Bosch ZBR42-3A, ZBR28-3A, ZWB42-3A, ZBR16-3A, ZBR35-3A Installation And Service Instructions Manual

...Page 1

WARNING:

Improper installation, set-up, modification, operation

or maintenance of the heating system can cause

personal injury and property damage.

Follow these instructions precisely.

If you require assistance or further information, contact

a trained and certified installer or the gas supply

company.

WARNING:

The operating instructions are part of the technical

documents that must be handed over to the owner or

operator of the heating system.

Explain to the owner or operator how to use the heating

system using the operating instructions. Make sure that

they are familiar with all required information for the

safe and proper operation of the heating system.

NOTE:

In Massachusetts, this appliance must be installed by

a licensed plumber or gas fitter.

These instructions are available in English and French.

Please keep these instructions for future reference.

6 720 613 303-00.1O

Gas Condensing Boiler

Greenstar

ZBR16-3A... | ZBR28-3A... | ZBR35-3A... | ZBR42-3A... | ZWB28-3A... | ZWB42-3A...

Installation and Service Instructions for Contractors

6 720 643 068 (2011/06) CA/US

Page 2

2 | Contents

Contents

1 Guideline to symbols and safety instructions . . . . 4

1.1 Guideline to symbols . . . . . . . . . . . . . . . . . 4

1.2 Safety instructions . . . . . . . . . . . . . . . . . . . 4

2 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.1 ZBR - Boiler for space heating and

loading of indirect fired DHW tanks . . . . . .6

2.2 ZWB - Combi boiler for space heating and

DHW generation . . . . . . . . . . . . . . . . . . . . .7

3 Information about the appliance . . . . . . . . . . . . . . 8

3.1 Proper use . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Overview of boiler types . . . . . . . . . . . . . . 8

3.3 Rating plate . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Appliance description . . . . . . . . . . . . . . . . 9

3.5 Accessories . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Product dimensions and minimum

clearances . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.7 Appliance layout heating boiler ZBR..-3A . 12

3.8 Appliance layout combi boiler ZWB..-3A . 14

3.9 Electrical wiring heating boiler ZBR..-3A . 16

3.10 Electrical wiring combi boiler ZWB..-3A . 18

3.11 Technical data heating boiler ZBR16-3A... 20

3.12 Technical data heating boiler ZBR28-3A... 22

3.13 Technical data heating boiler ZBR35-3A... 24

3.14 Technical data heating boiler ZBR42-3A... 26

3.15 Technical data combi boiler ZWB28-3A... 28

3.16 Technical data combi boiler ZWB42-3A... 30

3.17 Condensate composition . . . . . . . . . . . . . 32

4 Regulations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

4.1 Compliance with standards and

regulations . . . . . . . . . . . . . . . . . . . . . . . .33

4.2 Operating limits of the boiler . . . . . . . . . 33

4.3 Additional regulations for installation in

Massachusetts . . . . . . . . . . . . . . . . . . . . .34

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.1 Notes on installation and operation . . . . 35

5.1.1 Notes on installation and operation . . . . 35

5.1.2 Other important information . . . . . . . . . . 36

5.2 Comparing the size of the integrated

expansion vessel . . . . . . . . . . . . . . . . . . . 37

5.3 ZBR..-3A appliances (heating boilers):

Selecting an expansion vessel . . . . . . . . . 38

5.4 Selecting the installation location . . . . . . 38

5.5 Pre-installing pipes . . . . . . . . . . . . . . . . . 39

5.6 Mounting the appliance . . . . . . . . . . . . . 41

5.7 Installing a low water cut off (LWCO) . . 42

5.8 Connecting flue gas accessories . . . . . . . 43

5.8.1 Installation of the exhaust and air

intake system . . . . . . . . . . . . . . . . . . . . . . 44

5.8.2 Approved examples of horizontal and

vertical venting installation . . . . . . . . . . . 47

5.8.3 Vent and combustion air pipe lengths . . 50

5.9 Testing gas and water connections

for leaks . . . . . . . . . . . . . . . . . . . . . . . . . . 51

6 Making the electrical connections . . . . . . . . . . . 52

6.1 General notes . . . . . . . . . . . . . . . . . . . . . 52

6.2 Low voltage electrical connections in the

Heatronic boiler control . . . . . . . . . . . . . . 52

6.2.1 Open the Heatronic boiler control . . . . . 52

6.2.2 Connecting the outdoor temperature

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

6.2.3 Connecting the DHW tank temperature

sensor (only heating boiler ZBR..-3A) . . . 53

6.2.4 Connecting additional accessories . . . . . 54

6.3 Electrical connections in the junction box

(120 VAC) . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.3.1 Mounting rails for junction box . . . . . . . . 55

6.3.2 Connecting an external heating zone

pump or DHW recirculation pump . . . . . . 55

6.3.3 DHW tank loading pump or 3-way valve

with spring return (only heating boiler

ZBR..-3A) . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.3.4 Connecting mains power supply . . . . . . . 56

6.4 Connecting the LWCO device . . . . . . . . . 57

Copyright (optional information)6 720 643 068 (2011/06)

Page 3

Contents | 3

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.1 Before operating the appliance . . . . . . . . 59

7.2 Switching the appliance ON/OFF . . . . . . . 59

7.3 Setting up space heating . . . . . . . . . . . . . 60

7.4 Programming the FW 200 heating

control unit . . . . . . . . . . . . . . . . . . . . . . . 60

7.5 After commissioning . . . . . . . . . . . . . . . . . 60

7.6 ZBR..-3A appliances (heating boilers) with

DHW tank: Setting the DHW temperature 61

7.7 ZWB..-3A appliances (combi boilers):

Setting the DHW temperature . . . . . . . . . 61

7.8 Setting manual summer mode . . . . . . . . . 62

7.9 Setting frost protection . . . . . . . . . . . . . . 62

7.10 Activating the key pad lock . . . . . . . . . . . 63

8 ZBR..-3A appliances (heating boiler) with

DHW tank: Thermal disinfection . . . . . . . . . . . . . 63

9 Boiler circulator . . . . . . . . . . . . . . . . . . . . . . . . . . 64

9.1 Pump anti-seize protection . . . . . . . . . . . 64

9.2 Changing the pump curve of the

boiler pump . . . . . . . . . . . . . . . . . . . . . . . 64

10 Heatronic boiler control settings . . . . . . . . . . . . . 65

10.1 Guideline to service functions . . . . . . . . . 65

10.2 Overview of the service functions . . . . . . 66

10.2.1 First service level . . . . . . . . . . . . . . . . . . . 66

10.2.2 Second service level . . . . . . . . . . . . . . . . . 66

10.3 Description of the service functions . . . . 67

10.3.1 First service level . . . . . . . . . . . . . . . . . . . 67

10.3.2 Second service level . . . . . . . . . . . . . . . . . 73

11 Gas type conversion . . . . . . . . . . . . . . . . . . . . . . . 75

11.1 Converting to a different gas type . . . . . . 75

11.2 Installation location higher than 2,000 feet

(610 m) above sea level . . . . . . . . . . . . . 76

11.3 Setting the gas-air ratio (CO

or O2) . . . . 76

2

11.4 Dynamic gas pressure test . . . . . . . . . . . 78

14 Inspection and maintenance . . . . . . . . . . . . . . . . 81

14.1 Description of various steps . . . . . . . . . . 82

14.1.1 Calling up the latest fault (service

function 6.A) . . . . . . . . . . . . . . . . . . . . . . . 82

14.1.2 Fresh water filter (only combi boiler

ZWB..-3A) . . . . . . . . . . . . . . . . . . . . . . . . .82

14.1.3 Plate type heat exchanger

(only combi boiler ZWB..-3A) . . . . . . . . . . 82

14.1.4 Checking the electrodes . . . . . . . . . . . . . 83

14.1.5 Burner servicing . . . . . . . . . . . . . . . . . . . . 84

14.1.6 Heat exchanger block inspection and

cleaning . . . . . . . . . . . . . . . . . . . . . . . . . .84

14.1.7 Condensate trap cleaning . . . . . . . . . . . . 86

14.1.8 Checking the mixer diaphragm . . . . . . . . 86

14.1.9 Expansion vessel . . . . . . . . . . . . . . . . . . . 87

14.1.10 Setting the boiler water pressure . . . . . . 87

14.1.11 Testing system water quality . . . . . . . . . . 87

14.1.12 Inspecting electrical wiring . . . . . . . . . . . 87

14.2 Checklist for inspection and maintenance 88

15 Readings on the display . . . . . . . . . . . . . . . . . . . . 89

16 Faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 90

16.1 Troubleshooting . . . . . . . . . . . . . . . . . . . . 90

16.2 Faults that are shown on the display . . . . 91

16.3 Faults that are not shown on the display 94

16.4 Check sensor values . . . . . . . . . . . . . . . . 95

16.4.1 Outdoor temperature sensor . . . . . . . . . . 95

16.4.2 Additional supply temperature limiter . . . 95

16.4.3 Supply temperature sensor, External

supply temperature sensor, DHW tank

temperature sensor, DHW temperature

sensor . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

16.5 Replacement code plug . . . . . . . . . . . . . . 96

17 Commissioning log for the appliance . . . . . . . . . 97

18 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

12 Flue gas test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

12.1 Emissions test button . . . . . . . . . . . . . . . 79

12.2 Measuring CO content of flue gas . . . . . . 79

13 Environmental responsibility/disposal . . . . . . . . . 80

Index . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

6 720 643 068 (2011/06)Copyright (optional information)

Page 4

4 | Guideline to symbols and safety instructions

1 Guideline to symbols and safety instructions

1.1 Guideline to symbols

Warnings

Warnings are indicated in the text by a

warning triangle and a gray background.

In case of danger from electric shock, the

exclamation point on the warning triangle is

replaced with a flash.

Signal words at the beginning of a warning are used to

indicate the type and seriousness of the ensuing risk if

measures for minimizing damage are not taken.

• NOTE indicates that damage to property may occur.

• CAUTION indicates possible minor to medium personal

injury.

• WARNING indicates possible severe personal injury.

• DANGER indicates a potential for loss of life.

Important Information

Important information neither indicating

personal injury nor damage to property are

marked with this symbol. They are separated

by lines above and below the text.

1.2 Safety instructions

Safety first. Never risk your health or your life. Your own

safety must always take the highest priority.

Use approved personal protective devices and common

sense safety measures.

If you smell gas

B Turn off the gas cock (Æ page 58).

B Open windows and doors.

B Do not operate any electrical switches.

B Extinguish all open flames.

B From outside the building, call gas utility company and

a trained and certified heating contractor.

If you smell flue gas

B Switch OFF the appliance (Æ page 59).

B Open windows and doors.

B Inform a trained and certified heating contractor.

Danger of electric shock when the control panel is open

B Always disconnect the appliance from the mains power

before performing any work. Disconnect the emergency

shutoff switch or disengage the heating system circuit

breaker.

B Take measures to prevent accidental reconnection.

Additional symbols

Symbol Explanation

B

Æ

Cross-reference to other points in this

•

–

Tab. 1 Additional Symbols

Sequence of steps

document or to other documents

Listing/list entry

Listing/list entry (2nd level)

For appliances operating on room air: Danger of flue gas

poisoning if supply of combustion air is insufficient

B Safeguard supply of combustion air.

B The ventilation and exhaust openings must never be

plugged. The cross section of the ventilation and

exhaust openings must comply with the design

specifications at all times.

B Safeguard sufficient supply of combustion air also for

appliances installed at a later date, e.g. kitchen exhaust

fans, clothes dryers, and air conditioning units with vent

to the outside.

B Never install a barometric nor a thermally controlled

vent damper with this boiler.

B If the ventilation and exhaust openings do not comply

with the specifications, the heating system must never

be operated.

B Notify operator and building owner of the defect in

writing.

Copyright (optional information)6 720 643 068 (2011/06)

Page 5

Guideline to symbols and safety instructions | 5

Danger of explosion of flammable gases.

B Only employ a trained and certified contractor to carry

out work on the gas train.

Installation and conversion

Only have the appliance installed or modified by a trained

and certified heating contractor.

Always follow state of the art construction techniques for

installation and maintenance, and observe all applicable

codes and regulations.

Never modify any parts that carry flue gas.

Only trained and certified contractors are permitted to

carry out electrical work. Follow applicable code.

The DHW tank may only be used for heating domestic hot

water.

Never close the outlet of safety valves. Water may be

expelled from any safety valve during heat-up.

Inspection and maintenance

The operator is responsible for the safety and

environmental compliance of the heating system.

It is recommended to arrange a maintenance and

inspection contract with a trained and certified

contractor, covering an annual inspection and demanddependent maintenance. This guarantees high efficiency

and environmentally sound combustion.

Do not attempt to repair parts that have built in safety

features. Always replace the part.

Only use original Bosch spare parts. Bosch does not

accept responsibility for damage caused by third party

spare parts.

Combustion air/room air

B To prevent corrosion, keep the supply of combustion/

room air free of corrosive substances (e.g. halogenated

hydrocarbons that contain chlorine or fluorine

compounds).

B Avoid drawing in combustion air from outdoors that is

excessively loaded with dust or airborne particles.

Install adequate air filters under the following

circumstances:

– Air supply is contaminated with dust from dirt roads

and paths.

– Air supply is contaminated with dust from production

and processing facilities, e.g. quarries, mines, etc.

– Airborne seeds from thistles and similar plants.

– Halogen-hydrocarbon compounds, e.g. from paint

booths or hair salons.

Risk of system damage due to unsuitable fill water

Risk of system damage due to corrosion or scale formation

as the result of using fill and top-up water that does not

conform to the system-specific requirements.

Risk of system damage from freezing

The heating system can freeze up and burst in cold

weather if it is shut down or locked out.

B Leave the heating system turned on as much as

possible.

B Protect a disabled heating system from freezing by

draining the boiler and water pipes at the lowest point.

Perform maintenance annually. Check the complete

heating system for defects and malfunction.

Mitigate defects immediately to avoid larger scale system

damage.

To prevent damage to the appliance or the system from

descaling agents, remove parts to be descaled during the

process.

Explosive and easily combustible materials

Never use or store easily combustible materials (paper,

thinners, paints, etc.) near the appliance.

