Page 1

CONTENTS

Contents.............................................................................................................................................1

Safety Information.............................................................................................................................2

Electrostatic Discharge Sensitive (ESDS) Device Handling .........................................................2

Theory of Operation..........................................................................................................................3

Figure 1: PS1 signal flow Diagram....................................................................................................3

Theory of Operation.................................................................................................................... 4-26

Figure 2. Personalized Amplification System

Figure 3. Powerstand Input and Output Connections .......................................................................5

Figure 4. R1 Remote Control ............................................................................................................5

Figure 5. DSP Functional Block Diagram .........................................................................................7

Figure 6. DC Power Supply Block Diagram ......................................................................................7

Table 1. Adjustable Controls: Gain range and nominal settings ...................................................... 12

Table 2. Nominal and Peak Signal Levels .......................................................................................13

Table 3. LED Trigger Levels ............................................................................................................14

Figure 7. Nominal Bass Configuration, 2 Bass Modules ................................................................14

Figure 8. Light Bass configuration ..................................................................................................15

Figure 9. External power stand, total of 4 bass modules ................................................................15

Figure 10. “Heavy” Bass, total of 8 bass modules ..........................................................................16

Table 4. Ideal and actual bass EQ gains.........................................................................................16

Table 5. EQ lookup table for all operational modes.........................................................................17

Table 6. Peripheral pins on the microcontroller ...............................................................................22

Figure 11. PS1 Tone Control Range ...............................................................................................24

Test Procedures ........................................................................................................................ 27-31

PS1 Power Stand Tests...................................................................................................................27

Line Array Tests...............................................................................................................................30

Bass Module Tests ..........................................................................................................................31

Appendix .................................................................................................................................... 32-48

PS1 Power Stand Software Update Procedure ............................................................................32

PS1 Power Stand Test Cables .................................................................................................. 33-34

1. Amplifier Output Test Cable .......................................................................................................33

2. XLR Microphone Input Test Cable .............................................................................................34

3. Line Input 1/4” Phono Jack Test Cable ......................................................................................34

4. Insert Jack Test Cable.................................................................................................................34

5. L1 Line Array Test Cables...........................................................................................................35

6. Bass Module Test Cable .............................................................................................................35

IC Diagrams ............................................................................................................................... 36-48

TM

Components ...........................................................4

CAUTION: The Bose® Personalized Amplification SystemTM contains

no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on schematics

or by special notes on the parts list. Use only replacement parts that have critical characteristics

recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed parts are

acceptably insulated from the supply circuit before returning the unit to the customer.

Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug the AC line cord

directly into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a

leakage current tester or a metering system that complies with American National Standards

Institute (ANSI) C101.1 "Leakage Current for Appliances" and Underwriters Laboratories (UL)

6500 / IEC 60056 paragraph 9.1.1. With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe, conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket, metal cabinet, screwheads, metallic

overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not exceed 0.5 milliamp. Reverse the unit

power cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and connect a jumper

wire between the two prongs of the plug. (2) Turn on the power switch of the unit. (3) Measure

the resistance with an ohmmeter between the jumpered AC plug and each exposed metallic

cabinet part on the unit. When testing 3 wire products, the resistance measured to the product

enclosure should be between 2 and infinite MOhms. Also, the resistance measured to exposed

input/output connectors should be between 4 and infinite MOhms. When testing 2 wire products,

the resistance measured to exposed input/output connectors should be between 4 and infinite

MOhms. If it is not within the limits specified, there is the possibility of a shock hazard, and the

unit must be repaired and rechecked before it is returned to the customer.

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap or plastic trays.

2

Page 3

THEORY OF OPERATION

Figure 1: PS1 signal flow Diagram

3

Page 4

1. Power Stand PS1

1.1 Overview

THEORY OF OPERATION

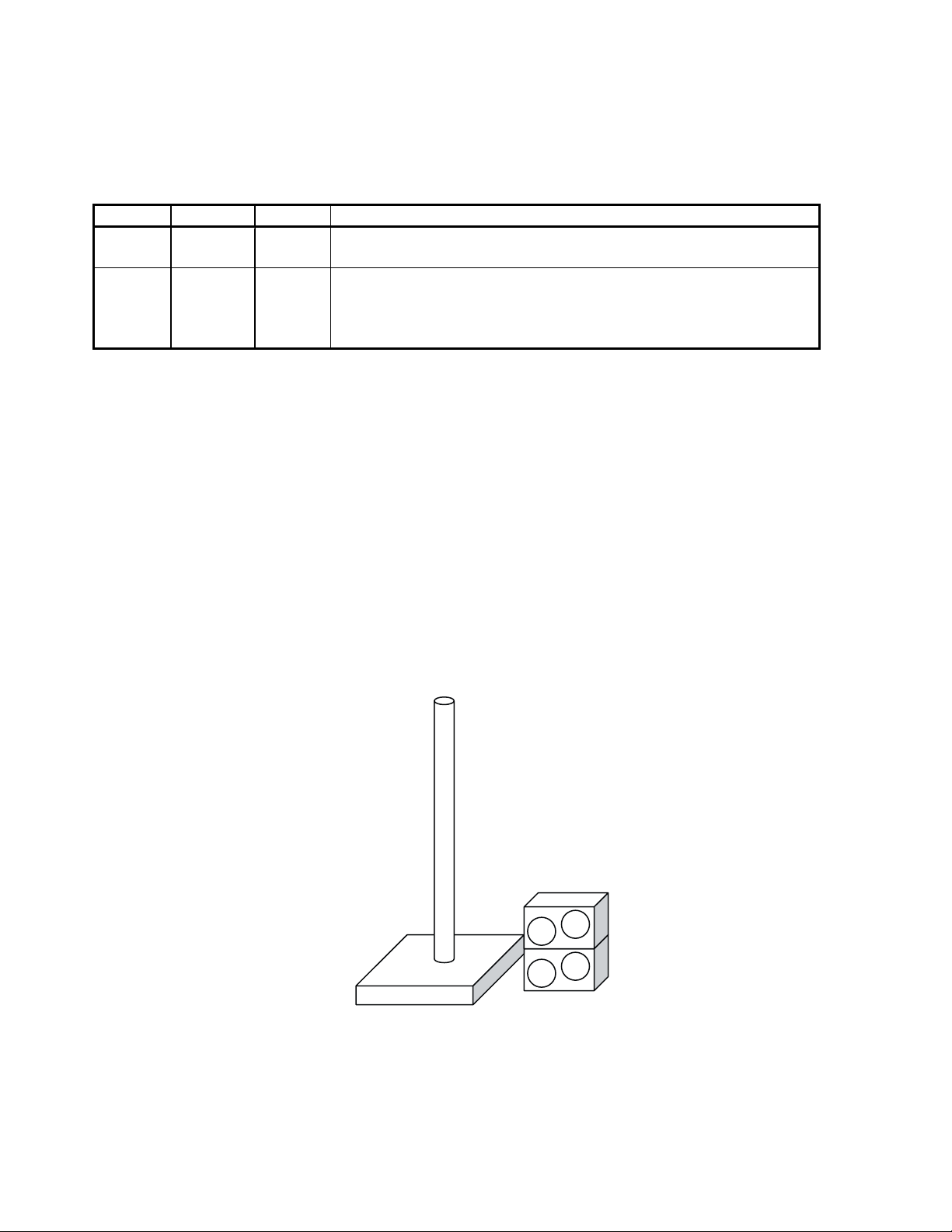

The Personalized Amplification

TM

System is essentially a Natural Amplification sound system,

with the following components:

PS1 Powerstand, L1 line array, R1 remote control, B1 bass loudspeaker, AC power cord, remote

control cable, loudspeaker cable (refer to figure 2 below).

R1 remote

control

PS1 power stand

Remote

control cable

AC power cord

B1 bass module 4-wire cable (blue)

Upper and Lower L1 Cylindrical

Radiator™ loudspeaker

B1 bass module

Figure 2. Personalized Amplification System Components

The system has the following features:

• All signal processing performed with DSP

• Remote control

• The ability to receive analog signal input and SPDIF digital signal input

• The ability to output analog signal and SPDIF digital signal.

• Channel volume control

• Master volume control

• Mixer

• Tone control

• 100 sets of parameter equalizer

• System equalizer for compensating speaker characteristic

• Noisegate

• Limiter

• Clip indicator

• DSP software update and 100 sets of preset coefficients update

• Power protection and amplification protection

4

Page 5

THEORY OF OPERATION

The system delivers 250W of output power for each of the three amplifiers housed in the power

stand. The system uses a 110V / 230V AC power supply, and has a 1M ohm input impedance at

the audio Ch1/Ch2 line input connector and 1.25k ohm input impedance at the audio Ch1/Ch2

MIC connector. Input signal headroom is 2.1Vrms max. A user could operate the system from

the input panel and the remote (refer to figures 3 and 4).

