Bradford White RE2H50S*-1NCWT Series, RE2H80T*-1NCWT Series Quick Manual

Quick Guide

RE

2H50S*-1NCWT

RE2H80T*-1NCWT

Heat Pump Water Heater

WATER HEATER SAFETY INFORMATION

This is the safety alert symbol. This symbol alerts you to potential hazards that can kill or hurt you and others. All safety

messages will follow the safety alert symbol and the word “DANGER”, “WARNING”, or “CAUTION”. These words are defined as:

DANGER

Indicates a hazardous situation which, if not avoided, will result in death or serious injury.

WARNING

Indicates a hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION

Indicates a hazardous situation which, if not avoided, could result in minor or moderate injury.

IMPORTANT SAFETY INSTRUCTIONS

When using electrical appliances basic safety precautions should be followed, including the following:

WARNING

Risk of Fire - DO NOT store or use gasoline or other flammable vapors and liquids in the vicinity of this or any other appliance.

Keep rags and other combustibles away.

If the water heater has been subjected to flood, fire, or physical damage, turn off power and water to the water heater.

Do not operate the water heater again until it has been thoroughly checked by qualified service personnel.

READ ALL INSTRUCTIONS BEFORE USING.

Safety Precautions

A. Do turn off power to water heater if it has been subjected to overheating, fire, flood or physical damage.

B. Do Not turn on water heater unless it is filled with water.

C. Do Not turn on water heater if cold water supply shut-off valve is closed.

NOTE: Flammable vapors may be drawn by air currents from surrounding areas to the water heater.

D. If there is any difficulty in understanding or following the Operating Instructions or the Care and Cleaning section, it is recommended

that a qualified person or serviceman perform the work.

CAUTION

Risk of Fire - Hydrogen gas can be produced in a hot water system served by this water heater that has not been used for a long

period of time (generally two weeks or more). HYDROGEN GAS IS EXTREMELY FLAMMABLE!! To dissipate such gas and to reduce risk

of injury, it is recommended that the hot water faucet be opened for several minutes at the kitchen sink before using any electrical

appliance connected to the hot water system. If hydrogen is present, there will be an unusual sound such as air escaping through the

pipe as the water begins to flow. Do not smoke or use an open flame near the faucet at the time it is open.

SAVE THESE INSTRUCTIONS

238-52324-00 02/18

IMPORTANT SAFETY INSTRUCTIONS.

!

READ ALL INSTRUCTIONS BEFORE USING.

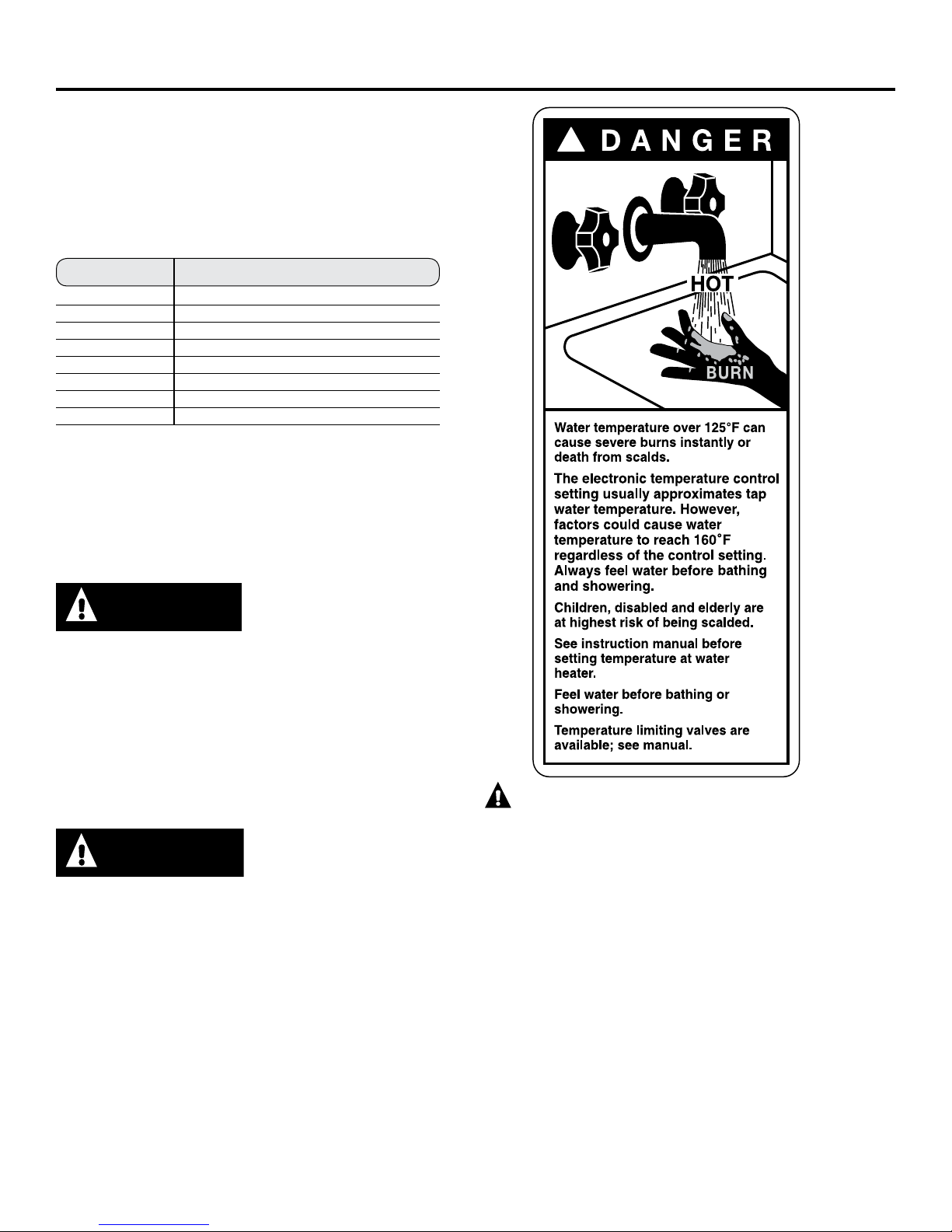

WATER TEMPERATURE ADJUSTMENT

Safety and energy conservation are factors to be considered

when selecting the water temperature setting via the water

heater’s user interface. Water temperatures above 125°F can

cause severe burns or death from scalding. Be sure to read and

follow the warnings outlined on the label pictured below. This

label is also located on the water heater near the top of the tank.

Time/Temperature Relationship in Scalds

Temperature Time to Produce a Serious Burn

120°F (49°C) More than 5 minutes

125°F (52°C) 1-1/2 to 2 minutes

130°F (54°C) About 30 seconds

135°F (57°C) About 10 seconds

140°F (60°C) Less than 5 seconds

145°F (63°C) Less than 3 seconds

150°F (66°C) About 1-1/2 seconds

155°F (68°C) About 1 second

Table courtesy of Shriners Burn Institute

The chart shown above may be used as a guide in determining

the proper water temperature for your home.

Thermostat has been set at the factory to 120°F (49°C) to reduce

the risk of scald injury.

NOTE: Households with small children, disabled or elderly

persons may require a 120°F (49°C) or lower thermostat setting

to prevent contact with “HOT” water.

DANGER

There is a Hot Water SCALD

Potential if the control water

temperature is set too high.

