A Division of Northern Star Industries, Inc.

P.O. Box 787 Iron Mountain MI 49801-0787

BOSS PRODUCTS

www.bossplow.com

RT3 POWER-V BLADE

TM

WITH SMARTHITCH2

INSTALLATION MANUAL

TABLE OF CONTENTS

WARNINGS...................................................................................................................................2

SNOWPLOW MOUNTING & REMOVAL PROCEDURE.............................................................. 3

SNOWPLOW ASSEMBLY PROCEDURE .................................................................................... 4

ELECTRICAL SYSTEM WIRING PROCEDURE.......................................................................... 9

HEADLIGHT ADAPTER INSTALLATION PROCEDURE............................................................. 14

ELECTRICAL SYSTEM WIRING SCHEMATIC (PLOW SIDE) .................................................... 15

ELECTRICAL SYSTEM WIRING SCHEMATIC (TRUCK SIDE) .................................................. 16

ELECTRICAL SYSTEM WIRING DIAGRAM ................................................................................ 17

RT3 V-BLADE MANIFOLD WIRING DIAGRAM ........................................................................... 18

HYDRAULIC VALVE ASSEMBLY PARTS LIST........................................................................... 19

HEADLIGHT AIMING PROCEDURE............................................................................................ 20

HYDRAULIC POWER UNIT FILL PROCEDURE ......................................................................... 21

V-BLADE CONTROLLERS ........................................................................................................... 22

TROUBLESHOOTING GUIDE...................................................................................................... 26

RECOMMENDED PUSHBEAM HEIGHT ..................................................................................... 32

RECOMMENDED BOLT TORQUE .............................................................................................. 32

BOSS PRODUCTS / Northern Star Industries, Inc. reserves the right under its continuous product improvement policy to change construction or

design details and furnish equipment when so altered without reference to illustrations or specifications used herein.

This product is covered under one or more of the following patents:

5,568,694 4,074,448 4,658,519 6,108,946 6,170,178 6,134,814

Other Patents Pending

DRIVEN TO BE THE BEST

MSC04082-9

WARNING

Many newer trucks are equipped with air bags. DO NOT under any circumstances disable or remove or

relocate any sensors or other components related to the operation of the air bags.

WARNING

Always follow the vehicle manufacturer’s recommendations relating to snowplow installation. For

recommended vehicle models refer to the BOSS Snowplow Application Chart and Selection Guide.

WARNING

Vehicles equipped with air bags are designed such that the air bags will be activated in a frontal collision

equivalent to hitting a solid barrier (such as a wall) at approximately 14 mph or more, or, roughly speaking,

a frontal perpendicular collision with a parked car or truck of similar size at approximately 28 mph or more.

Careless or high speed driving while plowing snow, which results in vehicle decelerations equivalent to or

greater than the air bag deployment threshold described above, would deploy the air bag.

WARNING

Read this manual carefully before operating this snowplow.

WARNING

When transporting, position plow so as not to block vision or plow headlights.

WARNING

DO NOT change blade position when traveling.

WARNING

DO NOT exceed 40 mph when transporting plow.

WARNING

DO NOT exceed 14 mph when plowing.

WARNING

Always lower blade when vehicle is not in use.

WARNING

Make sure plow is properly attached before moving vehicle.

WARNING

To comply with Federal Regulations and to assure a safe vehicle, the Front Gross Axle Weight Rating

(FGAWR), Rear Gross Axle Weight Rating (RGAWR), and the Gross Vehicle Weight Rating (GAWR) must

not be exceeded at any time.

WARNING

Due to the variety of equipment that can be installed on this vehicle, it is necessary to verify that the Front

Gross Axle Weight Rating (FGAWR), Rear Gross Axle Weight Rating (RGAWR), and the Gross Vehicle

Weight Rating (GAWR) are not exceeded at any time. This may require weighing the vehicle and adding

ballast as necessary. It may also limit payload capacity of the vehicle. It is the operator’s responsibility to

verify that these ratings are not exceeded.

