Page 1

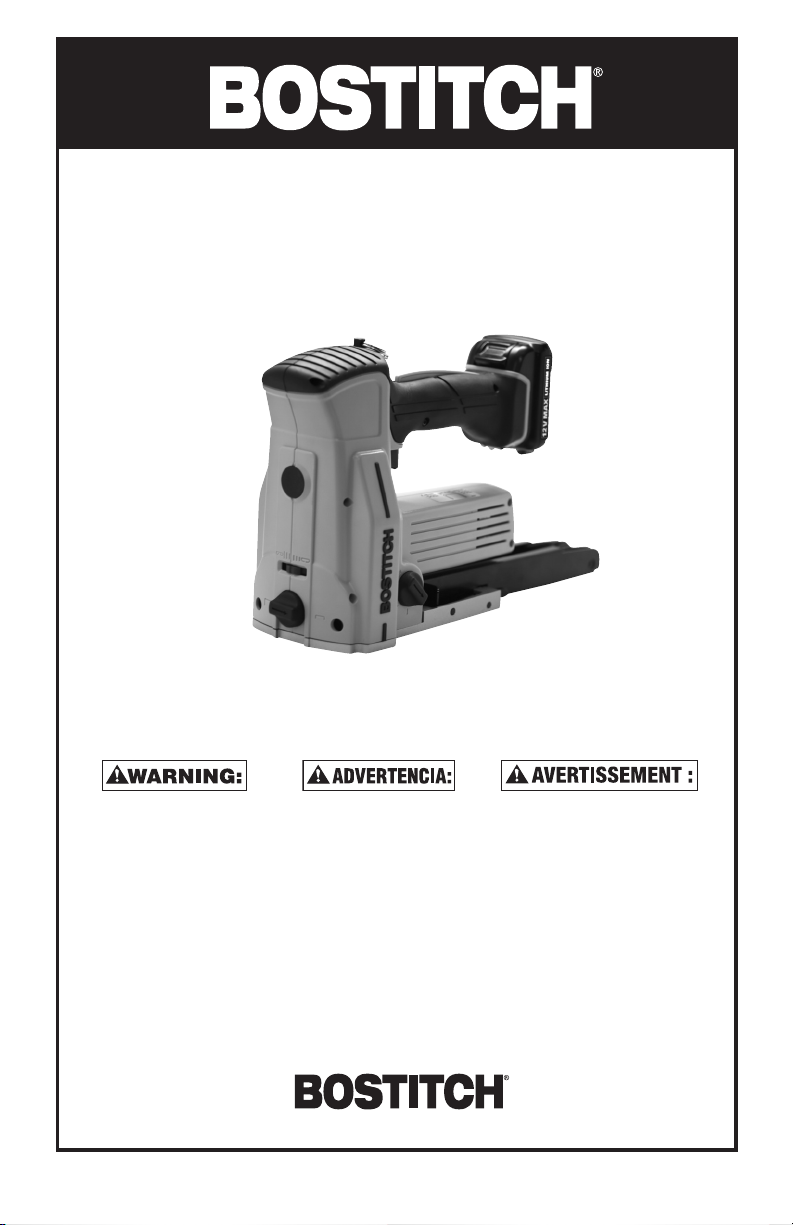

DSW-3519 / DSW-3522 /DSC-3219

CORDLESS CARTON CLOSING STAPLER

GRAPADORA AUTÓNOMA PARA

CIERRE DE CAJAS DE CARTÓN

AGRAFEUSE SANS FIL POUR LA FERMETURE

DE CAISSES CARTON

OPERATION AND MAINTENANCE MANUAL

MANUAL DE OPERACIÓN Y DE MANTENIMIENTO

MANUEL D’INSTRUCTIONS ET D’ENTRETIEN

DO NOT OPERATE THIS TOOL UNTIL YOU HAVE READ THIS INSTRUCTION MANUAL FOR

SAFETY, OPERATING AND MAINTENANCE INSTRUCTIONS. KEEP THESE INSTRUCTIONS

WITH THE TOOL FOR FUTURE REFERENCE. IF YOU HAVE ANY QUESTIONS, CONTACT YOUR

BOSTITCH REPRESENTATIVE OR DISTRIBUTOR.

NO OPERE ESTA HERRAMIENTA SIN HABER LEÍDO EL PRESENTE MANUAL DE INSTRUCCIONES

A LOS FINES DE CONOCER LAS INSTRUCCIONES DE SEGURIDAD, FUNCIONAMIENTO

Y MANTENIMIENTO. MANTENGA ESTAS INSTRUCCIONES CON LA HERRAMIENTA PARA

FUTURA REFERENCIA, SI TIENE ALGUNA DUDA, COMUNÍQUESE CON SU REPRESENTANTE

DE BOSTITCH O CON SU DISTRIBUIDOR.

NE PAS UTILISER CET OUTIL AVANT D'AVOIR LU CE MANUEL ET PRIS CONNAISSANCE

DES CONSIGNES DE SÉCURITÉ, DE FONCTIONNEMENT ET D'ENTRETIEN. SI VOUS AVEZ

DES QUESTIONS, CONTACTEZ VOTRE REPRÉSENTANT OU VOTRE CONCESSIONNAIRE

BOSTITCH.

9R205872RB 06/14

701 E. Joppa Road, Towson, Maryland 21286

Page 2

INTRODUCTION

The BOSTITCH Carton Closing stapler is a precision-built tool, designed for high

speed, high volume stapling. This tool will deliver efficient, dependable service when

used correctly and with care. As with any fine power tool, for best performance

the manufacturer’s instructions must be followed. Please study this manual before

operating the tool and understand the safety warnings and cautions. The instructions

on installation, operation and maintenance should be read carefully, and the manuals

kept for reference. NOTE: Additional safety measures may be required because of your

particular application of the tool. Contact your BOSTITCH representative or distributor

with any questions concerning the tool and its use. BOSTITCH Fastening Systems,

701E. Joppa Road, Towson, MD 21286.

INDEX

INTRODUCTION .................................... 2

LIMITED WARRANTY ............................3

DEFINITIONS: SAFETY GUIDELINES ...3

GENERAL POWER TOOL SAFETY

WARNINGS ...........................................3

STAPLER SAFETY WARNINGS ............. 5

TOOL LOADING SAFETY ...................... 6

OPERATIONAL SAFETY ........................6

Trigger Operated.............................6

Replacement parts ......................... 6

SYMBOLS .............................................6

BATTERY / CHARGER SAFETY ............7

Important Safety Instructions

for All Battery Packs ....................... 7

The RBRC™ Seal ...........................8

Important Safety Instructions

for All Battery Chargers ..................8

Chargers ........................................9

Charging Procedure .......................9

Charge Indicators ........................ 10

Important Charging Notes ............ 10

NOTE:

BOSTITCH tools have been engineered to provide excellent customer satisfaction and

are designed to achieve maximum performance when used with precision BOSTITCH

fasteners engineered to the same exacting standards. BOSTITCH cannot assume

responsibility for product performance if our tools are used with fasteners or

accessories not meeting the specific requirements established for genuine

BOSTITCH nails, staples and accessories.

Storage Recommendations .......... 11

SPECIFICATIONS ................................11

Tool ............................................... 11

Part/Staple Chart .......................... 11

Corrugate Thickness Chart ........... 12

Fastener Specifications .................12

ASSEMBLY ..........................................12

Loading The Tool ......................... 12

Battery Installation ........................12

OPERATION .........................................13

Operating the Tool ...................... 13

Tool Operation Check ................... 13

ADJUSTMENTS ................................... 14

Clinch Adjustment .......................14

Depth Of Drive Adjustment .......... 15

Magazine Removal ...................... 15

Jammed Staple Removal .............15

Leg Length Adjustment ................ 16

MAINTAINING AND SERVICING THE

POWER TOOL ..................................... 16

TROUBLE SHOOTING .........................16

2-ENG

Page 3

LIMITED WARRANTY

BOSTITCH Fastening Systems, (“BOSTITCH") warrants to the original retail purchaser

that this product is free from defects in material and workmanship, and agrees to repair

or replace, at BOSTITCH’s option, any defective product within 1 year from the date

of purchase. This warranty is not transferable. It only covers damage resulting from

defects in material or workmanship, and it does not cover conditions or malfunctions

resulting from normal wear, neglect, abuse, accident or repairs attempted or made by

other than our regional repair center or authorized warranty service center. The driver,

clinchers, motor and driver guides are wear components, therefore are only warranted

for workmanship and manufacturing defects.

THIS WARRANTY IS IN LIEU OF ALL OTHER EXPRESS WARRANTIES. ANY

WARRANTY OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR PURPOSE IS

LIMITED TO THE DURATION OF THIS WARRANTY. BOSTITCH SHALL NOT BE LIABLE

FOR ANY INCIDENTAL OR CONSEQUENTIAL DAMAGES.

This warranty is limited to sales in the United States and Canada. Some states do not

allow limitations on how long an implied warranty lasts, or the exclusion or limitation of

incidental or consequential damages, so the above limitations or exclusions may not

apply to you. This warranty gives you specific legal rights, and you may also have other

rights which vary from state to state.

To obtain warranty service, return the product at your expense together with proof of

purchase to a BOSTITCH Regional or authorized warranty repair center. You may call

us at 1-800-832-3080 or visit our website at www.BOSTITCH.com for the location of

authorized warranty service centers in your area.

DEFINITIONS: SAFETY GUIDELINES

The definitions below describe the level of severity for each signal word. Please read the

manual and pay attention to these symbols.

Indicates an imminently hazardous situation which, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, could

result in death or serious injury.

Indicates a potentially hazardous situation which, if not avoided, may

result in minor or moderate injury.

Indicates a practice not related to personal injury which, if not avoided,

may result in property damage.

GENERAL POWER TOOL SAFETY WARNINGS

Read all safety warnings and all instructions. Failure to follow the

warnings and instructions may result in electric shock, fire and/or serious injury.

SAVE ALL WARNINGS AND INSTRUCTIONS

FOR FUTURE REFERENCE

The term “power tool” in the warnings refers to your mains-operated (corded) power tool

or battery-operated (cordless) power tool.

1) WORK AREA SAFETY

a) Keep work area clean and well lit. Cluttered or dark areas invite accidents.

3-ENG

Page 4

b) Do not operate power tools in explosive atmospheres, such as in the

presence of flammable liquids, gases or dust. Power tools create sparks

which may ignite the dust or fumes.

c) Keep children and bystanders away while operating a power tool.

Distractions can cause you to lose control.

2) ELECTRICAL SAFETY

a) Power tool plugs must match the outlet. Never modify the plug in any

way. Do not use any adapter plugs with earthed (grounded) power tools.

Unmodified plugs and matching outlets will reduce risk of electric shock.

b) Avoid body contact with earthed or grounded surfaces such as pipes,

radiators, ranges and refrigerators. There is an increased risk of electric shock

if your body is earthed or grounded.

c) Do not expose power tools to rain or wet conditions. Water entering a power

tool will increase the risk of electric shock.

d) Do not abuse the cord. Never use the cord for carrying, pulling or

unplugging the power tool. Keep cord away from heat, oil, sharp edges or

moving parts. Damaged or entangled cords increase the risk of electric shock.

e) When operating a power tool outdoors, use an extension cord suitable for

outdoor use. Use of a cord suitable for outdoor use reduces the risk of electric

shock.

f) If operating a power tool in a damp location is unavoidable, use a ground

fault circuit interrupter (GFCI) protected supply. Use of a GFCI reduces the

risk of electric shock.

3) PERSONAL SAFETY

a) Stay alert, watch what you are doing and use common sense when

operating a power tool. Do not use a power tool while you are tired or

under the influence of drugs, alcohol or medication. A moment of inattention

while operating power tools may result in serious personal injury.

b) Use personal protective equipment. Always wear eye protection. Protective

equipment such as dust mask, non-skid safety shoes, hard hat, or hearing

protection used for appropriate conditions will reduce personal injuries.

c) Prevent unintentional starting. Ensure the switch is in the off position

before connecting to power source and/or battery pack, picking up

or carrying the tool. Carrying power tools with your finger on the switch or

energizing power tools that have the switch on invites accidents.

d) Remove any adjusting key or wrench before turning the power tool on.

