Bradford White RG140T*N, RG240T*N, RG230S*N, RG230T*N, RG240S*N Service Manual

...

Flammable Vapor Ignition Resistant

Water Heaters

SERVICE

MANUAL

Troubleshooting Guide

and Instructions for Service

(To be performed ONLY by

qualified service providers)

Manual 238-51542-00B REV 10/18

Models Covered

by This Manual:

RG130T*(N,X)

RG140T*(N,X)

RG150T(N,X)

LG250H65*(N,X)

RG230S*(N,X)

RG230T*(N,X)

RG240S*(N,X)

RG240T*(N,X)

RG250H*(N,X)

RG250L*(N,X)

RG250S*(N,X)

RG250T*(N,X)

(*) Denotes Warranty Years

Save this manual for future reference

Introduction 3 - - -

Troubleshooting Chart 4 - - -

Inner Door Gasket Removal, Inspection, and Replacement 9 RG-I

Thermocouple/Thermopile Testing and Replacement 12 RG-II

The Bradford White

®

Page Service Procedure

Pilot Assembly Inspection Cleaning and Replacement 15 RG-III

Piezo Igniter, Electrode Testing and Replacement 16 RG-IV

White Rodgers Gas Valve Testing and Replacement 17 RG-V

Honeywell Gas Control Testing, Disassembly, and Replacement 22 RG-VI

Burner Operation Inspection, Adjustment, Cleaning and Replacement 28 RG-VII

Resettable Thermal Switch Testing and Replacement 31 RG-VIII

ScreenLok

®

Flame Arrestor Cleaning

33 RG-IX

DipTube and Anode Inspection and Replacement 34 RG-X

Generic Parts List 36 - - -

2

2

INTRODUCTION

The Bradford White DEFENDER Safety System

®

The Bradford White DEFENDER Safety System®was designed to resist the ignition

of flammable vapors that can occur outside of the water heater. Use and installation

are nearly identical to previous versions of atmospherically fired and vented water

heaters. A number of exclusive design features are incorporated in the system that

will require additional knowledge on the part of the qualified service provider. The

following information will instruct service professionals on the function, proper

diagnosis and repair of water heaters employing the Bradford White DEFENDER

Safety System.

How the Safety System Works

During normal operation, air for combustion is drawn into the water heater through the

opening in the jacket. This air travels down and around the combustion chamber and

enters through holes in the very bottom of the corrosion-resistant combustion

chamber. The air then travels up through the oriented flame arrestor plate louvers,

where the velocity of the air is increased and its direction altered. The air then mixes

in a normal manner with the supplied gas and is efficiently combusted, producing very

low NOx emissions.

In the case where trace amounts of flammable vapors are present in the air flowing

into the combustion chamber, the vapors are harmlessly ignited by the burner / pilot

flame. If flammable vapors are in sufficient quantity to prevent normal combustion,

the burner/pilot flame is shut down.

Should the flammable vapors continue to the burner, the flame arrestor plate prevents

the flames from traveling backwards and igniting vapors outside of the combustion

chamber. The calibrated, multipurpose thermal switch recognizes this and shuts down

the pilot and main burner. This switch also deactivates the burner and pilot in the

unlikely event of restricted airflow caused by severe lint, dust or oil accumulation on

the arrestor plate.

