Bowers and Wilkins Signature 8-NT Owners manual

Installation Instructions

Contents

English 1

Français 4

Deutsch 8

Español 12

Italiano 16

Nederlands 20

Русский 24

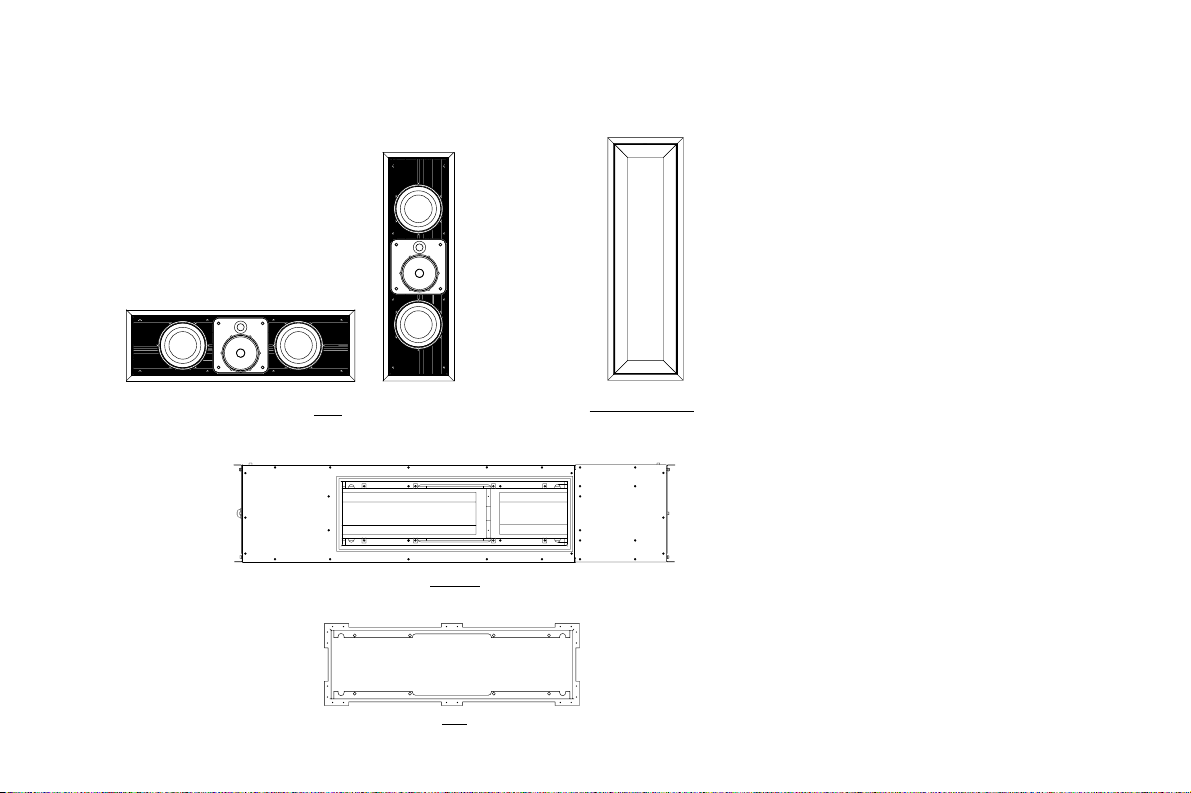

Cut-off diagrams

Wall frame and grille

PMK

Back box

Baffle

English

INTRODUCTION

Description

The Signature 8NT is a 3-way in-wall speaker

capable of true audiophile performance.

The total design is divided into four separate

modules:

1. Wall frame and grille

2. Baffle with drive units and crossover

3. PMK (Pre/post Mount Kit)

4. Back box

Separately packing each module enables parts

to be stored safely off site until they are needed.

The first two modules are required for all

installations and so are delivered together in a

master carton. See below in this section to find

out whether you need either the PMK or the

back box for your particular application. You will

need one of them, but not both.

The speaker may be bi-wired or bi-amplified if

desired. On delivery, the two pairs of input

terminals are shorted together for single wiring by

two looped link wires on the crossover board. To

bi-wire or bi-amplify, snip these link wires at the

top of the loop. This will allow enough length for

reconnection later if desired.

Do not begin the work until you have thoroughly

read this guide.

To get the best from the speaker, it is important

that it is installed in a proper manner. We suggest

you familiarise yourself fully with these

instructions before starting any work. If there is

any point you do not understand, help and

advice is available from the appointed B&W

distributor/importer in your country.

Installation options

Warning;

The speaker drive units create stray magnetic

fields, which may affect televisions containing

conventional cathode ray picture tubes. Keep the

speaker at least 50cm (20 in) clear of such

devices. Some particularly sensitive televisions

may require further spacing.

