Bosch UT-L 14, UT-L 8, UT-L 4, UT-L 18, UT-L 12 Technical Manual

...

Technical guide

Heating boiler

UNIMAT

UT-L

6 720 807 794(2013/04)EN

2 | Table of contents

UNIMAT6 720 807 794 (2013/04)

Table of contents

1 Oil/gas special boilers . . . . . . . . . . . . . . . . . . . . . 4

1.1 Types and heating output . . . . . . . . . . . . . . 4

1.2 Overview of models . . . . . . . . . . . . . . . . . . 4

1.3 Possible applications . . . . . . . . . . . . . . . . . 4

1.4 Features and benefits . . . . . . . . . . . . . . . . . 4

2 Basic principles . . . . . . . . . . . . . . . . . . . . . . . . . . 5

2.1 Basic principles of condensing technology . 5

2.1.1 Net and gross calorific values . . . . . . . . . . . 5

2.1.2 Boiler efficiency above 100 % . . . . . . . . . . . 5

2.2 Making optimal use of condensing

technology . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2.1 Matching to the heating system . . . . . . . . . 6

2.2.2 High standard seasonal efficiency [to DIN] 7

2.2.3 Design information . . . . . . . . . . . . . . . . . . . 7

2.3 Economic viability considerations . . . . . . . 7

2.3.1 Simplified comparison of conventional

boilers and condensing boilers or boilers

with condensing heat exchangers . . . . . . . 7

3 Technical description . . . . . . . . . . . . . . . . . . . . . . 8

3.1 UNIMAT UT-L boiler . . . . . . . . . . . . . . . . . . . 8

3.1.1 Equipment overview . . . . . . . . . . . . . . . . . . 8

3.1.2 Function principle . . . . . . . . . . . . . . . . . . . . 9

3.2 UNIMAT UT-L boiler . . . . . . . . . . . . . . . . . . 10

3.2.1 Version overview . . . . . . . . . . . . . . . . . . . . 10

3.2.2 Function principle . . . . . . . . . . . . . . . . . . . 11

3.3 Dimensions and specification for the

flue gas heat exchangers . . . . . . . . . . . . . 12

3.3.1 UNIMAT UT-L boiler . . . . . . . . . . . . . . . . . . 12

3.3.2 Integrated heat exchanger without

condensing technology — ECO 7 . . . . . . . 14

3.3.3 Integrated heat exchanger with

condensing technology — ECO6 . . . . . . . . 16

3.3.4 Stand-alone flue gas heat exchanger

without condensing technology — ECO 7 . 18

3.3.5 Stand-alone flue gas heat exchanger

with condensing technology — ECO 6 . . . 20

3.4 Connections . . . . . . . . . . . . . . . . . . . . . . . 22

3.4.1 Flow and return . . . . . . . . . . . . . . . . . . . . 22

3.4.2 Flue outlet connection . . . . . . . . . . . . . . . 22

3.4.3 Connector . . . . . . . . . . . . . . . . . . . . . . . . . 23

3.5 Characteristics . . . . . . . . . . . . . . . . . . . . . 24

3.5.1 Pressure loss on the water side . . . . . . . . 24

3.5.2 Pressure loss on the hot gas side . . . . . . . 25

3.5.3 Combustion chamber volume load . . . . . . 27

3.5.4 Boiler efficiency, standard seasonal

efficiency [to DIN] and standby loss . . . . 28

3.5.5 Flue gas temperature . . . . . . . . . . . . . . . . 30

4 Burner . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

4.1 General requirements . . . . . . . . . . . . . . . . 32

4.2 Information on burner selection . . . . . . . . 32

4.3 Matched pressure-jet burners . . . . . . . . . 32

4.4 Combustion details for the UNIMAT UT-L

boilers . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

5 Regulations and operating conditions . . . . . . . 35

5.1 Extracts from the regulations . . . . . . . . . 35

5.2 German Immissions Act (BImSchG) . . . . 36

5.2.1 Table extracted from the 1st BImSchV

“Small and medium-sized combustion

systems” . . . . . . . . . . . . . . . . . . . . . . . . . . 36

5.2.2 Information on flue gas tests pursuant to

BImSchV/TA Luft . . . . . . . . . . . . . . . . . . . 37

5.3 Operating requirements . . . . . . . . . . . . . 38

5.3.1 Operating conditions . . . . . . . . . . . . . . . . 38

5.3.2 Fuel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

5.3.3 Corrosion protection in heating systems 38

5.3.4 Corrosion protection if system out of

use for long periods . . . . . . . . . . . . . . . . . 39

5.3.5 Guidelines for water quality . . . . . . . . . . 39

5.3.6 Minimum requirements of water analyses

for designing a water treatment system . . 41

6 Sound pressure level from noise in the boiler

system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

6.1 Sound emissions from the boiler system 42

6.2 Noise in the installation room . . . . . . . . . 42

6.3 Noise at the chimney outlet . . . . . . . . . . 42

7 Boiler control and control system . . . . . . . . . . 43

7.1 CFB 810 control unit with CME 930

auxiliary module . . . . . . . . . . . . . . . . . . . . 43

7.2 CFB 930 and CFB 910 control units . . . . 44

7.3 Side control unit holder . . . . . . . . . . . . . 45

7.4 UNIMATIC display units and control units 46

7.5 BCO boiler control . . . . . . . . . . . . . . . . . 46

8 DHW heating . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

8.1 Systems for DHW heating . . . . . . . . . . . . 47

8.2 DHW temperature control . . . . . . . . . . . . 47

9 System examples . . . . . . . . . . . . . . . . . . . . . . . 47

9.1 Information regarding all system

examples . . . . . . . . . . . . . . . . . . . . . . . . . 47

9.1.1 Hydraulic connection . . . . . . . . . . . . . . . . 48

9.1.2 Control system . . . . . . . . . . . . . . . . . . . . 48

9.1.3 DHW heating . . . . . . . . . . . . . . . . . . . . . . 48

9.1.4 Pipework schemes . . . . . . . . . . . . . . . . . 49

9.2 Safety equipment to DIN-EN 12828 . . . . 52

9.2.1 Requirements . . . . . . . . . . . . . . . . . . . . . 52

9.2.2 Layout of safety components to DIN-EN

12828 . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

9.2.3 Safety equipment for the flue gas heat

exchanger . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.2.4 Maximum operating flow temperatures . 53

9.3 Sizing and installation information . . . . . 53

Table of contents | 3

6 720 807 794 (2013/04)UNIMAT

9.3.1 Boiler circuit pump in the bypass as shunt

pump . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

9.3.2 Boiler circuit pump as primary circuit pump .

55

9.3.3 Hydraulic balancing line . . . . . . . . . . . . . 56

9.4 1-boiler system with UNIMAT UT-L boiler:

boiler and heating circuit control unit . . .57

9.5 1-boiler system with UNIMAT UT-Lboiler:

boiler and heating circuit control unit

with hydraulic separation . . . . . . . . . . . . . 58

9.6 1-boiler system with UNIMAT UT-L boiler:

boiler circuit control unit . . . . . . . . . . . . . 59

9.7 1-boiler system with UNIMAT UT-L boiler:

boiler circuit control unit with hydraulic

separation . . . . . . . . . . . . . . . . . . . . . . . . 60

9.8 2-boiler system with two UNIMAT UT-L

boilers: boiler circuit control unit with

hydraulic separation . . . . . . . . . . . . . . . . . 61

9.9 1-boiler system with UNIMAT UT-L boiler

with flue gas heat exchanger: boiler circuit

control unit . . . . . . . . . . . . . . . . . . . . . . . .62

9.10 1-boiler system with UNIMAT UT-L boiler

with condensing heat exchanger: boiler

circuit control unit with hydraulic

separation . . . . . . . . . . . . . . . . . . . . . . . . 63

9.11 2-boiler system with UNIMAT UT-L boiler

without flue gas heat exchanger and UT-L

boiler with condensing heat exchanger:

boiler circuit control unit with hydraulic

separation . . . . . . . . . . . . . . . . . . . . . . . . 64

9.12 UNIMAT UT-L boiler with flue gas heat

exchanger or condensing heat exchanger:

return temperature raising . . . . . . . . . . . . 65

10 Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

10.1 Transport and handling . . . . . . . . . . . . . . 66

10.1.1 Delivery method and transport options . . 66

10.1.2 Handling dimensions . . . . . . . . . . . . . . . . 66

10.2 Design of installation rooms and

combustion air supply . . . . . . . . . . . . . . . 67

10.2.1 Installation location . . . . . . . . . . . . . . . . . 67

10.2.2 Combustion air supply . . . . . . . . . . . . . . 67

10.3 Installation dimensions . . . . . . . . . . . . . . 69

10.3.1 Installation room dimensions for the

UNIMAT UT-L boilers . . . . . . . . . . . . . . . . 69

10.3.2 Installation room dimensions for the

UNIMAT UT-L boilers with flue gas heat

exchanger . . . . . . . . . . . . . . . . . . . . . . . . . 70

10.4 Additional safety equipment to

DIN-EN 12828 . . . . . . . . . . . . . . . . . . . . . . 71

10.4.1 Safety equipment . . . . . . . . . . . . . . . . . . 71

10.4.2 Boiler safety equipment assembly to

DIN-EN 12828 . . . . . . . . . . . . . . . . . . . . . . 71

10.4.3 Intermediate return piece . . . . . . . . . . . . 72

10.4.4 Safety valve . . . . . . . . . . . . . . . . . . . . . . . 73

10.4.5 Flash trap to DIN-EN 12828 . . . . . . . . . . . 75

10.4.6 Return flow temperature safeguard

set (maintaining version) . . . . . . . . . . . . . 76

10.5 Additional devices for sound insulation . . 77

10.5.1 Requirements . . . . . . . . . . . . . . . . . . . . . . 77

10.5.2 Flue gas silencer . . . . . . . . . . . . . . . . . . . 77

10.5.3 Burner silencer hoods . . . . . . . . . . . . . . . 77

10.5.4 Boiler mounts to attenuate structure-

borne noise . . . . . . . . . . . . . . . . . . . . . . . 77

10.5.5 Boiler foundation . . . . . . . . . . . . . . . . . . . 78

10.6 Further accessories . . . . . . . . . . . . . . . . . 79

10.6.1 Drain connection and blow-down valve

assembly . . . . . . . . . . . . . . . . . . . . . . . . . 79

10.6.2 Walk-on boiler cover . . . . . . . . . . . . . . . . 79

11 Flue system . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

11.1 Requirements . . . . . . . . . . . . . . . . . . . . . . 81

11.1.1 General notes . . . . . . . . . . . . . . . . . . . . . . 81

11.1.2 Special information for flue systems of

boilers with condensing flue gas heat

exchangers . . . . . . . . . . . . . . . . . . . . . . . 81

11.1.3 Material requirements for flue systems of

boilers with condensing heat exchangers 81

12 Condensate drain . . . . . . . . . . . . . . . . . . . . . . . 82

12.1 Condensate . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.1 Creation . . . . . . . . . . . . . . . . . . . . . . . . . . 82

12.1.2 Condensate disposal . . . . . . . . . . . . . . . . 82

12.2 Neutralising system NE 2.0 . . . . . . . . . . . 82

12.2.1 Installation . . . . . . . . . . . . . . . . . . . . . . . . 82

12.2.2 Equipment level . . . . . . . . . . . . . . . . . . . . 82

12.2.3 Neutralising agent . . . . . . . . . . . . . . . . . . 82

12.2.4 Pump output graph . . . . . . . . . . . . . . . . . 82

Keyword index . . . . . . . . . . . . . . . . . . . . . . . . . . 84

4 | Oil/gas special boilers

UNIMAT6 720 807 794 (2013/04)

1 Oil/gas special boilers

1.1 Types and heating output

The UNIMAT UT-L boilers are special boilers for positive

pressure combustion in accordance with the

requirements of EN 303. They are constructed with

reference to the guidelines of the relevant TRD 300.

Bosch offers these boilers in the output range from

650 kW to 19200 kW.

The boilers are designed to produce low pressure hot

water with no more than 110 °C (shutdown temperature

of the high limit safety cut-out) for heating systems that

correspond to the requirements of DIN-EN 12828. The

boiler is available with excess pressures of 6 bar, 10 bar

and 16 bar.

1.2 Overview of models

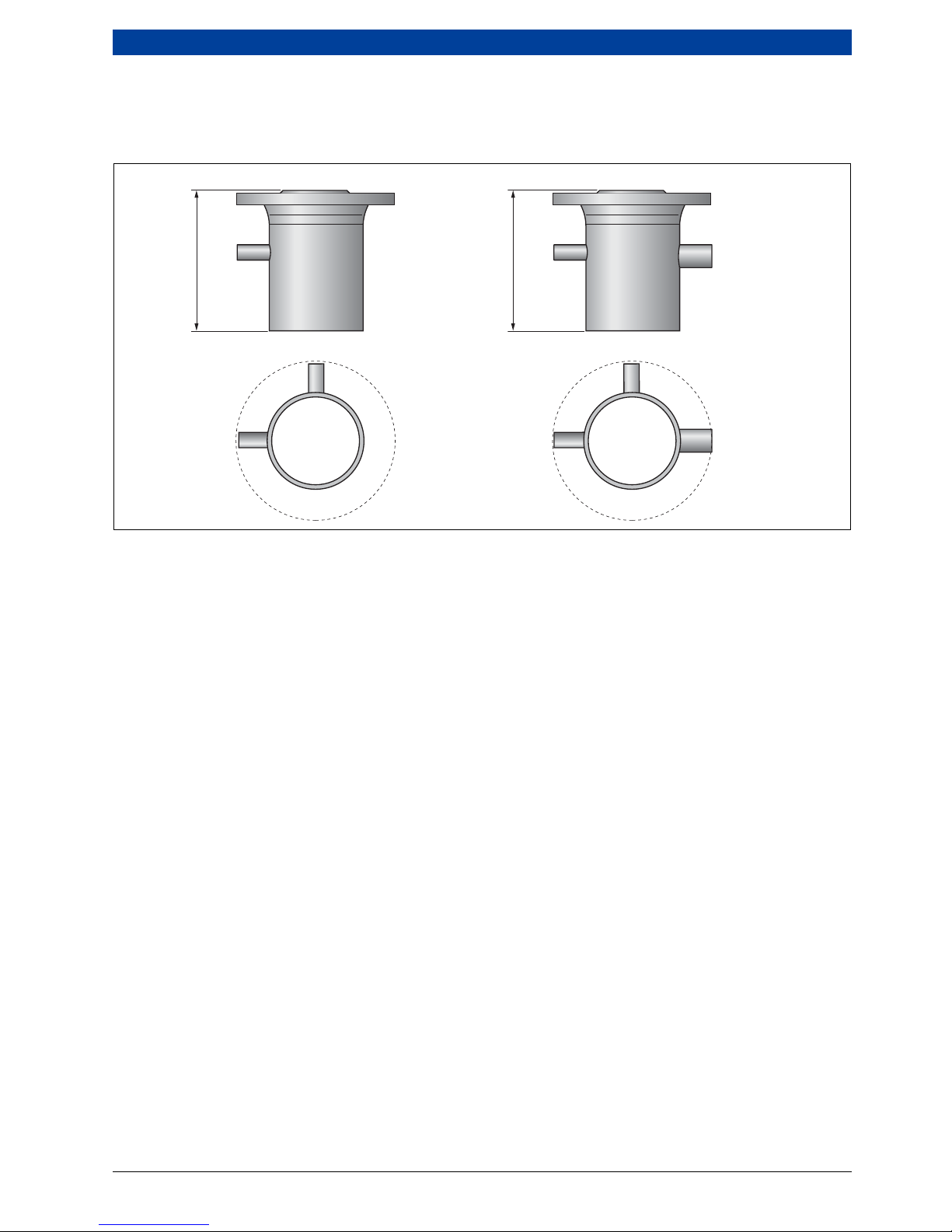

Fig. 1 UNIMAT UT-L boiler without heat exchanger

Fig. 2 UNIMAT UT-L boiler with heat exchanger or

condensing heat exchanger

1.3 Possible applications

The modular design and additional equipment mean the

boiler can be used in any application. A suitable version

is available for the requirements of any project.

The optimum application is in large-scale systems, e.g.

hospitals, industrial plants, district heating centres,

heating stations and commercial operations.

1.4 Features and benefits

• 3-pass design

The 3-pass technology enables the UNIMAT UT-L

boilers to achieve outstanding combustion figures.

• Optimised temperature characteristics

The boilers have a generously sized secondary heating

surface in the second pass, designed as a double row.

The inner hot gas reversing chamber, which is

completely surrounded by water, enables very low

temperatures in the front reversing area from the

second to the third pass. This significantly reduces

the thermal load of the door.

