réparation terminée.

Capuchon supérieur

et thermostat

Soufflet de

thermostat

Tige-poussoir

de 5/16"

La tige-poussoir doit

s’enfoncer d’une longueur

de 15/16" à 1-3/16" (24 à

30 mm) dans le soufflet

Problème Cause Solution

Fuites externes

dans le

système

Pas de

circulation

d’eau chaude

(eau froide

seulement)

Débit d’eau

limité

Fluctuation de

température ou

température

incorrecte

Les joints NPT ou les joints toriques sont

endommagés.

Défaillance du thermostat suivie de

l’activation de la vanne d’arrêt de sécurité.

Le robinet d’arrêt d’arrivée est partiellement

fermé ou la pression d’eau a fortement

chuté.

Accumulation de saleté et de débris sur le

tamis ou le siège de clapet, ce qui limite le

mouvement des clapets de non-retour.

Les sections de clapet de non-retour du

robinet ne bougent pas librement.

Lente défaillance du thermostat. Contrôler le thermostat comme décrit plus haut ou le changer.

La conduite d’alimentation d’arrivée vers

le robinet mélangeur est partagée avec

d’autres machines qui ne sont utilisées que

périodiquement, telles que des machines

à laver ou des stations à grand débit.

Cela peut réduire la pression d’arrivée au

robinet mélangeur à moins de 3 PSI. La

section de la conduite d’alimentation peut

être insuffisante pour alimenter à la fois le

robinet et les autres appareils.

La recirculation est déséquilibrée. Examiner la configuration de recirculation à la page 12.

Le piston ne bouge pas librement et doit

être nettoyé.

Remplacer les joints NPT et/ou joints toriques le cas échéant. Pour tout

remplacement de joints toriques, contacter le représentant Bradley et lui demander

un Kit de joint torique (S65-170).

Contrôler le thermostat :

1. Déposer le capuchon supérieur et le thermostat.

2. Enfiler la tige-poussoir de Ø 5/16 po dans le soufflet de thermostat.

3. Marquer la longueur dont la tige s’enfonce dans le soufflet (à température

ambiante, sous une force de 45 N [10 lb], cette longueur doit être d’environ 24 à

30 mm [15/16 à 1-3/16 po]).

4. Si la longueur de tige-poussoir n’est pas dans l’intervalle correct, le thermostat

doit être changé (il n’est pas réparable). Contacter le représentant Bradley et lui

demander un Kit de thermostat (S65-171).

Nettoyer les clapets de non-retour :

démonter les clapets de non-retour, nettoyer le siège et remonter. Ne pas déposer

le siège. Brosser les pièces avec une petite brosse métallique pour éliminer les

débris. Utiliser une pince à épiler pour extraire les débris du siège. Si le clapet de

non-retour doit être changé, contacter le représentant Bradley et lui demander un

Kit de clapet de non-retour (S27-102 - Laiton brut ou S27-292A - Chrome).

Nettoyer les clapets de non-retour comme décrit ci-dessus.

Augmenter la section de la conduite d’alimentation, reconfigurer l’alimentation ou

réguler l’usage de l’alimentation.

Voir les instructions de démontage et de nettoyage du piston à la page suivante.

Bradley • 215-1291 Rév. R; ECN 14-09-026 7/23/2014 13

Page 14

S19-2000, S19-2000EFX Installation

Dépannage : Démontage et nettoyage du piston

Déposer le capuchon supérieur et le

thermostat comme indiqué à la page 13.

A

Mettre la tige-poussoir de 5/8 po de côté.

À l’aide d’une clé à douille de 15/16 po,

desserrer la chemise de piston du corps de

robinet et l’extraire avec une pince à becs

B

fins.

Chemise de piston

À l’aide d’une clé à douille longue de 1/2

po, desserrer le siège supérieur du piston

C

de la chemise de piston et extraire les

pièces avec une pince à becs fins.

Démonter et nettoyer les pièces du piston avec

tout produit nettoyant convenant pour le laiton

et l’acier inoxydable (le cas échéant, utiliser du

D

papier de verre 400 grains pour polir et rectifier

le piston et la chemise).

Remonter le piston. Pousser le mécanisme vers le

haut et la bas à plusieurs reprises pour vérifier que

le piston bouge régulièrement et sans grippage. Si le

mouvement n’est pas régulier, répéter la procédure

E

D jusqu’à ce qu’il bouge librement ou le changer.

