Page 1

Bradford White Heat Pump Water Heater RE2H50, RE2H80

IMPORTANT SAFETY NOTICE

This information is intended for use by individuals

possessing adequate background of electrical,

electronic and mechanical experience. Any attempt to

repair a major appliance may result in personal injury

and property damage. The manufacturer or seller

cannot be responsible for the interpretation of this

information, nor can it assume any liability in connection

with its use. This quick reference guide is provided for

information purposes only and does not replace, modify

or change in any manner the Owner’s Manual and

Installation Instructions.

DISCONNECT POWER BEFORE SERVICING

IMPORTANT- RECONNECT ALL GROUNDING

DEVICES

All parts of this appliance capable of conducting

electrical current are grounded. If grounding wires,

screws, straps, clips, nuts or washers used to complete

a path to ground are removed for service, they must

be returned to their original condition and properly

fastened.

SPECIFICATIONS

Capacity................................................50/80 US gal

Tank Max Working Pressure

........................150 PSI

Water Temperature Set Point Range ..100F - 140F

Electrical

........................... 240/208VAC 60 Hz 1-PH

Circuit Breaker

..............................................30 Amp

Upper Element Wattage

...........................4500/3380

Lower Element Wattage

...........................4000/3004

REFRIGERATION SYSTEM

Compressor .................................................... 500 W

Refrigerant Charge (R134a)

..................29.1/30.9 oz

(50Gal/80Gal)

Compressor LRA

........................................... 14.0A

Compressor RLA

........................................... 2.56A

Typical High Side Pressure (70°F amb)

.... 210-280

PSIA

Typical Low Side Pressure (70°F amb)

55-65 PSIA

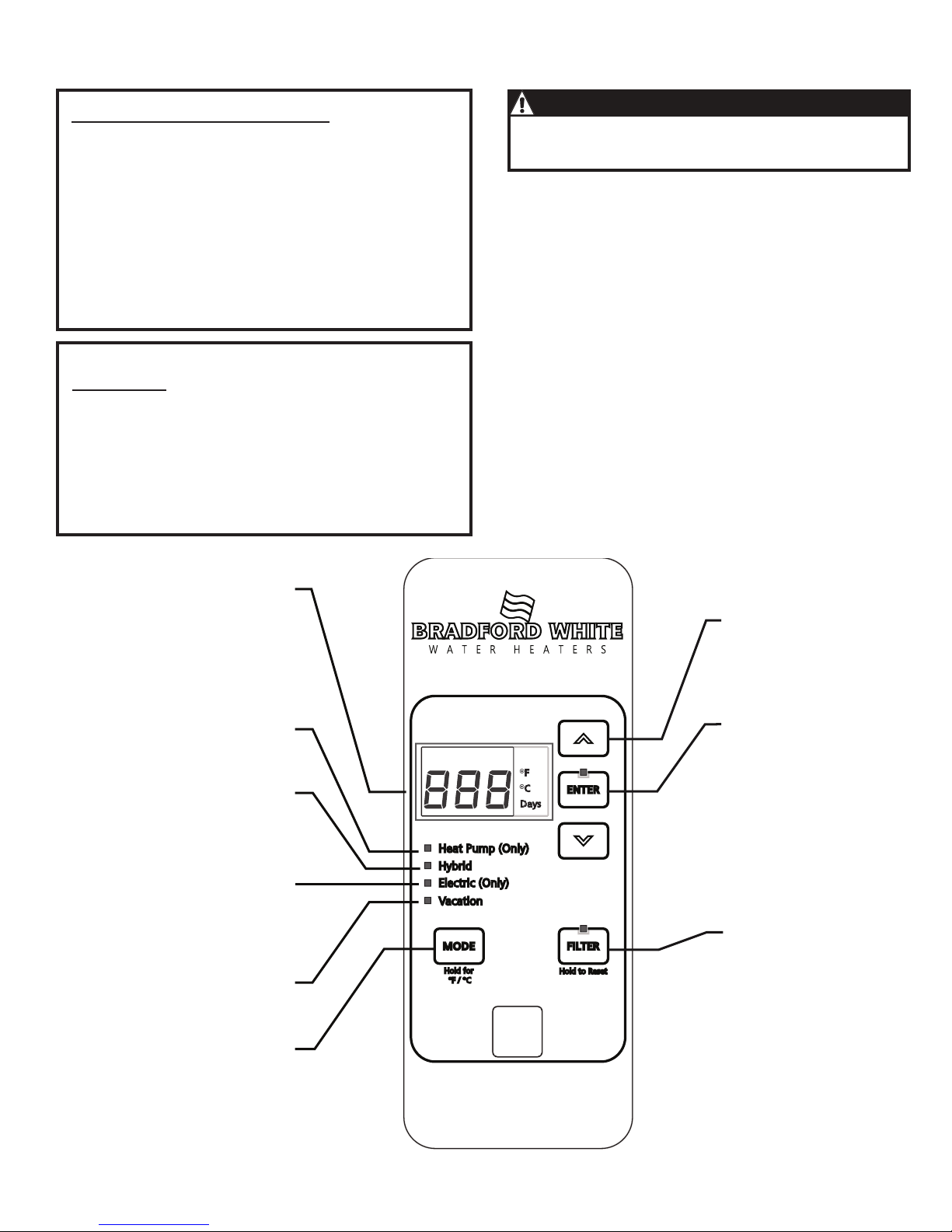

Heat Pump

(Only)

Utilizes heat pump only.

Hybrid

Utilizes the heat pump and

electric heating elements.

Electric

(Only)

Utilizes electric elements

only. Stops the fan, the

heat pump and the flow of

cool air.

Vacation

Use this mode for periods

away from home.

Mode

Press this button to toggle

through the various heating

modes. Press and hold to

switch between ºF and ºC.

Display

Displays the current

temperature or the number

of days for vacation mode.

To display setpoint if display

has gone blank, press any

button.

Arrow Pad

Use the up and down

arrows to manually change

the water temperature, or to

select days for Vacation Mode.

Enter

Press to confirm selections.

Filter

The red LED indicates that

the filter needs cleaning.

Press and hold to reset.

