Page 1

Programming Manual

Boxford 160 TCL

CNC Turning

Machine Tool

Boxford

Boxford Ltd.,

Wheatley, Halifax, West Yorkshire,

England, HX3 5AF.

(Registered Office)

Telephone: 01422 358311

Fax: 01422 355924

E-Mail: info@boxford.co.uk

Web: www.boxford.co.uk

Page 2

Boxford 160 TCL Contents

Contents

1 Introduction

2 Running the Demonstration Program

3 Axes and Tooling

3.1 Axes and Datums

3.2 Turret

3.3 Quick Change Toolpost

3.4 Gang Plate

3.5 Spindle Rotation and Tool Orientation

3.6 Tailstock

3.7 Chuck

3.8 Tool Libraries

3.9 Setting Up

4 Main Front End Menu

5 CAD and CAM Processing

5.1 Functions

5.2 Information Required

5.3 Creating a CAD Profile

5.4 CAD Window

5.5 Drawing Aids

5.6 Drawing Tools

5.7 Editing Tools

5.8 3D Renderer

5.9 Example

5.10 CAM Processing a Profile

5.11 CAM Processor Error Messages

6 DXF File Imports

Page 3

7 Administration Mode

7.1 Access & Password Setting

7.2 Tool Library

7.3 Material Cutting Data

7.4 Internal Machining Data

7.5 Park Position and Units

7.6 Language Settings

8 Manual Data Input CNC Programming

8.1 Operations and Programming Sheets

8.2 Absolute and Incremental Co-ordinates

8.3 Speeds and Feeds

8.4 Program Format

8.5 Preparatory Functions (G Codes)

8.6 Miscellaneous Functions (M Codes)

8.7 Canned Cycles

8.8 Inputting a New Program

8.8.1 Information required

8.8.2 Tabulated Format

8.8.3 Compact Format

8.9 Saving a Program

8.10 Examining an Existing Program

8.11 Editing a Program

8.11.1 New Programs

8.11.2 Existing Programs

8.11.3 MENU Editing Options

8.12 Continuing a Program

ContentsBoxford 160 TCL

9 CNC and CAM Machining

9.1 Initial Checks

9.2 Manufacture

9.3 Options During Machining

10 Manual Machining

11 Robotic Interfacing

Page 4

CNC Tutorials and Exercises

Tutorial 1: X and Y Co-ordinate Calculation -

Absolute and Incremental Co-ordinates

Exercise 1: Calculation of Co-ordinates

Tutorial 2: Linear Interpolation

Exercise 2: Linear Interpolation - Absolute Co-ordinates

Tutorial 3: Canned Cycles - Hole Drilling and Pocket Milling

Exercise 3: Canned Cycles - Programming a Tool Change

Tutorial 4: Circular Interpolation - Clockwise and Counter-clockwise

Exercise 4: Circular Interpolation

Tutorial 5: Combining Operations and Tool Changing

Exercise 5: Combining Operations

ContentsBoxford 160 TCL

Tutorial 6: Subroutines

Exercise 6: Subroutines

Tutorial 7: Mirror Images

Exercise 7: Mirror Images

Tutorial 8: Further Canned Cycles - Pitch Circle Drilling and Dish Milling

Exercise 8: Use of Canned Cycles - Pitch Circle Drilling and Dish Milling

Tutorial 9: Subroutines, Mirror Images and Circular Interpolation

Exercise 9: Subroutines and Mirror Images

Tutorial 10: Datum Shift and Jump to Line

Exercise 10: Datum Shift and Jump to Line

Operations Sheet

Programming Sheet

Page 5

1 Introduction

This manual gives guidance in using the 160TCL CAD/CAM software to create ISO

G&M code programs for turned components, and in component manufacture.

The 160TCL CAD/CAM software includes a demonstration program (called

DEMO), and a number of tutorial programs.

It is suggested the manual is used as follows:

1. Refer to section 2 and run the demonstration. This will provide rapid familiarisation

with the operation of the software and the machining process.

2. Study Section 3 to become proficient in setting up the tooling.

3. Refer to sections 4 and 5 to demonstrate the ease of operation of the integrated CAD

and CAM processor package.

4. Refer to Section 6 to become familiar with the conventions for importing DXF files

from third party CAD packages.

5. Refer to Section 7 for details of the functions available to administrators (tutors) of the

CAD/CAM system.

6. Use section 8 for detailed instruction in CNC programming.

Tutorial 1 is used as an example to demonstrate the stages of programming and

software operation.

7. Use the Tutorials and Exercises in the order in which they appear, to progress from

basic programming skills to proficiency in the more advanced features of CNC

programming.

8. When programs have been written and verified, refer to section 10 as required, to

machine components.

Page 6

2 Running the Demonstration ProgramBoxford 160 TCL

2 Running the Demonstration

Program

The demonstration program contains examples of parallel and radius turning, and a

finished component can be machined from the billet supplied with the machine. Run

the program as follows to provide a tutorial in programming and machining:

Set Up the Machine

Gang Plate: Set both tools into individual toolholders, then fix toolholders into suitable locations

Quick Change: Set both tools into individual toolholders. Fit the LH turning tool and toolholder

Check Tool Settings

1. Make sure the billet is securely fitted in the chuck. Check that the first tool to be used

is the LH turning tool (this is the reference tool). and the second tool is the parting tool.

Set these up as follows:

Turret: Fit LH turning tool in position 1, Parting tool in position 7. (Refer to Figure 3.2 in

Section 3 for tool positions in the turret).

on the gang plate to permit their use in sequence.

assembly into the X-axis slot of the toolpost (refer to Figure 3.4 in Section 3 for tool

fitting and axis slot). During machining, the machine will stop and it will be necessary

to remove and replace the reference tool with the parting tool assembly in the same

X-axis toolholder slot.

2. Run the Simulation and Manufacture software and check that it is correctly configured

by selecting CONFIG from the main menu. (Refer to Installation and User Manual

Section 5 - Configuring the 160 Software, if necessary).

3. From the main menu, select MACHINE and then Tools to display the Tool Data

Library. Check the settings of the LH turning tool and the parting tool, which should

be as follows:

NO. TURRET TYPE DESCRIPTION X OFF Z OFF

1 1 1 LH TURNING TOOL ( - as set - )

2 7 11 PARTING TOOL ( - as set - )

If the settings are incorrect, refer to Section 3 - Axes and Tooling, 3.9 Setting Up:

Select and Set LH Turning Tool, and

Select and Set Parting Tool.

Page 7

2 Running the Demonstration ProgramBoxford 160 TCL

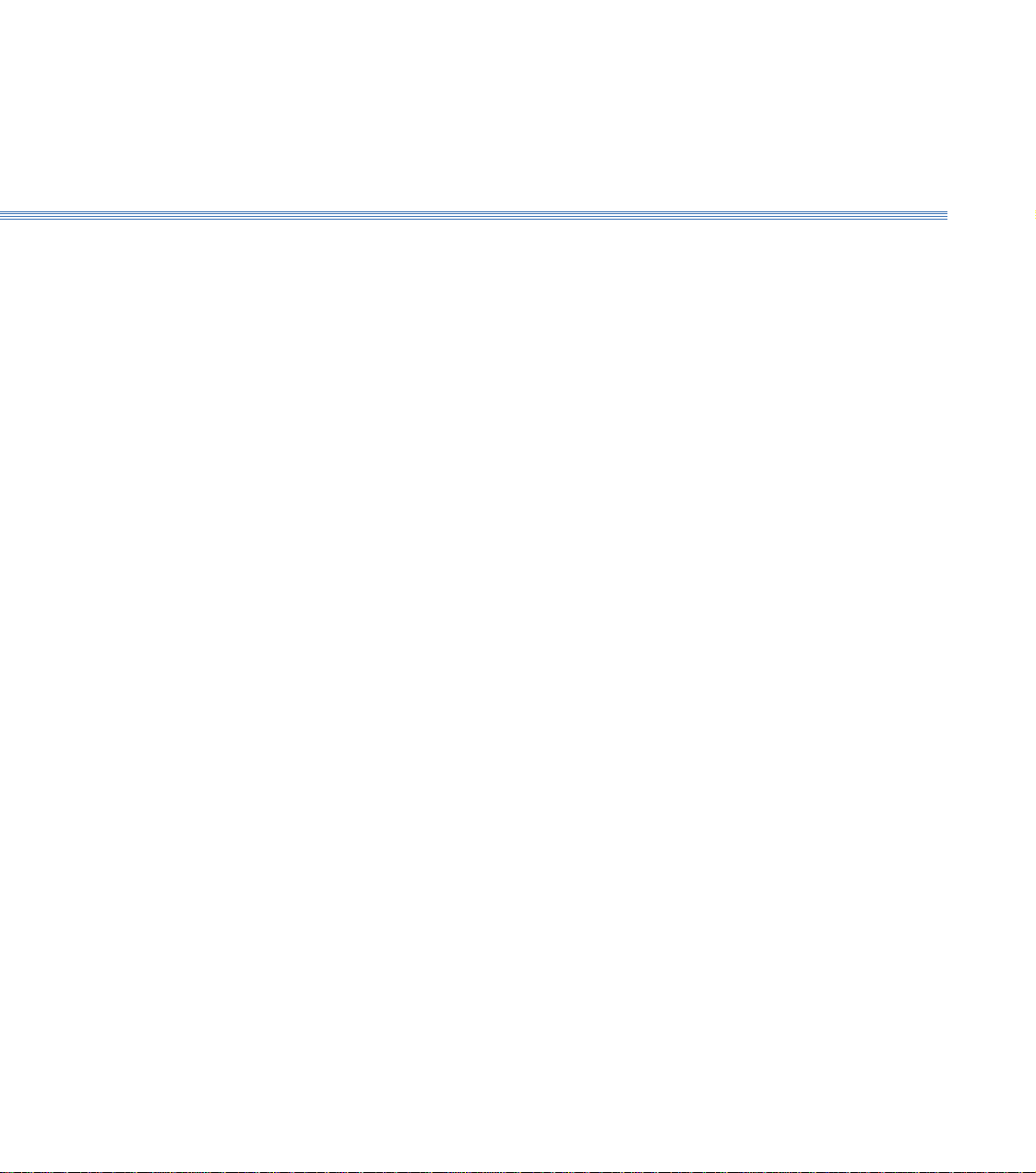

Select the Program

4. From the main menu select PROGRAM, then Program, and view Catalogue 1 to

identify the demonstration program which is called DEMO:

5. Select the program. The screen shows the Program display, with a 2D view of the

component:

Page 8

2 Running the Demonstration ProgramBoxford 160 TCL

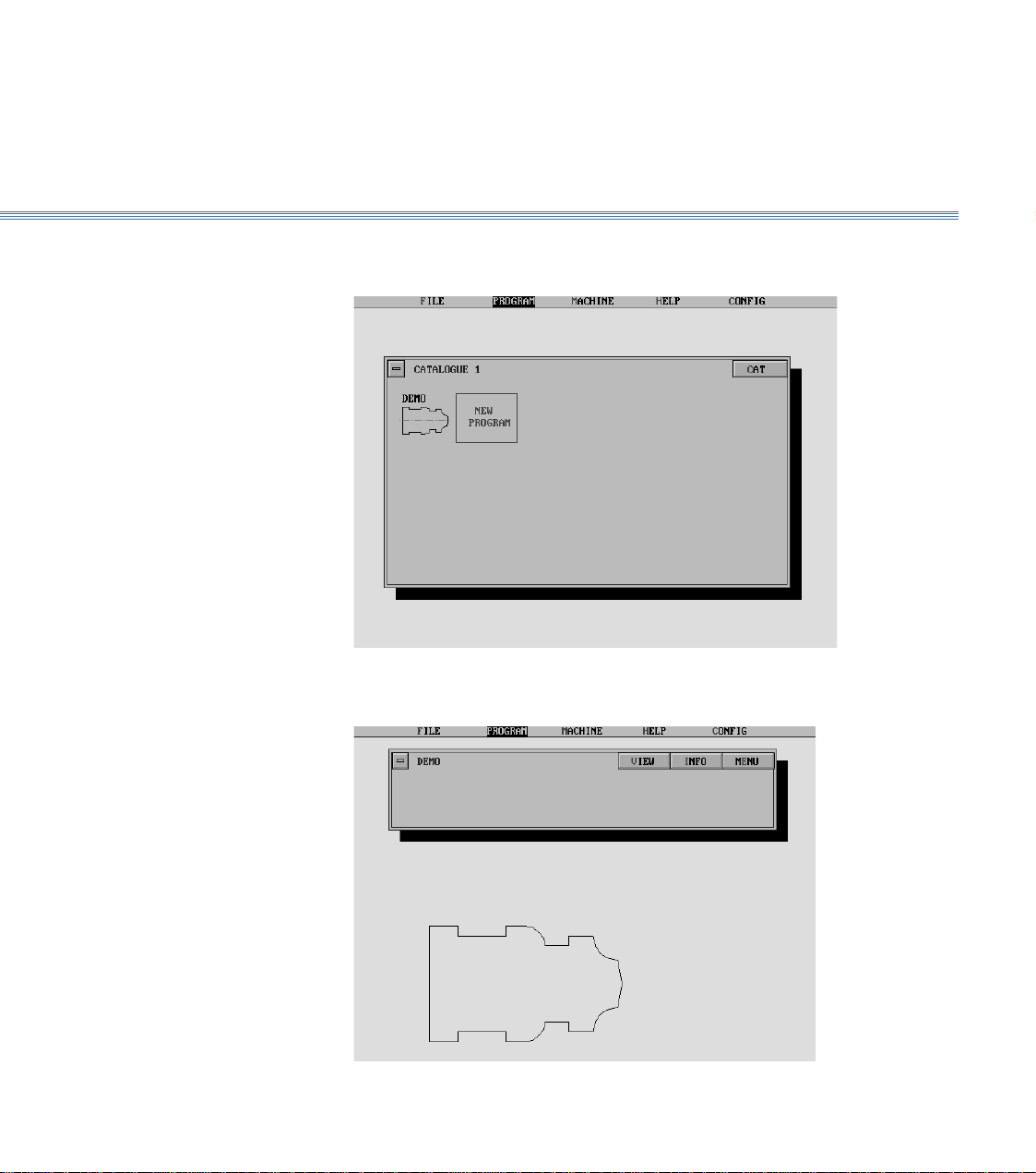

Increase

size

Rotate

clockwise

Rotate

anticlockwise

Decrease

size

Restore to

original size

View the Component

6. Select

VIEW

to produce a 3D view of the component. After a pause, the display

will show the 3D view:

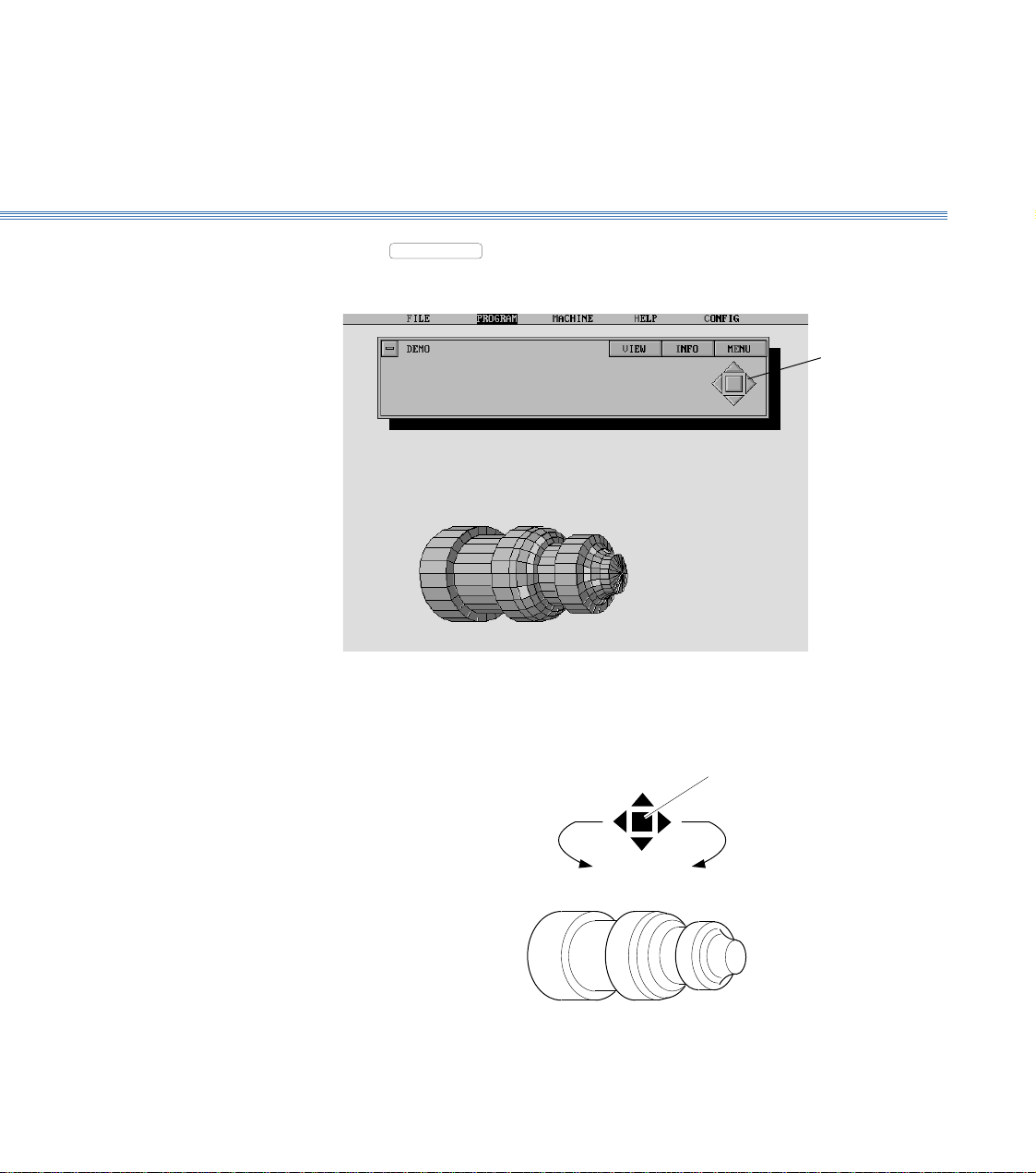

Manipulate the 3D view as follows:

Using a Mouse

Control

buttons

Page 9

2 Running the Demonstration ProgramBoxford 160 TCL

Using the Keyboard

Increase

size

Rotate

anticlockwise

Decrease

size

Note:

The time taken for the display to respond will depend on the speed of the PC and whether a co-processor

is fitted.