• Compact construction

The symmetrical secondary heating surfaces,

arranged in a circle around the combustion chamber,

enable the compact construction of these boilers.

This means they have a low weight and require only a

small floor area for installation. The burner door can

close on the right hand or left hand side.

• Environmentally responsible with low emissions

The 3-pass design and water-cooled combustion

chamber offer ideal conditions for operation with low

emissions, especially in conjunction with the

advanced burners that are matched to the boilers.

Meeting the highest demands regarding low

emissions, especially with oil combustion, is no

problem for the UNIMAT UT-L boiler with its

particularly large combustion chambers.

• Economic viability

Extremely high efficiency is possible, subject to the

temperature of the heating medium and the boiler

load. The radiation losses of the boiler are negligibly

low and the full utilisation of the burner control range

enables good efficiency at partial load.

• Operational reliability

Due to the optimised design of the combustion

chamber and the water guide system, the UNIMAT UTL boiler is very reliable and safe in operation. The low

water capacity enables a short heat-up time. This

means the dew point range in the heat-up phase is

quickly passed.

• Even load distribution

For even load distribution, the boiler is equipped with

a base frame of channel sections. If the floor of the

boiler room is even, an additional boiler foundation is

not required.

• Simple maintenance

The front boiler door can be pivoted right out, and can

be opened easily even when the burner is fitted. When

the door is open, the combustion chamber and

secondary heating surface are freely accessible, and

can be cleaned quickly and easily. The reversing

chamber is visible through the combustion chamber.

As an option, an inspection port on the water side is

available. This gives a better view of the heating

Unit UNIMAT UT-L boiler

Boiler size 650 to

19200

Safety temperature °C ≤ 110

Safety pressure bar ≤ 16

Measurements page 12 f.

Technical Data page 25

Table 1 Overview of UNIMAT boiler models UT-L

6 720 642 347-82.1il

6 720 642 347-83.1il

Basic principles | 5

6 720 807 794 (2013/04)UNIMAT

surfaces. It means the heating surfaces can be viewed

from the water chamber.

• Matching system technology

Numerous matching components are available for all

boilers, which enable optimisation of the entire

system.

2 Basic principles

2.1 Basic principles of condensing

technology

2.1.1 Net and gross calorific values

The net calorific value Hi (formerly Hu) specifies the

amount of heat that can be obtained from one cubic

metre of gas or one kilogram of fuel oil. With this

reference figure, the products of combustion are

present in a gaseous state.

Compared to the net calorific value Hi, the gross calorific

value H

s

(formerly Ho) also contains the condensation

heat from the water vapour as additional energy.

2.1.2 Boiler efficiency above 100 %

The condensing boiler or boiler with condensing heat

exchanger utilises not only the net calorific value H

i

in

order to produce heat, but also the gross calorific value

H

s

of a fuel.

For all efficiency calculations in German and European

standards, the net calorific value Hi is always selected at

100 % as a reference figure, meaning that a boiler

efficiency of over 100 % can result. This is the only way

of comparing conventional boilers and condensing

boilers or boilers with condensing heat exchangers.

Boiler efficiency can be raised by up to 15 % in

comparison with conventional boilers. Compared with

older systems, it is even possible to save up to 40 %

energy.

When comparing the energy utilisation of conventional

boilers and condensing boilers or boilers with

condensing heat exchangers, an energy statement such

as the example shown in Fig. 3 can result.

Condensation heat (latent heat)

• The proportion of condensation heat in natural gas is

approx. 11 %, relative to the net calorific value H

i

.

With low-sulphur fuel oil, the proportion of

condensation heat is approx. 7 %, relative to the net

calorific value H

i

.

This heat is unused in conventional boilers.

• By making use of the condensation in the water

vapour, the condensing boiler or boiler with

condensing heat exchanger enables considerable

utilisation of this heat potential.

Flue loss (sensible heat)

• With the conventional boiler, the heat in the flue gas,

which is at a relatively high temperature of 150 °C to

210 °C, escapes. This means an unused heat

proportion of around 6 % to 9 % is lost.

• The dramatic reduction of the flue gas temperatures

in a condensing boiler or boiler with condensing heat

exchanger down to 30 °C makes use of the sensible

heat in the hot gas and considerably reduces the flue

loss.

Energy statement comparing conventional boilers and

condensing boilers or boilers with condensing heat

exchangers

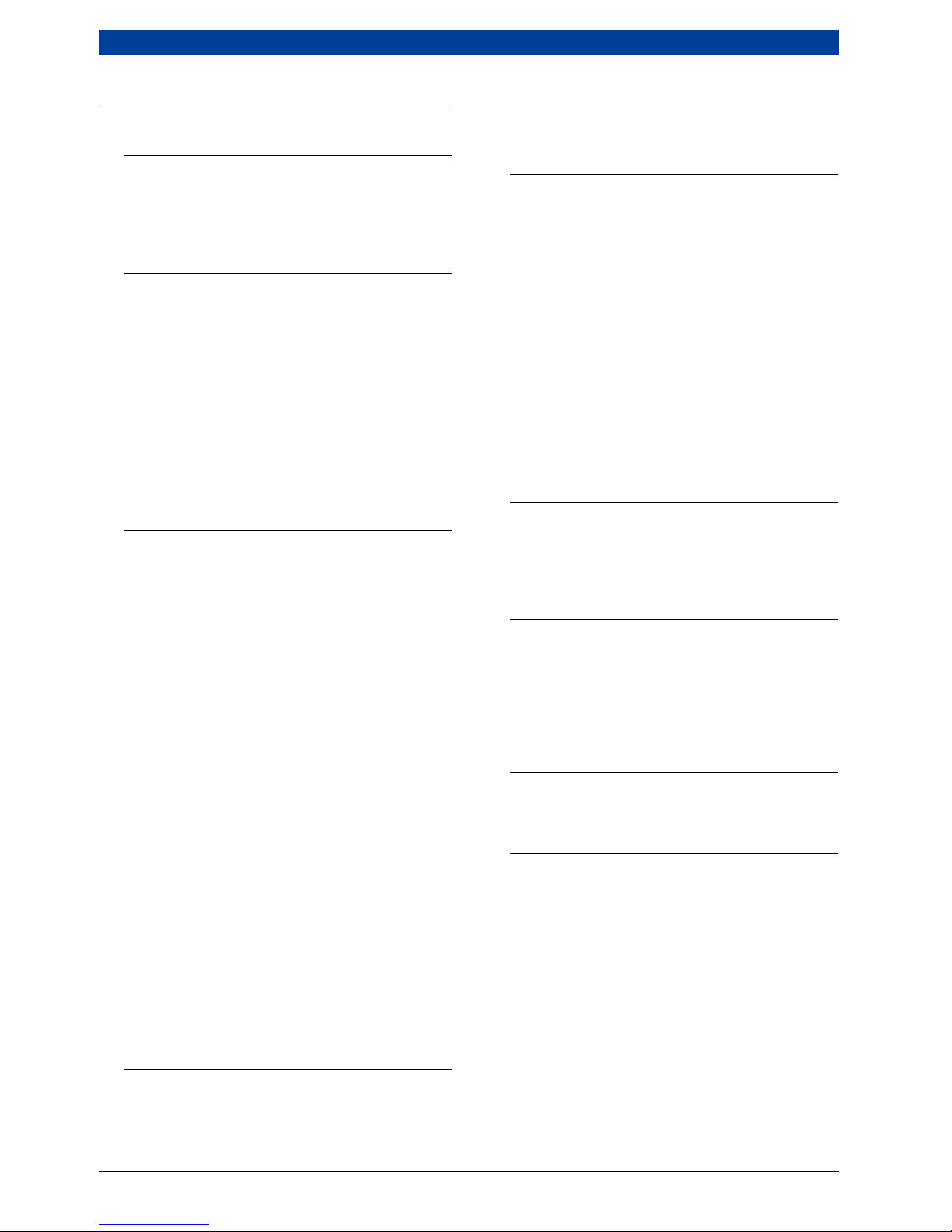

Fig. 3 Energy statement comparing conventional boilers

and condensing boilers or boilers with

condensing heat exchangers (example with

natural gas)

Conventional boiler

Condensing boiler or boiler with condensing

heat exchanger

η

K

Boiler efficiency

q

A

Flue losses (sensible heat)

q

L

Unused condensation heat (latent

heat)

q

S

Radiation losses

1)

Relative to net calorific value Hi= 100 %

qL = 11 %

q

A

= 5,9 %

q

S

= 0,1 %

q

L

= 1,5 %

q

A

= 1 %

q

S

= 0,5 %

6 720 642 347-75.1il

ηK = 94 %

111 %

1)

111 %

1)

ηK = 108 %

6 | Basic principles

UNIMAT6 720 807 794 (2013/04)

2.2 Making optimal use of condensing

technology

2.2.1 Matching to the heating system

Condensing boilers or boilers with condensing heat

exchangers can be installed in any heating system.

However, the available proportion of condensation heat

and the efficiency resulting from this type of operating

mode depend on the design of the heating system.

To be able to use the condensation heat of the water

vapour in the hot gas, the hot gas must be cooled to

below the dew point. The utilisation rate of the

condensation heat is therefore necessarily subject to the

system design temperatures and the hours run in the

condensation range. This is shown by the graphs in

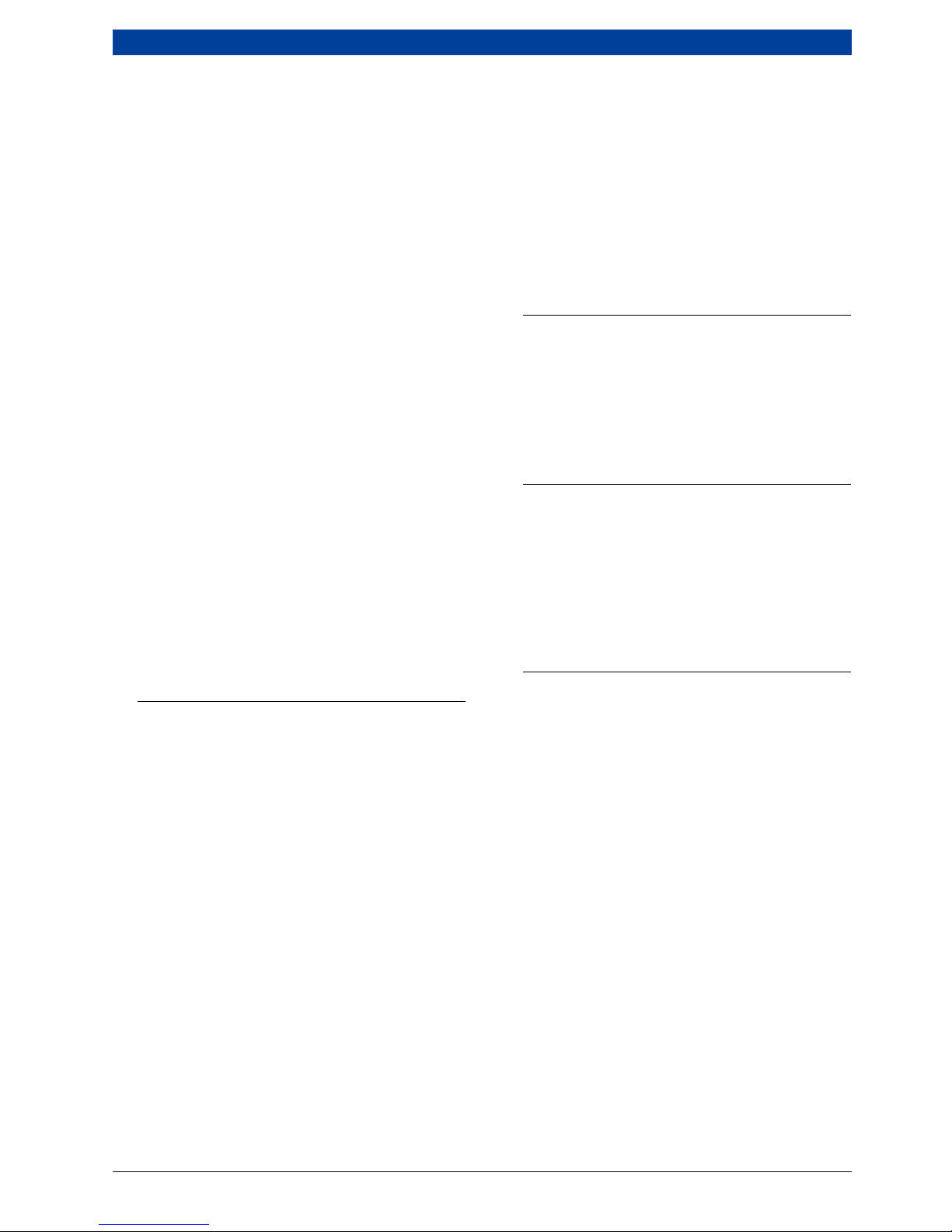

Fig. 4 and Fig. 5. The dew point is approx. 56° C for

natural gas and approx. 47° C for low-sulphur fuel oil.

Heating system 40/30 °C

In this heating system, the benefits of the performance

capacity of condensing technology can be seen

throughout the heating season. The low return

temperatures are always below the dew point, so

condensation heat is always created ( Fig. 4). This is

achieved with low temperature area heaters or

underfloor heating systems, which are ideal for

condensing boilers or boilers with condensing heat

exchangers.

Targeted utilisation of the condensing effect is possible

with the condensing heat exchanger (ECO 6) connected

separately to a low temperature heating circuit.

Fig. 4 Condensation heat utilisation at 40/30 °C

(example with natural gas)

A Proportion of operation with condensation heat

utilisation

a Annual heat load curve

b Dew point temperature curve (example with

natural gas)

c System temperatures

ϑ

A

Outside temperature

ϑ

HW

Heating water temperature

WHaAnnual heat load

Heating system 75/60 °C

Even with a design temperature of 75/60 °C, it is

possible to make above average utilisation of the

condensation heat for around 95 % of the annual heat

load. This applies for outside temperatures of –7 °C to

+20 °C ( Fig. 5).

Due to the safety supplements in the former DIN 4701

from 1959, older heating systems designed with 90/

70 °C are nowadays to all intents and purposes operated

as systems with 75/60 °C. Even if these systems were

run with system temperatures of 90/70 °C and

modulating, weather-compensated heating circuit

temperatures, they would still use the condensation

heat for 80 % of the annual heating load.

Fig. 5 Condensation heat utilisation at 75/60 °C

(example with natural gas)

A Proportion of operation with condensation heat

utilisation

a Annual heat load curve

b Dew point temperature curve

c System temperatures

ϑ

A

Outside temperature

ϑ

HW

Heating water temperature

W

Ha

Annual heat load

WHa [%]

– 15 – 10 – 5 5 10

6 720 803 977-30.1itl

15 20± 0

100

80

60

40

20

0

100

80

60

40

20

0

56

a

b

c

A

– 15 – 10 – 5 5 10 15 20± 0

100

80

60

40

20

0

56

80

60

40

20

0

95

W

Ha

[%]

6 720 803 977-31.1itl

a

b

c

A

Basic principles | 7

6 720 807 794 (2013/04)UNIMAT

2.2.2 High standard seasonal efficiency [to DIN]

The graphs in Fig. 4 and Fig. 5 show that the varying

proportion of condensation heat utilisation has a direct

influence on the energy utilisation of the condensing

boiler or boiler with condensing heat exchanger.

The high standard seasonal efficiency [to DIN] of gas

condensing boilers is based on the following influences:

• Achievement of high CO

2

levels. The higher the CO2

content, the higher the dew point of the hot gases.

• Lower system and return temperatures can be

maintained. The lower the system and return

temperatures, the higher the condensation rate and

the lower the flue gas temperature.

The UNIMAT UT-L boilers can be matched individually

to the prevailing system characteristics and

requirements, subject to the individual project.

2.2.3 Design information

In new installations, every opportunity should be

exploited to achieve optimum operation of the

condensing boiler or boiler with condensing heat

exchanger.

A high standard seasonal efficiency [to DIN] is achieved

if the following criteria are satisfied:

• Limit the return temperature upstream of the

condensing heat exchanger to a maximum of 50 °C, at

least partially. In this connection, it is significant that

the separate connections for the boiler and

condensing heat exchanger mean a partial flow rate of

20 % with a low design temperature (e.g. 40/30 °C) is

sufficient to achieve excellent condensing efficiency.

• Aim for a temperature spread between the flow and

return of at least 20 K.

• Avoid installations for return temperature raising (e.g.

4-way mixers, bypass circuits, low loss headers,

depressurised distributors, etc.).

For more detailed information on the hydraulic

connection, see chapter 9 on page 47 ff.

