Page 1

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

BOXLIGHT PRO80S3 Projector

User’s Manual

For Controller Firmware Revision 0.73

and Motor Control Firmware Revision 2.0

7 July 2008

BOXLIGHT, Inc.

NE 151 Highway 300, Suite A

PO Box 2609

Belfair, WA 98528

For Controller Firmware Revision 4B/6.3 2007.0206

Page 2

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

1. Introduction

The Boxlight PRO80S3 Projector is a three-chip DLP projector with a native resolution of 1280x720 pixels (16:9 aspect

ratio). The projector accepts 720p video through a DVI-D connector on the rear panel.

1.1 Controllers

The projector is controlled by a pair of MTV312M64 microcomputers. The first is the main controller and is responsible for

lamp ballast and formatter initialization. It continuously monitors the state of the formatters, the ballast and the video input

primarily to prevent the lamp from extinguishing due to loss of video or unintentional resetting of the formatters due to

power fluctuations. Communication with the controller is through an RS-232 interface using a simple command/parameter

protocol. The second processor manages the IR remote control functions: lens shift, focus and zoom. It has no external

communications interface except the IR receiver.

1.2 Rear Panel Connectors, Switches and Displays

There are four I/O connectors, two switches and nine LEDs on the rear panel.

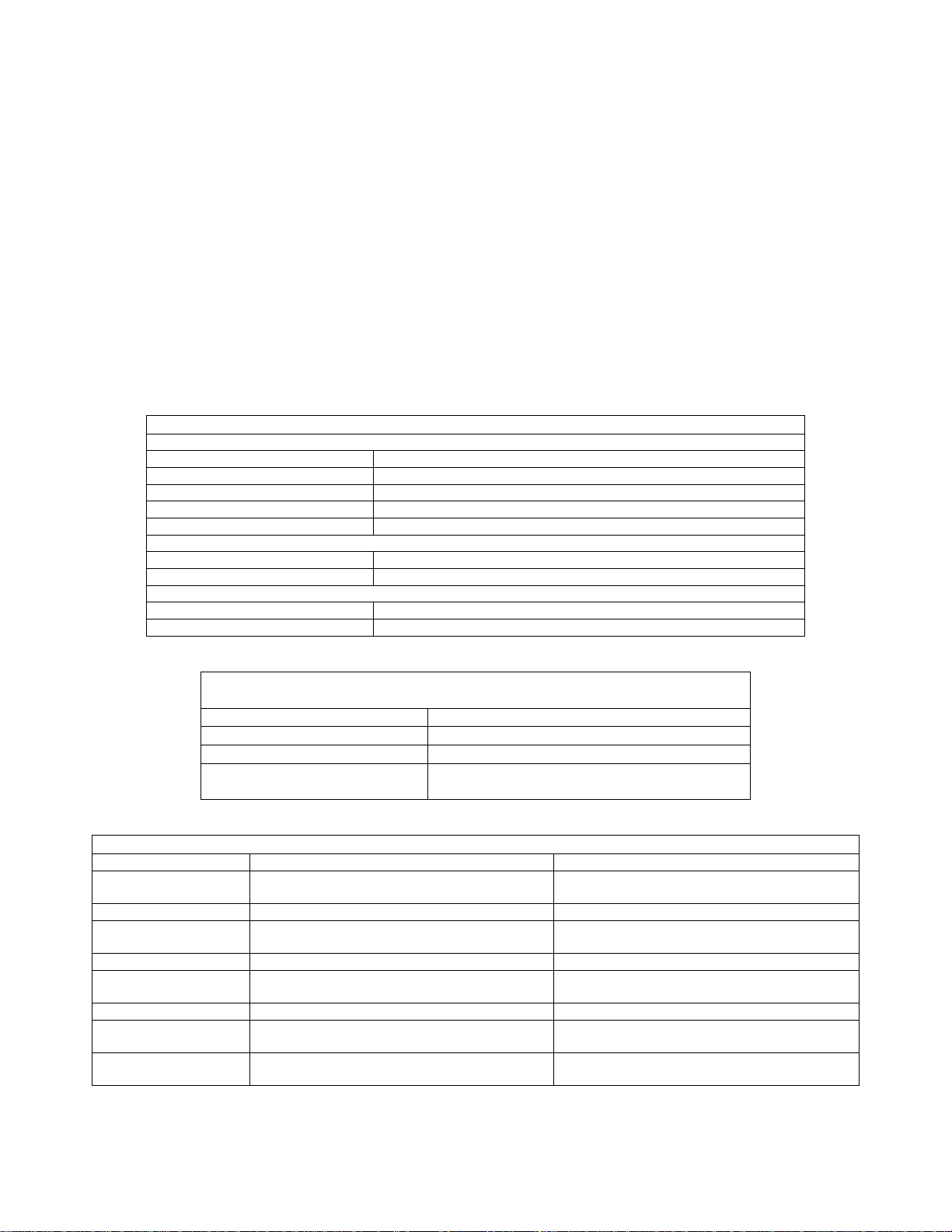

Rear Panel Connectors, Switches and Displays

Connectors

Connector/Switch/LED Purpose

DVI-D 720p Video Input. There is no scaler on board.

DB-9F Serial Communications with main µC – 9600,8,N,1

Film Projector Lockout Connector

RJ-45 NIC

Switch

2-position Rocker Switch Located just about the power connector – System Power ON/OFF

3-position Rocker Switch Soft Power ON/OFF and Shutter Control

LEDs

RED/GREEN LED Power State – located to the left of the Power/Shutter Control Switch

8 GREEN LEDs Projector Status – Located to the left of the DVI Connector

Multicolor LED

Power Sequence State

Color

RED

GREEN

YELLOW

(GREEN + RED)

State

Standby

Power On or Power-up Sequence

IF some STATUS LEDs ON – 5 minute power-down

ELSE power-off sequence

Status LED Operation

STATUS LED When ON Continuously When Flashing (or OFF)

LAMP DOOR

FAN Fans OK Fan Failure – Shutdown

LAMP

VIDEO SIGNAL Video Signal Detected No Video

FORMATTER

BALLAST TEMP Ballast Temperature OK Ballast Temperature High – Shutdown

READY

SHUTTER

Lamp Door Interlock OK

Lamp Thermal Switch Closed

Lamp Struck and Operating Lamp Extinguished

Formatters Initialized and Operating Formatter Failure (usually a communication failure) -

90 Second Lamp Cool-down Timer Expired, READY for

Power-up or Re-strike

Shutter OPEN

NORMAL Projection Mode

NOTE: There may be as much as a 2 second delay between an event that will cause a change in the STATUS LEDs, e.g.,

SHUTTER OPEN, and the actual display update.

Lamp Door Open or

Lamp Thermal Switch Open - Shutdown

Lamp Life time over system limited (1470 hours)

Shutdown

[READY OFF] 90 Second Lamp Cool-down Cycle in

Progress

Shutter CLOSED

CURTAIN mode

Page 2 of 33

Page 3

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

1.3 Power Sequencing

1.3.1 STANDBY

When the main power switch is turned ON, the projector comes up in STANDBY mode. It may be left in this state

indefinitely. Both controllers and the RS-232 circuitry are powered so that the unit can respond to serial commands, the IR

Remote Control or the rear panel switch. The ballasts, fans and formatters are not energized.

Note: The IR Remote POWER button is always active but the other buttons may be disabled. If the unit is powered up

using the IR Remote, all IR commands will be enabled. If the unit is powered up using the rear panel switch or via the

serial port, only the IR POWER button will be active. IR Remote buttons may be enabled or disabled with the IR+ and IRserial commands.

The projector may then be powered UP or DOWN using any of the methods above. The rear panel switch is

multifunctional. The following operation description assumes that the main power switch is ON:

If the projector is in STANDBY, the multicolor LED to the left of the switch will glow RED and on the 8 LED status display,

the READY LED will be ON. (

may be flashing

the lamp and initializing the formatters. The multicolor LED will glow GREEN. The projector will come up in CURTAIN

projection mode with the shutter closed. The STATUS LEDs will display the progress of the power-up sequence. When all

of the LEDs except for the SHUTTER LED are lit, the shutter may be opened.

1.3.2 POWER ON

If the projector is POWERED UP, a momentary depression of the right side of the switch (1/2 second or more) will open

the SHUTTER and put the formatters in NORMAL PROJECTION MODE. Subsequent depressions will toggle between

NORMAL MODE/SHUTTER OPEN and CURTAIN MODE/SHUTTER CLOSED.

Depressing the left side of the rocker switch will cause the SHUTTER to close and the formatters to go to CURTAIN

MODE and also initiates a 5-MINUTE POWER DOWN cycle. During this time the lamp, fans and formatters remain active.

The multicolor LED will glow YELLOW (both the RED and GREEN are ON). The STATUS LEDs should all be ON except

for SHUTTER. If no other action is taken for the next 5 minutes, the projector will go through the 60 SECOND POWER

OFF sequence: the lamp is extinguished and the fans are left running for 60 seconds before going back to STANDBY. If

the shutdown was not due to some anomaly, e.g., a fan failure, all of the STATUS LEDs will be OFF. If there was an

anomaly, one or more may be flashing.

The READY LED will go OFF when the lamp is extinguished. It will go back ON after 90 seconds indicating that the lamp

may be re-struck. A command to re-strike via any of the three methods - serial, IR or switch – may be issued at any time

but the re-strike will not occur until the 90-second lamp cool-down has expired.

1.3.3 5 MINUTE POWER DOWN

If the projector is in the 5 MINUTE POWER DOWN sequence, a momentary depression of the left side of the switch (1/2

second or more) will initiate the 60 SECOND POWER OFF sequence. The 5 MINUTE POWER DOWN may be canceled

by issuing an ON or OPEN command through the serial port, by depressing the right side of the rocker switch or – if the IR

remote is enabled - depressing the BLANK button to open the SHUTTER. The multicolor LED will again glow GREEN.