Contacter le représentant Bradley et lui demander un

Kit de piston/chemise (réf. S65-172).

Chemise de piston

Siège supérieur du piston

Piston

14 7/23/2014 Bradley • 215-1291 Rév. R; ECN 14-09-026

Page 15

Installation S19-2000, S19-2000EFX

Liste des pièces

5

Coude mâle-femelle

1/2"

Thermomètre

Té en laiton

1/2"

4

3

2

Mamelon en laiton

1/2" x 2"

Corps de

robinet

8

7

6

Bouchon de tuyau

1/2"

Coude mâle-femelle

1/2"

12

11

10

9

19

17

15

14

Clapet de

non-retour

18

16

13

Kit Thermostat S65-171

Repère Qté Désignation

11 1 Thermostat

12 1 Joint torique

13 1 Joint torique

Kit Piston et chemise S65-172

Repère Qté Désignation

2 1 Joint torique

3 1 Joint torique

4 1 Chemise

5 1 Ressort

6 1 Piston

7 1 Ressort

8 1 Vis de

surchauffe

9 1 Siège supérieur

Kit Joint torique S65-170

Repère Qté Désignation

2 1 Joint torique

3 1 Joint torique

12 1 Joint torique

13 1 Joint torique

Clapet de non-retour

Kit Portion centrale S65-303

Repère Qté Désignation

2 1 Joint torique

3 1 Joint torique

4 1 Chemise

5 1 Ressort

6 1 Piston

7 1 Ressort

8 1 Vis de surchauffe

9 1 Siège supérieur

10 1 Tige-poussoir

11 1 Thermostat

12 1 Joint torique

13 1 Joint torique

14 1 Capuchon de

commande

15 1 Vis calante

16 1 Étiquette

17 1 Vis calante

18 4 Vis 1/4

19 1 Capuchon

Conduites de raccordement flexibles

pour S19-2000EFX

Pour une utilisation avec S19-292,

commander réf. 269-653 (3 fournis

avec le robinet).

Numéros de kit pour la finition en laiton

brut. Contacter Bradley pour toute autre

configuration.

À compter de novembre 2001, le piston

(repère 7) remplace directement le support de

joint et le joint.

À compter de juin 2008, le capuchon de

commande en laiton (repère 15) est remplacé

par un capuchon en plastique. Toutes les

pièces internes sont identiques.

À compter d’juillet 2012, la commande de

réglage de température (repères 15, 17 et

19) est reconfigurée et compatible avec tous

les modèles à capuchon de commande en

plastique (juin 2008 à actuel).

Bradley • 215-1291 Rév. R; ECN 14-09-026 7/23/2014 15

Page 16

S19-2000, S19-2000EFX Instalación

Installation

THIS

SIDE

UP

Packing List

•

•

•

•

¡IMPORTANTE!

Lea en su totalidad este manual de instalación para garantizar una

instalación adecuada. Al completar la instalación, entregue este manual al

propietario o al Departamento de Mantenimiento. Es responsabilidad del

instalador cumplir cabalmente los códigos y las ordenanzas locales.

Saque las piezas del embalaje y asegúrese de haberlas sacado todas antes

de desecharlo. Si falta alguna pieza, no comience la instalación hasta

obtenerla.

Deberá ser posible acceder a las válvulas para realizar pruebas, ajustes y

mantenimiento en la posición instalada.

Asegúrese de purgar todas las tuberías de suministro de agua y que estén

completamente cerradas antes de comenzar la instalación. Los desechos

acumulados en las tuberías de suministro pueden provocar defectos en el

funcionamiento de las válvulas.

Las garantías de los productos se pueden encontrar en la sección

“Products” (Productos) del sitio web, bradleycorp.com.

Materiales recomendados para la instalación

• Cierre bloqueable en la salida si se suministra agua temperada a uno o más accesorios de emergencia.

• Cierre bloqueable de las entradas o de los suministros.

• (6) anclajes y sujetadores de pared de 1/4 pulg. para el gabinete montado en la superficie.

• (4) sujetadores de 1/4 pulg. (y anclajes de pared, si fuera necesario) para el gabinete empotrado.

• Uniones en todas las conexiones para facilitar el retiro de la válvula.