6 720 643 068 (2011/06)Copyright (optional information)

Page 6

6 | Scope of delivery

2 Scope of delivery

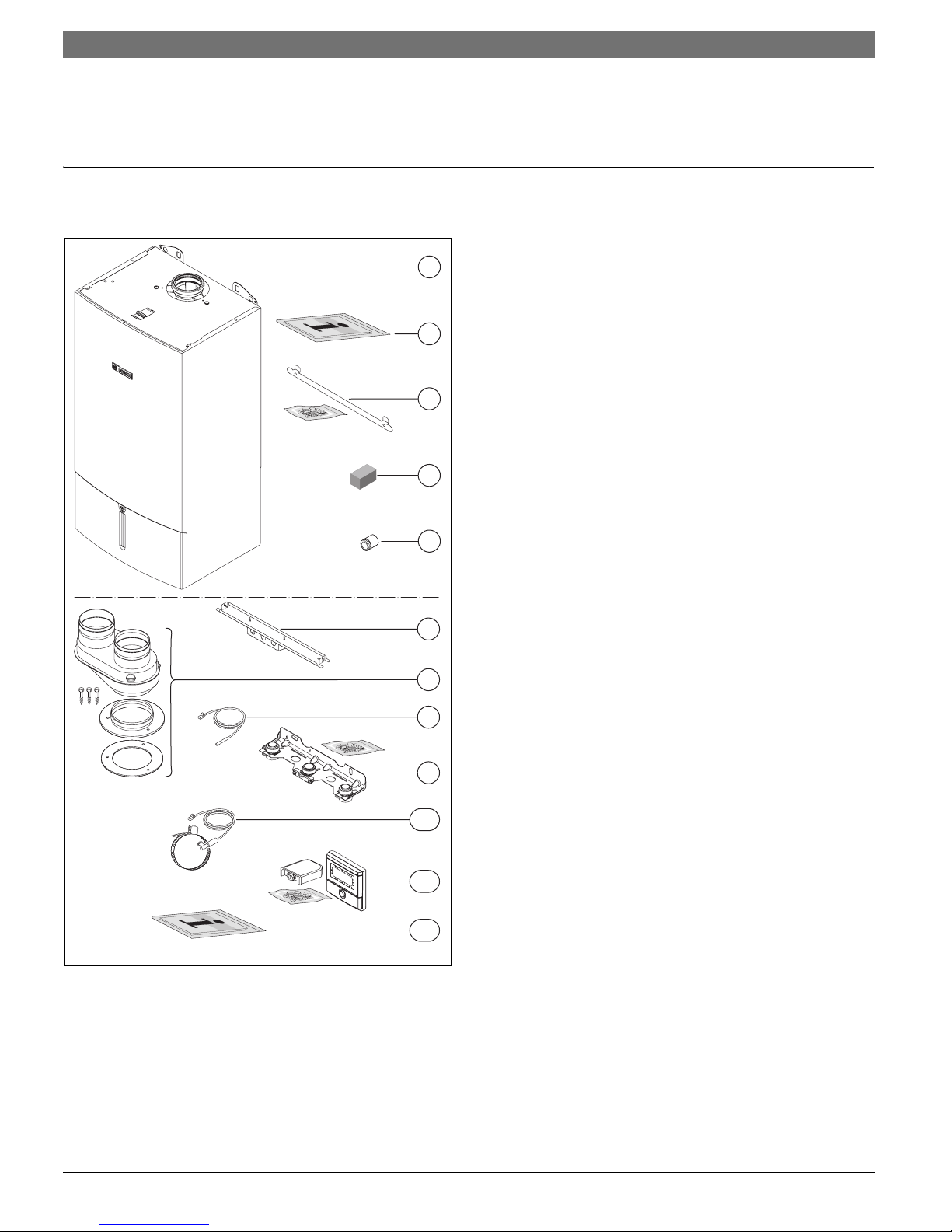

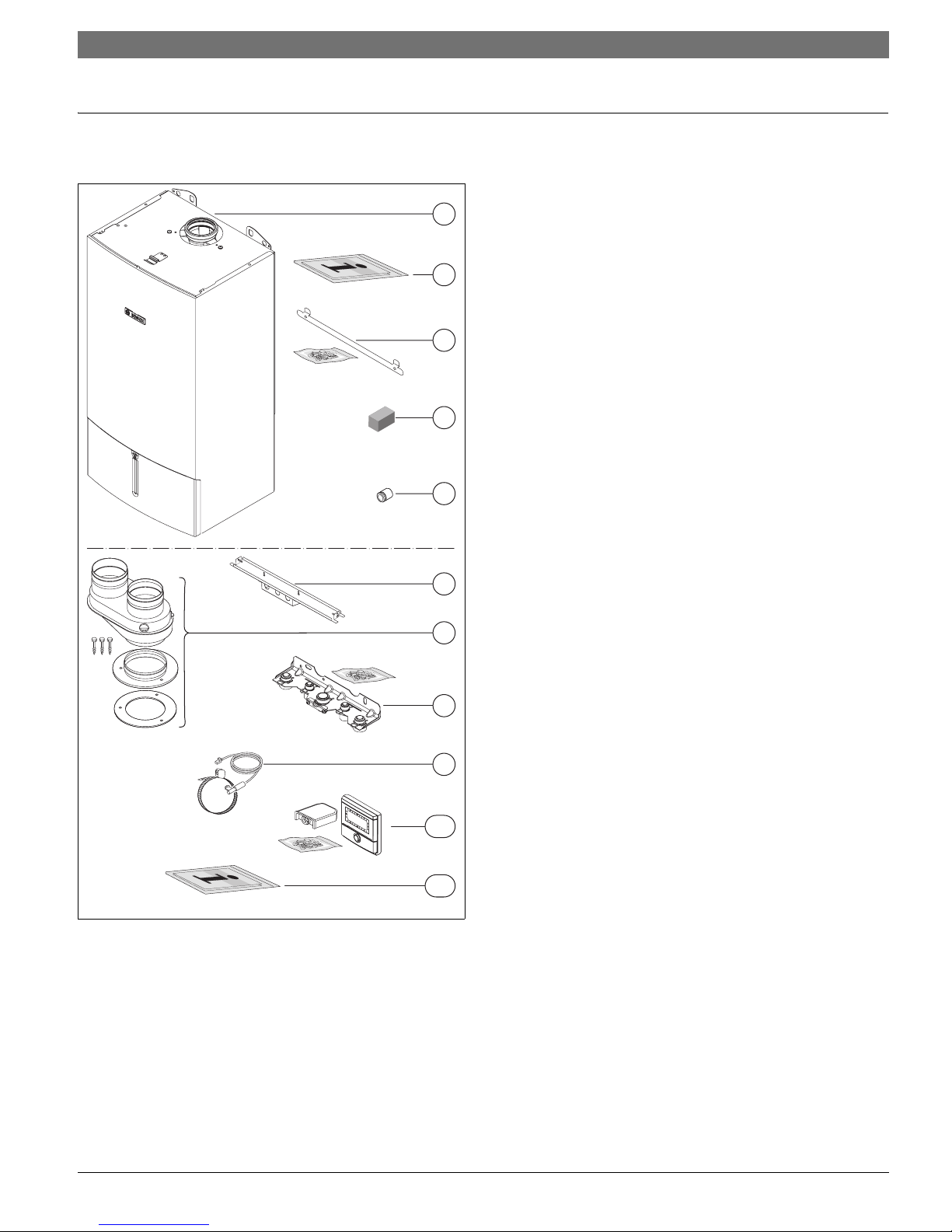

2.1 ZBR - Boiler for space heating and loading of indirect fired DHW tanks

Contents of package 1:

1

2

3

4

1 Gas condensing boiler

2 Set of documents for appliance

3 Mounting bracket with mounting kit

4 Gas conversion kit

5 Adapter for connection of a LWCO

6 720 641 933-22.1O

Fig. 1 Scope of delivery heating boiler ZBR..-3A

10

11

12

5

Contents of package 2:

6 Rail with connection box

6

7

8

7 Flue adapter

8 DHW tank temperature sensor (NTC)

9 Hydraulics connection plate with mounting kit

10 External supply temperature sensor (NTC)

11 Outdoor reset control FW 200 with mounting kit and outdoor

temperature sensor

12 Set of documents for outdoor reset control FW 200

9

Copyright (optional information)6 720 643 068 (2011/06)

Page 7

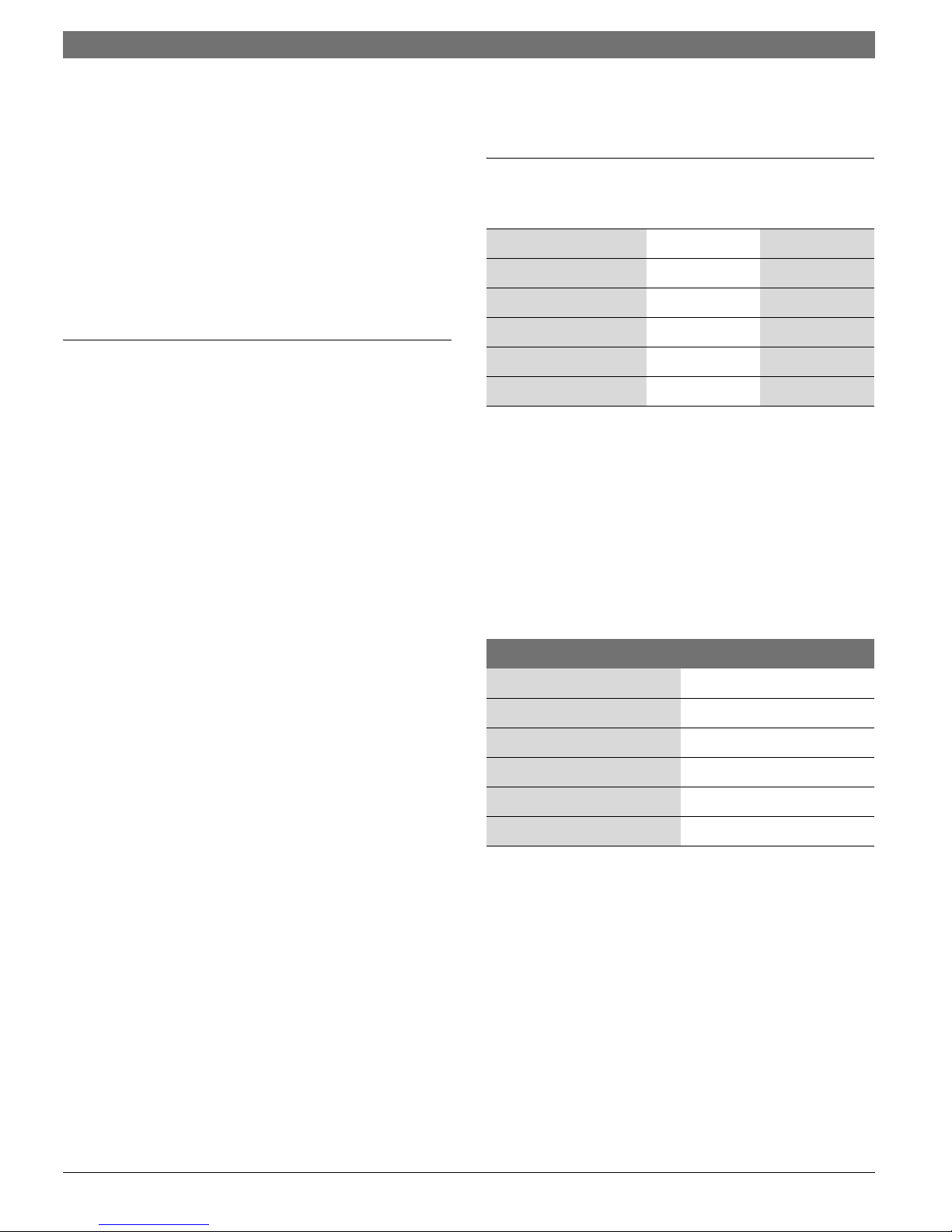

2.2 ZWB - Combi boiler for space heating and DHW generation

Contents of package 1:

1

2

1 Gas condensing boiler

2 Set of documents for appliance

3 Mounting bracket with mounting kit

4 Gas conversion kit

5 Adapter for connection of a LWCO

3

4

Scope of delivery | 7

Fig. 2 Scope of delivery combi boiler ZWB..-3A

5

6

7

8

9

10

11

6 720 641 933-04.1O

Contents of package 2:

6 Rail with connection box

7 Flue adapter

8 Hydraulics connection plate with mounting kit

9 External supply temperature sensor (NTC)

10 Outdoor reset control FW 200 with mounting kit and outdoor

temperature sensor

11 Set of documents for outdoor reset control FW 200

6 720 643 068 (2011/06)Copyright (optional information)

Page 8

8 | Information about the appliance

3 Information about the appliance

ZBR appliances are boilers for central heating and loading

of an indirect fired DHW tank.

ZWB appliances are combi boilers for central heating and

on demand DHW heating.

The appliances comply with South Coast Air Quality

Management District (SCAQMD) 2012 requirements:

(Type-1) 14 Ng/J NOx (and/or 20 ppm at 3% O2).

3.2 Overview of boiler types

Table 2 describes the meaning of the model number:

ZBR16-3

ZBR28-3

ZBR35-3

A 23

A 23

A 23

3.1 Proper use

The appliance may only be installed in closed loop hot

water central heating systems.

Any other purpose is considered improper use. Any

resulting damage is excluded from the manufacturer's

warranty.

The commercial and industrial use of the appliance for

generating process heat is not permitted.

