Page 1

Panaray® MA12 Modular Line Array

Loudspeaker System

©2006 Bose Corporation

Service Manual

Reference Number 263639-SM Rev. 01

Electronic Copy Only

Page 2

Contents

Warranty.............................................................................................................................................2

Specifications....................................................................................................................................3

Product Description..........................................................................................................................3

Accessories Used with the MA12 Loudspeaker System...............................................................3

Part List Notes...................................................................................................................................3

Packaging Part List, Panaray® MA12 Loudspeaker System (see Figure 1) .................................4

Figure 1. Panaray MA12 Loudspeaker Packaging View ..................................................................4

Main Part List, Panaray MA12 Loudspeaker System (see Figure 2) ............................................5

Figure 2. Panaray MA12 Loudspeaker System Exploded View .......................................................6

Part List, Panaray MA12 Loudspeaker Protection Circuit Board (see Figure 3).........................7

Figure 3. MA12 Protection Circuit Board Layout Diagram................................................................7

Figure 4. Panaray MA12 Loudspeaker Wiring Diagram...................................................................8

Disassembly Procedures .................................................................................................................9

Test Procedures ..............................................................................................................................10

Figure 5. Panaray MA12 Test Setup Diagram ................................................................................10

Service Manual Revision History...................................................................................................11

®

CAUTION: The Bose

contains no user-serviceable parts. To prevent warranty infractions,

refer servicing to warranty service stations or factory service.

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF

THE BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR

USED FOR ANY OTHER PURPOSE.

Panaray MA12 Modular Line Array Loudspeaker System

PROPRIETARY INFORMATION

Warranty

The Bose Panaray MA12 Modular Line Array Loudspeaker System is covered by a limited

5-year transferable limited warranty.

2

Page 3

Specifications

Description

Product Code

External Dimensions: 38.5 x 4.2 x 5.1 in. (978 x 107 x 130 mm)

Weight: Single Speaker: 22 lb. (10 kg)

Packed System: 24 lb. (11 kg)

Sensitivity: 88dB SPL, 120 Hz - 15 kHz (1W/1m free space)

System Protection: PTC, lamp

Impedance: 8 Ohms nominal, 7.5 Ohms minimum

Power Handling: 300 Watts continuous per IEC-268-5, 120 Hz high pass,

96 hours. Recommended amplifier power 150-300 Watts

Product Description

The Bose® Panaray® MA12 Modular Line Array Loudspeaker System is a modular system used

for mid/high frequency sound reproduction. It is a vented enclosure design using 12 full range

drivers housed in a closely spaced line.

The loudspeaker provides a means for mechanical attachment of two units to form a rigid single

line source by using the CB-MA12 coupling bracket (see table below). Each loudspeaker has

two Neutrik® connectors and one barrier style terminal so that multiple units can be connected

as a system in series and parallel.

The Bose Panaray MA12 Loudspeaker can be used with the Bose Panaray MB4 Modular Bass

Loudspeaker for dynamic full range reproduction.

Accessories Used with the MA12 Loudspeaker System

WB-MA12 wall mount bracket (0º – 10º pitch) 028333 028334

WBP-MA12 wall mount bracket (0º – 10º pitch, +/- 90º yaw) 028673 028674

CB-MA12 coupling bracket 028337 028338

PSA-12 stand adapter 029229 CVT-12 70V/100V transformer (non-RoHS complaint) 029388 029389

CVT-12 70V/100V transformer (RoHS complaint) 040190 040191

Black White

Part List Notes

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCBs are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with the

same safety characteristics as the recommended replacement part might create shock, fire

and/or other hazards.

4. This part is referenced for informational purposes only. It is not stocked as a repair part. Refer

to the next higher assembly for a replacement part.