3

3

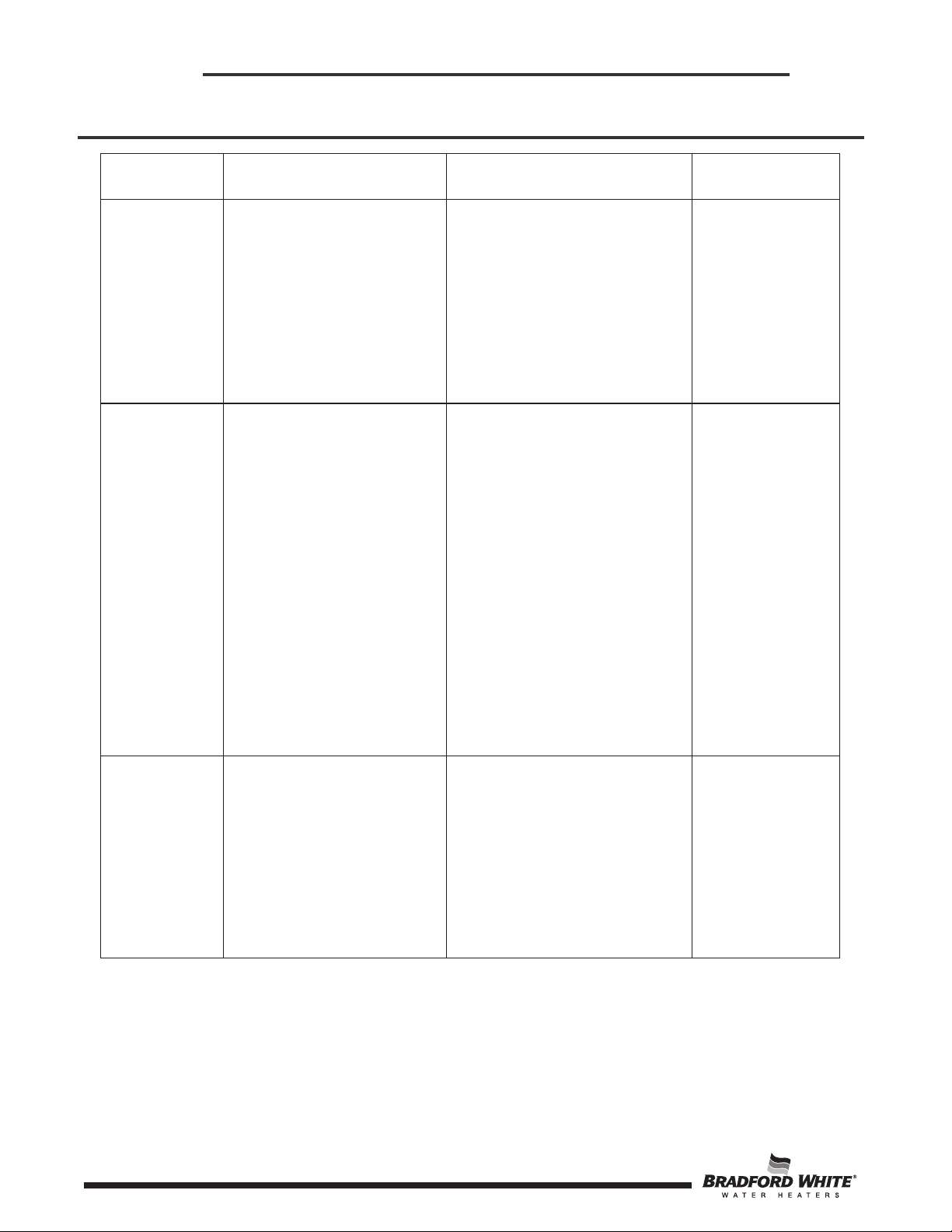

White Rodgers Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water Heaters

Symptom Probable Cause Corrective action

1.

Pilot will not light.

Pilot will not stay lit

when button is

released.

No incoming gas or too low

gas pressure.

2.

Gas control knob set to

wrong position.

3.

Pilot light button not being

fully depressed when

attempting to light pilot.

4.

Pilot orifice or pilot tube is

obstructed or kinked.

5.

Pilot electrode not sparking to

pilot.

6.

Piezo igniter not functioning.

1.

Poor thermocouple

connection at combination

thermostat/gas valve.

2.

Thermocouple not fully

engaged in pilot assembly

bracket.

3.

Pilot flame is not fully

enveloping the thermocouple

“hot” junction.

4.

Weak or defective

thermocouple.

5.

Open ECO on

combination thermostat/

gas valve.

6.

Defective magnet in

combination thermostat/gas

valve.

7.

Resettable thermal switch

has opened.

1.

Turn on gas supply and/or check

line pressure.

2.

Review lighting instruction. Set

combination/thermostat gas valve

to correct position.