1.3.4 60 SECOND POWER OFF

The 60 SECOND POWER OFF sequence first extinguishes the lamp, extinguishes the STATUS LEDs and resets the 90

second lamp cool-down timer. No re-strike will be permitted until it times out. If no further action is taken, after 60 seconds

the main power will be turned off – the fans go OFF - and the projector will be back in STANDBY.

Commands to restart the projector may be issued before the 60 SECOND POWER OFF sequence completes: serial ON

command, IR POWER button or left rocker switch. 60 SECOND POWER OFF will be canceled but the lamp will not restrike until the 90 second cool-down period has expired. The POWR STATE LED will show GREEN.

.) Depressing the left side of the switch momentarily (1/2 second or more) will power up the unit, turning on

If there were any problems encountered during the previous power-on cycle, other LEDs

Page 3 of 33

Page 4

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

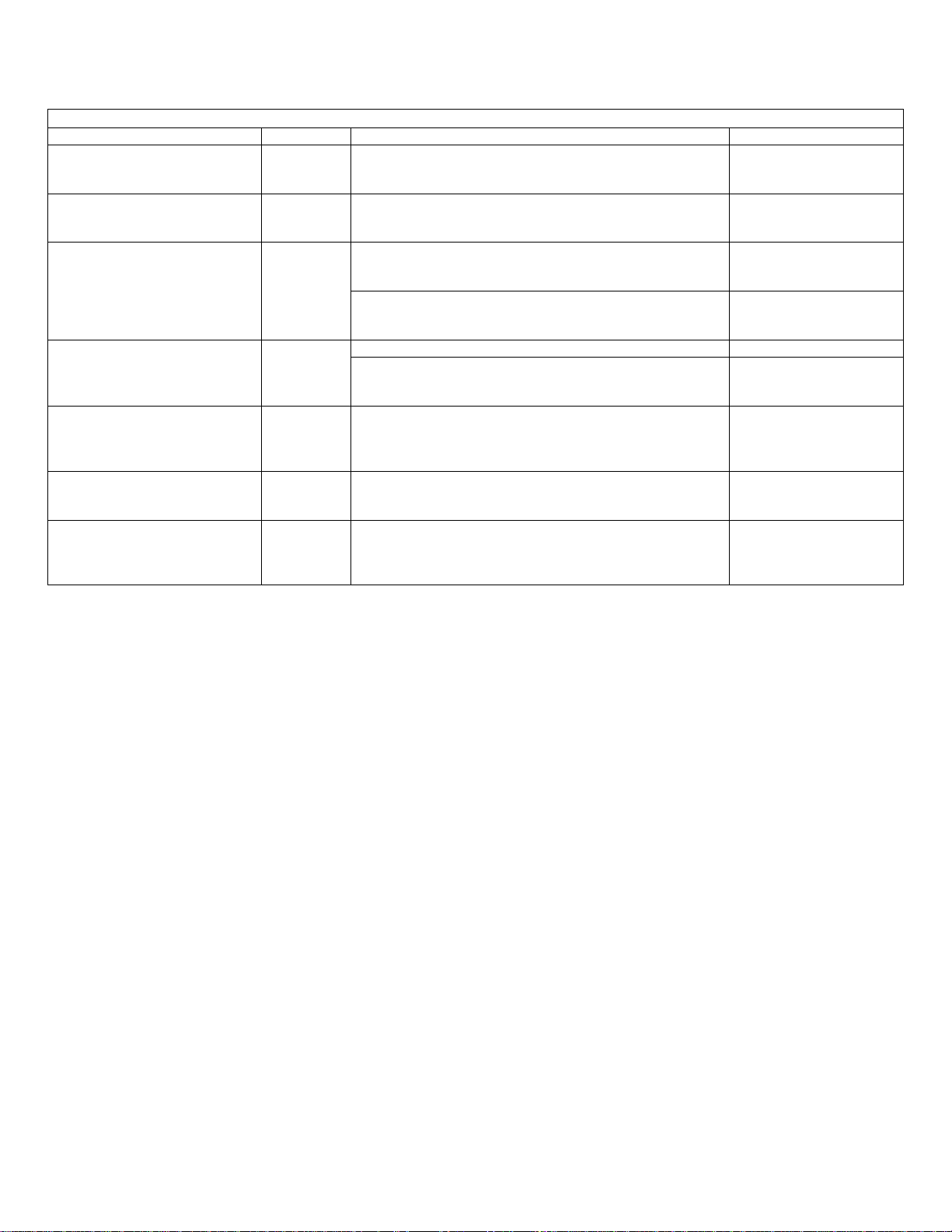

Power and Shutter Operation

Current State Power LED Action Resulting State

Serial Command – ON

STANDBY RED

POWER ON GREEN

5 MINUTE POWER DOWN YELLOW

60 SECOND POWER OFF YELLOW

SHUTTER CLOSED

SHUTTER OPEN GREEN

POWER ON,

SHUTTER CLOSED,

FILM PROJECTOR

INTERLOCK ACTIVE

GREEN or

YELLOW

GREEN

Rocker Switch - depress Left Side ½ second or more

IR Remote - depress POWER 2 seconds or more

Serial Command – OFF

Rocker Switch - depress Left Side ½ second or more

IR Remote - depress POWER 2 seconds or more

Serial Command – ON or OPEN

Rocker Switch - depress Right Side ½ second or more (shutter OPEN)

IR Remote – depress BLANK (if IR enabled)

Serial Command – OFF

Rocker Switch - depress Left Side ½ second or more

IR Remote - depress POWER 2 seconds or more

Wait 60 seconds – no additional action required STANDBY

Serial Command – ON

Rocker Switch - depress Left Side ½ second or more

IR Remote - depress POWER 2 seconds or more

Serial Command – OPEN

Rocker Switch - depress Right Side ½ second or more (shutter OPEN)

IR Remote - depress BLANK (if IR enabled)

Serial Command – CLOSE

Rocker Switch - depress Right Side ½ second or more (shutter OPEN)

IR Remote - depress FREEZE (if IR enabled)

Serial Command – no command available

Rocker Switch - depress Right Side 5 seconds or more to override Film

Projector Interlock

IR Remote - no command available

POWER ON

5 MINUTE POWER DOWN

POWER ON

Power Down Cancelled

60 SECOND POWER OFF

POWER ON

Lamp re-strike after 90 second

lamp cool-down

SHUTTER OPEN

Cancel 5 MINUTE POWER

DOWN

if in progress

SHUTTER CLOSED

SHUTTER OPEN

Override Film Projector

Lockout

1.4 Serial Communications

The controller UART must service communications from two sources: the RS-232 interface via the DB-9 connector on the

rear panel and the NIC interface. The NIC card controls a multiplexed that switches the UART between these two sources.

The controller firmware services three different command sets: one from the NIC card (which is not specified in this

document) and two from the RS-232 port. These two will be referred to as

human

and

machine

commands. The

human

interface is a verbose natural language interface that is intended for manufacturing and maintenance operations via a PC

running a terminal program attached to the port. Incoming character are typically echoed back to the terminal and a variety

of status messages are routinely sent, especially during power-up up and down sequences and when system anomalies

are detected and corrected. The

machine

interface is a terse command set. Incoming characters are not echoed and no

data is sent to the host unless requested.

The controller’s UART is selectable at 9600 or 19200 baud, 8-bits, no parity and 1 stop bit. The receiver is interrupt driven

with a 64 byte queue. The transmitter is polled and has no queue. XON/XOFF (^Q/^S) flow control is implemented in both

directions. The DB9-F connector is wired as a standard PC computer peripheral and may be connected to a PC running

an ASCII terminal program with a straight-through serial extension cable – not a null-modem.

1.5 Film Projector Lockout

The film projector lockout feature uses an external signal control either turning the projector on/off or closing/opening the

shutter depending if the film projector lockout mode has been set to lock out or power control mode. See the command

FPOL for more details.

1.6 Enhanced Color Correction (P7)

Commands have been included to utilize Texas Instruments’ Enhanced Color Correction Algorithm. When viewing

REC709 images use Entertainment Experiences' film look target color gamut by selecting index 5. When viewing

Tristimulus images use Entertainment Experiences' XYZ target color gamut by selecting index 6. See the ECC command

for more details.

Page 4 of 33

Page 5

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

1.7 Ambient Light Compensation

Commands have been included to utilize Texas Instruments’ Dgamma table selection. There are three Entertainment

Experience dgamma tables provided to compensate for low, medium and high ambient room light levels. For low light

levels use dgamma table 5. For medium light levels use dgamma table 9/10. For high light levels user dgamma table 14.

See the command GAMMA for more details.