A wrench or a key left attached to a rotating part of the power tool may result in

personal injury.

e) Do not overreach. Keep proper footing and balance at all times. This

enables better control of the power tool in unexpected situations.

f) Dress properly. Do not wear loose clothing or jewelry. Keep your hair,

clothing and gloves away from moving parts. Loose clothes, jewelry or long

hair can be caught in moving parts.

g) If devices are provided for the connection of dust extraction and collection

facilities, ensure these are connected and properly used. Use of dust

collection can reduce dust-related hazards.

4) POWER TOOL USE AND CARE

a) Do not force the power tool. Use the correct power tool for your

application. The correct power tool will do the job better and safer at the rate for

which it was designed.

b) Do not use the power tool if the switch does not turn it on and off. Any

power tool that cannot be controlled with the switch is dangerous and must be

repaired.

4-ENG

Page 5

c) Disconnect the plug from the power source and/or the battery pack from

the power tool before making any adjustments, changing accessories, or

storing power tools. Such preventive safety measures reduce the risk of starting

the power tool accidentally.

d) Store idle power tools out of the reach of children and do not allow

persons unfamiliar with the power tool or these instructions to operate the

power tool. Power tools are dangerous in the hands of untrained users.

e) Maintain power tools. Check for misalignment or binding of moving parts,

breakage of parts and any other condition that may affect the power tool’s

operation. If damaged, have the power tool repaired before use. Many

accidents are caused by poorly maintained power tools.

f) Keep cutting tools sharp and clean. Properly maintained cutting tools with

sharp cutting edges are less likely to bind and are easier to control.

g) Use the power tool, accessories and tool bits, etc. in accordance with

these instructions, taking into account the working conditions and the

work to be performed. Use of the power tool for operations different from those

intended could result in a hazardous situation.

5) BATTERY TOOL USE AND CARE

a) Recharge only with the charger specified by the manufacturer. A charger

that is suitable for one type of battery pack may create a risk of fire when used with

another battery pack.

b) Use power tools only with specifically designated battery packs. Use of any

other battery packs may create a risk of injury and fire.

c) When battery pack is not in use, keep it away from other metal objects,

like paper clips, coins, keys, nails, screws, or other small metal objects,

that can make a connection from one terminal to another. Shorting the

battery terminals together may cause burns or a fire.

d) Under abusive conditions, liquid may be ejected from the battery; avoid

contact. If contact accidentally occurs, flush with water. If liquid contacts

eyes, additionally seek medical help. Liquid ejected from the battery may

cause irritation or burns.

6) SERVICE

a) Have your power tool serviced by a qualified repair person using only

identical replacement parts. This will ensure that the safety of the power tool is

maintained.

STAPLER SAFETY WARNINGS

a) Always assume that the tool contains fasteners. Careless handling of the stapler

can result in unexpected firing of fasteners and personal injury.

b) Do not point the tool towards yourself or anyone nearby. Unexpected triggering

will discharge the fastener causing an injury.

c) Do not actuate the tool unless the tool is placed firmly against the workpiece.

If the tool is not in contact with the workpiece, the fastener may be deflected away

from your target.

d) Disconnect the tool from the power source when the fastener jams in the

tool. While removing a jammed fastener, the stapler may be accidentally activated if

it is plugged in.

e) Do not use this stapler for fastening electrical cables. It is not designed for

electric cable installation and may damage the insulation of electric cables thereby

causing electric shock or fire hazards.

5-ENG

Page 6

TOOL LOADING SAFETY

When loading tool: 1) Never place a hand or any part of body

in fastener discharge area of tool; 2) Never point tool at anyone; 3) Do not

pull the trigger or depress the safety lever as accidental actuation may occur,

possibly causing injury.

OPERATIONAL SAFETY

Always handle the tool with care: 1) Never engage in horseplay;

2) Never pull the trigger unless nose is directed toward the work; 3) Keep others

a safe distance from the tool while tool is in operation as accidental actuation

may occur, possibly causing injury.

Keep hands and body away from the discharge area of the tool.

Do not drive fasteners on top of other fasteners or with the tool

at an overly steep angle as this may cause deflection of fasteners which could

cause injury.

This stapler produces SPARKS during operation. NEVER use the

stapler near flammable substances, gases or vapors including lacquer, paint,

benzine, thinner, gasoline, adhesives, mastics, glues or any other material that

is -- or the vapors, fumes or by-products of which are -- flammable, combustible

or explosive. Using the stapler in any such environment could cause an

EXPLOSION resulting in personal injury or death to user and bystanders.

Trigger Operated

This is a trigger operated tool when the safety lever is depressed. The trigger operated

tool will cycle every time the trigger is actuated when the safety lever is depressed.

Replacement parts

Use only BOSTITCH replacement parts. Do not use modified parts.

SYMBOLS

• The label onyour tool may include the following symbols. The symbols and their

definitions are as follows:

V .....................volts

A .....................amperes

Hz ...................hertz

W ....................watts

or DC .....direct current

or AC/DC .. alternating or direct

current

6-ENG

or AC .........alternating current

....................safety alert symbol

................... Class II Construction

(double insulated)

................... earthing terminal

Ah ...................Ampere hours

Wh ..................Watt hours

Page 7

BATTERY / CHARGER SAFETY

Important Safety Instructions for All Battery Packs

When ordering replacement battery packs, be sure to include the catalog number

and voltage. The battery pack is not fully charged out of the carton. Before using the

battery pack and charger, read the safety instructions below and then follow charging

procedures outlined.

READ ALL INSTRUCTIONS

• Do not charge or use the battery pack in explosive atmospheres, such as

in the presence of flammable liquids, gases or dust. Inserting or removing the

battery pack from the charger may ignite the dust or fumes.

• NEVER force the battery pack into the charger. DO NOT modify the battery

pack in any way to fit into a non-compatible charger as battery pack may

rupture causing serious personal injury.

• ChargethebatterypacksonlyindesignatedBOSTITCHchargers.

• DO NOT splash or immerse in water or other liquids.

• Do not store or use the tool and battery pack in locations where the

temperature may reach or exceed 105°F (40 °C) (such as outside sheds or

metal buildings in summer). For best life store battery packs in a cool, dry location.

NOTE: Do not store the battery packs in a tool with the trigger switch locked

on. Never tape the trigger switch in the ON position.

battery pack case is cracked or damaged, do not insert into the charger. Do not crush,

drop or damage the battery pack. Do not use a battery pack or charger that has received

a sharp blow, been dropped, run over or damaged in any way (e.g., pierced with a nail, hit

with a hammer, stepped on). Damaged battery packs should be returned to the service

center for recycling.

Fire hazard. Never attempt to open the battery pack for any reason. If the

Fire hazard. Do not store or carry the battery pack so that metal

objects can contact exposed battery terminals. For example, do not place the

battery pack in aprons, pockets, tool boxes, product kit boxes, drawers, etc., with

loose nails, screws, keys, etc. Transporting batteries can possibly cause fires if

the battery terminals inadvertently come in contact with conductive materials

such as keys, coins, hand tools and the like. The US Department of Transportation

Hazardous Material Regulations (HMR) actually prohibit transporting batteries in

commerce or on airplanes (e.g., packed in suitcases and carry-on luggage) UNLESS they

are properly protected from short circuits. So when transporting individual battery packs,

make sure that the battery terminals are protected and well insulated from materials that

could contact them and cause a short circuit.

SPECIFIC SAFETY INSTRUCTIONS FOR LITHIUM ION (Li-Ion)

• Do not incinerate the battery pack even if it is severely damaged or is

completely worn out. The battery pack can explode in a fire. Toxic fumes and

materials are created when lithium ion battery packs are burned.

• If battery contents come into contact with the skin, immediately wash area

with mild soap and water. If battery liquid gets into the eye, rinse water over the

open eye for 15 minutes or until irritation ceases. If medical attention is needed, the

battery electrolyte is composed of a mixture of liquid organic carbonates and lithium

salts.

• Contents of opened battery cells may cause respiratory irritation. Provide

fresh air. If symptoms persist, seek medical attention.

7-ENG

Page 8

flame.

Burn hazard. Battery liquid may be flammable if exposed to spark or

The RBRC™ Seal

The RBRC™ (Rechargeable Battery Recycling Corp oration) Seal on the

nickel cadmium, nickel metal hydride or lithium ion batteries (or battery

packs) indicate that the costs to recycle these batteries (or battery packs)

at the end of their useful life have already been paid by BOSTITCH. In

some areas, it is illegal to place spent nickel cadmium, nickel metal

hydride or lithium ion batteries in the trash or municipal solid waste stream and the RBRC

program provides an environmentally conscious alternative.

RBRC™, in cooperation with BOSTITCH and other battery users, has established

programs in the United States and Canada to facilitate the collection of spent nickel

cadmium, nickel metal hydride or lithium ion batteries. Help protect our environment and

conserve natural resources by returning the spent nickel cadmium, nickel metal hydride

or lithium ion batteries to an authorized BOSTITCH service center or to your local retailer

for recycling. You may also contact your local recycling center for information on where

to drop off the spent battery.

RBRC™ is a registered trademark of the Rechargeable Battery Recycling Corporation.

Important Safety Instructions for All Battery Chargers

SAVE THESE INSTRUCTIONS: This manual contains important safety and operating

instructions for battery chargers.

• Beforeusingthecharger,readallinstructionsandcautionarymarkingsonthecharger,

battery pack and product using the battery pack.

shock may result.

Shock hazard. Do not allow any liquid to get inside the charger. Electric

rechargeable battery packs. Other types of batteries may overheat and burst resulting in

personal injury and property damage.

the charger can be shorted by foreign material. Foreign materials of a conductive nature,

such as, but not limited to, grinding dust, metal chips, steel wool, aluminum foil or any

buildup of metallic particles should be kept away from the charger cavities. Always unplug

the charger from the power supply when there is no battery pack in the cavity. Unplug the

charger before attempting to clean.

• DO NOT attempt to charge the battery pack with any chargers other than the

ones in this manual. The charger and battery pack are specifically designed to work

together.

• These chargers are not intended for any uses other than charging BOSTITCH

rechargeable batteries. Any other uses may result in risk of fire, electric shock or

electrocution.

• Do not expose the charger to rain or snow.

• Pull by the plug rather than the cord when disconnecting the charger. This will

reduce the risk of damage to the electric plug and cord.

• Make sure that the cord is located so that it will not be stepped on, tripped

over or otherwise subjected to damage or stress.

• Do not use an extension cord unless it is absolutely necessary. Use of

improper extension cord could result in risk of fire, electric shock or electrocution.

• When operating a charger outdoors, always provide a dry location and use an

extension cord suitable for outdoor use. Use of a cord suitable for outdoor use

reduces the risk of electric shock.

Burn hazard. To reduce the risk of injury, charge only BOSTITCH

Under certain conditions, with the charger plugged into the power supply,

8-ENG

Page 9

• An extension cord must have adequate wire size (AWG or American Wire

Gauge) for safety. The smaller the gauge number of the wire, the greater the capacity

of the cable, that is, 16 gauge has more capacity than 18 gauge. An undersized cord

will cause a drop in line voltage resulting in loss of power and overheating. When using

more than one extension to make up the total length, be sure each individual extension

contains at least the minimum wire size. The following table shows the correct size to

use depending on cord length and nameplate ampere rating. If in doubt, use the next

heavier gauge. The lower the gauge number, the heavier the cord.

Minimum Gauge for Cord Sets

Volts Total Length of Cord in Feet (meters)

Ampere Rating

More

Than

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 14 14 12 Not Recommended

• Do not place any object on top of the charger or place the charger on a soft

surface that might block the ventilation slots and result in excessive internal

heat. Place the charger in a position away from any heat source. The charger is

ventilated through slots in the top and the bottom of the housing.

• Do not operate the charger with a damaged cord or plug.

• Do not operate the charger if it has received a sharp blow, been dropped or

otherwise damaged in any way. Take it to an authorized service center.

• Do not disassemble the charger; take it to an authorized service center when

service or repair is required. Incorrect reassembly may result in a risk of electric

shock, electrocution or fire.

• Disconnect the charger from the outlet before attempting any cleaning. This

will reduce the risk of electric shock. Removing the battery pack will not reduce

this risk.

• NEVER attempt to connect 2 chargers together.