3.

Review lighting instruction. Fully

depress pilot lighting button.

4.

Clean, repair or replace.

5.

Verify correct electrode position.

Replace pilot assembly.

6.

Replace piezo igniter.

1.

Check connection at combination

thermostat/gas valve. Proper

tightness should be finger tight

plus ¼ turn.

2.

Inspect thermocouple to ensure

that it is fully engaged into pilot

bracket.

3.

Adjust tip of thermocouple to be

fully engulfed by pilot flame.

4.

Check thermocouple and replace

if necessary.

5.

Check ECO continuity and replace

combination thermostat/gas valve

if necessary.

6.

Check magnet operation and

replace combination

thermostat/gas valve if necessary.

7.

Determine cause of switch

activation. To reset, depress

button on resettable thermal

Service

Procedure

1.

See Service

Procedure RG-V,

Page 12.

2.

See Service

Procedure RG-III,

Page 10.

3.

See Service

Procedure RG-III,

Page 10.

4.

See Service

Procedure RG-IV,

Page 11.

1.

See Service

Procedure RG-II,

Page 8.

2.

See Service

Procedure RG-V,

Page 14.

3.

See Service

Procedure RG-V,

Page 13.

switch located on inner door.

1.

Adjust temperature dial on

combination thermostat/gas

valve.

2.

Check temperature dial

setting on combination

thermostat/gas valve.

3.

Check gas supply and line

pressure.

4.

Check combination

thermostat/gas valve for

proper operation, replace if

necessary.

1.

See installation

and operation

manual.

2.

See Service

Procedure RG-V,

Page 12.

3.

See Service

Procedure RG-V,

Page 12.

Pilot will light but

the main burner

will not come on.

1.

Combination thermostat/gas

valve set too low for desired

water temperature.

2.

Combination

thermostat/gas valve

temperature is satisfied.

3.

Insufficient gas supply or

low gas pressure.

4.

Combination thermostat/gas

valve has wide differential or

is out of calibration.

4

4

White Rodgers Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water Heaters

Symptom Probable Cause Corrective action

Pilot goes out

periodically (after

heating cycles,

once a day, once

a week etc.)

Not enough hot

water.

1.

Insufficient combustion air

supply.

2.

Incorrect, clogged vent

system/vent terminal or

location.

3.

Inconsistent gas supply or

gas pressure.

4.

Combination thermostat/gas

valve set too low for desired

water temperature.

5.

Cold inlet water temperature

is very cold.

6.

High demand periods.

7.

Incorrectly sized water

heater for application.

8.

Combination thermostat/gas

valve is out of calibration/not

functioning.

9.

Out of spec dip tube is

diluting hot water with cold

water.

1.

Verify adequate combustion air

is available to the unit. Check

and clear Jacket slot openings of

any dirt, dust, restrictions or

other obstructions. Inspect flame

arrestor plate and clean with stiff

bristled brush and/or vacuum to

remove any debris accumulation.

2.

Check venting for proper sizing

and proper operation

3.

Check gas supply and line

pressure.

1.

Check dial on combination

thermostat/gas valve.

2.

Extremely cold water going into

the heater will decrease the

amount of hot water produced. It

may be necessary to temper

incoming water supply.

3.

Adjust high demand usage.

4.

Contact Plumbing professional.

5.

Check combination

thermostat/gas valve for proper

operation, replace if necessary.

6.

Inspect dip tube and replace if

necessary.

Service

Procedure

1.

See Service

Procedure RGVIII, Page 22.

2.

See Service

Procedure RG-V,

Page 14.

1.

See Service

Procedure RG-V,

Page 12.

2.

See Service

Procedure RG-IX,

Page 23.

5

5

g

g

V

Observe green LED indicator on Gas Control.

Status flash codes are displayed with a three

second pause before repeating. Check and repair

the system as noted in the troubleshooting table

below.

Honeywell V1 Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water Heaters

LED Status Control Status Probable Cause Service Procedure

If the pilot will not stay lit

None (LED not

on or flashing)

Pilot assembly is not lit

Gas control is not

powered. Light Pilot.

replace pilot assembly. If

problem persists replace

as control.