Safety Controls

The water heater is equipped with a temperature-limiting control

(TCO) that is located above the heating element in contact with

the tank surface. If for any reason the water temperature becomes

excessively high, the temperature-limiting control (TCO) breaks

the power circuit to the heating element. Once the control opens,

it must be reset manually. Resetting of the temperature limiting

controls should be done by a qualified service technician.

CAUTION

condition must be investigated by a qualified service technician

and corrective action must be taken before placing the water

heater in service again.To reset the temperature-limiting

control:

1. Turn off the power to the water heater.

2. Remove the jacket access panel(s) and insulation.

The thermostat protective cover should not be removed.

3. Press the red RESET button.

4. Replace the insulation and jacket access panel(s) before

turning on the power to the water heater.

The cause of the high temperature

FOR INSTALLATIONS

IN THE STATE OF CALIFORNIA

California Law requires that residential water heaters must

be braced, anchored or strapped to resist falling or horizontal

displacement due to earthquake motions. For residential

water heaters up to 52 gallon (236.4 L) capacity, a brochure

with generic earthquake bracing instructions can be obtained

from: Office of the State Architect, 400 P Street, Sacramento,

CA 95814 or you may call 916.324.5315 or ask a water heater

dealer.

Applicable local codes shall always govern installation. For

residential water heaters of a capacity greater than 52

gallons (236.4 L) consult the local building jurisdiction for

acceptable bracing procedures.

California Proposition 65 Warning: This product contains

chemicals known to the State of California to cause cancer,

birth defects or other reproductive harm.

SAVE THESE INSTRUCTIONS

2

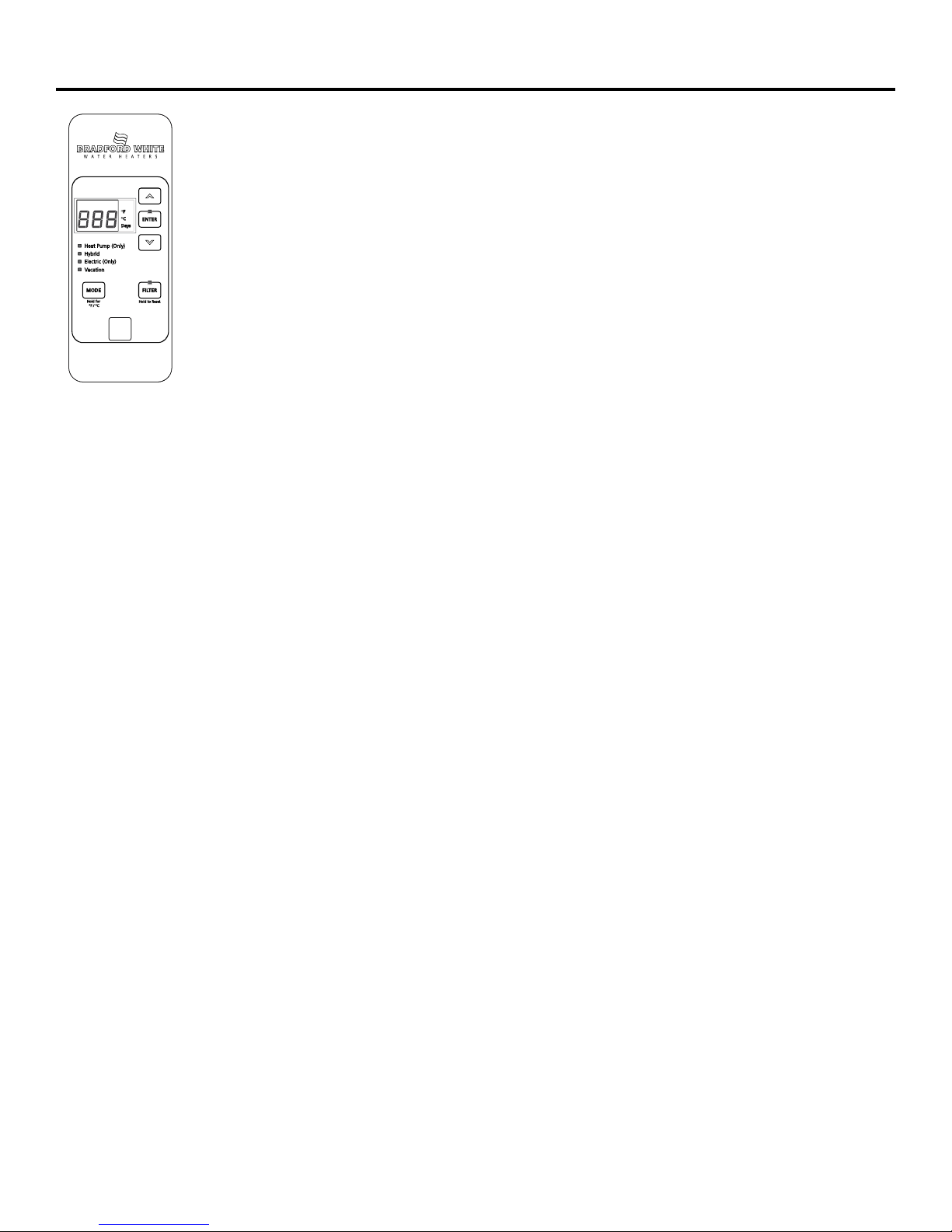

About the control panel.

This water heater defaults to the Hybrid

operating mode. Available modes are listed

below and can be selected using the MODE

button.

Heat Pump (Only) Mode—RECOMMENDED

FOR MAXIMUM SAVINGS

Heat Pump is the most energy-efficient mode

for this water heater. It takes heat from the

surrounding air to heat the water. The time

it takes to heat the water is longer in this

mode, so it may not be sufficient if you have

a high-demand situation such as a large

household or company.

Hybrid Mode

Hybrid mode combines the energy

efficiency of Heat Pump (Only) with the recovery speed

and power of the Electric (Only) mode in most water usage

situations. Hybrid mode will allow the unit to perform like

a standard electric water heater while providing significant

energy savings.

Cold Climate Eciency setting (CCE)

For installations where ambient conditions may be considered

cold, an available Cold Climate Eciency (CCE) setting can be

activated in the control to achieve additional energy savings

in Hybrid mode.

In some regions, rebates may be available which require

this setting to be used to qualify [e.g. compliance with NEEA

Northern Climate specication Tier 3 requirements]. Check

with your local utility for available rebates and requirements.

The CCE setting is activated by pressing and holding the

DOWN arrow and the Filter button at the same time for 5

seconds. “CCE” will display temporarily when CCE settings

have been activated [“dUC” may display on some models]. To

deactivate the CCE setting, press and hold the same buttons

[DOWN arrow & Filter button] at the same time for 5 seconds.

“Std” will display temporarily when CCE settings have been

deactivated and the water heater has returned to normal

operation of the selected mode.

A ducting kit is also available for use with your heat pump

water heater if desired. [see www.BradfordWhite.com for

details].

Ducting kits may be installed to achieve directed ow of

inlet and outlet air for heat pump operation independent of

whether the CCE setting is activated. Ducting kits may also

be installed to allow water heater installation in rooms less

than 700cu.ft. or without louvered doors, as specied in the

installation instructions.

NOTE: Energy Guide unit performance, energy consumption

and savings are based on non-ducted installations in Hybrid

mode operation at a temperature setting of

135°F (57°C).

Electric (Only) Mode

This mode uses only the upper and lower heating resistance

elements to heat the water, stopping the cool air discharge

during heat pump operation. The time it takes to heat the

water is less in this mode, but it is the LEAST energy-ecient

mode.