Herramientas necesarias para el ajuste de temperatura

• Llave Allen de 5/64 pulg.

• Destornillador de paleta.

Instale el gabinete opcional (si no va a instalar el gabinete, siga con el Paso 2)

1

Si se instala el modelo S19-2000EFX en el gabinete lavaojos desplegable S19-292,

consulte las instrucciones de montaje que se suministran con el gabinete.

Gabinete empotrado:

1. Orificio de colocación en la pared de 292 mm (11-1/2 pulg.) de ancho x

330 mm (13 pulg.) de alto.

2. Inserte y fije el gabinete con cuatro sujetadores de 1/4 pulg.

(proporcionado por el instalador) anclados apropiadamente a la pared.

3. Instale los dos anclajes y tornillos a través del soporte de la válvula en

la parte trasera del gabinete en una abrazadera firme (proporcionada por

el instalador) o en la pared. Esto servirá de apoyo a la válvula.

4. Instale los niples de la válvula y la mitad de la válvula de bolas de la

unión, usando sellador para tubos o cinta de teflón. Instale la otra mitad de

la válvula de bolas de la unión en el tubo de entrada y salida.

5. Inserte la válvula en el soporte del gabinete (primero el lado derecho).

Continúe con el procedimiento de instalación de la válvula.

6. Ponga firmemente la brida de pared en la pared y aplique masilla para

fijarla en su lugar.

16 7/23/2014 Bradley • 215-1291 Mod. R; ECN 14-09-026

Gabinete montado en la superficie:

1. Mida y marque la ubicación de los orificios de

montaje del gabinete en las dimensiones que se

muestran en la siguiente página. Instale seis anclajes

de pared de 3/8 pulg. (proporcionados por el instalador).

2. Ponga el gabinete en la pared y fíjelo en su lugar con

seis sujetadores de pared de 3/8 pulg. (proporcionados

por el instalador).

3. Instale los niples de la válvula y la mitad de la válvula

de bolas de la unión, usando sellador para tubos o

cinta de teflón. Luego, instale la otra mitad de la válvula

de bolas de la unión en el tubo de entrada y salida.

4. Inserte la válvula en el soporte del gabinete (primero

el lado derecho de la válvula). Continúe con el

procedimiento de instalación de la válvula.

Page 17

Instalación S19-2000, S19-2000EFX

Gabinete empotrado opcional

Vista frontal

9¾"

(248)

5"

(127)

Puerta

11"

(279)

Caja

11¼"

(286)

Puerta

(76)

5³⁄₈"

(137)

3"

13"

(330)

Gabinete opcional montado

en la superficie

5½"

(140)

9¾"

(248)

Puerta

Brida de

pared

14½"

(368)

Vista inferior

11"

(279)

Salida de

NPT de 1/2"

2½"

(64)

7½"

(190)

(51)

2"

Salida de

NPT de ½"

⁹⁄₃₂"(7) de diá.

Orificios

(4) a cada lado,

(8) Total

Vista lateral

2"

(51)

6½"

(165)

(51)

(mm)

2"

2½"

(64)

12½"

(318)

2¼"

(57)

Entradas de

NPT de ½"

11¼"

(286)

Puerta

(76)

2½"

(64)

12½"

(318)

Ubicación de los orificios

de montaje

⁵⁄₁₆" (8) de diá. Orificios

3"

5"

(127)

11"

(279)

Caja

Entradas de

NPT de ½"

6½"

(165)

2¼"

(57)

8½"

(216)

3¼"

(83)

(6) en total

¾"

2"

(19)

11"

(279)

(51)

(51)

2"

7"

(178)

5½"

(140)

Bradley • 215-1291 Mod. R; ECN 14-09-026 7/23/2014 17

Page 18

S19-2000, S19-2000EFX Instalación

Conexión de las tuberías de suministro y accesorios

2

Agua temperada

(para el accesorio)

Revise si hay filtraciones, presurizando la

unidad LENTAMENTE.

Revise la temperatura cuando se alcance un caudal de

agua de 11 a 19 LPM (3 a 5 gpm) (lo equivalente a un

lavado ocular o facial) y ajuste de ser necesario.

Cuando los topes de retención se encuentran en

la posición de abertura completa (funcionamiento),

el vástago se extenderá aproximadamente 13 mm

(1/2 pulg.) desde la tuerca.

