YD30M COBALT-mini

INSTALLATION AND OPERATING INSTRUCTIONS

© BQT Solutions (SEA) Pte Limited Page

1

CONTENTS

1. DESCRIPTION

2. PRODUCT UNBOXED

3. DIMENSIONS

o 3.1. Lock

o 3.2. Strike Plate

o 3.3. Fitting Tab

o 3.4. Housing

o 3.5. Dress Plate

4. PRE - INSTALLATION ASSESMENT

o 4.1. Mechanical

o 4.2. Electrical

5. INSTALLATION

o 5.1. Mortise Installation

o 5.2. Surface installation

6. WIRING

o 6.1. Fail Safe connection

o 6.2. Fail Secure connection

o 6.3. Jumper position

7. OPERATION

o 7.1. Fail Safe Operation

o 7.2. Fail Secure Operation

8. SPECIFICATIONS

9. MAINTENANCE

10. WARRANTY

11. UPGRADE

Pg. 2

Pg. 2

Pg. 3

3

3

3

3

3

Pg. 4

4

4

Pg. 5

5

6

Pg. 8

8

8

9

Pg. 9

9

9

Pg. 10

Pg. 10

Pg. 10

Pg. 10

© BQT Solutions (SEA) Pte Limited Page

2

1. DESCRIPTION

The COBALT-mini is a motor driven low voltage electric lock designed to secure commercial and residential doors.

It is supplied with a matching strike plate and due to its small size it is perfect for installing into a mortise for a

concealed solution. The COBALT-mini offers two unique features not commonly found in this style of lock;

1. The ability to ‘pull’ a door in tight against a seal.

2. The ability to release when requested even if there is excessive load on the door.

The bolt pin of the COBALT-mini operates on a cam action which enables the bolt pin to pull a door into place. In

practice as the door closes it may come to rest in a position that is not fully closed, especially if it closing against a

door seal of some type. The COBALT-mini senses when the door is within 8mm of being fully closed and activates

the bolt pin. The bolt pin then rotates out and pulls the door from its resting position to the closed and sealed

position.

With the door secured and locked the COBALT-mini can be given an unlock signal and it will instantly unlock. If the

door is loaded (pre-load) when the unlock signal is given the COBALT-mini will still unlock, even with loads in

excess of 100Kg on the door. Critically the ability of the COBALT-mini to instantly release with excessive pre-load

on the door even occurs in the event of a power failure if the lock is configured as fail safe.

Additional features of the COBALT-mini are;

Multi-voltage input (12-24VDC)

Very low current consumption

Door position and Bolt position monitors

High physical strength – 10,000N holding force

Fail safe / fail secure on site conversion with the re-positioning of a single jumper

2. PRODUCT UNBOXED

Along with the COBALT-mini and matching strike there are also 10G

Self Tapping and M5 Machine Screws supplied. Four fitting tabs are

also enclosed and can be used in conjunction with the M5 screws for

recessing the lock or strike plate to metal doors and frames.

The 7 way wire loom supplied is used to ease installation as the wiring

can be done without the lock being installed until the very end.

Wire Loom

Mounting Screws Fitting Tabs Strike Plate Lock

© BQT Solutions (SEA) Pte Limited Page

3

3. DIMENSIONS

3.1 Lock

3.2 Strike Plate

3.3 Fitting Tab

3.4 Housing

Available separately

3.5 Dress Plate

Available separately

© BQT Solutions (SEA) Pte Limited Page

4

4. PRE - INSTALLATION ASSESMENT

4.1 Mechanical

The COBALT-mini is designed for mortise installations as this offers a discrete solution as the lock and strike plate

can be embedded into the door and frame. In some instances however mortise installation is not possible so by

utilizing the YD30M housing, surface installation of the COBALT-mini is possible. Whichever installation method is

chosen it is important that the lock and strike plate are aligned correctly. The strike plate has an opening to accept

the bolt pin and centring this opening with the bolt pin will ensure correct operation.

The COBALT-mini can be installed vertically or horizontally but is not designed to be mounted in a floor

cavity firing upwards or in a wet environment.