• The charger is designed to operate on standard 120V household electrical

power. Do not attempt to use it on any other voltage. This does not apply to the

vehicular charger.

Not More

Than

120V 25 (7.6) 50 (15.2) 100 (30.5) 150 (45.7)

240V 50 (15.2) 100 (30.5) 200 (61.0) 300 (91.4)

AWG

Chargers

Your tool uses a BOSTITCH charger. Be sure to read all safety instructions before using

your charger.

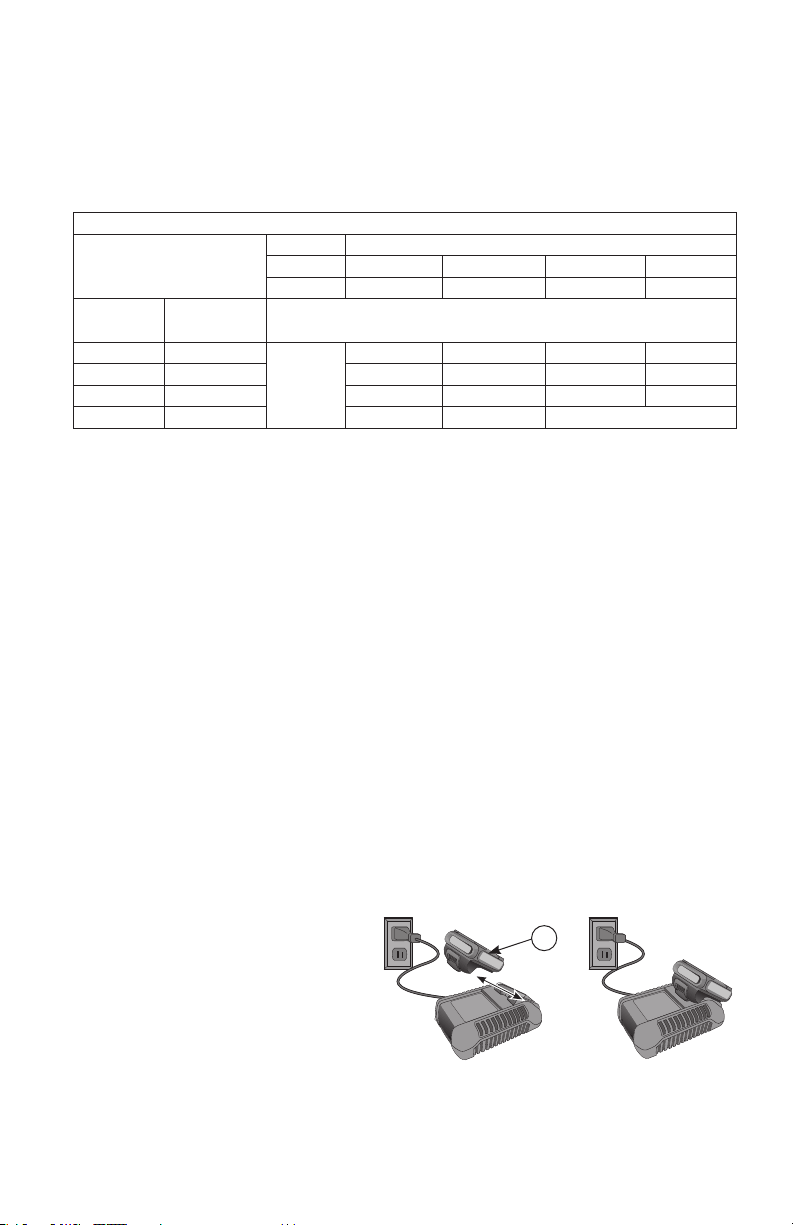

Charging Procedure

1. Plug the charger into an

appropriate outlet before inserting

the battery pack.

2. Insert the battery pack (6) into the

charger, as shown, making sure

the pack is fully seated in charger.

The red (charging) light will blink

continuously, indicating that the

charging process has started.

3. The completion of charge will be indicated by the red light remaining ON continuously.

The pack is fully charged and may be used at this time or left in the charger.

6

9-ENG

Page 10

Charge Indicators

This charger is designed to detect certain problems that can arise. Problems are indicated

by the red light flashing at a fast rate. If this occurs, re-insert the battery pack into the

charger. If the problem persists, try a different battery pack to determine if the charger

is working properly. If the new pack charges correctly, then the original pack is defective

and should be returned to a service center or other collection site for recycling. If the new

battery pack elicits the same trouble indication as the original, have the charger and the

battery pack tested at an authorized service center.

HOT/COLD DELAY

This charger has a hot/cold delay feature: when the charger detects a battery that is hot,

it automatically starts a delay, suspending charging until the battery has cooled. After the

battery has cooled, the charger automatically switches to the pack charging mode. This

feature ensures maximum battery life. The red light flashes long, then short while in the

hot/cold delay mode.

LEAVING THE BATTERY PACK IN THE CHARGER

The charger and battery pack can be left connected with the charge indicator showing

Pack Charged.

WEAK BATTERY PACKS: Weak batteries will continue to function but should not be

expected to perform as much work.

FAULTY BATTERY PACKS: This charger will not charge a faulty battery pack. The charger

will indicate faulty battery pack by refusing to light or by displaying problem pack or charger.

NOTE: This could also mean a problem with a charger.

PROBLEM POWER LINE

Some chargers have a Problem Power Line indicator. When the charger is used with

some portable power sources such as generators or sources that convert DC to AC,

the charger may temporarily suspend operation, flashing the red light with two fast blinks

followed by a pause. This indicates the power source is out of limits.

Important Charging Notes

1. Longest life and best performance can be obtained if the battery pack is charged

when the air temperature is between 65°F and 75°F (18° – 24°C). DO NOT charge

the battery pack in an air temperature below +40°F (+4.5°C), or above +105°F

(+40.5°C). This is important and will prevent serious damage to the battery pack.

2. The charger and battery pack may become warm to the touch while charging. This

is a normal condition, and does not indicate a problem. To facilitate the cooling of

the battery pack after use, avoid placing the charger or battery pack in a warm

environment such as in a metal shed or an uninsulated trailer.

3. If the battery pack does not charge properly: a) Check operation of receptacle by

plugging in a lamp or other appliance; b)Check to see if receptacle is connected to a

light switch which turns power off when you turn out the lights; c)Move the charger

and battery pack to a location where the surrounding air temperature is approximately

65°F – 75°F (18° – 24 °C); d) If charging problems persist, take the tool, battery pack

and charger to your local service center.

4. The battery pack should be recharged when it fails to produce sufficient power on jobs

which were easily done previously. DO NOT CONTINUE to use under these conditions.

Follow the charging procedure. You may also charge a partially used pack whenever

you desire with no adverse effect on the battery pack.

5. Foreign materials of a conductive nature such as, but not limited to, grinding dust, metal

chips, steel wool, aluminum foil, or any buildup of metallic particles should be kept away

from charger cavities. Always unplug the charger from the power supply when there is

no battery pack in the cavity. Unplug the charger before attempting to clean.

6. Do not freeze or immerse the charger in water or any other liquid.

10-ENG

Page 11

shock may result.

Shock hazard. Don’t allow any liquid to get inside the charger. Electric

housing of the battery pack breaks or cracks, return to a service center for recycling.

Never attempt to open the battery pack for any reason. If the plastic

Storage Recommendations

1. The best storage place is one that is cool and dry, away from direct sunlight and

excess heat or cold.

2. For long storage, it is recommended to store a fully charged battery pack in a cool

dry place out of the charger for optimal results.

Battery packs should not be stored completely depleted of charge. The

battery pack will need to be recharged before use.

SAVE THESE INSTRUCTIONS FOR FUTURE USE

SPECIFICATIONS

Tool

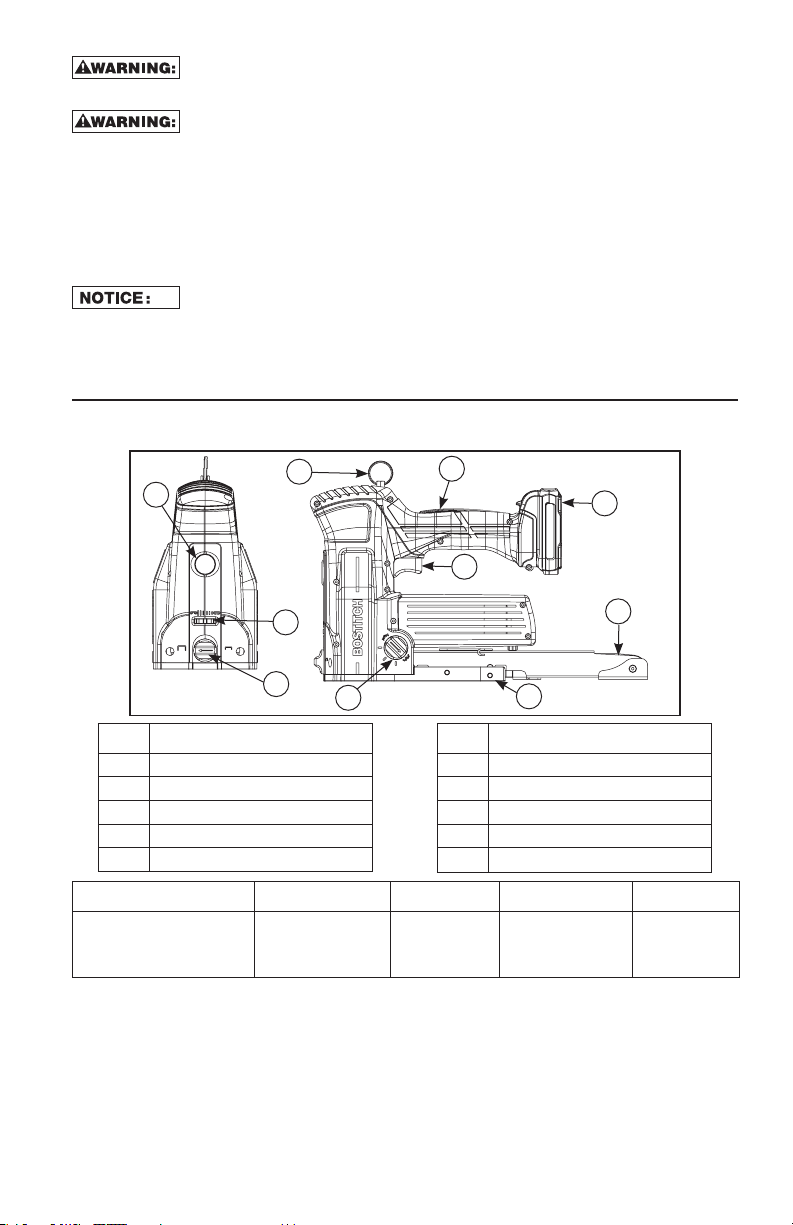

4

1

2

3

10

5

6

7

8

9

NO. COMPONENT

1 Driver Bolt Cover

2 Clinch Dial

3 Leg Length Dial

4 Tool Hanger

5 Safety Lever

NO. COMPONENT

6 Battery

7 Trigger

8 Magazine

9 Base

10 Depth Adjustment Knob

MODEL LENGTH HEIGHT WIDTH WEIGHT

DSW-3519

DSW-3522

DSC-3219

13.5"

(342.9 mm)8"(203.2 mm)

11-ENG

4.5"

(114.3)

6.2 lb

(2.81 kg)

