Page 1

Table of Contents

SAFETY INFORMATION ................................................................................................................... 2

Electrostatic Discharge Sensitive (ESDS) ..................................................................................... 3

120V Version Specifications ........................................................................................................ 4-5

230V Version Specifications ........................................................................................................... 6

120V Disassembly/Assembly Procedures .................................................................................. 7-9

230V Disassembly/Assembly Procedures ..............................................................................10-12

BMA-125 Test Procedures 120V .............................................................................................. 13-16

BMA 125 Test Procedures 230V....................................................................................................16

Part List Notes................................................................................................................................ 17

120V Main Assembly Part List ...................................................................................................... 18

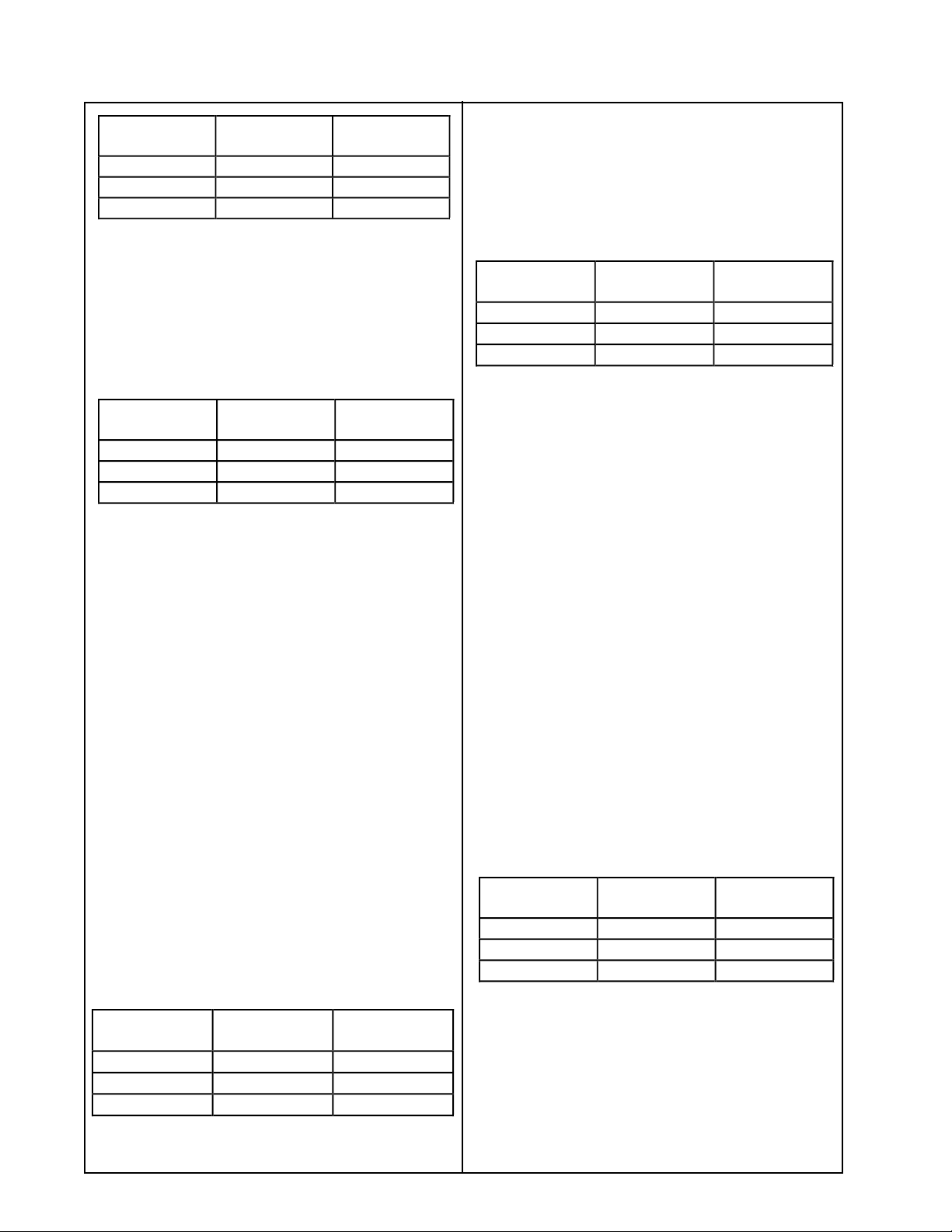

Figure 1. 120V Chassis Layout...................................................................................................... 19

120V Amp PCB Part List ........................................................................................................... 20-22

120V Tone/Volume Control PCB Part List............................................................................... 23-24

120V Equalizer PCB Part List................................................................................................... 25-26

230V Main Assembly Part list .................................................................................................. 27-28

230V Amp PCB Part List ........................................................................................................... 29-31

230V Tone/Volume/Equalizer PCB Part List............................................................................32-35

Input Module 2B37 Part List.......................................................................................................... 36

Input Module 2B50 Part List..................................................................................................... 37-38

Figure 2. 2B37 Schematic and PCB Layout................................................................................... 39

Figure 3. 2B50 Schematic and PCB Layout................................................................................... 40

Figure 4. 120V Driver PCB Layout................................................................................................. 41

Figure 5. 120V Tone/Volume Control PCB Layout ......................................................................... 41

Figure 6. 120V Equalizer PCB Layout (Solder Side) ..................................................................... 42

Figure 7. 120V Equalizer PCB Layout (Component Side) ............................................................. 42

Figure 8. 230V Driver PCB Layout................................................................................................. 43