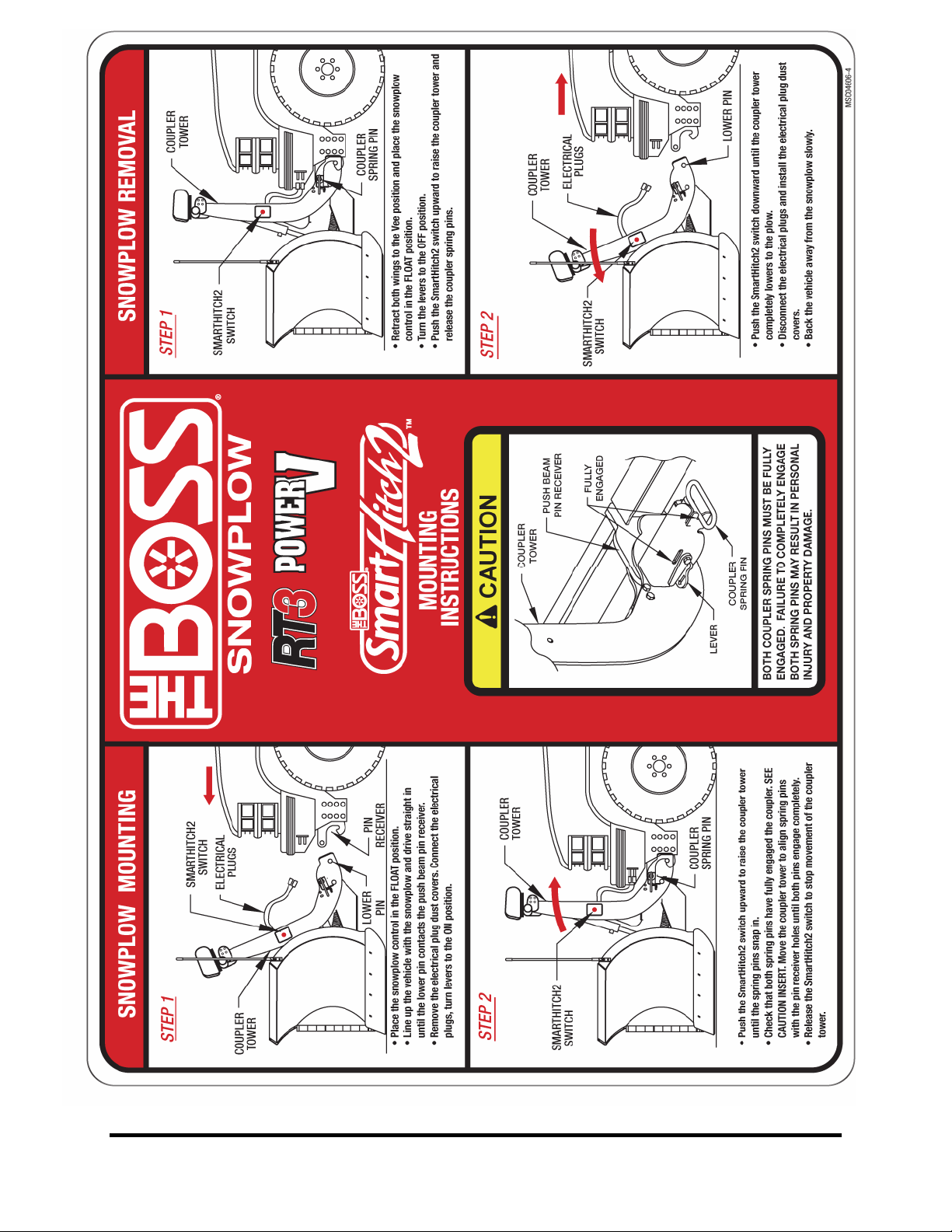

Snowplow Mounting Procedure

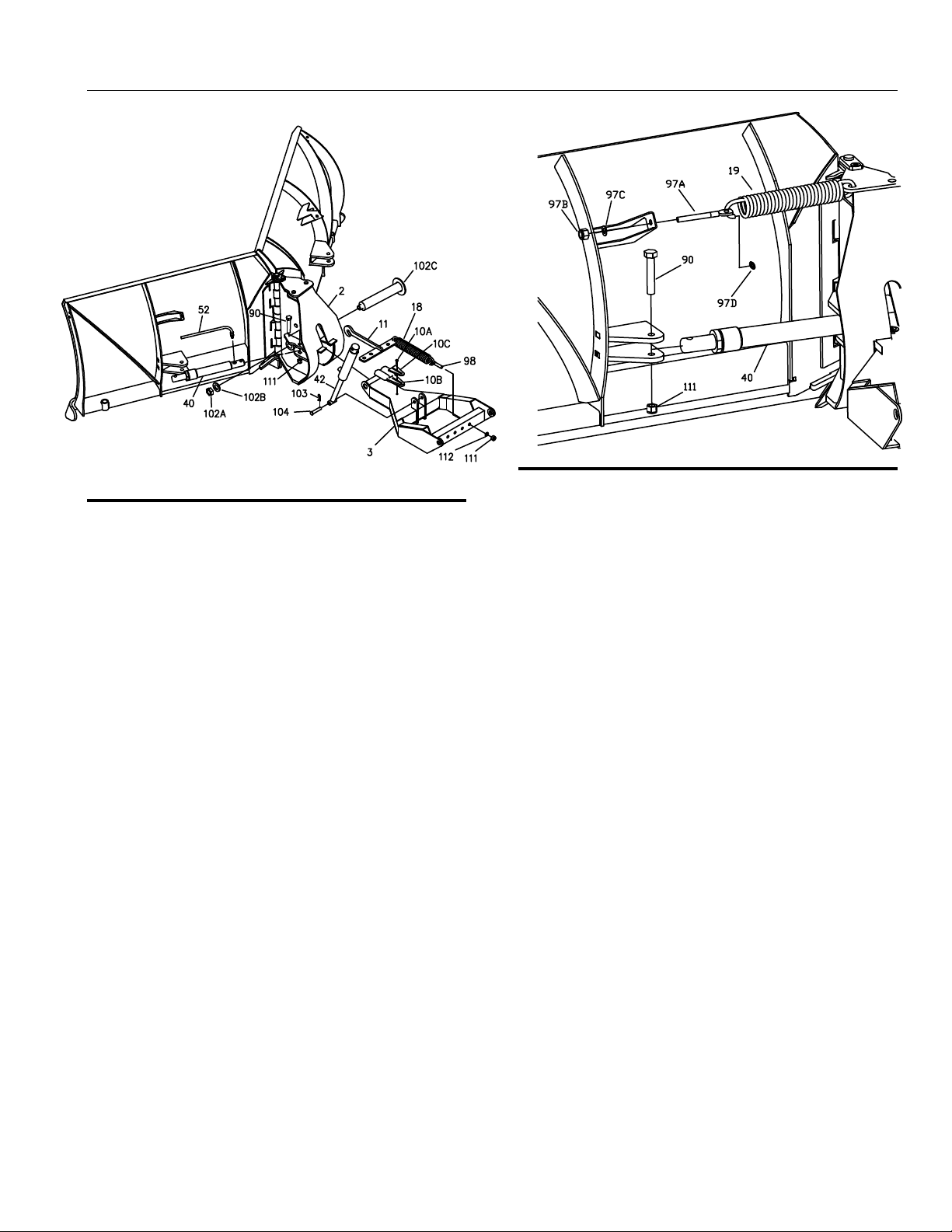

Figure 1. Mounting and Removal Instructions MSC04606

3

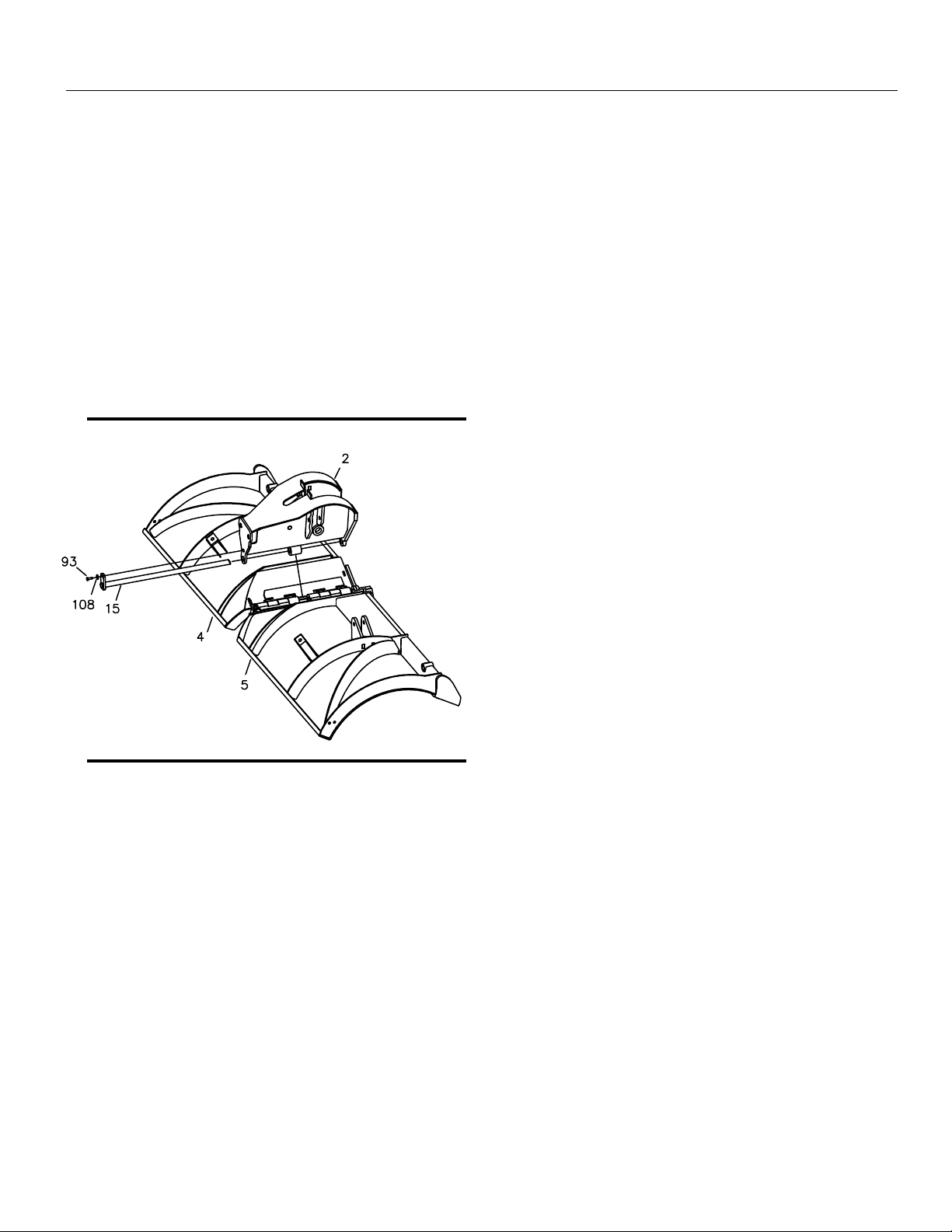

Snowplow Assembly Procedure

Snowplow Assembly

Procedure

Note: This manual is used for the installation of all V-

Plows. Part numbers and illustrations may vary.

1. Begin the assembly procedure by cutting down

each corner of the plow box so that each wall of

the box will lie flat on the floor. Lay the top of the

box flat on the floor. The top of the box can be

used as a mat and will help prevent scratching the

blade halves during installation.

2. Remove Left Blade Half (5) and Right Blade Half

(4) from the crate. Lay each blade half flat on the

box top, face down.

5. Secure Center Hinge Pin (15) to the top of Center

Section (2) using one HDW01771 3/8”-16 X 1 ¼”

Hex Head Cap Screw (93), and one HDW01718

3/8” Split Lock Washer (108).

Note: Plow shoes are optional. If added they should

be mounted flush with the bottom of the cutting edge

when the plow is mounted on the truck to be used for

plowing. When plowing on a solid level area (parking

lots, roads, and driveways) plow shoes can be raised

up to increase cutting edge contact on the plowed

surface. When plowing dirt, gravel, or grass plow

shoes should be lowered below the cutting edge

surface to prevent the plow from digging into the

plowed surface.

Figure 2. Blade Assembly Procedure. G10123

3. Align the center bushings on Left Blade Half (5)

with the center bushings on Right Blade Half (4).

Position CHA09716 Center Section (2) on top of

both blades so that all bushings align.

4. Insert MSC01507 Center Hinge Pin (15) through

Left Blade Half (5), Right Blade Half (4) and

Center Section (2).

4

Snowplow Assembly Procedure

Figure 3. Push Frame Assembly Procedure. G10122

6. Stand Blade Assembly and Center Section (2) on

the Cutting Edges with both wings forward in the

scoop position.

7. Remove the loose Horizontal Hinge Pin (102C)

that is inserted in the Center Section (2).

8. Slide TFR09708 Push Frame (3) into Center

Section (2). Re-insert Horizontal Hinge Pin (102C)

through Center Section (2) and Push Frame (3)

then secure with washer (102B) and nut (102A).

