B&R PP21, PP41 User Manual

Power Panel

User's Manual

Version: 1.4 (July 2002)

Model No.: MAPP01-E

We reserve the right to change the contents of this manual without warning. The information

contained herein is believed to be accurate as of the date of publication, however, Bernecker +

Rainer Industrie-Elektronik Ges.m.b.H. makes no warranty, expressed or implied, with regards

to the products or the documentation contained within this book. In addition, Bernecker + Rainer

Industrie-Elektronik Ges.m.b.H. shall not be liable in the event of incidental or consequential

damages in connection with or arising from the furnishing, performance, or use of these

products.

Software names, hardware names, and trademarks used in this document are registered by the

Power Panel User's Manual 1

2 Power Panel User's Manual

Chapter 1: Power Panel

Chapter 2: Technical Appendix

Index

Power Panel User's Manual 3

4 Power Panel User's Manual

Contents

Chapter 1: Power Panel ................................................................... 7

1. Safety Guidelines .................................................................................................. 7

1.1 Introduction ...................................................................................................... 7

1.2 Intended Use .................................................................................................... 7

1.3 Transport and Storage ..................................................................................... 7

1.4 Installation ........................................................................................................ 8

1.5 Operation ......................................................................................................... 8

1.5.1 Protection against Touching Electrical Parts .............................................. 8

2. Safety Notices ....................................................................................................... 9

3. Manual History ...................................................................................................... 9

4. General Information ............................................................................................ 10

4.1 Introduction .................................................................................................... 10

4.2 Features ......................................................................................................... 10

4.3 Photo .............................................................................................................. 11

5. Power Panel PP21 .............................................................................................. 12

5.1 Order Data ..................................................................................................... 12

5.2 Photo .............................................................................................................. 13

5.3 Technical Data ............................................................................................... 13

5.4 Images ........................................................................................................... 17

5.5 Dimensions .................................................................................................... 18

6. Power Panel PP41 .............................................................................................. 19

6.1 Order Data ..................................................................................................... 19

6.2 Photo .............................................................................................................. 20

6.3 Technical Data ............................................................................................... 20

6.4 Images ........................................................................................................... 24

6.5 Dimensions .................................................................................................... 25

7. Power Panel Expansion EX101 Module ............................................................. 25

7.1 General Information ....................................................................................... 25

7.2 Order Data ..................................................................................................... 25

7.3 Photo .............................................................................................................. 26

7.4 Technical Data ............................................................................................... 27

7.5 Images ........................................................................................................... 27

7.6 Dimensions .................................................................................................... 28

7.7 Installation ...................................................................................................... 29

8. IF370 CAN Interface Module ............................................................................... 30

8.1 General Information ....................................................................................... 30

8.2 Order Data ..................................................................................................... 30

Power Panel User's Manual 5

Contents

8.3 Photo .............................................................................................................. 30

8.4 Technical Data ............................................................................................... 30

8.5 Status LEDs ................................................................................................... 31

8.6 Pin Assignments ............................................................................................ 31

9. Mounting Instructions .......................................................................................... 32

10. Device Label ..................................................................................................... 33

11. Programming ..................................................................................................... 33

11.1 Programming the PLC CPU ......................................................................... 33

11.2 Visualization ................................................................................................. 33

12. Description of Components ............................................................................... 34

12.1 Status LEDs ................................................................................................. 34

12.2 Power Supply ............................................................................................... 34

12.3 Interfaces ..................................................................................................... 35

12.3.1 CAN Interface ......................................................................................... 35

12.3.2 RS232 Interface ..................................................................................... 36

12.4 Operating Mode Switch ................................................................................ 36

12.5 Programming System Flash ......................................................................... 37

12.6 PCMCIA Slot ................................................................................................ 37

12.6.1 Limitations when using Memory Cards .................................................. 38

12.7 Power Panel Interface .................................................................................. 38

12.8 Screw-in Module Overview .......................................................................... 38

12.9 Data/Realtime Buffering ............................................................................... 39

12.10 Digital Inputs .............................................................................................. 40

12.10.1 Terminal Block Connections ................................................................ 40

12.10.2 Input Circuit Diagram ........................................................................... 40

12.10.3 Connection Example ............................................................................ 41

12.11 Digital Outputs ............................................................................................ 41

12.11.1 Terminal Block Connections ............................................................... 41

12.11.2 Output Circuit Diagram ......................................................................... 42

12.11.3 Output Circuit Diagram for Potential-Free Relay Contact .................... 42

12.11.4 Connection Example for Outputs 1 - 8 ................................................ 42

12.11.5 Connection Example for Potential-Free Relay Contact ........................ 43

13. Changing the Battery ........................................................................................ 44

13.1 Battery Data ................................................................................................. 44

13.2 Buffer Duration ............................................................................................. 44

Chapter 2: Technical Appendix .................................................... 47

1. Décor Foil (polyester foil) .................................................................................... 47

2. Characters for LC Displays (English/Katakana) .................................................. 48

6 Power Panel User's Manual

Power Panel • Safety Guidelines

Chapter 1 • Power Panel

1. Safety Guidelines

1.1 Introduction

Programmable logic controllers (e.g. PLCs, etc.), operating and monitoring devices (e.g.

Industrial PCs, Power Panels, Mobile Panels, etc.) as well as the B&R uninterruptible power

supplies have been designed, developed and manufactured for conventional use in industry.

They were not designed, developed and manufactured for any use involving serious risks or

hazards that without the implementation of exceptionally stringent safety precautions could lead

to death, injury, serious physical damage or loss of any other kind. Such risks and hazards

include in particular the use of these devices in the monitoring of nuclear reactions in nuclear

power plants and of flight control systems, in flight safety, in the control of mass transportation

systems, in medical life support systems, and in the control of weapons systems.