ZBR42-3

ZWB28-3

ZWB42-3

A 23

A 23

A 23

Tab. 2 Appliance types

Z Central heating appliance

W DHW heating

B Condensing technology

R Constant temperature control

16 Output up to 54,600 BTU/hr (16 kW)

28 Output and DHW output up to 95,500 BTU/hr (28 kW)

35 Output up to 119,400 BTU/hr (35 kW)

42 Output and DHW output up to 143,300 BTU/hr (42 kW)

-3 Version

A Fan-supported appliance

23 Natural gas (NG)

Appliance AHRI Efficiency Rating

ZBR16-3

ZBR28-3

ZBR35-3

ZBR42-3

96.1 %

95.9 %

95.0 %

94.3 %

ZWB28-3

ZWB42-3

Tab. 3 Initial AHRI Rating

95.9 %

94.3 %

Copyright (optional information)6 720 643 068 (2011/06)

Page 9

Information about the appliance | 9

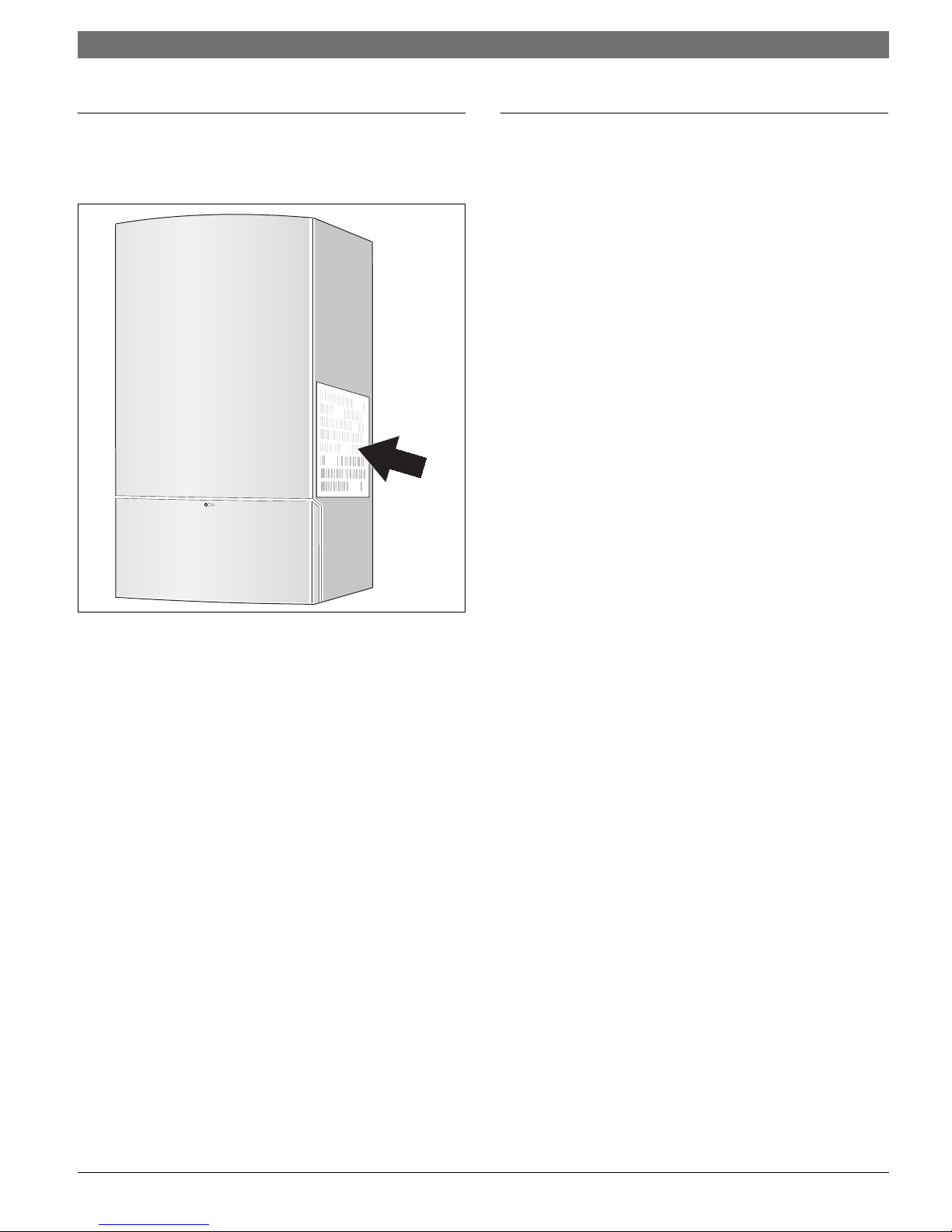

3.3 Rating plate

The rating plate is located at the right side of the

appliance.

6 720 641 933-84.1O

Fig. 3 Position of the rating plate

The rating plate contains the appliance output, model

number, approval data and serial number.

3.4 Appliance description

• Appliance for wall installation, regardless of chimney

and room size

• Outdoor reset control FW 200

• Intelligent boiler pump control

• Heatronic boiler control with 2-wire BUS

• Three-speed boiler circulator

• Automatic air vent (combi boiler ZWB..-3A only)

• Display

• Automatic ignition

• Continuously-controlled output

• Full protection via the Heatronic with flame rod and

solenoid valves

• No minimum circulating water flow rate required

• Suitable for radiant floor heating

• Flue adapter for flue gas and combustion air with test

ports

• Variable speed fan

• Gas premix burner

• Temperature sensor and temperature control for space

heating

• Supply temperature sensor

• Temperature limiter

• Safety relief valve, pressure gauge

• Expansion vessel (combi boiler ZWB..-3A only)

• Connection possibility for DHW tank temperature

sensor (NTC) (heating boiler ZBR..-3A only)

• Flue gas temperature limiter

• DHW priority (combi boiler ZWB..-3A only)

• Motorized 3-way valve (combi boiler ZWB..-3A only)

• Hydraulics connection plate

6 720 643 068 (2011/06)Copyright (optional information)

Page 10

10 | Information about the appliance

3.5 Accessories

Here you will find a list of typical accessories

for this appliance. Refer to the Bosch Product

Catalog for a complete overview of all

available accessories.

• FB 100 room control

• Modules for system expansions:

– ISM2 for solar systems (DHW heating, space heating

support, pool heating)

– IPM2 for one or two heating zones with pump control

and motorized mixing capability

Copyright (optional information)6 720 643 068 (2011/06)

Page 11

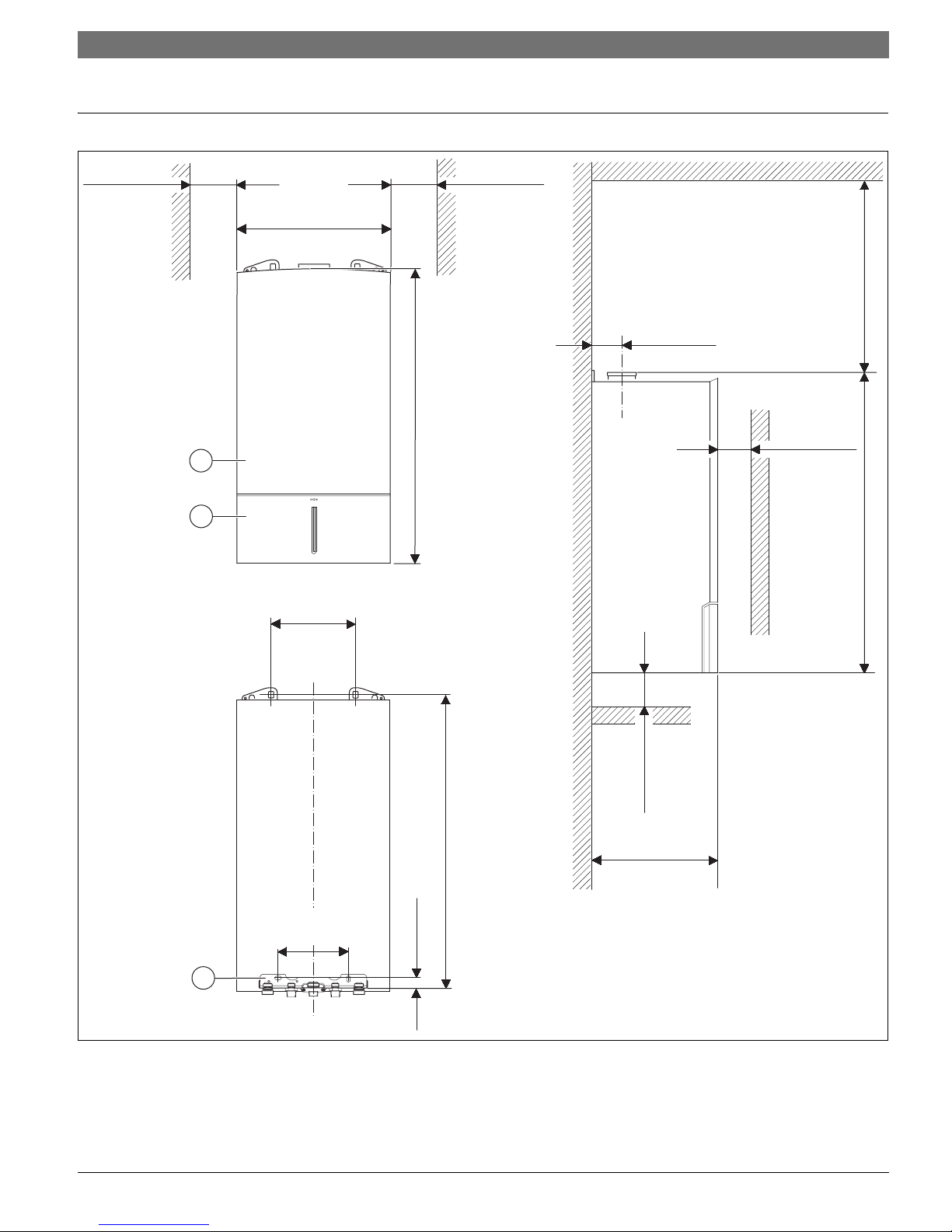

3.6 Product dimensions and minimum clearances

Information about the appliance | 11

≥ 4" *

(102 mm) *

≥ 4" *

(102 mm) *

17-21/64"

(440 mm)

≥ 15"

3-11/32"

(381 mm)

(85 mm)

(850 mm)

33-15/32"

1

≥ 4" **

(102 mm) **

2

(862 mm)

33-15/16"

9-29/64"

(240 mm)

7-7/8"

(200 mm)

3

Fig. 4 Dimensions and minimum clearances (front view, rear view, side view)

1 Appliance jacket

2 Service cover

3 Hydraulics connection plate

33-27/64"

1-3/16"

(30 mm)

≥ 4" *

(102 mm) *

13-57/64"

(849 mm)

(*) Zero clearance from combustibles permitted, but 4" (102 mm)

recommended for serviceability

(**) Distance to door, if mounted inside a closet

(353 mm)

6 720 643 068 (2011/06)Copyright (optional information)

6 720 641 933-01.1O

Page 12

12 | Information about the appliance

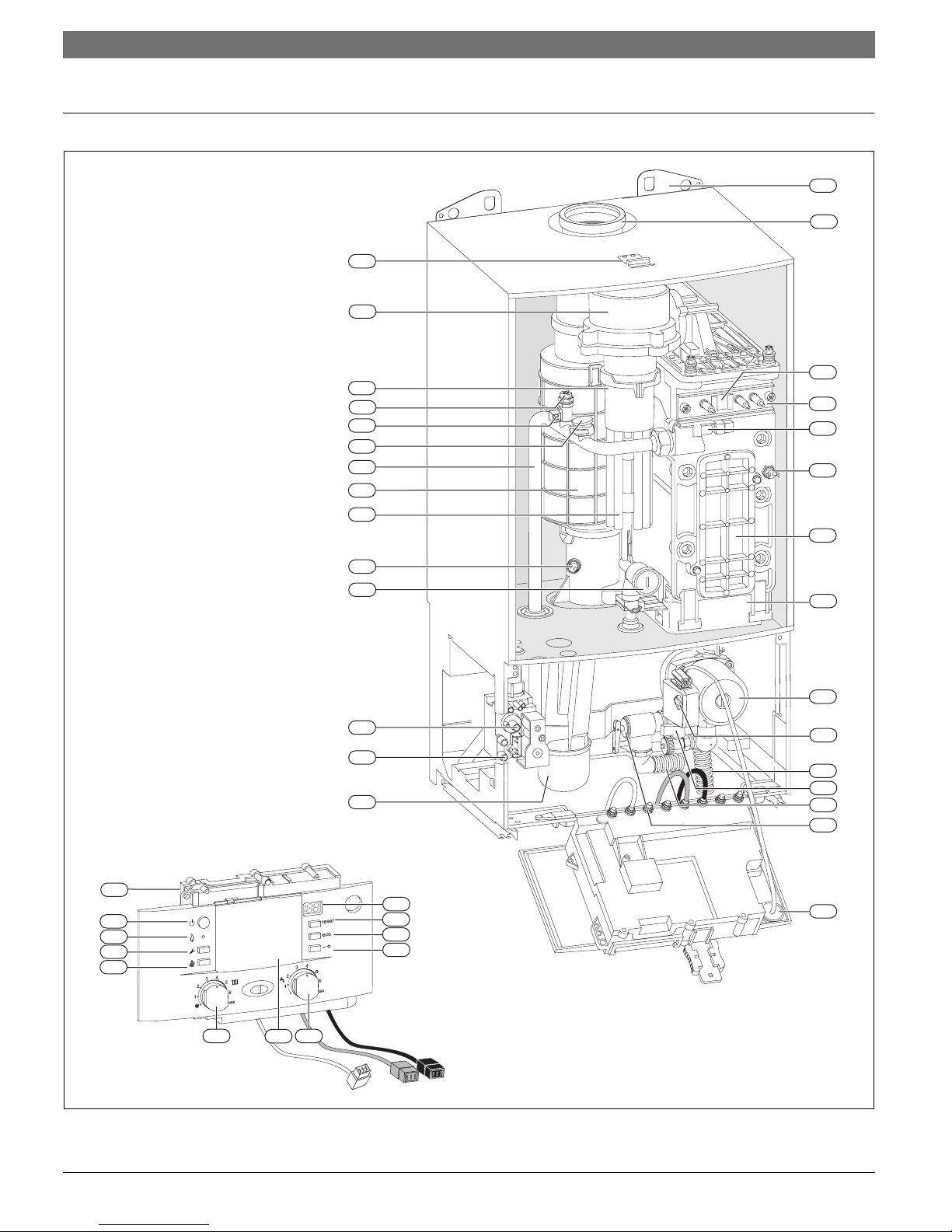

3.7 Appliance layout heating boiler ZBR..-3A

26

25

24

23

22

21

20

19

18

27

28

29

30

31

32

33

17

16

34

35

15

36

14

37

38

13

39

40

1

12

2

3

4

11

10

9

41

5

min

6

Fig. 5 Appliance layout heating boiler ZBR..-3A

8

7

6 720 641 933-02.1O

Copyright (optional information)6 720 643 068 (2011/06)

Page 13

Key to Fig. 5:

1 Heatronic boiler control

2 ON/OFF switch

3 Burner flame indicator

4 Service button

5 Emissions test button

6 Boiler high limit dial

7 Mounting socket for outdoor reset controls

8 DHW thermostat

9 Key pad lock

10 ECO button

11 Reset button

12 Display

13 Condensate trap

14 Test ports for inlet gas pressure

15 Adjustment screw, minimum gas volume

16 Maximum gas adjuster

17 Flue gas temperature limiter

18 Combustion air intake

19 Exhaust pipe

20 Boiler supply pipe

21 Connection for optional low water cut off (LWCO)

22 Additional supply temperature limiter

23 Manual air bleeder

24 Gas/air premix chamber

25 Fan

26 Bracket

27 Wall hanging bracket

28 Exhaust pipe

29 Sight glass

30 Set of electrodes

31 Supply temperature sensor

32 Boiler block temperature limiter

33 Inspection and cleanout cover

34 Condensate collector

35 Boiler circulator

36 Pump speed switch

37 Condensate drain hose

38 Drain cock

39 Safety relief valve discharge hose

40 Pressure relief valve (heating zone)

41 Boiler water pressure gauge

Information about the appliance | 13

6 720 643 068 (2011/06)Copyright (optional information)