1.

One flash and

three second

pause

LED on

continuously

(solid)

If setpoint knob is in “PILOT”

position then pilot flame is

detected. Turn setpoint knob

to desired setting.

2.

If the setpoint knob is

already at the desired

setting, the water heater is

satisfied.

Setpoint knob has been recently

turned to the “OFF” position. Wait

until LED goes out before

attemptin

to relight.

1.

Gas control is

powered and waiting

for setpoint knob to

be turned to a water

temperature setting.

2.

Water heater is

satisfied and

operating normally.

Setpoint knob was

turned to “OFF”

position.

Normal operation.

LED will not go out and the

control will function

normally the is lit.

Two flashes

and three

second pause

Three flashes

and three

second pause

6

Weak pilot signal detected.

System will reset when pilot

flame is sufficient.

Insufficient water heating.

System will reset.

1.

Thermopile failure.

2.

Unstable pilot.

3.

Pilot tube block or

restricted.

1.

Thermal sensor out

of calibration.

2.

Faulty gas control.

1.

See service procedure IV

2.

See service procedure II

3.

See service procedure II

Replace gas control.

6

g

y

Observe green LED indicator on Gas Control.

Status flash codes are displayed with a three

second pause before repeating. Check and repair

Honeywell V1 Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water Heaters

the system as noted in the troubleshooting table

below.

LED Status Control Status Probable Cause Service Procedure

Four flashes

three second

pause

Five flashes

and three

second pause

Six flashes

and three

second pause

Seven flashes

and three

second pause

Eight flashes

and three

second pause

Excessive tank temperature.

System must be reset.

Temperature sensor fault.

Water leak detected by

accessory module

Gas control electronic fault

detected.

Standing pilot remains on while

setpoint knob is in “OFF”

position.

1.

Temperature sensor

out of calibration.

2.

Faulty gas control.

1.

Damage to the

temperature sensor.

2.

Temperature sensor

resistance out of

ran

e.

Excessive amount of

water in drain pan/water

dam.

1.

Control needs to be

reset.

2.

Control is wet or

ph

sically damaged.

Pilot valve stuck in

open position.

Replace gas control

Replace gas control

1. Check T&P valve.

2. Check all water fittings.

3. Pressurize and leak test

tank.

1. Reset gas control

2. Replace gas control.

Replace gas control

7

7

Honeywell V2 Gas Control Troubleshooting Chart

Flammable Vapor Ignition Resistant Water Heaters

Observe colored LED indicator on Gas Control.

Status flash codes are displayed with a three

second pause before repeating. Check and repair

the system as noted in the troubleshooting table

below.

LED Status Control Status Probable Cause Service Procedure

If the pilot will not stay lit

replace pilot assembly. If

problem persists, replace

gas control.

Normal operation.

Normal operation.

1. See service procedure

IV.

2. See service procedure II.

3. See service procedure II.

None (LED not on

or flashing)

One flash every

four seconds

(LED green)

One flash every

second

(LED green)

Two flashes

(LED yellow)

Millivolt power is not

present. Light pilot.

Not an error. Indicates

pilot is lit and main

burner is off.

Not an error. Indicates

main valve is open and

main burner is lit.

Low thermopile voltage;

main valve not turned

ON.

Gas valve is functioning normally.

Gas valve is not powered. Light

pilot.

You can now turn the know to a

desired setpoint temperature

None. Control will automatically

shut main burner off when water

temperature reaches the setpoint

temperature.

Check thermopile and its

connections. Check pilot flame.

Check the valves and the water

temperature sensor. Reduce the

Four flashes

(LED red)

Temperature cut-out

limit reached.

water temperature setpoint.

Thoroughly check

out main valve operation and water

Replace gas control

temperature control before walking

away.

Check water temperature sensor

Five flashes

(LED red)

Water temperature

sensor failure.

and its connection for open

circuits, shorts, or differences in

resistance between the two sensor

Replace gas control

elements.

