Page 1

EHF1838K & LHF2025K

HARDWOOD FLOORING STAPLERS

ENGRAPADORAS PARA PISOS DE MADERA

AGRAFEUSES POUR BOIS DUR À PARQUET

OPERATION and MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

BEFORE OPERATING THIS TOOL, ALL OPERATORS SHOULD STUDY THIS MANUAL TO

UNDERSTAND AND FOLLOW THE SAFETY WARNINGS AND INSTRUCTIONS. KEEP THESE

INSTRUCTIONS WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS,

CONTACT YOUR BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

ANTES DE OPERAR ESTA HERRAMIENTA, TODOS LOS OPERADORES DEBERÁN ESTUDIAR

ESTE MANUAL PARA PODER COMPRENDER Y SEGUIR LAS ADVERTENCIAS SOBRE SEGURIDAD

Y LAS INSTRUCCIONES. MANTENGA ESTAS INSTRUCCIONES CON LA HERRAMIENTA PARA

FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON SU REPRESENTANTE DE

BOSTITCH O CON SU DISTRIBUIDOR.

LIRE ATTENTIVEMENT LE PRÉSENT MANUEL AVANT D’UTILISER L’APPAREIL. PRÉTER UNE

ATTENTION TOUTE PARTICULIÈRE AUX CONSIGNES DE SÉCURITÉ ET AUX AVERTISSEMENTS.

GARDER CE MANUEL AVEC L’OUTIL POUR FUTUR RÉFÉRENCE. SI VOUS AVEZ DES QUESTIONS,

CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE BOSTITCH.

189854RC 08/16

Page 2

Definitions: Safety Alert Symbols and Words

This instruction manual uses the following safety alert symbols and words to alert you to hazardous

situations and your risks of personal injury or property damage.

Indicates an imminently hazardous situation which, if not avoided, will result in death or

serious injury.

Indicates a potentially hazardous situation which, if not avoided, could result in death or

serious injury.

Indicates a potentially haz ard ous situation which, if not avoided, may result in minor or

mod er ate injury.

Used without the safety alert symbol indicates potentially hazardous situation which, if not

avoided, may result in property damage.

INTRODUCTION

The Bostitch EHF1838K & LHF2025K are precision-built tools, designed for high speed, high volume fastening.

These tools will deliver efficient, dependable service when used correctly and with care. As with any fine

power tool, for best performance the manufacturer’s instructions must be followed. Please study this manual

before operating the tool and understand the safety warnings and cautions. The instructions on installation,

operation and maintenance should be read carefully, and the manuals kept for reference. NOTE: Additional

safety measures may be required because of your particular application of the tool. Contact your BOSTITCH

representative or distributor with any questions concerning the tool and its use. BOSTITCH Fastening

Systems,701 E. Joppa Road, Towson, Maryland 21286, U.S. & Canada Only, É.-U. et Canada seulement.

INDEX

Safety Instructions ..............................................3

Tool Components...............................................4

Tool/Fastener Specifications .....................................5

Air Supply and Connections ......................................6

Loading the Tool ...............................................7

Adjustment Instructions .......................................8 & 9

Tool Operation ................................................10

Tool Operation Check .......................................... 11

Maintaining the Pneumatic Tool .................................11

Troubleshooting ..............................................12

Maintenance Checklist..........................................13

Other Bostitch Flooring Products .................................14

NOTE:

Bostitch tools have been engineered to provide excellent customer satisfaction and are

designed to achieve maximum performance when used with precision Bostitch fasteners

engineered to the same exacting standards. Bostitch cannot assume responsibility for

product performance if our tools are used with fasteners or accessories not meeting the

specific requirements established for genuine Bostitch nails, staples and accessories.

LIMITED WARRANTY — U.S. and Canada Only

Bostitch Fastening Systems “Bostitch” warrants to the original retail purchaser that the product purchased is free

from defects in material and workmanship, and agrees to repair or replace, at Bostitch’s option, any defective

Bostitch branded pneumatic stapler or nailer for a period of seven (7) years from date of purchase (one (1) year from

the date of purchase for compressors and tools used in production applications). Warranty is not transferable.

Proof of purchase date required. This warranty covers only damage resulting from defects in material or

workmanship; it does not cover conditions or malfunctions resulting from normal wear, neglect, abuse,

accident or repairs attempted or made by other than our national repair center or authorized warranty service

centers. Driver blades, bumpers, o-rings, pistons and piston rings are considered normally wearing parts.

For optimal performance of your Bostitch tool always use genuine Bostitch fasteners and replacement parts.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESS OR IMPLIED, INCLUDING BUT NOT

LIMITED TO THE IMPLIED WARRANTIES OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR

PURPOSE. BOSTITCH SHALL NOT BE LIABLE FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

Some states and countries do not allow limitations on how long an implied warranty lasts, or the exclusion

or limitation of incidental or consequential damages, so the above limitations or exclusions may not apply to

you. This warranty gives you specific legal rights, and you may also have other rights which vary from state to

state and country to country. To obtain warranty service in the U.S. return the product, together with proof of

purchase, to the U.S. Bostitch National or Regional Independent Authorized.

Warranty Service Center. In the U.S. you may call us at 1-800-556-6696 or visit www.BOSTITCH.com for the

location most convenient for you. In Canada please call us at 1-800-567-7705 or visit www.BOSTITCH.comus at

1-800-556- 6696 or visit www.BOSTITCH.com for the location most convenient for you. In Canada please call

us at 800-567-7705 or visit www.BOSTITCH.com

-2-

Page 3

SAFETY INSTRUCTIONS

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator

and others in the work area when connecting to air supply, loading, operating or servicing

this tool. Eye protection is required to guard against flying fasteners and debris, which

could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

CAUTION: Additional Safety Protection will be required in some environments. For

example, the working area may include exposure to noise level which can lead to hearing

damage. The employer and user must ensure that any necessary hearing protection is

provided and used by the operator and others in the work area. Some environments will

require the use of head protection equipment. When required, the employer and user must

ensure that head protection conforming to ANSI Z89.1 is used.

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

Do not use supply sources which can potentially exceed 200 psig (

burst, possibly causing injury.

The connector on the tool must not hold pressure when air supply is disconnected. If a

wrong fitting is used, the tool can remain charged with air after disconnecting and thus will

be able to drive a fastener even after the air line is disconnected possibly causing injury.

Do not pull trigger or depress contact arm while connected to the air supply as the tool

may cycle, possibly causing injury.

Always disconnect air supply: 1.) Before making adjustments; 2.) When servicing the tool;

3.) When clearing a jam; 4.) When tool is not in use; 5.) When moving to a different work

area, as accidental actuation may occur, possibly causing injury.

14 kg/cm

2

) as tool may

LOADING TOOL

When loading tool: 1.) Never place a hand or any part of body in fastener discharge area

of tool; 2.) Never point tool at anyone; 3.) Do not pull the trigger or depress the trip as

accidental actuation may occur, possibly causing injury.

OPERATION

Always handle the tool with care: 1.) Never engage in horseplay; 2.) Never pull the trigger

unless nose is directed toward the work; 3.) Keep others a safe distance from the tool while

tool is in operation as accidental actuation may occur, possibly causing injury.

The operator must not hold the trigger pulled on contact arm tools except during fastening

operation as serious injury could result if the trip accidentally contacted someone or

something, causing the tool to cycle.

Keep hands and body away from the discharge area of the tool. A contact arm tool may

bounce from the recoil of driving a fastener and an unwanted second fastener may be

driven possibly causing injury.

Check operation of the contact arm mechanism frequently. Do not use the tool if the arm is

not working correctly as accidental driving of a fastener may result. Do not interfere with

the proper operation of the contact arm mechanism.

Do not drive fasteners on top of other fasteners or with the tool at an overly steep angle as

this may cause deflection of fasteners which could cause injury.

Do not drive fasteners close to the edge of the work piece as the wood may split, allowing

the fastener to be deflected possibly causing injury.

This nailer produces SPARKS during operation. NEVER use the nailer near flammable

substances, gases or vapors including lacquer, paint, benzine, thinner, gasoline, adhesives,

mastics, glues or any other material that is -- or the vapors, fumes or by-products of which are

-- flammable, combustible or explosive. Using the nailer in any such environment could cause

an EXPLOSION resulting in personal injury or death to user and bystanders.

-3-

Page 4

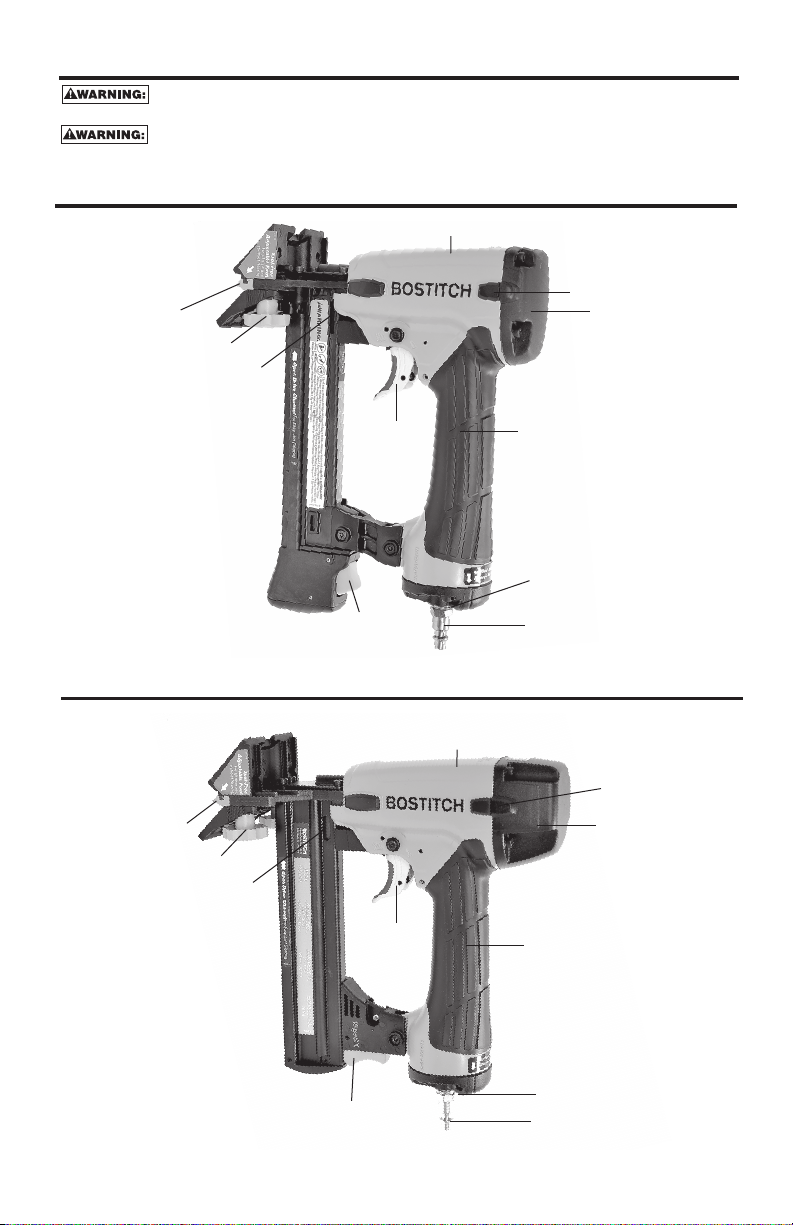

MAINTAINING THE TOOL

When working on air tools note the warnings in this manual and use extra care when

evaluating problem tools.

If the tool has been dropped or you suspect tool damage perform tool operation check as

defined in the tool operation check section.