Page 14

14 | Information about the appliance

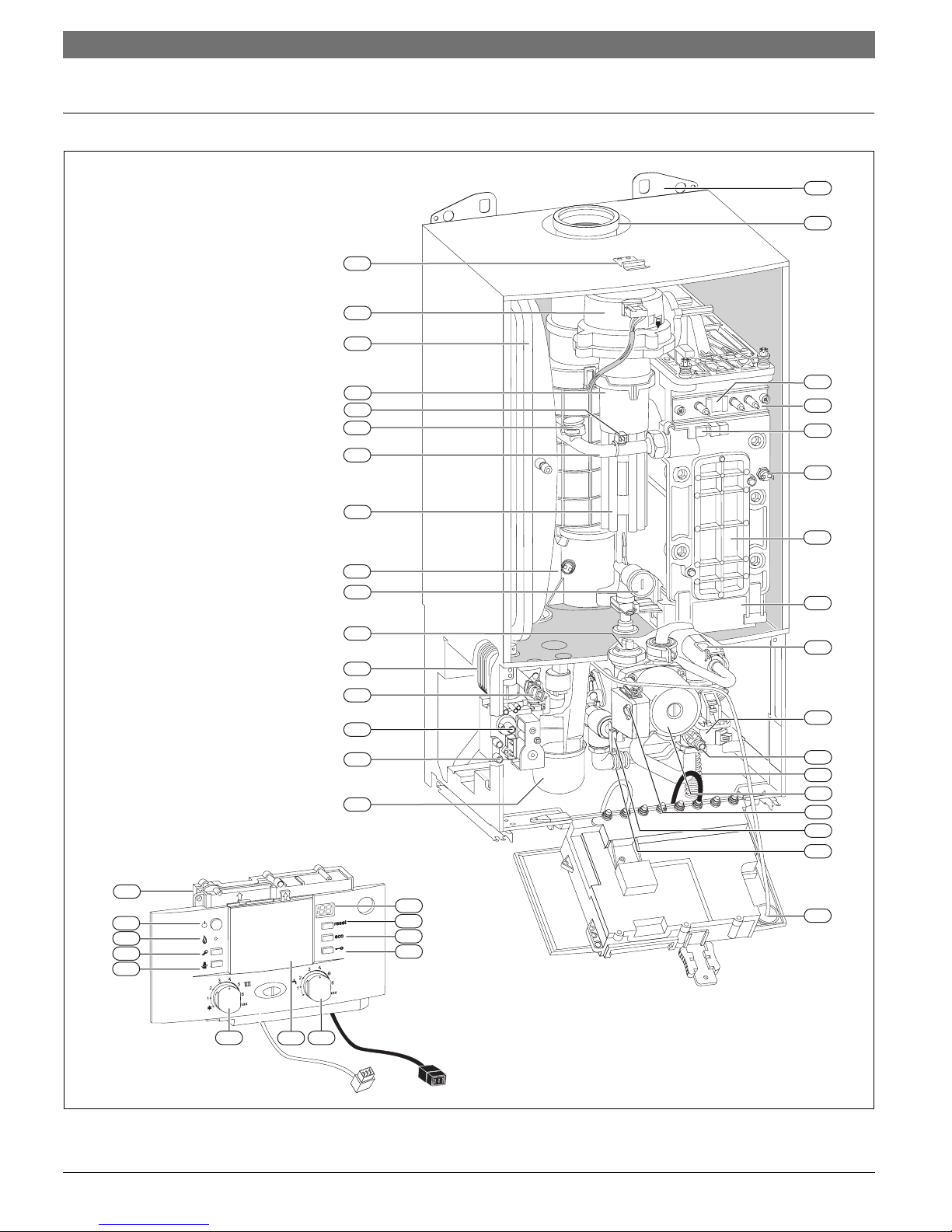

3.8 Appliance layout combi boiler ZWB..-3A

28

27

26

29

30

25

24

23

22

21

20

19

18

17

16

15

14

13

31

32

33

34

35

36

37

38

39

40

41

42

43

44

1

2

3

4

5

min

6

Fig. 6 Appliance layout combi boiler ZWB..-3A

8

7

12

11

10

9

45

6 720 641 933-03.1O

Copyright (optional information)6 720 643 068 (2011/06)

Page 15

Key to Fig. 6:

1 Heatronic boiler control

2 ON/OFF switch

3 Burner flame indicator

4 Service button

5 Emissions test button

6 Boiler high limit dial

7 Mounting socket for outdoor reset controls

8 DHW thermostat

9 Key pad lock

10 ECO button

11 Reset button

12 Display

13 Condensate trap

14 Test ports for inlet gas pressure

15 Adjustment screw, minimum gas volume

16 DHW temperature sensor

17 Plate-type heat exchanger

18 Automatic air vent

19 Maximum gas adjuster

20 Flue gas temperature limiter

21 Combustion air intake

22 Supply pipe

23 Connection for optional low water cut off (LWCO)

24 Additional supply temperature limiter

25 Gas/air premix chamber

26 Expansion vessel

27 Fan

28 Bracket

29 Wall hanging bracket

30 Exhaust pipe

31 Sight glass

32 Set of electrodes

33 Supply temperature sensor

34 Boiler block temperature limiter

35 Inspection and cleanout cover

36 Condensate collector

37 Flow meter

38 3-way valve

39 Drain cock

40 Condensate drain hose

41 Boiler circulator

42 Pump speed switch

43 Pressure relief valve (heating zone)

44 Safety relief valve discharge hose

45 Boiler water pressure gauge

Information about the appliance | 15

6 720 643 068 (2011/06)Copyright (optional information)

Page 16

16 | Information about the appliance

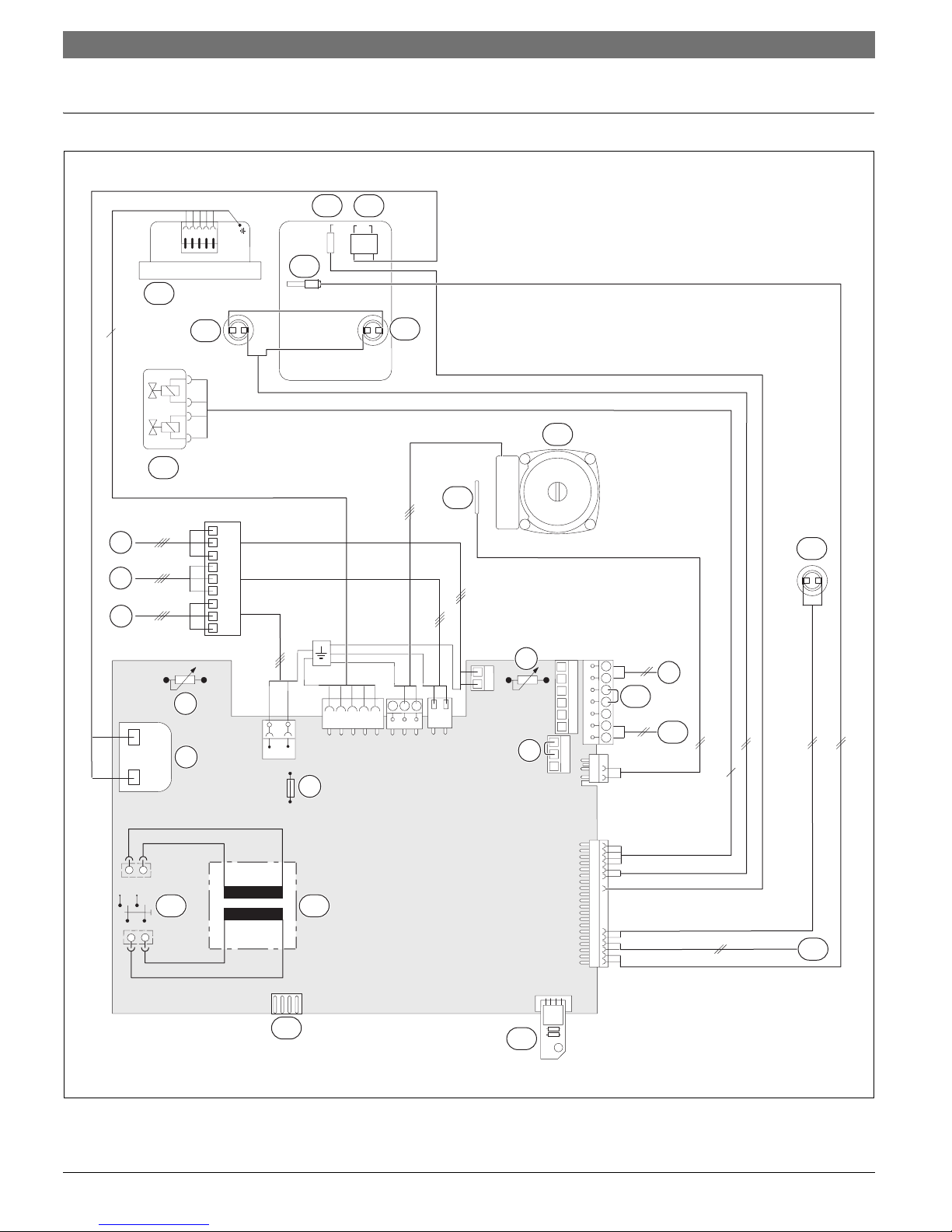

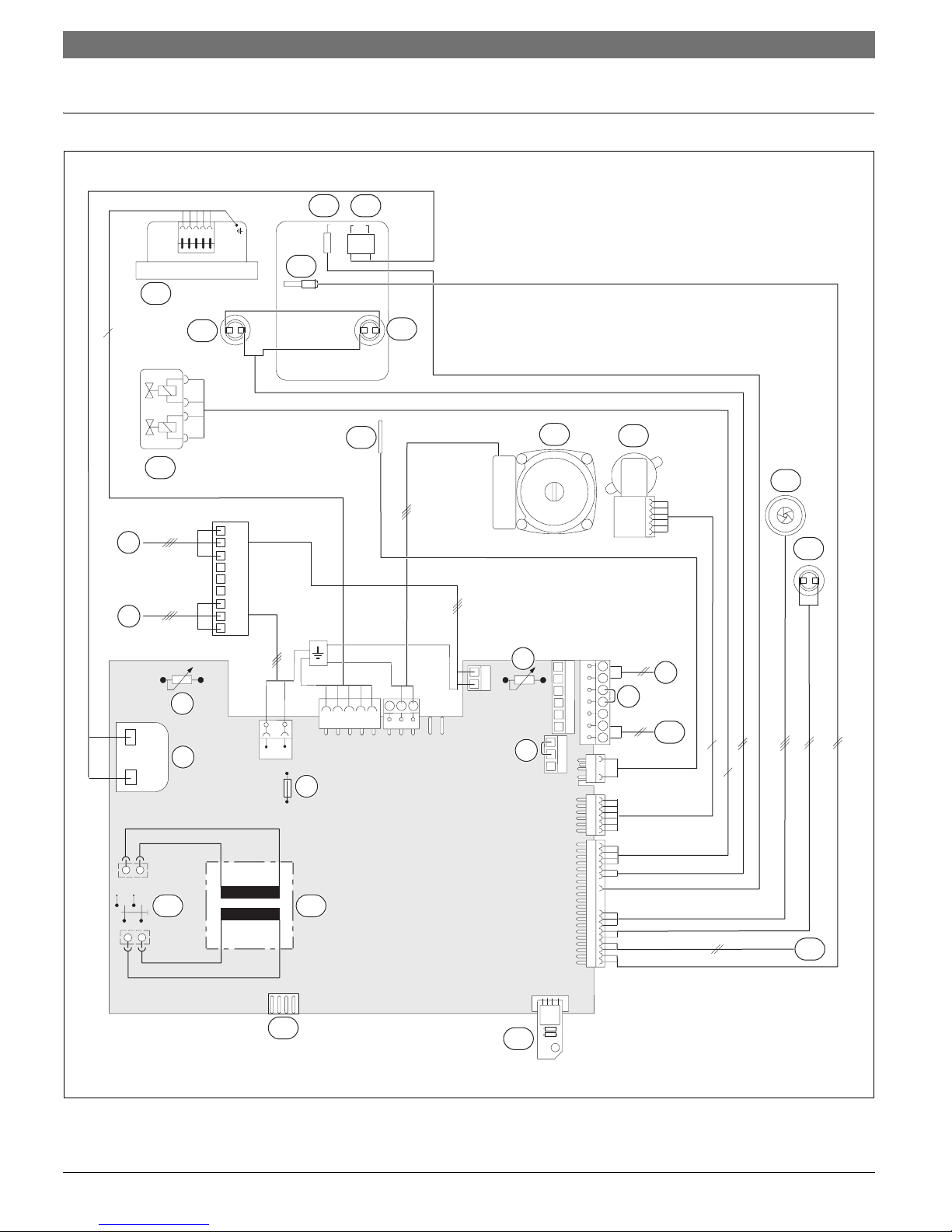

3.9 Electrical wiring heating boiler ZBR..-3A

20

21

19

17

6

18

22

24

16

23

9

5

4

3

8

7

6

5

4

23

1

7

NP

LP

2

L

N

LS NS

L

1

N

8

B

B

4

2

F

9

A

8

7

9

10

11

4

25

6

9 VAC

120 VAC

25 VAC

14 15

120 VAC

13

Fig. 7 Electrical wiring diagram heating boiler ZBR..-3A

12

26

6 720 641 933-23.1O

Copyright (optional information)6 720 643 068 (2011/06)

Page 17

Information about the appliance | 17

Key to Fig. 7:

1 Ignition transformer

2 Boiler high limit dial

3 120 VAC connection

4 DHW tank primary pump or 3-way valve

5 External heating pump for unmixed heating circuit (secondary circuit) 2) or DHW recirculation pump

6 Fuse T 6.3 A (120 VAC)

7 DHW thermostat

8 External safety high limit or low water cut off (LWCO)

9 BUS connection, e.g. heating control

10 Room thermostat – dry contact

11 Outdoor temperature sensor

12 Code plug

13 Diagnostic interface

14 ON/OFF switch

15 Transformer

16 Gas valve

17 Fan

18 Flue gas temperature limiter

19 Supply temperature sensor

20 Flame rod electrode

21 Ignition electrode

22 Boiler block temperature limiter

23 DHW tank temperature sensor (NTC)

24 Boiler circulator

25 Additional supply temperature limiter

26 External system supply temperature sensor

1)