1. Check T&P valve.

Six flashes

(LED red)

Solid ON

(LED red)

8

Tank leakage detected

by accessory module.

Not an error-indicates

that the control is in

OFF mode.

Control recovers after receiving

message from accessory module.

None; wait until LED turns off if

you want to restart system.

2. Check all water fittings.

3. Pressurize and leak test

tank.

LED will go out and the

control will function normally

the pilot is lit.

8

Inner Door Removal Procedure

)

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal,

Inspection, and Replacement

Step 1.

Rotate knob of the combination

thermostat/gas valve to the “OFF” position.

Step 2.

Step 3.

Remove outer jacket burner access door.

Inner Door Removal.

a) Disconnect resettable thermal switch wire leads

(leading from gas control/gas valve).

b) Remove (2) hex drive screws from right side inner door.

c) Remove (2) hex drive screws from flange section of inner door.

d) Remove (2) hex drive screws from left side inner door.

e

Remove inner door and inspect per step 4.

Step 4. Fully inspect inner door gaskets for the following:

>Tears

>Missing material

>Cracks

>Other imperfections that will inhibit proper seal

>Gasket adhesion to inner door

>Material left on combustion chamber (around opening)

>Dirt or debris

If the gasket is not affected by any of the above, gasket replacement is not required. If replacement

is required, proceed to Inner Door Gasket Replacement Procedure.

