Page 1

FREESPACE™ BUSINESS

MUSIC SYSTEM

©

1993 Bose Corporation Service Manual

Page 2

TABLE OF CONTENTS

1. SAFETY INFORMATION.......................................................................................... 2

2. SPECIFICATIONS.................................................................................................... 3

3. BLOCK DIAGRAM.................................................................................................... 6

4. THEORY OF OPERATION....................................................................................... 7

5. DISASSEMBLY/ASSEMBLY PROCEDURES......................................................... 13

6. TROUBLESHOOTING TIP FOR HUM AND RFI REMOVAL................................... 18

7. TEST PROCEDURES.............................................................................................. 19

8. PARTS LISTS AND EXPLODED VIEWS................................................................. 23

9. SCHEMATICS AND PCB LAYOUTS....................................................................... 47

CAUTION: THE FREESPACE™ BUSINESS MUSIC SYSTEM

CONTAINS NO USER-SERVICEABLE PARTS. TO PREVENT

WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY

SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

1

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet.(Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 "Leakage Current for Appliances" and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal waterpipe,

conduit,etc.) to all exposed metal parts of the unit (antennas,handle bracket,

metal cabinet,screwheads,metallic overlays,control shafts,etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliamp. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD

THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE

CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug.(2)Turn on the power

switch of the unit. (3) Measure the resistance with an ohmmeter between the

jumpered AC plug and each exposed metallic cabinet part on the unit. When the

exposed metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 Megohms. When there is no return path to the chassis, the

reading must be "infinite". If it is not within the limits specified, there is the possibility of a shock hazard, and the unit must be repaired and rechecked before it

is returned to the customer.

2

Page 4

SPECIFICATIONS

Dimensions Module: 9.1"H x 12.6"W x 20.1"D (23.1x32x51.05 cm)

Satellite: 3.75"H x 4.5"W x 4.5" D (9.5x11.4x11.4 cm)

Weight Module: 37 lbs. (16.8 kg.)

Satellite: 1.24 lbs. (0.56 kg.)

Driver 1-8" Woofer

Complement 4-2.24" Twiddlers™

Finish Module: Black or white,scratch-resistant,satin-finished

vinyl

Satellites: Black or white,painted polymer finish

PERFORMANCE SPECIFICATIONS

Amplifier Topology Class G (High efficiency)

Amplifier Power Woofer channel (single): 100 watts min. into 4Ω @100Hz

Satellite channels (each): 50 watts min. into 8Ω @ 1 kHz

Output Short Circuit Current Threshold: 5 ± 0.2 amperes

Protection Duration: Infinite

Input Impedance System: Balanced: 13.0 kΩ

Unbalanced: 26.5 kΩ

Satellites: 4Ω

Woofer: 4Ω

Distortion Bass Channel @ 100 W,100 Hz <0.1% THD typical

L/R Channels @ 50 W,1 kHz <0.1% THD typical

Output Noise Bass Channel (80 kHz LPF,inputs shorted) <1 mV

L/R Channels (A weighted,inputs shorted) <300µVrms

Output Hum Bass Channel <500µVrms (unweighted)

Compressor Attack time: 10 ± 5 ms

Release time: 80 ± 20 ms

Attenuation Range: 12 dB

Channel @1kHz >40 dB

Separation @10 kHz >30 dB

3

Page 5

Dynamic 0-16 dB variable boost @ 55 Hz (level dependent)

Equalization

Crossover Transition 180 Hz

Frequency

Input Sensitivity 0.4 Vrms @1kHz produces rated

Turn-On Delay 80ms ± 40 ms

(Auto)

Turn-on 300 µVrms ± 100 µVrms

Threshold

Turn-Off Delay 90 sec. ± 30 sec.

(Auto)

PERFORMANCE SPECIFICATIONS (Continued)

power in L/R channel

outputs (at full volume)

Acoustic Output 95 dB SPL in IEC standard room @ 50W

Power Consump- 350 W max.

tion

Standby Power 8 W max.

Consumption

DC Offset Bass Channel,L/R Channels <70mVDC

(with audio inputs shorted)

4

Page 6

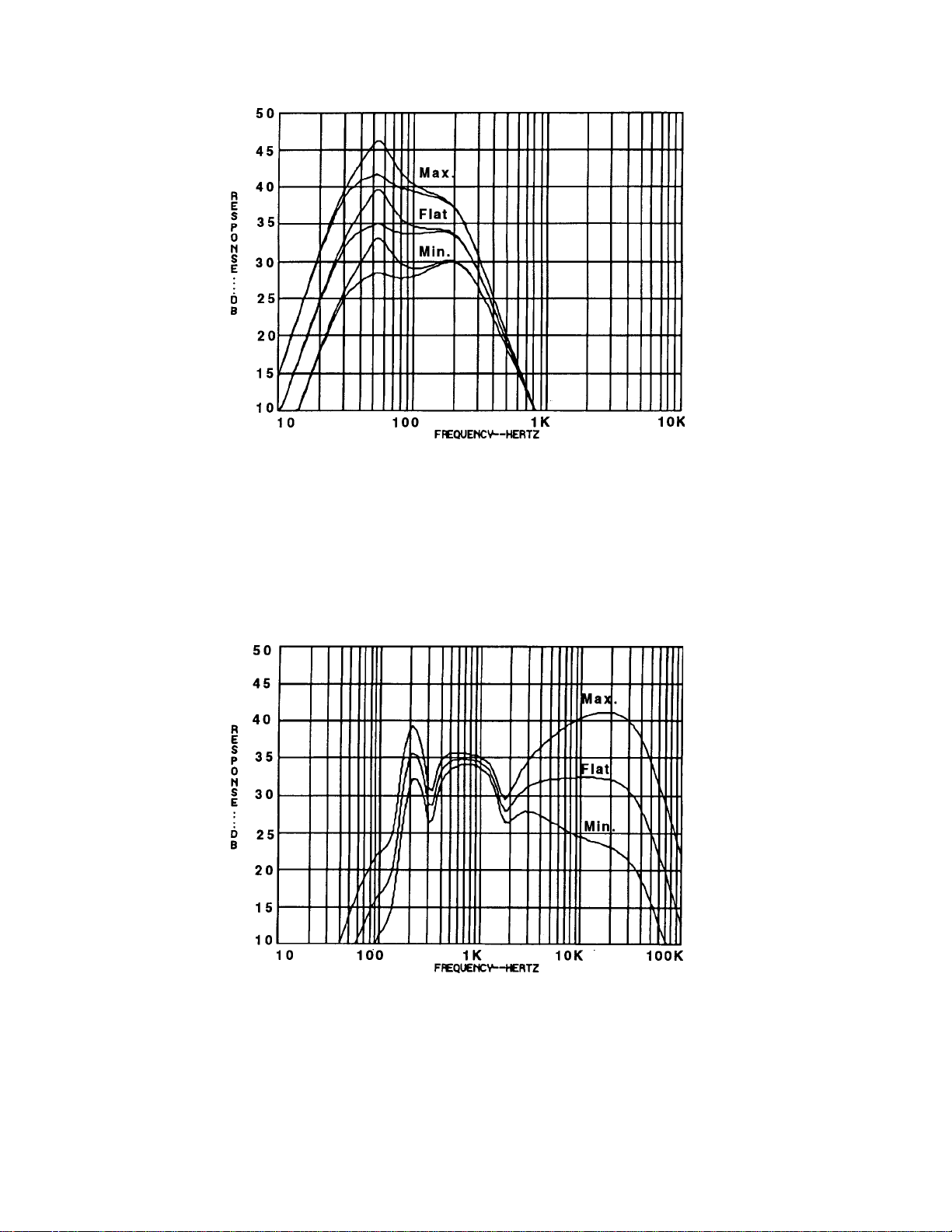

Frequency Response Curves

Bass channel frequency response curve with tone controls at min.,

max., and flat positions (for 30 and 200 mVrms input level)

Figure 1. Bass Channel Frequency Response Curve

Left/right channel frequency response with tone controls at min.,

max.,and flat positions.

