Page 1

~

_

'"

,·U

/',

(..., _

.

. ' ._--- -

...

~

- -

BOXFORD

CNC

MACHINE

Z-

\( ~ (->,\

280B

&

":-.

(.1'

\Cc

TURNMASTER

PROGRAMMING

MANUAL

~.

~·c

\ -~.

Page 2

SAFETY

INTRODUCTION

CONTENTS

SECTION

SECTION

1:

2:

FIRST

1.1.1

1.1.

1.

1.2.2

1.2.3

1.

1.

1.3.2

1.

1.3.4

1.3.5

STEPS.

2

2.1

2.4

3.1

3.3

FURTHER

2.1

2.2

2.3

2.4

Installation.

Machine

Machine

Manual

Pneumatic

Machine

Operations

Absolute

Program

Specification.

Function

operation.

Facilities.

Offset.

And

And

Format

Programming - G

Programming - M

EXPLANATIONS

GOO,

G02

G03

G70,

GOL

1n

in

GIL

OF

GOZ, G03.

detail.

detail.

G80,

Keyboard. (Power

Programming

Incremental

And

Axis

Directions.

Codes.

Codes.

G

CODES.

G82

G81,

Facing.'

On).

Sheets.

Co-Ordinates.

SECTION

3:

2.5

2.6

2.7

MAIN

3.1

3.2

3.3

3.4

3.5

3.6

3.1

3.8

3.9

MENU

G82,

G84,

G94, G95,

Grooving,

G90,

G91.

G96,

G83.

G9,.

OPTIONS.

The

Main

Menu.

Yrite A New

Program.

Edit/Continuation.

Test

Print

Execute

Help Date

File

Machine

Run

A Program.

Program.

A

Program.

A

Library.

Index.

feedback/Offsets.

Page 3

SECTION

4:

MAINTENANCE

AND

REPAIRS.

4.1.1

4.1.

4.1.3

4.1.4

4.2.1

4.2.2

4.3.1

2

ElectricalOverview

Electrical

Electrical

Electrical

Foundation

LUbrication

Power

fault

Diagrams.

Diagram.

Diagram.

..

Supplies.

Finding.

Arrangement Drawings.

Page 4

COPYRIGHT

~ll

right~

1n a

electronic,

prior

THE

retr1eval

permission

HEALTH

(C)

Boxford

reserved.

system,

mechanical,

of

AND

SAfETY

Limited

No

part

or

transmitted,

photocopying,

Boxford

AT

WORK

1991.

of

this

Limited.

ACT

1974.

publication

in

any form

recording

may

he

or

or

otherwise,

reproduced,

by

any

means,

without

stored

the

'-'

Under

equipment

The

parameters

cause

practices

instructions

Many

including:

*

...

this

regarding

equipment,

any

danger

are

safety

Fully

protection

Positive

and

feed

* Delayed

protect

*

>Ie

*

'"

'"

>Ie

...

'"

...

'"

'"

*

*

Mandatory

cycle

advance

Ideal

Feed

Cycle

F'eed

Single

rate

hold.

Emergency

Power on

Low

voltage

Machine

Fully

Integrated

'Power

Act

information

when

set

for

its

or

observed

supplied.

features

enveloping

for

microswitch

hold.

response

against

graphics

can

be

commenced and

of

the

position

over-ride

stop.

block

isolator

enclosed

on'

operation.

stop

indicator

control

electrical

indicator

its

safe

used

hazard

in

mechanical

and

have

been

transparent

spindle

protection

to

spindle

accidental

run

actual

for

machines

to

push

main

button

lamp.

circuitry

switch.

motor.

lamp.

has

to

use.

normal

to

health

they

are

incorporated

and

feed

use

required

step

metal

control

•

panel

be made

or

and

and

used

available

prescribed

electrical

safety

in

accordance

in

chip/work

hold.

on

forward/reverse

in

manual mode.

for

by

removal

controls.

jog

.

and power

the

new

step

in

rates.

wiring.

guard

pUlley

programs

execution

the

to

users

applications

performance,

if

normal

with

the

design

with

and

machining

end

X/Z

positive

guard

before

of

of

this

within

should

engineering

the

of

this

microswitch

for

jog

buttons

the

graphics

cycle.

the

Dot

equipment

spindle

to

machining

in

Whilst

manual

proper'

Wheatley,

Fax:

we

use

0422

attempt

if

there

of

Halifax,

355924.

this

to

give

is

any

equipment

West

the

fullest

doubt

Yorkshire,

whatsoever

the

user

HX)

possible

about

should

SAF.

Tel:

user

aspects

contact

0422 358311.

informat~on

relat1n~

Boxford

L~m1ted,

in

~o

the

the

Page 5

INTRODUCTION

The

Boxford

guide

performance

We

great

useful

on

We

thoroughly

Our

advice

the

emphasise

extent

life

the

care

suggest

commercial

or

280

user

and

of

taken

therefore

digested

information

TH

of a new

maximum

our

belief

upon

the

the

in

and

is a British

lathe

useful

however,

adoption

lathe,

its

that

and

technical

its

installation,

the

adhered

departments

should

made

CNC

towards

life.

of

performance

advice

to

this

that

safe

as

be

its

safety

and

closely

required.

lathe,

safe

on

working

and

its

operation

information

as

will

be

and

our

operation,

the

lathe

practices,

accuracy

and

routine

offered

possible.

pleased

objectives

optimum

relies

and

that

depend

maintenance.

should

to

supply

are

to

to a very

the

largely

be

further

Please

stamped

quote

at

the

the

Lathe

lower

Model and Machine

right

BOXFORD

hand

LTD

corner

of

HALIFAX

Serial

the

(0422 358311)

Number

bed

in

(which

all

communications.

may

be found

Page 6

INSTALLATION

1.1.1

Siting

The machine

is

The Machine

capable

should

of

supporting

Equipment and an

sufficient

Machine

Under

normal

bolted

clamp

bolts

Foundation

In

cases

should

levelling

Electrical

The

280TM

plus a neutral

the

415

Fixing

down,

where

be

provided

and

requires

volts.

space

operating

but

are

Diagram

the

straightness

Supply

line.

be

located

Operator,

should

be

the

combined

without

provided

on a

conditions

for

optimum

accuracy

recommended and

4.2.1.

machine

to

prevent

is

checks

a

20A 3 phase

A

~ariation

\--

firm,

noticeable

for

it

is

bolt

to

the

holes

be

free

machine from

have been

415V

of

plus

preferably

weights

cleaning

not

and

cutting

are

standing

AC

power

or

minus

concrete,

of

Machine,

deflection.

and

maintenance

essential

for

performance

provided -refer

some

being

form

moved

completed.

supply

15

(suitably

volts

floor

Accessories,

purposes.

the

machine

foundation

to

of

location

bodily

once

earthed)

is

tolerable

which

to

on

be

or

Air

Supply

If

the

power

tailstock,

operate

pressure

machine

them.

and

capable

is

The

supplied

it

will

supply

of

with a parts

be

necessary

required

giving

approximately

to

should

catcher,

run a

be

at

1.0

power

suitable

85

pounds

cubic

chuck/collet

air

supply

per

square

feet

per

minute.

or

to

inch

Page 7

1.1.2

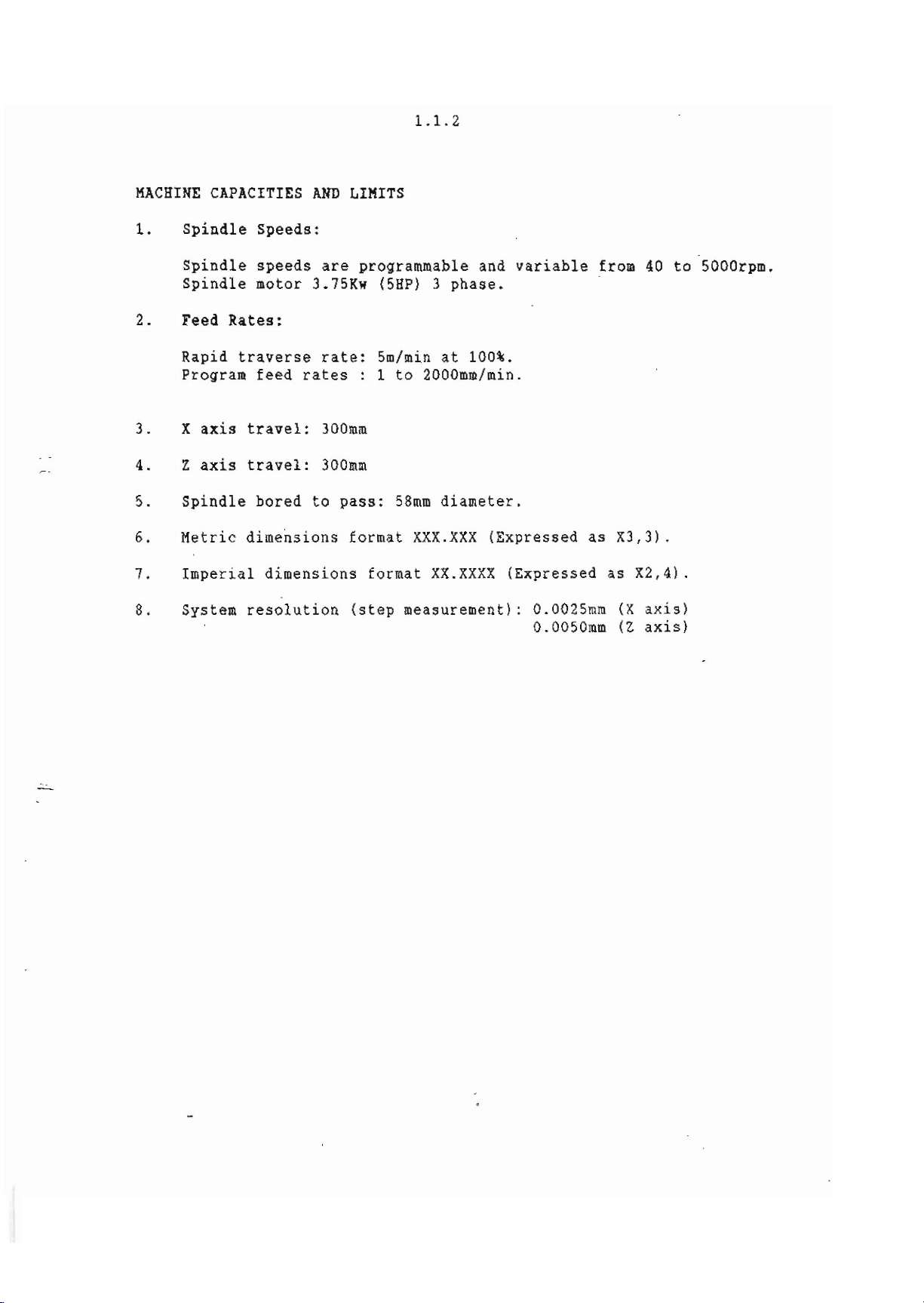

MACHINE

1.

Spindle

Spindle

Spindle

2. Feed

Rapid

Program

3.

4.

5.

6.

7.

8.

X

axis

Z

axis

Spindle

Metric

Imperial

System

CAPACITIES

Speeds:

speeds

motor

Rates:

traverse

feed

travel:

travel:

bored

dimensions

dimensions

resolution

AND

are

3.75Kw

rate:

rates:

300mm

300mm

to

pass:

LIMITS

programmable and

(5HP) 3 phase.

5m/min

1

format

format

(step

to

58mm

at

100%.

2000mm/min.

diameter.

XXX.XXX

XX.XXXX

measurement):

variable

(Expressed

(Expressed

O.0025mm

O.0050mm

from

as

X3,3).

as

X2,4).

(X

(Z

40

to

axis)

axis)

5000rpm.

Page 8

1.