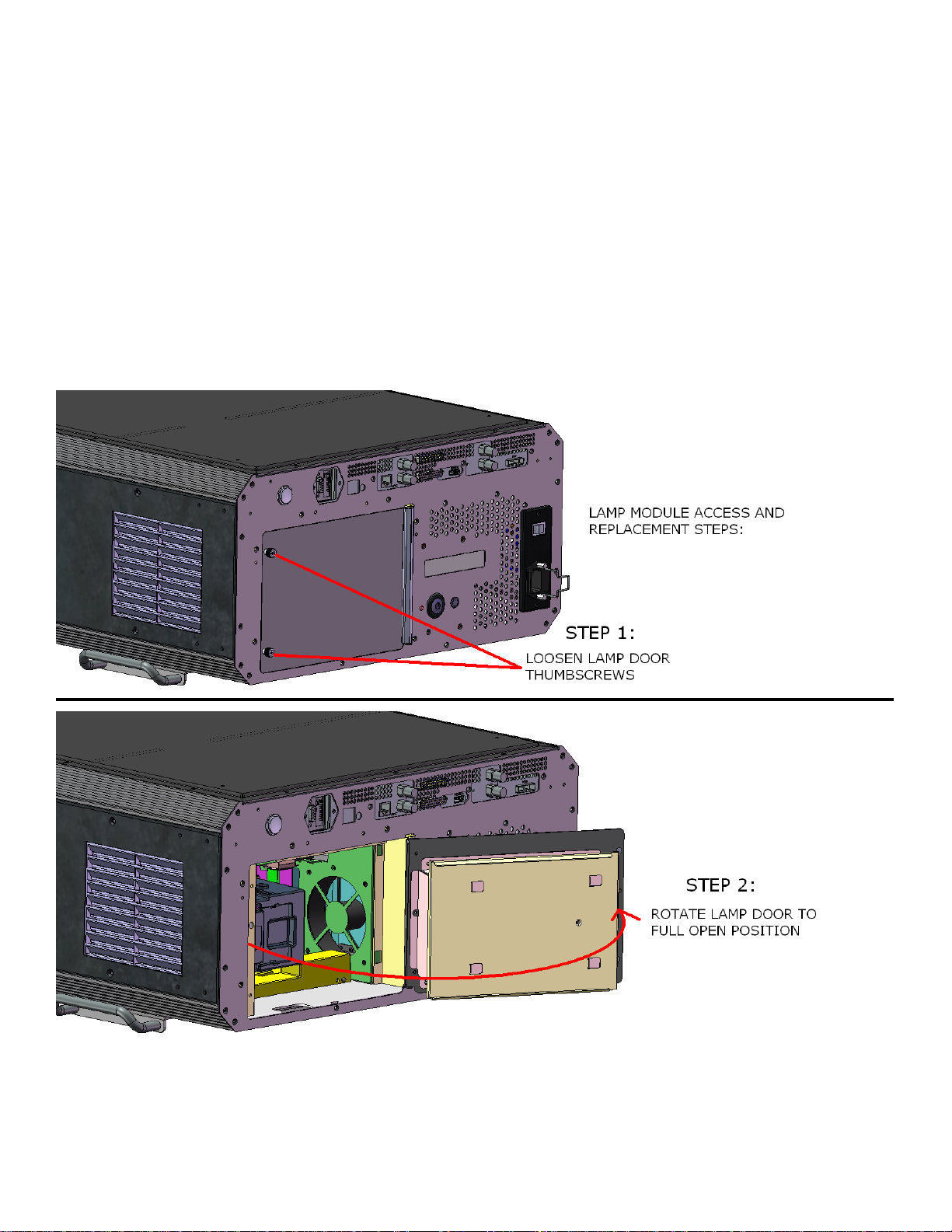

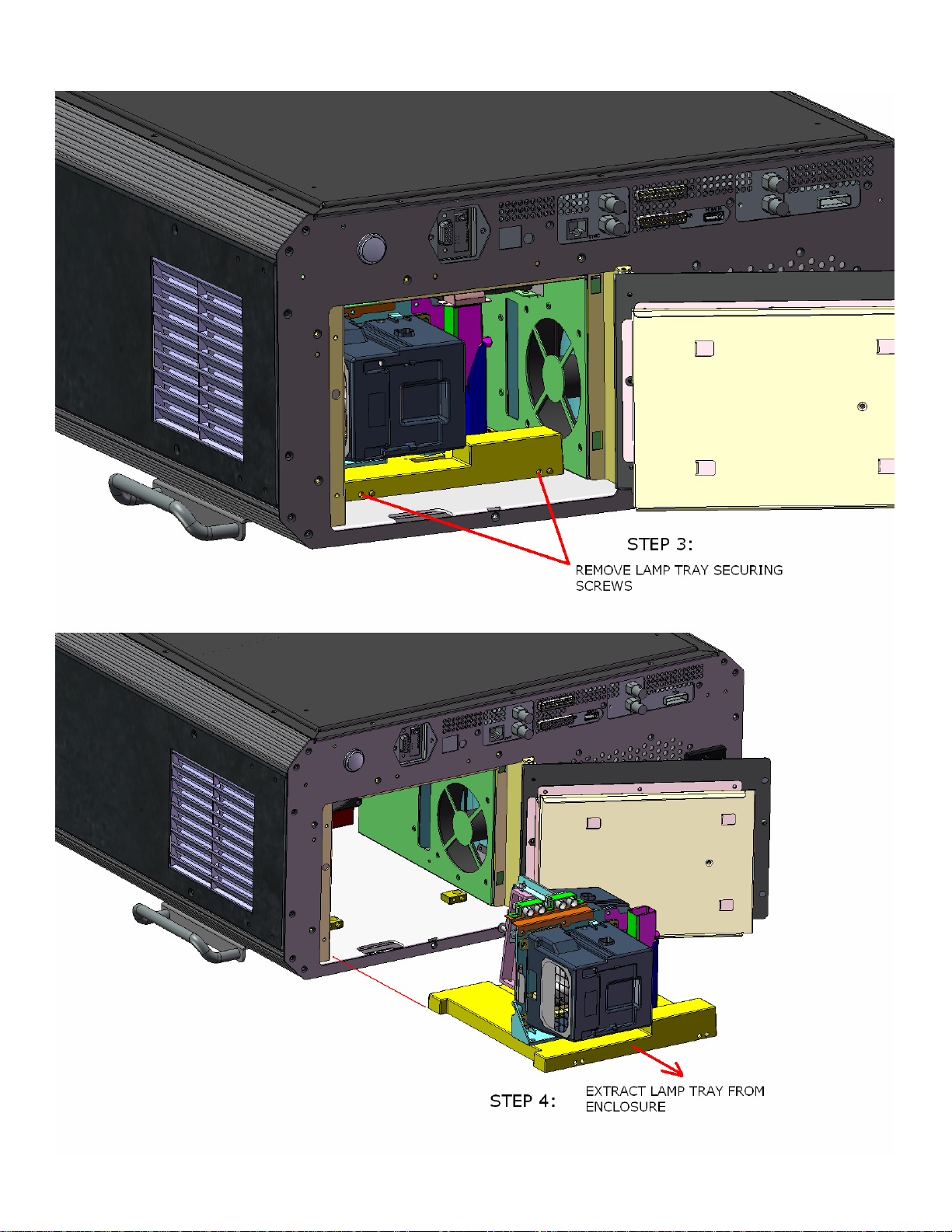

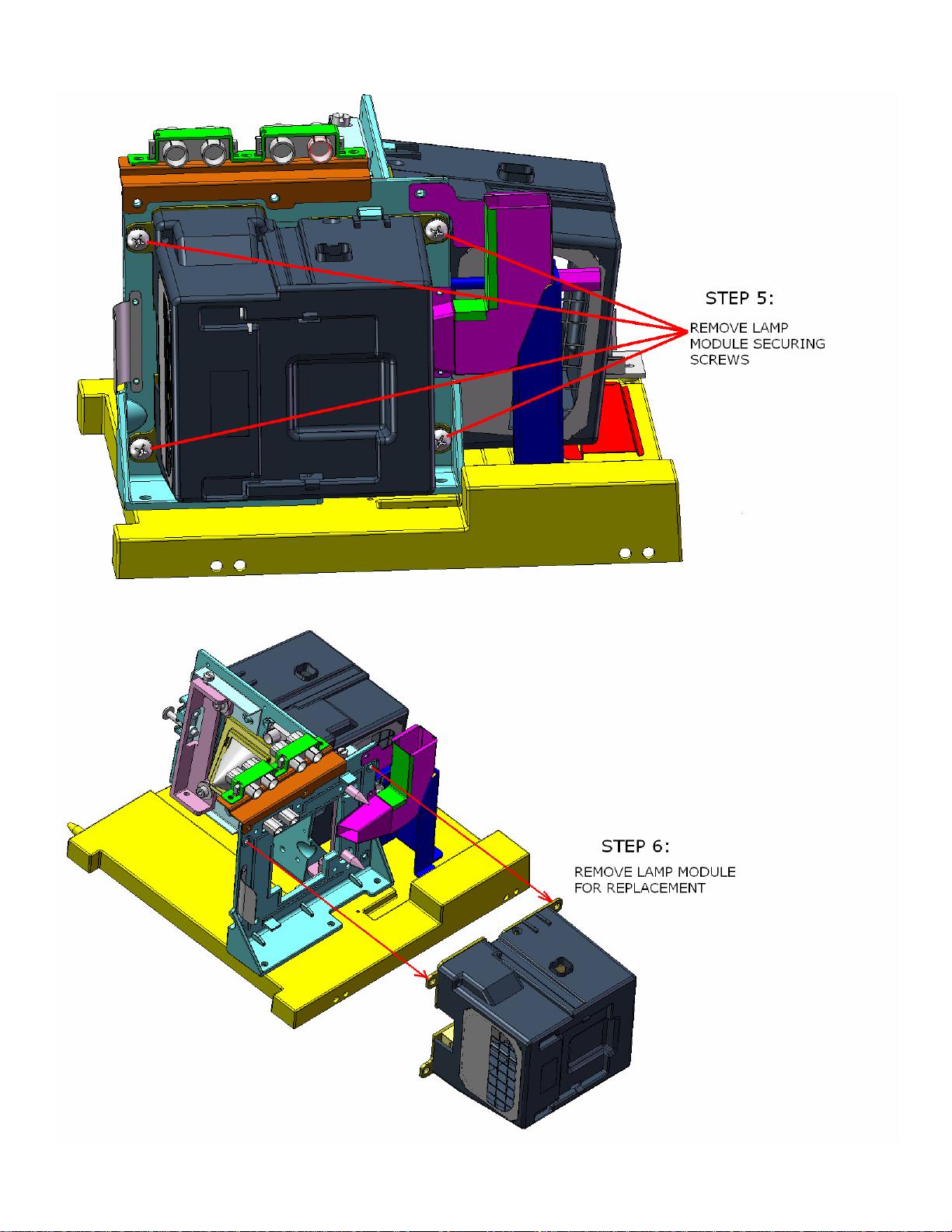

1.8 Lamp Module Replacement

High pressure lamp may explode if improperly handled. Refer servicing to qualified service personnel. The customer

should never attempt to disassemble the lamp or to dispose of the lamp casing other than by returning to the dealer. If the

lamp breaks, leave the area immediately and stay away for at least 30 minutes and ventilate the room so as not to inhale

the mercury vapor. If you inhale the mercury vapor, see a physician immediately and follow their instructions. Lamp

replacement is recommended after 3000 hours of use. Wait 60 minutes after turning off and unplugging the projector

power cord before performing the lamp replacement.