Figure 2. Left/Right Channel Frequency Response Curve

5

Page 7

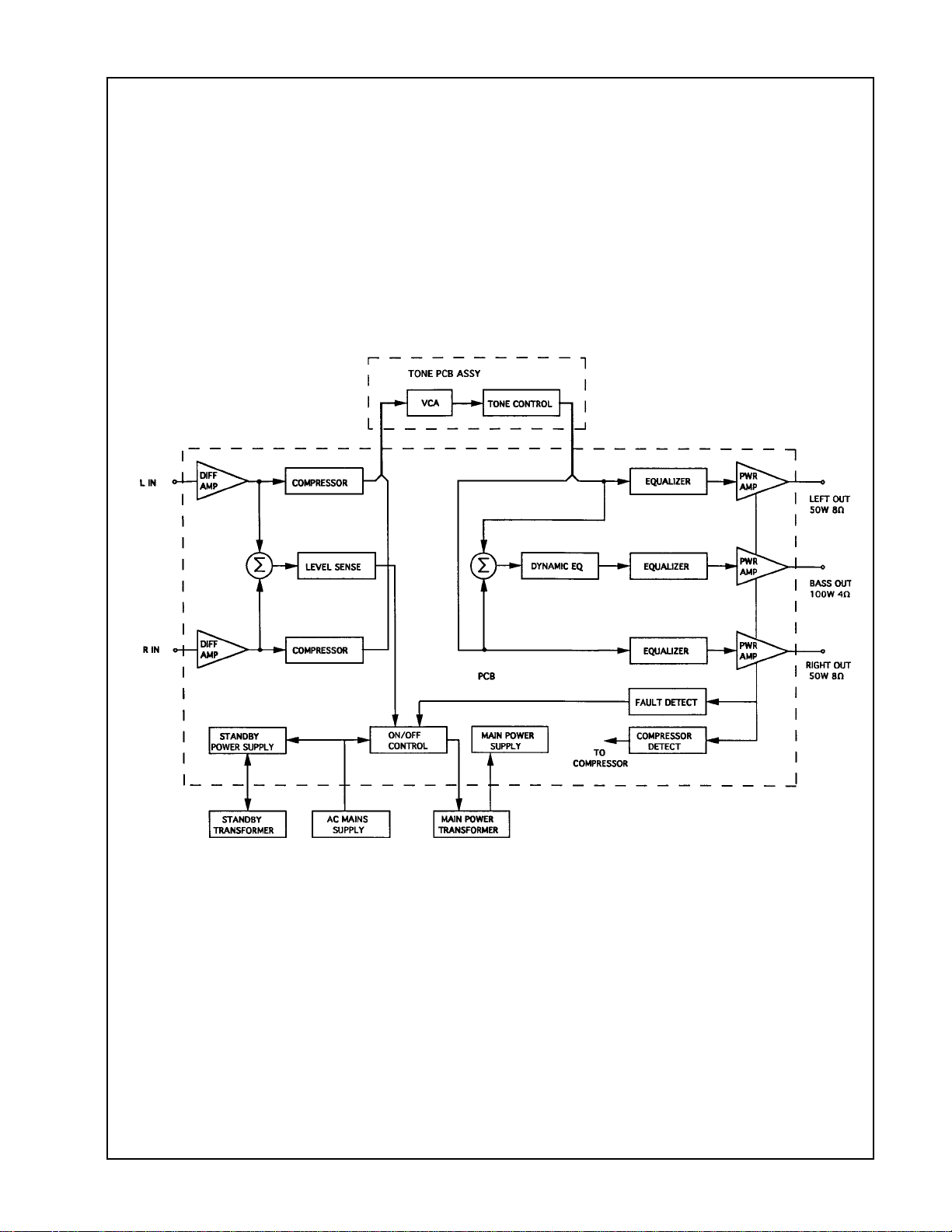

BLOCK DIAGRAM

MAIN

Figure 3. Main PCB (Amplifier) Block Diagram

6

Page 8

THEORY OF OPERATION

The following discussion references the Main PCB Schematic and Block Diagram. The

schematic is located in the back of this manual and the block diagram is shown in Figure 3.

GENERAL

The FreeSpace™business music system electronics module powers the FreeSpace loudspeaker system,which is a derivative of the AM-5

system, FreeSpace is meant to be used in conjunction with the customer's audio source.

The FreeSpace system offers the following features:

- Automatic turn-on/ turn-off (audio sense or signal from the customer's audio source)

- Automatic (Bose

®

patented) dynamic equalization

- Bi-amplification for better power distribution to speakers

- High Efficiency Class G Power Amp stages (100W + 50W +50W)

- Active equalization for smoother frequency response

- Amplifier short-circuit protection

- Bass/treble room compensation controls

- Differential input stage (to reject hum)

- Dynamic compressor to prevent amplifier output overload distortion

- Electronic remote volume

®

powered loudspeaker system. As a powered

BLOCK DIAGRAM DESCRIPTION

Refer to the block diagram and schematic mentioned above. For discussion of L/R channels,

only the right channel is discussed. Left channel operation is identical.

1. Power Supply

Two power supplies are used in the FreeSpace system. One is a low power regulated ±15VDC

supply used to power the signal processing circuitry, the other is the high voltage main power

supply used to power the three Class G power amplifier stages. Two voltages are provided for

class G operation, ±20VDC and ±40VDC. The regulated ±15VDC supply always remains

energized as long as the unit is wired to an active mains voltage source. The main power

amplifier supply is turned on and off by the audio sensing circuit (discussed elsewhere).

7

Page 9

2. Differential Amplifier

Audio input is at barrier strip P5, which is located on the I/O PCB Assembly (see the schematic

located in the back of this manual). This connects directly to the left and right differential

amplifier buffers on the Main PCB. This stage neatly accomplishes several functions: provides

rejection of common-mode interference (like hum) that might be picked up by the long audio

cable between the FreeSpace™ system and the customer's audio source; provides input

overload protection through diodes (D101-104); strips off radio frequency interference through

capacitors C203 and 204; provides DC blockage by capacitors C201 and 202; and provides

a 10 dB gain through op-amp U201 .

3. Compressor

U201 (pins 5,6,and 7), under normal audio conditions, operates as a conventional inverting opamp stage with a gain of 6 dB. However, when overload is present at the speaker outputs,

transistor U205 (pins 5,6 and 7) receives a turn-on signal from the compressor detect stage.

When this happens the transistor acts as a variable resistor to ground, and with resistor R207

forms a voltage divider network that attenuates the audio signal. The amount of attenuation

and timing action is carefully controlled by the compressor detect stage (discussed later).

4. Audio Sense

The FreeSpace system remains in standby mode until audio is detected at its inputs. Audio

sense occurs after the compressor gain stage where the left and right signals are summed

through resistors R222 and R224. The signal is preamplified by inverting op-amp summer

stage U203 (pins 1,2,and 3), and is presented at the pin 1 input of turn-on chip U204 (NJM2072).

Diodes D109 and D110 are necessary to prevent overload of the turn-on chip at high volume

levels. With audio input ≥0.3 mVrms, U204 pin 7 goes high, and through diode D111 turns on

transistor Q401. This triggers relay K1 to energize the main power transformer. Turn-on

(settling) time of the power amplifier section is approximately 80 ms.

Without audio input,U204 pin 7 will go low after approximately 90 seconds, and will de-energize

relay K1 and the main supply. This turn-off time is set by capacitor C217 .

5. Tone /Electronic Volume Control

A separate tone control PCB attaches to the Main PCB through a seven conductor ribbon cable

connector. Power is derived from the main board. The tone control is a standard Baxandall

circuit with +/- 6 dB bass and treble controls. Volume control function is accomplished through

the use of current-controlled amplifier IC U502 (CA3280). The gain of U502 is directly

proportional to the current flowing into pins 3 and 6 from transistor Q502. This current is

proportional to the voltage at the base of Q502. This voltage is adjusted by the external 10K

potentiometer that indirectly attaches across connector J502 through the I/O PCB barrier strip

terminal P5,pins 7 and 8. At minimum volume (0Ω between J502,pins 1 and 2),the voltage at

the base of Q502 should be .36 ± .1 VDC.

At maximum volume (10 KΩ between J502,pins 1

and 2),the voltage at the base of Q502 should be 4.6 ± .1VDC. A schematic is located at the

back of this manual.

8

Page 10

6. High Frequency Equalization

High frequency equalization is achieved through four cascaded active EQ stages consisting of

U101, U102, U103 and U104. The purpose of equalization is two-fold. (1) It provides very sharp

low frequency roll-off below 180 Hz (the crossover frequency of the acoustics) to prevent

overload of the L/R speakers; and (2) It provides finely tailored correction in the L/R speaker

pass band so that overall frequency response of the system is correct.

7. Automatic Dynamic Loudness

In order to compensate for the ear’s loss of bass response at low listening levels, a Bose

patented automatic loudness circuit is employed. This circuit automatically senses the volume

level of the incoming audio signal, and properly adjusts the amount of low frequency bass boost.

When the volume level is high, the frequency response of the circuit is flat. When the volume

level is decreased (at the customer's audio source or through the electronic volume control),

the low frequency gain is increased in the region between 50 and 150 Hz.

Circuit operation is as follows: After passing through the Tone Control PCB, audio at U201 and

U202 (pin 7) is summed by resistors R101 and R131. The AC signal at pin 5 of level detect opamp U203 is negative -peak detected, and is presented across emitter resistor R236. The peak

detected signal has a 4 second hold time, and a 4 sec / 10 dB release time constant which is

developed within the feedback loop of U203 (pins 5,6 and 7). The voltage across R236 is

converted to a current source through transistor Q203, and flows into pin 5 of transconductance

amp U206. U206 and U207 (pins 1,2 and 3) form a variable gain stage (delta-G). Action is

such that increased current into pin 5 of U206 causes gain of the stage to decrease.