Both when using programmable logic controllers and when using operating and monitoring

devices as control systems in conjunction with a Soft PLC (e.g. B&R Automation Runtime or

comparable products) or a Slot PLC (e.g. B&R LS251 or comparable products), the safety

precautions applying to industrial control systems (e.g. the provision of safety devices such as

emergency stop circuits, etc.) in accordance with applicable national and international

regulations must be observed. The same applies for all other devices connected to the system,

such as drives.

Chapter 1

Power Panel

All tasks such as installation, commissioning and service may only be carried out by qualified

personnel. Qualified personnel are persons who are familiar with transport, mounting,

installation, commissioning and operation of the product and have the appropriate qualifications

(e.g. IEC 60364). National accident prevention guidelines must be followed. The safety

guidelines, connection descriptions (rating plate and documentation) and limit values listed in the

technical data must be read carefully before installation and commissioning and must be

observed.

1.2 Intended Use

Electronic devices are generally not fail-safe. In the event of a failure on the programmable

control system, operating or monitoring device or uninterruptible power supply, the user is

responsible for ensuring that other devices that may be connected, such as motors, are made

safe

1.3 Transport and Storage

During transport and storage, the devices must be protected from excessive stress (mechanical

load, temperature, humidity, aggressive atmosphere).

Power Panel User's Manual 7

Power Panel • Safety Guidelines

1.4 Installation

• The installation must take place according to the documentation using suitable

equipment.

• The devices may only be installed when isolated from the power supply and by

qualified personnel.

• General safety regulations and nationally applicable accident prevention guidelines

must be observed.

• Electrical installation must be carried out according to the relevant guidelines (e.g.

line cross section, fuse, protective ground connection).

1.5 Operation

1.5.1 Protection against Touching Electrical Parts

The operation of programmable logic controlllers, operating and monitoring devices and

uninterruptible power supplies necessarily means that certain components must carry

dangerous voltage levels of over 42 VDC. A life-threatening electric shock could occur if you

touch these parts. This could result in death, severe injury or material damage.

Before turning on programmable control systems, operating and monitoring devices and the

uninterruptible power supply, ensure that the housing is properly connected to protective ground

(PE rail). The ground connection must be established even when testing the operating and

monitoring devices and the uninterruptible power supply or when operating them for only a short

time.

Before turning the device on, make sure that all voltage-carrying parts are securely covered.

During operation, all covers must remain closed.

8 Power Panel User's Manual

2. Safety Notices

Safety notices are organized as follows:

Power Panel • Safety Notices

Safety Notice Description

Disregarding the safety regulations and guidelines can result in severe injury or heavy damage to material

or the product.

Disregarding the safety regulations and guidelines can result in injury or damage to material and the product.

European dimension standards are valid for all dimension diagrams (e.g.

dimension diagrams, etc.).

3. Manual History

Version Date Comments

1.4 22.05.2002 Changes/New features

- Safety guidelines added

- Error correction: Digital inputs for PP21/PP41: Electrical isolation for input - output Yes

or digital outputs for PP21/PP41: Electrical isolation for input - output Output - Input Yes

- Pin assignment RS232 interface updated

- Guidelines for using PCMCIA memory cards regarding Tasks added

- Input and output circuit diagrams added

- Technical data regarding switching threshold for digital inputs for PP21 and PP41 deleted

Table 1: Safety notices

Chapter 1

Power Panel

1.3 04.12.2001 Changes/New features

1.2 09.11.2001 Changes/New features

- Operating system updates using the MEMCARD and mode switch described in more detail

- PCMCIA interface description added

- 7AT324.70 screw-in module included

- "Mode switch" picture replaced

- Battery buffer time improved (10 minutes guaranteed)

- Correction of description for the inputs and outputs (they are electrically isolated)