2.1

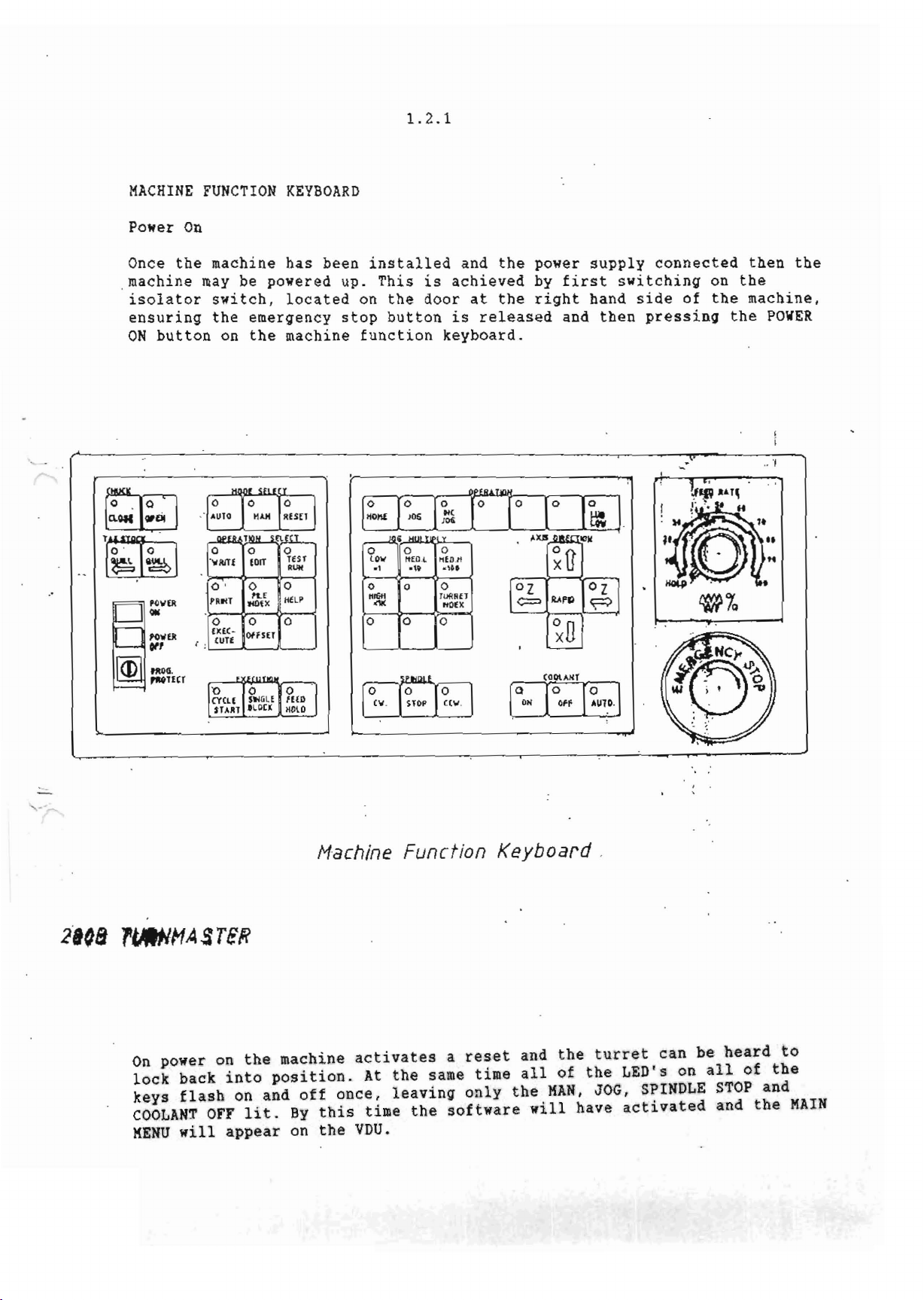

MACHINE

Power

Once

. machine

isolator

ensuring

ON

button

'~""ER

OM

,.,

....

Of'

fltIlG.

;

(J)

,aoucr

FUNCTION

On

the

may

ER

machine

be

switch,

the

emergency

on

the

0'

o

ft-f

'~tlT

lNOtX

KEYBOARD

has

been

powered up.

located

stop

machine

o

HfLP

o

installed

This

on

the

button

function

0

0

HIGH

-<11(

0 0

and

is

achieved

door

at

is

keyboard.

0

tlEO.H

.'u

0

TUflRfT

"OEX

0

the

power

by

the

right

released

oz

c=

RAPIl

(OOlAlIT

(010lOI

~

first

and

supply

switching

hand

then

connected

side

of

pressing

on

the

the

then

the

machine,

POWER

the

On

power on

lock

keys

back

flash

COOLANT

MENU

will

into

orr

appear

the

on

lit.

M-achine

machine

position.

and

off

By

on

once,

this

the

Function

activates

At

the

leaving

time

the

VDU.

a

reset

same

only

software

Keyboard

and

time

all

the

will

the

of

MAN,

turret

the

JOG,

have

can

LED's on

SPINDLE

activated

be

all

heard

of

S·TOP

and

and

the

to

the

.

KAIN

Page 9

1.

2.2

1

of

2

MANUAL

The

prior

SPINDLE

With

the

of

OPERATION

280TM

to

OPERATION

the

relevant

the

spindle

commences

spindle

key

achieved.

direction

revolving

illuminate

COOLANT

It

may

coolant

pipes

coolant

Coolant

M08

OPERATION

be

on key

being

off

is

and

H09

illuminated.

using

the

may

of

course

CNC

control

machine

in

direction

direction

to

rotate.

with

To

key

press

after

the

decrease

until

the

the

necessary

illuminates

open,

the

key.

program~able

respectively

To

do

this

coolant

on

he

used

being

manual

used.

mode

key on

keys

To

increase

illuminated

the

spindle

the

required

spindle

spindle

to

use

coolant

the

coolant

on and

but

press

key.

the

the

stop

has

is

only

the

as

a manual machine

the

spindle

manual

red

the

LED

speed

speed

key

LED

speed

until

press

is

and

operation

the

stopped.

in

a manual

LED

and,

subject

emitted.

off

with

if

key.

the

The M

the

auto

may

be

illuminates

of

the

the

required

the

opposite

obtained.

LED

on

operation.

to

To

stop

the

use

of

coolant

codes

for

setting

started

panel.

and

spindle

speed

To

stop

the

stop

the

taps

coolant

the

miscellaneous

key

may

be

up

up by

On

the

press

pressing

pressing

spindle

the

is

spindle

the

spindle

key

will

Pressing

on

the

press

LED

is

overridden

purposes

one

the

coolant

the

~odes

by

JOG

OPERATION

When

mode

tbe

and

machine

selects

illuminated

and Z

set

be moved

It

required

by

may

jog

the

he

keys

at

that

to

automatically

the

moves

slides

key.

An

alternative

them

labelled

active.

chosen,

being

the

at

incremental

INC

As a safety

is

lit.

amount on

is

the

lights

may

feedrate

the

same

the

be moved.

overrides

at

to

JOG

and

the

smallest

Pressing

the

powered on

JOG

operation.

on

the

two

be

used

to

knob from 0 up

time

maximum

If

or

jog

so,

whatever

rapid

moving

jog

the

measure

traverse

the

distances.

LED

the

increment

either

key which

LOW

MED.L

MED.H

HIGH

x

x

x

x

of

is

1

10

100

lK

the

control

Confirmation

keys.

jog

With

the

to

each

then

axis

rate

pressing

is

feedrate

rate.

slides

at a continuous

To

will

illuminate

default

of

the

axis

illuminated.

O.OliT1lB

=

0.10mm

=

1.00mIll

=

lO.OOmm

=

automatically

the

slides

the

maximum

individually.

not

fast

the

value

Care

use

this

increment,

.Olmm

jog

and

keys

or

or

or

or

of

this

machine

around

the

jog

enough

centre

is

set

must be

teedrate

facility

indicating

when

is

indicated

will

0.0004!'!

0.0040"

0.0400"

0,.4000'"

defaults'to

may

in

this

machine

rate.

for

rapid

on

taken

Both

the

key

the

when

press

the

facility

this

by

increment

be

seen

state

at a rate

axes

distance

dial

using

is

to

the

key

facility

the

the

manual

by

the

and

move

is

LED

axis

the

X

may

this

is

by

This

5mall

facility

'l\oV~S

to

is

be

particularly

"!lade

"Ind

useful

:H:r:l\ri'lte

when

t-nol

setting

I)fts~ts

tool

to

he sP.t.

offsets

as

it

allows

Page 10

1.2.2

2

ot

2

Manual

TURRET

To

index

Pressing

station

held

down

Operation

INDEX

the

turret

tbe

key

and

then

until

cont'd.

manually

labelled

stop.

the

station

For

first

'turret

an

index

required

ensure

index'

of

is

causes

more

in

the

MAN

than

position

mode

the

one

turret

station

.

key

is

illuminated.

to

index

the

key

one

may

be

.;

....

Page 11

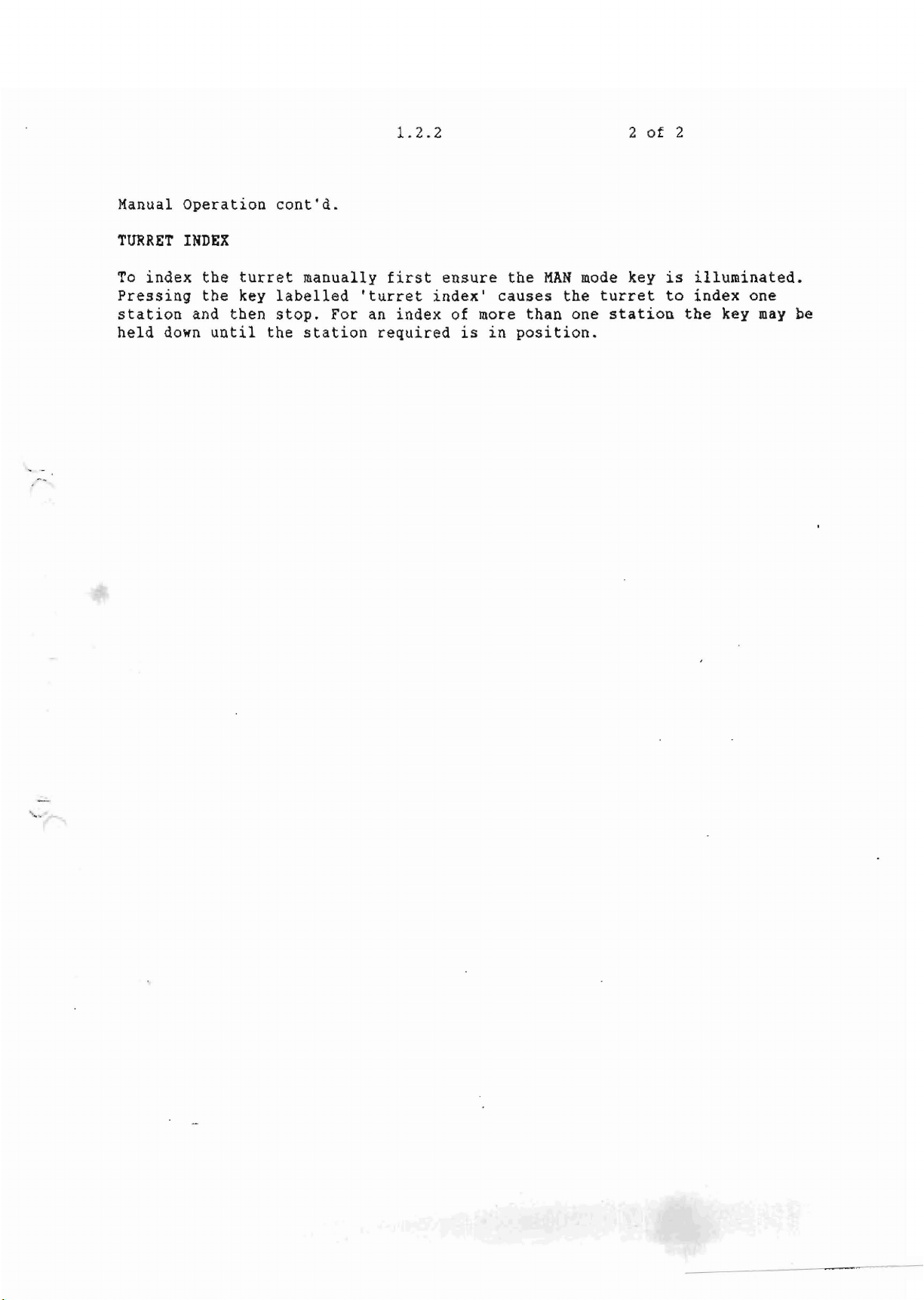

1.2.4

1

of

2

MACHINE

The machine

exact

point

In

all

centreline

of

workholding

front

OFFSET

offset

distance

on

the

instances

of

end

of

from a datum

cross

the

device

the

The X and Z datum

type

of

which

type

turret,

stations

On

a machine

the

centre

the

cross

The two

before

these

of

values

workholding

and

values

the

tooling

then

the Z axis

fitted

of

the

slide.