Rotate

clockwise

HOME

Restore

original view

Show the Program

Details

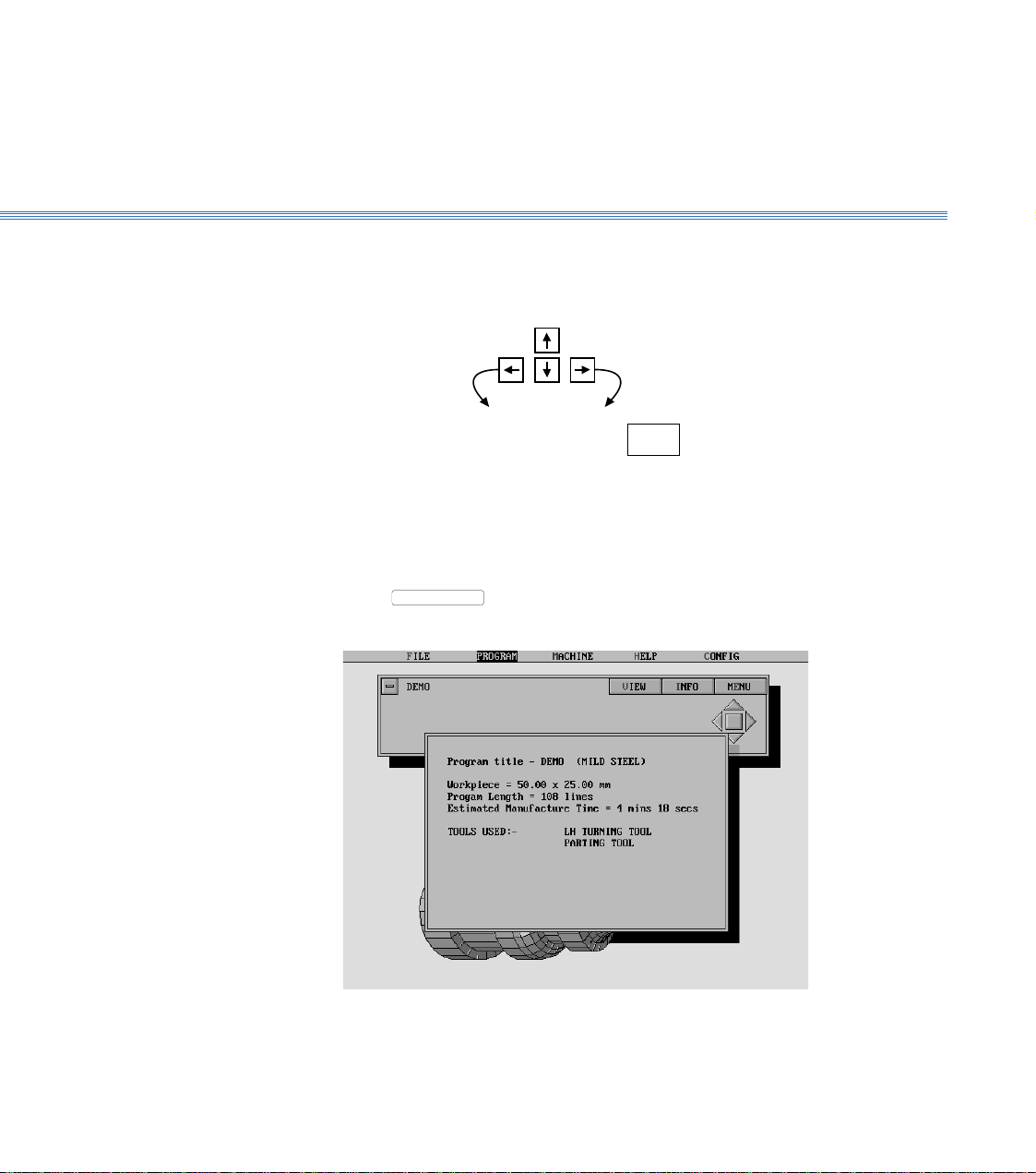

7. Select

INFO

to show the program details:

8. Turn off the program details display. (Click off the display window or press Return).

Page 10

Boxford 160 TCL 2 Running the Demonstration Program

Display the Program

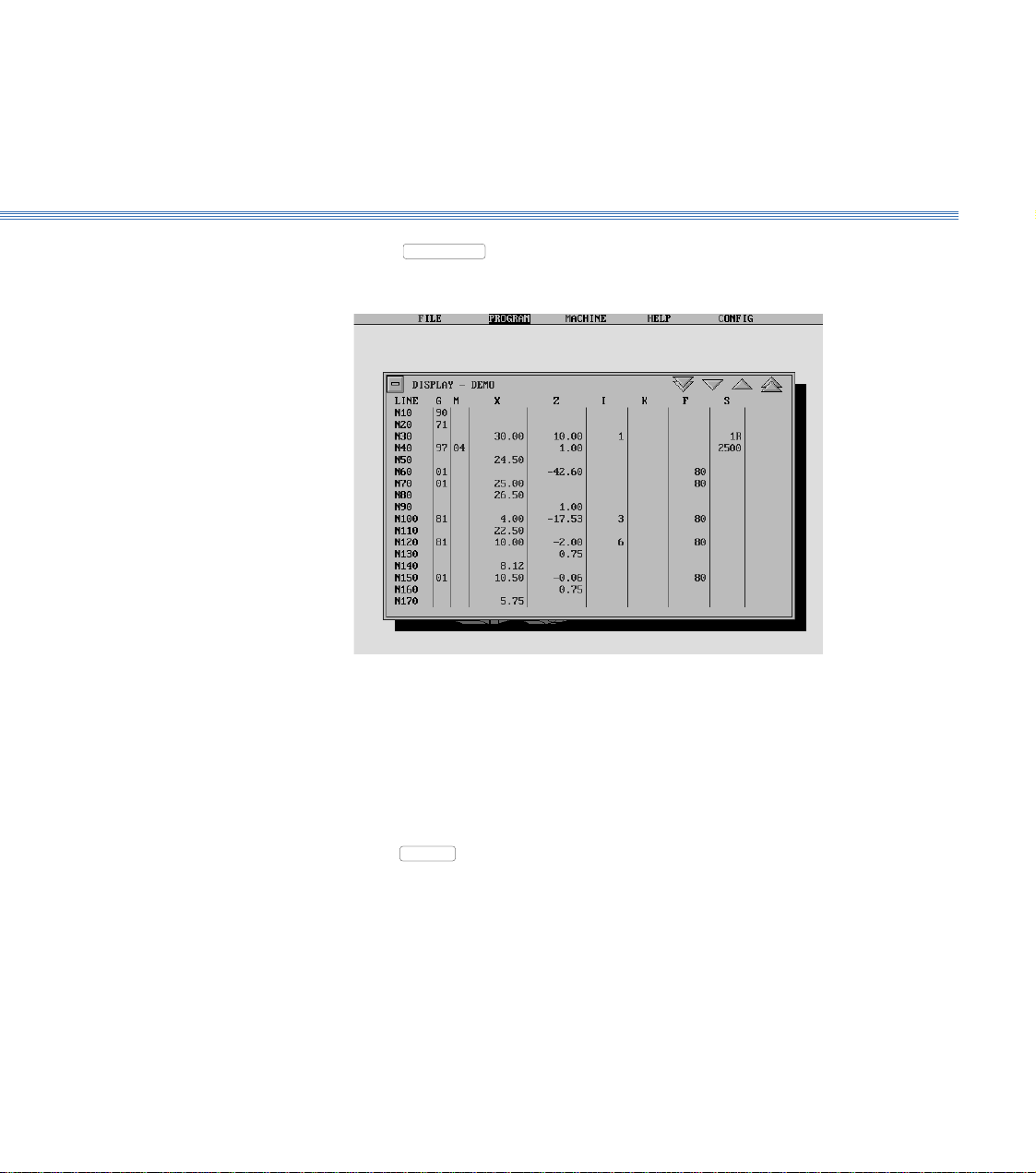

9. Select

MENU

, and then Display:

10. Turn off the program display.

Using a Mouse

Click on the 'off' button

Using the Keyboard

Press

ESC

.

Page 11

2 Running the Demonstration ProgramBoxford 160 TCL

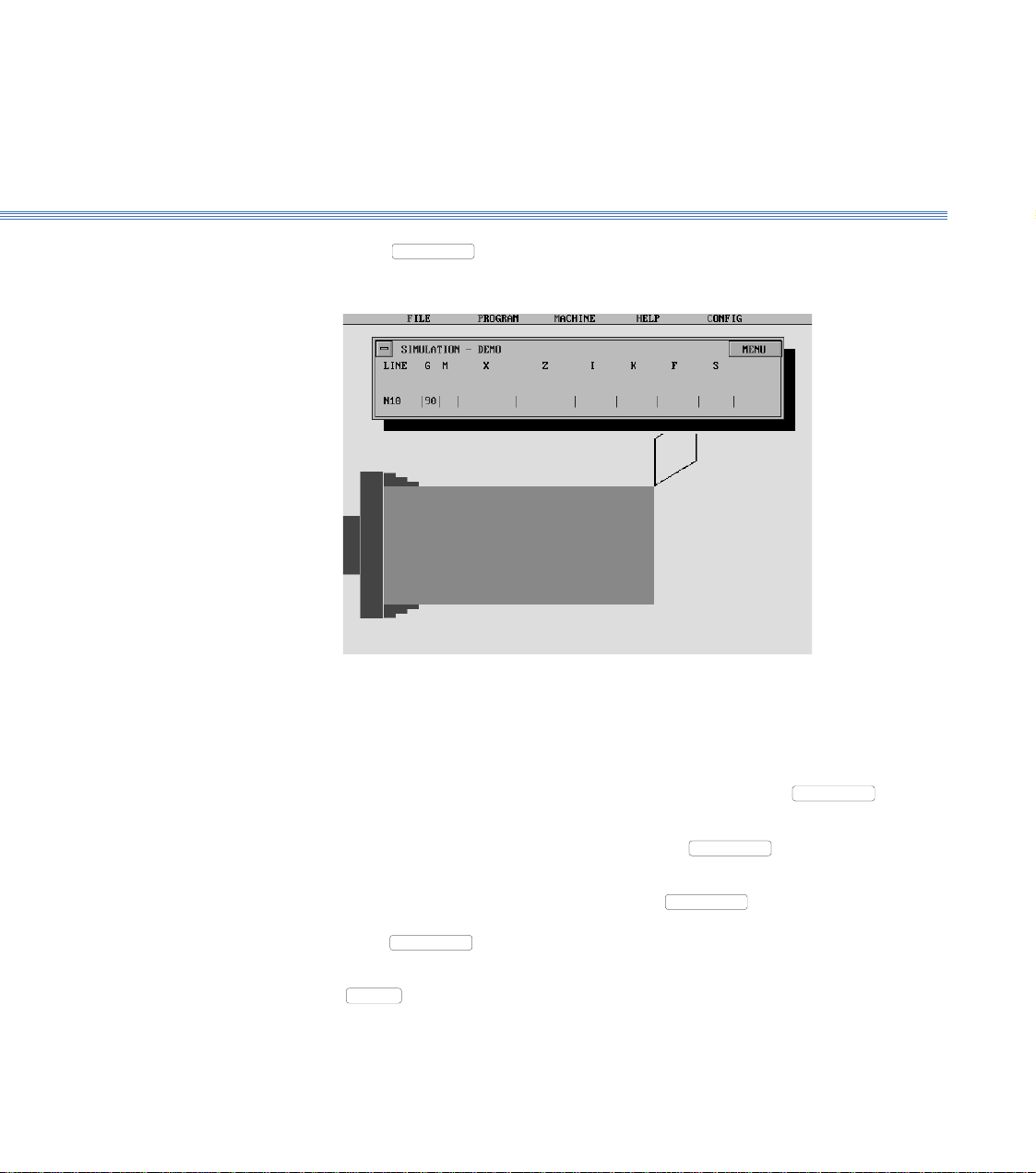

Simulate Machining

- 2D

11. Select

MENU

, then 2D Simulate:

Repeatedly click the mouse button or press Return to move through the program line-

by-line. The simulation shows the tool movement and metal removed as each line of

the program is executed.

To move forward through the program to a specific line, select

MENU

, and then

Go to Line. Type the required line number when prompted, and press Return.

To produce a 3D view of the workpiece, select

MENU

and then 3D View. To

return to the 2D view, click the mouse button or press Return.

To run the simulation automatically, select

MENU

and then Fast Mode; the

program will be run in a continuous sequence. To return to line-by-line simulation,

select

MENU

and then Step Mode.

To end the simulation before the end of the program, click on the 'off' button or press

ESC

.

At the end of the program the screen returns to the program display.

Page 12

2 Running the Demonstration ProgramBoxford 160 TCL

Simulate Machining

- 3D

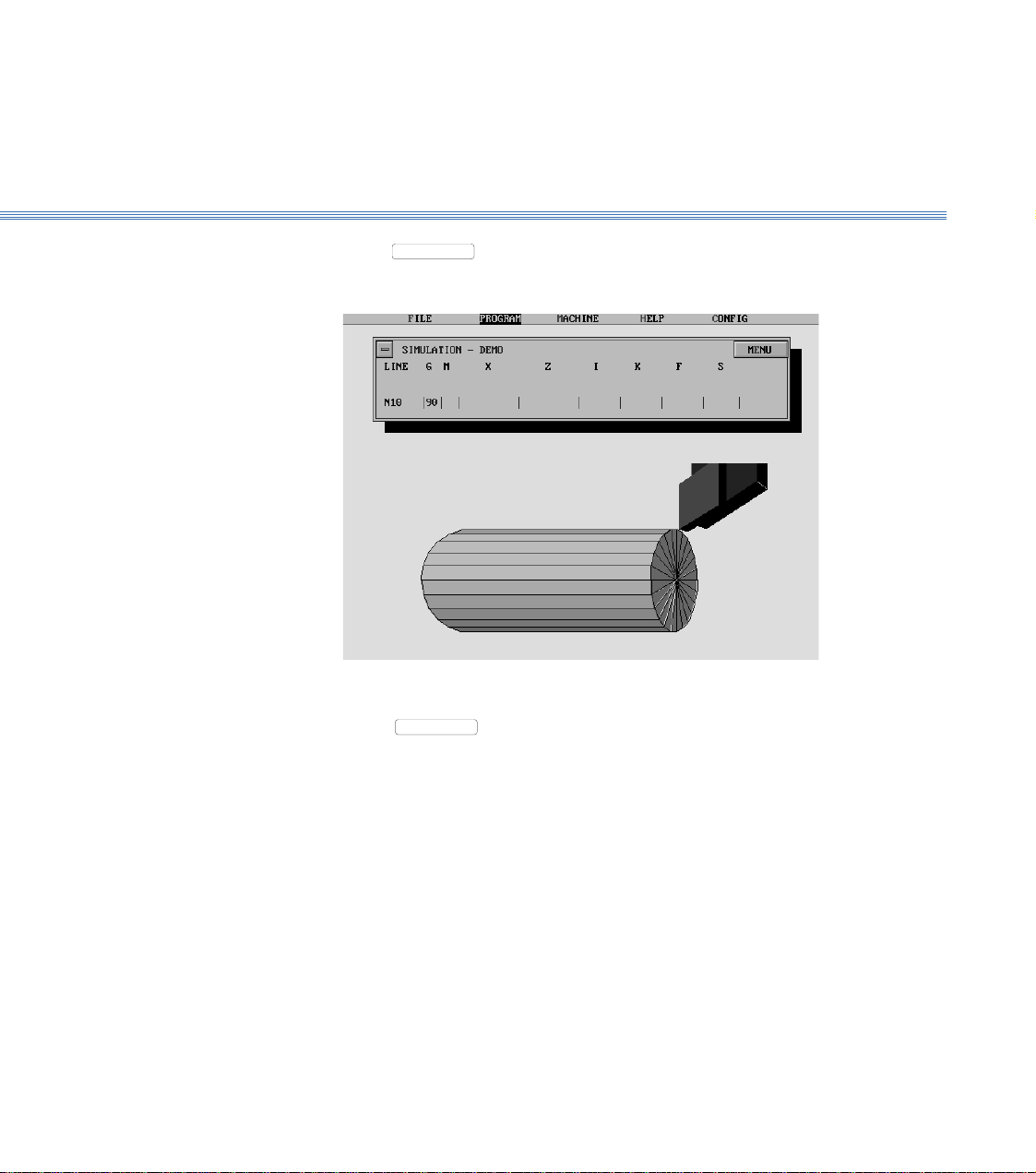

12. Select

Select

simulation, until the screen again shows the program display.

13. Turn off the program display.

MENU

MENU

, then 3D Simulate:

, and demonstrate the use of the options available as for 2D

Machine the

Component

Refer to Section 9 - CNC and CAM Machining.