Table 2: Manual history

Power Panel User's Manual 9

Power Panel • General Information

4. General Information

4.1 Introduction

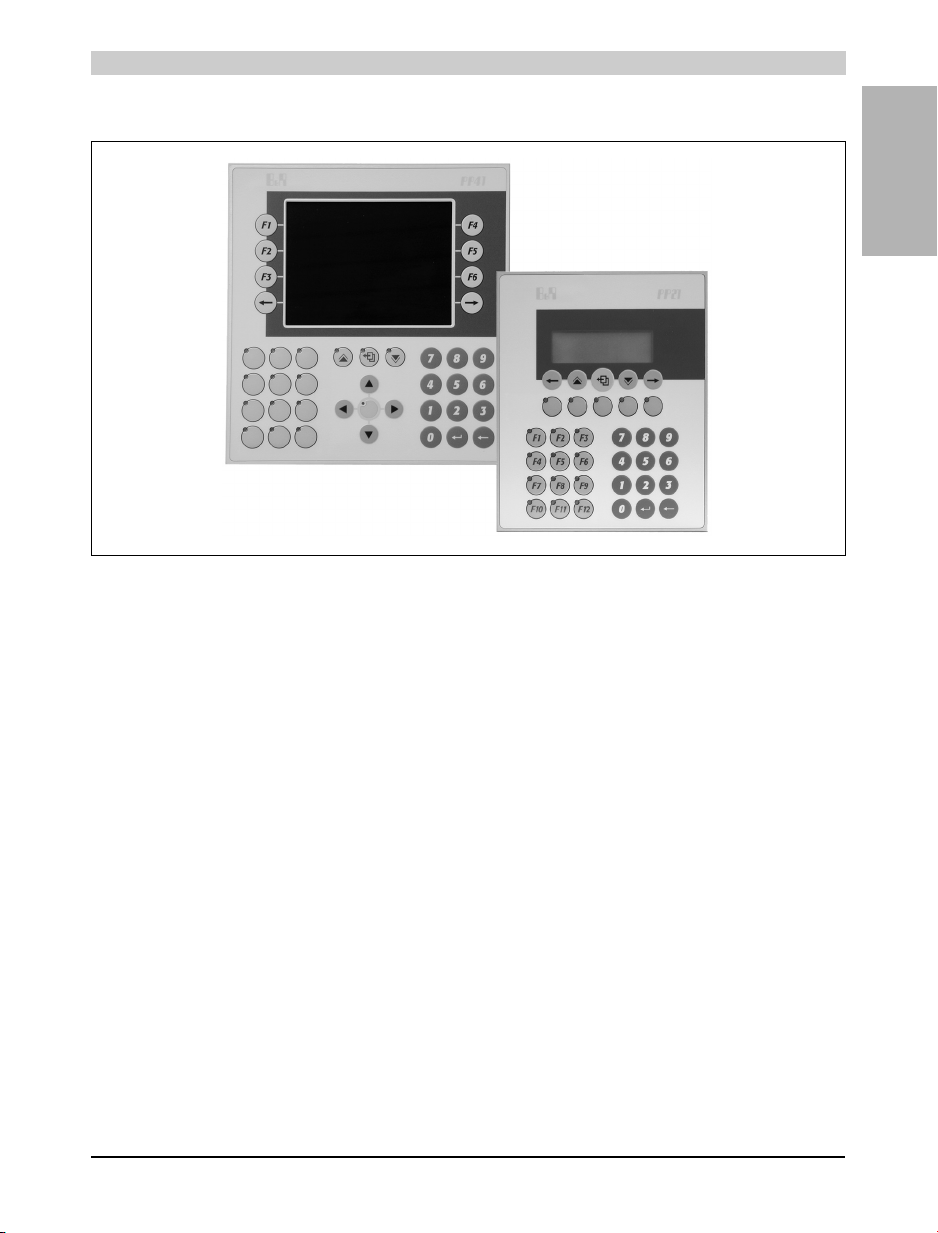

B&R offers the B&R Power Panel PP21 and PP41 for automation of small to midsize machines

and systems. The Power Panel is a combination of operator panel and controller in one device.

A 4 x 20 character text display or a ¼ VGA graphic display can be selected. Each Power Panel

is equipped with a powerful PLC CPU including integrated digital I/O and six slots for B&R

SYSTEM 2003 screw-in modules. An expansion module is offered for the Power Panel PP41

which allows the operation of B&R SYSTEM 2005 interface module inserts.

The visualization application is created using B&R Automation Studio™. Programming the PLC

CPU is done using B&R Automation Studio™ or PG2000.

4.2 Features

• 24 VDC supply voltage

• Software compatible with B&R 2000 PLC family

• PCMCIA Slot

• 10 digital inputs

• 8 digital outputs

• 1 potential-free relay contact

• RS232 Interface

• CAN bus interface

• 6 slots for B&R SYSTEM 2003 screw-in modules, 3 of which support additional functions

(TPU) such as event counting, trigger functions, stepper motor control, frequency

measurement or communication modules

• Expansion module for the Power Panel PP41 which allows the operation of B&R SYSTEM