When installing the COBALT-mini vertically, take note of which way the door is closing from. It the door is

approaching form the left the bolt pin is at the top, if the door is approaching from the right then the bolt pin is at the

bottom, as indicated below:

4.2 Electrical

The first consideration is to establish where to run the wires and decide on what feedback is required from the lock.

There are a total of seven available connections; three are compulsory power connections whilst the remaining four

provide optional door and bolt position feedback. These optional connections can be integrated into access control

or alarm systems to provide full monitoring.

The correct gauge of wire needs to be chosen as voltage drop across the power wires (+ and -) can limit the locks

operation. For all the remaining connections, a lower gauge wire can be used as these are only signal wires. The

following chart shows the maximum distance that the power supply can be away from the lock, assuming the power

supplies output 12VDC or 24VDC:

AWG

AREA (mm2)

MAXIMUM DISTANCE (m)

12VDC

24VDC

24

0.20 7 20

22

0.33

11

32

20

0.52

17

51

18

0.82

27

82

16

1.31

43

130

14

2.08

69

206

Door closing

from the right,

the lock is

installed with

the bolt pin at

the bottom.

Door closing

from the left,

the lock is

installed with

the bolt pin at

the top.

© BQT Solutions (SEA) Pte Limited Page

5

5. INSTALLATION

Two installation examples are detailed on the following pages; mortise and surface, however any combination of

the two can be achieved. Whichever installation method is chosen it is vital to ensure that the lock face plate

and the strike plate align correctly and the gap between the lock face plate and strike plate does not

exceed 8mm when the door is closed.

5.1 Mortise Installation

A typical mortise installation is described with the lock fitted into the door frame and the strike plate secured into the

door. It is possible to install the lock into the door and the strike plate into the frame however with this method

running wiring to the lock requires additional work.

5.1.1 Cutting the mortises

Referring to the dimension drawings in Section 3;

mortises are cut into the door and door frame

suitable to fit the strike plate and lock. Wooden

doors and frames require full mortises where metal

doors and frames, being hollow, often only require

a single rectangle cut-out to accommodate the lock

face plate or strike plate. For these installations the

supplied fitting tabs can be used to secure the lock

and strike plate in place.

The mortise behind the lock body needs to have

enough space to accommodate the wiring.

5.1.2 Wiring the lock

Wires are run from the power supply to the lock. A

hole needs to be drilled in the back of the mortise

to bring the wires out and a connection can be

made to the supplied wire loom which in turn plugs

into the lock. The jumper needs to be positioned

for fail safe / fail secure configuration as per the

instructions on the lock cover.

The Red, Black and Blue wires are essential

connections whilst the Violet and White are

optional. Detailed wiring instructions are found in

Section 6.

5.1.3 Fitting the lock and strike plate

The lock is slid back into the mortise, making sure

that the wiring integrity is maintained and secure in

place with the supplied 10G self-tapping screws.

Before the strike plate is installed the fitting tabs

are secured in behind the cut-out using the

supplied M5 machine screws. The strike plate is

then placed into the cut out and the remaining M5

screws are used to secure it.

Strike plate

installed in

the door using

the fitting tabs.

Lock secured

directly into

the door frame.

Cut-out in a

wooden door

frame to

accommodate

the lock.

Cut-out in a

metal door to

accommodate

the strike plate.

© BQT Solutions (SEA) Pte Limited Page

6

5.1.4 Checking the operation

With the lock and strike installed and wiring

complete the door is closed to check the alignment

and operation. The key area for alignment is the

bolt pin; the pin is designed to touch the leading

edge of the strike plate hole to pull the door in, but

it cannot be allowed to touch the sides of the hole

as this will limit its unlocking ability. If its rubs or

touches the side of the strike plate hole, either the

lock or strike plate needs to be re-positioned.

5.2 Surface Installation

By using a YD30M housing, the lock and or strike plate can be surface mounted to the door or door frame

eliminating the need for cutting mortises. Housings are available with adhesive tape supplied for easy application to

glass doors in addition to having screw hole mounting points for wood and metal doors.