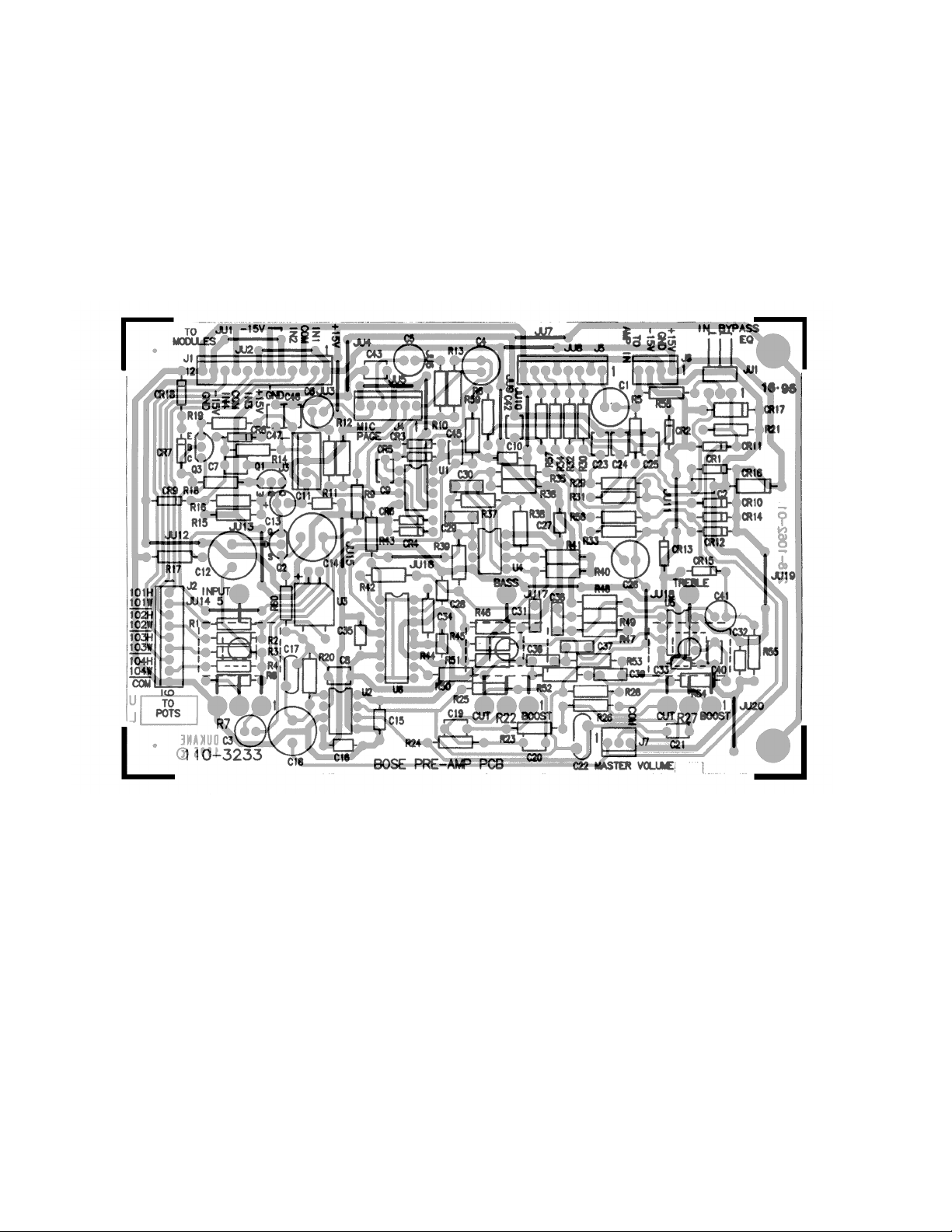

Figure 9. 230V Tone/Volume/Equalizer PCB Layout .................................................................... 44

Figure 10. and 11. 230V wiring diagram ...................................................................................45-46

1

Page 2

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 "Leakage Current for Appliances" and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position and then in

OFF position, measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket,

metal cabinet, screw heads, metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliampere. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZARD

THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO THE

CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug. (2)Turn on the power

switch of the unit. (3) Measure the resistance with an ohmmeter between the

jumpered AC plug and each exposed metallic cabinet part on the unit. When the

exposed metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 Megohms. When there is no return path to the chassis, the

reading must be "infinite". If it is not within the limits specified, there is the possibility of a shock hazard, and the unit must be repaired and rechecked before it

is returned to the customer.

2

Page 3

Electrostatic Discharge Sensitive (ESDS)

Device Handling

This unit contains ESDS devices. We recommend the following precautions when

repairing, replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive

floor mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic

bags, bubble wrap or plastic trays.

CAUTION: THE FREESPACE® BUSINESS MUSIC AMPLIFIER

CONTAINS NO USER-SERVICEABLE PARTS. TO PREVENT

WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY

SERVICE STATIONS OR FACTORY SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

3

Page 4

120V VERSION SPECIFICATIONS

Power Output 125W

Output Regulation Direct output: 0.5dB, no load to full load

Transformer outputs: 1.5dB, no load to full load

Input Sensitivity 2B37 dual input module

Input 1: Microphones: 1KΩ/350µV

Auxiliary: 10KΩ/100mV

Input 2: Microphones: 1KΩ/350µV

Auxiliary: 10KΩ/1V

Input 3 & 4: See instruction sheet enclosed with

module

Input 5: 10KΩ/100mV

Input 6: Mic Page: 150Ω/800µV

Nominal Load Voltage

Output Impedance 70.7V 40Ω (transformer)

25V 5Ω (transformer)

31.65V 8Ω (transformer)

22.35V 4Ω (direct)

Functional Outputs EQ Out: 1.0V into 600Ω (post-master volume)

Line Out: 1.0V into 600Ω (post-master volume)

Tape Out: 650mV int o 10K Ω (pre-master volume)

Mixer Output: 1.0V into 600Ω (pre-master volume)

Frequency Response

at 9dB below rated

output (EQ

bypassed)

EIA SE101A

Power Bandwidth at

rated output/THD

(EQ bypassed)

S/N Ratio All Controls left: 90dB

Tone Controls Bass: ±3dB at 85Hz

Direct:

Transformer:

Direct:

Transformer:

Input 5, Mic Page: 55dB

Modules-Low Z Mic: 60dB

Auxiliary: 70dB

Treble: ±3dB at 12.5KHz

20Hz - 20KHz, ±1dB

20Hz - 20KHz, +1dB/-2dB

20Hz - 20KHz, ±1dB (1% THD)

50Hz - 20KHz, +1dB/-2dB (1% THD)

4

Page 5

120V VERSION SPECIFICATIONS

(Continued)

Mute >30dB (Mute Input 3, 4, 5)

Control Interaction <1dB

Power Outlet Unswitched AC Outlet 120VAC 60HZ, 500W

AC Power

Consumption

Temperature Range 12° F to 140° F (-10° C to + 60° C)

Output Protection Electronic foldback and

thermal overload (both

self-restoring)

DC offset detection (for

direct coupled output)

Size 17"W x 12.75"D x 4.5"H (43.2 X 32.4 x

Weight 27lb (12.3 Kg)

Optional Modules 2B37 Dual input module Mic (screws)/Aux

2B50 Dual input module Mic (screws)/Stereo summing input (Aux)

2B42 Dual input module Aux/Telephone

120VAC, 60HZ at 3.0A at rated output

(0.15A at idle)

11.4 cm) (desk mount)

19"W x 12.75"D x 5.25"H (48.2 x 32.4 x

13.3 cm) (rack mount)

5

Page 6

230V VERSION SPECIFICATIONS

Power Output 125W

Output Regulation Direct output: 0.5dB, no load to full load

Transformer outputs: 1.5dB, no load to full load

Input Sensitivity 2B37 dual input module

Input 1: Microphones: 200Ω/400mV

Input 2: Auxiliary: 10KΩ/1V

Input 3 & 4: See instruction sheet enclosed with module

Input 5: 10KΩ/100mV

Input 6: Mic Page: 150Ω/800µV

Output Impedance 100V 40Ω (transformer)

22.35V 4Ω (direct)

Functional Outputs EQ Out: 1.0V into 600Ω (post-master volume)

Line Out: 1.0V into 600Ω (post-master volume)

Tape Out: 650mV into 10KΩ (pre-master volume)

Mixer Output: 1.0V into 600Ω (pre-master volume)

Frequency Response at

9dB below rated output

(EQ bypassed)

EIA SE101A

Power Bandwidth at

rated output/THD (EQ

bypassed)

S/N Ratio All level Controls left: 90dB

Tone Controls Bass: ±3dB at 85Hz

Mute >30dB (Mute Input 3, 4, 5)

Control Interaction <1dB

AC Power Consumption 230VAC, 50HZ at 1.6A at rated output (0.7A at

Temperature Range 12° F to 140° F (-10° C to + 60° C)

Output Protection Electronic foldback and

Direct:

Transformer:

Direct:

Transformer:

Input 5, Mic Page: 55dB

Modules-Low Z Mic: 60dB

Auxiliary: 70dB

Treble: ±3dB at 12.5KHz

thermal overload (both selfrestoring)

DC offset detection (for

direct coupled output)

20Hz - 20KHz, ±1dB

20Hz - 20KHz, +1dB/-2dB

20Hz - 20KHz, ±1dB (1% THD)

50Hz - 20KHz, +1dB/-2dB (1% THD)

idle)

Size 17"W x 15"D x 5.75"H (43.2 X 38.1 x 14.6 cm)

(desk mount)

19"W x 15"D x 5.25"H (48.2 x 38.1 x 13.3 cm)

(rack mount)

Weight 25lb (11.3 Kg)

6

Page 7

120V DISASSEMBLY/ASSEMBLY PROCEDURES

1. Top Cover Removal

1.1 Remove the ten screws that secure the

top cover to the chassis. There are five on

each side.

1.2 Lift the cover up.

2. Top Cover Replacement

2.1 Place the top cover over the chassis

and align the five screw holes on the top

cover with the screw holes on the chassis.

2.2 Replace the ten screws that secure the

top cover to the chassis. There are five

screws on each side.

3. Input Module Removal

3.1 Remove the four screws that secure

the input module to the chassis.

5.3 Remove the three nuts that secure the

input Five, bass and treble controls to the

chassis.