2005 interface module inserts

10 Power Panel User's Manual

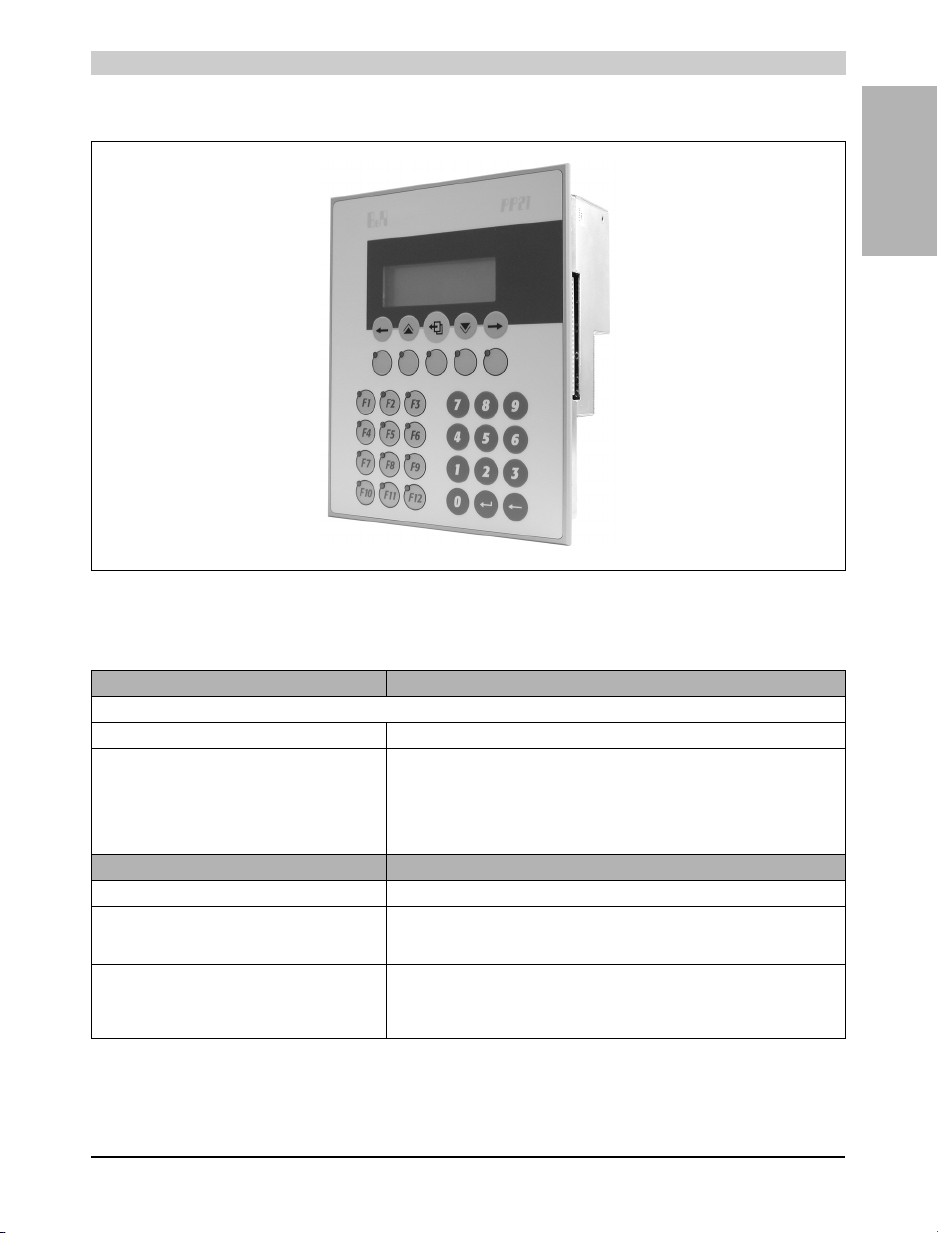

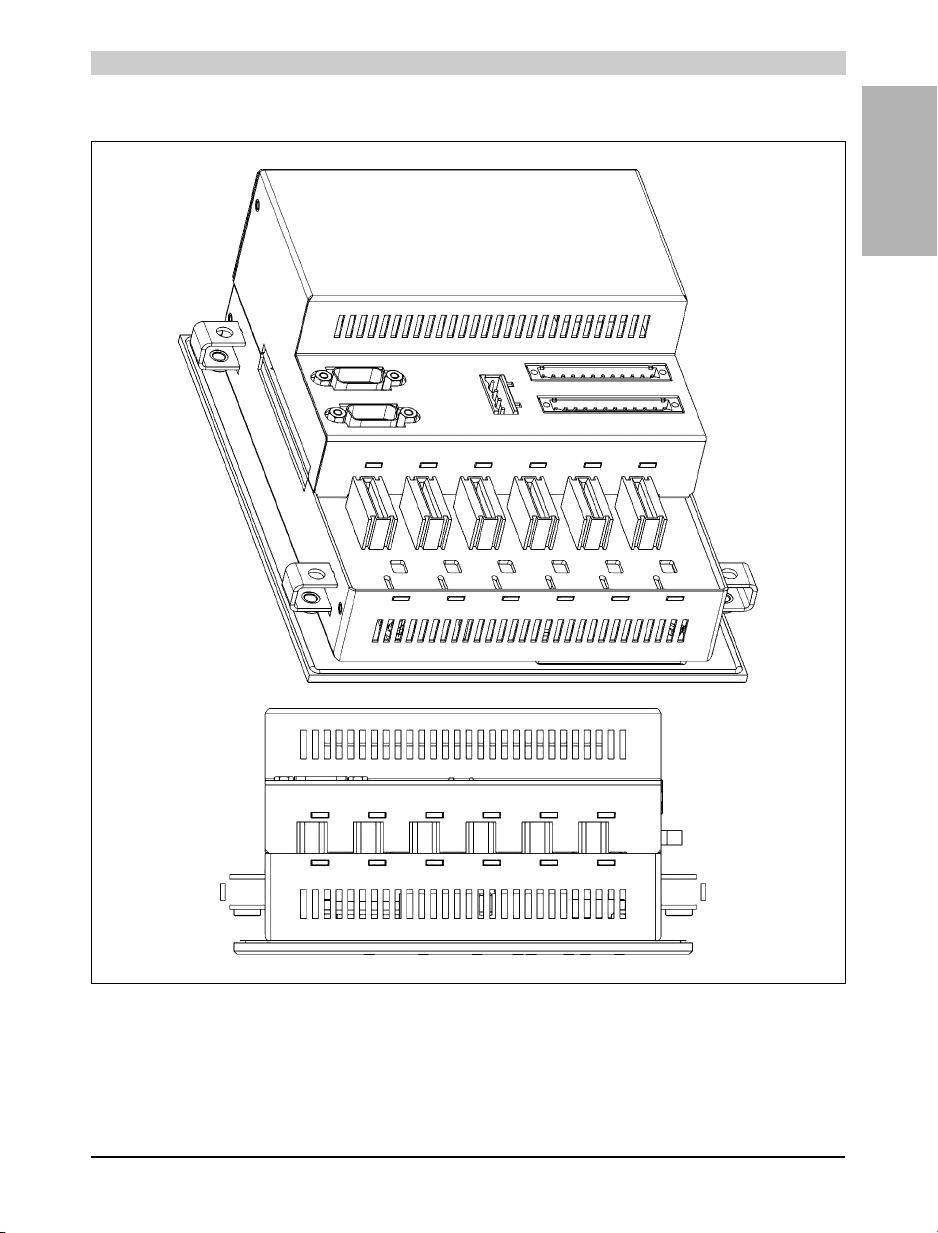

4.3 Photo

Figure 1: Power Panel

Power Panel • General Information

Chapter 1

Power Panel

Power Panel User's Manual 11

Power Panel • Power Panel PP21

5. Power Panel PP21

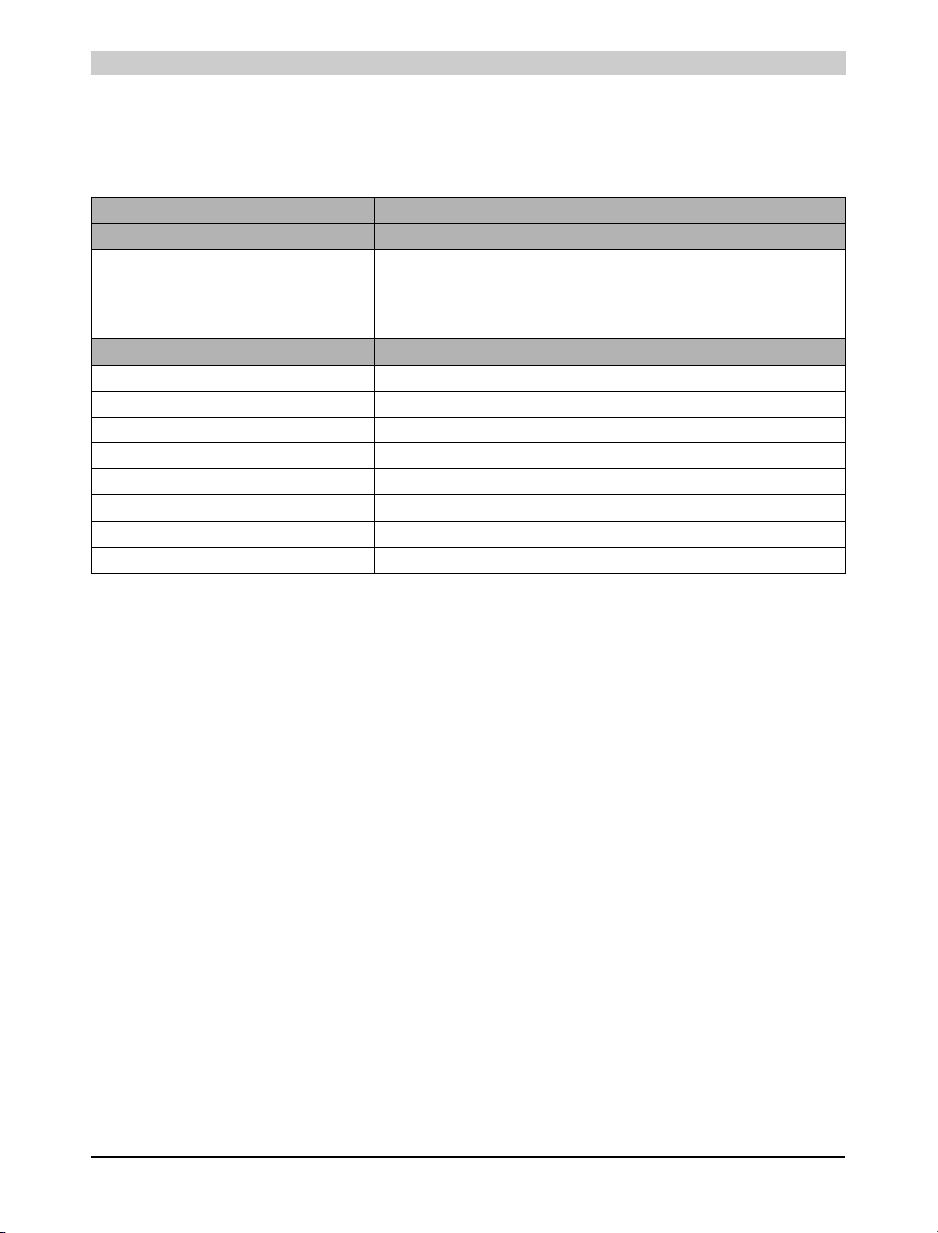

5.1 Order Data

Model Number Short Description

Power Panel

4P0420.00-490

0AC201.9 Lithium batteries, 5 pcs., 3 V / 950 mAh, button cell

0MC111.9 PCMCIA memory card, 2MB FlashPROM

0MC211.9 PCMCIA memory card, 2MB SRAM

4A0035.00-000 Set of legend strips for 4P0420.00-490 (for 10 devices)

7TB712.9 Terminal block, 12 pin, screw clamps

7TB712.91 Terminal block, 12 pin, cage clamps

7TB712:90-02 Terminal block, 12 pin, 20 pcs., screw clamps

7TB712:91-02 Terminal block, 12 pin, 20 pcs., cage clamps

1) All parts required to install the Power Panel, including key legend sheets, are included in its delivery. The backup battery and the 4 pin

1)

Power Panel PP21, LC display 4x20 characters, background lighting, 34 function keys,

system compatible 2003 CPU, 700Kb SRAM, 1.4MB FlashPROM, 1 PCMCIA slot, 1

RS232 interface, 1 CAN interface: electrically isolated, network capable, 6 slots for screwin modules, 10 digital inputs 24 VDC, 8 digital outputs 24 VDC, 0.4 A, IP65 protection (from

front), 155 x 190 mm (WxH), 24 VDC, Order TB712 terminal blocks separately!

Accessories

Table 3: Order data for the Power Panel PP21

terminal block for the supply are also included. Two 12 pin terminal blocks must be ordered separately.