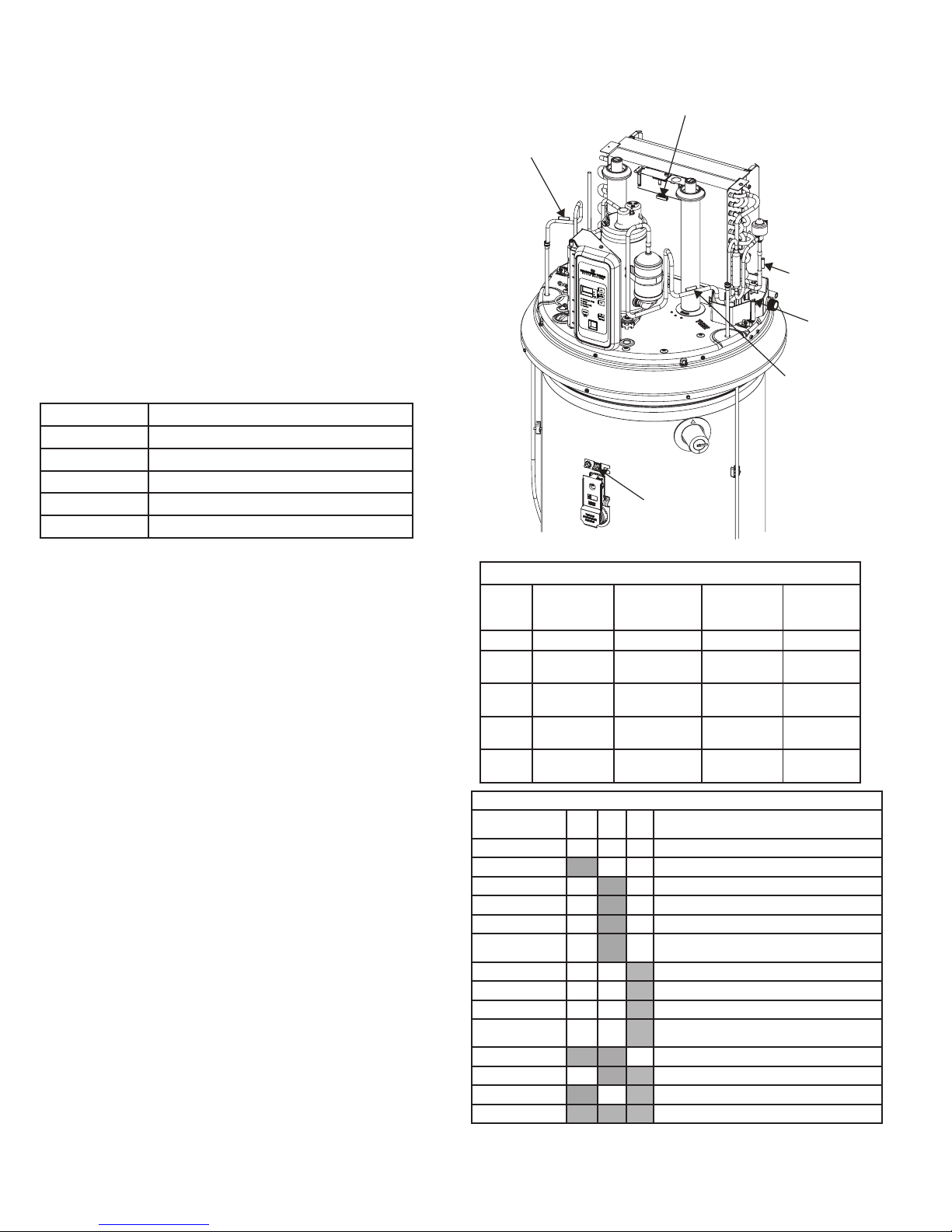

T2 Tank Sensor

T3b Evaporator

Outlet Sensor

T4 Compressor

Outlet Sensor

T3a Evaporator

Inlet Sensor

T5 Ambient Air

Sensor

Condensate

Overflow Senso

r

Double wall heat exchanger, suitable for potable water

connection.

CAUTION

238-52395-00 02/18

Page 2

Temperature Sensors

Sensor Description

(wire color)

Normal

temperature

Range

Resistance

range in ohms

Resistance at

77º F

T2 Tank (white) 30º F-160º F 34K-1.75K 10K

T3a Evaporator

Inlet (red)

15º F-130º F 57K-3K 10K

T3b Evaporator

Outlet (white)

15º F-130º F 57K-3K 10K

T4 Compressor

Outlet (blue)

30º F-250º F 188K-3K 55K

T5

Ambient (yellow)

15º F-130º F 57K-3K 10K

SERVICE MODE

The Service Mode can be accessed by pressing and holding the UP

Arrow and Enter buttons simultaneously for 5 seconds. You will first

hear a single beep when pressing the buttons, then a two-tone sound

indicating the action was successful. A moment later, you will see

the first display of the thermistor T2 alternating with its temperature

displayed in the units selected (degrees F or C). The Service Mode

will time out after 15 minutes of button inactivity.

Five functions are available in Service Mode: View Thermistors,

Heating Component Status and Control, View Faults and Counters,

Personality, and Software Revision. You may switch from one function

to another by pressing the Mode button. The operating mode LED will

illuminate to indicate which service mode is selected. An explanation

of the five functions follows:

View Thermistor (Hidden LED) - Each of the 5 thermistors can be

monitored for the temperature they sense. The thermistor designation

appears on the display and alternates with the temperature in degrees

of the units selected - Fahrenheit or Celsius. Pressing the Down

Arrow button switches the display to the next thermistor in the list.

The following table shows the thermistors’ designations and their

function in the unit.

Designation Function

T2 Tank (Water) Temperature

T3a Evaporator Inlet Temperature

T3b Evaporator Outlet Temperature

T4 Compressor Discharge Temperature

T5 Ambient Air Temperature

Heating Component Status and Control, EEV Operation (Heat

Pump (Only) LED) - This function displays the status (on/off) for

each of the heating components - Lower Element, Upper Element,

Compressor (with fan), and Fan - and allows you to turn it on or off.

The first component is the Lower electric element (LE). On status is

signified by a 1 and off is 0. Pressing the Down Arrow button switches

to the Upper Element (UE). Pressing Down Arrow again switches to

the Compressor (with fan) (Co). Pressing the Down Arrow once more

switches to the fan (Fn) . Only one component can be on at one time.

The electric elements will only stay on for 5 minutes without refreshing

by pressing any button on the front panel. The compressor timeout

is 10 minutes. Press the Down Arrow button again to check EEV

Operation. The position will be displayed. Press the Enter button to

open the EEV in increments of 10, from 80 to 450. After reaching

450, pressing Enter will close the valve in increments of 10.

View Faults and Counters (Hybrid LED) - The control counts the

number of times a fault is recorded. A fault code is not displayed until

the number of counts in the fault table (refer to page 2) has been

reached. For example, if the upper element fails to draw current each

time the control energizes the upper element, the count will increase

by 1. However, if the element responds normally, the count will

decrement by 1.

The View Faults and Counters function displays any fault codes in the

system. Pressing the Down Arrow takes you to the next fault code, if

any. If no fault codes are active, “- - -” is displayed. Pressing the Filter

button switches the display to the fault counters. The displayed fault

code alternates with its count value. For example, if the thermistor

T3a has registered 3 failures, its value will be 3 and the display will

alternate between “F5” and “3”.

To clear all fault codes and fault counters, press and hold the Enter

button for 5 seconds and listen for the beep.

Personality (Electric (Only) LED)- This function allows the user to

verify that the correct parameter set has been programmed into the

control board (refer to Personality Table on page 2). The Personality

allows the software to properly control the heating system. The

Personality of the water heater cannot be changed, except by

replacing the control board.

