Page 1

CONTENTS

Safety Information............................................................................................................................ 3

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 4

Warranty Information....................................................................................................................... 4

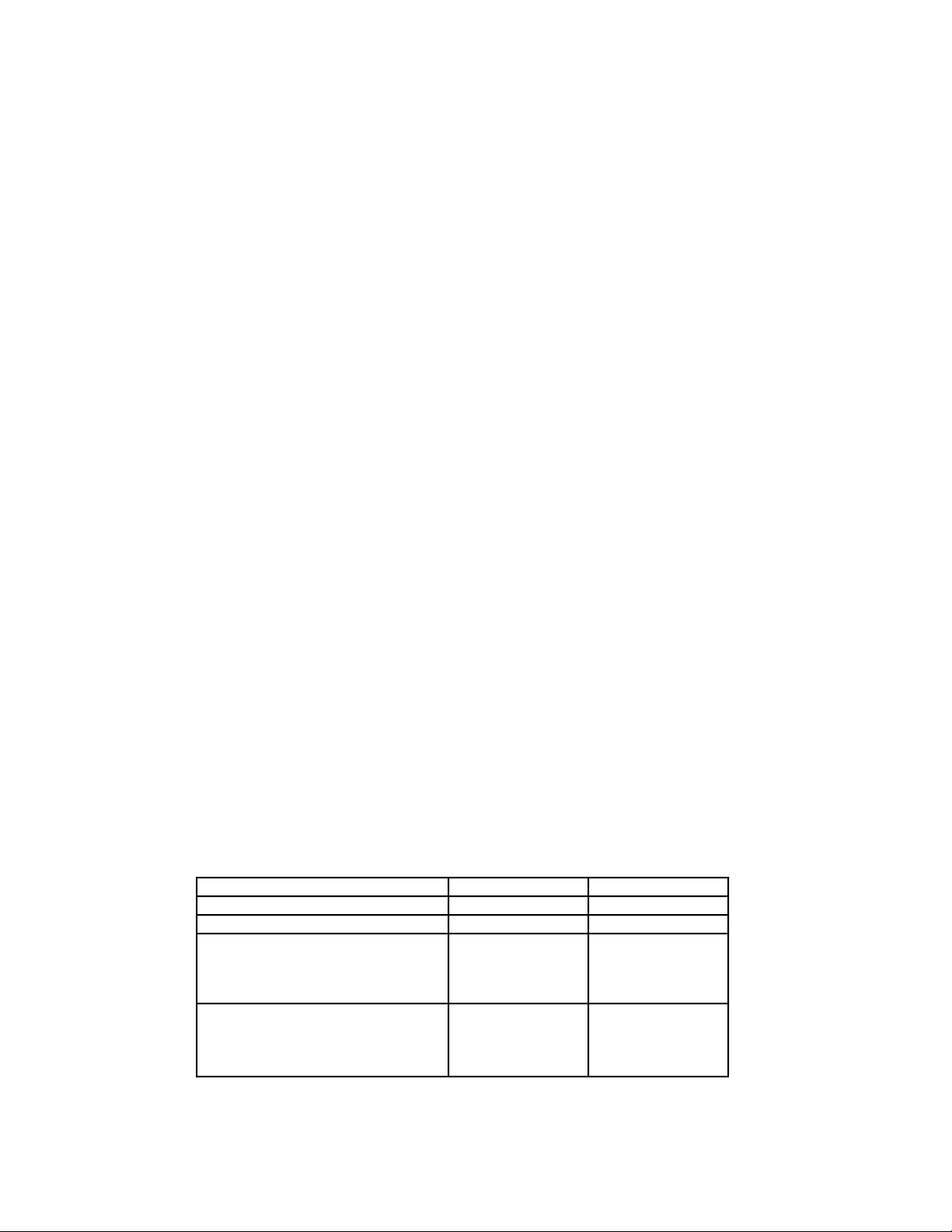

Table 1. Amplifier Comparison Chart................................................................................................4

AmPlus™ 100 Amplifier Specifications ......................................................................................... 5

AmPlus 50 Amplifier Specifications............................................................................................... 6

AmPlus 100 Theory of Operation .............................................................................................. 7-10

AmPlus 50 Theory of Operation ................................................................................................... 11