3

Page 4

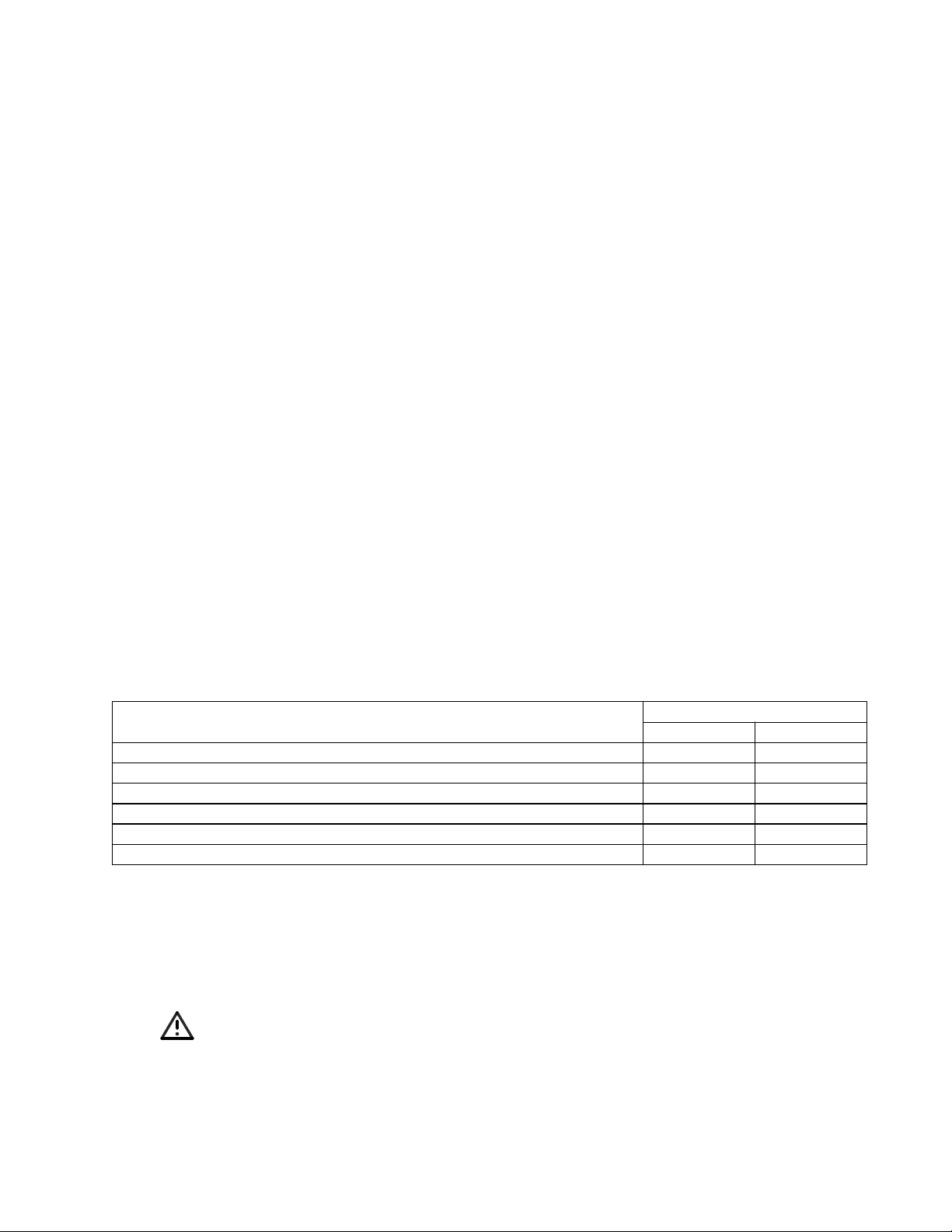

Packaging Part List

Item

Description Bose® Part

Vendor Part

Qty. Note

ESOB

Panaray® MA12 Loudspeaker System (see Figure 1)