for

machine

if

is

on

the

slide

the

'X' datum

spindle.

has

device.

points

system

the

X

with a quick

location

the

machine

leaves

either

altered,

2aOTM

point

when

The Z datum

been

for

the

is

axis

datum

datum

stud

the

a

collision

or

plays a very

at

the

the

slides

point

at

chosen.

cross

chosen.

is

taken

is

taken

change

and

the

offset

will

factory.

involving

the

machines

important

spindle

are

the

point

In

all

slide

spindle

end

at

HOME

varies

cases

differ

For a machine

as

the

as

the

front

toolpost

Z datum

the

is

usually

However

the

it

may

turret

software

role

of

the

position.

end

is

depending

the

datum

once

again

fitted

centreline

face

of

X datum

taken

have

is

as

been

be

necessary

occurs

RESET.

as

it

machine

always

on what

point'

depending

~ith

of

the

disc.

is

taken

the

front

set

or

is

to

the

is

a

disc

the

by

Boxford

to

the

the

a

type

the

on

ID

from

of

alter

type

To

gain

on

the

operation

The

following

Should

following

access

the

display

OLD

NEW

to

select

screen

old

values

appears

Z

VALUE:

Z UALUE;

CORRECT 1

I,

I.

the

machine

panel

will

now

be

zero

after

e

offset

followed

be

displayed

(eg.

pressing

L

values

after

by

the

with

a

software

the

To

insert

the

press

both

appears

the

or

'NO'.

press

"offset"

datums key.

the

"write"

the

or

the

EOB

key

key.

old

values

RESET)

key

alter

in

key.

labelled

then

only.

the

the

After

values a confirmation

and

is

answered

appropriate

soft

key

"offset"

in

X and

Z.

the

1~.

.~.::;=======--

values

value

@,L

for

and

entering

prompt

by

pressing

of

'YES'

Page 12

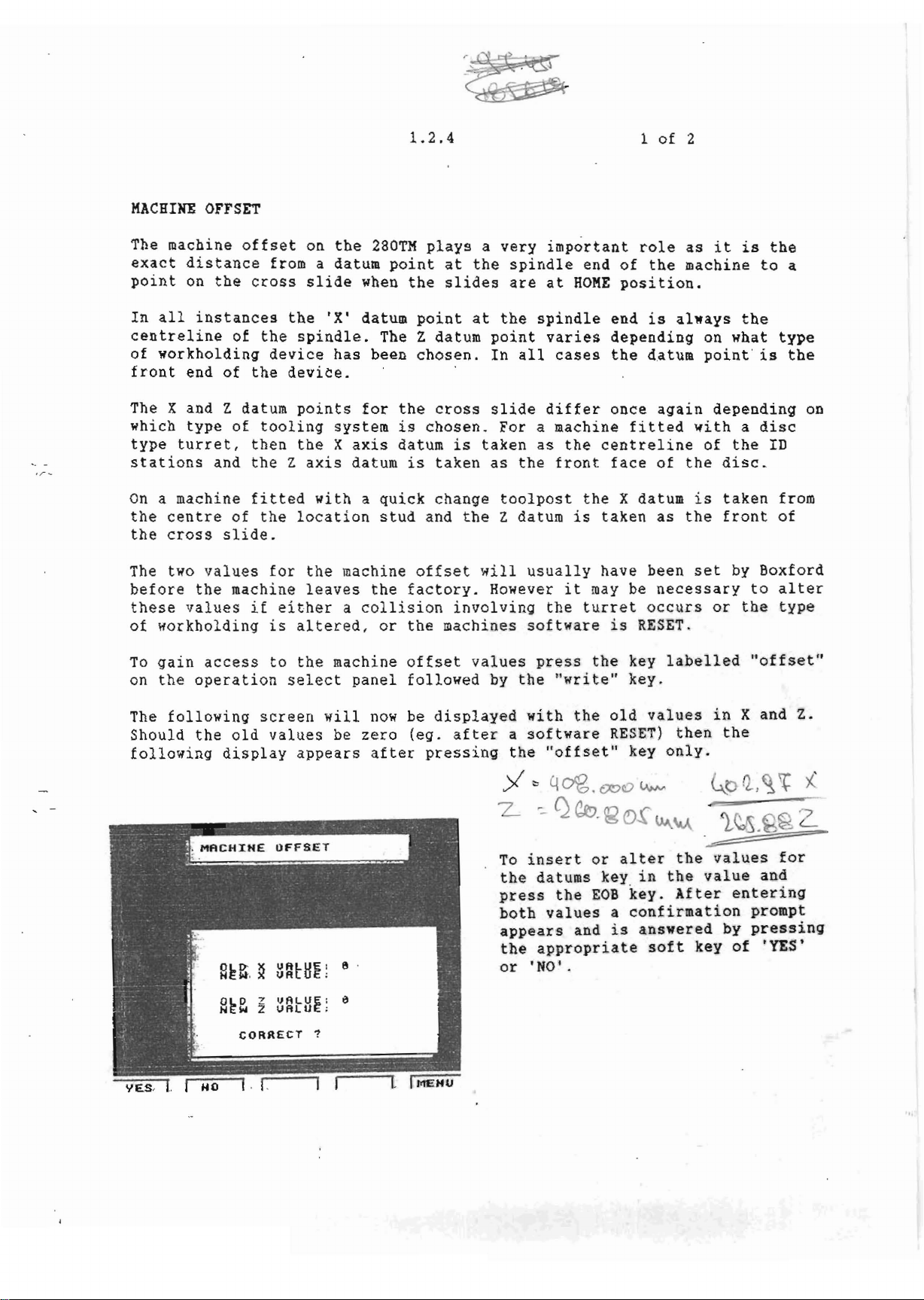

1.2.4

2

of

2

Machine

Offset

Answering 'NO'

input,

This

are

whereas

screen

used

shows J

for

debugging.

option 1 should

this

Pressing

following

menu.

the

screen

softkey

cont'd.

will

erase

answering

items

Only

be

chosen

labelled

from which a

the

'YES'

~hich

from

values

displays

"1"

causes

choice

entered

the

1 I

the

may

be made.

and

allow

following

screen

for

new

screen.

values

to

be

Page 13

1.3.1

1

of

3

OPERATIONS

following

The

be made:

1.

2.

3.

4.

Drawing

Examine

datum

Machining

Decide

the

machine

finish

operations

Tooling

Choose

degree

by

appropriate

Programming

AND

PROG~AMMING

points

the

drawing,

if

necessary.

on

the

operation,

profile)

should

appropriate

diamond

require

material

and

be

tools

insert

diameter

SHEETS

consideration

choose

from which

(eg.

the

sequence

performed.

for

Lff copy

drill.

so

that

a work datum and

the

part

rough

each

turn

in

machining

turning

15mm

which you

tool

and

a

logical

re-dimension

is

to

be

dia.,

sequence,

rough

think

centre

approach

from

machined.

chamfer,

that

ego

drill

these

roughing

can

this

Consider

55

followed

All

sheet

found

Decide on

rates,

of

these

and programming

overleaf.

incremental/absolute

spindle

decisions

speeds

should

sheet.

etc.

Blank

dimensions,

be

systematically

forms

for

linear

recorded

you

to

interpolation

on

copy

and

an

operating

use,can

feed

be

Page 14

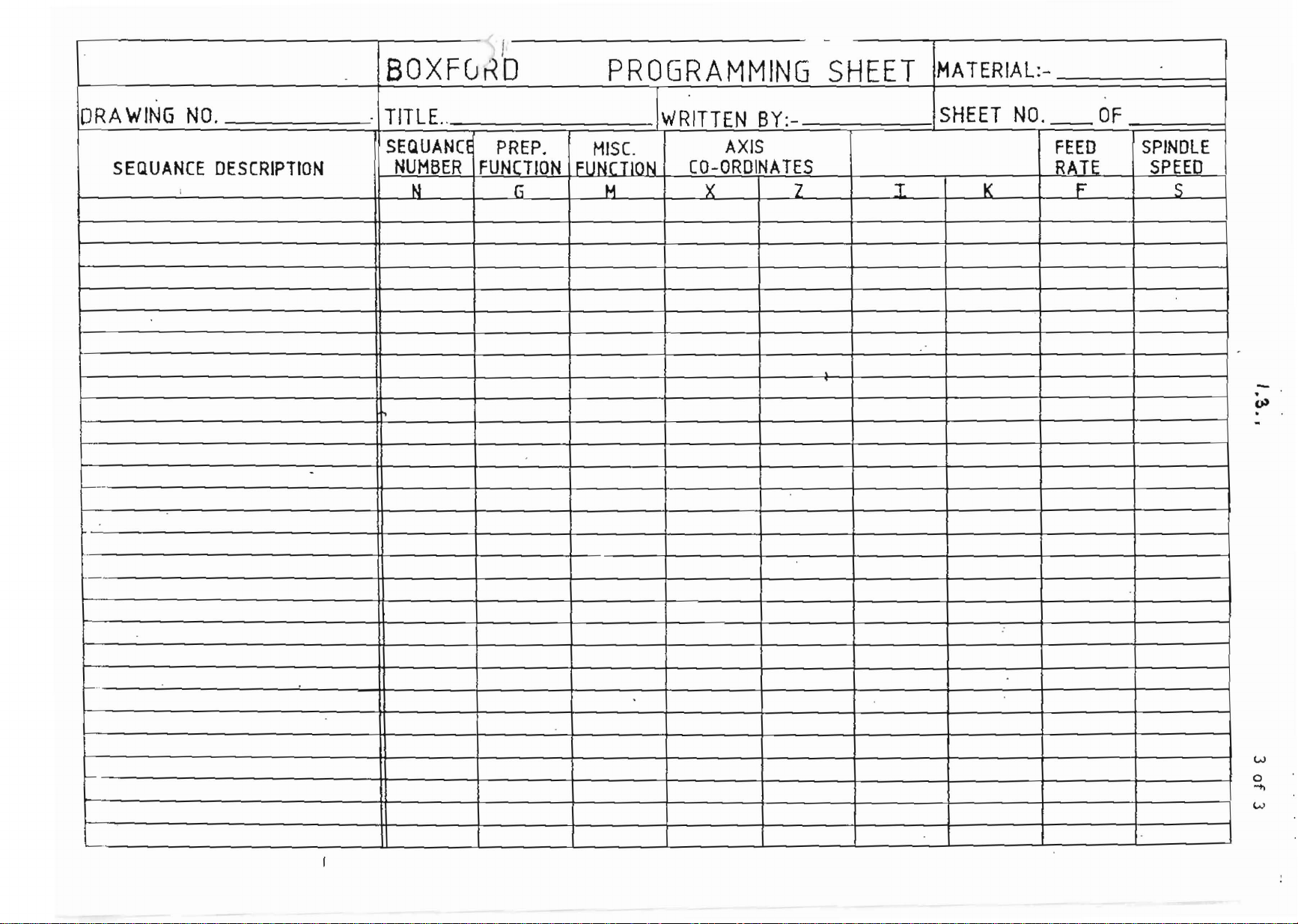

i

BOXFuKO

PROGRAMMING

-

SHEET

MATERIAL:-

DRAWING

SEQUANCE

1----

..

.

--

NO.

DESCRIPTION

i

TITLE

o

SEQUANCE

NUMBER

~

-

..

PREP.

FUNCTION

N G M X Z I

MISe.

FLJNl

WRITTEN

TION

BY:-

AXIS

CO-ORDINATES

SHEET

NO.

K F S

FEED

RATE

Of

SPINDLE

SPEED

.-

C))

.