Follow these steps to set Electric (Only) mode:

1. Select Electric (Only) mode using the Mode button.

2. Input the total days to remain in Electric (Only) mode using

the UP arrow, or remain in Electric (Only) mode indenitely

by selecting “---”.

3. Press ENTER

At the end of the selected time period, the unit will switch

back to the previously selected more energy-ecient mode.

NOTE: In this mode the green LED light will ash after 48

hours as an indication that the unti is not operating in the

most energy ecient mode. The unit will continue to operate

in this mode and does not indicate an operating issue.

NOTE: With the CCE setting active, Electric (Only) mode can

be set for 1-7 days.

Vacation

This feature is used when you will be away from the home for an

extended period of time and hot water is not needed. In this mode,

the unit will drop the water temperature down to 50ºF (10°C) and

will use the most efficient heating mode to conserve energy while

the heater is sitting idle. The unit will automatically resume heating

one day before your return, so that hot water will be available.

For example if you will be gone 14 days, follow these steps:

1. Select VACATION by using the Mode button

2. Input total days you will be gone (in this example, 14) by pressing

the UP arrow button (the default is 7 days)

3. Press ENTER.

The unit will drop the water temperature down to 50ºF (10°C) for

one day less than you will be gone (in this example, for 13 days). At

the end of the day before you return (in this example, the 13th day),

it will automatically return to the previous operating mode and

heat the water to the original temperature setting so hot water is

available upon your return.

To access any of these modes:

1. Press the MODE button on the control to the desired operating

mode.

2. The green light will be illuminated on the chosen mode.

To Adjust the Temperature

Follow these steps:

1. Press the UP or DOWN arrow on the control panel key pad to

desired temperature.

2. Press ENTER to accept the new setting.

Note: To change between °F and °C, press and hold MODE.

In winter months, the water heater will take longer to heat

incoming water to a preset point due to the colder temperature of

the incoming water.

3

Care and cleaning.

DRAINING THE WATER HEATER

2. Turn o the cold water supply.

CAUTION: Risk of Shock - Shut off power to

the water heater before draining water.

DANGER: Risk of Scald - Before manually

operating the relief valve, make certain no one will be exposed

to the hot water released by the valve. The water drained from

the tank may be hot enough to present a scald hazard and

should be directed to a suitable drain to prevent injury or

damage.

To drain the water heater, follow these steps:

1. Attach a garden hose to the drain valve located at the

bottom of the unit and direct that hose to a drain.

EXTENDED SHUTDOWN PERIODS OR VACATIONS EXCEEDING VACATION MODE OPTIONS

If the water heater is to remain idle for an extended period of

time, the power and water to the appliance should be turned

off and the water heater drained to conserve energy and

prevent a buildup of dangerous hydrogen gas. This unit has

no power button, power can only be shut off at the circuit

breaker or disconnect switch.

If the water heater has an anode depletion sensing feature

(some models) and the water heater cannot be drained, it is

recommended to leave the power turned on with the water

heater in vacation mode to ensure that the feature will

continue to operate properly while still conserving energy.

3. Admit air to the tank by opening a hot water faucet or

lifting the handle on the relief valve

4. Open the drain valve with a at screwdriver.

Note: See page 15 for product schematic.

Use a flat slot

screwdriver to

turn valve.

The water heater and piping should be drained if they might

be subjected to freezing temperatures.

After a long shutdown period, the water heater’s operation

and controls should be checked by qualified service

personnel. Make certain the water heater is completely filled

again before placing it in operation.

NOTE: Refer to the Hydrogen Gas Caution in the Operating

Instructions (see page 3).

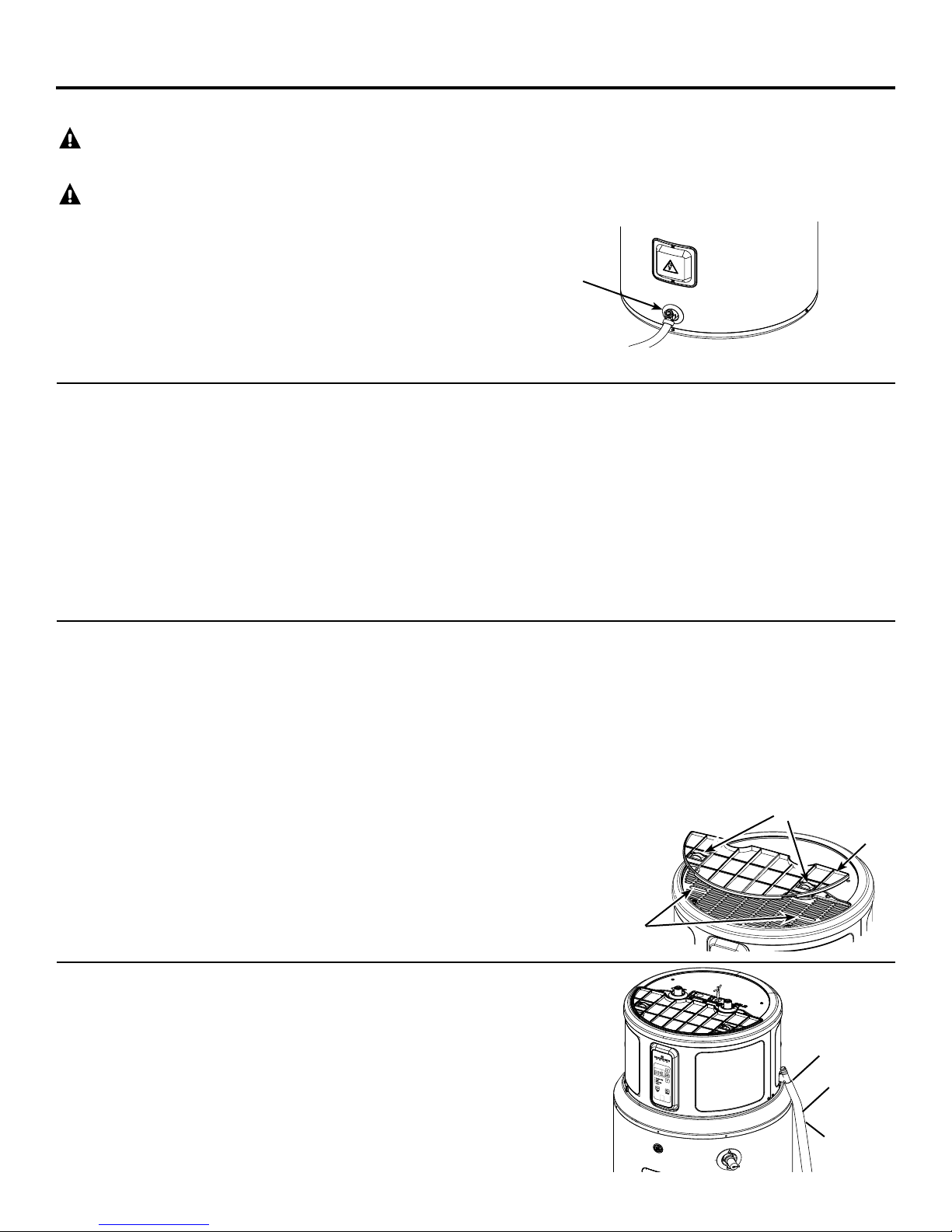

CLEANING THE FILTER

In the Hybrid, Heat Pump and High Demand/Boost modes, the heater

moves air through the system and out the back of the unit. The filter

is in place to protect the evaporator from dirt and dust.