12 Power Panel User's Manual

5.2 Photo

5.3 Technical Data

Power Panel • Power Panel PP21

Figure 2: Power Panel PP21

Chapter 1

Power Panel

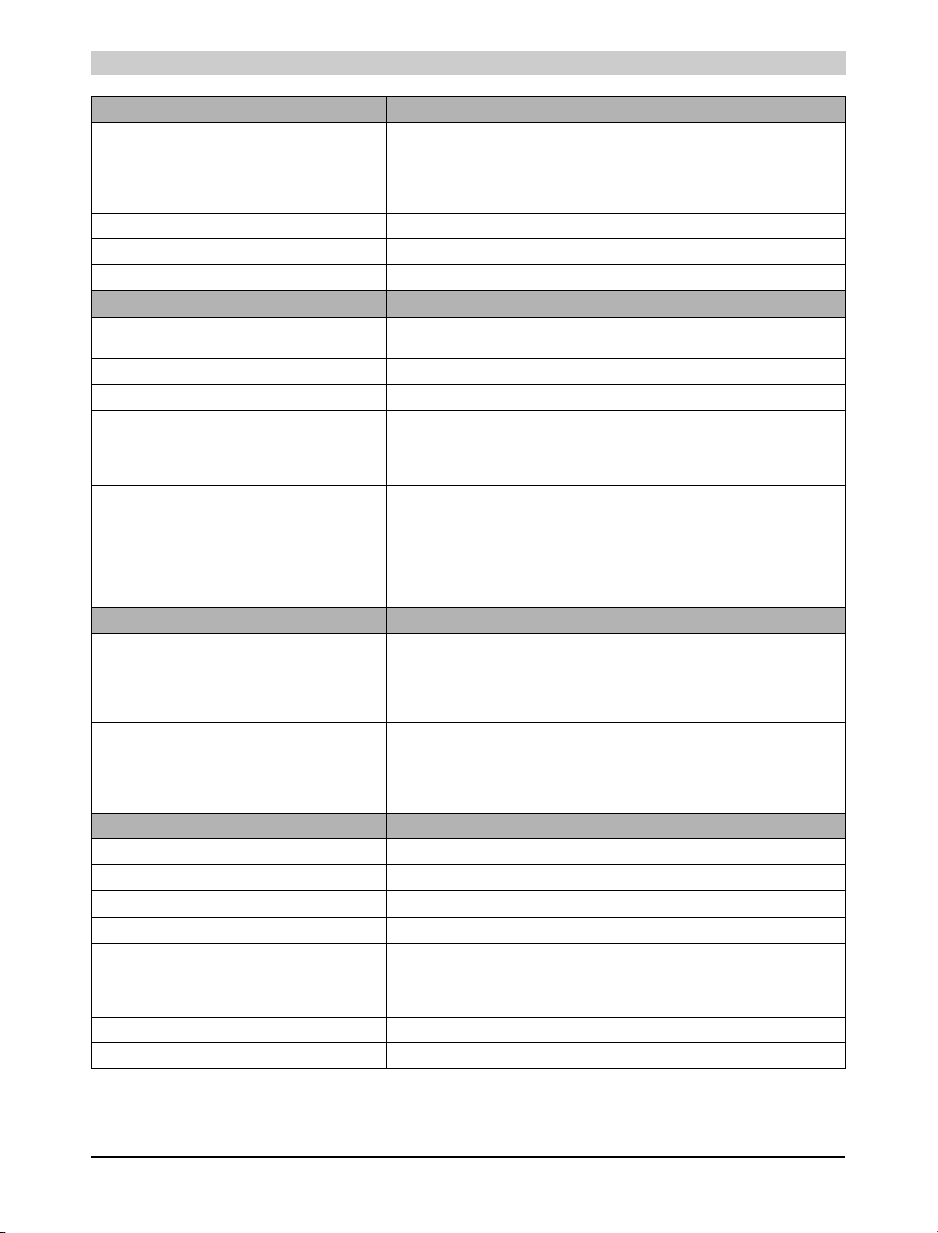

Product ID PP21

General Information

C-UL-US Listed In preparation

Standards

Temperature

Shock / Tests Carried Out

Vibration / Tests Carried Out

Emission / Tests Carried Out

Immunity / Tests Carried Out

Processor

Additional I/O Processor Handles I/O data points

Instruction Cycle Time

(Average value with 70% bit and

30% analog processing)