The variable gain stage is followed by a 55 Hz, Q=2.3 band pass filter (U207 pins 5,6 and 7).

The output of this stage is summed through resistor R247 with the flat response signal present

at resistor R248. This creates a composite frequency response curve with varying levels of 55

Hz boost. The overall desired loudness contour response is visible at U208 pin 1.

®

8. Low Frequency Equalization

A single stage Sallen-Key 2nd order high-pass / low pass network (U208 pins 5,6 and 7)

provides bass channel equalization and low frequency roll-off to prevent subsonic low

frequency overload.

9. Power Amplifier

All three power amplifiers are of identical topology and use high efficiency Class G power amp

stages. The L/R amplifier channels are both rated at 50W. The bass channel is 100W, and

because of its higher power, uses higher current output transistors and slightly different

component values. Otherwise,operation is the same.

9

Page 11

The basic concept behind Class G operation is simple. It takes advantage of the fact that music,

even at loud volume settings, has only brief moments where peak voltage from the amplifier

is needed. Unfortunately, with conventional Class B amplifiers, this peak voltage is always

supplied to the output transistors and most of the time is wasted as heat. The result is that larger

and more expensive power supplies and heatsinks are needed (or power output transistors are

operated hotter with less reliability).

With Class G however, the amplifier operates off of two different power supply voltages. When

the music is low the amp runs off of the low voltage supply, thus conserving power. When

musical peaks occur, the amplifier “intelligently” switches to the higher voltage supply. On

average, this voltage “conservation” translates to efficiency almost double that of class B.

Detail operation of the amp is as follows: First, it is important to understand that a Class G amp

is really just a class B amp with special circuitry added to it to allow switching between two

different power supply voltages. In the case of the bass amplifier, this switching action is

accomplished on positive peaks by transistors Q335, Q334 and Q333, and on negative peaks

by transistors Q342,343, and Q344.

A positive signal at op-amp input U303 pin 3 causes op-amp supply current to flow into pin 7

through transistor Q336. Q336 is used simply to buffer the +40V high voltage amp supply down

to a safe +15V for the op-amp. This current also flows through resistor R353 and diode D325.

R353 and D325, together with driver transistor Q332 and R355, form a current mirror which

multiplies the current through Q336 by the ratio R353/R355. This increased current flows

through driver transistor Q332, through diode D330, and into the base of output transistor Q337.

The hFE current gain of Q337 (about 40) provides final current amplification before reaching

speaker output.

Class G switching action occurs as follows: the voltage at the anode of D330 tracks one diode

drop above the output voltage of the amp. When this voltage exceeds the nominal +20V power

supply rail transistor Q335 conducts. This in turn causes transistors Q334 and Q333 to turn

on. When Q333 turns on, it acts as a switch and connects the +40V supply present at its emitter

to the collector of output transistor Q337. When this occurs, the +20V supply, normally fed

through diode D329, is turned off because the +40V causes the diode to be reversed biased.

When the music voltage drops below +20V, the reverse happens. The +40V supply is turned

off, and the +20V supply is turned on again.

The power amplifier topology is complementary. Therefore, operation of the amplifier on

negative half cycles is identical to positive cycle operation except for component reference

designations.

10. Short Circuit Protection

The left and right power amp stages have short circuit protection. This is necessary to prevent

damage to the amplifier from possible customer misuse. For example, the customer could

accidentally short the speaker cable wires that connect to the cube speakers. If this happens,

all three amplifiers will momentarily mute for about 3-4 seconds, and will continue to mute until

the abnormal condition is removed.

10

Page 12

This is achieved with the use of a .12 Ω resistor (R313 for right channel) in series with each

amplifier output. Under normal conditions, peak current to the 8 Ω speakers should never

exceed 3.5 amperes. If current flow exceeds 4.5 amperes, then Q309 will conduct and trigger

monostable multivibrator circuit U401 (pins 1,2 and 3). Pin 1 will go high (for about three

seconds) and will trigger mute transistors Q409 and Q408 through diode D406. Turn-on of

Q408 causes all three amplifiers to mute. Referring to the bass power amplifier, actual muting

occurs by turning on transistors Q331 and Q340, which cause both driver transistors (Q332 and

Q341) to turn off. When the driver transistors are off ,there can be no current flow through the

output transistors.

11. DC Offset Protection

If any one of the three amplifier channels should fail, it is likely that a large DC voltage will occur

at the output of that channel. If this occurs, the DC offset detect circuit will cause the

FreeSpace™ main power supply to shut down. It will remain shut-down until the unit is

disconnected from the power source. This provides a safe indication to the customer that the

unit requires service.

Detailed operation is as follows: Outputs of each amplifier are summed by resistors R407,R408

and R409, and low pass filtered by capacitor C401. For a sustained DC offset ,capacitor C401

will charge either negative or positive. A positive offset will trigger transistor Q404. A negative

offset will trigger transistor Q405. This in turn causes transistor Q403 to conduct, and latches

Q404 permanently on. Transistor Q402 then shorts the base of Q401 to ground. Q401 is the

transistor that controls turn-on of relay K1 that is used to energize power transformer T2.

Therefore, when Q401 is disabled, main power is shut down.

12. Compressor Detect

The output of each amplifier is half-wave detected through diodes D409,D410 and D411

respectively. This voltage is divided down by resistors R422 and R423, and is presented at the

emitter of transistor Q410. Power supply voltage is similarly divided down by R425 and R426,

and is presented at the base of Q410. Diodes D419 and D420 simulate the saturation voltage

drop that occurs in the power amp stage. Therefore, when audio output of any amplifier comes

within two volts of the instantaneous power supply voltage, Q410 will conduct, which signals

the compressor (limiter) to act. Current from Q410 charges hold capacitor C405 and release

capacitor C422. Voltage at C405 is buffered by transistor U205 (pins 1,2 and 3) and decreased

down to a logarithmic voltage by resistor R438 and transistor U205 (pins 12,13 and 14). This

voltage is then presented to the base of compressor transistors U205 (pins 5,6 and 7) and U205

(pins 8,9 and 10) which are described in the compressor section.

The DC control voltage present across capacitor C405 is derived through the use of an

improved hold and release characteristic. This results in lower compressor distortion. In

conventional limiters this DC control voltage is derived by a simple series diode and parallel RC

network to ground. Unfortunately, for low frequency overload, this results in substantial ripple

voltage present on the DC gain control voltage. This results in the all too common problem of

mid-range voices or instruments being badly “modulated” by low frequency overload. This

problem is solved by having two separate capacitors, one that “holds” the smooth DC voltage

just long enough to prevent low frequency ripple (approximately 40ms) and the other (C422)

that quickly releases the hold cap (through diode D412) at the proper time to maintain overall

100ms release time.

11

Page 13

NOTES FOR FUTURE REFERENCE

12

Page 14

DISASSEMBLY/ ASSEMBL Y PROCEDURES

NOTE: Figure numbers of exploded views will

be referred to throughout these procedures.

Certain parts will be referenced. The item

number in each figure which corresponds to the

part will be enclosed in parentheses-i.e.-rod

cover (4).

1. Mounting Hardware Removal

NOTES: Refer to Figure 4 for Procedures 1 and 2

unless otherwise specified.

Older versions of the unit contain different

mounting hardware than newer versions of the

unit.

If you have an older version of the unit,the

mounting hardware will consist of 2 threaded tie

rods (not shown) and 4 acorn nuts with washers

(not shown). Refer to step A. for disassembly

instructions.

If you have a newer version of the unit,the

mounting hardware will consist of 2 long screws

(3) which thread into 2 pem nuts (part of the

mounting straps (5). These screws have a hex

head with a built-in washer. Some newer units also

have 1 additional washer located on the end of

each screw. Refer to step B. for disassembly

instructions.

A. For older units: Remove 1 7/16" acorn nut

(with washer) from each threaded tie rod. Another

tool may be needed to hold the acorn nut on the

other end of each rod to prevent the rod from

turning.

Slide each tie rod through the holes located in the

mounting straps. (The rod covers (4) will also slide

off). Remove the mounting straps by pulling them

carefully away from the unit.

2. Mounting Hardware Replacement

A. For older units: Position the 2 mounting straps

(5) so that their screw holes line up with the 2

wide "channels" (between the fins) on each edge

of the heatsink (Figure 6,Item 1). See Figure 4

for proper strap orientation. Slide the 2 threaded

tie rods through the holes located in the mounting

straps. Make sure that the rod covers (4) are in

place before securing the rods to the straps.

NOTE: 2 of the acorn nuts (not shown) should

already be secured on the end of each tie rod.

B. Replace 2 of the 7/16" acorn nuts (with

washers). Another tool may be required to hold

the other acorn nut on each rod.

C. For newer units: Position the 2 mounting

straps so that their screw holes line up with the 2

wide "channels" (between the fins) on the edges

of the heatsink. See Figure 4 for proper strap

orientation. Some newer units have washers that

are located on each screw. Make sure that the

washers are in place before sliding the rod covers

on. Make sure that the rod covers are in place

before securing the screws to the straps. Thread

the 2 long screws (3) into each pem nut (part of

the mounting straps). Make sure that both long

screws are securely fastened.