A clean air filter is important to get the highest efficiency. Occasionally this filter will need to be cleaned (minimum once per year). When

the filter requires cleaning, the Red light above the Filter button will be

illuminated and an audible beep will sound.

NOTE: If the filter gets too dirty, the unit will automatically switch to

Electric/Standard mode and energy savings will be lost.

Leave the power on. Remove the filter from

the top of the unit. Squeeze two tabs and lift to remove the air filter.

Once it has been removed, the filter can be vacuumed or wiped clean

with a damp cloth or rinsed with warm water.

Once the filter has been cleaned and dried, it can be replaced by

aligning it into the slots in the top of the unit and pushing it down into

place.

CLEARING THE CONDENSATION DRAIN TUBE

The main drain is intended to carry all condensate away. If it is

clogged, the heat pump will stop operating, the display will show

F20, and an alarm will sound. Press any button to silence the

alarm, then clear the condensate drain by removing any drain

lines and connections, and clearing debris. Reattach drain lines

and connections, then allow the water heater to run.

Periodically inspect the drain lines and clear any debris that may

have collected in the lines.

After the clean filter has been reinstalled, press and hold the FILTER

button. If a heating cycle is on when the filter fault is reset, it will continue in electric mode to finish the cycle. After that, it will automatically revert to the mode it was in prior to being switched.

IMPORTANT: Filter must be cleaned when the alarm is displayed. A

dirty filter will make the system work harder and result in a reduction

of efficiency and possible damage to the system. In order to get the

best energy efficiency available, make sure your filter is clean.

Tabs

Filter

Slots

See Installation

Instructions for

more information.

Overow

Main drain line

Direct the

main drain

tube into a

drain

4

Anode Rod Maintenance and Service.

ANODE ROD

The anode rod should be removed from the water heater’s tank and

inspected once every 3 years service, and replaced when more than

6” (15.2 cm) of core wire is exposed at either end of the rod. For more

information contact us at www.bradfordwhite.com.

NOTE: Artificially softened water requires that the anode rod be

inspected annually.

Due to shock hazard and to prevent accidental water leaks, this

inspection should be done by a qualified servicer or plumber, and

requires that the electric power and cold water supply be turned off

before servicing the anode rod.

NOTICE: Do not remove the anode rod from the water heater’s tank

except for inspection and/or replacement, as operation with the

anode rod removed will shorten the life of the glass-lined tank and

will void warranty coverage.

The anode rod consumption and replacement are not covered by

warranty.

Some areas have water conditions that may cause an odor to

develop in the water heater. Aluminum-Zinc alloy replacement rods

are available to address the condition.

Additional information for products with an anode depletion

sensing feature:

When the system indicates that the anode depletion sensing anode

rod is approaching end of life, it is recommended to replace it. To

silence the alarm, press the Anode button once. Call Bradford White

Tech Service to order or to replace the anode depletion sensing

anode rod. After replacing, reset the Anode alarm by pressing and

holding the Anode button for 10 seconds until the control beeps and

the LED above the button turns off.

If an Aluminum-Zinc anode rod is installed to address a water odor

condition, the anode depletion sensing feature must be disabled.

Upon power-up after installing an Aluminum-Zinc anode rod, the

control will sound an alarm. To quiet the alarm and disable the

feature, first press the Anode button once to silence the alarm, then

press the Anode button 3 times. The control will beep and a message

will scroll on the display confirming that the feature has been

disabled. Annual inspections of the anode rod are recommended

since the water heater will no longer be capable of alerting for a

depleted anode rod. To enable the feature if an anode depletion

sensing anode rod is installed, press the Anode button 3 times. The

control will beep and a message will scroll on the display confirming

that the feature has been enabled.

NOTE: If the water heater has been installed with a device that

periodically cuts power to the water heater, the accuracy of the

anode rod depletion sensing feature may become compromised and

anode rod inspection every 2-3 years is recommended.

If the water heater will be inactive for a long period of time and the

water heater cannot be drained, it is recommended to leave the

power turned on with the water heater in vacation mode to ensure

that the feature will continue to operate properly while still conserving

energy.

NOTE: Refer to the Hydrogen Gas Caution in the Operating

Instructions (see page 1).

Tools needed:

• T20 Torx Screwdriver • Socket Extention 12” long

• Slot Screwdriver • 1-1/16” Socket

• Tape • Socket Wrench

• Softset Sealant • Anode Rod, if needed

To service the Anode Rod:

1. Disconnect power, shut off the water supply, and partially drain

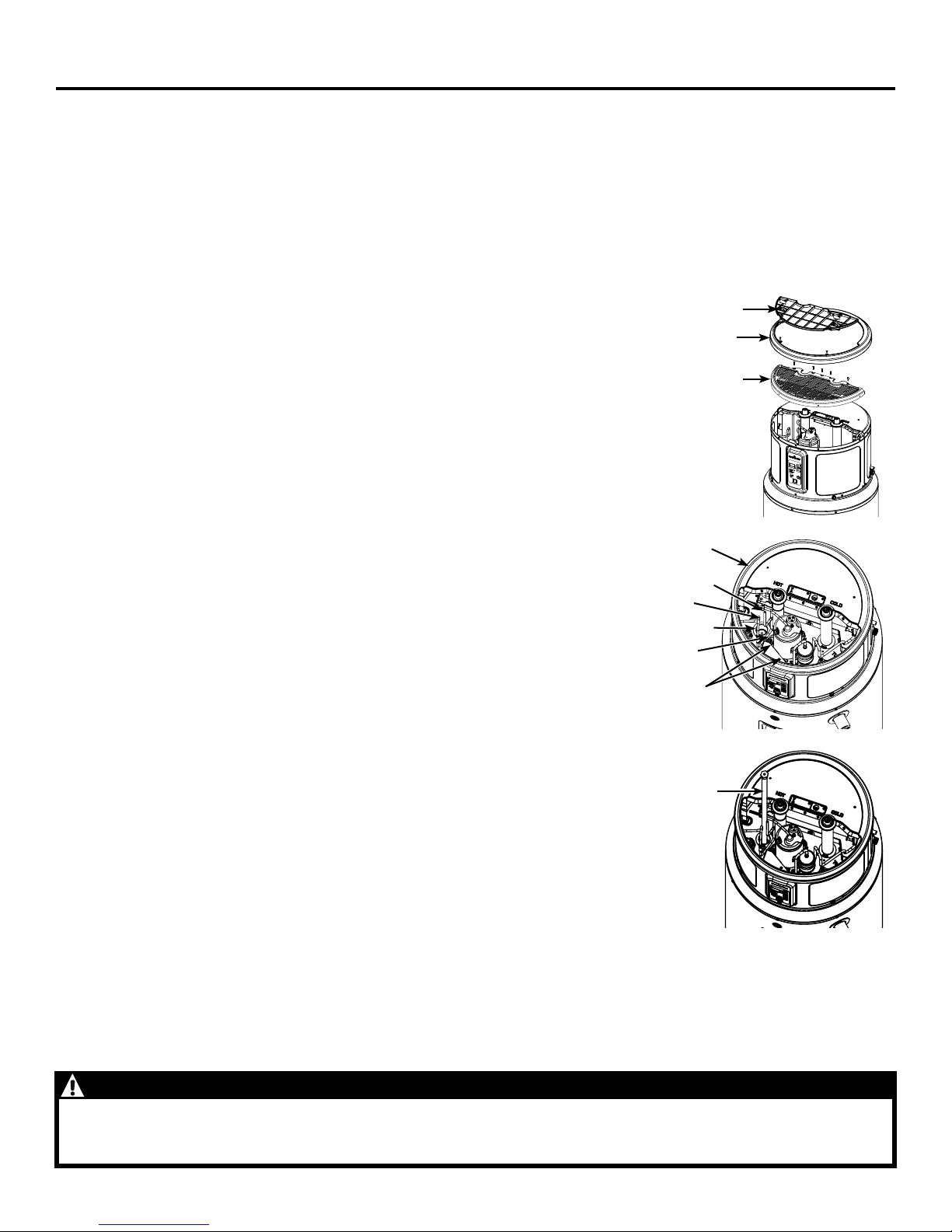

2. Remove the filter, trim ring,

3. Reinstall the trim ring,

4. Remove insulation to

5. Using a 1-1/16”

6. To install the

7. Turn water supply on, open a tap to remove any air in

one or two gallons from the water heater through the lower

drain valve.

