Bradford White RE2H50, RE2H80 User Manual

Bradford White Heat Pump Water Heater RE2H50, RE2H80

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate background of electrical,

electronic and mechanical experience. Any attempt to

repair a major appliance may result in personal injury

and property damage. The manufacturer or seller

cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection

with its use. This quick reference guide is provided for

information purposes only and does not replace, modify

or change in any manner the Owner’s Manual and

Installation Instructions.

DISCONNECT POWER BEFORE SERVICING

IMPORTANT- RECONNECT ALL GROUNDING

DEVICES

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to complete

a path to ground are removed for service, they must

be returned to their original condition and properly

fastened.

SPECIFICATIONS

Capacity................................................50/80 US gal

Tank Max Working Pressure

........................150 PSI

Water Temperature Set Point Range ..100F - 140F

Electrical

........................... 240/208VAC 60 Hz 1-PH

Circuit Breaker

..............................................30 Amp

Upper Element Wattage

...........................4500/3380

Lower Element Wattage

...........................4000/3004

REFRIGERATION SYSTEM

Compressor .................................................... 500 W

Refrigerant Charge (R134a)

..................29.1/30.9 oz

(50Gal/80Gal)

Compressor LRA

........................................... 14.0A

Compressor RLA

........................................... 2.56A

Typical High Side Pressure (70°F amb)

.... 210-280

PSIA

Typical Low Side Pressure (70°F amb)