3. Junction Box Cover Removal

B. For newer units: Unscrew the 2 long screws

from the 2 pem nuts (part of the mounting

straps). Pull the screws through the holes

located in the mounting straps. (The rod covers

will also slide off). On newer units there may also

be 1 washer located on the end of each screw. It

is not necessary to remove either washer.

Remove the straps by pulling them carefully

away from the unit.

NOTE: Refer to Figure 4 for Procedures 3 and 4

unless otherwise specified.

A. Loosen the 4 screws (9) which secure the

junction box cover (8). Slide the cover so that the

screws are released from the smaller section of

the screw hole. Lift the cover away from the

junction box (7).

13

Page 15

4. Junction Box Cover Replacement

7. Tone Control PCB Assembly Removal

A. Position the junction box cover (8) over the 4

screws (9) still secured to the junction box (7).

Lower the cover into place.

B. Slide the cover until all 4 screws are engaged

with the narrow slot in each screw hole. Secure

the cover to the junction box with the 4 screws.

5. Panel Assembly Removal

A. Remove the mounting hardware (Procedure

1) and the junction box cover (Procedure 3).

NOTE: Refer to Figure 4 for Procedures 5 and

6 unless otherwise specified.

B. Remove 14 screws (2) which secure the panel

assembly (1) to the unit.

NOTE: If the panel assembly does not need to

be completely removed,then it may not be

necessary to unhook the connectors as directed

in step C.

NOTE: Refer to Figure 4 for Procedures 7 and

8 unless otherwise specified.

A. Remove the mounting hardware (Procedure

1), junction box cover (Procedure 3),and panel

assembly (Procedure 5).

B. Remove the 2 control knobs (21) using either

your fingers or a flat blade screwdriver.

C. Remove the 2 3/8" hex nuts (22) and washers

(23) which secure the PCB (24) to the unit.

D. Push the control knob shafts through the holes

in the unit and carefully lift the PCB away from

the unit.

8. Tone Control PCB Assembly Replacement

A. Slide the control knob shafts through the holes

in the unit. Make sure that the PCB is solder side

up.

C. Unhook connectors J303 (woofer output) and

J101 from the Main PCB Assembly (Figure 6,

Item 13) and connector J502 from the Tone

Control PCB Assembly (24).

D. Carefully lift the panel assembly away from

the unit.

6. Panel Assembly Replacement

A. Lower the panel assembly (1) into position.

B. Plug in connectors J303 (woofer output) and

J101 to the Main PCB Assembly (Figure 6,Item

13) and connector J502 to the Tone Control PCB

Assembly (24) if they were previously

disconnected.

C. Secure the panel assembly to the unit with 14

screws (2).

D. If no further troubleshooting is required,reinstall the junction box cover (Procedure 4) and

the mounting hardware (Procedure 2).

B. Secure the PCB (24) to the unit with 2 3/8"

hex nuts (22) and washers (23).

C. Replace the 2 control knobs (21) by pushing in

gently towards the unit. The knobs are keyed and

will only fit one way.

D. If no further troubleshooting is required,reinstall the panel assembly (Procedure 6) ,the

junction box cover (Procedure 4) ,and the

mounting hardware (Procedure 2).

9. Woofer Removal

NOTE: Refer to Figure 4 for Procedures 9 and

10 unless otherwise specified.

A. Remove the mounting hardware (Procedure

1),junction box cover (Procedure 3),and the

panel assembly (Procedure 5).

B. Remove the 6 screws (2) which secure the

woofer (19) to the unit, and lift the woofer

carefully away from the unit.

14

Page 16

10. Woofer Replacement

A. Cut the wires connected to the woofer

terminals as close to the terminals as possible.

(These wires are the woofer connection cable

(20)).

B. Strip the ends of the cable and connect to the

replacement woofer (19). Make sure that the red

wire is connected to the positive (+) terminal and

the black wire is connected to the negative (-)

terminal.

NOTE: If no further troubleshooting is

required,restore any connections that may have

been desoldered or disconnected.

C. Replace the panel assembly (Procedure

6),junction box cover (Procedure 4),and

mounting hardware (Procedure 2).

13. I/O PCB Assembly Removal

NOTE: Refer to Figures 6 and 9 for Procedures

13 and 14 unless otherwise specified.

C. Secure the woofer to the unit using 6 screws

(2).

D. Re-connect the woofer connection cable (20)

to the Main PCB Assembly (Figure 6,Item 13)connector J303. Make sure all other connections

to the appropriate PCBs are restored. Repeat the

woofer test procedures.

E. If no further troubleshooting is required, reinstall the panel assembly (Procedure 6),junction

box cover (Procedure 4),and the mounting

hardware (Procedure 2).

11. Main PCB (Amplifier) Assembly Removal

NOTE: Refer to Figure 6 for Procedures 11 and

12 unless otherwise specified.

A. Remove the mounting hardware (Procedure

1),junction box cover (Procedure 3),and the

panel assembly (Procedure 5).

A. Remove the mounting hardware (Procedure

1),junction box cover (Procedure 3), and panel

assembly (Procedure 5).

B. Remove the 2 11/32" nuts (Figure 6,Item 12)

that secure the PCB (Figure 6,Item 11) to the

rear panel (Figure 6,Item 3). Lift the PCB

carefully away from the panel.

NOTE: Unhook connectors P1 through P4 only if

necessary.

C. The barrier strip connector (Figure 9,Item 3)

is soldered to the PCB. Desolder the 16

connections.

NOTE: If the barrier strip connector needs to be

replaced, remove the 4 screws (Figure 9,Item 4)

which secure it to the I/O plate (Figure 9,Item 1).

D. Lift the PCB carefully away from the I/O plate.

B. Remove 9 screws (14) which secure the PCB

(13) to the rear panel (3).

C. Remove 4 screws (4) which secure the

heatsink couplers to the rear panel.

12. Main PCB (Amplifier) Assembly Replacement

A. Secure the 2 heatsink couplers to the rear

panel (3) with 4 screws (4).

B. Secure the PCB to the rear panel (3) with 9

screws (14).

14. I/O PCB Assembly Replacement

A. Align the PCB (Figure 6,Item 11) and I/O

plate (Figure 9,Item 1). The shaft of

potentiometer R8 fits through a hole in the plate.

NOTE: If the barrier strip connector (Figure

9,Item 3) was replaced,proceed as follows: Align

the I/O plate gasket (Figure 9,Item 2) with the

I/O plate,and then secure the connector to the

plate with 4 screws (Figure 9,Item 4).

B. The barrier strip connector needs to be

soldered to the PCB. Solder all 16 connections

to the PCB.

15

Page 17

C. Lower the PCB through its slot on the rear

panel (Figure 6,Item 3).

D. Secure the PCB to the panel with 2 11/32" hex

nuts (Figure 6,Item 12).

D. If no further troubleshooting is required,re-

install the panel assembly (Procedure 6),junction

box cover (Procedure 4),and mounting hardware

(Procedure 2).

NOTE: If connectors P1 through P4 were

unhooked,re-connect them.

E. If no further troubleshooting is required,reinstall the panel assembly (Procedure 6),junction

box cover (Procedure 4),and mounting hardware

(Procedure 2).

15. Power Transformer (T2) Removal

NOTE: Refer to Figure 4 for Procedures 15

and 16 unless otherwise specified.

A. Remove the mounting hardware (Procedure

1),junction box cover (Procedure 3),and panel

assembly (Procedure 5).

B. Remove 4 5/16" hex nuts (15) and washers

(16) that secure the power transformer (14) to the

rear panel (Figure 6,Item 3).

17. "Keep Alive" Transformer (T1) Removal

NOTE: Refer to Figure 6 for Procedures 17 and

18 unless otherwise specified.

A. Remove the mounting hardware (Procedure

1),junction box cover (Procedure 3),and panel

assembly (Procedure 5).

B. Remove 2 1/4" nuts (9) which secure the

transformer (8) to the rear panel (3).

C. The transformer primary and secondary wires

are hardwired to the Main PCB Assembly

(13).Make a note of the wire locations and

desolder all connections.

D. Lift the transformer away from the panel.

18. "Keep Alive" Transformer (T1) Replacement

C. Unhook the transformer primary connector

J402 and the transformer secondary connector

J403 from the Main PCB Assembly (Figure

6,Item13).

D. Lift the transformer carefully up from the

panel.

16. Power Transformer (T2) Replacement

A.Position the transformer (14) in its original

location.

B. Secure the transformer to the rear panel

(Figure 6,Item 3) with 4 5/16" hex nuts (15) and

4 washers (16).

C. Re-connect the transformer primary connector

J402 and the transformer secondary connector

J403 to the Main PCB Assembly (Figure 6,Item

13).

A. Secure the transformer (8) to the rear panel

(3) with 2 1/4" nuts (9).