5.4 Slide the PCB towards the rear of the

unit until the potentiometer's shafts clear

the holes in the chassis.

5.5 Lift the PCB up.

5.6 Remove the four screws that secure the

shield to the PCB.

5.7 Remove all wires attached to the PCB.

Note: Make a note of the wiring configura-

tion before removing any wires.

6. Tone/Volume Control PCB Replacement

6.1 Attach the wires to the PCB.

3.2 Remove the input connector from the

input PCB.

3.3 Slide the input module out from the

rear of the chassis.

4. Input Module Replacement

4.1 Slide the Input Module into the rear of

the chassis so that the labels are aligned

with the labels on the chassis.

4.2 Replace the four screws that secure

the input module to the chassis.

4.3 Connect the input connector to the

input PCB.

5. Tone/Volume Control PCB Removal

5.1 Remove the two screws from the

bottom of the chassis that secure the PCB

to the chassis.

5.2 Remove the input Five, bass and treble

control knobs by pulling straight away on

them.

6.2 Replace the four screws that secure

the shield to the PCB.

6.3 Lower the PCB into the chassis and

slide it forward until the shafts protrude out

the front of the chassis.

6.4 Replace the three nuts that secure the

input five, bass and treble control potentiometer to the chassis.

6.5 Replace the control shaft knobs by

pushing them on.

6.6 Replace the two screws located on the

bottom of the chassis that secure the PCB

to the chassis.

7. Input 1, 2, 3, 4 and Master Volume

Control Removal

7.1 Pull out on the knob to remove it.

7.2 Remove the nut that secures the pot's

shaft to the chassis.

7.3 Slide the pot out of the hole in the

chassis.

7

Page 8

120V DISASSEMBLY/ASSEMBLY PROCEDURES

7.4 Remove all the wires from the pot.

Note: Make note of the wiring configura-

tion.

8. Input 1, 2, 3, 4 and Master Volume

Control Replacement.

8.1 Attach the wires to the pot.

8.2 Insert the pot's shaft into the hole in

the chassis.

8.3 Replace the nut that secures the pot's

shaft to the chassis.

8.4 Replace the control knobs by pushing

them onto the pot's shaft.

9 Driver PCB Removal

9.1 Remove the four screws that secure

the Driver PCB to the chassis.

11.2 Remove the two screws that secure

the equalizer to the chassis.

11.3 Lift the equalizer PCB up.

12. Equalizer PCB Replacement

12.1 Lower the equalizer PCB into the

chassis.

12.2 Replace the two screws that secure it

to the chassis.

12.3 Connect the connector to the PCB.

13. Speaker Output Transformer Removal

13.1 Remove all the wires that connect the

transformer to the speaker output terminals

and the driver PCB.

Note: Make a note of the wiring configuration.

9.2 Remove all the connectors and wires

from the PCB.

Note: Make note of the wiring configuration.

9.3 Lift the Driver PCB up.

10. Driver PCB replacement

10.1 Lower the PCB into the chassis so

that the two large capacitors are located

toward the transformer. Align the screw

holes in the PCB with the standoffs on the

chassis.

10.2 Replace the four screws that secure

the driver PCB to the chassis.

10.3 Replace all the wires and connectors

to the driver PCB.

11. Equalizer PCB Removal

11.1 Remove the connector from the

equalizer PCB.

13.2 Remove the four nuts that secure the

transformer bracket to the chassis.

13.3 Remove the four screws and nuts that

secure the transformer bracket to the

transformer.

14. Speaker Output Transformer Replacement.

14.1 Replace the four screws and nuts that

secure the transformer bracket to the

transformer.

14.2 Lower the transformer into the chassis and align the transformer so that the

purple and brown wires face towards the

rear of the chassis.

14.3 Replace the four screws that secure

the transformer bracket to the chassis.

14.4 Replace the transformer's wires to the

speaker output terminals and the driver

PCB.

8

Page 9

120V DISASSEMBLY/ASSEMBLY PROCEDURES

19. Output Transistor and Heat sink

15. Power Transformer Removal

Replacement.

15.1 Remove the wires that connect to the

AC outlet, power switch and driver PCB.

Note: Make note of the wiring configuration.

15.2 Remove the four nuts that secure the

transformer bracket to the chassis.

15.3 Remove the four screws and nuts that

secure the transformer bracket to the

transformer.

16. Power Transformer Replacement

16.1 Replace the four screws and nuts that

secure the transformer bracket to the

transformer.

16.2 Lower the transformer into the chassis and align the transformer so that the

wires face towards the inside of the unit.

19.1 Push the transistor into the transistor

socket.

Note: Inspect the mylar insulator for

damage. Replace if necessary. Make sure

the transistor and the transistor socket are

flush with the heat sink.

19.2 Replace the two screws that secure

the transistor to the heat sink.

19.3 Lower the heat sink into the chassis

so that the screws holes in the heat sink

align with the screw holes in the chassis.

19.4 Replace the four screws that secure

the heat sink to the chassis.

16.3 Replace the four screws that secure

the transformer bracket to the chassis.

16.4 Replace the wires that connect to the

AC outlet, power switch and driver PCB.

17. Output Transistor and Heat sink

Removal

18.1 Remove the four screws that secure

the heat sink to the chassis.

18.2 Lift the heat sink up.

18.3 Remove the two screws that secure

the transistor to the heat sink.

18.4 With a pair of pliers, grab onto the

transistor and pull it out of the transistor

socket.

9

Page 10

230V DISASSEMBLY/ASSEMBLY PROCEDURES

1. Top Cover Removal

1.1 Remove the fourteen screws that

secure the top cover to the chassis. There

are seven on each side.

1.2 Slide the top cover toward the rear of

the unit and then lift it up.

2. Top Cover Replacement

2.1 Lower the top cover onto the chassis

and slide it toward the front of the unit.

2.2 Replace the fourteen screws that

secure the top cover to the chassis. There

are seven screws on each side.

3. Input Module Removal

3.1 Remove the four screws that secure

the input module to the chassis.

3.2 Remove the input connector from the

input PCB.

5.3 Remove the two nuts that secure the

PCB shield to the chassis.

5.4 Slide the PCB towards the rear of the

unit until the potentiometer shafts clear the

holes in the chassis.

5.5 Lift the PCB up.

5.6 Remove the four screws that secure

the shield to the PCB.

5.7 Remove the connectors from the PCB.

6. Tone/Volume/Equalizer PCB Replacement

6.1 Attach the connectors to the PCB.

6.2 Replace the four screws that secure

the shield to the PCB.

6.3 Lower the PCB into the chassis and

slide it towards the front of the unit until the

shafts protrude out the front of the chassis.

3.3 Slide the input module out from the

rear of the chassis.

4. Input Module Replacement

4.1 Slide the input module into the rear of

the chassis so that the labels are aligned

with the labels on the chassis.

4.2 Replace the four screws that secure

the input module to the chassis.

4.3 Attach the input connector to the input

PCB.

5. Tone/Volume/Equalizer PCB Removal

5.1 Remove the input five, bass and treble

control knobs by pulling them straight away

from the unit.

5.2 Remove the three nuts that secure the

input five, bass and treble controls to the

chassis.

6.4 Replace the three nuts that secure the

input five, bass and treble control pots to

the chassis.

6.5 Replace the control shaft knobs by

pushing them on.

6.6 Replace the two nuts that secure the

PCB shield to the chassis.

7. Input 1, 2, 3, 4 and Master Volume

Control Removal

7.1 Pull on the control knob to remove it.

7.2 Remove the nut that secures the pot's

shaft to the chassis.

7.3 Slide the pot out of the hole in the

chassis.

7.4 Remove all wires from the pot.

Note: Make note of the wiring configura-

tion.

10

Page 11

230V DISASSEMBLY/ASSEMBLY PROCEDURES

8. Input 1, 2, 3, 4 and Master Volume

Control Replacement

8.1 Attach the wires to the pot.

8.2 Insert the pot's shaft into the hole in

the chassis.