2)

1) Set the service function 1.F,Æ page 67

2) Set the service function 5.E, Æ page 71

6 720 643 068 (2011/06)Copyright (optional information)

Page 18

18 | Information about the appliance

3.10 Electrical wiring combi boiler ZWB..-3A

19

20

18

16

6

17

22

21

23

24

15

25

9

4

3

2

1

8

7

6

5

4

23

1

26

6

NP

LP

LS NS

L

N

7

B

B

4

2

F

9

A

8

7

8

9

10

6

4

5

9 VAC

120 VAC

13

25 VAC

14

120 VAC

12

Fig. 8 Electrical wiring diagram combi boiler ZWB..-3A

11

27

6 720 641 933-24.1O

Copyright (optional information)6 720 643 068 (2011/06)

Page 19

Key to Fig. 8:

1 Ignition transformer

2 Boiler high limit dial

3 120 VAC connection

4 External heating pump for unmixed heating circuit (secondary circuit)

5 Fuse T 6.3 A (120 VAC)

6 DHW thermostat

7 External safety high limit or low water cut off (LWCO)

8 BUS connection, e.g. heating control

9 Room thermostat – dry contact

10 Outdoor temperature sensor

11 Code plug

12 Diagnostic interface

13 ON/OFF switch

15 Transformer

14 Gas valve

16 Fan

17 Flue gas temperature limiter

18 Supply temperature sensor

19 Flame rod electrode

20 Ignition electrode

21 Boiler block temperature limiter

22 DHW temperature sensor

23 Boiler circulator

24 3-way valve (Space heating/DHW heating)

25 Flow meter (turbine)

26 Additional supply temperature limiter

27 External system supply temperature sensor

Information about the appliance | 19

1)

or DHW recirculation pump

1)

1) Set the service function 5.E, Æ page 71

6 720 643 068 (2011/06)Copyright (optional information)

Page 20

20 | Information about the appliance

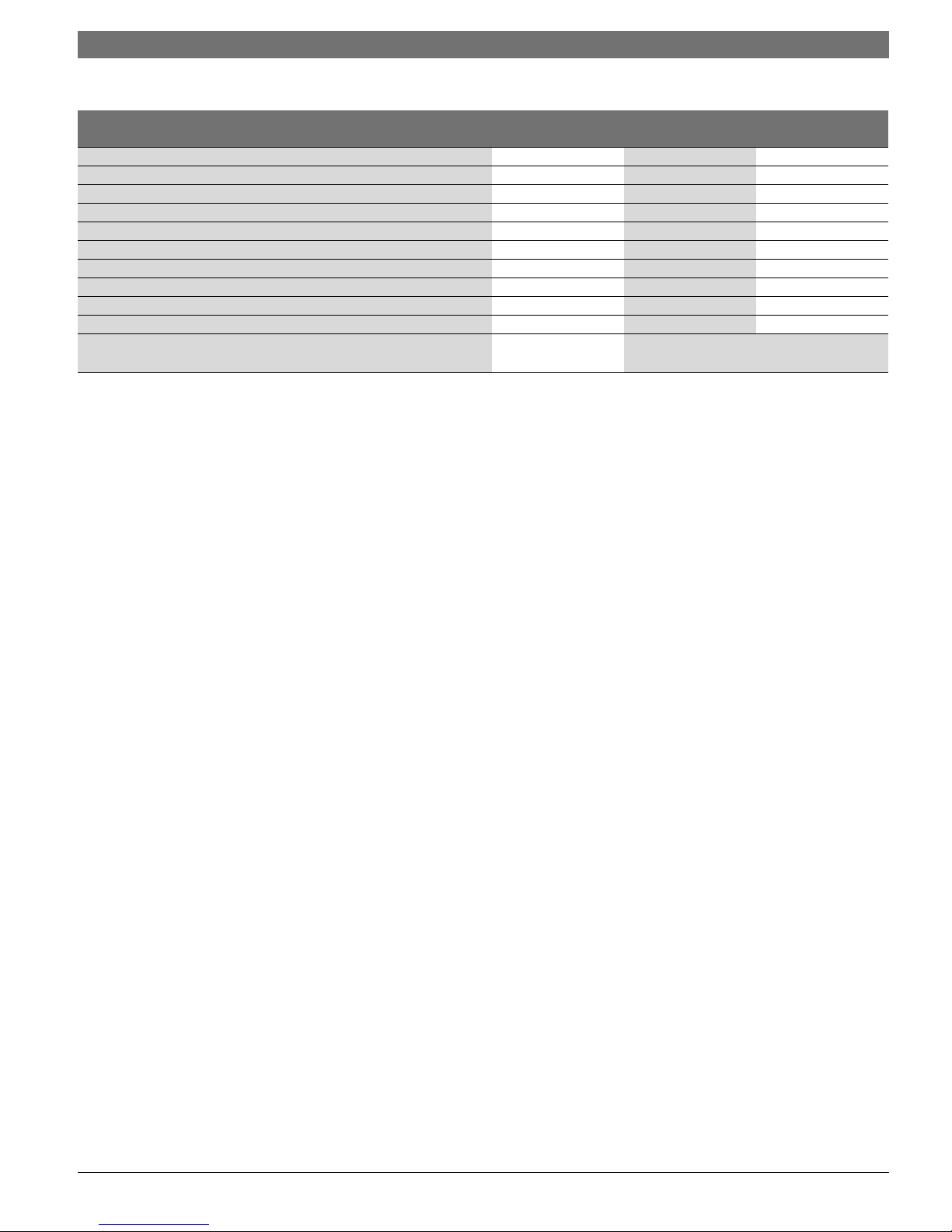

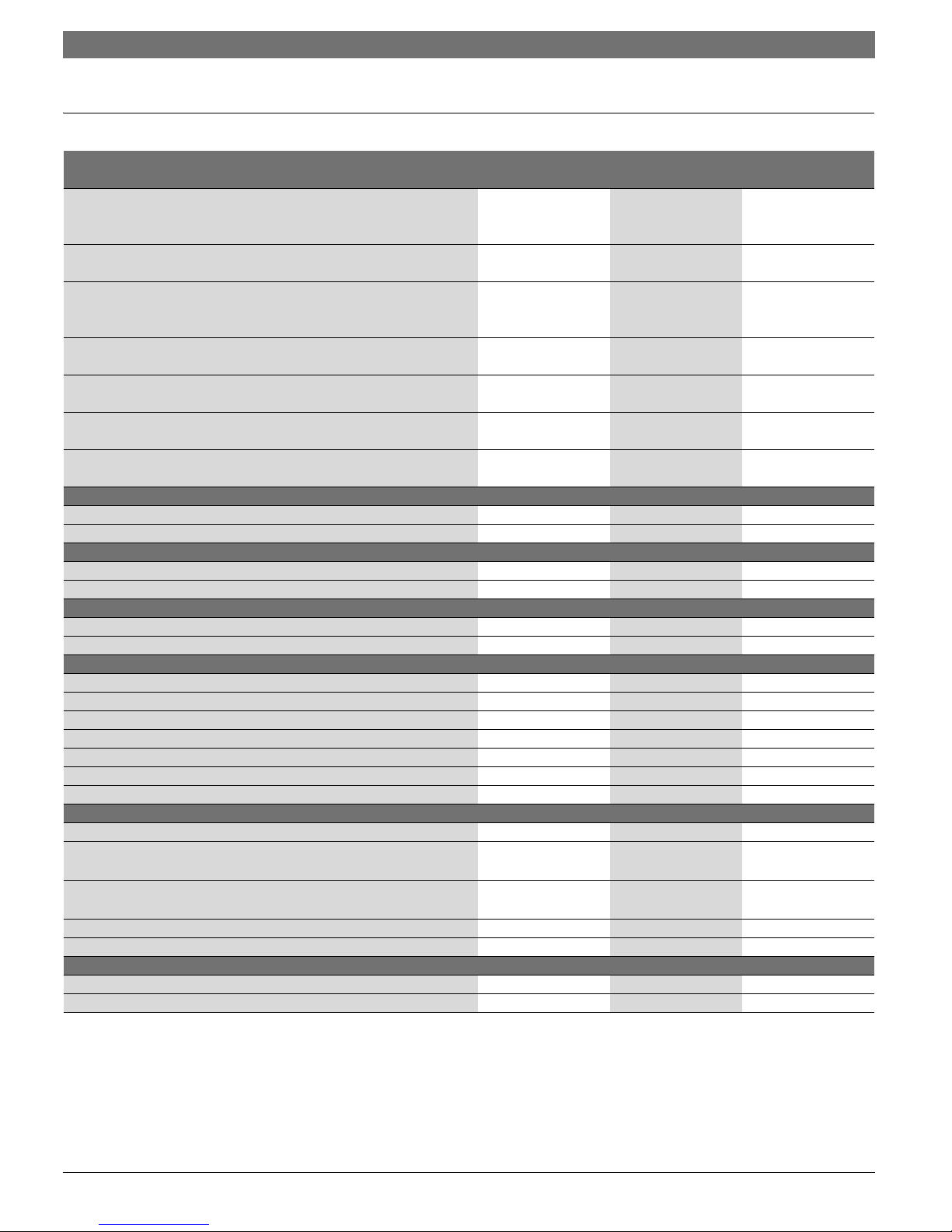

3.11 Technical data heating boiler ZBR16-3A...

Unit NG LPG (propane)

Output

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3 MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) –

LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 6.8/1.7 6.7/2.6

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.32 (1.2) 0.32 (1.2)

pH level, approx. 4.8 4.8

Tab. 4 Technical data heating boiler ZBR16-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 54,900 (16.1) 55,300 (16.2)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 54,300 (15.9) 54,600 (16.0)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 50,800 (14.9) 51,200 (15.0)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 51,500 (15.1) 51,900 (15.2)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 57,200 (16.8) 56,400 (16.5)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 12,600 (3.7) 21,500 (6.3)

) 122/86 °F (50/30 °C) BTU/hr (kW) 12,600 (3.7) 21,500 (6.3)

) 176/140 °F (80/60 °C) BTU/hr (kW) 11,300 (3.3) 19,400 (5.7)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 11,600 (3.4) 19,800 (5.8)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 12,900 (3.8) 21,500 (6.3)

min

) tank (Hi) BTU/hr (kW) 51,500 (15.1) 51,900 (15.2)

max

) tank (Hs)BTU/hr (kW)57,200 (16.8) 56,400 (16.5)

max

) tank (Hi)BTU/hr (kW)11,600 (3.4) 19,800 (5.8)

min

) tank (Hs)BTU/hr (kW)12,900 (3.8) 21,500 (6.3)

min

3

/hr (m3/h) 56 (1.6) –

= 2,500 BTU/ft3 (93.1 MJ/m3)ft

D-S

3

/hr (m3/h) – 22 (0.6)

°F ( °C)

°F ( °C)

136/133 (58/56) 136/133 (58/56)

99/88 (37/31) 99/88 (37/31)

Copyright (optional information)6 720 643 068 (2011/06)

Page 21

Information about the appliance | 21

Unit NG LPG (propane)

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 103.6 (47) 103.6 (47)

Dimensions, W x H x D

inch

(mm)

≤

33

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

33

Tab. 4 Technical data heating boiler ZBR16-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 22

22 | Information about the appliance

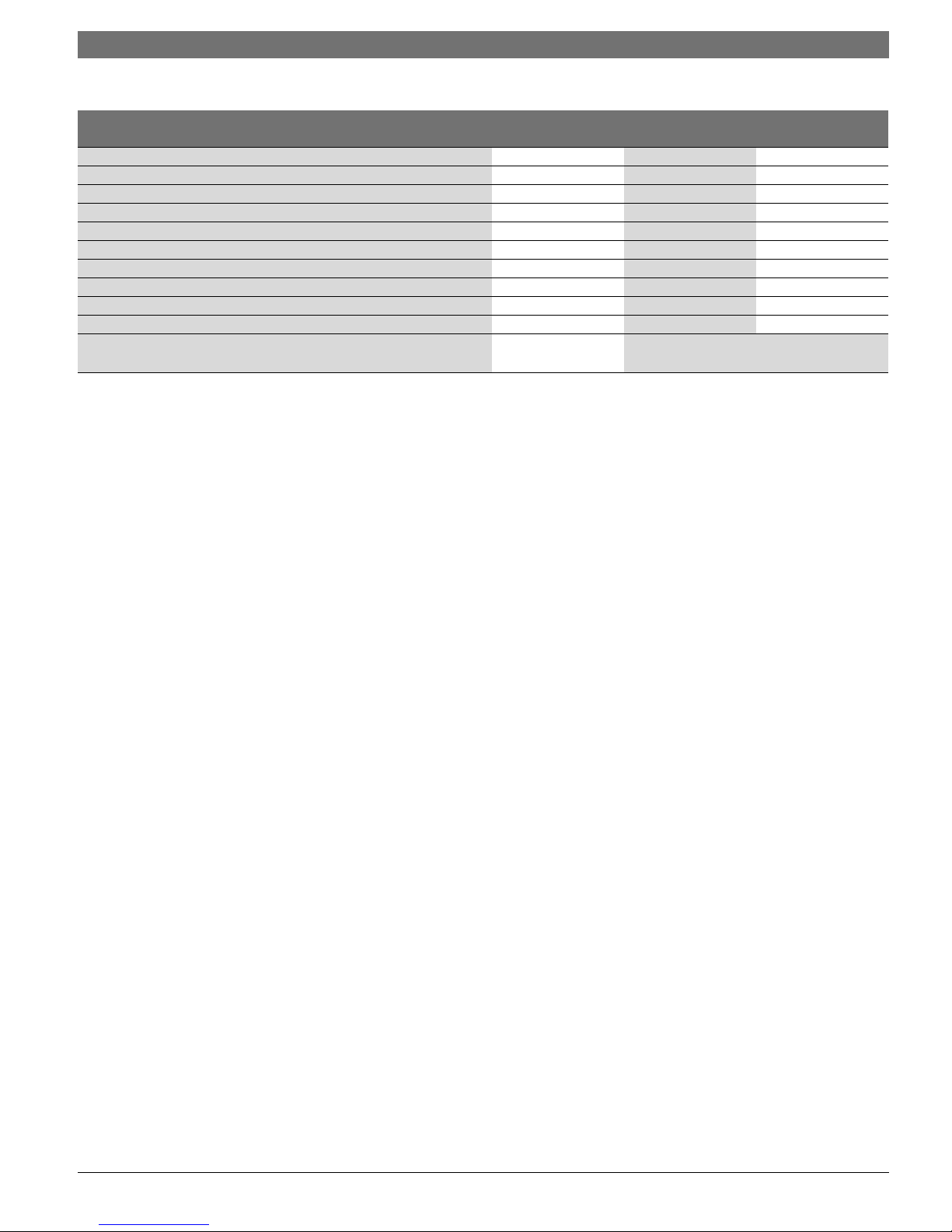

3.12 Technical data heating boiler ZBR28-3A...

Unit NG LPG (propane)