B. Re-connect the primary side and secondary

side connections to the Main PCB Assembly (13)

as follows:

• Solder the red primary wire to T404.

• Solder the black primary wire to T403.

• Solder the blue secondary wire to T405.

• Solder the white secondary wires (2) to T402

and T401 (order is irrelevant).

C. If no further troubleshooting is required,reinstall the panel assembly (Procedure 6),junction

box cover (Procedure 4), and mounting

hardware (Procedure 2).

16

Page 18

Satellite Procedures

NOTE: Refer to Figure 7 for an exploded view of

the satellite. Certain parts will be referred to in

these procedures. The item number which

corresponds to the part will be enclosed in

parentheses-i.e.-grille (3).

B. Connect the red wire to the positive (+)

twiddler terminal and the black wire to the

negative (-) twiddler terminal.

C. Lower the twiddler into the satellite enclosure

and secure the twiddler to the enclosure with 4

screws (7). Repeat the satellite test procedures.

1. Grille Removal

A. Grasp the top and bottom of the grille and

grille frame (3,5). Pull the assembly carefully

away from the satellite.

2. Grille Replacement

A. Align the grille feet (not shown) with the 4

holes in the satellite enclosure. Push the

assembly gently into place.

3. Twiddler Removal

A. Remove the 4 screws (7) holding the twiddler

(6) in place. Lift the twiddler out and cut the wires

connected to the twiddler as close to its terminals

as possible.

4. Twiddler Replacement

A. Strip the wires and connect to the replacement

twiddler (6).

5. Terminal Cover Removal

NOTE: There are catches on the top and bottom

(inside) of the terminal cover (10) that hook it into

the satellite enclosure. Take care when removing

the cover.

A. Using your fingers or a flat blade

screwdriver,pull the terminal cover carefully from

the satellite enclosure using the recesses in the

cover.

6. Terminal Cover Replacement

A. Snap the terminal cover (10) carefully into

place on the satellite enclosure.

7. Guillotine Connector Removal

A. Remove 2 screws (7) which hold the

connector (9) in place.

8. Guillotine Connector Replacement

NOTE: The positive (+) terminal of each twiddler

is marked with a red dot.

A. Secure the connector (9) to the satellite

enclosure with 2 screws (7).

17

Page 19

TROUBLESHOOTING TIP FOR HUM AND RFI REMOVAL

Hum and RFI (Radio Frequency Interference) are the most common problems when using

unbalanced signal sources and long signal leads. Once you have connected all equipment properly

and made all chassis grounds,adjust the BALANCE TRIM potentiometer located in the junction box.

See the figure below for reference. This shaft can be adjusted with a screwdriver. It is located to the

right of the ( ) symbol,just above the shield label in the SIGNAL INPUT section of the junction

box. Be careful not to contact the AC mains terminals,since this task must be performed with the

power on.

First,turn your signal source electronics off,but do not disconnect the signal leads. If the interference

stops,it is not the signal leads,but the equipment. Second,turn the remote volume control to full

volume (or disconnect the volume control leads). Then,adjust the potentiometer while listening for

minimum interference. Since the system has an automatic turn-on circuit,the system will stop

amplification less than 2 minutes after you turn off the source electronics. If adjustment is not

completed in this time,re-trigger the circuit. You can momentarily turn on the source electronics

(with a signal) or sometimes touch one of the audio terminals with a bare finger. Do not assume that

turning the power switch on and off will trigger the circuit. The internal protection circuitry may

interpret this action as a supply fault and keep the system off for at least two minutes.

At some point in a full rotation of the potentiometer,interference will drop then increase again,so you

must adjust to this minimum point. If this adjustment fails to remove interference,more tests should

be performed before blaming the amplifier or the cabling. Disconnect the signal leads from the

source equipment. Temporarily connect a 1 KΩ resistor between the two signal terminals of the

signal cable(s). Adjust the trim pot again. If the interference is eliminated,the fault is with the source

electronics. If cable termination has been done according to recommendations,then the problem

may still be with the type of isolation provided by equipment with unbalanced outputs. The "ironclad" solution to isolation problems is to use an audio isolation transformer for each channel. This

converts the unbalanced output into a balanced output with shield connection. If interference is still

audible,then a very large signal is being picked up. This may require re-routing of the audio leads,or

even tracking down defective electrical equipment such as fluorescent light ballasts or large

horsepower motors. Large and very close broadcast antennas as well as high power CB radios can

also be a problem. Fortunately,interference of such severity is rarely a problem if a quality

installation of the Free Space system is done.

18

Page 20

TEST PROCEDURES

Satellite Test Procedures

NOTE: Use these procedures only when

satellites come in to be serviced (without the

bass module).

1. Sweep Test

A. Connect an oscillator to a power amplifier.

Adjust the amplifier output to 4 Vrms. Connect

the amplifier leads to the satellite (cube speaker)

input terminals. Sweep the oscillator from 200 Hz

to 5 kHz. If any twiddler buzzes or sounds

distorted,replace it.

2. Phase Test

NOTE: Supply voltage should only be

momentarily applied to the satellite input

terminals to avoid possible damage to the

twiddlers.

1. Sweep Test

NOTE: This test can be performed with a fully

assembled bass module.

A. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 100

Hz,185 mVrms. Sweep the oscillator from 10300 Hz. There should not be any

loud,extraneous sounds. If there are any loud

buzzes or distortion, the woofer may be

defective. The Main PCB (amplifier) should also

be checked for possible problems.

NOTE: There should not be any buzzes or rattles

from within the module. Redress any wire or

component that buzzes or rattles.

2. Tone Control Test

NOTE: This test can be performed with a fully

assembled module.

A. Set a DC power supply to 2 volts. To ensure

that each twiddler is connected in phase, connect

the positive supply lead to the positive (+)

satellite input terminal (red) and the negative

supply lead to the negative (-) satellite input

terminal (black). The twiddler should move

outwards with the application of the supply

voltage.

NOTE: If any twiddler cone deflects inwards or

does not move,check all connections.

Bass Module Test Procedures

NOTES: Use these procedures only when a

module comes in to be serviced (without

satellites). All tests should be performed with the

bass and treble control knobs in the normal or

"detent" position. Remove the junction box cover

using Procedure 3 in the Disassembly/

Assembly Procedures section in order to

access the connection terminals for this unit.

A. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 100

Hz,185 mVrms.

B. Rotate the bass control knob fully clockwise

and counterclockwise from its center or “normal”

position. The bass level should increase and

decrease cleanly without making a scratchy

noise. Clean or replace any potentiometer that

makes this noise.

C. Repeat this procedure for the treble control

using a frequency of 4 kHz.

NOTE: Refer to Figures 1 and 2 for an

approximate bass and treble response for this

procedure.

19

Page 21

3. Frequency Response of L/R (Twiddler) Channels

4. Twiddler Power Output Test

NOTE: This test can be performed with a fully

assembled module.

A. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 1

kHz,30 mVrms for a 0 dB reference.

NOTE: There are 2 sets of twiddler output

terminals for each channel. Refer to the I/O PCB

Schematic before attempting any connections.

For the left channel,connections should be made

to pins 8 (+) and 5 (-). For the right

channel,connections should be made to pins 4

(+) and 1 (-). This note applies to Procedures 3

through 6.

B.Connect an 8Ω resistive load across either the

left or right twiddler output terminals. Using a dB

meter,measure the response according to the

chart given below.

C. Repeat this test for the other channel.

NOTE: This test can be performed with a fully

assembled module. Refer to the second note in

Procedure 3 before making any connections.

A. Connect an 8Ω resistive load and a voltmeter

across either the left or right twiddler output

terminals.

NOTE: These measurements can be obtained at

120 and 240 V. Results will vary depending on

the line voltage used.

B. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 1

kHz, 465 mVrms.

C. Measure the voltage across the load. It should

be approximately 20 volts (50 watts).The signal

should look undistorted when viewed on an

oscilloscope.

5. Twiddler Short Circuit Protection Test

Frequency Relative Response

100 Hz -17.6 dB ± 2.0 dB

210 Hz +1.3 dB ± 1.5 dB

320 Hz - 6.2 dB ± 1.8 dB

1 kHz 0 dB

1.8 kHz -6.5 dB ± 1.5 dB

10 kHz -2.0 dB ± 1.5 dB

36 kHz -5.3 dB ± 2.0 dB

NOTES: This test can be performed with a fully

assembled module. Refer to the second note in

Procedure 3 before making any connections.

A. Adjust the oscillator to 400 Hz, 180 mVrms.

Connect an 8Ω resistive load and a voltmeter

across either the left or right twiddler output

terminals. The output voltage should measure

approximately 8 Vrms. Momentarily short the left

or right twiddler output terminals. The signal

should mute for approximately 2-3 seconds.

6. Compressor Test

NOTE: This test can be performed with a fully

assembled module. Refer to the second note in

Procedure 3 before making any connections.

A. Connect an oscillator to the module's L/R

audio input terminals. Adjust the oscillator to 1

kHz,1.1 Vrms.