and front top cover as

show in Illustration A.

place a protective layer

of tape on sheet metal

edges, as show in

Illustration B.

uncover the anode rod

as show in Illustration

B. Unplug anode wire (on

some models).

Trim Ring

socket and

extension,

unscrew the

anode rod, then

lift out to inspect

as show in

Illustration C.

anode rod, seal

the threads with

soft set sealant,

thread into the port

and using the torque

wrench tighten to

50 ± 5 ft-lbs of

torque. Plug in the

wire for the anode

rod if present.

Reinstall the anode

rod insulation. If an

Aluminum-Zinc or

other non-sensing

anode rod is

installed, the anode depletion sensing feature must be disabled

and the wire end taped (some models).

plumbing system, inspect for leaks, then reassemble the unit

in reverse order as shown in Illustration A, and turn the power

on. Reset the Anode button (some models) by pressing and

holding for 10 seconds to indicate that a new anode depletion

sensing anode rod is installed.

Tape Process

Tube Pinch O

Wires

Anode Rod

Insulation Foam

Wires

Tape Corner

and Edges

Illustration B

Anode Rod

Illustration C

Filter

Trim Ring

Front

Top Cover

Illustration A

CAUTION - IMPORTANT SAFETY NOTICE

This information is intended to use by individuals possessing adequate background of electrical, electronic and mechanical experience. Any attempt to repair a major appliance may result in personal injury and property damage. The manufacturer or seller

cannot be responsible for the interpretation of this information, nor can it assume any liability in connection with its use.

5

Installation

8”

(20.3cm)

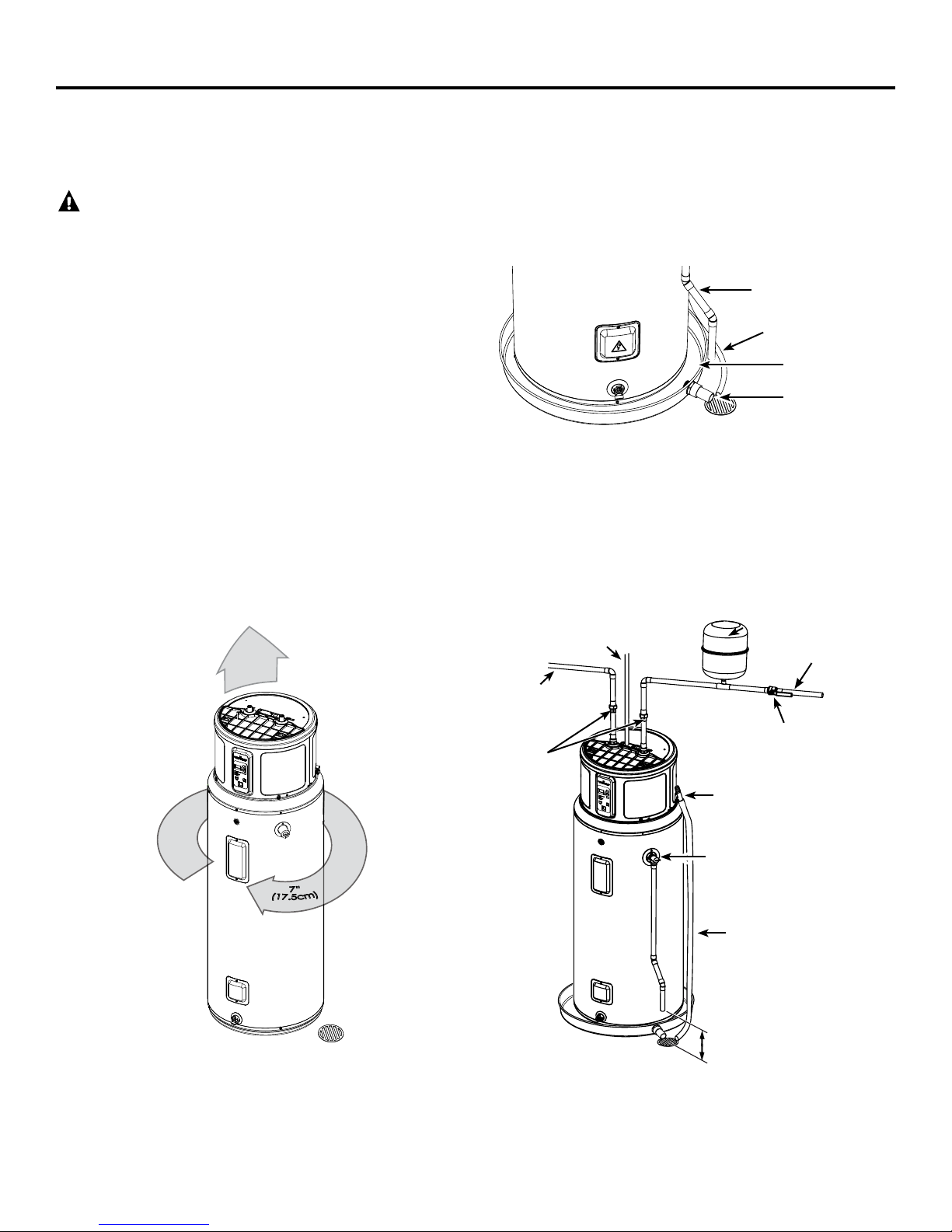

LOCATION

The water heater and water lines should be protected from freezing

temperatures and high-corrosive atmospheres. Do not install the water

heater in outdoor, unprotected areas.

CAUTION: Risk of Property Damage -

water heater should not be located in an area where leakage of

The

CATCH PAN INSTALLATION (If required)

NOTE: Auxiliary catch pan MUST conform to local codes.

Catch Pan Kits are available from the store where the water heater was

purchased, a builder store or any water heater distributor. The catch pan

should be 2” (5.1 cm) minimum larger than the Water Heater base diameter.

To prevent corrosion and improve Drain Valve access it is recommended that

the water heater be placed on spacers inside the catch pan.

the tank or connections will result in damage to the area

adjacent to it or to lower floors of the structure. Where such

areas cannot be avoided, it is recommended that a suitable

catch pan, adequately drained, be installed under the water

heater.

NOTE: The heat pump operating range is 35°F to 120°F (2°C to 49°C).

If the ambient temperature is outside of this range, the heat pump

will turn off and the electric elements will be used until the ambient

temperature

returns to within the operating range.