Output

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 12.0/3.2 11.6/4.8

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.6 (2.3) 0.6 (2.3)

pH level, approx. 4.8 4.8

Tab. 5 Technical data heating boiler ZBR28-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 93,800 (27.5) 93,800 (27.5)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 93,100 (27.3) 93,100 (27.3)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 89,400 (26.2) 89,400 (26.2)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 90,800 (26.6) 90,800 (26.6)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 100,800 (29.5) 98,600 (28.9)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 23,900 (7.0) 39,900 (11.7)

) 122/86 °F (50/30 °C) BTU/hr (kW) 23,900 (7.0) 39,600 (11.6)

) 176/140 °F (80/60 °C) BTU/hr (kW) 21,800 (6.4) 36,200 (10.6)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 22,200 (6.5) 36,800 (10.8)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 24,600 (7.2) 40,100 (11.7)

min

) tank (Hi) BTU/hr (kW) 90,800 (26.6) 90,800 (26.6)

max

) tank (Hs)BTU/hr (kW)100,800 (29.5) 98,600 (28.9)

max

) tank (Hi)BTU/hr (kW)22,200 (6.5) 36,800 (10.8)

min

) tank (Hs)BTU/hr (kW)24,600 (7.2) 40,100 (11.7)

min

3

/hr (m3/h) 99 (2.8) –

= 2,500 BTU/ft3 (93.1MJ/m3)ft

D-S

3

/hr (m3/h) – 39 (1.1)

°F ( °C)

°F ( °C)

147/133 (64/56) 147/133 (64/56)

117/90 (47/32) 117/90 (47/32)

Copyright (optional information)6 720 643 068 (2011/06)

Page 23

Information about the appliance | 23

Unit NG LPG (propane)

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 103.6 (47) 103.6 (47)

Dimensions, W x H x D

inch

(mm)

≤

39

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

39

Tab. 5 Technical data heating boiler ZBR28-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 24

24 | Information about the appliance

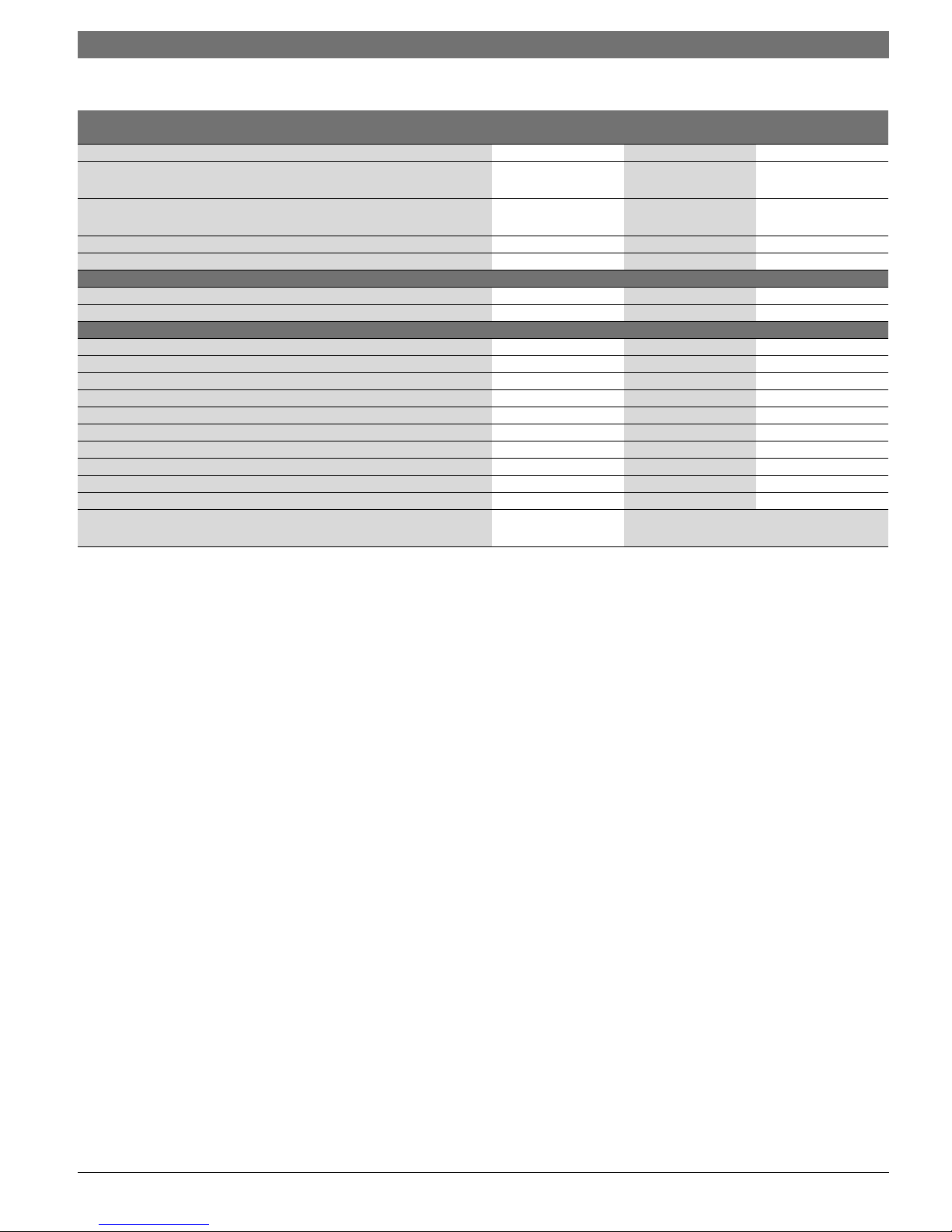

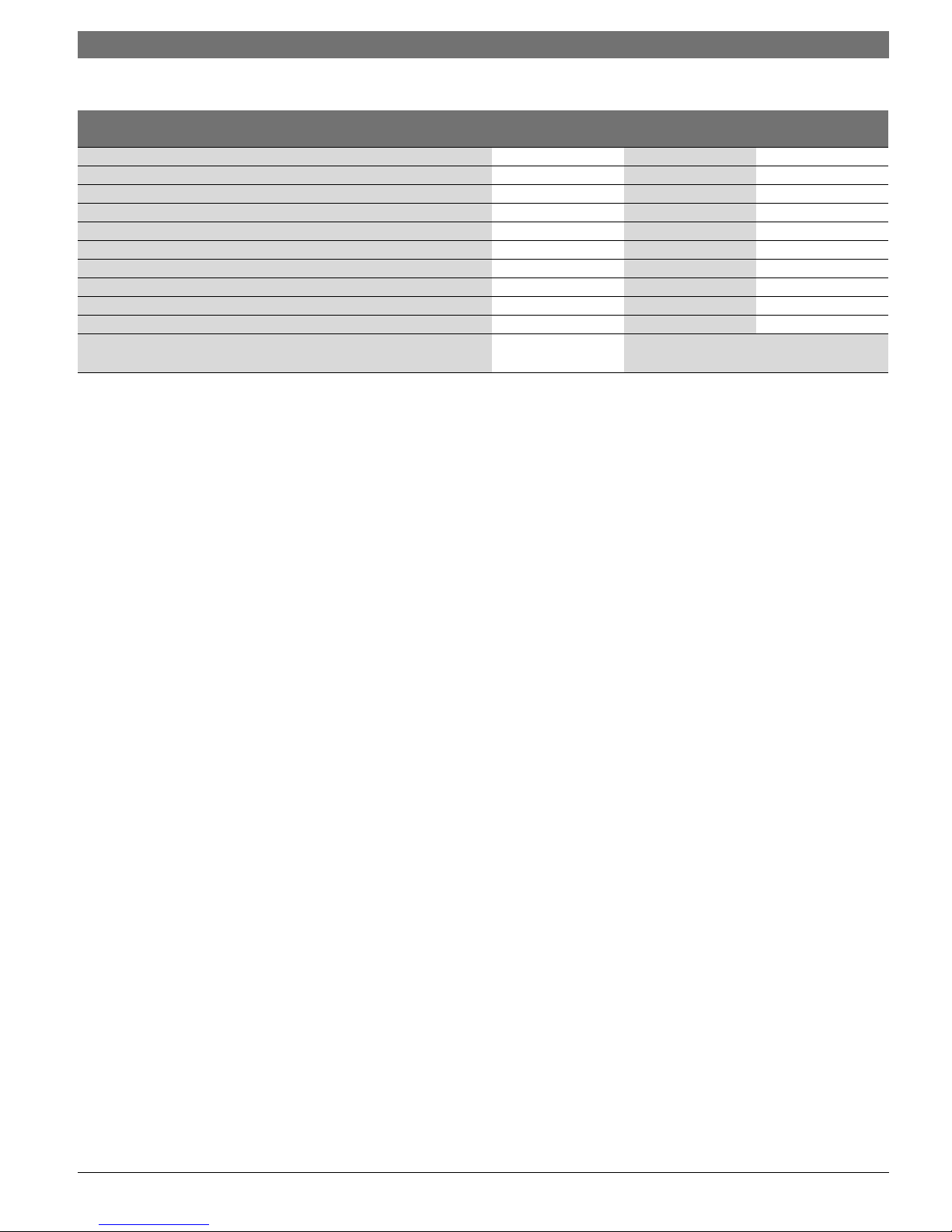

3.13 Technical data heating boiler ZBR35-3A...

Unit NG LPG (propane)

Output

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) –

LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 15.7/4.5 15.2/5.6

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.8 (3.1) 0.8 (3.1)

pH level, approx. 4.8 4.8

Tab. 6 Technical data heating boiler ZBR35-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 122,800 (36.0) 122,800 (36.0)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 121,800 (35.7) 121,800 (35.7)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 116,700 (34.2) 116,700 (34.2)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 118,700 (34.8) 118,700 (34.8)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 131,900 (38.6) 129,100 (37.8)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 35,100 (10.3) 46,100 (13.5)

) 122/86 °F (50/30 °C) BTU/hr (kW) 34,800 (10.2) 45,700 (13.4)

) 176/140 °F (80/60 °C) BTU/hr (kW) 31,700 (9.3) 42,000 (12.3)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 32,400 (9.5) 42,700 (12.5)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 36,000 (10.5) 46,400 (13.6)

min

) tank (Hi) BTU/hr (kW) 118,700 (34.8) 118,700 (34.8)

max

) tank (Hs)BTU/hr (kW)131,900 (38.6) 129,100 (37.8)

max

) tank (Hi)BTU/hr (kW)32,400 (9.5) 42,700 (12.5)

min

) tank (Hs)BTU/hr (kW)36,000 (10.5) 46,400 (13.6)

min

3

/hr (m3/h) 130 (3.7) –

= 2,500 BTU/ft3 (93.1MJ/m3)ft

D-S

3

/hr (m3/h) – 52 (1.5)

°F ( °C)

°F ( °C)

162/135 (72/57) 162/135 (72/57)

127/91 (53/33) 127/91 (53/33)

Copyright (optional information)6 720 643 068 (2011/06)

Page 25

Information about the appliance | 25

Unit NG LPG (propane)

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 103.6 (47) 103.6 (47)

Dimensions, W x H x D

inch

(mm)

≤

44

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

44

Tab. 6 Technical data heating boiler ZBR35-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 26

26 | Information about the appliance

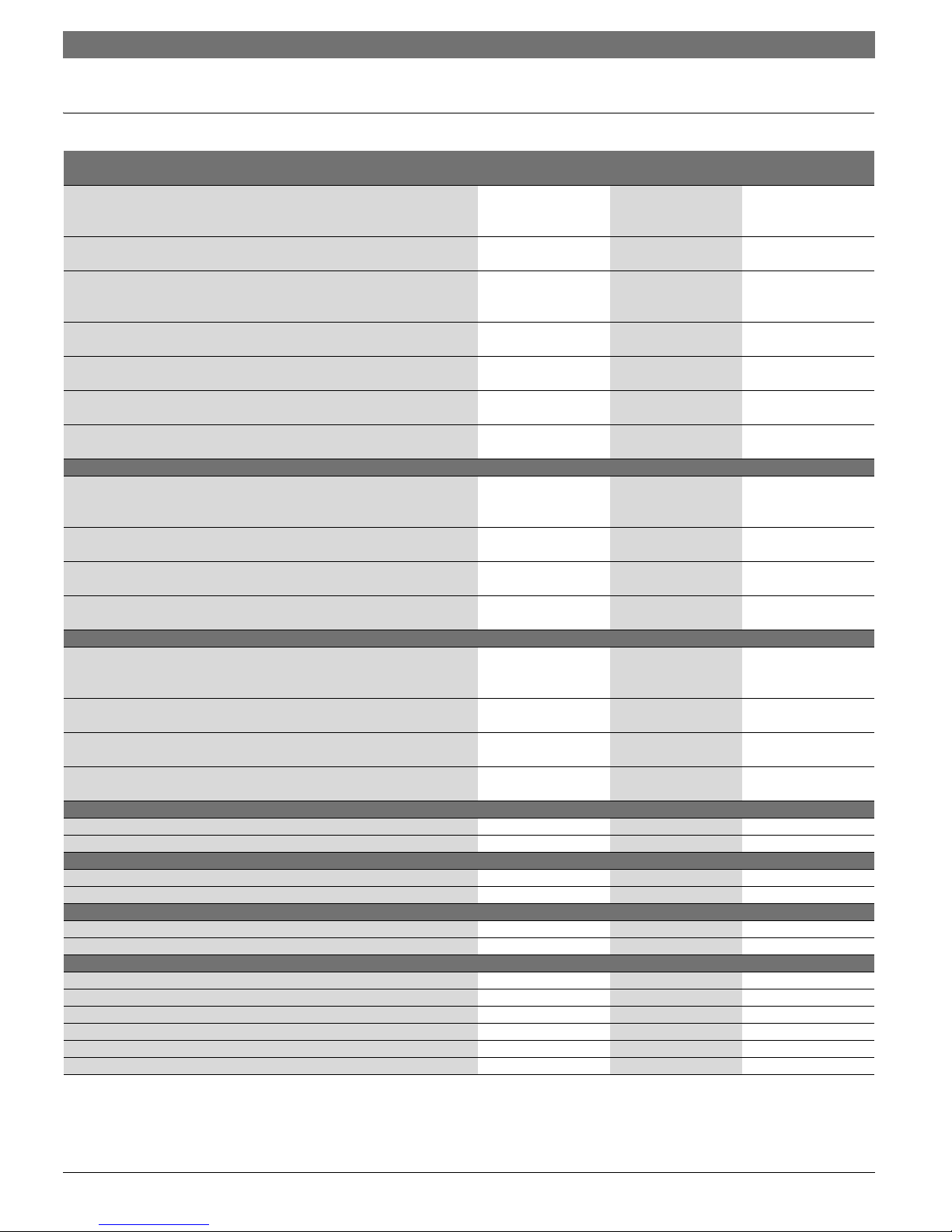

3.14 Technical data heating boiler ZBR42-3A...

Unit NG LPG (propane)

