Bosch WR400-1K, WR400-1 K P Installation Operation & Maintenance

Instantaneous gas water heater

Models

WR400-1K…

· Installation

· Operation

· Maintenance

The Bosch instantaneous water heater is a high efficiency,

space saving answer to your water heating needs.

All Bosch instantaneous water heaters heat water only as

required; no energy is lost maintaining a large volume of

water at elevated temperatures as in tank-type storage water heaters.

Suitable for heating potable water only. Not approved

for space heating purposes.

READ INSTRUCTIONS CAREFULLY BEFORE INSTALLING

NOTICE TO INSTALLER: Please leave this manual with

the owner or affix adjacent to

appliance.

ASTRAVAN DISTRIBUTORS, LTD.

6 720 603 100 (03.05) AL

123 Charles Street

North Vancouver, BC. V7H 1S1

Phone Canada: (604) 929-5488

Phone USA: (206) 860-8448

Web Site: www.astravan.com

WARNING: If the information in this manual is not

followed exactly, a fire or explosion may result

causing property damage, personal injury or death.

- Do not store or use gasoline or other flammable

vapors and liquids in the vicinity of this or any

other appliance.

- WHAT TO DO IF YOU SMELL GAS

- Do not try to light any appliance

- Do not touch any electrical switch; do not use

any phone in your building.

- Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions.

- If you cannot reach your gas supplier, call the

fire department.

- Installation and service must be performed by a

qualified installer, service agency or the gas

supplier.

Note: In case of problems please contact your salesman or installer.

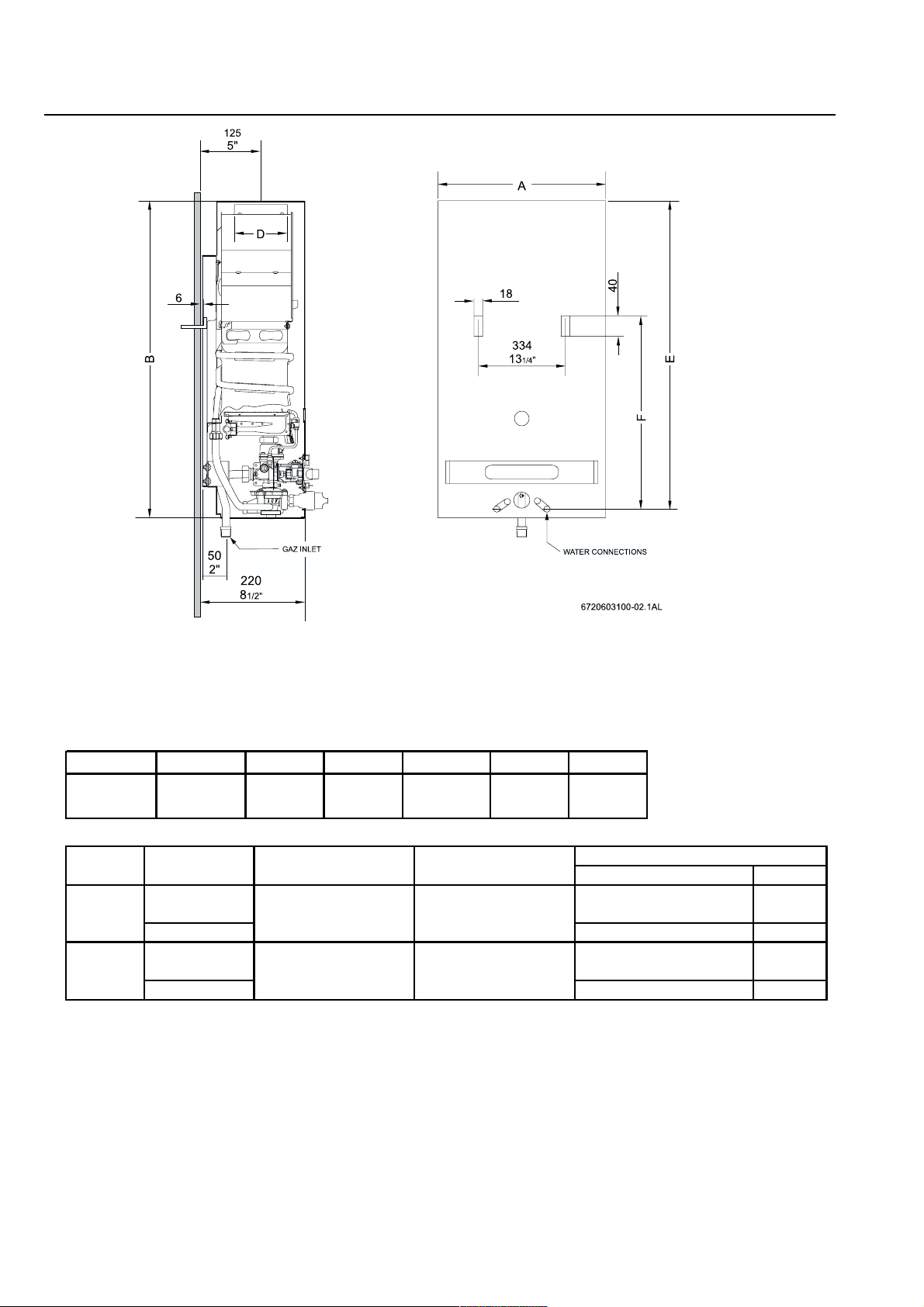

DIMENSIONS

Figure 1

Maximum hydrostatic water pressure – 1.03 Mpa (150 p.s.i.)

Maximum recommend working pressure – 0.69 Mpa (100 p.s.i.)

Minimum working pressure – 0.0138 Mpa (2 p.s.i.) at 2 Litres/min. (0.5 U.S. Gallons/min) free discharge

Minimum recommended inlet water pressure for use with showers 40 p.s.i.g.