Channel 1/2

U

nbal

U

nbal

Channel 3/4

Power amp patch, bass, remote and AC power connections

TRS

Bal/U

nbal

Figure 3. Powerstand Input and Output Connections

A

C

ommercia

udi

®

o Produc

917D

l

t

CH1

-12 +12 -12 +12

0

-12 +12

0

-12 +12 -12 +12

0 12

R1 remote control

Figure 4. R1 Remote Control

5

HIGH

MID

LOW

LEVEL

MASTER

0 12

CH2

00

0

-12 +12

0

0 12

SIG / OLSIG / OL

Page 6

THEORY OF OPERATION

Note: Refer to PS1 Power Stand schematic sheets in the service manual, reference number

264018-SM, for the following information. The information inside the brackets [ ] is the

component’s grid location on the schematic sheet.

The PS1 Power Stand combines the traditional functions of a mixer, digital controller (system

EQ and limiter), power amplifier and mechanical speaker stand. Figure 1 on page 3 shows the

signal flow through the power stand.

The power stand consists of five parts: a switching power supply, 3 channels of amplification on

a common PCB, and input panel PCB, DSP PCB, and MCU PCB. The power supply connects to

the MCU PCB via a the 8 pin connector CN409 [microprocessor PCB sheet 2, A1], four channels of analog inputs on the panel are connected to the DSP PCB via a 6 pin connector CN104

[DSP PCB sheet 1, B1], analog output signals on the DSP panel are connected to input panel

via a 3 pin connector CN115 [input panel PCB sheet 2, D1]. SPDIF IN on the input panel is

connected to the DSP PCB via a 2 pin connector CN112 [DSP PCB sheet 2, B4], SPDIF OUT

on the DSP PCB is connected to input panel via a 2 pin connector CN113 [DSP PCB sheet 2,

C8].

For Channel 1 or 2 the signal is input either through the balanced XLR connector or through the

¼” unbalanced connector. The ¼” connector has a very high impedance (900k ohms) to allow

direct connection of passive guitars or bass guitars. The signal is then amplified by the adjustable pre-amplifier. After the pre-amplifier, the signal can be accessed at the balanced XLR line

level output.

Next the signal is routed through a digitally controlled analog volume control. Then, the signal is

routed through the insert loop connector. If there is no plug in the insert jack, the signal will be

routed through. Otherwise the signal will be routed to the “ring” of the connector and is expected

to return from the “tip”. The signal is then digitized in the A/D converters and processed in

software. Software provides the following functions.

• Channel 1&2: measuring level for LED

• Channel 1&2: noise gate

• Channel 1&2: preset EQ

• Channel 1&2: channel volume

• Sum channels 1 to 4

• Master Volume Control

• System EQ and crossover (for L1 and B1)

• Limiter & soft clipper (for L1 and B1 amplifiers)

Signal Processing

Signal processing is mainly implemented by the DSP and includes the following functions:

• Noisegate & limiter

• Tone control & volume control

• Parameter equalize & System equalizer

• Clip calculate

The signal flow chart is as follows (refer to figure 1):

6

Page 7

THEORY OF OPERATION

t

DSP Processing Block Diag

Remote

Ch1/2 Preset

Ch1 In

Ch2 In

L

S-DATA Out

(to SPDIF)

R

Ch 3 In

Ch 4 In

User EQ Preset EQNoiseGate

User EQ Preset EQNoiseGate

Sys. EQ+X-Over, Hi

Limiter

Knee=+1.5dBV

Sys. EQ+X-Over, Lo Limiter

Master Vol. Range: -80 to +22dB (+10 @ 12:00)

Hi Out

Bass Ou

Figure 5. DSP Functional Block Diagram

Power supplies

To ensure that the system operates normally, the system must be supplied with seven different

voltage levels, +3.3V, +5V, +15V, -15V, +24V, +27V, and -27V. Refer to the block diagram below.

Figure 6. DC Power Supply Block Diagram

7

Page 8

THEORY OF OPERATION

110V AC is changed to about 300V DC, after passing through the EMI filter and the Diode

Bridge. Then, the voltage signal is divided two ways: one DC voltage goes through the switch

control & auxiliary circuit1 again, enters into the transformer primary1. The transformer1 has five

secondary windings, the first outputs +24V DC (for the input panel), the second outputs +15V

DC (for A/D, D/A buffer circuit), the third outputs –15V DC (for A/D, D/A buffer circuit), the fourth

outputs +5V DC (for MCU and other ICs), the fifth outputs +3.3V DC (for DSP, A/D & D/A IC).

Another DC voltage goes through the switch control & auxiliary circuit2 and enters into transformer primary2. The transformer1 has two secondary, the first outputs -27V DC (for AMP), the

second outputs +27V DC (for AMP).

Operation of the all voltage switching regulator is more complicated. The load of +3.3V is the

heaviest, so we get this +3.3V as feedback a signal and send it to the switch control & auxiliary

circuit1. When the system works, if +3.3V happens to waver, switch control & auxiliary circuit1

will change ‘open’ and ‘close’ time of switch circuit to regulate the transformer primary1, accordingly, the voltage of transformer1 secondary will keep stable. Of course, in this way, the effect of

stabilization for +3.3V is best, and that for other voltage is worse.

The regulation of the power supply for AMP is like this: we get the +27V as feedback signal and

send it to switch control & auxiliary circuit2. When system works, if +27V happens to waver,

switch control & auxiliary circuit2 will change ‘open’ and ‘close’ time of switch circuit to regulate

the transformer primary2, accordingly, the voltage of transformer2 secondary will keep stable.

When the system works, +5V can supply 100mA to MCU PCB, +3.3V can supply 260mA to

DSP PCB, +15V can supply 200mA to DSP PCB, -15V can supply 150mA to DSP PCB, and the

+24V can supply 50mA to the Input Panel PCB.

Microcontroller

A microcontroller on the MCU PCB is used for the following control functions:

• Relay DSP information to Remote

• Relay Remote information to DSP

• Control channel volume IC

• Check channel preset switch

• Check bass send state

• Check power & amplification protection

• Check the number of bass speaker

• Indicate current system working status with a three color LED

These functions are explained in detail on the next page.

8

Page 9

THEORY OF OPERATION

Relay DSP information to Remote

The DSP needs to transfer the clip state, channel volume data (cause the table for channel

volume in the DSP), and the system working status to the MCU. The communication adopts

software simulation UART, with two I/O pins as RX and TX. The communication rate is 4800bps,

add a start bit and stop, so every sending byte has 10 bits. Data is sent according to frame

format: frame head | every data | check sum. DSP will transfer a frame every 100ms, and every

sending will take about 15ms.

The MCU needs to transfer the clip state to the Remote. The communication adopts hardware

UART. Communication rate is 9600bps, Data is sent according to the MIDI protocol: MIDI channel number | MIDI parameter type | MIDI parameter value. The DSP will transfer a frame data

every 100ms, and every sending will take about 3.5ms.

Relay Remote information to DSP

The remote needs to transfer the Ch1EQHi, Ch2EQHi, Ch1EQMi, Ch2EQMi, Ch1EQLo,

Ch2EQLo, Ch1Volume, Ch1Volume, and the MasterVolume to MCU. The communication adopts

hardware UART. Communication rate is 9600bps, Data is send according to MIDI protocol: MIDI

channel number | MIDI parameter type | MIDI parameter value. DSP will transfer a frame data

every 100ms, and every sending will take about 30ms.

The MCU needs to transfer the Ch1EQHi, Ch2EQHi, Ch1EQMi, Ch2EQMi, Ch1EQLo,

Ch2EQLo, Ch1Volume, Ch1Volume, MasterVolume, Ch1Preset, Ch2Preset, BassChk, and the

CheckSum to the DSP. The communication adopts software simulation UART, with two I/O pin

as RX and TX. Communication rate is 4800bps, add start bit and stop, so every sending byte

has 10 bits. Data is send according to frame format: every data | check sum. DSP will transfer a

frame every 100ms, and every sending will take about 30ms.

Control channel volume IC

Because the design requires that the channel signal could change from –40dB to 0dB, we use a

volume control IC. There are three pins used to control the volume control IC: CLK, DATA, STB.

CLK, DATA and the STB time sequence is implemented by software.

Check channel preset switch

In the audio processing, there is a parameter equalizer, and the system supplies 100 sets of

coefficients for this function. A user could choose a different coefficient to get different sound

effects. This channel preset switch is a user interface to provide the function for choosing a

different coefficient.

Check bass send state

There is a bass-line out plug on the input panel. Through this plug, the system can connect to

additional power stands to drive additional bass modules. The bass send state only has two

logic states “0” or “1”, indicating unconnected and connected. Different states will choose different coefficients for the limiter and the system equalizer.