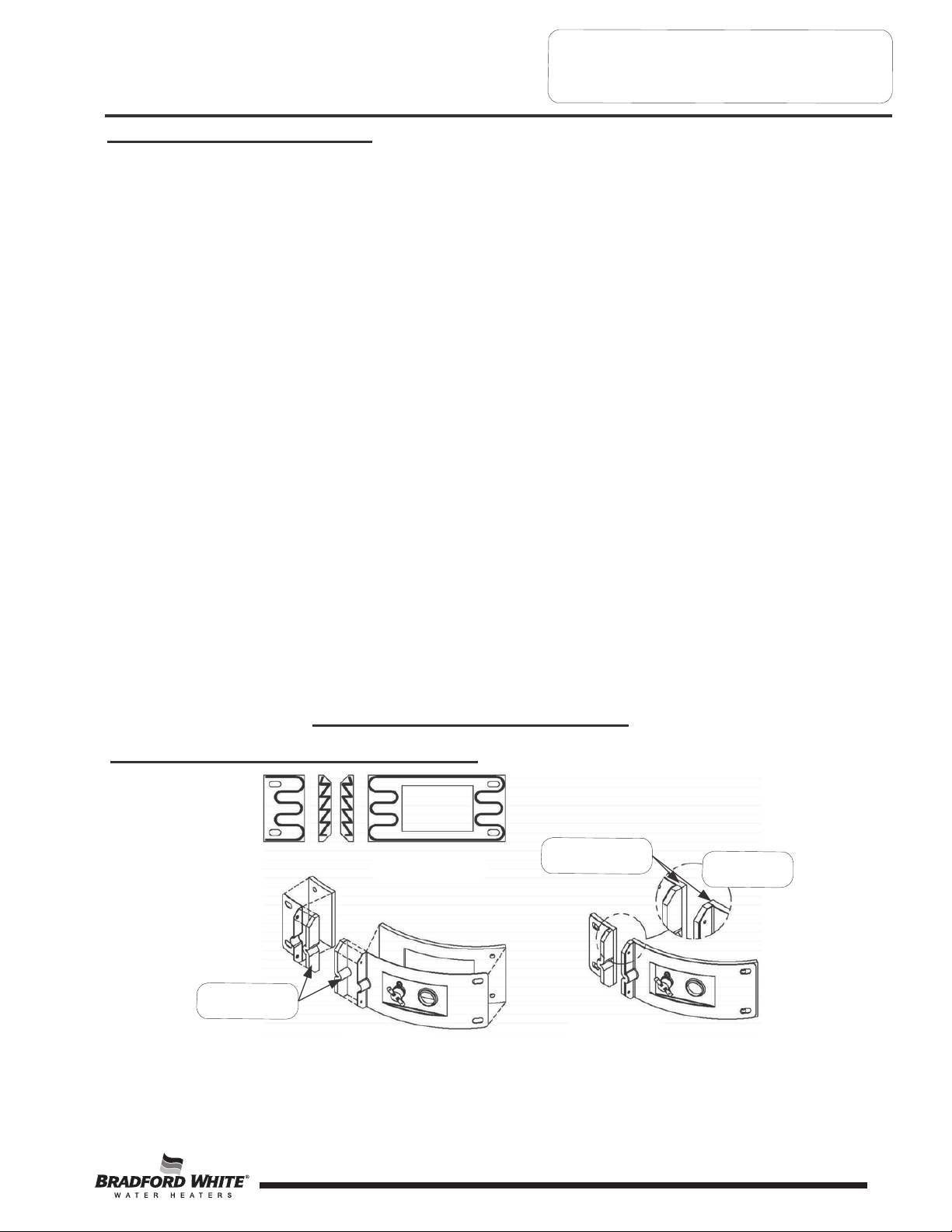

Inner Door Gasket Replacement Procedure

RECOMMENDED

PATTERN FOR RTV

SEALANT

PLACE FLANGE

SECTIONS FIRST

EXPANDED

VIEW

GASKET OVERLAP

MUST BE AS

SHOWN ±1/32"