20

B. Connect an 8Ω resistive load across either the

left or right twiddler output terminals.

Page 22

C. Connect a distortion meter across either the

left or right twiddler output terminals. The

distortion should be less than 3.0% THD.

D. Repeat the test for the other channel.

7. Air Leak Test

NOTE: This test can be performed with a fully

assembled module.

A. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 40

Hz,185 mVrms. Listen for air leaks around the

cabinet,edge of the amplifier panel,edge of the

heatsink,around the barrier strips (inside junction

box),tone control knobs,power switch, and panel

screws. If there is a“whooshing”noise,there is

probably an air leak in one of these

locations.Repair any air leaks as required.

8. Woofer Rub and Tick Test

A. Make up a temporary set of connections to the

woofer output connector J303 (disconnect from

the woofer). The positive wire should be

connected to pin 2 and the negative wire should

be connected to pin 1 . See the figure below for

a reference.

Pin 1 Pin 2

B. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 100

Hz,30 mVrms for a 0 dB reference.

C. Connect a 4Ω resistive load across the

woofer output. Using a dB meter,measure the

response according to the chart below.

NOTE: In order to perform this test,it is necessary to access the woofer. Refer to Procedure

9,steps A. and B.,Woofer Removal,in the

Disassembly/Assembly Procedures section.

A. Connect an oscillator to the module’s L/R

audio input terminals. Adjust the oscillator to 10

Hz,185 mVrms. No extraneous noises such as

rubbing,scraping or ticking should be heard.

NOTE: To distinguish between normal

suspension noise and rubs or ticks,displace the

cone on the woofer slightly with your fingers. If

the noise can be made to go away or get worse,it

is a rub or a tick and the woofer should be

replaced. If the noise stays the same,it is normal

suspension noise and the woofer is fine.

Suspension noises will not be heard with

program material.

9. Frequency Response of Bass Channel

NOTE: In order to perform the next three tests,it

is necessary to access the panel assembly which

contains the Main PCB. Refer to Procedure

5,Panel Assembly Removal, in the

Disassembly/Assembly Procedures section.

Frequency Relative Response

20 Hz -10.0 dB ± 1.5 dB

55 Hz +4.8 dB ± 1.8 dB

100 Hz 0 dB

200 Hz -1.0 dB ± 1.5 dB

400 Hz -11.4 dB ± 1.5 dB

10. Bass Channel Dynamic EQ Gain

NOTE: Use the same test setup as test

Procedure 9.

A. Adjust the oscillator to 55 Hz,200 mVrms.

The gain relative to the input should be

approximately 35.1 dB.

21

Page 23

11. Woofer Power Output Test

2. System Sweep Test

NOTE: Use the same test setup as Procedure

9,except remove the dB meter.

A. Connect a voltmeter across the 4Ω resistive

load.

NOTE: These measurements can be obtained at

120 and 240 V. Results will vary depending on the

line voltage used.

B. Adjust the oscillator to 100 Hz,555 mVrms.

C. Measure the voltage across the load. It should

be approximately 20.0 volts (100 watts). The

signal should look undistorted when viewed on an

oscilloscope.

Complete System Tests

NOTE: Use these procedures when a complete

FreeSpace™ business music system (module and

satellites) comes in to be serviced. All procedures

listed under Bass Module Test Procedures can

be used to test a complete system except as

indicated below.

1. System Phase Test

A. Use the procedures already given for the

satellites and the module,except use 185 mVrms

for both parts of the test. Use Procedure #1 under

Satellite Test Procedures and Procedure #1

under Bass Module Test Procedures. Make sure

that the satellites are connected to the bass

module.

3. Volume Control Test

A. Connect an oscillator to the module's L/R audio

input terminals. Adjust the oscillator to 4 kHz,185

mVrms.

B. Connect a set of satellites to either the 2 left or

the 2 right channels.

C. Attach the remote volume control to the

positive (+) and negative (-) volume control

terminals. At the 0 volume setting,the audio signal

should be faint or nonexistent,and at the

maximum volume setting,the audio signal should

be loud.

D. If there is no remote volume

control,momentarily short across the positive (+)

and negative (-) volume control terminals. The

signal should be faint or nonexistent.

A. Use the procedures already listed for the

satellites and the module. Use Procedure #2

under Satellite Test Procedures and Procedure

#10 under Bass Module Test Procedures.

22

Page 24

PARTS LISTS AND EXPLODED VIEWS

The following section contains parts lists and exploded views for the FreeSpace™ business

music system. The parts lists are broken down as follows:

-Bass Module Parts List and Exploded View.

-Bass Module Packaging Parts List and Exploded View

-Satellite Parts List and Exploded View.

-Satellite Packaging Parts List and Exploded View.

-Electrical and Mechanical Parts Lists. PCB layouts and schematics are located in

the back of the service manual.

NOTE: The notes section for the entire parts list is contained on page 24.

23

Page 25

PARTS LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. Refer to the Panel Assembly Parts List for parts located on the panel.

3. Refer to the Electrical Parts List for components located on this PCB. Components

with 500 series designators are located on this PCB.

4. This part is not illustrated.

5. This part replaces the original hardware which consisted of: 2 threaded tie rods, P/N 131032-4,

and 4 acorn nuts, P/N 145550.

!

6. This part is critical for safety purposes. Failure to use a substitute replacement with the same

safety characteristics as the recommended replacement part might create shock,fire and/or other

hazards.

7. Current production units slated for US and Japanese markets do not have this hardware

mounted on the junction box.

8. Current European units should contain two owner's manuals: the original manual, P/N 145549,

and the German version of the manual, P/N 149629.

9. Refer to the Electrical Parts List for components located on the PCB assemblies. 100-400 series

designators are located on the Main PCB and 0-99 designators are located on the I/O PCB.

10.Recent production runs of the bass module have 1 washer added to each long screw (Item 3 on

the Bass Module Parts List). This part is not illustrated in Figure 4,but a figure is provided here for

reference.

Long Screw

Washer

24

Page 26

Bass Module Parts List (Figure 4)

Item

Number

Description Part Number Qty.

Per

Module

1 Panel Assembly-120V 145530-1 1 1,2

Panel Assembly-230V 145530-2 1 1,2

Panel Assembly-100V 145530-3 1 1,2

2 Screw-HIRS,8-10x1,PAN,XREC/SQ 137527-16 20

3 Screw-Mach.,1/4 x 20,Hex Wshr. Hd. 148658 2 5

4 Cover-Rod 145983 2

5 Strap-Mounting,Black 145554-01 2

Strap-Mounting,White 145554-02 2

6 Cover-Terminal Block,Yellow 147524-32 1

7 Box-Junction,Black 145107-01 1

8 Cover-Junction Box 145108-01 1

9 Screw-Tapp,8-32 x 9/16,PAN,XRC 145727-09 4

See Note

10 Nut-Hex,Stnd.,Washer,KEPS 118260-08 4

11 Bushing-Rubber 146046 2 7

12 Plate-Anti-rotation 146047 1 7

13 Bushing-Strain relief 146048 1 7

14 Power Transformer-EI96,100/120V,T2or 145526 1 6

!

Power Transformer (alternate),T2

Power Transformer-220/240V,T2

135964 1 6

137819 1 6

15 Nut-Hex,M5 137448 4

16 Washer-M5 138513 4

17 Isolator-Vibration 140343 4

18 Cable Tie 135540 1

25

Page 27

Bass Module Parts List (Continued)

Item

Number

Description Part Number Qty.

Per

Module

19 Woofer-8" 146928 1

or

Woofer-8" (alternate) 142322 1

20 Cable-Woofer Connection 147795 1

21 Knob 136139 2

22 Nut-Hex 137446 2

23 Washer-1/4",Steel 131263-25 2 10

24 PCB Assembly-Tone Control 145525 1 1,3

-

Label-Tone Control 138446 1 4

See Note

26

Page 28

Figure 4. Bass Module Exploded View

27

Page 29

Bass Module Packaging Parts List (Figure 5)

Item

Number

Description Part Number Qty.

Per

Carton

1 Bracket-Wall Mount,Black 145553-01 1

2 Volume Control-Arctic White

(US)

Volume Control-Arctic White

135209-2

170245-01

1

1

(Eur.)

- Polybag (Volume Control) 143393 1

3 Insert-Diecut,Freespace 149240 1

4 Literature Kit-120V 146091-1 1

Literature Kit-230V 146091-2 1

Literature Kit-100V 146091-3 1

which consists of:

A Owner's Manual 145549 1 8

Owner's Manual (Eur.) 149629 1 8

B Warranty Card (US) 139610 1

Warranty Card (Eur.) 135970 1

C Polybag (Literature Kit) 103351 1

D Warranty Service List (US) 122766 1

See Note

E Envelope-Warranty Registration (US) 123001 1

Envelope (Eur.,Japan) 128450 1

F Wrench-Allen, 3/16" 145726 1

G Clip-U,1/4-20 145728 2

H Screw-Mach.,1-1/4",Socket Hd. Cap 145767-20 2

5 Packing-End Cap,EPS 139955 4

6 Polybag (Module) 137847 1

7 Carton 145531 1

28

Page 30

Figure 5. Bass Module Packaging Exploded View

29

Page 31

Panel Assembly Parts List (Figure 6)

Item

Number

Description Part Number Qty.