5.2.1 Securing the lock housing to wood

Before fitting the housing, determine exactly where

the wiring will enter the housing and drill one or two

8mm holes through the housing wall. Ensure the

holes are on the housing face that goes against

the wooden frame. Push the supplied grommet(s)

into the drilled hole(s). The two 10G Hex head selftapping screws supplied with the housing can then

be screwed into the wood but not tightened. The

two keyhole shaped cut outs in the housing fit over

these screw heads which are tightened with a ring

spanner once the housing is in place.

5.2.2 Wiring the lock

Wires are run from the power supply to the lock

through the drilled hole(s) in the housing. A

connection can be made to the supplied wire loom

which in turn plugs into the lock. The jumper needs

to be positioned for fail safe / fail secure

configuration as per the instructions on the lock

cover.

The Red, Black and Blue wires are essential

connections whilst the Violet and White are

optional. Detailed wiring instructions can be found

in Section 6.

Clearance

Bolt pin

Clearance

The bolt pin touches the leading edge of

the strike plate hole but there needs to be

clearance around the sides of the hole.

© BQT Solutions (SEA) Pte Limited Page

7

5.2.3 Fitting the lock into the housing

Once wired, the lock is slid into the housing and

secured in place with the supplied M5 machine

screws. Make sure that the wiring integrity is

maintained as the lock is screwed in place.

5.2.4 Fitting the strike plate housing to glass

For simple application to glass the YD30M housing

is supplied with self-adhesive tape. With the

backing removed the housing can be applied

directly to the glass. A flat stainless steel dress

plate is fitted on the opposite side of the glass to

give a clean finish. The protective coating on the

dress plate can be removed once it is in place.

5.2.5 Fitting the strike plate into the housing

The strike plate is placed into the housing and

secured in place with the supplied M5 machine

screws.

5.2.6 Checking the operation

With the lock and strike installed and wiring

complete the door is closed to check the alignment

and operation. The key area for alignment is the

bolt pin; the pin is designed to touch the leading

edge of the strike plate hole to pull the door in, but

it cannot be allowed to touch the sides of the hole

as this will limit its unlocking ability. If its rubs or

touches the side of the strike plate hole, either the

lock or strike plate needs to be re-positioned.