VIEW WITH

GASKETS IN

PLACE

ENLARGED

VIEW OF

FLANGE AREA

9

9

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal,

Inspection, and Replacement

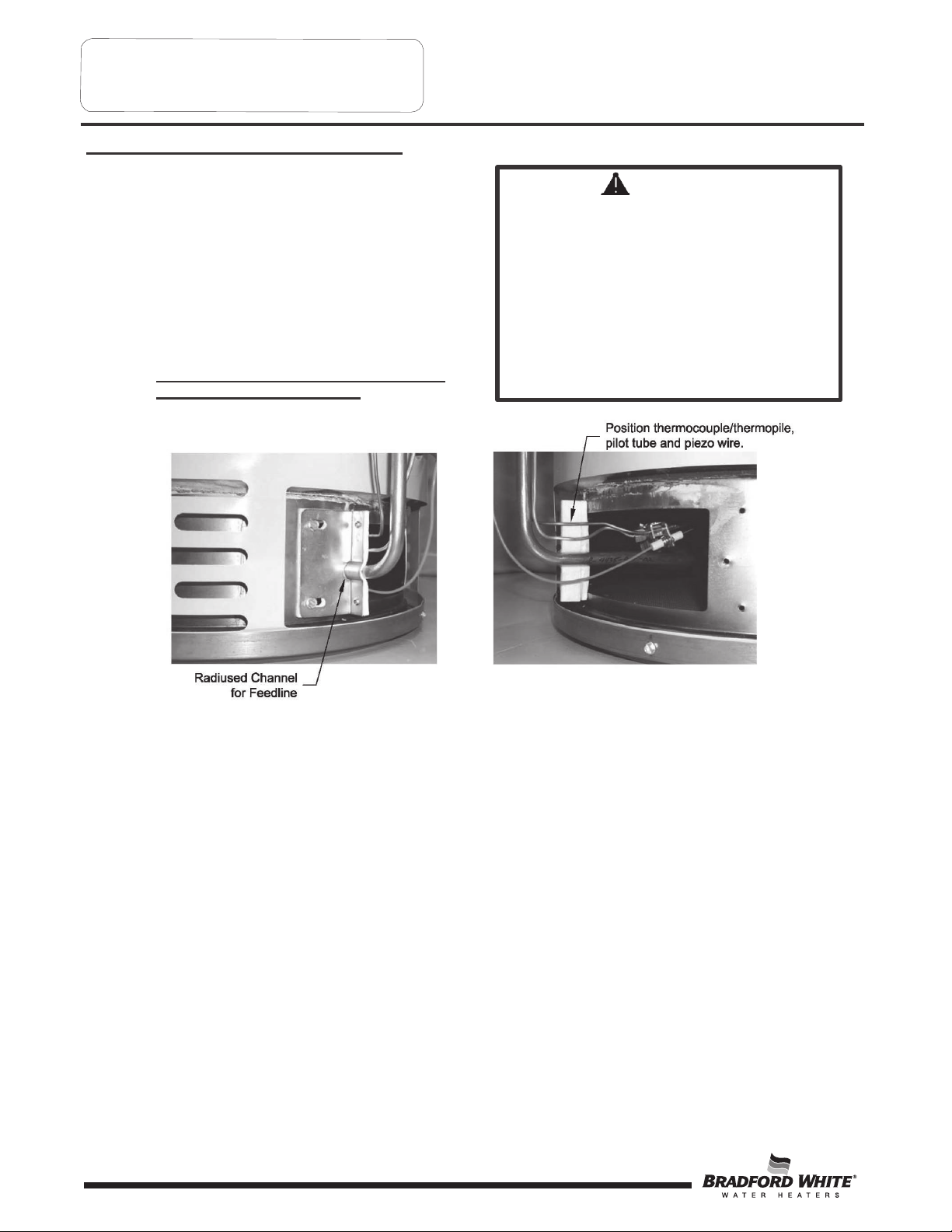

Installation of Inner Door with Gasket

Step 5.

Step 6.

Step 7.

Clean any residual gasket residue or other

debris from combustion chamber surface

before installing the inner door/gasket

assembly.

Place the left side inner door into position

first. Firmly position the radiused channel of

the inner door around the feedline. Using the

(2) hex drive screws from step 3d, secure left

side inner door in place

DO NOT OVER TIGHTEN SCREWS.

Position thermocouple, pilot tube and Piezo

wire against left side inner door flange gasket.

DO NOT ROUTE THROUGH RADIUSED

CHANNEL WITH FEEDLINE.

WARNING

Stripped fastener connections may allow

for seal breach of inner door. A seal

breach may result in a fire or explosion

causing property damage, personal injury

or death. Do not over tighten screws in

steps 8, 10 and 11.

If a fastener connection is stripped,

contact the manufacturer listed on the

water heater rating plate.

10

10

SERVICE PROCEDURE RG-I

Inner Door/Gasket Removal, Inspection

Replacement and Reinstallation

Step 8.

Step 9.

Firmly place right side inner door flange against the left side inner door flange and secure with (2)

hex drive screws from step 3c. DO NOT OVER TIGHTEN SCREWS.

Align right side inner door to combustion chamber and verify the fastener holes of the combustion

chamber are aligned with the right side inner door slotted opening. Verify seal integrity around

combustion opening. Secure right side inner door using (2) hex drive screws from step 3b.

DO NOT OVER TIGHTEN SCREWS. Verify both left and right sides of the inner door are properly

positioned and sealed against the combustion chamber.

Step 10.

Step 11.

Step 12.

Reconnect lead wires from combination thermostat/gas valve to resettable thermal switch (See

photo in step 3). Note, wire terminations are interchangeable with either resettable thermal switch

connections.

Replace outer jacket burner access door.

To resume operation, follow the instructions located on th e lighting instruction label or the lighting

instructions located in the installation and operation manual.

11

11

SERVICE PROCEDURE RG-II

Thermocouple/Thermopile Testing and

Replacement

CLOSED CIRCUIT THERMOCOUPLE TESTING (White Rodgers Control)

Step 1.

Closed circuit testing is the preferred method for testing thermocouple. Following the lighting

instruction label on the heater, proceed to light the pilot and allow to operate for three minutes. If

the pilot will not stay lit, hold the pilot button (located on the combination thermostat/gas valve)

down during this test.

Step 2.

Using a multimeter capable of measuring millivolts, connect one lead

using an alligator clip to the copper sheath of the thermocouple, use the second lead of the

multimeter to probe the top terminal located at the back of the combination thermostat/gas valve.

Step 3.

If meter reads 10 mv or higher, the thermocouple is OK. If reading is below 10 mv,

replace the thermocouple.

12

12

Loading...

Loading...