Page 12

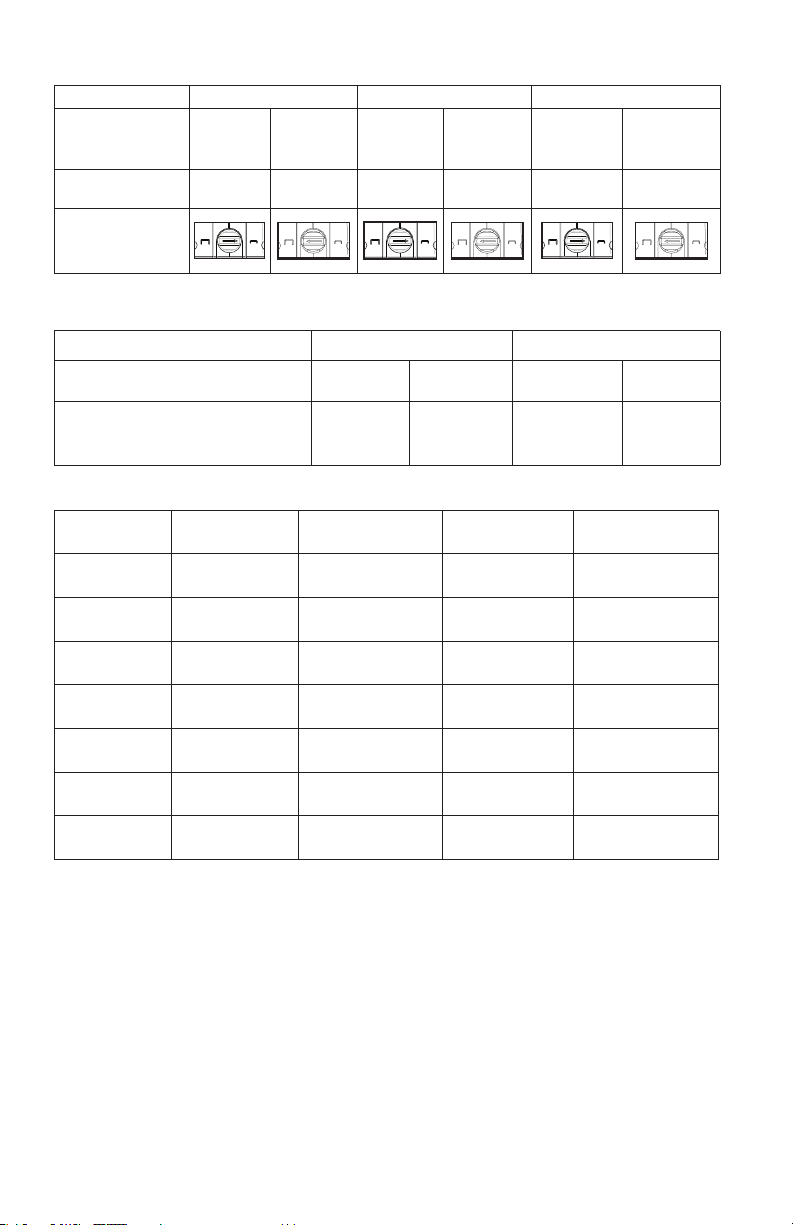

Part/Staple Chart

MODEL

BOSTITCH

STAPLE

LEG

LENGTH

DIAL

POSITION

DSW-3519 DSW-3522

SW74375/8

SW90405/8

5/8"

(16mm)

SW74373/4

SW90403/4

3/4"

(19mm)

SW74373/4

SW90403/4

3/4"

(19mm)

SW90407/8 B58C B34C

7/8"

(22mm)

DSC-3219

5/8"

(16mm)

Corrugate Thickness Chart

MODEL DSW-3519 / DSC-3219 DSW-3522

FASTENER

MAXIMUM RECOMMENDED

CORRUGATE THICKNESS

5/8"

(15 mm)

0.38"

(9.7 mm)

3/4"

(19 mm)

0.44"

(11.1 mm)

3/4"

(19 mm)

0.53"

(13.5 mm)

(14.6 mm)

Fastener Specifications

STAPLE

SERIES

TOOL

MODEL

SW74375/8 DSW-3519

SW90405/8 DSW-3519

SW74373/4

SW90403/4

DSW-3519

DSW-3522

DSW-3519

DSW-3522

SW90407/8 DSW-3522

B58C

DSC-3219

B34C DSC-3219

WIRE SIZE

.074" x .037"

(1.88 x .94 mm)

.090" x .040"

(2.29 x 1.02 mm)

.074" x .037"

(1.88 x .94 mm)

.090" x .040"

(2.29 x 1.02 mm)

.090" x .040"

(2.29 x 1.02 mm))

.074" x .037"

(1.88 x .94 mm)

.074" x .037"

(1.88 x .94 mm)

CROWN

WIDTH

1-3/8"

(35 mm)

1-3/8"

(35 mm)

1-3/8"

(35 mm)

1-3/8"

(35 mm)

1-3/8"

(35 mm)

1-1/4"

(32 mm)

1-1/4"

(32 mm)

LEG LENGTH

5/8"

(15 mm)

5/8"

(15 mm)

3/4"

(19 mm)

3/4"

(19 mm)

7/8"

(22 mm)

5/8"

(15 mm)

3/4"

(19 mm)

3/4"

(19mm)

7/8"

(22 mm)

0.58"

12-ENG

Page 13

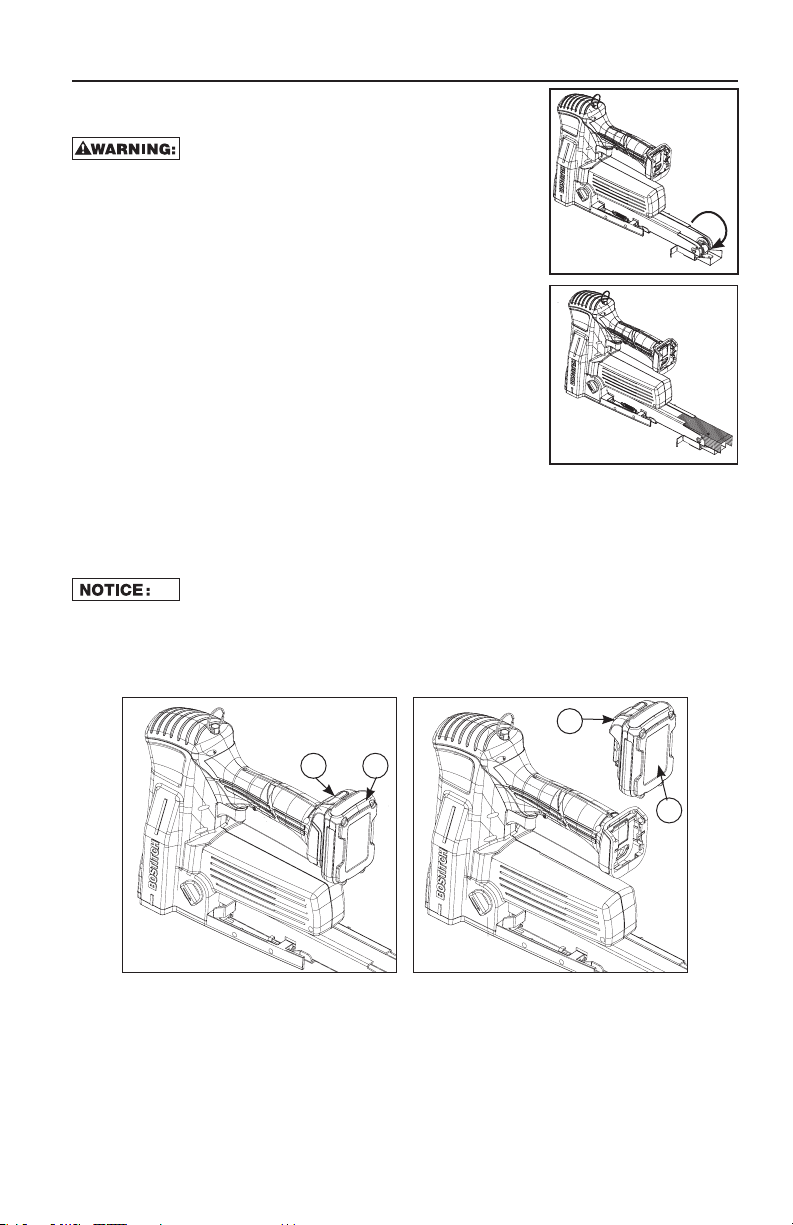

ASSEMBLY

Loading The Tool

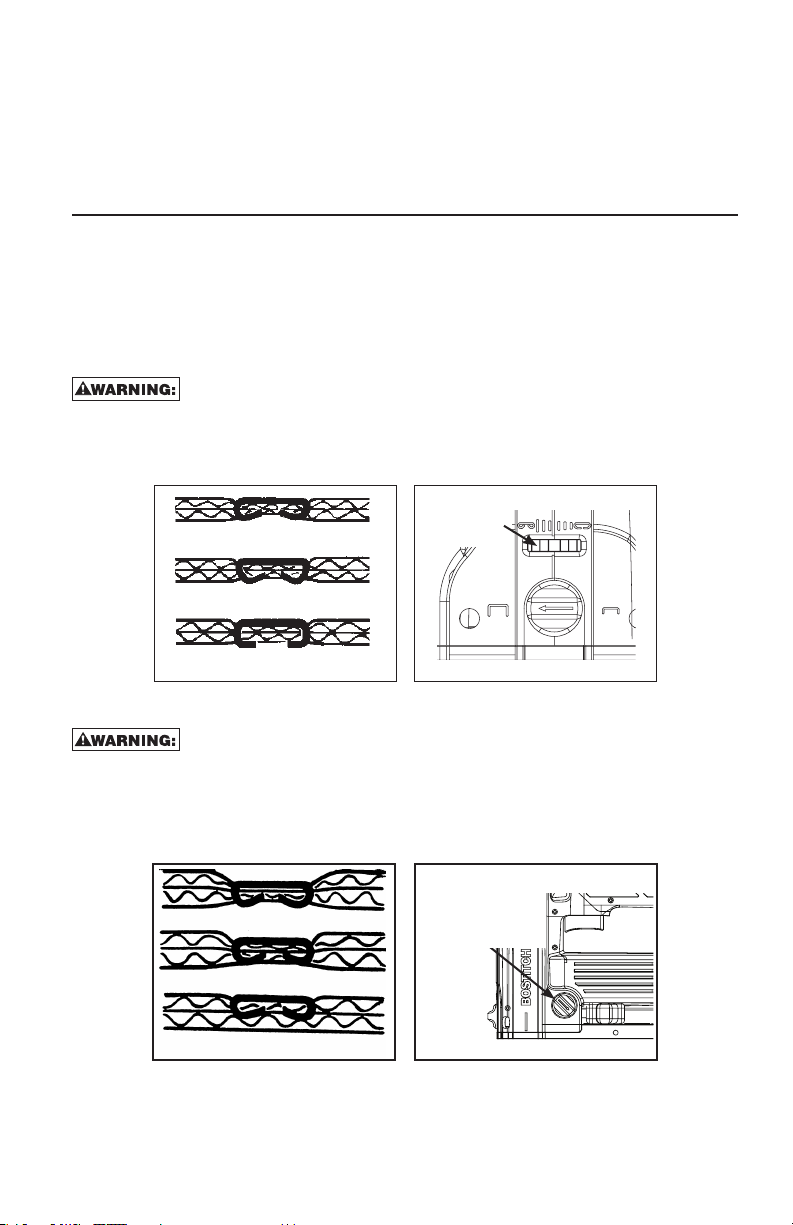

POSITION 1

When loading tool: 1) Never place a hand

or any part of body in fastener discharge area of tool;

2) Never point tool at anyone; 3) Do not pull the trigger

or depress the safety lever as accidental actuation may

occur, possibly causing injury.

1. Disconnect the battery.

2. Pull back the pusher until it is tucked under the rear of the

magazine in POSITION 1.

3. Check staple leg length.

Adjustment is provided in the tool for different staple leg

lengths.

A) To adjust the tool for leg length install the correct

clinchers and adjust the length dial to the setting

corresponding to the fastener being driven.

4. Load the staple stick from the rear of the tool

(POSITION2).