Software Revision (Vacation LED) - This function allows the user

to view the software revision that is programmed into the control. If

the software revision is not correct, the correct revision should be

uploaded.

Exiting Service Mode - To exit Service Mode without waiting for

15 minute timeout, press and hold the Up Arrow and Down Arrow

simultaneously for 5 seconds and listen for two beeps.

T2 Tank Sensor

T3b Evaporator

Outlet Sensor

T4 Compressor

Outlet Sensor

T3a Evaporator

Inlet Sensor

T5 Ambient Air

Sensor

Condensate

Overflow Senso

r

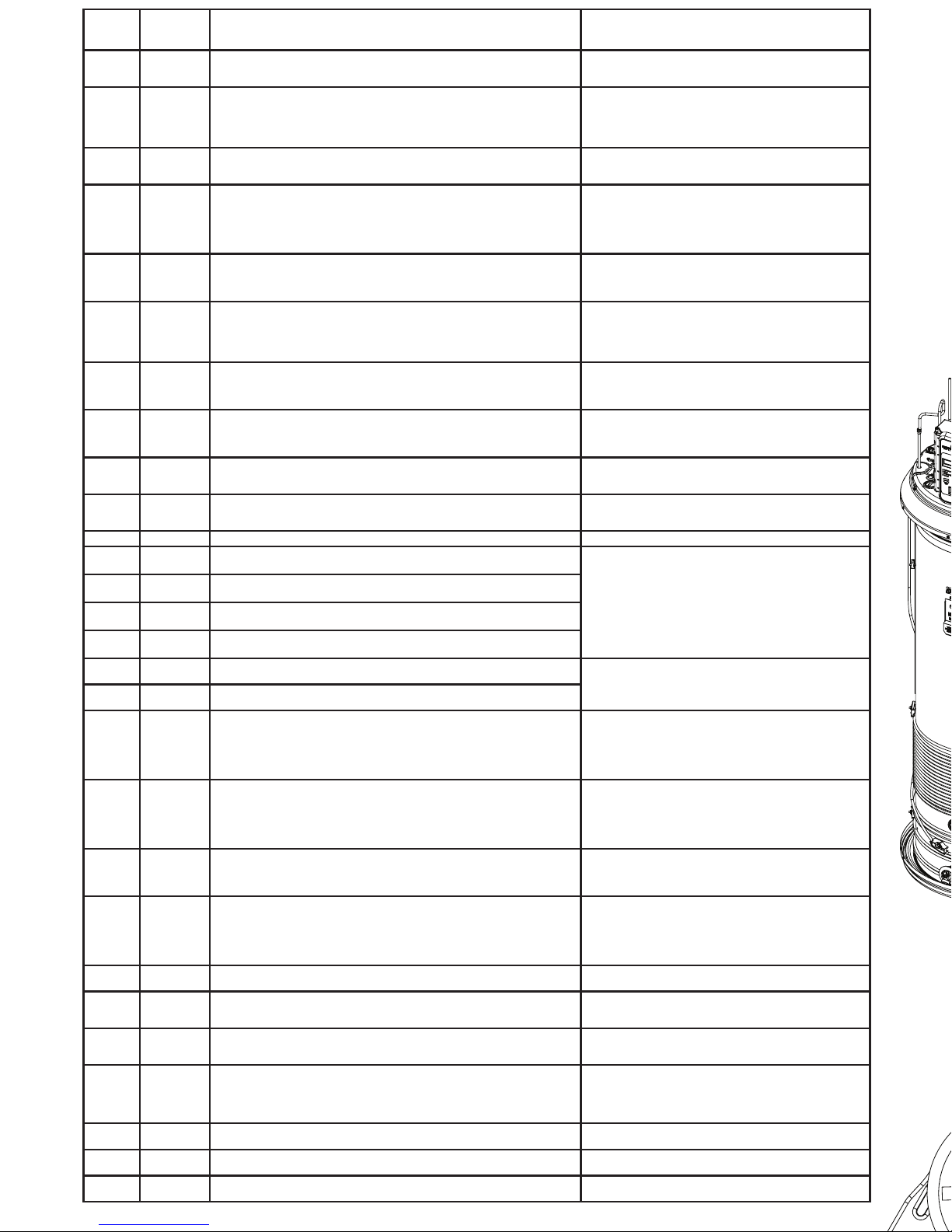

PASS/FAIL COMPONENT OPERATION

Selected Mode SS LE UE Temporary Mode (if component failure is

detected)

Any P P P Runs in selected mode

Any F P P Electric (Only) mode

Hybrid P F P Hybrid Mode (but uses SS when LE is called for)

Electric (Only) P F P Electric (Only) Mode (UE only)

Heat Pump (Only) P F P Heat Pump (Only) mode

High Demand/Boost P F P High Demand/Boost (but uses SS when LE is called

for)

Hybrid P P F Control uses SS and LE based on demand algorithm

Electric (Only) P P F LE Only Mode

Heat Pump (Only) P P F Heat Pump (Only) Mode

High Demand/Boost P P F High Demand/Boost (but uses LE when UE called

for)

Any F F P Electric (Only) Mode (UE only)

Any P F F Heat Pump (Only) Mode

Any F P F LE Only Mode

Any F F F Electric (Only) Mode, displays 1 fault codes

SS = Sealed System

LE = Lower Element

UE= Upper Element

238-52395-00 02/18

Printed in USA

Page 3

Electronic Expansion Valve (EEV)

This valve replaces the capillary tube typically used in

refrigeration appliances. The EEV meters the flow of liquid

refrigerant entering the evaporator at the rate that matches the

amount of refrigerant being boiled off in the evaporator (gas).

the valve also maintains the proper “superheat” (T3b-T3a).

+

Superheat is the temperature of a gas above the boiling point

of the liquid.

FAN SHROUD

CONDENSER COIL

(Non-replaceable)

Ω

L1

L2

Fault

Code

Displayed

Fault Counts

Before Code

Displayed

Condition Check

FC**

10

Control checks to ensure evaporator is free of frost. Continuously veries

that T3a sensor (evaporator inlet temperature) is greater than 20F after 30

minutes of run time.

Probable refrigerant leak. Find and Repair.

Check T3a sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

Fd**

10

Control checks to ensure evaporator superheat

+

is OK (controlled by EEV).

Continuously veries the temperature difference between T3a sensor (evap

inlet temp) and T3b sensor (evap outlet temp) is greater than 5F after 30

mins of run time. Control also veries that T3a is greater than 10F less than

T5 ambient sensor.

Possible refrigerant leak. Check sealed system for leak.

Check that lter is clean. Check T3a, T3b and T5 sensor

mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FE**

10

Control checks to ensure the compressor discharge temperature never

exceeds 240F. Continuously veries that T4 sensor (compressor outlet

temperature) is less than 240F every minute of run time.

Possible refrigerant leak. Check sealed system for leak.

Check T4 sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FF**

10

Control checks to ensure the Electronic Expansion Valve (EEV) is operating

properly and valve rotation is within range.

