Page 1

Programming Manual

Boxford 190 VMC

CNC Milling

Machine Tool

Boxford

Boxford Ltd.,

Wheatley, Halifax, West Yorkshire,

England, HX3 5AF.

(Registered Office)

Telephone: 01422 358311

Fax: 01422 355924

E-Mail: info@boxford.co.uk

Web: www.boxford.co.uk

Page 2

Boxford 190 VMC Contents

Contents

1 Introduction

2 Running the Demonstration Program

3 Axes and Tooling

3.1 Fitting Tooling

3.2 Axes, Datums and Offsets

3.3 Tool Storage

3.4 Tool Data Library and Catalogue

3.5 Setting Up

3.6 Datum Shift

4 Main Front End Menu

5 CAD

5.1 Cad Window

5.2 Drawing Aids

5.3 Drawing Tools

5.4 Editing Objects

5.5 Area Filling

5.6 Machining Considerations

6 CAM Processor

6.1 Settings

6. 2 CAM Processor Error Messages

7 File Imports

7.1 Drawing File Import

7.2 G&M Code Program Import

8 Administration Mode

8.1 Access & Password Setting

8.2 Tool Library

8.3 Material Cutting Data

8.4 Park Position and Units

8.5 CAM Processor Default Settings

8.6 Language Settings

Page 3

9 Cutter Path CAM Programming

9.1 Functions

9.2 Information Required

9.3 Drawing a Component

9.4 Example

9.5 Defining Straight Line Moves

9.6 Defining Arcs

9.7 Pockets and PCD Drilling

9.7.1 Rectangular Pockets

9.7.2 Circular Pockets

9.7.3 Slots

9.7.4 PCD Drilling

9.7.5 Dish Milling

9.8 Cutter Radius Compensation

9. 9 Tool Changing

9.10 Processing a Cutter Path

9.11 Editing a CAM Program

ContentsBoxford 190 VMC

10 Manual Data Input CNC Programming

10.1 Operations and Programming Sheets

10.2 Absolute and Incremental Co-ordinates

10.3 Speeds and Feeds

10.4 Program Format

10.5 Preparatory Functions (G Codes)

10.6 Miscellaneous Functions (M Codes)

10.7 Programming a Tool Change

10.8 Inputting a New Program

10.8.1 Information required

10.8.2 Tabulated Format

10.8.3 ZOOM Facility

10.8.4 Compact Format

10.9 Saving a Program

10.10 Examining an Existing Program

10.10.1 PROGRAM Display

10.10.2 ZOOM and VIEW Facility

Page 4

Boxford 190 VMC Contents

10.10.3 Simulation of Machining

10.11 Editing a Program

10.11.1 New Programs

10.11.2 Existing Programs

10.11.3 MENU Editing Options

10.11.4 Changing the Initial Tool

10.12 Continuing a Program

11 CNC and CAM Machining

11.1 Initial Checks

11.2 Manufacture

11.3 Options During Machining

12 Manual Machining

13 Robotic Interfacing

Page 5

CNC Tutorials and Exercises

Tutorial 1: X and Y Co-ordinate Calculation -

Absolute and Incremental Co-ordinates

Exercise 1: Calculation of Co-ordinates

Tutorial 2: Linear Interpolation

Exercise 2: Linear Interpolation - Absolute Co-ordinates

Tutorial 3: Canned Cycles - Hole Drilling and Pocket Milling

Exercise 3: Canned Cycles - Programming a Tool Change

Tutorial 4: Circular Interpolation - Clockwise and Counter-clockwise

Exercise 4: Circular Interpolation

Tutorial 5: Combining Operations and Tool Changing

Exercise 5: Combining Operations

ContentsBoxford 190 VMC

Tutorial 6: Subroutines

Exercise 6: Subroutines

Tutorial 7: Mirror Images

Exercise 7: Mirror Images

Tutorial 8: Further Canned Cycles - Pitch Circle Drilling and Dish Milling

Exercise 8: Use of Canned Cycles - Pitch Circle Drilling and Dish Milling

Tutorial 9: Subroutines, Mirror Images and Circular Interpolation

Exercise 9: Subroutines and Mirror Images

Tutorial 10: Datum Shift and Jump to Line

Exercise 10: Datu m Shift and Jump to Line

Operations Sheet

Programming Sheet

Page 6

1 Introduction

This manual gives guidance in using the 190VMC CAD/CAM software to create ISO

G& M code programs for milled components.

The 190VMC CAD/CAM software includes a demonstration program (called

190VMC), and a number of tutorial programs.

It is suggested the manual is used as follows:

1. Refer to section 2 and run the demonstration. This will provide rapid familiarisation

with the operation of the software and the machining process.

2. Study Section 3 to become proficient in setting up the tooling.

3. Refer to sections 4, 5 and 6 to demonstrate the ease of operation of the integrated CAD

and CAM processor package.

4. Refer to Section 7 to become familiar with the conventions for importing drawing files

from third party CAD packages and G & M programs from CAM packages.

5. Refer to Section 8 for details of the functions available to administrators (tutors) of the

CAD/CAM system.

6. Refer to section 9 for computer assisted cutter path generation.

7. Use section 10 for detailed instruction in CNC programming.

Tutorial 2 is used as an example to demonstrate the stages of programming and

software operation.

8. Use the Tutorials and Exercises in the order in which they appear, to progress from

basic programming skills to proficiency in the more advanced features of CNC

programming.

9. When programs have been written and verified, refer to section 6 as required, to

machine components.

Page 7

Boxford 190 VMC

2 Running the Demonstration Program

2 Running the Demonstration

Program

The demonstration program contains examples of linear and circular interpolation,

rectangular and circular pocket milling and pitch circle drilling, and a finished component

can be machined from the billet supplied with the machine. Run the program as follows

to provide a tutorial in programming and machining.

Setting Up the Machine

Check Tool Settings

1. Set up the tooling and billet as follows:

6mm slot drill fitted in cutter holder, secured in spindle.

3mm slot drill ready for the programmed toolchange.

Billet: plastic, length 75.00 mm, width 60.00mm, height 10.00mm, securely fitted in vice.

2. Run the software and check that the Simulation and Manufacture software is correctly

configured by selecting CONFIG from the main menu. (Refer to Section 5 - Installation

in the Installation and User manual, and Section 3 - Axes and Tooling).

3. From the main menu, select MACHINE and then Tools to display the Tool Data Library.

Check the setting of the reference tool, and the second tool, which should be as follows:

No. Type Pos Description Diameter Length Offset

1 2 1 Slot drill 6.00 7.50 0.00

2 2 2 Slot drill 3.00 7.50 0.00

If the settings are incorrect, refer to Section 3 - Axes and Tooling, 3.5 - Setting Up.

4. Turn off the display.

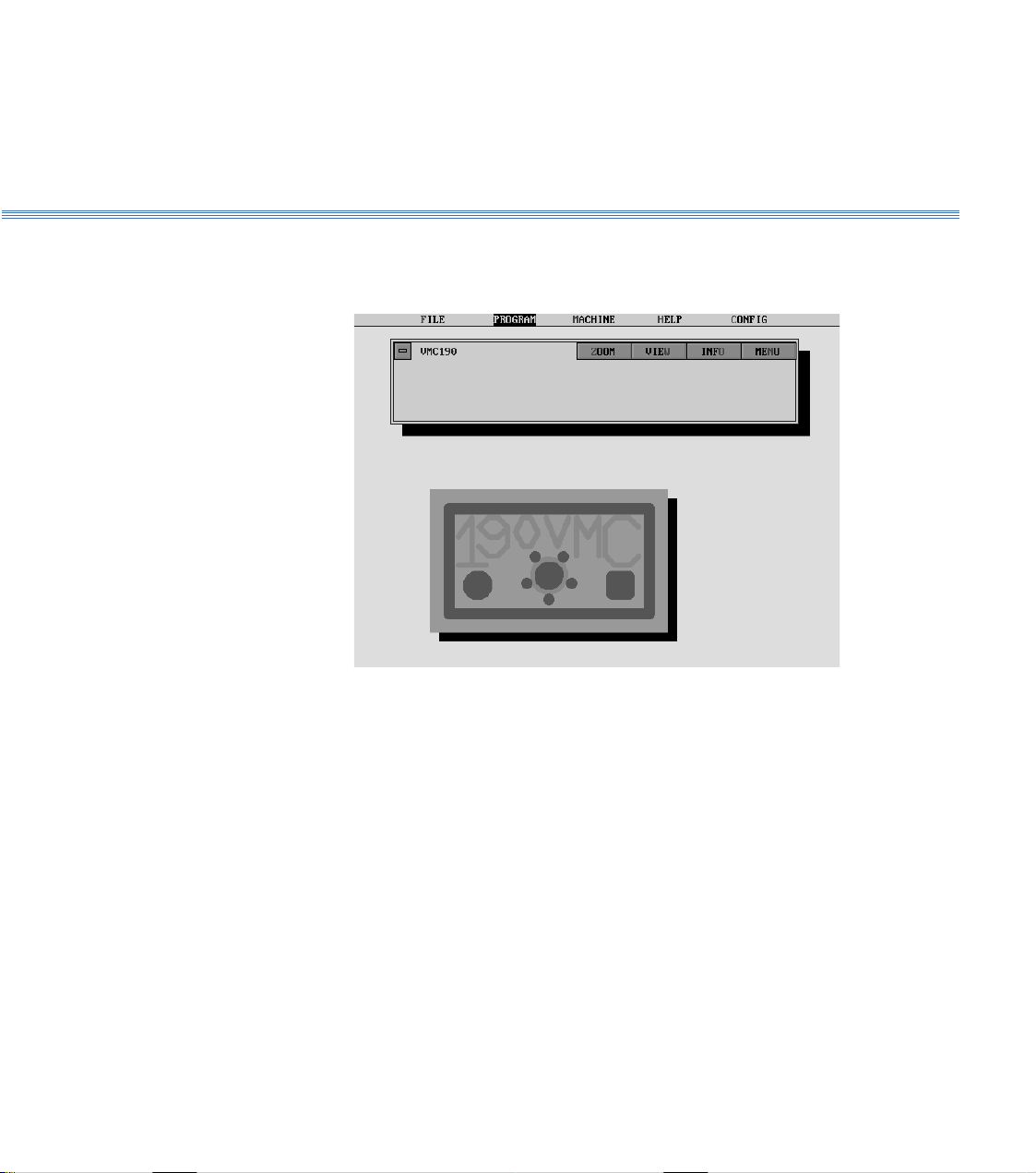

The screen shows: Main Menu

Page 8

2 Running the Demonstration ProgramBoxford 190 VMC

5. Select PROGRAM

The screen shows:

6. Select PROGRAM

The screen shows the Catalogue Display. View the catalogue to identify the demonstration

program, which is called VMC 190.

Page 9

Boxford 190 VMC

2 Running the Demonstration Program

7. Select VMC 190

The screen shows the Program Display with a 2D view of the component.

Page 10

2 Running the Demonstration ProgramBoxford 190 VMC

View the Component

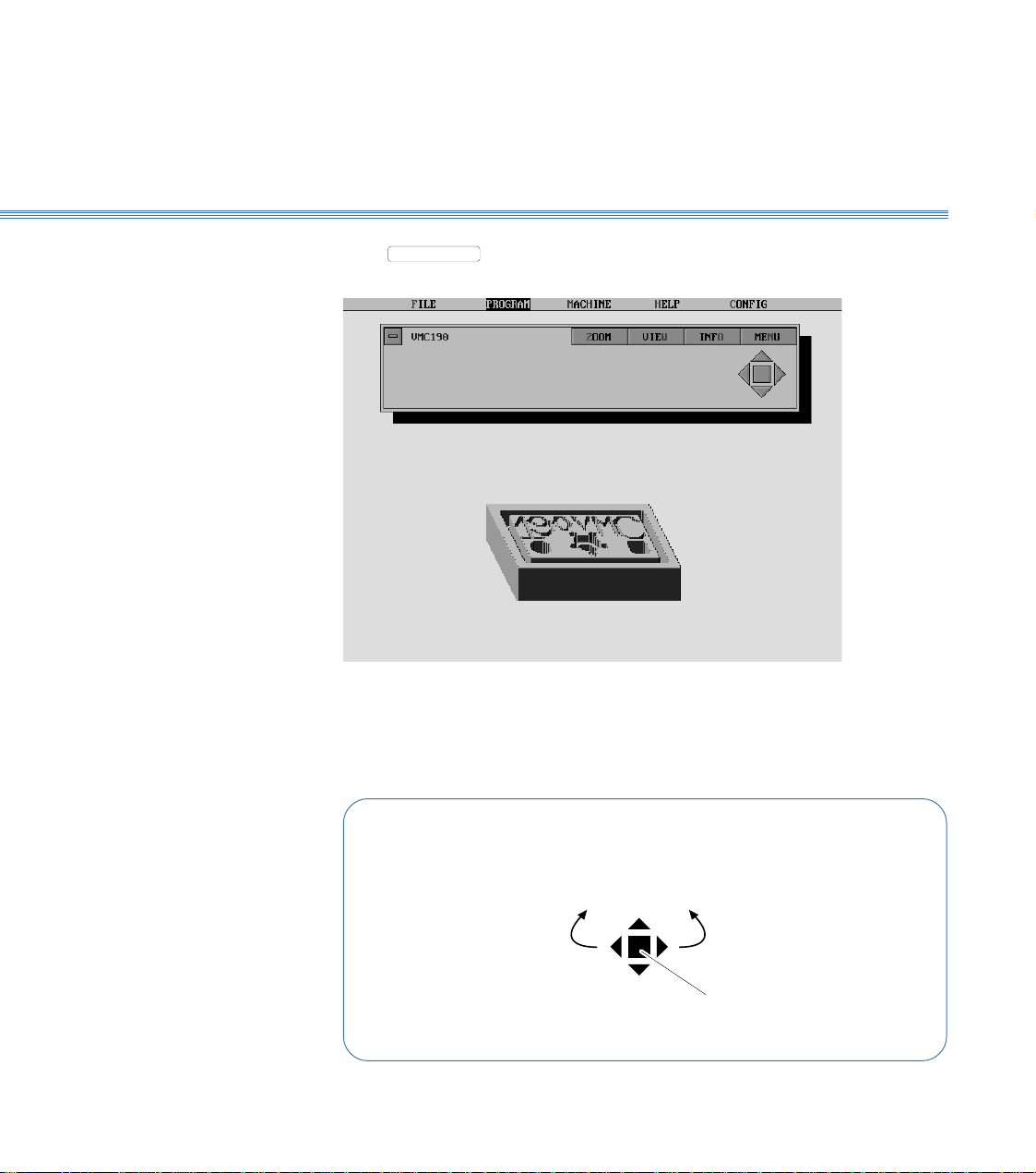

8. Select

VIEW

to produce a 3D view of the component. After a pause the display will

show the 3D view:

Manipulate the 3D view as follows:

Using a Mouse:

Click on the control buttons -

Rotate

clockwise

Increase

size

Decrease

size

Rotate

anticlockwise

Restore

original view

Page 11

Boxford 190 VMC

2 Running the Demonstration Program

Show the Program

Details

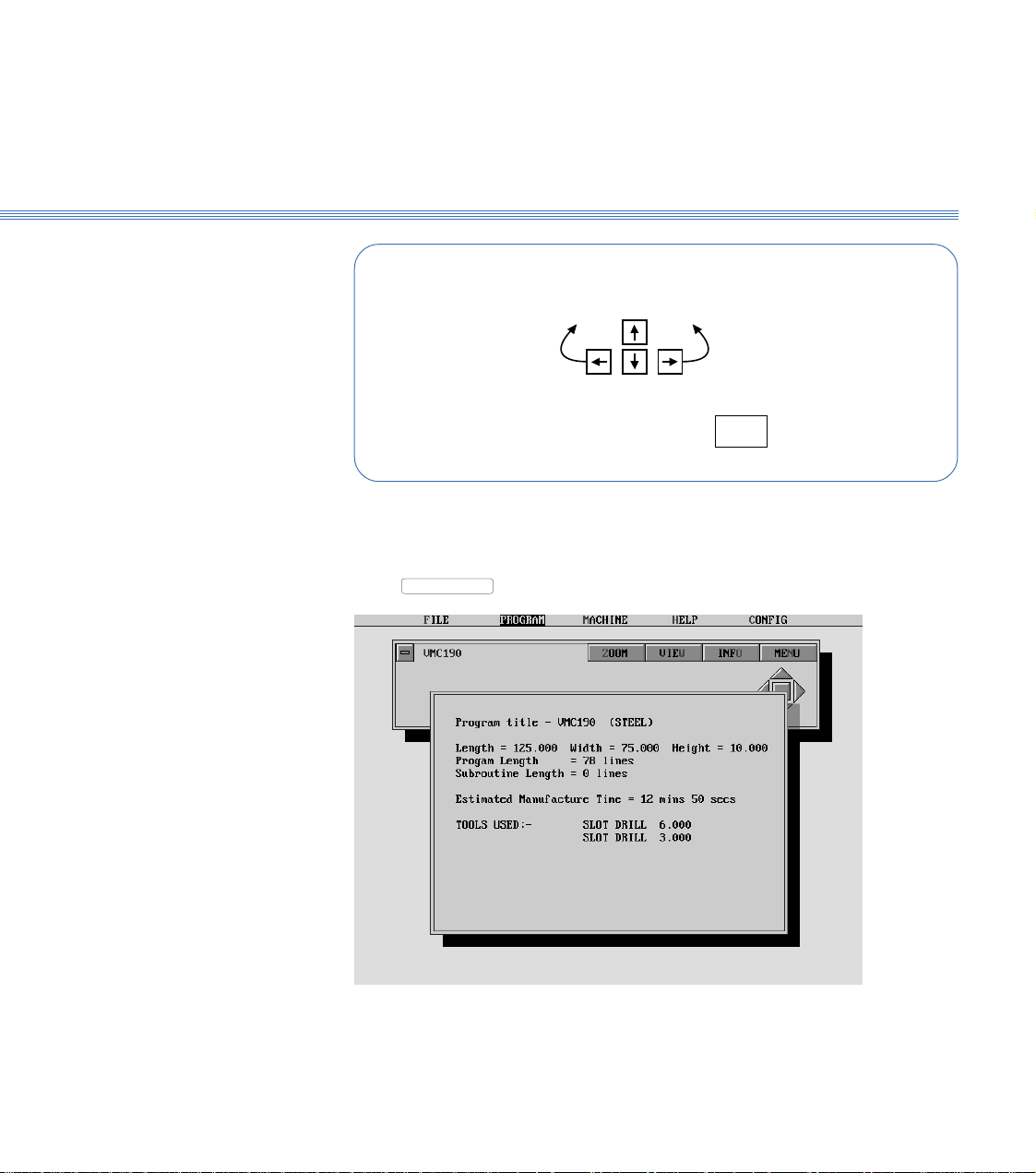

Using the Keyboard:

Rotate

clockwise

Increase

size

Decrease

size

Rotate

anticlockwise

HOME

Restore

original view

Note:

The time taken for the display to respond will depend on the speed of the PC and whether a co-processor

is fitted.

9. Select

INFO

to show the program details:

10. Turn off the program details display. (Click off the display window or press Return).

Page 12

2 Running the Demonstration ProgramBoxford 190 VMC

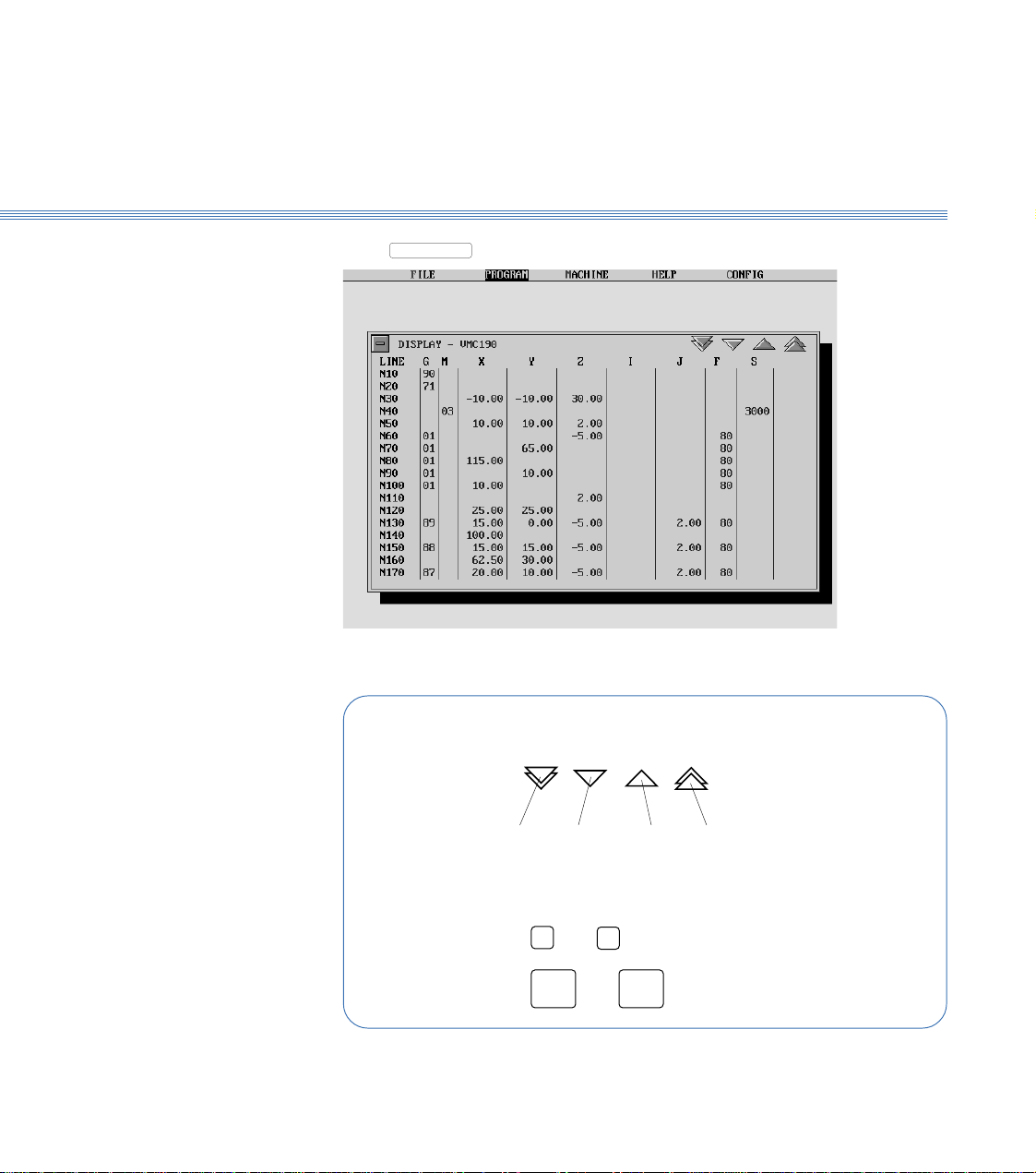

11. Select

MENU

and then Display:Display the Program

Scroll the display to examine the program:

Using a Mouse:

Click on the buttons

page

down

Using the Keyboard:

Press or to scroll 1 line

Page

Press or to scroll 1 page

12. Turn off the program display.

➔

up

1 line

down

1 lineuppage

up

➔

Page

down

Page 13

Boxford 190 VMC

2 Running the Demonstration Program

Zoom the Display

The ZOOM facility enables a rectangular area of the workpiece to be isolated and viewed

in greater detail for editing purposes. Full use of the facility is explained in Section 10 -

Manual Data Input CNC Programming, 10.8.3 - ZOOM Facility.

The following steps provide a brief demonstrations, returning to the display of the

complete workpiece.

13. Select

ZOOM

. The screen displays a 2D view of the workpiece with a menu bar at the

top, and sliders and arrow buttons arranged horizontally and vertically.

Explore the use of the REDUCE and ENLARGE options, and the sliders and arrow

buttons, to define a section of the workpiece with the rectangular selecting frame.

(RESET restores the frame to its original size).

14. Select

ACCEPT

. After a pause the screen shows the program EDIT display with a 3D

view of the selected area of the workpiece.

15. Select

ZOOM

, then Unzoom to restore the 3D view of the complete workpiece.

Page 14

2 Running the Demonstration ProgramBoxford 190 VMC

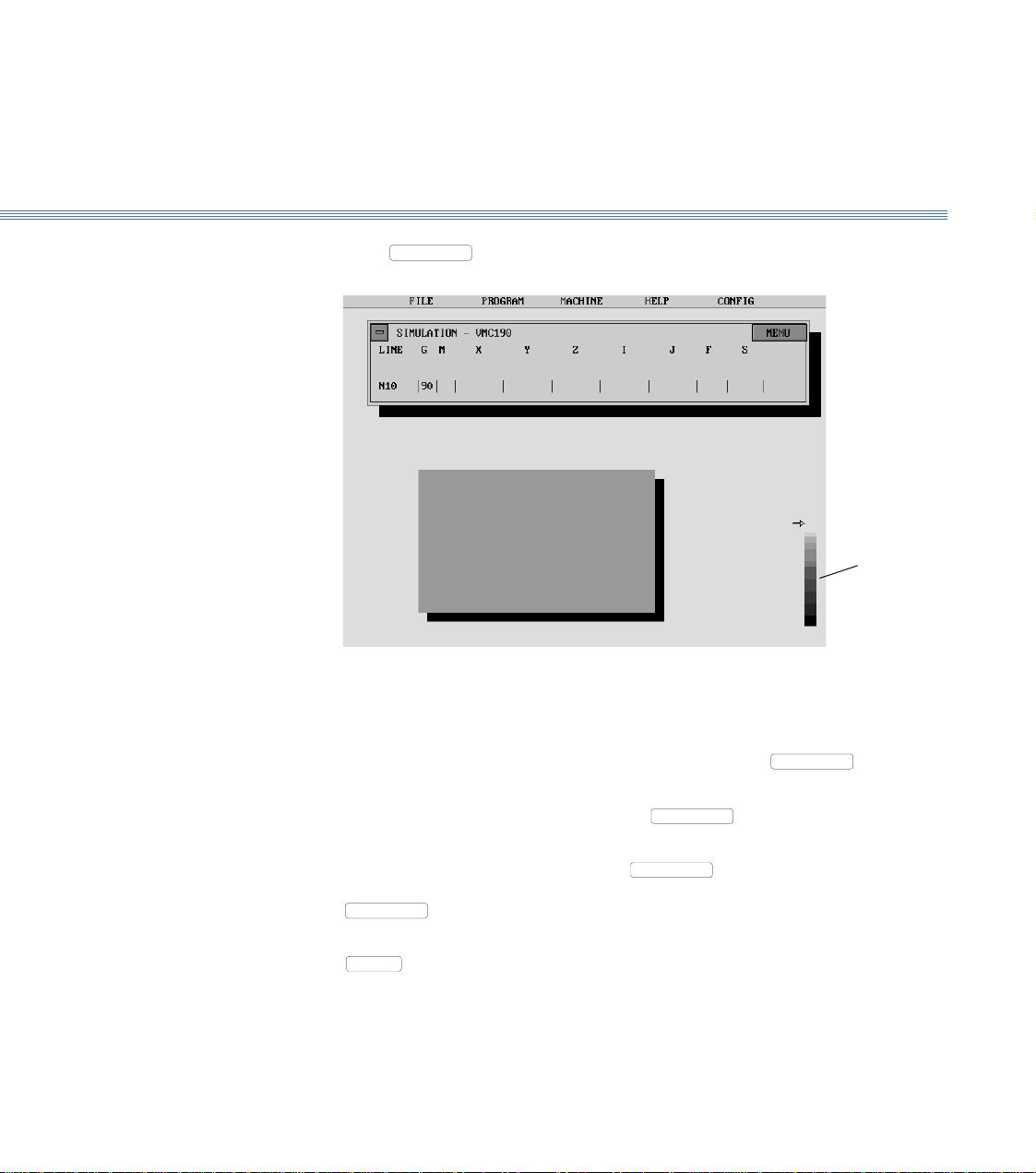

Simulate Machining

- 2D

16. Select

MENU

, then 2D Simulate:

Repeatedly click the mouse button or press Return to move through the program line-by-

line. The simulation shows the tool movement and metal removed as each line of the

program is executed.

To move forward through the program to a specific line, select

MENU

to Line. Type the required line number when prompted, and press Return.

tool

depth

display

, and then Go

To produce a 3D view of the workpiece, select

MENU

and then Solid View. To return

to the 2D view, click the mouse button or press Return.

To run the simulation automatically, select

MENU

and then Fast Mode; the program

will be run in a continuous sequence. To return to line-by-line simulation, select

MENU

and then Step Mode.

To end the simulation before the end of the program, click on the 'off' button or press

ESC

.

At the end of the program the screen returns to the program display.

Page 15

Boxford 190 VMC

2 Running the Demonstration Program

Simulate Machining

- 3D

Machine the

Component

17. Select

Select

MENU

MENU

, then 3D Simulate:

, and demonstrate the use of the options available as for the 2D

simulation, until the screen again shows the program display.

Refer to Section 11 - CNC and CAM Machining.