LHF2025K TOOL COMPONENTS

Frame

Easy-Sight

Tongue Engagement

Adjustable Precision Knobs

Reload Indicator

Trigger

Magazine

Release Button

EHF1838K TOOL COMPONENTS

Easy-Sight

Tongue Engagement

Adjustable Precision Knobs

Reload Indicator

Frame Protector

Frame Cap

Over-Molded Comfort Grip

Rear Exhaust

Air Fitting

Frame

Frame Protector

Frame Cap

Magazine

Release Button

Trigger

-4-

Over-Molded Comfort Grip

Rear Exhaust

Air Fitting

Page 5

TOOL SPECIFICATIONS

All dimensions in inches unless otherwise specied.

EHF1838K

Description

Engine Type

Operation Pressure Range

Maximum Operation Pressure

Fastener Type

Fastener Gauge

Fastener Range

Magazine Capacity

Length

Width

Height

Weight

70 to 120 psig (4.9 - 8.4 kg/cm2). Select the operating pressure in this range for best fastener performance.

The EHF1838K requires 1.94 cubic feet per minute or cfm (55 liters per minute or L/min) of free air at

80 PSI (5.6 kg/cm

feet per minute or cfm (54 liters per minute or L/min) of free air at 80 PSI (5.6 kg/cm

of 60 fasteners per minute. To determine the appropriately sized air compressor, take the actual rate at

which the tool will be run and compare the required cfm (L/min) to the compressor’s free air delivery

(cfm or L/min) at 80 PSI (5.6 kg/cm

For example, if your fastener usage averages 30 fasteners per minute, you need 50% of the required air

volume (cfm or L/min) that is required to operate the tool at the rate of 60 fasteners per minute. In this case,

be sure that your air compressor can deliver a minimum of 0.97 cfm (27.5 L/min) at 80 PSI (5.6 kg/cm

optimum performance.

2

) to operate at a rate of 60 fasteners per minute. The LHF2025K requires 1.90 cubic

18-ga Flooring Stapler 20-ga Flooring Stapler

Oil-free Oil-free

70-120 psig (4.9 - 8.4 kg/cm

120 psig (8.4 kg/cm

SX5035 Series SB97-1GLS

18 Gauge 20 Gauge

1” - 1-1/2” (25 mm - 38 mm) 1” (25 mm)

100 125

9-1/4” (235 mm) 9-1/4” (235 mm)

2-3/4” (70 mm) 2-3/4” (70 mm)

9-7/8” (251 mm) 8.5” (216 mm)

3.5 lb (1.57 kg) 2.9 lb (1.32 kg)

2

).

2

) 70-120 psig (4.9 - 8.4 kg/cm2)

2

) 120 psig (8.4 kg/cm2)

LHF2025K

2

) to operate at a rate

2

) for

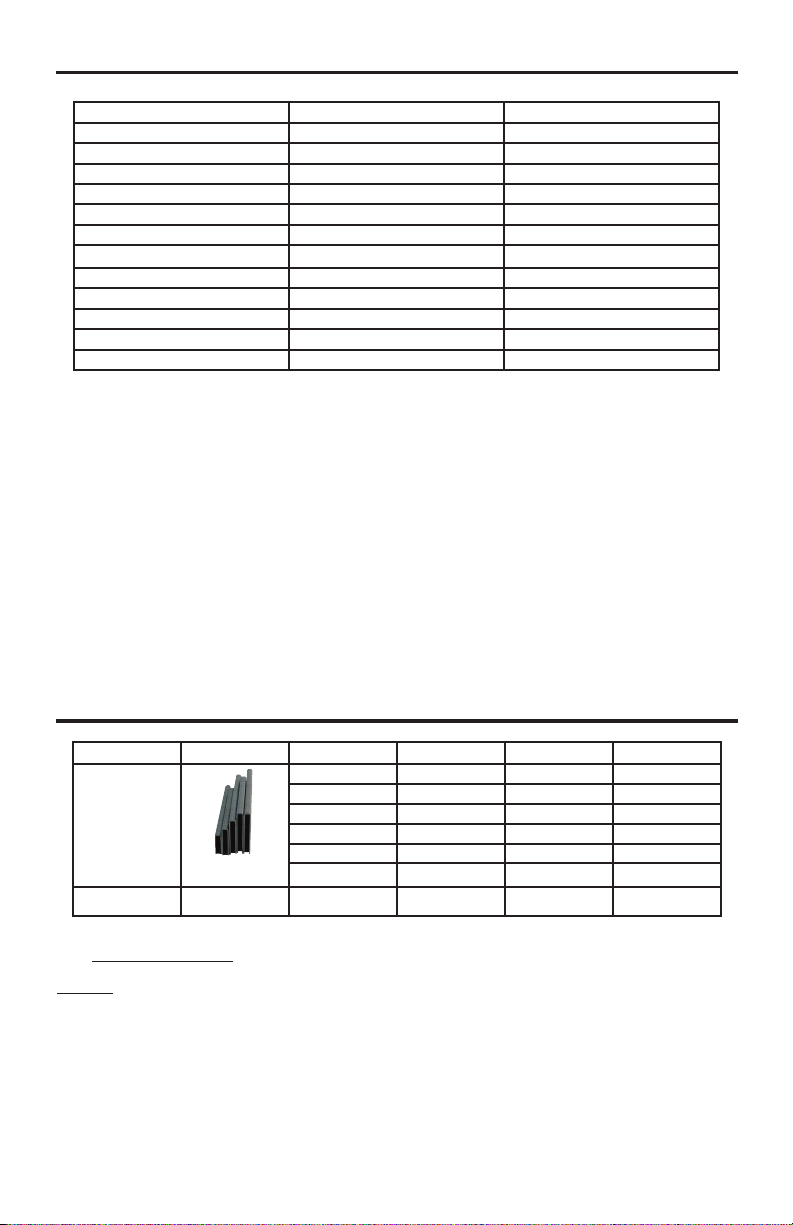

FASTENER SPECIFICATIONS

Tool Model Fastener Type

EHF1838K

Staples

LHF2025K Staples

*Visit www.BOSTITCH.com for further details.

NOTE:

BOSTITCH tools have been engineered to provide superior customer satisfaction and are designed to achieve

maximum perfomance when used with precision BOSTITICH fasteners engineered to the same exacting

standards. BOSTITCH cannot assume responsibility for product performance if our tools are used with

fasteners or accessories not meeting the specic requirements established for genuine BOSTITCH

fasteners and accessories.

Fastener SKU Crown Width Gauge Length

SX50351G

SX50351-1/8G

SX50351-3/16G

SX50351-1/4G

SX50351-3/8G

SX50351-1/2G

SB97-1GLS 3/16” (4.7 mm) 20 1” (25 mm)

7/32” (5.5 mm)

7/32” (5.5 mm)

7/32” (5.5 mm)

7/32” (5.5 mm)

7/32” (5.5 mm)

7/32” (5.5 mm)

18 1” (25 mm)

18 1-1/8” (28 mm)

18 1-3/16” (30 mm)

18 1-1/4” (32 mm)

18 1-3/8” (35 mm)

18 1-1/2” (38 mm)

-5-

Page 6

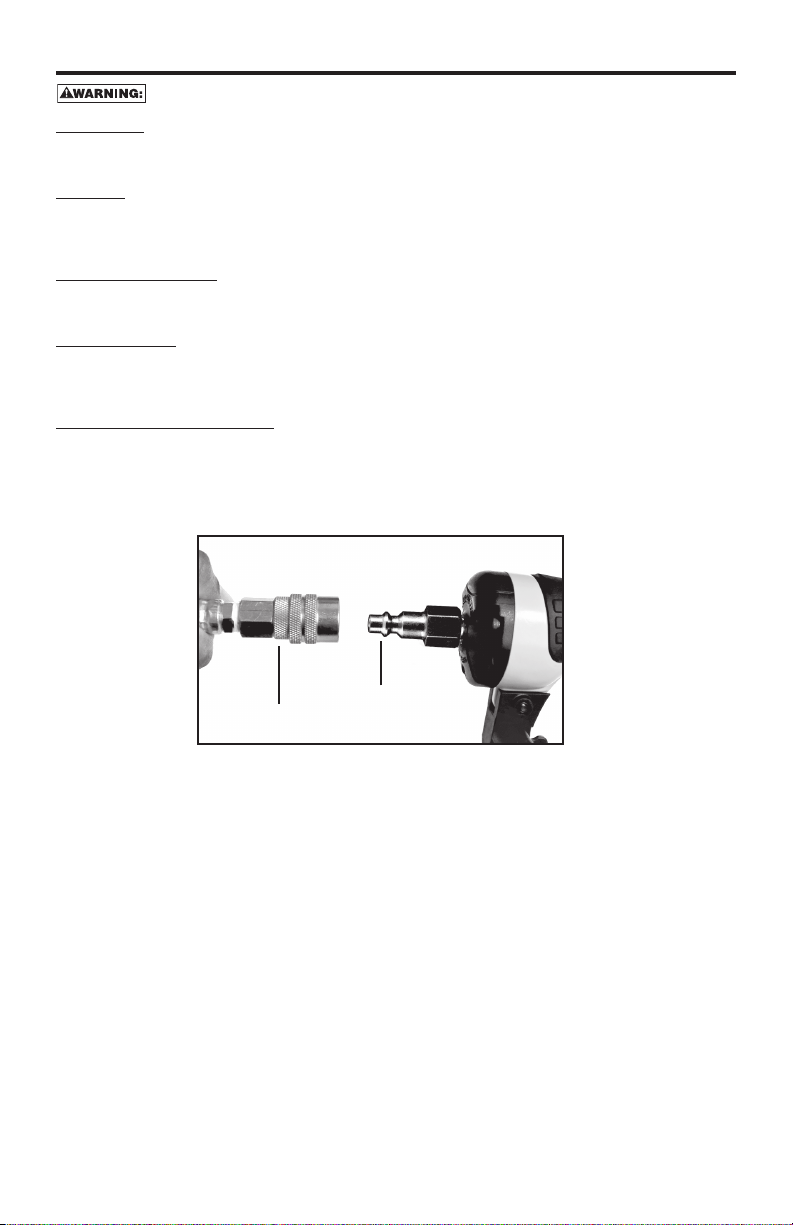

AIR SUPPLY AND CONNECTIONS

Do not use oxygen, combustible gases, or bottled gases as a power source for this tool as

tool may explode, possibly causing injury.

FITTINGS:

Install a male plug on the tool which is free flowing and which will release air pressure from the tool when

disconnected from the supply source.

HOSES:

Air hoses should have a minimum of 150 psig (10.6 kg/cm2) working pressure rating or 150 percent of the

maximum pressure that could be produced in the air system. The supply hose should contain a fitting that

will provide “quick disconnecting” from the male plug on the tool.

SUPPLY SOURCE:

Use only clean regulated compressed air as a power source for this tool. NEVER USE OXYGEN, COMBUSTIBLE

GASES, OR BOTTLED GASES, AS A POWER SOURCE FOR THIS TOOL AS TOOL MAY EXPLODE.

REGULATOR:

A pressure regulator with an operating pressure of 0 - 125 psig (0 - 8.8 kg/cm2) is required to control the

operating pressure for safe operation of this tool. Do not connect this tool to air pressure which can potentially

exceed 200 psig (14 kg/cm

OPERATING PRESSURE:

Do not exceed recommended maximum operating pressure as tool wear will be greatly increased. The air

supply must be capable of maintaining the operating pressure at the tool. Pressure drops in the air supply

can reduce the tool’s driving power. Refer to “TOOL SPECIFICATIONS” for setting the correct operating

pressure for the tool.

2

) as tool may fracture or burst, possibly causing injury.

Quick Disconnect Plug

Quick Connect Plug

-6-

Page 7

LOADING THE EHF1838K & LHF2025K

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator

and others in the work area when connecting to air supply, loading, operating or servicing

this tool. Eye protection is required to guard against flying fasteners and debris, which

could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side

shielded spectacles and face shields alone do not provide adequate protection.