8.3 Replace the nut that secures the pot's

shaft to the chassis.

8.4 Replace the control knobs by pushing

them onto the pot's shaft.

9. Driver PCB Removal

9.1 Remove the seven screws that secure

the driver PCB to the chassis. One screw is

located just below and between the two

large capacitors.

9.2 Remove the connectors and the wires

from the PCB.

Note: Make note of the wiring configuration.

12. Speaker Output Transformer Replacement

12.1 Lower the transformer into the chas-

sis so that the wires face toward the rear of

the unit.

12.2 Replace the four screws that secure

the transformer to the chassis.

12.3 Attach the wires to the driver PCB

and the speaker output terminals.

13. Power Transformer Removal

13.1 Remove the wires that connect to the

driver PCB, chassis terminal and the power

switch.

13.2 Remove the four nuts that secure the

transformer bracket to the chassis. Two of

the nuts are located on the bottom of the

chassis and two are located on the side of

the chassis.

9.3 Lift the driver PCB up.

10. Driver PCB replacement

10.1 Lower the PCB into the chassis so

that the two large capacitors are located

towards the front of the unit. Align the

screw holes in the PCB to the holes in the

chassis.

10.2 Replace the seven screws that

secure the driver PCB to the chassis.

10.3 Replace the wires and connectors to

the driver PCB.

11. Speaker Output Transformer Removal

11.1 Remove all the wires that connect the

transformer to the driver PCB and the

speaker output terminals.

13.4 Lift the transformer up.

13.5 Remove the Four screws that secure

the transformer to the transformer bracket.

14. Power Transformer Replacement

14.1 Replace the four screws that secure

the transformer bracket to the transformer.

14.2 Lower the transformer into the chassis so that the black and blue wires face

toward the driver PCB.

14.3 Replace the four nuts that secure the

transformer bracket to the chassis.

14.4 Attach the wires to the driver PCB,

chassis terminal and the power transformer.

11.2 Remove the four screws that secure

the transformer to the chassis.

11

Page 12

230V DISASSEMBLY/ASSEMBLY PROCEDURES

15. Output Transistor and Heat Sink

Removal

15.1 Remove the two nuts that secure the

heat sinks to the chassis.

15.2 Lift the heat sink up.

15.3 Remove the two screws that secure

the transistor to the heat sink.

15.4 With a pair of pliers, grab onto the

transistor and pull it out of the transistor

socket.

16. Output Transistor and Heat Sink

Replacement

16.1 Push the transistor into the transistor

socket.

Note: Inspect the mylar insulator for

damage. Replace if necessary. Make sure

the transistor and the transistor socket is

flush with the heat sink.

16.2 Replace the two screws that secure

the transistor to the heat sink.

16.3 Lower the heat sink into the chassis

so that the screw holes in the heat sink

align with the screws in the chassis.

16.4 Replace the two screws that secure

the heat sink to the chassis.

17. Fuse replacement

17.1 Use a flat blade screw driver to pry off

the fuse holder located on the AC receptacle.

17.2 Pull the card out to expose the fuse.

Lift the fuse out and replace it with a fuse of

equal value. See the part list for the part

number.

12

12

Page 13

BMA-125 120V Test Procedures

2. 4

Ω Output

General Test Setup

Connect a 4Ω, 5Ω, 8Ω and 40Ω 200W load

to the 4, 5, 8, and 40Ω outputs respectively.

Disconnect J1 (located at the equalizer

PCB) and add a jumper from pin 1 (yellow)

to pin 3 (violet) of the J1 connector. This

will bypass the internal equalizer.

Set the tone controls to the center (flat)

position unless otherwise noted.

1. Controls

1.1 Adjust Input Five to the full clockwise

position. Adjust the tone controls to their

center (flat) position and all other volume

controls to their full counter clockwise

position.

1.2 Apply a 100mVrms, 1KHz signal to

Input Five.

1.3 Using the Master volume control,

adjust the output across the 4Ω load to

1Vrms. Reference a dB meter to the

output.

1.4 Apply a 100mVrms, 85 Hz signal to

Input Five. Rotate the bass control to the

full counter clockwise position. Measure the

output. It should be -3 dB

± 1dB.

Note: Remove the “4Ω” to “PRI” jumper.

Connect a 4Ω load between “COM” and

“4Ω”.

2.1 Apply a 105Vrms, 1KHz signal to Input

Five. Adjust Input Five to full output at the

4Ω output (just before clipping).

2.2 Measure the voltage at the output. It

should be

2.3 Measure the distortion. It should be

< 0.5%.

2.4 With the 4Ω output adjusted to

24Vrms, reference a dB meter to the

output.

Measure the response according to the

following table.

Frequency Output

≥ 24Vrms.

(dB)

Tolerence

(dB)

20 Hz 0 -2

1 KHz ref -

20 KHz 0 -1.5

3. 8Ω Output

Note: Place a jumper between the output

connector labeled “4Ω” and the output

connector labeled “PRI”. Connect an 8Ω

load to the 8Ω output and the terminal

marked lo.

1.5 Rotate the bass control to the full

clockwise position. Measure the output. It

should be 3 dB

1.6 Apply a 100mVrms, 10KHz signal to

Input Five. Rotate the treble control to the

full counter clockwise position. Measure the

output. It should be -3.5 dB ± 1 dB.

1.7 Rotate the treble control to the full

clockwise position. Measure the output. It

should be 3.2 dB

± 1dB.

± 1 dB.

3.1 Apply a 120 mVrms, 1KHz signal to

Input Five. Adjust Input Five to full output at

the 8Ω output (just before clipping).

3.2 Measure the voltage at the 8Ω output.

It should be

3.3 Measure the distortion. It should be

< 0.5%.

3.4 With the 8Ω output adjusted to

31 Vrms, reference a dB meter to the

output. Measure the response according to

the following table.

13

≥ 32Vrms.

Page 14

BMA-125 120V Test Procedures

Frequency Output

(dB)

Tolerence

(dB)

50Hz 0 -2

1KHz ref -

20KHz 0 -2.8

3.5 Adjust Input Five until 11.2Vrms is

measured across the 8Ω load. Reference a

dB meter to the output.

3.6 Measure the response according to the

following table.

Frque ncy Output

(dB)

Tolerence

(dB)

20Hz 0 -2

1KHz ref -

20KHz 0 -2.5

4. 25 Volt Output

4.5 Adjust Input Five until 8.875 Vrms is

measured across the 8Ω load. Reference a

dB meter to the output.

4.6 Measure the response according to the

following table.

Frequency Output

(dB)

Tolerence

(dB)

20Hz 0 -2

1KHz ref -

20KHz - -2.5

5. 70 Volt Output

Note: Place a jumper between the output

connector labeled “4Ω” and the output

connector labeled “PRI”. Connect a 40Ω

load to the 70V output and the terminal

marked lo.

Note: Place a jumper between the output

connector labeled “4Ω” and the output

connector labeled “PRI”. Connect a 5Ω

load to the 25V output and the terminal

marked lo.

4.1 Apply a 120mVrms, 1KHz signal to

Input Five. Adjust Input Five to full output

at the 25V output (just before clipping).

4.2 Measure the output. It should be

≥ 25Vrms.

4.3 Measure the distortion. It should be

< .5%.

4.4 With the 25V output adjusted to

25Vrms, reference a dB meter to the

output. Measure the response according to

the following table.

Frequency Output

(dB)

Tolerence

(dB)

50Hz 0 -2

1KHz ref -

20KHz 0 -2.5

5.1 Apply a 105mVrms, 1KHz signal to

Input Five. Adjust Input Five to full output at

the 70 Volt output (just before clipping).

5.2 Measure the output. It should be

≥ 70.7 Vrms.

5.3 Measure the distortion. It should be

< .5%.

5.4 With the output adjusted to 70.7Vrms,

reference a dB meter to the output. Measure the response according to the following table.