_

~

..

w

o

"'+>

w

Page 15

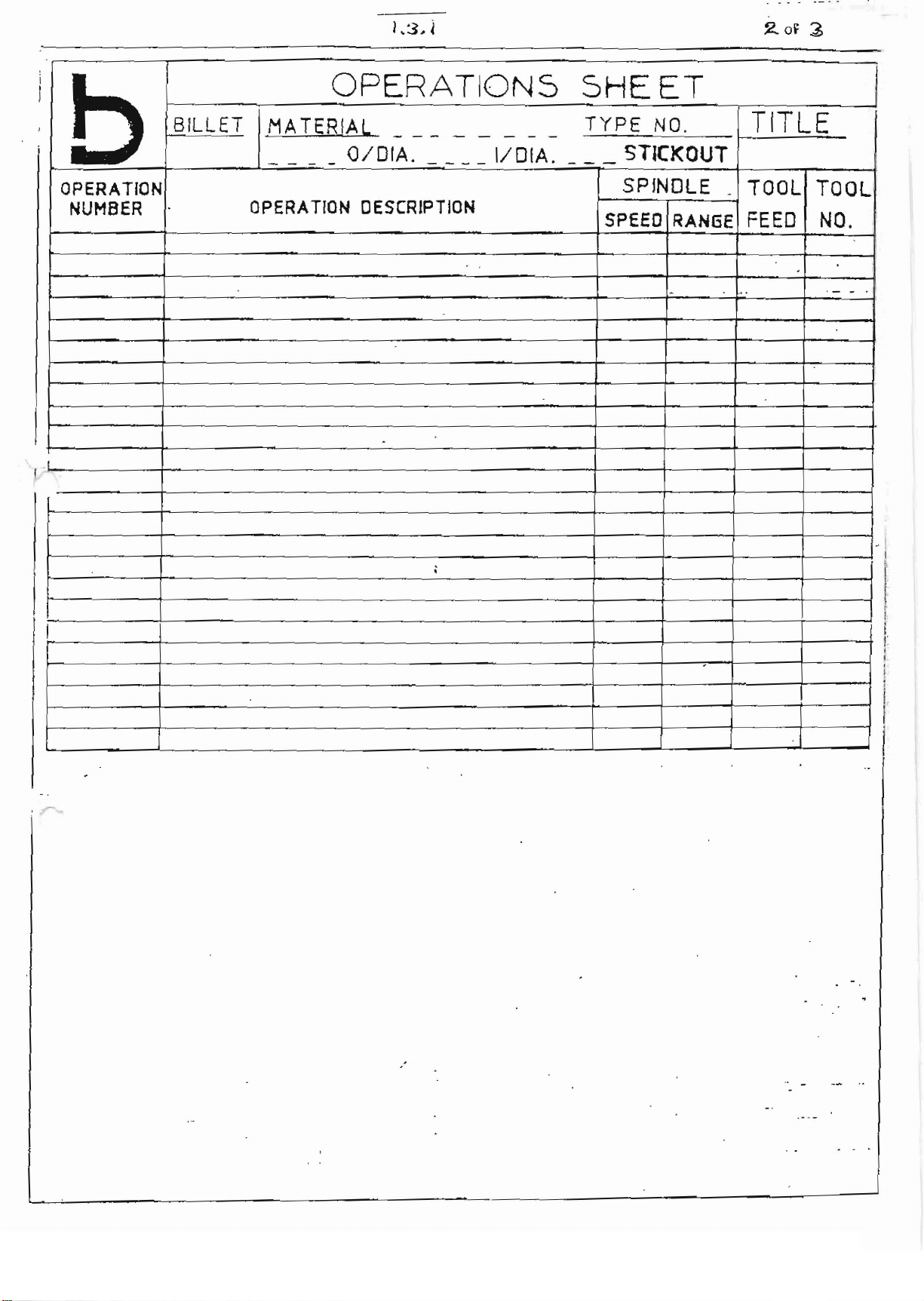

2.

of

1>

b

OPERATION

NUMBER

. 1

BILLET

OPERATIONS

MA

TERIAL

_ _ _

OPERATION

________

OIDIA.

DESCRIPTION

.

____

" "

\lOlA.

SHEET

TYPE

___

SPEEO

NO.

STICKOUT

SPfNOLE

_

RANGE

-

.

TITLE

TOOL

FEED

...

TOOL'

NO.

'-

- .

I

I

.'

;

I

i

r

I

I.

,

I

Page 16

1.

3.2

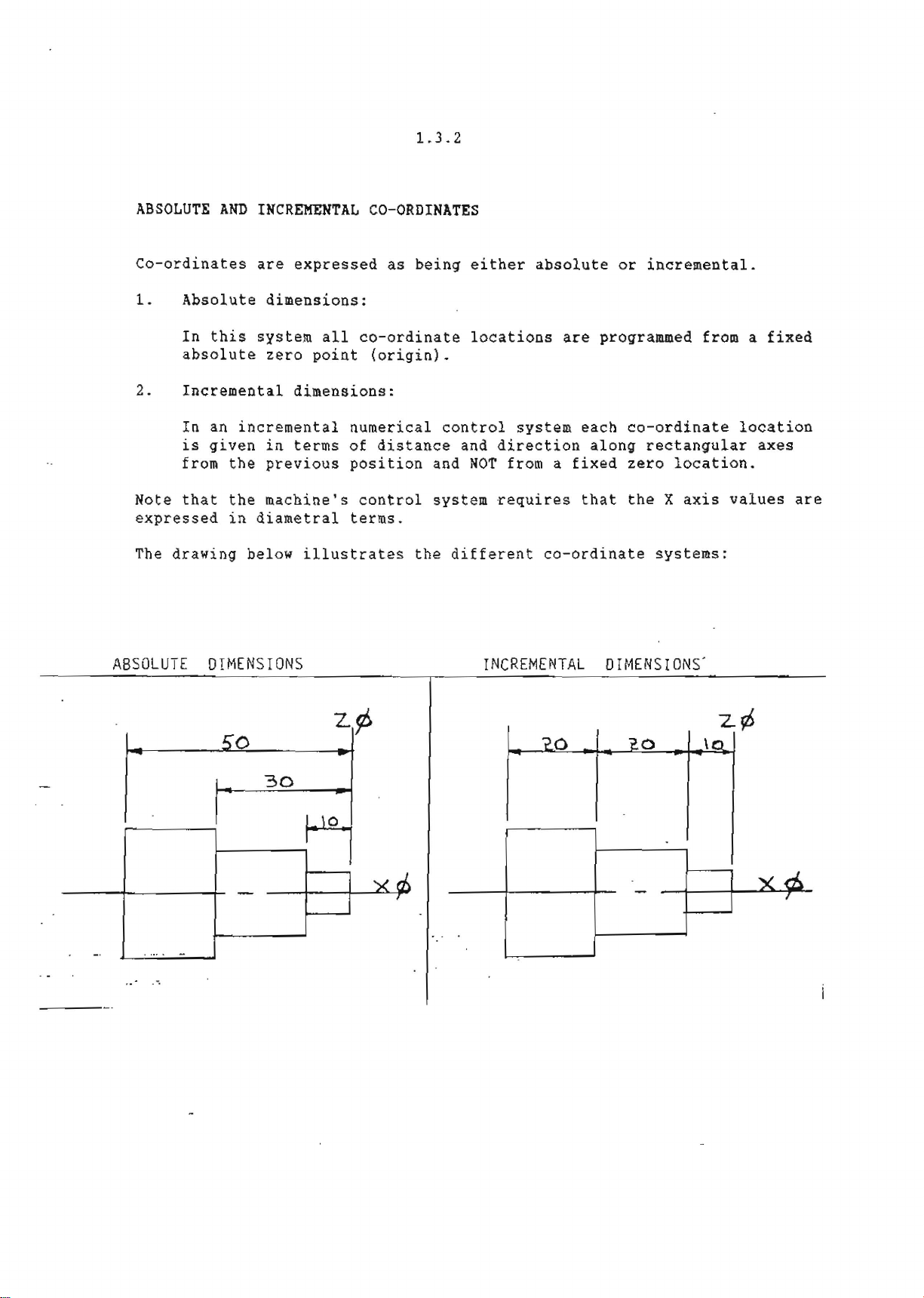

ABSOLUTE

Co-ordinates

1.

2.

Note

expressed

The

drawing

AND

Absolute

In

this

absolute

Incremental

In

an

is

given

from

that

the

the

in

INCREMENTAL

are

expressed

dimensions:

system

zero

incremental

in

previous

machine's

diametral

below

all

point

dimensions:

terms

illustrates

CO-ORDINATES

as

being

co-ordinate

(origin).

numerical

of

distance

position

control

terms.

control

and

system

the

either

locations

and

direction

NOT

from a

requires

different

absolute

are

system

fixed

co-ordinate

or

incremental.

programmed from a

each

co-ordinate

along

that

rectangular

zero

the X axis

location.

systems:

fixed

location

axes

values

are

ABSOLUTE

-

_.

. ,...

DIMENSIONS

50

- I

-

30

INCREMENTAL

?O

I

\0

I

DIMENSIONS'

,,0

-Xr:h

Page 17

1.3

_3

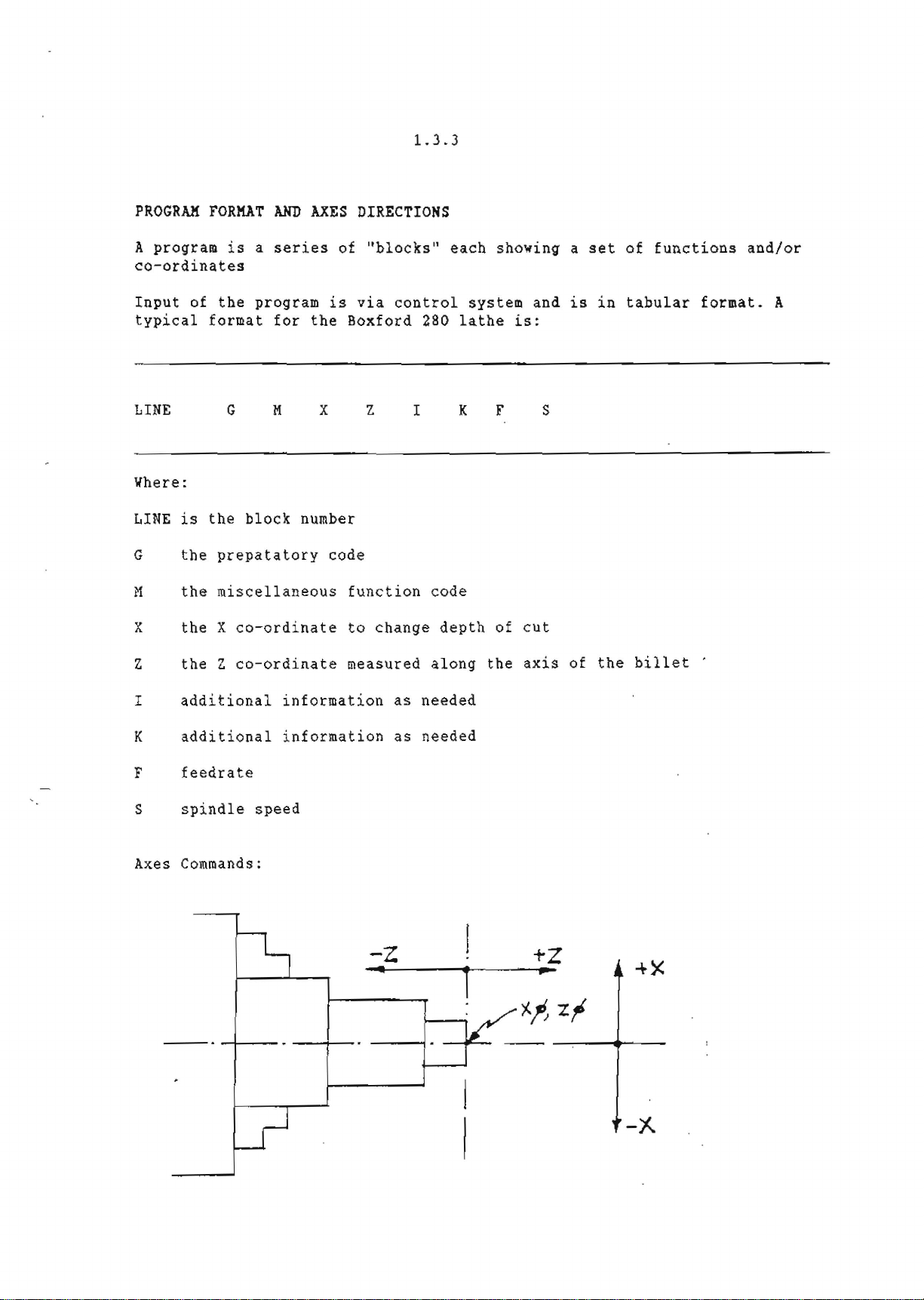

PROGRAM

A

program

co-ordinates

Input

typical

LINE

W'here:

LINE

G

M

x

FORMAT

of

the

format

is

the

the

prepatatory

the

miscellaneous

the X co-ordinate

AND

is a series

program

for

M x z

G

block

number

AXES

of

is

the

code

DIRECTIONS

"blocks"

via

control

Boxford

function

to

change

280

I K F s

code

each

system

lathe

depth

showing a

and

is:

of

cut

is

set

in

of

functions

tabular

and/or

format.