TO PREVENT ACCIDENTAL INJURIES:

• Never place a hand or any other part of the body in nail discharge area of tool while

the air supply is connected.

• Never point the tool at anyone else.

• Never engage in horseplay.

• Never pull the trigger unless nose is directed at the work.

• Always handle the tool with care.

• Do not pull the trigger or depress the trip mechanism while loading the tool.

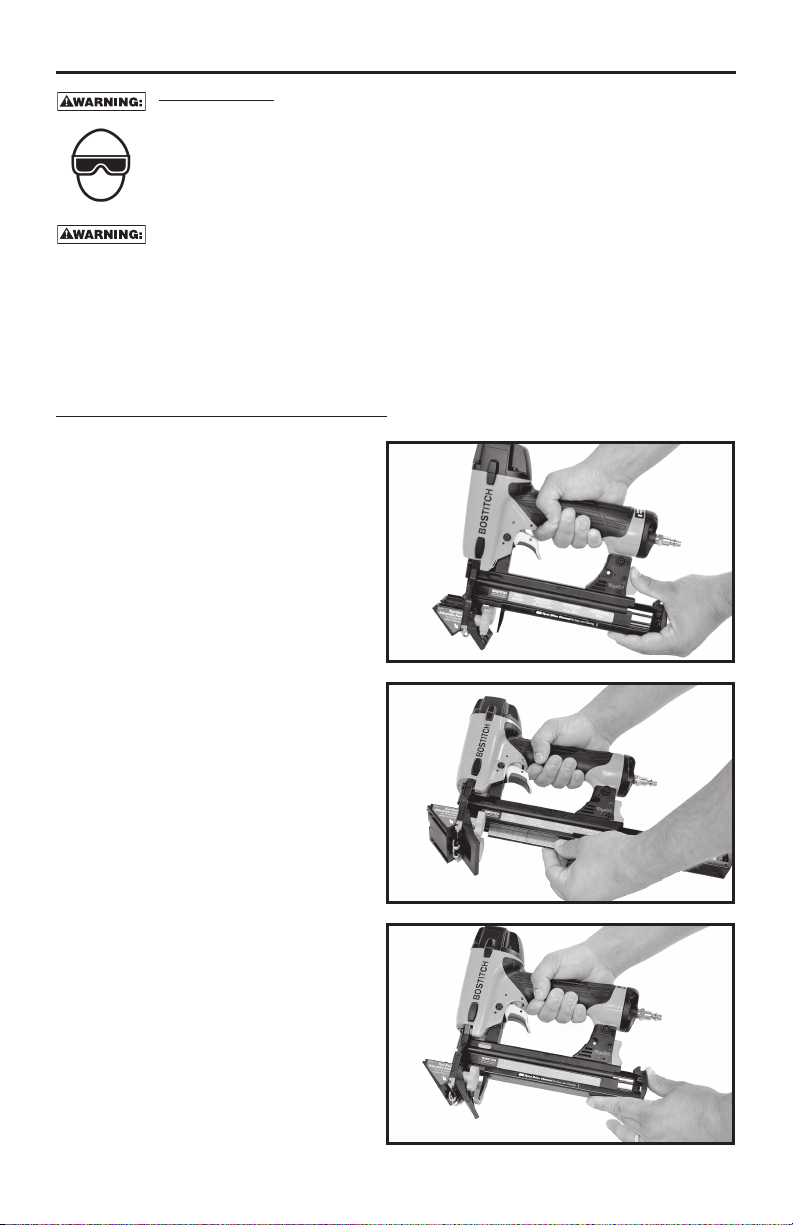

LOADING THE EHF1838K & LHF2025K

1. Depress magazine release button and

pull back magazine.

2. Open magazine fully and turn tool

sideways with discharge area pointed

away from yourself and others. Load

staples in channel.

3. Push magazine forward until latch is

engaged.

-7-

Page 8

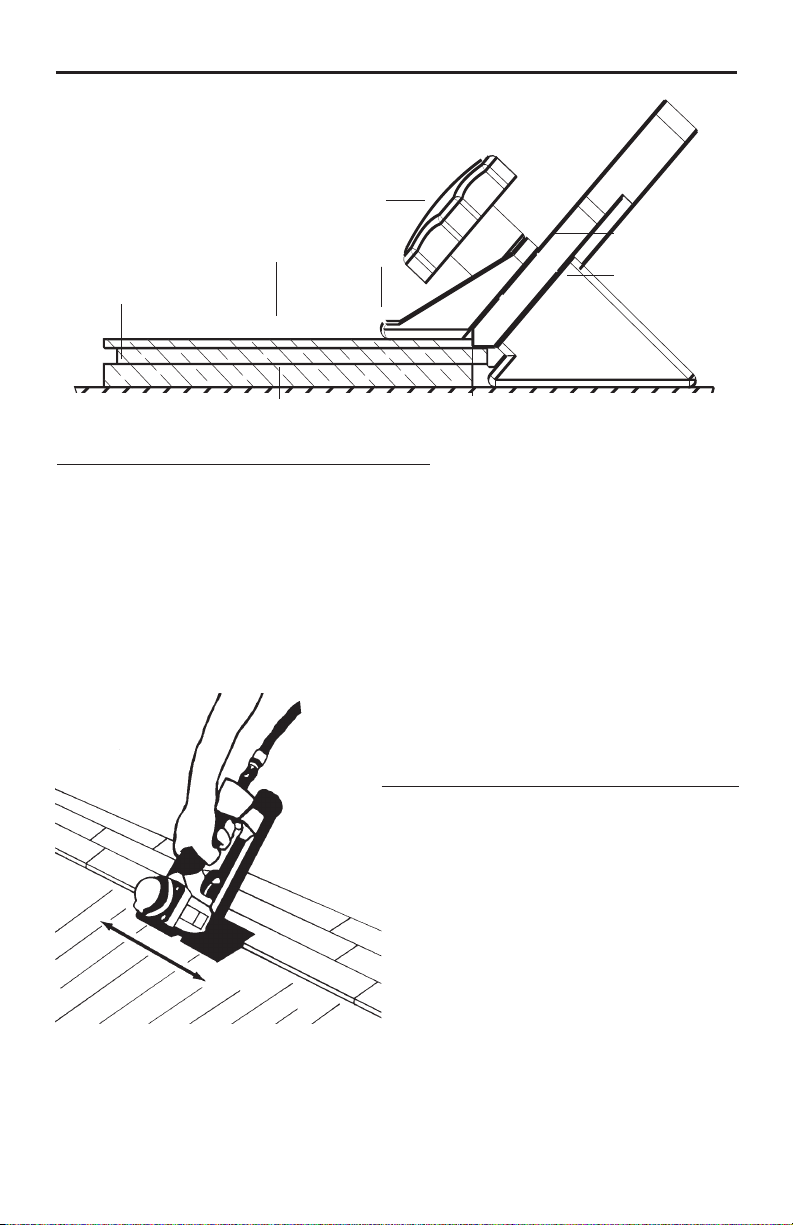

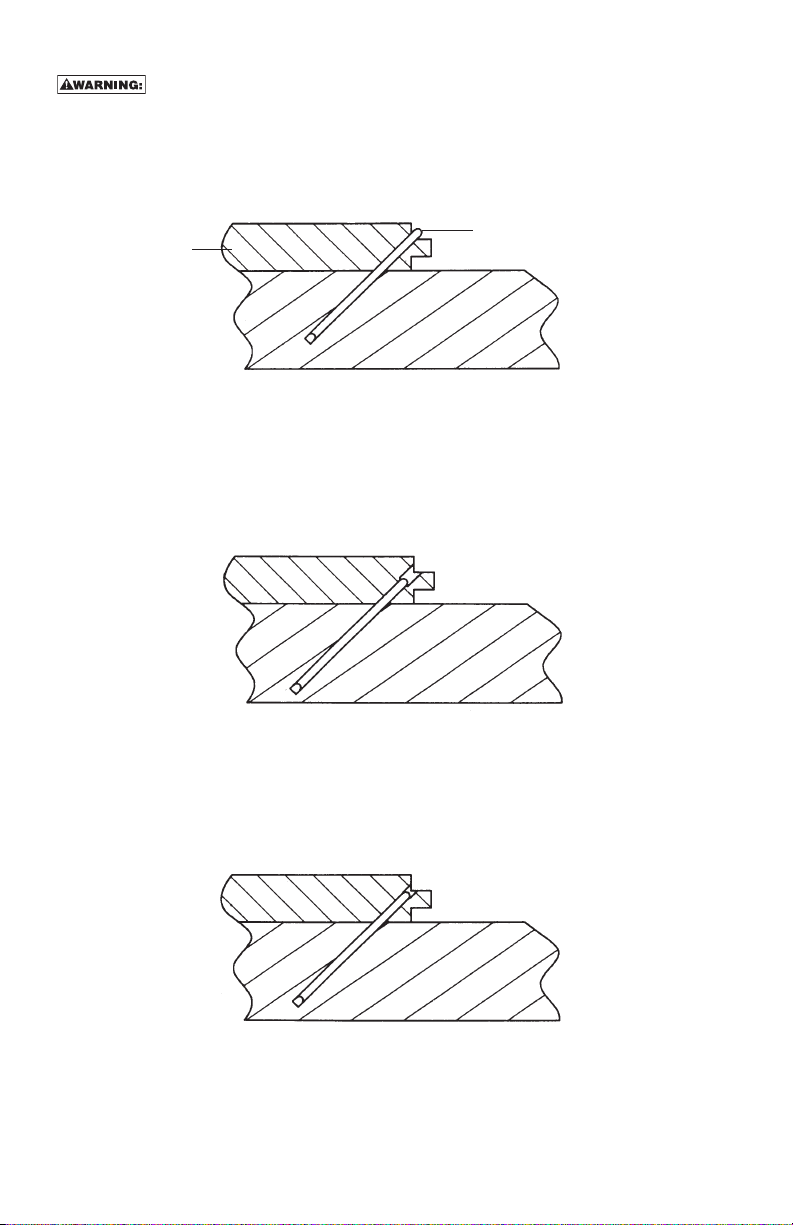

ADJUSTMENT INSTRUCTIONS

KNOB

FLOOR

VAPOR BARRIER

FOOT

NOSE

FRONT GUIDE

SUBFLOOR

TONGUE OF FLOORING

TO ADJUST THE TOOL TO THE FLOORING:

1. Loosen both Knobs until the Foot and Front Guide move freely.

2. Engage the Nose with the Tongue of Flooring.

3. Push the Front Guide to the subfloor and the Foot to the flooring.

4. Tighten both Knobs.

Refer to the ooring manufactures installation instructions for proper fastener and

fastening technique.

Important: Test the tool on a scrap piece of flooring to ensure proper staple placement and

compatibility. BOSTITCH cannot assume responsibility for product performance if the tool is

used improperly or not in accordance with the flooring manufacturer’s installation instructions.

With tool properly located on tongue of flooring,

slide the tool along the tongue without lifting

the tool off the floor while fastening as shown

above and to the left.

AIR PRESSURE:

Air pressure must be adjusted to properly

countersink the staples. Air pressure should be

set using a scrap piece of flooring to adjust the

air pressure for correct countersinking.

(See following page)

-8-

Page 9

BEFORE OPERATING THIS TOOL, STUDY THESE INSTRUCTIONS AND OPERATION

AND MAINTENANCE MANUAL FOR YOUR TOOL TO UNDERSTAND THE SAFETY

WARNINGS AND INSTRUCTIONS. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR

BOSTITCH REPRESENTATIVE OR DISTRIBUTOR. SAVE THESE INSTRUCTIONS FOR

FUTURE REFERENCE.