© BQT Solutions (SEA) Pte Limited Page

8

6. WIRING

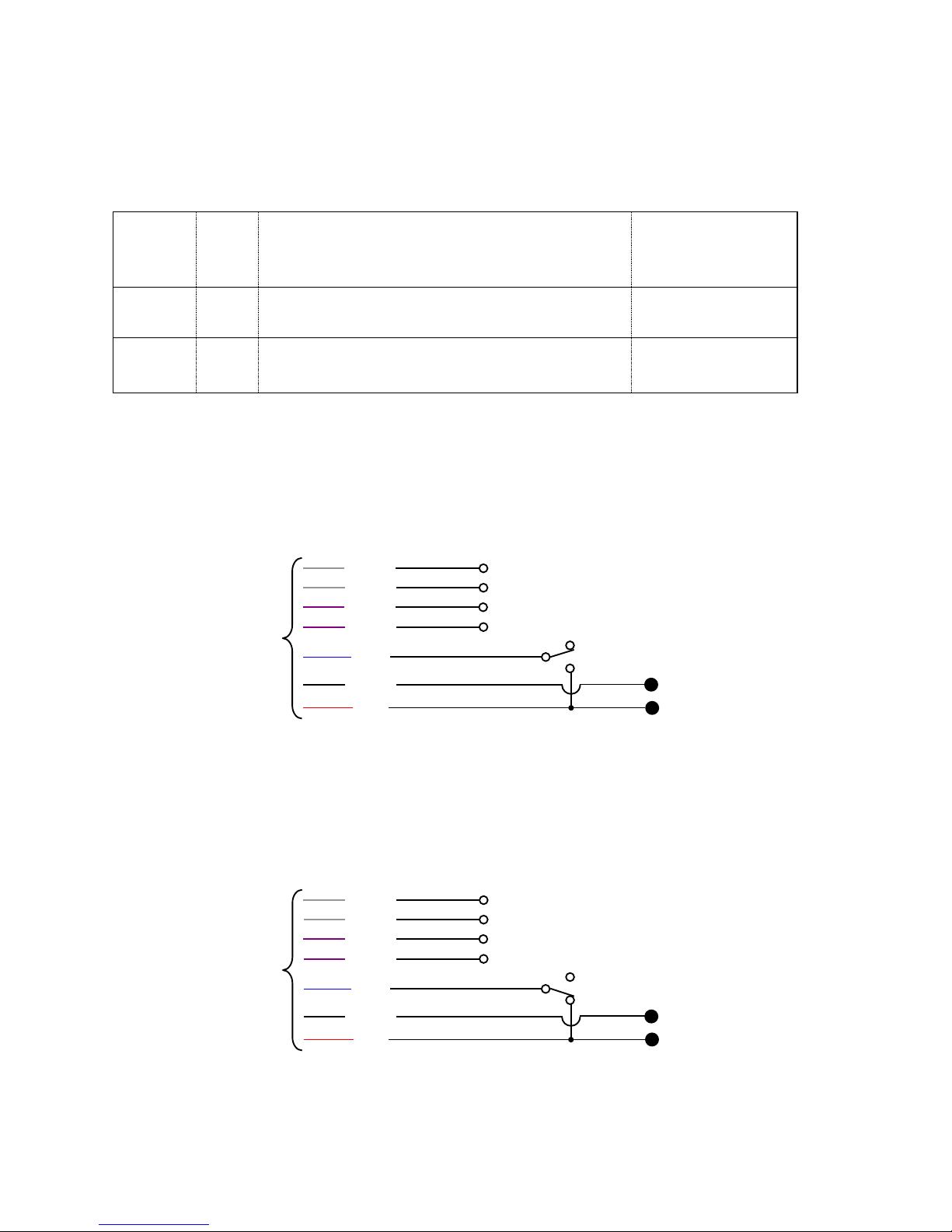

The COBALT-mini is supplied with a 7-way wire loom that plugs directly into the lock. The wires are colour coded

with three being essential connections and four optional. Control of the lock is achieved by using the three power

wires, whilst door and bolt position monitoring are available when desired. Connect the COBALT-mini as per the

chart:

RED

POS

Positive connection to DC power supply (12–24V)

Power

BLACK

NEG

Negative connection to DC power supply (12–24V)

BLUE

CTRL

Switched positive control input

VIOLET

NO

Contacts closed when bolt pins are extended, and

contacts open when bolt pins are retracted

Bolt Position Switch

VIOLET

COM

WHITE

NO

Contacts closed when door is aligned, and contacts

open when door is open

Door Position Switch

WHITE

COM

6.1 Fail Safe Connection

When wiring the COBALT-mini, the positive voltage is connected to RED, negative is connected to BLACK and a

switched positive voltage wire connected to BLUE. In Fail Safe configuration applying voltage to the COBALT-mini

signals it to lock. The lock signal in Fail Safe configuration is active high.

6.2 Fail Secure Connection

When wiring the COBALT-mini, the positive voltage is connected to RED, negative is connected to BLACK and a

switched positive voltage wire connected to BLUE. In Fail Secure configuration applying voltage to the COBALTmini signals it to unlock. The lock signal in Fail Secure configuration is active low. .