Page 16

Boxford 190 VMC

Axes and Tooling

3 Axes and Tooling

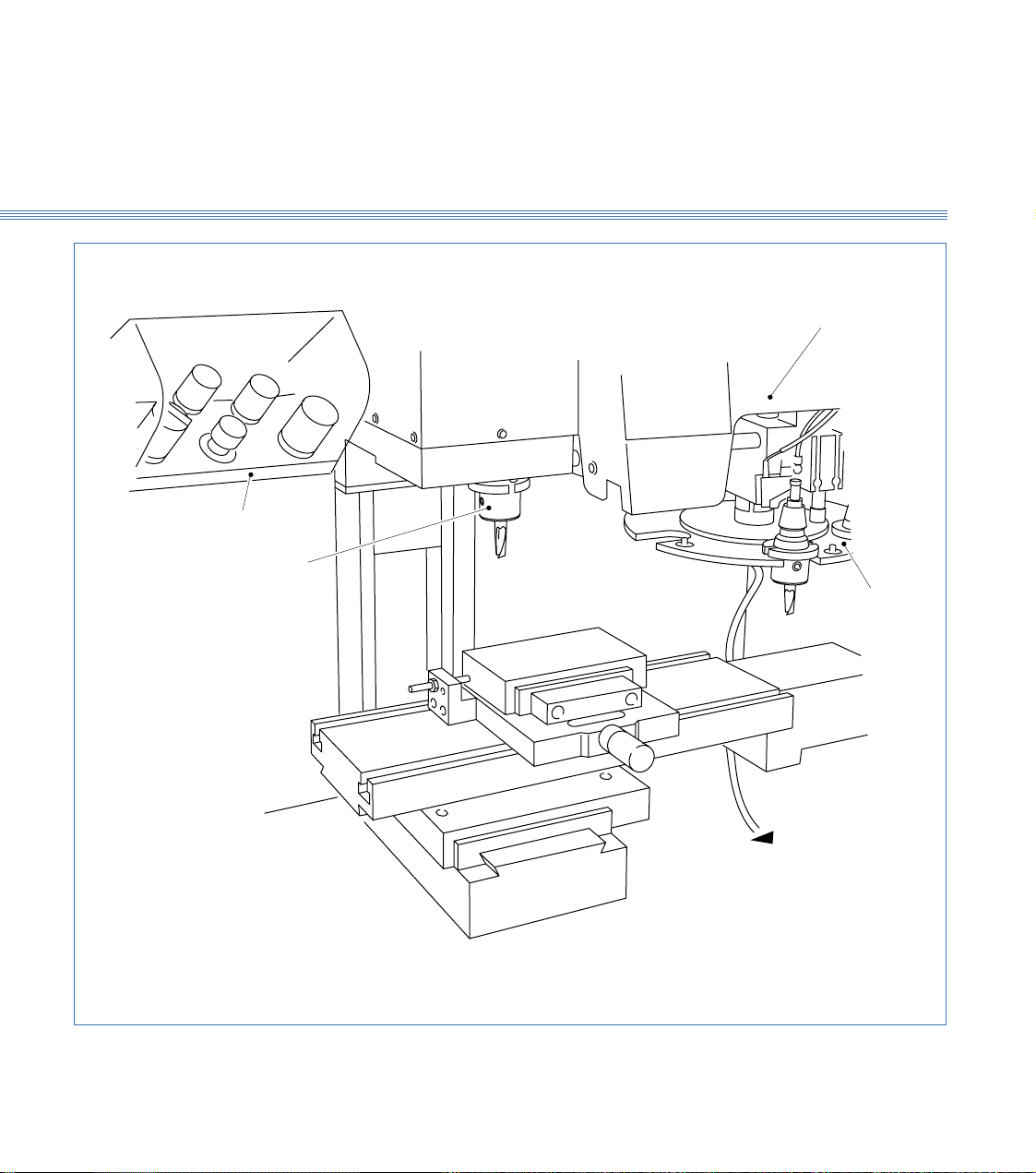

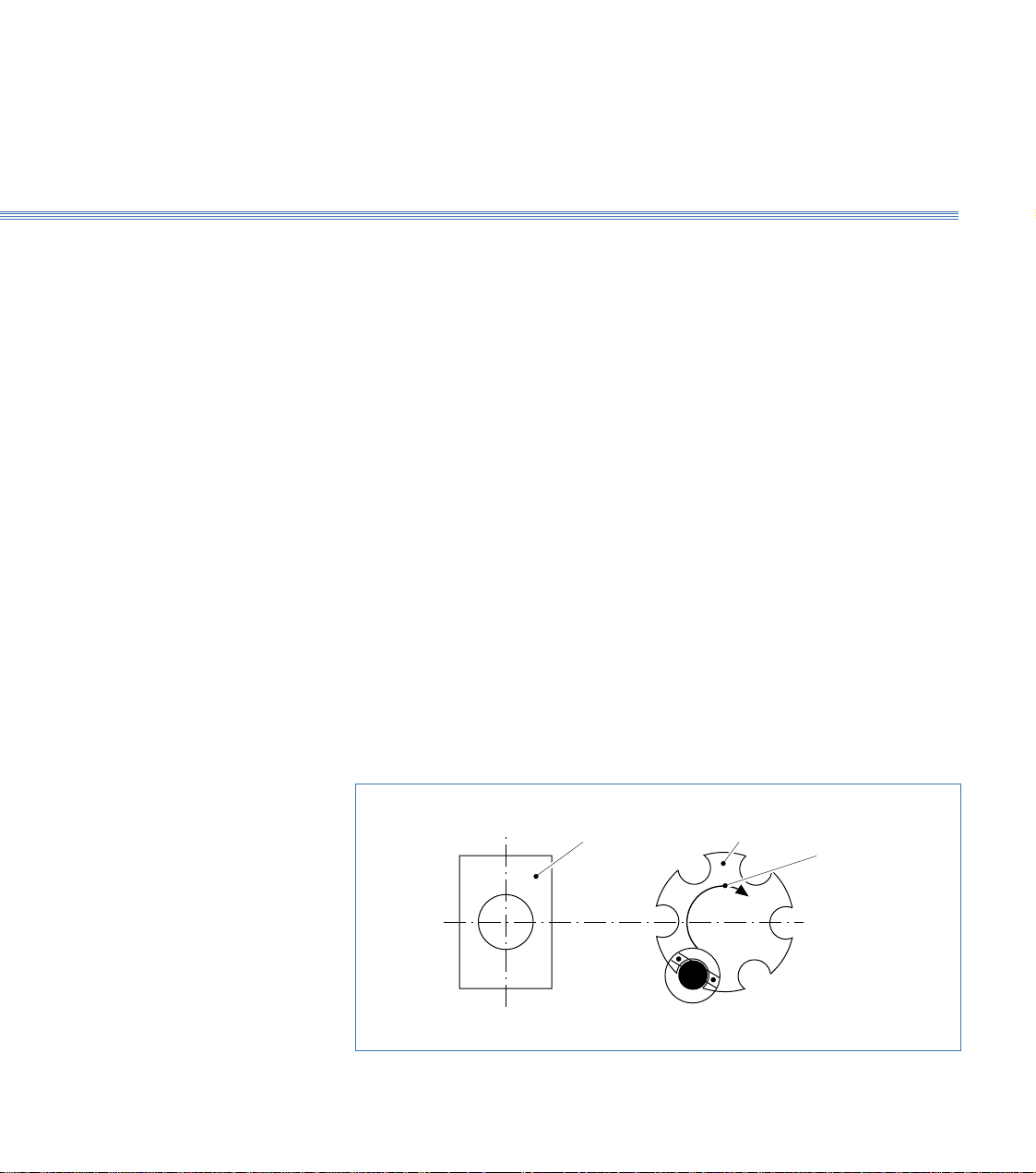

3.1 Fitting Tooling (Figure 3.1)

The cutting tool fits directly into a tool holder and is secured in position by a single

Allen screw.

The tool holder in turn fits into the machine spindle taper and is orientated by two dogs

which engage with the tool holder flange.

The tool holder pull stud is then drawn upwards by the spindle drawbar thus securing

the tool holder.

The drawbar can be manually operated by a lever on the side of the spindle or an

automatic tool changing device can be specified if required.

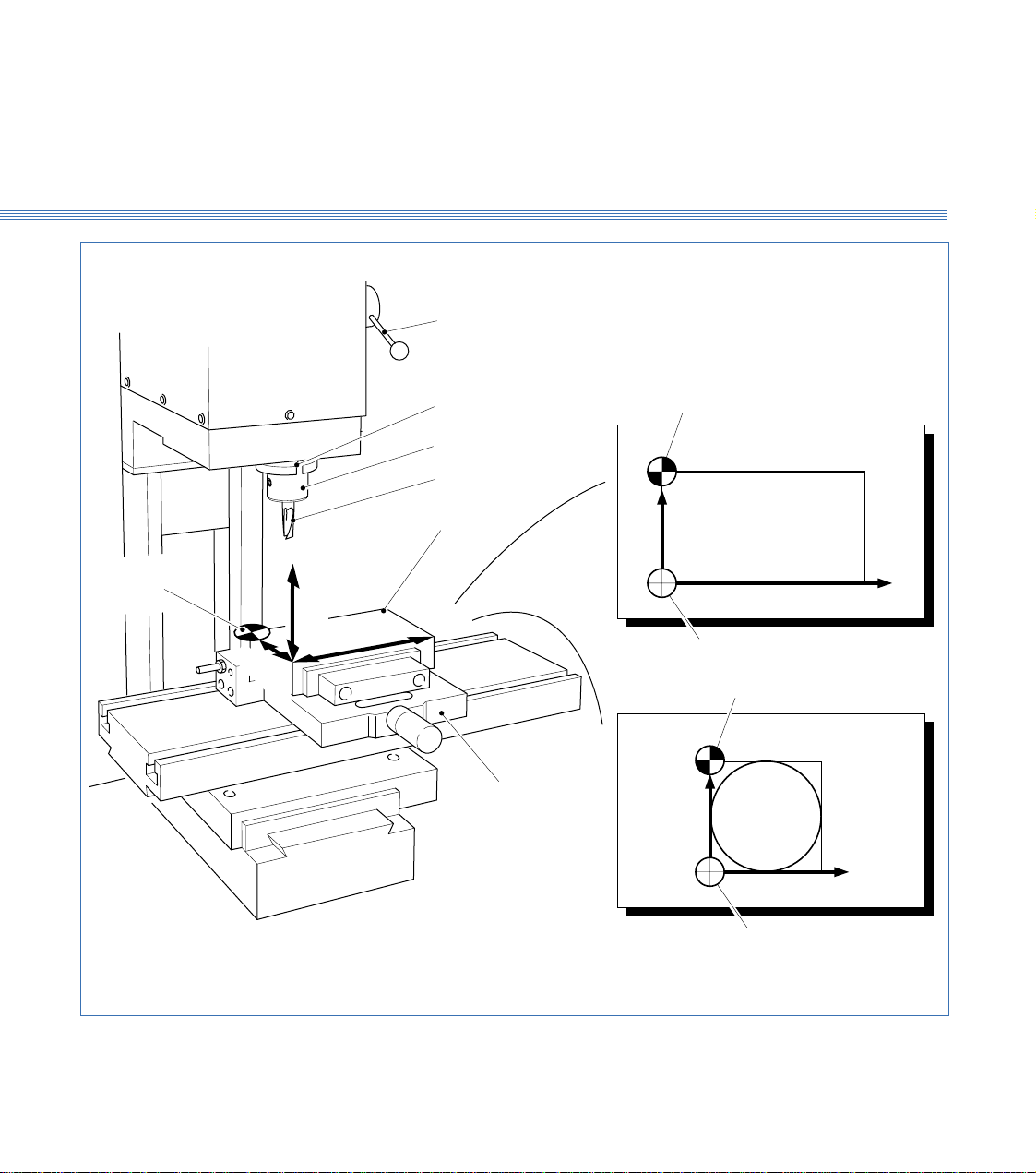

3.2 Axes, Datums and Offsets (Figure 3.1)

Axes

Datum Position

Figure 3.1 shows the movement of the tool in the X, Y and Z axes, in relation to the

billet. (In the X and Y axes the billet moves in relation to the tool, but for simplicity

and to conform with standard programming practice, it is the movement of the tool

in relation to the billet which must be considered).

On new machines, all Datum positions and Tool Offsets are set at the factory when tooling and clamping

is ordered with the machine.

The offsets of all required tools are set in relation to the machine Z datum.

Before any Tool Offsets can be set, the Machine Z Datum has to be defined.

From the machines Home Position, the Machine Z Datum is the measured distance from

the underside of the of the spindle head to the machine table top as shown in the diagram overleaf.

The X and Y Datum is the distance from the spindle centreline to a fixed point on the machine

table where the same corner of every workpiece locates to. (on a standard Vice, this is the imaginary

intersection of the vice rear jaw and the left hand end stop - a point where the Left Hand

corner of a workpiece locates to).

The datum position can be set to reference from Back Left, Back Right, Front Right

and Front Left corners of the workpiece (see section 3.5 - point 15 onwards for further

details).

Page 17

Boxford 190 VMC Axes and Tooling

Drawbar lever

3.1

DRAWING

Tool X,Y datum

Spindle

Tool holder

Cutting tool

Tool X,Y datum

+Y

Billet

Rectangular

billet

+X

+

Z

X

+

Drawing datum

Tool X,Y datum

Workholding vice

+Y

Circular

billet

-

+

Y

-

-

+X

Figure 3.1 Axes and Tool Datum

Drawing datum

Page 18

Boxford 190 VMC Axes and Tooling

3.2

Drawing Datum

Offsets

Dimensions on drawings are measured from the drawing datum. For convenience this

can be placed at the bottom left-hand corner of the billet and given X and Y co-

ordinates of zero. When a component is manufactured, the difference between the Y

co-ordinates of the tool and drawing datums is entered and the software compensates

for this difference.

The 190 software also allows the use of circular billets. For these, the X and Y datum

is usually at the bottom left hand corner of a square enclosing the billet.

Each tools offset is the distance from the Underside of the Spindle Head to the

tool end (bottom).

Underside of Head

Tool Z Offset

Machine Z Datum

Total Height of

Workpiece & Clamp

Machine Table Top

Page 19

Boxford 190 VMC Axes and Tooling

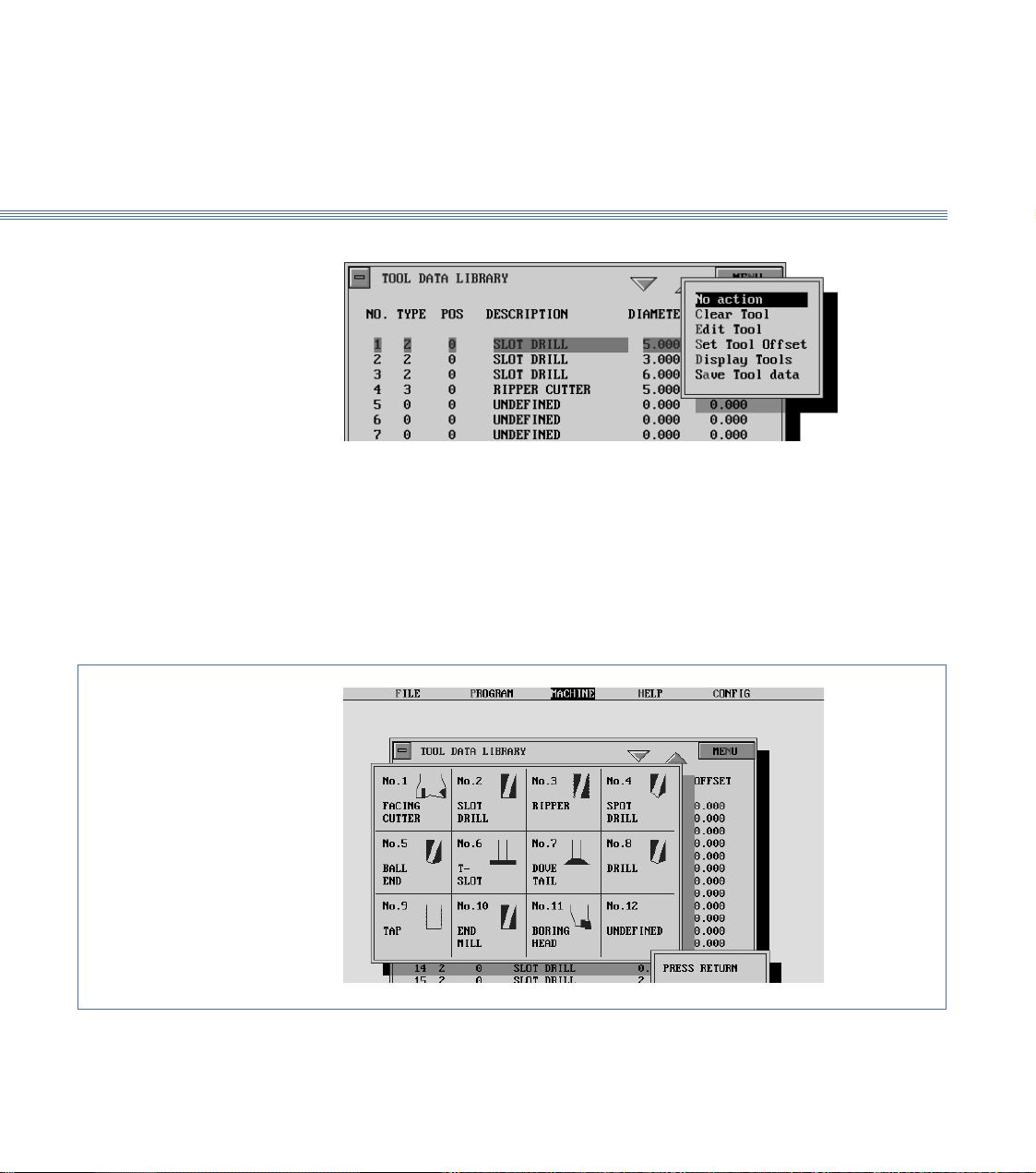

Tool rack

(basic 190VMC)

Spindle

3.2

Auto tool changer

Figure 3.2 Tool Storage

Carousel

To pressure gauge

Page 20

Boxford 190 VMC

3.3 Tool Storage (Figure 3.2)

3.3

Axes and Tooling

Tool Rack

(Figure 3.2)

Auto Tool Changer

(Figure 3.2)

Manual Operation

On the basic 190 VMC a tool rack is provided, as shown in Figure 3.2, to facilitate

storage of up to 5 tool holders and associated cutting tools.

It is advisable to store the tools in the same order as they will be called for in the

machining program.

Automatic tool changing equipment is supplied as an optional extra .

A carousel facilitates storage of up to 5 tool holders and associated cutting tools. Each

tool holder must be loaded into the correct carousel station so as to correspond with

the machining program prior to cycle start, i.e.:

Tool No.1 = Station No.1

Tool No.2 = Station No.2

The machine cycle start cannot be activated until the carousel has been indexed to Tool

No. 1, the reference tool station.

The auto tool changer is a pneumatic device requiring a compressed air supply of 80

lbf/in2.

Ensure therefore that the system pressure gauge reads 80 lbf/in2 prior to operating the

auto tool changer controls.

Pressing the Tool Change button on the main control panel will direct the auto tool

changer to remove the tool holder currently in the spindle, place it in the correct

carousel station, index the carousel to the next station, secure the next tool holder into

the spindle and retract.

Note:

When using the Tool Change button ensure that the spindle is at least 5mm below the upper Z+

limit of its travel.

Programming the Auto Tool

Changer

The CNC code for a tool change is the same as for a standard machine. Using the M

code M06 you must define the tool type e.g. type 2 (a slot drill), the diameter of the

tool and the station number 1 5 in the carousel, for example:

M06 I2 J6 F4

Where I = a slot drill

J = diameter of 6mm

F = station No. 4.

On completion of the part-program the machine will automatically change back to tool

1 allowing batch quantities to be machined.

