Page 1

802C System Controller

Original and SMD Version

®

®

Units with serial numbers beginning with 100000 are the original 802C's.

Units with serial numbers beginning with 200000 are the new SMD 802C's.

©

1997 Bose Corporation

Service Manual

1

Part Number 129292 REV 03

Page 2

Contents

Safety Information............................................................................................................................ 3

Electrostatic Discharge Sensitive (ESDS) Device Handling ........................................................ 4

Specifications................................................................................................................................... 5

Technical Description ...................................................................................................................... 6

Disassembly/Assembly Procedures .............................................................................................. 7

Figure 1. Locking Tab Screw Location ............................................................................................. 7

Figure 2. Original 802C PCB Exploded View................................................................................... 8

Figure 3. SMD 802C PCB Exploded View ....................................................................................... 8

Test Procedures .......................................................................................................................... 9-10

Part List Notes................................................................................................................................ 11

Main Part List.................................................................................................................................. 12

Figure 4. Main Parts Exploded View .............................................................................................. 13

Electrical Part List..................................................................................................................... 14-17

Voltage Conversion Instructions .................................................................................................. 18

Figure 5. Voltage Conversion Diagram .......................................................................................... 18

Figure 6. Top Cover Connection Diagram...................................................................................... 19

2

Page 3

SAFETY INFORMATION

1. Parts that have special safety characteristics are identified by the symbol on

schematics or by special notes on the parts list. Use only replacement parts that

have critical characteristics recommended by the manufacturer.

2. Make leakage current or resistance measurements to determine that exposed

parts are acceptably insulated from the supply circuit before returning the unit

to the customer. Use the following checks to perform these measurements:

A. Leakage Current Hot Check-With the unit completely reassembled, plug

the AC line cord directly into a 120V AC outlet. (Do not use an isolation

transformer during this test.) Use a leakage current tester or a metering

system that complies with American National Standards Institute (ANSI)

C101.1 “Leakage Current for Appliances” and Underwriters Laboratories

(UL) 1492 (71). With the unit AC switch first in the ON position, then in the

OFF position, measure from a known earth ground (metal water pipe,

conduit, etc.) to all exposed metal parts of the unit (antennas, handle bracket,

metal cabinet, screwheads, metallic overlays, control shafts, etc.), especially

any exposed metal parts that offer an electrical return path to the chassis.

Any current measured must not exceed 0.5 milliamp. Reverse the unit power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN

THE LIMITS SPECIFIED HEREIN INDICATE A POTENTIAL SHOCK HAZ ARD THAT MUST BE ELIMINATED BEFORE RETURNING THE UNIT TO

THE CUSTOMER.

B. Insulation Resistance Test Cold Check-(1) Unplug the power supply and

connect a jumper wire between the two prongs of the plug. (2) Turn on the

power switch of the unit. (3) Measure the resistance with an ohmmeter be-

tween the jumpered AC plug and each exposed metallic cabinet part on the

unit. When the exposed metallic part has a return path to the chassis, the

reading should be between 1 and 5.2 Megohms. When there is no return path

to the chassis, the reading must be “infinite”. If it is not within the limits specified,

there is the possibility of a shock hazard, and the unit must be repaired and re checked before it is returned to the customer.

PROPRIETARY INFORMATION

THIS DOCUMENT CONTAINS PROPRIETARY INFORMATION OF

BOSE

®

CORPORATION WHICH IS BEING FURNISHED ONLY FOR

THE PURPOSE OF SERVICING THE IDENTIFIED BOSE PRODUCT

BY AN AUTHORIZED BOSE SERVICE CENTER OR OWNER OF THE

BOSE PRODUCT, AND SHALL NOT BE REPRODUCED OR USED

FOR ANY OTHER PURPOSE.

3

Page 4

ELECTROSTATIC DISCHARGE SENSITIVE (ESDS)

DEVICE HANDLING

This unit contains ESDS devices. We recommend the following precautions when repairing,

replacing or transporting ESDS devices:

• Perform work at an electrically grounded work station.