Page 5 of 33

Page 6

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Page 6 of 33

Page 7

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Page 7 of 33

Page 8

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

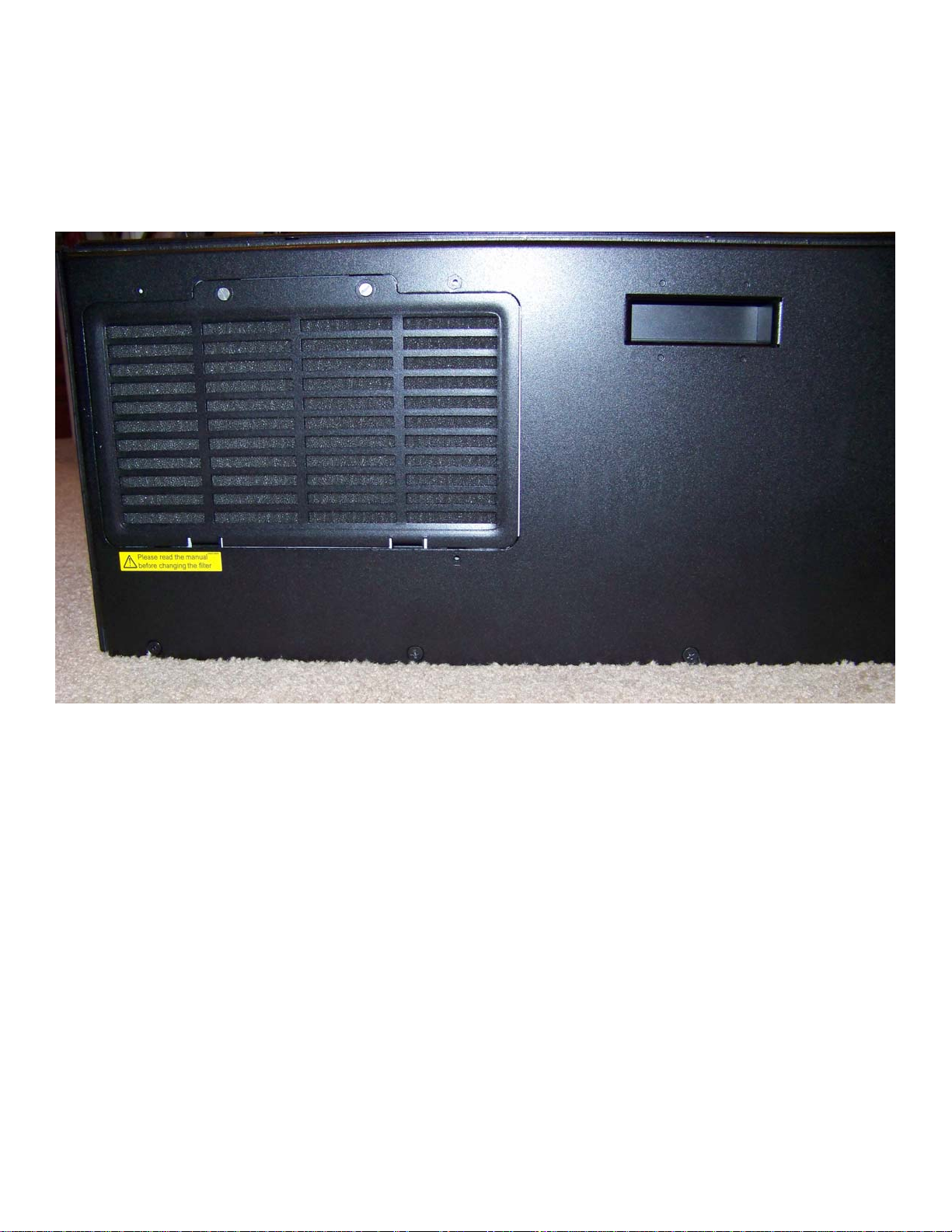

1.9 Filter Replacement

If the air filter is clogged with dust it can cause the projector to overheat , cause component failure or even catch on fire.

The filter should be replaced when clogged or when 10,000 hours of use has occurred. Contact the dealer to order a new

filter, never reuse an old filter. To replace the filter follow the steps that are provided in the following pages.

STEP 1: Remove the 2 screws.

Page 8 of 33

Page 9

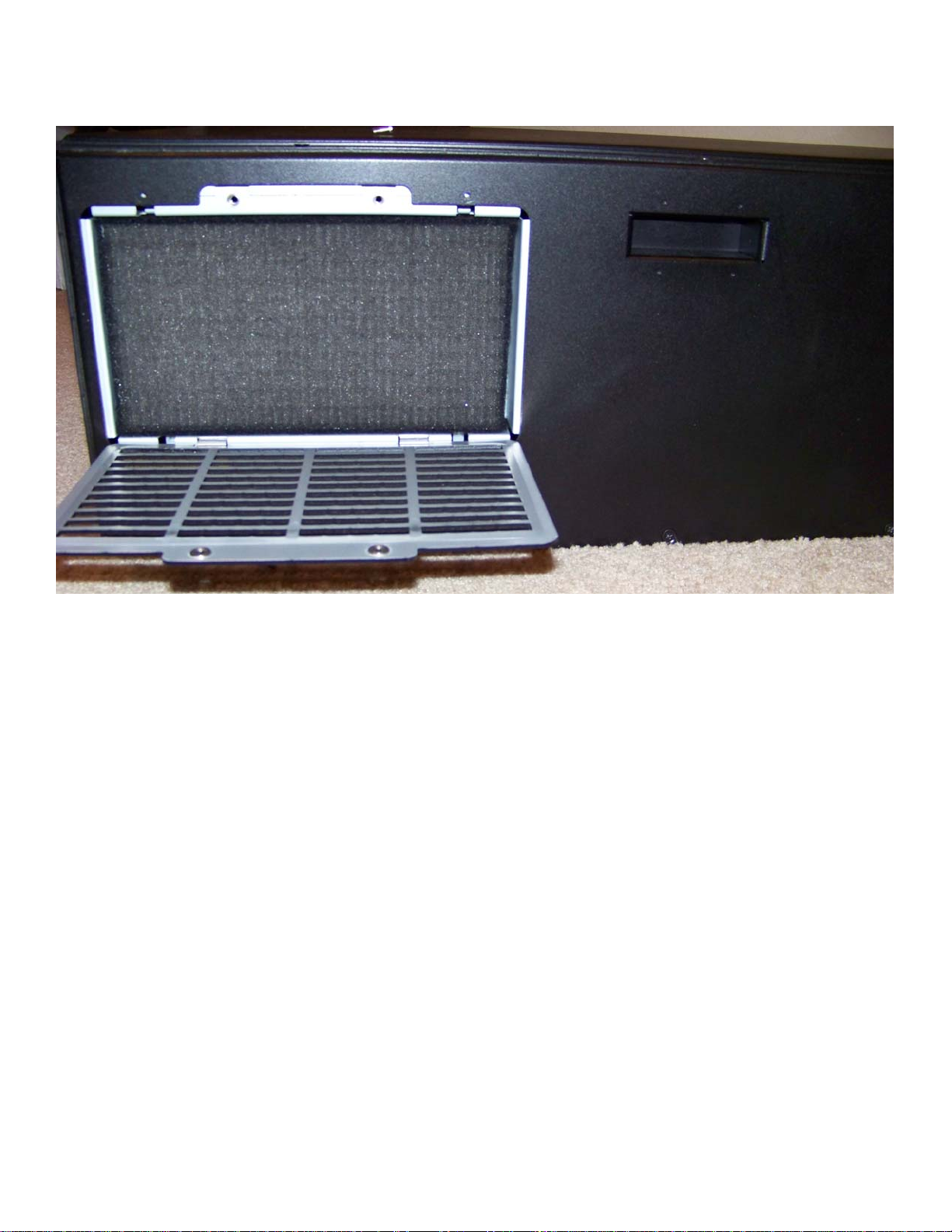

STEP 2: Lower the cover.

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Page 9 of 33

Page 10

STEP 3: Remove the filter.

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

STEP 4: Install the new filter, replace the filter cover and insert the 2 screws.

Page 10 of 33

Page 11

1.10 Remote Control Key

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Page 11 of 33

Page 12

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

2.

Human

Command Interface

The receive routine masks bit 7 of all characters received and buffers and echoes all printable ASCII characters. <TAB>s

are converted to <SPACE>s. Several other control characters are recognized or transmitted:

Name Designation HEX Operation

Backspace <BKSP>

TAB <TAB>

Line Feed <LF>

Carriage Return <CR>

DC1 – XON <CTRL-Q>

DC3 – XOFF <CTRL-S>

Escape <ESC>

08

09

0A

0D

11

13

1B

16

16

16

16

16

16

16

Queue pointer decremented; echoed

Converted to <SPACE>

Placed in queue, not echoed, otherwise ignored

Placed in queue, not echoed, command terminator

Flow Control – Re-enable xmtr/rcvr

Flow Control – Disable xmtr/rcvr

Not placed in queue. Terminates current operations, flush queue

A number of control characters are set up as

hot keys

to perform the function of the Mode, Pattern, etc. buttons on the

PCB and on the rear panel switch via the serial interface. No <CR> terminator is required for these commands to execute.

See the first entry in Section 3.2 of the commands descriptions.

2.1 The ! Hot Key

Typing or sending a single exclamation point (!) immediately after the prompt with no whitespace or control characters –

will repeat the last command (the exclamation point is not echoed). If ANY characters are sent between the prompt and

the “!” – even a <CR> - the previous command will be lost and cannot be repeated using the “!” option. “!” just re-processes

the current contents of the command buffer so it will also repeat illegal commands or commands with illegal or missing

parameters.