Check power & amplification protection

When the power supply and amplification have a problem, the system will indicate this to the

user by an LED on the input panel. The power & amplification protection signal also only has two

logic states “0” or “1”, indicating unprotected and protected.

9

Page 10

THEORY OF OPERATION

Bass module sensing circuitry

On the bass connector, there are four pins. 1+ and 1- outputs bass signal, 2+ and 2- is used to

check the number of bass modules connected to the power stand. When there is no bass

module connected, the resistance value between 2+ and 2- is greater than 10k ohms, when one

bass module is connected to the power stand, the resistance between 2+ and 2- is equal to 10k

ohms, when two bass modules are connected, the resistance value between 2+ and 2- is equal

to 5k ohms, when there are more than two bass loudspeakers, the resistance value between 2+

and 2- is less than 5k ohms. Once the system detects how many, if any bass modules are

connected to the power stand, it will adjust the output level and the EQ accordingly to provide

the proper outputs for that configuration.

System Status LED

On the input panel PCB, there is a three color LED. The different colors of this LED represent

different operating conditions for the power stand.

• Green: operating normally

• Green blink fast: updating software or preset

• Green blink slowly: software update success

• Red blink slowly: software update failure

• Orange: power or amplification protection enabled (fault condition)

Codec

In the system, there are five codec ICs: U386 (for Ch1 & Ch2 A/D), U385 (for Ch3 & Ch4 A/D),

U387 (for line & bass D/A) [DSP PCB sheet 1, B/C/D5], U431 (for SPDIF IN) [DSP PCB sheet 2,

D3], U435 (for SPDIF OUT) [DSP PCB sheet 2, B6].

U386, U385, U387, U431, and U435 include the following functions:

• U386: Two channels of 24-bit ADC, one for Ch1 analog input and one for Ch2 analog input.

The ADC will input signal levels in levels in excess of 2Vrms. Master mode.

• U385: Two channels of 24-bit ADC, one for Ch1 analog input and one for Ch2 analog input.

The ADC will input signal levels in levels in excess of 2Vrms. Slave mode.

• U387: Two channels of 24-bit DAC, one for Line analog output and one for Bass analog

output. Maximum output signal level is 2Vrms. Slave mode.

• U431: Two channels of 24-bit digital audio interface receiver.8:2 S/PDIF Input MUX, AES/

SPDIF input pins selectable in hardware mode.

• U435: Two channels of 24-bit digital audio transmitter. Output Ch1/Ch2 input signal. Slave

mode.

• A crystal oscillator which establishes the ADC/DAC/SPDIF OUT sampling rate, in this case,

it is 12.288MHz / 256 = 48KHz.

• SPDIF IN sampling rate is the same as playing frequency, generally 44.1KHz.

• U386, U385, U387, U431, U435: Standalone Hardware mode.

• Word rate clock for the audio data on the SDOUT pin. Frequency will be the sample rate.

• Serial bit clock for audio data on the SDOUT pin.

• a serial bit stream containing the 24-bit audio data.

• U386, U385: 3-wire serial digital output port, U387: 3-wire serial digital input port,

• U431: 3-wire serial digital output port, U435: 3-wire serial digital input port. I

data output/input these ports.

In addition, the timing of the data flow into and out of the DSP is driven by the codec.

The serial ports on the DSP run asynchronously to the 30MHz clock which drives the

DSP.

2

S format digital

10

Page 11

THEORY OF OPERATION

DSP

The DSP, U461 [DSP PCB sheet 3, B4] is an Analog Devices 21065L general purpose floating

point digital signal processor. There are two of these DSP ICs used in the system. Each is

capable of about 40MIPs of performance. The DSPs are mainly used to process sound effects.

They provide:

• Two channels noise gate

• Two channels tone control

• Two channels clip calculate

• Two channels parameter equalizer

• Four channels mixer

• Two channels system equalizer

• Two channels limiter

The DSPs have no internal ROM, at boot time they load themselves from the external FLASH

U462 [C7]. This boot process is more or less automatic, no intervention from the microcontroller

is required.

The signal required to connect the DSPs to the boot FLASH include:

• An external data address bus (24 bits, of which 18 are used)

• An external data bus (32 bits, of which 8 are used)

• Bus control signals

Finally the signals are brought out through a D/A stereo converter. The “left” channel contains

the signal for the L1, the “right” channel the signal for the bass module. The L1 signal is routed

to power amps 1 and 2, the B1 signal to power amp 3. The B1 signal is also available as a

balanced signal at the “Bass Line Out” TRS connector.

Each power amp has an external input that replaces the signal from the D/A converter when a

plug is inserted. In addition there is an “All Amps In” input that replaces the input signal to all 3

power amps when inserted. Individual inputs take precedence over the “All Amps Input”. Each

power amp output is available through a Neutrik

nally the outputs of power amp 1 and 2 are routed to a Molex connector in the base of the

power stand which connects to the L1s when inserted. Power Amp 1 gets routed to the upper L1

and power amp 2 to the lower L1.

®

Speakon® connector at pins 1+ and 1-. Inter-

11

Page 12

1.2 Gain Specifications

THEORY OF OPERATION

1.2.1 Purpose and Philosophy

The purpose of this specification is to define all relevant gain levels in the Bose

Amplification System™ Power Stand and to specify procedures, for how these gains can be

measured.

We’ll do this primarily by specifying a “nominal” level at each point. The “nominal” level represents the desired operating point. This is the level where we anticipate that the bulk of operation

occurs. Wherever warranted we will also do a headroom analysis in order to specify or derive

the maximum acceptable level before a stage clips or overloads.

The gain structure is designed in a way so that there is one point that handles the main system

constraint. This point is the digital limiter inside the DSP. If all levels are “nominal” the system

should just reach full output, the digital limiter should just be starting to work and all other

analog signals (except for the power amp, off course) should still have reasonable amounts of

headroom. This design allows controlling the high-signal behavior of the system completely in

software through the digital limiter and still offers good signal-to-noise properties.

1.2.2 Gains and Signal Levels

First, we need to define some reference levels for all the adjustable controls in the system. For

the “nominal” signal levels, we assume certain settings in those controls, and define the gain of

each adjustable section.

®

Personalized

Control Gain Range Nominal Comment

TRIM –

Microphone

PreAmp

TRIM –Line

PreAmp

Ch1, Ch2

Volume

(Remote)

Master

Volume

(Remote)

Next we define all the nominal signal levels for full power output. All signal levels are specified in

dBV unbalanced unless otherwise noted. All levels in front of the DSP can be measured as such

directly. The post-DSP peak output levels can only be observed when the limiter is switched off.

+8dB to +50dB

(XLR Balanced Input)

-12dB to +30dB (1/4”

Unbalanced Input)

-40dB to 0dB -10 dB @

-80dB to +22dB +10 dB @

Table 1. Adjustable Controls: Gain range and nominal settings

+21dB @

Pot center

+1dB @

Pot center

Pot center

Pot center

Center vs. Max/Min dependent on

Pot taper.

Center vs. Max/Min dependent on

available Pot tapers.

Adjustment range is restricted and

log taper is implemented by a lookup table, in order to make this a

usable control.

Adjustment range is defined and log

taper is implemented by a look-up

table, in order to make this a usable

control.

12

Page 13

THEORY OF OPERATION

Point Nominal Peak Comment

Line In, Trim

@ Max

Line In, Trim

@ 12:00

Line In, Trim

@ min

Mic., Trim @

max

Mic., Trim @

12:00

Mic., Trim @

min

Ch1, Ch2

Line out XLR

Dig. Vol.

Control, input

Dig. Vol.

Control,

output

Insert Send -10 dBV +8dBV,

Insert Return -10 dBV +6dBV Assumes FX device in loop is set for unity gain

A/D input -10 dBV +4.5dBV Assumes max voltage at the A/D = +6dBV=0dBFS,

D/A output 0 dBV +4.5dBV

Bass Out 0 dBV 0/+4.5dBV

Amp In 0 dBV 0 dBV Nominal levels throughout the system are

Amp Out 30 dBV 30 dBV This is maximum output at clip level ~250W

-30dBV unbal

-1dBV dBV

un-bal

+12dBV un-

bal

-50 dBV

balanced

-21 dBV

balanced

-8 dBV

balanced

+6 dBV

balanced

0 dBV +18dBV

-10 dBV +18dBV The nominal gain setting here is -10dB for the

- 12 dBV Ch1 / Ch2 Vol. + Master @ 12:00. Maximum input

limited by input INA163 output clipping.

+17 dBV Ch1 / Ch2 Vol. + Master @ 12:00. Maximum input

limited by input INA163 output clipping.

+18 dBV Ch1 / Ch2 Vol. + Master @ 12:00. Maximum input

limited by input Buffer.