Dimensions in Milimetres (inches)

Model dimensions A B D E F

WR400 - 1

Model Type of gas Altitude Input

WR400

WR400

milimetres

inches

Natural

Propane/LP 0.79 diam. 18

Natural

Propane/LP 0.79 diam. 18

460 755 130 diam. 740 542

18 1/8 29 3/4 5 1/8 diam. 29 1/8 21 11/32

Main Burner Orifices

Size, mm Qt.

standard 34.28 kW 1.20 diam. 18

(0 - 2,000 Pieds) (117,000Btu/hr)

high* 30.85 kW 1.20 diam. 18

(2,000 - 4,500 Pieds) ( 105,000Btu/hr)

* The high altitude ratings listed are Canadian Gas Association high altitude ratings and are only valid in Canada. In the

U.S., the National Fuel Gas Code, ANSI Z223.1/NFPA 54, recommends for high altitude installations above 2,000 feet,

that the input rate be reduced 4% for each 1,000 feet above sea level. – See page 8.

2

FOREWORD

This design complies with CAN1-4.3-77 and ANS1Z21.10.3b

1994 as an instantaneous gas water heater. In addition the

unit complies with CAN1-2.17- M80 use at high altitude,

2.000- 4.500 feet above sea level.

Installation, operation and maintenance information is

provided in this manual . Installation and operation

instructions should be thoroughly reviewed before

proceeding with installation of the BOSCH instantaneous

gas water heater.

The BOSCH instantaneous gas water heater is designed

to operate on natural or propane gas; however make sure

that gas on which heter is to operate is the same as specified

on the heater’s model/rating plate.

In addition of these instructions, the water heater shall be

installed in accordance with CAN1-B149 Installation Code

(in Canada) or ANSI Z223-1/NFFA 54 National Fuel Gas

Code (in U.S.) and/or local installation codes.

These shall be carefully followed in all cases.

INSTALLATION INSTRUCTIONS

Note: Proper plumbing, venting, gas connections and an

adequate supply of combustion air are required for

safe and reliable operation. Ability equivalent to that

of a licensed tradesman in the field involved is required

for installation and/or service of these water heaters.

LOCATION

Before installing the BOSCH instantaneous water heater

consideration must be given to proper location. The location

should be as close to a chimney or gas vent as practicable,

in an area with an adequate air supply and as centralized

with the piping system as possible. The heater should not

be located in an area where it will be subject to freezing.

The heater should be located in an area where leakage of

the heater or its connections will not result in damage to

the area adjacent to the heater or to lower floors of the

structure.

Note: When such locations cannot be avoided, it is

recommended that a suitable drain pan, adequately

drained, be installed under the water heater. The

pan must no restrict combustion air flow.

AIR REQUIREMENTS

For safe operation, sufficient air combustion, ventilation and

dilution of the flue gas must be available. An insufficient

supply of air will result in a yellow luminous burner flame,

causing carboning or sooting of the heat exchanger.

In order to prevent corrosion, make sure that the combustion

air is kept free of aggressive substances. Substances that

especially contribute to corrosion are halogenated

hydrocarbons (e.g., chlorine and fluorine) which are

contained in solvents, paint, adhesives, propellant gases,

various household cleaners, etc. Take precautionary

measures as necessary.

In unconfined spaces, in buildings of normal construction,

infiltration normally is adequate to provide air for combustion,

ventilation and dilution of the flue gases. However, a confined

space must be provided with two permanent openings to

provide combustion and ventilation air to the appliance. Each

opening shall have a free area on one square inch per 1,000

BTU/Hr* of total input rating of all the appliances in the

enclosure. One opening shall be within 12 inches of the top

and one within 12 inches of the bottom of the enclosure.

*Special Note

When the WR400-1 is installed in a confined space of

minimum size the openings described above must be

increased in to a size of 1 ½ square inches per 1,000 BTU/

Hr. In order words, when the WR400-1 is installed in a

minimum sized confined space the two openings that are to

be made in the enclosure within 12 inches of the top and

12 inches of the bottom must each have a minimum free

area of (1 ½ “) x (117) = 175.5 square inches.

3

For either a confined or unconfined space in a building of

tight construction with inadequate infiltration, air must be

drawn from the outdoors or from spaces that freely

communicate with the outdoors. Two permanent openings

located as indicated above are to be provided as follows:

1. When communicating with outdoors directly or by

means of vertical ducts, each opening shall have a

free area of not less than one square inch per 4,000

BTU/Hr of total input of all appliances in the space.

2. When communicating with outdoors by means of

horizontal ducts, each opening shall have a free area

of not less than one square inch per 2,000 BTU/Hr of

total input of all appliances in the space.