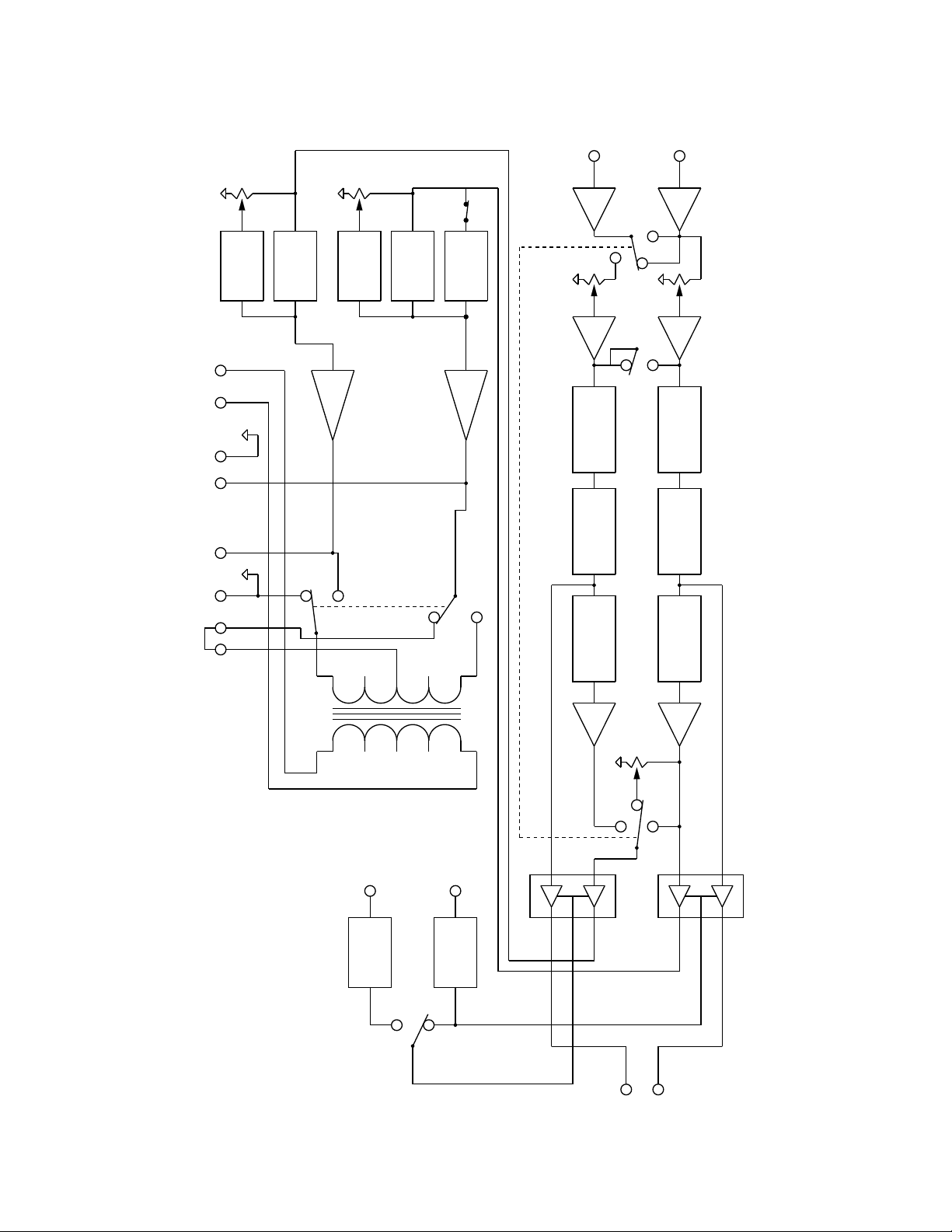

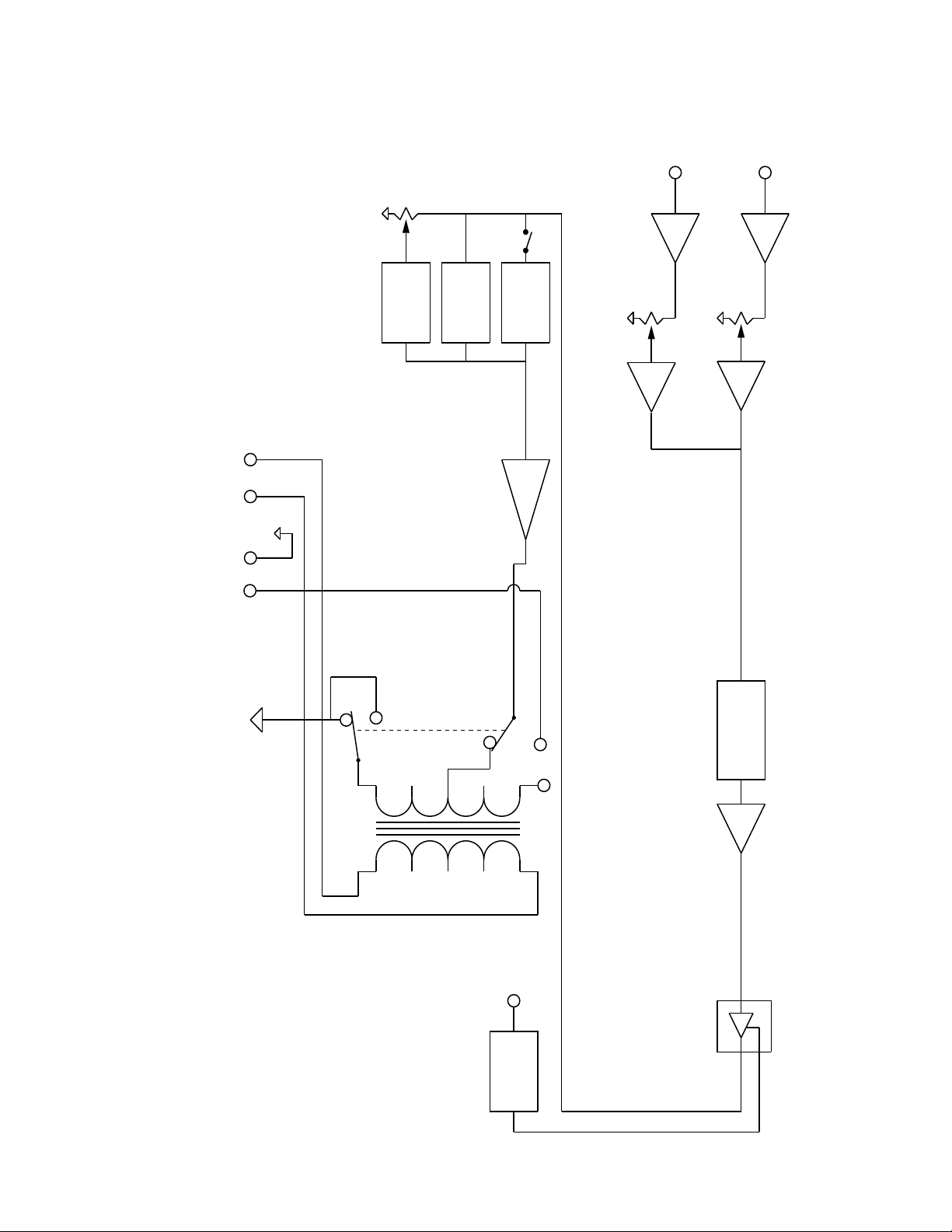

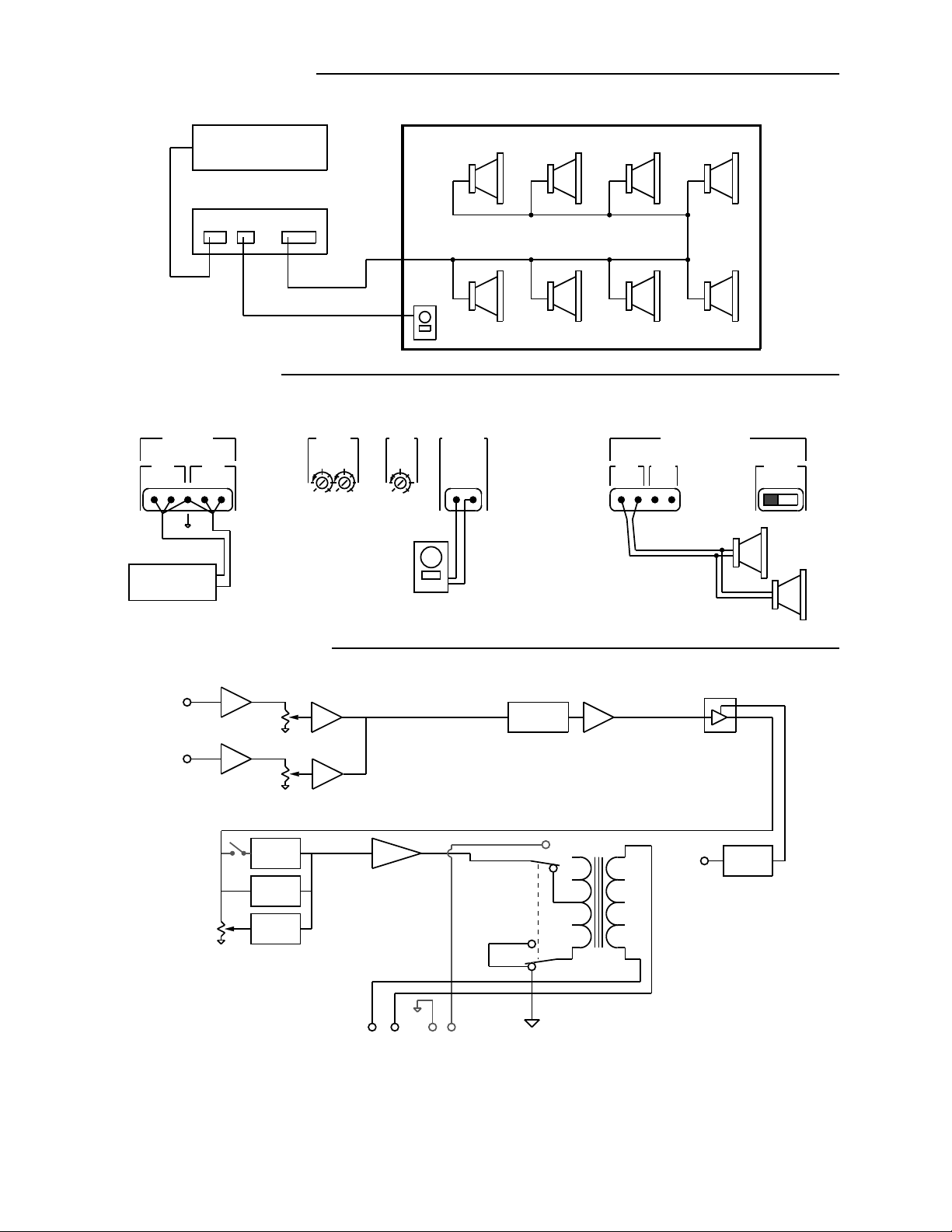

Figure 1. AmPlus 100 Amplifier block diagram............................................................................... 12

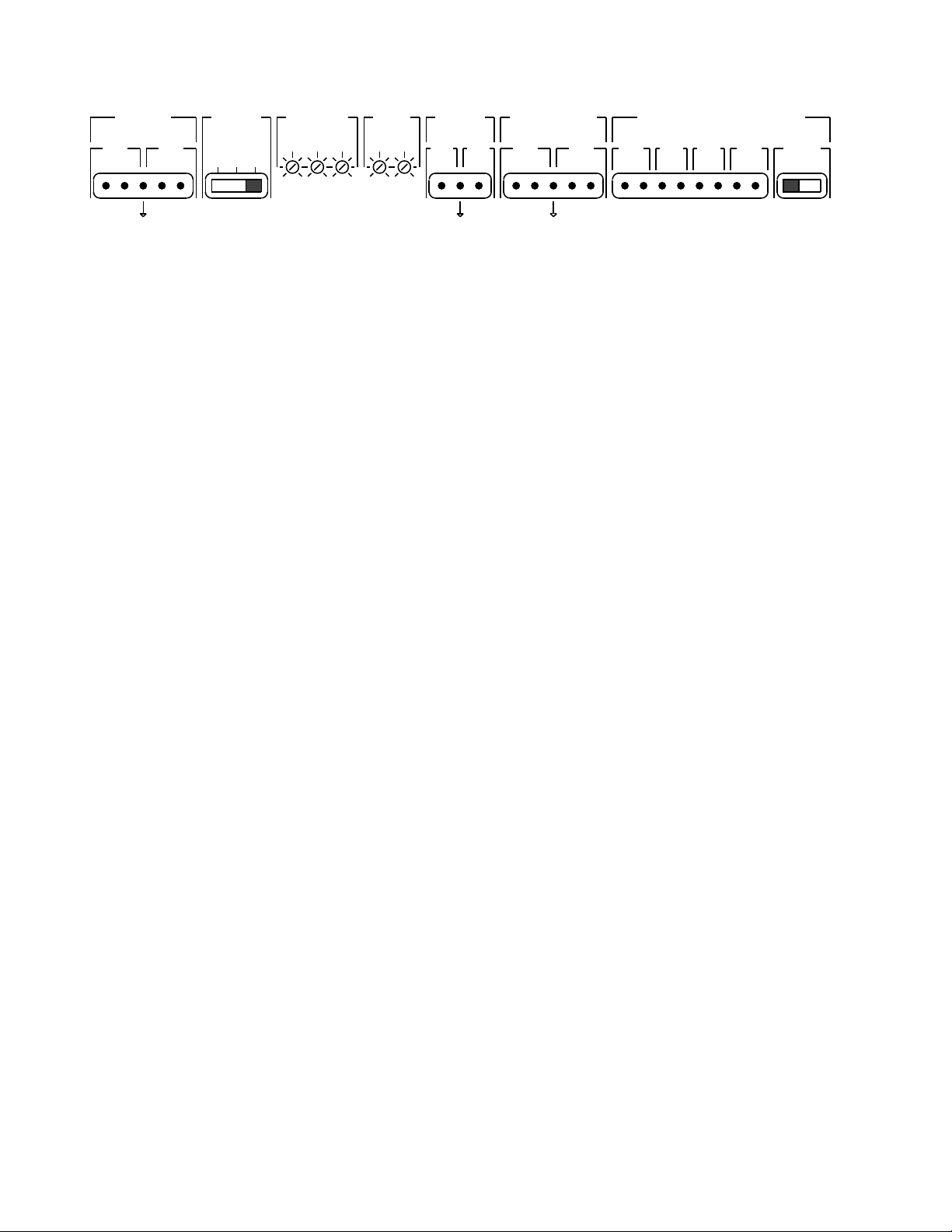

Figure 2. AmPlus 50 Amplifier block diagram................................................................................. 13

AmPlus 100 Amplifier Controls................................................................................................ 14-15

AmPlus 50 Amplifier Controls....................................................................................................... 16

Disassembly/Assembly Procedures ....................................................................................... 17-18

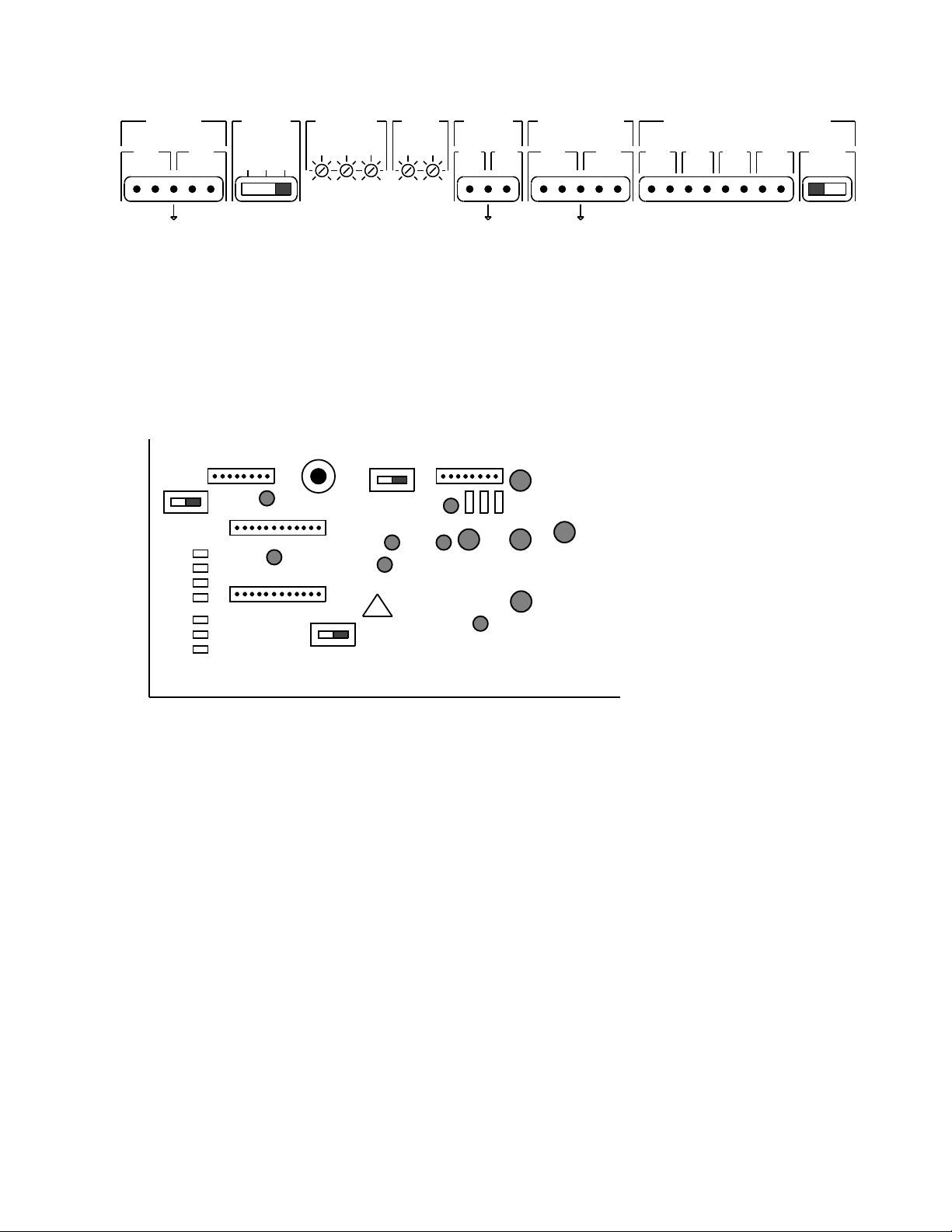

Figure 3. AmPlus 100 Amplifier exploded view .............................................................................. 19

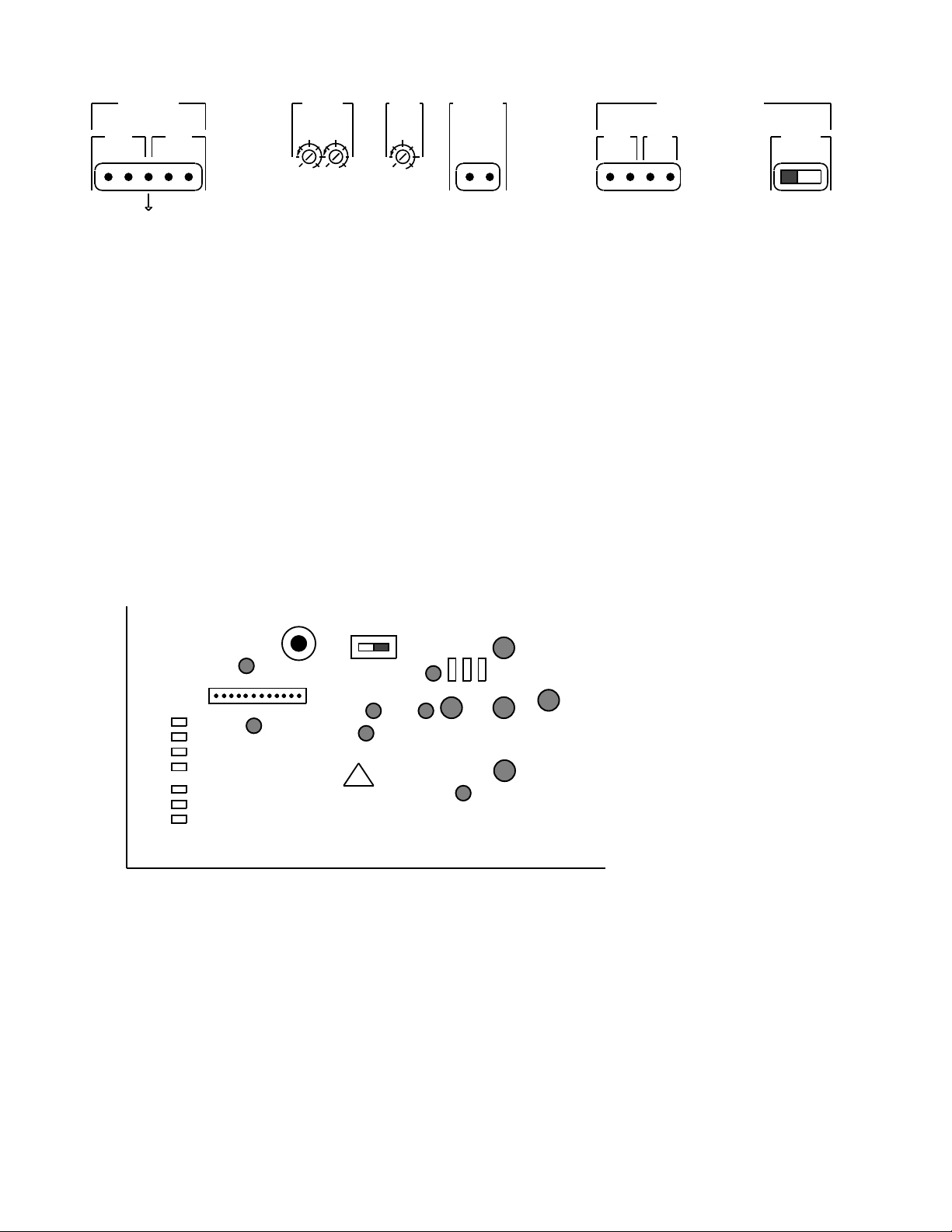

Figure 4. AmPlus 50 Amplifier exploded view ................................................................................ 20