DC Power Supply

NO - Locked

NC - Unlocked

-

+

WHITE

WHITE

VIOLET

VIOLET

BLUE

BLACK

RED

Wire loom from lock

Bolt Position Switch

Door Position Switch

DC Power Supply

NC - Unlocked

NO - Locked

-

+

WHITE

WHITE

VIOLET

VIOLET

BLUE

BLACK

RED

Wire loom from lock

Bolt Position Switch

Door Position Switch

© BQT Solutions (SEA) Pte Limited Page

9

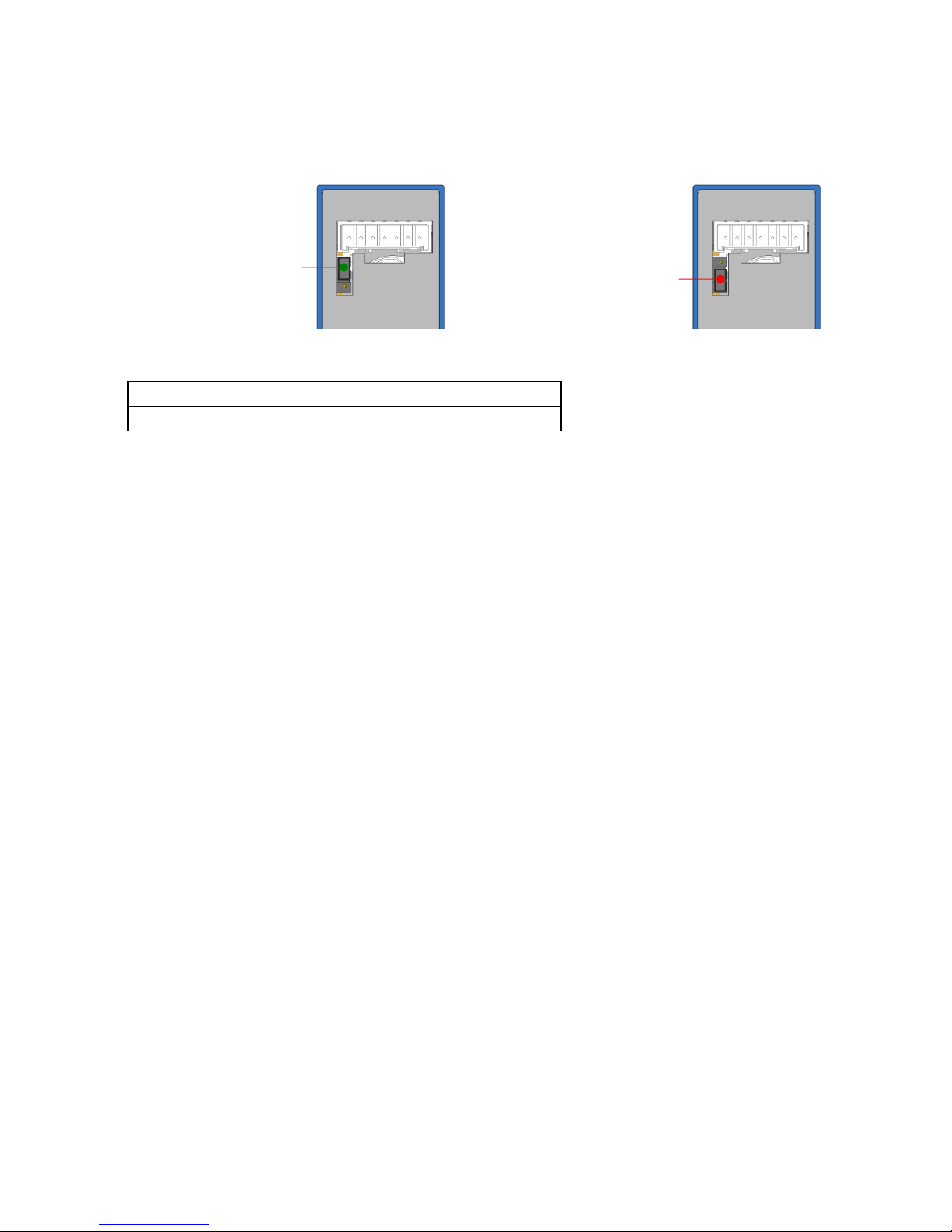

6.3 Jumper position

The fail mode of the COBALT-mini is factory set as Fail Safe, i.e. in the event of a power cut the COBALT-mini will

unlock. Before the lock is installed this can be changed to Fail Secure by repositioning the jumper located next to

the 7-way plug on the end of the lock. Select the desired jumper location as indicated:

7. OPERATION

7.1 Fail Safe Operation

Assume the lock is installed and wired, the door is open and there is voltage applied to the BLUE wire. As the door

closes the COBALT-mini senses the door approaching and activates the appropriate bolt pin to pull the door into

centre alignment. Once the first bolt pin has fully extended, the second bolt pin activates and drives to its full

extension. If the door closes to a centre aligned position quickly then both bolt pins activate at the same time rather

than one leading the other. The Bolt Position and Door Position monitors will have changed state as the door is

moved into place and secured.