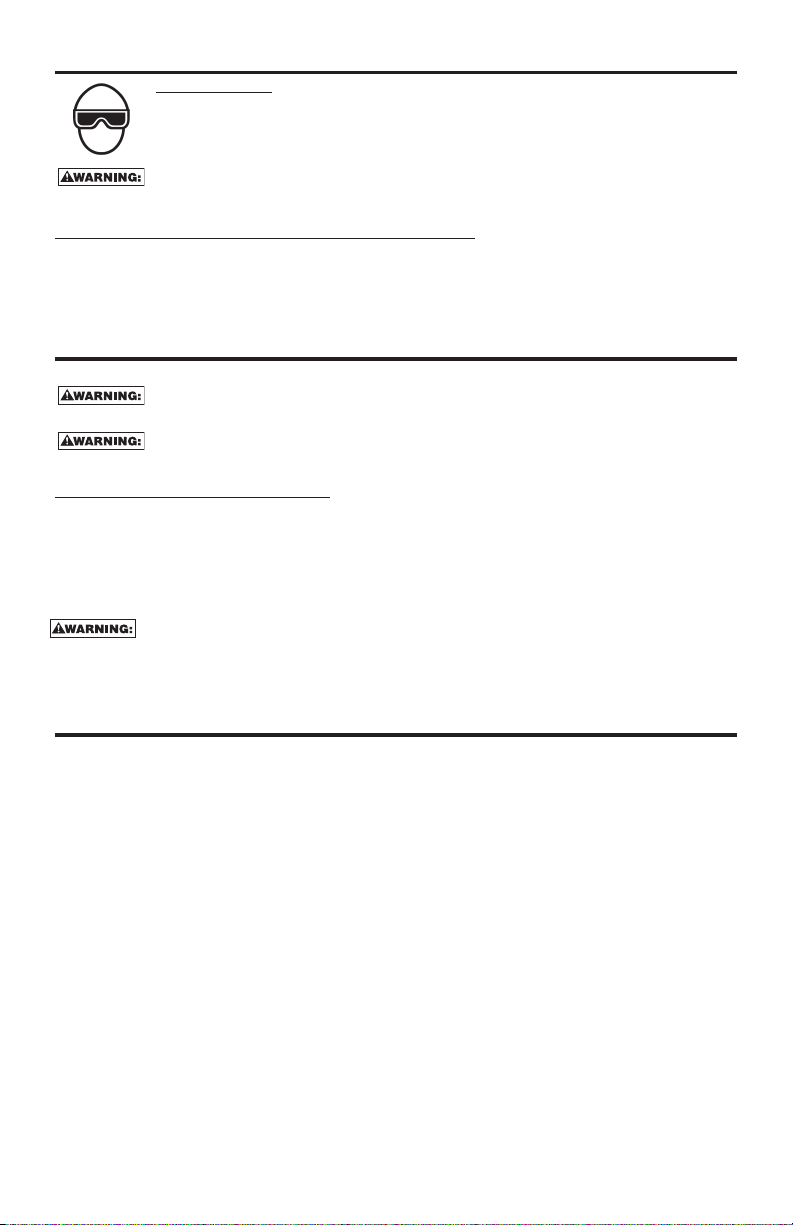

FLOOR

STAPLE

• Air pressure too low.

• Staple crown above tongue.

• Increase air pressure.

• Air pressure too high.

• Staple buried.

• Lower air pressure.

• Correct air pressure.

• Staple just below surface.

-9-

Page 10

TOOL OPERATION

EYE PROTECTION which conforms to ANSI specifications and provides protection against

flying particles both from the FRONT and SIDE should ALWAYS be worn by the operator

and others in the work area when connecting to air supply, loading, operating or servicing

this tool. Eye protection is required to guard against flying fasteners and debris, which

could cause severe eye injury.

The employer and/or user must ensure that proper eye protection is worn. Eye protection

equipment must conform to the requirements of the American National Standards

Institute, ANSI Z87.1 and provide both frontal and side protection. NOTE: Non-side shielded

spectacles and face shields alone do not provide adequate protection.

BEFORE HANDLING OR OPERATING THIS TOOL:

I. READ AND UNDERSTAND THE WARNINGS CONTAINED IN THIS MANUAL.

II. REFER TO “TOOL SPECIFICATIONS” IN THIS MANUAL TO IDENTIFY THE OPERATING SYSTEM

ON YOUR TOOL.

OPERATION

The operator must not hold the trigger pulled on contact trip tools except during fastening

operation, as serious injury could result if the trip accidentally contacted someone or

something, causing the tool to cycle.

Keep hands and body away from the discharge area of the tool. A contact trip tool may

bounce from the recoil of driving a fastener and an unwanted second fastener may be

driven, possibly causing injury.

SEQUENTIAL TRIP OPERATION:

In SEQUENTIAL TRIP MODE the contact trip operates in conjunction with the trigger to drive a fastener.

To operate a sequential trip tool, first position the contact trip on the work surface WITHOUT PULLING

THE TRIGGER. Depress the contact trip and then pull the trigger to drive a fastener. As long as the

contact trip is contacting the work and is held depressed, the tool will drive a fastener each time the

trigger is depressed. If the contact trip is allowed to leave the work surface, the sequence described

above must be repeated to drive another fastener.

If the tool has been dropped or you suspect tool damage perform tool operation check as

defined in the tool operation check section.

IN ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS

MANUAL OBSERVE THE FOLLOWING FOR SAFE OPERATION

• Use the BOSTITCH pneumatic tool only for the purpose for which it was designed.

• Never use this tool in a manner that could cause a fastener to be directed toward the user

or others in the work area.

• Do not use the tool as a hammer.

• Always carry the tool by the handle. Never carry the tool by the air hose.

• Do not alter or modify this tool from the original design or function without approval from

BOSTITCH, INC.

• Always be aware that misuse and improper handling of this tool can cause injury to

yourself and others.

• Never clamp or tape the trigger or contact trip in an actuated position.

• Never leave a tool unattended with the air hose attached.

• Do not operate this tool if it does not contain a legible WARNING LABEL.

• Do not continue to use a tool that leaks air or does not function properly. Notify your nearest

Bostitch representative if your tool continues to experience functional problems.

-10-

Page 11

TOOL OPERATION CHECK

CAUTION: Remove all fasteners from tool before performing tool operation check.

If the tool is dropped or you suspect tool damage perform tool operation check.

SEQUENTIAL TRIP OPERATION:

A. Press the contact trip against the work surface, without touching the trigger.

THE TOOL MUST NOT CYCLE.

B. Hold the tool off the work surface and pull the trigger.

THE TOOL MUST NOT CYCLE.

Release the trigger. The trigger must return to the trigger stop on the frame.

C. Pull the trigger and press the contact trip against the work surface.

THE TOOL MUST NOT CYCLE.

D. With finger off the trigger, press the contact trip against the work surface. Pull the trigger.

THE TOOL MUST CYCLE.

MAINTAINING THE PNEUMATIC TOOL

When working on air tools, note the warnings in this manual and use extra care evaluating

problem tools.

If the tool has been dropped or you suspect tool damage perform tool operation check as

defined in the tool operation check section.

CAUTION: Pusher spring (constant force spring). Caution must be used when working with the spring

assembly. The spring is wrapped around, but not attached to, a roller. If the spring is extended beyond

its length, the end will come off the roller and the spring will roll up with a snap, with a chance of

pinching your hand. Also the edges of the spring are very thin and could cut. Care must also be taken

to insure no permanent kinks are put in the spring as this will reduce the springs force.

REPLACEMENT PARTS:

Use only genuine BOSTITCH replacement parts. Do not use modified parts.

ASSEMBLY PROCEDURE FOR SEALS:

When repairing a tool, make sure the internal parts are clean and lubricated. Use Parker “O”-LUBE,

Magnalube, or equivalent on all “O”-rings. Coat each “O”-ring with lubricant before assembling.

AIR SUPPLY-PRESSURE AND VOLUME:

Air volume is as important as air pressure. The air volume supplied to the tool may be inadequate because of

undersize fittings and hoses, or from the effects of dirt and water in the system. Restricted air flow will prevent

the tool from receiving an adequate volume of air, even though the pressure reading is high. The results will

be slow operation, misfeeds or reduced driving power. Before evaluating tool problems for these symptoms,

trace the air supply from the tool to the supply source for restrictive connectors, low points containing water

and anything else that would prevent full volume flow of air to the tool.

-11-

Page 12

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

Trigger valve housing leaks air O-ring cut or cracked ....................Replace O-ring

Trigger valve stem leaks air O-ring/seals cut or cracked ..............Replace trigger valve assembly

Frame/nose leaks air O-ring or gasket is cut or cracked. . . . . . . . . Replace O-ring or gasket

Bumper cracked/worn ...................Replace bumper

Frame/cap leaks air Damaged gasket or seal ................. Replace gasket or seal

Cracked/worn head valve ...............Replace head valve

Loose cap screws ......................Tighten and recheck

Failure to cycle Air supply restriction ....................Check air supply equipment

Worn head valve .......................Replace head valve

Broken cylinder cap spring ...............Replace cylinder cap spring

Head valve stuck in cap .................Disassemble / Check / Lubricate

Lack of power; slow to cycle Broken cylinder cap spring ...............Replace cap spring

Rings/seals cut or cracked ...............Replace rings/seals

Exhaust blocked ........................Check bumper, head valve spring

Trigger assembly worn/leaks .............Replace trigger assembly

Dirt/tar build up on driver ................ Disassemble nose/driver to clean

Cylinder sleeve not seated correctly

on bottom bumper ......................Disassemble to correct

Air pressure too low .....................Check air supply equipment

Skipping fasteners;

intermittent feed Worn bumper ...........................Replace bumper

Tar/dirt in driver channel .................Disassemble and clean nose and driver

Air restriction/inadequate air flow through

quick disconnect socket and plug .........Replace quick disconnect fittings

Worn piston ring ........................Replace ring, check driver

Damaged pusher spring .................Replace spring

Low air pressure ........................Check air supply system to tool

Loose magazine nose screws ............Tighten all screws

Fasteners too short for tool. . . . . . . . . . . . . . . Use only recommended fasteners

Bent fasteners ..........................Discontinue using these fasteners

Wrong size fasteners ....................Use only recommended fasteners

Leaking head cap gasket ................Tighten screws/replace gasket

Trigger valve O-ring cut/worn ............Replace O-ring

Broken/chipped driver ...................Replace driver (check piston ring)

Dry/dirty magazine ......................Clean/lubricate use BOSTITCH Air Tool Lubricant

Worn magazine .........................Replace magazine

Fasteners jam in tool Driver channel worn ....................Replace nose/check door

Wrong size fasteners ....................Use only recommended fasteners

Bent fasteners ..........................Discontinue using these fasteners

Loose magazine/nose screws ............ Tighten all screws

Broken/chipped driver ...................Replace driver

-12-

Page 13

MAINTENANCE CHECKLIST

Maintenance Benet Procedure Service Interval

Inspect trigger performance Ensure trigger system is in

Drain condensation from air

compressor tanks and air

filters (if present)

Clean magazine assembly Prevents accumlation of

Clean nose assembly Prevents accumlation of

Ensure all fasteners remain

tight

Replace air fitting Maintains proper air flow to

Replace piston/driver

assembly

Replace O-rings Maintains engine for peak

Replace bumper Maintains engine for peak

Replace headvalve Maintains engine for peak

proper working order

Prevents accumlation of

moisture that can impede tool

performace

debris that could cause a jam

debris that could cause a jam

Prevent loose parts Tighten all fasteners with

engine for peak performance

Maintains consistent drive

quality

performance

performance

performance

Refer to Tool Operation

Check section in this manual

Open drain cock on tanks

and air filters and drain all

condensate

Blow clean with compressed air Daily

Blow clean with compressed air Daily

appropriately sized hex

wrench

Remove worn air fitting and

replace with new fitting

Refer to replacement part kit

instructions

Refer to replacement part kit

instructions

Refer to replacement part kit

instructions

Refer to replacement part kit

instructions

Daily

Daily

Weekly

50,000 Fasteners

150,000 Fasteners

250,000 Fasteners

250,000 Fasteners

250,000 Fasteners

Replace engine cylinder Maintains engine for peak

performance

Refer to replacement part kit

instructions

-13-

500,000 Fasteners

Page 14

OTHER BOSTITCH FLOORING PRODUCTS

MIIIFS

15.5 GAUGE

FLOORING STAPLER

MFN-201

16 GAUGE MANUAL

FLOORING NAILER

16 GAUGE FLOORING NAILER

HARDWOOD FLOORING JACK

MIIIFN

MIII JACK

PRO-1450

6.4 mm X 15 m (1/4” X 50’)

PREMIUM QUALITY

POLYURETHANE AIR HOSE

-14-

14.8”, 45 oz (37.6 cm, 1.27

kg) SOFT FACE HARDWOOD

HFM-3

FLOORING MALLET

Page 15

DEFINICIONES: SÍMBOLOS Y PALABRAS DE ALERTA DE SEGURIDAD

ATENCIÓN:

Este manual de instrucciones utiliza los siguientes símbolos y palabras de alerta de seguridad para alertarle de

situaciones peligrosas y de los riesgos de lesiones corporales o daños materiales.

indica una situación de peligro inminente que, si no se evita, provocará la muerte o

lesiones graves.