AmPlus 100 Test Setup Parameters............................................................................................. 21

Table 2. AmPlus 100 Initial Switch Settings ................................................................................... 21

Table 3. AmPlus 100 Signal Inputs table........................................................................................ 21

Table 4. AmPlus 100 Signal Outputs table..................................................................................... 21

AmPlus 100 Test Procedures................................................................................................... 22-25

Table 5. Source Input to 70/100V Speaker Output test table ......................................................... 22

Table 6. Source Input to 4Ω Speaker Outputs ............................................................................... 24

Table 7. Bass Performance tests ................................................................................................... 24

AmPlus 50 Test Setup Parameters ............................................................................................... 26

Table 8. AmPlus 50 Initial Switch Settings ..................................................................................... 26

Table 9. AmPlus 50 Signal Inputs table.......................................................................................... 26

Table 10. AmPlus 50 Signal Outputs table ..................................................................................... 26

AmPlus 50 Test Procedures .....................................................................................................27-30

Table 11. Source Input to 70/100V Speaker Output test table ....................................................... 27

Table 12. Source Inputs to 4Ω Speaker Output ............................................................................. 29

Table 13. Bass Performance tests ................................................................................................. 29

Installation Diagram Notes:........................................................................................................... 31

Figure 5. AmPlus 100 Simple Mono Installation............................................................................. 32

Figure 6. AmPlus 100 Large Mono Installation using Mixer Feature.............................................. 33

Figure 7. AmPlus 100 70/100 Volt Mode/Model 1B Acoustimass

Figure 8. AmPlus 100 Installation with Two 70/100V Listening Zones........................................... 35

Figure 9. AmPlus 50 Simple Mono Installation............................................................................... 36

Part List Notes................................................................................................................................ 37

Main Part List AmPlus 100 Amplifier (see Figure 10) ................................................................. 38

Figure 10. AmPlus 100 Amplifier exploded view ............................................................................ 39

Main Part List AmPlus 50 Amplifier (see Figure 11).................................................................... 40

Figure 11. AmPlus 50 Amplifier exploded view .............................................................................. 41

Electrical Part List..................................................................................................................... 42-46

Resistors ................................................................................................................................... 42-43

Capacitors ................................................................................................................................. 43-44

Diodes ............................................................................................................................................ 44

Transistors...................................................................................................................................... 44

Integrated Circuits .......................................................................................................................... 45

Miscellaneous ........................................................................................................................... 45-46

®

Bass Module Installation......... 34

1

Page 2

CONTENTS

This service manual has been updated with information from supplement 194101-S1.

This affects part numbers for C610 and C611.

AmPlus™ 50 and 100 Accessory Notes....................................................................................... 47

Table 14. AmPlus 50 and 100 Amplifiers and Accessories............................................................. 47

Packing List Power Amplifier Accessory Kit (see Figure 12) .................................................... 48

Figure 12. Accessory Kit Packing Diagram.................................................................................... 48

Part List Remote Volume Control (see Figure 13)....................................................................... 49

Figure 13. Remote Volume Control exploded view........................................................................ 49

Packing List AmPlus 50 and 100 Amplifier (see Figure 14) ....................................................... 50

Figure 14. AmPlus Series Amplifier Packing Diagram ................................................................... 50

Part List AmPlus 100 Amplifier Accessory Transformer (see Figure 15).................................. 51

Figure 15. AmPlus 100 Accessory Transformer exploded and packing view ................................. 51

Part List AmPlus 50 and 100 Amplifier Rack Mount Accessory Kit (see Figure 16) ................ 52

Figure 16. AmPlus 50 and 100 Amplifier Rack Mount Accessory Kit ............................................. 52

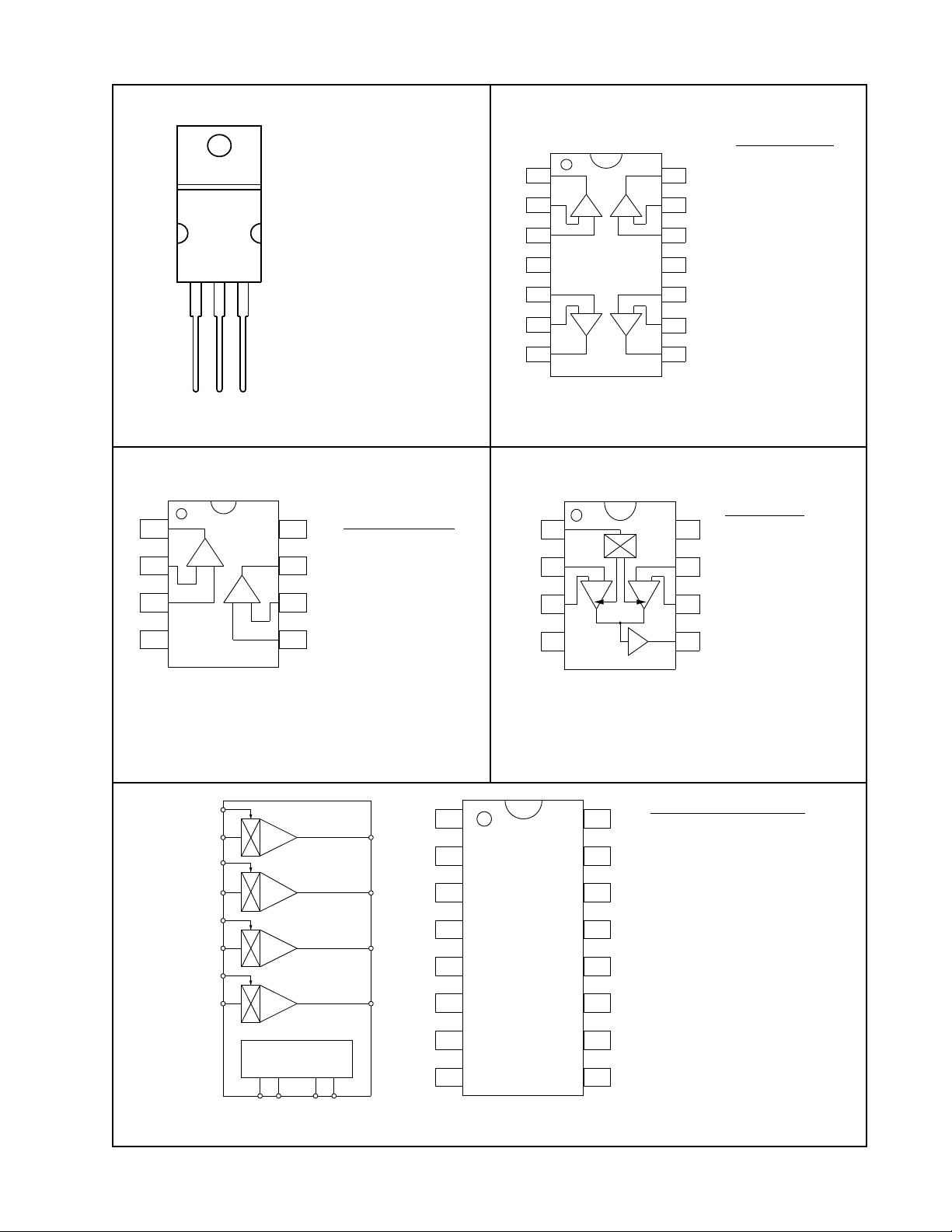

Device Pin-out Diagrams.......................................................................................................... 53-57

Troubleshooting Tips..................................................................................................................... 58

CAUTION: THE AMPLUS 100 AND AMPLUS 50 AMPLIFIERS CONTAIN

NO USER SERVICEABLE PARTS. TO PREVENT WARRANTY INFRACTIONS,

REFER SERVICING TO WARRANTY SERVICE STATIONS OR FACTORY

SERVICE.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

®

BOSE

CORPORATION WHICH IS BEING FURNISHED ONLY

FOR THE PURPOSE OF SERVICING THE IDENTIFIED BOSE

PRODUCT BY AN AUTHORIZED BOSE SERVICE CENTER OR

OWNER OF THE BOSE PRODUCT, AND SHALL NOT BE

REPRODUCED OR USED FOR ANY OTHER PURPOSE.

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that have

critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check

(1) With the unit completely reassembled, plug the AC line cord directly into a 120V

AC outlet. Do not use an isolation transformer during this test. Use a leakage

current tester or a metering system that complies with American National

Standards Institute (ANSI) C101. "Leakage Current for Appliances" and

Underwriters Laboratories (UL) 1492 (71).

(2) With the unit AC switch first in the ON position and then in the OFF position,

measure from a known earth ground (metal water pipe, conduit, etc.) to all

exposed metal parts of the unit (antennas, handle bracket, metal cabinet,

screwheads, metallic overlays, control shafts, etc.), especially any exposed

metal parts that offer an electrical return path to the chassis.

(3) Any current measured must not exceed 0.5 milliamp.

(4) Reverse the unit power cord plug in the outlet and repeat test.

ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED HEREIN

INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED

BEFORE RETURNING THE UNIT TO THE CUSTOMER.

B. Insulation Resistance Test Cold Check

(1) Unplug the power supply and connect a jumper wire between the two prongs

of the plug.

(2) Turn on the power switch of the unit.

(3) Measure the resistance with an ohmmeter between the jumpered AC plug

and each exposed metallic cabinet part on the unit. When the exposed

metallic part has a return path to the chassis, the reading should be

between 1 and 5.2 Megohms. When there is no return path to the chassis, the

reading must be "infinite". If it is not within the limits specified, there is the

possibility of a shock hazard, and the unit must be repaired and rechecked

before it is returned to the customer.

3

Page 4

ELECTROSTATIC DISCHARGE SENSITIVE

(ESDS) DEVICE HANDLING

This unit contains ESDS devices. We recommend the following procedures when repairing,

replacing, or transporting ESDS devices.

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station, or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert

unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags,

bubble wrap, or plastic trays.

WARRANTY INFORMATION

The following products are covered by a 5-year transferable limited warranty.

• Bose

• Equalizer Card

• Optional Opti-Voice

• Optional Source Input expansion card

®

AmPlus™ 100 and AmPlus 50

®

Page card

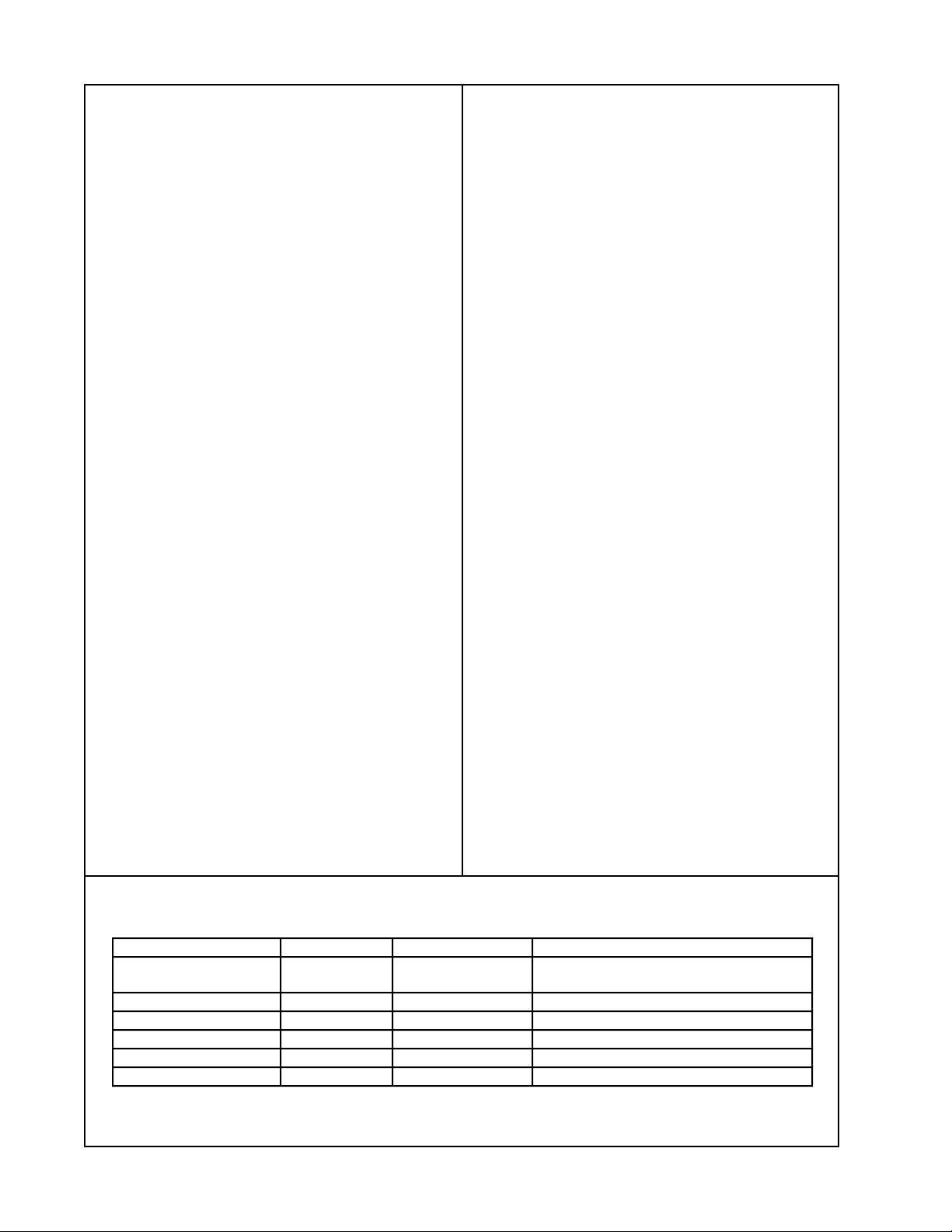

Table 1. Amplifier Comparison Chart

Features AmPlus 100 AmPlus 50

Inputs (balanced) 2 2

Line Outputs (balanced) 2 None

Outputs

-Channel 1

-Channel 2

-70V

Option Cards

-Opti-Voice® Page Card

-Opti-Source™ Card

-EQ Cards (various)