Frequency Output

(dB)

Tolerence

(dB)

50Hz 0 -2

1KHz ref -

20KHz 0 -2.5

6. Tape Output

6.1 Apply a 100mV, 1KHz signal to Input

Five.

6.2 Adjust Input Five to the full clockwise

position.

14

Page 15

BMA-125 120V Test Procedures

6.3 Measure the Tape Output. It should be

1Vrms ( -.21, +.26).

7. Mixer Output

10.2 Reference a dB meter to the 4Ω

output.

10.3 Short the two screws labeled mute

together.

7.1 Apply a 100mVrms, 1KHz signal to

Input Five.

7.2 Adjust Input Five to the full clockwise

position.

7.3 Measure the Mixer Output. It should be

1Vrms (-.2, +.29).

8. Line Output

8.1 Apply a 100mVrms, 1KHz signal to

Input Five.

8.2 Adjust Input Five to the full clockwise

position.

8.3 Measure the line output. It should be

.93Vrms (-.19, +.17).

9. Master Volume Control Range

9.1 Apply a 105mVrms, 1KHz signal to

Input Five. Adjust the Master volume

control to the full clockwise position. Adjust

Input Five to full output (just before clipping).

9.2 Reference a dB meter to the 4Ω

output.

9.3 Rotate the Master volume control to

the full counter clockwise position.

10.4 Measure the 4Ω output. It should be

≤ - 70dB.

11. Input 1 and 2: 400

Input

11.1 Apply a 400

Input 1 or 2. Move the selector switch to

the Mic setting.

11.2 Reference a dB meter to the applied

signal.

11.3 Measure the Line Output. It should be

67 dB

11.4 Reference a dB meter to the Line

Output.

11.5 Change the input signal to 20Hz. With

the Mic EQ switch in the FLAT setting,

measure the Line Output. It should be

-5.3 dB

the LOCUT setting, it should be -24.8 dB

± 4 dB.

11.6 Change the input signal to 20KHz.

With the Mic EQ switch in the FLAT setting,

measure the Line Output. It should be

-1 dB

the LOCUT setting, it should be -1 dB

± 1 dB.

± 2 dB. With the Mic EQ switch in

± 1 dB. With the Mic EQ switch in

µV Microphone

µVrms, 1KHz signal to

± 1 dB.

9.4 Measure the 4Ω output. It should be

≤ -50 dB.

10. Mute Control Attenuation

10.1 Apply a 105mVrms, 1KHz signal to

Input Five. Adjust the Master volume

control to the full clockwise position. Adjust

Input Five to full output (just before clipping).

11.7 Apply a 100mV, 1KHz signal to the

INPUT 1 RCA jack or 1Vrms, 1KHz to

INPUT 2.

11.8 Move the selector switch to the AUX

setting. The LINE output should be clean.

Note: Perform the AUX test on both

channels for the 220V variation.

15

Page 16

12. Input 3, 4

BMA-125 120V Test Procedures

Frequency Output (dB) Tolerence (dB)

12.1 Perform the test procedure 11, if the

optional input module is installed.

13. MIC PAGE INPUT

13.1 Apply a 800

the MIC PAGE INPUT. Rotate the PAGE

LEVEL pot to the full clockwise position.

13.2 Reference a dB meter to the applied

signal.

13.3 Measure the LINE output. It should be

60 dB

14. Model 8, 32 EQ

Note: Connect J1 to the EQ PCB. This will

insert the internal EQ. Do this if J1 was

disconnected according to the general test

setup procedure.

14.1 Apply a 100mVrms, 1KHz signal to

Input Five. Move the EQ selector switch to

the Model 8 position.

14.2 Adjust the Master and Input Five gain

controls to obtain a 5Vrms output from the

4Ω output.

± 4 dB.

µVrms, 1KHz signal to

20Hz -18.4 ±3

85Hz 14.5 ±1.5

250Hz 4.3 ±1.5

500Hz 1.2 ±1.5

1KHz ref 5KHz 9.2 ±1.5

12.5KHz 15.5 +.8, -2.2

20KHz 5.4 ±3

230V Variation Tests

Note: Perform all the proceeding tests

except 3, 4 and 5.

1. Remote Master Volume

1.1 Apply a 100mV, 1KHz signal to Input

Five.

1.2 Connect a 4

1.3 Adjust Input Five and the Master

volume control so that 24Vrms is measured

across the 4Ω load.

1.4 Reference a dB meter to the 4Ω

output.

Ω load to the 4Ω output.

14.3 Reference a dB meter to the 4Ω

output. Measure the response according to

the following table.

Frequency Output

(dB)

Tolerence

(dB)

20Hz -20.3 ±3

85Hz 13.2 ±1.5

250Hz 3.7 ±1.5

500Hz .9 ±1.5

1KHz ref 5KHz 5.8 ±1.5

12.5KHz 12.4 +.85,-2.15

20KHz 2.1 ±3

14.4 Move the EQ selector switch to the

Model 32 position. Measure the response

according to the following table.

1.5 Connect a 10KΩ pot to the terminals

marked Remote Master. Rotate the pot to

its minimum resistance position. Measure

the 4Ω output. It should be

2. 100V Output

Note: Remove the 4Ω to PRI jumper and

connect a 80Ω load to the 100V output.

2.1 Apply a 100mVrms, 1KHz signal to the

100V output.

2.2 Adjust Input Five to the full clockwise

position. Adjust the Master volume control

so that 100Vrms is measured across the

80Ω load. The signal should look clean.

16

≤ -40dB.

Page 17

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field

Service Manager is required before ordering.

2. The individual parts located on the PCB are listed in the electrical part list.

3.

with the same safety characteristics as the recommended replacement part might create

shock, fire and/ or other hazards.

This part is critical for safety purposes. Failure to use a substitute replacement

!

17

Page 18

120V Main Assembly Part List

(Figure 1)

Reference

Designator

Q101, 103 Transistor (MJ 15022) 185231 2

Q102, 104 Transistor (MJ 15023) 185232 2

S101-S104 Socket, transistor, W/TO-3CA 185310 4

S101-S104 Insulator, Wafer 183311 4

T101

T102

R101-104 Pot 5K LIN PNL 185247 4

R100, 105 Pot 5K LIN PNL ADJ 185285 2

C101 Cap 220µF 100V 20% 185241 1

F101

S101

2B50 Dual input module-Mic

2B37 Dual input module-Mic

!

!

!

!

!

!

!

Description Part Number Qty S ee

Power Transformer (T101) 185229 1 3

Output Transformer (T102) 185230 1 3

Cap 3300 Pf 1400V CER 185242 1 3

Fuse 4A 250V SLO BLO 185245 1 3

Power Switch 185271 1 3

Power Cord 185233 1

Bracket Heatsink Mtg 185234 4

Bracket Transformer 185235 1

Driver PCB 185236 1 1, 2

Tone/Volume PCB 185237 1 1, 2

Equalizer PCB 185239 1 1, 2

Heatsink 185240 1

Knob, Small 185243 7

Knob, Large 185244 1

Fuseholder 185246 3

Top Cover 185272 1

Terminal Strip, Barrier, 7Ckt 185273 1

Transistor Socket 185274 4

Connector, housing, 6 Ckt 185275 1

Foot 185276 4

180139-2B50 2

(screws)/Stereo summing input

(AUX)