9. Attach Lift Cylinder (42) to Push Frame (3) with

HDW05563 Clevis Pin (104) and HDW05544

Hairpin Cotter (103).

10. Hook MSC04200 Spring Yoke (11) to the cross

rod inside Center Section (2).

11. Hook one end of MSC01509 Trip Spring (18) to

Spring Yoke (11). Attach the opposite end of Trip

Spring (18) to the rear angle of Push Frame (3)

using HDW05601 Eyebolts (98), 5/8” Flat

Washers (112) and 5/8” Self-Locking Nuts (111) .

Tighten Self-Locking Nuts (111) finger tight.

12. Attach HYD09731 Angle Cylinders (40) to Center

Section (2) using HDW01706 5/8”-11 X 4” Hex

Head Cap Screws (90) and HDW01709 5/8”-11

Self Locking Nuts (111). DO NOT over-tighten the

nuts.

Note: You should be able to slightly slide the cylinder

up and down on the bolt after it has been tightened.

Figure 4. Angle Cylinder Installation. G10121

13. Pull both wings back into the ‘V’ position.

14. Hook one end of Return Spring (19) to the top

hole on Center Section (2). Hook the opposite end

of Return spring (19) to the blade spring mounting

bracket using ½” Spadebolt (97A), ½” Flat Washer

(97C), and ½” Self-Locking Nut (97B). Tighten

Spring (19) until there is a 1/32” space between

spring coils. Repeat this process for Return Spring

(19) on the opposite side of the plow.

15. Install one Push Nut Retainer (97D) on each end

of the Return Spring (19).

Note: Be sure Push Nut Retainer’s flanges are

pointing away from the Eyebolt and toward the open

end of the Return Spring.

16. Bolt the rod end of Angle Cylinder (40) to each

blade half using 5/8”-11 X 4” Hex Head Bolt (90)

and 5/8”-11 Self Locking Nuts (111). DO NOT

over tighten bolts. Repeat this process for Angle

Cylinder (40) on the opposite side of the plow.

Note: You should be able to slightly slide the cylinder

up and down on the bolt after it has been tightened.

5

Snowplow Assembly Procedure

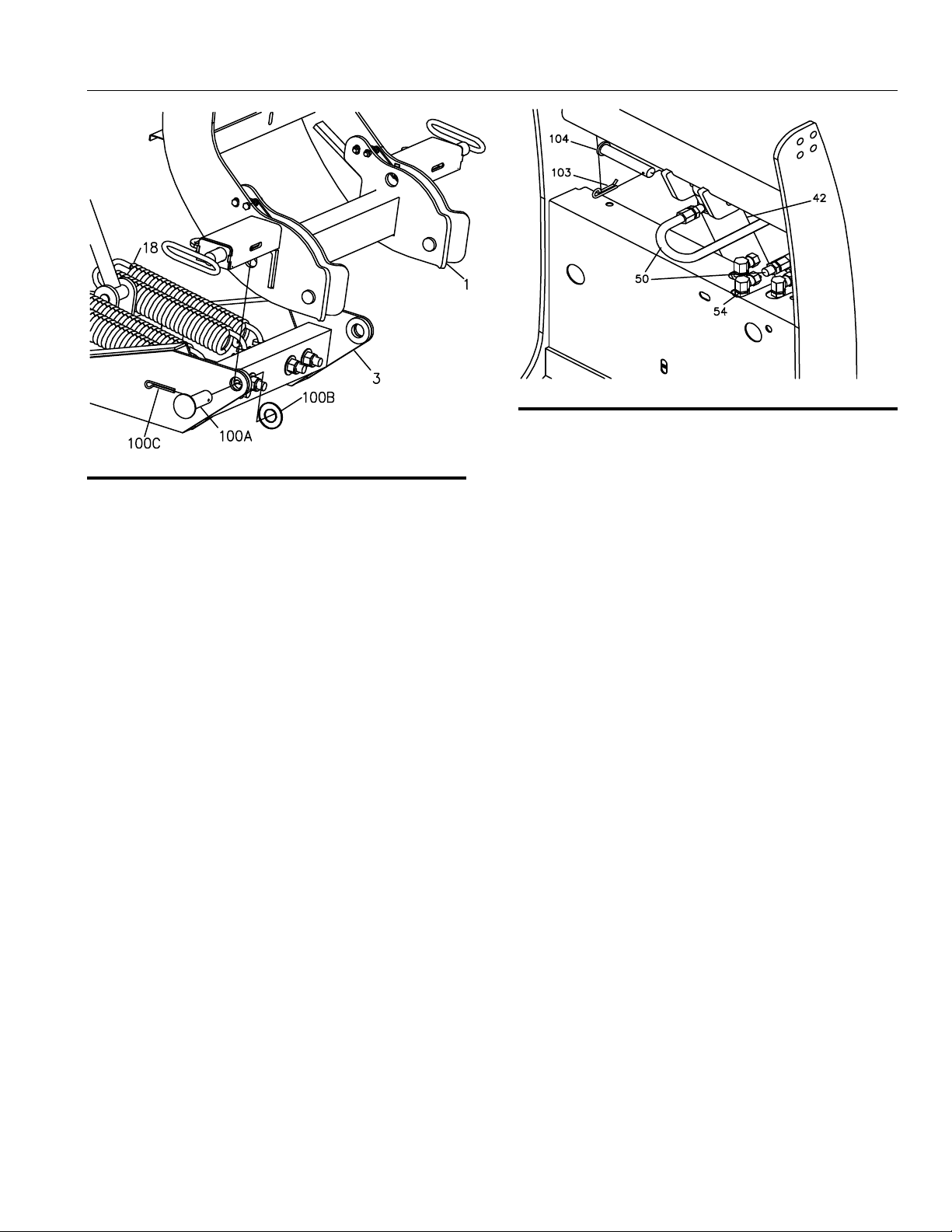

Figure 5. Coupler Assembly to Push Frame. G10119

17. Align pivot holes of Coupler Assembly (1) and

pivot holes of Push Frame (3).