55-65 PSIA

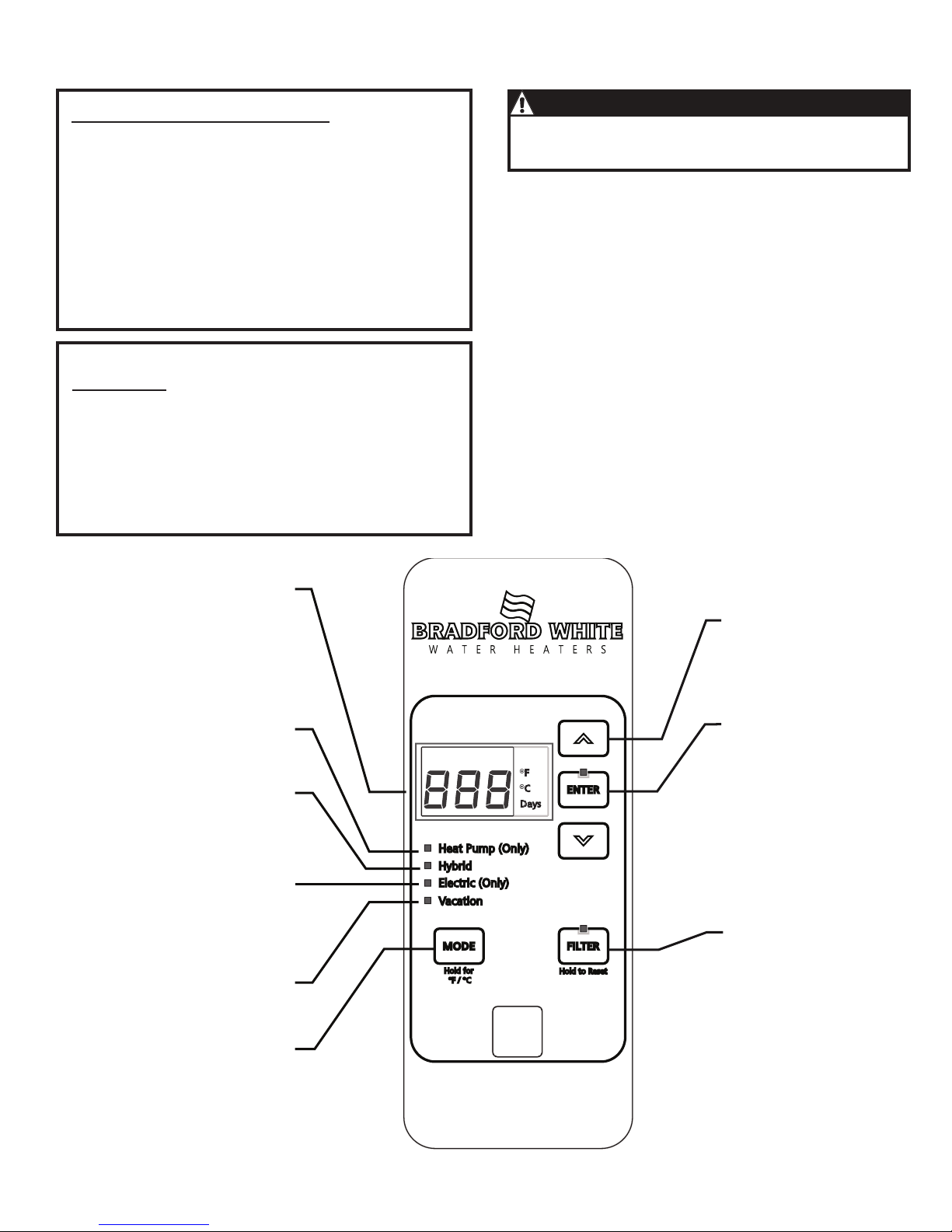

Heat Pump

(Only)

Utilizes heat pump only.

Hybrid

Utilizes the heat pump and

electric heating elements.

Electric

(Only)

Utilizes electric elements

only. Stops the fan, the

heat pump and the flow of

cool air.

Vacation

Use this mode for periods

away from home.

Mode

Press this button to toggle

through the various heating

modes. Press and hold to

switch between ºF and ºC.

Display

Displays the current

temperature or the number

of days for vacation mode.

To display setpoint if display

has gone blank, press any

button.

Arrow Pad

Use the up and down

arrows to manually change

the water temperature, or to

select days for Vacation Mode.

Enter

Press to confirm selections.

Filter

The red LED indicates that

the filter needs cleaning.

Press and hold to reset.