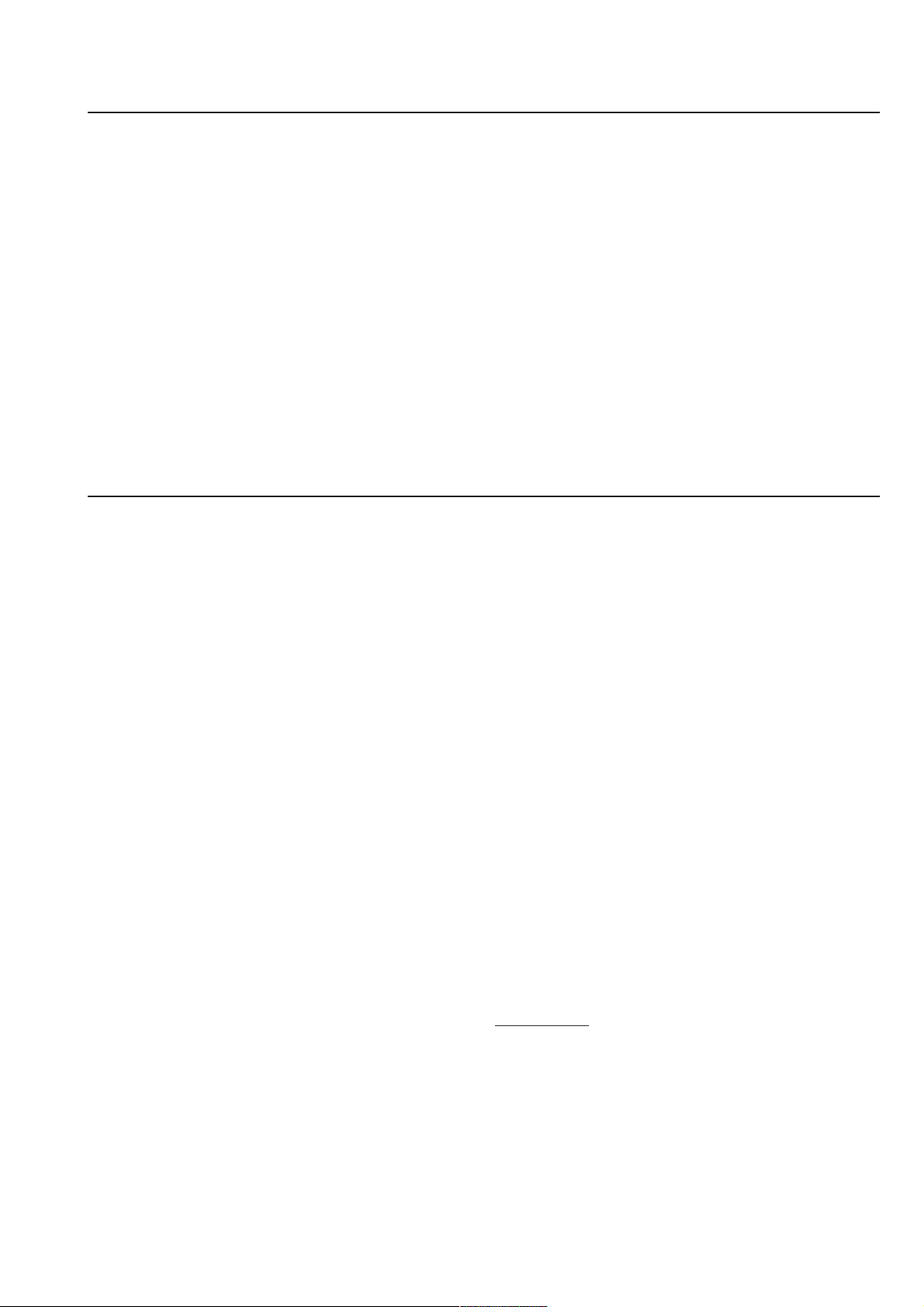

MOUNTING

The WR400-1 is design certified for mounting to a wall.

The heater must not be installed on a carpeted wall. The

heater must be mounted to the wall using appropriate

anchoring materials.

Note: If wall is a stud wall sheathed with plasterboard it is

recommended that support board(s), either 1 x 4’s or ½ “

(minimum) plywood first be attached across a pair of studs

and then the heaters should be attached to the support

boards. See Figure 2.

For detailed requirements see:

• In Canada, CAN/CGA- B149 Installation Codes

• In U.S.A., ANSI Z223.1/NFPA 54, National Fuel Gas

Code.

WARNING!

1. Flammable materials gasoline, pressurized

containers, or any other items or articles that are

potentially fire hazards must never be placed on or

adjacent to the heater. The appliance area must be

kept free of all combustible materials, gasoline and

other flammable vapors and liquids.

2. Do not obstruct the flow of combustion and

ventilation air to the appliance.

CLEARANCE

The WR400-1 is design certified for installation on a

combustible wall and for installation in an alcove or closet

with minimum clearances to combustible construction of

0mm from back, 102mm (4 inches) from sides, 305mm (12

inches) from top and bottom, and 102mm (4 inches) from

front. A minimum of 305mm (12 inches) shall be allowed for

maintenance of serviceable parts. Clearance from vent is

dependent upon the clearance rating of the venting material

used; type B-1 vent is approved for 1 inch clearance, B-2

vent for 2 inch, etc.

WALL STUDS

1”X4” SUPPORT BOARDS

Figure 2

Expansion and contraction of piping due to changing water

temperature in the pipes imparts movement to the heater

which, if mounted directly to a brittle, friable board, such as

plasterboard, can cause failure of mounting.

THIS APPLIANCE MUST BE INSTALLED IN ACCORDANCE WITH THE NATIONAL FUEL GAS CODE ANSI Z223.1/

NFPA 54 IN U.S.A OR CAN/CGA- B149 INSTALLATION CODES IN CANADA. LOCAL CODES AND/OR

REQUIREMENTS OF THE AUTHORITY HAVING JURISDICTION MUST BE FOLLOWED.