18. Insert 1” X 2 ½” Pivot Pin (100A) through Coupler

Assembly (1) and Push Frame (3). Secure with 1”

Flat Washer (100B) and 3/16” Cotter Pin (100C).

Note: The 10’ V-Blade plow uses a 5/16” x 2” Bolt

and a 5/16” Locknut in place of 3/16” Cotter Pin

(100C).

19. Tighten the four Trip Springs (18) on Push Frame

(3) until there is a 1/32” space between each

spring coil.

Figure 6. Assembly of Lift Cylinder Hydraulics. G10138

20. Remove the plug from the top end of Lift Cylinder

(42).

21. Attach one end of Hydraulic Hose (50) to Lift

Cylinder (42). Be sure to apply thread sealant

compound to the pipe threads on Hydraulic Hose

(50). Tighten connection securely.

22. Attach the top end of Lift Cylinder (42) to Coupler

Assembly (1) using HDW05563 Clevis Pin (104)

and HDW05544 Hairpin Cotter (103).

23. Route Hydraulic Hose (50) in “S” shape and

connect the loose end to the rear Hydraulic Fitting

(54). Tighten connection securely.

6

Snowplow Assembly Procedure

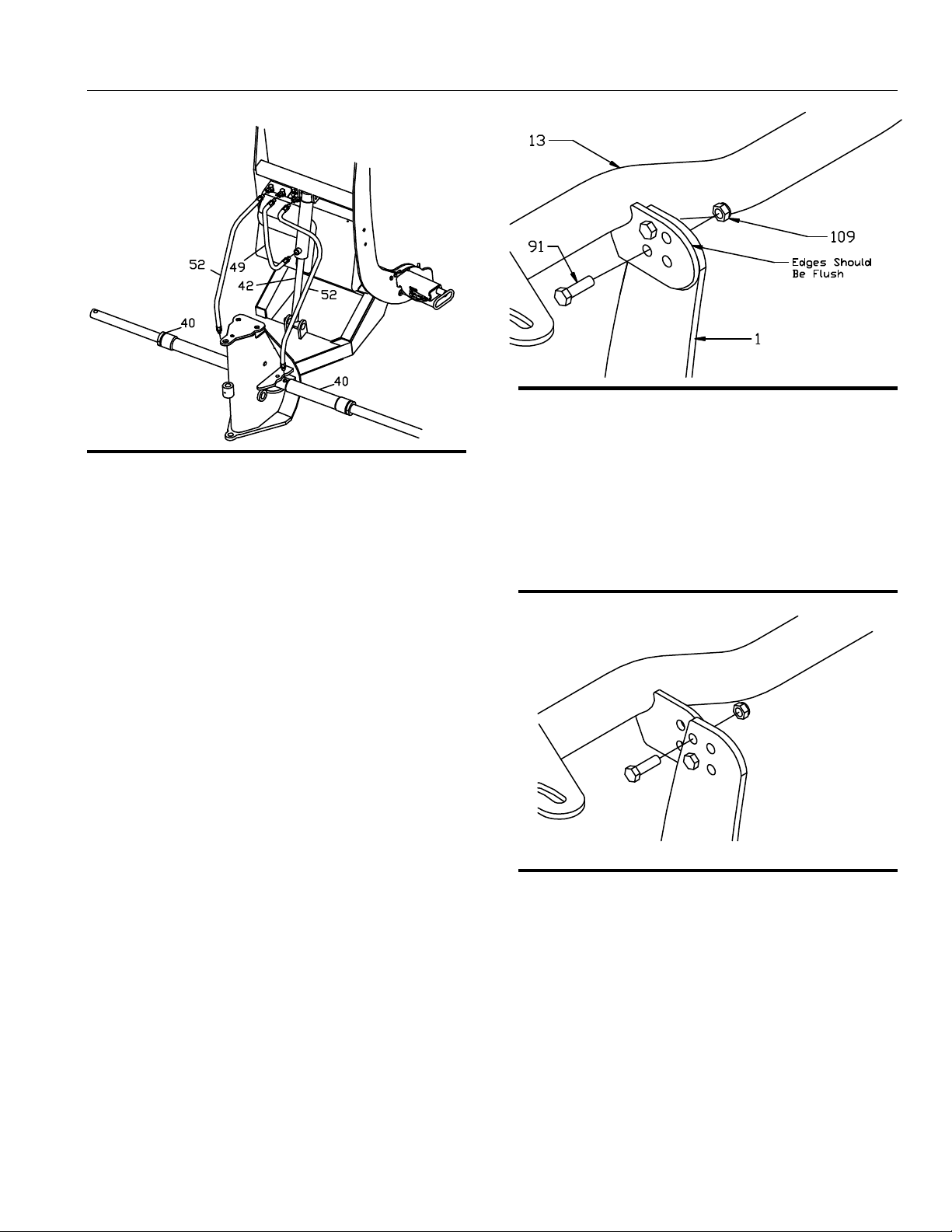

Figure 7. Assembly of Hydraulic Connections. G10013

24. Attach one end of Hydraulic Hose (49) to the

lower port of Lift Cylinder (42). Attach the

opposite end of Hydraulic Hose (49) to the center

Hydraulic Fitting (54). Tighten connection

securely.

25. Apply thread sealant compound (do not use

Teflon Tape) to the threads of the 3/8” MNPT end

of HYD07042 Hydraulic Hose (52). Thread the

hose into the port on Angle Cylinder (40) and

tighten securely.

Note: Do not apply thread compound to the ¼” end of

the hose.