Number

1 PACKING, END CAP 263624 1490-7393-0 2

2 POLYBAG N/A 1497-5102-0 1

3 MA12 LOUDSPEAKER REF REF 1

4 PACKING, CENTER 263625 1490-7433-1 1

5 OWNER’S MANUAL 263626 4301-5191-0 1

6 CARTON 263572 145A7780-0 1

Number

Number

Figure 1. Panaray MA12 Loudspeaker Packaging View

4

Page 5

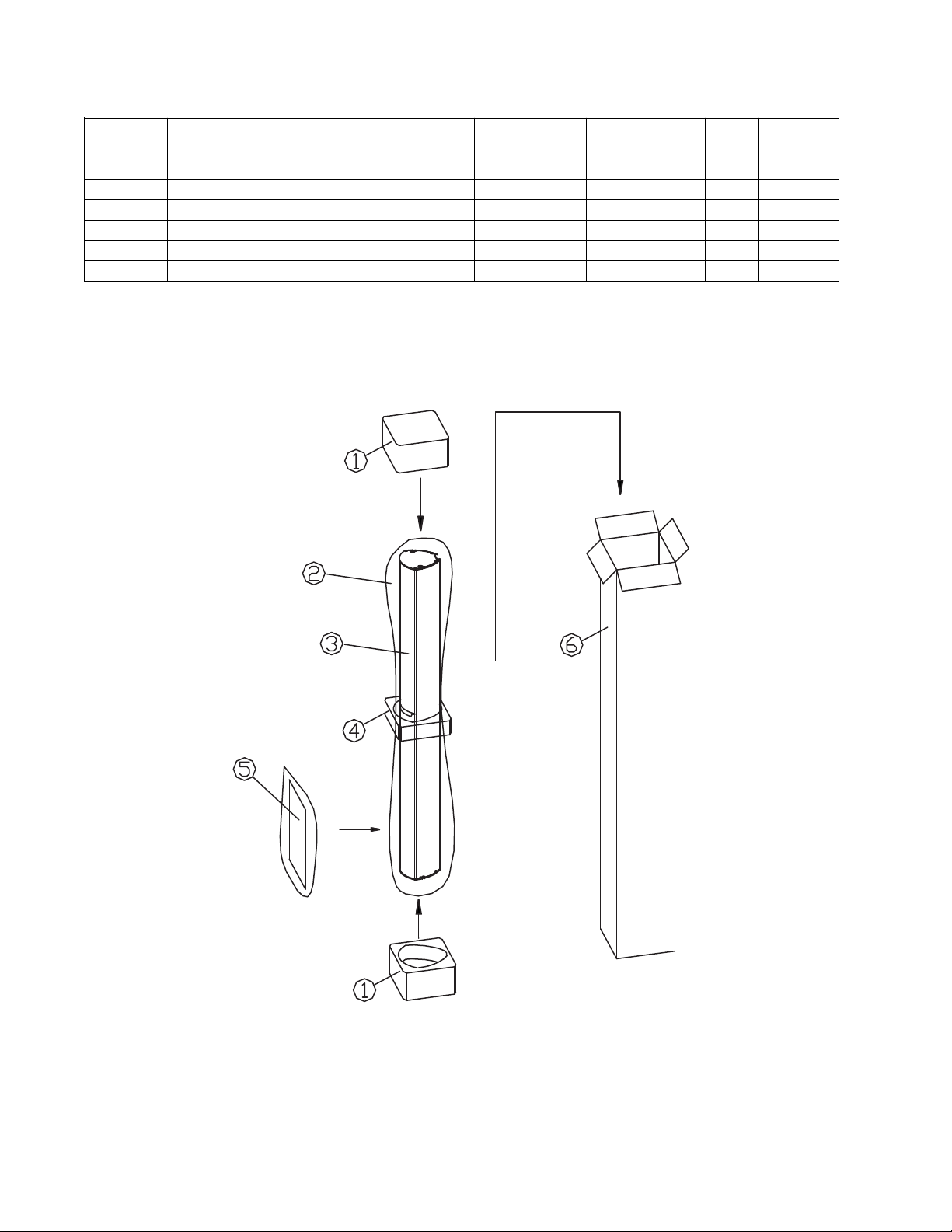

Main Part List

Part Number Item

Description

Qty Note

3

1

2

6

5

4

7

8

9

01

11

2

1

31

4

1

61

5

1

Panaray® MA12 Loudspeaker System (see Figure 2)

Number

1 SCREW, CONNECTOR, M3x13 - - 4 4

2 CONNECTOR, NEUTRIK 298548 298548 2

3 GASKET, ENDCAP 259133 259133 2

4 SCREW, ENDCAP, M3.5x13 - - 12 4

5 ENDCAP 259132-001 259132-002 2

6 GASKET, DRIVER 298549 298549 12

7 DRIVER, 2.25” 298550 298550 12

8 SCREW, BAFFLE, M4.5x12 - - 16 4

9 SCREW, DRIVER, M3.5x8 - - 48 4

10 U-CHANNEL, GRILLE - - 2M 4

12 LOGO, BOSE 298552-001 298552-002 1

11 GRILLE 298551-001 298551-002 1

13 U-CHANNEL FOR GRILLE COVER - - .35M

14 GRILLE TRIM - - 2 4

15 BARRIER TERMINAL - - 1 4

16 SCREW, BARRIER TERMINAL,

M3x14

- CVT-12 TRANSFORMER

(ACCESSORY ITEM)