2.3 Economic viability considerations

2.3.1 Simplified comparison of conventional boilers

and condensing boilers or boilers with

condensing heat exchangers

Fuel costs

•Given

– Building heat demand QN= 2000 kW

– Annual heating energy demand Q

A

=

3400000 kWh/a

– System design temperatures:

Ventilation ϑV/ϑR= 90/70 °C (proportion 20 %)

Radiators ϑV/ϑR= 75/60 °C (proportion 50 %)

Underfloor heating system ϑ

V/ϑR

= 40/30 °C

(proportion 30 %)

– Fuel costs K

B

=0.50Euro/m

3

– Conventional UNIMAT UT-L boiler, rated output

2000 kW, η

N

= 94,9 %

–UNIMATUT-L boiler with condensing heat

exchanger, rated output 2000 kW, η

N

= 102,3 %

The efficiency levels η

N

specified for the UNIMAT UT-L

boiler with condensing heat exchanger apply if the

underfloor heating systems are connected separately to

the condensing heat exchanger.

•Sought

– Fuel consumption

– Fuel costs

•Calculation

F. 1 Calculation of annual fuel consumption

B

V

Annual fuel consumption in m3/a

ηNStandard seasonal efficiency [to DIN] in %

H

i

Net calorific value; here natural gas simplified with

10 kWh/m

3

QANet heating energy demand in kWh/a

F. 2 Calculation of annual fuel costs

B

V

Annual fuel consumption in m3/a

KBFuel costs

KBaAnnual fuel costs

• Result

– UNIMAT UT-L boiler with rated output of 2000 kW:

Fuel consumption B

V

= 358272 m3/a,

Fuel costs KBa = 179136 Euro/a

– UNIMAT UT-L boiler with condensing heat

exchanger, with rated output of 2000 kW:

Fuel consumption BV = 332356 m3/a,

Fuel costs KBa = 166178 Euro/a

Central heating using the UNIMAT UT-L boiler with

condensing heat exchanger results in fuel cost savings of

approx. 11601 Euro per year.

B

V

Q

A

η

NHi

×

-----------------------

=

K

BaBVKB

×=

8 | Technical description

UNIMAT6 720 807 794 (2013/04)

Investment costs

The investment costs are based on the costs of a boiler

system. This includes the costs of the boiler, boiler

circuit control unit, pressure-jet burner and flue system,

as well as the costs of the safety equipment and return

flow temperature safeguard. The costs of the UNIMAT

UT-L boiler with condensing heat exchanger also include

the neutralisation of the condensate. Costs for

installation have not been taken into account.

Reflux of capital

In this example, the investment costs have been repaid

due to the lower fuel costs after about one year. It is

generally true that condensing technology pays for itself

faster the greater the output and the higher the fuel

costs. No subsidies have been taken into account in the

calculations. With the UNIMAT UT-L boilers, it is possible

to integrate further condensing heat exchangers. This

results in higher efficiency and therefore lower fuel

costs.

3 Technical description

3.1 UNIMAT UT-L boiler

3.1.1 Equipment overview

The UNIMAT UT-L boilers are oil/gas special boilers for

positive pressure combustion to EN 303. These boilers

are designed to produce low pressure hot water with no

more than 110 °C (shutdown temperature of the high

limit safety cut-out) for heating systems that correspond

to the demands of DIN-EN 12828. The permissible

overall pressure must not exceed the permissible

pressure stage of the boiler. The modular design of the

boiler and additional equipment enables universal

application.

• Round boiler casing made of textured aluminium

sheeting

• Visible parts of the boiler primed in anthracite grey

and red

• Thermal insulation (100 mm) and extremely well

insulated burner door

• Boiler pressure body with connections for flow,

return, safety valve and drain

• As an option with inspection port on the water side

• Bottom rear inspection aperture on flue gas collector

• Boiler base frame for even load distribution and easy

transportation

• Large burner door closing on the left hand side

(can be changed to the right hand side if required)

• Air-cooled combustion chamber sight glass

The following options are possible:

• Control unit holder

• Also available as a unit version (with boiler and

burner)

• Heat exchanger as integrated or stand-alone version

with and without the use of condensing technology

Scope of

investment

1)

1) Incl. accessories

Unit UNIMAT UT-L

boiler with a

rated output

of

2000 kW

UNIMAT UT-

L boiler with

condensing

heat

exchanger

with a rated

output of

2000 kW

Total

investment

costs

Euro 50000 63000

Table 2 Investment costs for conventional boilers and

boilers with condensing heat exchangers (values

rounded off)

Type of cost Unit

UNIMAT

UT-L boiler

with a rated

output of

2000 kW

UNIMAT UT-

L boiler with

condensing

heat

exchanger

with a rated

output of

2000 kW

Investment costs Euro 50000 63000

Costs linked to

capital

1)

1) Annuity 9,44 %, interest 5 %, maintenance 1 %

Euro/a 5220 6577

Fuel costs Euro/a 179136 166178

Total costs Euro/a 184356 172755

Table 3 Total costs for conventional boilers and boilers

with condensing heat exchangers (values rounded

off)

Technical description | 9

6 720 807 794 (2013/04)UNIMAT

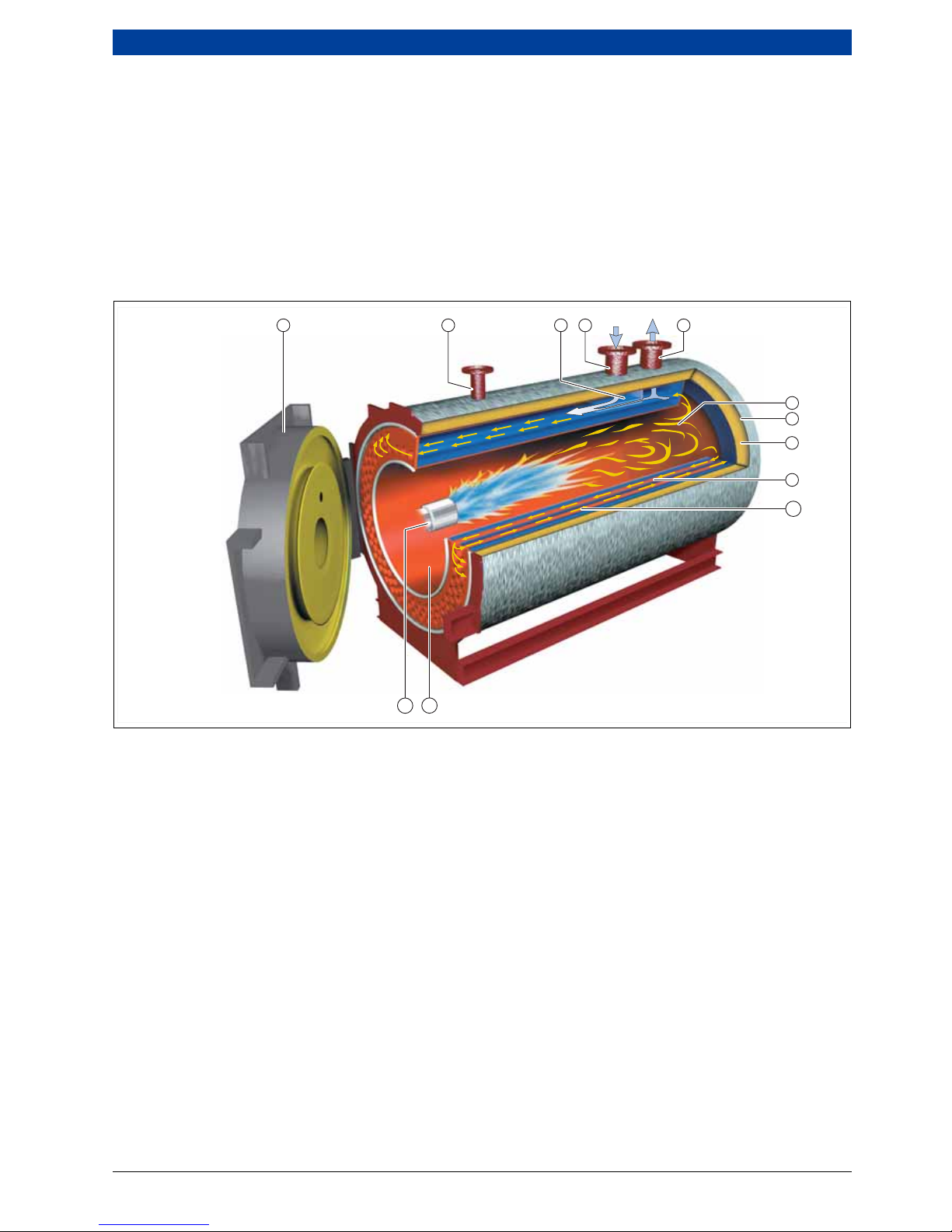

3.1.2 Function principle

Boiler technology

All UNIMAT UT-L boilers boilers have a water guide

element installed below the return connector. With this,

the return water generates an injector effect through its

velocity as it flows back, so hotter boiler water is added

and mixes with the cooler return water. The targeted

feed of the return water results in excellent flow across

the entire boiler cross-section. Due to the flat

temperature slope in the boiler block, the boiler overall

provides an extremely even temperature distribution.

The flow through the boiler results in condensation-free

and safe heating operation with a minimum return

temperature as low as 50 °C.

The boiler is built using the 3-pass design and the

countercurrent heat exchanger principle. Together with

an effective heating surface design, these are the

prerequisites for low emissions and high energy

efficiency. Subject to the system, the UNIMAT UT-L

boilers achieve very high standard seasonal efficiency

[to DIN], which can be increased to up to 106 % with the

boiler with condensing heat exchanger.

Fig. 6 Sectional view showing the function principle of the UNIMAT UT-L boiler

[1] Burner door

[2] Safety valve connector ( Fig. 51, page 73)

[3] Water guide system

[4] Return ( Fig. 50, page 72 and Fig. 53, page 76)

[5] Flow ( Fig. 49, page 71)

[6] Hot gas reversing chamber

[7] Protective aluminium casing

[8] High grade insulation without thermal bridges

[9] First secondary heating surface (second pass)

designed as a double row

[10] Second secondary heating surface (third pass)

[11] Combustion chamber (first pass)

[12] Blast tube

1

2

12 11

45

3

10

9

8

7

6

6 720 803 977-01.1ITL

10 | Technical description

UNIMAT6 720 807 794 (2013/04)

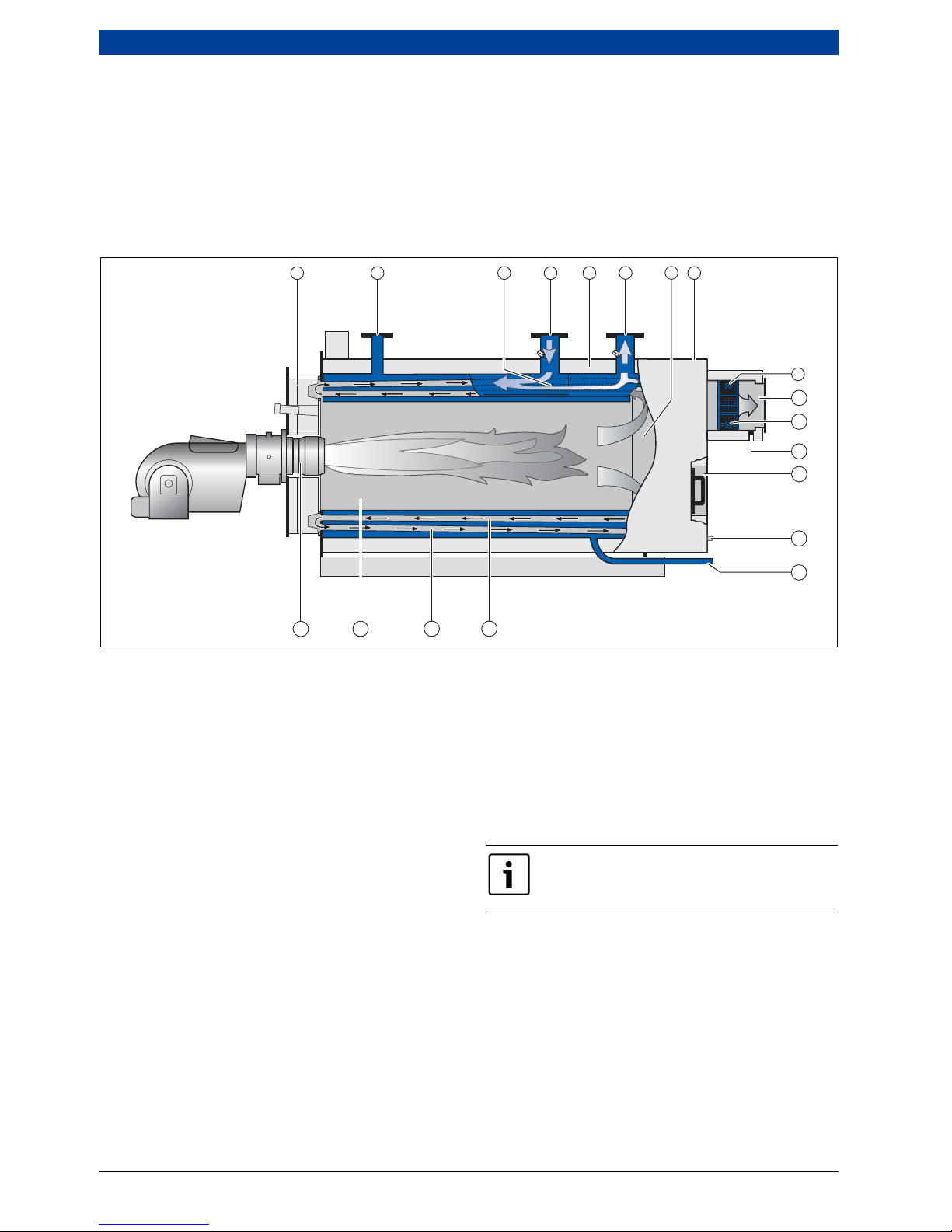

3.2 UNIMAT UT-L boiler

3.2.1 Version overview

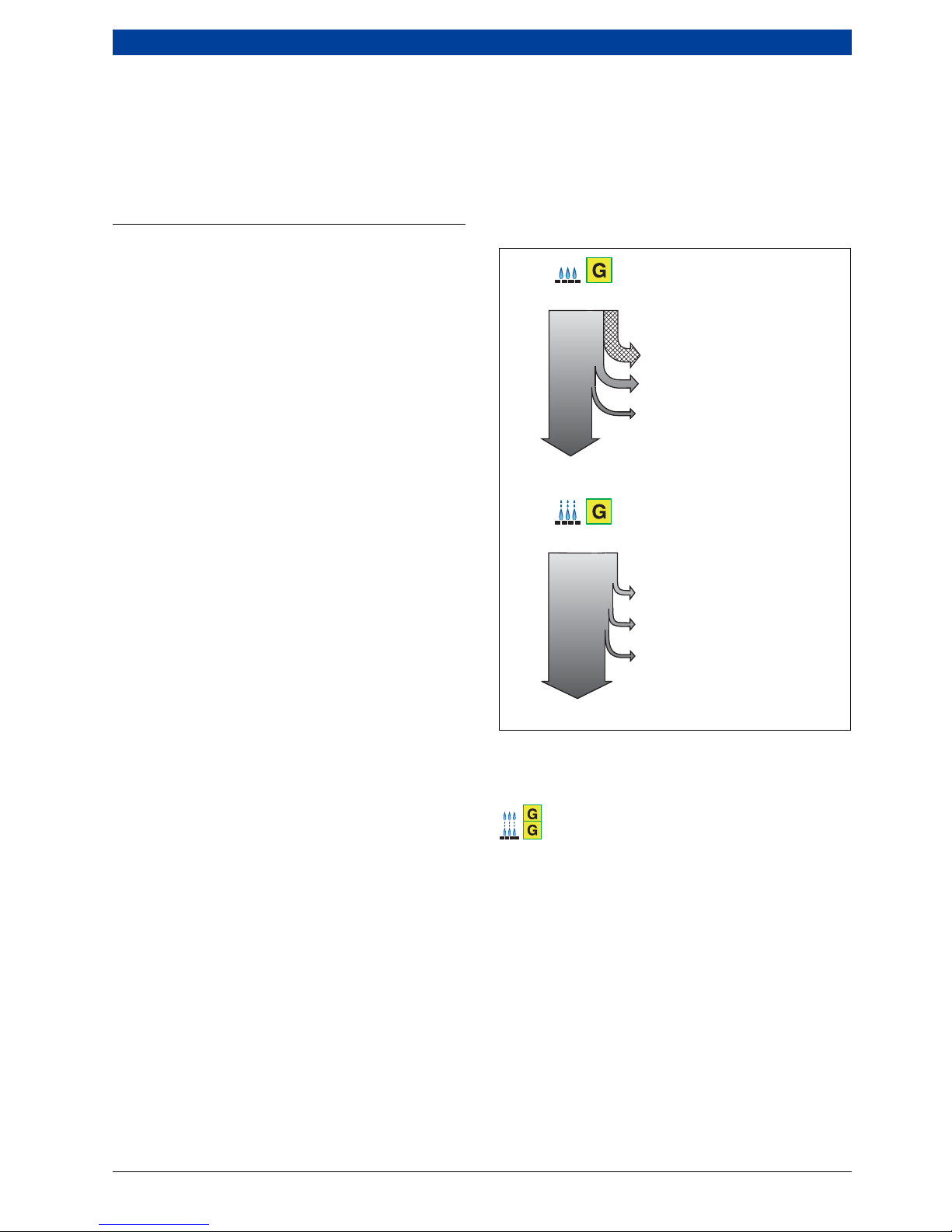

The conventional UNIMAT UT-L boiler can be fitted with

a flue gas heat exchanger to increase efficiency and

reduce the fuel required. The flue gas heat exchanger

can be supplied as an integrated version (integrated in

the flue gas collector chamber) or as a stand-alone

version (for installation downstream of the boiler). You

can choose between a galvanised steel version of the

heat exchanger bundle (ECO 7; without the use of

condensing technology) and a version of the heat

exchanger bundle in stainless steel (ECO 6; with the use

of condensing technology). The heat exchanger is

generally designed for modular construction. This means

the most suitably sized heat exchanger, or number

thereof, for the project in question can be chosen on an

individual basis.