Note: Do not get thread compound on the end of the

hose since the compound will contaminate the

hydraulic system.

26. Attach the loose end of HYD07042 Hydraulic

Angle Hose (52) to the corresponding fitting on

the hydraulic manifold. Tighten all hydraulic

connections securely.

Figure 8. Light Bar Assembly. (Standard) G10132

27. Attach Light Bar (13) to the top of Coupler

Assembly (1) using two Hex Head Cap Screws

(91) and Hex Head Self Locking Nuts (109).

Note: The light bar should be positioned as close to

the Coupler Tower as possible. Only two holes will be

aligned for normal installations. Only two bolts per side

are needed to secure the light bar.

Figure 9. Light Bar Assembly Adjustment. G10131

Note: Figure 9 illustrates that the Coupler Assembly

and Light Bar have two sets of 1 inch adjustment holes

for mounting on different vehicles. These adjustment

holes may be needed in order to move the light bar

away from the vehicle’s hood.

7

Snowplow Assembly Procedure

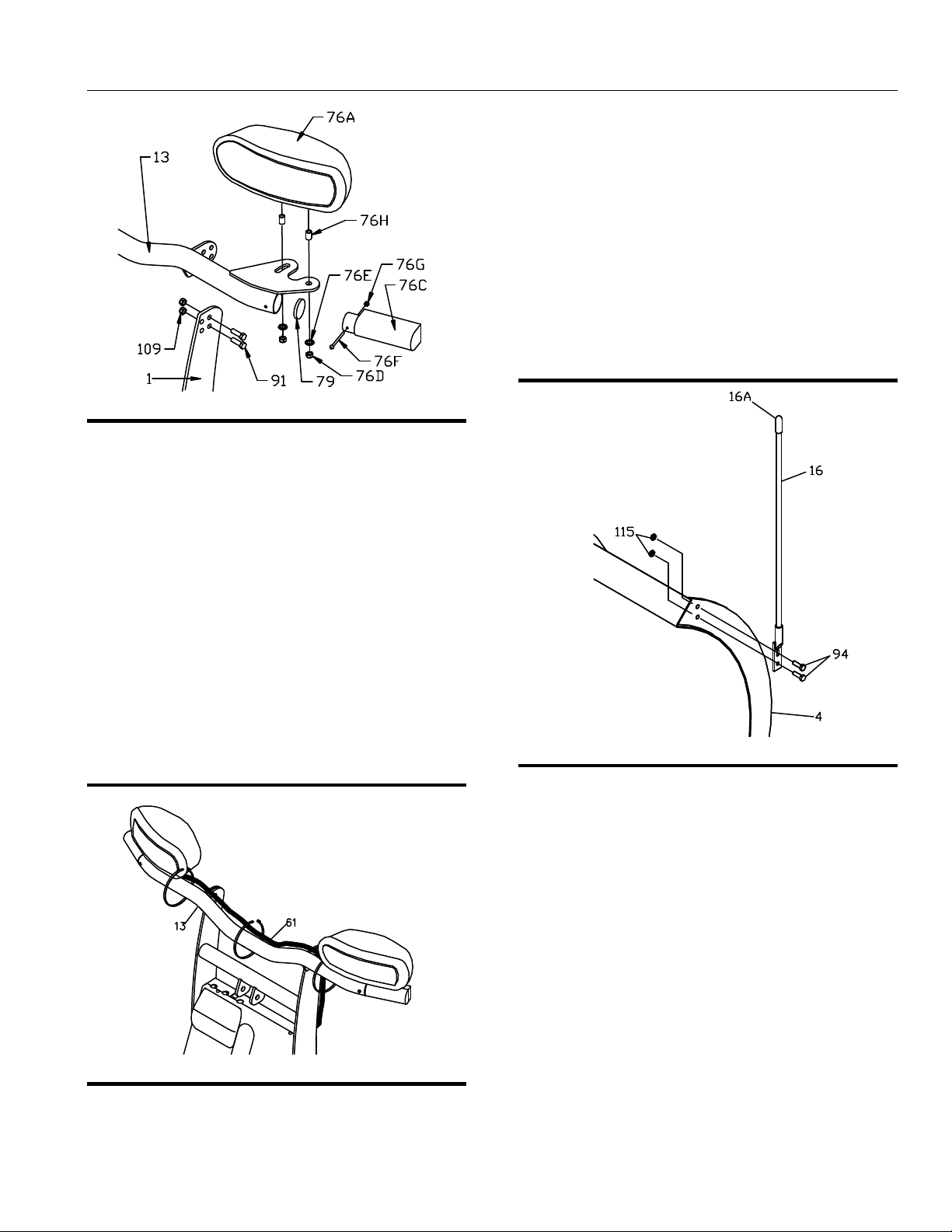

Figure 10. Headlight Mounting Assembly G10115

28. Insert Light Bar Seal (79) into the Light Bar and

seat it using the end of the Turn Signal (76C).

29. Attach Turn Signal (76C) into the end of Light Bar

(13) using one Machine Screw (76F) and Nut

(76G).

Note: Do not over tighten Machine Screw (76F).

30. Bolt Driver’s Side Headlight (76A) on to Light

Bar (13) using two bushings (76H), ½” Nuts

(76D) and ½” Star Washers (76E) as shown

above.

31. Repeat Steps 28 through 30 for Passenger’s

Side Headlight (76B) and Passenger’s Side

Turn Signal (76C).

33. Insert the unconnected ends of the Plow Wiring

Harness into the back of the coupler through

the rubber grommet.

34. Connect the Plow Side Wiring Harness to the

Hydraulic Valve Manifold as shown in Figure

26. HYD07044 with SmartHitch2TM Wiring

Diagram on page 18 of this manual.

Note: All wires need to be connected.