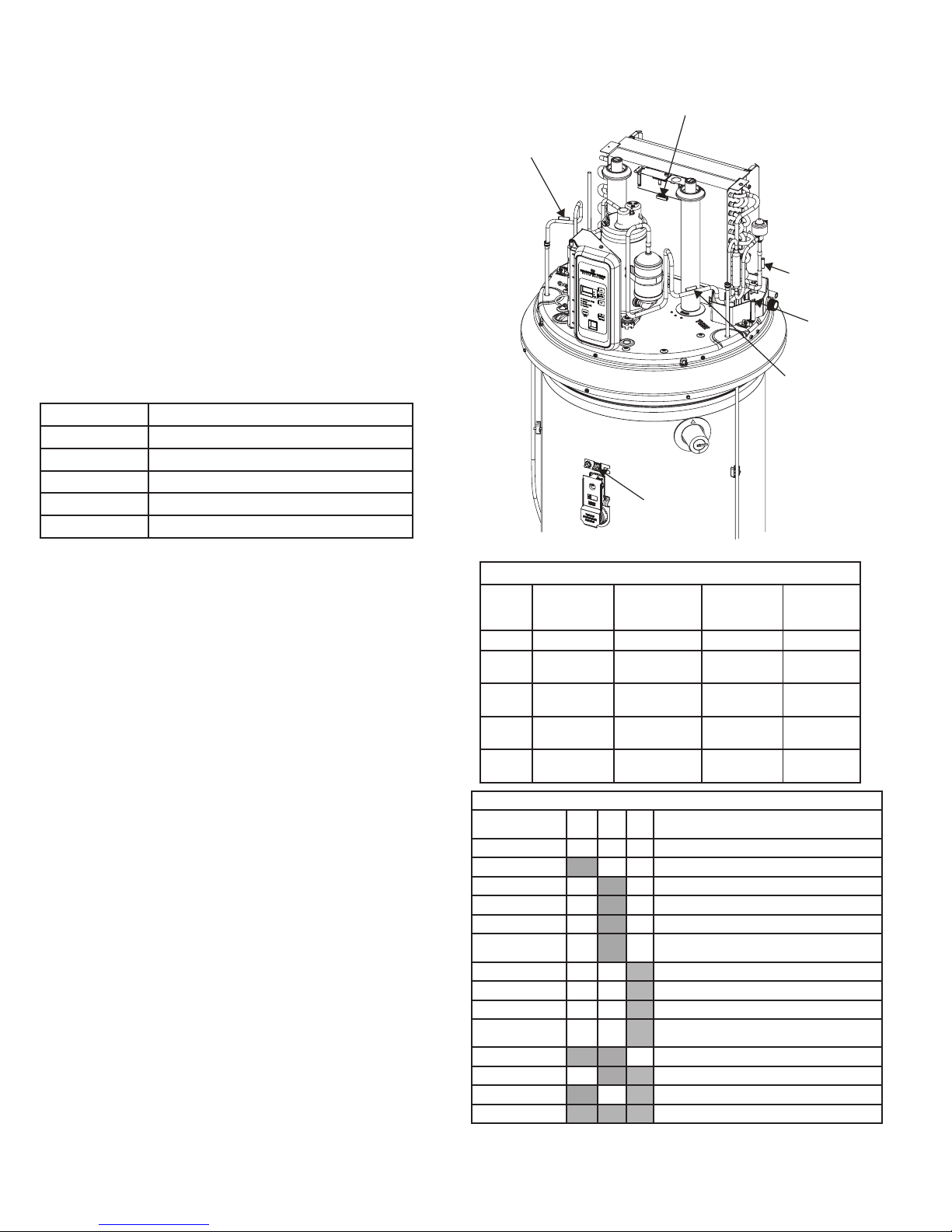

T2 Tank Sensor

T3b Evaporator

Outlet Sensor

T4 Compressor

Outlet Sensor

T3a Evaporator

Inlet Sensor

T5 Ambient Air

Sensor

Condensate

Overflow Senso

r

Double wall heat exchanger, suitable for potable water

connection.

CAUTION

238-52395-00 02/18

Temperature Sensors

Sensor Description

(wire color)

Normal

temperature

Range

Resistance

range in ohms

Resistance at

77º F

T2 Tank (white) 30º F-160º F 34K-1.75K 10K

T3a Evaporator

Inlet (red)

15º F-130º F 57K-3K 10K

T3b Evaporator

Outlet (white)

15º F-130º F 57K-3K 10K

T4 Compressor

Outlet (blue)

30º F-250º F 188K-3K 55K

T5

Ambient (yellow)

15º F-130º F 57K-3K 10K

SERVICE MODE

The Service Mode can be accessed by pressing and holding the UP

Arrow and Enter buttons simultaneously for 5 seconds. You will first

hear a single beep when pressing the buttons, then a two-tone sound

indicating the action was successful. A moment later, you will see

the first display of the thermistor T2 alternating with its temperature

displayed in the units selected (degrees F or C). The Service Mode

will time out after 15 minutes of button inactivity.

Five functions are available in Service Mode: View Thermistors,

Heating Component Status and Control, View Faults and Counters,

Personality, and Software Revision. You may switch from one function

to another by pressing the Mode button. The operating mode LED will

illuminate to indicate which service mode is selected. An explanation

of the five functions follows:

View Thermistor (Hidden LED) - Each of the 5 thermistors can be

monitored for the temperature they sense. The thermistor designation

appears on the display and alternates with the temperature in degrees

of the units selected - Fahrenheit or Celsius. Pressing the Down

Arrow button switches the display to the next thermistor in the list.

The following table shows the thermistors’ designations and their

function in the unit.