REQUIRED CLEARANCES:

There must be a 7” (17.5 cm) clearance between any object and the rear

and sides of the water heater in the event service is needed. A minimum 8“

(20.3cm) clearance above the water heater to remove the lter for cleaning

and for service access, and clear access to the front of the water heater, is

recommended. Installations that require 6” clearance on the sides or rear of

the water heater for earthquake straps are also acceptable. In these cases,

additional clearance must be provided on the opposite side of the unit to

allow for service access. The hot and cold water plumbing and electrical

connections must not interfere with the removal of the lter.

If a separate ducting kit is purchased, additional space is required above

and to the rear of the water heater for installation. Consult the ducting kit

manual for specific instructions. See www.bradfordwhite.com for details.

THERMAL EXPANSION

If check valve is present on inlet water line, use of a thermal expansion

tank is recommended. Check valves on the inlet water line are referred

to as a "closed system." A closed system can cause the check valve on

the water heater to operate more than intended, causing premature

failure. The suggested method of controlling thermal expansion is to

install an expansion tank in the cold water line between the water

heater and the check valve as shown.

TYPICAL INSTALLATION

To Electrical Junction Box

(use only copper conductors)

Hot water

outlet to

xtures

(suggested)

Relief Valve Drain

Condensate Drain

Catch Pan

Catch Pan

Drain

Thermal

expansion tank

To cold

water supply

Shut-o valve

Union

Model appearance may vary

6

Model appearance may vary

3/4” FNPT tting to

Condensate Drain Pan

Temperature &

Pressure Relief Valve

Condensate Drain

Tube

Relief Valve discharge

6” (15.2 cm) minimum

from the oor

or

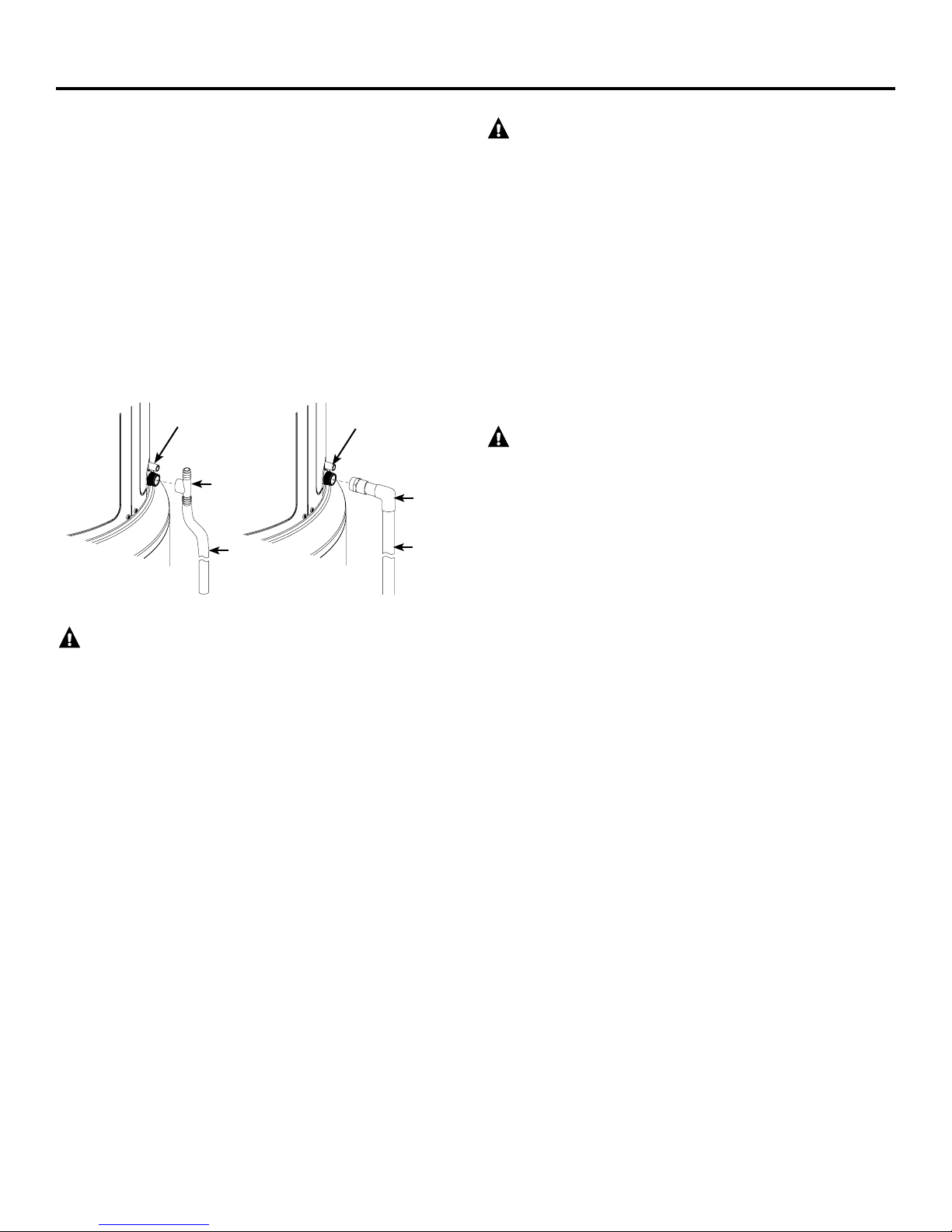

CONDENSATION DRAIN CONNECTION

This unit has a condensate drain; therefore a floor or other drain no

higher than 36” (91.4cm) above the floor must be available in close

proximity to the water heater to allow for the shortest possible drain

line with minimal turns to be installed. Drain must meet state and

local codes. It is important to install a 3/4” FNPT fitting suitable for

either rigid or flexible drain line to the primary drain port coming off

the side of the unit. Diameter reductions from a 3/4” drain line are

not recommended.

Ensure that the rigid or flexible drain line maintains a downward

slope to allow for proper gravity drainage of condensate to the drain

and to allow for proper function of the condensate drain blockage

sensor (see page 12). If no drain is available, then a common

condensate pump with a capacity no less than 1 gallon (3.8L)/day

must be purchased and installed. It is important to route the flexible

or rigid drain line so that the discharge water cannot contact live

electrical parts or cause water damage .

Condensate

Drain Overow

Fitting

Drain

Line

Condensate

Drain Overow

Fitting

Drain

Line

RELIEF VALVE

WARNING: Risk of Unit Damage - The

pressure rating of the relief valve must not exceed 150 PSI (1.03

kPa), the maximum working pressure of the water heater as

marked on the rating plate.

A new combination temperature/pressure-relief valve, complying with

the Standard for Relief Valves and Automatic Gas Shut-Off Devices for

Hot Water Supply Systems, ANSI Z21.22, is supplied and must remain

installed in opening provided and marked for the purpose on the water

heater. No valve of any type should be installed between the relief valve

and the tank. Local codes shall govern the installation of relief valves.

The BTUH rating of the relief valve must not be less than the input rating

of the water heater as indicated on the rating label located on the front

of the heater (1 watt=3.412 BTUH).

Connect the relief valve outlet to a suitable open drain so the discharge

water cannot contact live electrical parts or persons and to eliminate

potential water damage.

Piping used should be of a type approved for hot water distribution. The

discharge line must be no smaller than the outlet of the valve and must

pitch downward from the valve to allow complete drainage (by gravity)

of the relief valve and discharge line. The end of the discharge line should

not be threaded or concealed and should be protected from freezing. No

valve of any type, restriction or reducer coupling should be installed in the

discharge line.