Fig. 7 Function principle of the UNIMAT UT-L boiler with flue gas heat exchanger

[1] Burner door

[2] Safety valve connector ( Fig. 51, page 73)

[3] Water guide system

[4] Return ( Fig. 50, page 72 and Fig. 53, page 76)

[5] High grade insulation without thermal bridges

[6] Flow ( Fig. 49, page 71)

[7] Hot gas reversing chamber

[8] Protective aluminium casing

[9] Heat exchanger flow

[10] Heat exchanger

[11] Heat exchanger return

[12] Condensate connector

[13] inspection aperture

[14] Drain connection ( Fig. 56, page 79)

[15] First secondary heating surface (second pass)

designed as a double row

[16] Second secondary heating surface (third pass)

[17] Combustion chamber (first pass)

[18] Blast tube

43

8

67

521

9

10

12

13

11

12

14

15

16

1718

6 720 642 347-04.1il

Inspection aperture on the water side is

optional.

Technical description | 11

6 720 807 794 (2013/04)UNIMAT

3.2.2 Function principle

In the flue gas heat exchanger, heat is recovered from

the hotter boiler flue gas by channelling cooler mains

return water through the heat exchanger pipe to reduce

the flue gas temperature. The energy gained in this way

gives a higher boiler efficiency and therefore lower fuel

consumption and lower flue gas emissions.

With the fuels gas and low sulphur fuel oil, aim for as low

a water inlet temperature as possible at the flue gas heat

exchanger. This deliberately creates operation with

condensate (flue gas condensation), so that even higher

efficiency can be achieved.

If the flue gas heat exchanger is operated with fuel oil

(not low sulphur quality), ensure a corresponding

minimum water inlet temperature at the flue gas heat

exchanger of 60 °C to protect it from corrosion on the

flue gas side. With oil operation, an optional control on

the water side can be used to raise the water inlet

temperature at the flue gas heat exchanger to the

required minimum level by mixing in pre-heated water.

With oil operation, for flue gas heat exchangers with an

integral flue gas bypass, if the water inlet temperature

cannot be raised to the minimum level, the entire flue

gas flow from the boiler bypasses the flue gas heat

exchanger, using the flue gas control valve. A flue gas

temperature control unit is available as an option for an

additional charge.

12 | Technical description

UNIMAT6 720 807 794 (2013/04)

3.3 Dimensions and specification for the flue

gas heat exchangers

3.3.1 UNIMAT UT-L boiler

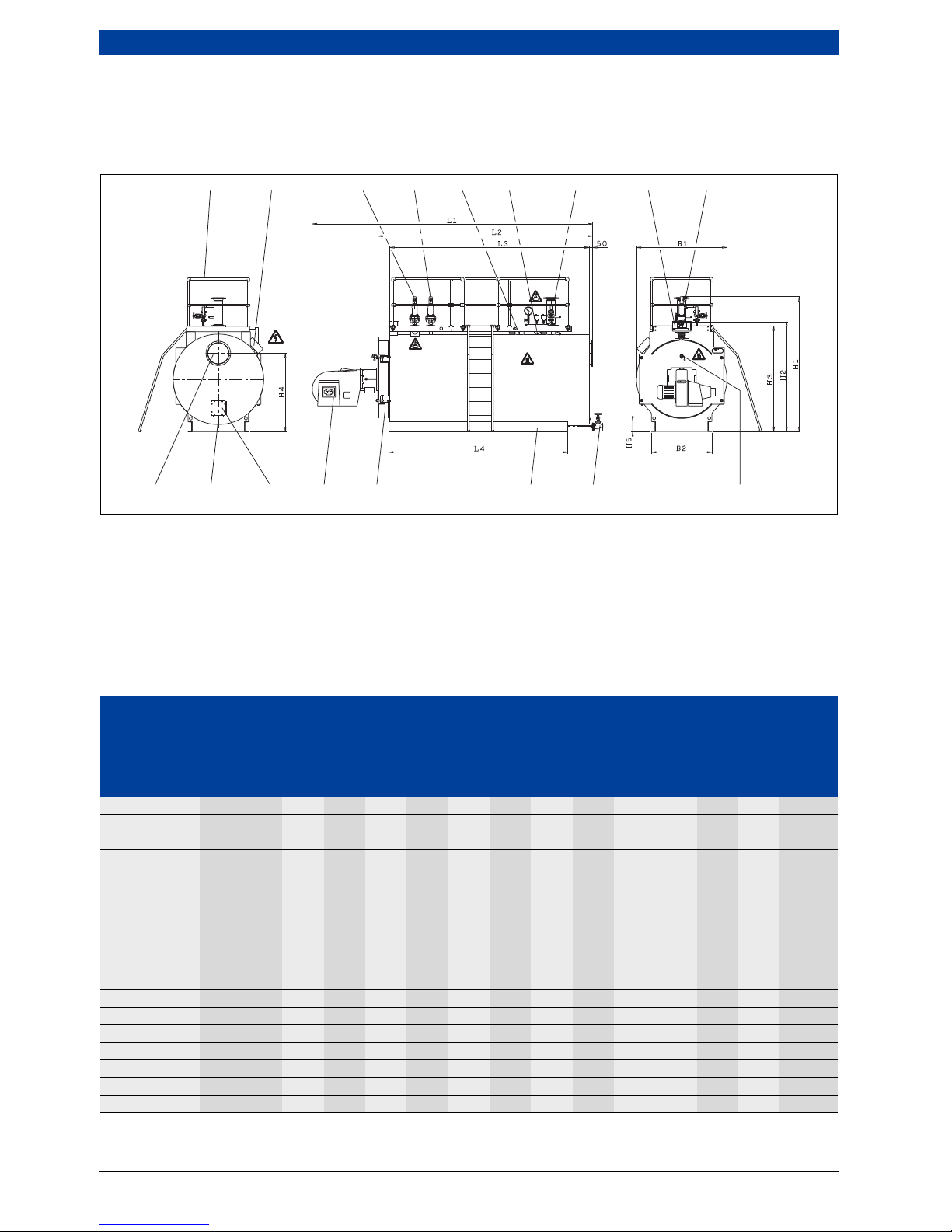

Fig. 8 UNIMAT UT-L boiler

51.002 Optional instrument housing

51.004 Optional terminal box

A01.000 Optional burner

D03.000 Flue gas connecting branch

D04.000 Boiler front door

D05.002 Inspection aperture on the flue gas side

D05.005 Flame inspection hole

D06.000 Base frame

D06.002 Lifting lug

D07.000 Optional maintenance platform

D08.000 Optional positive pressure safety valve 1

D08.100 Optional positive pressure safety valve 2

D10.000 Flow

D10.002 Optional intermediate flow piece

D11.000 Return

D12.001 Optional outlet shut-off valve

D12.503 Connection for flue gas condensate drainage

system

6 720 803 977-11.1itl

D07.000

D03.000 D12.503 D05.002 A01.000 D04.000 D06.000 D12.001 D05.005

51.004 D08.100 D11.000D08.000 D06.002 D10.000 51.002 D10.002

UNIMAT

UT-L boiler

Output limit Dimension(s)

Flue gas

connection

Base frame

L1

1)

L2 L3 B1 H12)H2 H33)H4 L4 B2

H5

Channel

section

Type kW [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

UT-L 1 650 3135 2295 2040 1174 2152 1540 1460 1055 1750 710 120 1055

UT-L 2 750 3516 2680 2425 1324 2302 1695 1610 1180 2100 910 120 1180

UT-L 4 1000 3516 2680 2425 1324 2302 1695 1610 1180 2100 910 120 1180

UT-L 6 1000 3786 2950 2695 1424 2402 1795 1710 1240 2350 910 120 1240

UT-L 8 1250 4056 3220 2960 1524 2502 1895 1810 1340 2560 930 160 1340

UT-L 10 1350 3778 2950 2695 1424 2402 1795 1710 1240 2350 910 120 1240

UT-L 12 1500 4503 3675 3420 1574 2552 1950 1860 1350 3060 1130 160 1350

UT-L 14 1900 4092 3220 2960 1524 2502 1895 1810 1340 2560 930 160 1340

UT-L 16 2000 4597 3725 3465 1674 2652 2050 1960 1415 3060 1130 160 1415

UT-L 18 2500 4654 3675 3420 1574 2552 1950 1860 1350 3060 1130 160 1350

UT-L 20 2500 5054 4075 3820 1724 2702 2100 2010 1490 3410 1150 200 1490

UT-L 22 3000 5895 4570 4250 1824 2817 2200 2110 1500 3920 1260 220 1500

UT-L 24 3050 4916 3725 3465 1674 2667 2050 1960 1415 3060 1130 160 1415

UT-L 26 3500 6025 4700 4380 1924 2917 2300 2210 1600 3920 1510 220 1600

UT-L 28 3700 5266 4075 3820 1724 2717 2100 2010 1490 3410 1150 200 1490

UT-L 30 4200 5761 4570 4250 1824 2817 2200 2110 1500 3920 1260 220 1500

UT-L 32 4250 6419 5090 4770 2124 3117 2505 2410 1750 4280 1510 220 1750

UT-L 34 5200 6385 4700 4380 1924 3007 2300 2210 1600 3920 1510 220 1600

Table 4 Main dimensions

Technical description | 13

6 720 807 794 (2013/04)UNIMAT

• For information and instructions regarding the

requirements for the boiler installation room, see

chapter 10.2, page 67.

• Equipment and complete dimensions according to

project-specific technical datasheet

• Dimensions given with ± 1 % tolerance

• These dimensions are designed for standard

insulation:

– 100-mm thick on back floor

– 100-mm thick on casing

• Sizing for the entrance:

– Transport height: additional clearance of at least

100 mm from dimension H1 or dimension H2

(valves fitted/not fitted)

– Minimum door clearance: additional clearance of at

least 200 mm from dimension B1 (valves fitted/not

fitted)

• The height of the boiler room is determined by the

system equipment. The clearance above the

maintenance platform should be at least 2 m.

UT-L 36 5250 6655 5320 5000 2274 3357 2655 2560 1850 4480 1520 240 1850

UT-L 38

4)

6000 6855 5520 5200 2424 3507 - 2710 2000 4650 1610 240 2000

UT-L 40 6500 6775 5090 4770 2124 3207 2505 2410 1750 4280 1510 220 1750

UT-L 42 7700 7235 5320 5000 2274 3462 2655 2560 1850 4480 1520 240 1850

UT-L 44

4)

8000 7683 5980 5655 2574 3762 - 2875 2100 5050 1630 280 2100

UT-L 46

4)

9300 7435 5520 5200 2424 3612 - 2710 2000 4650 1610 240 2000

UT-L 48

4)

10000 8285 6315 5990 2724 3912 - 3010 2200 5320 1890 280 2200

UT-L 50

4)

11200 8121 5980 5655 2574 3947 - 2875 2100 5050 1630 280 2100

UT-L 52

4)

12000 9086 7050 6725 2924 4297 - 3239 2440 6000 1890 280 2440

UT-L 54

4)

12600 7162 6315 5990 2724 4097 - 3010 2200 5320 1890 280 2200

UT-L 56

4)

14000 8803 7530 7170 3224 4597 - 3542 2600 6390 2100 320 2600

UT-L 58

4)

14700 9086 7050 6725 2924 4377 - 3239 2440 6000 1890 280 2440

UT-L 60

4)

16400 9566 7530 7170 3224 4677 - 3542 2600 6390 2100 320 2600

UT-L 62

4)

17500 9227 7980 7620 3424 4877 - 3770 2820 6790 2100 320 2820

UT-L 64

4)

19200 9227 7980 7620 3424 4877 - 3770 2820 6790 2100 320 2820

1) The dimension L1 is a recommended dimension and is subject to the burner manufacturer, type and the actual output. If a flue gas heat

exchanger is included in the standard delivery, the corresponding dimension of length in accordance with datasheet DA170/DA171

must be taken into account.

2) Minimum transport dimensions when valves, burner and terminal box have been removed (without cable conduit; with cable conduit +

75 mm on the right).

3) Maximum dimension above boiler connector, lifting lug or door mounting.

4) UNIMATIC positioned at the side.

UNIMAT

UT-L boiler

Output limit Dimension(s)

Flue gas

connection

Base frame

L1

1)

L2 L3 B1 H12)H2 H33)H4 L4 B2

H5

Channel

section

Type kW [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

Table 4 Main dimensions

14 | Technical description

UNIMAT6 720 807 794 (2013/04)