• Wear wrist straps that connect to the station or heel straps that connect to conductive floor

mats.

• Avoid touching the leads or contacts of ESDS devices or PC boards even if properly

grounded. Handle boards by the edges only.

• Transport or store ESDS devices in ESD protective bags, bins, or totes. Do not insert unprotected devices into materials such as plastic, polystyrene foam, clear plastic bags, bubble wrap

or plastic trays.

CAUTION: THE 802®C SYSTEM CONTROLLER CONTAINS NO USER-SERVICEABLE

PARTS. TO PREVENT WARRANTY INFRACTIONS, REFER SERVICING TO WARRANTY

SERVICE STATIONS OR FACTORY SERVICE.

4

Page 5

SPECIFICATIONS

O

Input Connections:

(per channel)

Output Connections:

(per channel)

Input Impedance: Balanced input, 4kΩ

Electronic Crossover

Frequency: 180Hz (bi-amplified mode only)

Maximum Output Level: 4 Volts (+12dB into 600Ω, 50Hz-16kHz)

Total Harmonic Distortion: Less than .02% at 1 Volt (0dB)

Output Noise: Less than 20uV (-9dBV) A-weighted

ne (1) balanced female XLR connector

One (1) unbalanced 1/4" phone jack

Two (2) 1/4" phone jacks per channel

(outputs used depend upon mode selected)

Unbalanced input, 42kΩ

Less than .2% at 8 Volts (18dB)

Power Requirements: 120 Vac, 50-60Hz, 3.5 Watts

Dimensions: 1 3/4"H x 10" W x 5" D

Weight: 1.97 lbs (.895 kg)

220 Vac, 50-60Hz, (European)

100 Vac, 50-60Hz, (Japan)

(4.4 x 25.4 x 12.7 cm)

5

Page 6

TECHNICAL DESCRIPTION

®

The 802

functions of three equalizers, an automatic switching circuit, and an electronic crossover. The

802C system controller automatically selects the proper crossover function and equalization

curve for a given system application through use of a switching network operating in conjunction with the unit's output jacks. In addition to signal routing based on equalization requirements, the switching network indicates mode of operation on its front panel. The front panel

also includes high-cut and low-cut switches which decrease line output by 4dB at 55Hz and by

10dB at 16kHz. Sharp subsonic and ultrasonic band-limiting filters reduce power waste, stage

noise, high-frequency instability, and interference. The 802C system controller retains the

compact dimensions of its predecessor, the Bose

space of a standard 19" equipment rack with the optional RMK-8 Rack Mount Kit.

In an on-going process of manufacturing updates, as technology permits, Bose Corporation

has begun using SMD (surface mount devices) components on its 802C controller. The new

SMD components are such a space saving feature that this new version permits us to eliminate the "piggy-back" PCB and place all electronics on one single printed circuit board. This

manual will identify the different procedures, PCB layouts, and components where necessary.

There is no difference in the operation or function between the original 802C and the

802C SMD units.

C System Controller is a sophisticated signal processing device which combines the

®

802E active equalizer, and fits into one

6

Page 7

DISASSEMBLY/ASSEMBLY PROCEDURES

Note: Refer to the Figures (2 and 3) for the

following procedures.

1. Top Cover Removal

1.1 Remove the four screws (two located

at the rear of the unit and one located on

each side of the unit) that secure the top

cover to the chassis.

1.2 Lift the rear of the top cover slightly

and slide it forward until the front of the top

cover is clear of the switches.

2. Top Cover Replacement

2.1 Align the front of the top cover with the

switches and LED's and slide the cover into

place.

2.2 Secure the top cover into place.

3. 302EQ ("piggy-back") PCB Removal

Note: The original 802C has two PCB's.

The following procedure will discuss the

removal of the "piggy-back" PCB.

Note: The "piggy-back" PCB does not

need to be removed when removing the

main PCB.