Iindica una situación de peligro potencial que, si no se evita, provocará la muerte o

lesiones graves.

indica una situación de peligro potencial que, si no se evita, provocará lesiones leves o

moderadas.

utilizado sin el símbolo de alerta de seguridad indica una situación de peligro potencial que,

si no se evita, puede provocar daños en la propiedad.

INTRODUCCIÓN

Los modelos Bostitch EHF1838K y LHF2025K son herramientas construidas a precisión, diseñadas para funcionar a alta velocidad y con alto volumen. Estas

herramientas entregan un servicio eficiente y fiable cuando se usan correctamente y con cuidado. Al igual que con toda herramienta automática de calidad, deben

seguirse las instrucciones del fabricante para obtener el óptimo rendimiento. Estudie este manual antes de operar la herramienta y tome nota de las advertencias

y precauciones de seguridad. Deben leerse en detalle las instrucciones sobre la instalación, operación y mantenimiento, y deben conservarse los manuales para

referencia. NOTA: Pueden necesitarse medidas adicionales de seguridad según la aplicación particular de la herramienta. Comuníquese con su representante o

distribuidor de BOSTITCH por cualquier pregunta sobre la herramienta y su uso. BOSTITCH Fastening Systems, 701 E. Joppa Road, Towson, Maryland 21286, EE.

UU. y solo Canadá, É.-U. et Canada seulement.

ÍNDICE

Instrucciones de seguridad ................................................ 16

Componentes de las herramientas .......................................... 17

Especificaciones de la herramienta/Sujetador .................................18

Suministro de aire y conexiones ............................................ 19

Cargar la herramienta .....................................................20

Instrucciones de ajuste ...............................................21 & 22

Operación de la herramienta...............................................23

Verificación de la operación de la herramienta ................................. 24

Mantenimiento de la herramienta neumática .................................. 24

Localización de fallas .................................................... 25

Lista de verificación de mantenimiento .......................................26

Otros productos Bostitch para pisos ........................................ 27

NOTA:

Las herramientas BOSTITCH se han diseñado para brindar una satisfacción excelente al cliente y lograr

máximo rendimiento al utilizarse con fijaciones de precisión BOSTITCH diseñadas con las mismas normas

estrictas. BOSTITCH no puede asumir responsabilidad alguna por el rendimiento del producto si se

utilizan nuestras herramientas con fijaciones o accesorios que no reúnen los requisitos específicos

establecidos para los clavos, grapas y accesorios genuinos de BOSTITCH.

GARANTÍA LIMITADA — Sólo EE.UU. y Canadá

BOSTITCH Fastening Systems “BOSTITCH” garantiza al comprador del comerciante original que el producto comprado está exento

de defectos en material y fabricación, y se compromete a reparar o reemplazar, a opción de BOSTITCH, cualquier engrapadora o

clavadora neumática defectuosa de marca BOSTITCH por un período de siete (7) años desde la fecha de compra (un (1) año de la

fecha de compra en el caso de compresores y herramientas utilizadas en aplicaciones de producción). La garantía no es transferible.

Se requiere presentar evidencia de la fecha de compra. Esta garantía solamente cubre daños resultantes de defectos en material o

fabricación, y no cubre condiciones o desperfectos resultantes del desgaste normal, negligencia, abuso, accidente o reparaciones

intentadas o efectuadas por terceros ajenos a nuestro centro nacional de reparaciones o a los centros de servicio bajo garantía. Las

aspas del impulsor, topes, juntas tóricas, pistones y aros de pistones se consideran componentes de desgaste normal. Para obtener

el rendimiento óptimo de la herramienta BOSTITCH siempre use fijaciones y piezas de repuesto genuinas de BOSTITCH.

ESTA GARANTÍA SUSTITUYE TODA OTRA GARANTÍA, EXPRESA O IMPLÍCITA, INCLUIDAS ENTRE OTRAS, LAS GARANTÍAS

IMPLÍCITAS DE COMERCIABILIDAD O IDONEIDAD PARA UN FIN PARTICULAR. BOSTITCH NO SERÁ RESPONSABLE DE DA—OS

FORTUITOS O CONSECUENCIALES.

Algunos estados y países no permiten limitaciones a la duración de una garantía implícita ni la exclusión o limitación de daños fortuitos

o consecuenciales, de modo que las limitaciones o exclusiones anteriores pueden no corresponder a su caso. Esta garantía le

concede derechos legales específicos, y usted puede tener también otros derechos que varían de un estado a otro y de un país a otro.

Para obtener servicio bajo garantía en los EE.UU. devuelva el producto, junto con el comprobante de compra, al Centro de Servicio

bajo Garantía Autorizado Independiente Nacional o Regional de BOSTITCH en los EE.UU. Dentro de los EE.UU. usted puede

llamarnos al 1-800-556-6696 o visitar www.BOSTITCH.com para ver la ubicación que más le convenga. En Canadá llámenos al at

1-800-567-7705 o visite www.BOSTITCH.com

-15-

Page 16

INSTRUCCIONES DE SEGURIDAD

El operador y otros en el área SIEMPRE deben llevar PROTECCIÓN OCULAR en conformidad con las

especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y por el LADO, cuando

se haga la conexión al suministro de aire, así como al cargar, operar o dar servicio a esta herramienta.

Se exige protegerse la vista para resguardarse contra fijaciones o residuos que vuelen, lo cual puede

causar lesiones graves a los ojos.

El empleador y/o el usuario deben asegurar que se protejan debidamente los ojos. El equipo de

protección ocular debe estar en conformidad con los requisitos del Instituto Nacional Americano de

Normas (American National Standards Institute), ANSI Z87.1 y proteger por delante y por el costado.

NOTA: Los anteojos o caretas sin protección lateral por sí solos no dan una protección adecuada.

PRECAUCIÓN: En algunos ambientes se necesitará protección adicional de seguridad. Por ejemplo, el

área de trabajo puede exponer a un nivel de ruido que lesione el oído. El empleador y el usuario deben

comprobar que se cuente con la protección necesaria del oído y que el operador y los demás presentes

en el área la usen. Algunos ambientes exigirán el uso de casco protector. Cuando sea necesario, el

empleador y el usuario deben verificar que se proteja la cabeza en conformidad con la norma ANSI

Z89.1.

SUMINISTRO DE AIRE Y CONEXIONES

No use oxígeno, gases combustibles ni gases envasados en cilindros para operar esta herramienta

porque puede explotar, causando posibles lesiones.

No use fuentes de suministro que tengan el potencial de superar 14 kg/cm

herramienta puede explotar, causando posibles lesiones.

El conector de la herramienta no debe contener presión cuando se desconecte el suministro de

aire. Si se usa el conector indebido, la herramienta puede mantenerse cargada con aire después de

desconectarla y podría impulsar una fijación incluso después de desconectar la línea de aire, causando

posibles lesiones.

No accione el gatillo ni oprima el brazo de contacto mientras esté conectado al suministro de aire

porque la herramienta puede hacer un ciclo, causando posibles lesiones.

Siempre desconecte el suministro de aire: 1.) Antes de hacer ajustes; 2.) Al dar servicio a la

herramienta; 3.) Al despejar un atasco; 4.) Cuando no está en uso la herramienta; 5.) Al avanzar a

otra área de trabajo, porque puede activarse accidentalmente, causando posibles lesiones.

2

(200 psig) dado que la

CARGA DE LA HERRAMIENTA

Al cargar la herramienta: 1.) Nunca ponga la mano ni ninguna otra parte del cuerpo en el área aplicadora

de descarga de la herramienta; 2.) Nunca apunte la herramienta a ninguna persona; 3.) No accione el

gatillo ni pulse el disparador porque puede activarse accidentalmente, causando posibles lesiones.

FUNCIONAMIENTO

Siempre maneje la herramienta con cuidado: 1.) Nunca participe en juegos rudos; 2.) Nunca accione

el gatillo a menos que la punta esté dirigida hacia el trabajo; 3.) Mantenga a los demás a una distancia

segura de la herramienta mientras esté en funcionamiento porque puede activarse accidentalmente,

causando posibles lesiones.

El operador no debe sostener el gatillo accionado en las herramientas con brazos de contacto salvo

durante la aplicación de fijaciones ya que pueden ocurrir lesiones graves si el disparo tomara contacto

accidentalmente con algo o alguien, ocasionando que la herramienta haga un ciclo.

Mantenga las manos y el cuerpo alejados del área de descarga de la herramienta. Una herramienta con

brazo de contacto puede rebotar al aplicar una fijación haciendo salir otra, causando posibles lesiones.

Revise frecuentemente el funcionamiento del mecanismo del brazo de contacto. No use la

herramienta si el brazo no funciona correctamente ya que puede impulsarse accidentalmente una

fijación. No interfiera con el funcionamiento adecuado del mecanismo del brazo de contacto.

No aplique clavos o grapas encima de otras ni con la herramienta en un ángulo demasiado agudo pues

esto puede ocasionar su deflexión, pudiendo causar lesiones.

No aplique grapas cerca del borde de la pieza con la cual esté trabajando pues la madera puede

dividirse, permitiendo la deflexión del clavo o grapa, causando posibles lesiones.

Esta clavadora produce CHISPAS durante la operación. NUNCA use la clavadora cerca de sustancias,

gases ni vapores inflamables, incluidos lacas, pintura, bencina, gasolina, adhesivos, mástique,

pegamentos ni ningún otro material que sea inflamable, combustible o explosivo -- o vapores,

emanaciones o subproductos que puedan serlo. Si se usa la clavadora en cualquier ambiente de

este tipo podría causar una EXPLOSIÓN produciendo lesiones físicas o fatales para el usuario y las

personas en la cercanía.

-16-

Page 17

MANTENIMIENTO DE LA HERRAMIENTA

Al trabajar con herramientas neumáticas, observe las advertencias de este manual y tenga sumo cuidado al

evaluar herramientas con problemas.

Si la herramienta se ha caído o si sospecha daño a la herramienta, realice una comprobación de funcionamiento

de la herramienta tal como se define en la sección de comprobación de funcionamiento de la herramienta.