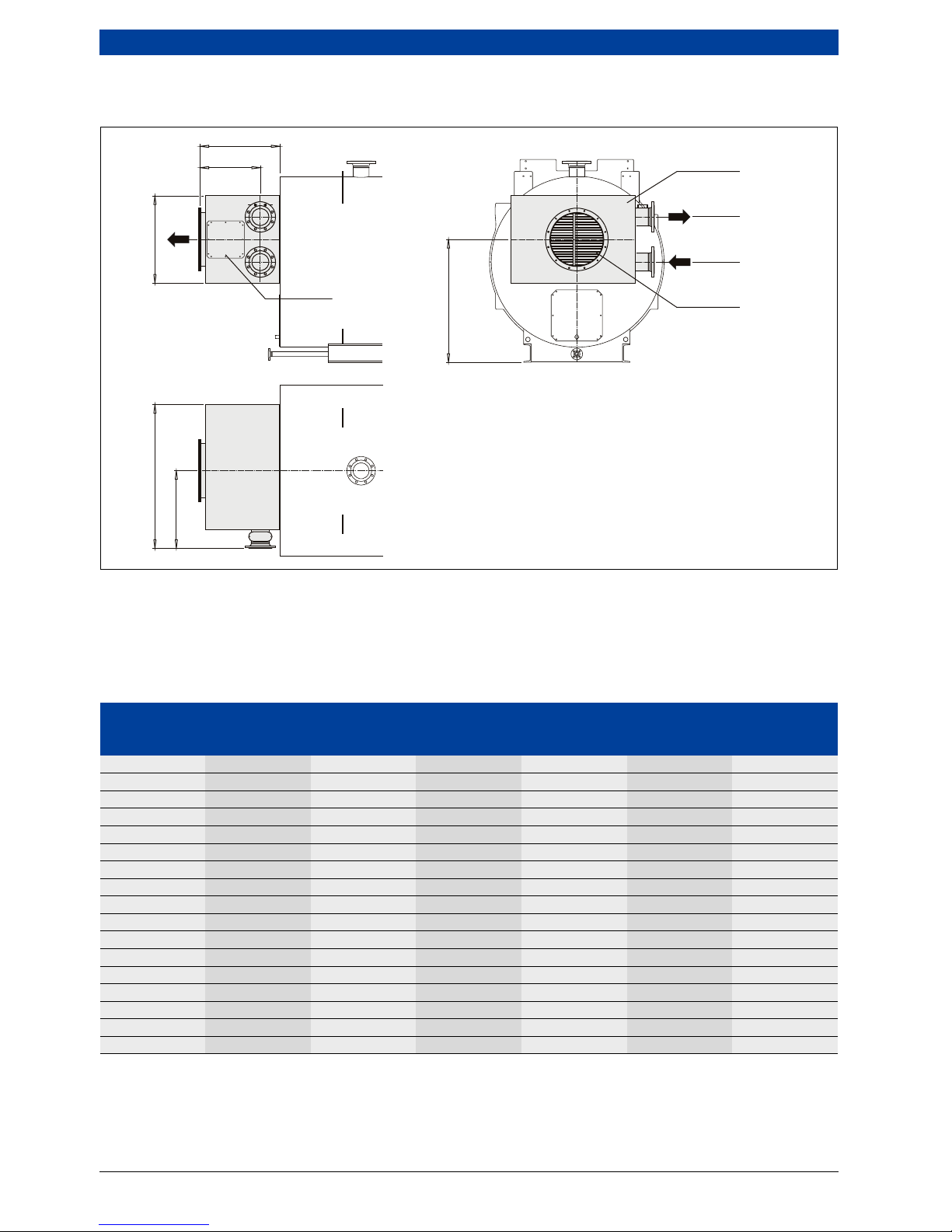

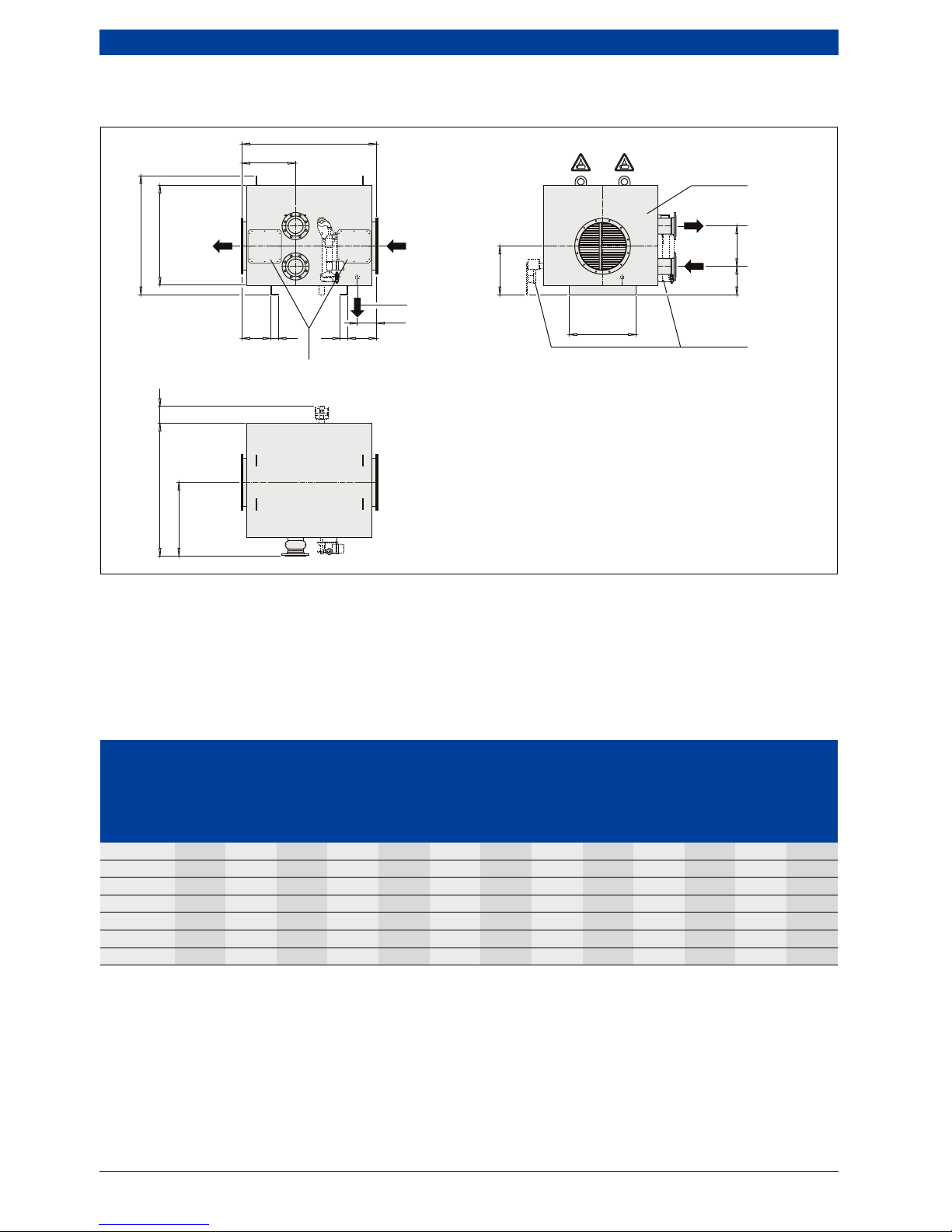

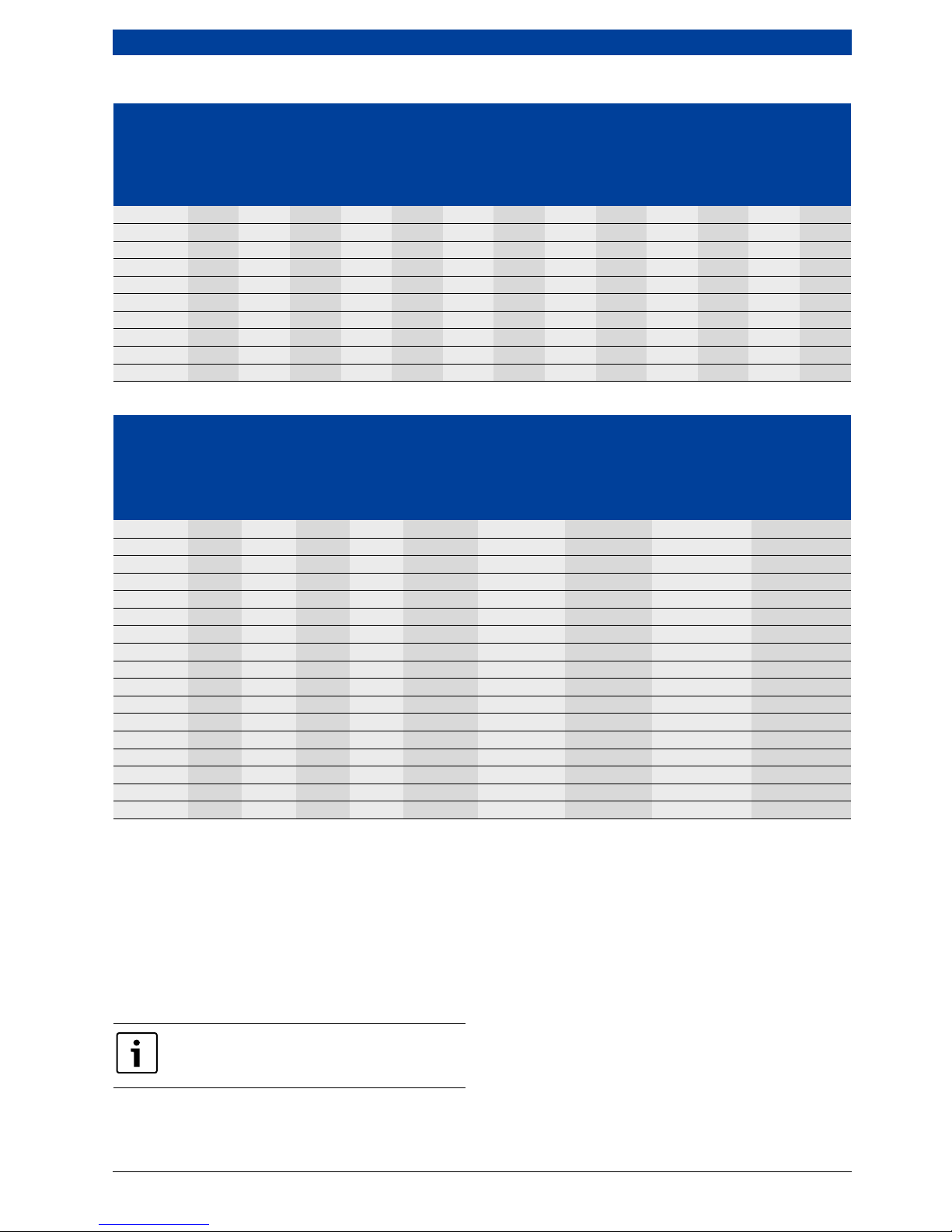

3.3.2 Integrated heat exchanger without condensing technology — ECO 7

Fig. 9 Integrated heat exchanger without condensing technology — ECO 7

W32.000 Flue gas heat exchanger

W32.510 Connection for water outlet

W32.008 Inspection aperture on the flue gas side

W32.509 Connection for water inlet

D03.000 Flue gas connecting branch

1)

If the heat exchanger is designed to have several

bundle elements, the dimensions increase by

300 mm per bundle.

2)

For heat exchangers having a water inlet/water

outlet with an internal diameter of DN150, the

dimensions increase by 50 mm.

740

1)

2)

560

W32.509

W32.000

D03.000

W32.510

H2

H1

B1

B2

W32.008

6 720 803 977-10.1itl

Heat exchanger

Shipping weight Water capacity Measurements

1 bundle 2 bundle B 1

2)

B 2 H 2

ECO 7 [~kg] [~kg] [l] [mm] [mm] [mm]

390/245 90 140 10 809 490 459

510/325 110 180 15 929 550 539

600/378 140 220 20 1019 595 592

690/432 160 260 26 1109 640 646

750/485 190 310 29 1169 670 699

890/592 230 370 37 1309 740 806

930/618 250 400 42 1349 760 832

1000/672 280 440 46 1419 795 886

1110/752 300 480 52 1529 850 966

1300/885 350 550 64 1719 945 1099

1350/965 420 670 85 1769 970 1179

1550/1045 480 780 98 1969 1070 1259

1600/1072 540 890 119 2019 1095 1286

1750/1178 600 980 125 2169 1170 1392

1900/1258 660 1060 148 2319 1245 1472

2050/1365 760 1240 173 2469 1320 1579

2200/1472 850 1390 200 2619 1395 1686

Table 5 Main dimensions

Technical description | 15

6 720 807 794 (2013/04)UNIMAT

• For information and instructions regarding the

requirements for the boiler installation room, see

chapter 10.2, page 67.

• These dimensions are designed for 100-mm thick

insulation.

• Connections W32.509 and W32.510 can be made on

the right hand or left hand side.

• Dimensions given with ± 1 % tolerance; weights given

with ± 3 % tolerance.

UNIMAT UT-L UT-L 1 UT-L 2 UT-L 4 UT-L 6 UT-L 8 UT-L 10 UT-L 12 UT-L 14 UT-L 16 UT-L 18 UT-L 20

H1 [mm] 950 1060 1060 1050 1150 1050 1205 1150 1215 1205 1240

UNIMAT UT-L UT-L 22 UT-L 24 UT-L 26 UT-L 28 UT-L 30 UT-L 32 UT-L 34 UT-L 36 UT-L 38 UT-L 40 UT-L 42

H1 [mm] 1260 1215 1330 1240 1260 1360 1330 1495 1550 1360 1495

UNIMAT UT-L UT-L 44 UT-L 46 UT-L 48 UT-L 50 UT-L 52 UT-L 54 UT-L 56 UT-L 58 UT-L 60 UT-L 62 UT-L 64

H1 [mm] 1705 1550 1750 1705 1900 1750 2030 1900 2030 2150 2150

Table 6 Dimension H1 depends on the boiler size

UNIMAT UT-L UT-L 1 UT-L 2 UT-L 4 UT-L 6 UT-L 8 UT-L 10 UT-L 12 UT-L 14 UT-L 16 UT-L 18 UT-L 20

ECO 7 heat

exchanger

510/325 510/325 510/325 510/325 600/378 600/378 600/378 690/432 690/432 750/485 750/485

390/245 510/325 600/378 690/432

600/378

UNIMAT UT-L UT-L 22 UT-L 24 UT-L 26 UT-L 28 UT-L 30 UT-L 32 UT-L 34 UT-L 36 UT-L 38 UT-L 40 UT-L 42

ECO 7 heat

exchanger

890/592 890/592 930/618 930/618

1000/

672

1000/

672

1110/

752

1110/

752

1300/

885

1300/

885

1350/

985

750/485 890/592 930/618

1000/

672

1110/

752

1110/

752

1300/

885

690/432 750/485 890/592 930/618

1000/

672

1110/

752

UNIMAT UT-L UT-L 44 UT-L 46 UT-L 48 UT-L 50 UT-L 52 UT-L 54 UT-L 56 UT-L 58 UT-L 60 UT-L 62 UT-L 64

ECO 7 heat

exchanger

1350/

965

1550/

1045

1550/

1045

1600/

1072

1600/

1072

1750/

1178

1750/

1178

1900/

1258

2050/

1365

2050/

1365

2200/

1472

1300/

885

1350/

965

1550/

1045

1600/

1072

1600/

1072

1750/

1178

1900/

1258

1900/

1258

2050/

1365

1300/

885

1350/

965

1550/

1045

1600/

1072

1750/

1185

1900/

1258

1110/

752

1300/

885

1600/

1085

Table 7 Assignment of heat exchanger ECO 7 to boiler size

The tube bundles highlighted in bold

correspond to the assignment for the limit

output of the UNIMAT UT-L.

If the boiler is operated with low heating

output, a smaller flue gas heat exchanger

can also be selected under certain

circumstances.

16 | Technical description

UNIMAT6 720 807 794 (2013/04)