CAUTION:

To reduce the risk of excessive pressures and temperatures in this

water heater, install temperature and pressure protective equipment

required by local codes and no less than a combination temperature

and pressure relief valve certified by a nationally recognized testing

laboratory that maintains periodic inspection of production of listed

equipment or materials, as meeting the requirements for Relief Valves

and Automatic Gas Shutoff Devices for Hot Water Supply Systems,

ANSI Z21.22. This valve must be marked with a maximum set pressure

not to exceed the marked maximum working pressure of the water

heater. Install the valve into an opening provided and marked for this

purpose in the water heater, and orient it or provide tubing so that

any discharge from the valve exits only within 6 inches above, or at

any distance below, the structural floor, and does not contact any live

electrical part. The discharge opening must not be blocked or reduced

in size under any circumstances.

TO FILL THE WATER HEATER

WARNING: Risk of Unit Damage - The tank

must be full of water before heater is turned on. The water

heater warranty does not cover damage or failure resulting

from operation with an empty or partially empty tank.

Make certain the drain valve is completely closed.

Open the shut-off valve in the cold water supply line.

Open each hot water faucet slowly to allow the air to vent from the

water heater and piping.

A steady flow of water from the hot water faucet(s) indicates a full water

heater.

"F11” fault code during installation: If the unit is powered on without a

full tank, the error code “F11” will show in the display. Turn o the power,

ll the tank with water (see above), then turn the power back on.

NOTE: The DRY TANK DETECTION feature on tank is for the aid of installer

and should NOT be used as the primary control to prevent operation with

an empty or partially lled tank. Power should NEVER be applied to the

water heater until installer has veried tank is lled and all air has been

purged from system.

NOTICE:

Do not mis-wire electrical connections. 240V AC or 208AC must be

applied across L1 and L2 wires as shown in ‘Water heater junction

box’ illustration. Failure to do so will VOID the warranty, and can result

in 120V applied to water heater, which may damage the compressor

or other electrical components.

If 4-conductor wire is supplied to the water heater, cap the neutral,

and connect the remaining wires as illustrated.

NOTE REGARDING UTILITY POWER-MANAGEMENT DEVICES

(Sometimes called Peak Load Reduction Switches):

Some power-management switching devices or even some basic

timer switches exist that REDUCE voltage from 240V to 120V during

high-electricity-demand periods. These devices must be removed

from the circuit providing power to the water heater because of the

potential unit damage noted above.

However, switching devices which cut power from 240V to 0V on a

periodic basis are acceptable.

“bAd linE” fault code during installation: If “bAd linE” is shown on

the display, the unit is not receiving the correct voltage as a result of

incorrect wiring. To correct this fault, turn the power o to the unit,

correct the wiring issue, then turn the power back on.

7

Installation

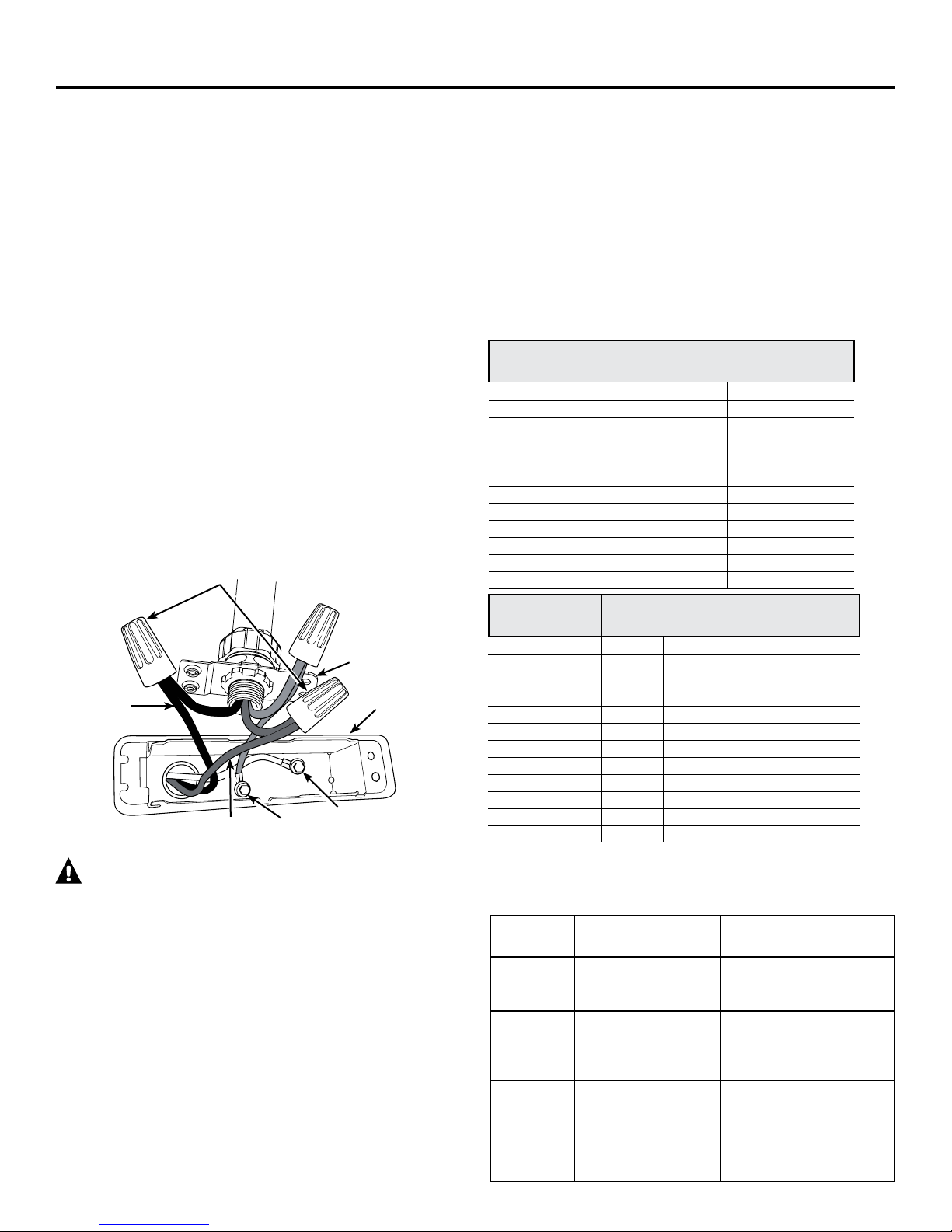

ELECTRICAL CONNECTIONS

A separate branch circuit with copper conductors, overcurrent protective

device and suitable disconnecting means must be provided by a qualified

electrician.

All wiring must conform to local codes or latest edition of National Electrical

Code ANSI/NFPA 70.

The water heater is completely wired to the junction box at the top of the

water heater. An opening for 1/2” electrical fitting is provided for field wiring

connections.

The voltage requirements and wattage load for the water heater are

specified on the rating label on the front of the water heater.

The branch circuit wiring should include either:

1. Metallic conduit or metallic sheathed cable approved for use as a

grounding conductor and installed with fittings approved for the

purpose.

2. Nonmetallic sheathed cable, metallic conduit or metallic sheathed

cable not approved for use as a ground conductor shall include

a separate conductor for grounding. It should be attached to the

ground terminals of the water heater and the electrical distribution

box.

To connect power to the water heater:

1. Turn the power o.

2. Remove the screw/screws holding the junction box top cover.

3. Install L1 to L1, L2 to L2 and ground to the green ground wire

connected to the bottom of the junction box.