Designation Function

T2 Tank (Water) Temperature

T3a Evaporator Inlet Temperature

T3b Evaporator Outlet Temperature

T4 Compressor Discharge Temperature

T5 Ambient Air Temperature

Heating Component Status and Control, EEV Operation (Heat

Pump (Only) LED) - This function displays the status (on/off) for

each of the heating components - Lower Element, Upper Element,

Compressor (with fan), and Fan - and allows you to turn it on or off.

The first component is the Lower electric element (LE). On status is

signified by a 1 and off is 0. Pressing the Down Arrow button switches

to the Upper Element (UE). Pressing Down Arrow again switches to

the Compressor (with fan) (Co). Pressing the Down Arrow once more

switches to the fan (Fn) . Only one component can be on at one time.

The electric elements will only stay on for 5 minutes without refreshing

by pressing any button on the front panel. The compressor timeout

is 10 minutes. Press the Down Arrow button again to check EEV

Operation. The position will be displayed. Press the Enter button to

open the EEV in increments of 10, from 80 to 450. After reaching

450, pressing Enter will close the valve in increments of 10.

View Faults and Counters (Hybrid LED) - The control counts the

number of times a fault is recorded. A fault code is not displayed until

the number of counts in the fault table (refer to page 2) has been

reached. For example, if the upper element fails to draw current each

time the control energizes the upper element, the count will increase

by 1. However, if the element responds normally, the count will

decrement by 1.

The View Faults and Counters function displays any fault codes in the

system. Pressing the Down Arrow takes you to the next fault code, if

any. If no fault codes are active, “- - -” is displayed. Pressing the Filter

button switches the display to the fault counters. The displayed fault

code alternates with its count value. For example, if the thermistor

T3a has registered 3 failures, its value will be 3 and the display will

alternate between “F5” and “3”.

To clear all fault codes and fault counters, press and hold the Enter

button for 5 seconds and listen for the beep.

Personality (Electric (Only) LED)- This function allows the user to

verify that the correct parameter set has been programmed into the

control board (refer to Personality Table on page 2). The Personality

allows the software to properly control the heating system. The

Personality of the water heater cannot be changed, except by

replacing the control board.

Software Revision (Vacation LED) - This function allows the user

to view the software revision that is programmed into the control. If

the software revision is not correct, the correct revision should be

uploaded.

Exiting Service Mode - To exit Service Mode without waiting for

15 minute timeout, press and hold the Up Arrow and Down Arrow

simultaneously for 5 seconds and listen for two beeps.