Probable refrigerant leak. Find and Repair.

Check EEV wiring at control, placement of EEV coil on

EEV valve body, and operation. Conrm audible pulse of

valve homing sequence at power restart.

Check T3a and T3b sensors mounting, wiring and

resistance.

FG 10

Control checks to ensure Ambient temperature is within an acceptable range

of 35ºF < [T5 ambient] <120ºF before starting the heat pump. If not, the unit

will switch to Electric (Only) Mode for that heating cycle only.

NO fault code is shown on the display.

No failure is assumed, but this information is provided for

completeness.

FI** 10

Control checks to ensure evaporator superheat

+

is <20ºF AND the EEV

position is <450 after 30 minutes of run time. If outside these limits, this

provides an early indication of a refrigerant leak. (Note: Target superheat is

generally 10ºF, and EEV generally operates at a position much lower than

450.)

Probable refrigerant leak. Find and Repair.

Check T3a, T3b, T5 sensor mounting, wiring and resistance.

Check EEV wiring at control, coil placement, and operation.

FJ 10

Control checks to ensure that the AC current draw is <= 20.5A while the

compressor and lower heating element are both enabled. If current draw is

>20.5A, the compressor will be disabled.

Check lower heating element rated wattage. Element

wattage is stamped on the heating element terminal block.

Correct wattage can be found on the water heater’s rating

plate.

FL 10

Control checks to ensure that T3a and T3b evaporator inlet and outlet

temperatures are within 2.5ºF of the T5 ambient temperature 20

minutes after defrost begins.

Check airow: fan operation, dirty lter, dirty evaporator.

Check T3a, T3b, T5 sensor mounting, wiring and resistance. Check EEV wiring at control, coil placement, and

operation.

F2

1

T2 tank temperature sensor failure Just before compressor starts, control

checks T2 sensor is within 30F - 170F temperature range.

Check T2 sensor mounting, wiring and resistance.

Use service mode to monitor T2 sensor temperature.

If T2 sensor checks OK, control assembly may have failed.

F3

10

Compressor failure. Control energizes compressor, but current sensor

detects no current ow.

Check compressor run capacitor.

Check compressor, overloads, relay and wiring.

Use service mode to manually cycle compressor on/off.

F4 10 Fan Failure Check fan, wiring, and control connection.

F5

10

T3a sensor (evap inlet temperature) failure. The control detects the thermistor output is at or nearly shorted or open circuit.

Check respective temperature sensor mounting, wiring to

control and resistance.

Use service mode to monitor sensor temperature.

If temperature sensor checks OK, control assembly may

have failed.

F6

10

T3b sensor (evap outlet temperature) failure. The control detects the thermistor output is at or nearly shorted or open circuit.

F7

10

T4 sensor (compressor outlet) failure. The control detects the thermistor

output is at or nearly shorted or open circuit.

F8

10

T5 sensor (ambient temperature) failure. The control detects the thermistor

output is at or nearly shorted or open circuit.

F9 10

Lower heating element failure. Control energizes lower element, but cur

-

rent sensor detects no current ow.

Check respective heating element and wiring connections

at element and control.

Use service mode to cycle element and check current

draw. Control assembly may have failed.

F10 10

Upper heating element failure. Control energizes Upper element, but cur-

rent sensor detects no current ow.

F11 1

Dry Tank fault. Control checks to ensure that the T2 tank temperature

sensor has not risen more than 5ºF during the rst 22 minutes after the unit

is powered on. (The compressor is engaged for 20 minutes after a 2 minute

wait for the system to allow the high and low side pressures to equalize.)

After 1 failed Dry Tank test, “F11” is displayed. After 5 failed tests, an audible

alarm will sound.

Check to ensure the tank is full of water. If full:

Check T2 sensor mounting, wiring and resistance.

Use service mode to monitor T2 sensor temperature.

If T2 checks OK, control assembly may have failed.

bAd linE

(F12)

1

The voltage is too low at power-up. The control monitors the input line voltage1 minute after power-up, and if the voltage is below 155V, the fault code

will be displayed.

Check electrical supply line connections. Voltage should

measure within +10/-15% of either 208 or 240 VAC,

depending upon power supply. Badline counts stored in

“F12” and can be monitored via the Control when placed in

diagnostics mode.Check heating elements are not shorted

to ground.

F13

1

Stuck Key fault. This indicates there is a button on the front panel that is

stuck down. This button is inoperable. Other buttons work normally. If the

button becomes free, the fault code will clear by itself.

Check to see if all buttons are operable.

Ensure control board is fully snapped into control housing.

If board is fully seated, control assembly has failed.

DirtyFilter**

(F14)

5

Filter LED is on, and audible alarm is sounding. Filter is too dirty to enable

proper function of unit. Number of “Dirty Filter” counts are stored in the

“F14” code and can be monitored via the Control when it is placed in Diagnostics Mode. The evaporator is operating at a colder

temperature than the ambient temperature as measured by T5.

Check to ensure Filter is clean. Filter cleaning instructions

are found in the owner’s manual.

Repeated dirty lter alarms that do not resolve by cleaning

are an indication of a sealed system leak. Find and repair

AND ash software to version 4.21 or later, or replace

control.

F15 10

DataFlash fault. The microcontroller has detected a problem in the DataFlash (permanent memory storage).

Control assembly may have failed.

F18 10

Current transformer miswired. F3, F9, and F10 fault codes have all

occurred during the same heating cycle.

Check that red L2 wire is through the CT201 current

transformer on the board. If it is, board needs to be

replaced

F19 10

Low line voltage during compressor operation. Sagging voltage occurs

over time, not at startup like a fault F12- bAd linE.

Check incoming line voltage is within +10/-15% of either

208 or 240 VAC, depending upon power supply.

Check heating elements are not shorted to ground.

F20 10

Condensate drain pan port blocked. Water heater will only operate in

Electric (Only) mode until the drain port is cleared and the sensor

is no longer in contact with water.

Check main drain on condensate drain pan. Unblock if

necessary. Check that the sensor is in the correct position

in the drain pan, on the screw post near the main drain

port. Ensure drain ttings do not reduce diameter at the

drain pan port and cause water to build up in pan.

F21 1

Application Update Failure. A problem occurred while updating the control

application.

Cycle power and try to complete the update again. If prob-

lems persist, reash software or replace the control board.

F22 1

Parametric Data Update Failure. A problem occurred while updating

parametric data.

Cycle power and try to complete the update again. If prob-

lems persist, reash software or replace the control board.

F23 10

Micro A/D Failure. The control has detected a microcontroller input port has

failed.

The control needs to be replaced.

* on some models ** Technicians use TB01-16

238-52395-00 02/18

Page 4

Electronic Expansion Valve (EEV)

This valve replaces the capillary tube typically used in

refrigeration appliances. The EEV meters the flow of liquid

refrigerant entering the evaporator at the rate that matches the

amount of refrigerant being boiled off in the evaporator (gas).

the valve also maintains the proper “superheat” (T3b-T3a).