180140-2B37 2

(screws)/AUX

Note

18

Page 19

T101

POWER

TRANSFORMER

T102

AUDIO

TONE/VOLUME PCB

DRIVER PCB

INPUT

MODULE

INPUT

MODULE

C101

Q101, 103

Q102, 104

S101

POWER

R100

MASTER

TREBLE

BASS

INPUT 5

INPUT 4 INPUT 3

INPUT 2 INPUT 1

R27

R22 R7

R104

R103

R102 R101

F101

EQUALIZER

SWITCH

R105

PAGE LEVEL

EQUALIZER

PCB

Figure 1. 120V Chassis Layout

19

Page 20

120V AMP PCB

Resistors

Reference

Designator

R1 5.1Ω, 5%, 1/4W,

R2, 41 10KΩ, 5%, 1/4W,

R4 47KΩ, 5%, 1/4W,

R5 POT, 100KΩ, LIN

R6 51KΩ, 5%, 1/4W,

R7 750Ω, 5%, 1/4W,

R8 680Ω, 5%, 1/4W,

R9 470Ω, 5%, 5W 185321

R10, 11 10Ω, 5%, 1/4W,

R12 2.4KΩ, 5%, 1/4W,

R13 6.8KΩ, 5%, 1/4W,

R14 180KΩ, 5%,1/4W,

R15, 40 5.1KΩ, 5%, 1/4W,

R16 1.5Ω, 5%, 1/4W,

R17 150Ω, 5%, 1/4W,

R18, 21, 22, 26,

27, 30

R19 3.9Ω, 5%, 5W 185330

R20 POT, 200Ω, LIN

R23 620Ω, 5%, 5W 185332

R24, 29, 36 1.0KΩ, 5%, 1/4W,

R25, 28, 46, 47 120Ω, 5%, 1/4W,

R31-34 .22Ω, 5%, 5W 185335

R35 360Ω, 5%, 2W 185336

R37 43KΩ, 5%, 1/4W,

Description Part Number See Note

185286

CF

185433

CF

185316

CF

185317

FLAT PCB

185318

CF

185319

CF

185320

CF

185322

CF

185323

CF

185324

CF

185325

CF

185326

CF

185327

CF

185328

CF

100Ω, 5%, 1/4W,

CF

FLAT PCB

CF

CF

CF

185329

185331

185442

185334

185337

20

Page 21

120V AMP PCB

Resistors (continued)

Reference

Description Part Number See Note

Designator

R38 100KΩ, 5%, 1/4W,

CF

R39 200KΩ, 5%, 1/4W,

CF

R42 82Ω, 5%, 1/4W,

CF

R45 15KΩ, 5%, 1/4W,

CF

Capacitors

Reference

Description Part Number See Note

Designator

C2, 11 4.7 UF, 50V,

ELCT NP

C3, 4 470, PF 500V,

CER, 10%

C5 10 PF, 1KV, CER,

10%

C6 30 PF, 1KV, CER,

10%

C7, 8 220, UF, 50V,

ELCT RDL

C9 .1 UF, 200V,

MYLAR

C10 1000 PF, 50V,

CER, 10%

C12, 13 6800 UF, 50V,

ELCT RDL

C14, 15 22 UF, 50V,

ELCT, RDL

C16 3.3 UF, 50V,

ELCT RDL

C17 100 UF, 50V,

ELCT RDL

C20 150 PF, 500V,

CER, 10%

C21 220 UF, 25V,

ELCT RDL

185427

185339

185340

185341

185342

185343

185344

185345

185346

185347

185348

185349

185350

185351

185352

185353

185354

21

Page 22

120V AMP PCB

Diodes

Reference

Description Part Number See Note

Designator

CR1, 2 ZENER, 5.1V,

185355

1/4W

CR3-9, 16, 19-21 RECTIFIER 185356

CR10, 11 ZENER, 15V,1W 185357

CR12-15

!

6 AMP, 200V 185358

CR17 ZENER, 12.0V 185359

CR18 ZENER, 22.0V 185360

Transistors

Reference

Description Part Number See Note

Designator

Q1, 2, 3, 5, 13, 15 2N5210 185365

Q4 MPS-A93 185366

Q6 MPSU06 185367

Q7 MJE253 185368

Q8 2N5088 185369

Q9 2N5086 185370

Q10 MPSU56 185371

Q11 MJE243 185372

Q12 MPS6566 185373

Q15, 16 MPS6518 185374

Miscellaneous

Reference

Description Part Number See Note

Designator

(Q7,11) BRK T , HEAT

185375

SINK, (2)

(Q7, 11) LK WASH, #4,

185376

SPLIT SR (2)

(Q7, 11) NUT, 4-40 HEX,

185377

DBL CHAM (2)

!

K1

J1 12 PIN, FRICTION

DPDT, 24V 185364

185361

LOCK

J2 CONNECTOR 185362

J3 MOLEX, SQ

185363

WIRE, 6 POS

22

Page 23

120V Tone/Volume Control PCB

Resistors

Reference

Description Part Number See Note

Designator

R2, 3, 4, 5, 7, 26,

27, 28, 30

R6 47KΩ, 5%, 1/4W,

1.2KΩ, 5%, 1/4W,

CF

185393

185316

CF

R8, 39 100Ω, 5%, 1/4W

185429

CF

R9, 10, 13, 16 1.0KΩ, 5%, 1/4W,

185442

CF

R11, 40 1OKΩ, 5%, 1/4W,

185433

CF

R12 51Ω, 5%, 1/4W,

185398

CF

R14, 15, 41, 42,

43

R17, 18 100KΩ, 5%, 1/4W,

VARISTOR-TVS

14V

185399

185427

CF

R19 3.3KΩ, 5%, 1/4W,

185401

CF

R20, 21, 34 20KΩ, 5%, 1/4W,

185402

CF

R22 POT, 5KΩ, PCB,

185403

MTG

R23 8.2KΩ, 5%, 1/4W,

185404

CF

R24, 37 5.1KΩ, 5%, 1/4W,

185326

CF

R29, 31 POT, 100KΩ,

185406

PCB, MTG

R32, 33 150KΩ, 5%, 1/4W 185407

R35 75KΩ, 5%, 1/4W 185408

R36 91KΩ, 5%, 1/4W 185409

R38 75Ω, 5%, 1/4W,

185410

CF

Capacitors

Reference

Description Part Number See Note

Designator

C1 30 PF, 1KV, CER,

10%

C2, 3, 11, 12 47 µF, 25V,

ELECT RDL

C4, 5 100 µF, 25V,

ELCT RDL

185345

185417

185419

23

Page 24

120V Tone/Volume Control PCB

Capacitors (continued)