A

Z

I

K

F

S

Axes Commands:

the Z co-ordinate

additional

additional

feedrate

spindle

----+--

information

information

speed

measured

as

as

-z

......

along

needed

needed

1

the

axis

+z

~

of

the

billet

-'I--

Page 18

1.

3.

4

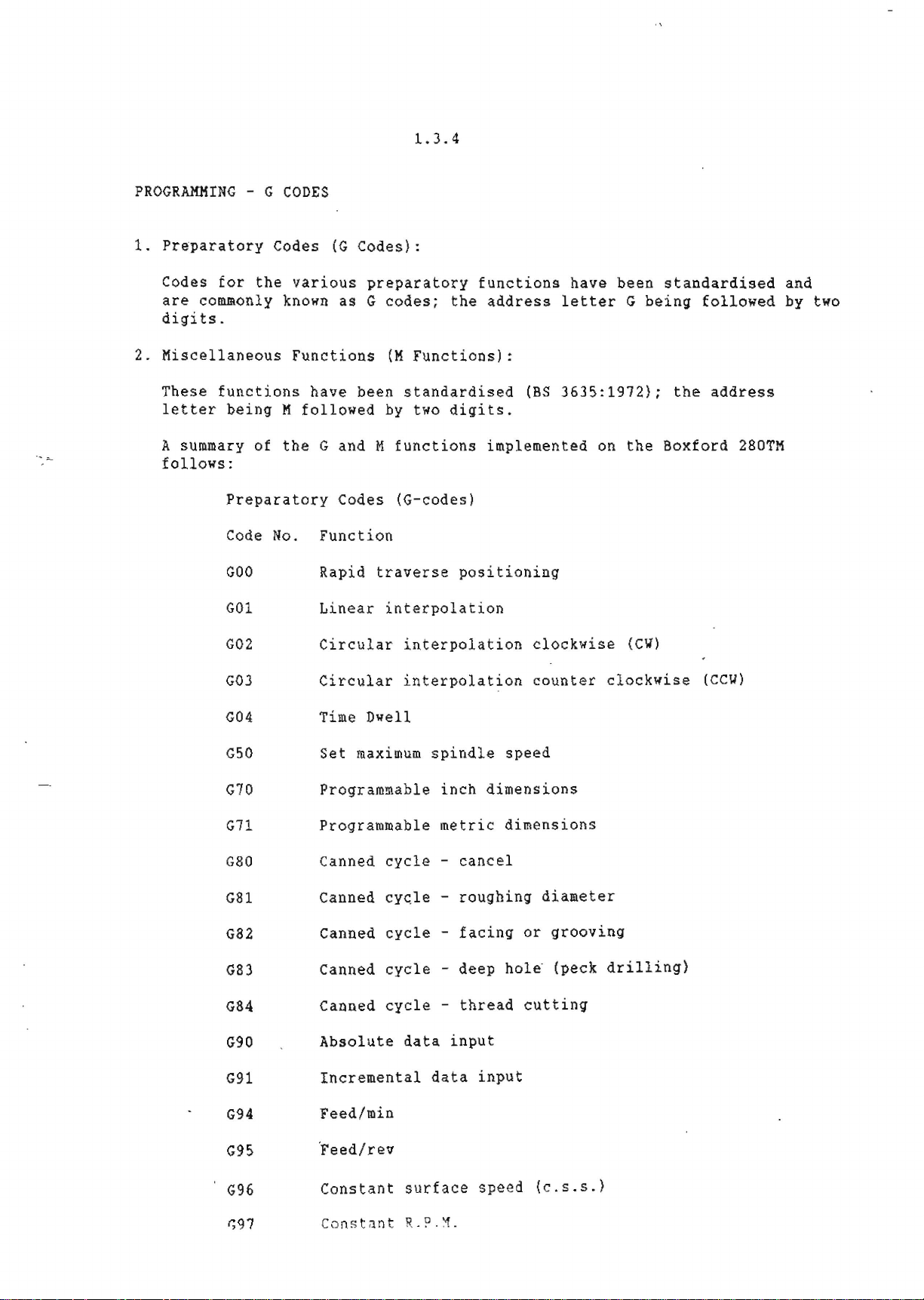

PROGRAMMING

1.

Preparatory

Codes

are

commonly

- G

for

digits.

2.

Miscellaneous

These

letter

A summary

functions

being M followed

follows:

Preparatory

Code

GOO

GOl

Codes

the

of

No.

CODES

known

the

(G

Codes):

various

as G codes;

Functions

have been

G and M

Codes (G-codes)

Function

Rapid

Linear

preparatory

(M

Functions):

standardised

by

two

functions

traverse

interpolation

functions

the

address

(BS

digits.

implemented on

positioning

have

letter

3635:1972);

been

G

being

the

standardised

followed

the

address

Boxford

280TM

and

by

two

G02

GOJ

G04

G50

G70

Circular

Circular

interpolation

interpolation

Time Dwell

Set

maximum

Programmable

G7l Programmable

G80

Gal

G82

G83

G84

G90

G91

Canned

Canned cyc.le

Canned

Canned

Canned

Absolute

Incremental

cycle -cancel

cycle

cycle

cycle -thread

data

spindle

inch

metric

roughing

-

-

facing

speed

dimensions

dimensions

- deep hole-

input

data

input

clockwise

counter

diameter

grooving

or

(peck

cutting

(CV)

clockwise

drilling)

(cc~)

G94

G95

G96

r,97

Feed/min

Feed/rev

Constant

Const~nt

surface

R.?~.

speed

(c.s.s.)

Page 19

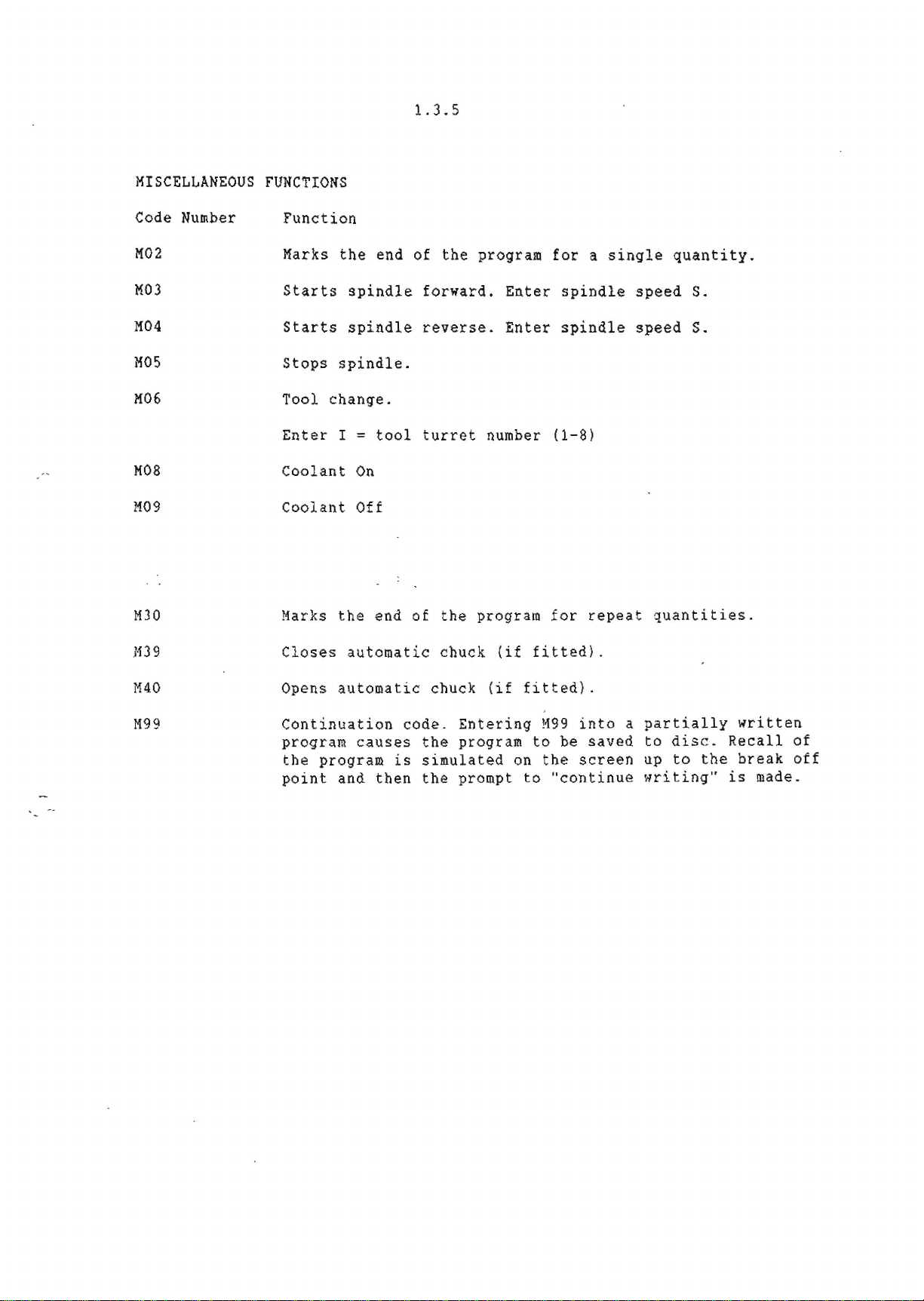

1.

3.5

MISCELLANEOUS

Code

M02

M03

M04

M05

Number

M06

MOB

M09

M30

FUNCTIONS

Function

Marks

Starts

Starts

Stops

Tool

Enter

the

spindle

spindle

spindle.

change.

I =

Coolant

Coolant

Marks

the

On

Off

end

tool

end

of

the

forward.

reverse.

turret

of

the

program

Enter

Enter

number

program

for a single

spindle

spindle

(1-8)

for

repeat

speed

speed

quantity.

S.

S.

quantities.

1139

M40

M99

Closes

Opens

automatic

automatic

Continuation

program

the

point

causes

program

and

then

chuck

code.

the

is

simulated

the

chuck

Entering

program

prompt

(if

(if

fitted}.

fitted).