65 Watts

65 Watts

100 Watts

Yes

Yes

Yes, 2

70 Watts

None

50 Watts

Yes, 1

No

No

4

Page 5

AMPLUS™ 100 AMPLIFIER SPECIFICATIONS

Power Output

Stereo: 65W per channel into 4Ω

50W per channel into 8Ω

70V bridged mono: 100W into 98Ω

Ω: 50W @ 70V output into 98Ω

70V/4

65W @ Ch2 output into 4Ω

Input Sensitivity

315mV required to drive both channels

to full power in any mode.

Input Attenuation

0dB to -

∞

Input Impedance

32kΩ balanced, 11kΩ unbalanced

Line Output Impedance

600Ω

Line Output Distortion

≤0.2%

Frequency Response

(active EQ bypassed)

4Ω output: 40Hz - 16kHz, ±1dB

70V output: 60Hz - 16kHz, ±1dB

Special Features

Remote volume control

Turn on/off muting

Clip detection and limiter

Short circuit protection

DC offset protection

Thermal limiting

Stable into reactive loads

RFI protection

UL and TUV approvals

Terminations

Inputs and outputs are quick-connect

terminal blocks

Optional Accessories

EQ Cards (Model 1B, Models 8 and 25/32)

Source Card

Page Card

Operating Temperature Range

(passively cooled)

12˚F to 120˚F (-10˚C to +50˚C)

AC Power Consumption

350 Watts max, 100/120Vac, 50-60Hz

350 Watts max, 220/240Vac, 50-60Hz

THD@ Rated Power

4Ω output: ≤2% THD (40Hz - 16kHz)

70V output: ≤2% THD (60Hz - 16kHz)

Hum and Noise

Line output: 92dB

Power amplifier output: 80dB below rated

output with 4Ω load

Controls

Inputs 1 and 2, input attenuation, remote

volume, bass adjust 1 and 2, Input Mode

and Amplifier Mode switches.

LED Indicators

Power: front panel

Size

(Desk Mount)

17"W x 10"D x 3 3/4"H

(43.2 x 25.4 x 9.52 cm)

(Rack Mount, chassis supported)

19"W x 10"D x 3 3/4"H

(48.3 x 25.4 x 9.52 cm)

Weight

25 lb (11.3 kg)

Associated Equipment

Rack mount kit

Second zone transformer

5

Page 6

AMPLUS™ 50 AMPLIFIER SPECIFICATIONS

Power Output

70V Mono: 50W into 98Ω

Ω Mode: 70W outputs into 4Ω

4

Input Sensitivity

315mV required to drive amplifier to full

power in any mode.

Input Attenuation

0dB to -

∞

Input Impedance

32kΩ balanced, 11kΩ unbalanced

Input/Output Configurations

1. Mono into 4Ω load

2. Mono into 70V load

3. As an extension to the AmPlus 100

amplifier

Frequency Response

(active EQ bypassed)

4Ω output: 40Hz - 16kHz, ±1 dB

70V output: 60Hz - 16kHz, ±1 dB

THD@ Rated Power

4Ω output: ≤2% THD (40Hz - 16kHz)

70V output: ≤2% THD (60Hz - 16kHz)

Hum and Noise

Power amplifier output: 80dB below rated

output with 4Ω load

Controls

Inputs 1 and 2, input attenuation, remote

volume, bass adjust affects bandwidth of

50Hz - 150Hz by 0 - 10dB, Amplifier Mode

switches.

Special Features

Remote volume control

Turn on/off muting

Clip detection and limiter

Short circuit protection

DC offset protection

Thermal limiting

Stable into reactive loads

RFI protection

UL and TUV approvals

Terminations

Inputs and outputs are quick-connect

terminal blocks

Optional Accessories

EQ cards (Model 1B, Models 8 and 25/32)

Operating Temperature Range

(passively cooled)

12˚F to 120˚F (-10˚C to +50˚C)

AC Power Consumption

200 Watts max, 100/120Vac, 50-60Hz

200 Watts max, 220/240Vac, 50-60Hz

Size

(Desk Mount)

17"W x 10"D x 3 3/4"H

(43.2 x 25.4 x 9.52 cm)

(Rack Mount, chassis supported)

19"W x 10"D x 3 3/4"H

(48.3 x 25.4 x 9.52 cm)

Weight

20 lb (9.1 kg)

LED Indicators

Power: front panel

Associated Equipment

Rack mount kit

6

Page 7

AMPLUS™ 100 THEORY OF OPERATION

Introduction:

The AmPlus 100 Business Music Amplifier is a two channel amplifier intended for business

music and other installed sound systems. Its two inputs pass through the Opti-Voice

Opti-Source™ Option Cards and Equalizer cards, if they are installed. These cards expand the

number of inputs and outputs of the basic AmPlus 100, adding special features of paging, source

selection, and priority override.

Sheet 1 of 3

Refer to the AmPlus 100 schematic diagram, sheet 1 of 3 for the following information.

Note: The designators inside the brackets “[ ]” are the schematic grid coordinates which

are provided in order to make it easier to locate components on the schematic sheet

indicated in the description.

The Channel 1 and Channel 2 Inputs at J1 [D8] are the "A" inputs on the AmPlus 100

and accept line level sources. U100A [D7] and U101B [C7] are unity gain, differential input

amplifiers, with inputs well protected against RF and ESD. Ch 2 coming from U101B can

pass through S1 [D7], the Mono/Dual Mono/2-Ch switch, in the 2-Ch position. In other

positions of S1, Ch 2 is ignored unless S7 [C7], the 2-Ch/Mixer switch, is in the Mixer

position, in which case Ch 2 and Ch 1 are mixed in the proportion set by R1 and R2, the

Ch 1 and Ch 2 gain trim switches. After buffers U106A/B, the Ch 1 and Ch 2 signals are

presented to one of the two inputs of U102 [D6] and U103 [C6], op amps with a pair of

input stages and a selector mechanism, acting as a selector switch. If no option card is in

the #1 position at J2 [C7], U102/103 pass the Ch 1 and Ch 2 A input signals straight

through; if either a source or a page option card is in the #1 slot at J2, its output will be

selected to pass forward into the AmPlus 100 signal path.

If an option card is installed in the #1 slot at J2, then the Ch 1 and Ch 2 A input signals

are sent to the option card, and will be processed on that option card and returned to the

AmPlus 100 along with the other signals contributed by the option card. The switching

action of U102/103 is controlled by the DC level on pin 1. Normally, with no option card in

the #1 slot at J2, this pin is pulled high, but when an option card is in place it shorts J2-5,

pulling U102/103 pin 1 toward ground.

®

Page and

Continuing forward on Sheet 1, [coordinates 5D and 5C], the Ch 1 and Ch 2 signals

encounter another pair of switched op amps, U104/105 and the option card #2 connector

at J3 [C6]. Signal flow here is handled in the same manner as around option card #1: if no

option card is installed in slot #2 at J3, the signals pass through; otherwise, they enter the

option card and are processed along with that card's sources before being returned to the

main AmPlus 100 signal path.

Equalizer cards can be placed in J9 [D5] (for Ch 1) and in J10 [C5] (for Ch 2). If there is

no EQ card in J9, the output from U104 passes through the unity gain buffer U100B, but

if there is an EQ card, it "overrides" the signal from U104, substituting equalized audio from

the EQ card. A similar arrangement for Ch 2 uses U101C. Special switching in the Ch 2

path after U101C allows the use of a single EQ card in the J9 slot in the cases where the

source is being handled in mono or dual mono (in dual mono, R3, the Zone 2 Trim, is

engaged). When the switch S1 is in the Mono or Dual Mono position, the Ch 1 signal is

taken through an inverting stage (U101A) and passed to the Ch 2 path. Inverting the

signal phase for the CH2 output compensates for the fact that the connector for the Ch 1

output results in the Ch 1 speaker signal also being inverted. U105 provides this phase

inversion for Ch 2 signals when S1 is in the two channel mode.

7

Page 8

AMPLUS™ 100 THEORY OF OPERATION

Sheet 1 of 3 (continued)

Note that the U104/105 output is also taken directly, before the EQ card, to two of the

volume control VCAs (U204A, D), for use as Line Outputs. U204B, C implement the

volume control for the main CH1 and CH2 paths that will move forward in the AmPlus 100

itself.

U204 [C2] is a quad, current in /current out, voltage controlled amplifier. Sections U204A,

D, pins 4 and 13, (line output) are controlled only by the remote volume control action,

whereas sections U204B, C, pins 5 and 12, (main path) are also controlled, in an OR'd

fashion, by the signals CLIP / SC1 [D1] and CLIP / SC2 [A1]. The CLIP / SC signals

become active when the power amplifier is clipping and/or attempting to drive a short

circuit. This reduces the volume control setting, preventing distortion when a user plays

the system too loud, as well as reducing power dissipation when there is a short circuited

load.

Connector J4 [A8] ties one or two 10K rheostat-connected remote volume control

potentiometers into Q201/221, whose outputs are steered by S5 [B4] (1 Remote / 2

Remotes) into U200 A, B, C, D, [B, C3] which inverts and scales the voltages to the

appropriate range needed to control the VCAs. U203A, B [B4] buffer the CLIP / SC

signals and OR them into the appropriate sections of U204 via diodes D200, 203. J12

[A8] is reserved for a possible future level control option.

U201A, U202B [B / C1] are the line output buffers, whose outputs are passed through

series R/shunt C elements for RFI management. At the junction of the resistors, FETs

Q401, 403 [A, B6] provide a power-up/power-down mute so that equipment connected to

the line outputs will not experience thumps or pops.

Sheet 2 of 3

Refer to the AmPlus 100 schematic diagram, sheet 2 of 3 for the following information.

Sheet 2 concludes the processing of the Ch 1 and Ch 2 signals, preparing them for the

power amplifiers. Circuits on this sheet deal largely with dynamic EQ and switchable EQ,

all directed toward the bass region. The CH1 signal (DYNEQ1) entering Sheet 2 [C8] is

sent in parallel to five points. Two paths pass through S4 [D6], which selects HP Out

(150Hz high pass filter off) or HP In (150Hz high pass filter in). Another path, through R4

[D8], Ch 1 Bass Boost Adjust (50-150Hz) and a bandpass filter, U300B [D5], determines

how much bass boost will be present. The signals out of S4 and the bandpass filter are

summed in U300A [C4], along with yet another equalized signal.

To develop Dynamic EQ (an equalization where the amount of bass boost applied

varies inversely with the signal level), the DYNEQ1 signal [C8] is fed to circuits

composed of U300D, Q300, Q301, Q302, U303, U300C, U302A, and U304. U300C,

Q300, Q301, Q302 develop a current proportional to the rectified signal level. This current

enters the control pin of U302A, a transconductance amplifier, whose output current is

multiplied by its control current. U302A is in the negative feedback loop of U300D, which

now passes the signal DYNEQ1 with a gain controlled inversely by its own level. At

small signals, the gain is the highest. Next, the output of U300D passes through one of

two bandpass filters, shaping the signal into a bass boost signal. U304 [C4] selects

between two bandpass filters, one centered at 55Hz and appropriate for the Free Space

Model 1B Acoustimass® Module, the other at 90Hz, appropriate for full range systems,

such as the Model 8, Model 25 and Model 32 Loudspeakers.

®

Switching to the 55Hz bandpass filter is automatically handled by sensing when a

Model 1B EQ card has been inserted in the Ch 1 EQ card socket [J9 on sheet 1 at

coordinates D5] (signal EQGND [D1, sheet 1, and B8, sheet 2] is shorted to ground by

the Model 1B EQ card when it is plugged in).