2.2 ASCII Control Characters

In almost all cases sending an <ESC> character will terminate current operations and return a command prompt. It can

also be used when sending commands manually through a terminal to cancel any characters typed in after the prompt.

Whitespace characters - <TAB> and <SPACE> - are treated identically. Line feeds - <LF> - are queued but are otherwise

ignored by the code. A “newline” is always a <CR><LF> pair. The prompt is a newline followed by a > and a space.

Single <BKSP> characters are echoed and back up the queue pointer. A <BKSP> sent to the projector is not converted to

a “destructive” backspace string - <BKSP><SPACE><BKSP> when echoed. Only a single ASCII <BKSP> will be echoed.

If the terminal program can be configured to send <BKSP><SPACE><BKSP> when the Backspace Key is pressed, this

option should be selected.

Commands sent to the board in either mode can be terminated with either a single <CR> or a <CR><LF> pair. The <LF>

character triggers command parsing and execution. The <LF> is ignored. Neither commands nor hex data is casesensitive.

Page 12 of 33

Page 13

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

2.3 ZOOM, FOCUS and Lens Shift Commands

ZOOM, FOCUS and Lens Shift Serial Commands

The following commands turn on the specified motors. The motors will stay energized until an <ESC> character is sent to

the projector. The last character of each command is an ASCII digit from 0 to 3 with no intervening whitespace. This

determines motor speed with 0 being the slowest and 3 the fastest. All of the motors have clutches or limit switches to

prevent damage if they are allowed to run after reaching a mechanical limit.

Command

Description

0 ≤ n ≤ 3

Dn Move image DOWN

Ln Move image to the LEFT

FFn Move FOCUS away from Projector – FOCUS FAR

FNn Move FOCUS toward Projector – FOCUS NEAR

Rn Move image to the RIGHT

Un Move image UP

ZIn ZOOM IN – Projected Image Smaller

ZOn ZOOM OUT – Projected Image Larger

The following NUDGE commands turn on the specified motors for a short period. No <ESC> character need be sent. The

last character of each command is an ASCII digit from 0 to 3 with no intervening whitespace. This determines period the

motor is energized with 0 being the shortest and 3 the longest.

Command

Description

0 ≤ n ≤ 3

NDn Nudge image DOWN

NLn Nudge image to the LEFT

NFFn Nudge FOCUS away form Projector – FOCUS FAR

NFNn Nudge FOCUS toward Projector – FOCUS NEAR

NRn Nudge image to the RIGHT

Nun Nudge image UP

NZIn Nudge ZOOM IN – Nudge Projected Image Smaller

NZOn Nudge ZOOM OUT – Nudge Projected Image Larger

Page 13 of 33

Page 14

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

2.4 User Commands

User Serial Commands

Command Brief Description

CLOSE Close Shutter and put Formatters in Curtain Mode

DGAMMA DGAMMA Dowlnoad

FPOL TOGGLE the Film Projector Lockout Polarity

Gamma Select Gamma Table

GETP Get IR Remote

IR+ Enable IR Remote

IR- Disable IR Remote except POWER Button (default at Power-up)

LH Display Lamp 1 or 2 Age Data

LAMPON1 Turn On Lamp1*

LAMPON2 Turn On Lamp2*

LAMPOFF1 Turn Off Lamp1*

LAMPOFF2 Turn Off Lamp2*

M+ If V- enable display of non-critical (informational) messages – preceded by %

M- If V- disable display of non-critical (informational) messages – preceded by %

OFF Main Power Shutdown

ON Main Power ON

ONS

Main Power ON and Start Signal Lamp mode

∗

OND Main Power ON and Start Dual Lamp mode*

OPEN Open Shutter and put Formatters in Normal Projection Mode

P ID Check Projector Serial Number

SIZE Set Display Size

SETP Set Lamp Power Mode*

STS Check Shutter Status

V+ Enable Verbose Mode

V- Disable Verbose Mode (see M+ and M- above also)

VER Display Controller Firmware Revision

2.5 Enhanced Color Correction Commands

DEBUG/Maintenance Serial Commands

Command Brief Description

ECC Enable/Disable P7 Color Correction and Select Target Data

MDNLD Download Measured Color Gamut Data for Storage in BLUE Formatter EEPROM

RDMCGD Display Measured Color Gamut Data

RDTCGD Display Specified Target Color Gamut Data

TDNLD Downlaod User-Defined Target Color Gamut Data for Storage in EEPROM

1

∗

: mark for MH-69 only.

Page 14 of 33

Page 15

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

2.6 DEBUG/Maintenance Commands

DEBUG/Maintenance Serial Commands

Command Brief Description

BAUD Change immediate and power-up baud clock

FH Display the FORMATTER Register Help Table

FR Read Register from ALL Formatters

FRB Read BLUE Formatter Register

FRG Read GREEN Formatter Register

FRR Read RED Formatter Register

FW Write Register to ALL Formatters

FWB Write to BLUE Formatter Register

FWG Write to GREEN Formatter Register

FWR Write to RED Formatter Register

OCMD Send Command to Ostram Ballast and Display Response

RST Reset and Reinitialize Formatters

Page 15 of 33

Page 16

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

3.

3.1 Lens Shift, ZOOM and FOCUS Commands

The following commands turn on the specified motors. The motor will stay energized until an <ESC> character is sent to

the projector. The last character of each command is an ASCII digit form 0 to 3 with no intervening whitespace. This

determines motor speed with 0 being the slowest and 3 the fastest.

If an N prefix is appended to the command mnemonic the command is a NUDGE. NUDGE commands turn on the

specified motors at full speed for a timed period. An <ESC> character is not needed to terminate the command. The

purpose is to generate small changes in image position, focus or size. The last numeric character of the command

determines period the motor is energized with 0 being the shortest and 3 the longest. Due to backlash in the motor/drive

assemblies, a single NUDGE – especially a 0 or 1 – may not generate any noticeable change.

All of the motors have clutches or limit switches to prevent damage if they are allowed to run after reaching a mechanical

limit.

Un, Dn, Ln, Rn, Lens Shift Un, Dn, Ln, Rn,

Nun, NDn, NLn, NRn Nun, NDn, NLn, NRn

UP, DOWN, LEFT and RIGHT. Move the projected image.

Example: U3

NL1

FFn, FNn, NFFn, NFNn FOCUS FFn, FNn, NFFn, NFNn

FOCUS FAR and FOCUS NEAR. FOCUS FAR move the focus away from the projector while FOCUS NEAR moves it

toward the projector.

Example: FN0

NFF3

ZIn, ZOn, NZIn, NZOn ZOOM ZIn, ZOn, NZIn, NZOn

ZOOM IN and ZOOM OUT. ZOOM IN makes the projected image smaller while ZOOM OUT makes it larger.

Example: ZI2

NZ01

Human

Command Descriptions

Page 16 of 33

Page 17

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

3.2 User Commands

Control Characters

Several ASCII Control Characters are recognized to control Brightness, Contrast, Display Mode, Patterns and Orientation.

These are

<CTRL-Z> Brightness – Decrement Lower Level

R/G/B Brightness=1D/1D/1D

<CTRL-X> Brightness – Increment Lower Level

R/G/B Brightness=1C/1/C/1C

<CTRL-W> Contrast – Decrement Upper Level

R/G/B Contrast=03/03/03

<CTRL-E> Contrast – Increment Upper Level

R/G/B Contrast=02/02/02

<CTRL-N> Cycles through the Projection modes

CURTAIN

<CTRL-O> Cycles through the Projection orientations (FRONT, REAR, CEILING, etc.)

REAR-CEILING

<CTRL-P> Cycles through the Patterns (when in PATTERN MODE)

PATTERN = 6

CLOSE, OPEN SHUTTER Control CLOSE, OPEN

OPEN opens the projector’s shutter and puts the formatters in NORMAL projection mode if:

OPEN cancels a 5 MINUTE POWER DOWN sequence if it has been initiated.

CLOSE closes the projector’s shutter and puts the formatters in CURTAIN projection mode if the main power is ON, i.e.,

the fans are running.

Syntax: open

close

hot keys

a) The power is ON AND

b) The Film projector interlock is inactive

– i.e., no need to press ENTER.

Page 17 of 33

Page 18

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

DGAMMA Download to De-gamma Mailbox DGAMMA

Download de-gamma tables to the formatter’s degamma mailbox. DGAMMA takes three parameters. The first is a single

letter (r, g, b or a) specifying which formatter (or all of them) gets the table. The second is also a single letter (b or w)

specifying whether the table is formatted as bytes or words (16 bits). The last is a decimal parameter which specifies the

number of entries (1/2 the total number of bytes). Valid values for this parameter are 256, 512, 1024, or 2048. After the

command is issued, the user will be prompted to send the table as a series of hexadecimal bytes or words. Each entry is

16 bits. If byte mode is selected, send the LSB first. The table can be formatted rather loosely. Any ASCII character less

than ‘0’ (3016) is treated as a terminator. Any number of terminators may be inserted between values so the table can be

a single column of values separated by “newlines” or a column of comma separated values or even a string of hex digits

without any terminations as long as leading zeros are included with each byte or word.

If all formatters are to be loaded, a prompt will be issued after each successful download and a total of three separate

tables will have to be sent.

Syntax: dgamma {r|g|b|a} {b|w} {256,512,1024,2048}

> dgamma

Invalid De-Gamma Destination

> dgamma b 256

Data Size must be 'B' or 'W'

> dgamma b b 256

De-Gamma Download to BLUE FormatterXMIT EXACTLY 512 bytes of hexadecimal data

FPOL Film Projector Interlock FPOL

The film projector interlock feature operates in two modes:

or no parameters.

In

lockout

the Feature Film Projector. The lockout, when active, closes the shutter on the

in CURTAIN mode and prevents the shutter from being re-opened until the lockout becomes inactive. Depending on the

installation, the Feature Film Projector could be active or inactive when a voltage of about 5 volts is applied to the External

Interlock connector. FPOL sets or toggles the polarity of the sensing circuitry between

and

the interlock is not connected, the projector will not be locked out. There is a way to override the lockout by depressing the

right side of the Power/Shutter rocker switch for more than 5 seconds.