Note: The SmartHitch2TM switch is pre-wired from

the factory.

Figure 12. Assembly of Blade Guides. G10071

35. Attach Blade Guides (16) to Blade Assembly (4)

using Hex Head Cap Screws (94) and Self

Locking Nuts (115).

Figure 11. Secure Wiring Harness G10126

32. Secure Wiring Harness (61) to Light Bar (13)

as shown above.

8

Electrical System Wiring Procedure

Electrical System Wiring

Procedure

WARNING!

WARNING!

WARNING!WARNING!

Before starting any Electrical Wiring Procedure

make sure that the engine is not running and that

the engine has had sufficient time to cool down.

Failure to do so may result in serious bodily injury

or death.

WARNING!

WARNING!

WARNING!WARNING!

Before starting any Electrical Wiring Procedure

make sure to disconnect the battery. Failure to

do so may result in serious bodily injury or death.

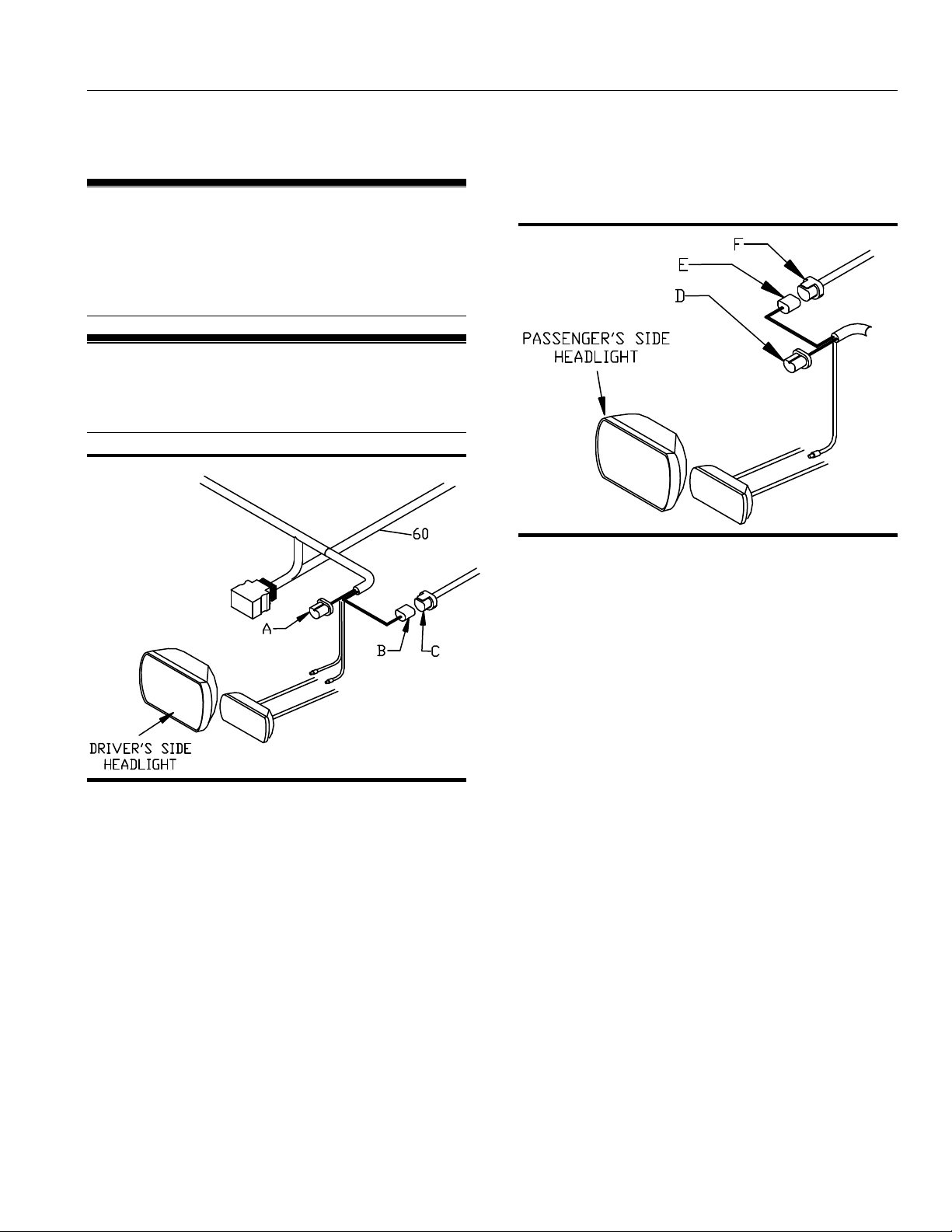

Figure 13. Driver’s Side Headlight G10140

Note: Dielectric grease should be applied to all

electrical connections.

1. Disconnect the driver’s side headlight connector

plug (C) from the back of the driver’s side vehicle

headlight.

2. Connect the Blue Sealed Beam Connector (A)

from Wiring Harness (60) into the back of the

driver’s side vehicle headlight.

3. Connect the Black Rubber Connector (B) from

Wiring Harness (60) into the OEM Wiring Harness

(C). OEM Wiring Harness (C) is the vehicle

connector that was unplugged from the back of

the headlight in Step 1.

Note: If your connectors do not match the connectors

on the wiring harness or you have a four-headlight

system a Headlight Adapter Kit will be needed. If you

are installing a Headlight Adapter Kit, See “Headlight

Adapter Installation Procedure” located in this manual.

Figure 14. Passenger’s Side Headlight G10141

4. Disconnect the passenger’s side OEM Wiring

Harness (F) from the back of the passenger’s side

vehicle headlight.

5. Connect the Blue Sealed Beam Connector (D)

from Wiring Harness (60) into the back of the

passenger’s side vehicle headlight.