4

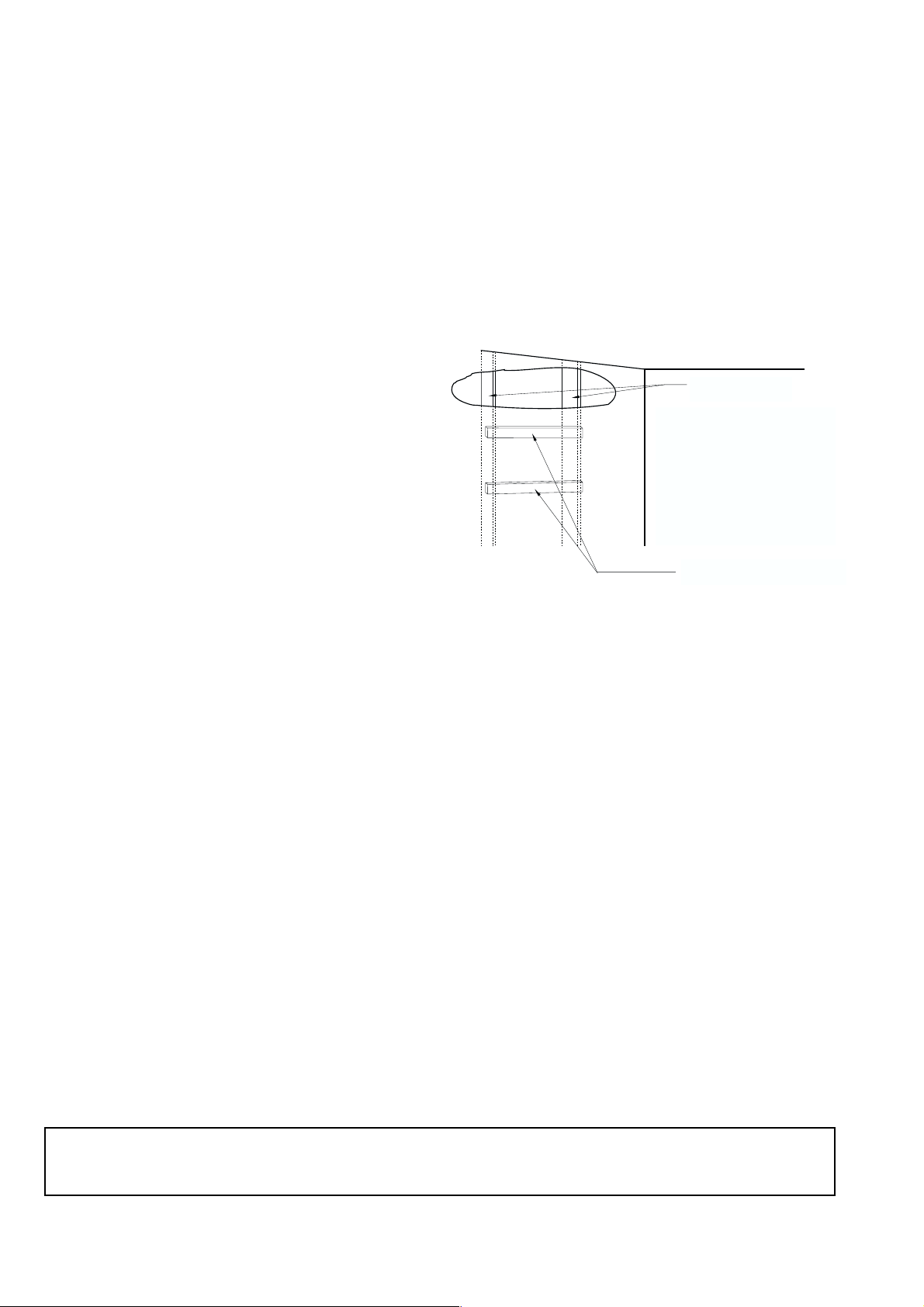

DRIP TRAY

If the water heater is being mounted above a floor of

combustible construction the drip tray ( shipped loose in

the carton with the water heater) must be attached to the

bottom of the front cover of the water heater at the time of

installation. The drip tray should be attached to the front

cover, using screws provided, as shown in Figure 3.

Failure to use drip tray when installing unit above a floor of

combustible construction will cause an unsafe condition and

possible fire and will be in violation of A.G.A. and C.G.A

certification of the unit.

For high altitude use the adaptor must be installed as shown

in Figure 4, without alteration, before connecting the six

inch flue to the unit. The adaptor must be secured to the

draft diverter outlet with a minimum of two screws.

Also, in Canada, the gas pressure regulator supplied with

the water heater is factory preset to deliver gas to the water

heater at the proper pressure setting for high altitude

operation, see PRESSURE REGULATION section of this

manual.

WARNING!

Failure to increase the vent size of the WR400-1 to six

inches and/or to assure that manifold pressure is set to proper

value listed on rating plate for applications at altitudes in

range of 2,000 to 4,500 ft. above sea level will cause unsafe

venting, asphyxiation, and voids C.G.A. Certification.