To unlock the door, voltage is removed from the BLUE wire. The COBALT-mini will immediately release and will do

so even when significant load is being applied to the door. With the door now open the Bolt Position and Door

Position monitors change state again. The COBALT-mini will remain unlocked as long as the door is open but will

instantly re-lock when voltage is applied to the BLUE wire and the door is closed.

In the event of a power failure, voltage is removed from the BLUE wire and the COBALT-mini unlocks.

7.2 Fail Secure Operation

Assume the lock is installed and wired, the door is open and voltage is removed from the BLUE wire. As the door

closes the COBALT-mini senses the door approaching and activates the appropriate bolt pin to pull the door into

centre alignment. Once the first bolt pin has fully extended, the second bolt pin activates and drives to its full

extension. If the door closes to a centre aligned position quickly then both bolt pins activate at the same time rather

than one leading the other. The Bolt Position and Door Position monitors will have changed state as the door is

moved into place and secured.

To unlock the door, voltage is applied to the BLUE wire. The COBALT-mini will immediately release and will do so

even when significant load is being applied to the door. With the door now open the Bolt Position and Door Position

monitors change state again. The COBALT-mini will remain unlocked as long as the door is open but will instantly

re-lock when voltage is removed from the BLUE wire and the door is closed.

In the event of a power failure, voltage is removed from the BLUE wire and the COBALT-mini locks if the door is

closed.

Fail Safe

= Fail Unlocked

= Power To Lock

= PTL

Fail Secure

= Fail Locked

= Power To Open

= PTO

Jumper in Fail Safe position.

Jumper in Fail Secure position.

© BQT Solutions (SEA) Pte Limited Page

10

8. SPECIFICATIONS

MATERIALS

Bolt Pin

SS17-4PH, 10mm Thick, 13mm extension

Strike Plate

SS304, 3mm Thick

Lock Face Plate

SS304, 3mm Thick

MECHANICAL

Cycle life

> 300,000

Strike Gap

< 7mm

Holding Force

> 10,000N (1000kg)

Side Load Release

> 1,000N (100kg)

Door Misalignment

Up to 8mm

ELECTRICAL

Voltage at Lock

12 – 24VDC ±15%

Current Usage

Holding Current

< 50mA@12V

< 30mA@24V

Operating Current

< 250mA@12V

< 200mA@24V

Initial Power Up*

< 1800mA@12V

< 600mA@24V

Monitor Switches

Bolt position – 30VDC, 0.1A

Door position – 100VDC, 0.5A

CERTIFICATIONS

Patent

Pending PCT/IB2013/053737

FCC

Part 15 Subparts A & B – Unintentional Radiators

CE

EN 61000-6-1: 2007, EMC Directive 2001/108/EC Immunity

EN 61000-6-3: 2007, EMC Directive 2001/108/EC Emissions

* Initial power up of the lock requires up to 1800mA@12VDC and up to 600mA@24VDC for up to 6 seconds but only occurs

when the power has been completely removed for an extended period then re-applied, for example after a power outage.

Normal Operating Current after initial power up is <250mA@12VDC and <200mA@24VDC.

9. MAINTENANCE

The COBALT-mini has been lubricated at assembly and applying any other type of lubricant may void the warranty.

Removing the lock cover may void the warranty. A dry cloth can be used to polish the stainless steel face plate and

strike plate as required.

10. WARRANTY

The COBALT-mini is covered with a manufacturers 12month warranty against faulty or malfunctioning parts,

components or product. At the manufacturer’s discretion, either a replacement lock or affected part will be supplied

to remedy the fault or the lock can be returned at the customer’s expense to the manufacturer for repair.

Mistreatment or ill-use of the lock may void the warranty. COBALT-mini is a trademark of BQT Solutions (SEA) Pte

Limited. BQT Solutions (SEA) Pte Limited will not be liable for any direct, indirect, incidental or consequential loss

or damage in any way related to this product.

11. UPGRADE

The COBALT-mini is designed by BQT Solutions (SEA) Pte Limited and manufactured by BQT Solutions (NZ)

Limited. BQT Solutions (SEA) Pte Limited reserves the right to upgrade or change this product without prior notice.

For more information visit www.bqtsolutions.com

© BQT Solutions (SEA) Pte Limited Page

11

NOTES

Version 3.0

Loading...

Loading...