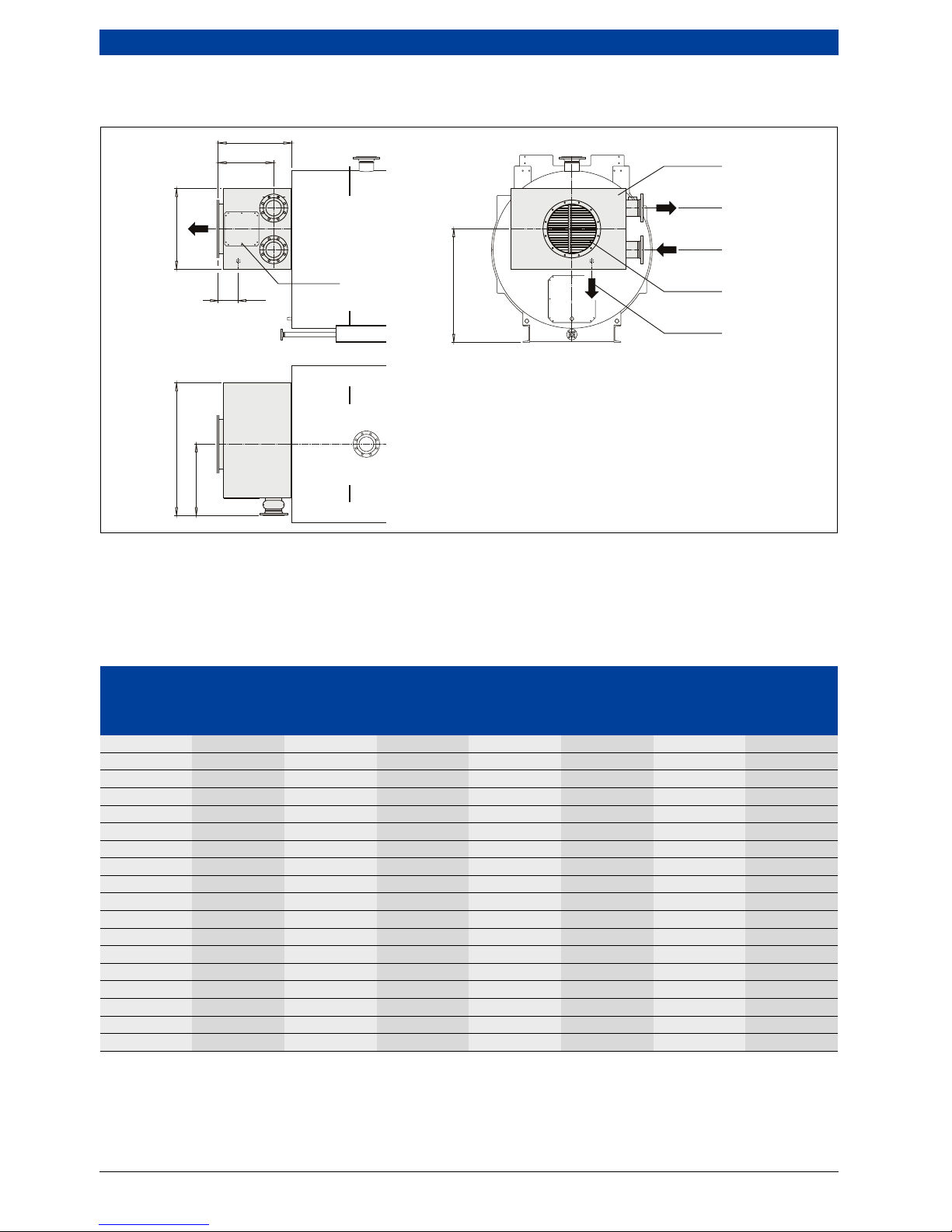

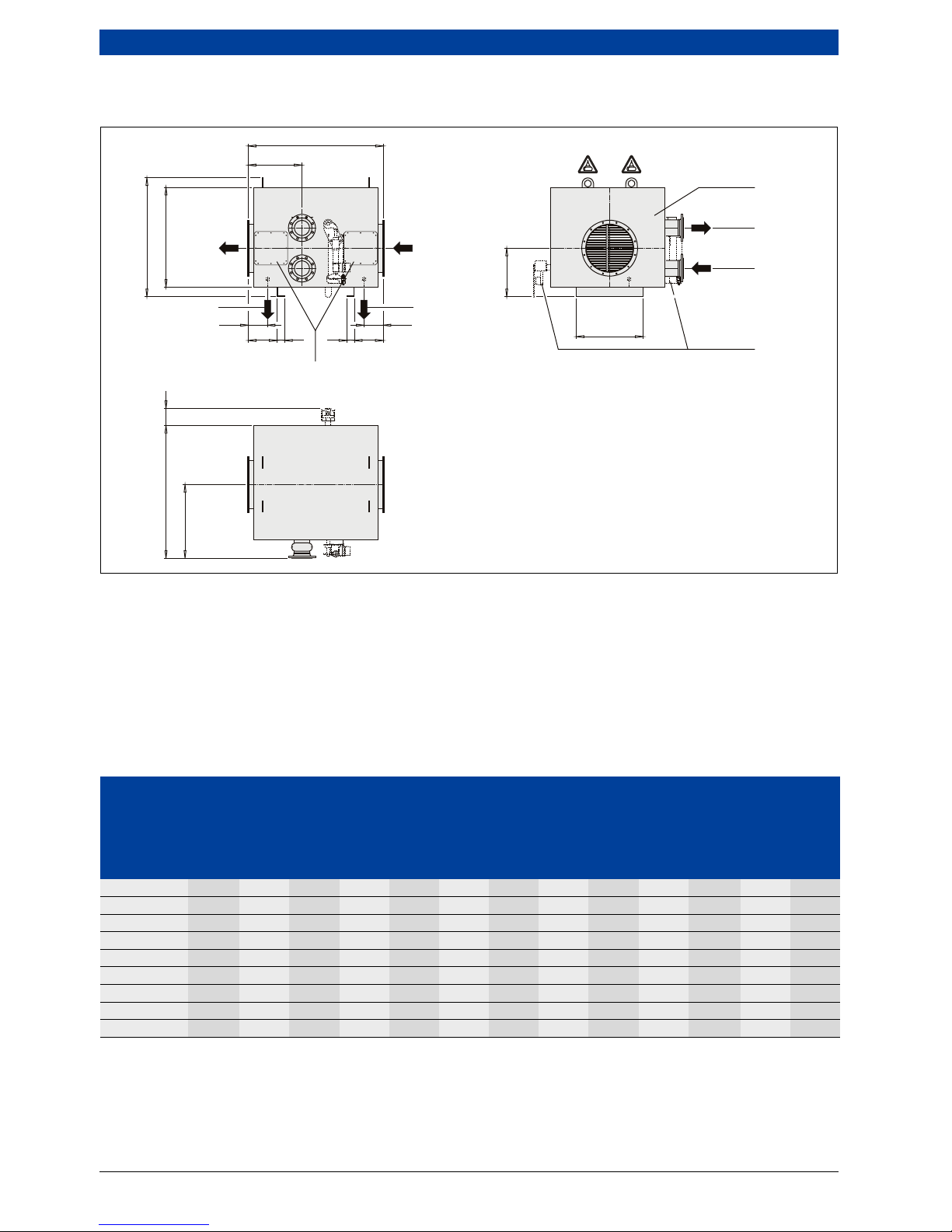

3.3.3 Integrated heat exchanger with condensing technology — ECO6

Fig. 10 Integrated heat exchanger with condensing technology — ECO 6

D03.000 Flue gas connecting branch

W32.000 Flue gas heat exchanger

W32.008 Inspection aperture on the flue gas side

W32.507 Connection for flue gas condensate

W32.509 Connection for water inlet

W32.510 Connection for water outlet

1)

If the heat exchanger is designed to have several

bundle elements, the dimensions increase by

300 mm per bundle.

2)

For heat exchangers having a water inlet/water

outlet with an internal diameter of DN150, the

dimensions increase by 50 mm.

740

1)

2)

560

200

W32.509

W32.000

W32.507

D03.000

W32.510

H2

H

1

B1

B2

W32.008

6 720 803 977-12.1itl

Heat

exchanger

Shipping weight Measurements Port

1 bundle 2 bundle

Water

capacity

B 1 B 2

2)

H 2 W32.506

ECO 6 [~kg] [~kg] [mm] [mm] [mm] [mm] [DN]

390 / 260 90 140 10 794 475 474 1"

510 / 335 110 180 15 914 535 549 1"

600 / 385 140 220 20 1004 580 599 1"

690 / 460 170 260 26 1094 625 674 1"

750 / 485 190 310 29 1154 655 699 1"

850 / 560 230 360 37 1254 705 774 1"

890 / 610 250 400 42 1294 725 824 1"

930 / 635 270 440 46 1334 745 849 1"

1000 / 685 290 470 52 1404 780 899 2"

1110 / 760 320 520 64 1514 835 974 2"

1300 / 885 400 650 85 1704 930 1099 2"

1350 / 985 460 750 98 1754 955 1199 2"

1550 / 1060 540 880 119 1954 1055 1274 2"

1600 / 1085 570 950 125 2004 1080 1299 2"

1750 / 1185 630 1040 148 2154 1155 1399 2"

1900 / 1285 730 1210 173 2304 1230 1499 2"

2050 / 1385 820 1360 200 2454 1305 1599 2"

2200 / 1485 930 1550 228 2604 1380 1699 2"

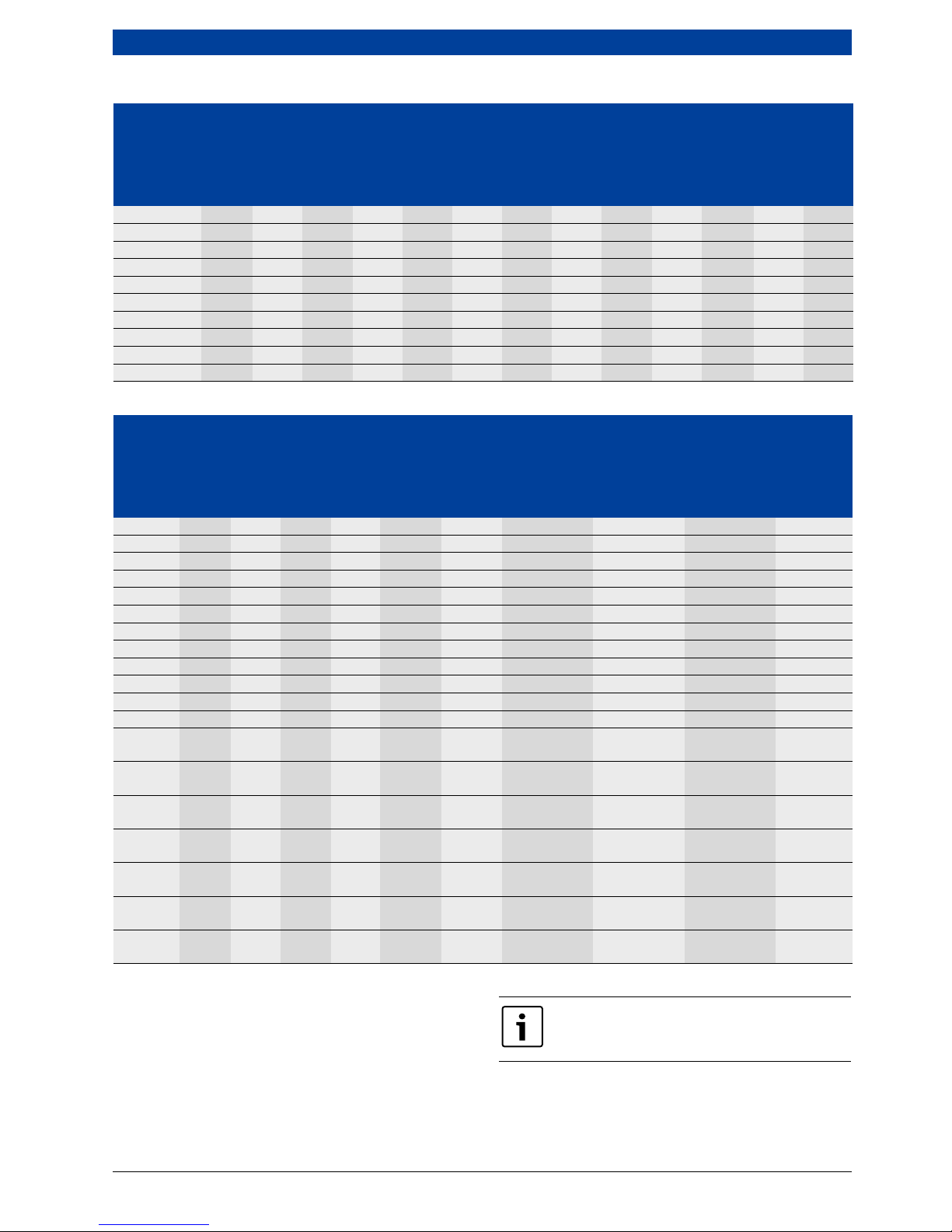

Table 8 Main dimensions

Technical description | 17

6 720 807 794 (2013/04)UNIMAT

• For information and instructions regarding the

requirements for the boiler installation room, see

chapter 10.2, page 67.

• These dimensions are designed for 100-mm thick

insulation.

• Connections W32.509 and W32.510 can be made on

the right hand or left hand side.

• Dimensions given with ± 1 % tolerance; weights given

with ± 3 % tolerance.

• Pipe thread to DIN 2999.

UNIMAT UT-L UT-L 2 UT-L 4 UT-L 6 UT-L 8 UT-L 10 UT-L 12 UT-L 14 UT-L 16 UT-L 18 UT-L 20 UT-L 22

H1 [mm] 1060 1060 1050 1150 1050 1205 1150 1215 1205 1240 1260

UNIMAT UT-L UT-L 24 UT-L 26 UT-L 28 UT-L 30 UT-L 32 UT-L 34 UT-L 36 UT-L 38 UT-L 40 UT-L 42 UT-L 44

H1 [mm] 1215 1330 1240 1260 1360 1330 1495 1550 1360 1495 1705

UNIMAT UT-L UT-L 46 UT-L 48 UT-L 50 UT-L 52 UT-L 54 UT-L 56 UT-L 58 UT-L 60 UT-L 62 UT-L 64

H1 [mm] 1550 1750 1705 1900 1750 2030 1900 2030 2150 2150

Table 9 Dimension H1 depends on the boiler size

UNIMAT UT-L UT-L 1 UT-L 2 UT-L 4 UT-L 6 UT-L 8 UT-L 10 UT-L 12 UT-L 14 UT-L 16 UT-L 18 UT-L 20

ECO 6 heat

exchanger

510/335 510/335 600/385 600/385 690/460 690/460 690/460 750/485 750/485 850/560 890/610

390/260 510/335 510/335 600/385 600/385 690/460 750/485 850/560

510/335 600/385 690/460

UNIMAT UT-L UT-L 22 UT-L 24 UT-L 26 UT-L 28 UT-L 30 UT-L 32 UT-L 34 UT-L 36 UT-L 38 UT-L 40 UT-L 42

ECO 6 heat

exchanger

890/610 890/610 930/635 930/635

1000/

685

1000/

685

1110/

760

1110/

760

1300/

885

1300/

885

1350/

985

850/560 890/610 930/635

1000/

685

1110/

760

1110/

760

1300/

885

750/485 890/610 890/610 930/635

1000/

685

1110/

760

UNIMAT UT-L UT-L 44 UT-L 46 UT-L 48 UT-L 50 UT-L 52 UT-L 54 UT-L 56 UT-L 58 UT-L 60 UT-L 62 UT-L 64

ECO 6 heat

exchanger

1350/

985

1550/

1060

1550/

1060

1600/

1085

1600/

1085

1750/

1185

1750/

1185

1900/

1285

2050/

1385

2050/

1385

2200/

1485

1300/

885

1350/

985

1550/

1060

1600/

1085

1600/

1085

1750/

1185

1900/

1285

1900/

1285

2050/

1385

1300/

885

1350/

985

1550/

1060

1600/

1085

1750/

1185

1900/

1285

1110/

760

1300/

885

1600/

1085

Table 10 Assignment of heat exchanger ECO 6 to boiler size

The tube bundles highlighted in bold

correspond to the assignment for the limit

output of the UNIMAT UT-L.

If the boiler is operated with low heating

output, a smaller flue gas heat exchanger

can also be selected under certain

circumstances.

18 | Technical description

UNIMAT6 720 807 794 (2013/04)

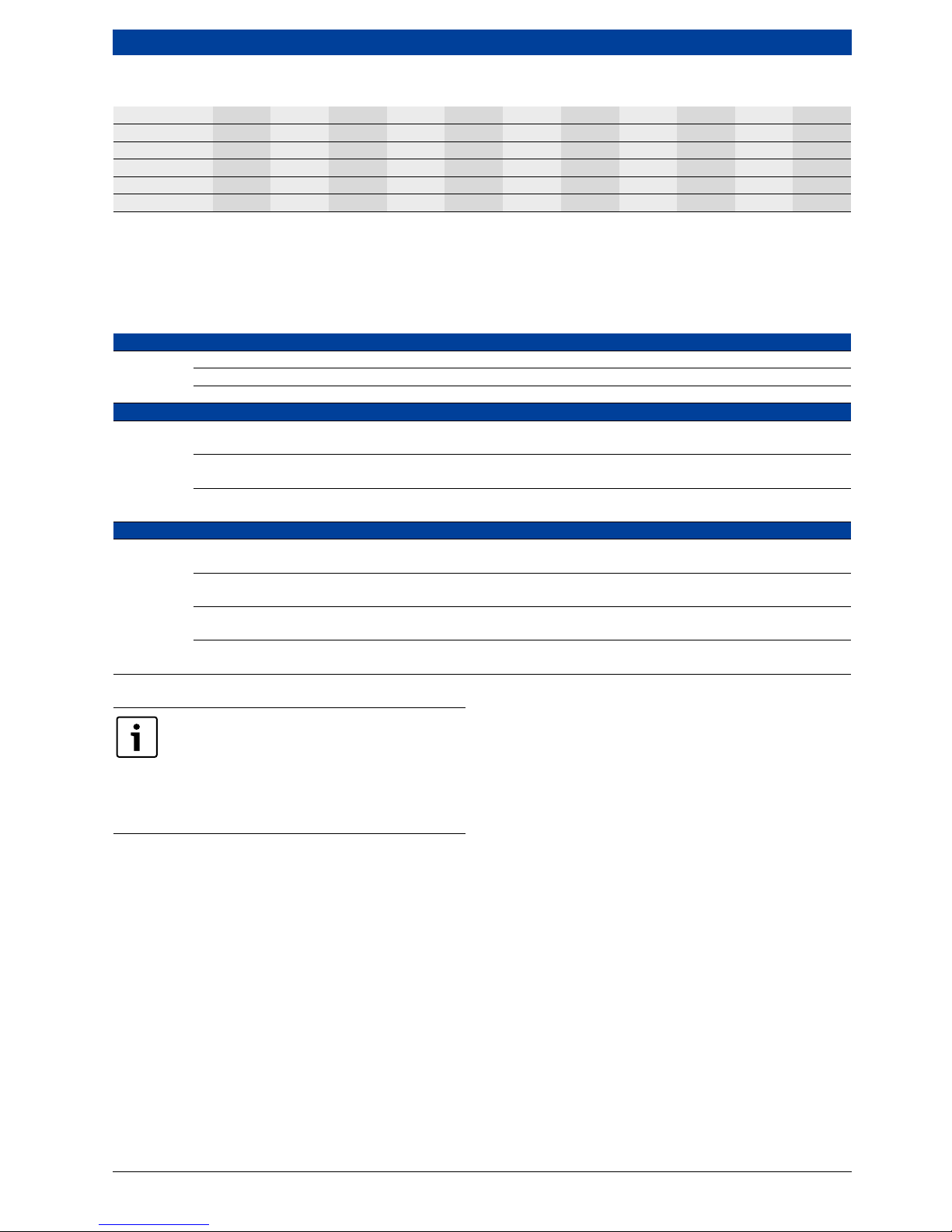

3.3.4 Stand-alone flue gas heat exchanger without condensing technology — ECO 7

Fig. 11 Stand-alone flue gas heat exchanger without condensing technology – ECO 7

W32.000 Flue gas heat exchanger

W32.002 Optional flue gas control valve

W32.008 Inspection aperture on the flue gas side

W32.506 Connection for drainage system

W32.509 Connection for water inlet

W32.510 Connection for water outlet

W32.540 Connection for flue gas inlet

W32.541 Connection for flue outlet

1)

If the heat exchanger is designed to have several

bundle elements, the dimensions increase by 300

mm per bundle.