3.1 Perform procedure 1.

4.2 Perform procedure 2.

5. Main PCB Removal

5.1 Perform procedure 1.

5.2 Remove the 6 knurled nuts securing

the input and output jacks to the chassis.

5.3 Remove the 5 screws that secure the

main PCB to the chassis.

5.4 On the rear of the unit, at the XLR

jacks there is a small hole with a locking

screw inside (see Figure 1). Insert a small

flathead screwdriver into the hole and

rotate the locking screw 1/8 turn counterclockwise to release the locking tab.

5.5 Lift the front of the PCB up slightly.

Gently pull the PCB out while pushing on

the center of the XLR jacks.

6. Main PCB Replacement

6.1 Carefully slide the PCB into the chas-

sis while aligning the XLR jacks into their

housing.

6.2 Lock the XLR jacks into place by

inserting a small screwdriver into the small

hole in the XLR jack and rotate the screw

clockwise 1/8 turn.

3.2 Locate the four plastic stand-offs (three

are located in the corners of the PCB and

one is located between C125 and C225).

3.3 With small needle-nose pliers, squeeze

the retaining tab of each stand-off while

gently lifting up on the PCB to release the

lock. Grasp the PCB at the middle of each

side and lift the PCB off of the connectors.

4. 302EQ ("piggy-back") PCB Replacement

4.1 Replace the "piggy-back" PCB (on the

original 802C controller) by placing the

board over the connectors and pushing the

board down onto the stand-offs.

6.3 Replace the 5 screws that hold the

PCB into place in the chassis.