T2 Tank Sensor

T3b Evaporator

Outlet Sensor

T4 Compressor

Outlet Sensor

T3a Evaporator

Inlet Sensor

T5 Ambient Air

Sensor

Condensate

Overflow Senso

r

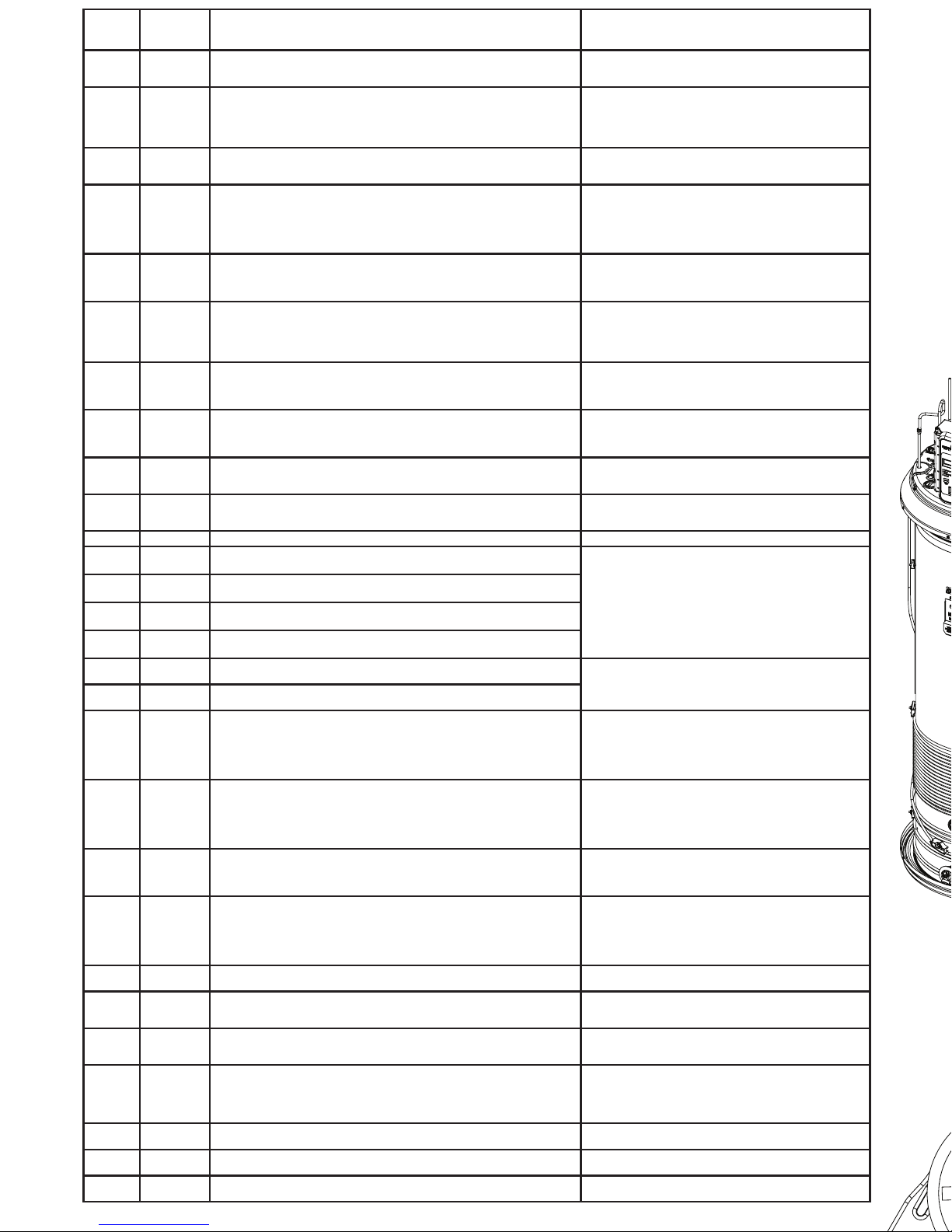

PASS/FAIL COMPONENT OPERATION

Selected Mode SS LE UE Temporary Mode (if component failure is

detected)

Any P P P Runs in selected mode

Any F P P Electric (Only) mode

Hybrid P F P Hybrid Mode (but uses SS when LE is called for)

Electric (Only) P F P Electric (Only) Mode (UE only)

Heat Pump (Only) P F P Heat Pump (Only) mode

High Demand/Boost P F P High Demand/Boost (but uses SS when LE is called

for)

Hybrid P P F Control uses SS and LE based on demand algorithm

Electric (Only) P P F LE Only Mode

Heat Pump (Only) P P F Heat Pump (Only) Mode

High Demand/Boost P P F High Demand/Boost (but uses LE when UE called

for)

Any F F P Electric (Only) Mode (UE only)

Any P F F Heat Pump (Only) Mode

Any F P F LE Only Mode

Any F F F Electric (Only) Mode, displays 1 fault codes

SS = Sealed System

LE = Lower Element

UE= Upper Element

238-52395-00 02/18

Printed in USA

Electronic Expansion Valve (EEV)

This valve replaces the capillary tube typically used in

refrigeration appliances. The EEV meters the flow of liquid

refrigerant entering the evaporator at the rate that matches the

amount of refrigerant being boiled off in the evaporator (gas).

the valve also maintains the proper “superheat” (T3b-T3a).

+

Superheat is the temperature of a gas above the boiling point

of the liquid.