M99

to

on

the

to

into a partially

be

saved

screen

"continue

to

up

writing"

disc.

to

the

written

Recall

break

is

made.

of

otf

Page 20

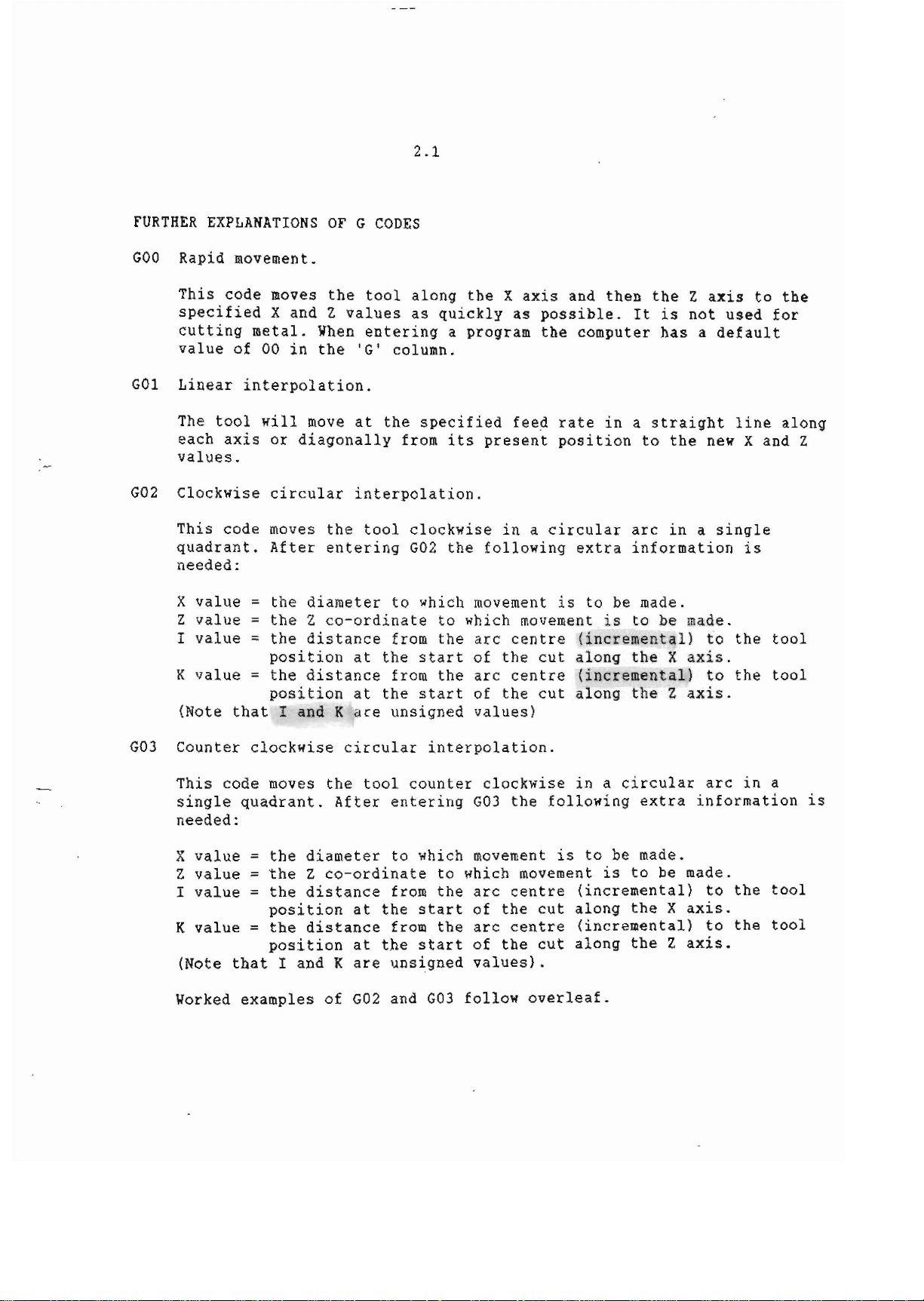

2.1

FURTHER

GOO

Rapid movement.

This

specified

cutting

value

GOl

Linear

The

each

values.

G02

Clockwise

This

quadrant.

needed:

X

value

Z

value

I

value = the

K

value = the

(Note

EXPLANATIONS

code moves

X and Z

metal.

of

00

in

When

the

interpolation.

tool

axis

will

or

diagonally

move

circular

code moves

After

=

the

=

the Z co-ordinate

entering

diameter

distance

position

distance

position

that

I and K

OF G CODES

the

tool

along

values

as

entering

'G'

column.

at

the

from

interpolation.

the

tool

clockwise

G02

to

from

at

the

from

at

the

ace

unsigned

the X axis

quickly

a program

specified

its

as

feed

presen~

in a circular

the

following

which movement

to

which movement

the

arc

centre

start

start

the

of

arc

of

the

centre

the

values)

and

then

possible.

the

computer has a

rate

in a straight

position

extra

is

to

be made.

is

(incremental)

cut

along

(incremental)

cut

along

the Z axis

It

is

not

default

to

the

new

arc

in a single

information

to be made.

to

the X axis.

to

the Z axis.

to

used

line

X and Z

is

the

the

the

for

along

tool

tool

G03

Counter

This

single

clockwise

code moves

quadrant.

needed:

X

value

Z

value

I

value = the

=

=

the

the

diameter

distance

position

K

value = the

position

(Note

that

I and K

Worked examples

circular

the

tool

After

Z

co-ordinate

at

distance

at

are

of

G02

interpolation.

counter

entering

to

which movement

to

from

the

from

the

the

start

the

start

unsigned

and

GO)

clockwise

GO)

the

in a circular

following

is

which movement

arc

of

arc

of

centre

the

centre

the

(incremental)

cut

along

(incremental)

cut

along

values).

follow

overleaf.

to

be made.

is

arc

extra

to

information

be made.

to

the X axis.

to

the Z axis.

in

the

the

a

is

tool

tool

Page 21

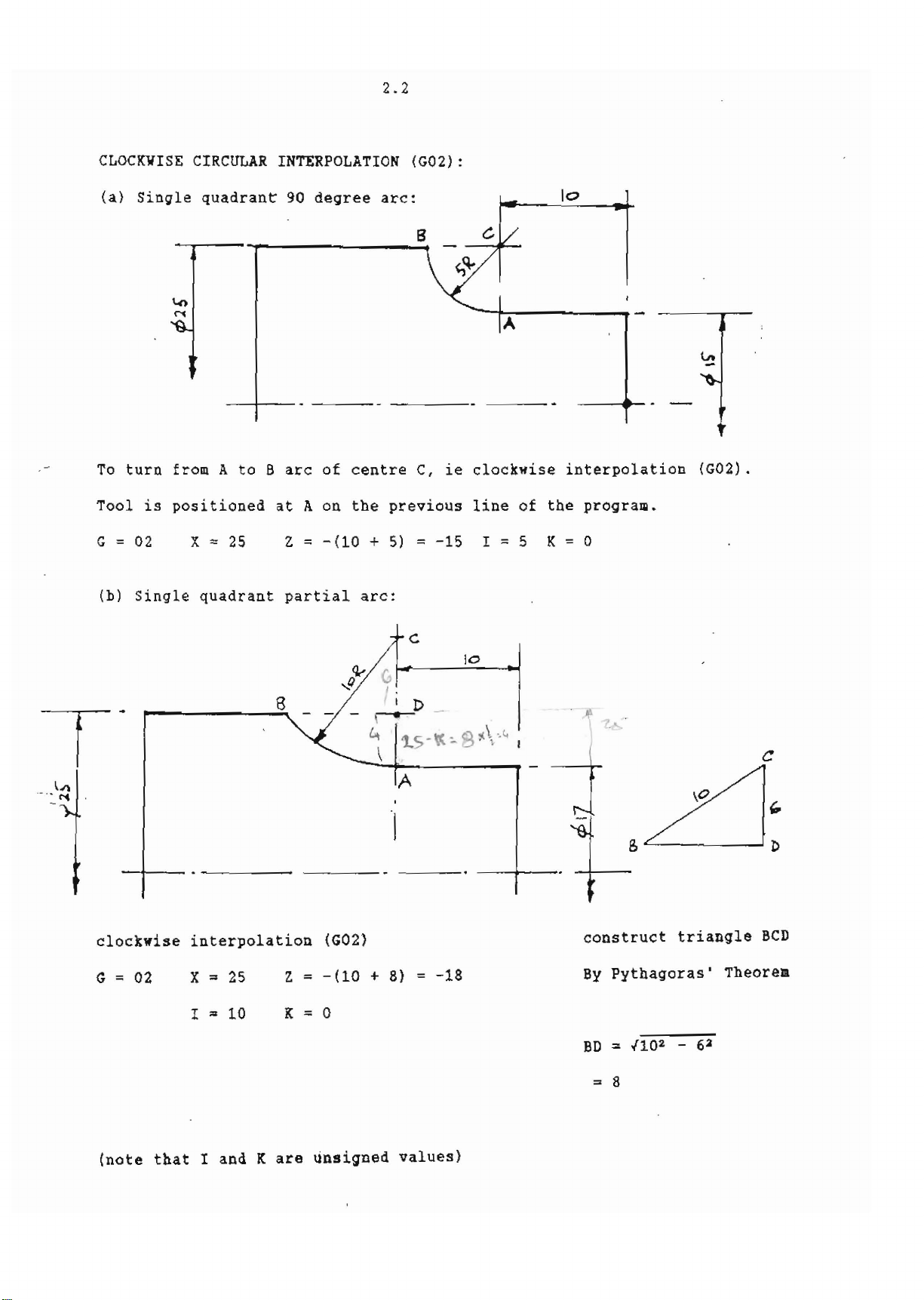

2.2

CLOCKYISE

(a)

Single

To

turn

Tool

G = 02

(b)

from A

is

positioned

Single

CIRCULAR

quadrant

to B arc

x

:::::

25

quadrant

INTERPOLATION

90

at

A on

Z =

partial

deQree

of

-(10

arc:

centre

the

previous

+

5) =-15

arc:

(G02):

C,

ie

10

clockwise

line

of

I =5 K =0

interpolation

the

(G02).

program.

clockwise

G =

02

8

interpolation

X :::I

25

I

::

10

K = 0

Z =

(G02)

-(10

Co

]0

G

/ .

I I

t>

.--.--

~

15

-

-\(

~

<3 :(\.

.

.1..

~

1.

I

\ c

A

+

8) = -18

construct

By

Pythagoras'

BD

=

f10

triangle

2

-

Theorem

2

6

BCD

(note

that

:::z

8

I

and

K

are

unsigned

values)

Page 22

2.3

COUNTER

(a)

To

turn

(G03)

Tool

G =03 x =

CLOCKWISE

Single

from B

•

is

positioned

quadrant

CIRCULAR

to A arc

at B on

25

90

degrees

of

Z =

-(10 + 6)=

INTERPOLATION

arc:

centre

the

C,

ie

previous

-16

(GO)}:

counter

line

of

I =0

10

clockwise

the

program.

K =6

interpolation

(b)

To

G

Single

turn

=

03

quadrant

from a

X =

25

1=0

partial

I

I

,

I ' I

~

to A arc

z =

-(10

K =

p.

/1

:: ..'

of

+

7.07

arc.

centre

2.07)

_8

C

=

-12.07

10

_

c

To

calculate

of A construct

AD ~ (25 -

CD =AD

= 5

co-ordinates

triangle

15)/2

= 5

A

ACD

Radius

n~

~

Ie

1.01 -

=

5/sin45

~

=2.01

=

7.07

Page 23

2.4

G50

G70

G71

Gao

G81-G84 Canned

Codes Gal -

to

repetitive

In

the

point

is

pOlnt.

Set

maximum

ego

G50

Programmable

Used when

Programmable

Used when

Canned

the

control

each

previous

is

incr

cycle

GS4

operations.

case

called

- S3000.

the

line

spindle

the

metric

the

cancel.

cycles.

are

system

tool

of

the

.

On

speed.

Spindle

imperial

input

input

referred

stand

completion

dimensions

dimensions.

dimensions

of

the

must be

code

will

dimensions.

to

as

lathe;

positioned

at a point

off

point.

of

the

not

exceed

are

in

are

metric.

'canned

their

2mm

All

cycle

3000rpm

inches.

cycles'.

use

simplifies

at

the

start

(0.1

inch)

information

the

tool

during

These

point

from

within

will

program.

codes

the

programming

ot

the

the

work.

the

return

are

built

cycle

This

canned

to

its

in

of

on

cycle

start

G8l

G82

Outside

Using

provided

X

axis

location

additional

value = total

X

value

Z

value = number

I

F

value

Cancel

This

G82

The

position

information

diameter

this

that

is

on

=

=

G81

fixed

Facing:

start

in

at

diameter

total

stand

feed

point

-

fixed

code

information

with

cycle

enables

the Z axis

the

2mm

the

previous

cut

and

length

off

of

rate.