Output at elevation 0 - 2000 feet (0 - 610 m)

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Output at elevation 2000 - 4500 feet (611 - 1372 m) above sea level

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Output at elevation 4500 - 7000 feet (1373 - 2134 m) above sea level

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) –

LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Tab. 7 Technical data heating boiler ZBR42-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 137,500 (40.3) 137,500 (40.3)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 137,500 (40.3) 137,500 (40.3)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 134,400 (39.4) 134,400 (39.4)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 136,500 (40.0) 136,500 (40.0)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 151,600 (44.4) 148,300 (43.5)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 35,500 (10.4) 46,400 (13.6)

) 122/86 °F (50/30 °C) BTU/hr (kW) 35,100 (10.3) 46,100 (13.5)

) 176/140 °F (80/60 °C) BTU/hr (kW) 31,700 (9.3) 42,000 (12.3)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 32,400 (9.5) 42,700 (12.5)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 36,000 (10.5) 46,400 (13.6)

min

) tank (Hi) BTU/hr (kW) 136,500 (40.0) 136,500 (40.0)

max

) tank (Hs)BTU/hr (kW)151,600 (44.4) 148,300 (43.5)

max

) tank (Hi)BTU/hr (kW)32,400 (9.5) 42,700 (12.5)

min

) tank (Hs)BTU/hr (kW)36,000 (10.5) 46,400 (13.6)

min

) 104/86 °F (40/30 °C) BTU/hr (kW) 123,750 (36.3) 129,250 (37.9)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 123,750 (36.3) 129,250 (37.9)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 120,960 (35.5) 126,336 (37.0)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 122,850 (36.0) 128,310 (37.6)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 136,440 (40.0) 139,402 (40.9)

max

) tank (Hi) BTU/hr (kW) 122,850 (36.0) 128,310 (37.6)

max

) tank (Hs)BTU/hr (kW)136,440 (40.0) 139,402 (40.9)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 114,125 (33.5) 119,625 (35.1)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 114,125 (33.5) 119,625 (35.1)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 111,552 (32.7) 116,928 (34.3)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 113,295 (33.2) 118,755 (34.8)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 125,828 (36.9) 129,021 (37.8)

max

) tank (Hi) BTU/hr (kW) 113,295 (33.2) 118,755 (34.8)

max

) tank (Hs)BTU/hr (kW)125,828 (36.9) 129,021 (37.8)

max

3

/hr (m3/h) 149 (4.2) –

= 2,500 BTU/ft3 (93.1MJ/m3)ft

D-S

3

/hr (m3/h) – 59 (1.7)

Copyright (optional information)6 720 643 068 (2011/06)

Page 27

Information about the appliance | 27

Unit NG LPG (propane)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 18.0/4.5 17.5/5.6

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.9 (3.5) 0.9 (3.5)

pH level, approx. 4.8 4.8

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 103.6 (47) 103.6 (47)

Dimensions, W x H x D

°F ( °C)

°F ( °C)

inch

(mm)

171/135 (77/57) 171/135 (77/57)

133/91 (56/33) 133/91 (56/33)

≤

45

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

45

Tab. 7 Technical data heating boiler ZBR42-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 28

28 | Information about the appliance

3.15 Technical data combi boiler ZWB28-3A...

Unit NG LPG (propane)

Output at elevation 0 - 2000 feet (0 - 610 m)

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal output (P

Max. nominal output (P

max

max

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) –

LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Expansion vessel

Pre-charge pressure psi (bar) 10.9 (0.75) 10.9 (0.75)

Total contents Gal (L) 3.17 (12) 3.17 (12)

DHW

Max. DHW flow rate gpm (l/min) 2.64 (10) 2.64 (10)

Nominal DHW quantity (at 140 °F (60 °C) outlet temperature) gpm (l/min) 2.03 (7.7) 2.03 (7.7)

Outlet temperature °F ( °C) 104 - 140 (40 - 60) 104 - 140 (40 - 60)

Max. cold water inlet temperature °F ( °C) 140 (60) 140 (60)

Max. approved DHW pressure psi (bar) 150 (10.3) 150 (10.3)

Minimum water pressure psi (bar) 4.35 (0.3) 4.35 (0.3)

Specific flow rate to EN 625 (D) gpm (l/min) 3.75 (14.2) 3.75 (14.2)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 12.0/3.2 11.7/4.9

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.6 (2.3) 0.6 (2.3)

pH level, approx. 4.8 4.8

Tab. 8 Technical data combi boiler ZWB28-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 93,800 (27.5) 93,800 (27.5)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 93,100 (27.3) 93,100 (27.3)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 89,400 (26.2) 89,400 (26.2)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 90,800 (26.6) 90,800 (26.6)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 100,800 (29.5) 98,600 (28.9)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 23,900 (7.0) 39,900 (11.7)

) 122/86 °F (50/30 °C) BTU/hr (kW) 23,900 (7.0) 39,600 (11.6)

) 176/140 °F (80/60 °C) BTU/hr (kW) 21,800 (6.4) 36,200 (10.6)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 22,200 (6.5) 36,800 (10.8)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 24,600 (7.2) 40,100 (11.7)

min

) DHW (Hi) 113°F (45°C) BTU/hr (kW) 93,600 (27.4) 93,600 (27.4)

) DHW (Hs) 140°F (60°C) BTU/hr (kW) 91,400 (26.8) 91,400 (26.8)

) DHW (Hi) BTU/hr (kW) 90,800 (26.6) 90,800 (26.6)

max

) DHW (Hs)BTU/hr (kW)100,800 (29.5) 98,600 (28.9)

max

) DHW (Hi)BTU/hr (kW)22,200 (6.5) 36,800 (10.8)

min

) DHW (Hs)BTU/hr (kW)24,600 (7.2) 40,100 (11.7)

min

3

/hr (m3/h) 99 (2.8) –

= 2,500 BTU/ft3 (93.1MJ/m3)ft

D-S

3

/hr (m3/h) – 39 (1.1)

°F ( °C)

°F ( °C)

147/133 (64/56) 147/133 (64/56)

117/90 (47/32) 117/90 (47/32)

Copyright (optional information)6 720 643 068 (2011/06)

Page 29

Information about the appliance | 29

Unit NG LPG (propane)

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 110.2 (50) 110.2 (50)

Dimensions, W x H x D

inch

(mm)

≤

39

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

39

Tab. 8 Technical data combi boiler ZWB28-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 30

30 | Information about the appliance

3.16 Technical data combi boiler ZWB42-3A...

Unit NG LPG (propane)

Output at elevation 0 - 2000 feet (0 - 610 m)

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal output (P

Min. nominal output (P

Min. nominal output (P

min

min

min

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Max. nominal output (P

Max. nominal output (P

max

max

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Min. nominal thermal load (Q

Min. nominal thermal load (Q

Output at elevation 2000 - 4500 feet (611 - 1372 m) above sea level

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal output (P

Max. nominal output (P

max

max

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Output at elevation 4500 - 7000 feet (1373 - 2134 m) above sea level

Maximum nominal output (P

Maximum nominal output (P

Maximum nominal output (P

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Max. nominal output (P

Max. nominal output (P

max

max

Max. nominal thermal load (Q

Max. nominal thermal load (Q

Gas connection value

Natural Gas – Hs = 1,010 BTU/ft3 (37.3MJ/m3)ft

Liquid Propane Gas – H

Permissible inlet gas pressure

NG in. W.C. (mbar) 3.5-10.5" (8.7-26.1) –

LPG (propane) in. W.C. (mbar) – 8-13" (19.9-32.3)

Expansion vessel

Pre-charge pressure psi (bar) 10.9 (0.75) 10.9 (0.75)

Total contents Gal (L) 3.17 (12) 3.17 (12)

DHW

Max. DHW flow rate gpm (l/min) 3.963 (15) 3.963 (15)

Nominal DHW quantity (at 140 °F (60 °C) outlet temperature) gpm (l/min) 3.61 (11.4) 3.61 (11.4)

Outlet temperature °F ( °C) 104 - 140 (40 - 60) 104 - 140 (40 - 60)

Max. cold water inlet temperature °F ( °C) 140 (60) 140 (60)

Max. approved DHW pressure psi (bar) 150 (10.3) 150 (10.3)

Minimum water pressure psi (bar) 4.35 (0.3) 4.35 (0.3)

Tab. 9 Technical data combi boiler ZWB42-3A...

) 104/86 °F (40/30 °C) BTU/hr (kW) 137,500 (40.3) 137,500 (40.3)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 137,500 (40.3) 137,500 (40.3)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 134,400 (39.4) 134,400 (39.4)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 136,500 (40.0) 136,500 (40.0)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 151,600 (44.4) 148,300 (43.5)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 35,500 (10.4) 46,400 (13.6)

) 122/86 °F (50/30 °C) BTU/hr (kW) 35,100 (10.3) 46,100 (13.5)

) 176/140 °F (80/60 °C) BTU/hr (kW) 31,700 (9.3) 42,000 (12.3)

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 32,400 (9.5) 42,700 (12.5)

min

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 36,000 (10.5) 46,400 (13.6)

min

) DHW (Hi) 113°F (45°C) BTU/hr (kW) 137,500 (40.3) 137,500 (40.3)

) DHW (Hs) 140°F (60°C) BTU/hr (kW) 135,800 (39.8) 135,800 (39.8)

) DHW (Hi) BTU/hr (kW) 136,500 (40.0) 136,500 (40.0)

max

) DHW (Hs)BTU/hr (kW)151,600 (44.4) 148,300 (43.5)

max

) DHW (Hi)BTU/hr (kW)32,400 (9.5) 42,700 (12.5)

min

) DHW (Hs)BTU/hr (kW)36,000 (10.5) 46,400 (13.6)

min

) 104/86 °F (40/30 °C) BTU/hr (kW) 123,750 (36.3) 129,250 (37.9)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 123,750 (36.3) 129,250 (37.9)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 120,960 (35.5) 126,336 (37.0)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 122,850 (36.0) 128,310 (37.6)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 136,440 (40.0) 139,402 (40.9)

max

) DHW (Hi) 113°F (45°C) BTU/hr (kW) 123,750 (36.3) 129,250 (37.9)

) DHW (Hs) 140°F (60°C) BTU/hr (kW) 122,220 (35.8) 127,652 (37.4)

) DHW (Hi) BTU/hr (kW) 122,850 (36.0) 128,310 (37.6)

max

) DHW (Hs)BTU/hr (kW)136,440 (40.0) 139,402 (40.9)

max

) 104/86 °F (40/30 °C) BTU/hr (kW) 114,125 (33.5) 119,625 (35.1)

max

) 122/86 °F (50/30 °C) BTU/hr (kW) 114,125 (33.5) 119,625 (35.1)

max

) 176/140 °F (80/60 °C) BTU/hr (kW) 111,552 (32.7) 116,928 (34.3)

max

) heating (Hi) 180/79 °F (82/26 °C) BTU/hr (kW) 113,295 (33.2) 118,755 (34.8)

max

) heating (Hs) 180/79 °F (82/26 °C) BTU/hr (kW) 125,828 (36.9) 129,021 (37.8)

max

) DHW (Hi) 113°F (45°C) BTU/hr (kW) 114,125 (33.5) 119,625 (35.1)

) DHW (Hs) 140°F (60°C) BTU/hr (kW) 112,714 (33.0) 118,146 (34.6)

) DHW (Hi) BTU/hr (kW) 113,295 (33.2) 118,755 (34.8)

max

) DHW (Hs)BTU/hr (kW)125,828 (36.9) 129,021 (37.8)

max

3

/hr (m3/h) 149 (4.2) –

= 2,500 BTU/ft3 (93.1MJ/m3)ft

D-S

3

/hr (m3/h) – 59 (1.7)

Copyright (optional information)6 720 643 068 (2011/06)

Page 31

Information about the appliance | 31

Unit NG LPG (propane)

Calculation values for calculating cross-section to EN 13384

Flue gas mass flow at maximum/minimum nominal output gps 18.0/4.5 17.5/5.6

Flue gas temperature 176/140 °F (80/60 °C) at maximum/minimum

nominal heat input

Flue gas temperature 104/86 °F (40/30 °C) at maximum/minimum

nominal heat input

CO2 at max. nominal output % 9.4 11.0

CO2 at minimum nominal output % 8.6 10.4

Condensate

Max. condensate quantity (tR = 86 °F (30 °C)) gph (l/h) 0.9 (3.5) 0.9 (3.5)

pH level, approx. – 4.8 4.8

General

Voltage VAC 120 120

Frequency Hz 60 60

Max. power consumption (central heating mode) W 205 205

Max. power consumption (Stand-by) W <6 <6

Noise level dB(A)

Maximum supply temperature °F ( °C) 194 (90) 194 (90)

Max. permissible operating pressure (PMS) heating psi (bar) 30 (2.07) 30 (2.07)

Permissible ambient temperature °F ( °C) 32 - 122 (0 - 50) 32 - 122 (0 - 50)

Nominal water capacity (heating) Gal (L) 0.925 (3.5) 0.925 (3.5)

Weight (without packaging) lbs. (kg) 110.2 (50) 110.2 (50)

Dimensions, W x H x D

°F ( °C)

°F ( °C)

inch

(mm)

171/135 (77/57) 171/135 (77/57)

133/91 (56/33) 133/91 (56/33)

≤

45

17-21/64" × 33-15/32" × 13-57/64"

(440 × 850 × 353)

≤

45

Tab. 9 Technical data combi boiler ZWB42-3A...