In

power control

voltage of about 5 volts is applied – the projector will turn on and will remain on until the voltage is removed. The shutter

will automatically open at completion of the power-up sequence whether or not there is any active video.

If the projector is in power

Typing fpol without a parameter will have no effect.

If the projector is in

The polarity parameter is stored in EEPROM and once established it is not necessary to set it again.

mode the film projector interlock circuitry senses current in the External Interlock connector that is attached to

active-when-not-energized

mode [FPOL 2], the polarity is nor selectable. When the External Interlock connector is energized – a

fpol 0 [ set lockout

fpol 1 [ set lockout

lockout

fpol [ toggle lockout polarity: 0 Þ 1, 1 Þ 0] or

fpol 0 [ set lockout

fpol 1 [ set lockout

fpol 2 [ set

power control

[FPOL 1]. The unit is shipped with the polarity set to 0 [

control

active-when-energized

mode, to take it out of this mode attach a terminal to the serial port and type:

] or

active-when-not-energized

mode:

active-when-energized

] or

active-when-not-energized

mode]

]

] or

lockout

mode and

power control

mode. FPOL takes either one

E-Cinema Projector

active-when-energized

active-when-energized

and puts its formatters

[FPOL 0]

] so that if

Page 18 of 33

Page 19

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

NOTE: When the projector is in

It locks out the other power on/off methods – serial port commands (

power control

mode, the External Interlock has absolute control over the projector power.

on

and

off

), the rear panel rocker switch and the IR

remote. To control the power or enable the IR remote during setup or testing, a terminal must be connected to the serial

interface and serial commands (

with

fpol 2

.

Syntax: fpol [0 | 1 | 2]

> fpol

FP Polarity = 1

>

Film Projector ON

IR= 08

> fpol

FP Polarity = 0

>

Film Projector OFF

> fpol 0

FP Polarity = 0

> fpol 1

FP Polarity = 1

>

Film Projector ON

> fpol 2

FP Polarity = 2

GAMMA GAMMA Table Select GAMMA

Select GAMMA Table. It will store to EEPROM, and when system boots up will reload the gamma setting.

Syntax: GAMMA {Table Num} 0 < num < n

>gamma 2

Set Gamma index = 2

fpol, ir+, etc.

) must be issued. The projector can be returned to

power control

mode

Page 19 of 33

Page 20

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Index Name Owner

0 Graphic Enhanced TI

1 NTSC TI

2 NTSC Enhanced TI

3 PAL SECAM TI

4 PAL SECAM Enhanced TI

5 EE Ambient Light Compensation #1 –

EE

for low light level

6 EE Ambient Light Compensation #2 EE

7 EE Ambient Light Compensation #3 EE

8 EE Ambient Light Compensation #4 EE

9 EE Ambient Light Compensation #5 –

EE

for medium light levels

10 EE Ambient Light Compensation #6 –

EE

for medium light levels

11 EE Ambient Light Compensation #7 EE

12 EE Ambient Light Compensation #8 EE

13 EE Ambient Light Compensation #9 EE

14 EE Ambient Light Compensation #10 –

EE

for high light levels

SETP LAMP POWER MODE SETP

GETP GETP

OSRAM Lamp support change lamp Output power. The output wattage of the lampdriver can be adjusted by command.

SETP is used to setup the lamp output wattage. For now, user can adjust 2 mode, 250W or 300W. And if system is

working in dual lamp mode, then it is set for dual lamp. It can’t separately set lamp setting. GETP is used to read lamp

output wattage. It can separately read the lamp setting.

Syntax: SETP {Power Mode} 0:250W ; 1:300W

GETP {Lamp Num} 1:Lamp1 ; 2: Lamp2

> setp 0

Set Lamp1 250W!

Set Lamp2 250W!

> getp 1

Lamp1 = 250W

IR+, IR- IR Remote Enable/Disable IR+, IR-

Enable (IR+) or disable (IR-) the infrared remote control interface. The IR remote POWER button is always

enabled. If the

projector is powered up using the IR remote, all other IR buttons are also enabled until an IR- command is issued or

POWER OFF.

Syntax: ir+

ir-

> ir+

IR Enable !!

> irIR Disable !!

Page 20 of 33

Page 21

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

LAMPON1 LAMPON1

LAMPON2 LAMP On/Off LAMPON2

LAMPOFF1 LAMPOFF1

LAMPOFF2 LAMPOFF2

Turn ON/OFF the lamp, when system is powered on. LAMPON1 is turn lamp 1 on; LAMPOFF1 is turn lamp1 off.

LAMPON2 is turn lamp 2 on; LAMPOFF2 is turn lamp2 off. In dual-lamp mode, user turn off one lamp, the system will

switch to single lamp mode, and store the mode to EEPROM.

Syntax: LAMPON1

LAMPOFF1

LAMPON2

LAMPOFF2

> lampoff1

LAMP1 OFF !

> lampoff2

LAMP2 OFF !

> lampon1

LAMP1 ON !

> lampon2

LAMP2 ON !

M+, M- Informational Message Reporting Control M+, M-

Syntax: m+

m-

> m+

Monitor Info. On !!

> mMonitor Info. Off !!

ON, OFF, ONS, OND POWER Control ON, OFF, ONS, OND

Power sequencing commands. See section 1.3 for more details.

ON and OFF Power Sequencing Commands

Command Current State Resulting State

STANDBY [RED] POWER ON

ON

ONS

OND

5 MINUTE POWER DOWN [YELLOW] POWER ON – Power Down Cancelled

60 SECOND POWER OFF [YELLOW] POWER ON – Lamp re-strike after 90 second

POWER ON [GREEN] NO CHANGE

lamp cool-down

STANDBY [RED] NO CHANGE

POWER ON [GREEN] 5 MINUTE POWER DOWN – Shutter closed

OFF

5 MINUTE POWER DOWN [YELLOW] 60 SECOND POWER OFF – Lamp OFF,

Shutter closed

60 SECOND POWER OFF [YELLOW] NO CHANGE

Page 21 of 33

Page 22

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

System boot up will reload the settings, as below:

a. Gamma setting

b. P7 setting

c. MCGD & TCGD

d. Lamp mode

e. Brightness & Contrast

f. Image Orientation

Syntax: ON → Main Power On and Turn On lamp which last power off select lamp mode. If lamp mode is Single

lamp mode, then turn on the lamp which lifetime is small, then the other one.

OFF → Main Power Off.

ONS → Main Power On and Turn On Single lamp mode which lifetime is small, then the other one.

OND → Main Power On and Turn On Dual lamp.

> on

Power On – Dual_Lamp

Lamp1 S/N = feng1

Lamp1 Time = 9:21

Lamp1 Strikes = 45

Lamp1 is Off !

Lamp2 S/N = feng2

Lamp2 Time = 9:43

Lamp2 Strikes = 74

Lamp2 is Off !

>

Powering Up

> ond

Power On -Dual_Lamp

Lamp1 S/N = feng1

Lamp1 Time = 3:15

Lamp1 Strikes = 35

Lamp1 is Off !

Lamp2 S/N = feng2

Lamp2 Time = 3:37

Lamp2 Strikes = 64

Lamp2 is Off !

>

Powering Up

> ons

Power On -Signal_Lamp Lamp 1

Lamp1 S/N = feng1

Lamp1 Time = 9:23

Lamp1 Strikes = 46

Lamp1 is Off !

Lamp2 S/N = feng2

Lamp2 Time = 9:45

Lamp2 Strikes = 75

Lamp2 is Off !

>

Powering Up

Page 22 of 33

Page 23

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

P_ID Show Projector ID P_ID

Read Projector ID.

Syntax: p_id

> p_id

Projector Serial Number=123456

SIZE Display Size SIZE

Native image size on the HD2+ engine is 1280 x 720. Parameters are entered in decimal.

Syntax: size {HSIZE} {VSIZE} - 640 ≤ HSIZE ≤ 1280, 480 ≤ VSIZE ≤ 720

> size 1280 720

Size: 1280X720

STS Display Shutter Status STS

Display Shutter Status.

Syntax: STS

> STS

Shutter is On !

V+, V- VERBOSE Mode Control V+, V-

Enable (V+) or disable (V-) VERBOSE mode on the serial interface. When VERBOSE is enabled all messages –

informational, error and status, etc. – are sent as human readable text. When disabled those messages are sent as a 6

character ASCII group. There are two types of messages: critical and non-critical. Non-critical messages can be enabled

or disabled using the M+ and M- commands. The first character of non-critical messages is a percent sign (%). Critical

messages are headed by an exclamation point (!). The next two characters form a unique 8-bit hexadecimal code

identifying the message (see below). The last three characters are a dollar sign ($) followed by a <CR> and <LF>.

DGAMMA and most of the DEBUG/Maintenance commands output verbose messages regardless of whether VERBOSE

is enabled or disabled.