+

Superheat is the temperature of a gas above the boiling point

of the liquid.

FAN SHROUD

EEV

EVAPORATOR COIL

CONDENSER COIL

(Non-replaceable)

5.1 Ω

5.03

Ω

R

C

S

R

S

C

Condensate Pan

WRAPPER / TANK AREA

EVAPORATOR

FAN SHROUD

TCO

DLB

CT

UELECOMPFAN

L1

L2

(Tank) T2

(Eva porator Inlet) T3a

(Eva porator Outlet) T3b

(Compr essor Discha rge) T4

(Ambient) T5

T5

T3a

T3b

COMP

OL

LE

UE

EEV

Sheet Metal

COM

COM

COM

COM

COM

NO

NO

NO

NO

NO

NC

1

2

3

4

Control Board

RJ-45

Run

Capa citor

R

S

OL

C

K305 / 6

J701

J702

J703

J501

K301K302

K303

K304

CT201

J301

J302

J303

J801

J502

Level

Sensor

TOP COVER

MID TOP COVER

SHROUD AREA

BLACKRED

YELLOW

PURPLE

ORANGE

BROWN

GRAY

BLUE

BROWN

PINK

T2

GRAY

BROWN

YELLOW

BLACK

PINK

BLUE

YELLOW

4500W

12.8Ω ~ 18.75A

4000W

14.4Ω ~ 16.67A

238-52395-00 02/18

Blue - L1

Black - Run Capacitor

Yellow - L2

Personality Model Number

000 No Model

53A RE2H50S*-1NCWT

83A RE2H80T*-1NCWT

Page 5

Bradford White Chauffe-eau à thermopompe RE2H50, RE2H80

REMARQUE IMPORTANTE SUR LA

SÉCURITÉ

Cette information est dédié aux personnes possédant

une expérience adéquate en électricité, électronique

et mécanique. Toute tentative de réparation d’un

gros appareil peut occasionner des blessures et des

dommages matériels. Le fabricant ou le vendeur ne peut

être responsable de l’interprétation de cette information

ni n’assume aucune responsabilité à l’égard de son

utilisation. Ce guide de référence condensé n’est fourni

qu’à titre informatif seulement et il ne remplace ni ne

modifie d’aucune manière le manuel d’utilisation et les

instructions d’installation.

DÉBRANCHER L’ALIMENTATION AVANT LA

RÉPARATION

IMPORTANT- REBRANCHER TOUS LES

DISPOSITIFS DE MISE À LA TERRE

Toutes les pièces de cet appareil transportant un

courant électrique sont mises à la terre. Si les câbles,

vis, courroies, pinces, écrous ou rondelles utilisés afin

de terminer un cheminement de mise à la terre sont

enlevées pendant la réparation, ces pièces doivent être

réinstallées comme à l’origine et fixées correctement.

FICHE TECHNIQUE

Capacité .................................189,3/302 L (50/80 gal)

Pression de fonctionnement maximale du chauffe-eau

.. ..............................................................................150

lb/po² (1,03 kPa)

Échelle de température du point

de consigne .................. 37,7 à 60 °C (100 à 140 °F)

Électricité ...........................240/208 VCA 60 Hz 1-PH

Disjoncteur.............................................................30 A

Puissance de l’élément supérieur .............. 4500/3380

Puissance de l’élément inférieur ................ 4000/3004

SYSTÈME FRIGORIFIQUE

Compresseur ......................................................500 W

Charge de fluide frigorigène (R134a) ....... 825 g/876 g

(189/303 L)

Compresseur LRA ............................................. 14,0A

Compresseur RLA ............................................. 2,56A

Pression côté élevé typique (70°F amb) ... 210-280

PSIA

Pression côté bas typique (70°F amb)

..55-65 PSIA

Thermopompe (Seulement)

Pour utiliser seulement la thermopompe.

Hybride

Pour utiliser la thermopompe et les

éléments chauffants électriques.

Afficheur

Affiche la température actuelle et le

nombre de jours du mode vacances.

Pour afficher le point de réglage actuel si

si l’affichage s’est effacé, appuyez sur

n’importe quel bouton.

Électrique (Seulement)

Pour utiliser seulement les éléments électriques.

Pour arrêter la thermopompe et la

circulation d’air frais.

Vacances

Utilisez ce mode lorsque vous

partez loin de la maison.

Mode

Appuyez sur ce bouton pour basculer entre les

divers modes de chauffage. Appuyez et maintenez

enfoncé pour basculer entre les degrés F ou C.

Touche à flèche

Utilisez les flèches vers le haut ou le bas pour

modifier manuellement la température de l’eau

ou sélectionner les jours du mode de vacances.

Sauvegarde

Appuyer pour confirmer les choix.

Filtre

Le témoin DEL rouge indique que le filtre doit être

nettoyé. Appuyez et maintenez enfoncé pour

réinitialiser.

T5 Air ambiant

Échangeur de chaleur à double paroi, adapté pour le

raccordement à l’eau potable.

MISE EN GARDE

238-52395-00 02/18

Page 6

Soupape de détente électronique (EEV)

Cette soupape remplace le tube capillaire utilisé typiquement

dans les appareils frigorifiques. La soupape de détente

électronique mesure le débit de liquide frigorifique pénétrant

dans l’évaporateur selon un rythme correspondant à la

quantité de réfrigérant bouilli de l’évaporateur (gaz). Cette

soupape maintient également une “surchauffe” adéquate

(T3b-T3a).

+

La température de surchauffe d’un gaz se situe au-dessus du

point d’ébullition d’un liquide.

FLASQUE DU

VENTILATEUR

Ω

R

S

C

L1

L2

Code

d’erreur

Compte d’erreurs avant

l’afchage du

code

Situation Vérier les items suivants :

FC**

10

Le contrôle fait une vérication pour s’assurer que l’évaporateur ne comporte

pas de givre. Vérication continuelle du capteur T3 (température d’entrée de

l’évaporateur) pour s’assurer qu’elle est supérieure à 20 °F après 30 minutes

de fonctionnement.

Fuite de réfrigérant possible. Trouvez et réparez la fuite. Montage,

câblage et résistance du capteur T3a. onctionnement de la soupape

de détente électronique. Vériez le câblage de la soupape de détente

électronique (EEV) à la commande, la position du serpentin, et le

fonctionnement.

Fd**

10

Vérication de commande pour assurer la surchauffe+adéquate. Vérie continuellement si la différence de température entre le capteur T3a (temp. entrée de

l’évaporateur) et le capteur T3b (temp. sortie de l’évaporateur est supérieure à -15 ºC

(5 ºF) après 30 minutes de fonctionnement. Vérication de commande pour assurer

que la température du T3a est supérieure à -12,2 ºC (10 ºF), inférieure au capteur

ambiant T5.

Fuite de réfrigérant possible. Vériez l’absence de fuite dans le

système scellé..