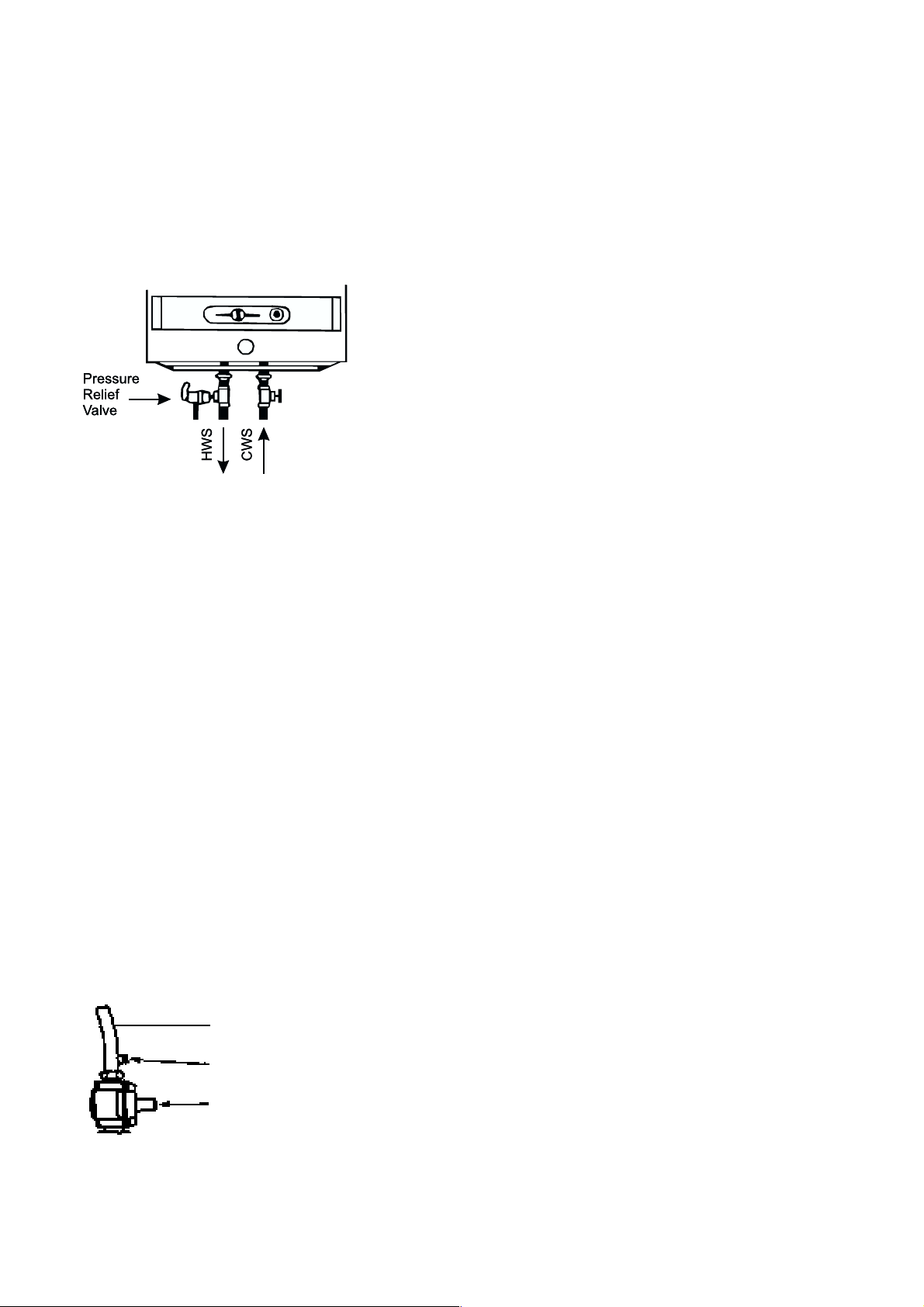

WATER CONNECTIONS

DRIP TRAY

Figure 3

VENTING

The BOSCH instantaneous water heaters have built-in draft

diverters and are designed for indoor installation only. The

draft diverter outlet must be connected to a clear,

unobstracted vent of the same size, or larger, refer to:

• In Canada, CAN/CGA- B149 Installation Codes for

detailed requirements.

• In U.S.A., ANSI Z223.1/NFPA 54, National Fuel Gas

Code for detailed requirements.

The flue connection for the WR400-1 is 130 mm (5 inches);

however, in Canada for installations at high altitude (2,0004,500 ft. above sea level) a six inch (6”) flue is required.

5” x 6” adaptor used

on high altitude model

WR 400 only

The BOSCH instantaneous water heaters are provided with

two S- bend water connectors/adaptors that must be

connected to inlet and outlet connections on water valve

assembly, see Figure 1 and Figure 5, below.

Water valve and S-bends, top view

Figure 5

The purpose of the S- bend water connectors/ adaptors is

to provide threaded water connections that meet standards

used in North America, ANSI Standard Taper Pipe Thread

(1/2 “ NPT). The cold water supply should be connected to

S- bend attached to inlet of water valve and the hot water

connection should be made to S- bend attached to the outlet

of water valve.

Figure 4

If plastic piping is to be used, a 1.5 meter (approx. 5 feet)

length of metal piping must be attached to both the cold

water inlet and hot water outleet of the water heater.

Note: A shut-off valve should be placed in the cold water

supply line to the heater to facilitate servicing the

heater.

5

RELIEF VALVE

The listed pressure relief valve supplied must be installed

near the hot water outlet at time of installation of the heater.

No valve is to be placed between the relief valve and the

heater. A drain line must be connected to the relief valve to

direct discharge to a safe location. Do not install reducing

coupling or any other restriction in the discharge line. The

discharge line must be installed so as to allow complete

drainage of both the valve and the line. See figure 6.

Figure 6

Check to make sure that the gas listed on the rating plate is

the same as the gas listed on the pressure regulator. See

PRESSURE REGULATION section of this manual for

information regarding gas pressure settings.

Note: Before attaching the gas supply line, be sure that all

gas pipe is clean on the inside. To trap any dirt or

foreign material in the gas supply line, a drip leg must

be readily accessible and not subject to freezing

conditions. Install in accordance with the

recommendations of the serving gas supplier.

Joint compounds (pipe dope) shall be applied sparingly and

only to the male threads of pipe joints. Do not apply

compound to the first two threads. The joint compound used

must be resistant to the action of liquified petroleum gases.

Before placing water heater in operation check for gas

leakage. Soap and water solution, or other material

acceptable for this purpose, shall be used in locating gas

leaks. Matches, candles, lighters, or other ignition sources

shall not be used for this purpose.

GAS CONNECTIONS

Before connecting the gas supply to the heater, check

heater’s model/rating plate to make sure that the gas on

which heater is to operate is the same as specified on the

model/rating plate.