GSO.

code

{programmed on

the Z axis.

is

needed:

cycle

several

movements

stand-off

line.

is

needed:

depth,

the

of

in

the Z direction.

cuts

required.

can

After

the

ie

final

travel

be uSed

entering

roughing.

cuts

point

After

the

to

are

and

entering

difference

diameter

the

in

for

either

previous

~

be

the

the

Z

G82

axis,

(exclude

taken

same. The

automatically

tool

between

Gal

is

the

ie

Facing

line}

the

is

following

start

programmed

following

the

original

stand

the

length

cut

or

Grooving.

from a

additional

point

off).

plus

stand

to

in

off

the

this

any

X

value = total

Z

value =total

I

F

value

value

= number

=

cut

depth -it

O.5mm:

to

clear

diaMeter plus

cut

width

of

cuts.

f.eedr3te.

the

lmm.

(exclude

is

end,

usual

ie

enter

the

to

stand

go

a

past

value

off).

the

of

centre

the

stand

line

off

by

Page 24

G82

2.5

Grooving:

G83

This

exceeding

necessary

required

programming

tool

face

groove

Enter

X

Z

I

F

Cancel

Peck

This

From

drill

After

cuts

canned

is

was

take

G82

value

value

value

value

G82

drilling

code

the

in

withdrawing

further

depth.

2.0mm

set

=

=

= number

=

stand

the

cycle

4.0mm.

to

create

This

using

wide

as

the

the

tool

and

then

the

difference

diameter

the

additional

feedrate.

with

is

GSO.

-

canned

used

off

-Z

direction

in

the

is

used

Before

a

is

codes

and

side

to

add

of

of

cuts.

to

drill

point

from

-Z

to

cut a rectangular

entering

slot

the

of

width

accomplished

GOO

and

that

during

nearer

its

stand

the

following

between

bottom

width

cycle.

holes

(X

= 0, Z =

a

distance

the

hole

direction

the

canned

2mm

using

G01. Remember

the

offset

the

chuck.

off

.position.

values:

the

stand

of

the

of

the

groove,

deeper

2)

equal

(to

remove

by an amount which

cycle

+

the

the

After

off

groove.

than

-the

first

to

swart)

width

that

routine

eg

twice

twice

section

routine

of

parting

the

cutting

diameter

lOrom

the

movement

the

the

determined

groove

the

off

parting

the

and

of

it

is

tool

tool

reference

this

narrow

the

width

to

and

off

the

-4.0mm = 6.0mm.

drill

drill

drill

diameter.

takes

diameter.

returns

by:

the

and

(K

multiplied

This

entering

Z

I

K

F

Cancel

"pecking"

G83

follow

value

value = drill

value = reduction;

value =feed

=

G83

total

the

required

with

by

is

repeated

depth

diameter.

second

depth

rate.

GSO.

the

with:

of

a

decimal

and

first

until

hole

subsequent

is

depth).

the

(exclude

value.

reached,

total

the

This

pecks

ego

depth

standoff).

is

the

get

reduced,

.9

or

.99.

-Z

is

reached.

percentage

until

by

the

After

~hich

Page 25

2.6

G84

Thread

G84

The

than

to

line

value

Z

I

value = depth

I(

value

F

value = pitch.

Cutting

Note:

the

Cancel

G84

cutting

External

start

the

be

cut

previous

=

=

tool

after

computer

G8~

Internal

outside

Thread:

point

(the

to

total

pitch).

number

for

up

value

shape

the

looks

with

thread:

-

canned

for

diameter

stand

the

length

of

thread

of

to

of

K.

is

first

for

G80

cycle

the

threading

off

G84

from

cuts.

1mm

pitch

6.

movement

the

for

of

the

point).

being

called.

stand

(measured

The

minimum

-

in

spindle

external

cycle

point

This

position

off.

on

is

larger

for

the X axis

zero

or

in

the X axis

on

the

After

entering

diameter,

10

cuts

values

there

marker

internal

diameter

is

programmed on

eg

1.23

this

and

pitch

of

is a pause

point.

threads.

is

2mm

of

the

G84

follow

for

is

greater

material

the

Imm

suitable

increase

whilst

with:

the

G90

G91

Tilis

the

Cancel

is

programmed

tool

G84

Absolute

All

dimensions

is

taken

Incremental

All

dimensions

fixed

location.

is

with

data

on

18 and

G80.

input.

are

the

centre

data

are

in

the

taken

input.

taken

the

stand

line

same

point

from a

of

from

way

fixed

the

the

as

the

15

1mm

datum.

billet

previous

external

in

the X axis.

The

at

the

position,

thread

X=O,

free

Z ~ 0

end.

and

except

not

that

position

from a

Page 26

3.1

MAIN

The

sub menus and a

MENU

MAIN

MENU

offers

variety

a

choice

of

features.

of

eight

main

facilities,

each

of

which

offer

This

they

section

are

presented

covers

in

the

the

use

order

of

the

in

items

which

available

they

appear.

on

the

MAIN

MENU

and

Page 27

3.2

1

of

4

WRITE

Before

has

to

A

most

be

emergency

panel

and key

characters

to

a number. A

will

(end

be

of

specified

now

requested

the

workpiece.

CORRECT'

relevant

NEW

PROGRAM

of

written

stop

button

in a program

and

should,

prompted

block)

in

metric

to

Pressing

presents

soft

key

the

other

and

title

to

with

try

key and

or

enter

the

the

facilities

we

will

is

released

if

at

more

again.

confirm

imperial

the

outside

the

prompt

first

now

title.

all

possihle,

than

After

whether

by

Eoa

key

'TAILSTOCK

of

four

on

the

look

and

The

at

press

title

six

characters

keying

the

pressing

diameter,

to

confirm

REQUIRED' _ After

tool

You

tool

tool

tool

whilst

and would be

with

MAIN

how

the

should

begin

in

material

the

inside

library

are

shape

locations

shapes

no

MENU

to

WRITE

do

can

this.

key

not

with a letter

will

the

title,

dimensions

relevant

diameter

the

dimensions

pages

now

required

to

each

are

the

24th

assigned

tool

present.

be

used,

Ensure

on

the

exceed

be

six

reje~ted

press

soft

and

pressing

is

presented.

to

of-the

available.

cutting

is a null

a program

the

operators

as

opposed

the

are

key.

length

are

assign

eight

23

tools,

station

to

,a

and you

EOB

to

be

You

are

'ALL

the

a

of

location

of

the

To

enter

number

a

S5

pressed.

As

with

'input'

NB.

a

of

degree

The

tool

soft

Care

and

vice

tool

the

must be

Should a tool

then

24) to"

pressing

that

type

tool

left

hand

current

1,

to

key

and

versa

position

the

location

press

type

tool

assign

enter

taken

when

soft

and

the

soft

to

reside

turning

tool

number

a

tool

the

number

not

to

assign

using a rotary

not

be

required

key

labelled

increments

in

so

will

type

key

labelled

that

a 3 would

now

to

this

of

the

external

turret.

to

'Skip'

the

current

'Input'

position

have

tool

type

e.g.

be

keyed

incremented

position

of

tools

have a tool

assigns

the

tool

Tool

tool.

to

internal

type

null

to

the

and key

location

in

and

to

2.

press

assigned

tool

ne~t

in

the

Eoa

the

locations

to

(numher

number.

1

has

it,

Page 28

3.1

MAIN

The

sub

MENU

MAIN

menus and a

MENU

offers

variety

a

choice

of

features.

of

eight

main

facilities,

each

of

which

offer

This

they

section

are

presented

covers

in

the

the

use

order

of

the

in

items

which

available

they

appear.

on

the

MAIN

MENU

and

Page 29

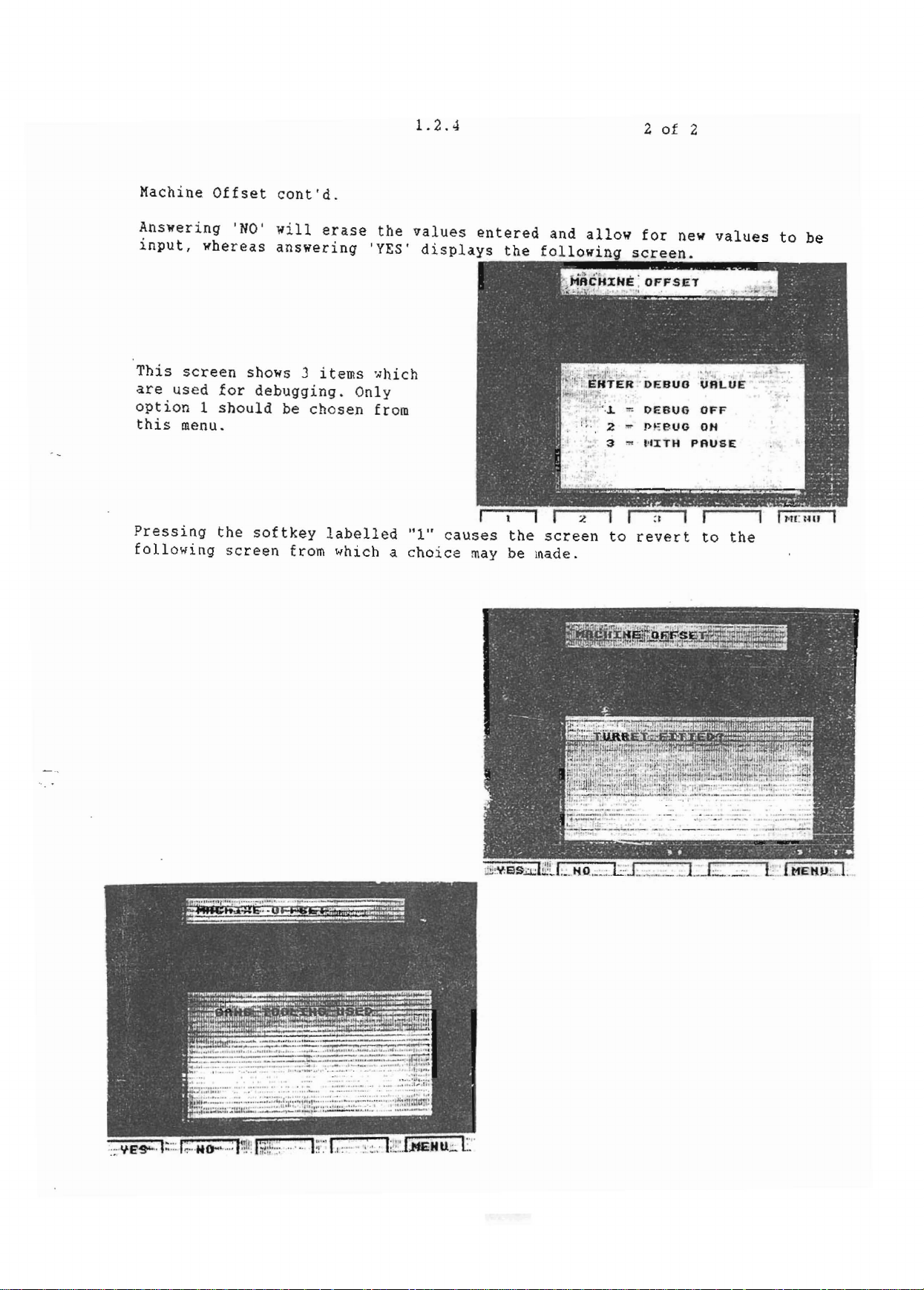

~rite

As

copy

out

"on

a

well

printout

connect

line".

New

as

connected.

Program

being

may

an

Epson

Press

cont'd.

able

be

obtained

compatible

the

soft

to

view

key

the

four

and

stored

printer

labelled

pages

for

to

'print'

of

tools

reference.

the

printer

and

on

To

port

confirlll

the

VDU, a hard

obtain a print

and

place

the

printer

it

is

TOOL

~

1-

90

0"'1

RHOMBO

LH

R~&Mg:HD

LU

R~&",R3!t>

LH

~

4

7

EX

EXT

IHT

0

TOOL

SELECTXOf,l

60

TRXAHGU(.RR

LH

GROOVING

PARTING

LU

SELECTION

60

TR1i.nH~lhflR

~

J.8

55

O"'J

RHDMBO

RH

EX

I>

R~ijM2ij1D

HEUT

~

l.J

'f

2

W

::5

8

.1.J.

DE'<J

EXT

EXT

Oer

OFF

e:XT

(~-6>

.....