Montage, câblage et résistance des capteurs

T3a, T3b et T5. Fonctionnement de la soupape de détente

électronique. Vériez le câblage de la soupape de détente

électronique (EEV) à la commande, la position du serpentin, et

le fonctionnement.

FE**

10

Vérication de commande pour assurer que la température d’évacuation du compresseur ne dépasse pas 115,5 ºC (240 ºF). Vérication de commande continuelle pour

que le capteur T4 (température de sortie du compresseur) est inférieure à 115,5 ºC

(240 ºF) à chaque minute de fonctionnement.

Fuite de réfrigérant possible. Vériez l’absence de fuite dans le

système scellé.

Montage, câblage et résistance du capteur T4.

Vériez le câblage de la soupape de détente électronique (EEV) à la

commande, la position du serpentin, et le fonctionnement.

FF**

10

Vérication de commande pour s’assurer que la soupape de détente

électronique (EEV) fonctionne correctement et que la rotation de la soupape

s’effectue dans les limites.

Fuite de réfrigérant possible. Trouvez et réparez la fuite. Vériez le

câblage de la soupape de détente électronique (EEV) à la commande,

la position du serpentin sur le corps de soupape, et le fonctionnement.

Conrmez l’audition d’une pulsation de séquence de guidage de la

soupape à la remise sous tension. Montage, câblage et résistance du

capteur T3a et T3b.

FG 10

Vérication de commande pour s’assurer que la température ambiante se situe dans

une plage acceptable de 35ºF < [T5 ambiant] < 120 ºF avant le démarrage de la

thermopompe. Sinon, l’appareil passera en mode

Électrique (uniquement)

pour ce

cycle de chauffage seulement.Le code de panne NO apparaît sur l’afcheur.

Aucune panne n’est considérée, cette information est fournie

en complément.

FI** 10

Vérication de commande pour s’assurer que la surchauffe+de l’évaporateur est infé-

rieure à 20ºF ET que la position EEV est inférieure à 450 après 30 minutes d’exécution.

Des valeurs se trouvant à l’extérieur de ces limites sont une indication précoce d’une

fuite de réfrigérant. (Remarque : En règle générale, la surchauffe ciblée est de 10 ºF et

la soupape EEV fonctionne à une position bien inférieure à 450.)

Fuite de réfrigérant possible. Trouvez et réparez la fuite. Vériez

le montage, le câblage et la résistance des capteurs T3a, T3b et T5.

Vériez le câblage de la soupape de détente électronique (EEV) à la

commande, la position du serpentin, et le fonctionnement.

FJ 10

Vérications du contrôle pour s’assurer que tout le courant alternatif circulant

est de <=20,5 A alors que le compresseur et l’élément chauffant inférieur sont

actifs. Si le courant circulant est >20,5 A, le compresseur sera désactivé.

Vérier la tension nominale de l’élément chauffant inférieur. La

tension de l’élément est marquée sur la plaque à bornes de

l’élément chauffant. La bonne tension peut être indiquée sur la

plaque signalétique du chauffe-eau

FL 10

Vérications du contrôle pour s’assurer que les températures d’entrée et de sortie

des évaporateurs T3a et T3b se situent dans une échelle de 2,5 °F de la température

ambiante du T5 20 minutes après le début du dégivrage.

Vériez la circulation d’air : fonctionnement du ventilateur, ltre

sale, évaporateur sale.du T3a, T3b et T5.Vériez le câblage de la

soupape de détente électronique (EEV) à la commande, la position du

serpentin, et le fonctionnement.

F2

1

Panne de la sonde thermique du réservoir T2. Avant le démarrage du compresseur, la

commande de la sonde thermique du réservoir vérie si la température du capteur T2

se situe entre -1,1 et 76,6 ºC (30 et 170 ºF).

Montage, câblage et résistance du capteur T2. Utilisez le mode

d’entretien pour surveiller la température du capteur T2. Si le capteur

T2 vérie OK, le montage de la commande peut avoir échoué.

F3

10

Panne du compresseur. La commande alimente le compresseur, mais le

capteur actuel ne détecte pas de courant.

Vériez le condensateur de démarrage du compresseur. Vériez

le compresseur, les surcharges, le relais et le câblage. Utilisez le

mode d’entretien pour mettre le compresseur sous et hors tension en

alternance.

F4 10 Panne du ventilateur

Vériez le ventilateur, le câblage et la connexion de la commande.

F5

10

Panne du capteur T3a (température d’entrée de l’évaporateur). La commande détecte que la sortie du thermistor est sur le point d’être court-circui

-

tée ou que le circuit est ouvert.

Vériez respectivement le montage du capteur de température, le

câblage à la commande et la résistance.

Utilisez le mode service pour surveiller la température du capteur.

Si le capteur de température vérie OK, le montage de la commande

peut avoir échoué.

F6

10

Panne du capteur T3b (température de sortie de l’évaporateur). La commande détecte que la sortie du thermistor est sur le point d’être court-circuitée ou que le circuit est ouvert.

F7

10

Panne du capteur T4 (sortie du compresseur). La commande détecte que la

sortie du thermistor est sur le point d’être court-circuitée ou que le circuit est

ouvert.

F8

10

Panne du capteur T5 (température ambiante). La commande détecte que la

sortie du thermistor est sur le point d’être court-circuitée ou que le circuit est

ouvert.

F9 10

Panne de l’élément inférieur. La commande alimente l’élément inférieur, mais

le capteur ne détecte pas de courant.

Vériez respectivement l’élément chauffant et les connexions de

câblage à l’élément et la commande.

Utilisez le mode service pour allumer et éteindre l’élément en alter-

nance et vériez l’appel de courant.

Le montage de la commande peut avoir échoué.

F10 10

Panne de l’élément supérieur. La commande alimente l’élément inférieur,

mais le capteur ne détecte pas de courant.

F11 1

Erreur de réservoir vide. Vérication de commande pour s’assurer que le capteur de

température T2 du réservoir n’a pas augmenté de plus de 5 ºF dans les 22 premières

minutes suivant la mise sous tension de l’appareil. (Le compresseur est activé pendant 20 minutes après un délai d’attente de 2 minutes du système pour permettre la

stabilisation des pressions hautes et basses). Le code F11 apparaîtra après un essai

de réservoir vide échoué. Une alarme se fera entendre après 5 essais échoués.

Vériez que le réservoir est rempli d’eau. S’il est plein, vériez

le montage du capteur T2, le câblage et la résistance.

Utilisez le mode service pour surveiller la température du

capteur T2. Si le capteur T2 vérie OK, le montage de la commande peut avoir échoué.

bAd linE

(F12)

1

La tension est trop basse lors de la mise en marche. La commande surveille

la tension de la ligne d’entrée 5 secondes après la mise en marche, et si la

tension est sous 155V, le code de panne sera afché.

Vériez les connexions de la ligne d’alimentation électrique. La tension

devrait mesurer +10/-15 % de 208 ou 240 Vca selon le type d’alimentation électrique. Le comptage des lignes défectueuses est mémorisé

dans « F12 » et il peut être surveillé au moyen de la commande

lorsque placé en mode diagnostic. Vériez que les éléments chauffants

ne sont pas court-circuités à la terre.