6.4 Perform procedure 2.

Figure 1. Locking Tab Screw Location

7

Page 8

Figure 2. Original 802C PCB Exploded View

Figure 3. SMD 802C PCB Exploded View

8

Page 9

TEST PROCEDURES

1. Mode Indicator Test

1.1 Depending on the output jack configu-

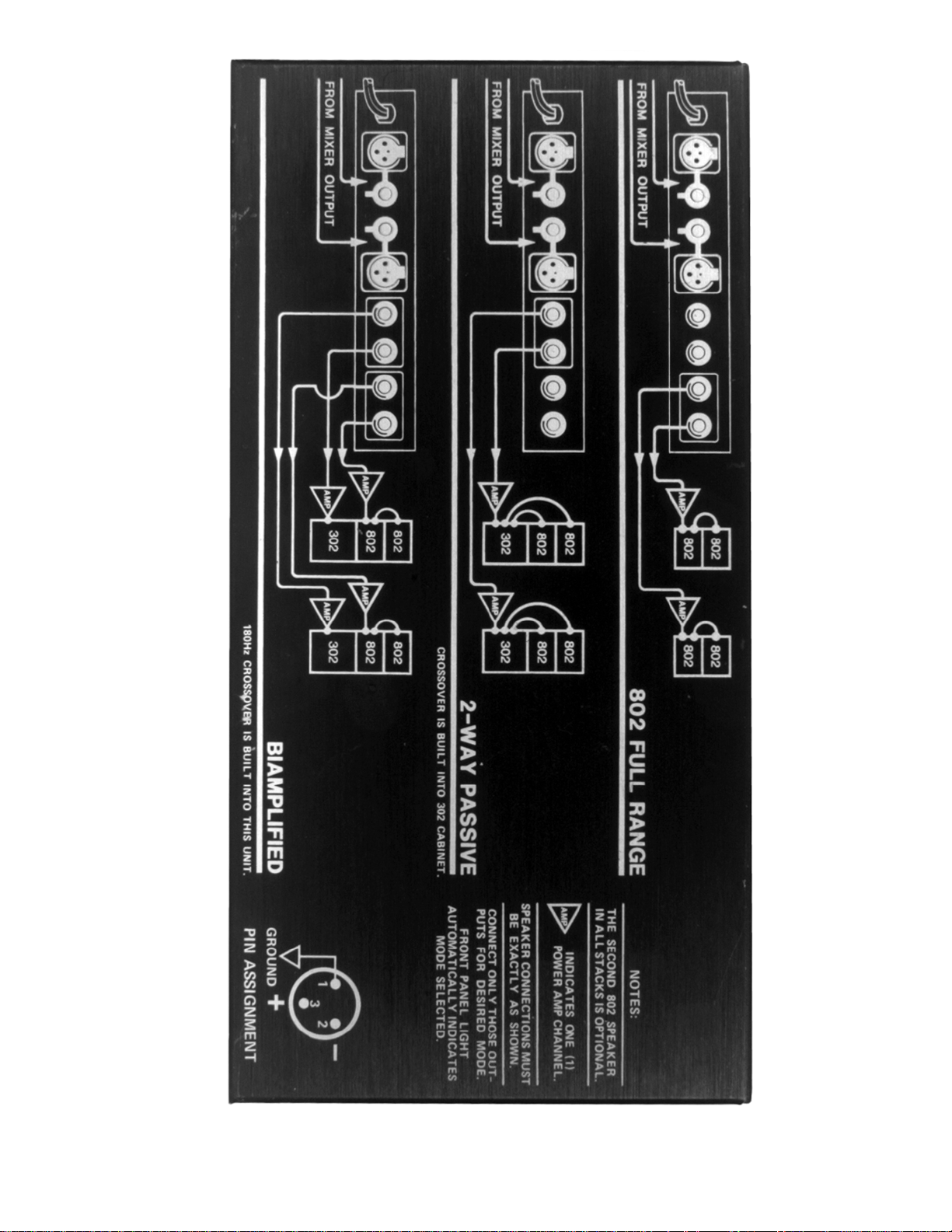

ration (see top cover diagram on page 17),

equalization curves and output vary. You

must test all modes of the 802C to assure

proper operation.

1.2 Perform the test below to verify that the

mode select operation is working properly.

Note: You can insert one or both of the

output jacks into the unit for this test.

LED Indicator Status

Output

Jacks

Inserted

No Jacks

Inserted

Inserted into

802 AMP

Inserted into

302 AMP

Inserted into

802 and 302

AMP

2. 802 Full Range Frequency Response

802

Full

Range

On Off Off

On Off Off

Off On Off

Off Off On

Passive

2-Way

Bi-

AMP

Note: Set both the Lo and Hi cut switches

IN for the following response table.

Lo and Hi Cut Switch Response Table

Frequency Output Tolerance

55Hz +9.3dB ± 1.8dB

750Hz 0dB

(reference)

15kHz +6.9dB ± 2.0dB

3. 302 Passive Frequency Response

3.1 Apply a 750Hz, 500mVrms signal to

the input of the 802C.

3.2 Reference a dB meter to the 302 AMP

output jacks.

3.3 Refer to the frequency response table

below and verify the response of the unit.

Passive Frequency Response Table

Frequency Output Tolerance

30Hz -8.8dB ± 2.5dB

55Hz +6.2dB ± 1.5dB

150Hz -3.2dB ± 1.5dB

250Hz +3.2dB ± 1.8dB

750Hz 0 dB

(reference)

3kHz 0.9dB ± 1.5dB

15kHz +15.3dB ± 1.8dB

-

-

2.1 Apply a 750Hz, 500mVrms signal to

the input of the 802C.

2.2 Reference a dB meter to the 802 AMP

output jacks.

2.3 Refer to the frequency response table

below and verify the response of the unit.

Full Range Frequence Response Table

Frequency Output Tolerance

55Hz +14.0dB ± 1.5dB

30Hz 0dB ± 2.5dB

250Hz +2.7dB ± 1.2dB

750Hz 0dB

(reference)

3kHz +2.3dB ± 1.5dB

7.5kHz +12.0dB ± 1.5dB

15kHz +16.9dB ± 1.8dB

-

4. Bi-Amp Frequency Response

Note: This test is performed with both the

802 AMP and the 302 AMP output jacks

used at the same time.