The Signature 8NT can be installed in drywall or

solid construction in either vertical or horizontal

orientation. With existing drywall construction,

the speaker can readily be retrofitted in the

vertical orientation. However, horizontal

orientation requires cutting into vertical wall

studs, so is a major job, more akin to new

construction than normal retrofit.

The wall frame and grille

The wall frame is installed after final plastering,

but before decorating. The grille mesh and frame

may be painted as desired before the baffle and

drivers are fitted.

The baf

fle

The baffle contains all the working parts of the

system. Having it separate from the frame makes

it easier to fit the frame and avoids possible

damage to the drivers during decorating.

The back box

In drywall construction, the back box provides

extra sound insulation between adjacent rooms

and a safety barrier to the spread of fire between

the wall cavity and the room. If you are working

with solid walls, the back box gives a defined

working volume that extends beyond the

immediate area of the speaker itself. Any smaller

volume and the speaker will have a restricted

bass performance. For extra flexibility in

installation, for example keeping clear of other

objects in the wall, the speaker may be

positioned either in the centre of the back box, or

to one end. (Figure 16 )

The PMK

The PMK is used in drywall construction

whenever the back box is not required, whether

new construction or retrofit.

PLANNING THE SPEAKER POSITION

Overview

Consider carefully where the speakers are to be

placed in the room according to the application.

The following are guidelines but, as with any

custom installation, specific on-site conditions

may require adaptation. In particular, the position

of wall studs in drywall construction may

necessitate adjustment of the recommended

speaker position.

The speaker may be installed in either vertical or

horizontal orientation, the latter normally used for

centre channel applications to allow positioning

above or beneath the screen.

In order to maintain optimum horizontal

dispersion through the upper crossover region

and cover a spread of listeners, the centre

portion of the baffle containing the midrange and

tweeter should be rotated by 90º so that the

drivers are positioned one above the other.

The summing axis of the midrange and tweeter is

deliberately tilted 5º towards the midrange driver

and this, together with the ability to rotate of the

centre portion of the baffle, permits greater

freedom when planning the vertical position of

the speakers. If the speaker is to be mounted

with its centre above ear height, turn the subbaffle so that the tweeter is above the midrange.

If it is to be mounted below ear height, have the

tweeter below the midrange. Try to keep the

centre within 10º of ear height for best results.

Beyond 10º, a response dip at crossover will

begin to develop, which will make the sound

seem more recessed. Consider 15º the

maximum to allow. (Figure 1)

In horizontal orientation, the speaker will cross

normally spaced vertical drywall studs, so special

stud construction will be required to give the

necessary clearance, even if not using the back

box.

2-channel audio

Aim to have the speakers and the front centre

listener approximately at the corners of an

equilateral triangle. The listening distance will

then determine the speaker separation. If you are

restricted, err on the side of having the speakers

closer together to avoid the 'hole in the middle'

effect. (Figure 2)

The height of the speakers should ideally be

such that the centre of the baffle is within 10º of

ear height.

Multi-channel left/right front

The angle between the speakers at the listener is

normally less than for 2-channel audio. Normally

this means the speakers are within 0.5m (20 in)

of the side of the screen.

The height should be chosen so that the centre

of the baffle is as close to screen centre height

as possible, while keeping within 10º of ear

height.

Multi-channel centre front

If using an acoustically transparent projection

screen, position the speaker as close to screen

centre as possible, while keeping within 10º of

ear height. Use vertical orientation.

In all other cases, orient the speaker horizontally

and place it either immediately above or below

the screen.

Multi-channel surround

Place the speakers with the centre of the baffle

around 60cm (2 ft) above ear height to give a

more diffuse sound than from the front speakers.

For 5.1 channel systems, the two surround

speakers should be positioned an angle of

approximately 120º round from front centre.

(Figure 3) For 6.1 EX systems, the two side

speakers should be more forward than this,

almost in line with the listeners. One speaker

should be placed on the rear wall directly in line

with the centre of the listening area. Alternatively

two rear speakers may be used side by side, one

either side of a stud in drywall construction.

(Figure 4) For 7.1 systems, the two rear speakers

should be further apart. A good guideline is for

them to have an angular spread of about 40º to

the listeners. (Figure 5)

1

CHECK THE CONTENTS

INSTALLATION PROCEDURES

Stage 1 – cutting the sheetrock

(plasterboard)

Simple retrofitting is only possible with vertical

orientation. For horizontal orientation, follow the

instructions for new construction.

Use a stud-finding tool to find the position of the

wall studs. Preferably choose a cavity that has no

other services running through it in order to avoid

the likelihood of rattles. There should be a

minimum of 120cm (4 ft) between any cross

studs to allow sufficient working volume behind

the speaker.

Using the template provided and a spirit level,

mark and cut out the hole for the speaker.