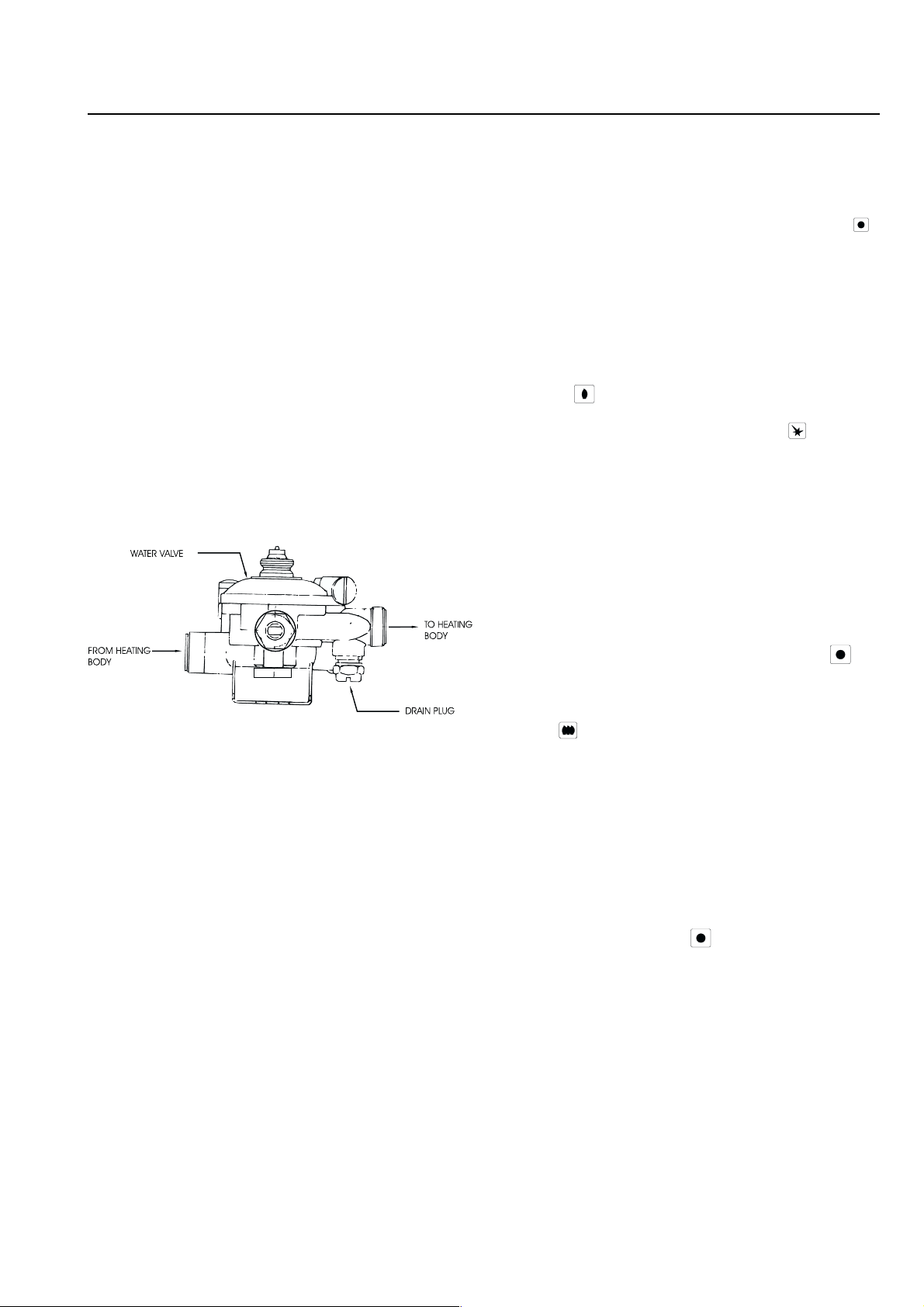

The WR400-1 instantaneous water heaters are supplied

with a gas pressure regulator that must be installed on the

heater before attaching the gas supply line. See figure 7.

Failure to install the gas pressure regulator as shown in

figure 7 will be a violation of A.G.A. and C.G.A. certification

of the unit.

BOSCH water heaters are shipped from the factory with

the gas pressure regulators preset for the gas shown on the

rating plate to the correct pressure:

• In Canada, for high altitude operation;

• In U.S.A., for standard altitude operation unless

specifically marked as a high altitude unit.

WARNING!

The heater and its individual shutoff valve must be

disconnected from the gas supply piping system during any

pressure testing of that system at test pressures in excess

of 3.45 kPa (1/2 psig).

The water heater must be isolated from the gas supply piping

system by closing its individual manual shutoff valve during

any pressure testing of the gas supply piping system at test

pressures equal to or less than 3.45 kPa (1/2 psig).

The water heater, including the pressure regulator provided

with in, must not be operated at gas supply pressures in

excess of 3.45 kPa (1/2 psig). If overpressure has occurred

such as through improper testing of the gas lines or

emergency malfunction of the supply system, the gas valve

and regulator must be checked for safe operation. Make

sure that the outside vent valves are protected against

blockage. These are part of the gas supply system, not the

water heater. Vent blockage may occur during ice storms.

Figure 7

6

GAS INLET PIPE

PRESSURE TAP

PRESSURE

REGULATOR

OPERATING INSTRUCTIONS

WARNING!

If the water heater has been damaged or exposed to fire or

sooting, or if any part has been underwater, do not use.

Immediately call a qualified service technician to inspect

the appliance and to replace any part of the control system

and any gas control which has been underwater and to clean

the heat exchanger assembly and water valve.