Abrir

Cerrar

Se muestra el modelo

S19-2000

Ajuste la temperatura con el agua corriendo

3

Revise la temperatura cuando se alcance

aproximadamente un caudal de agua de 11 a 19 LPM

(3 a 5 gpm) (lo equivalente a un lavado ocular).

Ningún accesorio de emergencia que proporcione este

dispositivo tiene un caudal mínimo inferior a 5,7 L/min.

Se debe revisar la temperatura final de este dispositivo y ajustarla,

según sea necesario. La configuración estándar de la temperatura

predeterminada de fábrica es de 29 °C (85 °F) (el rango de la válvula

es de 18 °C a 32 °C [65 °F a 90 °F]). Para ajustar, inserte la llave

Allen a través del orificio en la tapa, en el tornillo de ajuste. Consulte

a las autoridades médicas o de seguridad correspondientes sobre la

temperatura óptima recomendada para la aplicación en particular.

Vástago de tope

de retención

CALIENTE

Orificio en la tapa

5/64" Llave Allen

Tuerca del

vástago

C

FRÍA

F

Pruebe la unidad

4

Cierre la válvula de entrada de agua caliente o la válvula de retención de suministro para cortar el suministro de agua caliente. Con

el suministro de agua caliente cerrado, verifique que siga fluyendo agua fría. Si el agua fría fluye correctamente, vuelva a abrir el

suministro de agua caliente.

Cierre la válvula de entrada de agua fría o la válvula de retención de suministro para cortar el suministro de agua fría. Con el

suministro de agua fría cerrado, verifique que se haya detenido el flujo de agua caliente a menos de 1,9 LPM (0,5 gpm). Si se

detiene el agua caliente, vuelva a abrir completamente el suministro de agua fría.

Pruebe el sistema semanalmente (abra el suministro de agua y verifique que el control de la temperatura establecida que se

desea sea constante).

¡NO SE SALTE ESTE PASO!

18 7/23/2014 Bradley • 215-1291 Mod. R; ECN 14-09-026

Page 19

Instalación S19-2000, S19-2000EFX

Instalación de recirculación opcional de agua

5

La recirculación del agua en el sistema proporciona regulación constante de la temperatura del agua. Purgue las tuberías

de suministro completamente antes de terminar la instalación. Cierre todos los accesorios y etiquételos como no disponibles

para usarse durante el proceso de recirculación.

Válvula de

retención (Típ.)

Agua fría

Calentador

de agua

FRÍA

Bajada de

trampa de

calor de 28"

(711 mm)

Tanque de

almacenamiento

CALIENTE

Válvula de equilibrio (Típ.)

Flujo de agua temperada

Flujo de retorno

Interruptor de temperatura

Agua

temperada

recirculada

Bomba de recirculación

1. Apague la bomba de recirculación y abra el suministro de agua en los accesorios de emergencia (se requiere un caudal de agua

de 11 a 19 LPM [3 – 5 GPM]).

2. Deje que el agua corra a través del sistema hasta que alcance una temperatura constante. Si no obtiene la temperatura

necesaria, consulte el paso n.° 3 en la página anterior para volver a ajustar la temperatura.

3. Tan pronto como el agua alcance la temperatura apropiada, encienda la bomba de recirculación (antes de proceder, asegúrese

de que se haya alcanzado la temperatura adecuada en el sistema).

4. Revise la temperatura del agua en la bomba de retorno. Si la temperatura excede el nivel apropiado en 1 °C (2 °F), ajuste el

interruptor del límite superior de temperatura (esto apagará la bomba). Espere hasta que la temperatura del agua de retorno esté a

3 °C (5 °F) por debajo del nivel apropiado y ajuste el interruptor del límite inferior (esto volverá a encender la bomba).

5. Abra completamente la válvula de equilibrio.

6. Desconecte todos los accesorios y asegúrese de que no fluya agua por el sistema (el tubo de entrada de agua fría debe sentirse

tibio al tacto).

7. Deje que el sistema funcione sin agua durante 30 minutos o más. Si, después de treinta minutos, aumenta la temperatura del

agua, puede volver a ajustar la temperatura cerrando lentamente la válvula de equilibrio hasta que se alcance la temperatura

adecuada.