Page 13

Boxford 160 TCL

Datum Position: On new machines, all Datum positions and Tool Offsets are set at the factory when tooling and clamping

Axes and Tooling

3 Axes and Tooling

3.1. Axes and Datum

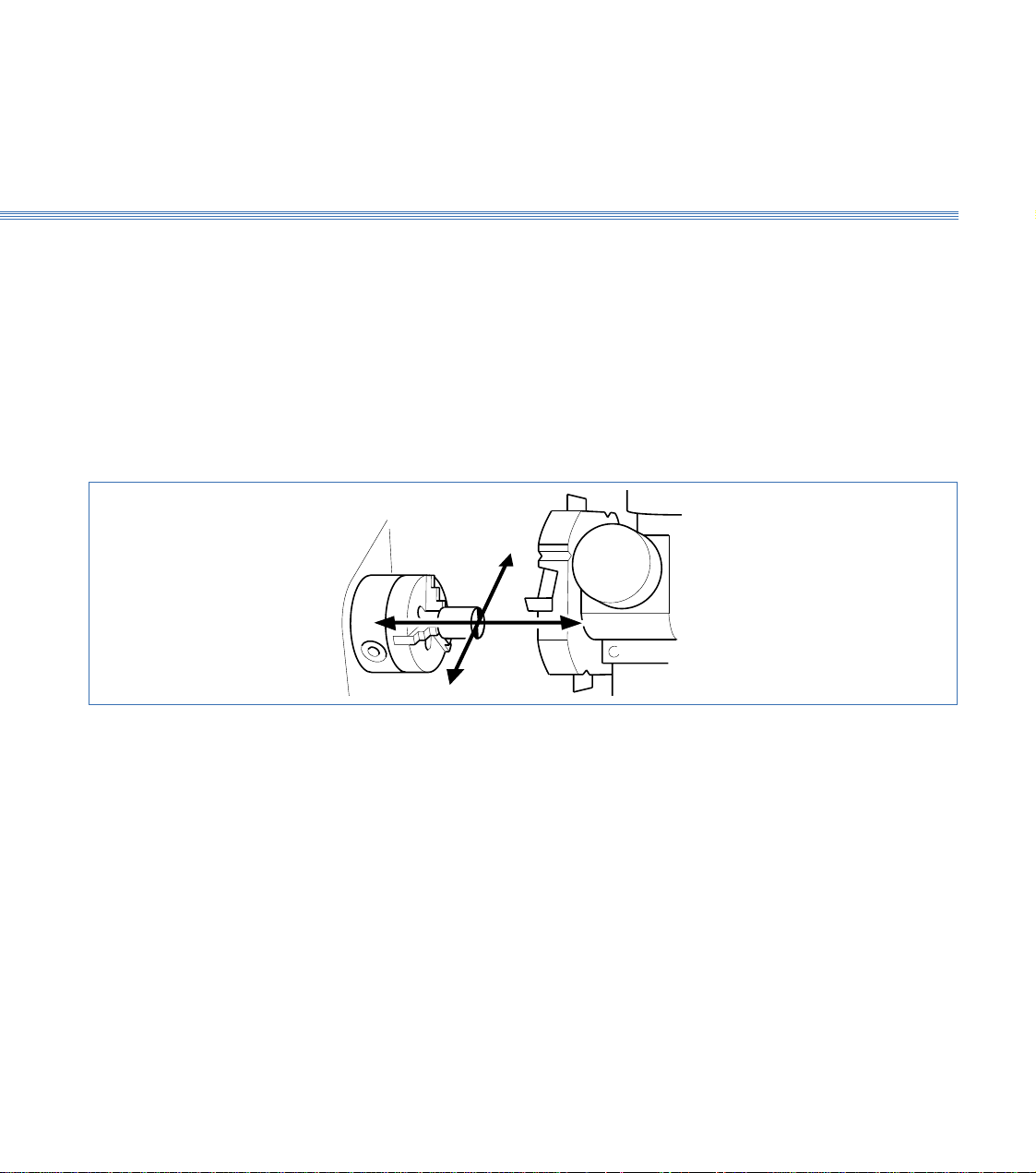

Axes: The toolholder can move in two axes, X and Z, (see Figure 3.1).

is ordered with the machine.

The offsets of all required tools are set in relation to the machine X and Z datum.

Before any Tool Offsets can be set, the Machine X and Z Datum has to be defined.

These value are provided with the machine documentation and are printed on a label

located inside the machine end guard.

+X

-Z +Z

-X

Figure 3.1 Axes and Datum Position

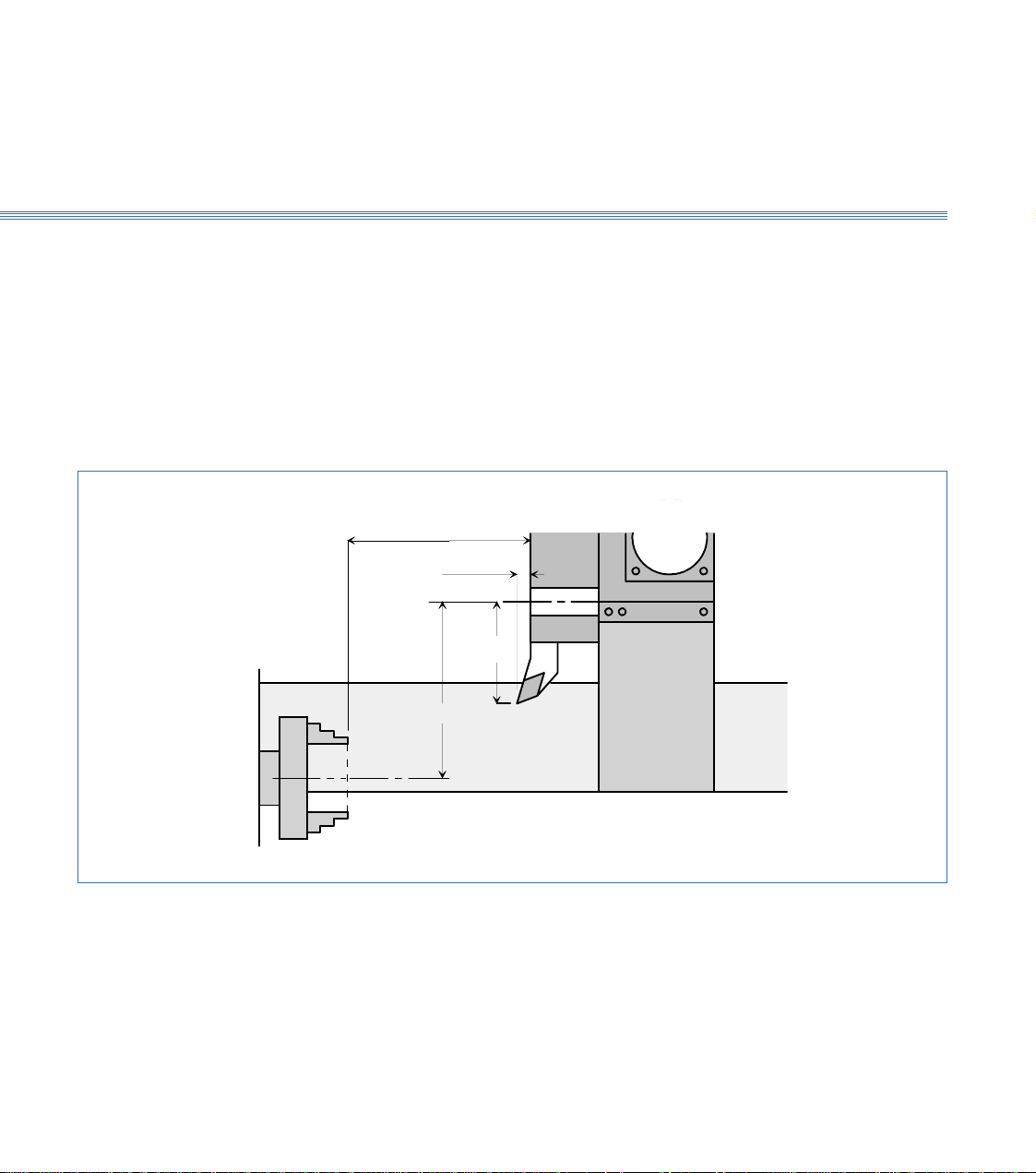

Machines with Turrets: From the machines Home Position, the Machine Z Datum is the measured distance from

the front face of the chuck jaws to the turret disc front face as shown in the diagram 3.2.

The Y Datum is the measured distance from the spindle centreline to the centreline of the internal

tool bores on the turret.

Page 14

Boxford 160 TCL Axes and Tooling

3.1

Tool Offsets: The Tool Z offset is the distance from the Turret Disc front face to the Tool Cutting

tip point.

The X offset is the distance from the centreline of the internal tool bores on the turret

to the Tool Cutting Tip Point (therefore theoretically all drills should have an X offset

of Zero).

The X offset is always twice the measured distance because the Boxford software uses

X values specified in Diameter (not radius).

Datum Z Value

Centre Line

of Internal

Tool Holder

Figure 3.2 Turret

Tool Z Offset

Tool X Offset

Datum X Value

Centre Line of Spindle

TURRET

Page 15

Boxford 160 TCL

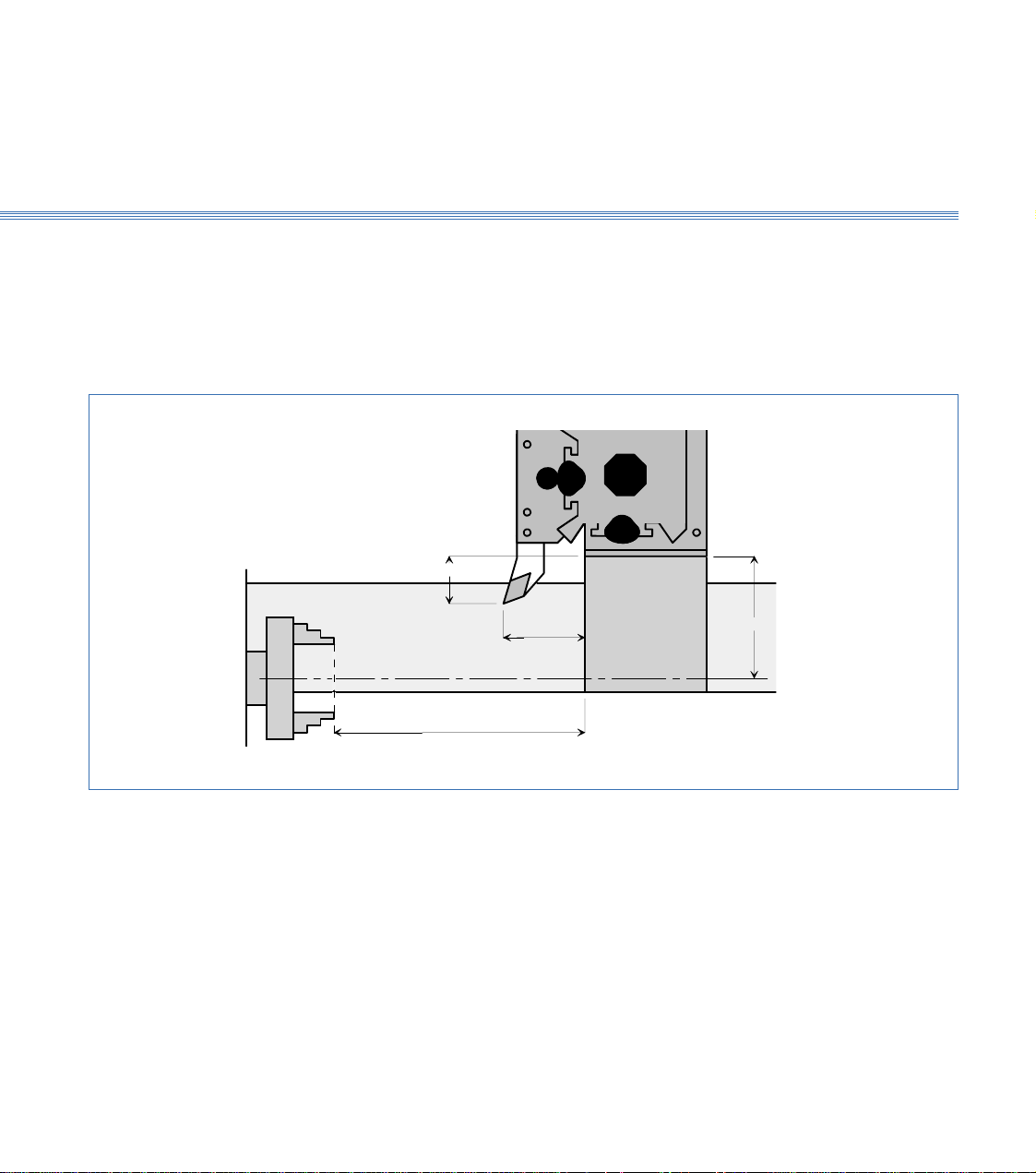

Machines with Quick Change Tool Posts:

From the machines Home Position, the Machine Z Datum is the measured distance from

the front face of the chuck jaws to the front face of the machine cross slide as shown in the diagram

below. (figure 3.3)

The Y Datum is the measured distance from the spindle centreline to the bottom face of the tool

post mounting plate.

Tool X Offset

Axes and Tooling

3.1

Tool Z Offset

Centre Line of Spindle

Datum Z Value

Datum X Value

Figure 3.3 Quick Change

Tool Offsets: The Tool Z offset is the distance from the Cross Slide front face to the Tool Cutting

tip point.

The X offset is the distance from the bottom face of the tool post mounting plate to

the Tool Cutting Tip Point.

The X offset is always twice the measured distance because the Boxford software uses

X values specified in Diameter (not radius).

Page 16

Boxford 160 TCL Axes and Tooling

3.1

External tools: 1, 3, 5, 7

Internal tools: 2, 4, 6, 8

Figure 3.4 Turret Tool Positions

4

3

2

8

1

Machines without homing switches:

1: Reference tool

7: Second tool

5

6

7

Page 17

Boxford 160 TCL

Axes and Tooling

3.2

3.2 Turret (Figure 3.4)

The turret is a motor driven, disc type toolpost with positions for up to eight tools, four

external and four internal; each position is numbered.

Tools can be accessed by indexing the turret using the TURRET INDEX push button

on the machine controls or from the software.

Fitting Tools

Setting Tool Height

External tools are secured in radial slots by tapered clamp blocks held by two fixing

screws. Longitudinal positioning is achieved by pushing the tool towards the turret

centre so that it touches the location stop. Internal tools are secured in their predrilled

holes with tubular toolholders and two sunken screws.

This will normally have been set at the factory and should require no adjustment. If

it is found to be incorrect it is recommended that a Boxford service engineer is called.

However it is permissible to adjust it by putting a tool into the working position, then

inserting packing as appropriate between the turret toolpost and cross-slide. If this does

not achieve correct tool height, or other tools heights are still incorrect, contact the

factory.