NOTE: Install electric connections according to local codes or latest

edition of National Electrical Code ANSI/NFPA 70.

240V

Application of any external insulation, blankets or water pipe insulation

to this water heater will require careful attention to the following:

• Do not cover the temperature and pressure-relief valve.

• Do not cover access panels to the heating elements.

• Do not cover the electrical junction box of the

water heater.

• Do not cover the operating or warning labels attached to the water heater

or attempt to relocate them on the exterior of the insulation blanket.

• Do not block the air inlet/outlets in the top covers or rear of the unit.

NOTE: This guide recommends minimum branch circuit sizing based on

the National Electric Code. Refer to wiring diagrams in this manual for

eld wiring connections.

BRANCH CIRCUIT SIZING GUIDE

Total Water Recommended Over-Current Protection

Heater Wattage (fuse or circuit breaker amperage rating)

208V 240V 277V 480V

3,000 20 20 15 15

4,000 25 25 20 15

4,500 30 25 25 15

5,000 30 30 25 15

5,500 35 30 25 15

6,000 40 35 30 20

8,000 50 45 40 25

9,000 – 50 45 25

10,000 – – 50 30

11,000 – – 50 30

12,000 – – – 35

L1 (Black)

L2 (Red)

House Ground

(Green)

WARNING: Proper ground connection is essential.

The presence of water in the piping and water heater does not

provide sufficient conduction for a ground. Nonmetallic piping,

dielectric unions, flexible connectors, etc., can cause the water

heater to be electrically isolated. Do not disconnect factory

ground.

The manufacturer’s warranty does not cover any damage or defect caused

by installation, attachment or use of any type of energy-saving or other

unapproved devices (other than those authorized by the manufacturer)

into, onto or in conjunction with the water heater. The use of unauthorized

energy-saving devices may shorten the life of the water heater and may

endanger life and property.

The manufacturer disclaims any responsibility for such loss or injury resulting

from the use of such unauthorized devices.

If local codes require external application of insulation blanket kits, the

manufacturer’s instructions included with the kit must be carefully followed.

8

Junction box

cover

Junction box

Factory Ground

Total Water Copper Wire Size AWG Based

Heater Wattage on N.E.C. Table 310-16 (167°F/75°C.)

208V 240V 277V 480V

3,000 12 12 14 14

4,000 10 10 12 14

4,500 10 10 10 14

5,000 10 10 10 14

5,500 8 10 10 14

6,000 8 8 10 12

8,000 8 8 8 10

9,000 – 8 8 10

10,000 – – 8 10

11,000 – – 8 10

12,000 – – – 8

NORMAL STARTUP CONDITIONS:

Once tank is full and power is energized, you may experience the following:

NOTE: Heat Pump operating range is 35°F - 120°F (2°C-49°C).

Elapsed

Time

0 to 2 minutes

2 to 22

minutes

22

minutes

and beyond

HEWH Actions Comments

Unit will go through

self-check and display

countdown

Compressor and fan

turn on

Compressor and fan turn

off, heating elements

turn on. After initial

heat-up, elements turn

off and compressor

turns on.

This 2-minute off-time prevents compressor damage.

This 20-minute period is used

to ensure the tank is full of

water (Dry-fire prevention

algorithm).

The water heater is operat

ing in Hybrid mode. Quickly

provides initial amount of hot

water, then switches to effi

cient heat pump for majority

of heating.

-

-

Troubleshooting…

Before you call for service.... Save time and money! Review the chart below first and you may not need to call for service.

Problem Possible Causes What To do

CAUTION: For your safety, DO NOT attempt repair of electrical wiring, controls, heating elements or other

safety devices. Refer repairs to qualied service personnel.

Water heater makes sounds A fan is used to move air through

Water heater is making the

room cooler

Water dripping down the

outside of the heater

Not enough or not hot water Water temperature may be set

Water is too hot

Rumbling noise Water conditions in your home

The heater is beeping and the

display says F11

The heater is beeping and the

screen says “F17”

The heater is beeping and the

screen says, “FA-F8”

The heater is beeping and the

screen ashes an error code

Hot water has a rotten egg or

sulphur smell

the system

Room is not vented properly or is

too small

Heat is removed from the air to

heat the water

Condensate drain is clogged • Clear out any debris in the drain port on the unit.

Hot/Cold water connections are

not tightened

too low

Hot water usage pattern exceeds

the capability of the water heater in

current mode

Leaking or open hot water faucets

Long runs of exposed pipe, or hot

water piping on outside wall

Not enough clearance to allow air

to circulate for the heater pump

Room size is not appropriate for

water heater

Inadequate wiring • See the Installation Instruction section.

Manual reset limit (TCO) • See the Safety Control section, see page 4.

Water connections to unit re-

versed

Water temperature is set too high

Electric control has failed • Call for service.

caused a buildup of scale or

mineral deposits on the heating

elements

The water heater has not been

lled with water before powering up. Powering up the heater

without water will damage the

electric heaters. The water heater

warranty does not cover damage

or failure resulting from operation

with an empty or partially empty

tank.

The anode rod is not connected

properly and the water heater may

not be protected from corrosion.

There is an issue with the heat

pump system.

There is an issue with the water

heater that requires immediate

attention.

Certain water supplies with high

sulphate content will react with

the anode rod that is present in

all water heaters for corrosion

protection of the tank

• Some amount of fan sound is normal. If you hear an abnormal sound or the sound

level seems unusually loud, then contact service.

• If the room is smaller than 10’ x 10’ x 7’ (3m x 3m x 2.1m) then it must have a louvered door or other means to allow air exchange with surrounding rooms.

• This is normal.

• Tighten the inlet and outlet pipe connections.

• See About the Water Temperature Setting section.

• Change to dierent mode.

• Wait for the water heater to recover after an abnormal demand.

• Make sure all faucets are closed.

• Insulate piping.

• Make sure unit is 7" away from the wall and has 8" clearance above the air lter.

• If room size is less than 10’ x 10’ x 7’ (700 cu. ft.), install louvered door or similar

ventilation.

• Correct piping connections.

• See About the Water Temperature Setting section.

• Remove and clean the heating elements. This should only be done by a qualied

service personnel.

• Fill the tank completely with water. Press ENTER to stop the alarm and then cycle

power when the tank has been lled.

• If the unit has been conrmed to be lled with water, and an F11 code is expe-

rienced, it is possible that the code may be a false indicator due to certain unique

environment conditions encountered during the start up. If the unit is full of water,

turn the breaker off for about 10 minutes to allow the water temperature to

stabilize, then turn the breaker back on. If the F11 code persists, schedule service.

• Check that the tank is lled completely with water.

• If the tank is full of water and the F17 code persists, contact

service.

• The unit will automatically switch to another available mode to ensure you continue to have hot water. Contact service immediately and give them the codes listed on

the display screen.

• The heater may switch to another available heating mode. Contact service immediately. To stop the beeping noise (unless error code F2, F11, F17 or bAd linE) press

either the UP or DOWN arrow button and the alarm will stop and the display will go

back to normal (set temperature).

• The odor can be reduced or eliminated in most water heaters by replacing the

anode rod with less-active material rod. In some cases, an added step of chlorinating

the water heater and all hot water lines may be necessary, contact your local water

professional or plumber for options and instructions. A qualified servicer or plumber

should do this replacement.

9

Notes.

10

Loading...

Loading...