4.1 Apply a 750Hz, 500mVrms signal to

the input of the 802C.

4.2 Reference a dB meter to the 802 AMP

output jacks (while in the Bi-Amp mode).

4.3 Refer to the frequency response table

below and verify the response of the unit.

802 Bi-Amp Frequency Response Table

Frequency Output Tolerance

55Hz -20.1dB ± 2.5dB

230Hz +2.6dB ± 1.8dB

750Hz 0 dB

(reference)

15kHz +17.0dB ± 1.8dB

-

9

Page 10

TEST PROCEDURES

4.4 Apply a 100Hz, 500mVrms signal to

the input of the 802C.

4.5 Reference a dB meter to the 302 AMP

output jacks (while in the Bi-Amp mode).

4.6 Refer to the frequency response table

below and verify the response of the unit.

302 Bi-Amp Frequency Response Table

Frequency Output Tolerance

55Hz +3.7dB ± 1.5dB

100Hz 0dB

(reference)

230Hz -8.3dB ± 1.5dB

750Hz -25.8dB ± 2.5dB

5. Distortion Test

Note: Total harmonic distortion must be

measured in all modes to assure proper

operation.

-

6. Noise Test

6.1 All noise measurements are ANSI

A-weighted true rms, with the inputs

shorted.

6.2 Refer to the table below for the proper

noise levels.

Noise Table

Output Noise

802 Full

Range

302 Passive <20uV

802 Bi-Amp <20uV

302 Bi-Amp <10uV

<20uV

5.1 Apply a 750Hz, 5Vrms signal to the

input of the 802C.

5.2 Refer to the table below for the distortion specification for the corresponding

mode being tested.

Note: For the Bi-Amp 302 reading the

input signal should be a 100Hz, 5Vrms

signal.

Distortion Table

Output Frequency. Dist ortion

802 Full

Range

302 Passive 750Hz <0.1%

802 Bi-Amp 750Hz <0.1%

302 Bi-Amp 100Hz <0.1%

750Hz <0.1%

10

Page 11

PART LIST NOTES

1. This part is not normally available from Customer Service. Approval from the Field Service

Manager is required before ordering.

2. The individual parts located on the PCB are listed in the Electrical Part List.

3. This part is critical for safety purposes. Failure to use a substitute replacement with

the same safety characteristics as the recommended replacement part might create shock, fire

and or other hazards.

4. RC-4156 is to be used ONLY as a replacement for U5 and U6. This replaces the selected

LS-404 IC previously used in these locations. Due to the higher current needs of the RC-4156,

DAMAGE could occur to the power supply if this IC is used in other locations on the PCB.

5. This part is used on the 220V variation only.

11

Page 12

MAIN PART LIST

(See Figure 4)

Item

Number

1 COVER 135040

2 CHASSIS 133230 1

3 FEET 103593

4 SCREW, SHEET METAL,

4-40 x .25L

5 CONNECTOR, XLR 121810

6 NUT, KNURLED 121890

7 STRAIN RELIEF BUSHING 106346

8 LINE CORD, 100/120V

LINE CORD, 220V

9 LED 123487

10 BRACKET, LED 120975

11 SMD PCB ASSEMBLY - 1

12 SWITCH, KNOB 120989

13 SWITCH, DUAL 107461

14 SCREW, MACHINE, 4-40

x .187L

15 STANDOFF 123199 1

16 PCB ASSEMBLY (TOP) 122068

17 PCB ASSEMBLY (MAIN) - 1

- CARTON 121860

- FILLER 122640

- POLY BAG 100688

- ACCESSORY KIT 121783

- MTG KIT (802 COVER) 123037

- SWITCH, SLEEVE 120996

- INSULATOR 122855

- SCREW, MACHINE,

NYLON,

6-32 x .75L, 220V

- SCREW, MACHINE,

NYLON,

6-32 x .25L, 220V

- STANDOFF, HEX, 6 x

.375L

Description Part

Number

103118-04

111672

113608

103140-03

124843-12 5

128843-04 5

121828-06 5

Note

3

Reference

Designator

J1, 3 CONNECTOR, XLR,

INSERT

J2, 4-8 JACK, PHONE 121570

J9 WAFER, 7PIN, (2461) 123237-07

J9 CONNECTOR, 7PIN

(21458)