Page 18

Boxford 160 TCL Axes and Tooling

3.3

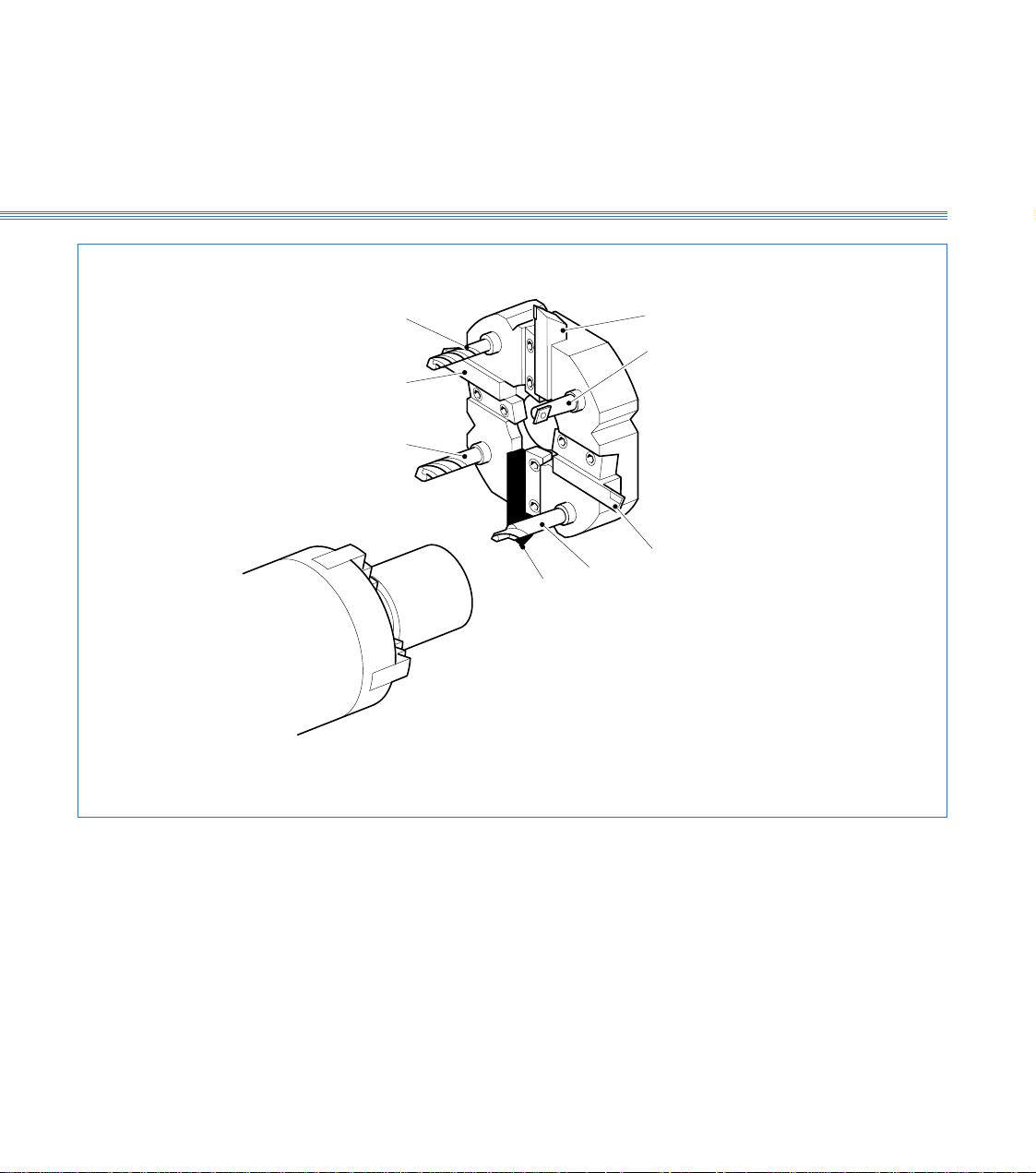

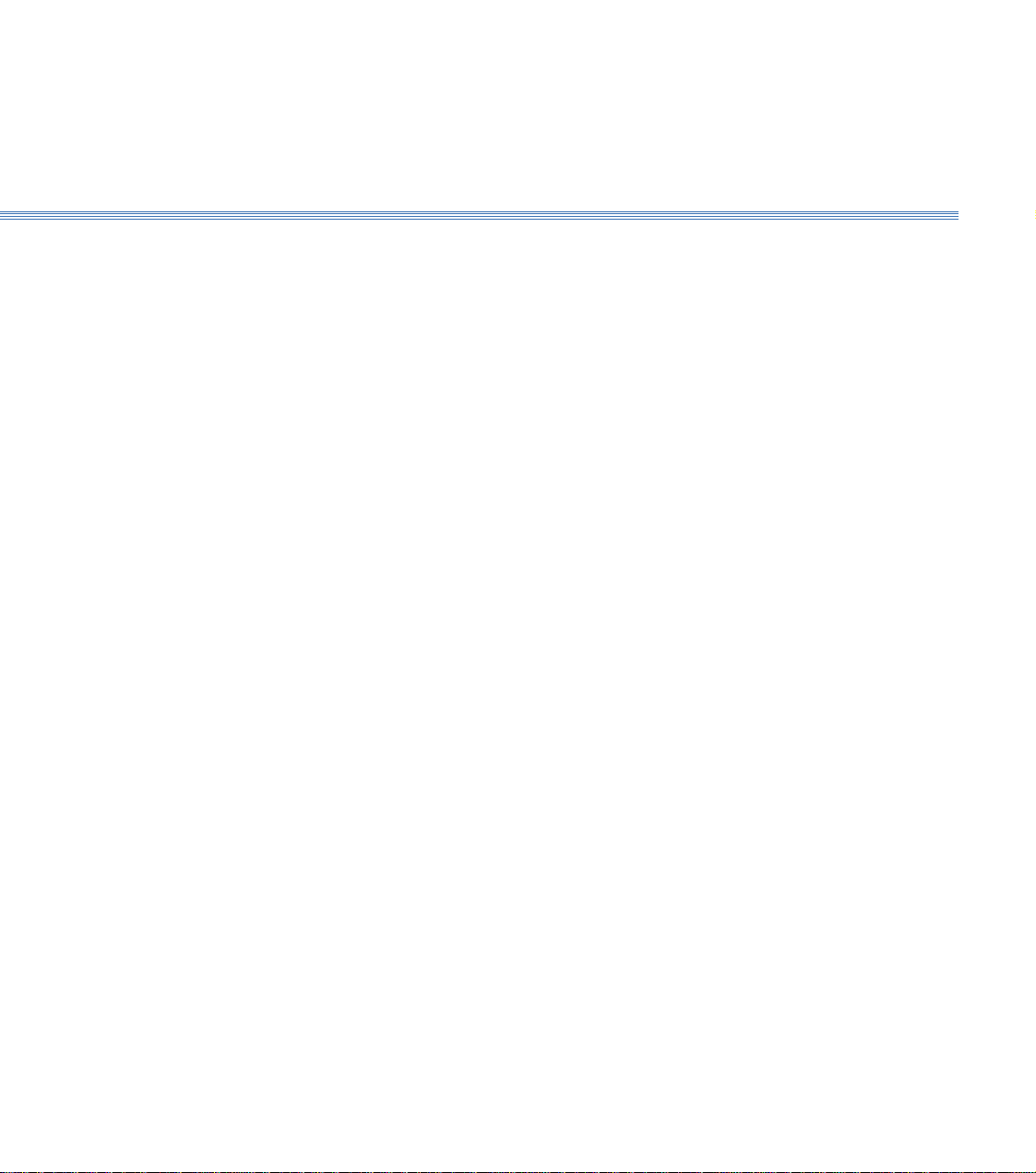

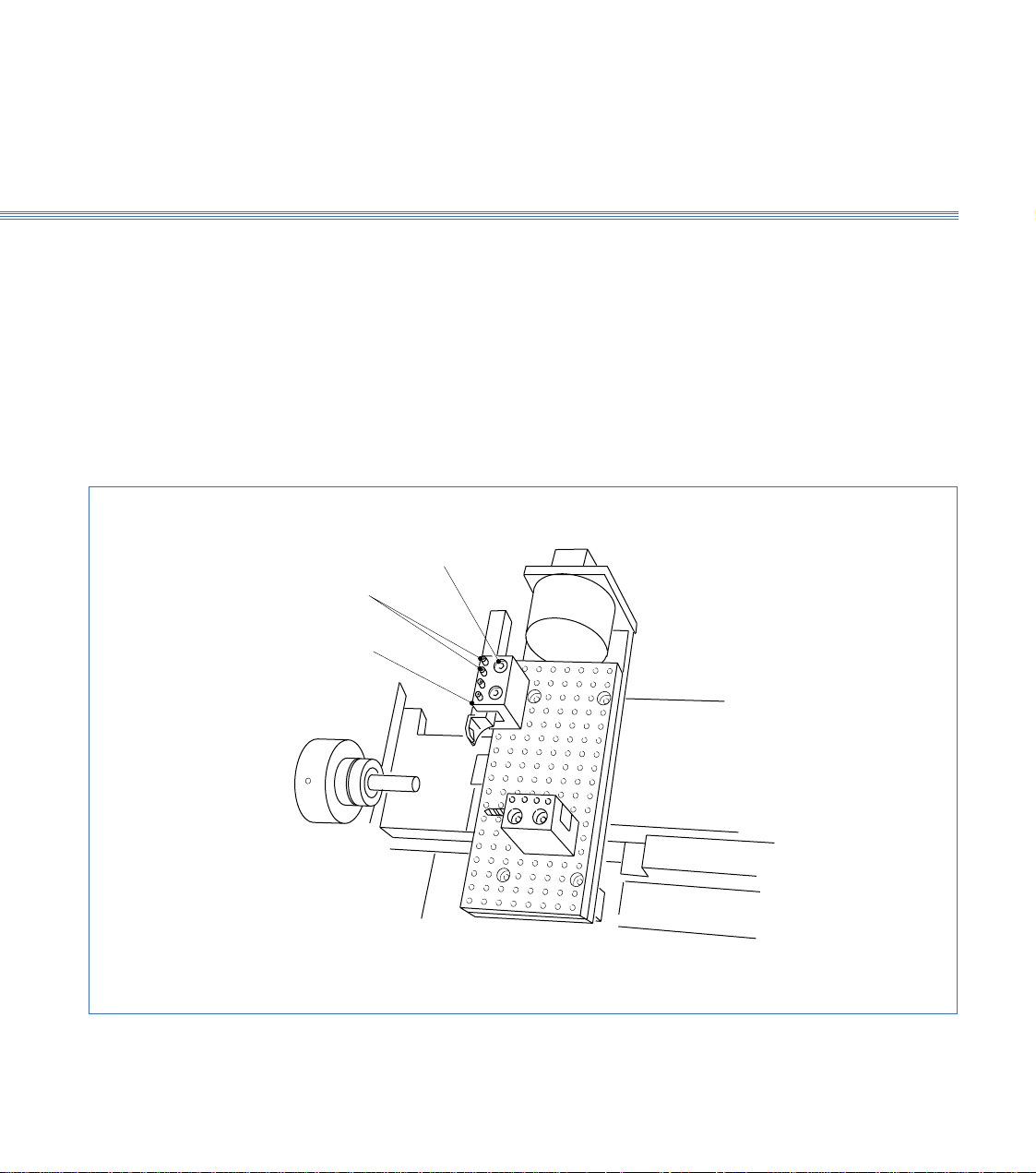

3.3 Quick Change Toolpost

Fitting Tools

(Figures 3.5 and 3.6)

The quick change toolpost has two slots to provide for convenient and rapid manual

tool changing. A toolholder with a tool already secured in it by the four securing screws

is placed into the shaped slots which provide instant positive location, and is rigidly held

there by tightening the single clamping screw, using the clamp screw key provided. The

toolpost will only accept a single toolholder at a time. External tools are fitted to the

X axis slot while internal tools use the Z axis slot.

A quick change toolpost can be fitted to the lower section of the X-axis cross slide in

addition to a gang plate.

Fit the LH turning tool into the standard flat bottomed toolholder by tightening the

four securing screws onto the tool shank. The tool should protrude approximately

20mm (0.75in) from the toolholder face. Keep this dimension consistent for all the

external tools. Put the toolholder into the toolpost and lock it into position using the

clamping screw.

Figure 3.5 Quick Change Toolpost

Tool Clamping Screw

Tool Tool Securing Screws

Page 19

Boxford 160 TCL

Axes and Tooling

3.1

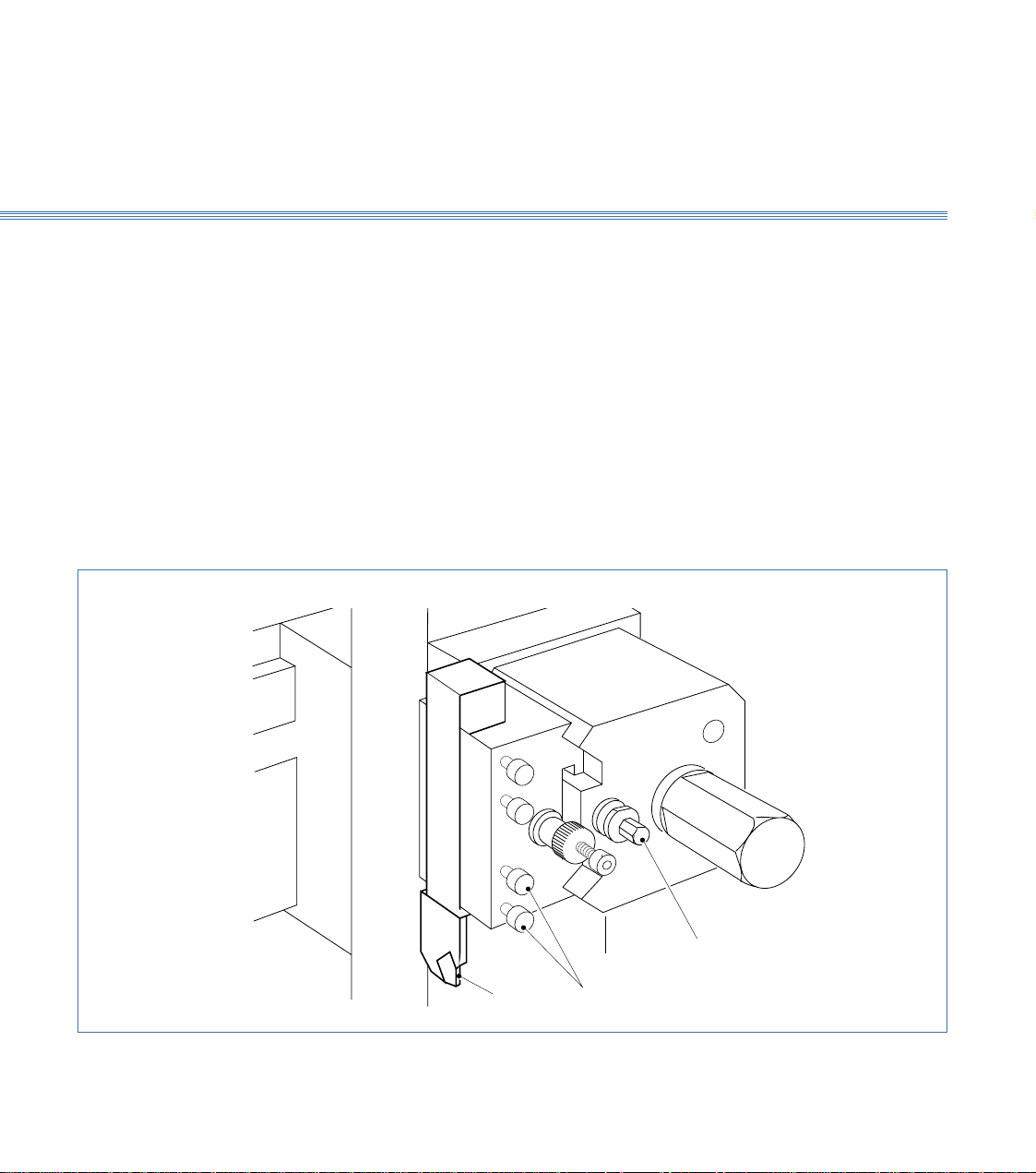

Height Setting-External Tools

1. Visually check the height to the workpiece centre point. The actual height from the top

2. To adjust the height slacken the toolpost clamp screw and the centre height adjustment

3. Check that the tool is exactly on the centre line by taking a light facing cut on the end

Tool

Clamping

Screw

Refer to Section 10 Manual Machining to move the tool manually to set the tool height,

which is checked by taking a light facing cut on the end of the workpiece. If adjustment

is needed to centre the tool, use the centre height adjustment screw on toolholder as

follows:

of the cross slide to the centre of the spindle is stamped on the left face of the bed

adjacent to the headstock cover.

Note:

Do not confuse this value with the machine serial no. which is also stamped here.

screw. Turn the knurled adjustment knob clockwise to raise the tool, anticlockwise to

lower it.

When the height is correct tighten the Allen screw then tighten the toolholder clamp

screw.

of the workpiece, using spindle in reverse direction. Repeat adjustment above as

necessary.

Constant

Centre Height

Adjustment Screw

Figure 3.6 Tool Fitting and Adjustment

Tool Securing

Screws

Page 20

Boxford 160 TCL Axes and Tooling

3.3

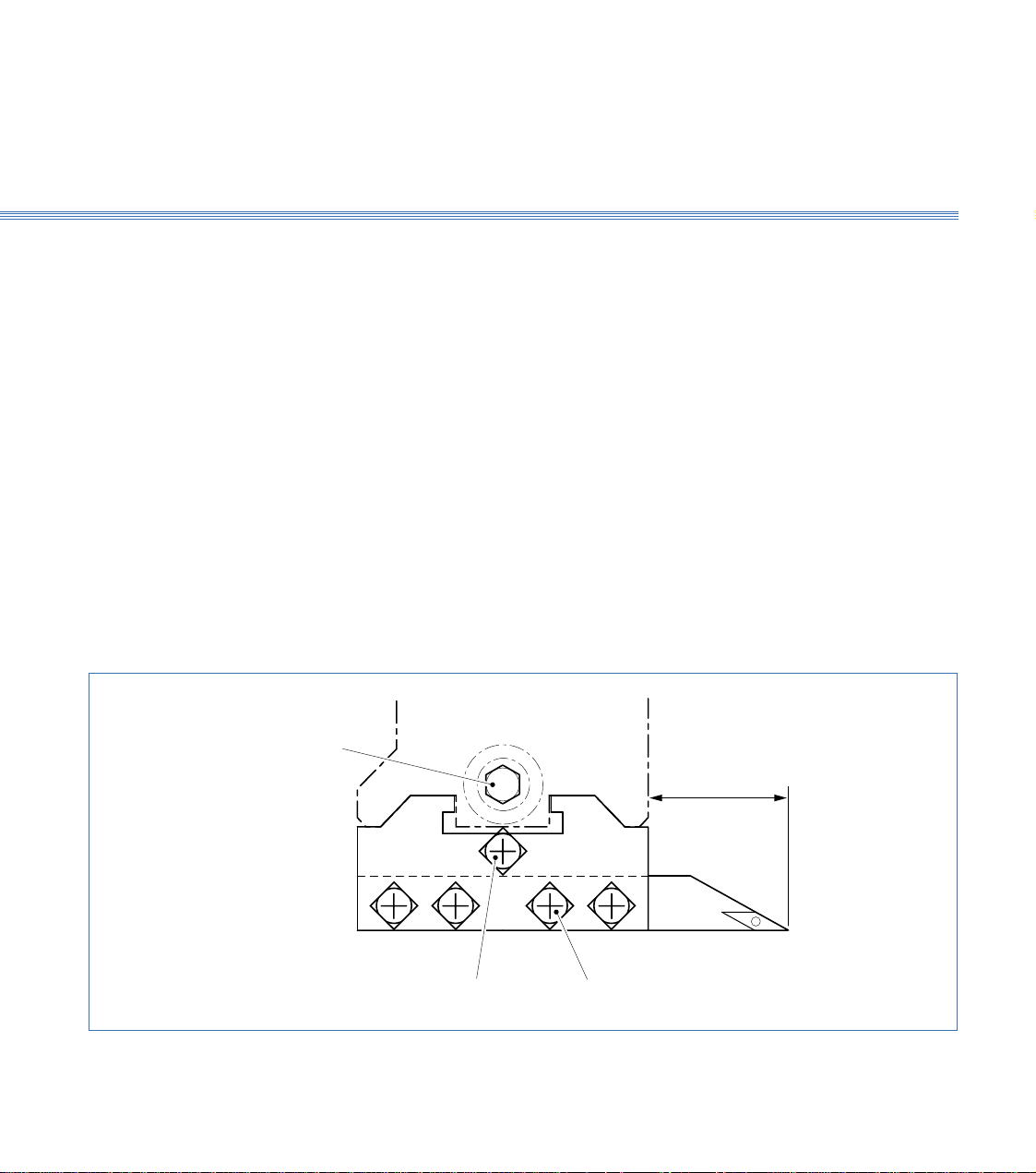

Height Setting - Internal Tools

Figure 3.7 Internal Tool Fitting Detail

These tools can be fitted directly into the V location toolholders intended for use with

the drills. Although not essential, it is better if they are located into a tubular holder.

This can easily be made as shown in Figure 3.7.

Put a toolholder with its tool on to the toolpost and set the centre height to the

workpiece centre line exactly as for external tools. Repeat this procedure for all of the

tools.

Drill Tube

Page 21

Boxford 160 TCL

Axes and Tooling

3.4

3.4 Gang Plate (Figure 3.8)

This is a plate with drilled holes enabling up to three simple channel shaped toolholders

to be clamped on to it. Tool positions are free, limited by hole line-up between

toolholder and gang plate and by ensuring that every tool mounted can reach the work

over the required range without fouling anything or causing other tools to foul

something.

Fitting the Tools

Setting Tool Height

Select a tool position and fit the channel toolholder using the securing screws. Clamp

the tool into it with the four clamping screws.

There is no tool height setting adjustment provided as this is pre-set at the factory. If

correction is needed, contact the factory.

Securing

Screws

Clamping

Screws

Channel

Toolholder

Figure 3.8 Gang Plate

Page 22

Boxford 160 TCL Axes and Tooling

3.5

3.5 Spindle Rotation and Tool Orientation

Rotation

(Figure 3.9)

Tool Orientation

The spindle can run forward (anticlockwise when viewed on chuck jaws) and in reverse

(clockwise when viewed on chuck jaws). Direction and speed of rotation are controlled

either by the SPIND FWD/SPIND REV buttons on the machine control panel (refer

to Installation and User Manual Section 6 Machine Controls) or by means of M codes

(M03 = Forward and M04 = Reverse) selected from software.

For machining a workpiece held in the chuck with the tool fitted in the normal way,

i.e. with the cutting edge uppermost, the direction of rotation is as follows:

Direction M Code

External turning, toolholder at back Reverse M04

External turning, toolholder at front Forward M03

Internal turning Forward M03

If tools are fitted upside down, take care to select the appropriate direction of spindle

rotation.