5. Slide the pusher from POSITION 1 until engaged behind the staples.

POSITION 2

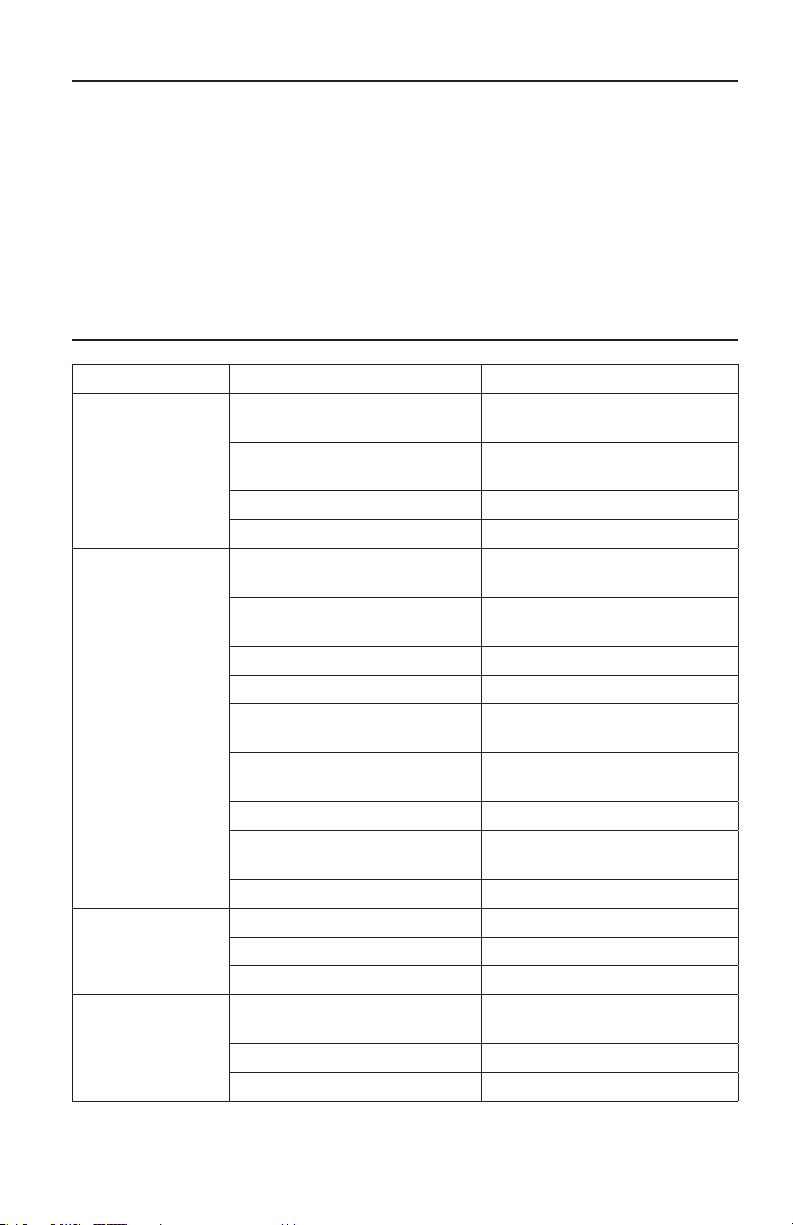

Battery Installation

INSTALLING AND REMOVING THE BATTERY PACK

Make sure your battery pack is fully charged. To install the battery pack

(6) into the tool handle, align the battery with the rails inside the tool’s handle and slide it

firmly into the handle until you hear the lock snap into place. To remove the battery pack

from the tool, press the release button (11) and firmly pull the battery pack out of the

tool handle. Insert it into the charger as described in the charger section of this manual.

11 6

11

6

13-ENG

Page 14

OPERATION

Operating the Tool

1. Install the battery on the tool.

2. Grasp the handle of the tool with one hand ensuring to depress the safety lever.

3. Align the tool on the work piece using the marks on the side of tool to indicate where

the fastener is ejected.

4. Depress the trigger to actuate the tool.

5. Once the cycle has completed move the tool to the next location.

SAFETY LEVER RELEASED POSITION

ALIGNMENT

MARKS

SAFETY LEVER DEPRESS POSITION

Tool Operation Check

Remove all fasteners from tool before performing tool operation

check.

TRIGGER OPERATED TOOL

A. With finger off the trigger, hold the tool with a firm grip on the handle ensuring that

the safety lever is depressed.

B. Place the nose of the tool against the work surface.

C. Pull the trigger to drive.

THE TOOL WILL CYCLE EACH TIME THE TRIGGER IS PULLED! THIS IS A FULL

CYCLE TOOL. PULL THE TRIGGER, AND CLINCHERS WILL DISCHARGE AND

RETRACT.

IN ADDITION TO THE OTHER WARNINGS CONTAINED IN THIS

MANUAL OBSERVE THE FOLLOWING FOR SAFE OPERATION:

• UsetheBOSTITCHtoolonlyforthepurposeforwhichitwasdesigned.

• Neverusethistoolina mannerthatcouldcausea fastenertobedirected

toward the user or others in the work area.

• Donotusethetoolasahammer.

• Alwayscarrythetoolbythehandle.

• Donotalterormodifythistoolfromtheoriginaldesignorfunction.

• Alwaysbeawarethatmisuseandimproperhandlingofthistoolcancause

injury to yourself and others.

• Neverleaveatoolunattendedwiththebatteryattached.

14-ENG

Page 15

• DonotoperatethistoolifitdoesnotcontainalegibleWARNINGLABEL.

• Donotoperatetoolifallcoversarenotinstalled.

• Donotoperatethetoolwhennotplacedonaworksurface.

• Donotusethisstaplerforfasteningelectricalcables.Itisnotdesignedfor

electric cable installation and may damage the insulation of electric cables

thereby causing electric shock or fire hazards.

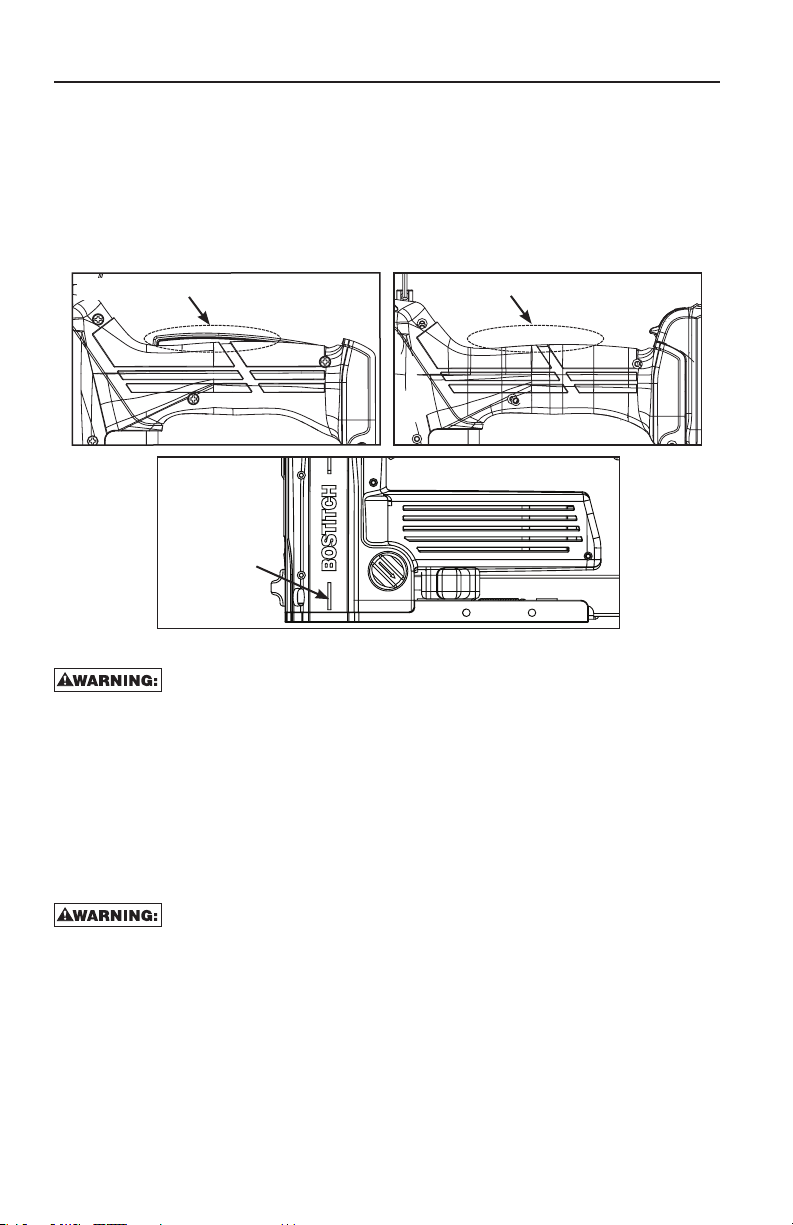

ADJUSTMENTS

Clinch Adjustment

To obtain maximum efficiency from the staple closure, it is important that the staple be

clinched properly. Proper clinching for any thickness board may be obtained by adjusting

the clincher setting with staples of proper leg length. Use the proper length staples for the

thickness of work to be stapled, otherwise unnecessary pressure is exerted and staple

crowns and legs will be distorted, or the clinch will be too loose.

Disconnect the battery before adjusting the clinch tightness of

the tool.

1. To loosen the fastener clinch turn the clinch dial to the right.

2. To tighten the fastener clinch, turn the clinch dial to the left.

CLINCH

TIGHT

MEDIUM

DIAL

LOOSE

Depth Of Drive Adjustment

Remove the battery before adjusting the depth of drive.

1. Push to release the locking feature, and turn the depth adjustment knob clockwise

to decrease the depth of drive.

2. Push to release the locking feature, and turn the depth adjustment knob counter

clockwise to increase the depth of drive.

DEPTH

DEEP

MEDIUM

SHALLOW

ADJUSTMENT

KNOB

15-ENG

Page 16

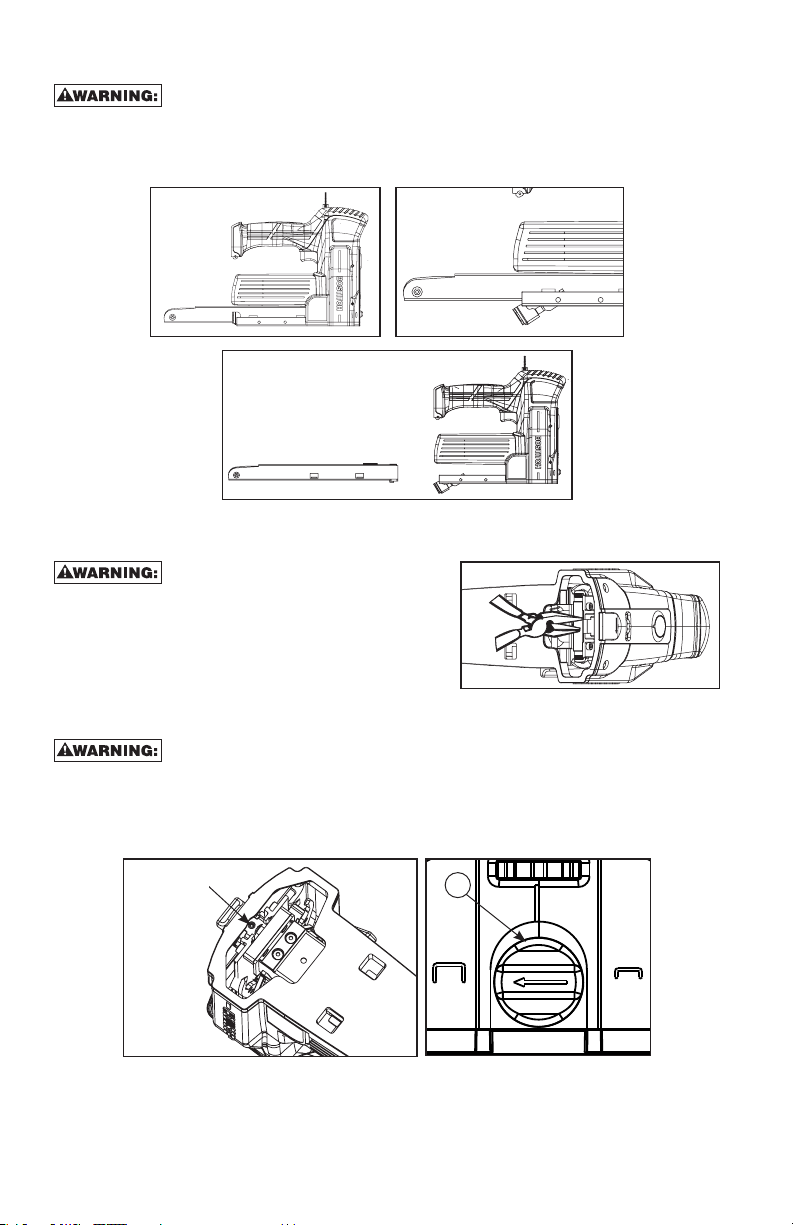

Magazine Removal

Remove the battery before removing the magazine.