Standard Memory

User RAM

System PROM

User PROM

IEC61131-2 / IEC60068-2-x

IEC61131-2 / IEC60068-2-27

IEC61131-2 / IEC60068-2-6

EN50081-2 / EN55022+A1

IEC61131-2 / IEC61000-4-x

0.4 µs

700 Kbyte SRAM

600 KByte FlashPROM

1.4 MByte FlashPROM

Table 4: Technical data for PP21

Power Panel User's Manual 13

Power Panel • Power Panel PP21

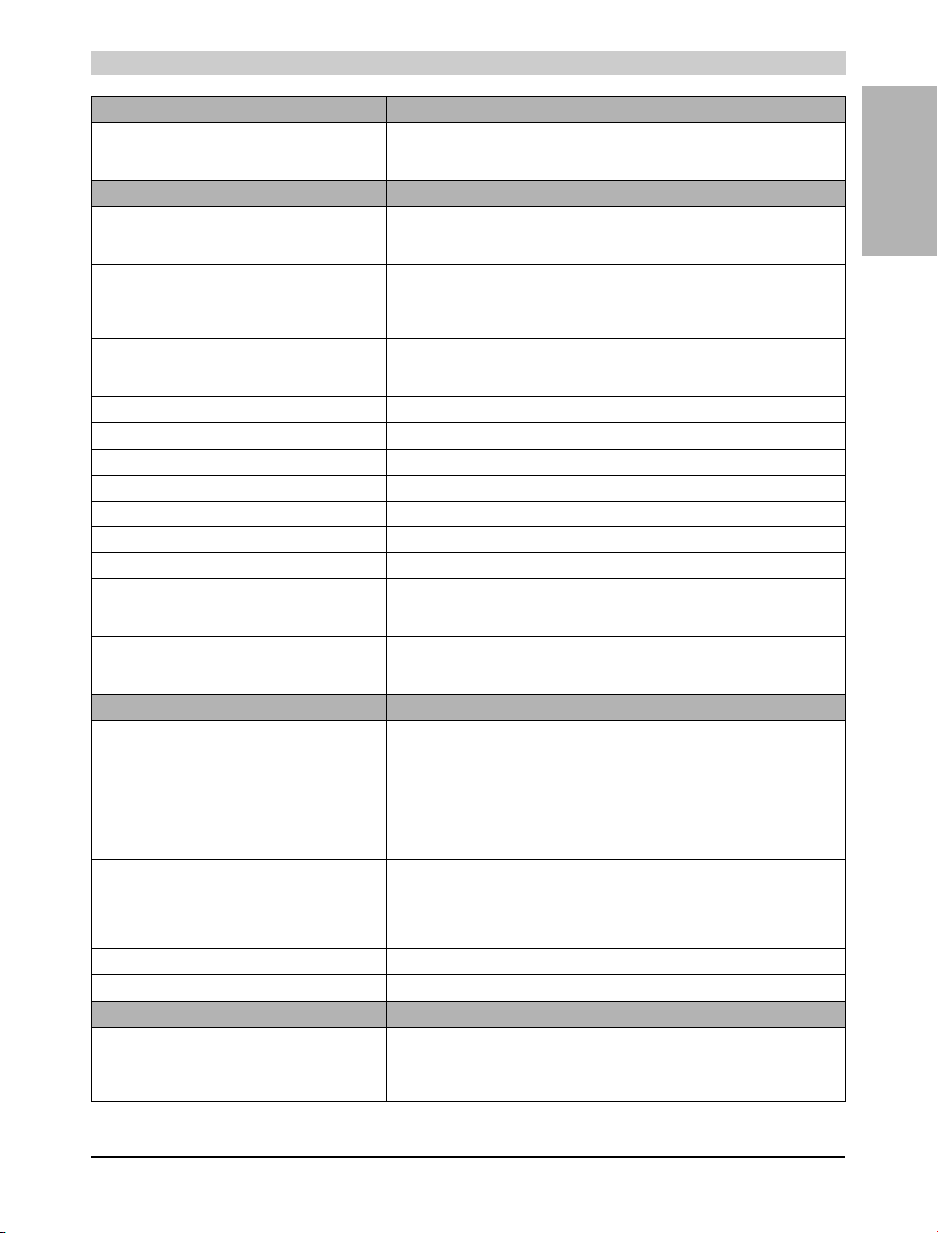

Product ID PP21

Data Buffering

Backup Battery

Buffer Current

Typical

Maximum

Hardware Watchdog Yes

Voltage Monitoring The internal supply is monitored for overvoltage and undervoltage

Fan No

Peripherals

Real-Time Clock

Resolution

Status Display LEDs

System Bus for Expansions No

Slots for B&R 2003 Screw-in Modules

Suitable for IF Modules (without CAN)

TPU Functionality Support

Suitable for CAN Communication

PCMCIA slot (See "PCMCIA Slot" on page 37.)

Standard

Card Height

Card Type

Memory Size

SRAM

FlashPROM

Standard Communication Interfaces

Application Interface IF1

Electrical Isolation

Design

Max. Distance

Max. Baud Rate

Application Interface IF2

Electrical Isolation

Design

Max. Distance

Max. Baud Rate

Digital Inputs

Number of Inputs 10

Inputs with Additional Functions (TPU) Inputs 1-4

Input Frequency (TPU) 50 kHz (Incremental encoder operation)

Wiring Sink

Input Voltage

Minimum

Nominal

Maximum

Input Current at Nominal Voltage Approx. 4 mA

Input Delay Max. 1 ms (not TPU)

Table 4: Technical data for PP21 (cont.)