LHF2025K COMPONENTES DE LA HERRAMIENTA

Armazón

Enganche de le

lengüeta Easy-Sight

Perillas de precisión ajustables

Indicador de recarga

EHF1838K COMPONENTES DE LA HERRAMIENTA

Enganche de le

lengüeta Easy-Sight

Perillas de precisión ajustables

Indicador de recarga

Gatillo

Depósito Botón de

liberación

Protector del armazón

Tapa del armazón

Agarre cómodo sobremoldeado

Escape posterior

Conector de aire

Armazón

Protector del armazón

Tapa del armazón

Gatillo

Depósito Botón de

liberación

-17-

Agarre cómodo sobremoldeado

Escape posterior

Conector de aire

Page 18

ESPECIFICACIONES DE LA HERRAMIENTA

Todas las dimensiones están en pulgadas a menos que se especifique lo contrario.

Descripción

Tipo de motor

Rango de presión operativa

Máxima presión operativa

Tipo de jación

Calibre de la jación

Gama de la jación

Capacidad del depósito

Largo

Ancho

Altura

Peso

Engrapadora para duela calibre 18 Engrapadora para duela calibre 20

4.9 - 8.4 kg/cm

Presión operativa:

4.9 a 8.4 kg/cm2 (70 a 120 psig). Seleccione la presión de operación dentro de este rango para el mejor

desempeño del sujetador.

NO SUPERE ESTA PRESIÓN OPERATIVA RECOMENDADA.

Consumo de aire:

La EHF1838K requiere 55 litros por minuto o L/min (1.94 pies cúbicos por minuto o cfm) de aire libre a 5.6

2

(80 PSI) para operar a una velocidad de 60 sujetadores por minuto. La LHF2025K requiere 54 litros

kg/cm

por minuto o L/min (1.90 pies cúbicos por minuto o cfm) de aire libre a 5.6 kg/cm

una velocidad de 60 sujetadores por minuto. Para determinar el tamaño adecuado del compresor de aire,

tome la velocidad real en la cual se utilizará la herramienta y compare los L/min (cfm) requeridos con la

entrega de aire libre (FAD) del compresor (L/min o cfm) a 5.6 kg/cm

Por ejemplo, si usted usa en promedio 30 sujetadores por minuto, necesita el 50 % del volumen de aire (L/

min o cfm) que se requiere para operar la herramienta a una velocidad de 60 sujetadores por minuto. En

este caso, para un rendimiento óptimo, asegúrese de que su compresor de aire pueda entregar un mínimo

de 27.5 L/min (0.97 cfm) a 5.6 kg/cm

2

(80 PSI).

EHF1838K LHF2025K

Sin aceite Sin aceite

2

(70 a 120 psig) 4.9 - 8.4 kg/cm2 (70 a 120 psig)

8.4 kg/cm

25 mm - 38 mm (1 pulg. a 1-1/2

2

(120 psig) 8.4 kg/cm2 (120 psig)

Serie SX5035 SB97-1GLS

Calibre 18 Calibre 20

pulg.)

100 125

235 mm (9-1/4 pulg.) 235 mm (9-1/4 pulg.)

70 mm (2-3/4 pulg.) 70 mm (2-3/4 pulg.)

251 mm (9-7/8 pulg.) 216 mm (8.5 pulg.)

1.57 kg (3.5 lb) 1.32 kg (2.9 lb)

2

(80 PSI).

25 mm (1 pulg.)

2

(80 PSI) para operar a

ESPECIFICACIONES DE FIJACIONES

Modelo de

herramienta

Tipo de jación

EHF1838K

Grapas

LHF2025K Grapas

* Si desea obtener más detalles, visite .

NOTA:

Las herramientas BOSTITCH se han diseñado para brindar una satisfacción excelente al cliente y lograr máximo

rendimiento al utilizarse con fijaciones de precisión BOSTITCH diseñadas con las mismas normas estrictas.

BOSTITCH no puede asumir responsabilidad alguna por el rendimiento del producto si se utilizan nuestras

herramientas con jaciones o accesorios que no reúnen los requisitos especícos establecidos para

jaciones y accesorios genuinos de BOSTITCH.

SKU de

la jación

SX50351G

SX50351-1/8G

SX50351-3/16G

SX50351-1/4G

SX50351-3/8G

SX50351-1/2G

Ancho

de corona

5.5 mm (7/32”)

5.5 mm (7/32”)

5.5 mm (7/32”)

5.5 mm (7/32”)

5.5 mm (7/32”)

5.5 mm (7/32”)

Calibre Largo

18 25 mm (1”)

18 28 mm (1-1/8”)

18 30 mm (1-3/16”)

18 32 mm (1-1/4”)

18 35 mm (1-3/8”)

18 38 mm (1-1/2”)

SB97-1G 4.7 mm (3/16”) 20 25 mm (1”)

-18-

Page 19

SUMINISTRO DE AIRE Y CONEXIONES

No use oxígeno, gases combustibles ni gases envasados en cilindros para operar esta herramienta

porque puede explotar, causando posibles lesiones.

CONECTORES:

Instale un enchufe macho en la herramienta que está fluyendo libremente y que liberará presión de aire de la

herramienta al desconectarse de la fuente de alimentación.

MANGUERAS:

Las mangueras de aire deben tener una presión nominal de trabajo mínima de 10.6 kg/cm2 (150 psig) de capacidad

nominal de presión de trabajo o un 150 por ciento de la presión máxima que podría producirse en el sistema de aire. La

manguera de suministro debe contar con un conector de “desconexión rápida” del enchufe macho en la herramienta.

FUENTE DE SUMINISTRO:

Use solamente aire comprimido regulado limpio como fuente de energía para esta herramienta. NUNCA USE

OXÍGENO, GASES COMBUSTIBLES O GASES ENVASADOS EN CILINDROS COMO FUENTE DE ENERGÍA PARA

ESTA HERRAMIENTA, PUES LA HERRAMIENTA PUEDE EXPLOTAR.

REGULADOR:

Se necesita un regulador de presión con una presión operativa de 0 - 8.8 kg/cm2 (0 a 125 psig) para controlar la

presión operativa con el fin de que la herramienta funcione en forma segura. No conecte esta herramienta a la presión

de aire que potencialmente pueda superar 14 kg/cm

causando posibles lesiones.

PRESIÓN OPERATIVA:

No supere la presión operativa máxima recomendada porque aumentará considerablemente el desgaste de la

herramienta. El suministro de aire debe ser capaz de mantener la presión operativa de la herramienta. Las caídas de

presión en el suministro de aire pueden reducir la energía impulsora de la herramienta. Consulte las “OPERACIÓN

DE LA HERRAMIENTA” para establecer la presión operativa correcta de la herramienta.

2

(200 psig) porque la herramienta puede fracturarse o explotar,

Enchufe de

desconexión rápida

Enchufe de

conexión rápida

-19-

Page 20

CARGA DE LA EHF1838K Y LA LHF2025K

El operador y otros en el área SIEMPRE deben llevar PROTECCIÓN OCULAR en conformidad

con las especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y

por el LADO, cuando se haga la conexión al suministro de aire, así como al cargar, operar

o dar servicio a esta herramienta. Se exige protegerse la vista para resguardarse contra

fijaciones o residuos que vuelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

de protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

delante y por el costado. NOTA: Los anteojos o caretas sin protección lateral por sí solos

no dan una protección adecuada.

PARA PREVENIR LESIONES ACCIDENTALES:

• Nunca coloque la mano ni ninguna parte del cuerpo en el área de descarga de clavos de

la herramienta mientras esté conectado el suministro de aire.

• Nunca apunte la herramienta hacia una persona.

• Nunca participe en juegos rudos.

• Nunca accione el gatillo a menos que la punta esté dirigida hacia el trabajo.

• Siempre maneje la herramienta con cuidado.

• No accione el gatillo ni oprima el mecanismo de disparo mientras carga la herramienta.

CARGA DE LA EHF1838K & LHF2025K

1. Oprima el botón de liberación del

depósito y mueva hacia atrás el

depósito.

2. Abra el depósito totalmente y gire la

herramienta de lado con el área de

descarga apuntando lejos de usted y

de otras personas. Cargue las grapas

en el canal.

3. Empuje el depósito hacia delante

hasta que se enganche el pestillo.

-20-

Page 21

INSTRUCCIONES DE AJUSTE

BOTÓN

NARIZ

GUÍA FRONTAL

BARRERA FRONTAL

PISO

SUBPISO

PIE

LENGÜETA DE

REVESTIMIENTO DEL PISO

PARA AJUSTAR LA HERRAMIENTA AL REVESTIMIENTO DE PISO:

1. Afloje ambos botones hasta que la guía frontal y de pie se muevan libremente.

2. Encaje la nariz en la lengüeta del revestimiento de piso.

3. Empuje la guía frontal contra el subpiso y el pie contra el revestimiento del piso.

4. Apriete ambos botones.

Consulte las instrucciones de instalación del fabricante del piso para utilizar una

técnica de remaches y sujeción apropiada.

Importante: Faites un essai de l’outil sur un débris de plancher pour assurer le

positionnement adéquat de l’agrafe et la compatibilité. BOSTITCH ne peut être responsable

de la performance du produit si l’outil n’est pas utilisé correctement ou s’il n’est pas utilisé

conformément aux instructions d’installation des fabricants de planchers.

Con la herramienta colocada apropiadamente

en la lengüeta del revestimiento de piso, deslice

la herramienta a lo largo de la lengüeta sin

levantar la herramienta del piso mientras clava,

tal como se muestra arriba y a la izquierda.

PRESIÓN DE AIRE:

La pression d’air doit être réglée pour obtenir

un enfoncement adéquat des agrafes. La

pression d’air doit être réglée en utilisant un

débris de plancher jusqu’à l’obtention d’un

enfoncement adéquat.

(Vea la página siguiente)

-21-

Page 22

ANTES DE OPERAR ESTA HERRAMIENTA, ESTUDIE ESTAS INSTRUCCIONES Y

MANUAL DE OPERACIÓN Y MANTENIMIENTO PARA SU HERRAMIENTA PARA QUE

ENTIENDA LAS ADVERTENCIAS E INSTRUCCIONES DE SEGURIDAD. SI TIENE ALGUNA

PREGUNTA, DIRÍJASE A SU REPRESENTANTE O DISTRIBUIDOR DE BOSTITCH. GUARDE

ESTAS INSTRUCCIONES PARA REFERENCIA EN EL FUTURO.

PISO

• Presión de aire demasiado baja.

• Corona de la grapa está encima de la lengüeta.

• Aumentar la presión de aire.

• Presión de aire demasiado alta.

• Grapa enterrada.

• Bajar la presión de aire.

GRAPA

• Corregir la presión de aire.

• Grapa justamente debajo de la superficie.

-22-

Page 23

OPERACIÓN DE LA HERRAMIENTA

El operador y otros en el área SIEMPRE deben llevar PROTECCIÓN OCULAR en conformidad

con las especificaciones ANSI y que proteja contra partículas que vuelen por DELANTE y

por el LADO, cuando se haga la conexión al suministro de aire, así como al cargar, operar

o dar servicio a esta herramienta. Se exige protegerse la vista para resguardarse contra

fijaciones o residuos que vuelen, lo cual puede causar lesiones graves a los ojos.

El empleador o el usuario deben asegurar que se protejan debidamente los ojos. El equipo

de protección ocular debe estar en conformidad con los requisitos del Instituto Nacional

Americano de Normas (American National Standards Institute), ANSI Z87.1 y proteger por

delante y por el costado. NOTA: Los anteojos o caretas sin protección lateral por sí solos

no dan una protección adecuada.

ANTES DE MANIPULAR U OPERAR ESTA HERRAMIENTA:

I. LEA DETALLADAMENTE LAS ADVERTENCIAS CONTENIDAS EN ESTE MANUAL.

II. CONSULTE LAS “ESPECIFICACIONES DE LA HERRAMIENTA” EN ESTE MANUAL PARA IDENTIFICAR

EL SISTEMA OPERATIVO DE LA HERRAMIENTA.