Bradley • 215-1291 Mod. R; ECN 14-09-026 7/23/2014 19

Page 20

S19-2000, S19-2000EFX Instalación

Solución de problemas de la válvula

mezcladora termostática

Antes de intentar solucionar problemas de la válvula

o desensamblar los componentes, revise lo siguiente:

• Que las válvulas de cierre o retención estén

completamente abiertas (el vástago ranurado

se extienda aproximadamente 13 mm (1/2 pulg.)

a partir de la tuerca del vástago) y que estén

abiertas todas las válvulas de retención de entrada

y salida

• Que los tubos de entrada de agua caliente y fría

estén conectados correctamente y que no existan

conexiones cruzadas ni válvulas de cierre o

retención con filtraciones.

• La salida del calentador de agua esté al menos a

11 °C (20 °F) por sobre la temperatura establecida.

Asegúrese de cerrar las válvulas de retención

correspondientes antes de desensamblar la válvula,

y vuelva a abrir las válvulas después de completar la

inspección y la reparación.

Tapa superior

y termostato

Fuelle del

termostato

Varilla de empuje

de 5/16"

La longitud de la varilla de

empuje se debiera extender

de 15/16" a 1-3/16" (24 a

30 mm) dentro del fuelle

Problema Causa Solución

Filtraciones

externas en el

sistema

No fluye agua

caliente (fluye

solamente agua

fría)

Flujo limitado de

agua

Fluctuación de

la temperatura

o temperatura

incorrecta

Es posible que se hayan dañado las juntas NPT o las

juntas tóricas.

Falló el termostato y, en consecuencia, se activó la

retención de seguridad.

Es posible que la entrada de la válvula de retención

esté parcialmente cerrada o haya disminuido

significativamente la presión de agua.

Se acumuló suciedad y desechos en la rejilla o asiento

de retención, limitando el movimiento de cierre y

retenciones.

Las secciones de cierre y retención de la válvula no se

mueven libremente.

El termostato lentamente comienza a fallar. Revise el termostato como se describe anteriormente o reemplácelo.

La tubería de suministro de entrada hacia la válvula

mezcladora se comparte con otras piezas del equipo

que se usan solamente en forma periódica, tales

como aparatos de lavandería o estaciones de flujo.

Esto puede reducir la presión de entrada hacia la

válvula mezcladora a menos de 3 PSI. Es posible

que el tamaño de la tubería de suministro no sea lo

suficientemente grande para dar suministro a la válvula

y a los otros aparatos.

La recirculación no está equilibrada. Revise la instalación de la recirculación en la página 19.

El pistón no se mueve libremente y se debe limpiar. Consulte la página siguiente para ver las instrucciones de desensamble

Remplace las juntas NPT o las juntas tóricas, donde sea necesario. Para

el reemplazo de las juntas tóricas, comuníquese con el representante

local de Bradley y consulte por el kit (S65-170) de sellos de juntas

tóricas.

Inspección del termostato:

1. Retire el termostato y la tapa superior.

2. Inserte una varilla de empuje de 5/16 pulg. de diá. en el fuelle del

termostato.

3. Marque la distancia en que la varilla de empuje se extiende dentro del

fuelle (a temperatura ambiente, con 45 N [10 lb] de fuerza, la distancia

debiera ser aproximadamente de 24 a 30 mm [15/16 pulg. a 1-3/16 pulg.]).

4. Si la longitud de la varilla de empuje no está en el rango apropiado,

se debe reemplazar el termostato (no se puede reparar). Comuníquese

con el representante local de Bradley y consulte por el Kit (S65-171) del

termostato.

Limpie las válvulas de cierre y retención:

Retire el cierre y las retenciones, limpie el asiento y vuelva a ensamblar

la válvula. No retire el asiento. Los componentes se pueden cepillar con

un cepillo de alambre de tamaño pequeño para eliminar los desechos.

Un par de pinzas funciona bien para sacar los desechos del asiento. Si

es necesario reemplazar el cierre y las retenciones, comuníquese con

el representante local de Bradley y consulte por el kit (S27-102: Bronce

áspero o S27-292A: Cromo) de retención/cierre.

Limpie las válvulas de cierre y retención como se describe anteriormente.

Aumente el tamaño de la tubería de suministro, vuelva a configurar la

tubería de suministro o regule el uso del suministro.

y limpieza.