FAN SHROUD

CONDENSER COIL

(Non-replaceable)

Ω

L1

L2

Fault

Code

Displayed

Fault Counts

Before Code

Displayed

Condition Check

FC**

10

Control checks to ensure evaporator is free of frost. Continuously veries

that T3a sensor (evaporator inlet temperature) is greater than 20F after 30

minutes of run time.

Probable refrigerant leak. Find and Repair.

Check T3a sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

Fd**

10

Control checks to ensure evaporator superheat

+

is OK (controlled by EEV).

Continuously veries the temperature difference between T3a sensor (evap

inlet temp) and T3b sensor (evap outlet temp) is greater than 5F after 30

mins of run time. Control also veries that T3a is greater than 10F less than

T5 ambient sensor.

Possible refrigerant leak. Check sealed system for leak.

Check that lter is clean. Check T3a, T3b and T5 sensor

mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FE**

10

Control checks to ensure the compressor discharge temperature never

exceeds 240F. Continuously veries that T4 sensor (compressor outlet

temperature) is less than 240F every minute of run time.

Possible refrigerant leak. Check sealed system for leak.

Check T4 sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FF**

10

Control checks to ensure the Electronic Expansion Valve (EEV) is operating

properly and valve rotation is within range.

Probable refrigerant leak. Find and Repair.

Check EEV wiring at control, placement of EEV coil on

EEV valve body, and operation. Conrm audible pulse of

valve homing sequence at power restart.

Check T3a and T3b sensors mounting, wiring and

resistance.

FG 10

Control checks to ensure Ambient temperature is within an acceptable range

of 35ºF < [T5 ambient] <120ºF before starting the heat pump. If not, the unit

will switch to Electric (Only) Mode for that heating cycle only.

NO fault code is shown on the display.

No failure is assumed, but this information is provided for

completeness.

FI** 10

Control checks to ensure evaporator superheat

+

is <20ºF AND the EEV

position is <450 after 30 minutes of run time. If outside these limits, this

provides an early indication of a refrigerant leak. (Note: Target superheat is

generally 10ºF, and EEV generally operates at a position much lower than

450.)

Probable refrigerant leak. Find and Repair.

Check T3a, T3b, T5 sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FJ 10

Control checks to ensure that the AC current draw is <= 20.5A while the

compressor and lower heating element are both enabled. If current draw is

>20.5A, the compressor will be disabled.

Check lower heating element rated wattage. Element

wattage is stamped on the heating element terminal block.

Correct wattage can be found on the water heater’s rating

plate.

FL 10

Control checks to ensure that T3a and T3b evaporator inlet and outlet

temperatures are within 2.5ºF of the T5 ambient temperature 20

minutes after defrost begins.

Check airow: fan operation, dirty lter, dirty evaporator.

Check T3a, T3b, T5 sensor mounting, wiring and resistance. Check EEV wiring at control, coil placement, and

operation.

F2

1

T2 tank temperature sensor failure Just before compressor starts, control

checks T2 sensor is within 30F - 170F temperature range.

Check T2 sensor mounting, wiring and resistance.

Use service mode to monitor T2 sensor temperature.

If T2 sensor checks OK, control assembly may have failed.

F3

10

Compressor failure. Control energizes compressor, but current sensor

detects no current ow.

Check compressor run capacitor.

Check compressor, overloads, relay and wiring.

Use service mode to manually cycle compressor on/off.

F4 10 Fan Failure Check fan, wiring, and control connection.

F5

10

T3a sensor (evap inlet temperature) failure. The control detects the thermistor output is at or nearly shorted or open circuit.

Check respective temperature sensor mounting, wiring to

control and resistance.

Use service mode to monitor sensor temperature.

If temperature sensor checks OK, control assembly may

have failed.

F6

10

T3b sensor (evap outlet temperature) failure. The control detects the thermistor output is at or nearly shorted or open circuit.

F7

10

T4 sensor (compressor outlet) failure. The control detects the thermistor

output is at or nearly shorted or open circuit.