1. Remove all fasteners from the magazine

2. Rotate the magazine release lever down to free the magazine (POSITION 2).

3. Pull the magazine back to remove from the tool (POSITION 3).

POSITION 1

POSITION 3

POSITION 2

Jammed Staple Removal

Remove the battery from the tool

before removing jammed staples.

1. Remove the magazine from the tool.

2. Carefully remove the jammed fastener from

the tool.

3. Reinstall the magazine.

Leg Length Adjustment

Remove the battery before adjusting the leg length.

1. Loosen the Leg Length Lock Screw on the bottom of the tool.

2. Turn the Leg Length Dial (3) with a flat blade screw driver until the arrow is pointed at

the correct setting for the staple being driven.

3. Tighten the Leg Length Lock Screw.

LEG

LENGTH

LOCK

SCREW

3

16-ENG

Page 17

MAINTAINING AND SERVICING THE POWER TOOL

A) Blow dirt and dust out of all air vents with clean, dry air at least once a week. To

minimize the risk of eye injury, always wear ANSI Z87.1 approved eye protection

when performing this.

B) Never use solvents or other harsh chemicals for cleaning the non-metallic parts of

the tool. These chemicals may weaken the plastic materials used in these parts. Use

a cloth dampened only with water and mild soap. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid

C To obtain service on your BOSTITCH power tool contact BOSTITCH customer service at

1-800-832-3080 for the location of the service center in your area.

TROUBLE SHOOTING

PROBLEM CAUSE CORRECTION

Skipping

fasteners/

intermittent

feed

Fasteners jam in

the tool

Slow drive

speed or stalling

Poor clinch Wrong leg length setting Set leg length according to

Loose magazine Re-engage the magazine

release lever

Fasteners out of spec. Replace with recommended

fasteners

Dirt/debris in the magazine Clean and dry the magazine

Dirt/debris in the drive channel Clean the drive channel

Wrong size fasteners Replace with recommended

fasteners

Bent fasteners Discontinue using these

fasteners

Broken/chipped driver Replace driver

Worn pusher Replace pusher

Loose magazine Re-engage the magazine

release lever

Fasteners out of spec. Replace with recommended

fasteners

Dirt/debris in the magazine Clean and dry the magazine

Dirt /debris in the drive

channel

Worn/damaged pusher spring Replace pusher spring

Discharged Battery Recharge battery

Depleted Battery Replace battery

Cardboard too thick Reduce cardboard thickness

Worn driver guide Replace the driver guide

Broken/bent clinchers Replace clinchers

Clean the drive channel

clinchers and fasteners

17-ENG

Page 18

Multiple

fasteners driven

Loose magazine Re-engage the magazine

release lever

at once

Staple is only

clinching the

top layer of

corrugate

Depth setting too shallow Set the tool to a deeper drive

setting

Fasteners are too short Replace with longer fasteners

Cardboard too thick Reduce cardboard thickness

Loose clinch Clinch setting too loose Adjust the clinch setting tighter

Fasteners are too long Replace with shorter fasteners

18-ENG

Page 19

INTRODUCCIÓN

La engrapadora BOSTITCH para cierre de cajas es una herramienta construida con

precisión, diseñada para el engrapado de alta velocidad así como de alto volumen.

Esta herramienta ofrece un servicio confiable y eficiente cuando se utiliza de la manera

correcta y con cuidado. Al igual que con cualquier herramienta eléctrica delicada, para

obtener el mejor rendimiento se deben seguir las instrucciones del fabricante. Estudie

este manual antes de operar la herramienta y entienda las advertencias y precauciones

de seguridad. Las instrucciones sobre la instalación, operación y mantenimiento se

deben leer con cuidado, y el manual debe estar a mano para referencia. NOTA: Es

probable que se requieran medidas adicionales de seguridad debido a su aplicación

específica de la herramienta. Comuníquese con su representante o distribuidor de

BOSTITCH por cualquier pregunta sobre la herramienta y su uso. BOSTITCH Fastening

Systems, 701 E. Joppa Road, Towson, MD 21286.

ÍNDICE

INTRODUCCIÓN ..................................18

GARANTÍA LIMITADA ..........................19

DEFINICIONES: NORMAS DE

SEGURIDAD ....................................... 19

ADVERTENCIAS GENERALES DE

SEGURIDAD PARA HERRAMIENTAS

ELÉCTRICAS ....................................... 20

ADVERTENCIAS DE SEGURIDAD

DE LA GRAPADORA............................22

SEGURIDAD DE CARGA DE LA

HERRAMIENTA ....................................22

SEGURIDAD OPERATIVA .................... 22

Accionada por gatillo .................... 23

Partes De Reemplazo ................... 23

SÍMBOLOS .......................................... 23

SEGURIDAD DE LA BATERÍA/EL

CARGADOR ........................................23

Instrucciones de seguridad

importantes para todas las

unidades de batería ...................... 23

El sello RBRC™ ...........................24

Instrucciones importantes de

seguridad para todos los

cargadores de baterías ................. 25

Cargadores ..................................26

Procedimiento de carga ...............27

Indicadores de carga ................... 27

Notas importantes sobre

la carga .........................................28

Recomendaciones de

almacenamiento ........................... 28

ESPECIFICACIONES ...........................29

La Herramienta ............................. 29

Tabla De Piezas/Grapa ................. 29

Cuadro De Espesor Del Cartón

Corrugado .................................... 29

Especificaciones Del Sujetador .....30

MONTAJE ............................................30

Carga De La Herramienta ............30

Instalación de la batería ................ 30

OPERACIÓN ........................................ 31

Operación De La Herramienta ..... 31

Comprobación De Operación De La

Herramienta .................................. 32

AJUSTES ............................................. 32

Ajuste De Los Remaches ............ 32

Ajuste De Profundidad De La

Penetración ..................................33

Extracción Del Cartucho ............... 33

Extracción De Grapas Atascadas . 34

Ajuste del largo de la pata ............ 34

MANTENIMIENTO Y SERVICIO DE LA

HERRAMIENTA ELÉCTRICA ................34

RESOLUCIÓN DE PROBLEMAS ......... 35

19-SP

Page 20

NOTA:

Las herramientas BOSTITCH han sido diseñadas para proporcionar una excelente

satisfacción al cliente y están diseñadas para lograr un rendimiento máximo cuando se

utilizan con los sujetadores de precisión BOSTITCH diseñados con las mismas normas

exactas. BOSTITCH no puede asumir responsabilidad alguna por el rendimiento

del producto si nuestras herramientas se utilizan con sujetadores o accesorios

que no cumplan con los requisitos específicos establecidos para clavos, grapas

y accesorios originales BOSTITCH.

GARANTÍA LIMITADA

BOSTITCH Fastening Systems, (“BOSTITCH”) garantiza al comprador minorista original

que este producto está libre de defectos en el material y la mano de obra, y acuerda

reparar o reemplazar, a opción de BOSTITCH, todo producto defectuoso en el plazo

máximo de 1 año de la fecha de compra. Esta garantía no es transferible. Cubre

únicamente daños derivados de defectos en el material o la mano de obra; no cubre

condiciones o averías resultantes de desgaste normal, negligencia, abuso, accidente o

reparaciones que se hayan intentado o realizado a través de otro servicio técnico que

no sea nuestro centro de reparación regional o un centro de servicio técnico de garantía

autorizado. Por lo tanto, el impulsor, las remachadoras y los componentes desgastados

de las guías del impulsor solo tienen garantía por defectos de mano de obra y fabricación.

ESTA GARANTÍA REEMPLAZA TODA OTRA GARANTÍA EXPRESA. TODA GARANTÍA

DE COMERCIABILIDAD O IDONEIDAD PARA UN PROPÓSITO EN PARTICULAR SE

LIMITA A LA DURACIÓN DE ESTA GARANTÍA. BOSTITCH NO SERÁ RESPONSABLE

POR NINGÚN DA—O INCIDENTAL O CONSECUENCIAL.

Esta garantía se limita a las ventas en los Estados Unidos y Canadá. Algunos estados

no permiten limitaciones sobre el tiempo que dura una garantía implícita o la exclusión

o limitación de daños incidentales o consecuenciales, de manera que las limitaciones o

exclusiones anteriores podrían no aplicarse a usted. Esta garantía le otorga derechos

legales específicos y es posible que usted tenga otros derechos que variarán según el

estado.

Para obtener el servicio de garantía, devuelva el producto a su costo junto con el

comprobante de compra al centro regional de BOSTITCH o a un centro autorizado

de reparación de garantía. Puede llamarnos al 1-800-832-3080 or visit our website at

www.BOSTITCH.com para conocer la ubicación de los centros autorizados de servicio

técnico de garantía en su área.

DEFINICIONES: NORMAS DE SEGURIDAD

Las siguientes definiciones describen el nivel de gravedad de cada palabra de señal. Lea

el manual y preste atención a estos símbolos.

Indica una situación de peligro inminente que, si no se evita, provocará

la muerte o lesiones graves.

Indica una situación de peligro potencial que, si no se evita, podría

provocar la muerte o lesiones graves.

20-SP

Page 21

Indica una situación de peligro potencial que, si no se evita, posiblemente

provocaría lesiones leves o moderadas.

Se refiere a una práctica no relacionada a lesiones corporales que

de no evitarse puede resultar en daños a la propiedad.

ADVERTENCIAS GENERALES DE SEGURIDAD PARA

HERRAMIENTAS ELÉCTRICAS

Lea todas las advertencias de seguridad e instrucciones. El

incumplimiento de las advertencias e instrucciones puede provocar descargas eléctricas,

incendios o lesiones graves.

CONSERVE TODAS LAS ADVERTENCIAS E

INSTRUCCIONES PARA FUTURAS CONSULTAS

El término “herramienta eléctrica” incluido en las advertencias hace referencia a las

herramientas eléctricas operadas con corriente (con cable eléctrico) o a las herramientas

eléctricas operadas con baterías (inalámbricas).

1) SEGURIDAD EN EL ÁREA DE TRABAJO

a) Mantenga el área de trabajo limpia y bien iluminada. Las áreas abarrotadas

y oscuras propician accidentes.

b) No opere las herramientas eléctricas en atmósferas explosivas, como

ambientes donde haya polvo, gases o líquidos inflamables. Las herramientas

eléctricas originan chispas que pueden encender el polvo o los vapores.

c) Mantenga alejados a los niños y a los espectadores de la herramienta

eléctrica en funcionamiento. Las distracciones pueden provocar la pérdida de

control.

2) SEGURIDAD ELÉCTRICA

a) Los enchufes de la herramienta eléctrica deben adaptarse al tomacorriente.

Nunca modifique el enchufe de ninguna manera. No utilice ningún enchufe

adaptador con herramientas eléctricas con conexión a tierra. Los enchufes

no modificados y que se adaptan a los tomacorrientes reducirán el riesgo de

descarga eléctrica.

b) Evite el contacto corporal con superficies con descargas a tierra como,

por ejemplo, tuberías, radiadores, cocinas eléctricas y refrigeradores.

Existe mayor riesgo de descarga eléctrica si su cuerpo está puesto a tierra.

c) No exponga las herramientas eléctricas a la lluvia o a condiciones de

humedad. Si entra agua a una herramienta eléctrica, aumentará el riesgo de

descarga eléctrica.

d) No maltrate el cable. Nunca utilice el cable para transportar, tirar o

desenchufar la herramienta eléctrica. Mantenga el cable alejado del calor,

el aceite, los bordes filosos y las piezas móviles. Los cables dañados o

enredados aumentan el riesgo de descarga eléctrica.

e) Al operar una herramienta eléctrica en el exterior, utilice un cable

prolongador adecuado para tal uso. Utilice un cable adecuado para uso en

exteriores a fin de reducir el riesgo de descarga eléctrica.

f) Si el uso de una herramienta eléctrica en un lugar húmedo es imposible

de evitar, utilice un suministro protegido con un interruptor de circuito por

falla a tierra (GFCI). El uso de un GFCI reduce el riesgo de descargas eléctricas.