8

Page 9

AMPLUS™ 100 THEORY OF OPERATION

Sheet 2 of 3 (continued)

Finally, the bass boost signal from the dynamic EQ path rejoins the other signals, (the

full range signal, high pass filtered if S4 is in the HP IN position, via S4 and R381, and the

manually adjusted bass boost signal via R4 and U300B) in the summing stage U300A

[C4]. Now, at last, the Ch 1 and Ch 2 signals are ready to enter the power amplifiers, via

connectors J7B [D1] and J8B [B1]. Note that Ch 2 is handled identically by the

companion circuits shown below Ch 1's circuits.

Connectors J7B / J8B send the power amplifier power rails (±20V and ±40V) as well as

±12V power and various grounds. The CLIP / SC signals are returned from the power

amplifiers via these connectors as well.

DC Offset detection circuits

Circuits that watch for excessive DC offsets of the power amplifier outputs are seen at

coordinates C1. Ultimately, these circuits control the operation of relay K600 [sheet 3, B4]

whose contacts enable the ±40V supply relays when K600 is energized. The op amp

circuits U700 and U701 [sheet 2, C2] watch the Ch 1 and Ch 2 power amplifier outputs

for DC offsets greater than about 2.4V. However, in order to keep the relay energized,

other conditions must also be met. The ±40V rails and the ±12V rails must each be within a

certain degree of symmetry. The Ch 1 power amplifier output is low pass filtered to pass

only the DC offset component and is full wave rectified in U700B [C1] and U701A [C2]. A

derived center tap from the ±40V supplies is also brought into the full wave rectifier B600

[sheet 3, B4]. The rectifier output is then compared to -2.4V in U701A [sheet 2, C2] (an op

amp used as a comparator). If the absolute value of the offset is less than 2.4V, U701A's

output is high, which holds Q700 off. Q700 off ensures that Q600 / 601 [sheet 3, B2] can

be on, which allows current to flow through the K600 relay coil, energizing it, and thus

allowing ±40V to be applied to the power amplifiers.

At coordinates [A, B 1, 2] on Sheet 2 of 3, the power amplifier output wiring is detailed.

The power amplifier outputs are always tied to the Ch 1, 2 ± output connector pins,

whether the amplifier mode switch S6 [A2] is in the Bridged or the 2 Channel position.

However, if S6 is in the Bridged position and if a jumper has been placed between the

two XFR CT pins, then the Ch 1 signal and the Ch 2 signals drive the output transformer

primary in concert, potentially delivering in excess of 100 watts to the 70 / 100V output

pins. Jumpers J409, 410 [sheet 2, A1] select between 70V and 100V operation.

Sheet 3 of 3

Refer to the AmPlus 100 schematic diagram, sheet 3 of 3 for the following information.

Sheet 3 outlines the power amplifier and power supply circuits. Channel 1 circuitry is

explained below, Channel 2 operation is identical. The Ch 1 amplifier is built around a

power amplifier IC, U500 [C6], augmented by class G transistors. For U500 audio output

levels between about ±20V, U500 acts on its own, with its power coming from the ±20V

rails via D502 / 509 [C, D5]. When the input signal rises, demanding an output in excess

of about ±20V, transistors Q500, 501, 502 (positive rail) and Q503, 504, 505 (negative

rail) come into play. Each of these transistor trios is driven by the input signal, via steering

diodes D501, 507, and turn on as the higher signal peaks dictate. When Q502 is on, it

handles part of the power dissipation by passing the loudspeaker current through power

devices in series with the U500 rails. This allows U500 to deliver higher voltage, higher

current power to its load while still staying within acceptable IC power dissipation limits.

For those portions of the audio output waveform greater than about ±20V, the class G

power transistors Q502, Q505 dissipate part of the power.

9

Page 10

AMPLUS™ 100 THEORY OF OPERATION

Sheet 3 of 3 (continued)

The power amplifier is equipped with a clip detector circuit, implemented with U503 [D7],

an LM311 comparator, and associated parts. The comparator watches the differential input

voltage at the power amplifier input pins and compares it to 120mV. If the power amplifier,

a feedback amplifier, is for any reason unable to deliver the output voltage requested by

the source, linear operation ceases and an error voltage develops across its input pins.

Inability to deliver the requested output voltage can occur if there is a short circuit on the

amplifier output, a DC offset from some kinds of failures, or from overdriving the amplifier.

Whatever the cause, if the input error voltage exceeds the threshold, the LM311 output

will go low, toward the -12V supply. Active (low-going) CLIP / SC signals are fed through

J7 pin 12 back to the VCA volume control IC, U204 on Sheet 1 [C2], where they turn the

gain down to eliminate the stress of the overload situation. If the power amplifier starts to

clip, the feedback signal acts as a limiter to keep the amplifier out of the distorted clipping

region.

The AmPlus 100 power supply can be configured for either 120V (60Hz) or 230V (50 or

60Hz) AC mains by the appropriate placement of jumpers J603, J605, J606. This is

shown on Sheet 3 at coordinates A6, 7, and 8. The AC mains voltage is stepped down

and rectified, creating unregulated ±40V and ±20V rail pairs for use by the power amplifier.

Regulators U600, 601 [A3] derive ±12V from the ±20V supplies for use by the op amp

circuits. The bridge rectifiers B600, and B601 are fused against overload, while the ±12V

supply is fused by 1/4 watt resistors R602, and R603. Also on Sheet 3, [B2], are Q600

and Q601, the relay drive transistors controlled by RELAY, from Sheet 2.

10

Page 11

AMPLUS™ 50 THEORY OF OPERATION

Introduction:

The AmPlus 50 Business Music Amplifier is a single channel amplifier in most ways

identical to the AmPlus 100. Both amplifiers are built in similar chassis using the same

PCBs, but most of the Ch 2 parts are omitted in AmpPlus 50.

Note: Refer to the appropriate AmPlus 50 Schematic diagram sheet as indicated below

for the following information.

Note: The designators inside the brackets “[ ]” are the schematic grid coordinates which

are provided to make it easier to locate components on the schematic sheet indicated in

the description.

Note: The components not used in the AmPlus 50 Amplifier are indicated on the schematic

diagram as optional (opt).

Sheet 1 of 3

The discussion for the AmPlus 100 applies to the AmPlus 50, with a few

exceptions. The Ch 1 and Ch 2 at J1[D8] inputs are summed after their input buffers

U100 and U101 [C/D7] and are passed through the Ch 1 path. There are no connectors

or slots for the #1 [J2] or #2 [J3] option cards, nor for the Ch 2 EQ card [J10]. There are no

line outputs, and only one remote volume control input [J4]. Only the DYNEQ 1 output

signal from Sheet 1 passes to Sheet 2. Only the CLIP / SC1 signal is passed into

Sheet 1.

Sheet 2 of 3

The discussion for the AmPlus 100 applies to the AmPlus 50, with a few exceptions.

Only the Ch 1 path of dynamic and fixed EQ circuits is populated, and only the Ch 1

power amplifier connector is provided. The output connector provides either 4 ohm or

70/100V CV, (Constant Voltage) outputs, as selected by S6 for Ch 1.

Sheet 3 of 3

The AmPlus 50 version is identical except that only the Ch 1 power amplifier module is

installed.

11

Page 12

(R5)

Gain

Ch. 2

Bass

(R4)

Gain

Ch. 1

Bass

(S4)

Filter

Switch

Pass

High-

Channel 2

Input

J1

section1 of 2

Switch (S1)

Input Mode

Mono

Channel 1

Input

Bass Boost

+ -

70V

Figure 1. AmPlus™ 100 Amplifier Block Diagram

+ -

CH. 1

Amplifier

Outputs

J6

CH. 2

CT

Power

+ -

XFMR

Dynamic

EQ

2 Ch.

Bass Boost

Power Amp 2

70V Bridged

Switch

(S6)

EQ

Mode

Amp.

Dynamic

Power Amp 1

2 Ch.

High Pass

Filter

70V Bridged

Level (R2)

Ch. 2

2 Ch.

(S7)

2-Ch.

Option Card 1

Channel 2

Option Card 2

Channel 2

EQ Card 2

Mono

Dual

Switch

Mix

Mixer

Trim (R3)

Zone 2

Option Card 1

Channel 1

Option Card 2

Channel 1

EQ Card 1

Level (R1)

Ch. 1

Remote

Zone 2

Control 2

VCA

2 Remotes

Remote

Zone 1

Assign Switch (S5)

Control 1

Remote Zone

VCA

1 Remote

12

VCA 2

2 Ch.

Switch (S1)

Section 2 of 2

Ch. 2

Mono

Dual

Mono

Input Mode

Ch. 1

J5

VCA 1

Line Outputs

Page 13

(R4)

Ch.1

Gain

Bass

(S4)

Filter

Switch

Pass

High

Channel 2

Input

J1

Channel 1

Input

Power

Amplifier

Outputs

Figure 2. AmPlus™ 50 Amplifier Block Diagram

+ -

70V

J6

+ -

Ch. 1

70V

Bass Boost

4 Ohm

(S6)

Switch

Mode

Dynamic

EQ

Amp

High Pass

Filter

Power Amp 1

70V

4 Ohm

Level (R2)

Ch. 2

Level (R1)

Ch. 1

EQ Card

13

Remote

Zone 1

Control 1

VCA

VCA

Page 14

AMPLUS™ 100 AMPLIFIER CONTROLS

INPUTS A

Ch1 Ch2

+- +-

2Ch

INPUT

MODE

dual

mono mono

LEVEL

Zone 2Ch2Ch1

-6 -6 -6

-10-10 -10

0 0 0-40 dB -40 dB -40 dB

BASS

LEVEL

Ch2Ch1

+10

OFF

OFF

+10

REMOTE

VOLUME

ZONE 1 ZONE 2

LINE OUTPUT

ZONE 1 ZONE 2

+-+-

POWER AMPLIFIER

70V ZONE1

4-16

ZONE 2

4-16

Ω

Ω

+-+-+-

XFR

CT

Inputs - The amplifier comes with two balanced inputs. They can be left and right channels

from a stereo source or two distinct monophonic (mono) sources for 2 - zone applications.

Two mono sources can also be mixed for single zone applications.

Input Mode - This switch determines how the Channel 1 and Channel 2 inputs are presented

to the power amplifier section of the AmPlus 100. There are 3 possible modes.

1. 2 - Channel/Mixer - the inputs remain separate, not summed. Channel 1 and

Channel 2 level potentiometers are active in this mode. Use this mode for:

a. Stereo (2 - channel).

b. Two distinct sources in a two zone application (2 - channel), 1 source per zone.

c. Two distinct sources in a single bridged mono zone (Mix).

MODE

70/100V 2 Ch

BRIDGED

Note: In Mix mode both sources, Channel 1 and Channel 2, are presented to the amplifier

simultaneously. When the internal source mix switch is in the MIX position, the Channel 1

attenuation controls the source connected to the Channel 1 input. The Channel 2 attenuation

controls the source connected to the Channel 2 input.

2. Dual Mono - The Channel 1 and Channel 2 inputs are summed to mono and presented to

the power amplifiers as two mono signals. This mode may also be used when driving a 70V

®

load from the Channel 1 amplifier outputs and a Bose

Model 1B Acoustimass® Bass Module

from the 4Ω Channel 2 outputs - see zone 2 level adjust.

3. Mono Mode - Both inputs, Channel 1 and Channel 2, are summed to mono. Only the

Channel 1 level pot is active.

Level - Channel 1 level adjust - In 2 - channel (stereo) mode, this pot affects the signal level

at the channel 1 low impedance (4Ω) outputs. In dual mono mode, it controls the zone 1 level.

In mono mode, it controls the level of all inputs.

Channel 2 level adjust - In 2-Channel (stereo) mode, this pot controls the signal level at the

channel 2 low impedance (4Ω) outputs. This pot is not active in dual mono or mono modes.

Zone 2 level adjust - This pot is only active when the input mode is dual mono. In this mode,

this pot controls the signal level at the channel 2 low impedance outputs. This pot is a slave to

the channel 1 pot; that is, the channel 1 pot controls the level of both zones in a 2-zone

system. However, the zone 2 pot can be used to fine-tune the bass level when using the

AmPlus 100 to drive a 70V load connected to the 70V output and a Model 1B Acoustimass

Bass Module connected to the channel 2 output. This pot may also be used to fine-tune the

bass level when using the AmPlus 100 to drive a 70V load connected to the 70V output and a

Model 1B Acoustimass Module connected to the channel 2 output.

14

Page 15

AMPLUS™ 100 AMPLIFIER CONTROLS

INPUTS A

Ch1 Ch2

+- +-

2Ch

INPUT

MODE

dual

mono mono

LEVEL

Zone 2Ch2Ch1

-6 -6 -6

-10-10 -10

0 0 0-40 dB -40 dB -40 dB

BASS

LEVEL

Ch2Ch1

+10

OFF

OFF

+10

REMOTE

VOLUME

ZONE 1 ZONE 2

LINE OUTPUT

ZONE 1 ZONE 2

+-+-

POWER AMPLIFIER

70V ZONE1

4-16

ZONE 2

4-16

ΩΩ

+-+-+-

XFR

CT

70/100V 2 Ch

BRIDGED

Bass Level - Use the bass level pots to increase the output level between 50 Hz and 150 Hz.