F13

1

Erreur de touche coincée. Ceci indique qu’un bouton du panneau frontal a

été enfoncé et est demeuré coincé. Ce bouton est défectueux. Les autres

boutons fonctionnent normalement. Si le bouton se dégage, le code d’erreur

disparaîtra.

Le fonctionnement correct de tous les boutons.

Assurez-vous que le panneau de commande est complètement

encliqueté dans son logement. Si le panneau est correctement

encliqueté, le montage de la commande a échoué.

DirtyFilter**

(F14)

5

Le témoin DEL du ltre est allumé et l’alarme émet un signal sonore. Le ltre

est trop sale et empêche l’appareil de bien fonctionner. Le nombre d’erreurs

de ltre sale est sauvegardé sous le code F14 et peut être surveillé par le

contrôle lorsque ce dernier est au mode de diagnostic. L’évaporateur fonctionne à une température plus froide que la température ambiante mesurée

par le T5.

Vériez le ltre et assurez-vous qu’il est propre. Les instructions

de nettoyage du ltre se trouvent dans le manuel du proprié-

taire.

Les alarmes de ltre sale répétitives se reproduisant après

avoir nettoyé le ltre peuvent être un indice de défectuosité

du ventilateur. Trouvez et réparez la fuite ET mettez le logiciel

ash à jour avec la version 4.21 ou supérieure, ou remplacez

la commande.

F15 10

Erreur des données permanentes - Le microcontrôleur a détecté un problème

de la mémoire de stockage permanente.

Le montage de la commande peut avoir échoué.

F18 10

Mauvais état du raccordement de courant du transformateur, les codes d’erreur F3,F9 et F10 sont survenus pendant le même cycle de chauffage.

Assurez-vous que le l rouge L2 est acheminé vers transformateur de

courant CT201 depuis le panneau de commande. Si c’est le cas, le

panneau de commande doit être remplacé.

F19 10

Faible tension de ligne pendant le fonctionnement du compression. Des échissements de tension se produisent avec le temps, mais pas au démarrage

comme dans le cas d’une erreur F12- bAd linE.

Vériez que la tension de la ligne d’entrée mesure +10/-15 %

de 208 ou 240 Vca selon le type d’alimentation électrique.

Vériez que les éléments chauffants ne sont pas court-circuités

à la terre.

F20 10

L’orice de fuite du plateau de dégivrage du condensat est obstrué. Le

chauffe-eau ne fonctionnera qu’en mode Électrique (uniquement) tant que

l’orice de fuite ne sera pas débloqué et que le capteur ne soit plus en

contact avec l’eau.

Vériez la conduite de uide principale du plateau de dégivrage de condensat. Débloquez si nécessaire. Assurez-vous que le capteur est positionné

correctement dans le plateau de dégivrage, sur la colonne à vis près de la

conduite de uide principale. Assurez-vous que les raccords de drain ne

réduisent pas le diamètre à l’orice du plateau de drainage, risquant une

accumulation d’eau dans celui-ci.

F21 1

Mise à jour de l’application a échoué. Un problème est survenu lors de mise

à jour de l’application de contrôle.

Allumez et éteignez l’appareil en alternance et tentez de mettre

à niveau une nouvelle fois. Si le problème persiste, remettez le

logiciel ash à niveau ou remplacez le panneau de commande.

F22 1

Paramétrique à jour des données échec. Un problème est survenu lors de

l’actualisation des données paramétriques.

Allumez et éteignez l’appareil en alternance et tentez de mettre

à niveau une nouvelle fois. Si le problème persiste, remettez le

logiciel ash à niveau ou remplacez le panneau de commande.

F23 10

Échec Micro A / D. Le contrôle a détecté un accès d’entrée du microcontrôleur a échoué.

Remplacer la carte de commande.

* sur certains modèles ** Techniciens utilisent TB01-16

238-52395-00 02/18

Page 7

MODE ENTRETIEN

L’accès au mode d’entretien se fait en appuyant et en maintenant

simultanément la flèche vers le haut et le bouton Enter pendant 5

secondes. Vous entendrez un signal sonore simple (1 bip) lorsque

vous appuyez sur les boutons puis un autre signal sonore double

(2 bips) vous indiquant la réussite de l’accès. Quelques instants

après, vous pourrez voir le premier affichage du thermistor T2 et sa

température en alternance selon les unités choisies (degrés Fahrenheit

ou Celsius). Le mode d’entretien s’éteindra après 15 minutes

d’inactivité du bouton.

Le mode d’entretien offre cinq fonctions : La visualisation des

thermistors, l’état et la commande des composants chauffants et la

visualisation des défauts et des compteurs, personnalité et révision de

logiciel. Vous pouvez basculer d’une fonction à une autre en appuyant

sur le bouton Mode. Le témoin DEL du mode de fonctionnement

s’allumera pour indiquer quel mode de service a été sélectionné. Voici

l’explication de ces trois fonctions :

Visualisation du thermistor (caché DEL)- La température captée

par les cinq (5) thermistors peut être surveillée. L’identité du thermistor

apparaît sur l’afficheur en alternance avec la température selon les

unités choisies - Fahrenheit ou Celsius. Appuyez sur la flèche vers le

bas pour basculer vers l’affichage du thermistor suivant sur la liste. Le

tableau suivant indique l’identité de chaque thermistor et sa fonction

dans l’appareil.

Identité Fonction

T2 Température (eau) du chaue-eau

T3a Température de l’entrée de l’évaporateur

T3b Température de sortie de l’évaporateur

T4 Température de sortie du compresseur

T5 Température d’air ambiant

État et contrôle du composant de chauffage, opération VDE (Témoin

DEL thermopompe (Seulement)) - Cette fonction affiche l’état (marche/

arrêt) de chaque composant chauffant - Élément inférieur, élément

supérieur et le compresseur (avec ventilateur) et ventilateur- et vous

permet de les éteindre ou de les mettre en marche. Le premier composant

est l’élément inférieur (LE). L’état de marche est indiqué par le chiffre 1

et l’arrêt est indiqué par le chiffre 0. Appuyez sur la flèche vers le bas

pour basculer vers l’élément supérieur (UE). Appuyez à nouveau sur la

flèche vers le bas pour basculer vers le compresseur (avec ventilateur),

(Co). Appuyez une fois de plus sur la flèche vers le bas pour passer au

ventilateur (Fn). L’afficheur n’indiquera qu’un seul composant à la fois. Les

éléments seront affichés pendant seulement cinq (5) minutes sans recours

au rafraîchissement à l’aide de l’un des boutons situés sur le panneau

frontal. La durée d’affichage du compresseur est de dix (10 minutes). La

position sera montré. Appuyez sur la touche Enter pour ouvrir le EEV par

incréments de 10, de 80 à 450. Après avoir atteint 450, en appuyant sur

Enter fermera la soupape par incréments de 10.