-32 dBV

balanced

-3 dBV

Balanced

+10dBV

balanced

+24 dBV

balanced

+18dBV

(debug)

0dBV

(normal)

+6/10.5bal

Table 2. Nominal and Peak Signal Levels

This nominal = the output level of a Shure SM58

microphone that is exposed to 104 dBSPL.

This nominal = the output level of an AKG C4000

microphone that is exposed to 120 dBSPL.

volume control +20 max out assumes Volume @

Max. (+10 max)

Peak @ 12:00 / Max Volume. Nominal is

conservative but should also work well for cheap

stomp boxes

Peak limited by A/D input overload.

D/A output filter gain = -1.5dB

The total excess gain in the DSP will be 16 dB, with

a nominal setting of +10dB. Again we assume

0dBFS = +6dBV. It is the responsibility of the digital

limiter to ensure that power amp does not clip, i.e.

that the output will not exceed 0 dBV

Limiter engaged (normal operation) / Debug

Bass Out can be used Balanced / Un-balanced

referenced to full output power, so nominal & peak

are the same

@ 4 ohms

The minimum input level that would allow the system to reach full output (with all gain controls

all the way up) is -72 dBV. This is the output level of a Shure SM58 being exposed to about 78

dB SPL and should be sufficient for almost any application.

This gain scaling puts the main responsibility for the high-signal performance of the system on

the digital limiters. The limiters need to make sure that the output never exceeds 0dBV. The extra

6 dB headroom in the DSP can be used to compensate for gain variance in the power amp and

to allow the DSP to overdrive the power amps for very short periods of time. It may turn out,

that, for certain instruments, this will be required to achieve maximum SPL at acceptable sound

quality.

13

Page 14

THEORY OF OPERATION

1.2.3 LED Trigger Level

The system has also two signal/clip LED indicators. The signal LED should turn on as soon as

the level reaches -30 dB versus nominal level and the clip LED should light at +6 dB versus

nominal level.

Control Signal Clip Comment

Input

LED

Remote

LED

1.3 Auto-detection, Operational Modes and Debug Mode

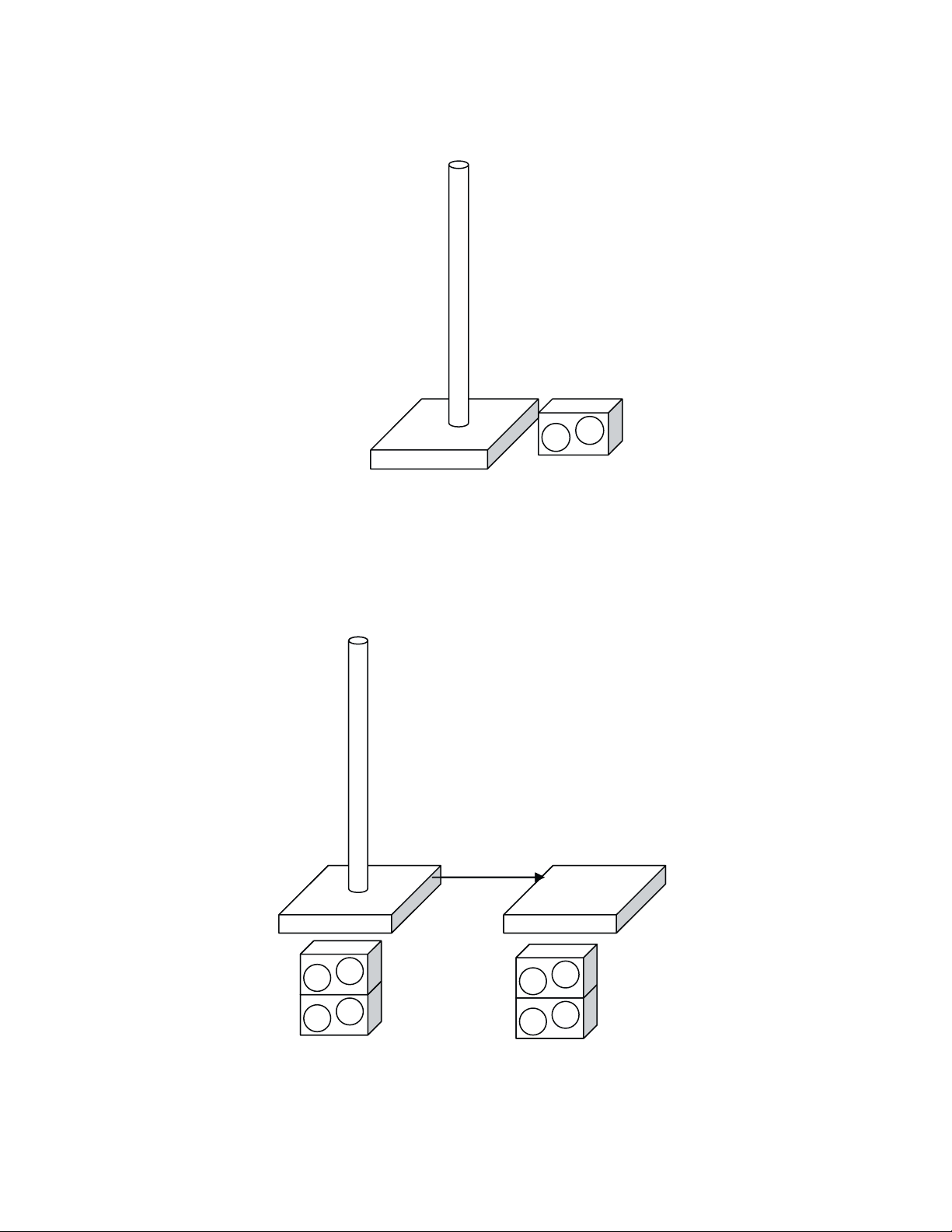

1.3.1 Rational and Operational Modes

The system can be set up in a variety of different bass configurations. There is some concern,

for example, that a system consisting of a power stand, 2 line arrays and 2 bass modules may

not produce enough bass output for (e.g.) bass players or a kick drum. To this end we have

provided the “Bass Send” output on the power stand that can be connected to the “All Amps In”

input of a second power stand. That second power stand does NOT have any line arrays connected but can drive between 1 and 6 additional bass modules. Figures 7-10 show typical

configurations.

-30 dBV +6 dBV At Mic/Line PreAmp Output. All levels unbalanced (at internal

measurement points)

-40 dBV -4 dBV At A/D input. This corresponds to -46 dBFS and -10 dBFS

respectively. There is 10 dB headroom between the clip

indicator coming on and the point where the A/D would

actually clip

Table 3. LED Trigger Levels

Nominal

Figure 7. Nominal Bass Configuration, 2 Bass Modules

14

Page 15

THEORY OF OPERATION

Light Bass

Figure 8. Light Bass configuration

External Power Stand

External Power Stand

With 2 Bass Modules

With 2 Bass Modules

Bass

Bass

Send

Send

All Amps

All Amps

In

In

Figure 9. External power stand, total of 4 bass modules

15

Page 16

THEORY OF OPERATION

External Power Stand

With 6 Bass Modules

Bass

Send

Figure 10. “Heavy” Bass, total of 8 bass modules

Ideally, at low levels all bass configurations should produce the same spectral balance, and the

main difference between the “light” system and the “heavy” system should be that the “heavy”

system can produce 18dB more SPL before the limiter kicks in.

If we label the system with 2 bass modules “nominal” and assign it a relative level of 0dB, we

would have to apply the following gains to achieve equal spectral balance.

All Amps

In

Total number

of bass modules

2 0 dB 0 dB

1 +6dB +6dB

4 - 6 dB -6 dB

6 -9.5 dB -6 dB

8 -12 dB -6 dB

Table 4. Ideal and actual bass EQ gains

Unfortunately, the first power stand (which provides the EQ and gain for all bass signals) has no

way of knowing how many bass modules are connected to the second external power stand and

currently there is no user interface that would allow the user to specify that in any way. Therefore, we have chosen to implement a constant drop of -6 dB whenever something is connected

to the bass send output. This will work perfectly for the first 3 cases in Table 5, but lead to excessive bass in the last 2 cases. The amount of excess bass is 3.5dB for 6 bass modules and 6dB

for 8 bass modules. Given the fact that the user probably wants lot of bass in these configurations, the excess bass is deemed acceptable.

Ideal EQ Gain Actual EQ Gain Comments

16

Page 17

THEORY OF OPERATION

EQ

1.3.2 Implementation

The power stands detects:

a) The number of bass modules B1 connected to “Amp3 out”. This is done by measuring the

impedance between pins 2+ and 2- of the “Amp 3 out” connector. The B1 bass module has a

10k ohm resistor between those to pins.

b) The insertion of a 1/4" jack into the “Bass Line Out”. A normalling connection of this jack is

connected directly to a flag pin on the DSP.