F8

10

T5 sensor (ambient temperature) failure. The control detects the thermistor

output is at or nearly shorted or open circuit.

F9 10

Lower heating element failure. Control energizes lower element, but cur

-

rent sensor detects no current ow.

Check respective heating element and wiring connections

at element and control.

Use service mode to cycle element and check current

draw. Control assembly may have failed.

F10 10

Upper heating element failure. Control energizes Upper element, but cur-

rent sensor detects no current ow.

F11 1

Dry Tank fault. Control checks to ensure that the T2 tank temperature

sensor has not risen more than 5ºF during the rst 22 minutes after the unit

is powered on. (The compressor is engaged for 20 minutes after a 2 minute

wait for the system to allow the high and low side pressures to equalize.)

After 1 failed Dry Tank test, “F11” is displayed. After 5 failed tests, an audible

alarm will sound.

Check to ensure the tank is full of water. If full:

Check T2 sensor mounting, wiring and resistance.

Use service mode to monitor T2 sensor temperature.

If T2 checks OK, control assembly may have failed.

bAd linE

(F12)

1

The voltage is too low at power-up. The control monitors the input line voltage1 minute after power-up, and if the voltage is below 155V, the fault code

will be displayed.

Check electrical supply line connections. Voltage should

measure within +10/-15% of either 208 or 240 VAC,

depending upon power supply. Badline counts stored in

“F12” and can be monitored via the Control when placed in

diagnostics mode.Check heating elements are not shorted

to ground.

F13

1

Stuck Key fault. This indicates there is a button on the front panel that is

stuck down. This button is inoperable. Other buttons work normally. If the

button becomes free, the fault code will clear by itself.

Check to see if all buttons are operable.

Ensure control board is fully snapped into control housing.

If board is fully seated, control assembly has failed.

DirtyFilter**

(F14)

5

Filter LED is on, and audible alarm is sounding. Filter is too dirty to enable

proper function of unit. Number of “Dirty Filter” counts are stored in the

“F14” code and can be monitored via the Control when it is placed in Diagnostics Mode. The evaporator is operating at a colder

temperature than the ambient temperature as measured by T5.

Check to ensure Filter is clean. Filter cleaning instructions

are found in the owner’s manual.

Repeated dirty lter alarms that do not resolve by cleaning

are an indication of a sealed system leak. Find and repair

AND ash software to version 4.21 or later, or replace

control.

F15 10

DataFlash fault. The microcontroller has detected a problem in the DataFlash (permanent memory storage).

Control assembly may have failed.

F18 10

Current transformer miswired. F3, F9, and F10 fault codes have all

occurred during the same heating cycle.

Check that red L2 wire is through the CT201 current

transformer on the board. If it is, board needs to be

replaced

F19 10

Low line voltage during compressor operation. Sagging voltage occurs

over time, not at startup like a fault F12- bAd linE.

Check incoming line voltage is within +10/-15% of either

208 or 240 VAC, depending upon power supply.

Check heating elements are not shorted to ground.

F20 10

Condensate drain pan port blocked. Water heater will only operate in

Electric (Only) mode until the drain port is cleared and the sensor

is no longer in contact with water.

Check main drain on condensate drain pan. Unblock if

necessary. Check that the sensor is in the correct position

in the drain pan, on the screw post near the main drain

port. Ensure drain ttings do not reduce diameter at the

drain pan port and cause water to build up in pan.

F21 1

Application Update Failure. A problem occurred while updating the control

application.

Cycle power and try to complete the update again. If prob-

lems persist, reash software or replace the control board.

F22 1

Parametric Data Update Failure. A problem occurred while updating

parametric data.

Cycle power and try to complete the update again. If prob-

lems persist, reash software or replace the control board.

F23 10

Micro A/D Failure. The control has detected a microcontroller input port has

failed.

The control needs to be replaced.

* on some models ** Technicians use TB01-16

238-52395-00 02/18

Loading...

Loading...