2)

For heat exchangers having a water inlet/water

outlet with an internal diameter of DN150, the

dimensions increase by 50 mm.

B1 B4

B2

L 1

L 2

200

L 3 8 0 L 480

H3H4

H5

W32.509

W32.000

W32.002

W32.008

W32.510

H2

H1

W32.540

W32.506

B 3

W32.541

0-90°

0-90°

6 720 803 977-13.1itl

Heat

exchanger

Measurements

L 1

1)

L 2

1)

B 1

2)

B 2 B 3 B 4 H 1 H 2 H 3

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

ECO 7 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

390 / 245 1120 1235 560 600 809 490 300 0 859 1002 459 602 534

510 / 325 1120 1310 560 600 929 550 400 0 939 1117 539 717 572

600 / 378 1120 1360 560 600 1019 595 500 0 892 1060 592 760 497

690 / 432 1120 1435 560 600 1109 640 500 0 846 1072 646 872 434

750 / 485 1120 1460 560 600 1169 670 600 0 899 1097 699 897 447

890 / 592 1120 1623 560 638 1309 740 750 0 1006 1247 806 1047 509

930 / 618 1120 1648 560 638 1349 760 750 0 1032 1272 832 1072 522

Table 11 Main dimensions

Technical description | 19

6 720 807 794 (2013/04)UNIMAT

• For information and instructions regarding the

requirements for the boiler installation room, see

chapter 10.2, page 67.

• These dimensions are designed for 100-mm thick

insulation.

• Connections W32.509 and W32.510 can be made on

the right hand or left hand side.

• Dimensions given with ± 1 % tolerance; weights given

with ± 3 % tolerance.

• Pipe thread to DIN 2999.

1000 / 672 1520 1840 760 780 1419 795 750 0 1086 1417 886 1217 547

1110 / 752 1520 1885 760 750 1529 850 900 0 1166 1472 966 1272 584

1300 / 885 1520 2025 760 765 1719 945 1100 0 1299 1607 1099 1407 647

1350 / 965 1520 2215 760 855 1769 970 1100 0 1379 1767 1179 1567 697

1550 / 1045 1520 2260 760 825 1969 1070 1350 0 1459 1832 1259 1632 734

1600 / 1072 1520 2230 760 900 2019 1095 1350 250 1486 1897 1286 1697 747

1750 / 1178 1920 2330 960 930 2169 1170 1550 250 1592 2017 1392 1817 797

1900 / 1258 1920 2270 960 930 2319 1245 1700 250 1672 2117 1472 1917 847

2050 / 1365 1920 2390 960 975 2469 1320 1700 250 1779 2247 1579 2047 897

2200 / 1472 1920 2470 960 1005 2619 1395 2000 250 1886 2367 1686 2167 947

Heat

exchanger

Measurements

Port Shipping weight

Water capacity

per bundle

L 3 L4 additional

weight with

bypass

W32.506 1 bundle 2 bundle

ECO 7 [mm] [mm] [mm] [DN] [~kg] [~kg] [~kg] [l]

390 / 245 353 380 353 285 1" 100 150 20 10

510 / 325 353 380 353 360 1" 130 200 40 15

600 / 378 353 380 353 410 1" 160 240 60 20

690 / 432 353 380 353 485 1" 190 290 80 26

750 / 485 353 380 353 510 1" 220 340 100 29

890 / 592 353 418 353 635 1" 270 410 150 37

930 / 618 353 418 353 660 1" 300 450 160 42

1000 / 672 553 560 553 710 1" 360 530 170 46

1110 / 752 553 530 553 785 1" 400 580 210 52

1300 / 885 553 545 553 910 1" 480 680 290 64

1350 / 965 553 635 553 1010 1" 550 800 380 85

1550 / 1045 553 605 553 1085 1" 650 940 440 98

1600 / 1072 553 680 553 660 1" 710 1050 420 119

1750 / 1178 753 710 753 690 1'' 850 1230 810 125

1900 / 1258 753 710 753 690 1" 940 1340 860 148

2050 / 1365 753 755 753 735 1" 1070 1550 960 173

2200 / 1472 753 785 753 753 1" 1200 1740 1090 200

Table 12 Main dimensions

Heat

exchanger

Measurements

L 1

1)

L 2

1)

B 1

2)

B 2 B 3 B 4 H 1 H 2 H 3

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

ECO 7 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

Table 11 Main dimensions

For the allocation of the ECO 7 stand-alone

heat exchanger to the boiler size, see

chapter 3.3.2, Tab. 7, page 15.

20 | Technical description

UNIMAT6 720 807 794 (2013/04)

3.3.5 Stand-alone flue gas heat exchanger with condensing technology — ECO 6

Fig. 12 Stand-alone flue gas heat exchanger with condensing technology – ECO 6

W32.000 Flue gas heat exchanger

W32.002 Flue gas control valve

W32.008 Inspection aperture on the flue gas side

W32.506 Connection for drainage system

W32.509 Connection for water inlet

W32.510 Connection for water outlet

W32.540 Connection for flue gas inlet

W32.541 Connection for flue outlet

• For information and instructions regarding the

requirements for the boiler installation room, see

chapter 10.2, page 67.

• These dimensions are designed for 100-mm thick

insulation.

• Connections W32.509 and W32.510 can be made on

the right hand or left hand side.

• Dimensions given with ± 1 % tolerance; weights given

with ± 3 % tolerance.

• Pipe thread to DIN 2999.

B1 B4

B2

L 1

L 2

200 200

L 3 8 0 L 480

H3

W32.509

W32.000

W32.002

W32.008

W32.510

H2

H1

W32.506

W32.540

B 3

W32.507

W32.541

0-90° 0-90°

6 720 803 977-14.1itl

Heat

exchanger

Measurements

L 1

1)

L 2

1)

B 1

2)

B 2 B 3 B 4 H 1 H 2 H 3

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

ECO 6 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

390 / 260 1120 1235 560 600 794 475 300 0 874 1002 474 602 534

510 / 335 1120 1310 560 600 914 535 400 0 949 1117 549 717 572

600 / 385 1120 1360 560 600 1004 580 500 0 899 1067 599 767 497

690 / 460 1120 1435 560 600 1094 625 500 0 874 1072 674 872 434

750 / 485 1120 1460 560 600 1154 655 600 0 899 1097 699 897 447

850 / 560 1120 1685 560 750 1254 705 750 0 974 1197 774 997 484

890 / 610 1120 1623 560 638 1294 725 750 0 1024 1247 824 1047 509

930 / 635 1120 1648 560 638 1334 745 750 0 1049 1272 849 1072 522

1000 / 685 1520 1840 760 780 1404 780 750 0 1099 1417 899 1217 547

Table 13 Main dimensions

Technical description | 21

6 720 807 794 (2013/04)UNIMAT

1)

If the heat exchanger is designed to have several

bundle elements, the dimensions increase by 300

mm per bundle.

2)

For heat exchangers having a water inlet/water

outlet with an internal diameter of DN150, the

dimensions increase by 50 mm.

1110 / 760 1520 1885 760 750 1514 830 900 0 1174 1472 974 1272 584

1300 / 885 1520 2025 760 765 1704 930 1100 0 1299 1607 1099 1407 647

1350 / 985 1520 2215 760 855 1754 955 1100 0 1399 1767 1199 1567 697

1550 / 1060 1520 2260 760 825 1954 1055 1350 0 1474 1832 1274 1632 734

1600 / 1085 1520 2230 760 900 2004 1080 1350 250 1499 1897 1299 1697 747

1750 / 1185 1920 2330 960 930 2154 1155 1550 250 1599 2017 1399 1817 797

1900 / 1285 1920 2270 960 930 2304 1230 1700 250 1699 2117 1499 1917 847

2050 / 1385 1920 2390 960 975 2454 1305 1700 250 1799 2247 1599 2047 897

2200 / 1485 1920 2470 960 1005 2604 1380 2000 250 1899 2367 1699 2167 947

2400 / 1630 1920 2980 960 1260 2804 1480 2200 250 2044 2562 1844 2362 1019

Heat

exchanger

Measurements Port Shipping weight

Water

capacity per

bundle

L 3 L 4 W32.506 W32.507 without bypass

additional

weight with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

W32.506 W32.507 1 bundle 2 bundle

ECO 6 [mm] [mm] [mm] [mm] [DN] [DN] [~kg] [~kg] [~kg] [~kg]

390/260 353 380 353 285 1" 1" 100 150 20 10

510/335 353 380 353 360 1" 1" 130 200 40 15

600/385 353 380 353 410 1" 1" 160 240 60 20

690/460 353 380 353 485 1" 1" 190 290 80 26

750/485 353 380 353 510 1" 1" 220 340 100 29

850/560 353 530 353 585 1" 1" 260 400 140 37

890/610 353 418 353 635 1" 1" 290 440 160 42

930/635 353 418 353 660 1" 1" 310 480 170 46

1000/685 553 560 553 710 1" 2" 370 550 180 52

1110/760 553 530 553 785 1" 2" 420 620 220 64

1300/885 553 545 553 910 1" 2" 530 780 300 85

1350/985 553 635 553 1010 1" 2" 600 890 380 98

1550/

1060

553 605 553 1085 1" 2" 700 1040 450 119

1600/

1085

553 680 553 660 1" 2" 740 1120 800 125

1750/

1185

753 710 753 690 1" 2" 890 1290 870 148

1900/

1285

753 710 753 690 1" 2" 1020 1490 890 173

2050/

1385

753 755 753 735 1" 2" 1140 1680 1030 200

2200/

1485

753 785 753 765 1" 2" 1290 1900 1160 228

2400/

1630

753 1040 753 940 1" 2" 1530 2300 1410 250

Table 14 Main dimensions

Heat

exchanger

Measurements

L 1

1)

L 2

1)

B 1

2)

B 2 B 3 B 4 H 1 H 2 H 3

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

without

bypass

with

bypass

ECO 6 [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm] [mm]

Table 13 Main dimensions

For the allocation of the ECO 6 stand-alone

heat exchanger to the boiler size, see

chapter 3.3.3, Tab. 10, page 17.

22 | Technical description

UNIMAT6 720 807 794 (2013/04)

3.4 Connections

3.4.1 Flow and return

3.4.2 Flue outlet connection

At design spread and rated output Suggested internal diameter

1)

1) Flanged connections designed as PN16 to DIN 2633; the internal diameters given should be taken as suggestions but can be determined

individually. Depending on the design, the flow and return connectors are restricted for certain boiler sizes.

ΔT=15K ΔT=20K ΔT=30K ΔT=40K

[kW] [kW] [kW] [kW]

> 175 ≤ 275 > 235 ≤ 367 > 352 ≤ 550 > 470 ≤ 734 DN50

> 275 ≤ 465 > 367 ≤ 620 > 550 ≤ 931 > 734 ≤ 1241 DN65

> 465 ≤ 705 > 620 ≤ 940 > 931 ≤ 1410 > 1241 ≤ 1881 DN80

> 705 ≤ 1102 > 940 ≤ 1469 > 1410 ≤ 2204 > 1881 ≤ 2938 DN100

> 1102 ≤ 1722 > 1469 ≤ 2296 > 2204 ≤ 3444 > 2938 ≤ 4592 DN125

> 1722 ≤ 2479 > 2296 ≤ 3306 > 3444 ≤ 4959 > 4592 ≤ 6612 DN150

> 2479 ≤ 4408 > 3306 ≤ 5877 > 4959 ≤ 8816 > 6612 ≤ 11755 DN200

> 4408 ≤ 6887 > 5877 ≤ 9183 > 8816 ≤ 13775 > 11755 ≤ 18367 DN250

> 6887 ≤ 9918 > 9183 ≤ 13224 > 13775 ≤ 19200 > 18367 ≤ 19200 DN300

> 9918 ≤ 13500 > 13224 ≤ 18000 – – DN350

> 13500 ≤ 17633 > 18000 ≤ 19200 – – DN400

Table 15 Internal diameters of flow and return connections subject to design spread and rated output

Rated output

1)

1) Actual output (according to type plate)

Flue outlet internal diameter

2)3)

D1

2) Dimensions to EN 12220

3) Recommended values; exact diameter is calculated for each specific project.

Flue outlet D1 (external)

3)

[kW] – [mm]

≤ 827 DN200 213

> 827 ≤ 1350 DN250 256

> 1350 ≤ 2050 DN315 322

> 2051 ≤ 3307 DN400 400

> 3308 ≤ 5167 DN500 503

> 5168 ≤ 8203 DN630 634

> 8204 ≤ 10403 DN710 711

> 10404 ≤ 13227 DN800 797

> 13228 ≤ 16712 DN900 894

> 16713 ≤ 19200 DN1000 1003

Table 16 Flue outlet connection subject to the rated output

Technical description | 23

6 720 807 794 (2013/04)UNIMAT

3.4.3 Connector

All UNIMAT UT-L boilers boilers are factory-fitted with

suitable flow and return connectors.

A temperature sensor and temperature control unit can

be connected to them.

Fig. 13 Connectors for UNIMAT UT-L boilers with test points for safety equipment (dimensions in mm; internal

diameters

Tab. 15, page 22, Tab. 38, page 75 and Tab. 39, page 78)

N1 Female connections with cylindrical female thread

R½ , 120 mm long

(with DN 32–150 connectors)

Female connections with cylindrical female thread

R½ , 60 mm long

(with DN 200–400 connectors)

N2 Female connections with cylindrical female thread

R½ , 60 mm long

(with DN 65–80 connectors)

Female connections with cylindrical female thread

R½ , 75 mm long

(with DN 32–50 connectors)

Female connections with cylindrical female thread

R½ , 40 mm long

(with DN 100–400 connectors)

N3 Female connections with cylindrical female thread

R¾ , 75 mm long

(with DN 32–150 connectors)

Female connections with cylindrical female thread

R¾ , 50 mm long

(with DN 200–400 connectors)

RK Return

VK Flow

250

N1

N2

RK VK

N1

N2

250

N3

6 720 642 347-13.1il

24 | Technical description

UNIMAT6 720 807 794 (2013/04)

3.5 Characteristics

3.5.1 Pressure loss on the water side

The pressure loss on the water side is the pressure

differential between the boiler flow and return

connections. It depends on the boiler size (and the

internal diameter of the connectors) and the flow rate.