(7-J.2)

~

3

R~5MgOto

Ltl

EXT

6

T.IAEAOXNG

TOOL

EXTERNAL

Y

9

60 ()..

TR~AHOU

H

R~~M&81D

U,

~

RU

.12

E T

EXT

~

AR

'f

13

na3~s§l~

tI

.l6

68

TRXAHGUI::,AR

LU

~

19

CENTRE

ORILL

e

22

LARGE

DRXl.L

<.l7-Z:>

D"9

XMT

TOOL

TOOL

......>

sELECTZOH

n

.1.4

O~OOUl:HO/

PA

rXHG

RN

EXT

t:

.1.7

OROOU:IHG

IHTf:ftHAL

SELECTZOH

<%%

28

~"'ALL

J.-8

......

23

TAP

DRILL

)

OFF

(~3-~8>

THRERDIHG

,(

J.9-24

P!J

.1.:5

R28,.,R8!o

LH

XHT

L

.1.8

IH1'E

Ll

HAL

>

e::

2.l

I'tEO

DRILL

<9-.1.6",

HULL

...

>

Page 30

3.2

3

of

4

.........

Writing a New

On

completion

'fwrd'

'back'

After

and

entered

....

-

will

displays

entering

asks

.

if

Program

of

the

display

the

the

a

'Yes/No

cont'd.

first

the

fourth

tool

check'

page

second

page.

type

of

page

number

is

required

tools,

whereas

for

position

Answering

not

once

to

been

column

need

fault.

pressing

pressing

after

allow

the

enter

made

to

eight

each

EOB

a

then

be

the

soft

the

soft

the

line

or

'NO'

to

the

user a second

key

has

line.

with

used

the

If

the

edit

to

key

key

display

block

this

been

a

mistake

data

facility

correct

labelled

labelled

changes

has

prompt

change

pressed

in

any

the

been

does

has

would

Answering

entered

on

correct.

to

prompt

the

cursor

before

NB.

It

being

is

the

'Yes'

the

line

Pressing

for

the

to

the

accepted.

advised

input

routine

to

this

after

the

next

beginning

that

prompt

soft

line

the

has

allows

pressing

key

labelled

in

the

of

the

YES

option

been

achieved.

the

the

EOB

'Yes'

program

line

and

be

user

key

where

the

used

to

reflect

by

asking

accepts

as

line

until

on

the

if

the

the

line

answering

can

then

be

familiarisation

data

line

is

and moves

'No'

moves

corrected

with

on

Page 31

3.2

4 of 4'

Writing a New

Vhichever

accepts

The

first

prompts

The

first

the

G columns

progr~mming.

column

input

'data

cursor

would need

park

be

INPUT

column

will

axis

again

the

As

INPUT

alone.

press

position

made

now

park

line.

this

of

the

three

as

to

line

to

set

of a tool

the

will

to

then

key

should

awaiting

move

position

press

Press

is

the

key

followed

Program

these

option

the,data

to

The second

either

jump

be

e.g.

rather

the

the

two

and

"".In

TI!:'SiTl

lines

of

the

set

path

address

into

pressed

X50.

than

be

used.

the

next

cursor

may

INPUT

the

I key and

last

piece

by

cont'd.

options

the

display

or

blocks

required

program

the

mode

line

imperial

po~ition

letter

the

relevant

followed

Because

pressing

The

address

into

be

inserted.

as

there

of

the

EOB

are

of

appear

requests

of

either

requests

or

metric

and a

key

on

by

there

the

cursor

column

the

Z column where

is

one more

enter

data

key

required

may

chosen

changes

the

program

across

for

absolute

for a 70

input.

tool

the

column.

the

is

EOB

should

to

After

a 1

in

be

pressing

to

reveal

the

either

or

turret

alpha

In

data

more

pressed

relating

than

key

to

now

move

entering

piece

the

on

the

the

o

o

o U

o 0

D.

are

compulsory

VDU.

90

or

or

incremental

or

71

The

third

number.

numeric

this

column

instance

one column.

enter

appear

to.

Pressing

the

data

the

of

data

block,

or

just

relevant

the

following:

91

to

be

line

keyboard

to

the X axis

the

back

for

value

to

to

select

either

the

soft

in

to

be

entered

reqQests

To

enter

and

the

entry

data

in

the

the

(20),

be

EOB

the

the

input

tool

the

key

that

entered

in

the

this

the

X key

to

line

Z key

Z

once

on

1.

key

in

G

the

From

going

required.

are

noticed.

cancel

that

which

letter

into

Pressing

Should

is

prompt

corrected

line

to

several

the

case

that

po~sible

option

40 onwards

contain

Should an

ways

If

the

(CAN)

as

the

key

error

the

the

column and

the

INPUT

error

to

by

pressing

the

to

make

error

of

correcting

error

can

is

cursor

one

not

answer 'No'

has

be used

not

with

the

key

be

been

was

noticed

will

the

user

the

be

noticed

be

the

erroneous

old

now

displays

noticed

to

chosen.

address

must

machine

made

to

value

it

delete

until

in

the

until

the

The

in

depending

before

prompt •

letter

decide

tool

keying

after

line

value

can

the

column which

what each

manufacture

the

the

erroneous

the

column.

in

then

corrected

after

CORRECT'

and

in

on

input

be

the

keying

line

the

data

the

position

key

characters.

INPUT

causes

overtyped

key

Pressing

value.

EOB

key

providing

is

in

in

the

of

the

in

was

has

cursor

by

has

error

the

program

component

a column

the

error

pressed

It

been

the

the

been

can

correct

same

the

pressed

to

new.

pressed

'Yes/No'

then

is

there

was

tben

may

address

move

be

value.

the

be

in

it

Page 32

EDIT/CONTINUATION

3.3

1

of

6

-This

extend

To

gain

released

of

the

option

programs

access

and

program.

allows

which

to

press

Pressing

programs

may

these

the

facilities

edit

to

be

have been

key on

the

EOB

altered,

terminated

ensure

the

key

presents

it

errors

the

emergency

operators

Selection

options

relevant

during

panel

the

following

of

is

numbered

are

creation.

either

made

found,

stop

and

by

button

enter

menu:

of

the

pressing

soft

key.

or

the

to

is

title

four

the

'I'

=

Continuation

Pressing

of

the

The M code found

reacts.

block

The program

M02

or

Should

revert

explained

'2'

=

Line

Choosing

make

deleting

the

any

display

the

soft

program up

Should

containing

may

M30

should

the

program have

to

the

under

Edit

this

corrections

whole

and

key

to

at

the

program have an

the

he

extended

be

program

Print

option

lines

the

program

labelled

the

point

the

end

M99

is

used.

an

M02

print

a Program.

allows

that

may

of

data.

1

activates

at

of

the

deleted

to

its

or

menu

the

is

and

user

be

necessary

Pressing

read

'which

program

M9~

conclusion

M30

it

as

and a prompt

at

its

offer

to

scan

the

into

the

a

graphical

was

terminated.

determines

its

last

to

at

which

end

then

the

facilities

through

including

soft

key

edit

how

block

continue

the-display

the

inserting

labelled

file.

sl~ulation

the

software

then

point

program and

is

either

which

2

the

shown.

are

and

changes

will

Page 33

3.3

2

of

6

Edit/continuation

• ~ •__•• ---__.-_

l.UU:

2. \

'.

..

.)

..

••

..

'.

CUU'OJ2

\

,

I

,

,

I

,

I

,

c

••

"

••

..

0'

"',.

,

,

,

,

,

,

,

,

,

,

'OO1JH

•••

••

..

r _

••••••••

, ,

,

"

I

, ,

,

I

I

\

,

,

TO

8eRO

:f

:)

... • COlO

$ •

__ •_.

•

~o

,.

.\

.....

• - 11.00 ~ ....

• D£L.E"U:: A

•

1E1I

11

fI

tC:"'R.-D

L

I"l

I.J

_. _••• _...............

,

,

,

,.

,

,

,

•

,

,

1l-4E

i".IN(

~

to

I

1'0"[

A.

t,n..;t

C~i"Nr;c.!'i

r

..

'lto .r....

cont'd

,

"

, ,

,

,

\

I

,

,

r

,

\1

~

_

rw.

•

TITLE

o

II....

t,DI

L..""rll).

.

__

t-QaJ:l1t

...

............

,

,

,

,

,

,

,

,

,

.)~IJ.O'II

(h"

~Il~'"

_

......

\

<

•

\2.

\

,

I

:

"".

,

J

,

,

,

,.

The

program

dimensions

shown

as

of

well

title

the

as a menu

along

with

material

with

the

are

5

options.

The

program

down

•

and

keys

on

by

the

may

be

using

the

keyboard.

scrolled

two

up

cursor

1 =

ADD

A LINE.

It

may

be

option

program

between

by

The

may

The

the

line

now

line

allows

so

the

soft

of

be

number

SUbsequent

until

2 ;

As

exists.

two

labelled

yes

the

DELETE A LINE

well

as

Scroll

arrow

YES.

soft

key

renumbered

necessary

this

that

two

key

the

arrow

labelled

data

entered

will

l~nes

program

adding

the

symbols.

Care

has

been

into

sequence

to

to

be

line

symbols.

now

jumps

as

required

now

are

renumbered.

is

as

lines

line

Press

must be

pressed.

insert

done.

after

YES.

down a line

change

required.

to

a program

to

be

the

soft

taken

before

lines

Using

the

one

Press

and on

to

Further

deleted

key

as

Once

any

of

data

the

cursor

that

the

soft

and an empty

completion

the

next

lines

the

facility

so

that

labelled

there

again

is

the

further

to

a program and

keys,

is

to

be

key

labelled

line

the

one

in

sequence

of

data

to

it

appears

2

followed

no

second

line

action

numbers

can

scroll

inserted

appears.

EOB

key

may

delete

between

by

chance

be

taken.

this

the

appears

1

followed

Data

pressed.

and

be added

lines

also

the

the

one

once

are

the

Page 34

3.3

3

of

6

Edit/Continuation

3 =

EDIT A LINE

It

may

be

This

value

delete

the

symbols.

the

could

it

the

value

line

was,

Press

with

be-positioned

of

the

value

column.

the

value

To

delete

the

soft

press

will

4

=

Key

only

value

on

two

arrow

key

labelled

the

now

delete

GO

TO ALINE

cont'd.

required

be

an X

it

whole

to

be

the

at

to

in

the

same

a

value

symbols.

decimal

to

alter

co-ordinate

would be

line

altered

the

the

be

the

to

and

soft

soft

beginning

altered

new

alter,

until

key

key

value

line.

from a column

Press

YES.

point

the

Move

key

column.

one

easier

type

labelled

labelled

and

or

INPUT,

the

to

specific

or

maybe a

to

it

again.

it

appears

of

the

the

cursor

followed

should

scroll

the

soft

cursor

overtype

change

3 and

YES.

line.

by

the

key

into

the

piece

spindle

the

Scroll

between

confirm

The

flashing

Key

jumps

either

you wish

line

labelled

the

characters.

of

data

speed

specific

the

line

the

you

in

the

to

the

the

EOB

to

to

be

3

relevant

in a program.

but

whichever

value

two

wish

cursor

that

arrow

than

contains

to

will

address

start

key,

alter

edited

followed

of

if

another

between

by

column and

Pressing

edit

now

letter

the

it

the

EOB

to

is

~hen

near

program.

Enter

requested

5 =

Once

of

labelled

returns

'3'

= Column

This

column were

column

if

them) were

Press

editing

the

the

RECORD

the

the

machine.

Edit

method

edit

all

of

the

long

beginning

Press

number

line

CHANGES

program

YES

saves

the

display

of

required

would be

the

feedrate

required

soft

programs

of

the

soft

of

the

will

now

has

Pressing

the

to

editing

to

key

labelled

the

key

line

appear

been

the

edited

the

would be

to

be

both

values

be

there

program

labelled

to

be moved

between

edited

soft

version

MAIN

MENU.

used

altered

quicker

currently

altered

3 and

is

usually

to a line

4 and

the

it

must

key

labelled

of

if

to a new

and

easier

to

175mm/min.

the

following

to

then

the

many

set

a

need

near

the

and

two

be

program

to

to

soft

press

arrow

saved

5

followed

skip

the

key

the

symbols.

to