Stage 2 – preparing the cavity (Figure 6)

Pull the cable through to the top of the aperture

plus 30cm (1 ft) to facilitate connection.

Insert suitable absorbent wadding into the cavity,

but leave the area immediately behind the

aperture clear. Glass or mineral fibre normally

used for heat insulation and open cell foam are

suitable for this purpose, but ensure they comply

with the appropriate local fire and building

regulations.

Stage 3 – fitting the wall frame

Have on hand the PMK frame, the wall frame

(having removed the metal grille) and at least 2

screws from the wall frame module.

Stage 1 – fitting the PMK

Ensure the wall studding is properly prepared.

In vertical orientation, the PMK fits between two

adjacent studs on standard 40cm (16 in)

spacing. The speaker needs a minimum of 40

litres (1.4 cu ft) operating volume, so ensure there

is a minimum of 120cm (4 ft) clear height in the

cavity not obstructed by cross studs. (Figure 9)

In horizontal orientation, it is necessary to cut

through 2 vertical studs and therefore cross

studs should be fitted above and below the

speaker to support the wall. A clear vertical

spacing of 38cm (15 in) between the cross studs

is needed to provide the necessary volume for

the speaker. (Figure 10)

Keep the whole of the cavity available to the

speaker clear of services or ducting that may be

induced to rattle.

Screw the 6 brackets to the front of the PMK

frame using the self-tapping screws provided. In

vertical orientation, use the 6 anchor positions

down the long sides. (Figure 9)

In horizontal orientation, use the 4 anchor

positions along the short sides and the 2 central

ones along the long side. (Figure 10)

Screw or nail the brackets to the wall studs,

using a spirit level to ensure the frame is properly

square.

Stage 1 – fitting the back box

Ensure the wall studding is properly prepared so

that there is sufficient clearance for the back box

and its cable entry gland. The speaker baffle may

be positioned either in the centre or to one end

of the back box, allowing greater flexibility in

positioning the back box around the desired

speaker position. (Figure 16)

In vertical orientation, the back box fits between

two adjacent studs if on standard 40cm (16 in)

spacing. (Figure 13)

In horizontal orientation, it is necessary to cut

through 3 vertical studs and therefore cross

studs should be fitted above and below the back

box to support the wall. (Figure 14)

Attach the 4 brackets to the back box as

required to fix to the wall studs. Use 4 M6

machine screws and washers per bracket. If the

brackets are fitted to a short side, they overlap

and only 6 screws are required to fix 2 brackets.

Do not tighten the screws fully at this stage to

allow the brackets to slide. (Figures 13, 14 & 15)

Knock out one of the circular cable entry discs in

the back box and fit the cable entry gland. If

using vertical orientation, knock out the disc in

the short side at the open end. If using horizontal

orientation, knock out one of the discs in a long

side, preferably one nearest the open end.

Stage 1 – building in the back box

The back box is used to define the working

volume of the speaker and should be built in to

the brick or block work in a similar manner to a

window frame. The brackets, machine screws

and cable entry gland supplied will not be

required. Care must be taken to avoid the back

box rattling against the wall. It should therefore

be wedged in position such as to give a clear

gap all round. If it is desired to settle the back

box onto the lower course of bricks, use a

flexible mastic rather than cement or mortar. The

back box is not designed to take the weight of

the wall above, so a suitable lintel should be

used. (Figure 18)

Before positioning the back box in the wall,

knock out one of the circular cable entry discs in

the back box and fit the rubber grommet to

avoid chafing the cable. The cable entry gland is

not required. If the wall is an internal, single

thickness wall, it is probably easiest to use one

of the cable entries in the back face and run the

cable on the reverse side of the wall. (Figure 19)

To aid alignment, temporarily fit the front panel to

the back box the desired way round, using 2 of

the self-tapping screws. (Figure 16)

To prevent debris entering the back box, tape a

sheet of polythene or similar over the aperture

until all the brickwork is complete.

Wall frame and grille pack

Baffle assembly pack

PMK pack

Back box pack

Baffle with drivers and crossover

8x M6 x 25mm screws (baffle to frame)

Owner's Manual

M6 Allen Key

4x Card spacers

Wall frame

Metal grille with scrim attached

8x M5 x 30mm screws (frame to PMK or

back box)

PMK frame

6x brackets

12x self-tap screws

Cut-out template

Back box

Foam pad

Cable entry gland

2m foam gasket strip

22x self-tap screws (front panel to back box)

16x M6 screws (brackets to back box)

16x M6 washers (brackets to back box)

M6 Allen key

Existing drywall construction (retrofit)

without back box

New drywall construction

without back box

New drywall construction

with back box

New solid wall construction

with back box

Front panel

4x brackets

Rubber grommet

2

Loading...

Loading...