Once the initial tool is specified, which then sets the direction of rotation, ensure that

all subsequent tools are fitted in the same orientation to avoid the need to reverse the

direction of rotation at tool changes while running a program.

Page 23

Boxford 160 TCL

Axes and Tooling

3.5

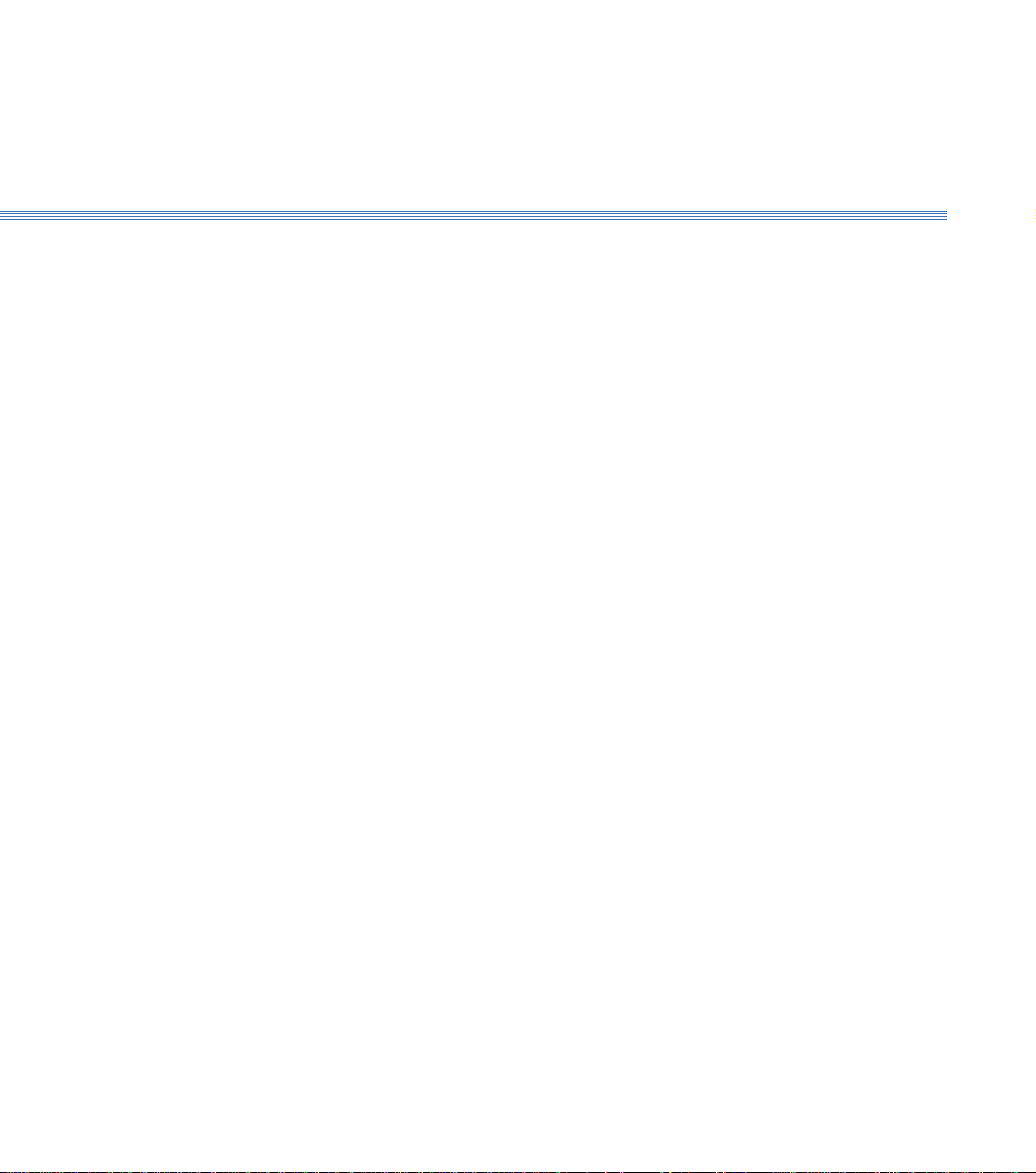

WORKPIECE IN CHUCK

REVERSE

+X

Tool holder at back

-Z

FORWARD

USING TAILSTOCK POSITIVE X VALUES ONLY

REVERSE

-X

+X

Tool holder at front

EXTERNAL TURNING

+Z

INTERNAL TURNING

-Z

FORWARD

-X

NEGATIVE X VALUES ONLY

Figure 3.9 Spindle Rotation and Tool Orientation

+Z

Page 24

Boxford 160 TCL Axes and Tooling

3.6

3.6 Tailstock (Figure 3.10)

The tailstock is bolted to the main slide. The upper part can be rotated about a

longitudinal axis to its working or parked positions. When not required, the upper part

is swung down and locked into its parked position to allow the toolholder its full travel

along the Z axis. The tailstock contains a quill to hold a centre, and is adjusted manually

in the Z axis.

Position Changing

and Securing

Two fixing screws secure the two halves of the tailstock rigidly into the working

position.

Removing these screws allows the top half of the tailstock to be swung down to rest

against the machine frame. This exposes a sunken Allen screw for securing the parked

tailstock section in place.

Fixing Screws

Figure 3.10 Tailstock

Locking Screw

Flat on

Handwheel

Page 25

Boxford 160 TCL

Axes and Tooling

3.7

3.7 Chuck

A manual or pneumatic chuck may be fitted. Pneumatic chucks are operated either by

using the CHUCK OPEN/CHUCK CLOSE pushbuttons on the machine control

panel (refer to Installation and User Manual Section 6 Machine Controls) or from

within software by use of appropriate M code (M40 = Open, M39 = Close).

Unless specified otherwise, pneumatic chuck jaws are prebored at the factory to 20mm

diameter. Should work with larger diameter workpieces be undertaken, the pneumatic

chuck jaws can be bored out to avoid the need to purchase another pneumatic chuck,

as follows:

1. Press the CHUCK CLOSE button and set the jaws to position to provide

sufficient material for boring. To move the jaws unfasten the two screws in the jaws,

raise the jaws from the serration plates and position them accordingly, then refasten

the screws ensuring that the jaws are equi-distant from the centre line of the chuck.

2. Make a washer 1mm thick with bore the same diameter that the chuck is to be bored.

The outside diameter of washer can be 30mm.

3. Press the CHUCK OPEN button.

4. Bore out the face of the jaws 1mm deep, 30.12mm diameter (0.12mm bigger than the

outside diameter of the washer).

5. Place the washer on to the machined jaw face and press the CHUCK CLOSE button

to clamp the outside diameter of the washer.

6. Revolve the chuck forward at approximately 2000 rev/min.

7. Bore out the jaws using the washer bore as a gauge. Use the axis control buttons to

provide tool movement with the FEED knob set to 75%.

8. When boring is complete stop the spindle and press the CHUCK OPEN button to

release the washer.

Page 26

Boxford 160 TCL

Axes and Tooling

3.8

3.8 Tool Libraries

The 160 software provides a Tool Data Library which enables details of tooling and

offsets to be entered and a Tool Library from which tools can be selected for inclusion

in the Tool Data Library. The library is set up by means of a tooling menu.

Before attempting to set up the tooling for the first time, view the libraries and the

tooling menu to become familiar with the details, as follows:

1. Switch on the PC, run the 160 software.

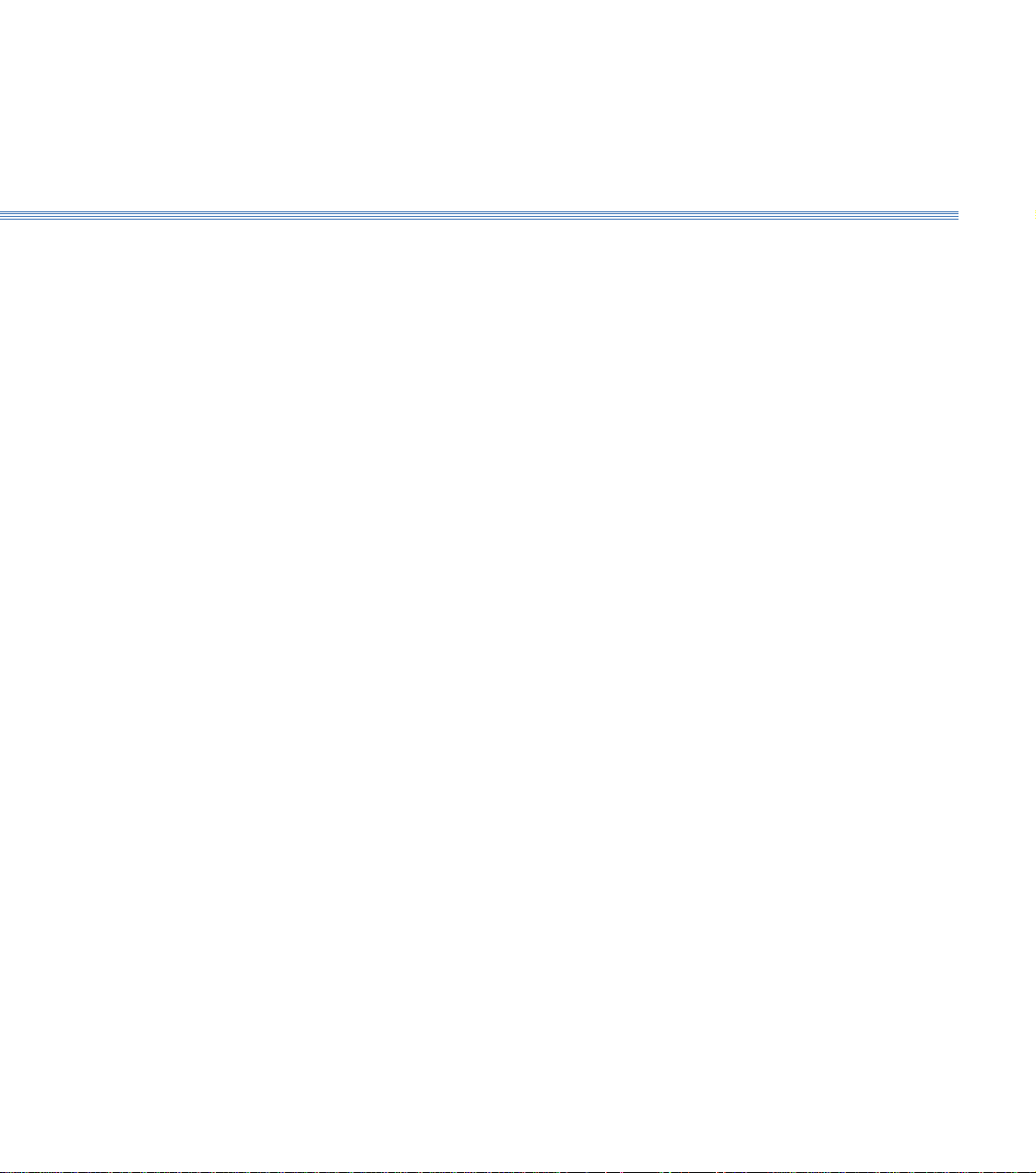

Tool Data Library

2. From the Simulation and Manufacture software main menu, select MACHINE and

then Tools.

The screen shows the Tool Data Library, (Figure 3.11). Practice selecting tools using

the mouse and keyboard.

1 2 3 4 5

1. Tool number used by CNC program to select required tool

2. Tool position on Turret (not used with Gang plate or Quick change tool

holder)

3. Tool type and description (selected from tool catalogue)

4. Tool offsets

5. Scroll buttons

To select a tool:

Using a mouse

Click on the scroll buttons (5) to highlight the required tool,

point to required tool and click mouse button.

Using the keyboard

Press ➔ or ➔ to highlight the required tool.

Figure 3.11 Tool Data Library

Page 27

Boxford 160 TCL Axes and Tooling

3.8

Tooling Menu

Tool Library

3. Select MENU to display the tooling menu:

The use of these options for setting and editing the Tool Data Library is detailed later

in this section.

Note:

After setting up or editing the library, always select Save Tool data.

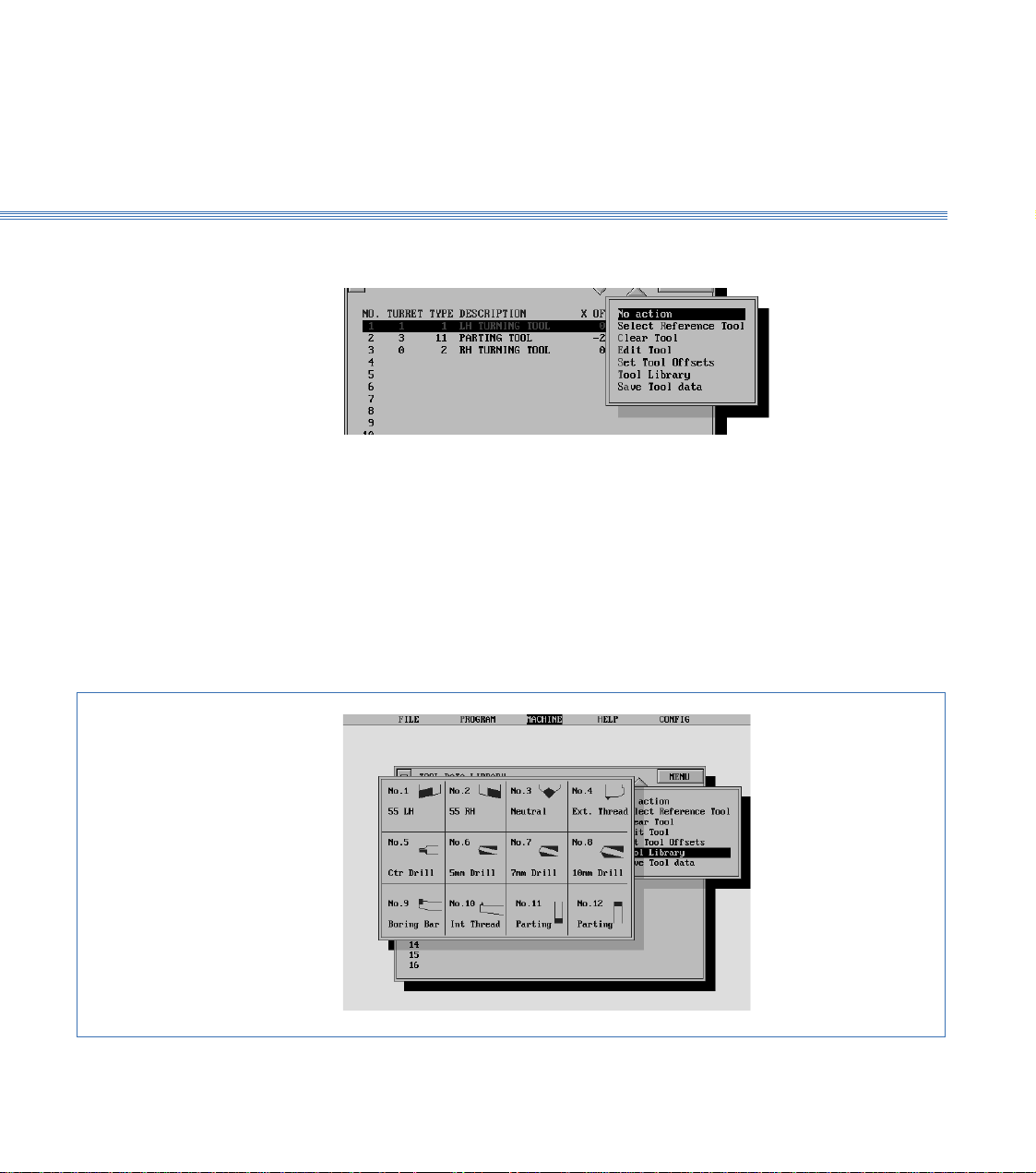

4. From the tooling menu, select Tool Library.

The screen shows the Tool Library, (Figure 3.12).

Turn off the Tool Library display to reveal the Tool Data Library.

Figure 3.12 Tool Library

Page 28

3.9Axes and ToolingBoxford 160 TCL

3.9 Setting Up

Note:

A billet of the appropriate size will be required for this procedure. In order to run the demonstration

program, a LH turning tool and a parting tool are required. To run the program, set up the LH

turning tool as the first tool and the parting tool as the second tool in the following procedure.

Fit Tooling

Configure Software

Set Datum Position

1. Fit the required tools into the toolholding system supplied.

With the quick change toolpost, fit the first tool required. After setting the offset of

the first tool, it will be necessary to substitute the next tool before setting its offset.

If the toolholder is too close to the chuck to allow the tools to be fitted, move the

toolholder away from the chuck under manual control, (see Section 10 - Manual

Machining).

2. Check that the POWER RESET button on the machine control panel has been pressed

to initialise the machine.

3. Run the Simulation and Manufacture software. From the main menu select CONFIG

and then Program.

4. On the PROGRAM display, set UNITS MODE to the units required for tool offsets

and programming.

5. If a turret is fitted, select CONFIG and then Hardware, and check that TURRET is

set to FITTED.

Note: It is only necessary to set the datum position when the machine is first installed, or if the original

setting is lost. In order to set the datum position, the information supplied with the machine will be

required; this information consists of an X and a Z axis measurement.

6. From the main menu, select MACHINE and then Datum Position. The screen

shows:

Page 29

Boxford 160 TCL 3.9 Axes and Tooling

Enter the X and Z axis measurements supplied with the machine, and select

SAVE

The screen returns to the main menu.

7. From the main menu, select MACHINE and then Tools to display the Tool Data

Library. Defaults of the first tool will be highlighted, for example:

Check the settings. If they are correct, continue at step 15 to set the second tool.

For the demonstration program, the settings should be as shown.

8. Select the tool to be edited by clicking on it with the mouse, or on the keyboard use

the

➔

keys to highlight the required tool and press Return.

➔

9. The screen shows the tool editing display, with the first item (Tool type) highlighted,

(refer to Figure 3.13).

Edit the display to show the required Tool type (and Turret position if applicable). Do

not edit the offsets.

10. Select

MENU

, and then Set Tool Offsets.

11. The screen shows:

.

Page 30

3.9Axes and ToolingBoxford 160 TCL

Follow the instructions, selecting AUTO mode on the machine control panel and

pressing both X axis buttons simultaneously, then both Z axis buttons, to home the

axes.