This is useful for compensating for poor bass cabinet loading or high levels of low-frequency

ambient noise. The channel 1 and channel 2 pots are active in all modes of operation.

Remote Volume - When using the amplifier to power one listening zone, connect the remote

control unit to the zone 1 (+) pin and the ground pin and set the internal remote volume switch

(see figure below) to 1 REMOTE. When using the AmPlus 100 for 2 - zone applications,

connect a second remote to the zone 2 (+) pin and the ground pin and set the internal remote

volume switch to 2 REMOTES.

High Pass

Mix

EQ 1

Filter

MODE

EQ 2

1 Remote

C

2 Remote

Line Outputs - Both line output responses are flat (regardless of whether or not you have

installed active equalizer cards). The remote volume control affects the line output levels. Both

outputs are active in stereo mode. Only zone 1 is active in dual mono and mono modes.

Power Amplifier Outputs - The 70V output becomes active when the amp mode switch is in

the 70V position. In this setup, both AmPlus 100 channels are bridged and provide up to 100

Watts to the 70V speakers.

- When the amp mode switch is in the 2-Channel position and a jumper is placed across the

Xfr. ct. pins, 50 Watts is available at the 70V output and 65 Watts is available at the channel

2 output. (see illustration at top of page)

- With the amp mode switch in the 2-Channel position, both channel 1 and channel 2 supply

65 Watts into a minimum load of 4Ω.

Internal High Pass Switch - When this switch is in the HPF ON position, frequencies below

150Hz are attenuated at 18dB/Oct. This low frequency roll-off occurs on Channel 1 only. Use

this switch for bandlimiting high frequency speakers connected to channel 1 in a bi-amplified

system. For example, the 70V/Model 1B system in Figure 7.

Internal Remote Volume Switch - For one zone applications, this switch should be in the 1

REMOTE position. For two zone applications, this switch should be in the 2 REMOTES

position.

15

Page 16

AMPLUS™ 50 AMPLIFIER CONTROLS

INPUTS A

Ch1

Ch2

+- +-

LEVEL

-6 -6

-10-10

0 0-40 dB -40 dB

BASS

OFF

GAIN

+10

Ch2Ch1

REMOTE

VOLUME

POWER AMPLIFIER

70V

4-16

Ω

+-+-

Inputs - The AmPlus 50 amplifier comes with two balanced inputs. They can be left or right.

Two mono sources can also be mixed. Since the AmPlus 50 is a single channel amplifier, a

stereo source is internally summed to mono.

Level - Channel 1 level adjust - This potentiometer controls the signal level of the channel 1

input source.

Channel 2 level adjust - This potentiometer controls the signal level of the channel 2

input source.

Bass Gain - Use the bass gain pot to increase the output level between 50 Hz and 150 Hz.

This is useful for compensating for poor bass cabinet loading or high levels of low frequency

ambient noise.

Remote Volume - Connect the remote volume control unit to the zone 1 (+) pin and the

ground pin to control the overall level of the amplifier remotely.

MODE

70/100V 4-16

High Pass

Filter

EQ 1

C

Power Amplifier Outputs - The 70V output is active when the amplifier Mode Switch is in the

70V position. The 4Ω output is active when the amplifier Mode Switch is in the 4Ω position.

Internal High Pass Filter Switch - When this switch is in the HPF ON position, frequencies

below 150 Hz are attenuated at 18dB/Oct. Use this switch for bandlimiting high frequency

speakers in a bi-amplified system.

16

Page 17

DISASSEMBLY/ASSEMBLY PROCEDURES

1. Top Cover Removal

Note: Refer to Figures 3 and 4, as

applicable, for the following procedures.

Note: The numbers in the parentheses

correspond to the callouts in Figures 3

and 4.

1.1 Unplug the power cable from IEC

connector on the rear of the amplifier.

1.2 Using a phillips-head screwdriver,

remove the five screws (1) that secure the

top cover (2) to the amplifier chassis (16).

1.3 Lift the top cover straight off.

2. Top Cover Replacement

2.1 Observing orientation, place the top

cover (2) straight down onto the amplifier

chassis (16).

2.2 Using a phillips-head screwdriver,

secure the top cover to the amplifier

chassis using the five screws (1) that

were removed in procedure 1.

3. Main PCB Removal

4. Main PCB Replacement

4.1 Orient the main PCB (8) so that the

connectors are aligned with the rear panel

of the amplifier chassis (16), and slide the

main PCB into place.

4.2 Secure the main PCB to the amplifier

chassis using the six screws (9) removed

in procedure 3.4.

4.3 Reconnect all connectors unplugged

in procedures 3.2 and 3.3.

4.4 Replace the top cover (2) using

procedure 2.

5. Amplifier Module Removal

5.1 Remove the top cover (2) using

procedure 1.

5.2 Unplug the appropriate cable

connector, (J7B or J8B), for the amplifier

module that you wish to remove.

5.3 Remove the two screws (12) that

secure the amplifier module to the amplifier

chassis (16) and lift the amplifier module

straight out.

3.1 Remove the top cover (2) using

procedure 1.

3.2 Unplug all of the cable connectors from

the rear panel of the amplifier.

3.3 On the main PCB (8), unplug the

connectors at J2, J7B, J3, J8B, J602, J601,

J400, J401, and J600.

3.4 Using a phillips-head screwdriver,

remove the six screws (9) that secure the

main PCB to the amplifier chassis (16).

3.5 Lift the main PCB at the edge nearest

the amplifier heatsinks, and slide the PCB

forward, until the main PCB connectors

clear the amplifier rear panel, then lift the

PCB straight up.

6. Amplifier Module Replacement

6.1 Place the amplifier module into the

appropriate spot in the amplifier chassis

(16) and secure it using the two screws

(12) removed in procedure 5.3.

6.2 Plug the amplifier module cable into the

appropriate connector (J7B or J8B) on the

main PCB (8).

6.3 Replace the top cover (2) using

procedure 2.

17

Page 18

DISASSEMBLY/ASSEMBLY PROCEDURES

7. Power Transformer Removal

7.1 Remove the top cover (2) using

procedure 1.

7.2 Unplug the transformer cables at J601

and J602 on the main PCB (8).

7.3 Remove the four nuts (5) that secure

the power transformer (7) to the amplifier

chassis (16).

7.4 Lift the power transformer straight out

of the amplifier chassis.

8. Power Transformer Replacement

8.1 Place the power transformer (7) into the

amplifier chassis (16), aligning it over the

chassis studs.

8.2 Secure the power transformer to the

amplifier chassis using the four nuts (5)

removed in procedure 7.3.

10. Audio Transformer Replacement

10.1 Place the audio transformer (3) into

the amplifier chassis (16) with the wires

facing toward the main PCB (8), aligning it

over the amplifier chassis studs.

10.2 Secure the audio transformer to the

amplifier chassis using the two nuts (5)

removed in procedure 9.3.

10.3 Plug the audio transformer cables

into the main PCB at J400 and J401.

10.4 Replace the top cover (2) using

procedure 2.

8.3 Plug the power transformer cables into

J601 and J602 on the main PCB (8).

8.4 Replace the top cover (2) using

procedure 2.

9. Audio Transformer Removal

9.1 Remove the top cover (2) using

procedure 1.

9.2 Unplug the audio transformer (3) cables

from the main PCB (8) at J400 and J401.

9.3 Remove the two nuts (5) that secure

the audio transformer to the amplifier

chassis (16).

9.4 Lift the audio transformer straight out of

the amplifier chassis.

18

Page 19

(5 PLACES)

1

2

3

(4 PLACES)

12

14

(7 PLACES)

7

5

11

10

(4 PLACES)

4

6

8

(6 PLACES)

9

(2 PLACES)

13

15

16

17

(2 PLACES)

18

Figure 3. AmPlus™ 100 Amplifier Exploded View

19

Page 20

(5 PLACES)

1

2

3

(7 PLACES)

(2 PLACES)

5

4

6

7

8

(6 PLACES)

9

(3 PLACES)

(2 PLACES)

10

11

12

13

14

15

16

17

Figure 4. AmPlus™ 50 Amplifier Exploded View

20

Page 21

AMPLUS™ 100 TEST SETUP PARAMETERS

Table 2. AmPlus 100 Initial Switch Settings

Control Name Reference Designator Default Setting

Input Mode S1 switch Left (2-Channel/stereo)

Source Trim - Channel 1 R1 potentiometer CW (no attenuation)

Source Trim - Channel 2 R2 potentiometer CW (no attenuation)

Zone 2 Trim R3 potentiometer CW (no attenuation)

Bass Adjust - Channel 1 R4 potentiometer CW (full gain)

Bass Adjust - Channel 2 R5 potentiometer CW (full gain)

High Pass Filter S4 switch left (HPF off)

Remote Volume Setup S5 switch left (1 remote)

Source Mix S7 switch left (2 - channel)

Amp Mode S6 switch left (70V/100V mode)

Table 3. AmPlus 100 Signal Inputs Table

Balanced Inputs

Function Location Type

Source Input

(Channel 1)

Source Input

(Channel 2)

Source Input

(Channel 1)

Source Input

(Channel 2)

(J1) Pins 1, 2, and 3 Connect source LO pin to the (-) terminal and

source HI pin to the (+) terminal. Tie the

source shield to the ground terminal.

(J1) Pins 3, 4, and 5 Connect source LO pin to the (-) terminal and

source HI pin to the (+) terminal. Tie the

source shield to the ground terminal.

Unbalanced (Single-ended) Inputs

(J1) Pins 1, 2, and 3 Connect source HI pin to the (+) terminal and

source ground to the (-) terminal.

(J1) Pins 3, 4, and 5 Connect source HI pin to the (+) terminal and

source ground to the (-) terminal.

Table 4. AmPlus 100 Signal Outputs Table

Function PCB Location Type

Line Output

(Channel 1)

Line Output

(Channel 2)

Power Amplifier

70V/100V (CV)

Power Amplifier

4Ω/Channel 1

Power Amplifier

4Ω/Channel 2

Power Amplifier

XFR (center tap)

J5 (Pins 1, 2, and 3) Impedance-balanced: tie LO to the (-) pin and

the HI to the (+) pin. Tie the source shield pin

to the ground terminal.

J5 (Pins 3, 4, and 5) Impedance-balanced: tie LO to the (-) pin and

the HI to the (+) pin. Tie the source shield pin

to the ground terminal.

J6 (Pins 1 and 2) Balanced; connect LO to the (-) pin and HI to

the (+) pin.

J6 (Pins 3 and 4) Unbalanced: connect LO to the (-) pin and HI

to the (+) pin.

J6 (Pins 5 and 6) Unbalanced: connect LO to the (-) pin and HI

to the (+) pin.

J6 (Pins 7 and 8) Jumper; short J6-7 and J6-8

21

Page 22

AMPLUS™ 100 TEST PROCEDURES

Test Setup Notes:

1. This amplifier is designed to be used

with balanced inputs at J1. If you have a

signal generator capable of supplying a

balanced input, refer to the balanced inputs

info in Table 3. If you can only drive the

amplifier using unbalanced (single-ended)

inputs, refer to the the unbalanced inputs

info in Table 3. Also refer to the appropriate

information (balanced or unbalanced) for

output levels in the various tables and text.

2. Before testing, make sure you have the

connectors for the inputs and outputs at J1,

J4, J5, and J6. The part number for the

connector kit that includes J1, J4, and J5 is

188620-001. The part number for the J6

connector is 190694-008 for the AmPlus

100 amplifier.

3. Be sure to set the unit switch positions in

accordance with Table 2. AmPlus 100 Initial

Switch Settings, before testing.

5. Source Input 1 and 2 (summed

internally) to 70/100V Output.

6. For the following tests, refer to Tables 3

and 4 for Signal Input and Signal Output

connections.

7. For Gain, Response, and Distortion

tests, the unit shall be driven from a 600Ω

source, and measured across a 10kΩ,

1/4 W resistor terminated across the (+)

and ground terminals at the Line Outputs,

and across the Speaker Output with a

98Ω, 100W load across the 70/100V

outputs.

8. Unless otherwise noted, the remote

volume inputs (J4-1 to J4-2 and J4-3 to

J4-2) are to be terminated with a 10kΩ

resistor.

9. Input Voltage Reference shall be

the actual input voltage present at the

input, not the open circuit generator output.

4. All tests are to be performed with option

cards and eq cards removed.

5. Definition of Signal Paths:

The five signal paths that are used during

testing are:

1. Source Input 1 to Line Output 1

2. Source Input 2 to Line Output 2

3. Source Input 1 to Speaker

Output 1 (4Ω).

4. Source Input 2 to Speaker

Output 2 (4Ω).