Page 21

Boxford 190 VMC

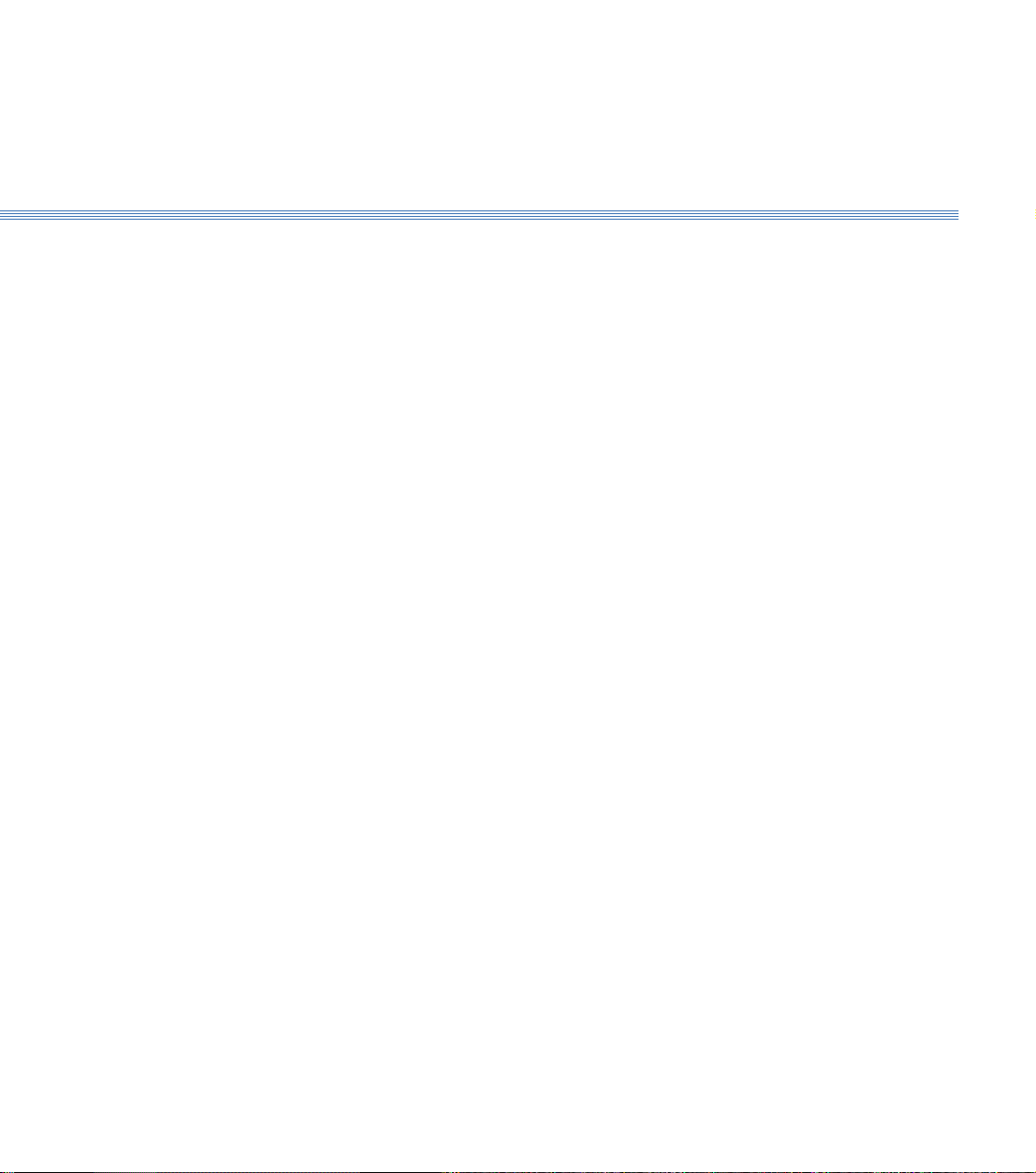

3.4

Axes and Tooling

3.4 Tool Data Library and Catalogue

The 190 software provides a Tool Data Library which enables details of tooling and

offsets to be entered and a tool catalogue from which tools can be selected for inclusion

in the library. The library is set up by means of a tooling menu.

Before attempting to set up the tooling for the first time, view the library, the tooling

menu and the catalogue to become familiar with the details, as follows:

1. Switch on the PC, run the 190 Software.

2. From the main menu, select MACHINE and then Tools.

Tool Data Library

Details of selected tool are highlighted.

When the display first appears, the initial

tool is highlighted. Other tools can be

selected as shown below.

The screen shows the Tool Data Library, (Figure 3.3). Practice selecting tools using

the mouse and keyboard.

3412

1. Tool number used by CNC program to select

required tool

2. Tool type (selected from tool catalogue)

3. Tool station (carousel)

4. Tool description (selected from tool carousel)

567

5. Scroll buttons

6. Tool offset

7. Tool flute length

To select a tool:

Using a mouse

Click on the scroll buttons (6) to highlight the required tool.

Using the keyboard

Press ➔ or ➔ to highlight the required tool.

Figure 3.3 Tool Data Library

Page 22

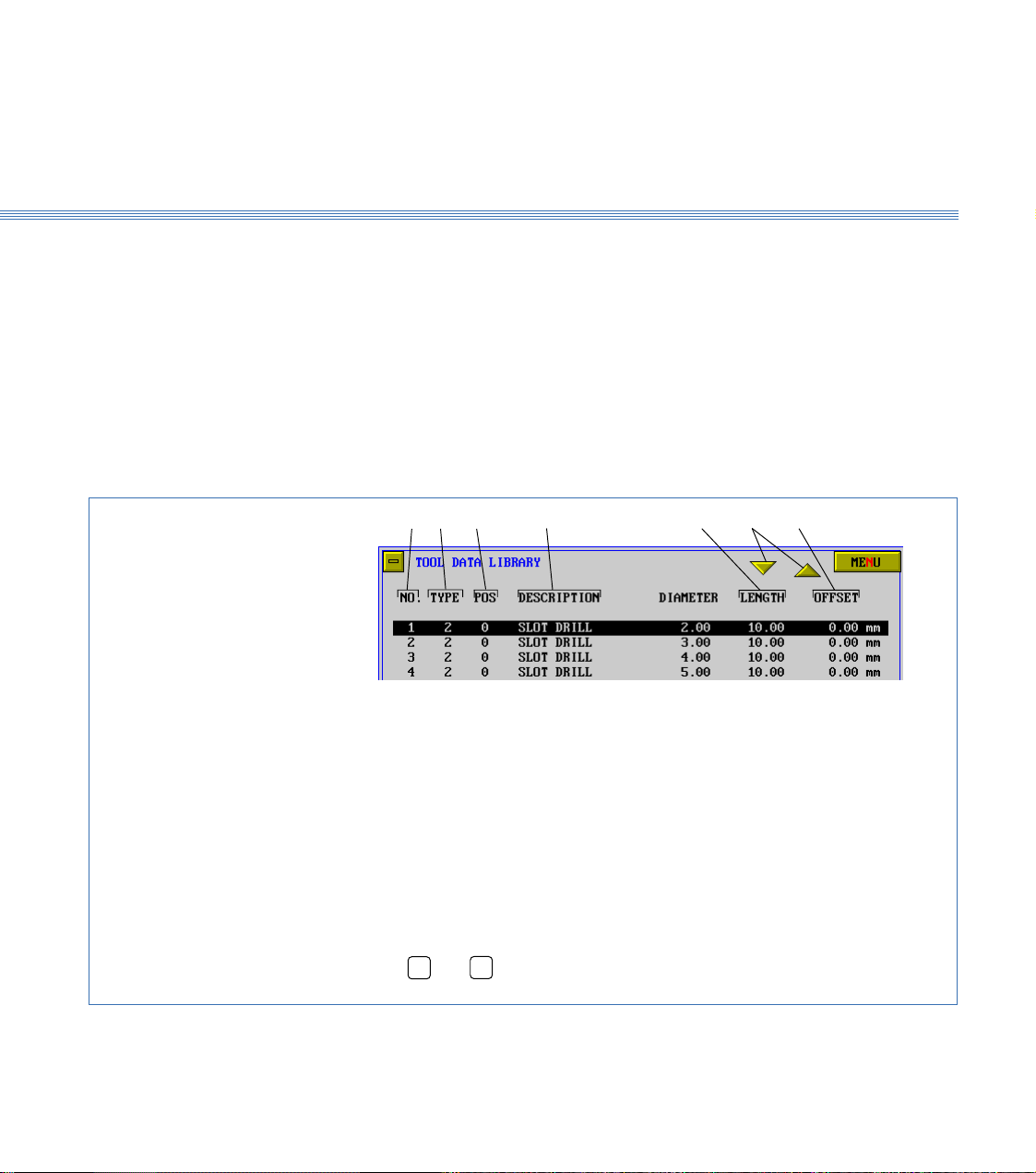

Boxford 190 VMC Axes and Tooling

3.4

Tooling Menu

Tool Catalogue

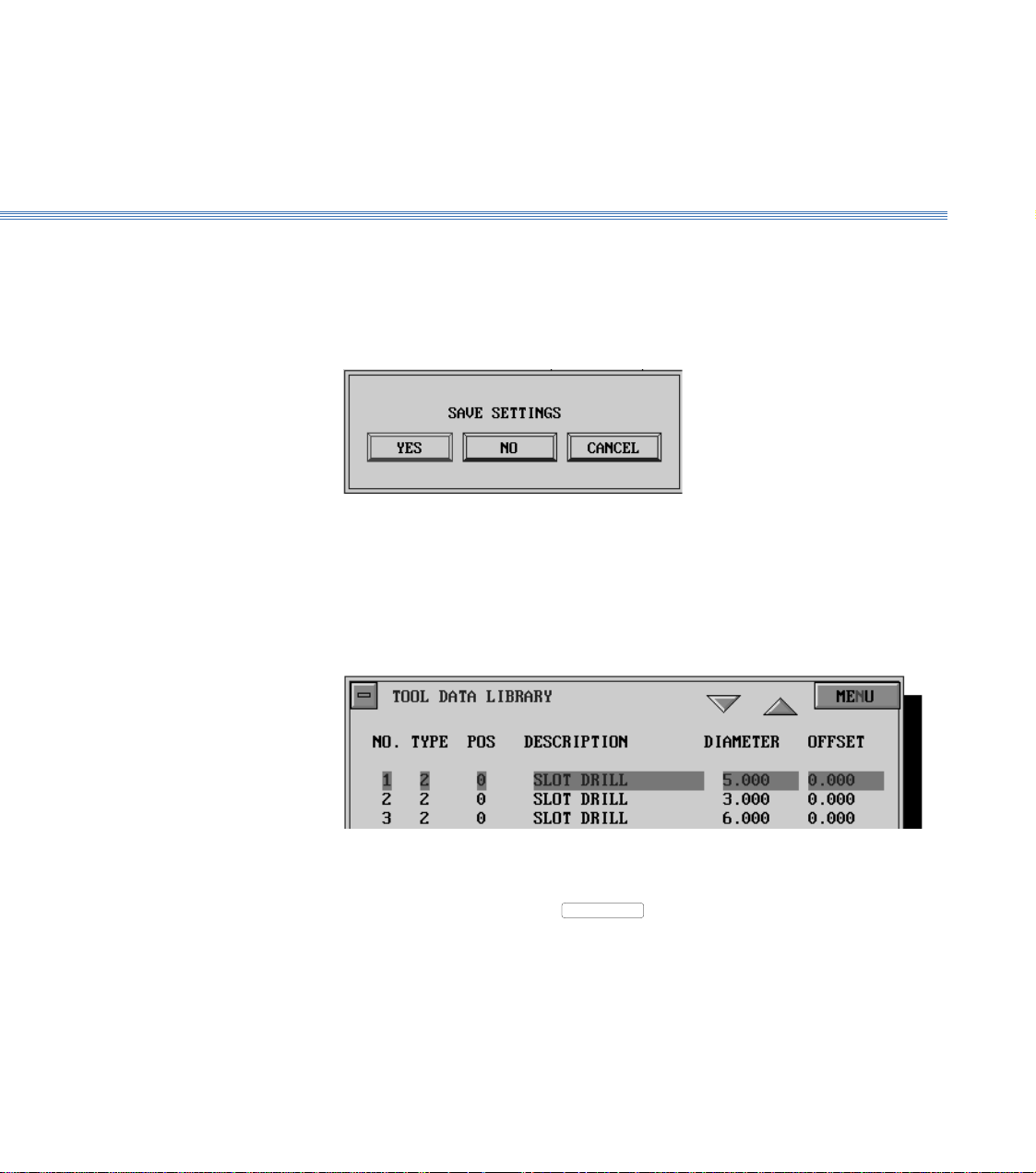

3. Select MENU to display the tooling menu:

The use of these options for setting and editing the Tool Data Library is detailed later

in this section.

Note:

After setting up or editing the library, always select Save Tool data.

4. From the tooling menu, select Display Tools.

The screen shows the tool catalogue, (Figure 3.4).

Turn off the tool catalogue display to reveal the Tool Data Library.

Figure 3.4 Tool Catalogue

Page 23

Boxford 190 VMC Axes and Tooling

Spindle Carousel Direction

of rotation

Fit reference

tool here

3.5

3.5 Setting Up

Note:

A billet of the appropriate size will be required for this procedure. In order to run the demonstration

program, a 5mm slot drill and a 5mm end mill are required. To run the program, set up the slot drill

as the initial tool and the end mill as the second tool in the following procedure. If you want to fit a

different initial tool or second tool, substitute the tool details as appropriate.

Fit Initial Tool

Fit the billet into the workholder, then fit the tooling as detailed below:

1. Basic 190 VMC with Tool Rack

Fit the 5mm slot drill into the tool holder and secure the tool

holder into the spindle by operating the drawbar lever (Figure 3.1).

If the spindle is too close to the work holding vice to allow the tool to be fitted then

use the manual controls to move the spindle up until sufficiently clear. (See Section 12

- Manual Machining).

2. 190 VMC with Auto Tool Changer

Fit the 5mm slot drill into the tool holder and secure the tool holder into the carousel

as shown in Figure 3.5.

Ensure that the spindle is in the correct Z+ position to facilitate auto tool changing.

Press the TOOL CHANGE button on the control panel.

The carousel will then traverse left to the spindle position, perform the actions of

removing a tool holder from the spindle, index to the reference tool, load and secure

the reference tool into the spindle, and retract.

The reference tool is now fitted in the spindle.