6 720 643 068 (2011/06)Copyright (optional information)

Page 32

32 | Information about the appliance

3.17 Condensate composition

The condensate volume and ingredients may change with

regionally and seasonally varying gas quality and air

quality. Typically the following ingredients and

concentrations can be expected:

Substance Value in ppm (mg/l)

Ammonium 1.2

Lead

Cadmium

Chrome

Halogenated

≤

≤

≤

≤

0.01

0.001

0.005

0.002

hydrocarbons

Hydrocarbons 0.015

Copper 0.028

Nickel

Mercury

≤

0.1

≤

0.0001

Sulfate 1

Zinc

Tin

Vanadium

≤

≤

≤

0.015

0.01

0.001

pH-value 4.8

Tab. 10 Typical condensate composition

Copyright (optional information)6 720 643 068 (2011/06)

Page 33

4Regulations

Regulations | 33

Observe all rules, regulations, standards and

guidelines applicable to the installation and

operation of this appliance in your country.

In the Commonwealth of Massachusetts,

this appliance must be installed by a

licensed plumber and gas fitter. Valves

external to the boiler must be fitted with

T-handles and condensate piping must be

installed in accordance with the State

Plumbing Code.

4.1 Compliance with standards and

regulations

The installation must conform to the requirements of the

authority having jurisdiction or, in the absence of such

requirements, to the latest edition of the National Fuel Gas

Code, ANSI Z223.1./NFPA 54. In Canada, installation must

be in accordance with the requirements of CAN/CSA

B149.1, Natural Gas and Propane Installation Code.

This wall mounted condensing gas boiler complies in its

design and mode of operation with the American National

Standard ANSI Z21.13/CSA4.9, latest edition for Gas Fired

Low Pressure Steam and Hot Water Boilers.

4.2 Operating limits of the boiler

The heat exchanger has been designed and certified in

accordance with the ASME Boiler and Pressure Vessel

Code, Section IV.

Maximum boiler temperature 194 °F (90 °C)

Maximum operating pressure 30 psi (2.07 bar)

Tab. 11 Operating limits

The hot water distribution system must comply with all

applicable codes and regulations. When replacing an

existing boiler, it is important to check the condition of the

entire hot water distribution system to ensure safe

operation. Common practice calls for inspecting an

existing system in its entirety and bringing it up to code.

All pipework should be properly cleaned and flushed.

Other confirmed approvals and certifications are indicated

by labels on the boiler.

Where required by the authority having jurisdiction, the

installation must conform to the Standard for Controls and

Safety Devices for Automatically Fired Boilers, ANSI/ASME

CSD-1.

Install CO detectors per local regulations. Boiler requires

yearly maintenance (Æ chapter 14, page 81).

6 720 643 068 (2011/06)Copyright (optional information)

Page 34

34 | Regulations

4.3 Additional regulations for installation in

Massachusetts

(a) For all side wall horizontally vented gas fueled

equipment installed in every dwelling, building or

structure used in whole or in part for residential purposes,

including those owned or operated by the Commonwealth

and where the side wall exhaust vent termination is less

than seven (7) feet [2150 mm] above finished grade in the

area of the venting, including but not limited to decks and

porches, the following requirements shall be satisfied:

1. INSTALLATION OF CARBON MONOXIDE DETECTORS.

At the time of installation of the side wall horizontal vented gas fueled equipment, the installing plumber or gasfitter shall observe that a hard wired carbon monoxide

detector with an alarm and battery back-up is installed

on the floor level where the gas equipment is to be

installed. In addition, the installing plumber or gasfitter

shall observe that a battery operated or hard wired carbon monoxide detector with an alarm is installed on

each additional level of the dwelling, building or structure served by the side wall horizontal vented gas fueled

equipment. It shall be the responsibility of the property

owner to secure the services of qualified licensed professionals for the installation of hard wired carbon monoxide detectors.

– In the event that the side wall horizontally vented gas

fueled equipment is installed in a crawl space or an

attic, the hard wired carbon monoxide detector with

alarm and battery back-up may be installed on the

next adjacent floor level.

– In the event that the requirements of this subdivision

can not be met at the time of completion of

installation, the owner shall have a period of thirty

(30) days to comply with the above requirements;

provided, however, that during said thirty (30) day

period, a battery operated carbon monoxide detector

with an alarm shall be installed.

2. APPROVED CARBON MONOXIDE DETECTORS. Each

carbon monoxide detector as required in accordance

with the above provisions shall comply with NPA 720

and be ANSI/UL 2034 listed and IAS certified.

3. SIGNAGE. A metal or plastic identification plate shall be

permanently mounted to the exterior of the building at

a minimum height of eight (8) feet above grade directly

in line with the exhaust vent terminal for the horizontally vented gas fueled heating appliance or equipment.

The sign shall read, in print size no less than one-half

(½) inch in size, “GAS VENT DIRECTLY BELOW. KEEP

CLEAR OF ALL OBSTRUCTIONS”.

4. INSPECTION. The state or local gas inspector of the side

wall horizontally vented gas fueled equipment shall not

approve the installation unless, upon inspections, the

inspector observes carbon monoxide detectors and signage installed in accordance with the provisions of

248 CRM 5.08(2)(a) 1 through 4.

(b) EXEMPTIONS: The following equipment is exempt from

248 CRM 5.08(2)(a) 1 through 4:

• The equipment listed in Chapter 10 entitled “Equipment

Not Required To Be Vented” in the most current edition

of NFPA 54 as adopted by the board; and

• Product Approved side wall horizontally vented gas

fueled equipment installed in a room or structure

separate from the dwelling, building or structure used

in whole or in part for residential purposes.

(c) MANUFACTURERS REQUIREMENTS - GAS EQUIPMENT

VENTING SYSTEM REQUIRED. When the manufacturer of

Product Approved side wall horizontally mounted gas

equipment provides a venting system design or venting

system components with the equipment, the instructions

provided by the manufacturer for the installation of the

equipment and venting shall include:

• Detailed instructions for the installation of the venting

system or the venting system components; and

• A complete parts list for the venting system design or

venting system.

ANUFACTURERS REQUIREMENTS - GAS EQUIPMENT

(d) M

VENTING SYSTEM

manufacturer of Product Approved side wall horizontally

vented gas fueled equipment does not provide the parts

for the venting of flue gases, but identifies special venting

systems, the following requirements shall be satisfied by

the manufacturer:

1. The referenced special venting systems shall be

included with the appliance or equipment installation

instructions; and

2. The special venting systems shall be Product Approved

by the Board, and the instructions for that system shall

include a parts list and detailed installation

instructions.

(e) A copy of all i nstructions for all Product Approved side

wall horizontally vented gas fueled equipment, all venting

instructions, all parts lists for venting instructions, and/or

venting design instructions shall remain with the appliance

or equipment at the completion of the installation.

NOT PROVIDED. When the

Copyright (optional information)6 720 643 068 (2011/06)

Page 35

5 Installation

Installation | 35

DANGER: Explosion!

B Close the gas cock prior to working on the

gas train.

B Check for gas leaks after carrying out work

on the gas train.

Installation, power connection, connection on

the gas and flue gas side and commissioning

must only be carried out by a contractor

certified for such work by the state or local

jurisdiction or the local gas or power utility.

5.1 Notes on installation and operation

When installing and operating the heating system observe

the following:

• The elevation of the installation location above sea level

must be taken into account (Æ Chapter 11.2).

• Follow all local building regulations regarding the

installation conditions on site.

• The local building regulations regarding air supply and

venting systems and the chimney flue connection.

• Electrical code requirements for connection to the

electrical power supply.

• The technical regulations of the gas company regarding

the connection of the gas burner to the local gas main.

• The regulations and standards relating to the DHW

heating system.

5.1.1 Notes on installation and operation

Fill and make-up water for the heating system

Unsuitable fill and make-up water can result in the heating

system scaling up or failing prematurely.

Water hardness in grains

per gallon (Ca(HCO

concentration in ppm)

soft: ≤9 grains

(

≤

150 ppm)

medium: 9 - 14.6 grains

(150 - 250 ppm)

hard: ≥14.6 (≥250 ppm) Required

Tab. 12 Water preparation for filling and maintaining the

heating system (water hardness)

pH-value Water preparation

7-8.5 Not needed

<7 or >8.5 Required

Tab. 13 Water preparation for filling and maintaining the

heating system (pH-value)

Recirculation pump/DHW recirculation lines

Total length DHW/

recirculation line

≤

33 ft (10 m) 0.66 gpm (2.5 l/min)

33 - 66 ft (10 - 20 m) 0.92 gpm (3.5 l/min)

3)2

Water preparation

Not needed

Recommended

Flow rate

66 - 98 ft (20 - 30 m) 1.32 gpm (5 l/min)

Tab. 14 Recommended flow rates

Use service function 6.d, to determine the

current flow rate (Æ page 71).

Electrical connection of the DHW recirculation pump

(Æ page 55).

Connect the DHW recirculation line with the cold water

inlet as close as possible to the Hydraulics connection

plate.

Open vented heating systems

B Convert open vented heating systems into closed

systems.

6 720 643 068 (2011/06)Copyright (optional information)

Page 36

36 | Installation

Gravity heating systems

B Connect the appliance to the existing piping system via

a low-loss header with a sludge separator.

Galvanized radiators or pipes.

To prevent gas formation:

B Do not use galvanized radiators or pipes.

Use of a room temperature control

B Do not install thermostatic valves on radiators in the

primary room.

Anti-freeze

NOTICE: Insufficient antifreeze can

accelerate corrosion.

B Follow manufacturer's instructions on

antifreeze concentration.

B Frost protection level has to be checked

annually during the regular scheduled

maintenance of the condensing boiler.

NOTICE: System damage!

B It is the installer's responsibility to ensure

that the heating system is compatible with

the boiler type and size installed.

B pH-value of the heating water to be kept in

the given ranges (Æ Tab. 13, page 35).

The following anti-freeze fluids are approved:

• Nalco (Varidos) FSK

• Alphi 11

• Glythermin NF

• Antifrogen N

• Intercool NFP-50 AA

• Tyfocor L

• NoBurst AL

Corrosion inhibitors

The following anti-corrosion agents are approved:

Designation Concentration

Nalco 77381 1 - 2 %

Sentinel X 100 1.1 %

Copal 1 %

Tab. 16 Corrosion inhibitors

Boiler sealer

This boiler is not approved for use with boiler sealer.

LPG

To protect the appliance against high pressure (ANSI/

Z223.1/NFPA54 (National fuel gas code) or CAN/CSA B

149.1 (Natural Gas and Propane installation code)):

B Install a pressure regulator with a safety valve.

5.1.2 Other important information

• The installation of this boiler must comply with all

national and local code and regulations.

• Only operate this boiler with the combined air/flue

system specifically designed and approved for it.

• Only use approved venting systems per the

manufacturer's instructions.

• Do not dispose of untreated boiler condensate in septic

systems.

• Inspect the sewer pipes for suitability before disposing

of untreated boiler condensate into them.

• Verify with the local authority that disposing of

untreated boiler condensate into public sewer systems

is permitted.

The following concentrations are approved:

Designation Concentration

Nalco (Varidos) FSK 22 - 55 %

Glythermin NF 20 - 62 %

Intercool NFP-50 AA

Tyfocor L

NoBurst AL

0 - 39 %

25 - 80 %

0 - 55 %

Tab. 15 Anti-freeze

Copyright (optional information)6 720 643 068 (2011/06)

Page 37

Installation | 37

5.2 Comparing the size of the integrated

expansion vessel

The following diagrams allow verifying that the integrated

expansion vessel has sufficient capacity for the intended

application, or if an additional expansion vessel is needed

(not for radiant floor heating).

The following standard conditions were used:

• Precharge volume 20% of the rated volume in the

expansion vessel

• Differential to the safety valve of 7.25 psi (0.5 bar)

• Precharge pressure of the expansion vessel equal to the

static system height above the boiler

• Maximum operating pressure: 30 psi (2.07 bar)

200

180

I

160

/°F

140

V

t

120

100

80

0 20 40 80 100

A

III

II

60

VA/gal

B

120

6720641933-13.1O

90

80

I

B

70

/°C

60

V

t

50

40

30

Fig. 10 Operating capacity of the expansion vessel in °C

and liters

Key to Fig. 9 and Fig. 10:

I Precharge pressure 7.25 psi (0.5 bar) (default setting)

II Precharge pressure 10.9 psi (0.75 bar)

III Precharge pressure 14.5 psi (1.0 bar)

t

Supply temperature in °F ( °C)

V

V

System capacity in gallons (liters)

A

A Within operating capacity of the expansion vessel (left of the

relevant curve)

B Additional expansion vessel required (right of the relevant

curve)

B If results are borderline: Determine precise vessel sizes.

B If the results are to the right of the curve: Install

additional expansion vessel.

III

A

0 75 150 300 375

II

225

VA/l

6720641933-27.1O

450

Fig. 9 Operating capacity of the expansion vessel in °F and

gallons

6 720 643 068 (2011/06)Copyright (optional information)

Page 38

38 | Installation

5.3 ZBR..-3A appliances (heating boilers):

Selecting an expansion vessel

External expansion vessel

B Determine size of the expansion vessel.

5.4 Selecting the installation location

Installation location requirements

Observe the current national and local codes and

regulations.

B Observe country-specific requirements.

B Observe installation instructions of the venting system

accessories and their clearances.

Combustion air

To avoid corrosion, keep the supply of combustion air free

of corrosive substances; contained in solvents, paints,

adhesives, propellants and domestic cleaning agents.

Industrial sources

Chemical cleaning Trichloroethylene, tetrachloroethyl-

ene, fluorinated hydrocarbons

Degreasing bath Perchloroethylene, trichloroethylene,

methylchloroform

Printing shops Trichloroethylene

Hair salons Aerosol propellants, hydrocarbons

containing fluorine and chlorine (diflu-

orodichloromethane)

Fig. 11 Sample installation - expansion vessel

6 720 641 933-20.1O

Household sources

Cleaning and

degreasing agents

Workshop

Solvents and thin-

ners

Aerosols Chlorofluorinated hydrocarbons (diflu-

Perchloroethylene, methylchloroform,

trichloroethylene, methylene chloride,

carbon tetrachloride, hydrochloric acid

Various chlorinated hydrocarbons

orodichloromethane)

Tab. 17 Corrosive materials

Surface temperature

The max. surface temperature of this appliance is below

185 °F (85 °C). According to ANSI/Z223.1/NFPA43

(National fuel gas code) and CAN/DAS B 149.1 (Natural

Gas and Propane installation code), the appliance is

approved for zero clearance to combustibles. For servicing

a clearance of 4" (102 mm) is recommended.

Copyright (optional information)6 720 643 068 (2011/06)

Page 39

5.5 Pre-installing pipes

60/100

80/125

250

200

3°

3°

150

100

87

111

B Secure the installation template (supplied with the

technical documentation) to the wall; observe the

minimum side clearances of 4 inches (102 mm)

(Æ page 11).