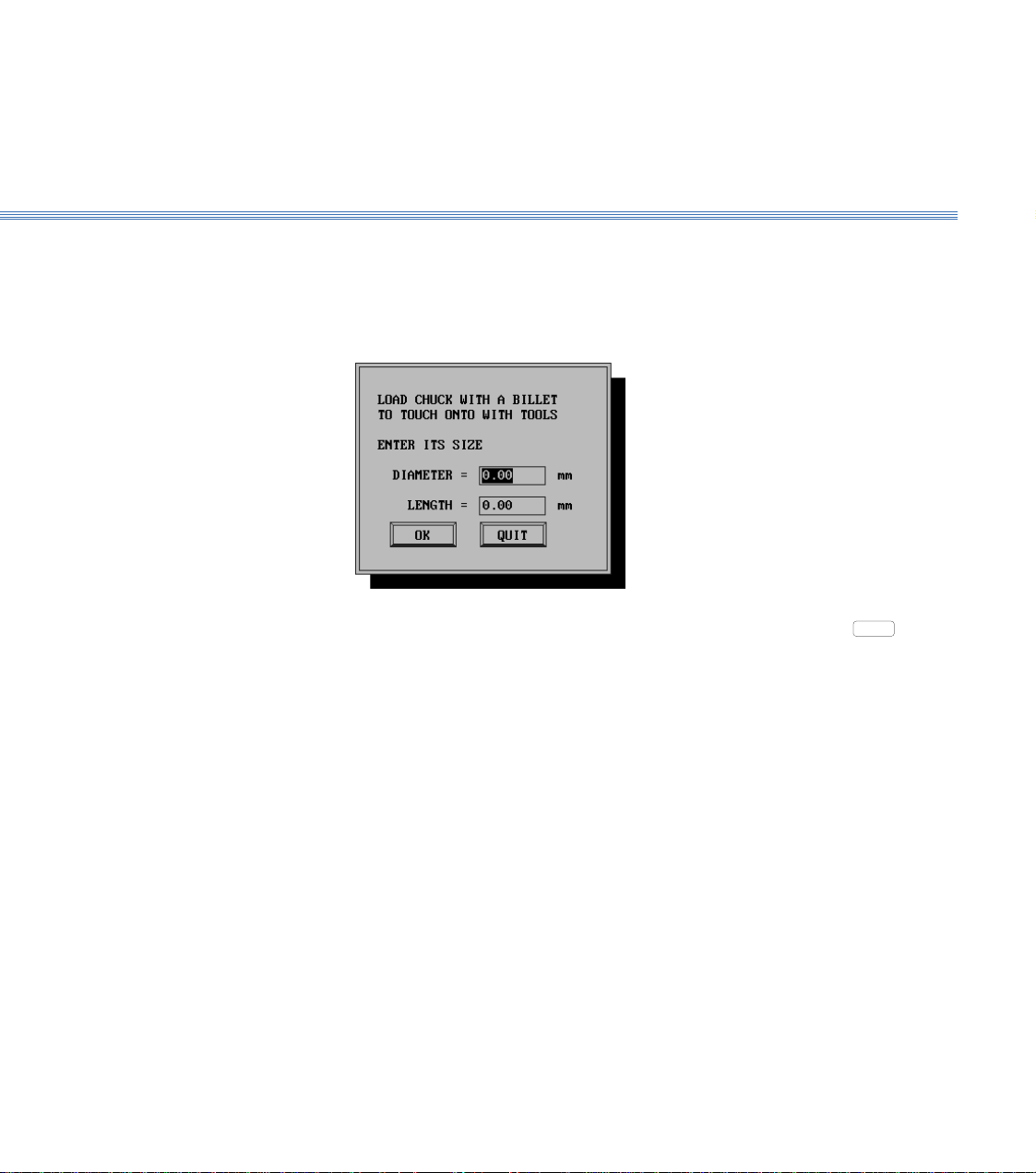

12. When the axes are homed, the screen shows:

Fit a billet into the chuck. Enter its diameter and length, and select

Return.

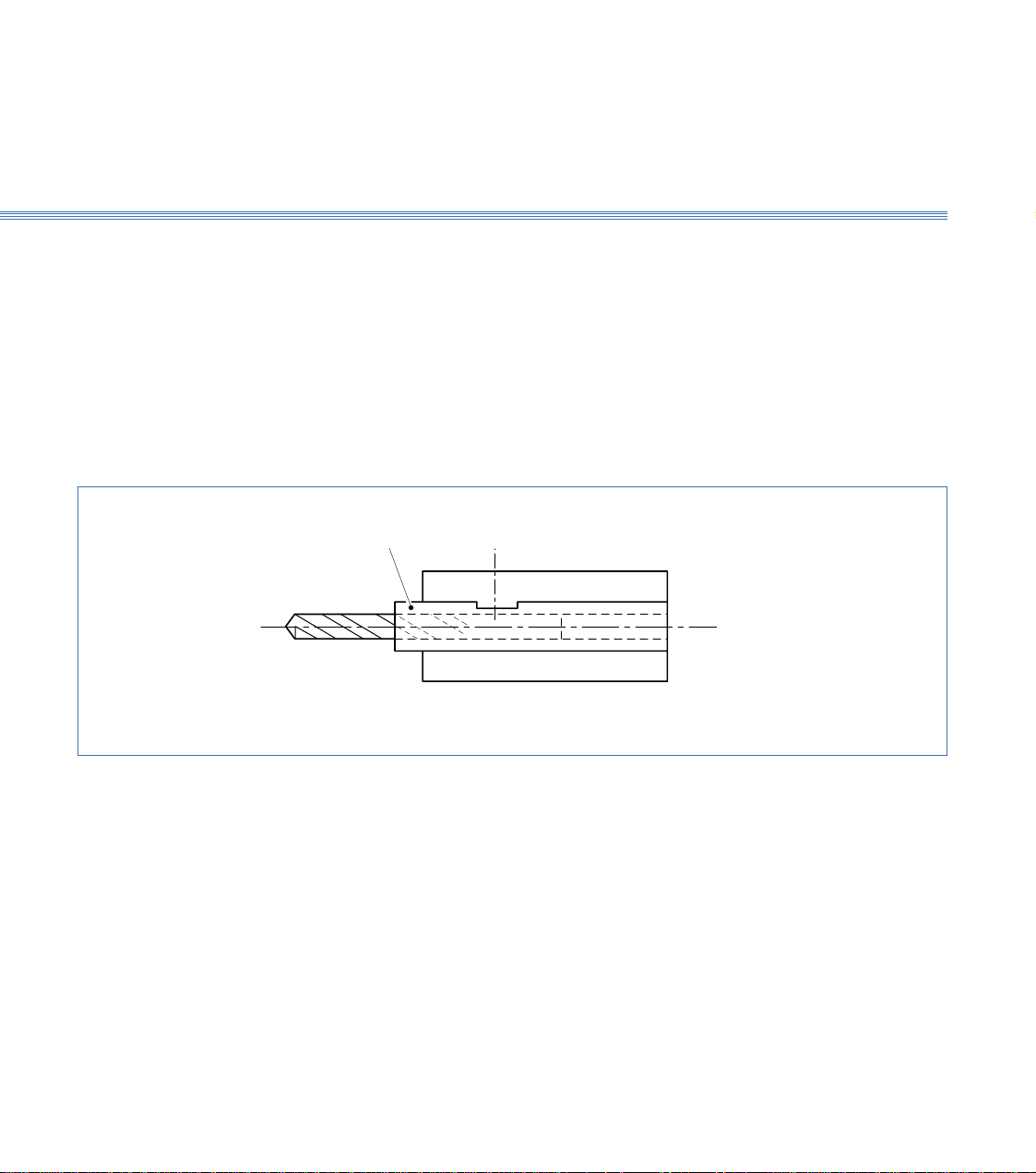

13. The screen shows the tool offsets setting display, (Figure 3.14).

On the machine control panel, select MANUAL mode. Using the X and Z axis buttons,

follow the instructions appropriate to a drill or other type of tool to position the point

of the tool on the reference diameter (the periphery of the billet).

OK

or press

Page 31

Boxford 160 TCL 3.9 Axes and Tooling

OK

1

2

1 To check tool type, press Escape or select

MENU

2 To check tool position, for Turret only, refer to Figure 3.2

3 Offsets for reference tool are zero.

and Tool library to view tool library.

To edit tool details:

Type required number in highlighted box

Press Return to accept last entry and highlight next box

When last box is highlighted, press Return: highlight will disappear

Press Return or click on

Figure 3.13 Tool Editing Display

CANCEL

to turn off display

3

, then select

Page 32

3.9Axes and ToolingBoxford 160 TCL

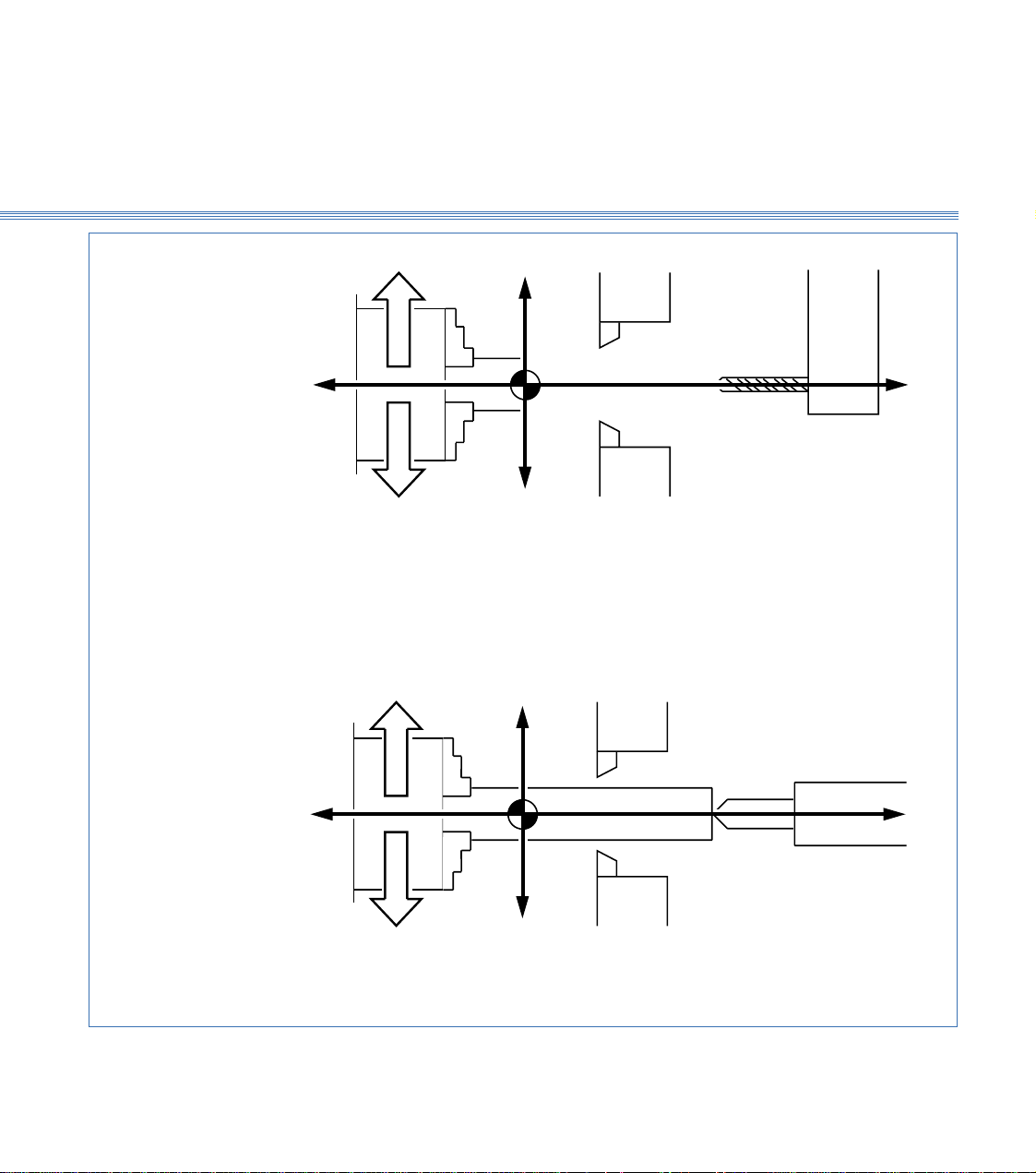

TOOLS OTHER THAN DRILLS

Tool position on axes

Tool position on axesDRILLS

Figure 3.14 Tool Offsets Setting Display

Page 33

Boxford 160 TCL 3.9 Axes and Tooling

Set Additional

Tool Offsets

14. When the tool is in the correct position, select

ACCEPT

. The screen shows:

Use the X and Z axis buttons to touch the point of the tool on the end of the billet,

and select

ACCEPT

.

15. The screen again shows the Tool Data Library.

To set the offset of the next tool, fit or index the tool and repeat the procedure from

step 7.

Note:

For setting the offsets of the second and any subsequent tools, it will not be necessary to home the axes

or enter the billet dimensions (steps 11 and 12).

When the offsets of all the required tools have been set, either select

then Save Tool Data, or click the 'off' button of the Tool Data Library display. If the

'off' button is clicked, the screen shows the message:

MENU

`and

Click on

or press Return to save the offsets.

YES

Page 34

4Main Front End Menu

When the Boxford CADCAM package is started, the Main Front End Menu screen

below is shown.

This menu is the central manager of the CADCAM tools within the Boxford TCL

package.

File Import &

Administration Functions

Program Simulate, Manufacture

and Machine Tool Driver

CAD and CAM Processor Exit to Windows Desktop

Page 35

Boxford 160 TCL

4 Main Front End Menu

In Standard User mode this menu accesses the File import filter.

In Administration mode (See section 7) additional CAM processor data settings can be

accessed and modified.

Accesses the Integrated Computer Aided Design package and CAM processor. (See

section 5)

Accesses the G&M program Simulator, Editor, Writer and Machine Tool driver. All

the configurations for connecting the TCL machine to the PC are set in this section

of the package (See Installation & User Manual).

Exits to the Windows desktop.

Page 36

New Programs

Existing Programs

CAD and CAM ProcessingBoxford 160 TCL

5 CAD and CAM Processing

5.1 Functions

The CADCAM programming features of the software provide the following

functions:

A new component is created by producing a profile on screen using the

integrated CAD system. When the profile is complete, it is processed by the

CAM system which converts it into a CNC program and saves it. The

appropriate G and M codes are included, and speeds, feeds, roughing cuts

and tool changes are incorporated into the program automatically.

Profiles stored in a CAD format can be edited. Programs created by the

CAM processor are presented in CNC format using absolute co-ordinates.

Programs created by the CAM processor and stored in a CNC catalogue can

only be viewed and edited in CNC format.

Page 37

Boxford 160 TCL CAD and CAM Processing

5.2

5.2 Information Required

To create a new CAM program you will need the following information:

1. Drawing:

The work datum is the centre of the right hand end of the bar. Since the

profile is symmetrical about the centreline of the bar, only positive X co-

ordinates need be dimensioned. All Z co-ordinates are negative, measured

from the end of the bar:

dimensions required

-Z

+X

datum

The drawing should make allowance for completing the chuck end of the

workpiece. If threads are incorporated, make allowance for undercutting

between the end of the thread and any shoulder.

For ease of programming, mark the co-ordinates of the start and end points

of each element of the profile as shown in the example in 5.4.

2. Tools Used:

Choose the appropriate tools for each machining operation, and set up the

tooling as for CNC machining.

3. Details of the billet:

Outside diameter

Inside diameter (if the billet is hollow or a tube)

Length

Hole Depth

Material (aluminium, brass, mild steel or plastic).

Page 38

CAD and CAM ProcessingBoxford 160 TCL

5.2

4. Program Name:

A name for your program (This must be a valid filename, without a file

extension.

5. Configuration Settings:

The STANDOFF option automatically adds the depth of cut to a 2mm

standoff (clearance between tool and workpiece) when using canned cycles.

This option, and other configuration settings, can be activated by selecting

CONFIG - Program from the main menu of the Simulation and Manufacture

software and making the required settings.

Page 39

Boxford 160 TCL CAD and CAM Processing

5.3

5.3 Creating a CAD Profile

Check Configuration

Input Program Details

1. From the main simualtion and manufacture menu, select CONFIG -

Program, and select STANDOFF if required.

2. From the main Front End Menu, select the CAD icon. To start a new profile,

select File - New or select the icon

Note:- If you want to open an existing file, select File - Open, or the icon,

and locate the required file.

The window below is displayed.

Input the details as follows:-

DIMENSIONS:- As required.

UNITS:- Metric of Imperial.

COMPONENT INFORMATION:- This is a field which allows more

detailed information about the profile to be entred alowing easier

identification. It is NOT the program file name.

CREATED BY:- Allows the user to name stamp their work.

When the information is correct, OK is selected. This brings up the CAD

Window.

Page 40

CAD and CAM ProcessingBoxford 160 TCL

5.4

5.4 CAD Window

The CAD program window provides a clear view of the current drawing,

various information areas, and a selection of icons with tools to cover the

most common drawing, editing and display functions.

Menu bar

Absolute

coordinates shows

the position of the

cursor relative to

the workpiece

datum (thecentre

of the component

front face)

Help message bar

Grid Snap

Grid Spacing

Tool bar

Status Bar

Billet area

Billet Information

Menu Selection

Menu items are normally chosen from the menu bar or the tool bar, using

the mouse (although keyboard alternatives are available). To choose a

menu item from the tool bar, position the pointer over the appropriate icon

and click the LH mouse button. Many items will cause the icon to stay

depressed until an alternative mode is selected from another icon.

Holding the mouse over an icon will bring up an icon Tool Tip.

Page 41

Boxford 160 TCL CAD and CAM Processing

5.4

Initial Set-up

Before starting to use the CAD system, a number of Initial Set-up steps must

be completed. Complete the following from the relevant menu:-

1. DRAWING TOOLS - SHOW GRID - Tick to show a drawing grid or untick

to clear.

2. CONFIGURATION - DEFAULTS - When in Administrator Mode (see

section 7 of this manual), the current Billet Information, Colours and Grid

Snap can be saved as the default setting for all New profiles. See below for

details.

From the Tool Bar:- 1. UNITS - Check the units. Specify Millimetres or Inches.