Figure 3.5 190 VMC with Auto Tool Changer - Reference Tool Position

Page 24

Boxford 190 VMC Axes and Tooling

3.5

Configure Software

Set Initial Tool Offset

3. Check that the POWER ON RESET button on the machine control panel is lit.

4. Run the 190 Software. From the main menu select CONFIG and then Program.

5. Set the required values and turn off the display.

The screen shows:

6. Select YES

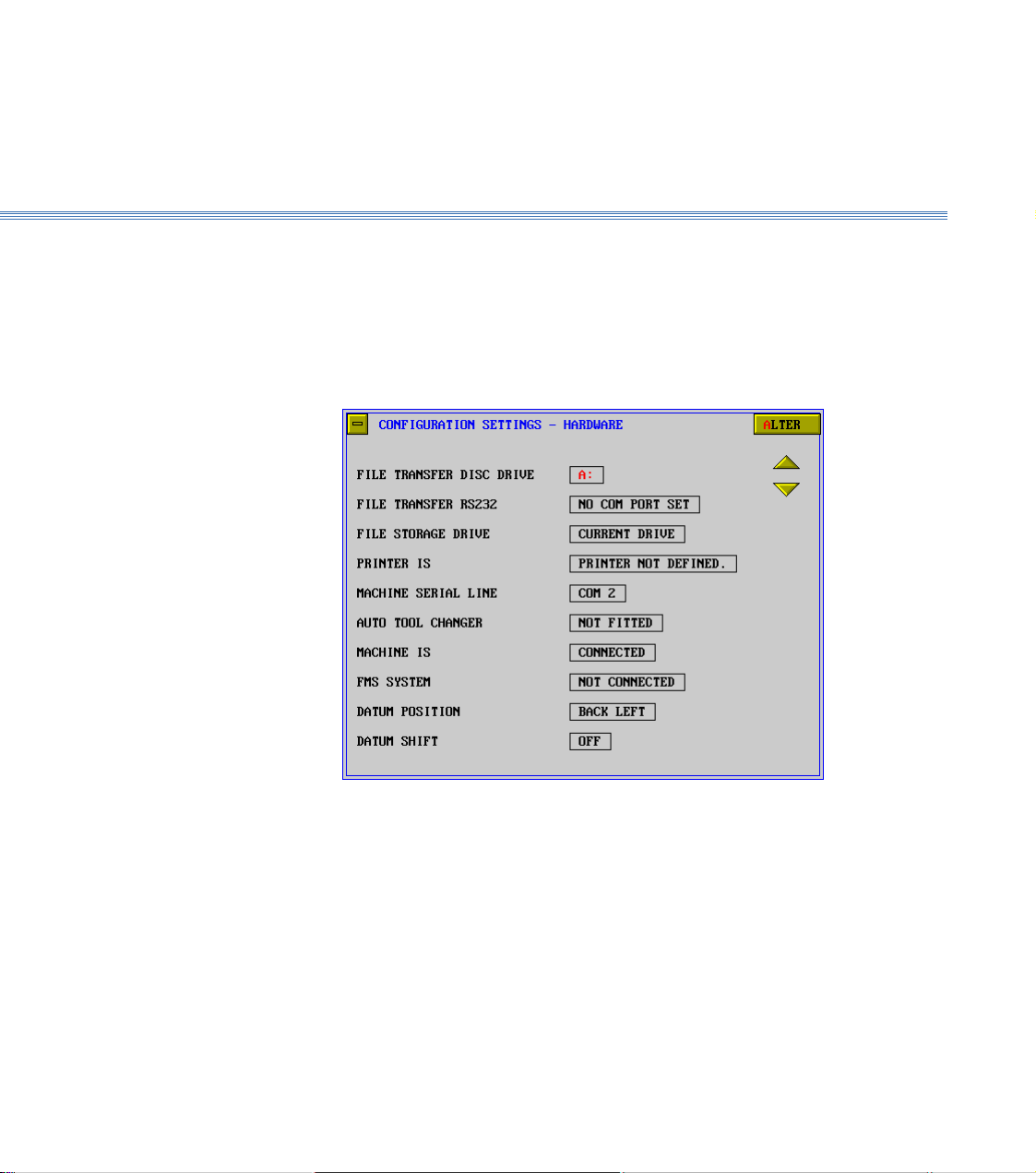

7. Select CONFIG and then Hardware. Make the required settings, turn off the display,

and save the settings.

The screen shows the Main Menu.

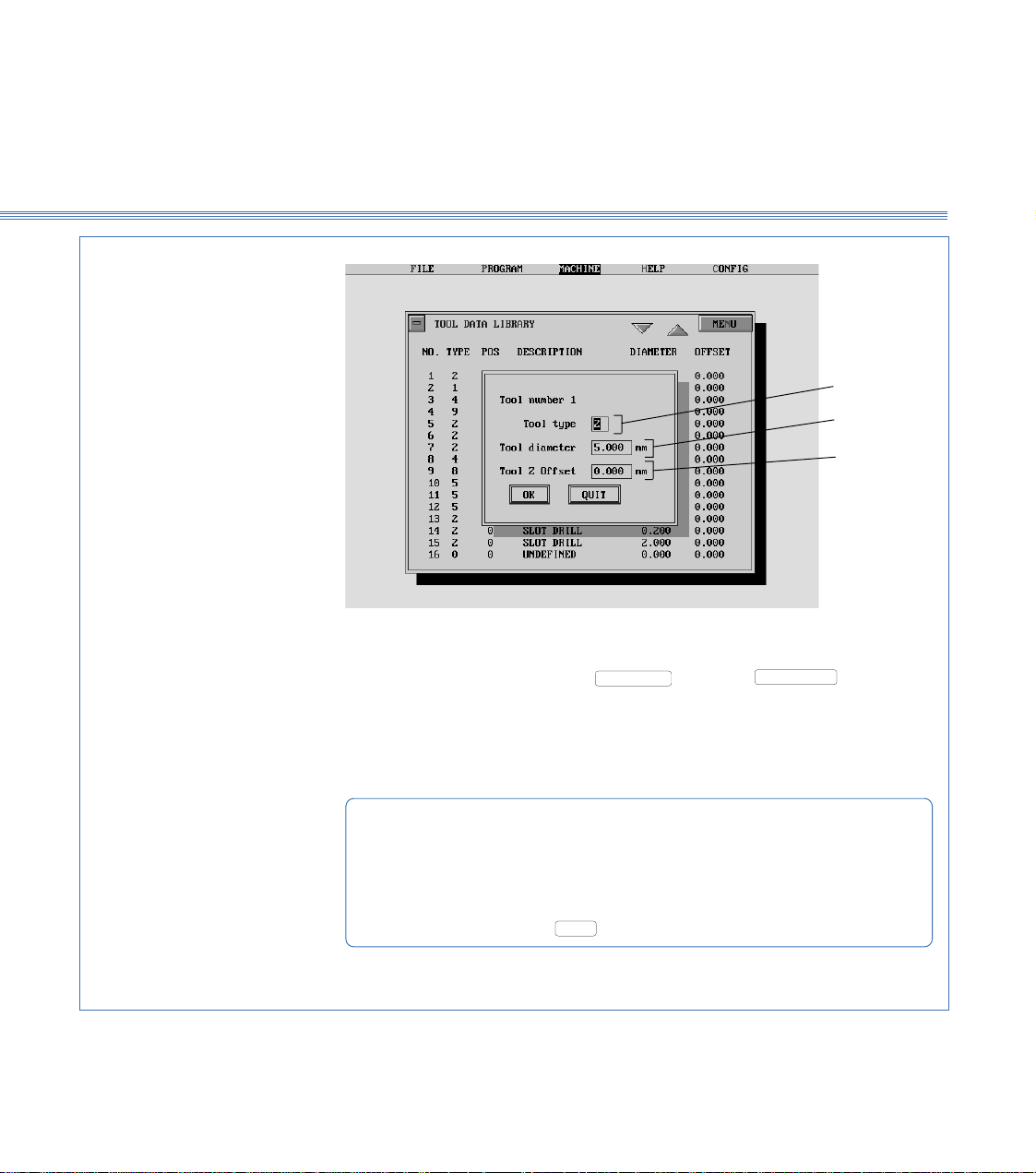

8. From the main menu, select MACHINE and then Tools to display the Tool Data

Library. The settings for the 5mm slot drill will be highlighted, for example:

Check the tool details (excluding the offset). If they are correct, continue at step 10 to

set the offset.

9. To edit the tool details, select

The screen shows the tool editing display, with the first item (Tool type) highlighted,

(Figure 3.6).

Edit the display to show the correct settings.

MENU

and then Edit tool.

Page 25

Boxford 190 VMC Axes and Tooling

QUIT

OK

3.5

1

2

3

1 To check tool type, press Escape or select

Display tools to view tool catalogue.

2 Diameter of slot drill is 5.00mm

3 Offset for reference tool is zero.

To edit tool details:

Type required number in highlighted box

Press Return to highlight next box

When last box is highlighted, press Return: highlight will disappear

Press Return or click on

Figure 3.6 Tool Editing Display

, then select

to turn off display

MENU

and

Page 26

Boxford 190 VMC Axes and Tooling

3.5

10. Select

If the touch-on point is to be the top of the billet, enter the height of the billet. If the

touch-on point is to be the base of the workholder, enter zero.

11. If the Software detects the machine is in Manual Mode, the user is prompted to

Cancel Manual Mode

The window below is shown.

MENU

, and then Set Tool Offset. The screen shows:

1. The machine RESET button is pressed.

2. a. The Z+ and Z- keys are pressed simultaneously (this axis must reach

home position before step b. can be started.

b. The X+ and X- keys are pressed simultaneously.

c. The Y+ and Y- keys are pressed simultaneously

2. ALTERNATIVELY, the F1 function key on the PC keyboard can be

pressed. This automatically performs steps a, b and c.

Page 27

Boxford 190 VMC Axes and Tooling

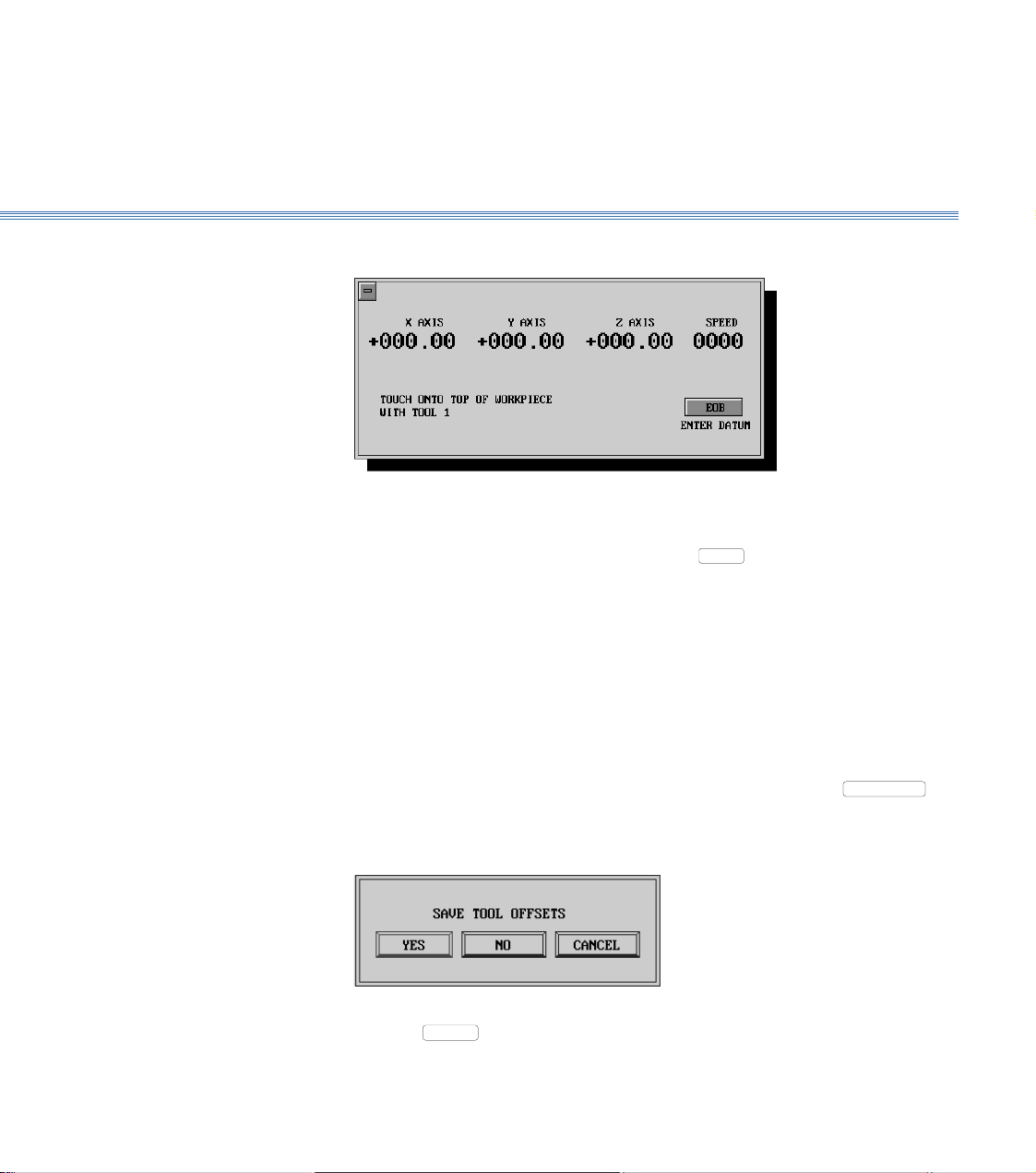

12. When the axes reach the home position, the screen shows:

On the machine control panel, select Manual mode. Using the axis control buttons,

touch the point of the tool on to the top of the billet.

3.5

Set Additional

Tool Offsets

13. When the tool is in the correct position, select

again shows the Tool Data Library.

If additional tool offsets are to be set, continue at step 14. If not, continue at step 15

to set the machine datum position.

14. To set the offset of the next tool, fit or index the tool and repeat the procedure from

step 8.

Note:

For setting the offsets of the second and any subsequent tools, it will not be necessary to enter the height

of the billet or to home the axes (steps 10 and 11).

When the offsets of all the required tools have been set, either select

then Save Tool Data, or click the 'off' button of the Tool Data Library display. If the

'off' button is clicked, the screen shows the message:

Click on

or press Return to save the offsets.

YES

or press Return. The screen

EOB

MENU

and

Page 28

Boxford 190 VMC Axes and Tooling

3.5

Set Machine

Datum Position

Note

It is only necessary to set the datum position if the workholder position is changed or the Datum

position (back, front, left, right) is changed

15. There are now a number of additional Datum Position options.

Datum Position - Select CONFIG and then Hardware.

The window below is shown.

With the DATUM POSITION option highlighted, the options can be accessed

and selected using ALTER.

The datum position is:- a point on the machine table where the same corner of every workpiece

locates to.

e.g. On a VMC machine fitted with a standard Vice, the workpiece BACK face locates

to the fixed rear vice jaw and the workpiece LEFT face locates to the vice end stop

- hence the setting would be BACK LEFT

The Datum Position is selected and the settings saved.

From the main menu, select MACHINE and then Datum Position.

Page 29

Boxford 190 VMC Axes and Tooling

3.5

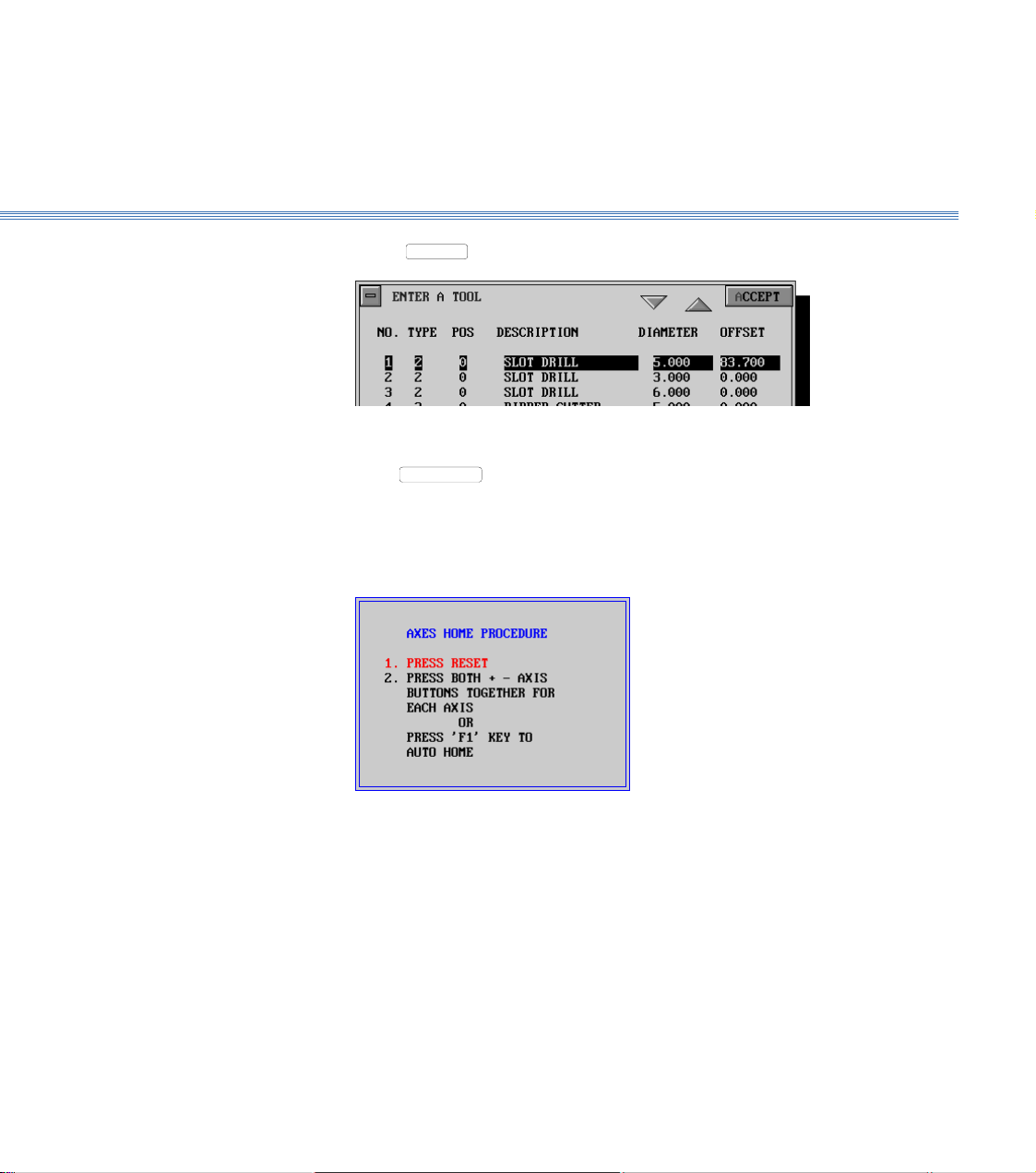

16. Select

SETUP

. The screen shows the Enter a Tool display:

17. Select a tool for which the offset has been set, (for example tool no. 1), and

select

ACCEPT

or press Return.