Page 23 of 33

Page 24

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Non-Verbose Message Codes

Non-critical (Informational) Messages [M+ and V-]

%01$ LAMP Door Closed and Lamp TEMP OK

%02$ FANS OK

%03$ Film Projector ON – During Power-up

%04$ Film Projector OFF – During Power-up

%05$ Video Signal Detected – During Power-up

%06$ Striking Lamp – During Power-up

%07$ Restrike – Ballast RESET

%08$ Restrike – Lamp Restrike

%09$ Restrike – Restrike Fail

%0A$ Ballast COMM Failure – typically non-critical unless it least to !88$

Critical Messages / Shutdown Messages [V-]

!80$ Lamp Door Open or Lamp Overtemp – if after Power-up ► Shutdown

!81$ FAN Problem – if after Power-up ► Shutdown

!82$ NO Video – during or after Power-up

!83$ Video Signal Detected - Video Restored

!84$ Lamp Lit - During Power-up

!85$ Formatter COMM Disabled - Check SW500 – Power-up sequence halted

!86$ Restrike - Lamp Lit - After Power-up - 30 second Warm up before Shutter OPEN

!87$ Restrike Count Exceeded ► Shutdown

!88$ Ballast not Responding - After Power-up ► try Restrike

!89$ Ballast OVERTEMP ► Shutdown

!8A$ Lamp Extinguished - After Power-up ► try Restrike

!8B$ Resetting Formatters – usually non-critical

!8C$ LAMP SYNC Signal Inactive – usually non-critical

!8D$ LAMP SYNC Detected – usually non-critical

!8E$ Film Projector ON - After Power-up – Shutter CLOSED

!8F$ Film Projector OFF - After Power-up

!90$ RED FORMATTER Status Read Error – usually non-critical

!91$ GREEN FORMATTER Status Read Error – usually non-critical

!92$ BLUE FORMATTER Status Read Error – usually non-critical

!A0$ Power-up Sequence Complete – Ready for shutter OPEN

!E0$ Invalid Parameter in Command line

!E1$ Missing Parameter(s) in Command line

!E2$ Unknown Command

!F0$ Lamp Time Read from EEPROM – Lamp Hour EEPROM Read Error

!F1$ Strike Count Read from EEPROM – Lamp Hour EEPROM Read Error

!F2$ Power Off – MAIN Power OFF – System in Standby Mode

!F3$ 5 Minute Power Down Can celled by OPEN or ON Command

!F4$ 5 Minute Power Down Initiated – Lamp OFF and 60 second cool down in 5 minutes

!F5$ Powering Up – Main Power ON - Initiating Power-up Sequence

!F6$ Powering Down – Lamp OFF – 60 second cool down

Syntax: v+

v-

VER VERSION VER

Display Controller Firmware Revision:

ver

* 720p MHF-69 Monitor – Rev. D03J

* 17 Nov 2006 *Syntax: ver

Page 24 of 33

Page 25

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

3.3 Enhanced Color Correction (P7) Commands

ECC Select P7 TARGET DATA ECC

Select the Target Color Data. This command takes a parameter – the target index – between 0 and 13. The following table

lists the GRBW CIE color coordinates for the selected ECC index. Note that indicates 1 through 9 do not specify the

Magenta, Cyan or Yellow CIE values. Indices 10 through 13 specify user-definable tables which may include the CMY

coordinates as well as GAIN values for each of the colors and WHITE. See TI document –

DDP1000, DDP1010, DDP1011 Based Modular Formatter Component Set

[Dwg #2503986, Rev. J or later] for details.

Product Specification for

Target Color Gamut Data

Index Description

GREEN RED BLUE WHITE

X Y X Y X Y X Y

0 OFF ECC OFF

1

2

ANSI - 3200°K

ANSI - 5400°K

.423 .399

.335 .349

.210 .710 .670 .330 .140 .080

3

4

5

6

7

8

9

ANSI - 6500°K

ANSI - 9300°K

EE-REC709

EE-XYZ

User 2

User 3

Native

.313 .329

.283 .297

N/A

N/A

User Selectable GREEN, RED, BLUE, MAGENTA, CYAN,

YELLOW and WHITE CIE Indices stored in EEPROM

(See TDNLD)

.316 .651 .655 .341 .147 .044 .296 .337

Syntax: ecc {target index}

> ecc2

EC Set Index 2

ECC Enable

Freeze Frame On

Freeze Frame Off

MDNLD Download Measured Color Gamut Data MDNLD

Download Measured Color data for storage on the BLUE Formatter’s EEPROM. When the command is entered, the

operator is prompted to send 16 bytes of data: the X and Y CIE coordinates of the un-enhanced GREEN, RED, BLUE and

WHITE colors. Each coordinate is 16 bits - 2 bytes - sent least significant byte first in hexadecimal. For each coordinate,

first multiply by 65536 and convert to hexadecimal. Output two hexadecimal bytes, LS byte first, for each of the 8

coordinates in order: Gx, Gy, Rx, Ry, Bx, By, Wx, Wy , Bx By ,WY and BY. The values can be manually typed from the

terminal or stored in a file and sent to the controller board using the terminal’s “Send Text File” utility. Characters typed of

sent will NOT be echoed. The 16 bytes sent may be <SPACE>, <TAB>, <CR> or <LF> separated.

After the data is downloaded, the coordinates will be displayed in decimal format for confirmation.

Page 25 of 33

Page 26

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Syntax: mdnld

> mdnld

Enter Gx,Gy,Rx,Ry,Bx,By,Wx,Wy,Bx,By,WB,BB(x100) 12 datas:

.323,.649,.664,.334,.146,.041,.291,.307,.310,.000,3000,123

GREEN = .323,.649

RED = .664,.334

BLUE = .146,.041

WHITE = .291,.307

BLACK = .310,.037

CONTRAST= 2439

RDMCGD Display Measured Color Gamut RDMCGD

Data in Use

Display the Measured Color Gamut Data that is currently in use. If the calibrated data in the EEPROM on the BLUE

Formatter has not been loaded or has been corrupted, a default table is loaded.

Syntax: rdmcgd

> rdmcgd

GREEN = .340,.650

RED = .640,.350

BLUE = .140,.033

WHITE = .290,.330

RDTCGD Display Target Color Gamut Data RDTCGD

Display the Target Color Gamut Data for the specified index. This command takes a parameter – the target index –

between 1 and 9.

Syntax: rdtcgd {1 ≤ target index ≤ 9}

For indices 1 through 4 (in this example index 4) the following will be output to the terminal:

> rdtcgd 4

GREEN = .210,.710

RED = .670,.330

BLUE = .140,.080

WHITE = .423,.399

TOLBOX = .010

For indices 5 through 8 (in this example index 8) the full contents of the used-definable table will be displayed. The third

value for each color is the GAIN. See TI document –

Modular Formatter Component Set

Copyright notice.

[Dwg #2503986, Rev. J or later] for details on the tolerance box specification and the

Product Specification for DDP1000, DDP1010, DDP1011 Based

Page 26 of 33

Page 27

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

> rdtcgd 8

GREEN = .337,.642,.000

RED = .642,.353,.000

BLUE = .140,.034,.000

MAGENTA = .000,.000,.000

CYAN = .000,.000,.000

YELLOW = .000,.000,.000

WHITE = .287,.326,.000

TOLBOX0 = .277,.336

TOLBOX1 = .297,.336

TOLBOX2 = .297,.316

TOLBOX3 = .277,.316

Use TOL BOX

Notice: 'P7 TCGD Data - 6300K - Copyright (c) 2006 Delta Products Corp.'

TDNLD Download User-Defined Target Color Gamut Data TDNLD

Download a User-definer Target Color Gamut Data Set for storage in controller board’s EEPROM. The command takes a

decimal parameter – the target index between 10 and 13 corresponding to the index used in the ECC command. When the

command is entered, the operator is prompted to send 140 bytes of data. A description of the data packet can be found in

the Texas Instruments document –

Component Set

byte listed here is 8816. This is used when actually communicating with the Formatters and should not be sent with the

TDNLD command. Byte 2 – the LS Byte of the GREEN CIE X coordinate is the first value sent. The command description

only defines bytes 2 through 140 – a total of 139. Add an extra 0 byte to the end so that full 140 bytes are sent. Unspecified

parameters such as GAIN values, CMY coordinates or the Copyright Notice should be sent as zeros.

The values can be manually typed from the terminal or stored in a file and sent to the controller board using the terminal’s

“Send Text File” utility. The 140 bytes sent may be <SPACE>, <TAB>, <CR> or <LF> separated.

Characters typed of sent will NOT be echoed.

Field Contents BYTES Positions Field Contents BYTES Positions

GREEN

RED

BLUE

MAGENTA

CYAN

YELLOW

WHITE

[Dwg #2503986, Rev. J or later] in the Target Color Gamut Data command description. Note that the first

X 2 Bytes 1-2 RESERVED – 00H 6 Bytes 43-48

Y 2 Bytes 3-4 X 2 Bytes 49-50

GAIN 2 Bytes 5-6

X 2 Bytes 7-8 X 2 Bytes 53-54

Y 2 Bytes 9-10

GAIN 2 Bytes 11-12 X 2 Bytes 57-58

X 2 Bytes 13-14

Y 2 Bytes 15-16 X 2 Bytes 61-62

GAIN 2 Bytes 17-18

X 2 Bytes 19-20 RESERVED – 00H 6 Bytes 65-70

Y 2 Bytes 21-22 TOL BOX MODE 1 Byte 71

GAIN 2 Bytes 23-24 RESERVED – 00H 1 Byte 72

X 2 Bytes 25-26

Y 2 Bytes 27-28

GAIN 2 Bytes 29-30 RESERVED – 00H 4 Bytes 137-140

X 2 Bytes 31-32

Y 2 Bytes 33-34

GAIN 2 Bytes 35-36

X 2 Bytes 37-38

Y 2 Bytes 39-40

GAIN 2 Bytes 41-42

Product Specification for DDP1000, DDP1010, DDP1011 Based Modular Formatter

TDNLD Data Format

W TOL BOX 1

W TOL BOX 2

W TOL BOX 3

W TOL BOX 4

Copyright Notice –

ASCII – 0 PADDED

Y 2 Bytes 51-52

Y 2 Bytes 55-56

Y 2 Bytes 59-60

Y 2 Bytes 63-64

64 Bytes 73-136

Page 27 of 33

Page 28

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Syntax: tdnld {5 ≤ target index ≤ 8}

> tdnld 5

XMIT EXACTLY 140 bytes of hexadecimal data

Download TCGD 5

down !!

GREEN = .265,.690,.513

RED = .665,.312,.150

BLUE = .140,.070,.078

MAGENTA = .373,.178,.270

CYAN = .176,.337,.659

YELLOW = .457,.522,.916

WHITE = .314,.351,.:00

TOLBOX0 = .309,.355

TOLBOX1 = .318,.362

TOLBOX2 = .319,.347

TOLBOX3 = .311,.341

Use TOL BOX

Notice: 'c)Copyright 2002 Texas Instruments Inc.'