Black White

- - 2 4

040190 040191 1

4

3

Figure 2. Panaray® MA12 Loudspeaker System Exploded View

5

Page 6

Part List

Item

Description Part Number Qty. Note

Panaray® MA12 Loudspeaker Protection Circuit Board (see Figure 3)

Number

PCB ASSY, PROTECTION CKT 298553 1

1 LAMP, GREEN DOT 298554 2

2 POLYSWITCH, RXE075 298555-075 1

Figure 3. MA12 Protection Circuit Board Layout Diagram

6

Page 7

PTC

LAMP

Screw

Terminal

LAM

P

Screw

Terminal

Figure 4. Panaray

®

MA12 Loudspeaker Wiring Diagram

7

Page 8

Disassembly Procedures

3

1

2

6

5

4

7

8

9

01

11

2

1

31

4

1

61

5

1

Note: Refer to the figure below for the

following procedures.

1. End Cap Removal

1.1 Using a Phillips-head screwdriver,

remove the six screws (4) that secure the

steel end cap (5) to the housing and grille

trim.

1.2 Gently pull the end cap away from the

housing.

Re-assembly Note: When replacing the end

cap, ensure that it is fully seated against the

housing for an airtight seal. Replace all six

screws to prevent air leaks.

2. Grille Assembly Removal

2.1 Remove the two screws at the front of

each end cap.

2.3 Gently pull the grille assembly away

from the housing. Be careful not to mark

the surface of the grille or the housing.

3. Driver Removal

3.1 Perform procedure 2.

3.2 Using a Phillips-head screwdriver,

remove the sixteen screws (8) that secure

the baffle to the housing.

3.3 Lift the baffle with the six drivers (7) out

of the housing.

3.4 Unplug the driver cable wires from the

driver you wish to remove.

3.5 Using a Phillips-head screwdriver,

remove the four screws (9) that secure the

driver to the baffle. Lift out the driver.

2.2 Take the grille trim (14) along with the Urubber channel (13) away from the end of

the grille (11).

3

8

Page 9

Test Procedures

Audio Signal

Generator

Power Amplifier

INPUT OUTPUT

Figure 5. Panaray® MA12 Test Setup Diagram

1. Air Leak Test

1.1 Set up the system for test as shown in

Figure 5.

1.2 Apply a 100 Hz, 10 Vrms sine wave to

the input connectors.

1.3 Listen carefully for any air leaks from

around the end cap, drivers and the baffle.

Air leaks will be heard as a hissing or sputtering sound. All repairs must be hidden.

Test duration should be 5 seconds minimum.

2. Rub and Tick Test

2.1 Perform disassembly procedure 3. It is

not necessary to unplug the wires at the

driver assembly terminals.

2.2 Connect a signal generator directly to

the terminals of the driver under test.

If the noise stays the same, it is normal

suspension noise and the driver is fine.

Suspension noise will not be heard with

program material.

3. Phase Test

3.1 Momentarily apply 10 VDC to the loud-

speaker input connector. Apply the positive

to pin “1+” and the negative to pin “1-” of the

®

Neutrik

connector.

3.2 When applying the DC voltage level,

observe the driver cones. They should all

move outward when the DC level is applied.

3.3 Rewire any incorrectly wired driver.

4. System Sweep Test

4.1 Set up the system for test as shown in

Figure 5.

2.3 Apply a 20 Hz, 5 Vrms sine wave to the

driver assembly.

2.4 Listen carefully for any extraneous

noises, such as rubbing, scraping or ticking.

Note: To distinguish between normal suspension noise and rubs or ticks, displace the

cone slightly with your fingers.

4.2 Apply a 10 Hz, 10 Vrms sine wave to the

loudspeaker input connector.

4.3 While listening to the output of the

system, sweep the input frequency slowly

from 10 Hz to 20 kHz.

4.4 Listen carefully for any extraneous

noises such as buzzing or ticking.

9

Page 10

Service Manual Revision History

Date Revision

Description of Change Change Driven

Pages

Level

1/02 00 Document released at revision 00. Service manual

10/06 01 Added RoHS compliant part numbers. RoHS initiative 4, 6

By

release

Affected

All

10

Page 11

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N: 263639-SM Rev. 01 10/2006 (P)

http://serviceops.bose.com

Loading...

Loading...