21-SP

Page 22

3) SEGURIDAD PERSONAL

a) Permanezca alerta, controle lo que está haciendo y utilice el sentido

común cuando emplee una herramienta eléctrica. No utilice una

herramienta eléctrica si está cansado o bajo el efecto de drogas, alcohol

o medicamentos. Un momento de descuido mientras se opera una herramienta

eléctrica puede provocar lesiones personales graves.

b) Utilice equipos de protección personal. Siempre utilice protección para

los ojos. En las condiciones adecuadas, el uso de equipos de protección, como

máscaras para polvo, calzado de seguridad antideslizante, cascos o protección

auditiva, reducirá las lesiones personales.

c) Evite el encendido por accidente. Asegúrese de que el interruptor esté

en la posición de apagado antes de conectarlo a la fuente de energía o

paquete de baterías, o antes de levantar o transportar la herramienta.

Transportar herramientas eléctricas con el dedo apoyado en el interruptor o

enchufar herramientas eléctricas con el interruptor en la posición de encendido

puede propiciar accidentes.

d) Retire la clavija de ajuste o la llave de tuercas antes de encender la

herramienta eléctrica. Una llave de tuercas o una clavija de ajuste que quede

conectada a una pieza giratoria de la herramienta eléctrica puede provocar

lesiones personales.

e) No se estire. Conserve el equilibrio y párese adecuadamente en todo

momento. Esto permite un mejor control de la herramienta eléctrica en

situaciones inesperadas.

f) Use la vestimenta adecuada. No use ropas holgadas ni joyas. Mantenga

el cabello, la ropa y los guantes alejados de las piezas en movimiento.

Las ropas holgadas, las joyas o el cabello largo pueden quedar atrapados en las

piezas en movimiento.

g) Si se suministran dispositivos para la conexión de accesorios con fines de

recolección y extracción de polvo, asegúrese de que estén conectados y

que se utilicen correctamente. El uso de dispositivos de recolección de polvo

puede reducir los peligros relacionados con el polvo.

4) USO Y MANTENIMIENTO DE LA HERRAMIENTA ELÉCTRICA

a) No fuerce la herramienta eléctrica. Utilice la herramienta eléctrica

correcta para el trabajo que realizará. Si se la utiliza a la velocidad para la que

fue diseñada, la herramienta eléctrica correcta permite trabajar mejor y de manera

más segura.

b) No utilice la herramienta eléctrica si no puede encenderla o apagarla con

el interruptor. Toda herramienta eléctrica que no pueda ser controlada mediante

el interruptor es peligrosa y debe repararse.

c) Desconecte el enchufe de la fuente de energía o el paquete de baterías

de la herramienta eléctrica antes de realizar ajustes, cambiar accesorios

o almacenar la herramienta eléctrica. Estas medidas de seguridad preventivas

reducen el riesgo de encender la herramienta eléctrica en forma accidental.

d) Guarde la herramienta eléctrica que no esté en uso fuera del alcance de

los niños y no permita que otras personas no familiarizadas con ella o con

estas instrucciones operen la herramienta. Las herramientas eléctricas son

peligrosas si son operadas por usuarios no capacitados.

e) Realice el mantenimiento de las herramientas eléctricas. Revise que

no haya piezas en movimiento mal alineadas o trabadas, piezas rotas

o cualquier otra situación que pueda afectar el funcionamiento de la

herramienta eléctrica. Si encuentra daños, haga reparar la herramienta

eléctrica antes de utilizarla. Se producen muchos accidentes a causa de las

herramientas eléctricas que carecen de un mantenimiento adecuado.

22-SP

Page 23

f) Mantenga las herramientas de corte afiladas y limpias. Las herramientas de

corte con mantenimiento adecuado y con los bordes de corte afilados son menos

propensas a trabarse y son más fáciles de controlar.

g) Utilice la herramienta eléctrica, los accesorios y las brocas de la

herramienta, etc. de acuerdo con estas instrucciones y teniendo en

cuenta las condiciones de trabajo y el trabajo que debe realizarse. El uso

de la herramienta eléctrica para operaciones diferentes de aquéllas para las que

fue diseñada podría originar una situación peligrosa.

5) USO Y MANTENIMIENTO DE LA HERRAMIENTA CON BATERÍAS

a) Recargue solamente con el cargador especificado por el fabricante. Un

cargador adecuado para un tipo de paquete de baterías puede originar riesgo de

incendio si se utiliza con otro paquete de baterías.

b) Utilice herramientas eléctricas sólo con paquetes de baterías

específicamente diseñados. El uso de cualquier otro paquete de baterías

puede producir riesgo de incendio y lesiones.

c) Cuando no utilice el paquete de baterías, manténgalo lejos de otros

objetos metálicos como sujetapapeles, monedas, llaves, clavos, tornillos

u otros objetos metálicos pequeños que puedan realizar una conexión

desde un terminal al otro. Los cortocircuitos en los terminales de la batería

pueden provocar quemaduras o incendio.

d) En condiciones abusivas, el líquido puede ser expulsado de la batería.

Evite su contacto. Si entra en contacto accidentalmente, enjuague con

agua. Si el líquido entra en contacto con los ojos, busque atención médica.

El líquido expulsado de la batería puede provocar irritación o quemaduras.

6) MANTENIMIENTO

a) Solicite a una persona calificada en reparaciones que realice el

mantenimiento de su herramienta eléctrica y que sólo utilice piezas de

repuesto idénticas. Esto garantizará la seguridad de la herramienta eléctrica.

ADVERTENCIAS DE SEGURIDAD DE LA GRAPADORA

a) Siempre asuma que la herramienta contiene remaches. El manejo descuidado

de la grapadora puede provocar el disparo imprevisto de remaches y lesiones

personales.

b No apunte la herramienta hacia usted mismo u otra persona cercana. El

disparo imprevisto descargará el remache y provocará una lesión.

c) No active la herramienta a menos que esta se encuentre ubicada firmemente

contra la pieza de trabajo. Si la herramienta no está en contacto con la pieza de

trabajo, el remache podría desviarse de su objetivo.

d) Desconecte la herramienta de la fuente de alimentación cuando el remache

se atora en la herramienta. Mientras quita el remache atorado, la grapadora podría

activarse accidentalmente si está enchufada.

e) No use esta grapadora para ajustar cables eléctricos. Dado que no está

diseñada para la instalación de cables eléctricos, podría dañar la aislación de los

cables eléctricos y causar una descarga eléctrica o peligro de incendio.

SEGURIDAD DE CARGA DE LA HERRAMIENTA

Al cargar la herramienta: 1) Nunca coloque su mano o ninguna

parte de su cuerpo en el área de la herramienta de descarga del sujetador; 2)

Nunca apunte la herramienta a ninguna persona; 3) No jale el gatillo ni presione

la palanca de seguridad ya que la actuación accidental podría causar una lesión.

23-SP

Page 24

SEGURIDAD OPERATIVA

Siempre maneje la herramienta con cuidado: 1) Nunca se ponga

a jugar mientras está manipulando la herramienta; 2) Nunca jale el gatillo a

menos que la nariz de la herramienta esté dirigida hacia el trabajo; 3) Mantenga

a otras personas a una distancia segura de la herramienta mientras que la está

operando, ya que una actuación accidental podría causar una lesión.

Mantenga las manos y el cuerpo lejos del área de descarga de la

herramienta.

No impulse sujetadores encima de otros sujetadores o con la

herramienta en un ángulo demasiado agudo, ya que esto podría causar la

deflexión de los sujetadores y una lesión.

Esta engrapadora produce CHISPAS durante la operación.

NUNCA use la engrapadora cerca de sustancias inflamables, gases o

vapores, incluyendo laca, pintura, benzina, solvente, gasolina, adhesivos,

masilla, pegamentos u otros materiales que sean inflamables, combustibles o

explosivos, o que sus vapores, humos o subproductos también lo sean. Usar

la engrapadora en estos entornos podría causar una EXPLOSIÓN que genere

lesiones personales o muerte al usuario o a las personas que están cerca.

Accionada por gatillo

Esta es una herramienta accionada por gatillo cuando se presiona la palanca de

seguridad. La herramienta accionada por gatillo efectuará un ciclo cada vez que se

dispare el gatillo cuando se presione la palanca de seguridad.

Partes De Reemplazo

Use sólo piezas de repuesto de BOSTITCH. No use piezas modificadas.

SÍMBOLOS

• Laetiquetade laherramientapuedeincluir los siguientessímbolos.Acontinuación,

se describen los símbolos y sus definiciones:

V .................. voltios

A .................. amperios

Hz ................ hercios

W ................. vatios

o DC ... corriente directa

o AC/DC corriente alterna o directa

o AC ....... corriente alterna

................. símbolo de alerta de

seguridad

................ construcción clase II

(aislamiento doble)

................ terminal de conexión a

tierra

Ah ................ horas amperes

Wh ............... horas vatios

SEGURIDAD DE LA BATERÍA/EL CARGADOR

Instrucciones de seguridad importantes para todas las

unidades de batería

Cuando solicite unidades de batería de repuesto, no olvide indicar el número de catálogo

y el voltaje. La unidad de batería no viene completamente cargada de fábrica. Antes de

usar la unidad de batería y el cargador, lea las siguientes instrucciones de seguridad.

Luego, siga los procedimientos de carga indicados.

24-SP

Page 25

LEA TODAS LAS INSTRUCCIONES

• No cargue o use la unidad de batería en atmósferas explosivas, como en

presencia de líquidos, gases o polvos inflamables. Puede que al insertar o sacar

la unidad de batería del cargador se inflamen el polvo o los gases.

• NUNCA fuerce la unidad de batería para que entre en el cargador. NO

modifique la unidad de batería en ninguna forma para que entre en un

cargador no compatible, pues puede producir una ruptura en la unidad de

batería y causar lesiones corporales graves.

• Cargue las unidades de batería sólo en los cargadores designados por BOSTITCH.

• NO salpique con ni sumerja en agua u otros líquidos.

• No guarde ni use la herramienta y unidad de batería en lugares donde

la temperatura pueda alcanzar o superar los 40 °C (105 °F), tales como

cobertizos o construcciones de metal durante el verano). Almacene las

unidades de batería en lugares frescos y secos para maximizar su vida útil.

NOTA: No almacene las unidades de batería en la herramienta con el

interruptor de gatillo en posición encendida fija. Nunca use cinta adhesiva

para mantener el interruptor de gatillo en posición ENCENDIDA.

Peligro de incendio. Nunca intente abrir la unidad de batería por ningún

motivo. Si la caja exterior de la unidad de batería se triza o daña, no la introduzca en el

cargador. No triture, deje caer o dañe la unidad de batería. No use una unidad de batería

o un cargador que haya sido golpeado, dejado caer, atropellado o dañado en cualquier

forma (por ejemplo, perforado por un clavo, golpeado con un martillo, pisado). Lleve sus

unidades de batería dañadas al centro de servicio para que sean recicladas.

Peligro de incendio. No guarde ni transporte la unidad de

batería de manera que objetos metálicos puedan hacer contacto con los

terminales expuestos de la batería. Por ejemplo, no ponga la unidad de batería

en delantales, bolsillos, cajas de herramientas, estuches de productos, cajones, etc.,

junto con clavos, tornillos, llaves, etc., sueltos. El transporte de baterías puede

causar incendios si sus terminales inadvertidamente entran en contacto con

materiales conductores como llaves, monedas, herramientas de mano y otros

por el estilo. El Reglamento sobre Materiales Peligrosos (HMR) del Ministerio de

Transporte de los Estados Unidos actualmente prohíbe el transporte de baterías en el

comercio o en aviones (por ejemplo, embaladas en maletas y maletines de mano) A

NO SER que estén debidamente protegidas para prevenir cortocircuitos. Por lo tanto,

cuando transporte unidades de batería individuales, asegúrese de que sus terminales

estén protegidos y debidamente aislados de materiales que pudieran entrar en contacto

con ellos y causar un cortocircuito.

INSTRUCCIONES DE SEGURIDAD ESPECÍFICAS PARA BATERÍAS DE IONES

DE LITIO (LI-ION)

• No incinere la unidad de batería, aunque esté completamente dañada o

descargada. La unidad de batería puede explotar si se quema. Cuando se

queman unidades de batería de iones de litio, se producen gases y materiales

tóxicos.