J10 WAFER, 6PIN (2461) 123237-06

J10 CONNECTOR, 6PIN

(21458)

P1, 2 TEMINAL, FASTON 111262 3

T1 TRANSFORMER,

110/220V

TRANSFORMER, 120V

TRANSFORMER, 100V

Description Part Number Note

121823

121970-07

121970-06

120993

121659-1

121824

12

3

Page 13

Figure 4. Main Parts Exploded View

13

Page 14

ELECTRICAL PART LIST

Resistors

Reference

Designator

R1, 2 2.7kΩ, 1/4 Watt, 5% 117704R3, 4 3.3kΩ, 1/4 Watt, 5% 117704R5-7, 11, 15, 118, 218 160kΩ, 1/4 Watt, 5% 117704R8, 9, 12, 13, 16, 17, 101, 210, 104,

204

R10, 14, 18 8.2kΩ, 1/2 Watt, 5% 122071-8225

R102, 103, 105, 122, 124, 202, 203,

205, 222, 224

R106, 206 1.9kΩ, 1/4 Watt, 1% 119976-

R107, 207 48.7kΩ, 1/4 Watt, 1% 119976R108, 208 20kΩ, 1/4 Watt, 5% 117704R109, 126, 130, 131, 209, 226, 230,

231

R110, 210 2.74kΩ, 1/4 Watt, 1% 119976-

R111, 113, 211, 213 1kΩ, 1/4 Watt, 5% 117704R112, 146, 152, 212, 246, 252 4.75kΩ, 1/4 Watt, 1% 119976R114, 214 13kΩ, 1/4 Watt, 2% 117704R115, 215 10kΩ, 1/4 Watt, 5% 117704R116, 125, 216, 225 8.2kΩ, 1/4 Watt, 2% 117704R117, 128, 129, 133, 134, 217, 228,

229, 233, 234

R119, 120, 219, 220 18kΩ, 1/4 Watt, 5% 117704-

R121, 136, 221, 236 22kΩ, 1/4 Watt, 5% 117704R123, 223 470Ω, 1/4 Wa tt, 5% 117704R127, 227 130kΩ, 1/4 Watt, 5% 117704R132, 141, 145, 153-158, 232, 241,

245, 253-258

R135, 159, 235, 259 510Ω, 1/4 Watt, 5% 122071-5115

R137, 237 47.5kΩ, 1/4 Watt, 1% 119976-

R138, 140, 238, 240 15.0kΩ, 1/4 Watt, 1% 119976R142, 242 3.0kΩ, 1/4 Watt, 1% 119976R143, 243 33kΩ, 1/4 Watt, 5% 117704-

330kΩ, 1/4 Watt, 5% 117704-

2.00kΩ, 1/4 Watt, 1% 119976-

23.7kΩ, 1/4 Watt, 1% 119976-

6.81kΩ, 1/4 Watt, 1% 119976-

6.04kΩ, 1/2 Watt, 1% 119976-

Description Part

Number

1212725

1213325

1211645

1213345

2212001

2211911

2214872

1212035

2212372

2212741

1211025

2214751

1211332

1211035

1218222

2216811

1211835

1212235

1214715

1211345

2216041

1214752

2211502

2213011

1213335

Note

14

Page 15

ELECTRICAL PART LIST

Resistors (continued)

Reference

Designator

R144, 244 56kΩ, 1/4 Watt, 2% 117704R148, 248 4.12kΩ, 1/4 Watt, 1% 119976R149, 249 23.7kΩ, 1/4 Watt, 1% 119976R150, 250 30.9kΩ, 1/4 Watt, 1% 119976R160, 260 22kΩ, 1/4 Watt, 5% 117704-