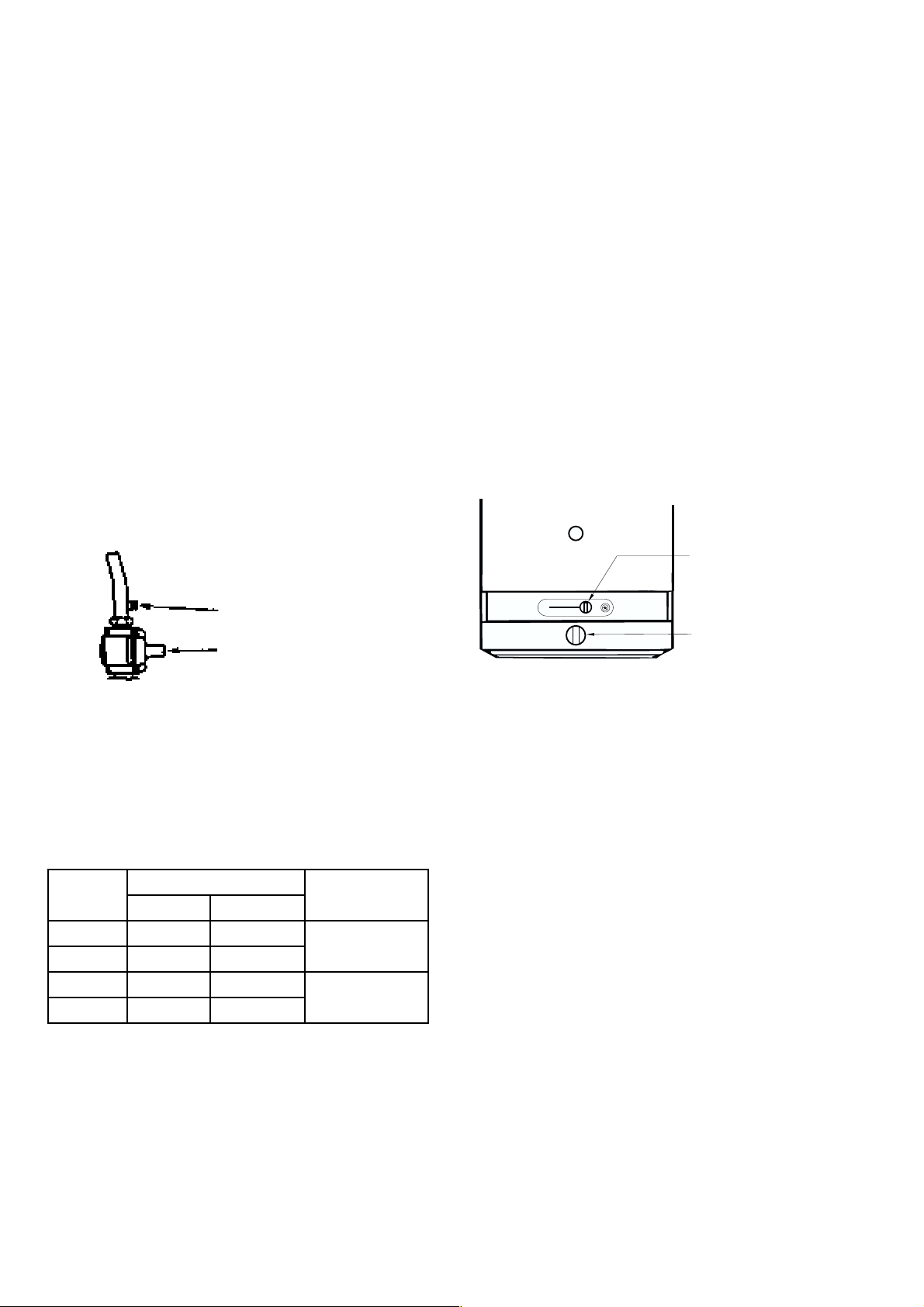

FILLING

Before proceeding with operation of the water heater make

sure that the system is filled with water:

• Make sure drain is closed. See figure 8, below.

• Open a nearby hot water faucet to permit the water to

fill the heater and piping.

• Close the hot water faucet after the water flows freely

and all air has escaped from the system.

The water heater is now ready to be lit.

LIGHTING INSTRUCTIONS

1. STOP! Read the safety information above on this plate.

2. The gas valve should be turned off by sliding the gas

valve button to the far left, under the “OFF” mark, .

3. Wait five (5) minutes to clear out any gas. If you then

smell gas, STOP! Follow “B” in the safety information

above on this plate. If you don’t smell gas, go to next

step.

4. The pilot burner is located behind the peephole located

in the front center of the jacket directly below this

instruction plate.

5. Slide the gas valve button to the right, under “PILOT”

MARK, .

6. Fully depress the gas valve button and light the pilot by

pressing the “PILOT IGNITER” button, . This may

have to be repeated.

7. Observe the pilot flame through the peephole. The gas

valve button should be held down at least 10 seconds

with pilot burning. When the gas valve button is released

the pilot should continue to burn:

• If the gas valve button does not pop up when released

stop and immediately call your service technician or

gas supplier.

• If the pilot does not stay lit, repeat steps 1 through 7.

• If the pilot will not stay lit after several tries, slide the

gas valve button to the left under the “OFF” mark and

call your service technician or gas supplier.