Depending on these detections, the PS1 will change system EQ and limiter settings. This information is collected by the DSP and determines EQ and limiter settings through a lookup table:

Number

of Bass

Modules

0 infinity No 0 0 No bass module:

1 10k ohm No 1 1 L1: crossover at 180 Hz

2 5k ohm No 2 1 L1: crossover at 180 Hz

0 Infinity Yes 3 2 This mode is for use with external

1 10k ohm Yes 4 1 Undefined state, user may be using

2 5k ohm Yes 5 1 This is the nominal case with an

?? 0 Either 6 0 Debug Mode: all EQ and limiters

Impedance,

Amp3

2+ - 2-

Bass

Send

connected

Bass

EQ

Comment

LA

L1: Select highpass at 110Hz

B1: 40-110Hz flat bandpass

B1: “nominal EQ” +6 dB

B1: “nominal EQ”

powered sub.

L1: crossover at 180 Hz

B1: flat 40Hz to 180Hz

an external 3rd party device with a

single B1

L1: crossover at 180 Hz

B1: “nominal EQ”

additional external power stand

connected

L1: crossover at 180 Hz

B1: “nominal EQ” -6 dB

are by-passed.

Table 5. EQ lookup table for all operational modes

1.3.3 Debug Mode

Debug mode is entered when a resistance of 1k ohm or less is detected between pins 2- and 2+

at the “Amp3 Out” connector. In debug mode, all system EQ’s are set to “flat” and the internal

limiters are bypassed. Most measurements should be done in debug mode.

A simple way to switch between the different modes is to create a “dummy” cable that brings out

pins 2- and 2+ to a banana plug. The modes can be switched by applying different numbers of

10k ohm resistors or a short between the leads of the banana plug. Pins 1+ and 1- of the

“dummy” cable can still be routed to a Speakon

®

connector to attach B1 bass modules.

17

Page 18

THEORY OF OPERATION

1.4 Power Supply Electronics

The PS1 is powered by a total of four distinct switch-mode power supplies. All of these are fed

approximately 340VDC from the single input filter PC Board which contains numerous EMI

filtering components, in addition to a bridge rectifier and storage capacitors C607 and C608

[FCC Filter PCB sheet1, C4]. NTC thermistors TH601 & TH602 [C2] provide added resistance

at start-up to lower the inrush current.

Three identical board assemblies provide a separate ±27VDC to each of the power amplifier

channels. These are regulated with a transformer-coupled, two-FET forward converter topology.

Isolation is provided by the main transformer T503 [27 Volt Power Supply PCB sheet 1, C4], and

by the gate-drive transformer T502 [A3]. In addition to the internal over-current protection provided in the controller IC, there is an external input which shuts down an individual channel’s

power supply if a fault is sensed by the respective amplifier channel.

The fourth SMPS PC Board assembly, known as the Auxiliary Power Supply, provides all of the

other low-voltage, low-power DC voltages required by the remainder of the PS1’s electronics.

These are ±15V, +24V, +5V and +3.3V. They are regulated with a direct-coupled, single-FET

flyback converter topology. Isolation is provided by the main flyback transformer T601 [Auxiliary

Power Supply PCB sheet 1, C2], and by two opto-couplers IC602 and IC606 [B3]. Feedback for

regulation is derived from the 3.3V digital and +15V analog outputs. Regulation of the other

outputs depends on close coupling of transformer T601’s secondaries.

The +24V output is used to power the cooling fans [sheet 2, D3], which are in turn driven in

proportion to the output signal level. +24V is also used to provide phantom power for the microphone inputs. +5 and +3.3V outputs are used primarily to power the DSP, A/D & D/A converters,

microcontrollers, remote control communications, etc. The ±15V outputs power the numerous

OpAmps and other analog circuitry.

1.5 Audio Signal Path

1.5.1 General Notes - All Analog Inputs and Outputs

All user-accessible inputs and outputs are protected from RF interference (EMI) and static

discharge (ESD) by rail-rail diode clamps, spark gaps, and RC filtering. Extensive filtering is also

applied to speaker, power and Remote connections to prevent transmitted or received interference. All Analog inputs and outputs are configured as non-inverting, i.e. all ins and outs are in

phase with each other. Standard polarity conventions apply; XLR connectors are wired pin 2

pos, pin 3 neg.

The remote control does not carry any analog signals, rather it transmits MIDI code bidirectionally over an 8-conductor MIDI cable.

1.5.2 Preamplifier

The INA163 low-noise instrumentation amplifier forms the core of the PreAmp section. Gain of

both the Mic and Line inputs is determined by the impedance between the RG pins 12 and 3,

which consists of Trim control VR101/102 [input panel PCB sheet 1, A3 and C3] and R133/

R168. The balanced microphone input is protected from EMI, ESD and DC voltages (including

phantom power) by a rail-rail diode clamp, spark gaps, and numerous R’s and C’s. The unbalanced Line input is buffered by FET-input OpAmp U101A [D2] / U103A [B2] to maintain the

very high input impedance which is often required by instruments with magnetic pickups. R105

and 107 attenuate the Line input to an appropriate level as it is fed into the INA163.

18

Page 19

THEORY OF OPERATION

Input “combo-jacks” J101 and J102 [C1, A1] are configured so that outputs from buffer amps

U101A & U103A are shorted to ground when a ¼” plug is not inserted into J101 or J102 – this

eliminates the OpAmps’s noise contribution when the Mic input is in use, or when the channel is

not being used. U101B and U103B provide “DC servo” feedback to the INA163’s to effectively

null out any DC that would appear on their outputs.

Phantom Power

Condenser microphones are popular for many applications; they require a balanced external

power source applied equally to pins 2 & 3 of the XLR-type microphone connector. In addition

to an on/off switch and pilot LED, additional circuitry is provided to enable the +24VDC Phantom

power supplies to ramp up and down at a relatively slow rate, thereby preventing turn-on and

turn-off pops and clicks.

1.5.3 Line Out

The Ch1 and Ch2 XLR balanced Line Outputs are driven by OpAmps U106 and U107 [A6, C6].

These stages translate the internal PreAmp output signal to a differential balanced output.

1.5.4 Digitally Controlled Analog Volume

Ch1 and Ch2 Volume controls are implemented though a Toshiba TCA9459F chip, U302 [microprocessor PCB sheet 1, C3]. This chip contains a resistor ladder and a series of analog switches

that attenuate the input according to serial commands from the microcontroller. Attenuation of

0dB to -89dB (plus “off”) is available in steps of 1dB, but the PS1’s software contains a look-up

table to access a subset of these steps. This optimizes the feel of the control over the range of

0 to -40dB. The range is restricted to prevent the user from inadvertently turning the signal path

completely off.

1.5.5 Channel Insert

J105 and J106 [input panel PCB sheet 1, B5] are stereo ¼” jacks configured with the output

(“Send”) connected to the Ring terminal, and the input (“Return”) connected to the tip. Usually,

this would be used with a special “insert Y-cord” to route the Ch1 or Ch2 signal to an external

effects device such as a reverb, chorus, etc. If a 2-conductor (mono) ¼” plug is fully inserted,

the signal will be routed directly into the A/D converter, bypassing all of Ch1 or Ch2’s PreAmp

and Channel Volume control circuitry.

1.5.6 Channel 3 & 4 Inputs

The input signals are received through J107 [C8] /J108 [A8]. These are unbalanced 1/4" jacks

which short the input to ground if nothing is inserted. The signal is attenuated by VR103/VR104,

AC coupled, buffered and amplified through U108A/U108B and then routed to the A/D converter

U385 [DSP PCB sheet 1, D5] (Crystal CS5361). Because there is no active circuitry between

the inputs and the level controls, judicious setting of the controls can allow Ch3 and Ch4 to

accept very high input levels.

1.5.7 Analog to Digital Converters (Analog)

The PS1 has two stereo A/D converters Crystal CS5361. U386 [C5] receives channels 1 and 2,

U385 receives channels 3 and 4. Each channel signal is received on the DSP board through

CN104 [B1]. Each signal is AC-coupled, buffered and balanced through op-amp pairs (U381A/B

– U384A/B). All eight resulting signals are clipped with diode pairs and routed to the A/D chips.

19

Page 20

THEORY OF OPERATION

1.5.8 Digital to Analog Converter (Analog)

The stereo D/A converter U387 [B5] is of type Crystal CS4392. It has two symmetrical outputs

that get turned into an unbalanced signal through difference amplifier U388A [D7] /U388B [B7].

These OpAmp sections also form additional 2-pole low-pass filters that help remove out-of-band

components from the audio output. The “left” output contains the signal for L1 Cylindrical Radiator™ loudspeaker and the “right” output contains the signal for the B1 bass module. These get

routed through CN115 back to the input panel board.