Description Part

Number

1215632

2214121

2212372

2213092

1212235

SMD Resistors

Reference

Designator

R1, 2 2.7kΩ, CHIP , 5% 124895-2725

R3, 4 3.3kΩ, CHIP , 5% 124895-3325

R5, 6, 7, 11, 15, 118, 218 160kΩ, CHIP, 5% 124895-1645

R8, 9, 12, 13, 16, 101, 104 330kΩ, CHIP, 5% 124895-3345

R102, 103, 105, 111, 122, 124, 202,

203, 205, 211, 222, 224

R106, 206 1,91kΩ, CHIP, 1% 124894-1911

R107, 207 48.7kΩ, CHIP, 1% 124894-4872

R108, 208 20kΩ, C H IP , 5% 124895-2035

R109, 126, 130, 131, 209, 226, 230,

231

R110, 210 2.74kΩ, CHIP, 1% 124894-2741

R112, 114, 212, 214 13.3kΩ, CHIP, 1% 124894-1332

R113, 213 1kΩ, CHIP, 5% 124895-1025

R115, 215 10kΩ, C H IP , 5% 124895-1035

R116, 125, 139, 152, 216, 225, 239,

252

R117, 128, 129, 133, 134, 217, 228,

229, 233, 234

R119, 120, 219, 220 18kΩ, CH IP , 5% 124895-1835

R121, 136, 160, 221, 236, 260 22kΩ, CH IP , 5% 124895-2235

R123, 223 470Ω, CHI P, 5% 124895-4715

R127, 227 130kΩ, CHIP, 5% 124895-1345

R132, 141, 145, 147, 151, 153-158,

232, 241, 245, 247, 251, 253-258

R137, 237 47.5kΩ, CHIP, 1% 124894-4752

R142, 242 3.01kΩ, CHIP, 1% 124894-3011

R143, 149, 150, 234, 249, 250 33kΩ, CH IP , 5% 124895-3335

R144, 244 56.2kΩ, CHIP, 1% 124894-5622

R146, 246 4.75kΩ, CHIP, 1% 124894-4751

R164, 264 26.7kΩ, CHIP, 1% 124894-2672

2.00kΩ, CHIP, 1% 124894-2001

23.7kΩ, CHIP, 1% 124894-2372

8.25kΩ, CHIP, 1% 124894-8251

6.81kΩ, CHIP, 1% 124894-6811

6.04kΩ, CHIP, 1% 124894-6041

Description Part

Number

Note

Note

15

Page 16

ELECTRICAL PART LIST

Capacitors

Reference

Designator

C1 .0047uF, 220V

.0047uF, 1.4KV, 100/120V

C2, 3 .015uF, FILM 118091-153

C 4 .01uF, CERAMIC DISC 119696-103

C5, 6 470uF, ELECTROLYTIC 110704

C7-10 1uF, ELECTROLYTIC 119942-1R0

C11-19, 22 .1uF, CERAMIC DISC 117502

C101, 117, 125, 201, 217, 225 22uF, ELECTROLYTIC 119944-220

C102, 202 2.2uF, ELECTROLYTIC 119943-2R2

C103-105, 203-205 .0068uF, FILM 118091-682

C106, 206 .33uF, FILM 123785-334

C107, 108, 121, 122, 207, 208, 221,

222

C109, 209 .0012uF, FILM 118091-122

C110, 126, 127, 210, 226, 227 470pF, CERAMIC DISC 119617-471

C111, 211 270pF, CERAMIC DISC 119617-271

C112, 113, 124, 212, 213, 224 .033uF, FILM 118091-333

C114, 214 .068uF, FILM 118091-683

C115, 116, 123, 215, 216, 223 .047uF, FILM 118091-473

C118, 119, 218, 219 .082uF, FILM 118091-823

C120, 220 .022uF, FILM 118091-223

.1uF, FILM 118091-104

Description Part

Number

120993

103447

Note

3

SMD Capacitors

Reference

Designator

C4 .01uF, CERAMIC, CHIP 124959-103

C11-22 .1uF, CERAMIC, CHIP 124959-104

C110, 126, 127, 210, 226, 227 470pF, CERAMIC, CHIP,

10%

C111, 211 270pF, CERAMIC, CHIP,

10%

Description Part

Number

124956-4712

124956-2742

Note

16

Page 17

ELECTRICAL PART LIST