Per

Assembly

1 Heatsink 145536 1 1

2 Gasket-Heatsink 145537 1

3 Panel-Mounting,Rear 144495-01 1 1

4 Screw-

Thrd. Form,PAN,4-20 x 3/8"

139761-06 15

5 Connector-Barrier Strip,3P 145543-3 1

6 Gasket-Barrier Strip,3 Term. 145544 1

7 Screw-

Tapp,6-32 x 3/4, PAN, XREC

146093-12 2

8 Transformer-Keep Alive,

!

145527 1 6

EI41/120V,T1 (US,Japan)

Transformer-Keep Alive,

146977 1 6

EI41/220V,T1 (Eur.)

See Note

9 Nut-KEP, #4-40 118260-04 2

10 Switch-Rocker, SPST, 11A 145541 1 3

!

11 PCB Assembly-I/O 145546 1 1,9

12 Nut-Hex,STND.,Washer,KEPS 118260-08 2

13 PCB Assembly-Main 145524 1 1,9

14 Screw-

Mach.,#6-32 x 5/16,PAN,XREC

146092-05 9

15 Cable Assembly-Volume Control 145539 1

16 Cable Tie 135540 3

17 Fuse-Slo-Blo,2.5A,5 x 20mm,

!

UL,FS1 (US,Japan)

Fuse-Slo-Blo,1.6A,5 x 20mm,

143668-2500

140346-1600

1 6

1 6

VDE,FS1 (Eur.)

18 Nut-Hex, #8-32, Steel 103237-832 1

30

Page 32

Figure 6. Panel Assembly Exploded View

31

Page 33

Satellite Parts List (Figure 7)

Item

Number

Description Part Number Qty.

1 Logo-White on Black 123981-1A2 1

Logo-White on Grey 123981-1B3 1

2 Nut-Push On,.078 125786 2

3 Grille-Black 145401-1 1

Grille-White 145401-2 1

4 Grille Insert-Left,Black 142080-11 1

Grille Insert-Right,Black 142080-21 1

5 Grille Frame-Left,Black 145396-11 1

Grille Frame-Left,White 145396-13 1

Grille Frame-Right,Black 145396-21 1

Grille Frame-Right,White 145396-23 1

6 Twiddler,2-1/4" (Gasket-Backed) 147525 1

7 Screw-HIRS,6-10x1/2,PAN,XREC 124773-08 6

See Note

Per

Satellite

8 Batting-Polyester 116082 N/A 1

9 Connector,Terminal Strip 136547 1

10 Terminal Cover-Left,Black 136546-11 1

Terminal Cover-Left,White 136546-13 1

Terminal Cover-Right,Black 136546-21 1

Terminal Cover-Right,White 136546-23 1

32

Page 34

Figure 7. Satellite Exploded View

33

Page 35

Satellite Packaging Parts List (Figure 8)

Item

Number

Description Part Number Qty.

Per

Carton

1 Polybag (Satellite Parts) 144677 4

2 Tape-Bag,Sealing 148425 4 1

3 Bracket-Black 149303-1 4

Bracket-White 149303-2 4

4 Wrench-Allen,3/32 141109 1

5 Sheet-Instruction 145824 1

6 Packing-Divider 145395 1

7 Packing-Tape Tube 146468 1

8 Packing-Insert 145399 2

9 Carton-Satellites 145398 1

See Note

Figure 8. Satellite Packaging Exploded View

34

Page 36

Electrical and Mechanical Parts Lists

The next section of this manual contains the electrical and mechanical parts lists. The

electrical parts list contains all electrical components located on the Main PCB,Tone

Control PCB and I/O PCB Assemblies. Each board has a specific series of reference

designators which are coded as follows:

• 0-99 series reference designators correspond to the I/O PCB Assembly

• 100-400 series reference designators correspond to the Main PCB Assembly

• 500 series reference designators correspond to the Tone Control PCB Assembly

The mechanical parts list contains hardware located on the I/O PCB and Main PCB

Assemblies.

NOTE: Fuse FS1 is located on the Main PCB. However,it is added to the PCB during

assembly of the panel. Refer to the Panel Assembly Parts List,Item 17.

35

Page 37

NOTES FOR FUTURE REFERENCE

36

Page 38

Electrical Parts List

Resistors

Reference

Description

Designator

R1-5 100Ω,5%,1/4W,

52 mm,CF

R6,7 10Ω,1%,1/4W,

MF

R101,131 4.7kΩ,5%,1/4W,

CF

R102,132,312,

337,362,376,377,

220Ω,5%,1/4W,

CF

378

R103,133,501,

502,508,509

R105,135,232,

239,240,309,315,

8.2kΩ,5%,1/4W,

CF

10kΩ,5%,1/4W,

CF

334,340,358,363,

411,415,417,421,

424,434,435,439,

517,521-523,

525-527

R106,136,258,427 5.6kΩ,5%,1/4W,

CF

R109,139 510Ω,5%,1/4W,

CF

R110,129,140,

159,226,238,254,

1kΩ,5%,1/4W,

CF

306,308,314,316,

323,324,331,333,

339,341,348,349,

356,359,364,371,

372,418,426,430

R111,112,141,142 56.2kΩ,1%,1/4W,

MF

R117,147 1.78kΩ,1%,1/4W,

MF

R119,149,225,

230,231,403,

100kΩ,5%,1/4W,

CF

407-409,416

R123,153 1.2kΩ,5%,1/4W,

CF

R124,154 30kΩ,5%,1/4W,

CF

R125,127,128,

155,157,158,227,

6.8kΩ,5%,1/4W,

CF

256,302,317,327,

343,352,366,436,

437

Part Number See Note

121243-1211015

121245-22110R0

141760

141750

141815

141742

141765

171328

141741

141779

141773

141743

171327

141755

141767

37

Page 39

Resistors (Continued)

Reference

Description Part Number See Note

Designator

R126,156,207,

218,233,235,402,

20kΩ,5%,1/4W,

CF

404,405,410,413,

420

R130,160,255,

325,350,373,414,

5.1kΩ,5%,1/4W,

CF

425,515,518

R201-204,212-215 1kΩ,1%,1/4W,

MF

R205,206,216,

217,251,253

20kΩ,1%,1/4W,

MF

R208,219 300Ω,5%,1/4W,

CF

R209,221,222,

224,229,429

47kΩ,5%,1/4W,

CF

R228 56Ω,5%,1/4W,

CF

R234 750kΩ,5%,1/4W,

CF

R236 2.4kΩ,5%,1/4W,

CF

R237 8.25kΩ,1%,1/4W,

MF

R241 300kΩ,5%,1/4W,

CF

R242 100kΩ,1%,1/4W,

MF

R243,244 26.7kΩ,1%,1/4W,

MF

R245 6.65kΩ,1%,1/4W,

MF

R246 4.32kΩ,1%,1/4W,

MF

R247,249 27kΩ,5%,1/4W,

CF

R248,506,507,

513,514

18kΩ,5%,1/4W,

CF

R250 5.11kΩ,1%,1/4W,

MF

R252 18.2kΩ,1%,1/4W,

MF

R257 680Ω,5%,1/4W,

CF

141749

141762

141771

141775

141754

141761

141764

141768

141751

141782

141756

141772

141776

141781

141777

141753

141813

141778

141774

141766

38

Page 40

Resistors (Continued)

Reference

Description Part Number See Note

Designator

!

51Ω,5%,1/4W,

Fusing

R303,319,328,345

R304,320,329,

346,422

!

390Ω,5%,1/4W,

CF

5.1Ω,5%,1/4W,

Fusing

R305,321,330,

347,355,370

!

200Ω,5%,1/2W,

Fusing

R307,322,332,342

R311,336,361,516 200Ω,5%,1/4W,

CF

R313,338 0.12Ω,5%,1W,

Metal Oxide

R351,367 33kΩ,5%,1/4W,

CF

!

100Ω,5%,1/4W,

Fusing

R353,368

R354,369 270Ω,5%,1/4W,

CF

!