1.5.9 Power Amp Inputs and Bass Line Out

J113 Bass Line Out jack [input panel PCB sheet 2, D3] provides a TRS balanced & buffered

version of the “right” / bass output from the D/A. This is used primarily for driving another PS1,

which in turn powers 2-6 additional B1 Bass Modules (see 1.3.1 figure 10, “Heavy Bass” configuration). Both + and – signals are resistor-isolated so that either balanced or unbalanced ¼”

phone connections may be used.

An “All-Amps-In” connector J112 [C1] allows a single input to drive all 3 amplifiers equally. This

will most often be driven from the Bass Line Out of another PS1 as mentioned above. J112’s

switching configuration allows both high and low frequency channels to drive the appropriate

channels when the All-Amps-In connector isn’t in use, and allows the addition of a buffer U112A

[B3] to maintain a greater than 10k ohm input impedance when the connector is used.

J114, 115 and 116 [C/D4] allow each power amplifier to be driven separately; this would generally only be used in special applications where a single “slave” PS1 is used to add bass from two

different “master” PS1’s.

1.5.10 Power Amplifiers

Note: Refer to the Digital Amplifier PCB schematic sheets for the following information.

Each of the PS1’s 3 amplifier channels is implemented with a 2-chip Class-D solution from

Philips. The three identical channels are located on one PCB assembly, but they are kept

independent by separate power supply, I/O and control connections. Each TDA8929T PWM

controller (U803, U806 and U809) [sheets 2, 3 and 4, C4] interfaces directly to two TDA8927J

(U801, U802, U804, U805, U807 and U808) power output stages. Normally, only one 8927 is

used, but in our case, the two halves of each 8927 are operated in parallel (doubling the available output current), and the two paralleled chips are driven out of phase to achieve the bridged

output configuration. Current sharing between the two halves of the 8927 chips is achieved by a

separate output LC filter for each section. The direct interface allows excess current in any one

of the output stages to immediately shut down all drive signals from the 8929 controller chip.

Numerous bypassing and filtering elements are added to the power amplifier to mitigate the

effects of the high currents at the nominal switching frequency of about 300 kHz.

In addition to the overcurrent shutdown path (amp shuts down power supply), there is other

outboard circuitry added to shut down an amplifier channel if the corresponding power supply

voltage is too low (usually due to extreme overdrive), and also another path to shut down a

channel’s power amp and power supply if excess DC voltage appears at the output.

20

Page 21

THEORY OF OPERATION

1.6 Digital Audio

1.6.1 Overview

The PS1 contains a DSP Analog Devices 21065L, U461 [DSP PCB sheet 3, B4] and a one time

programmable micro-controller U342 [microprocessor PCB sheet 2, C3]. The microcontroller

essentially interfaces to all peripherals and communicates the information from/to the peripherals to the DSP which contains most of the intelligence of the system. In addition the

microcontroller acts as a watchdog for the DSP, i.e. it will reset the DSP if the DSP chip hangs

up.

1.6.2 Audio Clocking

The audio signal processing is done at 48 kHz which gets created by an internal 12.288 MHz

(= 256*48kHz) oscillator. XTAL431 [DSP PCB sheet 2, B3] and distributed through U434 [B5].

The PS1 can receive SPDIF through the DATA In connector, but this data is received asynchronously to the actual audio data. This is different from most other Bose

master clock is derived from a digital input (if it exists).

®

products, where the

Digital audio is transported through an I

2

S interface (Serial data, Bit clock, Left/Right clock).

U386 [DSP PCB sheet 1, C5] (channel 1/2 A/D) generates the bit clock and the Left/Right clock.

These clocks get buffered through U433 [DSP PCB sheet 2, C5] and routed to U385 [DSP PCB

sheet 1, D4] (channel 3/4 A/D), U387 [B4] (D/A), SPORT 1 (serial port 1) of the DSP, and the

SPDIF transmitter U435 [DSP PCB sheet 2, B7] (Crystal 8046).

1.6.3 Digital to Analog and Analog to Digital Converters (Digital)

Both A/D converters (U385/U386) and the D/A (U387) are hardware configured. U386 is configured as a master and U385 as a slave. The DSP can reset the A/D through FLAG3 and the D/A

through FLAG2. The data is received by the DSP on SPORT1 (serial port 1) channel A (U385)

and channel B (U386). The DSP transmits the audio data again on SPORT1 (serial port 1)

channel A (to the D/A, U387) and channel B (SPDIF transmitter, U435).

1.6.4 SPDIF Interface

The SPDIF output provides the unprocessed audio received from channel 1 and 2. It is basically

a digital copy of the input signals to U386. The audio is sent by the DSP through channel B on

SPORT1 in I2S mode and received by U435, a Crystal 8046 SPDIF transmitter. U435 can be

reset by the DSP through FLAG1. U435 generates proper SPDIF signals and these get routed

through a transformer T431, through CN113 back to the Data Out connector on the panel board.

The “Data In” SPDIF input is NOT designed to receive actual audio, but to receive data that is

disguised as a SPDIF bit stream. The SPDIF input is clocked independent from the rest of the

system. The signal is received on the “Data In” connector on the panel board and routed through

CN112 to the DSP board and received by Crystal 8416 SPDIF receiver (U431), which performs

clock and data recovery. The data is transferred through an I2S interface to the DSP and received through SPORT0 on channel A. The DSP evaluates the data asynchronously. The DSP

can reset U431 through FLAG0 and can monitor the whether the U431 has valid audio through

FLAG8.

21

Page 22

THEORY OF OPERATION

1.7 Digital Signal Processor

1.7.1 Architecture

The DSP is an Analog Devices ADSP21065L processor. It boots from an EEPROM

SST20LE020, U462 [DSP PCB sheet 3, C7]. U462 accessed through boot memory space and

through external memory space 3. Either BMS or MS3 on the DSP will chip enable U462 and

then a standard write/read enable interface is used to address U462. The DSP is reset by the

microcontroller through RESET. Chip clock is locally provided through XTAL461 [A2] at 30 MHz

resulting in a 60 MHz internal clock speed.

1.7.2 Interface to Microcontroller

Besides the audio peripherals described in the previous section, the DSP only interface to the

microcontroller. The DSP receives data on FLAG4 (P10 on the micro), transmits data on FLAG5

(P11 on the micro) and FLAG11/P12 provide clocking. RESET/P13 provides the reset for the

DSP and the watchdog functionality. The interface signals are routed through CN341 [microprocessor PCB sheet 2, C8] between DSP and microcontroller board.

1.7.3 Internal LED

The DSP displays a “heartbeat” signal to an internal LED on the DSP board though FLAG10.

1.8 Microcontroller

1.8.1 Overview

The microcontroller is clocked by X341 [D3] (12 MHz) and provides interfaces between nearly all

peripherals.

Pins Interface Type

P24-P27 Preset switch CH 1, single digit static

P20-P23 Preset switch CH 2, tens digit static

P4-P7 Preset switch CH 1, sing le digit static

P0-P3 Preset switch CH 1, t ens digit static

P10-P13 DSP Interface SPI

P14-P15 Remote Modified MIDI

P37/ADC7 B1 detection from AMP3 Out Analog

P34 Power Amp Protection/Trouble Static

P33 Power Supply Protection Static

P30-P32 Interface to volume control chip I2C

P44-P45 Power LED (red/green) static

P43 Bass Sent detection from “Bass Line Out” static

Table 6. Peripheral pins on the microcontroller

1.8.2 Interface to Remote

Relay of DSP information to the Remote. The DSP in the power stand needs to transfer the clip

state, channel volume data (cause the table for channel volume in the DSP), system working

status to MCU. The communication adopts software simulation UART, with two I/O pins as RX

and TX. Communication rate is 4800bps, add start bit and stop, so every sending byte has 10

bits. Data is send according to frame format: frame head | every data | check sum. DSP will

transfer a frame every 100ms, and every sending will take about 15ms.

22

Page 23

THEORY OF OPERATION

The MCU needs to transfer the clip state information to the remote control. The communication

protocol adopts hardware UART. The communication rate is 9600bps, Data is sent according to

MIDI protocol: MIDI channel number | MIDI parameter type | MIDI parameter value. DSP will

transfer a frame data every 100ms, and every sending will take about 3.5ms.

Relay of Remote information to the Power Stand DSP. The remote needs to transfer the

Ch1EQHi, Ch2EQHi, Ch1EQMi, Ch2EQMi, Ch1EQLo, Ch2EQLo, Ch1Volume, Ch1Volume, and

MasterVolume information to the power stand MCU PCB. The communication adopts hardware

UART. The communication rate is 9600bps, Data is sent according to the MIDI protocol: MIDI

channel number | MIDI parameter type | MIDI parameter value. DSP will transfer a frame data

every 100ms, and every sending will take about 30ms.