Part Number change for U2 and U3 9/18/01 Also U5 and U6 has been replaced by part number

192166 which is an LS404 IC. The RC4156 is nolonger available.

Diodes

Reference

Designator

D1-5 ZENER, 18V, 1W, IN4746A 116995-4746A

D1, 101, 104, 201-204 1N4148, DIODE 121501

Z1 BRIDGE RECTIFIER 112027 3

Description Part

Number

Note

Transistors

Reference

Designator

Q1, 4, 5 TRANSISTOR NPN 117921

Q2, 3, 6 TRANSISTOR PNP 119168

Description Part

Number

Note

Integrated Circuits

Reference

Designator

U1, 8, 9 QUAD OP AMP, LS-404 120535/192166 4

U2 VOLT REG, 78L15 121116-1

U3 VOLT REG, 79L15 121117-1

U4 QUAD NAND CD-4011 121854

U5, 6 QUAD OP AMP, RC4156 192166 4

U7, 10 QUAD AW. SW. CD4066 119837

Description Part

Number

Note

17

Page 18

VOLTAGE CONVERSION INSTRUCTIONS

Voltage Conversions are to be performed on Military units. However it is possible to convert

a 110 Volt unit (by replacing the transformer) and a 220 Volt European unit.

1. 220 Volt to 110 Volt Conversion

Note: Conversions must be performed

with the line cord disconnected from any

power source. Refer to Figure 3 below for

the following procedures. The jumpers

listed in parentheses refer to the SMD

units.

1.1 Perform disassembly procedure 3,

PCB removal.

1.2 Locate jumper LK-31, (LK-35) in front

of the power transformer (near the line

cord), and remove it.

1.3 Add jumpers LK-32 (LK-42) and LK-33

(LK-43).

For European 220 Volt units.

1.4 Remove the 220 Volt line cord and

replace it with a 110 Volt line cord. Make

certain the line cord is properly installed in

the strain relief.

2. 110 Volt to 220 Volt Conversion

2.1 Perform disassembly procedure 3,

PCB removal.

2.2 Remove the two jumpers LK-32 (LK-

42) and LK-33 (LK-43).

For units with a 110 Volt transformer.

2.2 Remove the 110 Volt transformer and

C1 capacitor, and install 220 Volt components (see the part list).

2.3 Add jumper LK-31 (LK-35). Line cord

replacement is optional.

2.4 Perform assembly procedure 4, PCB

replacement.

2.5 Test the unit to confirm the voltage

conversion was perform correctly.

2.6 Add a 220 Volt label on the rear of the

unit just below the line cord.

1.5 Perform assembly procedure 4, PCB

replacement.

1.6 Test the unit to confirm the voltage

conversion was perform correctly.

1.7 Remove the 220 Volt label on the rear

of the unit.

220 Volt to 110 Volt Conversion 110 Volt to 220 Volt Conversion

Figure 5. Voltage Conversion Diagram

18

Page 19

Figure 6. Top Cover Connection Diagram

19

Page 20

SPECIFICATIONS AND FEATURES SUBJECT TO CHANGE WITHOUT NOTICE

®

®

Bose Corporation

The Mountain

Framingham Massachusetts USA 01701

P/N 129292 REV. 03 10/97 FOR TECHNICAL ASSISTANCE OR PART ORDERS, CALL 1-800-367-4008

Loading...

Loading...