If the Software detects the machine is in Manual Mode, the user is prompted to

Cancel Manual Mode

The window below is shown.

1. The machine RESET button is pressed.

2. a. The Z+ and Z- keys are pressed simultaneously (this axis must reach

home position before step b. can be started.

b. The X+ and X- keys are pressed simultaneously.

c. The Y+ and Y- keys are pressed simultaneously

2. ALTERNATIVELY, the F1 function key on the PC keyboard can be

pressed. This automatically performs steps a, b and c.

Page 30

Boxford 190 VMC Axes and Tooling

3.5

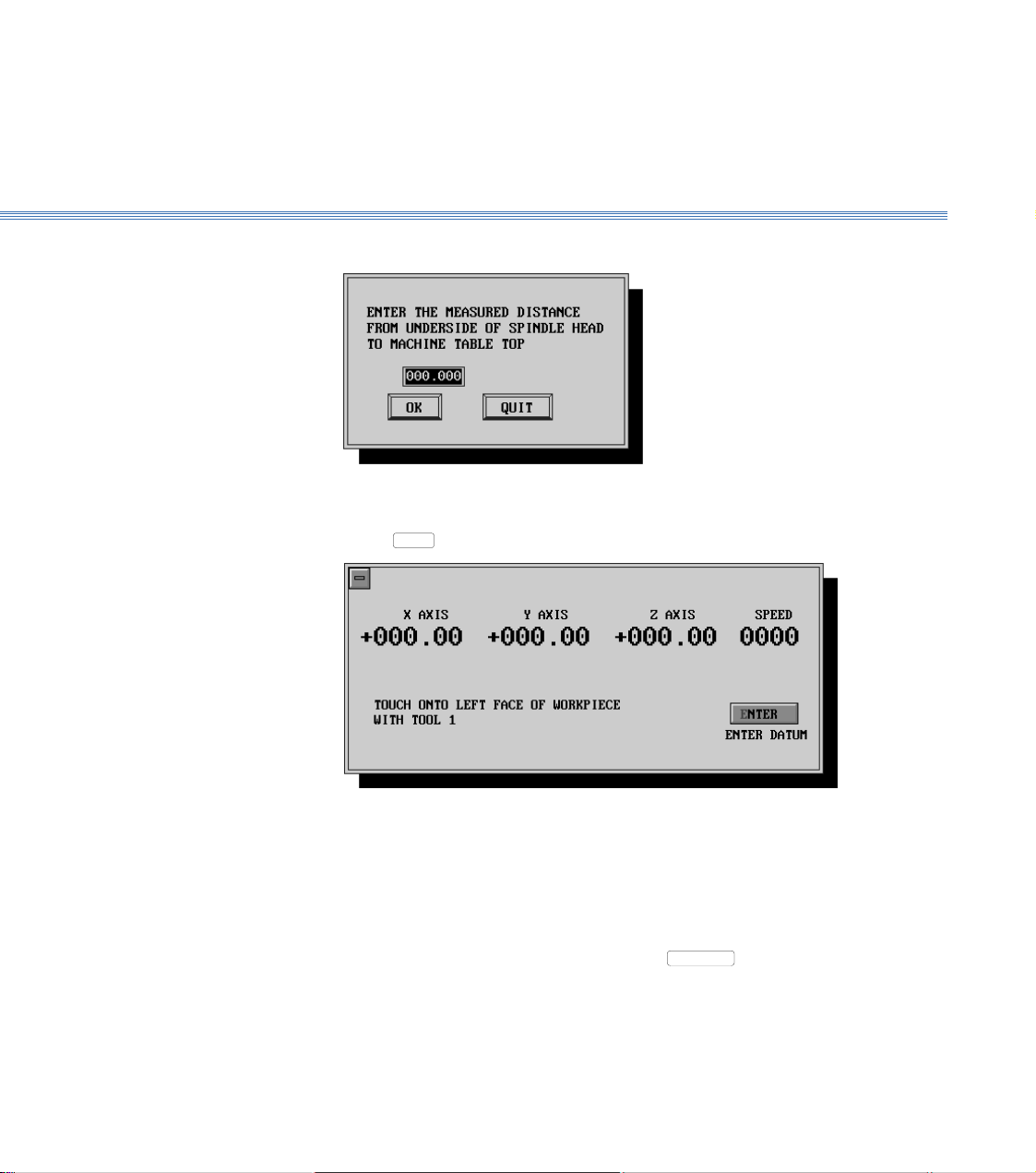

18. When the axes reach the home position, the screen shows:

Measure the dimension (from the underside of the spindle head to the machine table

top), and enter the value. (This establishes the Z axis datum).

19. Select

OK

or press Return twice. The screen shows:

Note:

The Face of the billet to touch on will depend on the Datum Position setting in the Hardware

configuration - see point 15

On the machine control panel, press MAN to select Manual mode. Use the axis control

buttons to touch the side of the tool on to the left face of the billet. (This establishes

the X axis datum; the software compensates for the radius of the tool).

20. When the tool is in the correct position, select

ENTER

or press Return. The message

on the display now prompts you to touch on to the rear face of the workpiece with the

selected tool.

Using the axis control buttons, follow the instructions to establish the Y datum in the

same way as for the X datum.

Page 31

Boxford 190 VMC Axes and Tooling

3.6

21. When the tool is in the correct position, select

shows:

Click on

The screen returns to the main menu.

YES

or press Return to save the offsets.

ENTER

or press Return. The screen

3.6 DATUM SHIFT

Datum Shift is a new feature which allows the user to input a temporary shift of the

Datum Position for individual components which cannot be located to the standard

datum position.

To activate this facility, CONFIG followed by Hardware is selected. The Datum

Shift option is highlighted and ALTER followed by ON selected

To define default values, Machine followed by Datum Position is selected.

The window below is shown.

The default X and Y Datum Shift values are entered (the distance from the standard

datum position to the temporary datum position). These can be left at 0.00 and defined

when individual components are manufactured.

Page 32

4 Main Front End Menu

When the Boxford CADCAM package is started, the Main Front End Menu screen

below is shown.

This menu is the central manager of the CADCAM tools within the Boxford VMC

package.

G&M Program Import &

Administration Functions

Program Simulate, Manufacture

and Machine Tool Driver

CAD and CAM Processor Exit to Windows Desktop

Page 33

Boxford 190 VMC

4.1 Main Front End Menu

In Standard User mode this menu accesses the G&M code program import filter. (See

section 7.2)

In Administration mode (See section 8) additional CAM processor data settings can be

accessed and modified.

Accesses the Integrated Computer Aided Design package (See section 5) and CAM

processor (See section 6)

Also used to access CAD package to import drawing files (See section 7).

Accesses the G&M program Simulator, Editor, Writer and Machine Tool driver. All

the configurations for connecting the VMC machine to the PC are set in this section

of the package (See separate Installation & User Manual together with this manual).

Exits to the Windows desktop.

Page 34

Boxford 190 VMC CAD

5 CAD

5.1 CAD Window The CAD program window provides a clear view of the current drawing, various

information areas, and a selection of icons with tools to cover the most common

drawing, editing and display functions.

Allows the setting of

line type, thickness

and colour

Simple prompts tell

you what to do next

Toolbar help explains

each icon

Pull out sub-menu.

Select a toolbox icon

to reveal the menu

Relocatable draw/edit

toolbox allows easy

access to all the main

draw/edit functions

Absolute coordinates shows the position of

the cursor relative to the workpiece datum

(the bottom left hand corner)

Coordinate data entry

box allows accurate

positioning and

drawing at any time

Relocatable drawing

aids toolbox has a

range of commonly

used functions

Workpiece area

Shows the angle from

the last point located

or drawn

Help message bar

Shows the distance from the

last point located or drawn

Menu Selection Menu items are normally chosen from the menu bar or the toolbox, using the mouse

(although keyboard alternatives are available). To choose a menu item from the

toolbox, position the pointer over the appropriate icon and click the LH mouse button.

Some items such as Grid, will cause the icon to stay depressed until it is chosen again.

Many of the items in the LH toolbox have pull out toolbars.

Page 35

Boxford 190 VMC CAD

These are activated by positioning the pointer on the icon then clicking the LH mouse

button. The required icon can be selected from the icon menu bar. This will select

the item, and change the icon in the toolbar to that chosen. Most menu items, e.g., text,

colour fill, etc., have a related dialogue box for settings. To access these dialogue boxes,

double click on the appropriate icon with the LH mouse button, or click on the icon

with the RH mouse button.

Initial Set-up Before starting to use the CAD system, a number of Initial Set-up steps must be

completed. Select the Set-up menu and complete the following:-

1. UNITS - Specify Millimetres or Inches. More advanced settings for Angle units and

co-ordinate display are also available.

2. WORKPIECE - Specify the X (length) and Y (width) dimensions.

3. GRID and STEP - Specify the X and Y spacing for the Grid and Steps. (The Grid

is visible and the Steps are graduations between the Grid points).

5.1

4. SET AS DEFAULT - If you want the CAD system to default to settings 1, 2 and 3

each time you start a new workpiece, then select this option.

Page 36

Boxford 190 VMC CAD

5.2

5.2 Drawing Aids

Drawing Aids The right hand toolbox contains a number of drawing aids which are active when

selected (icon is dark grey).

Grid Display - Toggles the grid display on and off.

Redraw - Refreshes the screen.

Grid Lock - Locks the cursor movement to the grid spacing.

Step Lock - Locks the cursor movement to the step spacing.

Attach - Attaches the cursor to various points. Set-up can be accessed by Right clicking

on the Attach icon.:-

Radial Lock - Constrains cursor movement to pre-defined angle increments. Set-up can

be accessed by Right clicking on the icon.

Zoom In - Performs a quick and simple zoom in facility on the workpiece area currently

in the centre of the screen.

Zoom Out - Performs a quick and simple zoom out facility on the workpiece area

currently in the centre of the screen.

Undo/Redo Last -Toggles between undo and redo of the last function

Advanced Zooms These functions are available from the Left Hand Toolbox.

Zoom In - Zooms in on a user defined window.

Zoom Last - Reverts to the last specified zoom.

Zoom Sheet - Displays the complete workpiece at maximum zoom.

Zoom All - Displays all drawn entities at maximum zoom.

Zoom = - Zooms in by a user defined magnification factor

Page 37

Boxford 190 VMC CAD

5.3

5.3 Drawing Tools

Drawing Tools The left hand toolbox contains a variety of drawing tools and are grouped by the type

of entity they are used to define. To view the options within each group, LH Click on

an icon to display the full selection of group icons.

Co-ordinate Entry With all drawing tools that require points to be specified, these can either be defined

with the mouse (using the grid) or by co-ordinate entry.

To enter a co-ordinate, type the values in the co-ordinate data entry field (see section

5.1). These values can be Absolute (distance from the bottom left hand corner of the

workpiece) or Incremental/Relative (distance from the last point). To toggle between

Absolute and Incremental/Relative Modes, Select the Abs or Rel icon to the left of

the data entry field.

Help and Prompts Prompts and help for each icon are displayed on the toolbars to aid the user.

Straight Lines

Single Line - Defines a single straight line - The Start and End point are specified.

Circles

Connected Lines - Draws a series of connected lines - The initial Start Point and then the

subsequent End Points are defined. To finish, either double click the LH mouse button

(this will fix the moving line), or click the RH mouse button (this will finish at the last

fixed point).

Chamfer - Draws a chamfer between two lines - The chamfer X and Y dimensions are

entered and the two lines to be chamfered selected. To define a number of different

sized chamfers, RH click on the Icon to access the dimensions.

Circle - Draws a circle with a given Centre and Point - The circle centre and a point on

the circumference are specified (Note:- the Distance readout is equivalent to the circle

radius).

Circle - Draws a circle with a given Centre and Radius - The circle Radius is entered and

the centre specified. To define a number of different sized circles, RH click the Icon

to access the radius value.

Page 38

Boxford 190 VMC CAD

Circle - Draws a circle through 2 points - The two points on the circle circumference

and the centre point are specified. (Note:- the Distance readout is equivalent to the

circle radius).

Circle - Draws a circle through 2 points with given radius - The radius is entered, the

2 points on the circle circumference and the centre point position specified.

To define a number of different sized circles, RH click the Icon to access the radius

value.

Note :- If two points are specified through which it is impossible for a circle of the

specified radius to pass, the error message NOT POSSIBLE is displayed.

Circle - Draws a circle through 3 points - The 3 points on the circle circumference are

specified.

Arcs

Arc - Draws an arc with a given Centre, Start and End points - The centre, start and

end points are specified. (Note:- the Distance readout is equivalent to the arc radius).

5.3

Arc - Draws an arc through 2 points - 2 points on the arc and the centre point are

specified. (Note:- the Distance readout is equivalent to the arc radius).

Arc - Draws an arc through 2 points with a given radius - The radius is entered, Minor

or Major arc type selected and 2 points on the arc specified.

To define a number of different sized arcs, RH click the Icon to access the Radius and

Major/Minorvalues.

Note :- If two points are specified through which it is impossible for an arc of the

specified radius to pass, the error message NOT POSSIBLE is displayed.

Arc - Draws and arc through 3 points. - The 3 points on the arc are specified.

Page 39

Boxford 190 VMC CAD

Fillet - Draws a fillet between two lines - The radius dimension is entered and the two

lines to be chamfered selected. To define a number of different sized fillets, RH click

on the Icon to access the radius value.

Ellipse

Ellipse - Draws an ellipse - The centre and corner of the box surrounding the box is

specified (see diagram below).

Theoretical box Corner

surrounding ellipse

Centre

+

5.3

Shapes

Rectangle - Draws a horizontal rectangle - Opposite corners of the rectangle are

specified.

Rectangle - Draws a rectangle at any angle - Two points define the first side of the

rectangle (and its angle). The third point determines the length or width of the

rectangle.

Triangle - Draws a triangle at any angle - The 3 points of the triangle are defined.

Parallelogram - Draws a parallelogram at any angle - Two point define the first side of

the parallelogram (and its angle). The third point determines the angle and length of

the opposite sides.

Page 40

Boxford 190 VMC CAD

5.3

Polygon - Draws a regular polygon with a given centre and vertex - The number of sides

is entered via the dialogue box below. The start angle can be entered at this point or

defined later. Clockwise or Anti-clockwise orientation of the angle can be specified.

The side length or Internal Radius or External Radius can also be specified

Internal Radius

Side

Length

OK

is selected and the centre point specified. If necessary, the external radius is

+

External

Radius

Start

Angle

set by specifying a second point.

Polygon - Draws a regular polygon with a given internal radius and centre. The Start

Angle can be entered at this point or defined later. Clockwise or Anticlockwise

orientation of the angle can be specified. The Internal Radius is specified.

is selected and the centre point specified.

OK

Page 41

Boxford 190 VMC CAD

Beziers

Open Bezier - Draws an open ended bezier curve - The initial Start Point and then the

subsequent End Points are defined. To finish, either double click the LH mouse button

(this will fix the moving bezier), or click the RH mouse button (this will finish at the

last fixed point).

Closed Bezier - Draws a closed bezier curve - The initial Start Point and then the

subsequent End Points are defined. To finish, and close the path either double click

the LH mouse button, or click the RH mouse button.

Open Polyline - Draws an open polyline (series of connected straight lines). The initial

Start Point and then the subsequent End Points are defined. To finish, either double

click the LH mouse button, or click the RH mouse button.

Note :- An Open Polyline differs from a series of connected straight lines because

when complete the lines are part of a single object).

Closed Polyline - Draws a closed polyline (series of connected straight lines. To finish,

and close the path either double click the LH mouse button, or click the RH mouse

button.