The power stand MCU PCB needs to transfer the Ch1EQHi, Ch2EQHi, Ch1EQMi, Ch2EQMi,

Ch1EQLo, Ch2EQLo, Ch1Volume, Ch1Volume, MasterVolume, Ch1Preset, Ch2Preset,

BassChk, and CheckSum information to the DSP. The communication adopts software simulation UART, with two I/O pins as RX and TX. Communication rate is 4800bps, add start bit and

stop, so every sending byte has 10 bits. Data is sent according to frame format: every data |

check sum. DSP will transfer a frame every 100ms, and every sending will take about 30ms.

1.9 Software and User Interface

The Bose

which is mostly implemented in software. In this chapter we describe how most of the functions

are implemented.

1.9.1 Gain Staging

Gain staging is the process of properly adjusting the gain of the system. The goal is to set the

gains as high as possible (to optimized signal/noise) without overdriving or clipping any electronic components. In contrast to home-audio products, musical instrument and microphones

have a large variation of output gains and gain staging is typically required.

On Channel 1 and 2, the user needs to set the trim control on the power stand so that the

overload LED just turns red for the loudest anticipated input signals and then back up a little.

This is done purely in analog and the goal is to not overload the preamplifier.

Next the user should adjust the channel volume on the remote so that the LED on the remote

does not turn red. The LEDs are calibrated so that for sine wave input, nothing connected to the

insert loop, and the channel volume at the 12 o’clock setting both LEDs turn red at the same

level.

1.9.2 Channel Volume

The microcontroller polls the remote in regular intervals, about 10 times per second. The

microcontroller then maps the settings to a range from -40 to 0 dB and programs the volume

control chip U302 through its digital control interface. The volume control should span a range of

40 dB with a linear (in dB) range from -30dB to -10dB from all the way down to 12 o’clock and a

range from -10dB to 0dB for 12 o’clock to “all the way up” setting.

®

Personalized Amplification System™ family of products has a simple user interface

1.9.3 Tone Controls

The microcontroller polls the remote in regular intervals. The microcontroller transfers the tone

control settings to the DSP which implements them for each channel as shown in Figure 11.

23

Page 24

THEORY OF OPERATION

PS1 tone controls

PS1 tone controls

PS1 tone controls

15

15

15

10

10

10

5

5

5

0

0

0

dBV/V

dBV/V

dBV/V

-5

-5

-5

-10

-10

-10

-15

-15

-15

-20

-20

-20

2

2

2

10

10

10

Frequency (hertz)

Frequency (hertz)

Frequency (hertz)

3

3

3

10

10

10

Figure 11. PS1 Tone Control Range

4

4

4

10

10

10

1.9.4 Master Volume

The microcontroller polls the remote in regular intervals. The microcontroller transfers the master volume setting to the DSP which implements them for each channel as shown in Figure 5.

The master volume should mute the system if all the way down and then ramp up to a nominal

value of 0dB at the center position. From the center position to “all the way up” the master

volume increases the gain by another 12 dB.

1.9.5 Preset Switching

The microcontroller polls the preset switches on the panel board in regular intervals and transfers the values to the DSP. If the DSP detects a change in the setting, it will mute the respective

channel, load the new filter coefficients according to a lookup table, clear the filter state coefficients and un-mute the channel again. This takes about 1 to 2 seconds.

Presets are basically a spectral correction (like an EQ) to the signal. Preset “00” corresponds to

flat. An easy preset to check is 97 which is a 1 kHz band pass filter (“telephone” sound). In

addition to the spectral EQ, there is also a noise gate available.

1.9.6 Bass Line Out Detection

The microcontroller polls the normalling switch on the Bass Line Out connector in regular intervals and transfers its state to the DSP. If the DSP detects a change in the state, it will mute the

entire power stand, latch in new system EQ coefficients through a lookup table, clear the system

EQ state variables and un-mute the power stand. This takes about 1 to 2 seconds.

1.9.7 Bass Module Detection

The microcontroller measures the resistance between the pins 2- and 2+ of the Amp3 Out

connector in regular intervals and transfers the setting to the DSP. If the DSP detects a big

enough change in the setting, it will mute the entire power stand, latch in new system EQ coefficients through a lookup table, clear the system EQ state variables and un-mute the power stand.

This takes about 1 to 2 seconds.

24

Page 25

THEORY OF OPERATION

1.10 Power Cycling

1.10.1 Power Up

When power is first applied, 110V AC is applied to the primary side of the transformer1, and at

the secondary side of the transformer1 will charge up +24V, +15V, -15V, +5V, +3.3V. And after 7

ms, they become stable almost at the same time. But +27V/-27 for amplification is late other

voltage about 6ms.

Power-up time complies with the following sequence:

• With +3.3V, +5V, +15V, -15V, the ADC/DAC/buffer circuit/MCU starts to work

• After power on 15ms, amplifier starts to work

• DSP uses RC reset. After about 300ms, DSP starts to work

• After DSP starts to work, DSP first resets ADC, then digital receiver, and then digital

transmitter, then DAC. Every reset time is 100ms

• After power on about 700ms, latest DAC’s reset is completed

At this point, normal signal processing commences. But in order to get correct remote value

& preset number & number of bass, DSP mutes input signal, and it should no more than

1.5 seconds from the time power is applied until the time audio appears at the speaker output.

1.10.2 Power Down

Upon power-down the muting circuitry comprised of Q810, Q811, DZ805, R895 and C959

[digital amplifier PCB sheet 3, D2] is responsible to mute any noise coming out from the output

of U387 CS4392 Digital-to-Analog converter.

The principle is to detect the voltage VDDA falling below 22 volts. This will cut off the DZ805

Zener diode and Q810 NPN transistor. This in turn will turn on Q811 NPN transistor and pull the

voltage of U806 pin 6 from 5 volt to 0 volt. This action will shut down the class-D amplifier U804

and U805 so that any noise will be muted.

1.11 Software and Preset / EQ Updates

The PS1 software and Preset /EQ files can be updated via the Data In jack J109 [input panel

PCB sheet 2, A1] on the PS1 input panel. Refer to the software update procedures in the appendix of this troubleshooting guide.

2. Remote R1

The Remote is a wired remote, connected to the PS1 power stand via an 8 pin MIDI cable.

There are a total of nine knobs on the remote, their functions is as follow:

• Knob for tone regulation

• Knob for channel volume control

• Knob for master volume control

• Two LEDs to indicate clip

The communication between the remote control and the PS1 power stand uses the MIDI protocol, operating at 9600baud. The remote control is non-repairable.

25

Page 26

THEORY OF OPERATION

3. Cylindrical Radiator™ Loudspeaker L1

The L1 Cylindrical Radiator speaker array consists of two sections, an upper and lower section,

with 12 drivers each for a total of 24 drivers. The lower array section plugs directly into the cavity

in the center of the PS1 power stand. Electrical connections are made via Molex connectors in

the PS1 and the bottom of the lower array section. The upper section of the line array plugs

directly into the top of the bottom section, aligned by a bayonet pin. Electrical connection is

made by another Molex connector to the top of the lower array section. The result is that there

are no cables needed to connect the line array sections to the PS1 power stand.

There is no crossover or protection circuitry in either section of the line array. All protection and

EQ is performed in the PS1 power stand. The drivers of both sections are replaceable, as are

the grilles and the Bose

4. Bass Module B1

The B1 bass module is a dedicated passive unit that houses two 5 1/4” drivers. The input is via

two 4-pole Neutrik® Speakon® connectors on the rear panel. Both of these inputs are paralleled,

allowing you to jumper multiple bass modules together. There are no crossover or protection

ciricuit components located on the input panel. All EQ and protection is performed in the PS1

power stand.

®

logo.

Pins 1+ and 1- of the input connector are used to apply the input signal to the bass module. Pins

2+ and 2- are connected to a 10k ohm resistor on the bass module rear panel PCB. This allows

the PS1 power stand to detect how many bass modules are connected to it from the Bass/Amp3

Out connector.

If the PS1 sees a 10k resistance, it knows that there is only one bass module connected and

adjusts the output level and EQ accordingly. If the PS1 sees 5k ohm resistance, it knows that

there are 2 bass modules connected, and again, adjusts the output level and EQ accordingly.

If the PS1 sees an infinite resistance, it knows that there is no bass module connected and

adjusts accordingly.

The woofers in the bass module are replaceable. The input panel, grille and Bose logo are also

replaceable.

26

Page 27

TEST PROCEDURES

PS1 Power Stand Tests

Equipment Required

• dB Meter

• Digital Multi-meter

• Audio Signal Generator

• Distortion Meter

• 3 - 4 Ohm, 250 Watt Load Resistors

• Test cables, see Appendix

Overall PS1 System Tests

Notes:

1. Connect 4 Ohm load resistors to the

channel 1, 2 and 3 outputs on the PS1

power stand using the test cables described

in the appendix of this troubleshooting guide.