Lithium battery 3 V / 950 mAh

10 µA

200 µA

Nonvolatile

1 sec

6

Slots 1-3

Slot 1 with interface module 4IF370.7

JEIDA V 4.0 or PCMCIA Standard Release 2.0

Slots 4-6

1

Max. 3 mm

Memory cards

Max. 4 MByte

Max. 4 MByte

RS232

No

9 pin DSUB plug

15 m / 19200 Baud

115.2 kBaud

CAN

Yes

9 pin DSUB plug

1,000 m

500 kBaud

18 VDC

24 VDC

30 VDC

14 Power Panel User's Manual

Power Panel • Power Panel PP21

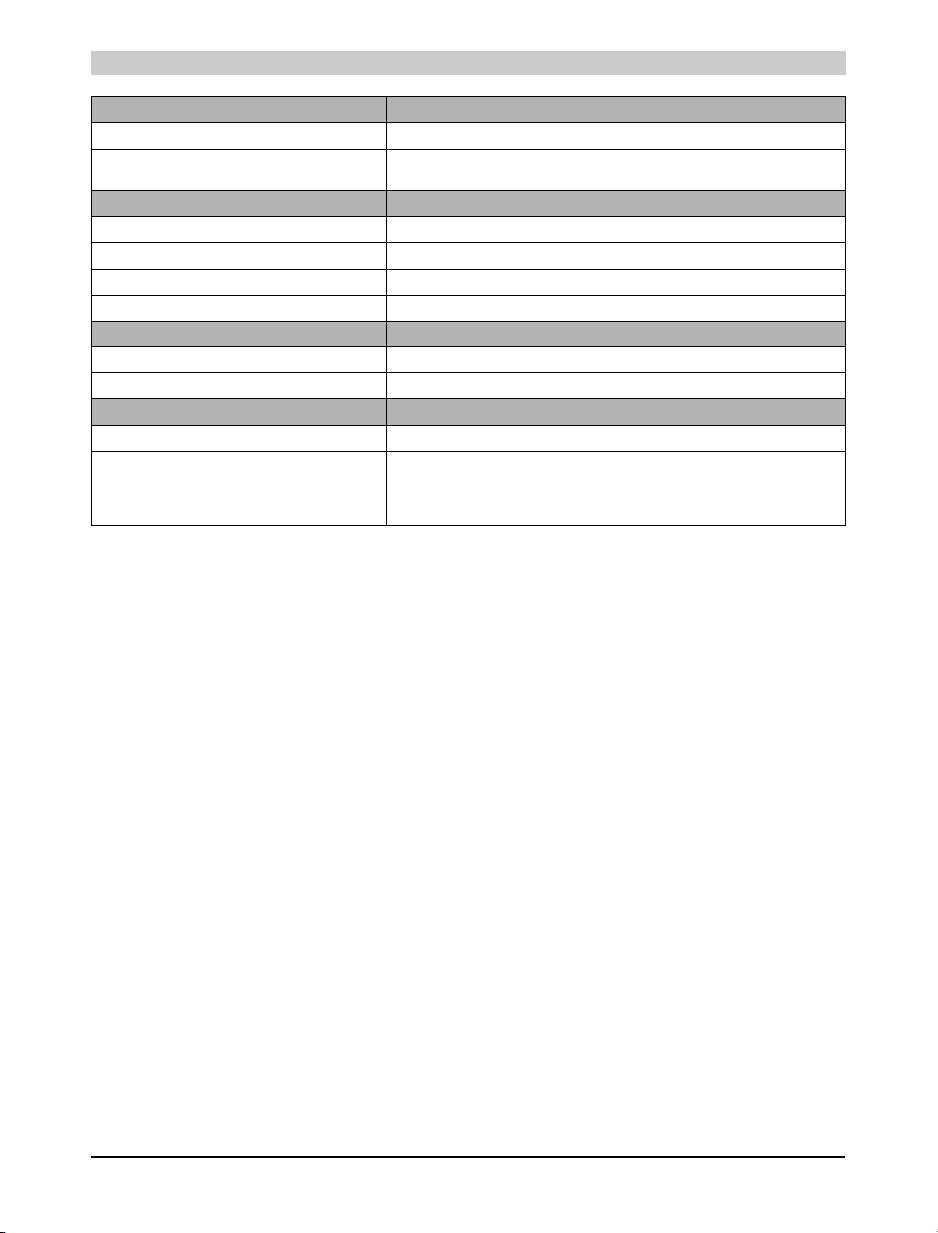

Product ID PP21

Electrical Isolation

Input - PLC

Input - Outp ut

Digital Outputs

Amount/Type

Highside Driver IC (Transistor)

Potential-Free Relay Contact

Switching Voltage

Minimum

Nominal

Maximum

Continuous Current per

Output

Module

Load for Potential-Free Relay Contact Max. 0.5 A

Leakage Current when Switched Off 12 µA

Overload Protection Yes

Switching On after Overload Cutoff Automatically within seconds (depends on the panel temperature)

Continuous Short Circuit Current Typ. 4 A

Internal Protective Circuit Yes

Braking Voltage when Switching Off Inductive Loads 47 V

Switching Delay

Log. 0 - Log. 1

Log. 1 - Log. 0

Electrical Isolation

Output - PLC

Output - Input

HMI

Display

Type

Number of Lines

Number of Characters/Line

Character Height

Background Lighting

Character Set

Reading Angle

Keyboard

Number of Keys

Design

Function Keys

System Keys

Front Multi-layered front with insertion slots for key legends

Protection According to IEC 60529 IP65 (from front)

Power Supply

Input Voltage

Minimum

Nominal

Maximum

Covered keypad with metallic snap-action disks

17, with LEDs, labeled with legend sheets

17 (number block, control keys)

Table 4: Technical data for PP21 (cont.)

Yes

Yes

8

1

18 VDC

24 VDC

30 VDC

Max. 0.4 A

Max. 3.2 A

Max. 450 µs

Max. 450 µs

Yes

Yes

LC Display

4

20

4.75 mm

LED

English/Katakana

Approx. 60 °

34 membrane keys

18 VDC

24 VDC

30 VDC

Chapter 1

Power Panel

Power Panel User's Manual 15

Power Panel • Power Panel PP21

Product ID PP21

Power Consumption Max. 20 W

Output Power for Screw-in Modules and

PCMCIA Interface

Operational Conditions

Installation Vertical, ±45°

Altitude Max. 3,000 m

Environment Temperature during Operation 0 to 50 °C

Relative Humidity during Operation 10 to 90% (non-condensing)

Storage Conditions

Storage Temperature -20 to 60 °C

Relative Humidity for Storage 5 to 95 % (non-condensing)

Mechanical Characteristics

Weight Approx. 1.25 kg

Dimensions

Width

Height

Depth

Table 4: Technical data for PP21 (cont.)

10 W

155 mm

190 mm

84.4 mm

16 Power Panel User's Manual

5.4 Images

Power Panel • Power Panel PP21

Chapter 1

Power Panel

Figure 3: PP21

Power Panel User's Manual 17

Loading...

Loading...