Reference

Description Part Number See Note

Designator

C6 56 PF, 50V, CER,

185420

20%

C8,9 47 µF, 10V, ELCT,

185421

RDL

C10 10V, 680 µFD 185412

C13,14 .015 µF, 50V,

185413

CER, 20%

C15 220 PF, 50V,

185414

CER, 20%

C16 22 PF, 1KV, CER,

185415

10%

C17, 18, 19, 20 .01 µF, 50V, CER,

185416

20%

C21, 22 33 µF, 25V, ELCT

185418

RDL

Transistors

Reference

Description Part Number See Note

Designator

Q1 2N5088 185369

Q2 VN0300M 185423

Integrated Circuits

Reference

Description Part Number See Note

Designator

U1, 2 LM833 185474

Miscellaneous

Reference

Description Part Number See Note

Designator

(Q5, 6) BRKT, HTSNK 185425

(Q5, Q6, U2, U3) LK WASH, 4

185426

SPLT SPRING

(Q5, Q6, U2, U3) NUT, 4-4- HEX

185427

DBL CHAM

(U2, 3) HEATSINK W/

185428

LEGS

(U2, 3) SCR 4-40 X 5/16 185429

24

Page 25

120V Equalizer PCB

Resistors

Reference

Description Part Number Reference

Designator

R1, 2, 4, 5, 16, 18 10.0KΩ, 1/4W, 1% 185524

R3 22.1KΩ, 1/4, 1% 185546

R6, 7, 9, 14, 20,

4.75KΩ, 1/4W, 1% 185560

22, 28

R8 93.1KΩ, 1/4, 1% 185541

R10, 23 25.5KΩ, 1/4W, 1% 185522

R11, 24 3.09KΩ, 1/4W, 1% 185544

R12, 15, 25, 27 8.25KΩ, 1/4W, 1% 185525

R13, 21 82.5KΩ, 1/4W, 1% 185291

R17 14.0KΩ, 1/4W, 1% 185496

R26 75.0KΩ, 1/4W, 1% 185498

R29, 30 47KΩ, 1/4W, 5%,

185316

CF

R31, 32 475Ω, 1/4W, 1% 185484

R33 AT C13 100Ω, 5%, 1/4W,

185429

CF

Capacitors

Reference

Description Part Number Reference

Designator

C1, 27 10 UF, 25V,

185501

ELECT, RDL

C2, 3, 10, 11 .0056, UF, 5% 185378

C4, 12 0.47, UF, 5% 185379

C5, 14 .068, UF, 5% 185380

C6, 7, 15, 16 .1UF, 5% 185381

C8, 17 .0068UF, 5% 185382

C9, 18 330 PF, 50V, 5%,

185383

CER

C19-26, 29, 30 .01 UF, 25V, 20%,

185384

CER

C28 2200, PF, 50V,

185385

5%, CER

Integrated Circuits

Reference

Description Part Number Reference

Designator

U1-4 LM833 185474

U5 NJM2120L 185387

25

Page 26

120V Equalizer PCB

Miscellaneous

Reference

Designator

J1 12 PIN, FRICTION

JU1 WIRE, SOL BARE,

U1-4 SOCKET, 8 PIN 185392

Description Part Number Reference

185361

LOW

185391

TND 22 A

26

Page 27

230V Main Assembly Part List

(Figure 10, 11)

Reference

Designator

Q101, 102 Transistor, MJ 15022 185231 2

Q103, 104 Transistor, MJ 15023 185232 2

T102 Transformer, Output 185279 1

T101 Transformer, Power 185280 1 3

R107, 108 510Ω, 5%, 1/4W CF 185281 2

R109 1Ω, 5%, 1/2W CF 185282 1

R101-104 Pot, 5KΩ, Lin, Pnl Mt 185247 4

R105 Pot, 10KΩ, Lin, Pnl Mt 185284 1

R106 Pot, 5KΩ, Lin, Pnl Mt 185285 1

C113, 114 470 pF, 250V, Cer 185270 2

C119 470 pF, 500V, Cer 10% 185287 1

C104, 105,

117, 118

C107, 108,

110, 111

C101-103.

106, 109, 112,

115

SW101

SW1 02 Slide, SPDT 185294 1

TS101

TS102 Terminal, Barrier 185297 1

TS103 Terminal Strip, 6 Cont 185298 1

TS104 Phono Jack, 3 Pos 185299 1

TS105 Phono Jack, 2 Pos 185300 1

TS106 Terminal Strip, 3 Cont 185301 1

TS107 Terminal Strip 185302 1

TS108 Terminal Strip, 3 Lug 185303 1

TS109 Terminal Strip 185304 1

(TS101- Red) Plug, Spkr Term, Red 185306 1

(TS101-Blk) Plug, Spkr Term, Blk 185307 1

P110

F101

S101-S104 Socket, Transistor,

S101-S104 Insulator Wafer 185311 4

!

!

!

!

.001 µF, 50V, Cer 20% 185288 4

.01 µF, 50V, Cer X7R 185289 4

.1 µF, 50V, Cer 185290 9

Power Switch 185293 1 3

Rcpt Spkr 185296 1

Rcpt, IEC W/Fuse 185308 1 3

Fuse, 250V, 1.6A 185309 1 3

W/TO-3 CA

Top Cover 185312 1

Foot 185276 4

Knob, SM, (R101-104) 185243 7

Knob, LG, (R105) 185315 1

Heat Sink 185316 2

125W Driver PCB 185278 1 1, 2

Pre AMP PCB 185277 1 1, 2

Description Part

Number

185310 4

Qty See

Note

27

Page 28

230V Main Assembly Part List (continued)

(Figure 2, 3)

Reference

Designator

2B50 Dual input module-Mic

2B37 Dual input module-Mic

!

!

!

Power Cord, EUR 185314 1 3

Power Cord, U.K. 185283 1 3

Power Cord, AUS 185286 1 3

(screws)/Stereo

summing input (AUX)

(Screws)/Stereo

summing input (AUX)

Description Part

Qty See

Number

180139-2B50 2

180140-2B37 2

Note

28

Page 29

230V AMP PCB

Resistors

Reference

Designator

R1 51KΩ, 5%, 1/4W,

R2, 45 5.1KΩ, 5%, 1/4W,

R3, 36 100KΩ, 5%, 1/4W,

R4 30Ω, 5%, 1/4W,

R5, 18, 21, 24, 25,

40, 41

R6 16KΩ, 5%, 1/4W,

R7 2.7KΩ, 5%, 1/4W,

R8 12KΩ, 5%, 1/4W,

R9,10,11, 37, 46 10KΩ, 5%, 1/4W,

R12,15 620Ω, 5%, 1/4W,

R13,16 390Ω, 5%, 1/4W,

R14,17 62KΩ, 5%, 1/4W,

R22, 23 43KΩ, 5%, 1/4W,

R26, 27 130Ω, 5%, 1/4W,

R28, 29, 30, 31 .39Ω, 5%, 5W 185439

R32, 33 1.3KΩ, 5%, 1/4W,

R34 3.9Ω, 5%, 5W 185441

R42, 43 1KΩ, 5%, 1/4W,

R47, 51 270Ω, 5%, 1/4W,

R49, 50 100Ω, 5% 1/2W

Description Part Number See Note

185425

CF

185426

CF

185427

CF

185428

VF

100Ω, 5%, 1/4W,

CF

CF

CF

CF

CF

CF

CF

CF

CF

CF

CF

CF

CF

CF

185429

185430

185431

185432

185433

185434

185435

185436

185437

185438

185440

185442

185443

185444

29

Page 30

230V AMP PCB

Transistors

Reference

Designator

Q1 MPS-A93 185465

Q2 2N5551 185466

Q3, 6 MJE340 185467

Q4, 5 MJE350 185468

Q7, 16 2N5088 185469

Q8, 15 2N5086 185470

Q9 2N3904 185471

Q10, 11 2N3906 185472

Q12, 13 2N5210 185473

Reference

Designator

U1 LM833 185474

U2 7815 185475

U3 7915 185476

Description Part Number See Note

Integrated Circuits

Description Part Number See Note

Diodes

Reference

Designator

CR1, 2, 5-7, 1721, 28-34, 37

CR8, 9 -14 RECTIFIER,

CR3, 4 ZENER, 9.1V 185479

CR15, 16 3A, 200V 185480

CR22 ZENER, 10V 185481

CR23, 24, 26, 27 6A, 200V 185482

Description Part Number See Note

SILICON 185477

185478

IN4937

!

30

Page 31

230V AMP PCB

Miscellaneous

Reference

Designator

!