2. GRID SPACING - Specify the spacing for the Grid.

The default value is 1.00mm as shown. Along the Z axis the pitch of the grid

is equal to the value set. Along the X axis the pitch is half the set value, since

each element of the profile is mirrored below the centreline of the workpiece.

For example, setting the grid snap to 5.00mm produces the following grid:

+X

-Z

centreline

2.5mm

Note:

5mm

The setting can be edited later during the creation of a profile if required.

3. BILLET DIMENSIONS - Check and modify the billet dimensions.

4. COLOUR SELECTION - Modify the screen display colours.

Printing Prints the currently displayed view of the complete billet and any displayed

dimensions.

Page 42

CAD and CAM ProcessingBoxford 160 TCL

5.5

5.5 Drawing Aids

Drawing Aids The tool bar contains a number of drawing aids which are active when

selected (icon is highlighted).

Undo - Undoes the last drawn or edited entity.

Delete - Deletes the currently selected entity.

Redo - Redoes the last drawn or edited entity.

Zoom Window - Zooms in on a user defined window.

Zoom In - Performs a quick and simple zoom in facility on the billet

area currently being worked on.

Zoom Out - Performs a quick and simple zoom out facility on the billet area

currently being worked on.

Grid Snap - Toggles locking the cursor movement to the grid on and off.

Profile View - Toggles the billet view between half and full.

Advanced Zooms A number of zooms to a specified percentage value can be selected from

the drop down menu.

Alternatively, FIT can be selected to fit the drawn entities and billet to

the current screen area.

Status Bar

When defining points with the mouse, the status bar provides dynamic co-

ordinate readouts for the X axis (diameter reading), Z axis and Radius when

applicable.

The currently active Zoom, Snap and Drawing Tool are displayed.

Node Position

Hovering the mouse cursor over a node (point) will display the node

number and absolute co-ordinates.

Page 43

Boxford 160 TCL CAD and CAM Processing

5.6

5.6 Drawing Tools

Drawing Tools

The Tool Bar contains a variety of drawing tools.

The following drawing tools require points to be defined with the mouse

(using the grid).

Help and Prompts Help for each icon is displayed on the Help Message Bar to aid the user.

Straight Line - Defines a single straight line - The Start and End point are

specified. The start point MUST be the end point of the last drawn

entity. The system prevents any point other than this from being defined

as the start point.

Arcs - Draws a single arc - The Start and End point are specified. The start

point MUST be the end point of the last drawn entity. The arc direction and

radius is set with the mouse amd fixed with the LH button. After drawing

a single arc, the system reverts to Straight Line mode.

Continuous Path - Draws a series of connected straight lines and/or arcs.

The End point of each entity is defined with the LH button. Line and Arc

mode are toggled between using the RH button. This mode is the default

drawing mode for all new drawings and will be familiar to users who have

worked with previous versions of Boxford software. Press ESC to exit.

Thread- Draws external and internal threads along the Z axis - The Start and

End point are specified follwed by the Pitch and Hand in the dialogue box

shown below.

Note: If the Thread tool is greyed out, the system has detected that due to lathe machining

conventions, the next entity can not be a thread. If a right hand thread is selected,

the two dotted lines represent the minimum undercut required for the specified

thread. There must NOT be any entities drawn in this area.

Fillet - Draws a fillet between two perpendicular lines - The fillet radius is

entered and the required corner intersection selected.

Chamfer - Draws a 45° chamfer between two perpendicular lines - The

chamfer distance is entered and the required corner intersection selected.

Page 44

CAD and CAM ProcessingBoxford 160 TCL

5.6

Co-ordinate Entry As an alternative to defining an entity using the mouse, a coordinate entry

sytem is available. Note:- Co-ordinates not on the current grid can be

defined.

Co-ordinate Entry - Defines Lines and Arcs using a coordinate entry system.

The following dialogue box of options is available. (Note:- the Absolute

point displayed is the end position of the last defined entity. If an arc is

required, define the arc direction CW(clockwise) or CCW (counter clockwise)

and the Arc radius. Ensure a valid arc radius that can pass through the start

and end point is defined.

To enter a number of entities,tick the 'Enter more points' check box.

Absolute Point (x,z): - Define the end point of the entity as an absolute

coordinate from the billet datum (centre of front face).

Length and Angle: - Define the cord length of an entity and the angle as

shown in the diagram below. See next page for angle conventions.

C

o

r

dLe

n

g

t

h

End Point

0°

L

ine

le

g

n

A

o

90°

r

A

r

c

Start Point

Page 45

Boxford 160 TCL CAD and CAM Processing

5.6

Angle Conventions

For all co-ordinate entries requiring an angle, the conventions shown in the

diagram below should be used.

0°

90°

0°

90°

180°

90°

90°

0°

270°

180°

270°

0°

90°

270°

0°

Absolute Point (x,z): - Define the end point of the entity as an incremental

move from the end of the last entity co-ordinate.

Displace X and Angle: - Define an incremental move in X and the angle as

shown in the diagram below. Note angles should be to the conventions

shown above.

End Point

XinØ

0°

le

g

An

L

i

n

e

o

90°

r

A

r

c

Start Point

Displace Z and Angle: - Define an incremental move in Z and the angle as

shown in the diagram below. Note angles should be to the conventions

shown above.

Z

L

i

End Point

0°

n

eo

e

l

g

n

A

r

A

r

c

90°

Start Point

Page 46

CAD and CAM ProcessingBoxford 160 TCL

5.6

Auto Dimensioning The Auto Dimensioning function toggles between three modes.

Please note:- auto dimensioning is an extremely difficult operation for the

system to complete on the large variety of profiles that can be defined on the

CAD system. In some cases the position of the dimension will be a

compromise to allow all dimensions to be displayed.

1. Standard Mode - Dimensions the billet only (default start up mode).

2. Incremental Mode - Dimensions all points on the profile with the Z

dimension relative to the previous and next point as shown below.

2. Absolute Mode - Dimensions all points from the billet datum.

Page 47

Boxford 160 TCL CAD and CAM Processing

5.7

5.7 Editing Tools

Editing Node Positions

Editing Entities Moving a mouse cursor over an entity and clicking the RH mouse button

Moving the mouse cursor over a node (point), pressing and holding

the Right Hand mouse button, allows the node to be dragged to a new

position. Releasing the RH mouse button fixes the node to the new position.

A node can also be moved using the co-ordinate entry system. See the

section 'Editing Entities' - Properties below.

will highlight the entity and display the dialogue box shown below.

Depending on the type of entity selected, some of the options will be greyed

out as they are not applicable to to the specified entity.

Insert Node - Inserts a node at the midpoint of the entity which adds an

additional straight line entity. Note if this option is used on an ARC, the arc

will be converted into two diagonal lines as shown below.

Insert Fillet - Inserts a fillet between the selected entity and following entity.

Thr radius is specified as shown below.

Page 48

CAD and CAM ProcessingBoxford 160 TCL

5.7

Delete Object - Deletes the selected object, connecting the end point of the

previous object to the start point of the next object as shown in the diagram

below.

Convert to Line - Converts an arc into a diagonal straight line.

Convert to Arc - Converts a diagonal straight line into an arc.

Convert to Thread - Converts a horizontal straight line into a thread.

The pitch and hand of thread are entred as shown below.

Note:- If a horizontal straight line does not have this edit option available,

it is because it is not in a suitable position, in relation to other entities within

the profile, to be threaded.

Modify the Arc Radius - Unlocks the arc radius allowing it to be re-specified

with the mouse position and fixed with the LH button.

Properties - Displays the properties of the entity. The co-ordinates diplayed

are the end point of the entity. Co-ordinates can be modidifed to move the

end point to a new (valid) position. Arc radii and/or direction can be

modified. See section 5.6 - Drawing Tool - Co-ordinate Entry for specific

details on co-ordinate conventions.

When an entity has been highlighted with the RH mouse button, the

properties field is also accessible through the icon on the tool bar.

Page 49

Boxford 160 TCL CAD and CAM Processing

5.8

5.8 3D Renderer

At any point during the design of a profile, a 3D rendred image can be

viewed and manipulated.

'Launch 3D Render' is selected from the 'View' menu.

If the profile has not being named and saved, the user is prompted to do so

at this point.

If the profile has been modified and not re-saved, the box below is shown.

Select YES to overwrite the old profile.

Select NO to abort and use the File - Save As option to rename the file before

launching the 3D Renderer.

The 3D Renderer window, as shown below, is launched.

Page 50

CAD and CAM ProcessingBoxford 160 TCL

5.8

The 3D Renderer defaults to an automatic animation mode which continually

spins the model around the vertical axis.

The user can overide the animation and manipulate the model with the tools

provided from the window menus. These are as follows.

Model Control Solid Render - Solid Renders the image as shown on the previous page.

Wire Frame Render - Diplays a wire frame image as shown below.. This can

be useful for speeding up the animation on computers which are close the

the required minimum specification.

Animate - Initiates the default automatic animation mode.

Freeze Animation - Stops the automatic animation allowing manual

manipulation of the model.

Print - Prints an image of the model in its current position. Textual model

data is also produced.

Copy Image to Clipboard - Copies an image of the model in its current

position to the clipboard for pasting into 3rd party packages. Note the black

background is converted to white.

Rendering Material Allows the shading of the model to be changed to represent Steel, Plastic, or

Wax. Wax is the default material.

Rotate Model Jogg Left, Jogg Right, Jogg Up, Jog Down - Joggs the model in the required

direction by one increment. Alternatively, use the keyboard hot key.

Home - Re-sets the model position to its home position.

Spin Left, Spin Right - Rotates the model around the Z axis (centre line). This

is a useful for viewing a screw thread.

Page 51

Boxford 160 TCL CAD and CAM Processing

5.8

Using the Mouse

In addition to the mouse menu and keyboard controls, the model can be

manipulated using the mouse.

Move the cursor over the model. Press and HOLD DOWN the LH mouse

button. The model can now be dragged to any position. To fix in the

required position, release the mouse button.

Examples of the positional possibilities are shown below.

Page 52

CAD and CAM ProcessingBoxford 160 TCL

5.9

5.9 Example (Figure 5.1)

Figure 5.1 shows a drawing of a component whose profile consists of

straight lines, arcs and a thread. The co-ordinates of the start and end points

of each element have been marked in the top half of the billet outline.

The straight lines and arcs can be machined with the LH turning tool (1) and

parting tool (11). To cut the thread it will be necessary to fit an external

threading tool and to add this to the Tool Data Library.

Start a new CAD Profile as detailed in 5.3 and use the File - Save option to

name it EXAMPLE. Refer to 5.4, 5.5, 5.6 and 5.7 for guidance in producing

the profile shown in Figure 5.1.

Co-ordinates shown in the format: X, Z

10mm x 0.75mm pitch RH

21,-39

17,-45

0,-45

Z -50

16,-29

21,-29

10,-14

10,-16

Figure 5.1 Example of Drawing for CAM Program

15,-9

8R 8R

X +25

8,-1

8,-4

0,0

Page 53

Boxford 160 TCL CAD and CAM Processing

1. Place the cursor in the top half of the billet outline.

2. A cross is displayed which is connected to the datum by a straight line:

5.9

3. Watch the co-ordinate display and drag the cross-hairs to set the end point

of the line in the correct position. The line will behave like a rubber band,

and X and Z co-ordinates of the display will change as the cross is moved;

when they read X = 8.00, Z = 1.00, select the LH mouse button. Ensure that

grid snap is set to 1.00mm or less.

4. The first line of the profile will remain on the display, and will be mirrored

by a symmetrical line in the bottom half of the billet outline if displayed.

Page 54

CAD and CAM ProcessingBoxford 160 TCL

5.9

5. Repeat this procedure to draw the next straight line of the profile, dragging

the cross to the end point of each line and checking the co-ordinate display

before selecting the LH mouse button:

If you make a mistake, select to erase the last line and repeat the

procedure.

Manual Input

Using the RH mouse button, select each object and selecte 'Delete Object'.

1. Select ; the screen will show the co-ordinate entry window:

The absolute co-ordinates of the end point of the last element to be drawn

are shown. Since no element has yet been drawn the co-ordinates are those

of the datum.

2. Enter the absolute co-ordinates of the end point of the first line: X = 8, Z =

-1, and select OK.

The first line of the profile will appear, mirrored by a symmetrical line in

the bottom half of the billet outline.

3. Repeat this procedure to set the end point of the next line of the profile:

X = 8, Z = -4

If you make a mistake, select to erase the last line, and repeat the

procedure.

Page 55

Boxford 160 TCL CAD and CAM Processing

5.9

Drawing Arcs

In Continuous Path Mode ,arcs are selected with the RH mouse button.

If the Arc Tool is selected from the tool bar, in addition to the procedure

detailed below, the start point must first be defined with a LH mouse click

over the end point of the last drawn entitiy.

An arc is drawn in three stages as follows:

1. Set End Points

Drag the cross to the end point of the arc. Check the co-ordinates on the

display. Adjust the position of the cross until the co-ordinates are correct,

and fix the position with the RH mouse button.

Drag to end point of arc (15,-9)

then release button

'rubber band'

Start of arc (8,-4) end point of last straight line

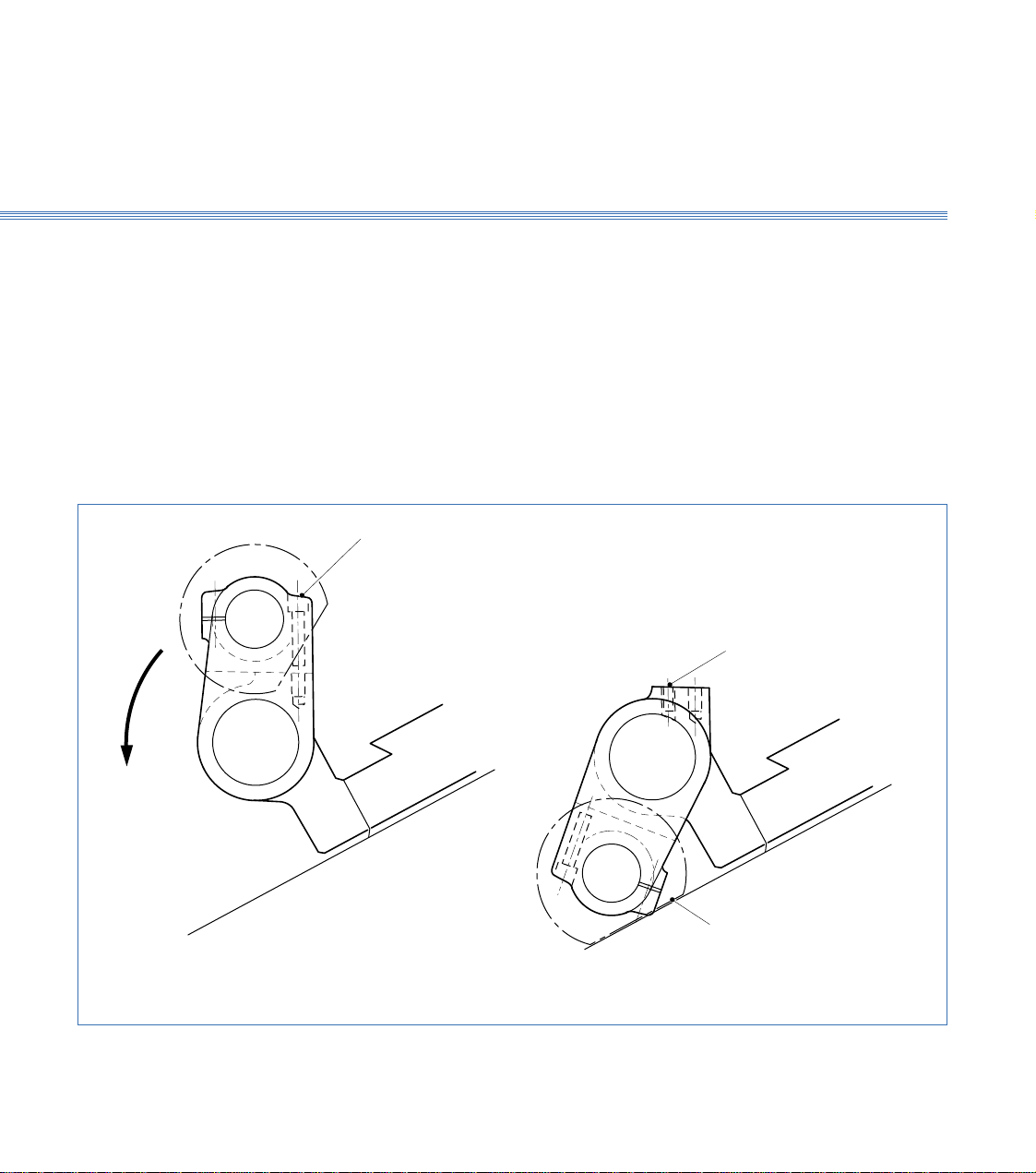

2. Select Direction and Radius

Move the cross away from the end point (1); the cross will be joined to the

end point by a straight line which is the tangent to the arc at the end point.

Swing the cross around the end point (2); the arc will switch from counter-

clockwise to clockwise, and the radius will vary as the cross is moved:

1

2

Clockwise arc

Counter clockwise arc

For the example, select a counter-clockwise arc and set the radius at

8.00mm. Check the co-ordinate display for the correct setting:

X = 15.00 Z = -9.00 ARC RADIUS = 8.00mm

Page 56

CAD and CAM ProcessingBoxford 160 TCL

5.9

3. Enter Setting

When the setting is correct, click the LH mouse button.

If you make a mistake, select to erase the arc, and repeat the procedure.

Draw the second arc, setting the end point at X = 10, Z = -14. Select a counter-

clockwise arc, and set the radius at 8.00mm.

Using the RH mouse button, select each object and select 'Delete Object'.

Manual Input

1. Select

2. The screen shows the co-ordinate entry window:

The X and Z co-ordinates shown are those of the end point of the last

element in the profile (A). Enter the co-ordinates of the end point of the arc

(B):

In the 'Arc Properties' section, shown below, select CCW (counter-clockwise)

and enter the radius of the arc. (For the example, enter 8.00mm).

8.00

B

A

3. Select OK: the arc will appear on the display, and will be mirrored by a

symmetrical arc in the bottom half of the billet outline.