>

>

>

3.4 DEBUG/Maintenance Commands

BAUD Switch BAUD Clock BAUD

Immediate BAUD clock change. Only two rates are supported – 9600 and 19200. The clock rate on the terminal

programmed will have to be changed to continue. This command also sets the BAUD clock that will be set at start-up.

Syntax: baud {9600 | 19200}

FH FORMATTER Register Help FH

This command prints the register numbers, R/W status and name of the accessible DDP1011 formatter registers:

Syntax: fh

> fh

00 RW Brightness

01 RW Contrast

02 RW Projection Mode

03 RW Image Orientation

04 RW Mirror Park

05 RW Image Freeze

06 RW Vertical Frequency

07 RW Vertical Frequency Offset

08 RW Color Temperature Gain

09 RW Input Image Size

0A RW Image Position

0B RW Test Pattern Select

0C RW Formatter Input Data Type

0F RW 3D Sequence Set Select

10 RW Pulsed Lamp Data

11 RW Pulsed Lamp Ballast Sel

31 RW Color Space Matrix Select

32 WO Color Space Matrix Dnld

Page 28 of 33

Page 29

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

33 RO Color Space Matrix Read

34 RW De-Gamma Table Select

35 RW De-Gamma Dnld Dest

36 WO De-Gamma Dnld Mailbox

40 RO System Configuration

41 RW DMD Bin Voltage Method Sel

42 RW DMD Bin Voltage Level Sel

43 RW Convergence

44 RW Formatter Color

45 RW Processing Path Select

46 RW Sequence Set Select

47 RO Sequence Sets Available

48 RO Sequence Set Data

49 RW Select LAMPSYNC Output

4A RW Flash MEM Access Time Sel

4C RW Command Sync ENABLE

50 RO System Status

51 WO System RESET

53 RO VERSION

55 RO Special Feature STATUS

60 WO Target Color Gamut Data

61 WO Measured Color Gamut Data

63 RW Enhanced Color Corr. Disable

FR, FRR, FORMATTER Register Read FR, FRR,

FRG, FRB FRG, FRB

Read formatter registers:

FR - Read all formatters

FRR - Read RED formatter

FRG - Read GREEN formatter

FRB - Read BLUE formatter

The required parameter is the hexadecimal register number. The output is formatted as a stream of 8-bit or 16-bit

hexadecimal values as specified in the TI document –

Modular Formatter Component Set

Syntax: fr[r|g|b] {register number}

> fr 0

RED Formatter Brightness Register: 1500 1500 1500

GREEN Formatter Brightness Register: 1500 1500 1500

BLUE Formatter Brightness Register: 1500 1500 1500

> frr 0

RED Formatter Brightness Register: 1500 1500 1500

> frg 0

GREEN Formatter Brightness Register: 1500 1500 1500

> frb 0

BLUE Formatter Brightness Register: 1500 1500 1500

[Dwg #2503986, Rev. J]. See FW below.

Product Specification for DDP1000, DDP1010, DDP1011 Based

Page 29 of 33

Page 30

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

FW, FWR FORMATTER Register Write FW, FWR,

FWG, FWB FWG, FWB

Write formatter registers:

FW - Write all formatters

FWR - Write RED formatter

FWG - Write GREEN formatter

FWB - Write BLUE formatter

The first parameter is the hexadecimal register number. One or more additional parameters are required – the data to be

written. See the TI document –

Component Set

Protocol Pad

[Dwg #2503986, Rev. J] – for details. The first byte in the spec –

bytes are not entered in the parameter list. As an example, the Brightness Register (0016) lists the following

Product Specification for DDP1000, DDP1010, DDP1011 Based Modular Formatter

Number of bytes being sent

– and the

data:

Byte Description

1 Number of data bytes being sent (06h)

2 Green (lsb)

3 Green (msb)

4 Red (lsb)

5 Red (msb)

6 Blue (lsb)

7 Blue (msb)

8 Protocol Pad

Thus three words are required. To write the following data to the BLUE formatter BRIGHTNESS register:

Green = 1484

16

, Red = 18E0

16

and Blue = 0AF9

16

type: fwb 0 1484 18e0 af9

To write to all Test Pattern Select register (0B

16

):

Byte Description

1 Number of data bytes being sent (03h)

2 Test Pattern Number

3 Vertical Frequency Value (lsb)

4 Vertical Frequency Value (msb)

5 Protocol Pad

6 Protocol Pad

7 Protocol Pad

8 Protocol Pad

with Test Pattern select = 06

16

and Vertical Frequency Value = 1771

16

type: fw b 6 1771

Syntax: fw[r|g|b] {register number} {data1 [data2]…[datan]}

To write the Brightness or Contrast in R/G/B channel,please follow the below command.

R/G/B Brightness:

Fw {Brightness} {Green-Brightness}{Red-Brightness}{Blue-Brightness}

>fw 0 7000 8000 9000

RED Formatter Brightness Register : 7000 8000 9000

GREEN Formatter Brightness Register : 7000 8000 9000

BLUE Formatter Brightness Register : 7000 8000 9000

Page 30 of 33

Page 31

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

R/G/B Contrast:

Fw {Contrast} {Green-Contrast}{Red-Contrast}{Blue-Contrast}

>fw 0 8000 9000 7000

RED Formatter Contrast Register : 7000 8000 9000

GREEN Formatter Contrast Register : 7000 8000 9000

BLUE Formatter Contrast Register : 7000 8000 9000

OCMD Ballast Communications OCMD

This command is used for sending commands to the Osram Lamp ballast. The first parameter determines which of the two

ballast ports is addressed. The second is the ballast register address (hexadecimal – e.g., STATUS = 22

16

). See the

Osram documentation for register details. If the command requires data to sent those bytes are appended to the

command (hexadecimal and space delimited). If the command causes the ballast to return data – no just echo the

command – the response will be output in hexadecimal bytes. The ballast status command is special in that the status bits

are decoded (see below). Examples:

Syntax: ocmd { 1 | 2 } {ballast command} [data

> ocmd 2 22

Command response = E0

LAMP BALLAST 2 STATUS BYTE:

RUN UP IN PROGRESS

MAX IGN TIME EXCEEDED

LAMP BURNING

> ocmd 2 3e

Command has no response.

> ocmd 2 60 96

Command response = 9D

> ocmd 2 60 98

Command response = D9

1

] [data2] … [datan]

RST Reset and Re-initialize the Formatters RST

Perform hardware RESET of the 3 formatters and re-initialize them:

Syntax: rst

> rst

Reset Formatter Board Now !!

MCGD OK to Read

ECC Index 2

ECC Enable

Freeze Frame On

Freeze Frame Off

Reload Gamma Index = 1

Page 31 of 33

Page 32

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

4. Infrared Remote Control Interface

An IR interface is included for Lens Positioning, Zoom and Focusing adjustments. The IR remote control that is handled by

the firmware is Model T320L by Umate Corp., Taipai, Taiwan. It emits the following

Button Code Assuming

RECS80

codes:

Operation/Action

LSB First

POWER 8C73817E16 Toggle Main Power

Mouse Knob N/A Not decoded

L Mouse Button N/A Not decoded

R Mouse Button N/A Not decoded

UP Arrow 8C73837C16 Pan UP

DOWN Arrow 8C7343BC16 Pan DOWN

RIGHT Arrow 8C7323DC16 Pan RIGHT

LEFT Arrow 8C73C33C16 Pan LEFT

ENTER 8C73A35C16 Reserved

Keystone UP 8C73A15E16 Brightness/Contrast – Increment Lower Level

Keystone DOWN 8C7321DE16 Brightness/Contrast – Decrement Lower Level

Volume UP 8C7331CE16 Brightness/Contrast – Increment Upper Level

Volume DOWN 8C73F10E16 Brightness/Contrast – Decrement Upper Level

MENU 8C73E11E16 Change Mode – same as <CTRL-N>

STATUS 8C7311EE16 Change Pattern – same as <CTRL-P>

MUTE 8C73916E16 Change Orientation – same as <CTRL-O>

AUTO 8C73619E16 Focus FAR

SOURCE 8C73C13E16 Focus NEAR

ZOOM+ 8C7385AE16 ZOOM OUT – Image larger

ZOOM- 8C73B14E16 ZOOM IN – Image smaller

BLANK 8C738D2E16 Open Shutter – same as OPEN

FREEZE 8C73718E16 Close Shutter – same as CLOSE

Control buttons other than those listed in BOLD above generate no activity.

4.1 Pan, Zoom and Focus Speed and Nudge Functions

The Pan, Zoom and Focus buttons can be used to manually control the projected image. All of the motors may be driven

at one of four speeds to make small incremental adjustments. In addition a nudge function is implemented. When any of

the control keys are pressed and released, the associated motors will be turned on for a short period of time, causing a

small incremental change in the image. In the following descriptions this nomenclature is used:

P = a quick button press and release – press and release time each less that about 0.25 seconds

H = the button is held down

PP = two quick button presses and releases – down times and intervening up times each less that about 0.25

seconds, etc.

..PH = One or more quick button presses and releases followed by a hold

The nudge function generates small changes in lens position,etc., by applying power to the associated motor for one of

four time intervals: 12.5, 25, 50 or 100 milliseconds. Nudges are generated by a number of quick button depressions and

releases. Nudge increments are controlled by the number of quick button presses – up to four. More than four are treated

the same as four.

P – smallest change – 12.5 msec

PP – 25 msec

PPP – 50 msec

PPPP – largest change – 100 msec

PP..PP – largest change – 100 msec

Page 32 of 33

Page 33

BOXLIGHT PRO80S3 Projector Preliminary User’s Manual

Continuous changes are generated by a number of quick presses followed by a hold. Motor speeds are determined by the

number of quick button presses – up to three – before holding the button down.

H – very slow

PH – slow

PPH – medium

PPPH – fast

PP..PH – fast

Release the button to stop the motor. Note that there is about a 0.25 to 0.35 second delay between button release and

motor off.

Page 33 of 33

Loading...

Loading...