6. Connect the Black Rubber Connector (E) from

Wiring Harness (60) into the OEM Wiring Harness

(F). OEM Wiring Harness (F) is the vehicle

connector that was unplugged from the back of

the headlight in Step 4.

9

Electrical System Wiring Procedure

NOTICE

Before splicing into any electrical circuit, identify

the circuit with a test lamp. Failure to test circuits

may result in vehicle damage.

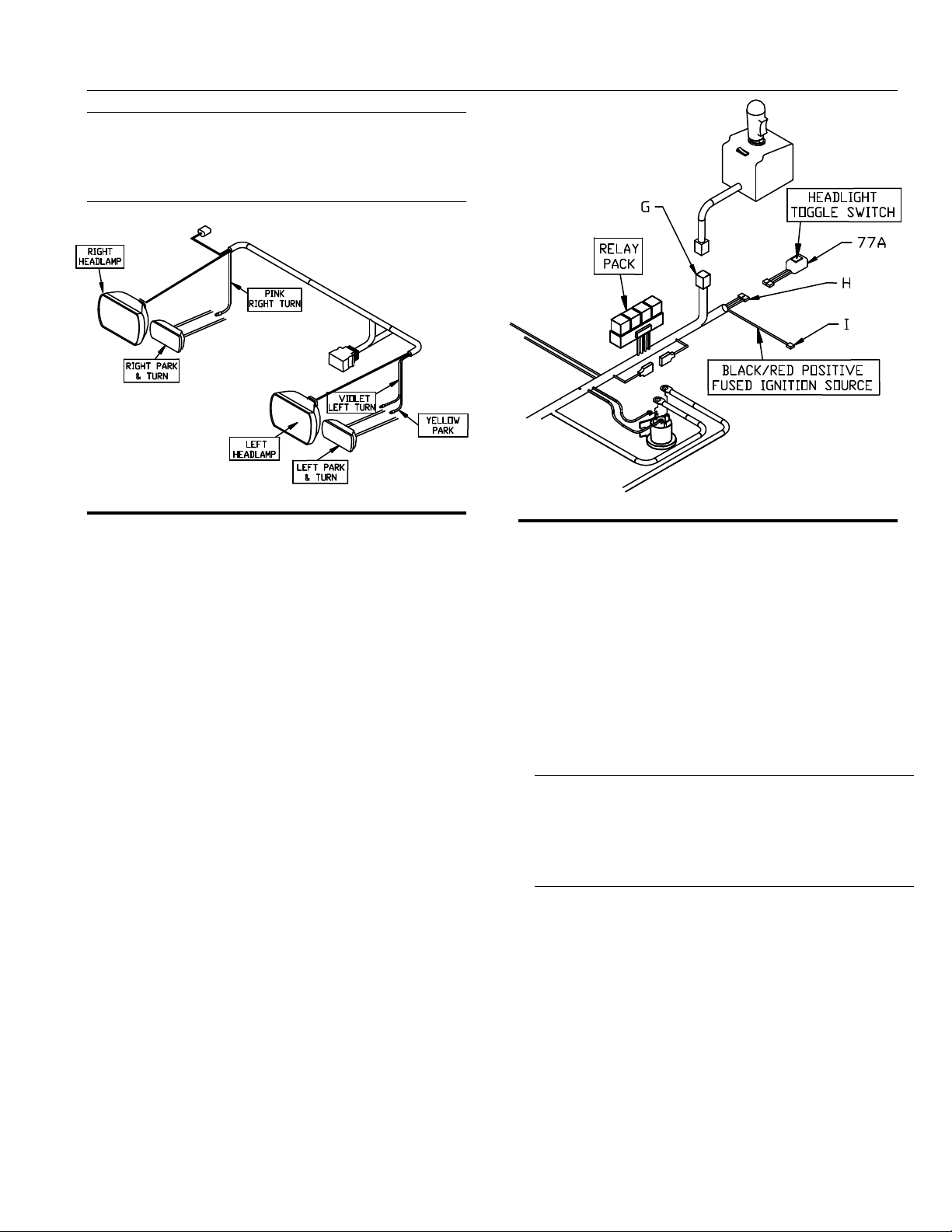

Figure 15. Connecting Park and Turn G10143

Note: Some trucks require a turn signal relay kit.

7. Connect the PINK wire from Wiring Harness (60)

to the passenger’s side turn signal wire. Use the

splice connector provided to you in the hardware

kit.

8. Connect the VIOLET wire from Wiring Harness

(60) to the driver’s side turn signal wire. Use the

splice connector provided to you in the hardware

kit.

9. Connect the YELLOW wire from Wiring Harness

(60) to the driver’s side park light wire. Use the

splice connector provided to you in the hardware

kit.

Note: Be sure that the firewall is clear of obstructions

before drilling in Step 10.

10. Drill a 1-1/4" diameter hole through the firewall.

The hole should be located on the driver’s side, in

an easily accessible area.

Figure 16. Internal Cab Wires G10144

11. Pull the two BLACK wires (H), BLACK/RED wire

(I), and the 9 Pin Molex connector (G) from the

engine compartment into the cab through the

1-1/4” diameter hole in the firewall.

12. Install MSC03761 Split Rubber Grommet (Not

Shown) into the hole that was cut in the firewall.

13. Connect the Two Tab Connectors (H) to

MSC04747 Headlight Toggle Switch (77A) as

illustrated in the figure above.

NOTICE

Position the switch where it will not interfere

with driver’s ability to see and where it will not

affect the driver’s ability to operate the motor

vehicle.

14. Choose an area of the vehicle’s dashboard for the

light toggle switch to be mounted. Clean the area

thoroughly. Allow the area to dry completely.

15. Remove the adhesive backing and apply the

switch to the clean area of the dashboard. Apply

pressure for 30 seconds.

10

Loading...

Loading...