• Si el contenido de la batería entra en contacto con la piel, lave el área de

inmediato con agua y un jabón suave. Si el líquido de la batería entra en contacto

con sus ojos, enjuáguelos con agua y los ojos abiertos por 15 minutos o hasta que

cese la irritación. Si se requiere de asistencia médica, el electrolito de la batería está

compuesto por una mezcla de carbonatos orgánicos líquidos y sales de litio.

• El contenido de los elementos abiertos de la batería puede causar irritación

en el tracto respiratorio. Salga al aire fresco. Si los síntomas persisten, busque

asistencia médica.

25-SP

Page 26

Peligro de quemaduras. El líquido de la batería puede ser inflamable si

se expone a chispas o llamas.

El sello RBRC™

El sello RBRC™ (Rechargeable Battery Recycling Corporation) en las

baterías (ounidades de batería) de níquel cadmio, níquel e hidruro

metálico o de iones de litio indica que el costo de reciclaje de estas

baterías (o unidades de batería) al llegar al final de su vida de servicio ya

ha sido pagado por BOSTITCH. En algunas áreas, es ilegal depositar

baterías de níquel cadmio, níquel e hidruro metálico o de iones de litio gastadas en la

basura o la corriente de residuos sólidos urbanos; el programa RBRC proporciona una

alternativa ecológica.

RBRC™, en cooperación con BOSTITCH y otros usuarios de baterías, han establecido

programas en los Estados Unidos y Canadá para facilitar la recolección de baterías de

níquel cadmio, níquel e hidruro metálico o de iones de litio gastadas. Al llevar sus baterías

de níquel cadmio, níquel e hidruro metálico y de iones de litio gastadas a un centro

de servicio autorizado por BOSTITCH o al minorista local para que sean recicladas,

ayuda a proteger el medio ambiente y a conservar recursos naturales. También puede

comunicarse con el centro de reciclaje de su localidad para mayor información sobre

dónde llevar sus baterías gastadas.

RBRC™ es una marca comercial registrada de Rechargeable Battery Recycling

Corporation.

Instrucciones importantes de seguridad para todos los

cargadores de baterías

GUARDE ESTAS INSTRUCCIONES: Este manual contiene instrucciones de seguridad

y operación importantes para los cargadores de baterías.

• Antes de usar el cargador, lea todas las instrucciones y advertencias que se

encuentren en el cargador, la unidad de batería y el producto que usa la unidad de

batería.

Peligro de descarga eléctrica. No permita que ningún líquido se

introduzca en el cargador. Puede producir descargas eléctricas.

Peligro de quemaduras. Para reducir el riesgo de lesiones, sólo cargue

unidades de batería recargables marca BOSTITCH. Otros tipos de batería podrían

sobrecalentarse y reventar lo que podría resultar en lesiones corporales y daños a su

propiedad.

Bajo ciertas condiciones, cuando el cargador está enchufado a una

toma de corriente, el cargador puede hacer cortocircuito si entra en contacto con

algún material ajeno. Los materiales ajenos de naturaleza conductora, como el polvo de

esmerilado, las placas de metal, la lana de acero, el papel de aluminio y otros, o cualquier

acumulación de partículas metálicas deberían mantenerse alejados de las cavidades del

cargador. Desenchufe siempre el cargador cuando no haya una unidad de batería en su

cavidad. Desenchufe el cargador antes de intentar limpiarlo.

• NO intente cargar la unidad de batería con otros cargadores que no sean los

descritos en este manual. El cargador y la unidad de batería fueron específicamente

diseñados para trabajar en conjunto.

• Estos cargadores no fueron diseñados para ser utilizados para más que

cargar las baterías recargables BOSTITCH. Cualquier otro uso puede producir

riesgo de incendios, descargas eléctricas o electrocución.

• No exponga el cargador a la lluvia o a la nieve.

26-SP

Page 27

• Tire del enchufe y no del cable cuando desconecte el cargador. De esta forma

se reduce el riesgo de daño al enchufe y cable.

• Asegúresedequeelcablenoseaubicadodemaneraquepodríaserpisado,

causar que alguien tropiece con él o ser expuesto a otro tipo de daños y

desgastes.

• No use un alargador a menos que sea absolutamente necesario. El uso de

un alargador incorrecto podría producir riesgo de incendios, descargas eléctricas o

electrocución.

• Cuando opere un cargador al exterior, hágalo siempre en un lugar seco y use

un alargador apropiado para uso al exterior. El uso de un alargador apropiado

para uso al exterior reduce el riesgo de descarga eléctrica.

• Los hilos del alargador deben ser de un calibre apropiado (AWG o American

Wire Gauge) para su seguridad. Mientras menor sea el calibre del hilo, mayor la

capacidad del cable. Es decir, un hilo calibre 16 tiene mayor capacidad que uno de

18. Un cable de un calibre insuficiente causará una caída en la tensión de la línea

dando por resultado una pérdida de energía y sobrecalentamiento. Cuando se utilice

más de un alargador para completar el largo total, asegúrese que los hilos de cada

alargador tengan el calibre mínimo. La tabla siguiente muestra el tamaño correcto a

utilizar, dependiendo de la longitud del cable y del amperaje nominal de la placa de

identificación. Si tiene dudas sobre cuál calibre usar, use un calibre mayor. Cuanto

menor sea el número del calibre, más resistente será el cable.

Calibre mínimo para juegos de cables

Voltios Largo total del cable en metros (en pies)

Capacidad nominal

en amperios

120V 7,6 (25) 15,2 (50) 30,5 (100) 45,7 (150)

240V 15,2 (50) 30,5 (100) 61,0 (200) 91,4 (300)

Desde Hasta AWG

0 6 18 16 16 14

6 10 18 16 14 12

10 12 16 16 14 12

12 16 14 12 No recomendado

• No coloque ningún objeto encima del cargador ni coloque a este sobre una

superficie blanda que pudiera bloquear las ranuras de ventilación y resultar

en un calor interno excesivo. Coloque el cargador en un lugar alejado de cualquier

fuente de calor. El cargador se ventila a través de las ranuras que se encuentran en

la parte superior e inferior de la caja protectora.

• No opere el cargador si su cable o enchufe están dañados.

• No opere el cargador si ha recibido un golpe agudo, si se ha caído o si ha

sido dañado de alguna otra forma. Llévelo a un centro de servicio autorizado.

• No desarme el cargador; llévelo a un centro de servicio autorizado cuando

deba ser reparado. Si es reensamblado incorrectamente, puede causar descargas

eléctricas, electrocución o incendios.

• Desenchufe el cargador antes de intentar limpiarlo. Esto reducirá el riesgo

de descargas eléctricas. El retirar el paquete de baterías no reducirá este riesgo.

• NUNCA intente conectar 2 cargadores entre sí.

27-SP

Page 28

• El cargador está diseñado para operar con una corriente eléctrica estándar

residencial de 120 V. No intente usarlo con ningún otro voltaje. Esto no aplica

al cargador vehicular.

Cargadores

Su herramienta utiliza un cargador BOSTITCH. Asegúrese de leer todas las instrucciones

de seguridad antes de utilizar su cargador.

Procedimiento de carga

1. Enchufe el cargador en una toma

de corriente apropiada antes de

insertar la unidad de batería.

2. Inserte la unidad de batería (6) en

el cargador, como se muestra,

comprobando que quede bien

colocado dentro del mismo. La

luz roja (de carga) parpadeará

continuamente para indicar que se ha iniciado el proceso de carga.

3. La luz roja se quedará ENCENDIDA continuamente cuando se haya completado el

proceso de carga. La unidad estará entonces completamente cargad y podrá ser

utilizado de inmediato o dejarse en el cargador.

6

Indicadores de carga

Este cargador ha sido diseñado para detectar ciertos problemas que pudieran surgir.

Estos problemas se indican mediante una luz roja intermitente rápida. Si esto ocurre,

vuelva a colocar la unidad de batería en el cargador. Si el problema persiste, pruebe con

otra unidad de batería para determinar si el cargador está funcionando debidamente. Si

la segunda unidad de batería carga correctamente, significa que la primera está fallada

y debería ser llevada a un centro de servicio u otro lugar de colección para su reciclaje.

Si la segunda unidad de batería hace que el cargador indique el mismo problema que la

primera, lleve el cargador y la unidad de batería a un centro de servicio autorizado para

su examinación.

RETARDO POR UNIDAD CALIENTE/FRÍA

Este cargador tiene una función de retardo por unidad caliente/fría: cuando el cargador

detecta una batería caliente, inmediatamente empieza un retardo por unidad caliente y

suspende la carga hasta que la batería se haya enfriado. Una vez enfriada la batería, el

cargador pasará automáticamente a la modalidad de carga de la unidad. Esta función

asegura la máxima duración de su batería. La luz roja parpadeará a intervalos largos,

luego cortos cuando esté en modalidad de retardo por unidad caliente/fría.

PERMANENCIA DE LA UNIDAD DE BATERÍA EN EL CARGADOR

El cargador y la unidad de batería pueden dejarse conectados con la luz del cargador

indicando que la unidad está cargada.

UNIDADES DE BATERÍA DESGASTADAS: Las baterías desgastadas seguirán

funcionando pero no debe esperarse que tengan capacidad para la misma cantidad de

trabajo.

UNIDADES DE BATERÍA DEFECTUOSAS: Este cargador no cargará una unidad de

batería defectuosa. El cargador indicará que la unidad de batería es defectuosa al no

iluminarse o al indicar que existe un problema con la unidad o el cargador.

NOTA: Esto también puede significar que hay un problema con el cargador.

28-SP

Page 29

LÍNEA DE ALIMENTACIÓN CON PROBLEMAS

Algunos cargadores tienen un indicador de Línea de alimentación con problemas.

Cuando el cargador se utiliza con algunas fuentes de alimentación portátiles, como

generadores o fuentes que convierten CC a CA, el cargador puede suspender

temporalmente el funcionamiento, ocasión en la que la luz roja se encenderá y apagará

rápidamente dos veces, seguido de una pausa. Esto indica que la fuente de alimentación

está fuera de los límites.

Notas importantes sobre la carga

1. Se puede obtener una mayor duración y un mejor rendimiento si la unidad de batería

se carga a una temperatura ambiente de 18 – 24 °C (65 – 75 °F). NO cargue la

unidad de batería a una temperatura ambiental inferior a +4,5 °C (+40 °F) o superior

a +40,5 °C (+105 °F). Esto es importante y evitará causar daños graves a la batería.

2. Puede que el cargador y la unidad de batería se calienten ligeramente durante el

proceso de carga. Esto es normal y no representa ningún problema. Para facilitar el

enfriamiento de la unidad de batería después del uso, evite colocar el cargador o la

unidad de batería en un lugar cálido, como un cobertizo metálico o un remolque sin

aislamiento térmico.

3. Si la unidad de batería no se carga correctamente: a) Verifique el funcionamiento de

la toma enchufando una lámpara u otro aparato; b) Revise que la toma de corriente

no esté conectada a un interruptor de luz que corte la corriente cuando se corte la

luz; c) Mueva el cargador y la unidad de batería a un lugar donde la temperatura

ambiental sea aproximadamente 18 – 24 °C (65 – 75 °F); d) Si el problema de carga

continúa, lleve la herramienta, unidad de batería y el cargador a su centro de servicio

local.

4. La unidad de batería debería ser recargada cuando no sea capaz de producir

suficiente potencia para trabajos que eran fácilmente realizados antes. NO

CONTINÚE usándola bajo estas circunstancias. Siga el procedimiento de carga.

También puede cargar una unidad de batería que haya sido usada parcialmente

cuando lo desee, sin dañarla.

5. Los materiales ajenos conductores por naturaleza, tales como, pero sin limitarse a,

el polvo del esmerilado, las virutas metálicas, la lana de acero, el papel de aluminio

o cualquier acumulación de partículas metálicas deberían mantenerse alejados de

las cavidades del cargador. Desenchufe siempre el cargador de la toma de corriente

cuando no haya una unidad de batería en su cavidad. Desenchufe el cargador antes

de intentar limpiarlo.

6. No congele ni sumerja el cargador en agua o cualquier otro líquido.

Peligro de descarga eléctrica. No permita que ningún líquido se

introduzca en el cargador. Puede producir descargas eléctricas.

Nunca intente abrir la unidad de batería por ningún motivo. Si la caja

plástica de la unidad de batería se triza o rompe, llévela a un centro de servicio para su

reciclaje

Recomendaciones de almacenamiento