OPERACIÓN

El operador no debe sostener el gatillo accionado en las herramientas con disparo de

contacto salvo durante la aplicación de fijaciones ya que pueden ocurrir lesiones graves

si el disparador tomara contacto accidentalmente con algo o alguien, ocasionando que la

herramienta haga un ciclo.

Mantenga las manos y el cuerpo alejados del área de descarga de la herramienta. Una

herramienta con disparo de contacto puede rebotar al aplicar una fijación haciendo salir

otra, causando posibles lesiones.

FUNCIONAMIENTO DEL DISPARO SECUENCIAL:

En el MODO DE DISPARO SECUENCIAL el disparo de contacto funciona en conjunto con el gatillo para impulsar

una fijación. Para usar una herramienta con disparo secuencial, primero coloque el disparo de contacto sobre

la superficie de trabajo SIN ACCIONAR ELGATILLO. Oprima el disparo de contacto y luego accione el gatillo

para aplicar una fijación. Siempre y cuando el disparo de contacto toque el trabajo y se mantenga oprimido,

la herramienta aplicará una fijación cada vez que se oprima el gatillo. Si se deja que el disparo de contacto se

separe de la superficie de trabajo, debe repetirse la secuencia descrita más arriba para colocar otra fijación.

Si la herramienta se ha caído o si sospecha daño a la herramienta, realice una comprobación

de funcionamiento de la herramienta tal como se define en la sección de comprobación de

funcionamiento de la herramienta.

ADEMÁS DE LAS OTRAS ADVERTENCIAS CONTENIDAS

EN ESTE MANUAL OBSERVE LO SIGUIENTE PARA LA

OPERACIÓN SEGURA

• Use la herramienta neumática BOSTITCH solamente para el fin que fue diseñada.

• Nunca use esta herramienta de tal modo que pueda causar la salida de una fijación hacia

el usuario u otros presentes en el área de trabajo.

• No use la herramienta como martillo.

• Siempre lleve la herramienta tomándola por la empuñadura. Nunca lleve la herramienta tomándola

por la manguera de aire.

• No altere ni modifique el diseño o función original de esta herramienta sin la aprobación de

BOSTITCH, INC.

• Siempre tenga presente que el uso indebido o la manipulación incorrecta de esta herramienta

puede causarle lesiones a usted y a los demás.

• Nunca use abrazaderas ni cinta para bloquear el gatillo o el disparo de contacto en

la posición activada.

• Nunca deje una herramienta sin supervisión con la manguera de aire conectada.

• No opere esta herramienta si no cuenta con una ETIQUETA DE ADVERTENCIA legible.

• Deje de usar la herramienta si tiene fugas de aire o no funciona bien. Notifique al representante

más cercano de Bostitch si la herramienta continúa experimentando problemas funcionales.

-23-

Page 24

REVISIÓN FUNCIONAL DE LA HERRAMIENTA

PRECAUCIÓN: Retire todas las fijaciones de la herramienta antes de revisar cómo funciona.

Si la herramienta se ha caído o sospecha daño a la herramienta, realice una comprobación

de funcionamiento de la herramienta.

FUNCIONAMIENTO DEL DISPARO SECUENCIAL:

A. Presione el disparo de contacto contra la superficie de trabajo, sin tocar el gatillo.

NO DEBE HACER UN CICLO LA HERRAMIENTA.

B. Sostenga la herramienta sin tocar la superficie de trabajo y accione el gatillo.

NO DEBE HACER UN CICLO LA HERRAMIENTA.

Libere el gatillo. El gatillo debe regresar al tope del gatillo del armazón.

C. Accione el gatillo y presione el disparo de contacto contra la superficie de trabajo.

NO DEBE HACER UN CICLO LA HERRAMIENTA.

D. Con el dedo lejos del gatillo, presione el disparo de contacto contra la superficie de trabajo. Accione el

gatillo.

DEBE HACER UN CICLO LA HERRAMIENTA.

MANTENIMIENTO DE LA HERRAMIENTA NEUMÁTICA

Al trabajar con herramientas neumáticas, observe las advertencias de este manual y tenga

sumo cuidado al evaluar herramientas con problemas.

Si la herramienta se ha caído o si sospecha daño a la herramienta, realice una comprobación

de funcionamiento de la herramienta tal como se define en la sección de comprobación de

funcionamiento de la herramienta..

PRECAUCIÓN: Resorte de empuje (resorte de fuerza constante). Debe tenerse cuidado al trabajar con el

ensamblaje del resorte. El resorte va envuelto alrededor de un rodillo, no conectado al mismo. Si el resorte

se extiende más allá de su longitud, el extremo se saldrá del rodillo y el resorte se enrollará con un chasquido,

posiblemente pellizcándole la mano. Los bordes del resorte también son muy finos y podrían cortar. Debe

tenerse cuidado para asegurar que no se hagan dobleces permanentes en el resorte porque esto reducirá la

fuerza del mismo.

PIEZAS DE REPUESTO:

Al cambiar piezas, solamente use repuestos genuinos BOSTITCH. No use piezas modificadas.

PROCEDIMIENTO DE ENSAMBLAJE PARA LOS SELLOS:

Al reparar una herramienta, fíjese en que las piezas internas estén limpias y lubricadas. Use Parker “O”-LUBE,

Magnalube u otro lubricante equivalente en todas las juntas tóricas. Cubra cada junta tórica con lubricante antes del

ensamblaje.

PRESIÓN Y VOLUMEN DEL SUMINISTRO DE AIRE:

El volumen de aire es tan importante como la presión de aire. El volumen de aire suministrado a la herramienta puede

ser inadecuado debido a accesorios y mangueras de tamaño inferior o por los efectos de suciedad y agua en el

sistema. El flujo de aire restringido impedirá que la herramienta reciba un volumen de aire adecuado, aun cuando la

lectura de presión sea alta. Los resultados serán funcionamiento lento, fijaciones mal dirigidas o menor potencia de

impulso. Antes de evaluar los problemas de las herramientas según estos síntomas, inspeccione el suministro de aire

desde la herramienta a la fuente de suministro en busca de conectores restrictivos, puntos bajos que tengan agua y

cualquier otra cosa que impida el flujo del volumen completo de aire a la herramienta.

-24-

Page 25

SOLUCIÓN DE PROBLEMAS

PROBLEMA CAUSA CORRECCIÓN

El alojamiento de la válvula de

disparo tiene fuga de aire La junta tórica está cortada o agrietada ..........Cambie la junta tórica

El vástago de la válvula de disparo La junta tórica o los sellos están ................Cambie el ensamblaje de la válvula de disparo

tiene fuga de aire cortados o agrietados

El armazón o la punta tiene fuga de aire La junta tórica o la empaquetadura está ......... Cambie la junta tórica o la empaquetadura

cortada o agrietada

El tope está agrietado o desgastado .............Cambie el tope

El armazón o la tapa tiene fuga de aire La empaquetadura o el sello está dañado ........Cambie la empaquetadura o el sello

La válvula cabezal está agrietada o desgastada ..Reemplace la válvula cabezal

Los tornillos de casquete están sueltos ..........Apriete y revíselos de nuevo

No hace ciclos El suministro de aire está restringido ............ Revise el equipo de suministro de aire

La válvula cabezal está desgastada .............Reemplace la válvula cabezal

El resorte en la tapa del cilindro está roto ........Cambie el resorte de la tapa del cilindro

La válvula cabezal está pegada en la tapa ........Desarme / Revise/ Lubrique lo necesario

Falta alimentación; el ciclo es lento El resorte en la tapa del cilindro está roto ........Cambie el resorte de la tapa

Las juntas tóricas o los sellos están cortados ....Cambie las juntas tóricas o los sellos

o agrietados

Escape bloqueado ............................Revise el tope, el resorte de la válvula cabezal

El ensamblaje del gatillo está desgastado .......Cambie el ensamblaje del gatillo

o tiene fugas

Hay acumulación de suciedad o alquitrán .......Desarme la punta o el impulsor para limpiar

en el impulsor

El manguito del cilindro no está asentado

correctamente en el tope inferior ...............Desármelo para corregir esto

La presión de aire está demasiado baja ..........Revise el equipo de suministro de aire

Se saltan las fijaciones;

alimentación intermitente El tope está desgastado ........................Cambie el tope

Hay alquitrán o suciedad en el canal del impulsor ..Desarme y limpie la punta y el impulsor

Restricción de aire/flujo indebido de aire a través

del enchufe y la toma de desconexión rápida .....Cambie los accesorios de desconexión rápida

Está desgastado el anillo del pistón ..............Cambie el anillo, revise el impulsor

El resorte de empuje está dañado ...............Cambie el resorte

Hay baja presión de aire .......................Revise el sistema de suministro de aire a la herramienta

Los tornillos en la punta del depósito ............Apriete todos los tornillos

están sueltos

Las fijaciones son demasiado cortas para ....... Use solamente las fijaciones recomendadas

la herramienta

Hay fijaciones dobladas ........................Deje de usar estas fijaciones

Las fijaciones son del tamaño incorrecto .........Use solamente las fijaciones recomendadas

La empaquetadura de la tapa cabezal tiene fugas . Apriete los tornillos o cambie la empaquetadura

La junta tórica de la válvula de disparo está .....Cambie la junta tórica

cortada o desgastada

El impulsor está roto o picado ...................Cambie el impulsor (revise el anillo del pistón)

El depósito está seco o sucio ...................Limpie/lubrique con Lubricante para herramientas neumáticas BOSTITCH

El depósito está desgastado ....................Cambie el depósito

Se atascan las fijaciones en la herramienta El canal del impulsor está desgastado ...........Cambie la punta, revise la puerta

Las fijaciones son del tamaño incorrecto .........Use solamente las fijaciones recomendadas

Hay fijaciones dobladas ........................Deje de usar estas fijaciones

Hay tornillos sueltos en el depósito o la punta ....Apriete todos los tornillos

El impulsor está roto o picado ...................Cambie el impulsor

-25-

Page 26

V

Mantenimiento Benecio Procedimiento Intervalo

de servicio

Inspeccione el

funcionamiento del gatillo o

disparador

Drene la condensación de los

tanques y filtros de aire del

compresor de aire (si la hay)

Limpie el ensamblaje del

depósito

Limpie el ensamblaje de la

punta

Asegure que todas las

fijaciones se mantengan

apretadas

Reemplace el conector

de aire

Reemplace el ensamblaje de

pistón/impulsor

Cambie las juntas tóricas Mantiene el motor para lograr

Cambie el tope Mantiene el motor para lograr

Cambie la válvula cabezal Mantiene el motor para lograr

Reemplace el cilindro del

motor

Confirme que el sistema de

disparo funcione bien

Previene la acumulación de

humedad que p uede impedir

el buen rendimiento de la

herramienta

Previene la acumulación de

residuos que pudieran causar

atascos

Previene la acumulación de

residuos que pudieran causar

atascos

Prevenga las piezas sueltas Apriete todas las fijaciones

Mantiene el flujo de aire

correcto al motor para lograr

óptimo rendimiento

Mantiene la calidad constante

de impulso

óptimo rendimiento

óptimo rendimiento

óptimo rendimiento

Mantiene el motor para lograr

óptimo rendimiento

Consulte la sección Revisión

funcional de la herramienta

en este manual

Abra la llave de drenaje en

los tanques y filtros de aire y

drene todo el condensado

Limpie soplando con aire

comprimido

Limpie soplando con aire

comprimido

con la llave hexagonal del

tamaño apropiado

Remove worn air fitting and

replace with new fitting

Remítase a las instrucciones del

paquete de piezas de repuesto

Remítase a las instrucciones

del paquete de piezas de

repuesto

Remítase a las instrucciones

del paquete de piezas de

repuesto

Remítase a las instrucciones

del paquete de piezas de

repuesto

Remítase a las instrucciones

del paquete de piezas de

repuesto

Diariamente

Diariamente

Diariamente

Diariamente

Semanalmente

50,000 fijaciones

150,000 fijaciones

250,000 fijaciones

250,000 fijaciones

250,000 fijaciones

500,000 fijaciones

-26-

Page 27

OTHER BOSTITCH FLOORING PRODUCTS

MIIIFS

ENGRAPADORA PARA

DUELA CALIBRE 15.5

MFN-201

CLAVADORA MANUAL

PARA PISO CALIBRE 16

CLAVADORA PARA DUELA

GATO 2 EN 1 PARA PISO DE

MIIIFN

CALIBRE 16

GATO MIII

MADERA

PRO-1450

MANGUERA DE AIRE DE

POLIURETANO DE PRIMERA

CALIDAD DE 6.4 mm X 15 m

(1/4 pulg. X 50 pies)

-27-

HFM-3

MAZO PARA PISOS DE

MADERA DURA DE CARA

SUAVE DE 37.6 cm, 1.27 kg

(14.8 pulg., 45 oz)

Page 28

LIGNES DIRECTRICES EN MATIÈRE DE SÉCURITÉ - DÉFINITIONS

Il est important que vous lisiez et compreniez ce mode d’emploi. Les informations qu’il contient concernent VOTRE SÉCURITÉ

et visent à ÉVITER TOUT PROBLÈME. Les symboles ci-dessous servent à vous aider à reconnaître cette information.