130Ω,5%,1/2W,

Fusing

R357,365

R401,438 2kΩ,5%,1/4W,

CF

R406,428,503,

504,510,511

1MΩ,5%,1/4W,

CF

R412 12kΩ,5%,1/4W,

CF

R419 3.3MΩ,5%,1/4W,

CF

R423 82Ω,5%,1/4W,

CF

R431,432 2.2Ω,5%,1/2W,

CF

R505,512 24kΩ,5%,1/4W,

CF

R519 4.3kΩ,5%,1/4W,

CF

R520,524 56kΩ,5%,1/4W,

CF

VR501,502 Rotary-25KBX2,

Linear

141287 6

141759

141288 6

141290 6

141747

141783

141757

141286 6

141752

141289 6

141748

141812

141745

141758

141769

141770

141814

171330

171331

141268

39

Page 41

Capacitors

Reference

Description Part Number See Note

Designator

C1-5 0.001µF,5%,Film 137123-102

C6-8 0.033µF,5%,Film 137123-333

C101,102,114,115 0.056µF,5%,50V,

171319

Mylar

C104,105,117,118 0.12µF,5%,50V,

141732

Mylar

C107,108,120,

121,503,504,508,

0.047µF,5%,50V,

Mylar

141811

509

C109,110,122,123 0.082µF,5%,50V,

141738

Mylar

C111,124,203,

204,209,210,215

C112,125 470pF,5%,125V,

0.001µF,5%,50V,

Mylar

141705

171321

Polystyrene

C113,126,206,

212,404

C127,128 0.0068µF,5%,50V,

2.2µF,20%,50V,

Electrolytic

141693

171320

Mylar

C129,130,426 0.01µF,10%,50V,

141702

Ceramic

C201,202,207,

208,216,219,220,

10µF,20%,25V,

Electrolytic

141686

222,229,403,405,

408,409,422,505,

510,515,518,519

C205,211,401 100µF,20%,25V,

141687

Electrolytic

C214,218,402,

423

C217 470µF,20%,10V,

1µF,20%,50V,

Electrolytic

141692

141685

Electrolytic

C221 0.0018µF,5%,50V,

141734

Mylar

C223,227 0.15µF,5%,50V,

141733

Mylar

C224 0.1µF,5%,50V,

141731

Mylar

C225,226 0.47µF,5%,50V,

141737

Mylar

C228 0.01µF,5%,50V,

141730

Mylar

C230 1000pF,10%,50V,

141701

Ceramic

40

Page 42

Capacitors (Continued)

C301,305,307,

311,313,317,410,

0.1µF,+80/-20%,

50V,Ceramic

141809

411,413-416,421,

511,512

C302,304,308,

310,314,316

C319-324 330pF,10%,50V,

4700pF,5%,100V,

Mylar

141739

141700

Ceramic

C406 470µF,20%,35V,

141690

Electrolytic

C407 220µF,20%,35V,

141688

Electrolytic

C412 0.01µF,125VA,

141704

Ceramic

C417,418 10000µF,20%,

141248

50V,Electrolytic

C419,420 4700µF,20%,25V,

141247

Electrolytic

C501,506 0.0012µF,5%,50V,

141810

Mylar

C502,507 10pF,50V,Ceramic 141807

C513,514 330pF,10%,50V,

141808

Ceramic

C516,517 100pF,10%,50V,

144059

Ceramic

Diodes

D101-116,301,

1N4148,Switching

302,304,306,308,

309,311-314,316,

318,320,321,323,

324,325,326,328,

330,332,334,335,

401-414,419,420

D117 Zener,BZX55-

C6V2,6.2V,0.5W

D305,310,317,

322,329,333

1N5402,Silicon

Rectifier,D0-

201AD

1N5402,Silicon

or

Rectifier,D0-27

D415-418 1N4002,1A,Silicon

Rectifier,D0-41

Z401,402

Rectifier,

KBU6GKBU

Rectifier,

or

RS604,RS6

116997

141252

141250

141249

141251

41

Page 43

Transistors

Reference

Designator

Q201,305,306,

311,320,321,326,

335,336,340,401,

402,404-407,501

Q202,203,301,

309,310,313,316,

324,325,328,331,

339,342,403,409,

410,502

!

Q302,317,332

!

Q303,308,318,

323

!

Q304,319,334

!

Q307,315,322,

330

!

Description Part Number See Note

NPN,2SC1815GR,

141260

T0-92

PNP,2SA1015GR,

141263

T0-92

PNP,2SB549Q 112287 6

PNP,BD244B,

137652 6

T0-220

PNP,2SA817A,

141262 6

T0-92

NPN,BD243B,

137651 6

T0-220

NPN,2SD415Q 112886 6

Q312,327,341

!

NPN,2SC1627A,

T0-92

Q314,329,343

!

PNP,TIP36B,

T0-218

Q333,338

!

NPN,TIP35B,

T0-218

Q337,344

Q408 NPN,2SC2362E,

T0-92

U205 Array-MPQ3904,

P-Dip

141259 6

137654 6

137653 6

141261

141258

42

Page 44

Integrated Circuits

Reference

Description Part Number See Note

Designator

REG1

Regulator-15V,1A,

NJM7815A

or

15V,1A,

LM7815CT

,TO-220

TO-220

or

15V,1A,

LM7815

TO-220AB

REG2

Regulator-1A,NJM7915A,

TO-220

1A,

or

-15V,LM7915CT

TO-220

1A,-

or

15V,UA7915UC

TO-220

U101-104,

Op Amp-IC4559

201-203,207,208,

401,501,503

or

IC4558

U204 Sensor-Signal

Level,NJM2072,

P-Dip

U206 Op-Amp-Trans-

conductance,

CA3080,P-Dip

U301,302 Op-Amp,Wide

Band,JFET,I/P,

LF351N,P-Dip

U303 Op-Amp,Low

Drift,JFET,I/P,

LF411,P-Dip

U502 Amplifier,Dual

Variable

Operational,CA3280

,

15V

107410

,

,

107385

,

,

108568

127373

141266

127374

141265

125903

171333

43

Page 45

Connectors

Reference

Description Part Number See Note

Designator

P1,2,4 Header-Right

Angle,2 pin,4.0mm

P3 Header-Right

Angle,4 pin,2.5mm

N/A Housing Assy.,

2+2 pin,210mm,

Left channel

N/A Housing Assy.,

2+2 pin,265mm,

Right channel

J101 Header-7 pin,

I-type,B7B-XH-A

J201 Housing Assy.,

4+4 pin,445mm

J201 Header-4 pin,

I-type,B4B-XH-A

J301-303 Header-2 pin,

I-type,B2P-VH

J401 Header-2 pin,

I-type,LB02TV

J402 Header-3 pin,

I-type,STV-8-3W

J403 Header-5 pin,

I-type,STV-8-5W

J501 Connector Assy.,-

7 pin,300mm

J502 Header-2 pin,

L-type,B2PS-VH

134290-02

145402-04

171322

171323

141792

171324

141790

141787

141788

171325

141791

141816

171332

Miscellaneous Components

Reference

Description Part Number See Note

Designator

!

K1

Relay10A24VDC,250V,

SPST,VS-24MBVD3

or

10A,240V,

MX1-24D-A01,1P1T

L1,2 Inductor-0.5mH,

10%

R8 Potentiometer-

Dual,2K,Detent

171326 6

145725

149281

44

Page 46

Mechanical Parts Lists

I/O PCB Assembly Mechanical Parts List (Figure 9)

Item

Number

Description Part Number Qty. See Note

1 Plate-I/O 145538 1

2 Gasket-I/O Plate 145545 1

3 Connector-Barrier Strip,8 pos. 145542-8 2

4 Screw-Tapp,6-32 x 3/4,PAN,XREC 146093-12 4

Figure 9. I/O PCB Assembly Exploded View (Mechanical Parts)

45

Page 47

NOTE

The parts given in this list are not illustrated. However,the description column provides

location information for these parts.

Main PCB Assembly Mechanical Parts List

Item

Number

Description Part Number Qty. See Note

- Fuse Holder-5x20 mm

[F1]

- Heatsink

[REG1 and REG2 are attached to it]

- Heatsink Coupler (Double)

[Has 12 transistors attached to it]

- Heatsink Coupler (Single)

[Has 6 transistors attached to it]

- Heatsink (B)

[Z401 and Z402 are attached to it]

- Screw-Machine,M3x6x0.5 B/H,Zinc

Plated

[Secures REG1 and REG2 to heatsinks]

- Screw-3x12 B/H, ZN H.S.

[Secures Z401 and Z402 to black heatsink]

- Screw-3x8 B/H H.S. BK

[Secures 18 transistors to heatsink couplers

and secures the black heatsink to the PCB]

- Screw-3x6 BH S.T.

[Secures both heatsink couplers to PCB at the

ends of each coupler]

171334 2

141661 2 1

141271 1 1

141272 1 1

141274 1 1

171624 2

141284 2

141285 20

141283 4

46

Page 48

SCHEMATICS AND PCB LAYOUTS

Three schematics are enclosed backed by their respective PCB layouts. The following PCB

assemblies are contained here:

.I/O PCB schematic backed by its PCB layout and etch layer

.Main PCB schematic backed by its PCB layout and etch layer

.Tone Control PCB schematic backed by its PCB layout and etch layer

47

Page 49

NOTES FOR FUTURE REFERENCE

48

Page 50

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

1/93: REV.0

Bose Corporation

The Mountain

Framingham, Massachusetts USA 01701

P/N 149524

FOR TECHNICAL ASSISTANCE OR PARTS ORDERING,CALL 800-367-4008

Loading...

Loading...