Visualisation des erreurs et des compteurs (DEL hybride) – Le

contrôle compte le nombre de fois qu’une erreur est enregistrée. Un

code d’erreur ne s’affiche pas tant que le nombre compté ne dépasse

pas le barème d’erreurs (consultez la page 2). Par exemple, si l’élément

supérieur n’est pas alimenté chaque fois que la commande de mise sous

tension de l’élément supérieur, le nombre augmente de 1. Toutefois, si

l’élément répond normalement, le nombre diminue de 1.

La fonction de visualisation des erreurs et des compteurs affiche tous

les codes d’erreurs du système. Appuyez sur la flèche vers le bas pour

passer au code d’erreur suivant, le cas échéant. L’affichage “- - -” indique

qu’aucun code d’erreur n’est actif. Appuyez sur le bouton Filter (filtre) pour

passer à l’affichage des compteurs d’erreurs. Le code d’erreur et la valeur

du compte s’affichent alternativement. Par exemple, si la thermistance T3a

a enregistré 3 erreurs, sa valeur sera de 3 et basculera entre « F5 » et «

3 ».

Pour effacer tous les codes d’erreurs et les compteurs d’erreurs, appuyez

et maintenez le bouton Enter (sauvegarder) pendant 5 secondes et

attendez le signal sonore.

Personnalité (DEL pour Électrique (Seulement) – Cette fonction

permet à l’utilisateur de vérifier le bon réglage des paramètres

programmés depuis le tableau de commande (consultez le tableau

Personnalité à la page 2). Cette fonction de personnalité permet au logiciel

de contrôler adéquatement le système de chauffage. La personnalité du

chauffe-eau ne peut pas être modifiée sauf si l’on remplace le tableau de

commande.

Révision du logiciel (témoin DEL de vacances) – Cette fonction permet

à l’utilisateur de visualiser la révision du logiciel programmé au contrôle.

Veuillez télécharger la bonne révision du logiciel si ce dernier n’est pas à

jour.

Quitter le mode d’entretien - Pour quitter le mode d’entretien sans

attendre le temps d’arrêt de quinze (15) minutes, appuyez et maintenez

les flèches vers le haut et vers le bas enfoncé simultanément pendant cinq

(5) secondes et attendre les deux bips.

Capteurs de température

Capteur Description

(Couleur

de l)

Échelle de

température

normale

Plage de

résistance en

ohms

Résistance à

25 ºC

(77 ºF)

T2 Réservoir

(Blanc)

1 à 71 ºC

(30 à 160 ºF)

34K-1.75K 10K

T3a Entrée

Évaporateur

(Rouge)

9,4 à 54,4 ºC

(15 à 130 ºF)

57K-3K 10K

T3b Sortie

Évaporateur

(Blanc)

9,4 à 54,4 ºC

(15 à 130 ºF)

57K-3K 10K

T4 Sortie

Compresseur

(Bleu)

1 à 121 ºC

(30 à 250 ºF)

188K-3K 55K

T5 Ambiant

(Jaune)

9,4 à 54,4 ºC

(15 à 130 ºF)

57K-3K 10K

T4 Sortie du

Compresseur

T5 Air ambiant

T3a Capteur d'entrée

de l'évaporateur

T3b Capteur de sortie

de l'évaporateur

T2 Sonde thermique

du réservoir

Condensate

Overflow Sensor

238-52395-00 02/18

Mode temporaire (si la panne du composant est détectée)

Mode choisi SS LE UE

Mode temporaire (si la panne du composant est détectée)

Tous P P P Fonctionnement au mode choisi

Tous F P P Mode Électrique (Seulement)

Hybride P F P Mode Hybride (mais utilise SS lorsque LE est

sollicité)

Électrique (Seulement)

P F P Mode Électrique (Seulement) (UE seulement)

Thermopompe(seulement)

P F P Mode thermopompe (seulement)

Demande élevée/

optimale

P F P

Demande élevée (avec utilisation SS lorsque LE est

sollicité)

Hybride P P F

Commande utilisant SS et LE selon la demande

d’algorithme

Électrique (Seulement)

P P F Mode LE seulement

Thermopompe(seulement)

P P F Mode thermopompe (seulement)

Demande élevée/

optimale

P P F Demande élevée (utilise LE lorsque UE est sollicité)

Tous F F P Mode Électrique (Seulement) (UE seulement)

Tous P F F Mode thermopompe (seulement)

Tous F P F Mode LE seulement

Tous F F F Mode Électrique (Seulement), afche 1 codes de

panne

SS = Système scellé

LE = Élément inférieur

UE= Élément supérieur

Page 8

Soupape de détente électronique (EEV)

Cette soupape remplace le tube capillaire utilisé typiquement

dans les appareils frigorifiques. La soupape de détente

électronique mesure le débit de liquide frigorifique pénétrant

dans l’évaporateur selon un rythme correspondant à la

quantité de réfrigérant bouilli de l’évaporateur (gaz). Cette

soupape maintient également une “surchauffe” adéquate

(T3b-T3a).

+

La température de surchauffe d’un gaz se situe au-dessus du

point d’ébullition d’un liquide.

FLASQUE DU

VENTILATEUR

SERPENTIN D'

ÉVAPORATEUR

SOUPAPE DE DÉTENTE

ÉLECTRONIQUE

SERPENTIN DU

(irremplaçable)

CONDENSEUR

5.1 Ω

5.03

Ω

R

C

S

R

S

C

Bleu – L1, surcharge du compresseur

Noir – Condensateur de marche

Jaune – L2, élément supérieur

TCO

DLB

CT

UELECOMPFAN

L1

L2

T5

T3a

T3b

COMP

OL

LE

UE

EEV

COM

COM

COM

COM

COM

NO

NO

NO

NO

NO

NC

1

2

3

4

RJ-45

R

S

OL

C

K305 / 6

J701

J702

J703

J501

K301K302

K303

K304

CT201

J301

J302

J303

J801

J502

ORANGE

T2

(Tank) T2

(Entrée évaporateur) T3a

(Sortie évaporateur) T3b

(Refoulement compresseur) T4

(Ambiant) T5

ZONE ÉPAULEMENT

Panneau de commande

NOIR

ROUGE

Feuille métalliquel

GRIS

COUVERCLE SUPÉRIEUR

ÉPAULEMENT VENTILATEUR

ÉVAPORATEUR

Plateau condensat

Capteu

niveau

BRUN

de marche

Condensateur

NOIR

COUVERCLE

MI-HAUTEUR

ZONE ENVELOPPE/RÉSERVOIR

JAUNE

JAUNE

ROSE

BLEU

BLEU

ROSE

GRIS

BRUN

BRUN

POURPRE

JAUNE

4500W

12.8Ω ~ 18.75A

4000W

14.4Ω ~ 16.67A

238-52395-00 02/18

Personnalité No modèle

000 No Model

53A RE2H50S*-1NCWT

83A

RE2H80T*-1NCWT

Loading...

Loading...