Indique une situation dangereuse imminente qui, si elle n’est pas évitée, causera la mort

ou des graves blessures.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

causer la mort ou de graves blessures.

Indique une situation potentiellement dangereuse qui, si elle n’est pas évitée, pourrait

causer des blessures mineures ou modérées

Utilisé sans le symbole d’alerte à la sécurité, indique une situation potentiellement

dangereuse qui, si elle n’est pas évitée, peut résulter en des dommages à la propriété.

INTRODUCTION

Les EHF1838K et LHF2025K de Bostitch sont des outils de précision, conçus pour la pose d’attaches à haute vitesse et à haut volume. Ces outils vous

donneront un rendement efficace et fiable lorsqu’utilisés correctement et avec soin. Comme pour tout outil de précision, il est important de suivre les

instructions du fabricant pour obtenir la meilleure performance. Veuillez étudier ce manuel avant d’utiliser l’outil et comprendre les avertissements et

les mises en garde de sécurité. Les instructions ayant trait à l’installation, le fonctionnement et l’entretien doivent être lues attentivement et les manuels

doivent être conservés pour référence. REMARQUE : Des mesures de sécurité additionnelles peuvent être requises en fonction de l’utilisation que

vous faites de l’outil. Communiquez avec votre représentant ou distributeur BOSTITCH pour toute question au sujet de cet outil et de son utilisation.

BOSTITCH Fastening Systems, 701 E. Joppa Road, Towson, Maryland 21286, U.S. & Canada Only, É.-U. et Canada seulement.

INDEX

Consignes de sécurité ...............................................29

Composants de l'outil ..........................................30

Fiche technique de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

Alimentation d’air et connexions .......................................32

Chargement de l’outil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33

Instructions de réglage.......................................... 34 & 35

Fonctionnement de l’outil .............................................36

Vérification du fonctionnement de l’outil .................................37

Entretien de l’outil pneumatique .......................................37

Dépannage .......................................................38

Liste des vérifications d’entretien.......................................39

Autres produits Bostitch pour planchers. ................................40

REMARQUE :

Les outils BOSTITCH ont été fabriqués afin d’offrir un degré de satisfaction de la clientèle très

élevé et sont conçus pour atteindre une performance maximale lorsqu’utilisés avec les attaches

BOSTITCH de précision fabriquées avec les mêmes normes élevées. BOSTITCH ne peut être

tenu responsable de la performance du produit si les outils sont utilisés avec des attaches

ou des accessoires ne répondant pas strictement aux exigences établies pour les clous,

agrafes et accessoires d’origine BOSTITCH.

GARANTIE LIMITÉE — É.-U. et Canada seulement

BOSTITCH Fastening Systems “BOSTITCH” garantit à l’acheteur d’origine au détail que ce produit est exempt de tout défaut de matériaux et de fabrication et accepte,

le cas échéant, de réparer ou de remplacer, à la discrétion de BOSTITCH, toute agrafeuse ou cloueuse de marque BOSTITCH défectueuse pour une période de sept

(7) ans à partir de la date d’achat (1 (un) an à partir de la date d’achat pour les compresseurs et les outils utilisés dans des applications de production). Cette garantie

n’est pas cessible. Une preuve de la date d’achat est requise. Cette garantie couvre uniquement les dommages résultant de défaut de matériaux et de fabrication, et ne

couvre pas les conditions ou défauts de fonctionnement résultant d’une usure normale, d’une négligence, d’un usage abusif, d’un accident, d’une réparation ou d’une

tentative de réparation par une entité autre que notre Centre de réparation national ou l’un de nos Centres de service de garantie autorisé. Les lames du mandrin, les

amortisseurs, les joints toriques, les pistons et les garnitures de piston sont considérés comme des pièces normales d’usure. Pour une performance optimale de

votre outil BOSTITCH, utilisez toujours des attaches et des pièces de rechange BOSTITCH d’origine.

CETTE GARANTIE REMPLACE TOUTE AUTRE GARANTIE, IMPLICITE OU EXPLICITE, COMPRENANT, MAIS SANS S’Y LIMITER, LES GARANTIES IMPLICITES

DE COMMERCIALISATION OU D’ADAPTATION À UN USAGE PARTICULIER. BOSTITCH NE SERA PAS TENUE RESPONSABLE DES DOMMAGES INDIRECTS OU

ACCESSOIRES.

Les limitations imposées par la durée d’une garantie implicite ou l’exclusion des dommages accessoires ou indirects n’étant pas reconnues dans certains États et

pays, les limitations ou exclusions précitées peuvent ne pas vous être adressées. Cette garantie vous confère des droits juridiques spécifiques qui s’ajoutent aux

autres droits éventuels qui peuvent varier d’une province, d’un État ou d’un pays à l’autre

Pour obtenir aux États-Unis des services liés à la garantie, retournez le produit à vos frais accompagné de la preuve d’achat à votre Centre de service national

américain ou à un Centre de service régional indépendant de garantie autorisé. Aux États-Unis, appelez-nous au 1-800-556-6696 ou visitez le www.BOSTITCH.com

pour connaître l’emplacement du Centre le plus près de chez vous. Au Canada, appelez-nous au 1-800-567-7705 ou visitez le www.BOSTITCH.com.

-28-

Page 29

CONSIGNES DE SÉCURITÉ

DES LUNETTES DE SÉCURITÉ se conformant aux normes ANSI et qui protègent des particules

projetées du côté FRONTAL ainsi que du côté LATÉRAL doivent TOUJOURS être portées par

l’opérateur et toute autre personnes se trouvant dans la zone de travail lors d’une connexion

à l’alimentation d’air, du chargement, de fonctionnement ou de l’entretien de cet outil. Une

telle protection est indispensable pour vous protéger contre les attaches et débris projetés,

susceptibles d’entraîner des blessures sérieuses.

L’employeur et/ou l’utilisateur doivent s’assurer que les lunettes de sécurité appropriées sont

portées. L’équipement de protection doit être conforme à la norme ANSI Z87.1 et fournir une

protection frontale et latérale. REMARQUE : Les lunettes sans protection latérale et les masques

faciaux ne fournissent pas la protection nécessaire.

ATTENTION: Des articles de sécurité additionnels devront être portés dans certains environnements.

Par exemple, la zone de travail peut comporter une exposition à un niveau de bruit qui pourrait

entraîner une diminution de l’acuité auditive. L’employeur et l’utilisateur doivent s’assurer qu’une

protection de l’ouïe est fournie et utilisée par l’opérateur et toute autre personne dans la zone

de travail. Certains environnements nécessiteront l’utilisation d’équipement de protection de la

tête. Lorsque requis, l’employeur et l’utilisateur doivent s’assurer qu’une protection de la tête se

conformant à la norme ANSI Z89.1 est utilisée.

ALIMENTATION D’AIR ET CONNEXIONS

N’utilisez pas d’oxygène, de gaz combustibles ou de gaz en bouteille comme source d’alimentation

pour cet outil puisque cela peut causer l’explosion de l’outil et causer des blessures.

N’utilisez pas des sources d’alimentation pouvant excéder 200 lb/po

causer l’éclatement de l’outil et causer des blessures.

Le connecteur de l’outil ne doit pas être sous pression lorsque l’outil est déconnecté. Si un raccord

incorrect est utilisé, l’outil peut demeurer sous pression après avoir été déconnecté et pourrait

donc décharger une attache même une fois la conduite d’air déconnectée et causer des blessures.

N’appuyez pas sur la gâchette et n’appuyez pas sur le bras de contact alors qu’il est connecté à

l’alimentation d’air, car l’outil pourrait alors être actionné et causer des blessures.

Veillez à toujours déconnecter l’alimentation d’air : 1.) Avant de procéder à des ajustements; 2.)

Au moment de réparer l’outil; 3.) Au moment de dégager un blocage; 4.) Lorsque l’outil n’est pas

utilisé; 5.) Au moment de se déplacer vers une zone de travail différente, puisque l’outil pourrait

être actionné accidentellement et causer des blessures.

2

(14 kg/cm2) car cela peut

CHARGEMENT DE L’OUTIL

Au moment de charger l’outil : 1.) Ne placez jamais la main ou toute autre partie du corps

dans la région de décharge d’attache de l’outil; 2.) Ne dirigez jamais l’outil vers quelqu’un; 3.)

N’appuyez pas sur la gâchette et n’appuyez pas sur le déclencheur puisqu’il pourrait être actionné

accidentellement et causer des blessures.

FONCTIONNEMENT

Veillez à toujours manipuler l’outil avec précaution : 1.) Ne vous chahutez jamais; 2.) N’appuyez

jamais sur la gâchette sans que le nez de pose soit dirigé vers la surface de travail; 3.) Maintenez

les autres à une distance sécuritaire alors que l’outil fonctionne puisqu’il pourrait être actionné

accidentellement et causer des blessures.

L’opérateur ne doit pas maintenir la gâchette enfoncée sur les outils à bras de contact sauf lors des

opérations d’attache puisque de graves blessures peuvent être causées si le déclencheur entrait

en contact avec quelqu’un ou quelque chose accidentellement, ce qui pourrait actionner l’outil.

Ne placez jamais la main ou le corps dans la zone de décharge de l’outil. Un outil à bras de contact

peut rebondir en raison du recul causé au moment de tirer une attache et une deuxième attache

pourrait être tirée inopinément et causer des blessures.

Vérifiez fréquemment le fonctionnement du mécanisme du bras de contact. N’utilisez pas l’outil

si le bras ne fonctionne pas correctement puisque cela peut causer le tir accidentel d’une attache.

Ne gênez pas le fonctionnement approprié du mécanisme de bras de contact.

Ne tirez pas d’attache sur une autre attache ou alors que l’outil est à un trop grand angle, car cela

peut causer une déflexion de l’attache et causer des blessures.

Ne tirez pas d’attache trop près du bord de la pièce de travail, car le bois pourrait fendre et

entraîner la déflexion de l’attache et causer des blessures.

La cloueuse produit des ÉTINCELLES lors du fonctionnement. N’utilisez JAMAIS la cloueuse près

de substances inflammables, de gaz ou de vapeurs, y compris la laque, la benzine, le diluant,

l’essence, les adhésifs, les mastics, les colles ou de tout autre matériau qui est – ou dont les

vapeurs, les émanations ou les sous-produits sont – inflammables, combustibles ou explosifs.