Page 57

Boxford 160 TCL CAD and CAM Processing

AB

5.9

4. For the example, repeat the procedure to draw the second arc. Set the radius

to 12.00mm and the co-ordinates of the end points to X = 10, Z = -14:

10,-14

If you make a mistake, select to erase the last arc, and repeat the

procedure.

Drawing Threads 1. For the example, draw the next three straight lines of the profile in

preparation for adding the threaded section:

2. Select and then the start point of the thread, last point:

The cursor is locked to the horizontal plane. Move the cross to the Z co-

ordinate of the end-point of the thread (B) and fix with the LH mouse button.

Page 58

CAD and CAM ProcessingBoxford 160 TCL

5.9

3. The window below is shown.

Select left hand or right hand thread as required. For the example, select

right hand thread. Change the THREAD PITCH value if required, entering

either a pitch (metric units) or threads per inch (Imperial units).

For the example, set the pitch to 0.75mm

4. Select OK ; the specified thread will appear on the profile.

5. For the example, draw the remaining straight lines to complete the profile:

Page 59

Boxford 160 TCL CAD and CAM Processing

5.9

3D Renderer

Select 'Launch 3D Render' from the 'View' menu.

If required, name and save, the profile at this point.

The Renderer window below is shown.

Select Model Control - Freeze Animation.

Using the controls described in section 5.8, try manipulating the model. In

paricular, try rotating the model using the keyboard + and - keys to animate

the screw thread.

Page 60

5.10 CAM Processing a Profile

When the CAD profile is complete and ready to be processed into a G&M

code CNC programme, select File - Process Billet.

If the profile has not being named and saved, the user is prompted to do so

at this point.

If the profile has been modified and not re-saved, the box below is shown.

Select YES to overwrite the old profile.

Select NO to abort and use the File - Save As option to rename the file before

re-processing.

5.10

CAD and CAM ProcessingBoxford 160 TCL

The CAM Processor Dialogue box shown below is displayed.

The various settings are as follows:-

Material Selecting the drop down provides a list of the available material types. (See

section 7 - 'Administrator Mode' for more details on adding user defined

materials and cut data).

The required material is selected from the list.

Page 61

Boxford 160 TCL CAD and CAM Processing

5.10

Material Dimensions

Tools Selecting the Tools Tab displays the tools currently available to the CAM

The material dimensions shown are those specified in the CAD system,

unless the profile was drawn up to the left hand end of the billet, in which

case a suitable parting off allowance is automatically added.

The material dimensions can be modified prior to processing.

This can be useful if the billet size, the component was designed for, is not

available. If a larger one is specified, the CAM processor will automatically

add the extra roughing cycles to remove the additional material.

processor for creating a G&M programme from a drawn profile.

The window below is shown.

When logged on to the sytem as a 'standard user', this window is for

information only.

When logged on as an administrator (see section 7 for details), the user can

define which tools are available to the CAM processor by heighlighting

them.

Depending on the type of component to be processed, a minimum number

of tools are required.

e.g. To process external profiles, the minimum tooling requirements are:-

1. LH Turning Tool (55° tip angle)

2. Parting Tool

3. External Threading Tool (If threads are to be cut).

Page 62

CAD and CAM ProcessingBoxford 160 TCL

5.10

Rough and Finish Turning

When in Administrator mode, if two LH Turning Tools are available, one

can be set to perform the Rough Turning Process and the other se to perform

the Finish Turning Process.

If a second LH Turning Tool is highlighted, window below is shown.

Roughing or Finishing is selected.

The second LH Turning Tool is automatically set to the alternative option.

Machine Info. Selecting the Machine Info. Tab displays the current machine parameter

which effect the CAM processor. The window is shown below.

When logged on to the sytem as a 'standard user', this window is for

information only.

When logged on as an administrator (see section 7 for details), the user can

modify the settings.

FMS Connected - When checked the CAM inserts the appropriate M81 codes

to communicate with the Robot port (see section 11 - Robot interfacing).

Tailstock Fitted - When checked the CAM will not face-off the billet end or

specifiy operations using internal tooling.

Page 63

Boxford 160 TCL CAD and CAM Processing

5.10

Processing

To process the profile and create a G&M CNC programme,

is selected.

The processor analyses the Drawing and produces a G&M code CNC programme

specifying Cutter Paths, Speeds, Feeds and Cut Depths appropriate to the material

type selected and the tooling available.

Tool Path Simulation When the profile has been processed the following dialogue box will be

displayed (Please note if processing reveals any errors this dialogue box will

be proceeded by an error message dialogue box - see section 5.11 for details).

The user is prompted to select a Catalogue number to place the file into.

Catalogues - All manufacture programs (G&M

programs) are filed in Catalogues. There are

9 catalogues available to the user.

A catalogue is selected. If a file of the same

name already exists in the selected catalogue,

the following dialogue box appears.

2

1

9

8

7

6

5

4

3

The file can be overwritten by selecting YES or NO can be selected

bringing up the following dialogue box.

The filename can be changed and/or the

catalogue changed. OK is selected.

Page 64

CAD and CAM ProcessingBoxford 160 TCL

5.10

A 2 Dimensional simulation of the cutter path is shown. This is the final user

check of the component that will Actually Be Machined. Any areas which

can not be removed because of tooling limitations will be omitted.

3 Dimensional View For details on 3D Views, View Manipulation and Cycle Details see sections

2 and 9.

Page 65

Boxford 160 TCL CAD and CAM Processing

5.11

5.11CAM Processor Error Messages

When Processing a drawing, the CAM processor compares the drawn

profile requirements with the Cutting Tools available and machine

parameters set. If any drawing requirements can not be satisfied, then an

error message (or messages) is displayed.

Billet Size If the billet specified in the CAM processor is too small then the window

below is shown.

Select Accept to revert to the minimum billet size or Retry to return to the

CAM window and re-specifiy the dimensions.

Tooling If there are insufficient tools available to machine the profile, an error

message is displayed. An example is shown below.

These are explained as follows.

INTERNALS CANNOT BE ACCURATELY CUT - Drills are not available to

machine the specified drilled holes in the profile.

NO CENTRE DRILL FOR DRILLING LARGE HOLES - Centre drill not in

library and selected as available.

NO EXTERNAL THREADING TOOL - External threading tool not in

library and selected as available. (could also be Internal Threading Tool).

Page 66

CAD and CAM ProcessingBoxford 160 TCL

5.11

The user can continue processing by selecting Ignore.

A program with the compromised settings (safe) is produced.

or, The user can abort processing by selecting Reprocess.

Profile Shape If areas of the profile can not be machined, an error message is displayed.

An example is shown below.

These are explained as follows.

INTERNALS CANNOT BE ACCURATELY CUT - Drills of the correct size

are not available to machine the specified drilled holes in the profile. If this

warning is ignored, the drilled holes will be machined with the nearest

diameter smaller drill.

INTERNALS SHAPING TOO SMALL FOR BORING BAR- The internal

profile above the maximum drill diameter and below the minimum boring

diameter cannot be shaped with the boring bar. See section 7 for minimum

bore details.

INSUFFICIENT UNDERCUT FOR RH THREAD - The drawn profile has

entities crossing the minimum undercut, shown on the drawing by two

dotted lines.

CANNOT SHAPE CHUCK END OF BAR - The left hand end of the profile

has a shape which can't be cut without the workpiece falling off.

To part off the profile, the last drawn entitie must be a vertical straight line.

The user can continue processing by selecting Ignore.

A program with the compromised settings (safe) is produced.

or The user can abort processing by selecting Reprocess.

Page 67

Boxford 160 TCL 6 DXF File Imports

6 DXF File Imports

DXF Files DXF (Drawing Exchange Format) is a file format for transferring drawing information

between CAD and CAM packages. Almost every CAD package will be able to export

a DXF file.

File Export Rules Which ever drawing package you export from, there are some guidelines which will

help you to successfully export DXF files suitable for importing into the Boxford

CADCAM package.

The Boxford CADCAM package requires the DXF file to include half the profile

together with a horizontal centre line, as shown in the following examples.

1. External Profile Only - To Parted Off

Half the P r of ile

Horizontal C entre Line

2. External Profile Only - NOT to be Parted Off

Horizontal Centre Line

Half the Profile

Page 68

Boxford 160 TCL

6 DXF File Imports

3. Combined External and Internal Profile - To be Parted Off.

Half the Profile

Horizontal Centre Line

4. Combined External and Internal Profile - NOT to be Parted Off.

Half the P rofi le

Horizontal Centre Line

5. External Profile manufactured from Tube - To be Parted Off.

Half the P rofi le

Leave Gap Here

Horizontal C entre Line

Tube

Inter na l

Radius

Page 69

Boxford 160 TCL 6 DXF File Imports

6. External Profile manufactured from Tube - NOT to be Parted Off.

Half the P rofile

Horizontal C entre Line

Tube

Interna l

Radius

7. Combined External and Internal Profile manufactured from Tube - To be parted

off.

Tube

Inter na l

Radius

Leave Gap Here

Half the P rof ile

Horizontal C entre Line

8. Combined External and Internal Profile manufactured from Tube - NOT

to be Parted Off.

Half the P rofile

Horizontal Centre Line

Tube

Internal

Radius

Page 70

Boxford 160 TCL

6 DXF File Imports

Horizontal Centre Line Problem - Different CAD packages have a variety of Centre Line Types some of which

(or even all) do not export as a Centre Line (they export as a series of Continuous

straight lines which make up the centre line).

The Boxford CADCAM package looks for a centreline in the DXF file to reference

the centre of the profile. If one is not found, the file Import is aborted.

Solution - Try different types of Centre Line and Find one that works.

Alternative Solution - If the Boxford CADCAM package does not find a centre line,

it will look for a line of different colour, or a line on a drawing Layer other than the

Half Profile Layer.

Draw the centre line as a different colour to the profile, or/and draw the centre line

on a different layer.

Half the Profile Continuous - The half profile must consist of entities which are connected together

to form a continuous path. There can be no gaps or entity overlaps or the File Import

will be aborted

A gap between entities could be as small as the drawing package resolution and not

visible on a high resolution monitor unless a high magnification drawing zoom is active.

Gap between

Entities

Incorrect Incorrect Correct

Overlap of

Entities

Connected Enti t ies

Page 71

Boxford 160 TCL 6 DXF File Imports

Half Profile Errors Profiles NOT conforming to Lathe cutting Conventions - There are a number of

entities which will cause a profile processing error. The Boxford CADCAM package

will abort the File Import in each case.

Examples of incorrect profiles are shown below - avoid these to successfully import

DXF files.

Holes - These Cannot be smaller at the front face of the profile than at the bottom of

the hole. Internal diameters cannot have recesses.

Holes

Incorrect CorrectIncorrect

Internal Straight Lines - The end point nearest the centre line cannot be Z+ve (to

the right) in relation to the other end point.

Internal Straight L ines

Z-ve Z+ve Z-ve Z+ve Z-ve Z+ve

Incorrect Correct

Corre c t

External Straight Lines - On a line facing the front face of the profile, the end point

nearest the centre line cannot be Z-ve (to the left) in relation to the other end point.

On a line facing the rear face of the profile (e.g. the first line of a recess or the line

defining the end of the profile), The end point nearest the centre line cannot be Z+ve

(to the right) in relation to the other end point.

Page 72

Boxford 160 TCL

6 DXF File Imports

External Straight L ines

Z-ve Z+ve Z-ve Z+ve Z-ve Z+ve

Incorrect Correct

Arcs - These must adhere to the same rules as straight lines, however it is not just the

start and end point which can cause the error, it is any point around the arc radius.

Generally, if at any point around the path of a continuous arc the Z co-ordinate sign

changes (-ve to +ve or vice versa), the arc will be invalid.

On some arcs this may be very difficult to see unless viewed under a high magnification

within the CAD package. Some examples are shown.

Correct

Internal Arcs

Z-ve Z+ve Z-ve Z+ve Z-ve Z+ve

Incorrect

External Arcs

Z-ve Z+ve

Incorrect

Incorrect

Z-ve Z+ve

Correct

Correct

Page 73

Boxford 160 TCL 6 DXF File Imports

Importing DXF Files From the CAD window, File - Import - DXF is selected.

The file to be imported is located and OPEN selected.

The window below is shown.

The units of the imported file are defined and OK selected.

Note:- If there are any Profile Errors, a message is displayed and the file

import aborted.

The profile is displayed and can be edited and processed like any other

profile created within the Boxford CADCAM package.

Page 74

Boxford 160 TCL Administration Mode

7 Administration Mode

7.1 Access & Password Setting

An administration mode is built into the Boxford CADCAM package allowing

authorised personnel to access and modify important CAM processor data files.

Any modifications that are defined will be applied to every future processed drawing.

Network Administrators To be able to use the Boxford administration mode and write to the relevant data

files, you must have read/write access to the Public Drive

Setting a Password With the Front End menu screen displayed, the F10 key is pressed, to define a

password, or modify and existing one. The dialogue box below is shown.

is selected.

The dialogue box below is shown.

The user is prompted to Enter CURRENT Password.

If an initial password is to be defined, is selected.

If an existing password is to be re-defined, the existing password is input and

selected.

OK

OK

Page 75

Boxford 160 TCL Administration Mode

7.1

The dialogue box below is shown.

The user is prompted to Enter NEW Password

The new Password is input selected followed by :-

OK

Accessing Admin. Mode Each time the software is started, the system defaults to Standard User mode. With

the Front End menu screen displayed, Administration mode is accessed by:-

a. Pressing the F10 key

b. Selecting

c. Inputting the current password and selecting

OK

d. Selecting

Selecting the Configuration Icon reveals a number of icons in addition to the Standard

User Import DXF file option (see section 6 for details).

Page 76

Boxford 160 TCL Administration Mode7.2

7.2 Tool Librar y

Accesses the tool library shown below.

New tools can be defined and existing Tools modified or removed.

Defining a New Tool Using the LH mouse button or keyboard cursor, Highlight an empty tool library

line.

Select The dialogue below is shown.

Edit Tool

From the Tool Type drop down, select the Tool type to be defined.

Input the Tool Diameter (if appropriate to the tool)

Edit an existing Tool Highlight the tool to be edited and Select

Remove an existing Tool Highlight the tool and select

Remove

Saving To close and save the tool library data, select

Edit Tool

Finish

Page 77

Boxford 160 TCL Administration Mode7.3

7.3 Material Cutting Data

Accesses the Material Cutting Data shown below.

This data is used by the CAM processor when creating a G&M code CNC programme

from a Profile.

For each Material Type, Cutting data for Roughing and Finishing operations can be

specified for different Tool types. New materials can be added and existing ones

Modified or Deleted.

Tool Type The Tool Type is selected from the drop down menu.

Page 78

Boxford 160 TCL Administration Mode

7.3

Material The Cutting Data file supplied with the software package includes a selection of

Default material types. User-defined materials can be added up to a maximum of six

material types in total.

Adding a New Material

Add Material

is selected. The dialogue box below is shown.

The user is prompted to Enter material to add to list.

The material name is input and selected.

OK

Deleting an Existing Material

The material to be deleted is selected using the Material drop down menu.

Delete Material

is selected. The dialogue box below is shown.

YES

is selected to confirm the material delete.

Page 79

Boxford 160 TCL Administration Mode

7.3

Feed The rate at which the axes move when cutting in mm/rev (mm per revolution).

Values can be set for Roughing and Finishing operations.

Speed The Constant Surface Speed in m/min (metres per minute) or the Constant

Spindle speed in RPM (revolutions per minute).

The units will automatically toggle depending on the Tool type selected.

Values can be set for Roughing and Finishing operations.

Depth of Cut The maximum depth of cut. The value is the maximum amount of material which can

be removed on diameter (i.e. it is 2 x the radial depth of cut).

Values can be set for Roughing and Finishing operations.

Note:- Unlike Feed and Speed, Depth of Cut is Material specific and not Tool

type specific. (i.e. there is only one Roughing and Finishing value per material).

Restoring Defaults is selected to return All the Cutting Data currently shown in the

Restore Defaults

Cut Data dialogue box to the Factory settings

Saving To save the modified Cutting Data, select

To exit without saving changes, select

OK

Cancel

Page 80

Boxford 160 TCL Administration Mode

7.4

7.4 Internal Machining Data

Accesses the Internal Machining data shown below.

Warning The Internal Machining Data is set at the factory to match the tooling supplied with

the TCL Machine and should only be modified if the internal tooling on the machine

is changed.

Max. Drill Size The maximum diameter Drill available on the TCL Machine.

Min. Bore Size The minimum internal diameter the Boring Bar will machine.

Min. Thread Size The minimum internal diameter the Internal Threading Tool can cut a thread at.

Restoring Defaults is selected to return All Internal Machining Data to the Factory

Saving To save the modified Cutting Data, select

Restore Defaults

settings

To exit without saving changes, select

OK

Cancel

Page 81

Boxford 160 TCL Administration Mode

7.5

7.5 Park Position and Units

Park Position Accesses the park position settings shown below.

The Park Position is the position of the Tool in relation to the workpiece datum

(front left corner) at Tool Changes and the Start/End of Cycle.

X, Y and Z values are specified.

Restoring Defaults

is selected to restore the Factory settings.

Restore Defaults

Saving

To save the modified Cutting Data, select

To exit without saving changes, select

OK

Cancel

Units Accesses the units settings for Administration mode as shown below.

Metric or Imperial units are selected. saves the setting.

OK

Page 82

Boxford 160 TCL Administration Mode

7.6

7.6 Language Settings

Language Settings Accesses the Language options for the software.

Note:- This sets the language for the CAD and CAM software but not

for the G&M Code CNC Programme Simulator and machine driver

which has its own configuration menu. See Installation and User manual for

details.

The icon is selected displaying the dialogue box below.

From the drop down menu, the required language is specified.

is selected to confirm the selection.

OK

For the new setting to take effect, the software must now be restarted by exiting to

the windows desktop and re-starting the software.

Page 83

Manual Data Input CNC ProgrammingBoxford 160 TCL

8 Manual Data Input CNC

Programming

8.1 Operations and Programming Sheets

Before commencement of programming the following points require consideration:

1. Drawing

The work datum is usually centre of the right hand end of the bar; this makes it easier

to set the tools. If necessary re-dimension the drawing from this datum.

+Z-Z

+X

-X

2. Machining

Decide on the sequence of the machining operations (e.g. rough turn, finish turn, screw

cut, part off.)

3. Tooling

Choose appropriate tools for each machining operation.

4. Programming

Decide on incremental or absolute dimensions, feed mm/min, spindle speed rev/min.