20 7/23/2014 Bradley • 215-1291 Mod. R; ECN 14-09-026

Page 21

Instalación S19-2000, S19-2000EFX

Solución de problemas: Desensamble y limpieza del pistón

Retire la tapa superior y el conjunto del

termostato según se muestra en la Página

20. Ponga la varilla de empuje de 5/8 pulg.

A

a un costado.

Con una llave de cubo de 15/16 pulg.,

afloje el revestimiento del pistón del

cuerpo de la válvula y saque las piezas

B

con un alicate de punta de aguja.

Revestimiento

del pistón

Con una llave de cubo de 1/2 pulg.,

afloje el asiento superior del pistón del

revestimiento del pistón y saque las piezas

C

con un alicate de punta de aguja.

Desmonte y limpie las piezas del conjunto del

pistón con cualquier limpiador adecuado para

la limpieza de bronce y acero inoxidable (de ser

D

necesario, use una lija de grano 400 para pulir

y afinar tanto el pistón como el revestimiento).

Vuelva a ensamblar el conjunto del pistón. Empuje

el mecanismo hacia arriba y hacia abajo varias

veces para asegurarse de que el pistón se mueva

suave y constantemente. Si es constante, repita el

Procedimiento D hasta que se mueva libremente

E

o cámbielo. Comuníquese con el representante

local de Bradley y consulte por el Kit del pistón y

revestimientos (número de pieza S65-172).

Asiento superior del pistón

Pistón

Revestimiento

del pistón

Bradley • 215-1291 Mod. R; ECN 14-09-026 7/23/2014 21

Page 22

S19-2000, S19-2000EFX Instalación

Desglose de piezas

5

Codo de rosca macho y

hembra de 1/2"

Termómetro

T de bronce

de 1/2"

Niple de bronce

de 1/2" x 2"

12

4

3

2

Cuerpo de la

válvula

8

7

6

Tapón de tubo

de 1/2"

10

Codo de rosca macho

y hembra de 1/2"

11

9

19

15

14

Tope de

retención

17

18

16

13

Kit S65-171 del termostato

Artículo Cantidad Descripción

11 1 Termostato

12 1 Junta tórica

13 1 Junta tórica

Kit S65-172 del pistón y revestimientos

Artículo Cantidad Descripción

2 1 Junta tórica

3 1 Junta tórica

4 1 Revestimiento

5 1 Resorte

6 1 Pistón

7 1 Resorte

8 1 Tornillo de sobre-

calentamiento

9 1 Asiento superior

Kit S65-170 de juntas tóricas

Artículo Cantidad Descripción

2 1 Junta tórica

3 1 Junta tórica

12 1 Junta tórica

13 1 Junta tórica

Tope de

retención

Kit S65-303 de la sección central

Artículo Cantidad Descripción

2 1 Junta tórica

3 1 Junta tórica

4 1 Revestimiento

5 1 Resorte

6 1 Pistón

7 1 Resorte

8 1 Tornillo de sobre-

calentamiento

9 1 Asiento superior

10 1 Varilla de empuje

11 1 Termostato

12 1 Junta tórica

13 1 Junta tórica

14 1 Tapa de control

15 1 Tornillo de ajuste

16 1 Etiqueta

17 1 Tornillo de ajuste

18 4 Tornillo de 1/4

19 1 Tapa

Tuberías flexibles de conexión para el

modelo S19-2000EFX

Cuando se usa con el modelo S19-292,

el n.° de solicitud de pieza es 269-653

(se suministran 3 con la unidad).

Números de kit para acabado de bronce

áspero. Comuníquese con Bradley para

consultar por otras configuraciones.

A partir de noviembre de 2001, el pistón

(artículo 7) reemplaza al soporte del sello y al

sello como un repuesto directo.

A partir de junio de 2008, la tapa de control de

bronce (artículo 15) se reemplazó por una tapa

de plástico. Todos los componentes internos

son idénticos.

A partir de julio de 2012, se ha actualizado

el control de ajuste de temperatura (artículos

15, 17 y 19) y con compatibles con todas las

unidades que usen la tapa de control plástica

(junio de 2008 hasta la actualidad).

22 7/23/2014 Bradley • 215-1291 Mod. R; ECN 14-09-026

Loading...

Loading...