K1

J1 4 PIN FRICTION

J2 MOLEX, 6 PIN 185485

J3 MOLEX, 5 PIN 185486

(U2, 3) HEATSINK W/

(Q5, Q6) BRKT, HTSNK 185488

(Q5, Q6, U2, U3) LK WASH, 4

(Q5, Q6, U2, U3) NUT, 4-4- HEX

(U2, U3) SCR, 4-40 X 5/16 185491

Description Part Number See Note

SPDT, 24V COIL 185483 3

185484

LOCK

185487

LEGS

185489

SPLT SPRING

185490

DBL CHAM

31

Page 32

230V Tone/Volume/Equalizer PCB

Resistors

Reference

Designator

R1, 2, 5, 6, 8 5.6KΩ, 5%, 1/4W,

R3, 4, 14, 16, 18 4.7KΩ, 5%, 1/4W,

R7 POT, 5KΩ, PCB

R9 7.5KΩ, 5%, 1/4W,

R10,11 1KΩ, 5%, 1/4W,

R12, 13, 20 105KΩ, 1%, 1/4W 185497

R15 10KΩ, 5%, 1/4W,

R17 200KΩ, 5%, 1/4W,

R19 39Ω, 5%, 1/4W,

R21, 44, 55 100KΩ, 5%, 1/4W,

R22, 27 POT, 100KΩ, PCB

R23, 25 150KΩ, 5%, 1/4W,

R24 20KΩ, 5%, 1/4W,

R26 75KΩ, 5%, 1/4W,

R28 91KΩ, 5%, 1/4W,

R29-34, R56-58 300Ω, 5%, 1/4W,

R35-37, 40 10KΩ, 1%, 1/4W,

R38, 41, 48, 53 4750Ω, 1/4W, 1% 185509

R39 22.1KΩ, 1%,

R42 38.3KΩ, 1%,

R43 2.4KΩ, 5%, 1/4W,

R45 93.1KΩ, 1/4W, MF 185513

R46 732KΩ, 1%, 1/4W,

R47 25.5KΩ, 1%,

Description Part Number See Note

185492

CF

185493

CF

185494

MTG

185495

CF

185442

CF

185433

CF

185499

CF

185500

CF

185427

CF

185502

MTG

185503

CF

185504

CF

185505

CF

185506

CF

185507

CF

185508

MF

185510

1/4W, MF

185511

1/4W, CF

185512

CF

185514

MF

185515

1/4W, MF

32

Page 33

230V Tone/Volume/Equalizer PCB

Resistors

Reference

Description Part Number See Note

Designator

R49 3.09KΩ, 1%,

185516

1/4W, MF

R50 825KΩ, 1%, 1/4W,

185517

MF

R51 82.5KΩ, 1%,

185518

1/4W, MF

R52, 54 8.25KΩ, 1%,

185519

1/4W, MF

R59 7150Ω, 1/4W 185520

Capacitors

Reference

Description Part Number See Note

Designator

C1, 4, 26 4.7 µF, 50V, ELCT

185521

NP

C2, 21 220 PF, 50V,

185463

CER, 20%

C3, 5, 6, 41 47 µF, 25V, ELCT

185523

RDL

C7, 43, 46, 47 .01 µF, 50V, CER,

185455

20%

C8 470 PF, 50V,

185461

CER, 20%

C9 56 PF, 50V, CER,

185526

20%

C10, 11, 15, 16,

27, 28, 32-35

.1 µF, 50V, CER,

20%

185527

C12, 14, 18 220 µF 185528

C13 4.7 µF, 50V, ELCT

185529

RDL

C17 5 PF, 1KV, CER,

185530

20%

C19, 20 .015 µF, 50V,

185531

CER, 20%

C22 22 PF, 1KV, CER,

185532

10%

C23, 24, 25 2200 PF, 50V,

185533

CER, 20%

C29, 30 .0056 µF 185534

C3 1 .047 µF 185535

C3 6 .068 µF 185536

33

Page 34

230V Tone/Volume/Equalizer PCB

Capacitors

Reference

Description Part Number See Note

Designator

C37, 38 .1 µF 185537

C3 9 .0068 µF 185538

C40 330 PF, 5%, CER 185539

C42 3900 PF, 50V,

185540

CER, 20%

C45 100 PF, 50V, CER 185453

Transistors

Reference

Description Part Number See Note

Designator

Q1 2N5086 185470

Q3 2N3904 185543

Integrated Circuits

Reference

Description Part Number See Note

Designator

U1, 2, 4, 5 LM833 185474

U6 DG211CJ 185545

Diodes

Reference

Description Part Number See Note

Designator

CR1, CR15, CR18 SIGNAL 185546

CR16, 17 ZENER, 18V 185547

34

Page 35

230V Tone/Volume/Equalizer PCB

Miscellaneous

Reference

Designator

J1 12 PIN FRICTION

JU1 3 PIN, 1 RT ANG

J2 9 PIN 185550

J3 FRICTION LK 185551

J4 6 PIN FRICTION

J5 8 PIN 185553

J6 FRICTION LK 185484

J7 3 PIN FRICTION

U1, 2, 4, 5 SOCKET, 8 PIN

U6 SOCKET, 16 PIN

Description Part Number See Note

185548

LOCK

185549

PC

185552

LK

185555

LK

185556

IC PCB

185557

IC PCB

35

Page 36

Input Module 2B37 Part List

Resistors

Reference

Description Part Number See Note

Designator

R1, 10 56KΩ, 1/ 4W, 5% 185394

R2, 11 24KΩ, 1/ 4W, 5% 185405

R3, 12 820Ω, 1/4W, 5% 185422

R4, 15 10KΩ, 1/ 4W, 5% 185433

R5, 7, 13, 14 20KΩ, 1 /4W, 5% 185402

R8 1.8KΩ, 1/4W, 5% 185386

R9, 16 1KΩ, 1/4W, 5% 185442

R17 22KΩ, 1/4W, 5% 185329

Capacitors

Reference

Description Part Number See Note

Designator

C1, 2, 10, 11 .01µF, 50V, CER 185416

C3, 12 100pF, 50V, CER 185453

C4 33µF, 25V, Elect 185418

C13-16 47µF, 25V, Elect 185417

C17, 18 .68µF, 50V, Elect 185338s

Integrated Circuits

Reference

Description Part Number See Note

Designator

U1, 2 LM833 108474

Miscellaneous

Reference

Description Part Number See Note

Designator

J1 Friction lock, 5

185333

Crkt

Transformer 185313

T1, 2

36

Page 37

Input Module 2B50 Part List

Resistors

Reference

Description Part Number See Note

Designator

R1, 2, 11, 15 5.6KΩ, 1/4W, 5% 185492

R3, 6, 7 604Ω, 1/4W, 1% 185559

R4, 5 100Ω, 1/4W, 5% 185429

R8 68Ω, 1/4W, 5% 185571

R9, 14 51KΩ, 1/4W, 5% 185425

R10 5100, 1/4W, 5% 185426

Capacitors

Reference

Description Part Number See Note

Designator

C1 1200 PF, CER,

185574

50V

C2-5, 8-10 .01 UF, CER, 25V 185455

C6, 7 10 UF, ELCT,

185575

RDL, 25V

C11, 12 47 UF, ELCT,

185573

RDL, 25V

C13, 20 .1 UF, CER, 50 V 185448

C14, 15 220 PF, CER, 50V 185463

C16 22 PF 185572

Integrated Circuits

Reference

Description Part Number See Note

Designator

U1 SSM2017 185305

U2 LM833 185474

Diodes

Reference

Description Part Number See Note

Designator

D1-6 SIGNAL 185546

37

Page 38

Input Module 2B50 Part List

(continued)

Miscellaneous

Reference

Description Part Number See Note

Designator

J1 3 PIN 185555

JU1 2 PIN 185558

J2 5 PIN 185551

J3, 4 RCA 185301

U1, 2 IC SOCKET, 8

185556

PIN

38

Page 39

Figure 2. 2B37 Schematic and PCB Layout

39

Page 40

Figure 3. 2B50 Schematic and PCB Layout

40

Page 41

Figure 4. 120V Driver PCB Layout

Figure 5. 120V Tone/Volume Control PCB Layout

41

Page 42

Figure 6. 120V Equalizer PCB Layout (Solder Side)

Figure 7. 120V Equalizer PCB Layout (Component Side)

42

Page 43

Figure 8. 230V Driver PCB Layout

43

Page 44

Figure 9. 230V Tone/Volume/Equalizer PCB Layout

44

Page 45

Figure 10. 230V Wiring Diagram

(Part 1)

45

Page 46

Figure 11. 230V Wiring Diagram

(Part 2)

46

Page 47

47

Page 48

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

®

BOSE CORPORATION

THE MOUNTAIN

FRAMINGHAM, MASSACHUSETTS USA 01701

P/N 177864 3/96: REV. 0 FOR TECHNICAL ASSISTANCE OR PART ORDERS, CALL 1 -800 -367 -4008

Page 49

FREESPACE® BUSINESS MUSIC AMPLIFIER

BMA-125

120/230V

®

120V Version shown

©1996 Bose Corporation

Service Manual

Part Number 177864

Loading...

Loading...