5.3

Text Strings

Text - Defines Linear Text strings - The start point is located bringing up the

dialogue box shown below.

At the prompt the required text is typed and selected.

Settings

Page 42

Boxford 190 VMC CAD

5.3

The dialogue box below is shown.

Font

The font type can be selected from the list of all the True Type fonts available on the

system. Font styles can also be selected.

Size

The font height can be selected (this is very easy to manipulate later - see Editing

Objects in section 5.4 for further details).

Alignment

The alignment from the previously defined start position can be set to Left, Right or

Cantered.

Attributes

The Line Type, Line Colour, Fill Type and Fill Colour can all be set. The default setting

is filled text with a thin outline. The relevance of these settings with regard to

machining is covered in section 5.6 (CAD Machining Considerations).

Once all the settings are correct, select The previous input box is displayed.

Select The text object appears on the workpiece.

OK

OK

Page 43

Boxford 190 VMC CAD

5.4

5.4 Editing Objects

Selecting Objects

Select - Objects can be selected by :-

1. Dragging a box around the objects to be selected.

2. Selecting Individual Objects with the LH mouse button and subsequent objects

(if required) with the RH mouse button (or SHIFT + LH button).

Once an object or group of objects are selected, the selected objects are drawn in pink

and surrounded by a dotted box (a marquee box) with handles. This is shown below.

These handles provide quick edit functions. For more advanced features, see

Transformations described later in this section.

Re-Size Re-Size Re-Size

Mirror Horizontally

Re-Position

(move)

Re-Size

Mirror

Vertically

Re-Size

Copy

Re-Size Re-Size Re-Size

Rotate

Re-Sizing

LH mouse clicking any square handle around the outside of the marquee box allows

the current selection to be re-sized. Clicking again redraws the selection to the new

specification.

Warning:- moving these handles alters the aspect ratio of the current selection. To re-

size whilst maintaining aspect ratio, select the square handles with the RH mouse

button.

Page 44

Boxford 190 VMC CAD

Re-Positioning (Moving) LH clicking on the central square handle allows the current selection to be moved.

Clicking again redraws the selection in the new position.

Mirroring The diamond (rhombic) handles, to the top and left, mirror the current selection

horizontally and vertically respectively.

Rotating The circular handle to the right allows the current selection to be rotated.

Copying The double square handle at the bottom performs a quick copy and paste of the current

selection, leaving the new object selected.

Editing Objects

When a selection is made, a toolbox appears in the right hand corner of the CAD

window. Selecting Start Edit greys the selection and provides a number of coloured

edit handles as shown below.

5.4

Page 45

Boxford 190 VMC CAD

The convention of these handle colours depends on the object selected and are

generally as follows.

Line Green = Start Node, Red = End Node - Each can be re-positioned.

Circles Red = Node on Circumference, Yellow = Centre Node - Each can be repositioned.

Arcs Green = Start Node, Red = End Node, Yellow = Centre Node - Each can be re-

positioned.

5.4

Closed Polylines

(including Shapes)

Open Polylines Green = Start Node, Red = End Node, Orange = Intermediate Nodes - Each can be

Closed Bezier Curves Red = Start and Finish Node, Orange = Intermediate Nodes, Yellow = Node Handles

Open Bezier Curves Green = Start Node, Red = End Node, Orange = Intermediate Nodes, Yellow = Node

Text Yellow = Bottom left hand corner of imaginary rectangular box enclosing each

Red = Start and Finish Node, Orange = Intermediate Nodes - Each can be re-

positioned.

re-positioned.

- Each can be re-positioned individually. Additionally, moving the yellow node handles

with the RH mouse button locks the angle between them allowing them to move

together

Handles - Movement as per Closed Beziers.

individual character. - Each character can be re-positioned.

Page 46

Boxford 190 VMC CAD

Transforming Objects Selected objects can be transformed using a variety of tools :-

Move/Copy - Moves, and/or copies the current selection. The user can opt to replace

the current selection or create a user-defined number of repeats. A reference point

(usually on the selected object) is located and then a new position for the reference

point. An example of a repeat Move/Copy is shown below.

5.4

Mirror - Mirrors the current selection. The user can opt to replace the current selection

or repeat it. Two defined points define the axis of reflection. An example of a repeat

Mirror is shown below.

Rotate - Rotates the current selection. The user defines the angle of rotation and can

opt to replace the current selection or create a user-defined number of repeats.

An example of repeat Rotate is shown below.

Page 47

Boxford 190 VMC CAD

Rectangular Array - Produces a grid of selected object copies. The number of columns

and rows and the X and Y spacing between them are specified. An example is shown

below.

Circular Array - Produces rotated copies of selected objects. The angle of rotation and

number of repeats are specified. The centre of rotation is defined. An example is

shown below.

5.4

Distort - Distorts the currently selected objects. The user can opt to replace the current

selection or create a user-defined number of repeats. The selected objects are

surrounded by a greyed outline with 4 handles. Re-positioning the handles and clicking

away from the selection will produce a distorted object which best fits the new handle

positions. An example of a replaced distort is shown below.

Page 48

Boxford 190 VMC CAD

Deleting Objects There are a number of ways to delete objects using either icons from the toolboxes or

Hot Key combinations.

Delete Last - Deletes objects one at a time in the order they were drawn (most recent

first).

Delete Any - Deletes individual entities - A hand pointer is provided to select the

individual objects to be deleted.

Delete Inside Box - Deletes entities within a user defined box (by dragging).

Delete Part of Entity Between two nearest intersections - Automatically trims a line back to the

nearest intersection. A hand pointer is provided to select the part of the entity to be

deleted. An example of tool use is shown below.

Before After

5.4

Useful Delete Hot Keys

Ctrl + Del - Deletes the current selection.

Ctrl + Backspace - Deletes the last drawn entities.

Alt + Del - Deletes all drawing entities.

Page 49

Boxford 190 VMC CAD

5.4

Setting/Editing

Object Attributes

Line Thickness From the top of the CAD window select

The attribute of an object (entity) defines the way it is machined. For details see section

5.6 (Machining Considerations).

Object attributes can be set before they are drawn, or the current selection can be edited

in the following way:-

The dialogue box below is shown.

The user can define:-

Line Type - continuous, dotted, dashes etc.

Line Pitch - the pitch of dotted and dashed lines

Width - Either Fine or Thick (with a user defined thickness).

Page 50

Boxford 190 VMC CAD

Line Colour From the top of the CAD window select

The dialogue box below is shown.

5.4

Text

Warning - Choose only colours from the custom Pallet (the reason for this is explained

in Section 5.6)

is selected.

OK

When a Text selection is made, a toolbox appears in the right hand corner of the CAD

window. Selecting Property brings up the text input box. The Text string, Font,

Effects, Line and Fill properties can all de redefined. See Text Strings in section 5.3 for

more details.

Page 51

Boxford 190 VMC CAD

5.5

5.5 Area Filling

Area Filling One of the most important Tools to understand is colour filling as this largely dictates

what is actually machined (see Section 5.6 for more details on machining considerations).

Area - Fills areas between closed boundaries, accounting for islands.

On selecting the area tool, the following dialogue box is shown.

is selected bringing up the colour selection dialogue box.

Warning:- As with line colour settings, choose only colours from the custom Pallet (the reason

for this is explained in Section 5.6).

is selected.

OK

The user is prompted to:-

1. Locate on edge of boundary on side for hatch - This is the outer boundary of the fill.

In the example shown below, if the area between the 2 circles is to be filled, the larger

circle is the outer boundary. The boundary is located with the hand pointer.

Outer Boundary

Island

Page 52

Boxford 190 VMC CAD

5.5

2. The user is asked if there are any islands within the outer boundary.

Looking at the example on the previous page, the smaller circle is an island within the

larger circle.

is selected and the Island located with the Hand Pointer.

YES

The window above is shown again allowing further islands to be defined. In this

example there are no more. is selected.

NO

The area is filled.

Outer Boundary

Filled Area

Island

Note:- If a number of filled areas are to be defined, the colour can be redefined by RH

clicking the fill icon.

Page 53

Boxford 190 VMC CAD

5.5

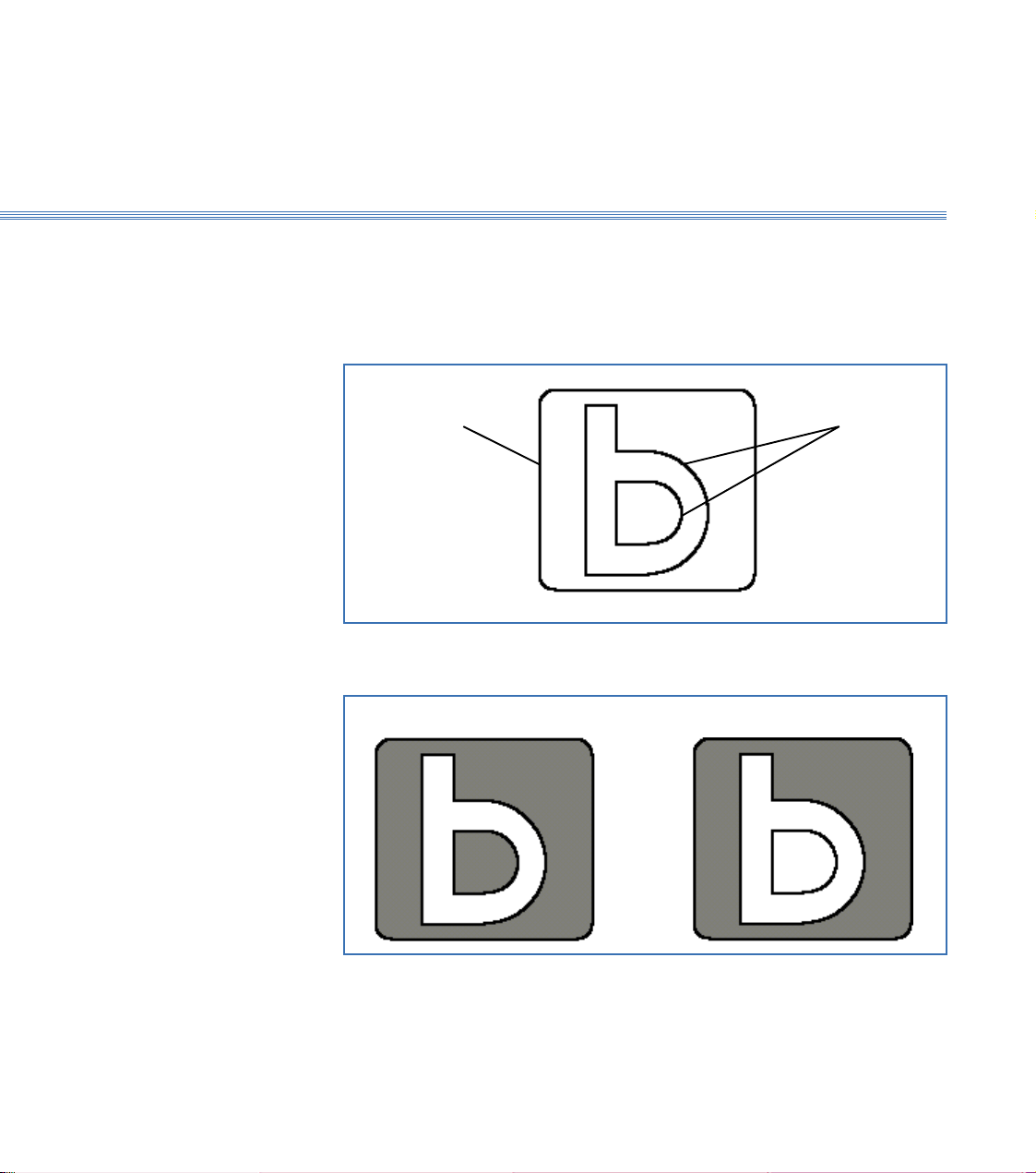

Text Strings Text strings can be filled by setting the fill attribute when the string is initially defined

(see 5.3), or by selecting Property (see 5.4) when the string is selected.

Text strings can also be islands within a closed outer boundary. In this case, some

characters constitute more than one island as shown below.

Outer

Boundary Islands

If the 2nd Island was not specified, the fill would be as diagram b below instead of the

required fill shown in diagram a.

a. Correct b.Incorrect

Page 54

Boxford 190 VMC CAD

5.6

5.6 Machining Considerations

Machining Considerations Sections 5.1 - 5.5 have concentrated on the drawing tools within the CAD system.

Some important machining considerations relating to the drawing will now be

discussed.

Colours Sixteen custom colours are available in the colour palette dialogue box. When the

drawing is Post Processed into a G&M code CNC programme, each colour can be

assigned a different depth.

At the Design Stage, all the user must consider is that any objects required to

be cut to a different depth, MUST be assigned a different colour (up to a

maximum of 16 colours).

Machined Objects Objects that are machined are :-

1. Lines with a width setting (not thin lines)

2. Filled Areas

Lines Any line with a width setting (other than thin) will be followed with a Slot Drill of the

equivalent diameter or the nearest one available from the Machine Tool Library (See

section 8 for more details).

Filled Areas Any areas filled with colour can be:-

a. Pocketed out with a variety of tools - (cutter diameter compensation is

automatically implemented)

b. Profiled - around the outside (e.g. for cutting out a shape).

c. Profiled - around the inside (e.g. for leaving a cut-out of the shape in a sheet

of material).

Additionally filled circles can be:-

a. Pocketed out with a variety of tools - or

b. Drilled with a drilling cycle using a drill of the equivalent diameter or

the nearest one available from the Machine Tool Library (See section 8).

Page 55

Boxford 190 VMC CAD

Problem Objects With the large variety of drawing tools available, it is important to understand:-

a: What can and what can not be machined.

b: What will be machined.

What cant be machined 1. Lines with a width narrower than the smallest diameter Slot Drill will

not be machined.

2. Filled Circles with a diameter smaller than the smallest diameter Drill

Filled areas which have sections narrower than the Edging Tool (see

section 8 for details of edging tool). This often happens when the pocket

is the internal fill of some fonts as shown below. The circles within the

text represent where the cutter diameter can machine up to.

Notice the difference between what was drawn and what will be machined.

Drawn Text Machined Text

5.6

Warning :- If you draw text too small none of it may be machined. Please

remember you are cutting resistant materials and not merely dropping ink onto

paper.

Page 56

Boxford 190 VMC CAD

5.6

What will be machined As described in the previous section, the system will attempt to machine EVERY Line

with a width setting and Filled Area.

For this reason it is important that Islands are correctly defined. If a filled object (1)

is on top of another filled object (2). object (2) will still be machined even though it

cannot be seen on the screen.

In the example below object (1) has been drawn on top of the solid filled (no Islands)

object (2). If object (1) is to be machined to a depth less than object (2) then it will be

machined away when object (2) is machined.

Overlaid Objects Objects When Seperated

11

22

Machining Order The objects will be machined on an individual basis working from the back of the

drawing (i.e. the back object is machined first and the front object last).

This can be useful if for instance an object is to be profiled (cut out) as the last operation.

Page 57

Boxford 190 VMC 6.1 CAM Processor

6 CAM Processor

6.1 Settings

When the CAD drawing is complete and ready to be processed into a G&M code

CNC programme, select

The user is required to enter a filename for the drawing (Please ensure this is no

longer than 8 characters).

The CAM Processor Dialogue box shown below is displayed.

File To Mill

Material

The various settings are as follows:-

Selecting the drop down provides a list of the available material types. (See Section

8 - Administrator Mode for details on adding user defined materials and cut data.).

The required material is selected from the list

Page 58

Boxford 190 VMC 6.1 CAM Processor

Edging Tool and Area Tool The drop down for these two tools is a list of the slot drills available in the

Machine Tool Library.

The Edging and Area tool are used to remove (pocket) all Colour Filled areas in

the drawing. There function is as follows.

Edging Tool - This tool performs the finish path around the pocket as shown

with the circular object below

The edging tool is also used to profile around a colour which has been set to

Outside or Inside (see DEPTHS later in this section).

Area Tool - This (usually larger) tool is used to remove the bulk of material from

filled areas as shown with the circular pocket below.

Page 59

Boxford 190 VMC 6.1 CAM Processor

Warning To ensure filled areas are correctly removed, it is strongly recommended

that the ratio between the Edging Tool and The Area tool is 1:2 (e.g. 2mm

Edging Tool & 4mm Area Tool).