Figure 8

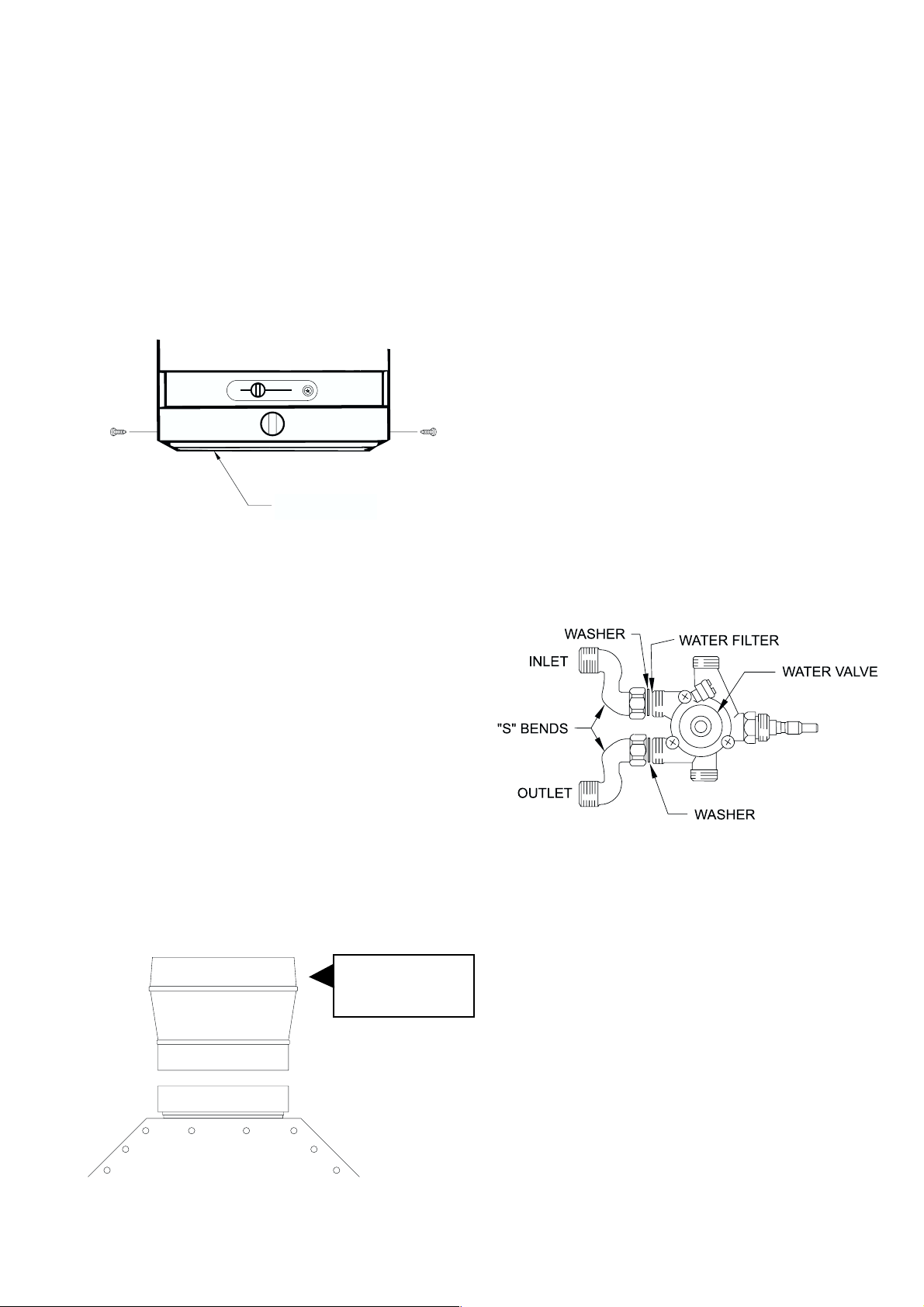

SERVICE HINT

The strainer (screen) in the water valve, located in the inlet

of the water valve, may require occasional cleaning due to

foreign material in the water supply. This will restrict the

flow of water and may effect heater operation and prolong

filling time. To inspect the strainer, close the cold water supply

valve ahead of the heater, disconnect the S- bend from the

inlet of the water valve and remove strainer from inlet. Clean

if required, replace strainer in inlet to the water valve,

reconnect S- bend and turn on water supply.

Light the water heater in accordance with the instructions

on the Lighting and Operating Plate on the water heater.

For your convenience, the instructions are repeated below:

8. Slide gas valve button to the far right, under the “ON”

mark . The heater will now fire when water is drawn

at a rate greater than the threshold flow rate (see

manual*).

Note: If main burner should fail to ignite, make sure pilot is

burning. If not, repeat lighting procedure steps 1 through 8.

TO TURN OFF GAS TO APPLIANCE

1. Slide the gas valve button to the far left, off position,

under the “OFF” mark, and close the heater’s

individual shutoff valve.

* = see TEMPERATURE REGULATION section.

7

PRESSURE REGULATION

The pressure regulator supplied with the water heater is

adjusted to operate on the gas specified on the rating plate,

and:

· In Canada, is factory preset to deliver gas at the high

altitude pressure setting listed on the rating plate and

as shown below;

· In the U.S.A., is factory preset to deliver gas at the

standard altitude setting listed on the rating plate and

as shown below.

The pressure setting of the gas pressure regulator should

be checked at installation to assure that the setting is correct

for the gas being used and the altitude at which the

appliance is installed. See rating plate of the unit, or Table

1, below, for proper setting.

In Canada, for a heater being installed at standard altitude

(0- 2,000 ft. above sea level), the manifold pressure should

be reset at installation to value shown on the rating plate, or

Table 1, below, for standard altitude.

Your appliance dealer and/or your local gas supplier should

be consulted in regard to any high altitude installation. If

filed adjustment is required it should be performed by a qualified serviceman experienced in such work.

TEMPERATURE REGULATION

The BOSCH WR400-1 is equipped with a modulating gas

valve which adjusts the flow of gas to the main burner in

proportion to the water flow rate. Within its heating capacity the WR400-1 attempts to maintain burner in proportion

to the water flow rate. Within its heating capacity the

WR400-1 attempts to maintain the set temperature rise

across the heater. This temperature rise can be set in range

of 25ºC –to- 50ºC (45º F – to – 90ºF), by means of the

water flow selector. See figure 10. With the gas control

button slid all the way to the right under the “ON” position

mark @ when the water flow selector is turned to the right

hand stop the water flow selector is turned to the right hand

stop the water heater is set for 50ºC (90ºF) temperature

rise; when the water flow selector is set to the left hand

stop it is set for 25ºC (45ºF) temperature rise.

PRESSURE TAP

PRESSURE

REGULATOR

Figure 9

The gas pressure specified below refer to flow pressure taken

at the pressure tap in the gas inlet pipe (just above the

pressure regulator), see figure 9 while the heater is operating

at full input.

Type Pressure tap Altitude

of gas kPa inches W.C.

Natural 1.41 5.7 standard

Propane 2.61 10.5 (0 - 2,000 ft)

Natural 1.14 4.6 high*

Propane 2.09 8.4 (2,000 - 4,500 ft)

* Note: The high altitude ratings listed are Canadien Gas

Association high altitude ratings for the appliances

and are only valid in Canada. In the U.S.A. the

National Fuel Gas Code, ANSI Z223.1/NFPA 54,

recommends for high altitude installations, above

2,000 feet, that the input rate be reduced 4% for

each 1,000 feet above sea level.

GAS CONTROL

SLIDE

WATER FLOW

SELECTOR

Figure 10

With the water flow selector turned to its right hand stop

position (50ºC rise setting) and with an inlet water

temperature of 10ºC (50ºF) the outlet water temperature

will be maintained at approximately 60ºC (140ºF) in the water

flow rate range of approximately 2 litres/min. (0.5 U.S.gals/

min) to 8 litres /min. (2.1 U.S. gals/min.).

The minimum flow rate for operation, the “Threshold Flow

Rate” referred to in the lighting instructions is 2 litres/min

(0.5 U.S. gals./min). If the water flow rate is below this level

the main burner will not fire. If the flow rate excess 8 litres/

min (2.1 U.S. gals/min.) the temperature rise across the heater

will decrease in proportion to the rate above this temperature.

HIGH TEMPERATURE LIMIT SWITCH

The BOSCH WR series instantaneous gas water heaters

are equipped with a high temperature limit switch with a set

point of approximately 90ºC (194ºF). If the water temperature

at the sensing points exceeds the set point the switch will

open, interrupting the safety circuit and stopping gas flow

to the pilot and main burner.

Outage as the result of high limit operation indicates that

the heater is not functioning properly. The heater should be

checked by a qualified serviceman and the reason for the

malfunction is corrected. To relight the pilot, follow

instructions provided on the unit.

8

Loading...

Loading...