Table 5. Source Input to 70/100V Speaker Output Test Table

Test Freq. Input (J1) Output (J6)

Gain 1kHz 1 kHz 31.5 mVrms 7.5Vrms± 0.75V (187915-1)

Response 1kHz 1 kHz (Ref) 31.5 mVrms 0dBr ± 0.1dB

Response 60 Hz 60 Hz 31.5 mVrms +9.3dBr ± 1.0dB

Response 10 kHz 10 kHz 31.5 mVrms -0.25dBr ± 1.0dB

THD 1 kHz 31.5 mVrms 0.2% + 0.8%

Noise none none -50dBV + 10.0dBV

1. Gain Test;

Source Input to Line Output

1.1 Apply a 100mVrms, 1kHz signal to the

Channel 1 and 2 Source Inputs.

1.2 Reference a dB meter to the

input level.

1.3 Measure the output level at the

Channel 1 and 2 Line Outputs.

11.0Vrms±0.75V (187915-2)

22

Page 23

AMPLUS™ 100 TEST PROCEDURES

1.4 The output level at J5 should be

+3.5dBr ± 1dB (balanced inputs), or

+13.5dBr ± 1dB (unbalanced inputs).

2. Gain Test;

Source Input to 70V/ 100V Speaker

Outputs

Note: Refer to Table 5. Source Input to 70/

100V Speaker Output test table for the

following tests.

2.1 Set up the unit as listed in the Test

Setup Notes section.

2.2 Apply a 31.5mVrms, 1kHz signal to the

Signal Input jacks at J1.

2.3 Measure the RMS Output Level using a

DMM. It should be as listed in Table 5.

3. Frequency Response Tests;

Source Input to 70/ 100V Speaker

Outputs

3.1 Set up the unit as listed in the test setup

notes section.

3.2 Reference a dB meter to the input level

and perform the Response 1kHz test as

listed in Table 5.

5. Noise Test;

Source Input to 70/100V Speaker

Outputs

5.1 Set up the unit under test as listed in

the Test Setup Notes section.

5.2 With no input signal applied, measure

the noise level in the bandwidth of 20Hz to

16kHz.

5.3 Noise level should be

-50dBV + 10.0dBV.

6. 70/ 100V Speaker Output Full Power

Test

6.1 Set up the unit under test as listed in

the Test Setup Notes section.

6.2 Apply a 280mVrms, 1kHz signal to both

Channel 1 and 2 Source Inputs.

6.3 Using a DMM, measure the output

level at the 70V/ 100V Speaker Outputs.

6.4 Output level should be 70Vrms

± 5.0V for 100/ 120V models.

6.5 Output level should be 100Vrms

± 7.0V for 220/ 240V models.

3.3 Reference a dB meter to the output

level. This is the reference level.

3.4 Perform the Response 60Hz and

Response 10kHz tests as listed in Table 5.

4. Total Harmonic Distortion (THD) Test;

Source Input to 70/ 100V Speaker

Output

4.1 Set up the unit under test as listed in

the Test Setup Notes section.

4.2 Apply a 31.5mVrms, 1kHz signal to both

Channel 1 and 2 Source Inputs and

measure the Total Harmonic Distortion at

the 70V/100V Speaker Outputs.

It should be 0.2% + 0.8%.

7. Power Amplifier Limiter Test

7.1 Set up the unit under test as listed in

the Test Setup Notes section.

7.2 Apply a 175mVrms (balanced inputs) or

95mVrms (unbalanced inputs),100Hz

signal to both Channel 1 and 2 Source

Inputs.

7.3 Using a DMM, measure the level at

the 70/ 100V Speaker Output jack.

7.4 The level should be 80Vrms ± 5.0V

with 1.0% + 2.0% THD for 100/ 120V

models.

23

Page 24

AMPLUS™ 100 TEST PROCEDURES

7.5 The level should be 115Vrms ± 10.0V

with 1.0% + 2.0% THD for 220/ 240V

models.

Note: For the following tests, set up the

unit under test as listed in the Test Setup

Notes section.

Note: Place 4Ω, 100W load resistors

across the 4Ω Speaker Outputs at J6 pins

3 & 4, and 5 & 6.

Note: Move the Amp Mode switch (S6)

from the 70/100V Bridged position to the

2-Channel position. This will enable the

4Ω outputs at J6.

8. Gain Test;

Source Inputs to 4

Ω Speaker Outputs

8.1 Set up the unit under test as listed in

the Test Setup Notes section.

8.2 Apply a 31.5mVrms, 1kHz signal to the

Signal Inputs at J1.

8.3 Reference a dB meter to the input level.

8.4 Perform the 1kHz Gain test as listed

in Table 6.

9. Response Test;

Source Input to 4

Ω Speaker Outputs

9.1 Apply a 31.5mVrms, 1kHz signal to the

Channel 1 and 2 Source Inputs at J1.

9.2 Reference a dB meter to this output

level at the 4Ω Speaker Output at J6.

This is the reference level.

9.3 Perform the 50Hz, 100Hz, 5kHz, and

10kHz Response tests for both channels

as listed in Table 6.

10. Bass Performance Test

10.1 Set up the unit under test as listed in

the Test Setup Notes section.

10.2 Apply a 31.5mVrms, 1kHz signal to

the Signal Input jacks at J1.

Table 6. Source Input to 4Ω Speaker Outputs

Test Name Frequency Input (J1) Output (J6)

1kHz Gain 1kHz

1kHz Resp 1kHz

50Hz Resp 50Hz

100Hz Resp 100Hz

5kHz Resp 5kHz

10kHz

10kHz

Response

THD

1kHz

31.5mV

31.5mV

31.5mV

31.5mV

31.5mV

31.5mV

+14.5dBV ± 1.0dB (balanced inputs)

+35.0dB

0dBr ± 0.1dB (REFERENCE)

± 1.0dB (unbalanced inputs)

-2 .0dBr ± 1.0dB (balanced inputs)

+7.0dB

± 1.0dB (unbalanced inputs)

+1.25dBr ± 1.0dB (balanced inputs)

+9.5dB

0dBr ± 1.0dB (balanced inputs)

+7.5dB

-0.25dBr ± 1.0dB (balanced inputs)

+10.0dB

± 1.0dB (unbalanced inputs)

± 1.0dB (unbalanced inputs)

± 1.0dB (unbalanced inputs)

31.5mV 0.2% + 0.8%

Table 7. Bass Performance Tests

Test Name Frequency Input (J1) Output (J6)

Bass, 1kHz 1kHz 31.5mV 0dBr ± 0.1dB

Bass, 20Hz 20Hz 31.5mV -4.5dBr ± 2dB

Bass, 100Hz 100Hz 31.5mV +11.0dBr ± 2dB

24

Page 25

AMPLUS™ 100 TEST PROCEDURES

10.3 Reference a dB meter to the output

level. This is the reference level.

10.4 Perform the 20Hz and 100Hz tests as

listed in Table 7.

Note: The following test is for channel 1

only, there is no high pass filter circuit for

channel 2.

11. Channel 1 High Pass Filter Test

11.1 Set up the unit under test as listed in

the Test Setup Notes section.

11.2 On the main PCB, place the High

Pass Filter switch (S4) to the HPF IN

position.

11.3 Apply a 31.5mVrms, 1kHz signal to the

Channel 1 Source Input.

11.4 Reference a dB meter to this output

level.

11.5 Apply a 31.5mVrms, 50Hz signal to

the Channel 1 Source Input.

11.6 Measure the output at Channel 1.

It should be -22.0dBr ± 3dB (balanced

inputs), or +12.5dBr ± 3dB (unbalanced

inputs).

12.5 Measure the output at the Channel 1

4Ω Speaker Outputs. It should be

-45dBV +5.0dBV.

12.6 Measure the output at the Channel 2

4Ω Speaker Outputs. It should be

-45dBV +5.0dBV.

12.7 On the main PCB, place the Remote

Zone Assign switch (S5) to the 2 Remotes

position.

12.8 Measure the output at the Channel 2

4Ω Speaker Outputs. It should be

-45dBV +5.0dBV.

13. D.C. Offset Test

13.1 Set up the unit under test as listed in

the Test Setup Notes section.

13.2 With both inputs terminated, and with

no signal applied, measure the D.C.

voltage at the Channel 1 and 2, 4Ω

Speaker Outputs.

13.3 It should be 0mVDC ± 10mVDC for

both channels.

12. Remote Volume Attenuation Test

12.1 Set up the unit under test as listed in

the Test Setup Notes section.

12.2 Place a jumper from J4-1 to J4-2 and

from J4-2 to J4-3. This will apply full

attenuation to the VCA's for both channel

1 and 2.

12.3 On the main PCB, place the Remote

Zone Assign switch (S5) in the 1 Remote

position.

12.4 Apply a 280mVrms, 1kHz signal to the

channel 1 and 2 Source Inputs.

25

Page 26

AMPLUS™ 50 TEST SETUP PARAMETERS

Table 8. AmPlus 50 Initial Switch Settings

Control Name Reference Designator Default Setting

Source Trim - Channel 1 R1 potentiometer CW (no attenuation)

Source Trim - Channel 2 R2 potentiometer CW (no attenuation)

Bass Adjust R4 potentiometer CW (full gain)

High Pass Filter S4 switch Left (HPF OFF)

Amp Mode S6 switch Left (70V/100V mode)

Table 9. AmPlus 50 Signal Inputs Table

Balanced Inputs

Function Location Type

Source Input

(Channel 1)

Source Input

(Channel 2)

Source Input

(Channel 1)

Source Input

(Channel 2)

(J1) Pins 1, 2, and 3 Connect source LO pin to the (-) terminal and

source HI pin to the (+) terminal. Tie the

source shield to the ground terminal.

(J1) Pins 3, 4, and 5 Connect source LO pin to the (-) terminal and

source HI pin to the (+) terminal. Tie the

source shield to the ground terminal.

Unbalanced (Single-ended) Inputs

(J1) Pins 1, 2, and 3 Connect source HI pin to the (+) terminal and

source ground to the (-) terminal.

(J1) Pins 3, 4, and 5 Connect source HI pin to the (+) terminal and

source ground to the (-) terminal.

Table 10. AmPlus 50 Signal Outputs Table

Function PCB Location Type

Power Amplifier

70V/100V (CV)

Power Amplifier

4Ω/Channel 1

J6 (Pins 1 and 2) Balanced; connect LO to the (-) pin and HI to

the (+) pin.

J6 (Pins 3 and 4) Unbalanced: connect LO to the (-) pin and HI

to the (+) pin.

26

Page 27

AMPLUS™ 50 TEST PROCEDURES

Test Setup Notes:

1. This amplifier is designed to be used

with balanced inputs at J1. If you have a

signal generator capable of supplying a

balanced input, refer to the balanced inputs

info in Table 9. If you can only drive the

amplifier using unbalanced (single-ended)

inputs, refer to the the unbalanced inputs

info in Table 9. Also refer to the appropriate

information (balanced or unbalanced) for

output levels in the various tables and text.

2. Before testing, make sure you have the

connectors for the inputs and outputs at J1,

J4, and J6. The part number for the

connector kit that includes J1, and J4 is

188620-001. The part number for the J6

connector is 190694-004 for the AmPlus 50

amplifier.

3. Be sure to set the unit switch positions in

accordance with Table 8. AmPlus 50 Initial

Switch Positions, before testing.

4. All tests are to be performed with the eq

card removed.

6. For the following tests, refer to Tables 9

and 10 for Signal Input and Signal Output

connections.

7. For Gain, Response, and Distortion

tests, the unit shall be driven from a 600Ω

source. Measurement at the Speaker

Outputs shall be performed with a 4Ω,

100W load across the 4Ω outputs, and

with a 98Ω/100W load resistor across the

70/100V Speaker Output.

8. Unless otherwise noted, the remote

volume input (J4-1 to J4-2) is to be

terminated with a 10kΩ resistor.

9. Input Voltage Reference shall be

the actual input voltage present at the

input, not the open circuit generator output.

1. Gain Test;

Source Input to 70V/100V Speaker

Output

Note: Refer to Table 11. Source Input to

70/ 100V Speaker Output test table for the

following tests.

5. Definition of Signal Paths:

The three signal paths that are used during

1.1 Set up the unit as listed in the Test

Setup Notes section.

testing are:

1. Source Input 1 to Speaker

Output 1 (4Ω).

1.2 Perform the Speaker CV Gain Test as

listed in Table 11.

2. Source Input 2 (summed with

channel 1) to Speaker Output 1 (4Ω).

3. Source Input 1 and 2 (summed

1.3 Measure the Output Level using a

DMM at J6.

internally) to 70/ 100V Output.

Table 11. Source Input to 70/100V Speaker Output test table

Test Freq. Input (J1) Output (J6)

Spkr CV Gain 1kHz 100mVrms 22.0V± 5.0Vrms (100/120V only)

32.0V±5.0Vrms (220/240V only)

Response 1kHz 1kHz 100mVrms 0dBr±0.5dB (REFERENCE)

Response 60Hz 60Hz 100mVrms +9.3dBr ± 1.0dB (balanced inputs)

+7.5dB±1.0dB (unbalanced inputs)

Response 10kHz 10kHz 100mVrms -0.25dBr ± 1.0dB (balanced inputs)

+9.0±1.0dB (unbalanced inputs)

THD 1kHz 100mVrms 0.2% + 0.8%

Noise none none -50dBV+ 10.0dBV

27

Page 28

AMPLUS™ 50 TEST PROCEDURES

2. Frequency Response Tests;

Source Input to 70/100V Speaker

Output

2.1 Set up the unit as listed in the Test

Setup Notes section.