It is permissible to set the Area and Edging Tools to be the same diameter to avoid

tool changes during manufacture. Experienced users can experiment with different

combinations for different drawing applications.

Edging & Area Finish Determines the Surface finish produced by the

Edging and Area Tools. Smooth or Coarse is

selected.

Block Size The X (Length) and Y (Width) dimensions are transferred from the drawing. The

user must specify the Z (height or thickness) dimension.

Depths The Colour Depth and Filled area settings are accessed by selecting

The dialogue box below is shown.

Page 60

Boxford 190 VMC 6.1 CAM Processor

For each colour used in the drawing (the others are ignored), the total required

depth is entered. This can include decimal values (2 Decimal places in Metric and

3 Decimal places in imperial). There are 16 colours available which match the 16

custom colours in the CAD colour palette. Hence 16 different depths can be

defined.

Warning If the user defines a depth which can not be achieved by the current tools in the

machine library, the user will be warned upon processing the drawing (see section

6.2 - Error Messages).

To the left of each colour is a drop down menu. These settings affect ONLY

COLOUR FILLED AREAS and not lines with a defined width.

AREA Pockets out all areas with this colour fill with the Area and Edging tools as

described earlier in this section (Edging Tool and Area Tool).

DRILL Uses a drilling cycle to drill circles with a drill of equivalent diameter or the nearest

one (always smaller) available from the machine tool library.

The system will first look for a twist drill of appropriate diameter. If one is not

available, it will look for a spot drill and then a slot drill.

Warning Only colours made up entirely of individually filled circles should be assigned as a

DRILL colour.

Page 61

Boxford 190 VMC 6.1 CAM Processor

INSIDE Profiles around the inside of colour filled pockets using the Edging Tool.

Compensation for the diameter is automatically implemented. This can be

particularly useful when cutting profiles out of thin sheet material.

An example is shown below.

OUTSIDE Profiles around the outside of colour filled pockets using the Edging Tool.

Compensation for the diameter is automatically implemented.

An example is shown below.

When all the Colour Depths and Area Setting are complete, is selected.

OK

Page 62

Boxford 190 VMC 6.1 CAM Processor

Processing To process the Drawing and create a G&M CNC programme, is

selected. The message below is displayed

Selecting saves the CAM processor settings with the drawing.

YES

The processor analyses the Drawing and produces a G&M code CNC programme specifying

Cutter Paths, Speeds, Feeds and Cut Depths appropriate to the material type selected and the

tooling available.

The following message is displayed.

Factors Affecting Processing There are a number of factors which will affect the processing time.

1. Pocketing out complicated areas (particularly text strings) will increase

processing time.

2. Processing lines with a defined Width will be relatively quick.

3. The higher specification the PC Computers Main Processor the quicker

processing will be.

4. If the user has accidentally specified an unusually deep pocket, processing

time will be significantly increased. If you suspect a mistake, press the ESC

key on the keyboard to abort processing.

Page 63

Boxford 190 VMC 6.1 CAM Processor

Tool Path Simulation When the drawing has been processed the following dialogue box will be displayed

(Please note if processing reveals any errors this dialogue box will be proceeded by

an error message dialogue box - see section 6.2 for details).

The user is prompted to select a Catalogue number to place the file into.

Catalogues - All manufacture programs (G&M

programs) are filed in Catalogues. There are 9

catalogues available to the user.

A catalogue is selected. If a file of the same

2

1

9

8

7

6

5

4

3

name already exists in the selected catalogue,

the following dialogue box appears.

The file can be overwritten by selecting or can be selected bringing up

YES

NO

the following dialogue box.

The filename can be changed and/or the catalogue changed. is selected.

OK

Page 64

Boxford 190 VMC 6.1 CAM Processor

A 2 Dimensional simulation of the cutter path is shown. This is the final user

check of the component that will Actually Be Machined. Any areas which can

not be removed because of tooling limitations will be omitted. (see section 5.6 for

more details)

Warning :- Please check this 2 Dimensional View very carefully.

3 Dimensional View For details on 3D Views, View Manipulation and Cycle Details see sections 2 and

10.

Page 65

Boxford 190 VMC 6.1 CAM Processor

2

6.2 CAM Processor Error Messages

When Processing a drawing, the CAM processor compares the drawing

requirements with the Cutting Tools available. If any drawing requirements can

not be satisfied, then an error message (or messages) is displayed.

An example is shown below.

The user can continue processing by selecting

A program with the compromised settings (safe) is produced.

or

The user can abort processing by selecting and reprocess the drawing

using different settings.

Error Messages There are a number of error messages which can be reported. Their description

and causes are as follows:-

Cut Depth - The Cut Depth (Total - not cut per pass) will never exceed the Tool

Length value defined in the tool library (see Section 8 for more details)

e.g. 2.0mm slot drill is unable to cut deeper than 10.000mm

Cutter Diameter - If a Tool from the Tool Library cannot match a line with

defined width, or a drilled hole with defined diameter, the processor will choose

the nearest smaller diameter tool.

e.g. 8.0mm drill was not found, using 6.0mm instead

If a line width or hole diameter less than the smallest tool are specified, the objects

will not be machined.

e.g. could not find a drill 1.5mm or less

Page 66

Boxford 190 VMC 7.1 File Imports

7 File Imports

7.1 Drawing File Import

File Types The following drawing file types can be imported.

1 Design Tools Files (*.dtd)

2 Acorn Draw Files (*.aff)

3 Designer V3 COMMS Files (*.dv3)

4 DXF Files (*.dxf)

5 Enhanced Metafiles (*.emf)

6 Windows Metafiles (*.wmf)

File Export Rules Which ever drawing package you export from, there are some guidelines which will

help you to successfully export files suitable for importing into the Boxford

CADCAM package.

Drawing Size - Set the drawing size (or custom paper size) to the Workpiece size

you intend to use.

Drawing Origin - Set the drawing Origin to be the Bottom Left corner of the

Drawing (paper) area.

Length

Width

Line Width - Unless you can accurately set line widths to a specified value, do not

export lines with a width. Line width attributes can be set in the Boxford

CADCAM package after importing.

Filled Areas - DO NOT export any colour filled areas. Colour filled areas are

assigned in the Boxford CADCAM package after importing.

Dimension Lines - DO NOT export any Dimension Lines.

Drawing Area

(Paper Size)

Drawing Origin

Page 67

Boxford 190 VMC 7.1 File Imports

Importing Drawing Files The CAD Icon is selected from the Boxford CADCAM package.

CAD Icon

Workpiece Size - The workpiece size is set-up to suit the file intended for import.

(this should be equivalent to the Drawing Area/Paper Size used to create the

original file).

File

Import File

is selected bringing up the dialogue box shown below. The file

type is selected from the drop down menu.

Page 68

Boxford 190 VMC 7.1 File Imports

The file to be imported is located and selected

Open

Import Filters The various import filters have differing import options, described as follows:

1 Design Tools Files (*.dtd)

Opens a Techsoft 2D Design Tools File.

3 Designer V3 COMMS Files (*.dv3)

Opens the file automatically (no user settings are required).

2 Acorn Draw Files (*.aff)

5 Enhanced Metafiles (*.emf)

6 Windows Metafiles (*.wmf)

On opening any of these file types, the following dialogue box appears.

The options are:-

Centre In Window - Centres the imported drawing entities in the centre of the

workpiece. Not selecting this option will maintain the relationship between the

drawn entities and the origin.

In Window

= =Centre

=

=

Imported Entities Workpiece

Page 69

Boxford 190 VMC 7.1 File Imports

Group - Loads the imported entities as a single grouped object.

Scale - Scales the imported entities by a user defined value.

4 DXF Files (*.dxf)

On opening a DXF file the following dialogue box appears.

The options are:-

Interpret Units and Position - Allows the import units to be specified and

maintains the relationship between the drawn entities and the origin.

The Units Interpretation and Position options are:-

Inch or mm - set to suit the file to be imported

Centre in Window - Centres the imported drawing entities in the centre of the

workpiece (see previous page for details)

Scale - Scales the imported entities by a user defined value.

Page 70

Boxford 190 VMC 7.1 File Imports

Fit to Media - Scales the imported entities to fit the workpiece whilst maintaining

the aspect ratio.

The scaling factor is limited by the first axis the entities fill (X or Y).

In the example below, the scaling is limited by the workpiece width (Y axis) and

the entities centred along the length (X axis).

Fit To

Media

= =

Width (Y)

Imported Entities Workpiece

Length (X)

Load as Group - Loads the imported entities as a single grouped object

Dimensioning preference - Ignore these options - DO NOT attempt to

import dimensions.

Processing Imported Files Once imported, individual entity attributes and colour filled areas can be specified

as described in Section 5.

The drawing is processed as normal, see Section 6 for details.

Page 71

Boxford 190 VMC 7.1 File Imports

2

7.2 G&M Code Programme Impor t

The following procedure imports a G&M code program produced on a Third

Party CADCAM package.

From the main front end menu is selected followed by

From the File Open dialogue box, the file to be opened is selected.

The dialogue box below is shown.

The user is prompted to select a Catalogue number to place the file into.

All manufacture programs (G&M programs) are filed in Catalogues. There are 9

catalogues available to the user.

A catalogue is selected. If a file of the same name already exists in the selected

catalogue, the following dialogue box appears.

The file can be overwritten by selecting or can be selected bringing up

the following dialogue box.

The filename can be changed and/or the catalogue changed. is selected.

YES

NO

OK

Page 72

Boxford 190 VMC 7.1 File Imports

A 2 Dimensional simulation of the cutter path is shown.

This simulation does not have to be completed. Pressing the ESC key will stop

the simulation and write the file to disc ready for manufacturing.

Manufacture For details on Manufacturing see section 11.

File Import Specification The required Import file specification is as per the following example.

2

G71

G101 X125.000 Y75.000 Z10.000

G00 X0.000 Y0.000 Z20.000

M05

M06 I2 J4

M03 S3000

G00 X61.875 Y38.403 Z2.000

G01 Z-1.000 F600.000

...

G01 X56.422 F600.000

G00 Z2.000

G00 Z20.000

G00 X0.000 Y0.000

M05

M06 I2 J2

M03 S3000

G00 X56.422 Y37.602 Z2.000

G00 X62.909 Y38.194

G01 Z-1.000 F600.000

...

G01 X62.909 Y38.194 F600.000

G00 Z2.000

G00 Z20.000

G00 X0.000 Y0.000

M05

M30

Units

Workpiece Size

X, Y, Z Park Position

Spindle Stop

I=Tool Dia. J=Type

Start Spindle S=RPM

Body of Program

G00 and G01 Moves

F=Feedrate

Tool Change

Body of Program

G00 and G01 Moves

F=Feedrate

Cycle End-make another

Further Details For specific post processor specifications please contact Boxford direct.

Page 73

Boxford 190 VMC Administration Mode

8 Administration Mode

8.1 Access & Password Setting

An administration mode is built into the Boxford CADCAM package allowing

authorised personnel to access and modify important CAM processor data files and

machine tool data files.

Any modifications that are defined will be applied to every future processed drawing.

Network Administrators To be able to use the Boxford administration mode and write to the relevant data

files, you must have read/write access to the Public Drive

Setting a Password With the Front End menu screen displayed, the F10 key is pressed, to define a

password, or modify and existing one. The dialogue box below is shown.

is selected.

The dialogue box below is shown.

The user is prompted to Enter CURRENT Password.

If an initial password is to be defined, is selected.

If an existing password is to be re-defined, the existing password is input and

selected.

OK

OK

Page 74

Boxford 190 VMC Administration Mode

8.1

The dialogue box below is shown.

The user is prompted to Enter NEW Password

The new Password is input selected followed by :-

OK

Accessing Admin. Mode Each time the software is started, the system defaults to Standard User mode. With

the Front End menu screen displayed, Administration mode is accessed by:-

a. Pressing the F10 key

b. Selecting

c. Inputting the current password and selecting

OK

d. Selecting

Selecting the Configuration Icon reveals a number of icons in addition to the

Standard User Import G&M file option (see section 7.2 for details).

Page 75

Boxford 190 VMC Administration Mode

8.2

8.2 Tool Library

Accesses the tool library shown below.

New tools can be defined and existing Tools modified or removed.

Defining a New Tool Using the LH mouse button or keyboard cursor, Highlight an empty tool library

line.

Select The dialogue below is shown.

Edit Tool

From the Tool Type drop down, select the Tool type

to be defined.

Input the Tool Diameter and Length.

The length is the maximum depth the Tool can cut

to, and is usually the flute length as shown in the

diagram opposite.

Edit an existing Tool Highlight the tool to be edited and Select

Remove an existing Tool Highlight the tool and select

Remove

Saving To close and save the tool library data, select

Flute

Length

Edit Tool

Finish

Page 76

Boxford 190 VMC Administration Mode

8.3

8.3 Material Cutting Data

Accesses the Material Cutting Data shown below.

This data is used by the CAM processor when creating a G&M code CNC

programme from a drawing.

For each Material Type, Cutting data can be specified for differing Tool types and

Tool Size ranges. New materials can be added and existing ones Modified or

Deleted.

Tool Type Slot Drill, Spot Drill and Drill can be selected (Note:- these are the only tools used

by the CAM processor).

Tool Size The Tool sizes are grouped in a range of diameters. Cutting parameters can be set

for each range.

Page 77

Boxford 190 VMC Administration Mode

8.3

Material The Cutting Data file supplied with the software package includes a selection of

Default material types. User-defined materials can be added up to a maximum of

six material types in total.

Adding a New Material

Add Material

is selected. The dialogue box below is shown.

The user is prompted to Enter material to add to list.

The material name is input and selected.

OK

Deleting an Existing Material

The material to be deleted is selected using the Material drop down menu.

Delete Material

is selected. The dialogue box below is shown.

YES

is selected to confirm the material delete.

Feedrate The rate at which the axes move in mm/min.

Speed The spindle speed in Revolution Per Minute (RPM)

Page 78

Boxford 190 VMC Administration Mode

8.3

Cut Depth/Pass The depth of cut per pass of a pocket, slot or hole.

Note:- this is not to be mistaken for the maximum achievable depth which is

limited by the tool length (see Section 8.2).

Process The surface finish settings. Two options are available - Smooth and Coarse.

Flatness

For each surface finish setting, a flatness value in microns can be set. The flatness

value determines the finish around curved paths.

As the flatness value increases curves (arcs) will visibly comprise of a number of

straight lines as shown in the diagram below.

Smooth Coarse

Drawn Curve

Machined Curve

Note:

The Default values have been carefully chosen and should only be changed by

experienced users.

Restoring Defaults is selected to return All Cutting Data to the Factory settings

Saving To save the modified Cutting Data, select

Restore Defaults

To exit without saving changes, select

OK

Cancel

Page 79

Boxford 190 VMC Administration Mode

8.4

8.4 Park Position and Units

Park Position Accesses the park position settings shown below.

The Park Position is the position of the Tool in relation to the workpiece datum

(front left corner) at Tool Changes and the Start/End of Cycle.

X, Y and Z values are specified.

Restoring Defaults

is selected to restore the Factory settings.

Restore Defaults

Saving

To save the modified Cutting Data, select

To exit without saving changes, select

OK

Cancel

Units Accesses the units settings for Administration mode as shown below.

Metric or Imperial units are selected. saves the setting.

OK

Page 80

Boxford 190 VMC Administration Mode

8.5

8.5 CAM Processor Default Settings

CAM Default Settings Accesses the CAM Processor settings shown below.

These default settings are used with every NEW CAD Drawing created.

The various parameters are set as described in section 6 of this manual.

Selecting saves the default CAM settings.

Page 81

Boxford 190 VMC Administration Mode

8.6

8.6 Language Settings

Language Settings Accesses the Language options for the software.

Note:- This sets the language for the CAD and CAM software but not

for the G&M Code CNC Programme Simulator and machine driver

which has its own configuration menu. See Installation and User manual for

details.

The icon is selected displaying the dialogue box below.

From the drop down menu, the required language is specified.

is selected to confirm the selection.

OK

For the new setting to take effect, the software must now be restarted by exiting to

the windows desktop and re-starting the software.

Page 82

Cutter Path CAM ProgrammingBoxford 190 VMC

9 Cutter Path CAM Programming

9.1 Functions

The CAM programming features of the 190 Software provide the following functions:

New Programs

Existing Programs

A new component is created by producing a cutter path on screen. When the cutter

path is complete, it is processed by the software which converts it into a CNC program

and saves the program. The appropriate G and M codes are included, and speeds and

feeds are incorporated into the program automatically.