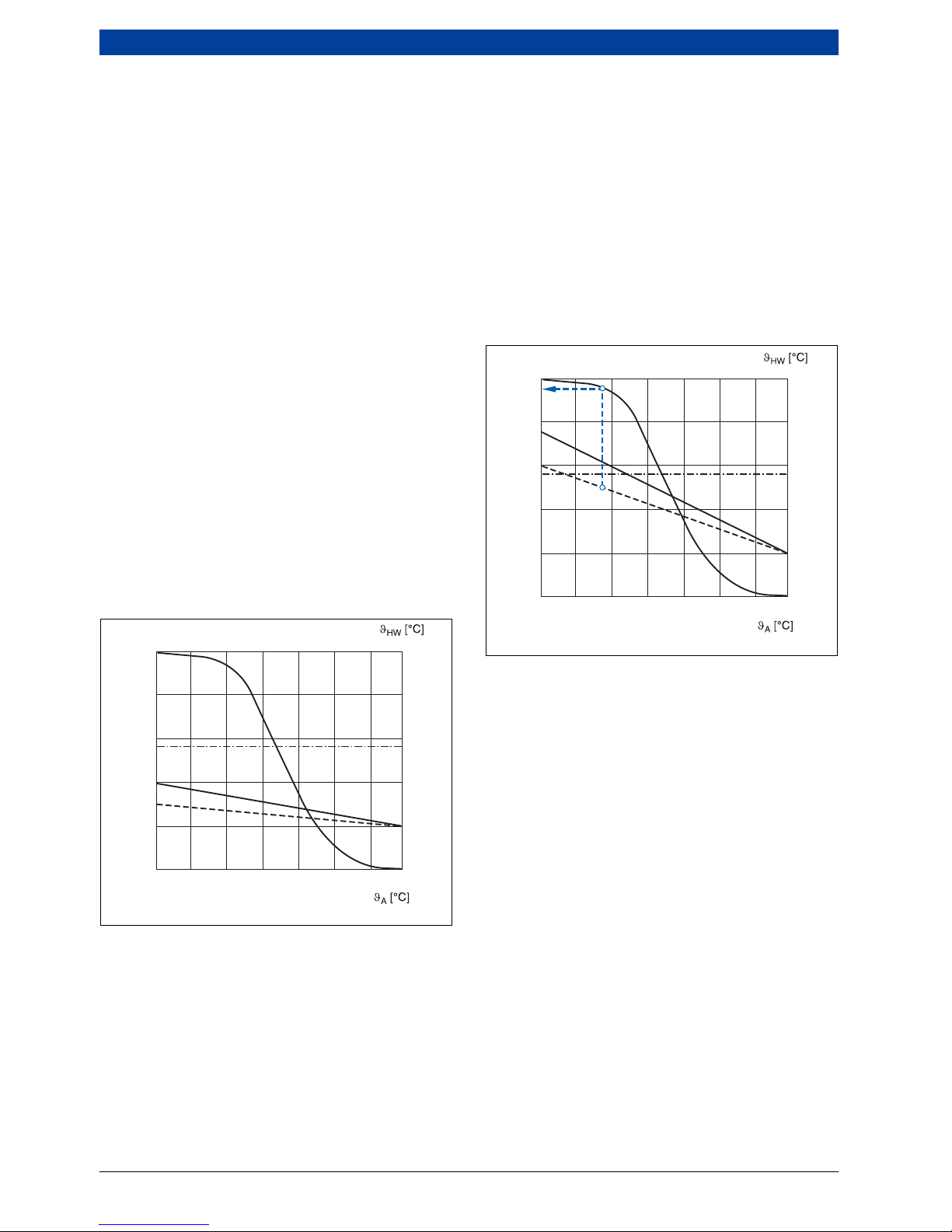

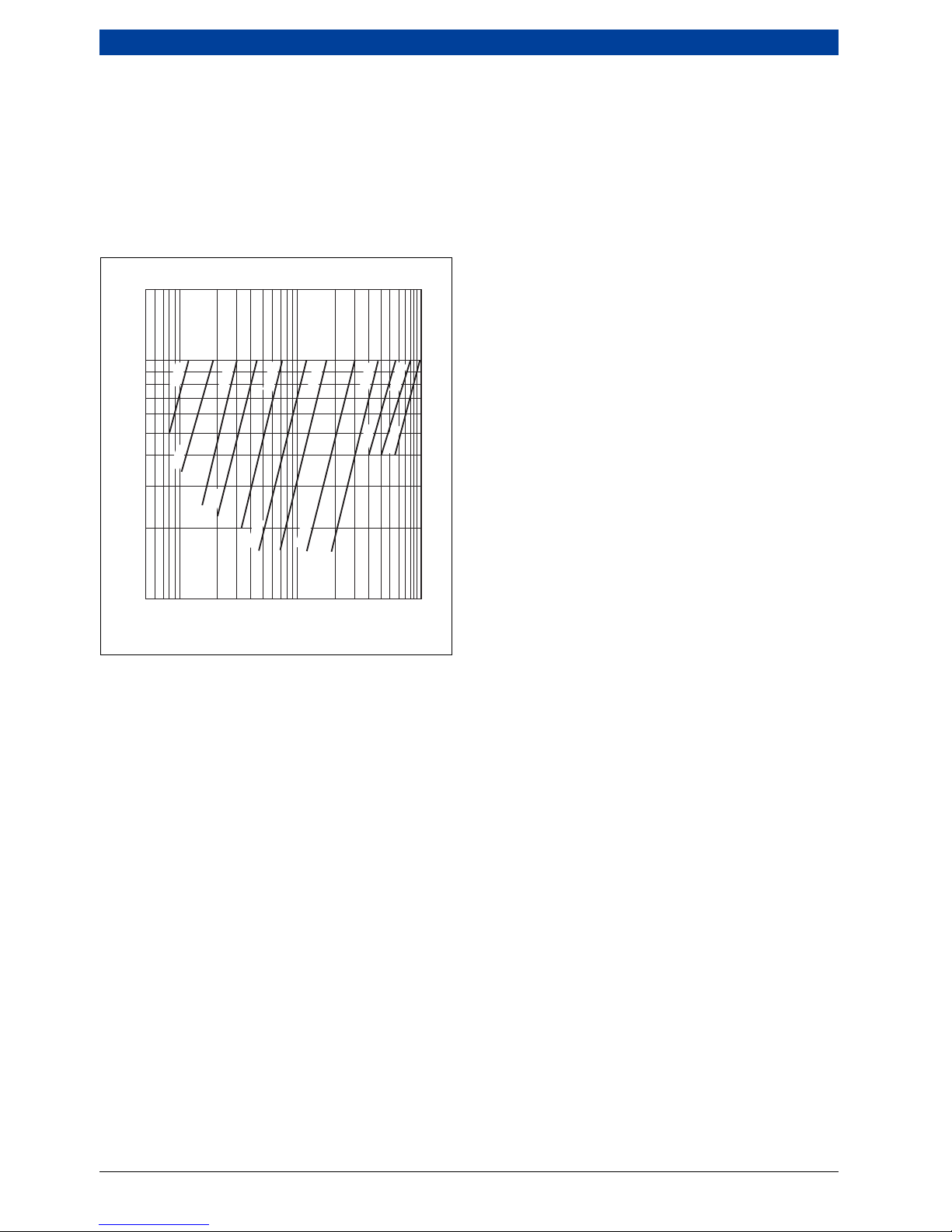

The graph in Fig. 14 shows the pressure loss on the

water side for the UNIMAT UT-L boilers.

Fig. 14 Pressure loss on the water side for UNIMAT UT-L

boilers (for internal diameters of flow and return

connections

page 22)

Δp

H

pressure loss on the heating water side

V

H

Flow rate

200

100

40

50

20

30

10

5 10 10050 1000

500

V

H

[m3/h]

Δp

H

[mbar]

6 720 642 347-14.1il

DN40

DN65

DN100

DN150

DN250

DN350

DN50

DN80

DN125

DN200

DN300

DN400

Technical description | 25

6 720 807 794 (2013/04)UNIMAT

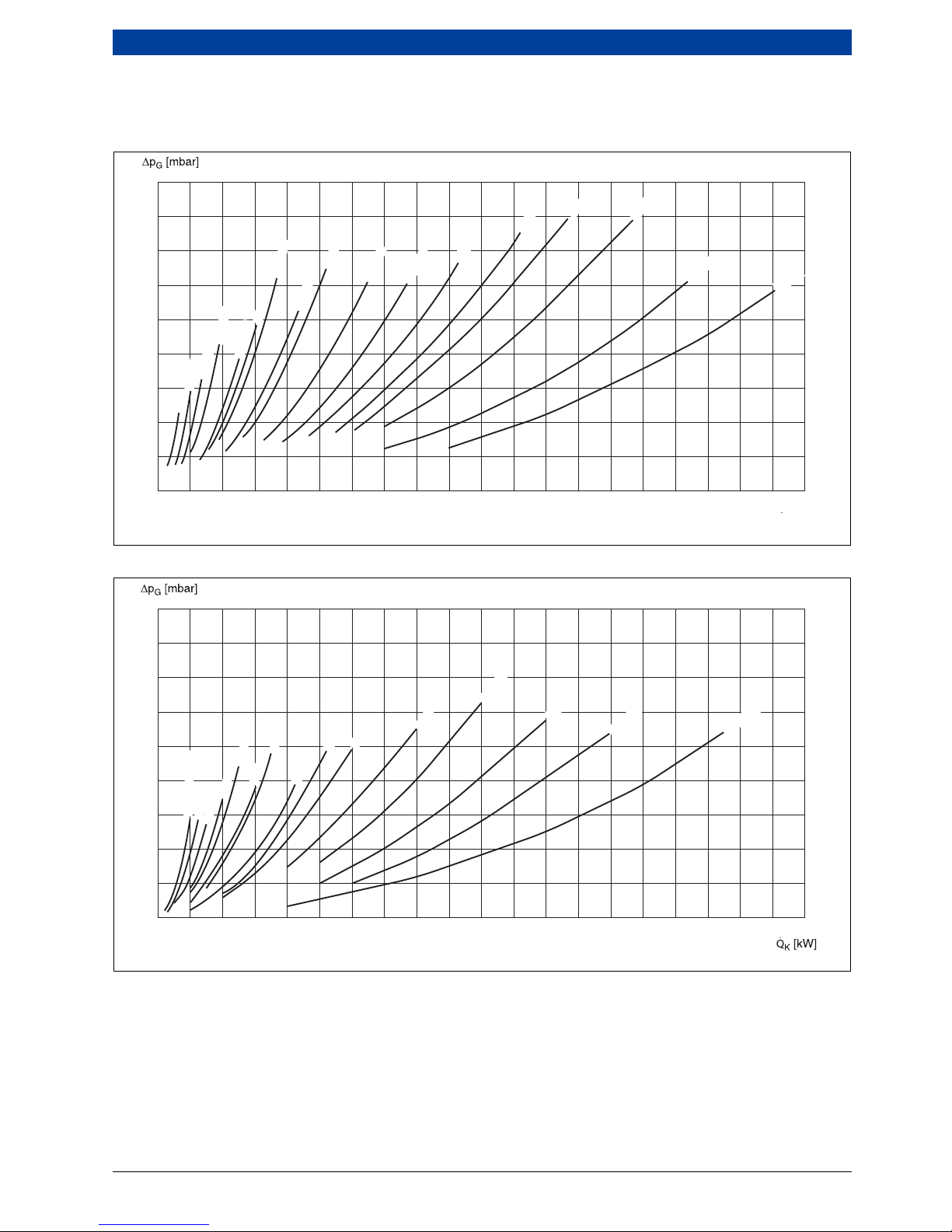

3.5.2 Pressure loss on the hot gas side

UNIMAT UT-L boiler

Fig. 15 Pressure loss on the hot gas side — overview 1

Fig. 16 Pressure loss on the hot gas side — overview 2

Δp

G

Pressure loss on the hot gas side

Q

K

Rated heating output

18

16

14

12

10

8

6

4

2

0

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

UT-L 4

UT-L 1

UT-L 10

UT-L 14

UT-L 18

UT-L 24

UT-L 28

UT-L 30

UT-L 34

UT-L 40

UT-L 42

UT-L 46

UT-L 50

UT-L 54

UT-L 58

UT-L 60

UT-L 64

QK [kW]

6 720 803 977-02.1ITL

18

16

14

12

10

8

6

4

2

0

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

UT-L 2/UT-L 6

UT-L 8

UT-L 12

UT-L 20

UT-L 16

UT-L 22

UT-L 26

UT-L 36

UT-L 38

UT-L 44

UT-L 48

UT-L 52

UT-L 56

UT-L 62

UT-L 32

6 720 803 977-03.1ITL

26 | Technical description

UNIMAT6 720 807 794 (2013/04)

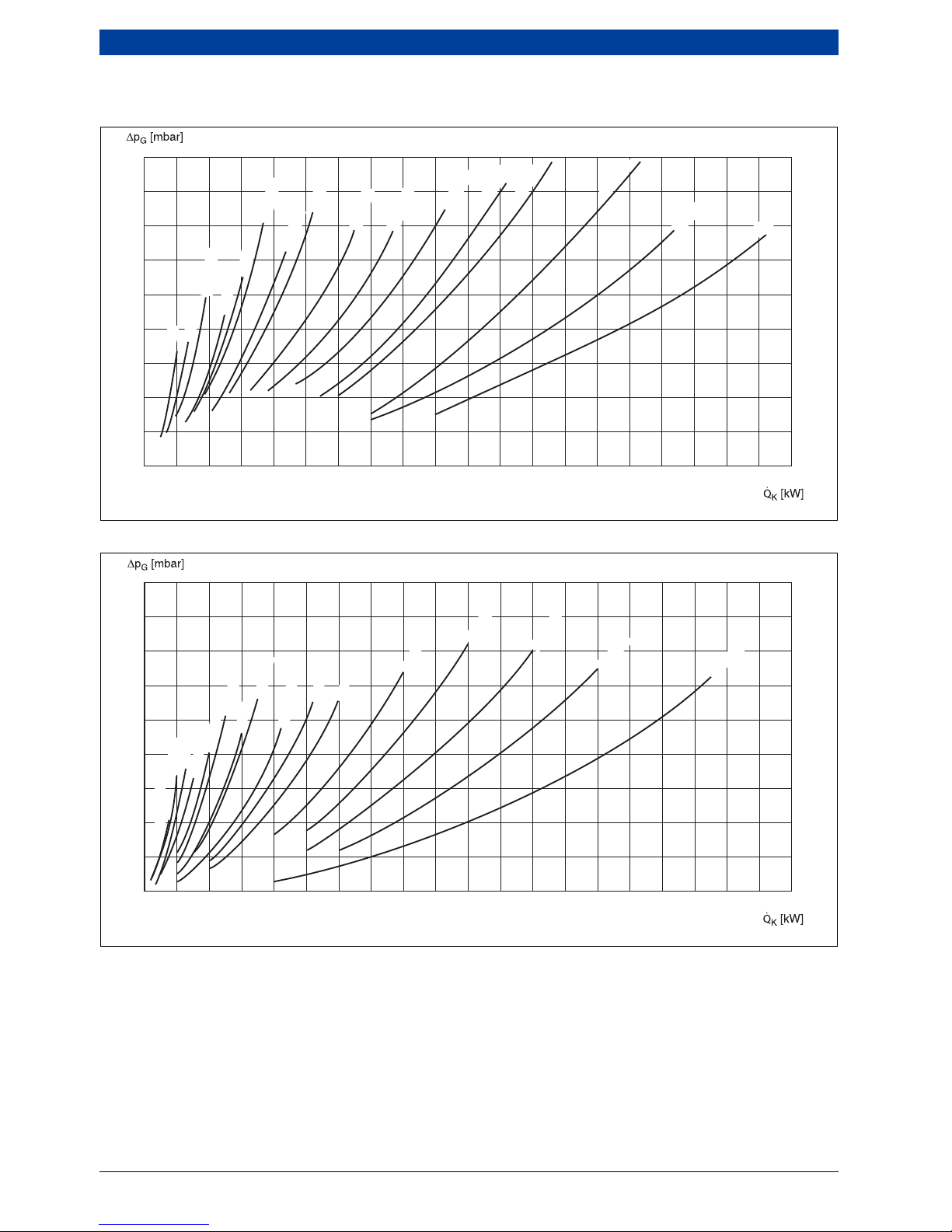

UNIMAT UT-L boiler with condensing heat exchanger

Fig. 17 Pressure loss on the hot gas side — overview 1

Fig. 18 Pressure loss on the hot gas side — overview 2

Δp

G

Pressure loss on the hot gas side

QK Rated heating output

18

16

14

12

10

8

6

4

2

0

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

UT-L 4

UT-L 10

UT-L 14

UT-L 18

UT-L 24

UT-L 28

UT-L 30

UT-L 34

UT-L 40

UT-L 42

UT-L 46

UT-L 50

UT-L 54

UT-L 58

UT-L 60

UT-L 64

6 720 803 977-04.1ITL

18

16

14

12

10

8

6

4

2

0

0 2000 4000 6000 8000 10000 12000 14000 16000 18000 20000

UT-L 2

UT-L 6

UT-L 8

UT-L 16

UT-L 12

UT-L 20

UT-L 32

UT-L 36

UT-L 38

UT-L 44

UT-L 48

UT-L 52

UT-L 56

UT-L 62

UT-L 26

UT-L 22

6 720 803 977-05.1ITL

Technical description | 27

6 720 807 794 (2013/04)UNIMAT

3.5.3 Combustion chamber volume load

To guarantee emissions values, some burner

manufacturers define aspects such as a maximum

combustion chamber volume load. Using the graphs in

Fig. 19 and Fig. 20, the most suitable boiler size for a

given combustion chamber volume load can be selected

for the UNIMAT UT-L boilers.

UNIMAT UT-L boiler

Fig. 19 Combustion chamber volume load for UNIMAT UT-L boiler, subject to the boiler output — overview 1

FVB Combustion chamber volume load

Q

B

Rated heating output

2,0

1, 9

1, 7

1, 5

1, 3

1,1

0

2000

4000

6000

8000

10000 14000

1600012000

18000

20000

UT-L 4

UT-L 10

UT-L 14

UT-L 18

UT-L 24

UT-L 28

UT-L 30

UT-L 34

UT-L 40

UT-L 42

UT-L 46

UT-L 50

UT-L 54

UT-L 58

UT-L 60

UT-L 64

QK [kW]

FVB [MW/m

3

]

6 720 803 977-06.1ITL

UT-L 1

Loading...

Loading...