2.2 Reference a dB meter to the input

level and perform the 1kHz Response

Test as listed in Table 11.

2.3 Reference a dB meter to the output

level. This is the reference level.

2.4 Perform the 60Hz and 10kHz

Response tests as listed in Table 11.

3. Total Harmonic Distortion (THD) Test;

Source Input to 70/100V Speaker

Output

3.1 Set up the unit under test as listed in

the Test Setup Notes section.

3.2 Apply a 100mVrms, 1kHz signal to both

Channel 1 and 2 Source Inputs and

measure the Total Harmonic Distortion at

the 70V/100V Speaker Output.

It should be 0.2% + 0.8%.

4. Noise Test;

Source Input to 70/100V Speaker

Outputs

4.1 Set up the unit under test as listed in

the Test Setup Notes section.

4.2 With no input signal applied, measure

the noise level in the bandwidth of 20Hz to

16kHz.

5. 70/ 100V Speaker Output Full Power

Test

5.1 Set up the unit under test as listed in

the Test Setup Notes section.

5.2 Apply a 280mVrms, 1kHz signal to both

Channel 1 and 2 Source Inputs.

5.3 Using a DMM, measure the output

level at the 70V/ 100V Speaker Output.

5.4 Output level should be 70Vrms

± 5.0V for 100/ 120V models.

5.5 Output level should be 100Vrms

± 7.0V for 220/ 240V models.

6. Power Amplifier Limiter Test

6.1 Set up the unit under test as listed in

the Test Setup Notes section.

6.2 Apply a 175mVrms (balanced inputs),

or 95mVrms (unbalanced inputs), 95Hz

signal to both Channel 1 and 2 Source

Inputs.

6.3 Using a DMM, measure the level at

the 70/ 100V Speaker Output jack.

6.4 The output level should be 70Vrms

± 5.0V with 1.0% + 2.0% THD for

100/ 120V models.

6.5 The output level should be 100Vrms

± 7.0V with 1.0% + 2.0% THD for

220/ 240V models.

4.3 Noise level should be

-50dBV + 10.0dBV.

28

Page 29

AMPLUS™ 50 TEST PROCEDURES

Note: For the following tests, set up the

unit under test as listed in the Test Setup

Notes section.

Note: Move the Amp Mode switch (S6)

from the Constant Voltage (CV) position to

the 4Ω position. This will enable the

4Ω output at J6.

Note: Place a 4Ω, 100W load resistor

across the 4Ω Speaker Output at

J6 pins 3 & 4.

Note: Refer to Table 12. Source Inputs to

4Ω Speaker Outputs for the following tests.

7. Gain Test;

Source Inputs to 4

7.1 Apply a 100mV, 1kHz signal to the

Signal Inputs at J1.

Ω Speaker Outputs

7.3 Measure the output level at the Signal

Outputs at J6. It should be +14.5dBV

± 1.0dB (balanced inputs) or +35.0dB

± 1.0dB (unbalanced inputs).

8. Response Test;

Source Input to 4

8.1 Set up the unit under test as listed in

the Test Setup Notes section.

8.3 Apply a 100mVrms, 1kHz signal to the

Channel 1 and 2 Source Inputs at J1.

8.4 Reference a dB meter to this output

level at the 4Ω Speaker Output at J6.

This is the reference level.

8.5 Perform the 50Hz, 100Hz, 5kHz, and

10kHz tests as listed in Table 12. Source

Inputs to 4Ω Speaker Outputs.

Ω Speaker Outputs

7.2 Reference a dB meter to this input

level.

Table 12. Source Inputs to 4Ω Speaker Output

Test Name Frequency Input (J1) Output (J6)

Gain 1kHz 100mV +14.5dBV ± 1.0dB (balanced inputs)

+35.0dBV ± 1.0dB (unbalanced inputs)

Resp 1k 1kHz 100mV 0dBr ± 0.1dB (REFERENCE)

Resp 50 50Hz 100mV -2.0dBr ± 1.0dB (balanced inputs)

+7.0dBr ± 1.0dB (unbalanced inputs)

Resp 100 100Hz 100mV +1.25dBr ± 1.0dB (balanced inputs)

+9.5dBr ± 1.0dB (unbalanced inputs)

Resp 5k 5kHz 100mV 0dBr ± 1.0dB (balanced inputs)

+7.5dBr ± 1.0dB (unbalanced inputs)

Resp 10k 10kHz 100mV -0.25dBr ± 1.0dB (balanced inputs)

+10.0dBr ± 1.0dB (unbalanced inputs)

THD 1kHz 100mV 0.2% + 0.8%

Noise none none -50dBV + 10.0dBV

Table 13. Bass Performance Tests

Test Name Frequency Input (J1) Output (J6)

Bass, 1kHz 1kHz 31.5mV 0dBr ± 0.1dB

Bass, 20Hz 20Hz 31.5mV -4.5dBr ± 2dB

Bass, 100Hz 100Hz 31.5mV +11.0dBr ± 2dB

29

Page 30

AMPLUS™ 50 TEST PROCEDURES

9. Bass Performance Tests

Note: Refer to table 13 for the following

tests.

9.1 Set up the unit under test as listed in

the Test Setup Notes section.

9.2 Apply a 31.5mVrms, 1kHz signal to the

Signal Input jacks at J1.

9.3 Reference a dB meter to the output

level. This is the reference level.

9.4 Perform the Bass 20Hz, and 100Hz

tests as listed in Table 13.

10. High Pass Filter Test

Note: This test checks the response of the

150Hz high pass filter.

11. D.C. Offset Test

11.1 Set up the unit under test as listed in

the Test Setup Notes section.

11.2 With both inputs terminated, and with

no signal applied, measure the D.C.

voltage at the Channel 1, 4Ω Speaker

Output.

11.3 It should be 0mVDC ± 10mVDC.

10.1 Set up the unit under test as listed in

the Test Setup Notes section.

10.2 On the main PCB, place the High

Pass Filter switch (S4) to the HPF IN

position.

10.3 Apply a 31.5mVrms, 1kHz signal to

the Channel 1 Source Input (J1).

10.4 Reference a dB meter to this output

level.

10.5 Apply a 31.5mV, 50Hz signal to the

Channel 1 Source Input.

10.6 Measure the output at Channel 1 (J6).

It should be -22.0dBr ± 3dB (balanced

inputs), or +12.5dBr ± 3dB (unbalanced

inputs).

30

Page 31

INSTALLATION DIAGRAM NOTES

The installation diagrams on the following pages are provided to give you an idea as to how

this product may be installed in the field, so that you can more easily troubleshoot a problem if

the unit has been removed from its installation for you to repair.

The diagrams are divided into three sections:

1. The first section is labelled "Example Listening Zone", and in block diagram format,

shows how the source is connected to the amplifier, and the amplifier is connected to the

loudspeakers as well as the remote volume control(s) for that type of installation.

2. The next section is labelled "Rear Panel Hookup", and shows the hookup on the rear panel

of the amplifier, as well as the various switch settings for that type of installation.

3. The bottom section is labelled "AmPlus™ 50 (or 100) Signal Flow", and in block diagram

format, depicts the signal flow and switch settings for the particular amplifier used for that type

of installation. The grayed out lines in the block diagram indicate signal paths and blocks not

used in that particular application.

Using this information, you should be able to more closely approximate the installation of the

unit in order to more easily troubleshoot it.

31

Page 32

Example Listening Zone

Source

AmPlus™ 100

Rear Panel Hookup

Remote

Volume

Control

Ch1

INPUTS A

Ch2

INPUT

MODE

dual

mono

2Ch

mono

-10

-40 dB

LEVEL

Zone 2Ch2Ch1

-6

-6

-10

-10

0

0

-40 dB

-40 dB

BASS

LEVEL

-6

OFF

OFF +10

0

+10

Ch2Ch1

REMOTE

VOLUME

ZONE 1 ZONE 2

+- +- +-+-+-

Internal Switch Settings

Source

Remote Volume: 1 Remote,

Ch. 1 High Pass Filter: OFF,

2 Ch./Mixer Switch: 2 Ch.

L

R

Note: Both bass pots are active

in this mode. Use both of these

controls to make bass level

adjustments.

Remote

Volume

Control

LINE OUTPUT

ZONE 1 ZONE 2

+-+-

70/100V ZONE 1

Tap settings

less than or

equal to 100W

AmPlus 100 Signal Flow

Ch. 1

Channel 1

Input

Channel 2

Input

Mono

Input Mode Switch

section 1 of 2

High

Pass

Filter

Switch

Bass

Level

Ch. 1

Level

Dual

Mono

Ch. 2

Level

High Pass

Filter

Dynamic

EQ

Bass Boost

2 Ch.

2 Ch/

Mixer

Switch

Option Card 1

Channel 1

Mix

2 Ch.

Option Card 1

Channel 2

Power Amp 1

Power Amp 2

Option Card 2

Channel 1

Option Card 2

Channel 2

70/100V Bridged

EQ Card 1

EQ Card 2

70/100V Bridged

2 Ch.

Amplifier

Mode

Switch

Zone 2

Level

Dual

Mono

2 Ch.

VCA 1

Mono

VCA 2

Zone 1

Remote

Zone 2

Remote

Input Mode Switch

section 2 of 2

POWER AMPLIFIER

ZONE 2

4-16

4-16

VCA

Control 1

Remote Switch

VCA

Control 2

XFR

CT

70/100V 2 Ch.

BRIDGED

1 Remote

2 Remotes

MODE

Line Outputs

ZONE 1

ZONE 2

Bass

Level

Ch. 2

Dynamic

EQ

Bass Boost

2 Ch.

Power

Amplifier

+ -

70/100V

+ -

ZONE 1

Outputs

+ -

ZONE 2

XFR

CT

Figure 5. AmPlus 100 Simple Mono Installation

32

Page 33

Example Listening Zone

Source 1

Source 2

AmPlus™ 100

Remote

Volume

Control

AmPlus™ 100

Rear Panel Hookup

BASS

LEVEL

-6

OFF

OFF +10

+10

0

Ch1

INPUTS A

Ch2

2Ch

INPUT

MODE

dual

mono

LEVEL

Zone 2Ch2Ch1

-6

-6

-10

-10

mono

-40 dB

-10

0

0

-40 dB

-40 dB

+- +- +-+-+-

Source 1

Source 2

1. Adjust the source 1

level with the ch. 1 pot.

3. Internal Switch Settings

Remote Volume: 1 Remote,

Ch. 1 High Pass Filter: OFF,

2 Ch./Mixer Switch: Mixer position

Note: Both bass pots are active in

this mode. Use both of these

controls to adjust bass level.

2. Adjust the source 2

level with the ch. 2 pot.

Remote

Volume

Control

Ch2Ch1

REMOTE

VOLUME

ZONE 1 ZONE 2

LINE OUTPUT

ZONE 1

Aux Amp 1

+-+-

ZONE 2

70/100V

POWER AMPLIFIER

ZONE 2

ZONE 1

4-16

4-16

Tap settings

less than or

equal to

100W

XFR

MODE

CT

70/100V 2 Ch.

BRIDGED

Tap settings

less than or

equal to

100W

AmPlus 100 Signal Flow

Source 1

Mono

High

Pass

Filter

Switch

Level

Source 2

Level

High Pass

Filter

Dynamic

EQ

Bass Boost

Dynamic

EQ

Bass Boost

Dual

Mono

2 Ch.

2 Ch/

Mixer

Switch

Mono

Source 1

Input

Mono

Source 2

Input

Input Mode Switch

section 1 of 2

Bass

Level

Ch. 1

Bass

Level

Ch. 2

Figure 6. AmPlus 100 Large Mono Installation using Mixer Feature

Option Card 1

Channel 1

Mix

2 Ch.

Option Card 1

Channel 2

Power Amp 1

Power Amp 2

+ -

70/100V

Option Card 2

Channel 1

Option Card 2

Channel 2

+ -

ZONE 1

70/100V Bridged

70/100V Bridged

Power

Amplifier

Outputs

2 Ch.

Amplifier

Mode

Switch

2 Ch.

+ -

ZONE 2

EQ Card 1

EQ Card 2

33

XFR

VCA 1

Dual

Mono

Mono

Zone 2

Level

CT

2 Ch.

Input Mode Switch

section 2 of 2

VCA 2

Zone 1

Remote

Zone 2

Remote

VCA

Control 1

Remote Switch

VCA

Control 2

Line Outputs

ZONE 1

ZONE 2

1 Remote

2 Remotes

Page 34

Example Listening Zone

Source

AmPlus™ 100

Model 1B

Module

Remote

Volume

Control

Rear Panel Hookup

Ch1

INPUTS A

Ch2

INPUT

MODE

dual

mono

2Ch

mono

LEVEL

Zone 2Ch2Ch1

-6

-6

-10

-10

-10

0-40 dB