2. Do not connect the R1 remote control for

the following tests. This has the same effect

as setting all of the controls on the remote to

the midpoint.

3. On the front panel of the PS1, set the

Channel 1 and Channel 2 Preset Select

switches to 00. This will put the PS1 into

debug mode for the following tests. In this

mode the crossover, the compressor and the

EQ are disabled. The DSP will pass a flat

response. The level controls and the clip

indicators still operate in this mode.

1.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30dBV signal to the channel

1 input.

1.4 Reference a dB meter to the input level.

Measure the gain output at the Amp 1 OUT

jack. It should be +48.5 dB

1.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 1.1 to 1.4 for the channel 2 Mic input.

2. Channel 1 and 2 Mic Input Frequency

Reponse and Distortion Tests

2.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

2.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

2.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30dBV signal to the channel

1 input.

+ 3dB.

1. Channel 1 and 2 Mic Input Gain Tests

1.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

1.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

2.4 Use an 80kHz low-pass filter on your

measuring equipment. Reference a dB meter

to the input level. Measure the frequency

response at the Amp 1 OUT jack. It should

be 0dB + 3dB from 30Hz to 15kHz.

2.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack. It should

be 0.25% max at 1kHz and 1.5% max at

15kHz.

2.6 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 2.1 to 2.5 for the channel 2 Mic input.

27

Page 28

TEST PROCEDURES

3. Channel 1 and 2 Mic Input Signal to

Noise Ratio (Dynamic Range) Tests

3.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

3.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

3.3 Using a balanced XLR male input cable,

apply a 1 kHz, -30dBV signal to the channel

1 input.

3.4 Reference a dB meter to the output level

at the Amp 1 OUT jack. Remove the input

signal and measure the A-Weighted output

level. It should be -80dB minimum.

3.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 3.1 to 3.4 for the channel 2 Mic input.

4. Channel 1 and 2 Line Input Gain Tests

4.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

4.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

4.4 Reference a dB meter to the input level.

Measure the gain output at the Amp 1 OUT

jack. It should be +28.5 dB + 4dB.

4.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 4.1 to 4.4 for the channel 2 Line input.

5. Channel 1 and 2 Line Input Frequency

Reponse and Distortion Tests

5.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

5.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

5.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -10dBV signal to

the channel 1 input.

5.4 Use an 80kHz low-pass filter on your

measuring equipment. Reference a dB

meter to the input level. Measure the frequency response at the Amp 1 OUT jack.

It should be 0dB + 3dB from 30Hz to 15kHz.

5.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack. It should

be 0.25% max at 1kHz and 1.5% max at

15kHz.

5.6 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 2.1 to 2.5 for the channel 2 Line input.

4.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -10dBV signal to

the channel 1 input.

28

Page 29

TEST PROCEDURES

6. Channel 1 and 2 Line Input Signal to

Noise Ratio (Dynamic Range) Tests

6.1 Place a 1/4” mono shorting plug into the

Amp 2 IN and Amp 3 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 2 and 3 amplifiers while

testing the channel 1 amplifier.

6.2 On the left hand side of the input/output

panel, set the channel 1 Mic Trim control to

the 6 setting. Ensure that the Line In +20dB

gain and the Phantom Power push buttons

are not pushed in.

6.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -10dBV signal to

the channel 1 input.

6.4 Reference a dB meter to the output level

at the Amp 1 OUT jack. Remove the input

signal and measure the A-Weighted output

level. It should be -80dB minimum.

6.5 Move the shorting plug from the Amp 2

IN jack to the Amp 1 IN jack and repeat

steps 6.1 to 6.4 for the channel 2 Line input.

8. Channel 3 and 4 Line Input Frequency

Reponse and Distortion Tests

8.1 Place a 1/4” mono shorting plug into the

Amp 1 IN and Amp 2 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 1 and 2 amplifiers while

testing the channel 3 amplifier.

8.2 On the left hand side of the input/output

panel, set the channel 4 Mic Trim control to

the 6 setting.

8.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -20dBV signal to

the channel 1 input.

8.4 Use an 80kHz low-pass filter on your

measuring equipment. Reference a dB

meter to the input level. Measure the frequency response at the Amp 1 OUT jack.

It should be 0dB + 3dB from 30Hz to 15kHz.

8.5 Measure the Total Harmonic Distortion

(THD) level at the Amp 1 OUT jack. It should

be 0.25% max at 1kHz and 1.5% max at

15kHz.

7. Channel 3 and 4 Line Input Gain Tests

7.1 Place a 1/4” mono shorting plug into the

Amp 1 IN and Amp 2 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 1 and 2 amplifiers while

testing the channel 3 amplifier.

7.2 On the left hand side of the input/output

panel, set the channel 3 Level control to the

6 setting.

7.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -20dBV signal to

the channel 1 input.

7.4 Reference a dB meter to the input level.

Measure the gain output at the Bass/Amp 3

OUT jack. It should be +40.1dB

7.5 Repeat steps 7.1 to 7.4 for the channel 4

Line input.

+ 3dB.

8.6 Repeat steps 8.1 to 8.5 for the channel

4 Line input.

9. Channel 3 and 4 Line Input Signal to

Noise Ratio (Dynamic Range) Tests

9.1 Place a 1/4” mono shorting plug into the

Amp 1 IN and Amp 2 IN jacks on the right

hand side of the input/output panel. This will

disable the channel 1 and 2 amplifiers while

testing the channel 3 amplifier.

9.2 On the left hand side of the input/output

panel, set the channel 3 Level control to the

6 setting.

9.3 Using an unbalanced 1/4” phono jack

input cable, apply a 1 kHz, -10dBV signal to

the channel 1 input.

29

Page 30

TEST PROCEDURES

9.4 Reference a dB meter to the output level

at the Bass/Amp 3 OUT jack. Remove the

input signal and measure the A-Weighted

output level. It should be -80dB minimum.

9.5 Repeat steps 9.1 to 9.4 for the channel 4

Line input.

Line Array Tests

Connect the Line Array section you are

testing to an amplifier using the test cables

described in the appendix of this troubleshooting guidel.

1. Air Leak Test

1.1 Apply a 100 Hz, 10 Vrms sine wave to

the unit under test.

1.2 Listen carefully for air leaks from around

the end cap, the transducers and the grille.

Air leaks will be heard as a hissing or sputtering sound. All repairs must be hidden.

Test duration should be 5 seconds minimum.

2. Transducer Rub and Tick Test

2.1 Remove the transducer you wish to test

using the disassembly procedures in this

manual. Do not unplug the wires at the

transducer assembly terminals.

Note: To distinguish between normal suspension noise and rubs or ticks, displace the

cone slightly with your fingers. If the noise

stays the same, it is normal suspension

noise and the driver is good. Suspension

noise will not be heard with program material.

3. Transducer Phase Test

3.1 Apply a DC voltage of 10V, positive

applied to the positive terminal of the line

array test cable and GND applied to the

GND terminal.

3.2 Notice carefully that all driver cones

should move outward when the DC voltage

is applied.

3.3 Rewire any incorrectly connected transducers.

4. Line Array Sweep Test

4.1 Connect the line array section under test

to the output of an amplifier being driven by

an audio signal generator. Use the line array

test cables described in the appendix of this

troubleshooting guide.

4.2 Apply a 10Hz, 10Vrms sine wave to the

input.

2.2 Connect a signal generator directly to the

terminals of the transducer assembly under

test.

2.3 Apply a 20 Hz, 5 Vrms signal to the

transducer assembly.

2.4 Listen carefully for any extraneous

noises such as rubbing, scraping or ticking.

4.3 While listening to the output of the

system, sweep the input frequency slowly

from 20Hz to 20kHz. Test duration should be

10 seconds minimum.

4.4 Listen carefully for any extraneous

noises such as buzzing and ticking.

30

Page 31

TEST PROCEDURES

Bass Module Tests

Connect the Bass Module under test to an

amplifier using the test cables described in

the appendix of this troubleshooting guide.

1. Air Leak Test

1.1 Apply a 100 Hz, 10 Vrms sine wave to

the unit under test.

1.2 Listen carefully for air leaks from around

the end cap, the transducers and the grille.

Air leaks will be heard as a hissing or sputtering sound. All repairs must be hidden.

Test duration should be 5 seconds minimum.

2. Transducer Rub and Tick Test

2.1 Remove the transducer you wish to test

using the disassembly procedures in this

manual. Do not unplug the wires at the

transducer assembly terminals.

2.2 Connect the transducer to an amplifier

that is driven by an audio signal generator.

Connect directly to the terminals of the

transducer assembly under test.

2.3 Apply a 10 Hz, 10 Vrms signal to the

transducer assembly.

2.4 Listen carefully for any extraneous